Page 1

Technical Instructions

2

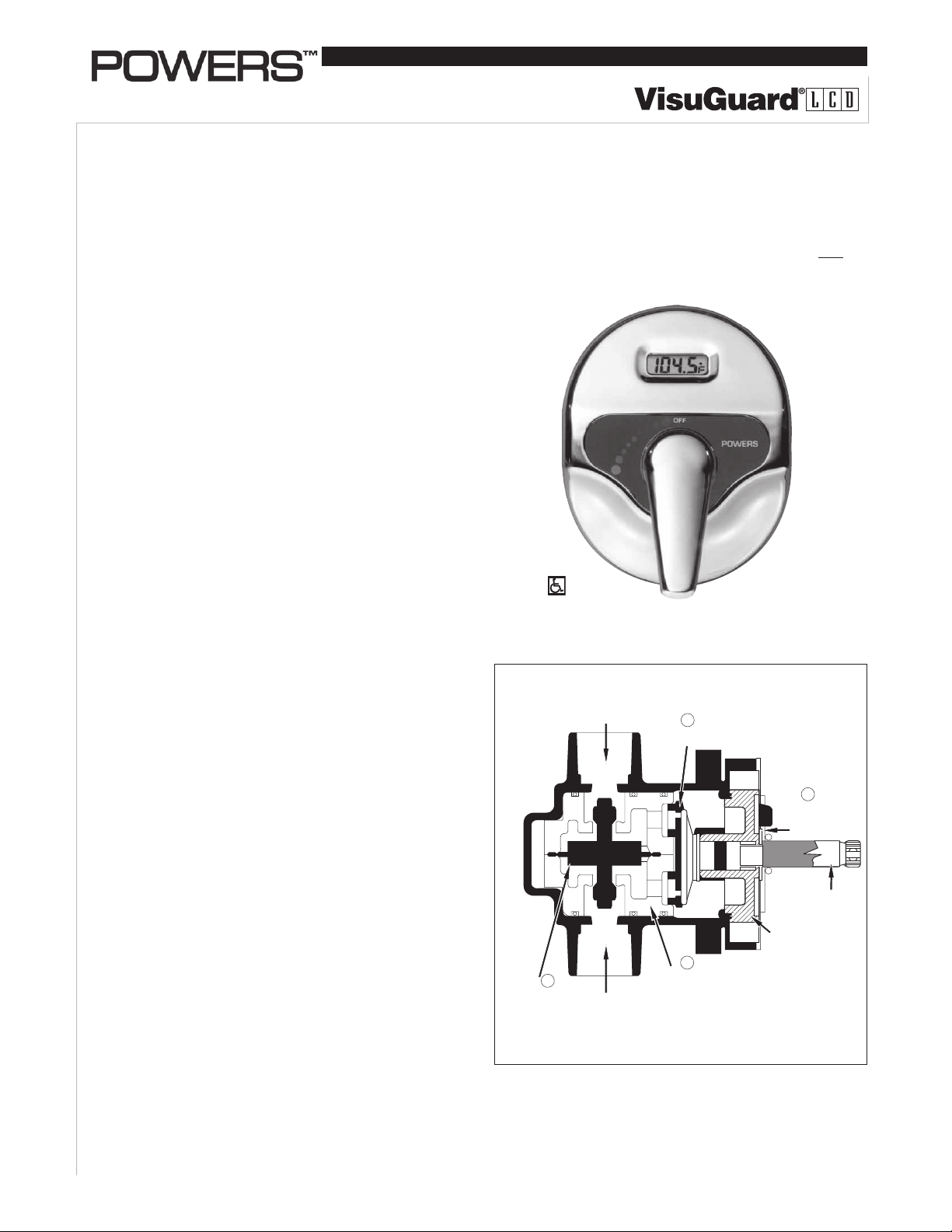

Celcon Chamber

4

Maximum

Temperature

Stop

Bonnet

Hot Water Supply

1

Balancing

Poppet

Assembly

Cold Water Supply

3

Mixing Plate

Stem

Description n

Concealed, tub and shower or shower only pressure

balancing mixer with battery operated, LCD temperature

display for use in shower applications. Features a single

AAA alkaline battery for up to four years of continuous life.

