Page 1

This Manual is Bookmarked

Operating Instructions and Parts Manual

8-inch Parallelogram Jointer

Model PJ-882

WMH TOOL GROUP

2420 Vantage Drive

Elgin, Illinois 60123 Part No. M-1610079

Ph.: 800-274-6848 Revision A 1/05

www.wmhtoolgroup.com Copyright © WMH Tool Group

Page 2

This manual has been prepared for the owner and operators of a Model PJ-882 Jointer. Its purpose,

aside from machine operation, is to promote safety using accepted operating and maintenance

procedures. To obtai n maximum lif e and effici ency from your jointer and t o aid in using i t safely, please

read this manual thoroughly and follow the instruc tions carefully.

Warranty and Service

WMH Tool Gr oup warrants ever y product it sell s. If one of our tools needs s ervice or repai r, one of our

Authorized Repair St ations located throughout the United States can provide quic k service or information.

In most cases, a WM H Tool Group Repair Station c an as si st in authorizi ng repair work, obtaining parts, or

perform routi ne or m ajor maintenance repair on your Powermatic product.

For the nam e of an A uthoriz ed Repair St ation in your area, pl ease call 1-800-274-6848, or v isit our web

site at www.wmhtoolgroup.com

More Information

Remember, WMH Tool Group i s consistently adding new products to the li ne. For complete, up-to-dat e

product information, check with your local WMH Tool Group distributor, or visit our web site at

www.wmhtoolgroup.com

WMH Tool Group Warranty

WMH Tool Group makes every effort to assure that it s produc ts meet high quality and durability standards

and warrants to the original retail consumer/purchaser of our products that each product be free from

defects in mat erials and workmanship as foll ows: 1 YEA R LIMITED WARRANTY ON ALL PRODUCTS

UNLESS SPECIFIED OTHERWISE. This Warranty does not apply to defects due directly or i ndirectly to

misuse, abuse, negl igence or acc idents, norm al wear-and-tear , repair or alterati ons outside our f aciliti es,

or to a lack of maintenanc e.

WMH TOOL GROUP LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD SPECIFIED ABOVE,

BEGINNING FROM THE DATE THE PRODUCT WAS PURCHASED AT RETAIL. EXCEPT AS STATED

HEREIN, ANY IMPLIED WARRANTIES OR MERCHANTABILITY AND FITNESS ARE EXCLUDED.

SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG THE IMPLIED WARRANTY LASTS,

SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU. IN NO EVENT SHALL WMH TOOL GROUP

BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR INCIDENTAL,

CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR

PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL

OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY

TO YOU.

To take advantage of this warranty, the product or part must be returned for examination, postage

prepaid, to an Authorized Repair Station designated by our office. Proof of purchase date and an

explanati on of the complaint m ust accompany the merchandi se. If our inspecti on discloses a defec t, we

will either repair or replace the product at our discret i on, or ref und the purc hase price if we cannot readi l y

and quickly provide a repai r or replac ement. We will return the repai red product or replacem ent at WMH

Tool Group’s ex pense, but if it is determ ined there i s no defect, or that the def ect resulted f rom causes

not within the scope of WMH Tool Group’s warranty, then the user must bear the cost of storing and

returning t he product . This warranty gives you specif ic legal ri ghts; y ou may also hav e other ri ghts, whic h

vary from state t o state.

WMH Tool Group sells through distribut ors only. Members of the WMH Tool Group reserve the right to

effect at any time, wit hout prior notice, alter ations to parts, fittings and accessory equi pment, which they

may deem necessary for any reason whatsoever.

