Page 1

OPERATION

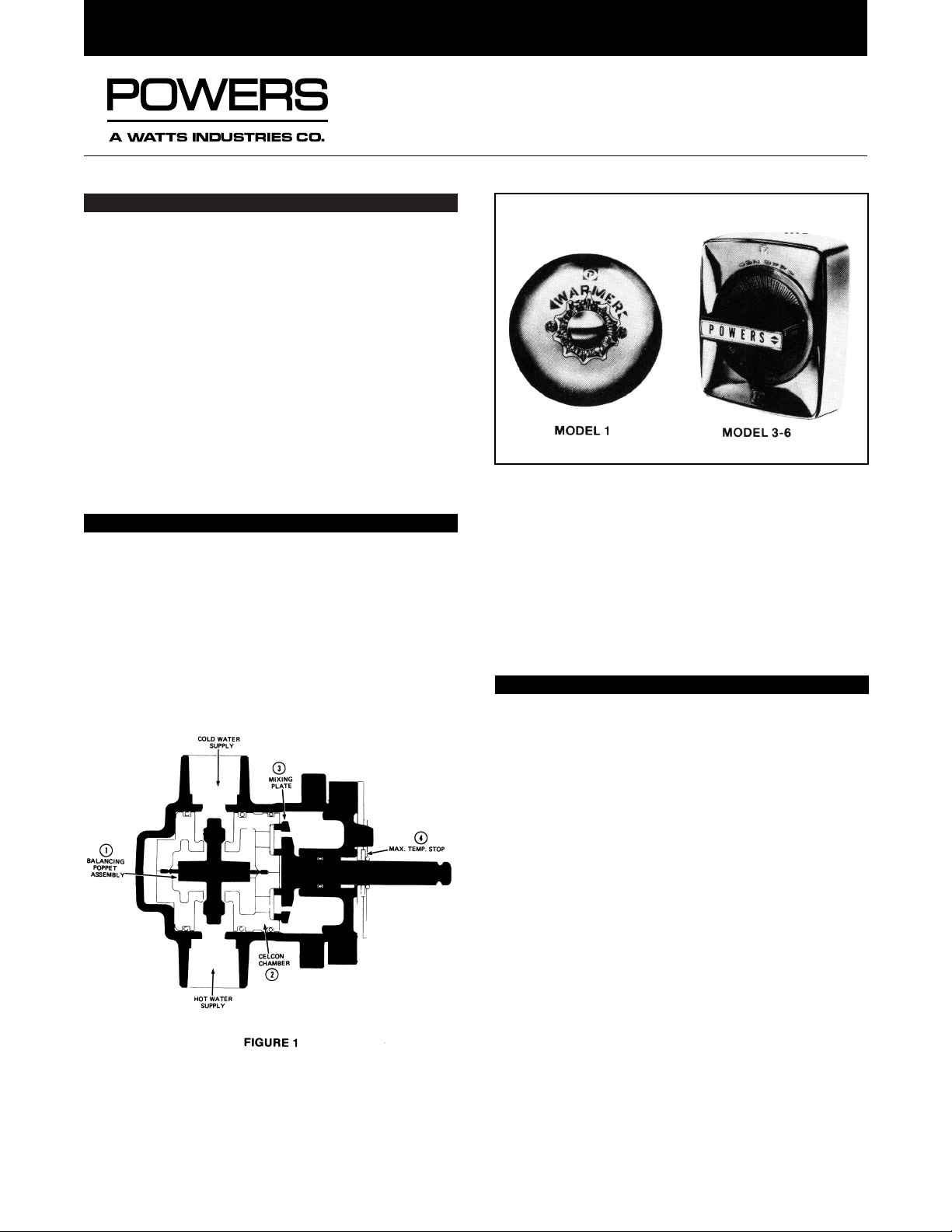

Hot and cold water enter their respective ports and the pressures are equalized through the action of the balancing poppet (1). The entire balancing poppet assembly is contained in

a celcon chamber (2). This chamber is replaceable as a complete cartridge. After the hot and cold presses are equalized,

they are mixed by the action of the mixing plate (3). As the

temperature adjustment stem is rotated from shutoff to maximum hot water temperature (approximately 180°), the mixing

plate passes the required proportion of hot and cold water to

produce the control point. With the adjustment stem in its full

clockwise position, shutoff is obtained by shutting off both

supplies. The maximum temperature stop (4) allows the user

to set the maximum discharge temperature. This mixer does

not recognize supply water temperature changes so any variation in the water temperature will affect the control point

and the maximum temperature setting.

