Page 1

Technical Instructions

!

WARNING

Read this Manual BEFORE using this equipment.

Failure to read and follow all safety and use information can result in death, serious personal injury,

property damage, or damage to the equipment.

Keep this Manual for future reference.

WARNING

!

FAILURE TO COMPLY WITH PROPER INSTALLATION AND

MAINTENANCE INSTRUCTIONS COULD CONTRIBUTE TO THE

VALVE FAILURE.

This Hot Water Master Tempering Valves cannot be used for

tempering water temperature at fixtures. Severe bodily injury

(i.e., scalding or chilling) and/or death may result depending

upon system water pressure changes and/or supply water

temperature changes. ASSE standard 1016, 1069 or 1070 listed

devices should be used at fixtures to prevent possible injury.

These Hot Water Tempering Valves are designed to be

installed at or near the boiler or water heater. They are not

designed to compensate for system pressure fluctuations and

should not be used where ASSE standard 1016, 1069 or 1070

devices are required. These valves should never be used to

provide “anti-scald” or “anti-chill” service.

The components of the system must be of materials with a

construction capable of withstanding the high limit output temperatures of the water heating source.

AIR OPERATED:

Rigid Stainless Bulb

Direct Action 744-1270

Reverse Action 744-1271

Rigid Copper Bulb

Direct Action 744-1213

Reverse Action 744-1214

Specifications n

IS-P-TC744-1

Accritem Controller

Model 3

WATER OPERATED:

Rigid Stainless Bulb

Direct Action 744-1217

Reverse Action 744-1218

!

WARNING

Need for Periodic Inspection and Yearly Maintenance:

Periodic inspection and yearly maintenance by a licensed contractor is required. Corrosive water conditions and/or unauthorized adjustments or repair could render the valve ineffective for

service intended. Regular checking and cleaning of the valve’s

internal components and check stops helps assure maximum

life and proper product function. Frequency of cleaning and

inspection depends upon local water conditions.

!

WARNING

You are required to consult the local building and plumbing

codes prior to installation. If the information in this manual is

not consistent with local building or plumbing codes, the local

codes should be followed. Inquire with governing authorities for

additional local requirements.

!

WARNING

Flush all pipes thoroughly before installation. Installation and

field adjustment are the responsibility of the installer.

Operation .................................... Direct or Reverse Acting

Adjustment Dial Range—Standard 50 to 350°F (10 to 177°C)

Maximum Supply Pressure (air or water)

at Room Temperature

Air Consumption (max.)

Maximum Operating Pressure

Maximum Operating Temperature

Temperature Response

Mounting

....................................................... 1/2" NPT

Air or Water Connections

Drain Connection (water only)

Shipping Weight

.......................................... 4 lbs. (1.8 kg)

Sensitivity (adjustable)

..........................35 psi (241.3 kPa)

......................... 218 cm 3/s (800 SCIM)

...................... 1724 kPa (250 psi)

........................400°F(204°C)

................................... 0.5°F(0.3°C )

..................................... 1/8" NPT

................................ 1/4" NPT

................................3.1 to 27.9 kPa/C

(1/4 to 2-1/4 psi/F)

Maximum Pressure on Wells

Stainless Steel no. 744-082

Copper no. 744-111

Well Dimensions

............................................ See page 6

.................. 1125 psi (7756 kPa)

............................ 525 psi (3619 kPa)

