Page 1

ESP™ Hydropanel™ II Pushbutton Sensor System

Single and Multiple Shower System Applications

Technical Instructions

Description

The ESP (Electronic Sensor Plumbing) Hydropanel™ II Pushbutton Shower

System combines modular shrouding with the convenience of electronic

water control. Hydropanel™ II shrouding provides a concealed shower

system where in-wall piping does not exist or may not be practical. The ESP

Pushbutton Shower System relies on Piezo sensor technology to deliver

tempered water to a shower for a predetermined length of time. The shower

automatically turns on when a bather presses the pushbutton, and automatically shuts off when a bather presses the pushbutton again, or when

the field adjustable run-time has been reached.

Multiple shower applications can utilize the ESP Group Control Box, which

centralizes ESP control for up to eight showers. A microprocessor in the

Group Control Box allows the shower system to be custom programmed for

maximum run time, remote override capability.

The Powers Series 450-ESP shower systems come complete with stainless

steel Hydropanel™ II shrouding, ESP Pushbutton Shower System, showerhead, piping, soapdish and mounting hardware.

The following instructions serve as a guide for installation of the Powers

ESP Hydropanel™ II Pushbutton Sensor shower systems. Powers recommends good safety practices and care when installing electrical equipment.

Please follow the procedures as outlined. For additional assistance, please

call the Powers Application Engineering Department at 1.800.669.5430.

n

IS-P-450P

ESP Hydropanel™ II Series 450-5100

Pushbutton Sensor Shower System

Installation n

Precautions Before Installation:

• Use a 24V AC step-down transformer.

• Do not supply power to, or plug in, the transformer until all

other wiring is complete. To prevent permanent damage to

the transformer, do not allow power transformer wires to

touch during wiring.

• Before connecting the solenoid valve, flush Hydropanel™

supply lines to ensure supply water will be free of grit, sand,

etc. The solenoid valve requires water free of all foreign matter to operate properly.

• To inhibit corrosion, a waterproof, multi-purpose grease may

be sprayed onto all electrical contacts.

• Follow the national/local codes and regulations for all

electrical wiring and plumbing.

• Use stainless steel screws for all component installations.

Tools Required:

• Slotted and Phillips screwdrivers.

• Drill with 5/8" bit.

• Pipe wrenches.

• Pipe dope/sealing compound.

• Allen Wrench(s) (included with shrouding).

The ESP Hydropanel™ II Shower System includes a

solenoid valve (non-metallic or brass) which receives tempered water though pre-installed piping. A Powers master

mixing valve such as the 430 Thermostatic mixing valve, or

Hi-Lo cabinet supply fixture, can be used to safely supply comfortable water to the ESP Hydropanel™ shower system.

