Page 1

Technical Instructions

Description n

Powers Flowrite II Water Mix (MI) Valves combine hot and

cold water proportionally to satisfy the demands of the controlling instrument.

The valve's linear inherent characteristic produces equal

changes in flow per unit of valve stroke regardless of plug

position. The valve is air operated and can be used in a variety of mixing applications.

Specifications n

VALVE

Body Sizes: ................................ 2 1/2" – 6"

Body Material: .......................... Cast Iron

(per ASTM A126-93 Class B)

End Connectors: ....................... 125 # Flanged

(per ASNI B16.1-1993)

Trim: ........................................... Bronze

Packing: ..................................... Spring loaded TFE packing

Seat Leakage: ........................... ANSI Class III; <0.1% leakage

Cv Range: .................................. 74-390

Rangeability: ............................. 100:1

Characteristics: ........................ Linear/Mixing

Maximum Pressure: ................ 200 psi @ Temp. <150°F

Max. Differential Press.: ......... 50 psi

Temperature Range: ................ 40 – 281° F

ACTUATOR

Housing Construction: ............. Die cast aluminum

Diaphragm Construction: ........ Replaceable molded neoprene

Diaphragm Area: ...................... 46 in2, 100 in

Maximum Press. and Temp: .. 35 psi and 200°F

Ambient Shipping Limits: ........ -40 to 220° F

Ambient Operating Limits: ...... -20 to 220° F

Air Connection: ......................... 46 in2 1/4" NPT

100 in2 1/8" FNPT

Position Indication: .................. 1/8" increments

Mounting: .................................. In any upright position with

actuator head above 45° of the

center line of the valve body.

Actuator head may be swiveled

to any convenient position.

Table of Contents n

Description ..................................................... 1

Specifications ................................................ 1

Application Information ............................... 2

Theory of Operation ..................................... 2

Valve Sizing and Selection ...................... 3-4

Close Off Data ................................................ 5

Temperature/Pressure Ratings ................. 5

Dimensional Data ......................................... 6

Installation ...................................................... 7

Maintenance ................................................. 7

Ordering Information .................................... 8

2

IS-P-596MI

Flowrite II

Iron Body Series 596 MI

596 MI with 46 in2 actuator shown

Sizes Actuators Available

2 1/2" 46 in 2 or 100 in 2 Diaphragm

3" 46 in 2 or 100 in 2 Diaphragm

4" 46 in

5" 100 in 2 Diaphragm

6" 100 in 2 Diaphragm

!

WA R N I N G

FAILURE TO COMPLY WITH PROPER INSTALLATION AND

MAINTENANCE INSTRUCTIONS COULD CONTRIBUTE TO

THE VALVE FAILURE.

Watts Hot Water Master Tempering Valves cannot be used

for tempering water temperature at fixtures. Severe bodily

injury (i.e., scalding or chilling) and/or death may result

depending upon system water pressure changes and/or

supply water temperature changes. ASSE standard 1016,

1069 or 1070 listed devices should be used at fixtures to

prevent possible injury.

The Watts Hot Water Tempering Valves are designed to be

installed at or near the boiler or water heater. They are not

designed to compensate for system pressure fluctuations

and should not be used where ASSE standard 1016, 1069 or

1070 devices are required. These Watts valves should never

be used to provide “anti-scald” or “anti-chill” service.

The components of the system must be of materials with a

construction capable of withstanding the high limit output

temperatures of the water heating source.

!

WA R N I N G

Need for Periodic Inspection: Periodic inspection by a

licensed contractor is recommended. Corrosive water

conditions, temperatures over 210°F, and or unauthorized

adjustments or repair could render the valve ineffective

for service intended. Regular checking and cleaning of the

valve’s internal components and check stops helps assure

maximum life and proper product function. Frequency of

cleaning and inspection depends upon local water conditions and water temperature.

2

or 100 in 2 Diaphragm

Page 2

Application Information n

Flowrite II 596MI Valves are used for mixing hot and cold-water

streams or bypassing flow with the valve in the return line. The

controlling instrument positions the mixing valve to obtain the

approximate mixture temperature.