2

Page 3

Table of Contents

Warranty and Servic e ..............................................................................................................................2

Table of Contents....................................................................................................................................3

Warning...................................................................................................................................................5

Introduction.............................................................................................................................................. 7

Description..............................................................................................................................................7

Specifications..........................................................................................................................................7

Unpacking ...............................................................................................................................................8

Contents of the Shipping Container............................................................................................. .........8

Installation and Assembly ........................................................................................................................9

Installing Switch Arm..........................................................................................................................10

Installing Cutt erhead Guard................................................................................................................10

Dust Collection...................................................................................................................................11

Grounding Instructions...........................................................................................................................11

Extension cords..................................................................................................................................12

230 Volt, Single Phase Operation.......................................................................................................12

Three Phase Operation......................................................................................................................12

Adjustments........................................................................................................................................... 13

Drive Belt Tension ..............................................................................................................................13

Drive Belt Replacement......................................................................................................................14

Fence Movement...............................................................................................................................14

Fence Stops.......................................................................................................................................15

Fence Removal..................................................................................................................................16

Locking Handles ............................................................................................................................... ..16

Table and Knife Adj ustments..............................................................................................................16

Setting Tables Parallel........................................................................................................................17

Setting Knives at Correct Height and Parallel To O utf eed Table..........................................................18

Outfeed Table Stop Screws................................................................................................................22

Setting Inf eed Table (Depth of Cut) ....................................................................................................22

Infeed Table Depth Stop.....................................................................................................................22

Infeed Table St op Scr ews...................................................................................................................23

Replacing Kniv es in the Cutterhead....................................................................................................23

Elimina t in g “P lay ” in Ta b les................................................................................................................24

Operating Controls.................................................................................................................................24

Operation...............................................................................................................................................24

Hand Placement.................................................................................................................................25

Surfacing............................................................................................................................................25

Edge Jointing .....................................................................................................................................25

Rabbeting ..........................................................................................................................................26

Jointing Short or Thin Work................................................................................................................26

Jointing Warped Surfaces...................................................................................................................26

Beveling.............................................................................................................................................26

Direction of Grain...............................................................................................................................27

Skewing (Shear Cutting).....................................................................................................................27

Maintenance..........................................................................................................................................28

Sharpening Knives.............................................................................................................................28

Cutterhead Repair s ............................................................................................................................29

Optional Accessories .............................................................................................................................32

Replacement Parts................................................................................................................................32

Parts List: Cutterhead Assembly .........................................................................................................33

Parts List: Fence Assembly................................................................................................................ 34

Fence Assembly.................................................................................................................................35

Parts List: Outfeed Table and Base Assembly ....................................................................................36

Outfeed Table and Base Assembly.....................................................................................................37

Parts List: Inf eed Table Assembly.......................................................................................................38

Infeed Table Assembly.......................................................................................................................40

Parts List: Stand A ssembly .................................................................................................................41

Stand Assembly .................................................................................................................................43

3

Page 4

Electrical Connections – 1 Phase, 230 Volt ............................................................................................44

Electrical Connections – 3 Phase, 230 Volt ............................................................................................45

Electrical Connections – 3 Phase, 460 Volt ............................................................................................46

4

Page 5

Warning

1. Read and understand the entire owners manual bef or e attempting assembly or operati on.

2. Read and understand the warnings po sted on the machine and i n this manual. Failure to comply with

all of these warnings m ay cause seriou s i njury.

3. Replace the warning labels if they become obscured or removed.

4. This joint er i s designed and intended for use by properly tr ained and ex per ienced personnel onl y . If

you are not familiar with the proper and safe operation of a jointer, do not use until proper training

and knowledge have been obtained.

5. Do not use this joint er for other than its intended use. If used for other pur pose s, WMH Tool Group

disclaims any real or implied warranty and holds itself harmless from any inj ur y that m ay result from

that use.

6. Always wear approved safety glasses/fac e shields while using this j oi nter. Everyday eyeglasses only

have impact resistant lenses; they are not safety glasses.

7. Before operating this jointer, rem ov e tie, rings, watches and other jewelry , and roll sleeves up past

the elbows. Remove all loose clothing and confi ne long hai r . Non-sl ip footwear or anti- skid floor

strips are recommended. Do not wear glov es.

8. Wear ear protector s (plugs or muffs) during ext ended peri ods of oper ation.

9. Some dust created by power sanding, sa wing, grindi ng, drilling and other construction activities

contain chemi c als known to cause cancer, birth defects or other reproductive harm. Some examples

of these chemic als are:

• Lead from lead based paint.

• Cry stalline silica from bricks, cement and other m asonry pr oduc ts.