Page 2

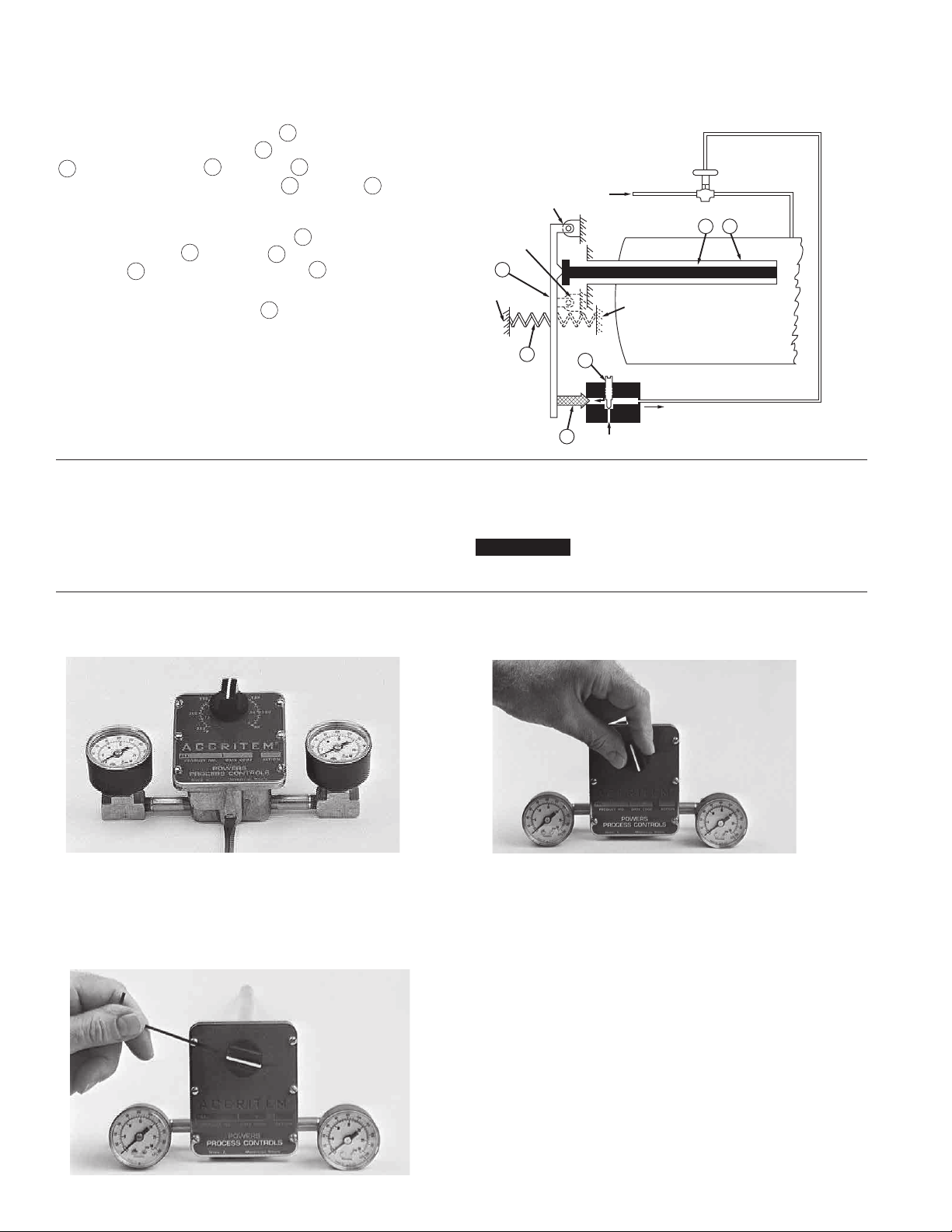

Operation Instructions n

Direct Action Controller

A temperature change in the medium being controlled creates a

change in length of the sensitive tube

ture lengthens the sensitive tube

away from the lever

2

3.

The lever

A, is moved to open the exhaust valve

1

. An increase in tempera-

1

and moves the Invar rod

3

, which pivots at Point

4

by spring

5

. This

permits the supply (air or water) (S) to increase the pressure in the

control line (R) and close the normally-open valve. A decrease in

temperature shortens the sensitive tube

rod against the lever

sure spring

to open the exhaust valve

5,

3.

The lever

3

nd moves the Invar

1 a

moves against the pres-

This exhausts the

4.

pressure in the control line and opens the valve.

The sensitivity adjustment screw

regulates the rate of flow

6

of the supply air (or water) to the controller to a change in temperature. Turning the screw clockwise increases the sensitivity

by reducing the flow and increasing the response time. Turning

the screw counterclockwise decreases the sensitivity by

increasing the flow and reducing the response time.

Also see Figure 8 on page 7.