SPECIFICATIONS

Operating Capacity

Model 1–3

................... 9 GPM @ 45 psi (.57L/sec @ 310 kPa)

Model 4 3-port

.......... 6 GPM @ 45 psi (.38L/sec @ 310 kPa)

4-port

To p

..........6 GPM @ 45 psi (.38L/sec @ 310 kPa)

Bottom

....6 GPM @ 4S psi (.38L/sec @ 310 kPa)

Model 6

.........................6 GPM @ 45 psi (.38L/sec @ 310 kPa)

Inlet and Outlet Sizes

Model 1–3: Inlet and Top

....................................1/2″ NPT

Bottom

...........................................3/4″ NPT

Model 4–6, all ports

..............................................1/2″ NPT

Maximum pressure (static)

........................ 125 psi (862 kPa)

Maximum inlet temperature

..............................180°F (82°C)

Built-in shutoff

...................................................All models

Roughing-in template

.........................................All models

Maximum temperature adjustment

.......................All models

MAINTENANCE

Troubleshooting Pointers

What to look for if:

1. The flow of water is less than desired.

a. Valves upstream from supply not fully open.

b. Low supply pressures.

c. Accumulation of lime deposits in hot water pipes,

restricting the flow of hot water.

d. Shower head clogged.

2. Flow of water is completely shut off.

a. Valves upstream from supply completely closed.

b. Failure of hot or cold water supply pressure. The

Hydroguard is constructed to restrict the flow of water

on hot or cold water supply failure,

3. The temperature of the water goes from hot to cold when

the adjustment handle is rotated counter-clockwise.

a. The water supplies are connected to the wrong port.

4. Flow of water continues when Hydroguard is shut off.

a. Worn SHUTOFF DISCS. Replace worn disc.

5. Maximum temperature is too low.

a. Accumulation of lime deposits in hot water pipes,

which restricts the flow of hot water.

b. The concealed maximum temperature is not at its

maximum adjustment.

c. Hot water temperature too low.

TECHNICAL INSTRUCTIONS

Hydroguard 400 Valves

Models 1–6

Form TI400 v2

A Watts Industries Co.

