Page 1

1. Attach checkstops to valve body. Screwed checkstops:

teflon tape is recommended to provide seal. Sweat check-

stops: to lessen potential for overheating of rubber sealing

discs during sweating in process, you must leave checkstop in full open position, or remove all internal parts to prevent melting of the rubber sealing discs.

2. Position mixer 2" ± 1/2" (51mm ± 13mm) from inlet center

to finished wall surface. Facing front of mixer, connect hot

water to left side and connect cold water to right side. The

valve has ‘C’ and ‘H’ cast into the body near the appropriate inlet ports.

3. When copper tubing is used, flared fittings are recommended. If flared fittings cannot be used, then the balance cartridge must be removed before soldering near the mixer

body. To remove the balance cartridge: remove the o-ring,

limit stop and sleeve, unscrew bonnet retainer and pull

bonnet out of the mixer body. Pull balance cartridge out

with either pliers or cartridge puller #401-202.

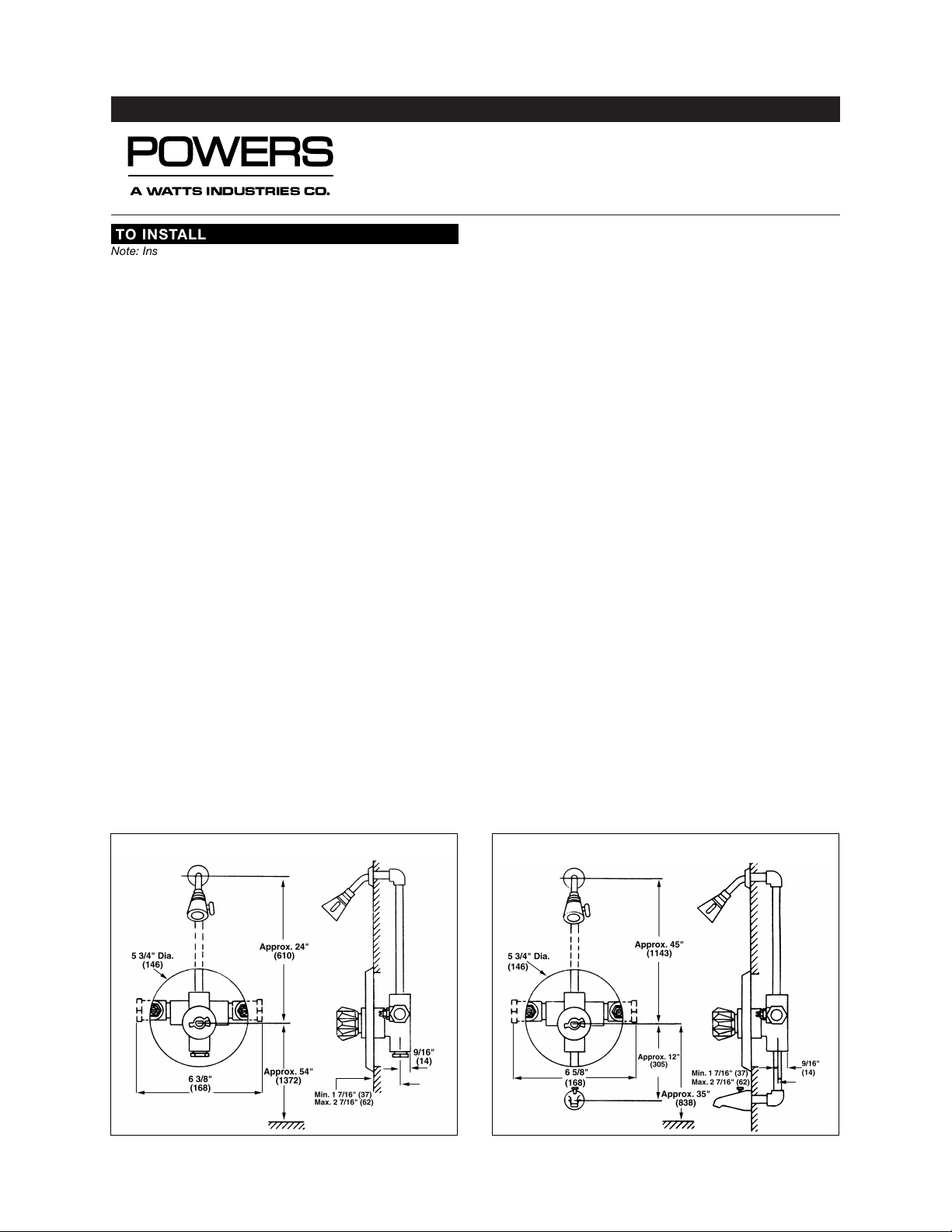

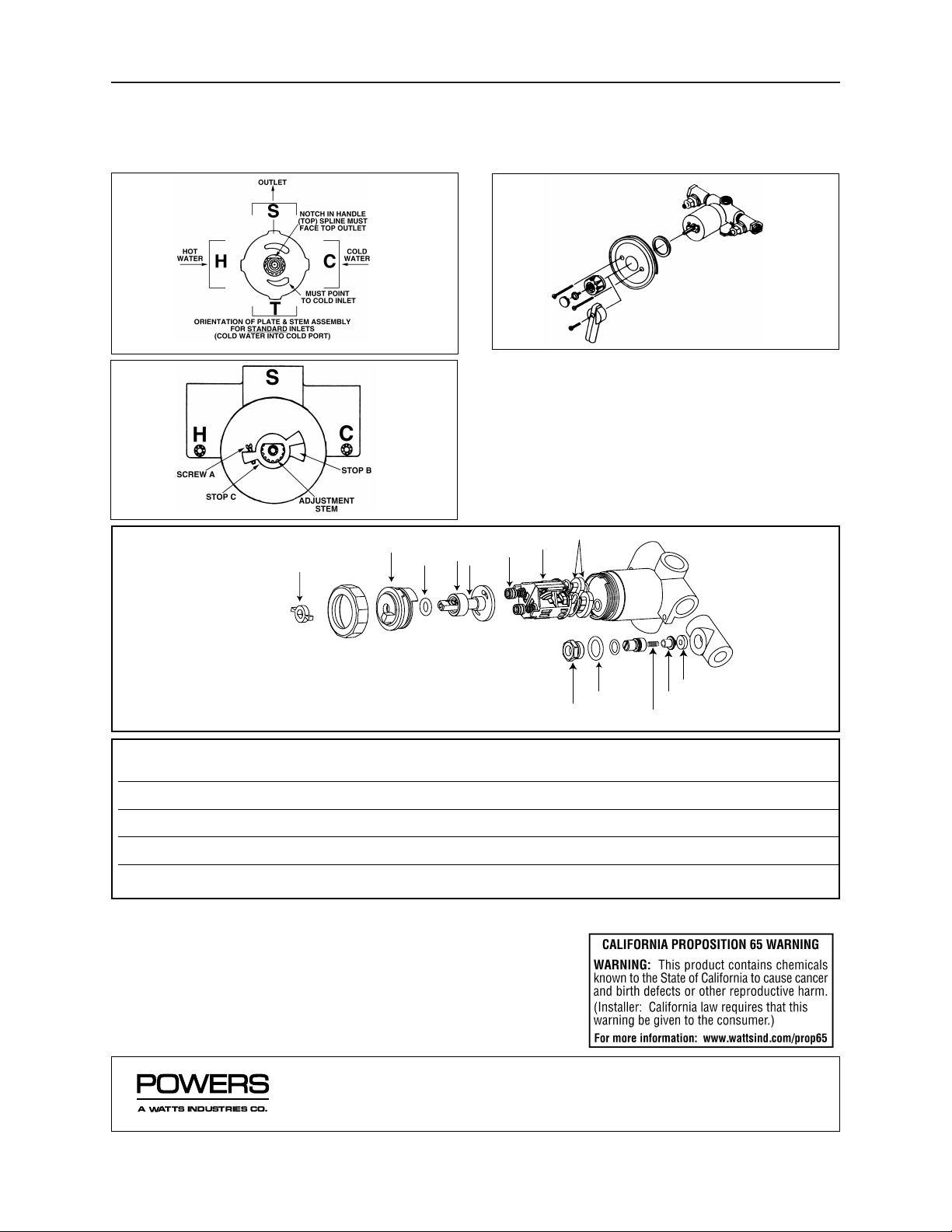

4. Biltmore is factory assembled for top outlet installation, see

Figure 1. For shower only installation, pipe top outlet directly to showerhead and plug bottom port. If reversed inlets

are required, place mixer stem in closed (full clockwise)

position, remove o-ring, limit stop and sleeve, unscrew and

remove bonnet retainer. Pull bonnet, stem and mixing plate

out of mixer body and rotate 180° making certain the alignment tabs on the bonnet are secure in the notches on the

mixer body. Replace bonnet retainer (limit torque to 20 ft.lbs.), slide sleeve over retainer, install limit stop over stem,

replace o-ring. With mixer in closed position, the notch in

the spline on the stem (Figure 3) must face top outlet for

standard inlet installation (cold water to cold port on right

side). For reversed inlets (cold water to hot port on left

side), the notch in the spline on the stem must face bottom

outlet.

