Page 1

• Up to 1380 lbs. of

force

• Excellent range

control

• Accurate repetitive

positioning

• Dual NAMUR

Accessory Mounts

• Field Reversible

• “Long-life” design

lasts over one

million cycles

46” Actuator

Powers’ most popular actuator is

powerful, durable, and versatile.

TABLE OF CONTENTS

Features . . . . . . . . . . . . . . . . . . . . . . . .2

Description . . . . . . . . . . . . . . . . . . . . .3

Guide to Applications . . . . . . . . . . . . .3

Operation . . . . . . . . . . . . . . . . . . . . . .3

Installing an Actuator . . . . . . . . . . . . .4

Changing Springs . . . . . . . . . . . . . .4-5

Changing Action . . . . . . . . . . . . . . .6-7

Preload . . . . . . . . . . . . . . . . . . . . . . . .8

Replacing a Diaphragm . . . . . . . . .9-10

Parts List . . . . . . . . . . . . . . . . . . .11-13

Spring Range Matrix . . . . . . . . . . . . .13

Modification Data Table . . . . . . .14-16

TI-593-672

Page 2

2

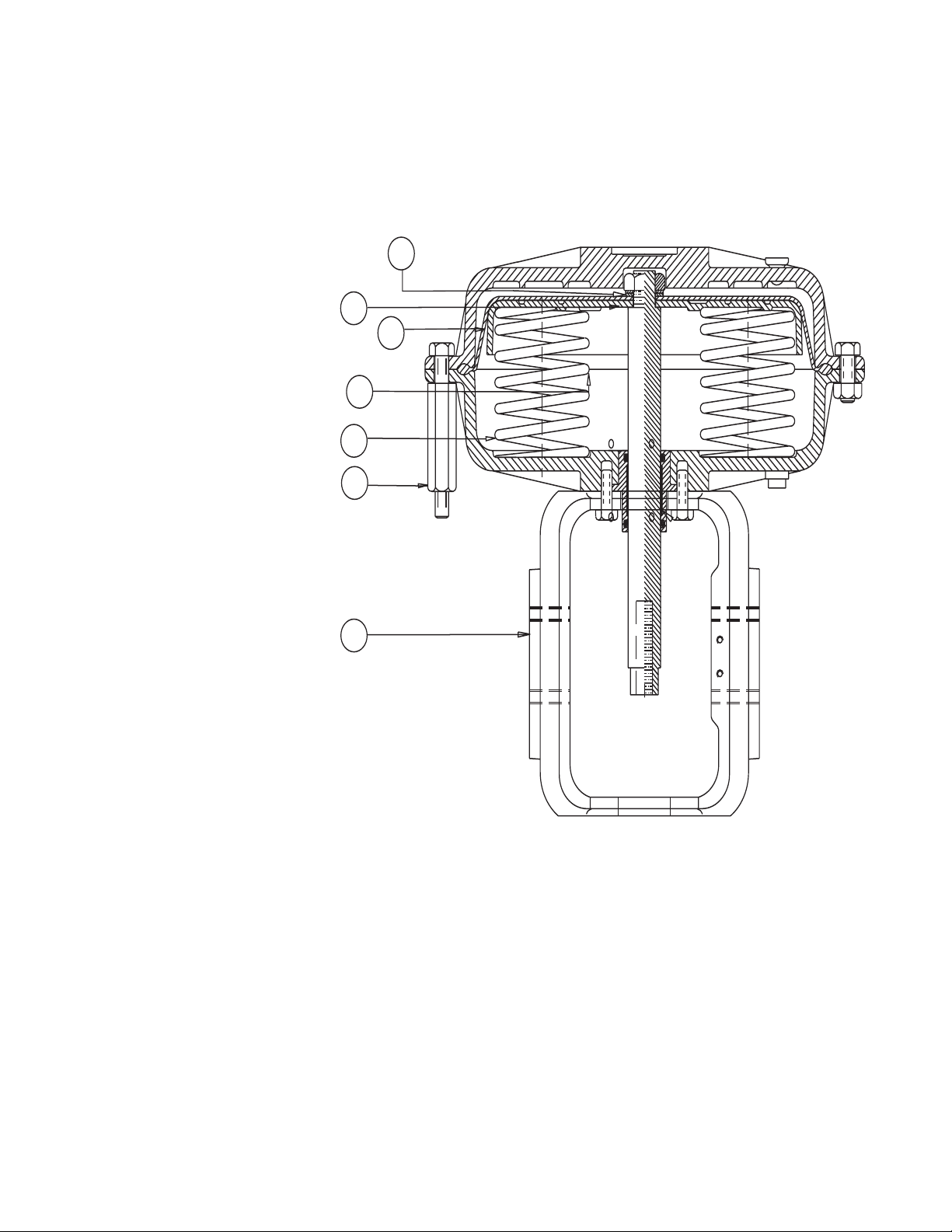

1. Optional stainless steel springs

extend operating life to over

one million cycles.

2. Nested spring design creates a

uniform stroke by eliminating

spring side flex.

3. 316 Stainless steel thrust

plate is corrosion resistant.

4. All stainless steel hardware

used in combination with SS

spring makes long-life

standard.

5. Molded fiber and reinforced

diaphragm greatly reduces the

risk of stress cracks.

6. Rolling diaphragm design

allows for even pressure

during the stroke cycle

making for more precise

control.

7. Field reversible design makes

changing the fail-safe mode

possible.

8. With *extended nut hardware,

preload can be safely released

for inspection.

9. Dual NAMUR mounts can be

used to quickly add or

reorient accessories.

FEATURES

*

5

3

6

2

1

8

9

Page 3

DESCRIPTION

Powers’ most popular actuator, the ‘46’, is a versatile, field reversible

design that is available on most Flowrite II valves. This actuator

provides:

• large effective area (1380 lbs of force at 30 psi) for powerful

valve close control

• excellent narrow range control signal performance

• accurate repetitive positioning due to large diameter

diaphragm, low friction actuator stem and bronze bearings, and

• dual NAMUR accessory mounts.

The 46 actuator and Flowrite II valves are designed to integrate intro a

highly flexible system. It is possible through the Flowrite II 46”

actuation system to adapt to changing application requirements by

reconfiguring the actuator through simple spring changes, stem

changes, etc. The purpose of these instructions is to suggest solutions

to meet your applications needs.

OPERATION

The actuator springs provide the necessary force to hold the stem in

the lowered or raised position.

On a Normally Open valve (ATC, D/A) assembly, the stem will

start its downward stroke whenever the control air pressure applied

against the actuator diaphragm area and upper housing exceeds the

holding force of the springs.

A further increase in control air pressure will initiate a continued

downward travel of the valve stem until the valve has completed its

stroke.

On a Normally Closed valve (ATO) assembly, the valve stem will

start its upward stroke whenever the control air pressure applied

against the actuator diaphragm area and the lower housing exceeds

the holding force of the springs.

A further increase in control air pressure will initiate a continued

upward travel of the valve stem until the valve has completed its

stroke.

The air pressure change to initiate full stem travel is known as the

throttling range or spring span. Standard spring span is equal to 8

psi (55 kPa) with no drop across the valve.