• Ar seni c and c hr om ium from chemically treated lum ber .

Your risk of exposure varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in a well-ventilated area and work with approved safety

equipment, such as face or dust masks that are specifically designed to filter out microscopic

particles.

10. Do not operate this machine while tired or under the influence of dr ugs, alcohol or any medication.

11. Make certain t he switc h is i n the OFF position before connecting the machine to the power supply.

12. Make certain t he machine is properly grounded.

13. Make all machine adjustments or maintenance with the machine unplugged from the power source.

14. Remove adjusti ng k ey s and wrenches. Form a habit of checking to see that keys and adjusting

wrenches are removed from the machine before turning it on.

15. Keep safety guards in place at all times when the machine is in use. If r em ov ed for maintenance

purposes, use extreme caution and replace the guards immediately.

16. Check damaged parts. Before further use of the machine, a guar d or other part that is damaged

should be carefull y c hec k ed to det ermine that it will operate properly and perform its intended

function. Check for alignment of moving parts, binding of moving parts, break age of parts, mounting

and any other conditions that may affect its operation. A guard or other part that is damaged should

be properly repaired or replaced.

17. Provide for adequat e space surrounding work area and non- glare, overhead lighting.

18. Keep the floor around the machine clean and free of scrap material, oil and grease.

19. Keep visit or s a safe di stanc e from the work area. Keep children away.

20. Make your workshop chil d pr oof with padlocks, master switc hes or by r em ov ing starter keys.

21. Give your work undiv ided attention. Looking ar ound, carrying on a conversati on and “ horse-play” are

careless acts that can r esul t in serious injury.

22. Maintain a balanced stanc e at all times so that you do not fall or lean against the knives or other

moving part s. Do not over r eac h or use exc essive force to perform any machi ne oper ation.

5

Page 6

23. Use the right tool at the corr ec t speed and feed rate. Do not force a tool or attac hm ent t o do a job for

which it was not designed. T he ri ght tool will do the job better and safer.

24. Use recommended accessories; improper accessories may be hazardous.

25. Maintain tool s with c ar e. Keep k nives sharp and clean for the best and safest performance. F ollow

instructions for lubricating and changing accessories.

26. Turn off the machi ne before cleaning. Use a brush or compressed air t o r em ov e chips or debris —

do not use your hands.

27. Do not stand on the machine. S erious injury could occur if the machine tips over.

28. Never leave the machine running unattended. Turn the power off and do not leave the machine until

it comes to a complete stop.

29. Remove loose it em s and unnecessary work pieces from the area before starting the machine.

30. When working a piec e of wood on the j ointer, follow the 3-inch rul e: T he hands must never be closer

than 3 inches to the cutter head at any time.

31. Always use a hold-down or push bloc k when surfacing stock.

32. Do not joint materi al short er than 8 “, narrower than 3/4” or less than 1/4” thick.

33. Do not make cuts deeper than 3/4” when rabbeting. On other cut s such as edging, surfacing, etc.,

depth of cut should not be ov er 1/16” to avoid overloading the machine and to minimize chance of

kickback.

34. Never apply pressure to stock directly over the cutter head. This may result in the stock tipping into

the cutterhead along wi th the operator’s fingers. Never back the workpiece toward the infeed table.

Familiarize you r self with the following safety no tices used in this manual:

This means that if precautions are not heeded, it may result i n minor injury and/or

possible machine damage.

This means that if precautions are not heeded, it may result i n serious injury or possibly

even death.

- - SAVE THESE INSTRUCTIONS - -

6

Page 7

Introduction

This manual is provided by W MH Tool Group cov ering the safe oper ation and mai ntenance procedure s

for a Model PJ -882 Jointer. This manual contains instr uctions on i nstall ation, saf ety precautions, general

operating proc edures, maintenance i nstructions and part s breakdown. This mac hine has been designed

and constructed to pr ovi de years of troubl e free operation if used in accor dance with instr ucti ons set forth

in this manual . If ther e are any que sti ons or com m ents, please cont act ei t her your loc al suppl ier or W MH

Tool Group. WMH Tool Group can also be reached at our web site: www.wmhtoolgroup.com.