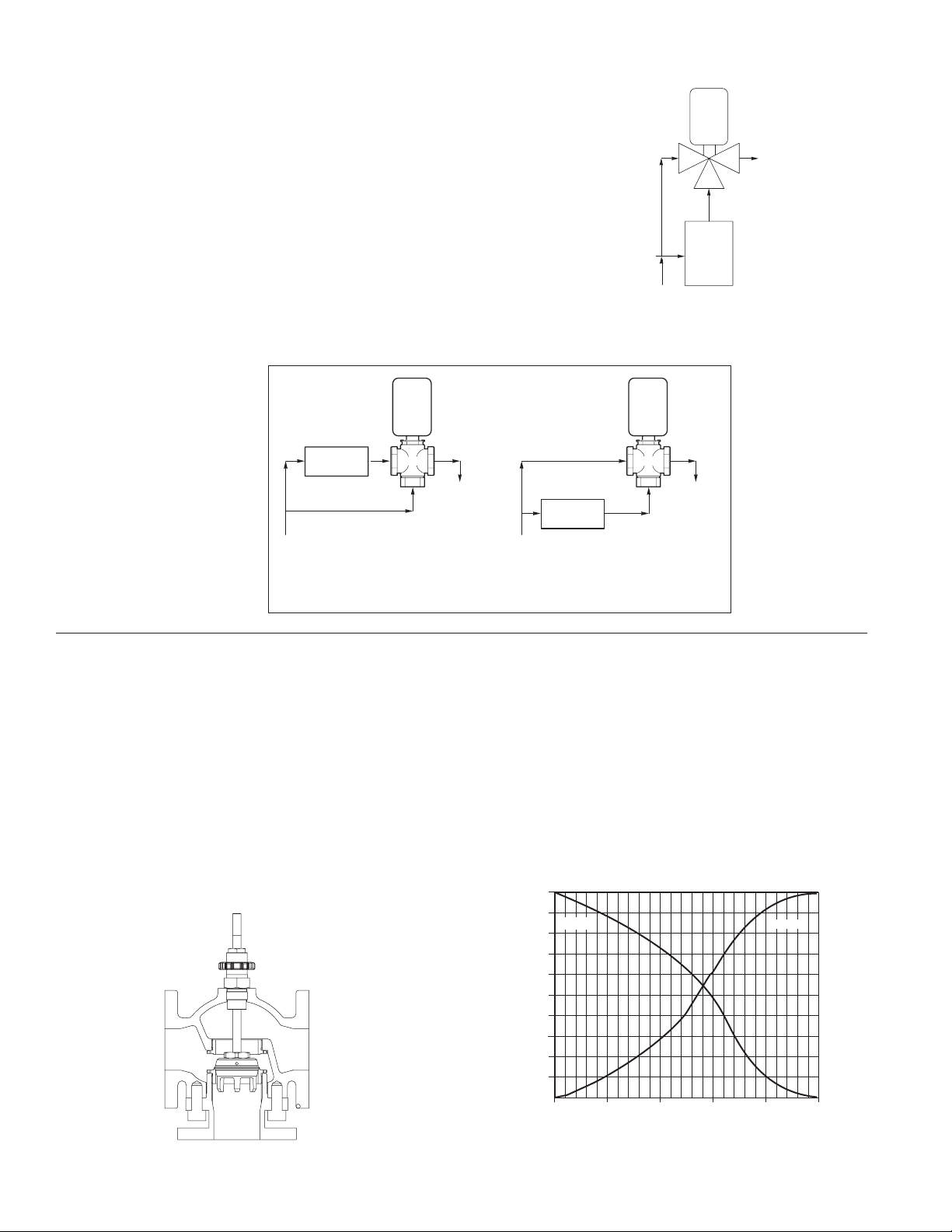

Figure 1 shows an example of a mixing application, a typical

boiler hot water control system. The cold inlet supply is fed to

the upper inlet port (A port) of the valve as well as through the

boiler for production of hot water to be fed into the bottom port

(B port).

Figure 2 shows an example of a bypass application, piping for

control of a heating or cooling coil, with the valve in the return

line. The controlling instrument positions the valve so that the

hot water will bypass the coil when the air is at the proper temperature. A pump is recommended in the coil loop to improve

the heat transfer characteristics of the coil.

Coil

Bypass

Supply Supply

Stem down flow through coil.

Stem up flow through coil bypass.

Valve

Return

Figure 1

Cold Water

Supply

Boiler Hot Water Control System

Figure 2

Bypass

Coil

Stem up flow through coil.

Stem down flow through coil bypass.