This throttling range is based on typical system pressure and will

vary slightly as the pressure drop across the valve changes. A

decrease in pressure at the diaphragm will initiate an upward

movement on a normally open valve assembly and a downward

movement on a normally closed valve assembly.

When the valve is at its wide open position, the disc and throttling

plug are farthest from the seat and there is maximum flow through

the valve.

Valve actuators equipped with a pilot positioner can utilize full

control air pressure at any point in the stem travel to initiate stem

movement or to maintain stem position.

However, the actuator springs still provide the necessary force to

move the stem in the opposite direction.

Use of a positioner will tend to provide faster response and to ensure

repeatability of stem position regardless of the load on the actuator.

However, in a system where available pressure and flow

requirements are relatively consistent, control valves can usually

perform adequately without a positioner.

GUIDE TO APPLICATIONS

To reverse actuator action, i.e., change an NO to an NC valve,

or an NC to an NO valve:

1. Refer to the Modification Tables for correct replacement parts.

2. Follow instructions for Reversing Actuator Action.

3. Follow instructions for Preload Adjustment.

To attempt valve sequencing with a 3-15 psi air signal OR to set

a NC valve assembly at a higher preload to maintain closeoff or

to increase the throttling range:

1. Refer to the Modification Tables for correct replacement parts.

2. Refer to Changing Springs.

3. Follow instructions for Preload Adjustment.

4. Use dimensions in the Spring Range Matrix.

To modify the actuator action, i.e., using the same actuator on a

different valve body or size:

1. Refer to Modification Tables for correct replacement parts.

2. Refer to Changing Springs.

3. Refer to Changing Action (changing stems).

4. Follow instructions for Preload Adjustment.

5. Use dimensions in the Spring Range Matrix.

To install an actuator on a valve and set the preload adjustment:

1. Follow Installing Actuator instructions.

2. Refer to Modification Tables for correct replacement parts.

3. Follow instructions in Preload Adjustment.

To replace a ruptured diaphragm:

1. Refer to Replacing the Diaphragm instructions.

3

Page 4

4

CHANGING SPRINGS (DIRECT ACTING ACTUATORS)

Springs can be changed or added if a higher shutoff rating is

required. This may become necessary under the following

conditions:

1. If the pressure of the medium passing through the valve increases,

2. If the valve size increases due to an increase in process demand, or

3. If valve body type is changed.

The Modification Data Tables (page 13-15) provide dimensional

data including part numbers, and number of springs required to

reconfigure an actuator.

Springs may be changed with the actuator assembled or removed

from the valve. For ease of instruction, pictures are shown with

actuators removed.

To change or add springs on a Direct Acting (DA, NO, ATC)

actuator assembled to the valve, follow steps 1, 2, 3, 4A, 5-10.

To change or add springs on a Direct Acting (DA, NO, ATC)

actuator removed to the bench, follow steps: 1-4A, 5-9.

To change or add springs on a Direct Acting (DA, NO, ATC)

actuator assembled to the valve and under preload, follow steps:

1, 3, 4B, 5-10.

1. Shut off controlled medium supply (steam, water, or other

liquid).

2. Reduce preload on the springs (refer to Decreasing Preload

on DA Actuators pg. 7).

3. Remove the control signal to the actuator.

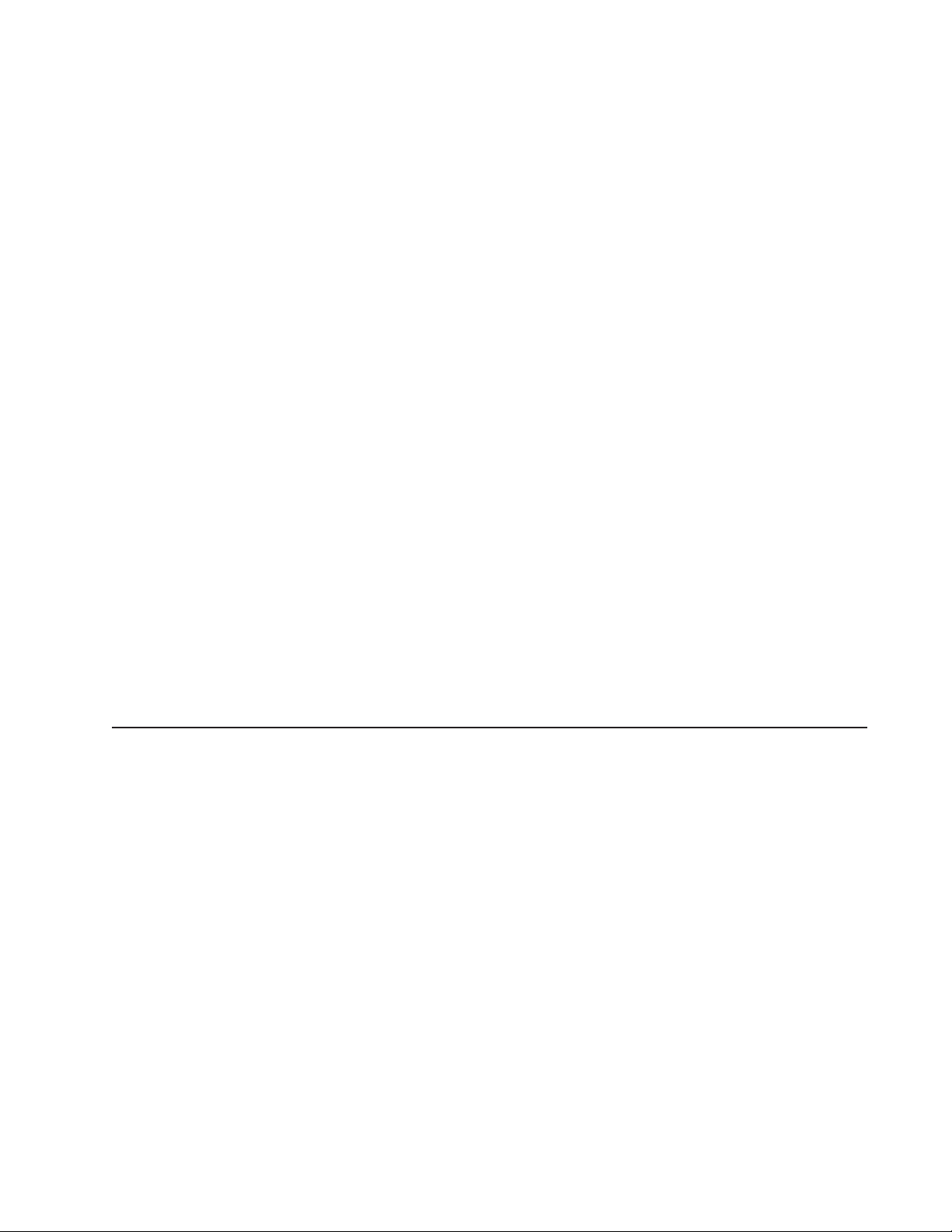

4A. (Fig. 1) Remove top housing nuts and bolts or (see above)

4B. (Fig. 1) Remove the three bolts attached to the short nuts,

then equally release the bolts attached to the long nuts.