Description

The Model PJ-882 Jointer is built upon a parallelogram design. This design allows independent

adjustment of sections of the infeed and outfeed tables to ensure the tables remain parallel with the

cutterhead and wit h each other. The fence has a tilting capacit y of 45 degrees forward and backward,

with positiv e stops.

Specifications

(1 Phase Model) (3 Phase Model)

Model Number................................................................. PJ-882...................................................PJ-882

Stock Number................................................................1610079................................................ 1610080

Maximum Cutting Width (in.)..................................................... 8............................................................8

Maximum Cutting Depth (in.)..................................................1/2.........................................................1/2

Rabbeting Capaci ty (in.)......................................................... 1/2.........................................................1/2

Cutterhead Speed (RPM)....................................................7,000.....................................................7,000

Motor...................................................... TEFC, 2HP, 1Ph, 230V................... TEFC, 3HP, 3Ph, 230/460V

(prewired 230V)

Starter..........................................................................magnetic................................................magnetic

Number of Knives..................................................................... 3............................................................3

Cuts Per Minute................................................................21,000................................................... 21,000

Cutterhead Diam eter (in.).................................................. 3-1/16....................................................3-1/16

Table Surface (L x W)(in.)..................................................83 x 8.................................................... 83 x 8

Fence Size (L x H)(in.).................................................38 x 4-3/4.............................................. 38 x 4-3/4

Fence Tilt (deg.).................................... 45 forward, 45 backward........................45 forward, 45 backward

Positiv e Stops (deg. )................................................. -45, 90, +45...........................................-45, 90, +45

Dust Chute Diameter (in.)......................................................... 4............................................................4

Overall Dimensions (L x W x H)(in.)......................... 84 x 28 x 44........................................... 84 x 28 x 44

Net Weight – approx. (l bs.).................................................... 610........................................................610

Shipping Weight – appr ox . (lbs.) ........................................... 744........................................................744

The above specifications were current at the tim e this manual was published, but becaus e of our polic y of

continuous im provement, WMH Tool Group reserv es the right to change specif ications at any tim e and

without pri or notic e, without incurring obligations.