Page 2

TI400 v2 Page 2

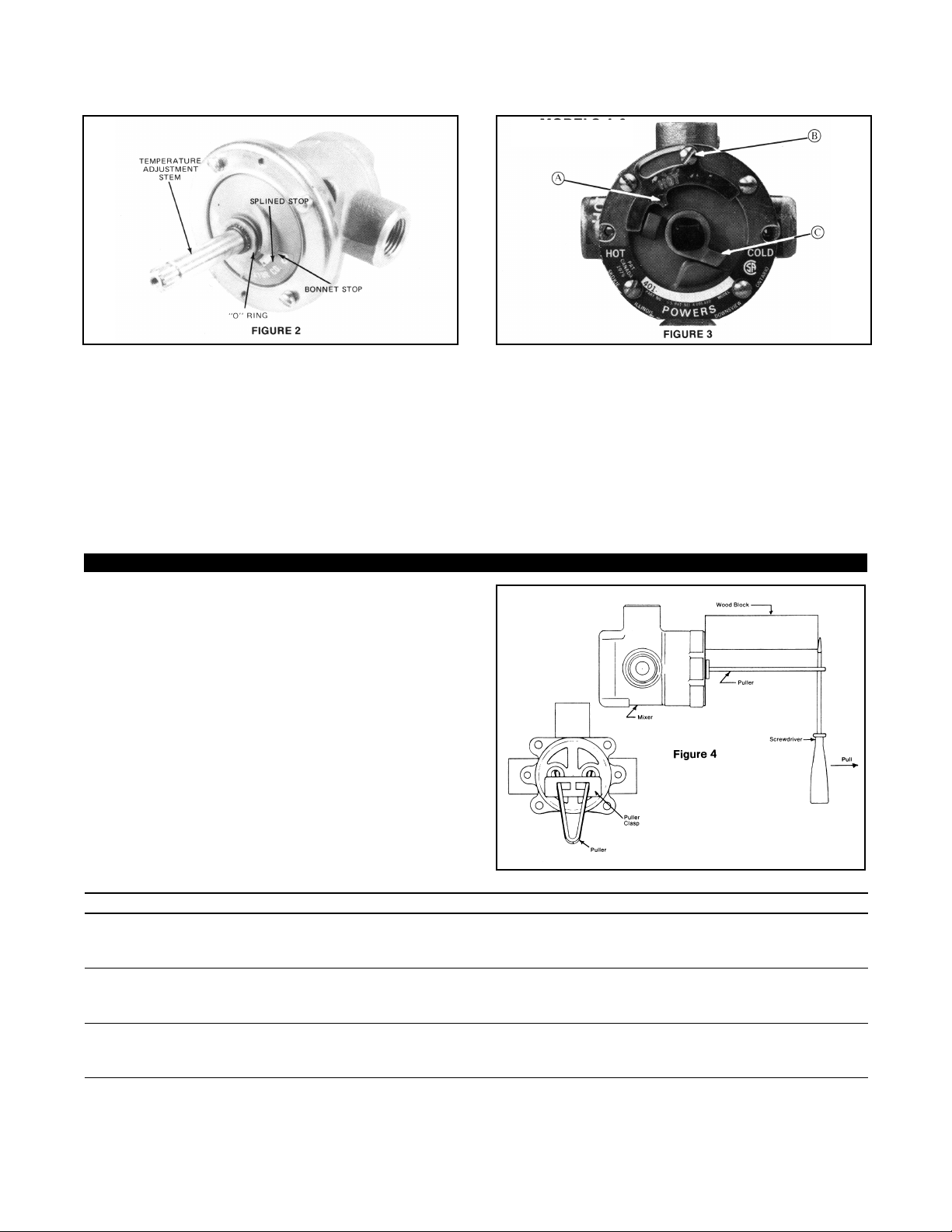

To Remove Balancing Cartridge Assembly

1. Insert hooked ends of puller into HOT and COLD outlet

ports of Balancing Cartridge. (See figure 4)

2. Push puller clasp into notches of puller.

3. Insert screwdriver or similar type bar through puller.

4. Place a 3″ wood or plastic block (do NOT use metal)

between bar end and mixer body. Pull other end of bar.

5. Release puller clasp, spread hooked ends of puller slightly and remove from cartridge.

To Install Balancing Cartridge

1. Apply small amount of oil or grease or soap to inner

surface of body.

2. Align cartridge and body holes.

3. Slowly push cartridge in, side O-rings. Be careful not to

pinch side O-rings.

MAXIMUM TEMPERATURE SETTING:

MODELS 1–3

CAUTION: MAXIMUM TEMPERATURE SETTING. To change

setting, remove splined stop by slipping O-ring up on stem.

(Do not remove from stem.) Rotate temperature adjustment

stem to required maximum temperature setting. Position

splined stop on adjustment stem so that it contacts bonnet

stop, See figure 2. Slip O-ring back to original position. Shutoff is made by rotating temperature adjustment stem clockwise. This mixer cannot sense supply water temperature

changes, so any variation in inlet temperatures will affect

control point and maximum temperature setting.

MODELS 4–6

MAXIMUM TEMPERATURE SETTING (Refer to figure 3). This

must be set on the job. Mixer will pass full HOT water.

Loosen screw B (do not remove). Rotate stem to get desired

maximum temperature. Move stop A until it touches stop C.

Tighten screw B. Special case—with high (over 140°F–60°C)

hot water. Remove screw B, turn stop A over as shown by

dashed lines (the word “HOT” will face in) replace screw B.

Reset stop A per above.

CAUTION: Adjustable stop A must be present for proper

operation.

BALANCING CARTRIDGE PULLER

Troubleshooting Recommended Repair Kit

Gasket and 1. Water leak at stem and/or bonnet 410-182

Disc Replacement 2. Flow of water continues after mixer is turned off. Includes items:

10, 14, 18, 19(2), 20(2), 23(2)

Balancing Cartridge 1. Variable or untempered discharge temperature. 410-183 (Models 1–3)

Replacement 401-175 (Models 4–6)

Includes items 18 through 24

Throttling Stem and 1. Flow continues after mixer is turned off. 410-378 (Models 1–3)

Plate Replacement 2. Handle splines on stem damaged. 401-176 (Models 4–6)

includes items 10, 14, 15, 16, 17 and 18

Note: When replacing cartridge “O” ring (item 23), coat the body surface with a small amount of grease or soap.