CAUTION: Springs under tension.

5. (Fig. 2A) Remove upper housing.

6. Remove stem nut, silver and black washers (Fig. 2B).

7. Remove diaphragm, and thrust plate (Fig. 2C).

8. Change or add springs as needed (Fig. 3A & 3B). Make sure

the springs are properly placed over the spring guides

and their configuration is symmetrical.

9. Reassemble parts in reverse order, then attach upper housing.

10. Adjust preload ref.

NOTE: Some actuator models have small springs nested inside

the larger springs. The small springs also fit over spring guides

and must also be placed symmetrically.

Fig 1 - Remove Housing Bolts

*(extended versions last and gradually)

Fig 2A - Remove Upper Housing

Fig 2B - Remove Stem Nut, & Washers

INSTALLING AN ACTUATOR

1. Place actuator assembly over valve stem. With actuator stem and

valve stem separated, place bonnet lock nut over valve stem onto

bonnet.

2. Apply air pressure to the actuator approximately 9 psi for a

Normally Closed valve assembly, and 3 psi for a Normally Open

Assembly.

3. Tighten the valve stem to the actuator stem by rotating the valve

stem (NOT THE ACTUATOR STEM).

4. Tighten the two locknuts together and rotate them clockwise.

Tighten the nuts to achieve the proper PRELOAD (as explained in

the Preload Section).

5. Remove air pressure.

6. Tighten the bonnet locknut on the bonnet (Fig.1).

Fig 1 - Tighten the Bonnet

Lock Nut on the Bonnet

Page 5

CHANGING SPRINGS (REVERSE ACTING ACTUATORS)

Springs may be changed with the actuator assembled or removed

from the valve. For ease of instruction, pictures are shown with

actuators removed.

To change or add springs on a Reverse Acting (RA, NC, ATO)

actuator assembled to the valve, follow steps 1-4A, 5-8.

To change or add springs on a Reverse Acting (RA, NC, ATO)

actuator removed to the bench, follow steps: 1-4A, 5-7.

To change or add springs on a Reverse Acting (RA, NC, ATO)

actuator assembled to the valve and under preload, follow steps:

1, 3, 4B, 5-8.

1. Shut off controlled medium supply (steam, water, or

other liquid).

2. Reduce preload on the springs (refer to Decreasing Preload

on DA Actuators pg. 7).

3. Remove the control signal to the actuator.

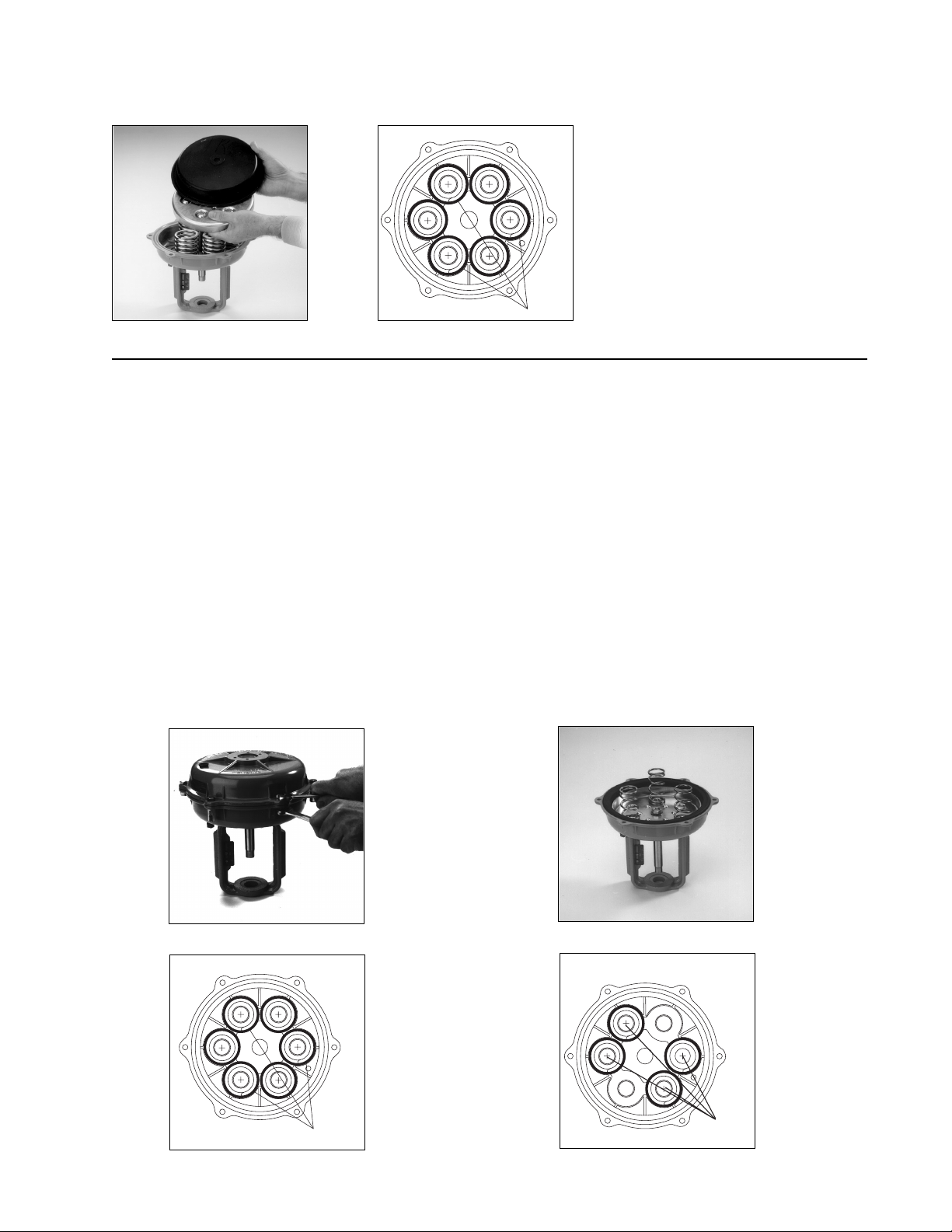

4A. (Fig. 1) Remove top housing nuts and bolts or (see above).

4B. (Fig. 1) Remove the three bolts attached to the short nuts,

then equally release the bolts attached to the long nuts.

CAUTION: Springs under tension.

5. (Fig. 2A) Remove upper housing.

6. Add or remove springs as needed for new configuration

(Fig 3A &Fig. 3B). Make sure the springs are properly placed

over the spring guides and their configuration is symmetrical.

NOTE: Some actuator models have small springs nested

inside the larger springs. The small springs also fit over

spring guides and must also be placed symmetrically.

7. Reassemble upper housing.

NOTE: Assemble bolts with long nuts first.

8. Adjust preload ref pg. 7.

Fig 1 - Remove Housing Bolts

Fig 2- Remove Upper Housing

Fig 3A - Typical 3-Spring Installation

NOTE: *Number required may vary. Refer

to page 14-15.