Rugged, brass valve body construction with diaphragmtype pressure balancing mechanism. Cartridge components manufactured of Celcon

corrosion. Adjustable handle rotation stop reduces risk of

handle overadjustment. Opens in cold water position to

maximize bather safety. Battery and temperature display

are housed in an easy-access, watertight enclosure.

Valve trim features:

• Ergonomically-designed,chrome-plated,metal-castfaceplate and handle

• ADA-complianthandleoperation

Specifications n

Connections ..... 1/2" NPT inlets and 1/2" sweat outlets

Battery

Temperature Display

Temperature Range (Display)

Capacity

......................................... [22 L/min @ 310 kPa]

........................................................ (±0.5 gpm [±1.9 L/min])

Maximum Inlet Temperature

Maximum Operating Pressure

Handle Rotation Stop

Wall Seal Gasket

Agency Approvals

............................... CSA approved, ADA-compliant handle

Shipping Weight

................................. Single AAA alkaline

......... 1/2" [13 mm] LCD readout

(factory set for either °C or °F; accurate to 1/10 of a degree )

...................... 6.0 gpm @ 45 psi differential

........... Standard and adjustable

...................... Supplied with valve

.... MeetsrequirementsofASSE1016

............................ 4.7 lbs. [2.1 kg]

®

to resist lime buildup and

-

58–158°F [-50–70°C ]

....

................ 180°F [82°C]

....... 125 psig [862 kPa]

IS-P-VISULCD

The maximum temperature stop (4) allows the user to set the

maximum discharge temperature. This mixer does not recognize supply water temperature changes, so any variation

in the water temperature will affect the control point and the

maximum temperature setting.

F473 shown

C473 Celsius

FIGURE 1 – OPERATION

Application n

The Visuguard LCD is particularly recommended in showers and shower bath installations for motels, hotels, dormitories, health care facilities, and single family residences.

Operation (SeeFigure 1) n

Hot and cold water enter their respective ports and the

flow of water is equalized through the action of the balance poppet (1). The entire balancing poppet assembly

is contained in a Celcon chamber (2). This chamber is

replaceable as a complete cartridge. After the hot and

cold flows are equalized, they are mixed by the action of

a mixing plate (3). As the temperature adjustment stem is

rotated from shutoff to maximum hot water temperature,

the mixing plate passes the required proportion of hot and

cold water to produce the control point. With the adjustment stem in its full clockwise position, shutoff is obtained

by closing both supplies.

NOTE: Following any maintenance of unit, maximum temperature stop must be reset. See page 4 for instructions.

