Page 1

Shown above: Model 420-RB-E-S-S-0-0

tronic faucets), checkstops (highly recommended) or other

accessories common to Powers’ cabinet supply offering.

DESCRIPTION

Hydroguard Series 420 Under-the-Counter thermostatic tempering valves are designed for all applications where the temperature of generated hot water must be controlled for safe,

economic use. A powerful liquid-filled motor quickly senses

and compensates for temperature fluctuations induced by

water temperature and pressure changes in the supply line.

Rugged construction features cast brass body and corrosionresistant internal components for years of dependable, trouble-free service. Screwdriver stem makes temperature adjustment quick and easy.

For restricted access control, the Series 420 valve can be

housed in a stainless-steel or white baked enamel steel cabinet and can be packaged with solenoid valve(s) (for ESP elec-

SPECIFICATIONS

Valve Construction:

Under-the-Counter thermostatic mixing valve, with heavy cast bronze body and brass stem with screwdriver adjustment.

Capacity..............................................Standard ................................................6 gpm [22.7 L/min]* (±0.5 gpm [1.9 L/min])

High ........................................................8 gpm [30.3 L/min]* (±0.5 gpm [1.9 L/min])

Low......................................................3.5 gpm [13.2 L/min]* (±0.5 gpm [1.9 L/min])

Maximum Hot Water Supply Temperature ......................................................................................................190°F [88°C]

Minimum Hot Water Supply Temperature

(not applicable to low temperature hot water valve) ....25°F [14°C] above set point

Maximum Operating Pressure ................................................................................................................125 psig [862 kPa]

Temperature Ranges........................................................................................................Standard......65–115°F [18–46°C]

High ..........120–175°F [49–79°C]

Low ..................40–90°F [4–32°C]

Maximum Static Pressure........................................................................................................................125 psig [862 kPa]

Minimum Flow and Pressure Differential: Minimum Flow

Minimum Pressure Differential

Standard Capacity ............................................................2.5 gpm [9.5 L/min]......................................10 psi [69 kPa]

High Capacity ....................................................................4.5 gpm [17 L/min] ....................................15 psi [103 kPa]

Low Capacity......................................................................1.0 gpm [3.8 L/min]........................................5 psi [34 kPa]

Shipping Weight................................................................................................................................................5 lbs. [2.3 kg]

The Hydroguard Series 420 Under-the-Counter standard and high capacity valves meet the above operating conditions

as stated in ASSE 1017 (45 psi pressure differential, hot water supply between 140°–180°F [60–82°C], cold water supply

less than 70°F [21°C]).

If your operating conditions vary from those stated in the standard, performance may vary as well. Consult your local

sales representative or a Powers factory engineer to discuss your specific application. All Powers Under-the-Counter

thermostatic mixing valves perform to the requirements of standards ASSE 1017 and CSA B125.

* At 45 psi differential [310 kPa], with hot water supply between 140°–180°F [60–82°C].

TECHNICAL INSTRUCTIONS

Hydroguard Series 420

Under-the-Counter Thermostatic Tempering Valve

OPERATION

Hot and cold water supplies enter the 420

Hydroguard through their respective inlet ports. Both

supplies mix in the chamber containing the valve

assembly. The resulting mixture flows across the

thermostatic motor, and the motor positions the

valve assembly to maintain the desired delivery

water temperature.

Delivery water temperature can be varied by turning

the adjustment stem. Turning the stem counterclockwise raises the temperature, and turning the stem

clockwise lowers the temperature. WARNING: A

valve without checkstops, left in the open position,

even with a downstream shutoff valve used, does

not prevent crossflow.

TI420U

(Operation continued on page 3)

Page 2

2

Page 3

3

OPERATION (continued from p. 1)

If the temperature of the mixture is higher than the

temperature setting, the thermostatic motor actuates

the valve assembly toward the hot water seat. Hot

water flow decreases and cold water flow increases.

Thus the mixture temperature is brought down to the

desired temperature. The reverse occurs when the

mixture temperature is lower than the temperature

setting.

A change in water temperature or pressure of either

hot or cold water supply will cause the thermostatic

motor to reposition the valve assembly to maintain

the desired delivery temperature.

420 Hydroguard supplies tempered water to

self-closing and/or solenoid valves, Powers recommends use of a shock absorber (Powers Part

No. 460-353) on the discharge line. This protects

the 420 Hydroguard thermostatic motor from

damage.

3. Locate the valve as close as possible to outlet

fixture to avoid waste of energy and water

except in applications where the valve is used as

a primary mixing valve to supply an entire building.