Fig 3A - Typical 4-Spring Installation

Fig 2C - Remove Diaphragm,

Thrust Plate

Fig 3A - Typical-Spring Installation

5

Springs

Springs

Springs

Page 6

6

CHANGING ACTION (DIRECT ACTING ACTUATORS)

All valve bodies used with Flowrite II Actuators are push-to-close.

Directing Acting actuators make the valve action Normally Open

(NO, DA, ATC); Reverse Acting actuators make the valve action

Normally Closed (NC, RA, ATO).

Changing the action of the actuator (DA to RA or RA to DA) will

therefore reverse the valve action from NO to NC, or NC to NO.

To change the actuator action, you change the stem and reverse the

order of the spring, diaphragm and thrust plate assembly.

Change Actuator Action from DA to RA or NO to ATC or NC

to ATO:

1. Shut off controlled medium supply (steam, water, or other

liquid).

2. Reduce preload on the springs (refer to Decreasing Preload

on DA Actuators).

3. Remove the control signal to the actuator.

4. Remove top housing nuts and bolts.

5. Remove upper housing. Remove stem nut, silver and black

washer. (Fig 2A).

6 Remove diaphragm, thrust plate and springs (Fig. 2B).

7. Hold the actuator stem in place and loosen the valve stem

locknuts (turn locknuts counterclockwise a number of times).

8. Hold actuator stem and tighten the two lock nuts together.

Turn the locknuts counterclockwise to rotate the valve stem

until the two stems are separated. (Fig. 3)

9. Pull actuator stem upward and remove from assembly

(Fig. 4).

10. Replace with RA actuator stem. Position stem with flats

pointing downward.

11. Thread valve stem into actuator stem by turning the locknuts

clockwise. Tighten by hand.

12. Place black washer on actuator stem. Invert diaphragm and

place inside of lower housing over the black washer. Invert

thrust plate and place on top of diaphragm. (Fig. 5)

13. Replace silver washer and tighten stem nut.

14. Place springs on thrust plate in same orientation as found in

lower housing. Properly seat springs over spring guides

(Fig. 6).

15. Replace upper housing assembly and tighten housing nuts

and bolts. (Fig. 1)

16. Connect control signal to 1/4" NPT fitting located on

bottom of actuator housing.

17. Adjust the preload per instructions on pg. 7.

Fig 1 - Remove Housing Bolts Fig 2A - Remove Upper Housing,

Stem, Nut and Washers

Fig 2B - Remove Diaphragm

and Thrust Plate

Fig 3 - Loosen Stem Locknuts

Fig 4 - Remove Stem Fig 5 - Reverse Replacement of

Diaphragm and Thrust Plate

Fig 5 - Reverse Replacement of

Diaphragm and Thrust Plate.

Four (4) springs shown. See

note on page 5.

Page 7

CHANGING ACTION (REVERSE ACTING ACTUATORS)

Change Actuator Action from RA to DA:

1. Shut off controlled medium supply (steam, water, or other

liquid).

2. Reduce preload on the springs (refer to Decreasing Preload

on RA Actuators).

3. Remove the control signal to the actuator.

4. (Fig. 1) Use a 1/2" wrench on the top housing bolts and hold

the bottom housing nuts with a 9/16" wrench.

5. (Fig. 2A) Remove upper housing.

6. Remember the orientation of springs on the thrust plate.

Remove springs, stem nut (Fig. 2B)...

7. …silver washer, thrust plate, diaphragm, & black washer

(Fig. 2C).

8. Hold the actuator stem in place and loosen the valve stem

locknuts (turn locknut counterclockwise a number of times).

9. Hold actuator stem and tighten the two lock nuts together.

Turn the locknuts counterclockwise to rotate the valve stem

until the two stems are separated. (Fig. 3)

10. Pull actuator stem upward and remove from assembly.

(Fig. 4).

11. Replace with DA actuator stem. Position stem with flats

pointing downward.

12. Thread valve stem into actuator stem by turning the locknut

clockwise. Tighten by hand.

13. Place springs in lower housing in same orientation as found

on thrust plate. Properly seat springs over the spring guides

14. Invert thrust plate and place on top of springs. Invert

diaphragm and place on top of thrust plate (Fig. 5).

15. Replace black washer, place silver washer on top of black

washer, and tighten stem nut (Fig. 6).

16. Replace upper housing assembly and tighten housing nuts

and bolts (Fig. 1).

17. Connect control signal to 1/4" NPT fitting located on the

top of the actuator housing.

18. Adjust the preload per instructions on pg. 7.

Fig 1 - Remove Housing Bolts Fig 2A - Remove Upper

Housing to Expose Springs

(4 Shown)

Fig 2B - Remove Springs,

Stem Nut

Fig 3 - Loosen Stem Locknuts Fig 4 - Remove and Replace

Stem

Fig 5 - Replace Springs,

Reversed Thrust Plate and

Diaphragm

Fig 2C - Remove Washers,

Thrust Plate, Diaphragm

Fig 6 - Replace Washers,

Tighten Stem Nut

7

Page 8

8

PRELOAD

The Normally Closed (NC, RC, ATO) valve assembly uses the

springs to hold the valve shut, against the upstream pressure

attempting to push the plug open.

1. All Normally Closed valve assemblies are factory set to a nominal

preload depending on size of 7-10 psi.

2. If your process requires a high air pressure signal (>7 psi) to start

the valve moving, it is necessary to decrease the actuator preload.

Adjust the preload so that the valve is fully closed with the

minimum air signal and fully open with the maximum air signal.

3. It is a characteristic of an unbalanced valve that as the pressure

drop across the valve increases, the effective spring range

increases. Consult one of our application engineers if you have

any questions about your particular application.

The Normally Open (NO, DA, ATC) valve assembly uses the

actuator springs to hold the valve open, and the upstream

pressure helps to hold the valve open.

1.If the maximum air signal applied to the valve does not allow the

valve to shut off tightly, decrease the preload.

2.If the valve starts closing at too low of an air signal, increase the

preload. The preload should be adjusted so that control air

pressure closes the valve tightly, and stem movement starts at an

acceptable point.

3. In some applications where a wide range of flow conditions are

encountered, it is desirable to install two valves in parallel and

sequence them.

Preload adjustment (also called spring tension adjustment) is

required under the following conditions:

1. The valve and actuator stem have been disengaged. (for packing

changes, stem changes, maintenance of valve assembly, etc.)

2. The action of the valve assembly has been reversed.

3. Valve sequencing is required. (Use of a positioner is

recommended if using a 3–15 psi control signal.)

4. Line pressure force exceeds the spring holding force on a

normally closed (NC) valve assembly, which causes the valve to

open with less than 7 psi signal preload.

5. Line pressure force adds to the spring holding force on a

normally open (NO) valve assembly, which causes the valve to

start closing at a preload greater than 3 psi signal

Deviation from this recommended preload setting will affect your

process. A higher preload setting requires a higher air signal at the

diaphragm to start stroking the valve. If the preload is too high,

with a given air signal a Normally Open valve will not close

completely, and a Normally Closed valve will not open completely

to overcome the initial preload setting.