Page 2

HOT

COLD

COLD

Outle t

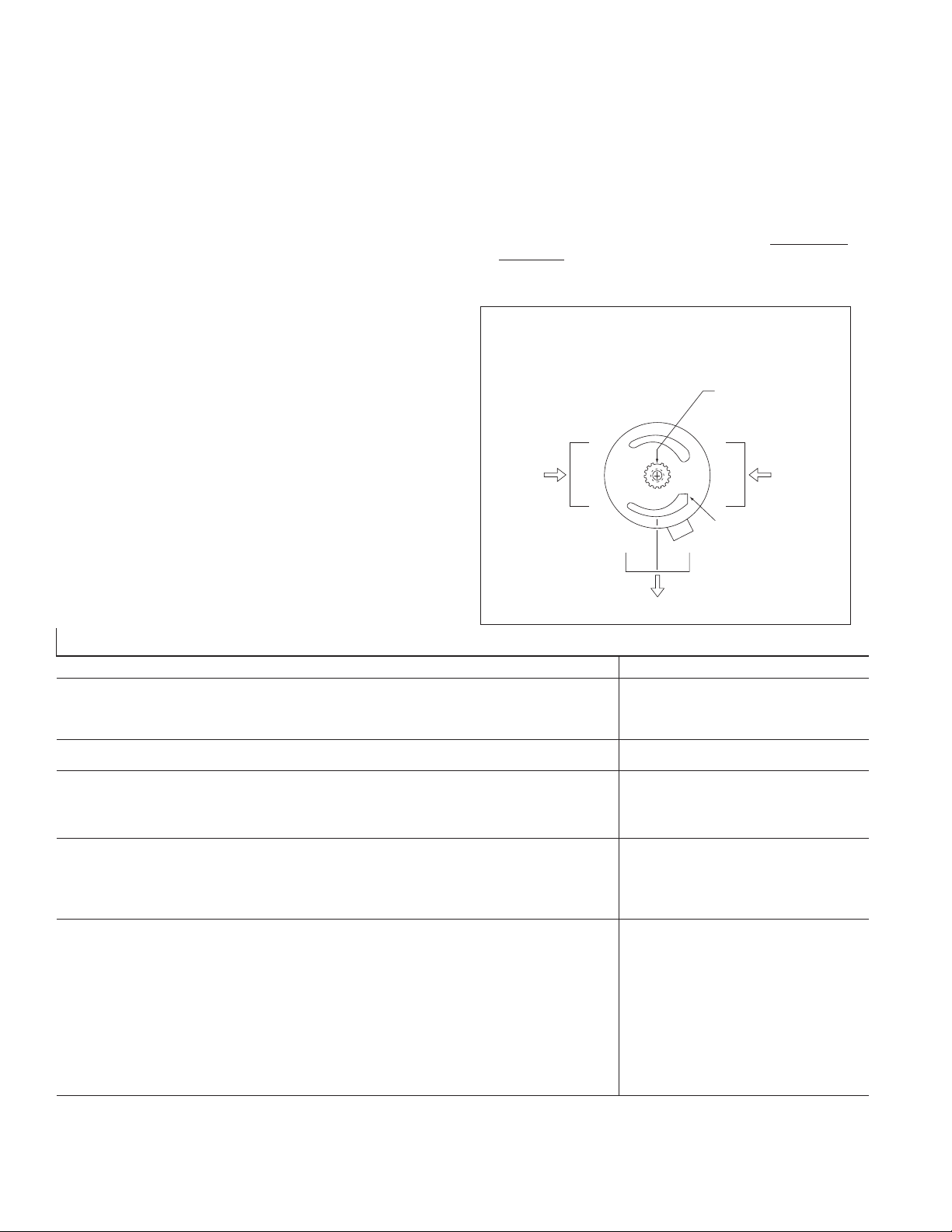

Orientation o f Plate and Stem Assembly

for STANDARD Inlets

(Cold Water i nto Cold port)

Must Point

to CO LD Inlet

Notch in Hand le

Splin e

Must FACE TOP

Water

HOT

Water

C

Maintenance n

Troubleshooting

What to look for:

1. The flow of water is less than desired.

a. Valves upstream from supply not fully open.

b. Low supply pressures.

c. Accumulation of lime deposits in hot water pipes,

restricting the flow of hot water.

d. Showerhead clogged.

e. Checkstops may not be fully open.

f. Low hot water supply temperature.

2. Flow of water is completely shut off.

a. Valves upstream from supply completely closed.

b. Failure of hot or cold water supply pressure.

The Hydroguard is constructed to restrict the flow

of water on hot or cold water supply failure.

c. Checkstops closed.

3. Flow is untempered hot or cold water.

a. The water supplies are connected to the wrong ports.

Reconnect valve supplies to proper ports.

b. Diaphragm is ruptured; replace with new cartridge.

c. Check for foreign material that may be clogging the car-

tridge strainers.

4. Flow of water continues when VisuGuard LCD is shut off.

a. Worn shut-off discs. Replace worn disc.

b. Scratched mixing plate.

c. Erosion.ContactaPowersapplicationsengineerto

order replacement parts.

5. Maximum temperature is too low.

a. Accumulation of lime deposits in hot water pipes, which

restricts the flow of hot water.

b. The concealed maximum temperature limit stop is

not at its maximum adjustment. See page 5 to set the

maximum temperature limit stop.

c. Hot water temperature is too low.

6. Standard inlets are desired.

See Figure 2 for instructions on standard inlets (with cold

water entering the COLD port). With mixer in closed position, the notch in the top spline on the stem must FACE

the outlet.