Sensitivity n

The sensitivity of the Accritem controller is adjusted by turning the restriction screw (Figure 2). (The restriction screw is

factory-set for air operation.) For water operation, the restriction

screw should be opened a minimum of 1/2 turn and controller

recalibrated. Restriction screw must never be fully closed. Make

Figure 1

Positions “B” and “D” (dotted) show

pivot point (“B”) and spring when

controller is REVERSE acting.

Positions “A” and “C” (solid) show pivot

point (“A”) and spring when controller is

DIRECT acting.

3

C

Exhaust Air

A

B

D

5

6

R

4

S

Flowrite Valve

(Normally Open)

2 1

Tank

adjustments slowly, allowing about two (2) minutes after each

adjustment for the controller to balance.

NOTICE

If sensitivity is changed, controller must be recalibrated.

Calibration n

Figure 2

Loosen set screw and turn adjusting knob to indicate

temperature at bulb. Tighten set screw. Set controller for

desired control temperature.

Figure 4

Figure 3

Turn adjusting knob until 52 kPa (7-1/2 psi) control pressure shows on gauge. Read temperature at bulb with

an accurate thermometer.

Set restriction screw for desired sensitivity. Air: 1/8 turn

from closed (minimum). Water: 1/2 turn from closed

(minimum).

2

Page 3

Installation Instructions n

General Instructions

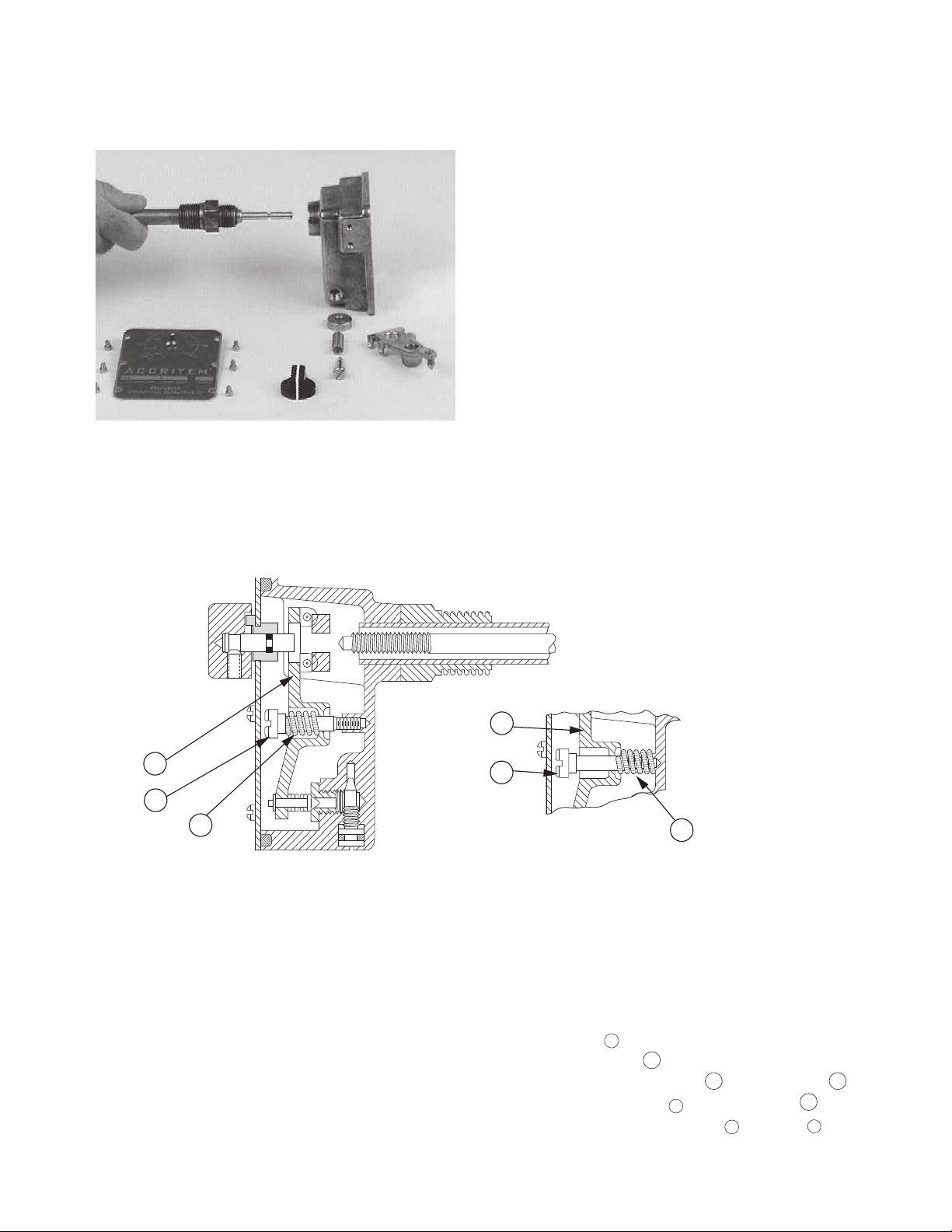

Figure 5.

To disassemble and replace sensitive tube assembly:

The Accritem Controller requires a clean, reliable supply

of compressed air or cold water at room temperature and

15 tgo 20 pounds of pressure. Other fluids may be used,

such as gas, oil, etc., providing provision is made for safe

disposal.

Select sensitive element location with care to insure satisfactory results. Bulb must project entirely into the liquid or air being

controlled.

Flush or blow out all lines before making final connections. Put

supply pressure through all control lines and check for leaks.

INSTALLATION FOR AIR OPERATION

Controller should normally be installed in horizontal position;

however, other positions may be used if the supply and control

connections are parallel with the ground and calibration is

checked after installation.

INSTALLATION FOR WATER OPERATION

Controller should normally be installed in horizontal position with

drain connection at bottom. For positive drainage at all times,