7

Page 8

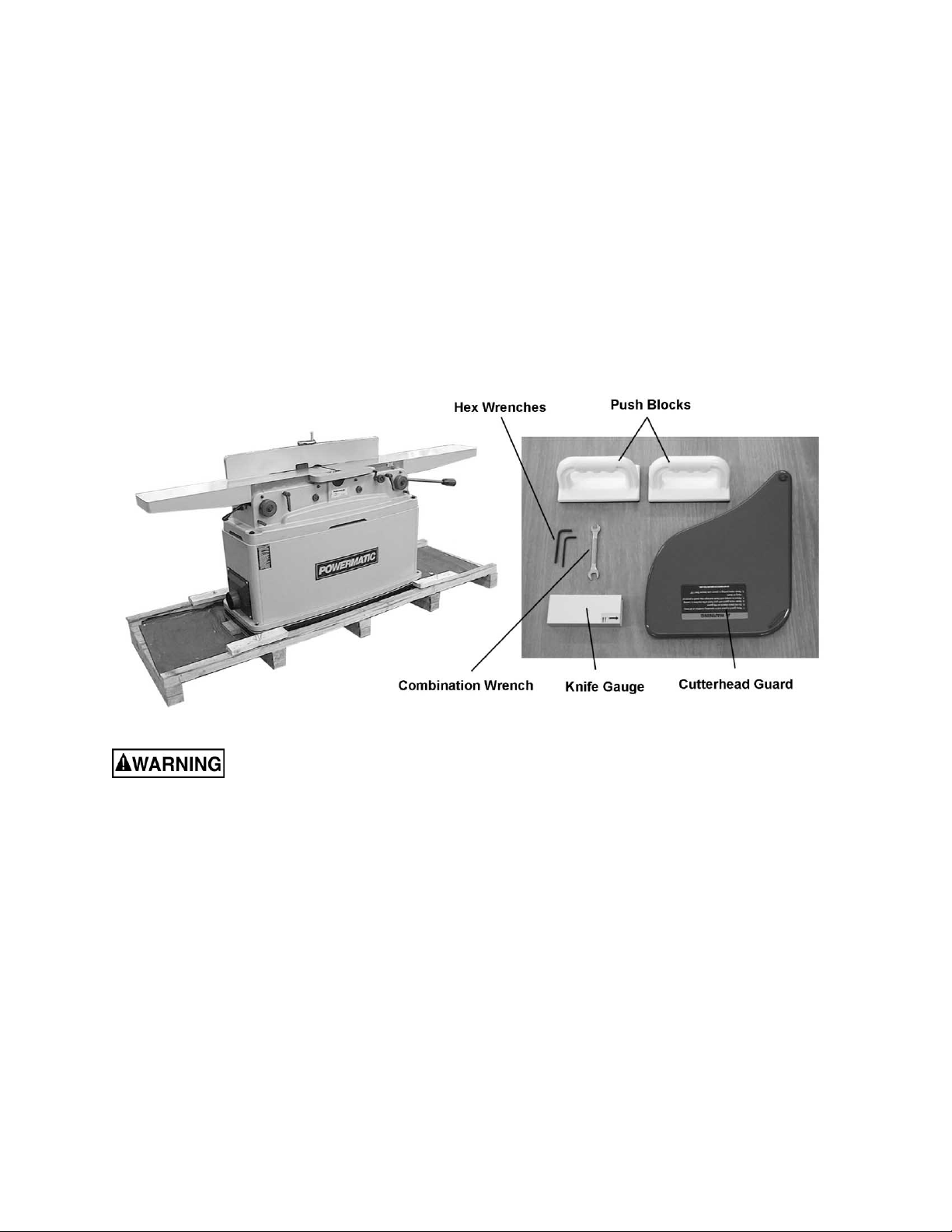

Unpacking

Open shipping cont ainer and check f or shipping

damage. Report any damage immediately to

your distributor and shipping agent. Do not

discard any shi pping materi al until the Joint er is

assembled and running properly.

Compare the cont ent s of y our cont ainer wit h the

following parts list to make sure all parts are

intact. Mi ssing parts, if any, should be reported

to your distributor. Read the instruction manual

thoroughly for assembly, maintenance and

safety instructions.

Contents of the Shipping Container

1 Jointer

1 Cutterhead guard

2 Push blocks

1 Combination wrench (8-10 mm)

2 Hex wrenches (3mm and 5 mm)

1 Aluminum k nife gauge

1 Owner's Manual

1 Warranty Card

Read and understand the ent ire contents o f this manual before attempting set-up

or operation! Failure t o co mpl y may cause seri ous injury.

8

Page 9

Installation and Assembly

Tools required for assembly

Forklift or hoist with straps/slings

14mm (or 9/16”) wrench or socket

Cross-point (Phillips) screwdriver

3mm and 5mm hex wrenches (provi ded)

1. Remove any boards or straps that secure

the Jointer to the pallet, and remove

protective wrapping.