Control

Valve

Return

A AB

B

Hot Water Inlet

Boiler

Valve

Return

Bypass Piping for Control of a Heating or Cooling Coil

Theory of Operation n

Air pressure from the controlling instrument enters the pressure

tight chamber of the actuator between the diaphragm and the

upper housing. An increase in control air pressure causes the

diaphragm to press down on the thrust plate, compressing the

springs and moving the valve stem downward. In the valve, this

reduces the flow through the "B" port and increases the flow

through the "A" port.

Conversely, A decrease in control air pressure reduces the

downward force on the actuator diaphragm, moving the

thrust plate and stem upward. The flow through the "B" port is

increased, and the flow through the "A" port is decreased.

Figure 3

A

B

Three-way valve

AB

In temperature mixing applications the hot inlet is usually

plumbed to the "A" side port, which will close on loss of signal.

Otherwise, the "B" lower port is used for hot, "A" upper side port

for cold, and the "AB" outlet for the mixed combination (see

Figure 3).

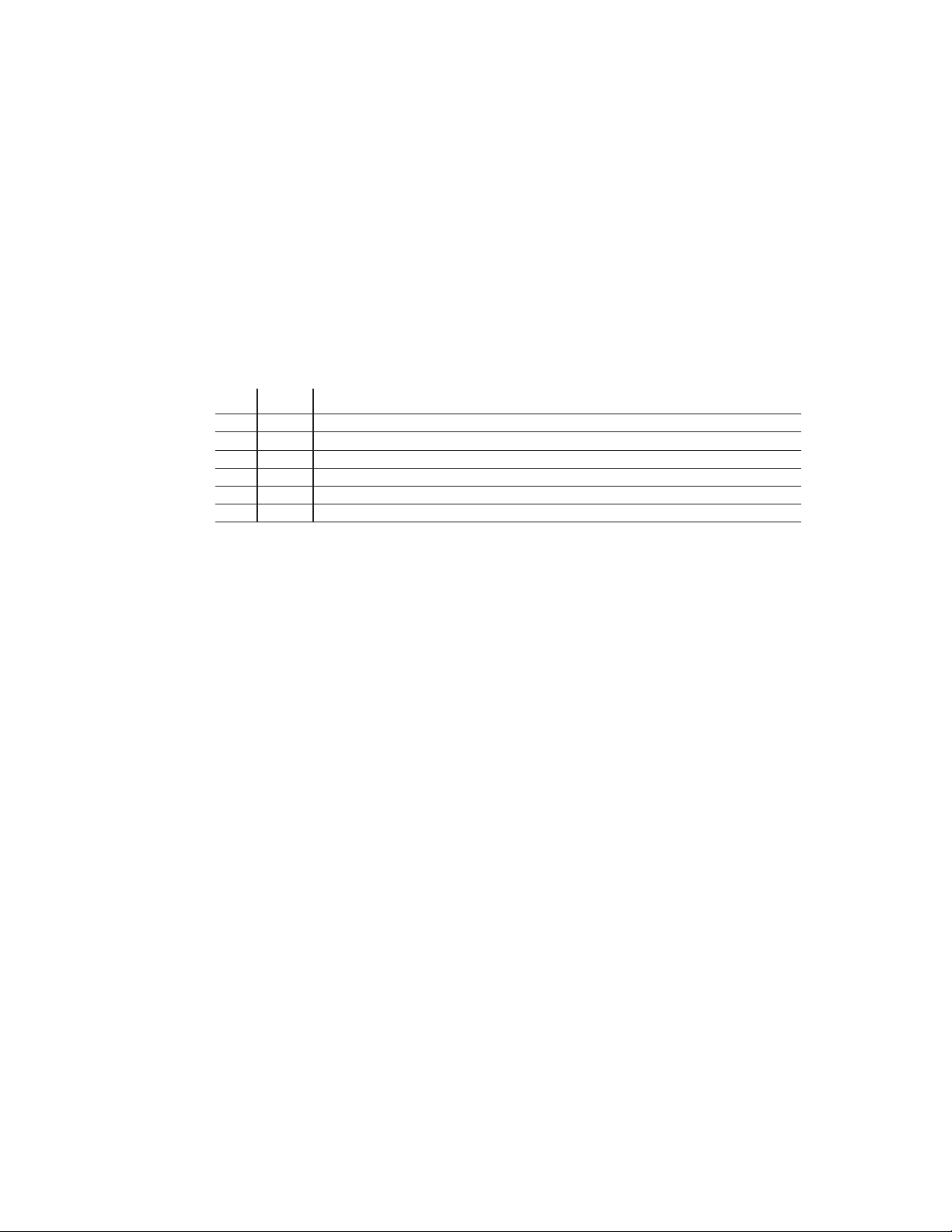

Three-way mixing valves are designed so that the flow from

either of the inlet ports to the outlet is approximately linear,

which means the total flow from the outlet is almost constant

over the stroke of the valve stem. See Figure-4 for typical flow

characteristics of 596 MI.