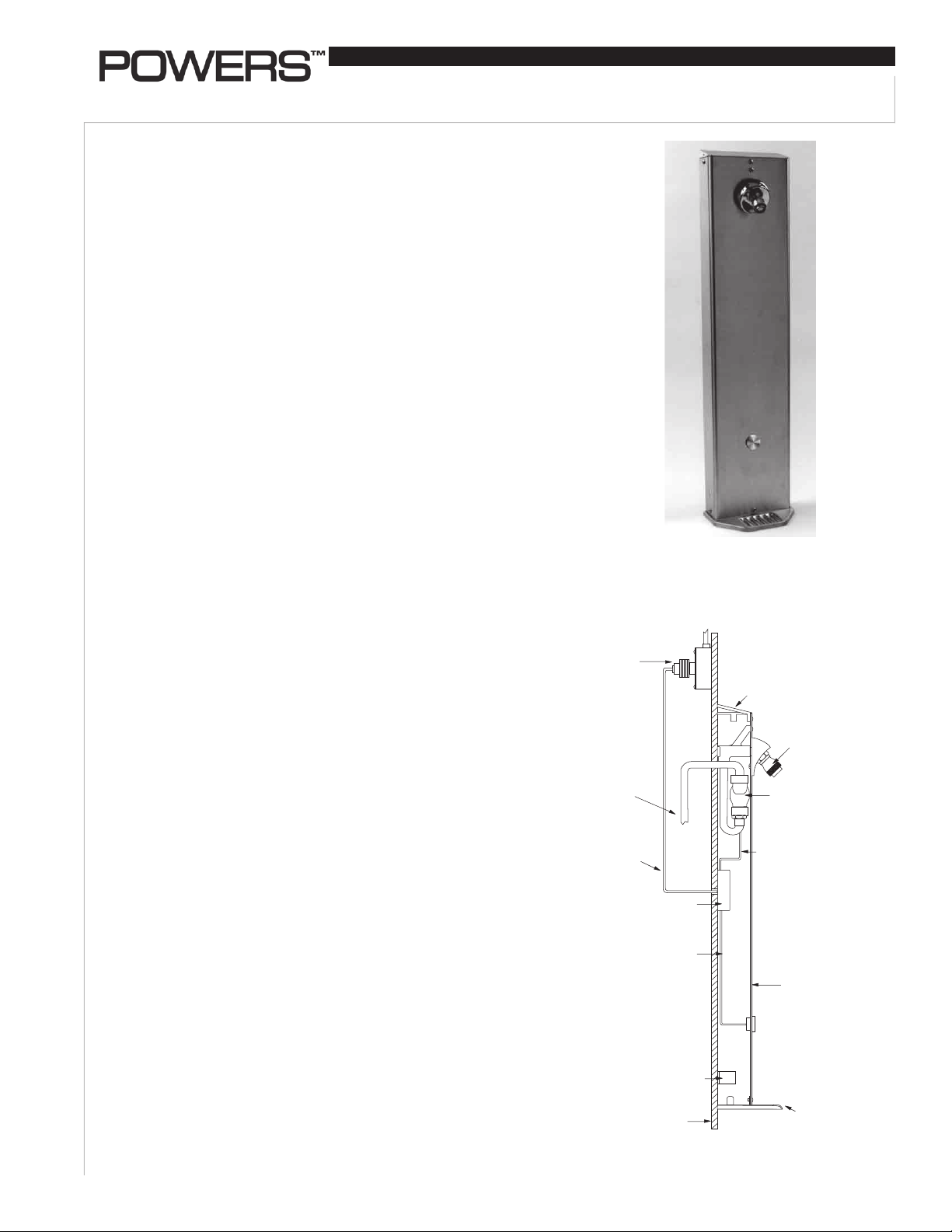

Figure 2

Transformer

(Box Type

Shown)

Chrome-Plated

End Cap

Inlet Piping

(Supplied

by others;

thru-wall or

from ceiling)

Wiring

Control Box

Wiring

Mounting

Bracket

Finished

Wall

Wiring

Typical Shower Installation

Showerhead

(Fixed Shown)

Solenoid

Valve

(Non-metallic

Shown)

Hydropanel

Shrouding

Soapdish

Page 2

Figure 3

SOLENOID INLET

1/2" NPT Brass

3/4" NPT Non Metallic

30

[762.0]

6

[154.4]

2-1/4

[57.15]

7-3/32

[180.18]

C for Solenoid

L

C for Hydropanel unit

L

11/16

[17.46]

2.5 [63.5] Brass

1.5 [38.1] Non-Metallic

2-1/2

[63.5]

77

[1955.8]

19-1/4

[488.95]

2

[50.8]

2-1/2

[63.5]

1-1/4

[31.8]

For Suggested

Showerhead

Heights see

Installation:

Positioning the

ESP Hydropanel™

II unit

7/16

[11.11]

7-1/2

[190.5]

Front and Side Views - Dimensions of the ESP Hydropanel™ II Pushbutton Shower

Position the ESP Hydropanel™ II Unit

Determine the horizontal position of the unit according to

shower room layout, and mark the centerline (Figure 3). For multiple shower applications, the recommended minimum distance

between the centerline of two units is 36 inches.

Determine the floor-to-showerhead height for the unit.

Recommended heights are listed below:

Men 77" [1955.8mm]

Youth 66" [1676.4mm]

Women 70" [1778mm]

Youth 60" [1524mm]

Determine where the inlet piping will connect to the solenoid.

For the non-metallic solenoid, this connection is typically 1-1/2"

below showerhead height, and 2-1/4" left of centerline. For a

brass solenoid, it is 2-1/2" below showerhead height, and 2-1/4"

left of centerline.

Install the Solenoid and Piping Assembly

The piping and Hydropanel™ II shrouding come pre-assembled

(Figure 4). To detach, remove the screws at the showerhead (A)

and bottom bracket (C and C'). Slide the piping out of shrouding;

the showerhead remains part of the shroud.

WARNING: Before installing solenoid, flush the pipes to

ensure supply water is free of grit and sand.