Note: hot and cold inlets should be re-identified for

reversed inlets to avoid confusion during future mixer

maintenance.

5. For tub and shower installations, see Figure 2. Pipe bottom

outlet port ‘T’ directly to a diverter tub spout. The Biltmore

is equipped with a built-in diverter fitting in the mixer body,

so it is not necessary to use a twin ell. Pipe top outlet port

‘S’ to the showerhead. For tub installation only, plug top

outlet port ‘S’. Be certain that bottom outlet port ‘T’ is

piped to the tub. If outlet connections are reversed, the

mixer will not function properly.

6. Rough-in procedure: a cardboard sleeve protector is furnished with each Biltmore to protect the chrome plated

sleeve from damage during piping installation. When piping

installation is completed, the installer should remove the

cardboard sleeve protector and slide rough-in guide onto

mixer stem (guide stem is same notched shape as mixer

stem) and snap into place. The rough-in guide will not fit

over the cardboard sleeve protector.

The rough-in guide will insure proper size opening for mixer

and checkstop shut-off and repair accessibility, as well as

protect the chrome plated sleeve from damage during drywall and tile installation.

Position mixer so finished wall surface will be within the 1"

(25mm) dimension on rough-in guide (Figure 6). This

insures the center line of the mixer connections will be

2"±1/2" (51mm ± 13mm) from the finished wall surface.

After wall is completed, remove rough-in guide and attach

dial to mixer body with the screws furnished (Figure 4). To

install dial gasket, peel backing off gasket and attach gasket to inside dial plate.

INSTALLATION INSTRUCTIONS

BILTMORE SERIES 800

Pressure Balancing Valves

Figure 1: Rough-in Dimensions

- inches (millimeters)

A Watts Industries Co.

TO INSTALL

Note: Installation should be in accordance with accepted plumbing

practices. Flush all piping thoroughly before installation. If thin wall

installation is required, refer to Installation Instruction #129-075.

Figure 2: Rough-in Dimensions

- inches (millimeters)

Form II800 v3

Page 2

II800 v3 Page 2

7. MAXIMUM TEMPERATURE SETTING (refer to Figure 5). This

must be set at the jobsite. Mixer will pass full HOT water.

Rotate stem to desired maximum temperature. Adjust screw

A until it touches stop B.

CAUTION: Adjustable stop C must be utilized for proper

operation.

Figure 3

Figure 5

Figure 4

13

1

14

6

7

8

15

3

2

9

10

11

12

TROUBLESHOOTING RECOMMENDED REPAIR KIT

GASKET AND DISC 1) Water leak at stem and/or bonnet 800-030

REPLACEMENT 2) Flow of water continues after mixer is turned off Includes items: 2,3,7(2),9(2),10(2),13(2),15(2)

BALANCING CARTRIDGE 1) Variable or untempered discharge temperature 900-259

Includes items: 2, 3 7(2), 8,15(2)

STEM AND PLATE 1) Flow continues after mixer is turned off 800-032A

REPLACEMENT 2) Handle splines on stem damaged, not grasping Includes items: 1,2,3,6,7(2)

INTERNAL REBUILD KIT Note: Required if both Balancing Cartridge and Stem and Plate 800-163

replacement kits needed Includes items: 2,3,6,7(2),8,15

CHECKSTOP REBUILD KIT 1) Checkstop will not shut-off or allow full flow 900-049

2) Crossover Includes items: 9(2),10(2),11(2),12(2),3(2)

REPAIR KITS: for further

information on repair and

maintenance, see TI800-1.

Form II800v3 0311 EDP# 6512222 Printed in U.S.A.

USA office: Phone: 800.669.5430 • Fax: 847.824.0627

www.powerscontrols.com

Canadian office: Phone: 888.208.8927 • Fax: 888.882.1979

© 2002 Powers, a Watts Industries Co.

A Watts Industries Co.

Loading...

Loading...