Figure 4

100%

90%

"A" Port

80%

70%

60%

50%

40%

Rated Flow

30%

20%

10%

0%

0%

20%

40%

StrokeStem In

60%

Rated Flow vs Stroke Diagram

2

"B" Port

80%

Stem Out

100%

Page 3

Valve Sizing and Selection n

NOTE: Supply pressures (inlet) are affected by piping sched-

ule, internal surface conditions, and vertical runs (back pressure) so the actual flowing pressure is best measured at the

point of valve use.

Proportional to Mix Supply Flows

Proportional valves when used to blend two water flows control the output by varying the water temperature to the heat

exchanger at constant flow. These valves require high pressure drops for good control results. They can be sized for a

pressure drop of 20% of the flowing pressure or equal to 25% of

the pressure drop through the heat exchanger at full flow.

Table - 1 Water Capacity in Gallons Per Minute

Valve Cv

Size Rating Differential Pressure (∆ in psi)

5 10 15 20 25 30 35 40 45 50

2.5 74 165 234 287 331 370 405 438 468 496 523

3 101 226 319 391 452 505 553 598 638 678 714

4 170 380 538 658 760 850 931 1006 1075 1140 1202

5 290 648 917 1123 1297 1450 1588 1716 1834 1945 2051

6 390 872 1233 1510 1744 1950 2136 2307 2467 2616 2758

Proportional to Bypass Flow

Proportional mixing valves when used to bypass flow are piped

on the outlet side of the hot water source to throttle the water

flow and thereby control heat output. These valves are usually

selected to take a pressure drop up to 50% of the flowing pressure through the valve.

3

Page 4

Valve Sizing and Selection cont. n

Cavitation, Flashing and Choked Flow:

Limitations on Valve Pressure Drop

A concern in high temperature water systems is the potential

for cavitation, which is caused by the downstream pressure

being lower than that of the vapor pressure of the fluid. This

basically causes the water to "boil" and can result in reduced

flow/capacity, excessive noise, vibration, wear and should be

avoided if possible. If the pressure downstream of the area

restriction rises rapidly above the vapor pressure, the vapor

bubbles will collapse violently (implode). The bubble collapse is

an affirmation of cavitation. Use the following equation below

to estimate the maximum allowable pressure drop across the

valve.

Pmax = 0.5 (P1 – Pv)

Where:

Pmax = Maximum allowable pressure drop

P1 = Absolute inlet pressure (psia)

Pv = Absolute vapor pressure (refer to psia - Table 2)

Absolute pressure = gage pressure + 14.7

Table-2 Vapor Pressure of Water

Flashing is a phenomenon where the flowing high temperature

water inlet experiences a significant pressure drop, with the

outlet pressure below the vapor pressure of the water (as in

cavitation) and is converted to a vapor within the control region

of the valve.

This can also produce a choked flow condition where the rapidly expanding vapor prohibits any increase in flow, even though

P1 (inlet) pressure is increased.

Water Vapor Water Vapor

Temp. Pressure Temp. Pressure

(°F) (psia) (°F) (psia)

40 0.12 140 2.89

50 0.18 150 3.72

60 0.26 160 4.74

70 0.36 170 5.99

80 0.51 180 7.51

90 0.70 190 9.34

100 0.95 200 11.53

110 1.28 210 14.12

120 1.69 220 17.19

130 2.22 230 20.78

4

Page 5

Close Off Data n

Varying the preload is possible to adjust close offs between the upper and lower ports.

Table 3 - Close Off Data

Close Off ( ∆ P in psi)

Signal-to-Actuator

Valve Size Actuator (Positioner)

(in) Size (in2) 3-15 PSI 1-17 PSI 0-30 PSI

Upper Port Lower Port Upper Port Lower Port Upper Port Lower Port

2.5 46 8 8 27 27 73 73

100 (1M) 13 98 55 125 55 125

3 46 3 3 16 16 48 48

100 (1M) 6 66 35 94 35 125

4 46 0 0 6 6 24 24

100 (1M) 1 34 17 50 17 125

5 100 (1M) 0 21 9 31 9 97

6 100 (1M) 0 13 5 20 5 66

Temperature/Pressure Ratings n

Never exceed the temperature/pressure ratings of the valve (see figure 5). The shaded

area shows the acceptable region.