NOTE: A service stop can be installed directly upstream of the

solenoid to facilitate maintenance and repair.

4-3/4

[120.65]

FLOOR LINE

The non-metallic solenoid has 3/4" NPT end connections, and a

straight through flow path to minimize pressure loss. Make sure

the manual override switch is in the "OFF" position, or else water

will flow regardless of sensor activity.

End Cap

A

B B'

The brass solenoid has 1/2" NPT end

connections.

Connect the supply line to the solenoid. Use only thread sealant on male

threads. Do not use Teflon tape; it

will clog the solenoid valve. Connect

the inlet piping so water flows in the

direction of the arrow on the solenoid.

C

D

Figure 4

To mount the upper bracket of the

C'

piping assembly, drill the holes at the

same height as the top of the showerhead (B and B').

Install Control Box

The control box (Figure 5), with standard cables, can be positioned up to 4 feet from the pushbutton/proximity sensor assembly and up to 2 feet from the solenoid valve. [Optional cable

extensions can extend these distances to 1000 feet from the

sensor assembly, and 300 feet from the solenoid valve.] Remove

the cover. Use the box as a template to mark positions on the

wall for two mounting screws. Drill holes and attach the box.

2

Page 3

Installation cont. n

attach wires

attach wires

Push the two power supply wires (supplied with ESP kit)

through the hole in the side of the Control Box. Insert one wire

into each power connector and tighten each screw for a secure

connection. Replace the cover.

Power connectionsRun-Time Potentiometer

Install the Transformer

The plug-in and box mount

transformers can be positioned

TIME ON

N

I

E

A

R

S

C

E

in a chaseway, closet or ceiling. Each can power up to eight

solenoids. For shower system

maintenance, a remote shutoff

SENSOR SOLENOID

switch can be installed.

WARNING: Do not supply

Sensor Port Solenoid Port

Figure 5

power to or plug in the transformer until all wiring is complete.

Plug-In Transformer

The plug-in transformer will connect to a

110V AC wall outlet. Connect the two power

cord wires from the Control Box (or GCB) to

the screw terminals on the secondary side

of the transformer (Figure 6). Tighten the

screws.

NOTE: The wires can be lengthened with 22

Figure 6

gauge bell wire.

Box Mount Transformer

The box mount transformer will mount

on a 110V AC supply electrical junction box. The "J" box should be inside

the chase wall or above the ceiling.

Connect the power supply wires from

the Control Box (or GCB) to the secondary side of the transformer (Figure

Figure 7

7). Tighten the screws.

ESP System Test

Before attaching shrouding, the ESP system should be tested.

First, position and support the Hydropanel™ shrouding within

all cable limits (on a chair, etc.). Do not turn on power or water

supply yet.

Shower Applications

Insert the plugs from the proximity

sensor and the solenoid into their

labeled ports on the Control Box

(Figure 5). The unit will not operate

Figure 8

properly if the connectors are not in

their correct ports.

Supply power to the transformer, and activate the sensor by

pressing the pushbutton (Figure 8). The solenoid should make

an audible click.

ESP Shower Time Adjustments

NOTE: To prevent repeat cycling, the Piezo sensor has a five

second "lock-out" after the shower has been turned on or off.

During the five seconds, no matter how many times the pushbutton is pressed, the sensor is programmed not to respond.

Also, the sensor is programmed to deactivate the shower if the

button is held in the active position (continuously invading the

proximity sensor's magnetic field).

Shower Applications

The ESP Control Box includes a potentiometer to set maximum

run-time, from 0 to 15 minutes (Factory setting is about 6 minutes). To adjust shower time, remove the cover of the Control

Box. Locate the slotted dial in the center of the circuit board

(Figure 5). With a small screwdriver, rotate the dial in small

increments, clockwise for more time, counterclockwise for less.

Turn dial carefully; overadjusting can damage the potentiometer. After each adjustment, test and time the shower.

Re-Attach the Shrouding

The bottom bracket (Figure 4,D) will attach to the wall 25-1/2"

below showerhead height (see Figure 3). Use the bracket as a

template to mark positions for two mounting holes. Drill holes

and attach the bracket.

The chrome plated end cap (Figure 4) on top of the shrouding

has a section marked to be broken out for vertical and horizontal piping clearance. To remove the marked piece, hit it sharply

with a hammer. Do not remove the entire end cap from the

shrouding.

