Page 1

Technical Instructions

Features

• Low cost

• Built-in volume booster

• Small size

• Field reversible

• Low air consumption

• Mounts at any angle

• Convenient external Span and Zero adjusts

• Light Weight

• Wide supply pressure range

• Low supply pressure sensitivity

Operating Characteristics n

Supply Pressure Range: ........................................ Min: 3 psig (21 kPa) above

max output

Max: 100 psig (700 kPa)

Supply Pressure Sensitivity: ................................. <±0.15% of span per 10 kPa

at midrange

(<±0.1% of span per psig)

Terminal Based Linearity: ..................................... <±1.0% of span

Repeatability: ........................................................... <0.5% of span

Hysteresis: ............................................................... <1.0% of span

Air consumption (Maximum): ............................... 0.1 SCFM (0.2m3/hr)

at midrange

Flow Rate at Midrange (Minimum): ..................... 4.5 SCFM (7.6m3/hr ANR) at

25 psig (175 kPa) supply;

12 SCFM (20.0 m3/hr ANR) at

100 psig (700 kPa) supply

Port Sizes: ................................................................ 1/4 NPT (pneumatic);

1/2 NPT (electric)

Size: ........................................................................... 2-1/8 in. x 2-1/8 in. x 4 in.

(54 mm x 54 mm x 102 mm)

Weight: ..................................................................... 2.1 lb (0.94 kg)

Impedance (nominal):

512-117 ... 180

512-015 ... 180

512-027 ... 220

Description n

This transducer is an electropneumatic device that reduces a supply

pressure to a regulated output pressure that is directly proportional to an

electrical input signal. It uses a supply pressure between 18 and 100 psig

(125-700 kPa). An integral pneumatic volume booster is included in the

design to provide high flow capacity (up to 12 SCFM).

Three versions of the compact transducers are available. Listed below

are their model numbers, the current input accepted by each, and output

signal emitted by each.

• 512-117...4-20 mA Input/1-17 psi Output

• 512-015...4-20 mA Input/3-15 psi Output

• 512-027...4-20 mA Input/3-27 psi Output

n

IS-P-IP

IP Transducers

Series 512

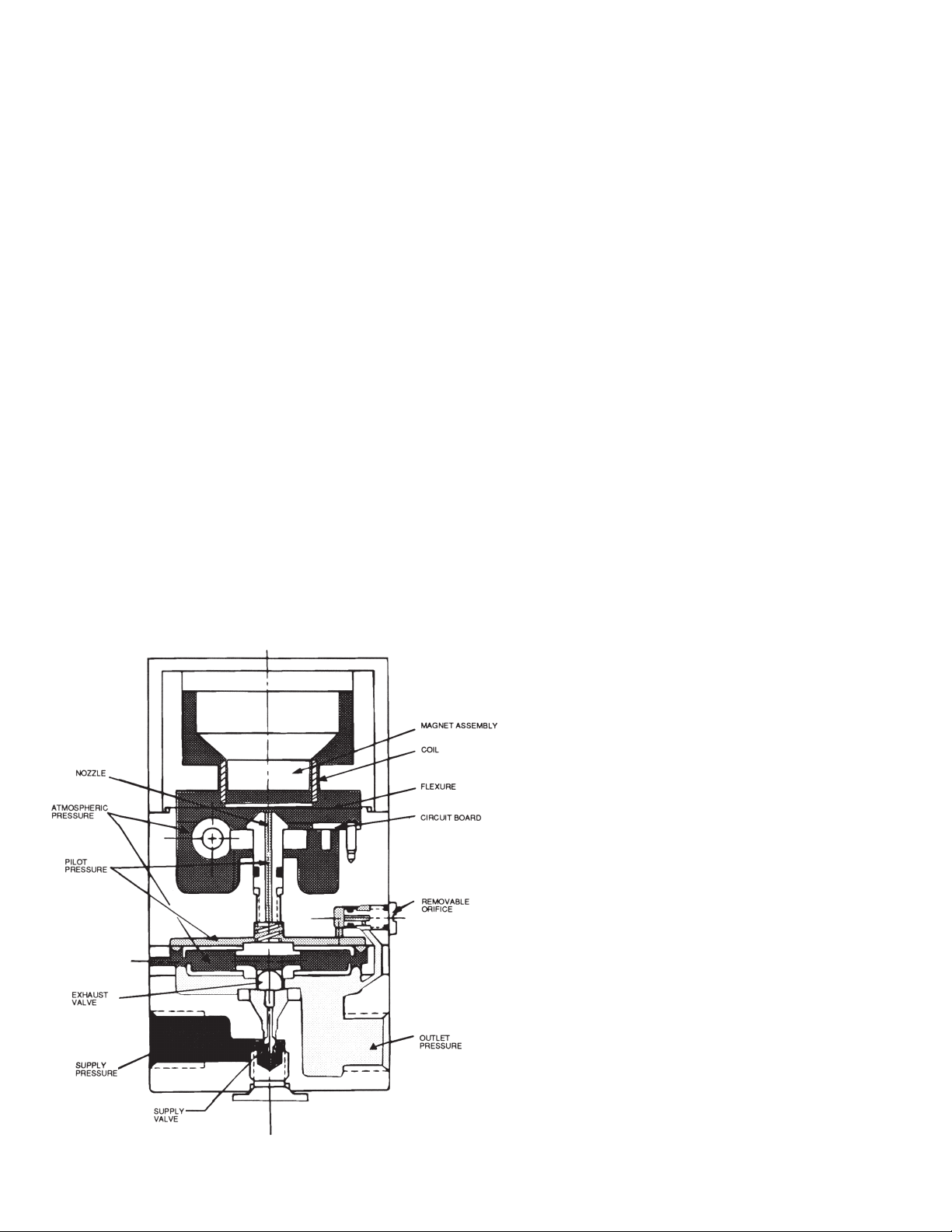

Operating Principle n

The I/P transducer is a force balance device

in which a coil (see figure 1 on page 2) is

suspended in the field of a magnet by a flexure. Current flowing through the coil generates axial movement of the coil and flexure.