FIGURE 2 – STANDARD INLETS

Troubleshooting n

Description Recommended Repair Kit Kit Number and Contents

1. Water leaks at stem and/or bonnet.

2. Flow of water continues after mixer is turned off.

1. Variable or untempered discharge temperature. Balance Chamber 410-183 Items 8, 12, 13, 14, 15, 16, 17

1. Flow continues after mixer is turned off.

2. Handle splines on stem damaged.

1. Cartridge slips while seated in body.

2. Flow of water continues after mixer is turned off,

and all other seals have been replaced.

Electronics

1. Display not working (blank).

2. Temperature does not change on display when

handle is turned.

3. Temperature display does not respond rapidly

when handle is turned.

Notes:

1. Use silicone provided on all O-rings and related surfaces. Never use grease.

2. Some kits contain parts for all models; discard extra parts as appropriate.

Gasket and Disc

Replacement

Throttling Stem and Plate

Replacement

Oversize 410 Inlet

Seal Kit

Battery not properly installed

or "dead".

Temperature probe not

installed.

Temperature probe not

properly installed.

410-182 Items 3, 3A, 8, 12, 16

410-378 Items 3, 3A, 8, 9, 10, 11, 12

Discard Extra O-rings

410-570 Items 3, 3A, 8, 12, 16

Disgard oversized O-ring (not shown)

Replace or reinstall battery correctly.

Remove plate and install.(See Figure 7)

Reinstall (See Figure 7).