4. Correct valve sizing affects valve and system

performance; under- or over-sizing of the mixing

valve(s) can cause poor operation and possibly

injury. Refer to Sizing Information on page 6.

Adherence to these guidelines and recommendations promotes safe product use and ensures proper valve performance.

1. Thermostatic water mixing valves are control

devices which must be cleaned and maintained

on a regular basis. Powers specifies periodic

maintenance at least once a year or immediately after any changes are made to the plumbing

system. Although annual cleaning is recommended, frequency of cleaning depends on

quality of local water conditions. Refer to

Preventive Maintenance on page 4 for recommended cleaning procedure.

2. Quick closing valves may cause damage to the

mixing valve by creating shock waves. When the

SAFETY & PERFORMANCE GUIDELINES

Note: All Powers products are subject to the Terms &

Conditions of Sale and Warranty Information, found in the

current Powers CPL Price List.

Page 4

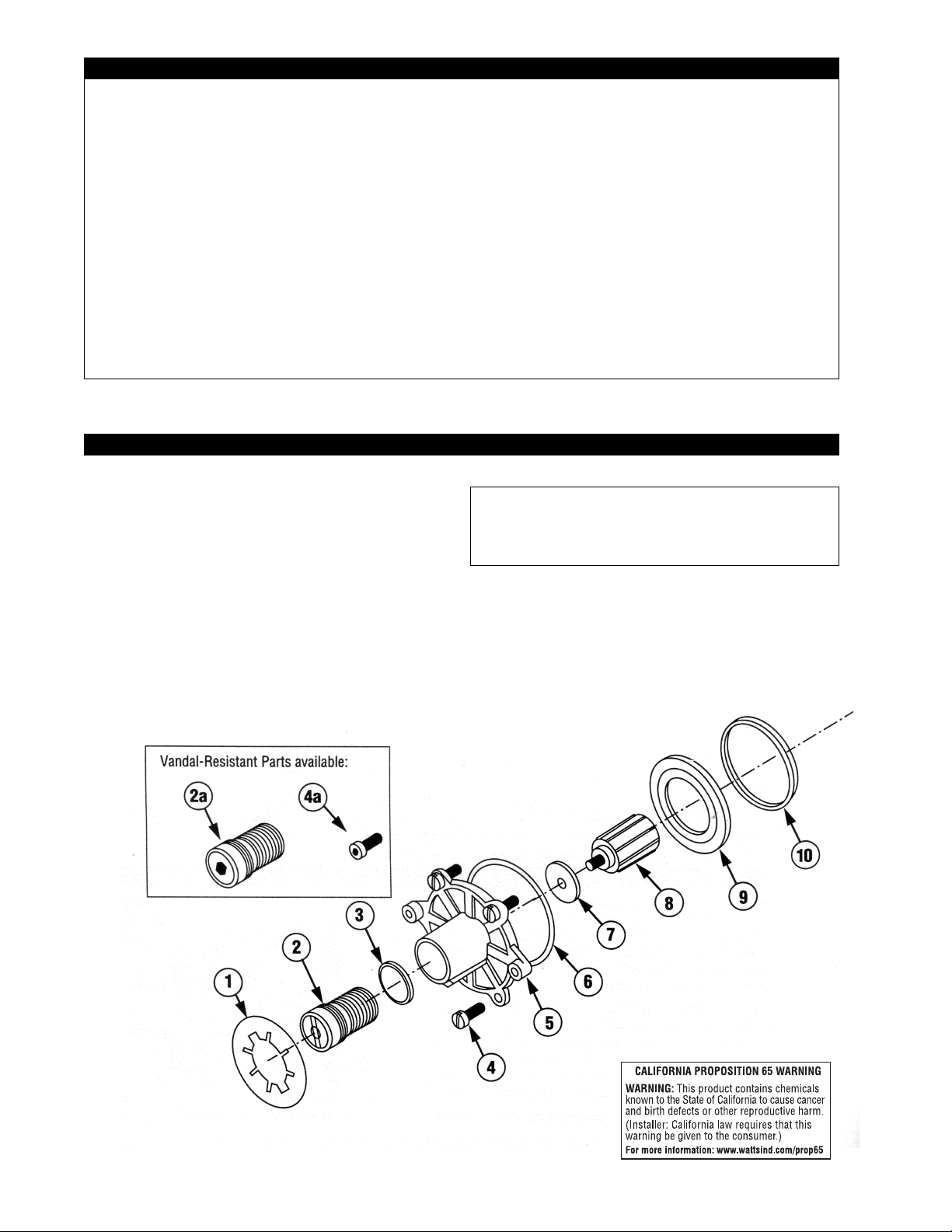

ALL MODELS

† NOTE: Item available in more than one repair kit. See repair kits on p. 4.