drain piping should be 3/8" minimum.

TO CHANGE CONTROLLER ACTION

(See Figures 6 and 7)

1. Turn adjusting knob clockwise to remove tension.

2. Remove adjusting knob and cover.

3. Remover lever spring retainer (D) and spring (E).

4. Relocate lever pivots (F).

5. Turn lever pivots to be snug without binding.

6. Replace lever spring retainer (D) and spring (E).

7. Replace cover and adjusting knob.

8. Recalibrate.

Figure 6

Lever

Lever

Spring

Retainer

Screw

7

8

9

DIRECT ACTING

SPRING LOCATION (in front of lever)

Spring

Retainer

Screw

The parts in Figure 7 are identified by letter in order of disassembly. For item number reference, see Parts Drawing: A (item

3) adjusting knob with set screw, B (item 10) cover screws, C

(item 2) cover plate, D (item 8) spring retainer screw, E (item 9)

lever spring, F (item 21) lever pivot, G (item 7) lever.

Always locate the controller as close as possible to the

controlled device. The piping between the controller and

controlled device (valve or damper motor) should be 1/8"

NPT brass pipe or 6.4 mm (1/4") OD copper tubing.

Difference in height between Accritem controller and controlled device should be kept to a minimum. When controller

is below controlled device, elevation cannot exceed 3 m (10")

with 104 kPa (15 psi) supply pressure. If controller is above

controlled device, adjust springs on valve or damper motor to

compensate for static head pressure.

7

8

9

REVERSE ACTING

SPRING LOCATION (behind lever)

Pressure Controller for Use with Water

Set pressure at 104–138 kPa (15–20 psi) when water is flowing.

Clean strainer at regular intervals.

Both Air and Water Controllers

To disassemble (Refer to Parts Drawing and Figure 5):

1. Remove knob 3after loosening its set screw.

2. Remove cover plate

2

.

3. Remove spring retainer screw 8and lever spring 9.

4. Back out one lever pivot 20and remove lever 7.

5. Unscrew sensitive tube assembly 20from body1.

3

Page 4

Figure 7

1/4" NPT to Drain (Water Operated Only)

B (6 screws)

E

G

C

F

(2 pivots)

A

To reassemble:

1. Install new sensitive tube assembly 19to body

2. Install lever 7. Tighten the lever pivot screws

1

.

21

required. The lever must be in the exact center of the

body and must move freely but without side play.

3. Install screws

31

and gaskets 32on water-operated

controller.