Figure 5

596MI

Temperature — F

Pressure — psig

Temperature and Pressure Ratings

5

Page 6

Dimensional Data n

Table-4 Dimensions for 596MI Series Valves

Nominal Pipe Size 2-1/2" 3" 4" 5" 6"

A 8.500 9.500 11.500 13.000 14.000

STROKE 0.875 0.875 0.875 1.750 1.750

B 5.375 6.375 8.500 8.750 9.750

C 3.500 3.750 4.500 5.000 5.875

D 10.375 10.375 10.375 N/A N/A

E 10.000 10.000 10.000 N/A N/A

F 16.625 16.625 16.625 19.000 19.000

G 10.313 10.313 10.313 10.313 10.313

Valve Weight (lbs) 62.00 82.00 115.00 180.00 264.00

Weight w/46" 75.00 95.00 128.00 N/A N/A

Weight w/100" 87.00 107.00 140.00 205.00 289.00

Figure 6

100" Actuator

G

E

F

C

B

46" Actuator

D

A

2-1/2" to 6" Valve Bodies

Table - 5 Flange Detail for American Standard 125 lb. Cast Iron Pipe Flanges

Flanges Drilling Bolting Length of

Valve Flange Flange Diameter of Diameter of Number Diameter Machine

Size Diameter Thickness Bolt Circle Bolt Holes of Bolts of Bolts Bolts

A B C D E

2-1/2" 7" 11/16" 5-1/2" 3/4" 4 5/8" 2-1/2"

3" 7-1/2" 3/4" 6" 3/4" 4 5/8" 2-1/2"

4" 9" 15/16" 7-1/2" 3/4" 8 5/8" 3"

5" 10" 15/16" 8-1/2" 7/8" 8 3/4" 3"

6" 11" 1" 9-1/2" 7/8" 8 3/4" 3-1/4"

Figure 7

E

D

B

C

A

6

Page 7

Installation n

Inspection

Inspect the package and contents for damage. If damaged,

notify the appropriate carrier immediately.

If consultation is necessary, please contact Powers Customer

Service for assistance.

Requirements

• Pipe wrenches

• Flange gaskets, bolts / nuts

• Installer must be a qualified, experienced technician

Mounting / Orientation

1. The valve should be mounted in a location that is within the

ambient limits of the actuator. When selecting a location,

allow sufficient room for valve linkage, actuator, and other

accessories and for service of the product.

2. The preferred mounting position for the valve is with the valve

stem vertical above the valve body. Avoid mounting the valve

so that the valve stem is below horizontal.

3. The valves must be piped with two inlets ("A" and "B" ports)

and one outlet ("AB" port).

CAUTION!

• Install the valve with the flow in the direction of the flow

arrows ("A" and "B" ports are inlets and "AB" port is the outlet).

• Do not exceed the ratings of the device.

• Avoid locations where excessive moisture, corrosive fumes, or

vibration are present.

Flanged Connection

The 596 series flanged valve bodies conform to ANSI Standard

125 Lb. Cast Iron Pipe Flanges. The companion flanges (not

provided) should be the same specification as the valve. The

125 Lb. Flanges have plain flat faces and should not be bolted to

a raised faced flange.

1. All parts should be clean to assure the best results.

Figure 8 - Installation of Flanged End Valves

2. The pipe with the companion flanges installed should be

properly supported and aligned. Be sure the companion

flange is flush with the face of the valve body flange and lined

up squarely.

3. Use a gasket material (not provided) that is recommended

for the medium being handled. CAUTION! Do not apply pipe

dope to the valve flange, gasket, or companion flange.

4. See Figure-7 for flange and flange bolt details. Figure-8

Valve

Body

Gasket:

Supplied by Others

Companion

Flange

shows the proper way a flanged valve should be mounted.

Maintenance n

Regular maintenance of the total system is recommended to assure sustained performance. See Table-6 for maintenance kit part numbers.