2

Page 3

1

2

3

4

5

6

7

8

9

3

10

11

18

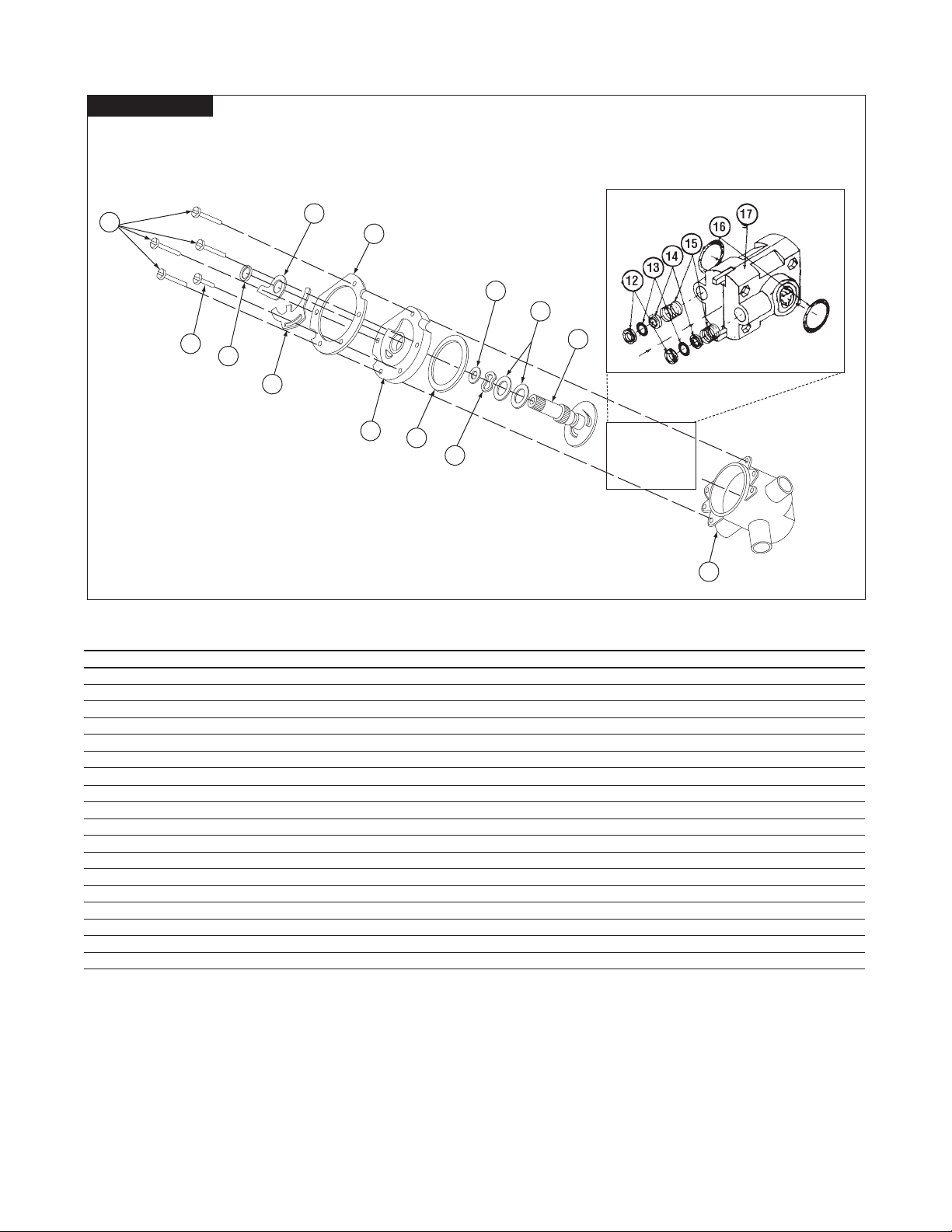

Parts n

Valve Assembly

Series 470 VisuGuard LCD Pressure equalizing mixer.

Poppet-type construction. Adjustable maximum temperature stop.

Item Part Description Kit/Part No. Quantity Material

1 Bonnet Screws (10-32 x 5/16") 030-885 4 Stainless Steel

2 Adjustment Stop Screw (10-32 x 5/16") 030-884 1 Stainless Steel

3 O-Rings (3/8" x 1/2" x 1/16") 047-020 4 Buna-N

4 Maximum Temperature Stop 401-218 1 Brass

5 Adjustment Stop 401-278 1 Stainless Steel

6 Support Ring 410-377 1 Stainless Steel

7 Bonnet 401-162 1 Noryl

8 Bonnet Gasket (Rainbow Style) 410-146* 1 Rubber

9 Wavy Washer 410-145* 1 Stainless Steel

10 Flat Washers 410-144 4 Synthane

11 Throttling Stem 410-375 – Brass Stem Celcon Plate

12 Shut-off Disc 400-023 1 Buna-N

13 O-Rings (2) 410-366 25 Buna-N

14 Guide 410-427 1 Brass

15 Spring 410-138 1 Monel

16 O-Ring 047-031 1 Buna-N

17 Cartridge 410-440 1 Celcon

18 Valve Body – 1 Brass

3

Page 4

29

28

27

26

25

24

23

22

21

19

20

30

31

Parts n

See laser etched ring to

determine valve model.

Series 473 VisuGuard LCD Pressure equalizing mixer.

Poppet-type construction. Adjustable maximum temperature stop.

Item Part Description Kit/Part No. Quantity Material

19 Nut, Ferrule, and 5/8” Sweat Plug 473-044 1 Brass & Copper

20 Probe Fitting N/A Brass

21 3 Port Mixer with Probe Fitting 473-033 1 Brass

22 Temperature Display with Probe 473-039 Various

23 Display Lens 473-041 1 Lexan

24 Gasket Display 473-041 1 Foam

25 Cover Plate 473-038 1 Chrome Plated Metal

26 Graphic Insert 473-043 1 Polycarbonate

27 Stem Gasket 473-045 1 Foam

28 Cover Plate Screws (Powder Coated) 473-042 10 Stainless

29 Handle & Set Screw 473-035 1 Chrome Plated Metal & Stainless

30 WindowPlateforNon-Electronic

Model N473 & N474

31 Set Screw 088-200 1 Stainless Steel

NLA 1 Chrome Plated Metal

VisuGuard LCD Kits

Kit/Part No. Description Includes:

473-035 Handle Kit Handle and Set Screw

473-037 StemExtensionKit StemExtension,(2)Longtrimplatescrews

473-038 Cover Plate Kit Cover Plate, Graphic Insert, Screws and Gaskets

473-039 Temperature Display Kit ElectronicDisplay(F/C),Housing,LensandGasket

473-041 Lens Kit Lens and Gasket

473-042 Coated Screw Kit (10) Powder Coated Screws

473-043 Graphic Insert Kit Graphic Insert

473-044 Installation Kit Cover Plate Gasket, Stem Gasket, Compression Nut,

473-045 Gasket Kit Cover Plate Gasket, Stem Gasket, and (2) Coated Screws

Ferrule, and Plug

4

Page 5

5/16’’ 1/16’’

Temperature

probe

Servicing n

1. Remove the dial assembly and handle. See page 3 for relationship of parts. Close checkstops or upstream valves.

Unscrew four bonnet assembly screws and remove bonnet

assembly by gently pulling on stem. Remove discs, O-rings,

seals, and springs from chamber.