NA = item not available as an individual commercial part.

Item # Product # Description Material

13–19 Valve Assembly

13 Override Stem Brass

14 Cold Water Shut Off Plate Rubber

15 Override Spring Stainless Steel

16 Hot Water Disc Retainer Brass

17 Hot Water Shut Off Disc Bronze

18 Override Spring Retainer Brass

19 Retaining Spring E-Clip Copper

20 227-109 Return Spring Stainless Steel

21 227-389 Hot Water Seat—Low Capacity Noryl

420-155 Hot Water Seat—High Capacity Noryl

420-250A Hot Water Seat—Std. Capacity Noryl

22 N/A Body Bronze

Item # Product # Description Material

1 N/A Nameplate Aluminum

2 420-184A Adjustment Stem Brass

2a 420-184H Vandal-Resistant Adj. Stem Brass

3 047-114 Stem O-Ring Buna-N

4 420-214 Screws (12 per kit) Stainless Steel

4a 080-050 Vandal-Resistant Screws (12) Stainless Steel

5 420-201 Bonnet Brass

6† Bonnet O-Ring Buna-N

7 046-171 Washer Brass

8† Thermostatic Motor —

9 227-233 Retaining Ring Delrin

10 † Combination Seat O-Ring Buna-N

11 † Combination Seat Delrin

12 † Motor Sleeve Brass

PARTS LIST

4

Page 5

Recommended Used for

Problem Kit Type Repair Kit No. Model(s) Includes Items

•Variable or untempered Motor Replacement 420-519V (High temp) 1–9 Thermal Motor, Bonnet O-Ring,

discharge temperature 420-519 (Std. temp) 1–9 Motor Sleeve (6, 8, 12)

420-519W (Low temp) 1–9

•Water leaks at valve shut off, Combination Seat 420-559 (High capacity) 1–9 Combination Seat, Combination Seat Oshut-off disk and/or hot Replacement 420-521 (Std. capacity) 1–8 Ring, Retaining Ring, Bonnet O-Ring

water seat have been 420-559 (Std. capacity) 9 (6, 9, 10, 11)

replaced 420-522 (Low capacity) 1–9

• Low flow, desired temp- Low Temperature 420-203 1-8 Bonnet O-Ring,Combination Seat O-Ring

erature cannot be reached Hot Water 420-557 9 (Mdls. 1-8 kit only), Combination Seat

Conversion Kit (Mdl. 9 kit only), Valve Assembly

(Mdl. 9 kit only)

•Water leaks at bonnet/body O-Ring Kit 420-524 1–9 Stem O-Ring, Bonnet O-Ring,

Combination Seat O-Ring (3, 6, 10)

•Variable or untempered dis- Valve Replacement 420-563 (High capacity) 1–9 Bonnet O-Ring, Valve Assembly

charge temperature continues 420-525 (Std. capacity) 1–8 (6, 13–19)

after motor replacement 420-560 (Std. capacity) 9

420-560 (Low capacity) 1–9

•Worn hot water seat Valve and Hot 227-340 (Std. capacity) 5-8 Bonnet O-Ring, Combination Seat O-Ring,

Water Seat 420-561 (Std. capacity) 9 Valve Assembly, Return Spring, Hot Water

Seat (6, 10, 13-19, 20, 21)

REPAIR KIT PART NUMBERS

Figure 2.

3. Flow is untempered hot or cold water…

• accumulation of lime deposits in hot water pipes,

restricting the flow of hot water

• thermostatic motor failure; replace with new thermostatic motor

• hot and cold water supplies are connected to the

wrong ports

4. Maximum temperature specified for the 420

Hydroguard cannot be obtained…

• accumulation of lime deposits in hot water pipes,

restricting the flow of hot water

• hot water supply temperature is too low

5. Variable discharge temperature occurs…

• extreme pressure variations in supply lines

• valve operating below minimum capacity requirements

PREVENTIVE MAINTENANCE

Every Six Months: Check and adjust the maximum

temperature setting (see instructions below).

Every Twelve Months:

1. Shut off water supply.

2. Open up checkstops (if any).

3. Clean strainers (if any) and check for free movement of checkstop poppet.

4. Remove the bonnet and check for freedom of

movement of internal components.

5. Test the thermostatic motor as described in

Thermostatic Motor Testing Section (page 5).

