Page 1

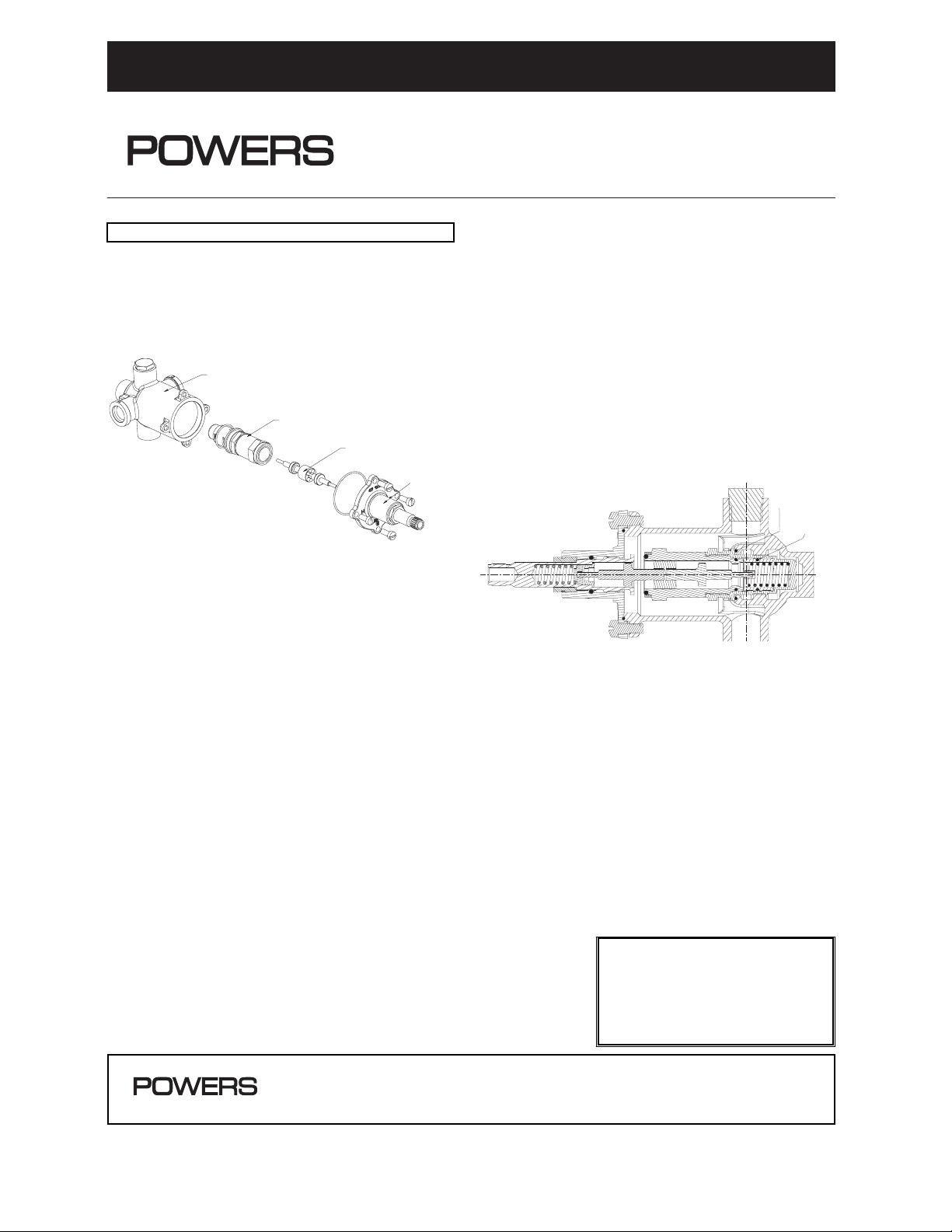

The following instructions explain how to retrofit your existing

427/428 HydroGuard to the new, enhanced version which utilizes

wax elements. The combination of these design concepts results

in a valve with enhanced performance. See the exploded view of

this new assembly below:

Before you begin your upgrade, take the time to ensure you have

all the necessary pieces. Your retrofit kit, for each valve, consists of the

following (refer to above diagram when taking inventory):

1. Cartridge Assembly (with one loose “O” ring).

2. Motor Assembly.

3. Bonnet Assembly (with one loose “O” ring).

4. Wrench (not shown).

5. Lubricant.

After you verify that you have everything needed to complete the

retrofit, proceed with the next section.

Retrofit:

Follow the instructions below to perform your retrofit. Save all

components until you have successfully completed your retrofit.

Disassembly:

1. Remove the handle and trim plate.

2. Turn off hot & cold water supply-stops (required for this retrofit).

3. Remove 4 bonnet screws and bonnet assembly.

4. Remove internal components from valve body.

5. Using wrench (225 350), remove cylinder.

6. At this point you should have an empty valve body.

You are now ready to put the new components into your

existing valve.

Reassembly:

1. Ensure the inside of the valve body is free of deposits

and debris. Clean as necessary.

2. Look inside the body. If there are two grooves then install

the smaller “O” ring on the cartridge as shown in Figure 2

(model 3 or earlier). Otherwise, install larger “O” ring on to

the “O” ring groove in the body.

3. Screw cartridge assembly into the body. Installation

torque 150 in/lbs. (Caution: Do not overtighten, it will

effect performance).

4. Assemble two motor with motor adapter and place it

in the body.

5. Install bonnet assembly using four screws.

6. With handle, rotate the stem assembly clock-wise, until

it bottoms out on the cartridge. At this point your valve

is in the “OFF” position.

See cut-away above to see how everything goes together.

7. Turn the hot and cold water supplies back on and verify

there is no leakage.

8. Maximum temperature setting adjustment must be set on

the job based on application. For point-of-use applications,

we recommend 110

°F (43°C).

The high temperature limit stop is located on the bonnet.

Rotate handle to the maximum desired outlet temperature.

With an open-end wrench, screw high temperature limit stop

into bonnet until it touches stem’s shoulder. Close valve and

open it to full hot to verify settings.

9. Install trim and handle.

10. Your retrofit is complete.

If you have any problems, comments, or suggestions, please

contact your Powers representative. We are interested in

feedback from the field.

INSTALLATION INSTRUCTIONS

Upgrade Kit HydroGuard®e427/e428

Kit # 427-200/201/202

H427-200/201/202

Form II 427R v2

EXISTING VALVE BODY

KIT, CARTRIDGE ASSEMBLY

KIT, MOTOR ASSEMBLY

KIT,

BONNET ASSEMBLY

Figure 1

Figure 2

RETROFIT INSTRUCTIONS

CALIFORNIA PROPOSITION 65 WARNING

WARNING: This product contains chemicals

known to the State of California to cause cancer

and birth defects or other reproductive harm.

(California law requires this warning to be given

to customers in the State of California.)

For more information: www.wattsind.com/prop65

© 2003 Powers, a division of Watts Water Technologies, Inc.

USA Phone: 1.800.669.5430 • Fax 1.847.824.0627

Canada Phone: 1.888.208.8927 • Fax 1.888.882.1979

www.powerscontrols.com

Form II 427R v2 0347 EDP# 6512251 Printed in U.S.A.

LARGER

"O" RING

SMALLER

"O" RING

Loading...

Loading...