To decrease preload on RA actuators or increase preload on DA

actuators:

1. To prevent the plug and seat from scoring, lift the valve plug off

the seat before adjusting the preload by applying air pressure to

the actuator, approximately 9 psi for a Normally Closed valve

assembly, and 5 psi for a Normally Open Assembly.

2. Hold the actuator stem in place (DO NOT turn actuator stem

during this process) and loosen the valve stem locknut by turning

the locknuts counterclockwise a number of times.Press the two

locknuts together.

3. Hold the actuator stem in place (DO NOT turn the actuator

stem), turn the valve stem clockwise and retighten the locknut.

(Fig. 1).

To increase preload on R.A. actuators or decrease preload on

D.A. actuators:

1. To prevent the plug and seat from scoring, lift the valve plug off

the seat before adjusting the preload by applying air pressure to

the actuator, approximately 10 psi for a Normally Closed valve

assembly, and 5 psi for a Normally Open Assembly.

2. Hold the actuator stem in place (DO NOT turn actuator stem

during this process) and loosen the valve stem locknuts by

turning the locknuts counterclockwise a number of times. Press

the two locknuts together.

3. Hold the actuator stem in place (DO NOT turn the actuator

stem), turn the valve stem locknuts counter-clockwise and

retighten the locknut (Fig. 1).

Fig 1 - Rotate Lock Nuts to

Adust Preload

Page 9

9

REPLACING A DIAPHRAGM (DIRECT ACTING ACTUATORS)

The diaphragm can be changed with the actuator assembled or

removed from the valve. For ease of instruction pictures are shown

with actuators removed.

To change a diaphragm on a Direct Acting (DA, NO, ATC)

actuator assemble to the valve follow steps: 1-4A, 5-9.

To change a diaphragm on a Direct Acting (DA, NO, ATC)

actuator removed to the bench follow steps: 1-4A, 5-8.

To change a diaphragm of a Direct Acting (DA, NO, ATC)

actuator assemble to the valve and under preload follow steps:

1-3, 4B, 5-9.

1. Shut off controlled medium supply (steam, water, or other

liquid) and remove the control signal to the actuator.

2. Reduce preload on the springs (refer to Decreasing Preload on

DA Actuators), see pg. 7.

3. Remove the control signal from the actuator.

4A. (Fig. 1) Remove top housing nuts and bolts or (see above)

4B. (Fig. 1) Remove the three bolts attached to the short nuts, then

equally release the bolts attached to the long nuts.

CAUTION: Springs under tension.

5. Remove upper housing (Fig. 2)

6. Remove stem nut, washer and diaphragm. (Fig. 3)

7. Place new diaphragm over thrust plate. Make sure that the lip of

the diaphragm is seated properly in the groove of the actuator

housing.

8. Reassemble in reverse order.

NOTE: Assemble bolts with long nuts first.

9. Adjust preload, refer to pg. 7.

Fig 1 - Remove Housing Bolts Fig 2 - Remove Stem Nut, and

Washers

Fig 3 - Remove Diaphragm (Leave

Thrust Plate On).

Page 10

10

REPLACING A DIAPHRAGM (REVERSE ACTING ACTUATORS)

The diaphragm can be changed with the actuator assembled or

removed from the valve. For ease of instruction pictures are shown

with actuators removed.

To change a diaphragm on a Reverse Acting (RA, NC, ATO)

actuator assemble to the valve follow steps: 1-4A, 5-10.

To change a diaphragm on a Reverse Acting (RA, NC, ATO)

actuator removed to the bench follow steps: 1-4A, 5-9.

To change a diaphragm of a Reverse Acting (RA, NC, ATO)

actuator assemble to the valve and under preload follow steps:

1-3, 4B, 5-10.

1. Shut off controlled medium supply (steam, water, or other

liquid) and remove the control signal to the actuator.

2. Reduce preload on the springs. Follow procedures for

Decreasing Preload on DA Actuators on pg. 7.

3. Remove the control signal to the actuator.

4A. (Fig 1) Remove top housing nuts and bolts or see above

4B. (Fig 1) Remove the three bolts attached to the short nuts, then

equally release the bolts attached to the long nuts.

CAUTION: Springs under tension.

5. Remove upper housing (Fig 2).

6. Remember the orientation of the springs. Remove springs, stem

nut...(Fig. 3).

7. ...silver washer, thrust plate, diaphragm, & black washer

(Fig. 4).

8. Replace with new diaphragm. Make sure the lip of the

diaphragm is seated properly in the groove of the actuator

housing.

8. Reassemble in reverse order.

NOTE: Assemble bolts with long nuts first.

10. Adjust preload, refer to pg. 7.

Fig 1 - Remove Housing Bolts Fig 2 - Remove Upper Housing, Remove

Springs (4 Shown)

Fig 3 - Remove Stem Nut...

Fig 4 - Remove Thrust Plate and Old

Diaphragm

Page 11

11

PARTS LIST - DA ACTUATOR

ITEM PART NUMBER QUANTITY PART DESCRIPTION

1 See Chart 1 Yoke (Cast Iron)

2 672-632A 1 Top Housing Machined

3 672-633A 1 Bottom Housing Machined

4 See Chart 1 Stem, D.A.

5 081-008 3 Nut, Housing

6 080-033 3 Bolt, Housing

7 672-646 See Chart Spring, Small

8 672-645 See Chart Spring, Large

9 672-626 1 Diaphragm

10 672-627 1 Thrust Plate, Steaming

11 672-618E 1 Bushing, Stem

12 084-015 2 “O” Ring

13 672-470A 1 Label Warning

14 043-009C 1 Cap Plug, 1/4”