4. Install parts 8and 9 . (Note relationship for direct

and reverse acting. See Figure 6.)

5. Back out adjustment screw 5until collar

19

touches

the pivots on the lever 7.

D

as

2

6. Install cover plate

7. Install adjustment knob with set screw

.

3

. The knob

indicator (white line on side of knob) should be opposite

the dial marking corresponding to the room temperature.

Tighten the knob set screw very firmly.

8. Turn the adjusting knob to the desired control temperature

for approximate calibration.

9. Recalibrate as required after the controller is installed and

connected to the supply and control lines.

NOTICE

On units with a date code of 3L48 and later: When replacing a

knob (744-036) or cover plate (744-170), a new knob (744-234)

and cover plate (744-170D) must be ordered.

Parts n

Direct-Acting

Pivot

21

Reverse-Acting

Pivot

21

1/8" NPT

Return

AA

1/8" NPT

Air Supply

Air Operated

Water Operated

Section “A–A”

21

73 (2-7/8")

250

100

130

300

160

180

C

350

PRODUCT NO.

Skokie, Il.

F

POWERS

PROCESS CONTROLS

92

(3-5/8")

31

32

150

70

40

10

DATE CODE

Mississauga, Ontario

100

50

R

ACTION

Front View of Cover

4

Page 5

350

300

250

150

100

50

180

10

40

70

100

130

160

C

F

POWERS

PROCESS CONTROLS

Skokie, Il.

Mississauga, Ontario

PRODUCT NO.

DATE CODE

ACTION

R

21

21

21

31

32

Front View of Cover

Air Operated

Water Operated

Section “A–A”

1/4" NPT to Drain (Water Operated Only)

1/8" NPT

Air Supply

1/8" NPT

Return

Reverse-Acting

Pivot

Direct-Acting

Pivot

AA

92

(3-5/8")

73 (2-7/8")

Parts n

1

2

292 (11-1/2")40 (1-19/32")57 (2-1/4")

6

5

13 (1/2")

3

20

4

19

7

8

Direct-Acting

Spring Location

9

10

18

17

11* 12 13 15 16

*Used in Water-Operated Controllers Only

Parts List n

Part Numbers

No.

Item Part Name Air or Gas Water Req’d Material

1 Body — — 1 Brass

2 Cover Plate 744-170D 744-170D 1 —

3 Adjusting Knob

w/ Set Screw 744-234 744-234 1 —

4 Quad Ring — 047-043 1 —

5 Adjustment Screw 744-175 744-175 1 Brass

6 Stop Pin 744-061 744-061 1 Brass

7 Lever — — 1 Brass

8 Spring Retainer

Screw 744-124 744-124 1 Brass

9 Lever Spring 225-073 430-021

1 Stainless Steel

u

10 Cover Screw 030-041 030-041 6 Brass

11 O-Ring Not used 047-050 1 Silicone Rubber

30

18

8

9

Reverse Acting Spring Location

Water Operated

17

Basic Accessory Kit No. 744-102 is included with each Accritem Controller but is not

shown. Parts included in Kit No. 744-102 are (two of each item are included):

1/8" NPT x 1-1/2" (38mm) lg. brass nipple

1-1/2" (38mm) pressure gauge 0–30 psi

1/8" NPT brass tee

.................................................Part No. 043-351

.......................Part No. 042-513

........................Part No. 142-0373

Part Numbers

No.

Item Part Name Air or Gas Water Req’d Material

12 Retaining Ring 100-124* 100-124** 1 Phos. Bronze

13 Valve 744-155* 744-163** 1 Phos. Bronze

15 Valve Spring 744-075* 744-075** 1 Phos. Bronze

16 Valve Seat 744-063* 744-131**

17 Restriction Screw

†

744-072 744-134s Brass

18 O-Ring 047-049

l

047-045 1 Buna-N

s

1 Phos. Bronze

19 Thrust Collar — — 1 Brass

20 Sensitive Tube 744-191 744-191 Stainless Steel

Assembly 744-172 744-172 1 Sensitivity Tube

21 Lever Pivot 744-154 744-154 2 Stainless Steel

30 Insert — — 1 Stainless Steel

31 Sealing Screw — 030-895 4 Stainless Steel

32 Gasket — 744-083 4 Rubber

(Pkg. of 10)

u

†

Also order O-ring (see item 18).