Table - 6 Maintenance Kits for 596MI Valves

Valve Description Replacement Replacement Valve Repair Kit*

Pack Assembly Gaskets

2.5 596 Pack 596250G MIGOBMTK

3 596300G MIHOBMTK

4 596400G MIJOBMTK

5 596500G MIKOBMTK

6 596600G MILOBMTK

* Kit includes replacement packing and stem & plug assembly.

Water System Maintenance

All systems are susceptible to valve and system problems caused

by improper water treatment and system storage procedures.

These guidelines are provided to help avoid valve and water system problems resulting from improperly treated water or storage

procedures and to obtain maximum life from the valves.

To maintain non-damaging conditions, follow these guidelines:

• Clean the system prior to start up.

• Use filtration equipment where needed.

• Properly store off-line systems and monitor water treatment

results.

• Follow the advice of a water treatment professional.

Durability of valve stems and packings is dependent on maintaining non-damaging water conditions. Inadequate water treatment

or filtration can result in corrosion, scale, and abrasive particle

formation. Scale and particulates can result in stem and packing

scratches and can adversely affect packing life and other parts

of the hydronic system.

7

Page 8

Ordering Information n

M I

596-

Size Order Code

2 1/2" 250

3" 300

4" 400

5" 500

6" 600

End Connections

125# Flange F

Valve Trim

Bronze B

Action

Mixing M

Packing

Teflon T

Actuator Select Code n

Code Pneumatic Diaphragm Actuators

46 46 Sq. in, 1" Max Valve Stroke with Stainless Steel Springs,

adjustable start w/ 7 ~ 12 lb. Fixed span

4X 46 Sq. in, 1" Max Valve Stroke with Extended Springs

(requires positioner), adjustable start w/22 lb. span.

1M 100 Sq. in, 5-10 psi Spring Range (Mixing Valves)

Accessories Select Code n

Code Description

Bellofram 1000 I/P’S

IS 3–15 psi

TS 1–17 psi

US 3–27 psi

Control/Air Type 900X I/P

ES 0–30 psi

Utility Positioner and I/P

BS 4–20 mA

Utility Positioner

PS 3–15 psi

RS 3–9 psi

SS 9–15 psi

No Accessories

OS No Accessories

Accessories

Select Code

(see below)

Actuator

Select Code

(see below)

I/P Transducers n

The "standard" 3-15 psi signal was originally designed as a transmission signal, not a valve actuation signal. The Fluid Controls

Institute (in Standard 87-2) has recommended that a 1–17 psi

air signal range be used when directly actuating a control valve

without a positioner. Powers concurs with this recommendation, and therefore, offers a 1–17 psi I/P transducer and a 0–30

psi I/P transducer and the Accritem pneumatic controller for

maximum close-off. 3-15 psi I/P transducers should be used in

conjunction with positioners.

Positioners n

Positioners are used for one or more of the following reasons:

1) To split range valves.

2) To eliminate unwanted valve movement caused by line pressure variations

3) To minimize the effects of "stick-slip"

4) To speed response time and/or

5) To increase close-off rating when I/Ps are used.

Warranty n

The Seller warrants that the equipment manufactured by it and covered by this order or contract is free from defects in material and workmanship and, without

charge, equipment found to be defective in material or workmanship will be repaired, or at Seller’s option replaced F.O.B. original point of shipment, if written

notice of failure is received by Seller within one (1) year after date of shipment (unless specifically noted elsewhere), provided said equipment has been properly

installed, operated in accordance with the Seller’s instructions, and provided such defects are not due to abuse or decomposition by chemical or galvanic action.

THIS EXPRESS WARRANTY IS IN LIEU OF AND EXCLUDES ALL OTHER WARRANTIES, GUARANTEES, OR REPRESENTATIONS, EXPRESS OF IMPLIED. THERE ARE

NO IMPLIED WARRANTIES OF MERCHANTABILITY OR OF FITNESS FOR A PARTICULAR PURPOSE. The Seller assumes no responsibility for repairs made on the

Seller’s equipment unless done by the Seller’s authorized personnel, or by written authority from the Seller. The Seller makes no guarantee with respect to material

not manufactured by it.

A Watts Wat er Technologies Company

IS-P-596MI 1043 EDP# 6512249 © 2010 Powers

USA: Phone: 1.800.669.5430 • Fax 1.847. 229 . 0526 • www.powerscontrols.com

Canada: Phone: 1.888.208.8927 • Fax 1. 888 .479. 2887 • www.powerscontrols.ca

Loading...

Loading...