2. TO REMOVE THE BALANCE CHAMBER, using a balance

chamber extraction tool (Part No. 401-202) is highly recommended. To use the extraction tool, follow instructions below:

a. Insert hooked ends of extraction tool into HOT

and COLD outlet ports of the balance chamber

(see Figure 4 below).

Figure 4 – BALANCE CHAMBER REMOVAL

Balance

Chamber

Extraction

Tool

b. Insert screwdriver down through end of extraction tool.

c. Place a wood or plastic block (do not use metal)

between screwdriver and valve body. Firmly ease

screwdriver away and downward,using wood for added

leverage ascartridge is gradually pulled out.

3. Replace necessary items and reassemble. Place a small

amount of silicone gel on the O-rings only.

4.

CAUTION: Do not pinch cartridge O-rings during assembly.

5. Replace bonnet with new bonnet gasket. Proceed to step 6

to reset maximum temperature setting.

Figure 5 – MAXIMUM TEMPERATURE SETTING

Maximum

Temperature

Stop

Adjustment Stem

Fin

Adjustment Stop

Adj. Stop Screw

Battery Replacement n

1. Remove Handle and Cover Plate.

2. Remove thermistor (temperature probe) by loosening small nut

on probe fitting (item 20).

3. Remove electronics enclosure (black) on back of cover plate

(attached with four screws).

4. Once enclosure is removed, carefully remove lens and electronic LCD display. Battery and battery holder are located on

back side of display.

5. Remove and replace battery (AAA alkaline).

6. Reverse procedure to reassemble.

Note: See Figure 7 for proper installation of temperature probe.

Figure 6

AAA Battery

Maximum Temperature Setting n

6. MAXIMUM TEMPERATURE SETTING (refer to Figure 5).

This must be set on the job and following any maintenance

or servicing to the valve. Mixer is factory set to pass full

HOT water.

Figure 7

a. Loosen adjustment stop screw (do not remove).

Gradually rotate stem counterclockwise to get desired

maximum water temperature. (Maximum Temperature

Stop will rotate along with the stem when the stem is

rotated.)

b. Once stem has been rotated to desired temperature,

slide adjustment stop clockwise until fin on adjustment

stop touches the maximum temperature stop.

c. While holding adjustment stop in place, tighten adjust-

ment stop screw.

d. Replace handle. Confirm maximum temperature has

been set properly by operating the valve using the handle.

CAUTION: Adjustment stop must be present for proper operation.

5

Page 6

Notes n

6

Page 7

Notes n

7

Page 8

Warranty n

The Seller warrants that the equipment manufactured by it and covered by this order or contract is free from defects in material and workmanship and, without

charge, equipment found to be defective in material or workmanship will be repaired, or at Seller’s option replaced F.O.B. original point of shipment, if written

notice of failure is received by Seller within one (1) year after date of shipment (unless specifically noted elsewhere), provided said equipment has been properly

installed, operated in accordance with the Seller’s instructions, and provided such defects are not due to abuse or decomposition by chemical or galvanic action.

THIS EXPRESS WARRANTY IS IN LIEU OF AND EXCLUDES ALL OTHER WARRANTIES, GUARANTEES, OR REPRESENTATIONS, EXPRESS OF IMPLIED. THERE ARE

NO IMPLIED WARRANTIES OF MERCHANTABILITY OR OF FITNESS FOR A PARTICULAR PURPOSE. The Seller assumes no responsibility for repairs made on the

Seller’s equipment unless done by the Seller’s authorized personnel, or by written authority from the Seller. The Seller makes no guarantee with respect to material

not manufactured by it.

A Watts Water Technologies Company

USA: Phone: 1.800.669.5430 • Fax 1.847. 229. 0526 • www.powerscontrols.com

Canada: Phone: 1.888.208.8927 • Fax 1.888. 479.2887 • www.powerscontrols.ca

IS-P-VISULCD1001 EDP#6511204 ©2010Powers

Loading...

Loading...