15 082-005R 1 Washer, Stem

16 081-011 1 Nut, Stem

17 080-034 4 Bolt, Yoke

18 082-005 1 Washer, Stem

19 087-128 1 Vent Plug, 1/4” NPT

20 672-641 1 Bearing, Stem

22 672-620 1 Nameplate

23 See Chart 1 Locknut

24 900-326 3 Nut, Coupling 5/16 -18x2

25 900-327 3 Bolt, 5/16-18 x 3LG

CURRENT STD. SPRINGS STD. SPRINGS SS. SPRINGS SS. SPRINGS

ACTUATORS 672-642 672-615 672-645 672-646 STEM YOKE LOCK NUT

672022D 2 2 0 0 672-636 672-724 625-008

672033D 6 0 0 0 672-636 672-724 625-008

672044D 4 4 0 0 672-636 672-724 625-008

672601D 6 6 0 0 672-636 672-724 625-008

672602D 0 3 0 0 672-636 672-724 625-008

672603D 3 0 0 0 672-636 672-724 625-008

672604D 4 0 0 0 672-636 672-724 625-008

672605D 0 4 0 0 672-636 672-724 625-008

672606D 6 0 0 0 672-636 672-724 625-008

672607D 0 6 0 0 672-636 672-724 625-008

672651D 6 6 0 0 672-614 672-725 625-008

672653D 3 0 0 0 672-614 672-725 625-008

672654D 4 0 0 0 672-614 672-725 625-008

672655D 0 4 0 0 672-614 672-725 625-008

672656D 6 0 0 0 672-614 672-725 625-008

672657D 0 6 0 0 672-614 672-725 625-008

672666D 0 4 0 0 672-636B 672-725 625-008

672670D 0 6 0 0 672-636B 672-725 625-008

672671D 0 6 0 0 672-614B 672-725 625-008

672672D 0 4 0 0 672-614B 672-725 625-008

672726D 0 6 0 0 672-634 672-725 625-008

672727D 0 4 0 0 672-634 672-725 625-008

672728D 0 6 0 0 672-634 672-725 625-008

672-460D 0 0 0 3 672-636 672-724 625-008

672-474D 0 0 0 4 672-636 672-724 625-008

672-647D 0 0 0 6 672-636 672-724 625-008

672-474D 0 0 0 4 672-636 672-724 625-008

672-457D 0 0 0 6 672-636 672-724 625-008

672-461D 0 0 0 4 672-636 672-724 625-008

672-462D 0 0 0 6 672-636 672-724 625-008

672-463D 0 0 0 6 672-636 672-724 625-008

672-464D 0 0 0 6 672-636 672-724 625-008

672-648D 0 0 6 6 672-636 672-724 625-008

672-647D 0 0 6 0 672-636 672-724 625-008

672-474D 0 0 4 0 672-636 672-724 625-008

672-467D 0 0 4 4 672-636 672-724 625-008

672-465D 0 0 6 0 672-614B 672-725 625-008

672-466D 0 0 6 0 672-618E 672-725 625-008

672-469D 0 0 6 0 672-634 672-725 625-008

672-468D 0 0 6 0 672-634 672-725 625-008

15

18

9

2

25

24

3

10

11

1

4

Notes:

1. For other spring replacements, make sure that springs are

arranged symemtrically to ensure proper balance for the actuator.

2. Soak "O" rings in silicone oil prior to assembly.

Assemble and test per Eng. Spec. Y-672-1.

**

Apply Removable

16

Loctite Threadlocker #242

(10-12 ft.-lbs.)

"X"

13

NOT SHOWN

NOT SHOWN

22

23

NOT SHOWN

14

6

5

8

7

19

(10-12 ft.-lbs.)

17

20

**

12

Page 12

12

PARTS LIST - RA ACTUATOR

"X"

ITEM PART NUMBER QUANTITY PART DESCRIPTION

1 See Chart 1 Yoke (Cast Iron)

2 672-632A 1 Top Housing Machined

3 672-633A 1 Bottom Housing Machined

4 See Chart 1 Stem, D.A.

5 081-009 3 Nut, Housing

6 080-033 3 Bolt, Housing

7 672-645 See Chart Spring, Large

8 672-646 See Chart Spring, Small

9 672-626 1 Diaphragm

10 672-627 1 Thrust Plate, Steaming

11 672-618E 1 Bushing, Stem

12 084-015 2 “O” Ring

13 672-471 1 Label Warning

14 043-009C 1 Cap Plug, 1/4”

15 082-005R 1 Washer, Stem

16 081-011 1 Nut, Stem

17 080-034 4 Bolt, Yoke

18 082-005 1 Washer, Stem

19 087-128 1 Vent Plug, 1/4” NPT

20 672-641 1 Bearing, Stem

22 672-620 1 Nameplate

23 See Chart 1 Locknut

24 900-326 3 Nut, Coupling 5/16 -18x2

25 900-327 3 Bolt, 5/16-18 x 3LG

CURRENT STD. SPRINGS STD. SPRINGS SS. SPRINGS SS. SPRINGS

ACTUATORS 672-642 672-615 672-645 672-646 STEM YOKE LOCK NUT

672024R 2 4 0 0 672-636A 672-724 628-008

672033R 3 3 0 0 672-636A 672-724 628-008

672044R 4 4 0 0 672-636A 672-724 628-008

672601R 6 6 0 0 672-636A 672-724 628-008

672602R 0 3 0 0 672-636A 672-724 628-008

672603R 3 0 0 0 672-636A 672-724 628-008

672604R 4 0 0 0 672-636A 672-724 628-008

672605R 0 4 0 0 672-636A 672-724 628-008

672606R 6 0 0 0 672-636A 672-724 628-008

672607R 0 6 0 0 672-636A 672-724 628-008

672645R ? 0 0 672-636A 672-724 628-008

672651R 6 6 0 0 672-614A 672-725 628-008

672653R 3 0 0 0 672-614A 672-725 628-008

672654R 4 0 0 0 672-614A 672-725 628-008

672655R 0 4 0 0 672-614A 672-725 628-008

672656R 6 0 0 0 672-614A 672-725 628-008

672657R 0 6 0 0 672-614A 672-725 628-008

672666R 0 4 0 0 672-636D 672-725 628-008

672668R 0 4 0 0 672-634B 672-724 628-008

672669R 0 6 0 0 672-634B 672-724 628-008

672670R 0 6 0 0 672-636C 672-725 628-008

672671R 0 6 0 0 672-634C 672-725 628-008

672672R 0 4 0 0 672-634C 672-725 628-008

672726R 0 6 0 0 672-634A 672-725 628-008

672727R 0 4 0 0 672-634A 672-725 628-008

672728R 0 6 0 0 672-634A 672-725 628-008

672-648R 0 0 0 3 672-636A 672-724 628-008

672-460R 0 0 0 4 672-636A 672-724 628-008

672-474R 0 0 0 6 672-636A 672-724 628-008

672-647R 0 0 0 4 672-636A 672-724 628-008

672-475R 0 0 0 6 672-636A 672-724 628-008

2

18

10

25

24

15

3

20

11

1

4

Notes:

1. For other spring replacements, make sure that springs are arranged symemtrically

to ensure proper balance for the actuator.

2. Soak "O" rings in silicone oil prior to assembly.

Assemble and test per Eng. Spec. Y-672-1.

**

19

8

7

Apply Removable

Loctite Threadlocker

16

#242

(10-12 ft.-lbs)

6

5

9

14

(10-12 ft.-lbs)

17

**

12

13

22

23

NOT SHOWN

NOT SHOWN

NOT SHOWN

Page 13

13

SPRINGS II

672-645 Total

Actuator Area = 46”

Spring Valve Stroke

Rate (inches)

672-6142 672-646 (lbs.)