The flexure moves against the end of a

nozzle and creates a back pressure in the

nozzle by restricting air flow through it. This

back pressure acts as a pilot pressure to

an integral booster replay. Consequently, as

the input signal increases (or decreases, for

reverse acting), output pressure increases

proportionally. Zero and span are calibrated

by turning easily accessible adjusting

screws on the front face of the unit. The zero

adjusting screw causes the nozzle to move

relative to the flexure. The span adjusting

screw is a potentiometer that limits the current through the coil. A thermistor in series

with the coil provides temperature compensation.

Page 2

Mounting

Installation n

The 512 series transducers can be pipe, panel, or bracket

mounted in any position. Positions other than vertical will require

recalibration of the zero adjustment. For maximum output pressure stability, the transducer should be mounted in a vibrationfree location or such that vibration is isolated to the X and Z axis

shown on the dimensional drawing (see Figure 2 on page 3).

Field Reversible

All transducers are calibrated at the factory for direct acting

operation but may be used in the reverse acting mode by reversing the polarity of the signal leads and recalibrating. When calibrated for reverse acting applications, the transducers provide a

minimum of their full rated output pressure (i.e., 15, 17, or 27 psig)

upon input signal failure.

Mounting

Pipe:

Due to its light weight, the transducer may be supported using its

own plumbing on pipes used for air supply and output.

Panel (with access to rear of panel):

Attach transducer to panel using two 10-32 screws (supplied)

into the threaded holes on the back of the transducer.

Panel (with no access to rear of panel):

Attach bracket using tow 10-32 screws (supplied) into the

threaded holes on the back of the transducer. Use 10-32 screws

through holes in the bracket to mount transducer to panel.

Flowrite II Valve:

For mounting in the field, use mounting kit (optional accessory,

#512-005), which contains an adapator bracket (AB). First, attach

this AB to the yoke, then attach the mounting bracket (shown in

Figure 2-supplied with transducer) to the AB.

Mounting Notes:

1. Transducer may be mounted at any angle. See "Calibration."

2. Effect of external vibration can be kept at a minimum if unit

is mounted so that vibration is restricted to being along the X

and Z axes shown on the Dimensional Drawing, see figure 2.

Figure 1

Air Connections:

Supply

Connect air supply to 1/4 NPT port marked "IN" on base of unit.

Avoid getting pipe compound in air line and transducer.

Supply air must be instrument quality (filtered and dried).

2

Page 3

Output:

Connect output to 1/4 NPT port marked "OUT" on base of unit.

The two unmarked 1/4 NPT ports may be used as alternate output ports or for a gauge to measure output pressure. Unused

ports must be plugged.

Electrical Connections:

Connect electrical signal to leads exiting side of unit through 1/2

NPT conduit fitting. For direct acting (where increasing signal

increases output pressure), connect positive signal to black

lead and negative to white. For reverse acting (increasing signal

decreases output pressure), connect positive signal to white

lead and negative to black.

Calibration n

Transducer should be calibrated after mounting. If transducer is

calibrated in an upright position, then mounted at an angle, readjustment of the "ZERO" is necessary.

1. Remove plastic cap from "ZERO" and "SPAN" adjustment

screw access holes.

2. Set signal to low end of the signal scale. (For reverse acting,

set to high end of the signal scale).

3. Adjust "ZERO" screw until output pressure is set to the low

end of the output scale. Turn counterclockwise to increase

pressure, clockwise to decrease pressure. If output pressure

does not change when screw is turned, turn screw counterclockwise until pressure starts to rise.

4. Set signal to high end of the signal scale. (For reverse acting,

set to low end of the signal scale).

5. Adjust "SPAN" screw until output pressure is set to the high

end of the output scale.

6. Repeat steps 2, 3, 4, and 5 until no further readjustment is

necessary.

7. Replace protective caps.

Maintenance n

If internal clogging occurs due to improper filtering of the supply

air, the orifice can be cleaned without removing the unit from

its mounting or plumbing. Turn off the supply air. Unscrew and

remove the orifice assembly. Clean the orifice through the side

of the orifice assembly using a wire that has a smaller diameter

than 0.015 in. (0.38 mm). Shake out any loose particles inside of

the orifice assembly. Screw orifice assembly back into unit.

Figure 2

3

Page 4

ATTENTION INSTALLER: After installation, please leave this

Instruction Sheet for occupant’s information.

IMPORTANT: Inquire with governing authorities for local

installation requirements.

A Watts Water Technologies Company

USA: Phone: 1.800.669.5430 • Fax 1.847. 229.0526 • www.powerscontrols.com

Canada: Phone: 1.888.208.8927 • Fax 1.888. 479. 2887 • www.powerscontrols.ca

IS-P-IP 1028 EDP# 6512235 © 2010 Powers

Loading...

Loading...