6. Replace seals if cracked, cut, or worn.

7. Reassemble.

8. Adjust screwdriver stem to desired temperature.

1. The flow of water is less than desired…

• valves upstream from supply not fully open

• low supply pressures

• accumulation of lime deposits in hot water pipes,

restricting the flow of hot water

• checkstops not fully open

• clogged strainer screens in the checkstops

• clogged hot water seat

2. Flow of water is completely shut off…

• valves upstream from supply completely closed

• failure of cold water supply pressure (the 420

Hydroguard is designed to shut off on a cold

water supply failure)

• checkstops completely closed

TROUBLESHOOTING

Screwdriver

adjustment

stem

5

Page 6

NOTE:When replacing hot water seat, do not

over tighten!

Figure 6.

The hot water seat can be removed with a 7⁄8”

(22mm) socket wrench. (Max. 40 in–lbs. torque.)

NOTE: After completing any maintenance/repairs,

check maximum discharge temperature 115°

(46°C). Reset if necessary.

Pull out the combination seat with a pair of pliers,

pulling on the two opposing lugs. One plier can be

used by alternately pulling on the two opposite

lugs until the seat can be removed by hand. Pull

out the valve assembly and return spring as

shown in Figure 5.

Figure 5.

Figure 4.

Figure 7.

1. Remove the thermostatic motor. Make the following test to determine whether the thermostatic

motor is in operating condition.

2. Thermostatic motor bellows should offer firm, not

spongy resistance to a rigid blunt object inserted

inside the bellows. If it does not offer firm resistance, the thermostatic motor is not fully charged

and should be replaced.

3. Place the thermostatic motor sleeve in the motor

as shown in Figure 7. Immerse the thermostatic

motor into 75°F (24°C) water for a few minutes.

The thermostatic motor should cause an approximate 1/32″ (0.8mm) travel with the 25° (13°C) temperature difference. In other words, the top of the

sleeve should be approximately 1/32″ (0.8mm)

higher at 100°F (38°C) than it was at 75°F (24°C). If

this distance is much less, the thermostatic motor

has lost part of its charge and should be replaced.

THERMOSTATIC MOTOR TESTING

A new thermostatic motor can be substituted. Use pliers to separate motor from stem. Locate the pliers

near washer. To avoid damage, be certain not to

squeeze thermostatic motor too firmly. (See figure 4.)

Remove four bonnet screws and pull out bonnet

assembly. The motor and motor sleeve should come

out with the bonnet. If not, they can be easily pulled

out. When reassembling, the open end portion of the

motor sleeve should be projecting out of the motor.

SERVICING

(Before assembling valve, make certain both water supplies to the valve are shut off.)

Depth distance

should be 1/32″

Bonnet

Screws

Figure 3.

6

Page 7

DIMENSIONAL DATA AND CHECKSTOPS

Figure 8. Nameplate

SIZING

The flow chart below indicates the Hydroguard Series

420 discharge capacity in gpm for various pressure

differentials (the difference between the lowest inlet

pressure and the discharge pressure at the valve).

Valve sizing affects the performance and reliability of

the valve. Under- or over-sizing of the mixing valve(s)

can cause poor operation and possibly injury.

Warning: This is a water tempering device and is not

intended or designed for point-of-use shower applications. There is no limit stop. It is strongly recommended that checkstops be installed with this valve

even when a downstream shutoff is used.

MODEL IDENTIFICATION

To be sure you are installing appropriate parts into your

valve, determine the model number. The easiest way to

do that is to look at the date code (found on the nameplate of the valve). The date code (not to be confused

with the product or part number) is a four-digit code. Its

purpose is to record the model/version number of the

product itself and the date of manufacture. (See circle

"B" in the figure below for location of date code.)

In the example below, the Date Code is labeled by circle "B". The first digit, 8, indicates the model number.

The nameplate also indicates the temperature range of

the valve. In the figure below, circle "A" shows the location of the temperature range: "115" (a standard valve).

9

1

⁄ 16

(230)

Type D

7

3

⁄ 4

(197)

Type A, C

5

7

⁄ 8

(149)

Type E

7

Page 8

© April 2002 Powers, a Watts Industries Co.

3400 Oakton Street, Skokie, IL 60076 Phone: 800.669.5430 • 847.673.6700 • Fax: 847.673.9044

www.powerscontrols.com

5435 North Service Road, Burlington, Ontario, L7L 5H7 Canada • Phone: 888.208.8927 • Fax: 888.882.1979

TI420U 0218 EDP# 6508930 Printed in U.S.A.

Loading...

Loading...