Connect the outlet side of the solenoid to the showerhead piping by sliding the showerhead nipple (with the shrouding unit)

into the piping assembly. The bottom bracket will fit inside the

shrouding.

Before connecting shrouding with screws, turn on water supply

and activate the sensor to test the system. Water should flow

through showerhead. Press the pushbutton again to deactivate

the shower, then check all connections for leaks.

Use screws to attach the shrouding to the piping bracket and to

bottom mounting bracket (Figure 4, A and C).

Operation n

1) When a bather presses the pushbutton, the sensor sends a

signal through the control box to the solenoid. The solenoid

opens and allows tempered water to flow to the showerhead.

2) If the bather presses the pushbutton again, a signal is sent to

the solenoid to close and consequently shutoff the water.

3) If the bather does not press the pushbutton again, water will

automatically shutoff at the pre-set run-time. After shutoff,

the system is ready for the next user.

NOTE: To prevent repeat cycling, the proximity sensor has

a five second "lock-out" after the shower has been turned on

or off. During the five seconds, no matter how many times

the pushbutton is pressed, the sensor is programmed not to

respond. Also, the sensor is programmed to deactivate the

shower if the button is held in the active position (continuously

invading the proximity sensor's magnetic field).

3

Page 4

System Maintenance n

Routinely (twice a year) perform the following maintenance to

ensure safe continuous operation of ESP Hydropanel™ units.

1. Inspect electrical connections for corrosion.

2. Check for any loose connections. Tighten if necessary.

3. Check solenoid valve for proper operation. Make sure it is

free of dirt and lime build up.

4. Check that temperature of supply water is thermostatically

controlled for safe comfortable bathing.

Maintenance and Troubleshooting n

The following are problems that may occur with the ESP

Hydropanel™ II. Follow the listed steps toward a solution. For

any further problems, call Powers Application Engineering

Deptartment at 1.800.669.5430.

Shower Control:

1. If the shower does not activate when the pushbutton

is pressed:

a. Check that transformer feed wires are securely

attached to terminals at control box and at transformer.

b. Check that power is supplied to the transformer. Also,

use a voltmeter to check that power is being supplied

through the transformer. If power goes into the transformer but does not come out, replace the transformer.

2. If no water flows from showerhead when pushbutton

is pressed:

a. Check that the supply line is open and water is being

supplied.

Solenoid Valve Maintenance n

For brass solenoid: For maintenance instructions, use Powers

Kit #444 183 and refer to “Installation and Maintenance

Instructions,” Series 8210, included with the ESP Hydropanel™

II Kit.

b. Check that the solenoid wires are securely connected.

c. The maximum run-time may have elapsed. Wait 5

seconds for sensor delay, then press the pushbutton

again. For a longer shower-run time, reset potentiometer on control box.

3. If water runs continuously, regardless of sensor activity:

a. FIRST unplug solenoid from the control box.

b. If water continues to run...

• Debris and/or lime build-up may be preventing

solenoid from closing. Dismantle, clean and flush the

solenoid valve (see Solenoid Valve Maintenance).

c. If water stops after disconnecting power...

• The problem is electronic. Check that power wires

are connected properly in the Control Box, and check

all electrical connections.

Parts List n

No. Part # Description

1 444 416 Sensor Assembly for Pushbutton Shower

1A 444 416 Pushbutton Assembly

2 444 175 Solenoid Assembly (non-metallic)

3 444 175 Solenoid Assembly (brass)

4 444 161 Control Box, Individual Pushbutton Showers

5 444 118 Plug In Transformer

6 444 119 Box Transformer

1

1a

2

65

7

3

8

No. Part # Description

7 141 379 Swivel Showerhead

8 141 816 Fixed Showerhead

Not Shown 444 168 Installation Kit, Pusbutton Control Box

Not Shown 444145C Maintenance/Repair Kit, Solenoid (non-metallic)

Not Shown 444145D Diaphragm Repair Kit, Solenoid (non-metallic)

Not Shown 444 183 Maintenance/Repair Kit, Solenoid (brass)

4

A Watts Water Technologies C ompany

IS-P-450P 1030 EDP# 6512206 © 2010 Powers

USA: Phone: 1.800.669.5430 • Fax 1.847. 229.0526 • www.powerscontrols.com

Canada: Phone: 1.888.208.8927 • Fax 1.888. 479. 2887 • www.powerscontrols.ca

Loading...

Loading...