Number of Springs --- 0.125 0.1875 0.25 0.3125 0.375 0.5626 0.625 0.75 1 1.25 1.5

00 00.0000 0.0000 0.0000 0.0000 0.0000 0.0000 0.0000 0.0000 0.0000 0.0000 0.0000

20 164 0.4457 0.6685 0.8913 1.1141 1.3370 2.0058 2.2283 2.6739 3.5652 4.4565 5.3478

30 246 0.6685 1.0027 1.3370 1.6712 2.0054 3.0087 3.3424 4.0109 5.3478 6.6848 8.0217

40 328 0.8913 1.3370 1.7826 2.2283 2.6739 4.0116 4.4565 5.3478 7.1304 8.9130 10.6957

60 492 1.3370 2.0054 2.6739 3.3424 4.0109 6.0174 6.6848 8.0217 10.6957 13.3696 16.0435

02 104 0.2826 0.4239 0.5652 0.7065 0.8478 1.2720 1.4130 1.6957 2.2609 2.8261 3.3913

22 268 0.7283 1.0924 1.4565 1.8207 2.1848 3.2778 3.6413 4.3696 5.8261 7.2826 8.7391

32 350 0.9511 1.4266 1.9022 2.3777 2.8533 4.2807 4.7554 5.7065 7.6087 9.5109 11.4130

42 432 1.1739 1.7609 2.3478 2.9348 3.5217 5.2835 5.8696 7.0435 9.3913 11.7391 14.0870

62 596 1.6196 2.4293 3.2391 4.0489 4.8587 7.2893 8.0978 9.7174 12.9565 16.1957 19.4348

03 156 0.4239 0.6359 0.8478 1.0598 1.2717 1.9079 2.1196 2.5435 3.3913 4.2391 5.0870

23 320 0.8696 1.3043 1.7391 2.1739 2.6087 3.9137 4.3478 5.2174 6.9565 8.6957 10.4348

33 402 1.0924 1.6386 2.1848 2.7310 3.2772 4.9166 5.4620 6.5543 8.7391 10.9239 13.1087

43 484 1.3152 1.9728 2.6304 3.2880 3.9457 5.9195 6.5761 7.8913 10.5217 13.1522 15.7826

63 648 1.7609 2.6413 3.5217 4.4022 5.2826 7.9253 8.8043 10.5652 14.0870 17.6087 21.1304

04 208 0.5652 0.8478 1.1304 1.4130 1.6957 2.5439 2.8261 3.3913 4.5217 5.6522 6.7826

24 372 1.0109 1.5163 2.0217 2.5272 3.0326 4.5497 5.0543 6.0652 8.0870 10.1087 12.1304

34 454 1.2337 1.8505 2.4674 3.0842 3.7011 5.5526 6.1685 7.4022 9.8696 12.3370 14.8043

44 536 1.4565 2.1848 2.9130 3.6413 4.3696 6.5555 7.2826 8.7391 11.6522 14.5652 17.4783

64 700 1.9022 2.8533 3.8043 4.7554 5.7065 8.5613 9.5109 11.4130 15.2174 19.0217 22.8261

06 312 0.8478 1.2717 1.6957 2.1196 2.5435 3.8159 4.2391 5.0870 6.7826 8.4783 10.1739

26 476 1.2935 1.9402 2.5870 3.2337 3.8804 5.8217 6.4674 7.7609 10.3478 12.9348 15.5217

36 558 1.5163 2.2745 3.0326 3.7908 4.5489 6.8246 7.5815 9.0978 12.1304 15.1630 18.1957

46 640 1.7391 2.6087 3.4783 4.3478 5.2174 7.8275 8.6957 10.4348 13.9130 17.3913 20.8696

66 804 2.1848 3.2772 4.3696 5.4620 6.5543 9.8333 10.9239 13.1087 17.4783 21.8478 26.2174

SPRING RANGE MATRIX

The spring range matrix provides the theoretical spring ranges from

a given spring arrangement and valve stem travel.

You are encouraged to discuss your application with one of the

Powers application engineers.

In general, positioners are required to sequence valves. In some

circumstances it may be possible to sequence valves by changing

spring ranges and adjusting start points (preload adjustment).

Again, please consult with one of our application engineers for

assistance.

SPRING OPERATING SPAN (psi)

SPRINGS

CURRENT STD STD SS SS

ACTUATORS 672-642 672-615 672-646 672-645 STEM YOKE LOCK NUT

672-457R 0 0 0 4 672-634A 672-725 628-008

672-461R 0 0 0 6 672-634A 672-725 628-008

672-462R 0 0 0 6 672-634A 672-725 628-008

672-463R 0 0 0 6 672-634A 672-725 628-008

672-464R 0 0 3 6 672-636A 672-725 628-008

672-645R 0 0 0 6 672-636A 672-724 628-008

672-458R 0 0 6 6 672-634A 672-725 628-008

672-644R 0 0 6 6 672-634A 672-725 628-008

672-615 TOTAL SPRING VALVE STROKES

STANDARD RATE (lbs.) (inches)

Number of Springs 0.125 0.1875 0.25 0.3125 0.375

000.0000 0.0000 0.0000 0.0000 0.0000

1 245 0.6658 0.9986 1.3315 1.6644 1.9973

2 490 1.3315 1.9973 2.6630 3.3288 3.9946

3 735 1.9973 2.9959 3.9946 4.9932 5.9918

4 980 2.6630 3.9946 5.3261 6.6576 7.9891

5 1225 3.3288 4.9932 6.6576 8.3220 9.9864

6 1470 3.9946 5.9918 7.9891 9.9864 11.9837

Part No. Dia. Spring Rate

672-642 1.406” 82

672-615 2.175” 245

672-645 2.9” 82

672-646 1.459” 52

Page 14

14

TABLE 3

VALV E ASSEMBLY VALVE 46 ACTUATOR 46 SPRING 4C ACTUATOR 4C SPRING SPRING STEM VALVE

TYPE ACTION SIZE PART # PART# PART # PART# QUANTITY PART # TRAVEL (in)

WM N/A 1/2 672-022D 672-615 672-648D 672-646 6 672 636 1/8

N/A 1/2 672-022D 672-642 672-648D 672-646 6 672 636 1/8

N/A 3/4 672-022D 672-615 672-648D 672-646 6 672 636 3/16

N/A 3/4 672-022D 672-642 672-648D 672-646 6 672 636 3/16

N/A 1 672-022D 672-615 672-648D 672-646 6 672 636 1/4

N/A 1-1/4 672-022D 672-615 672-648D 672-646 4 672 636 5/16

N/A 1-1/2 672-022D 672-615 672-648D 672-646 4 672 636 5/16

N/A 2 672-022D 672-615 672-647D 672-646 4 672 636 5/16

MI N/A 2-1/2 672-671D 672-642 672-465D 672-646 6 672636B 5/8

N/A 3 672-671D 672-642 672-465D 672-646 6 672636B 3/4

N/A 4 672-671D 672-642 672-465D 672-646 6 672636B 1

*4X Actuators add 6 Springs #672-645.

MODIFICATION DATA TABLES

These tables provide actuator design information with regard to the

specific valve type and size. Use this information to determine

which springs to use, the number of springs required, and spring kit

part numbers.

These are the correct preload adjustments when mounting an

actuator on a valve or changing stems:

5 psi for NO assemblies

7-10 psi for NC assemblies

Use these pressure and the "Valve Travel" data to properly adjust the

stem length of your actuator/valve assembly.

Example:

Change a

Single Seat Stainless Trim reduced port 1/2A size valve, with a

normally open actuator assembly (593 VE A50 NO)

to a

Single Seat Stainless Trim 1/2" size valve with a Normally Closed

assembly (593 SS 050 NC).

1. Look up the references to the type of valve you want. In this

case, refer to the SS Valve Type, Table 4.

2. You need a new stem, part #672636A. You also need four

#672-615 springs.

3. Now install the new parts. Refer to the section on Changing

Actuator Action from DA to RA.