Page 3

TI400 v2 Page 3

Hydroguard 400

Models 1–3

PARTS LIST

1 034-224G Handle Screw (8-32 x 7⁄8″) C.P. Steel

2 420-301E Lever Handle C.P. Cast

3 420-314 (4) Plug Button C.P. Steel

4 034-515K Handle Screw (8-32 x 1⁄2″) C.P. Steel

5 420-300 Handle (includes items 3, 4, 5) —

5A 420-213 Insert

9 030-889 Bonnet Screws (10-24 x 7⁄8″) Stainless Steel

10 410-366 (25) O-Ring (3⁄8 x 1⁄2 x 1⁄16″) Buna-N

11 410-371 (6) Temperature Stop Brass

12 410-377 Support Ring Stainless Steel

13 410-346 Bonnet Noryl

14 410-366 (25) O-Ring (3⁄8 x 1⁄2 x 1⁄16″) Buna-N

15 410-368 (15) Washer Synthane

16 410-369 (10) Wavy Washer Stainless Steel

17 * Adjustment Stem —

18 * Bonnet Gasket Rubber

19 * Shut-Off Disc Buna-N

20 410-366 (25) O-Rings Buna-N

21 * Guide Brass

22 * Spring Monel

23 * O-Ring (3⁄4 x 15⁄16 x 3⁄32″) Buna-N

24 * Cartridge Celcon

25 N/A Body Bronze

26 400-062 Dial Plate (includes 27, 28, 31, 32) —

26A 401-086 Handle Only Duralac

27 401-090 Plug Button —

28 420-216 (20) Screw (8-32 x 2″) Steel

29 401-092 Button in Kit 400-085 Duralac

30 OBS Dial Plate with Diverter Assembly —

31 032-064 Screw (8-32 x 1⁄2″) Brass

32 401-088 Stem Guide C.P. Cast

34 OBS Body (Diverter) Bronze

Item Product No. Description Material Item Product No. Description Material

( ) Number of items per package.

* Available in kits (page 2).

NOTE: Model 1 dial is not available.

Page 4

TI400 v2 Page 4

Hydroguard 400

Models 4–6

PARTS LIST

1 401-090 Plug Button —

2 080-008 Screws Brass

3 401-230A Complete Dial Assembly —

4 401-231 Handle —

5 030-885 Bonnet Screws 10-32 x 1″ St. Steel

6 030-884 Adj. Stop Screw 10-32 x 5⁄16″ St. Steel

9 401-228 Adjustment Stop Stl. Zinc Pl.

10 401-366 (25) O-Rings 3⁄8 x 1⁄2 x 1⁄16″ Buna-N

11 401-165 Max. Temp. Stp Brass

12 410-377 Support Ring St. Steel

13 401-162 Bonnet Noryl

14 410-366 (25) O-rings 3⁄8 x 1⁄2 x 1⁄16″ Buna-N

15 410-368 (15) Flat Washer Synthane

16 410-369 (10) Wavy Washer St. Steel

17 * Throttling Stem Celcon

18 * Bonnet Gasket Rubber

19 * Shut-Off Discs Buna-N

20 * O-rings 13⁄4 x 17⁄8 x 1⁄16″ Buna-N

21 * Quad Rings Buna-N

23 * O-Ring 3⁄4 x 15⁄16 x 3⁄32″ Buna-N

24 * Balance Chamber Celcon

25 401-158 Body (4-Port) Bronze

401-160 Body (3-Port) Bronze

26 401-210 Strainer Caps Celcon

Item Product No. Description Material Item Product No. Description Material

( ) Number of items per package.

* Available in kits (page 2).

© Reprinted March 2002 Powers, a Watts Industries Co.

USA Phone: 800.669.5430 • Canada Phone: 888.208.8927

www.powerscontrols.com

A Watts Industries Co.

Form TI400 v2 0218 EDP # 6511203 Printed in U.S.A.

Loading...

Loading...