Material is Stainless Steel

s

Material is Silicone Rubber

l

* Included in Valve and Seat Kit for Model 3 (Air-Operated Accritem)

No. 744-168—parts are not available separately.

** Included in Valve and Seat Kit for Model 3 (Water-Operated Accritem)

No. 744-169—parts are not available separately.

Valve and Seat Kit for Model 3 (Air-Operated Accritem)

Valve and Seat Kit for Model 3 (Water-Operated Accritem)

..........744-168

......744-169

5

Page 6

Accessories n

Dimensions: Millimeters (Inches)

AIR

Accessory Kit No. 744-107

(Dotted line item not included)

Provides materials necessary to reduce the

incoming air supply pressure to within the

supply pressure range of the Accritem

Accritem Controller

Pressure-Reducing

Valve

1/8" Nipple

INOUT

1/4 x 1/8 Reducing Bushing

WATER

Accessory Kit No. 744-180

(Dotted line items not included)

Kit provides materials necessary to convert

the Accritem from air operation to water

operation.

To Controlled

Device

1/4" IPT

1/8" Nipple

Drip plug

Supply gauge may also be installed in extra outlet of PRV.

Place 1/4" Pipe Plug here

Brass Union Assembly No. 744-106

Provides pressure-tight connection for

installing Accritem in pipe or tank

where space does not permit rotation

of Accritem body.

3–50 psi

Pressure-Reducing Valve

(with integral strainer)

1/2" NPT

1/4" IPT

Water Inlet

Strainer

1/4 x 1/8 Reducing Bushing

Well Dimensions

mm (inches)

68

(2-11/16")

(3/4")

1-3/8" Hex

19

Set Screw (holds Accritem in well)

13

(1/2")

22 (7/8")

3/4" NPT

Accritem Well

281

(11-1/16")

6

16

(5/8")

Page 7

Operation n

Continued

Figure 8. Additional information on controller action and applications.

APPLICATION

HEATING COOLING MIXING

ACTION:

DIRECT Acting Normally OPEN valve Normally CLOSED valve Hot piped to Normally OPEN

port of valve

Valve OPENS on air failure Valve CLOSES on air failure Valve opens to HOT flow

on air failure

REVERSE Acting Normally CLOSED valve Normally OPEN valve Hot piped to Normally CLOSED

port of valve

Valve CLOSES on air failure Valve OPENS on air failure Valve opens to COLD flow

on air failure

7

Page 8

WARNING: This product contains chemicals known to the

State of California to cause cancer and birth defects or

other reproductive harm.

For more information: www.watts.com/prop65

Warranty n

The Seller warrants that the equipment manufactured by it and covered by this order or contract is free from defects in material and workmanship and, without

charge, equipment found to be defective in material or workmanship will be repaired, or at Seller’s option replaced F.O.B. original point of shipment, if written

notice of failure is received by Seller within one (1) year after date of shipment (unless specifically noted elsewhere), provided said equipment has been properly

installed, operated in accordance with the Seller’s instructions, and provided such defects are not due to abuse or decomposition by chemical or galvanic action.

THIS EXPRESS WARRANTY IS IN LIEU OF AND EXCLUDES ALL OTHER WARRANTIES, GUARANTEES, OR REPRESENTATIONS, EXPRESS OF IMPLIED. THERE ARE

NO IMPLIED WARRANTIES OF MERCHANTABILITY OR OF FITNESS FOR A PARTICULAR PURPOSE. The Seller assumes no responsibility for repairs made on the

Seller’s equipment unless done by the Seller’s authorized personnel, or by written authority from the Seller. The Seller makes no guarantee with respect to material

not manufactured by it.

A Watts Water Technologies Company

USA: Phone: 1.800.669.5430 • Fax 1.847. 229. 0526 • www.powerscontrols.com

Canada: Phone: 1.888.208.8927 • Fax 1. 888 . 479. 2887 • www.powerscontrols.ca

IS-P-TC744-1 1307 6512229 © 2013 Powers

Loading...

Loading...