4. Also consult the section Changing Springs on a Reverse Acting

Actuator. See Figure 3A & B for Typical 4 Spring Installation

for symmetrical spring orientation.

TABLE 2

VALV E ASSEMBLY VALVE 46 ACTUATOR 46 SPRING 4C ACTUATOR 4C SPRING SPRING STEM VALVE

TYPE ACTION SIZE PART # PART# PART # PART# QUANTITY PART # TRAVEL (in)

SI NO 2-1/2 672-672D 672- 642 672-466D 672-646 6 672-636B 5/8

NO 3 672-672D 672 -642 672-466D 672-646 6 672-636B 3/4

NO 4 672-672D 672 -642 672-466D 672-646 4 672-636B 1

NC 2-1/2 672-024R 672 -642 672-465R 672-646 6 672-636C 5/8

NC 3 672-024R 672 -642 672-465R 672-646 6 673-636C 3/4

NC 4 672-024R 672 -642 672-465R 672-646 6 673-636D 1

*4X Actuators add 6 Springs #672-645.

TABLE 1

VALV E ASSEMBLY VALVE 46 ACTUATOR 46 SPRING 4C ACTUATOR 4C SPRING SPRING STEM VALVE

TYPE ACTION SIZE PART # PART# PART # PART# QUANTITY PART # TRAVEL (in)

VE NO 1/2A 672-022D 672-642 672-648D 672-646 6 672-636 1/4

NO 1/2B 672-022D 672-642 672-648D 672-646 6 672-636 1/4

NO 1/2C 672-022D 672-642 672-648D 672-646 6 672-636 1/4

NO 1/2D 672-022D 672-642 672-648D 672-646 6 672-636 1/4

NC 1/2A 672-024R 672-642 672-648R 672-646 6 672-636A 1/4

NC 1/2B 672-024R 672-642 672-648R 672-646 6 672-636A 1/4

NC 1/2C 672-024R 672-642 672-648R 672-646 6 672-636A 1/4

NC 1/2D 672-024R 672-642 672-648R 672-646 6 672-636A 1/4

*4X Actuators add 6 Springs #672-645.

Page 15

15

TABLE 5

VALV E ASSEMBLY VALVE 46 ACTUATOR 46 SPRING 4C ACTUATOR 4C SPRING SPRING STEM VALVE

TYPE ACTION SIZE PART # PART# PART # PART# QUANTITY PART # TRAVEL (in)

DB NO 1 672-022D 672-615 672-648D 672-646 6 672-636 3/16

NO 1 672-022D 672-642 672-648D 672-646 6 672-636 3/16

NO 1-1/4 672-022D 672-615 672-648D 672-646 6 672-636 1/4

NO 1-1/2 672-022D 672-615 672-648D 672-646 6 672-636 1/4

NO 2 672-022D 672-615 672-648D 672-646 6 672-636 3/8

NC 1 672-024R 672-615 672-648R 672-646 6 672-636A 3/16

NC 1 672-024R 672-642 672-648R 672-646 6 672-636A 3/16

NC 1-1/4 672-024R 672-615 672-648R 672-646 6 672-636A 1/4

NC 1-1/2 672-024R 672-615 672-648R 672-646 6 672-636A 1/4

NC 2 672-024R 672-615 672-466D 672-646 6 672-636A 3/8

DI NO 2-1/2 672-672D 672-615 672-466D 672-646 6 672-636A 3/8

NO 3 672-672D 672-615 672-466D 672-646 6 672-636A 9/16

NO 4 672-672D 672-615 672-466D 672-646 6 672-636A 9/16

NO 5 672-672D 672-642 672-466D 672-646 6 672-636A 3/4

NO 6 672-672D 672-642 672-466D 672-646 6 672-634 1

NC 2-1/2 672-671R 672-615 672-465R 672-646 6 672-636A 3/8

NC 3 672-671R 672-615 672-465R 672-646 6 672-636A 9/16

NC 4 672-671R 672-615 672-465R 672-646 6 672-636A 9/16

NC 5 672-671R 672-642 672-465R 672-646 6 672-636A 3/4

NC 6 672-671R 672-642 672-465R 672-646 6 672-636A 1

*4X Actuators add 6 Springs #672-645.

VALV E ASSEMBLY VALVE 46 ACTUATOR 46 SPRING 4C ACTUATOR 4C SPRING SPRING STEM VALVE

TYPE ACTION SIZE PART # PART# PART # PART# QUANTITY PART # TRAVEL (in)

SS NO 1/2 672-607D 672-615 672-647D 672-646 6 672 636 3/8

NO 3/4 672-607D 672-642 672-647D 672-646 6 672 636 3/4

NO 1 672-607D 672-642 672-647D 672-646 6 672 636 3/4

SD NO 1-1/4 672-607D 672-642 672-647D 672-646 6 672 636 1

NO 1-1/2 672-607D 672-642 672-647D 672-646 6 672 636 1

NO 2 672-607D 672-642 672-647D 672-646 6 672 636 1

SP NC 1/2 672-607R 672-642 672-647R 672-646 6 672636A 3/8

NC 3/4 672607R 672 642 672-647R 672-646 6 672636A 3/4

NC 1 672607R 672 642 672-647R 672-646 6 672636A 3/4

NC 1-1/4 672605R 672 642 672-647R 672-646 6 672636A 1

NC 1-1/2 672605R 672 642 672-647R 672-646 6 672636A 1

NC 2 672605R 672 642 672-647R 672-646 6 672636A 1

*4X Actuators add 6 Springs #672-645.

TABLE 4

Page 16

VALV E ASSEMBLY VALVE 46 ACTUATOR 46 SPRING 4C ACTUATOR 4C SPRING SPRING VALVE

TYPE ACTION SIZE PART # PART# PART # PART# QUANTITY TRAVEL (in)

SB NO 1/2 672-727D 672-642 672-468D 672-646 4 9/16

NO 3/4 672-727D 672-642 672-468D 672-646 4 9/16

NO 1 672-727D 672-642 672-468D 672-646 4 3/4

NO 1 1/4 672-727D 672-642 672-468D 672-646 4 3/4

NO 1 1/2 672-727D 672-642 672-468D 672-646 4 3/4

NO 2 672-727D 672-642 672-468D 672-646 4 3/4

NC 1/2 672-726R 672-642 672-469R 672-646 6 9/16

NC 3/4 672-726R 672-642 672-469R 672-646 6 9/16

NC 1 672-726R 672-642 672-469R 672-646 6 3/4

NC 1 1/4 672-726R 672-642 672-469R 672-646 6 3/4

NC 1 1/2 672-726R 672-642 672-469R 672-646 6 3/4

NC 2 672-726R 672-642 672-469R 672-646 6 3/4

*4X Actuators add 6 Springs #672-645.

TABLE 6

USA office: Phone: 800.669.5430 • Fax: 847.824.0627

Canadian office: Phone: 888.208.8927 • Fax: 888.882.1979

© 2002 Powers, a Watts Industries Co.

www.powerscontrols.com

TI-593-672 0252 EDP # 1916068 Printed in U.S.A.

Loading...

Loading...