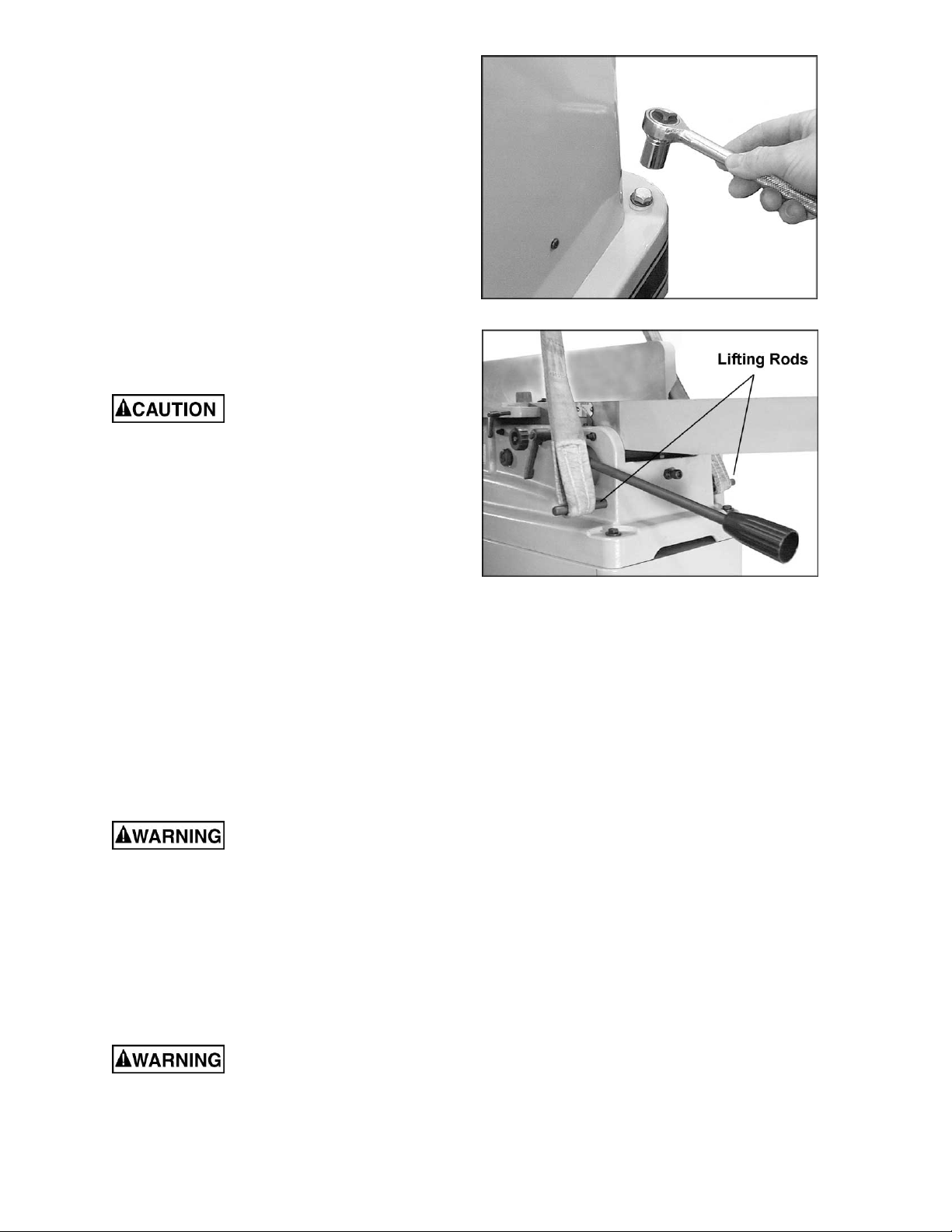

2. Use a 14mm (or 9/16”) wrench to remove

the four l ag screws at t he base of the stand

which helped secure the machine to the

pallet. One of these screws is shown in

Figure 1.

The Joint er should be raised

by straps placed arou nd the four lifting rods

(see Figure 2). Do NOT lift the machine

directly beneath the infeed and outfeed

tables, as this can cause misal ig nment of the

tables.

Figure 1

3. Pull the four lifting rods out as far as they

will go and run the straps around the rods

as shown in Figure 2. Using a forklift or

hoist, lift t he machine off the pallet and into

its desired location. When the straps are

removed, push the lift ing rods back in.

4. The Jointer should be locat ed in a dry ar ea,

on a sturdy fl oor, and with suff icient light ing

and ventilation. Leave plenty of space

around the machine for operations and

routine maintenance work.

5. If desired, the Jointer can be further

stabilized by securing it to the floor, using

lag screws through the four holes at the

base of the stand.

The jointer should be

disconnect ed from the power sou rce during

assembly procedures.

6. Exposed m etal areas of the Joi nt er, such as

the table and fence surfaces, have been

factory coated with a protectant. This can be

removed with a soft cloth dampened with

kerosene or mineral spirits. Do not use an

abrasive pad. Do not let solvent contact

plastic or rubber parts as it may damage

them.

Use caution when cleaning

around cut terhead. The knives are ext remely

sharp.

Figure 2

(straps not included)

9

Page 10

Installing Switch Arm

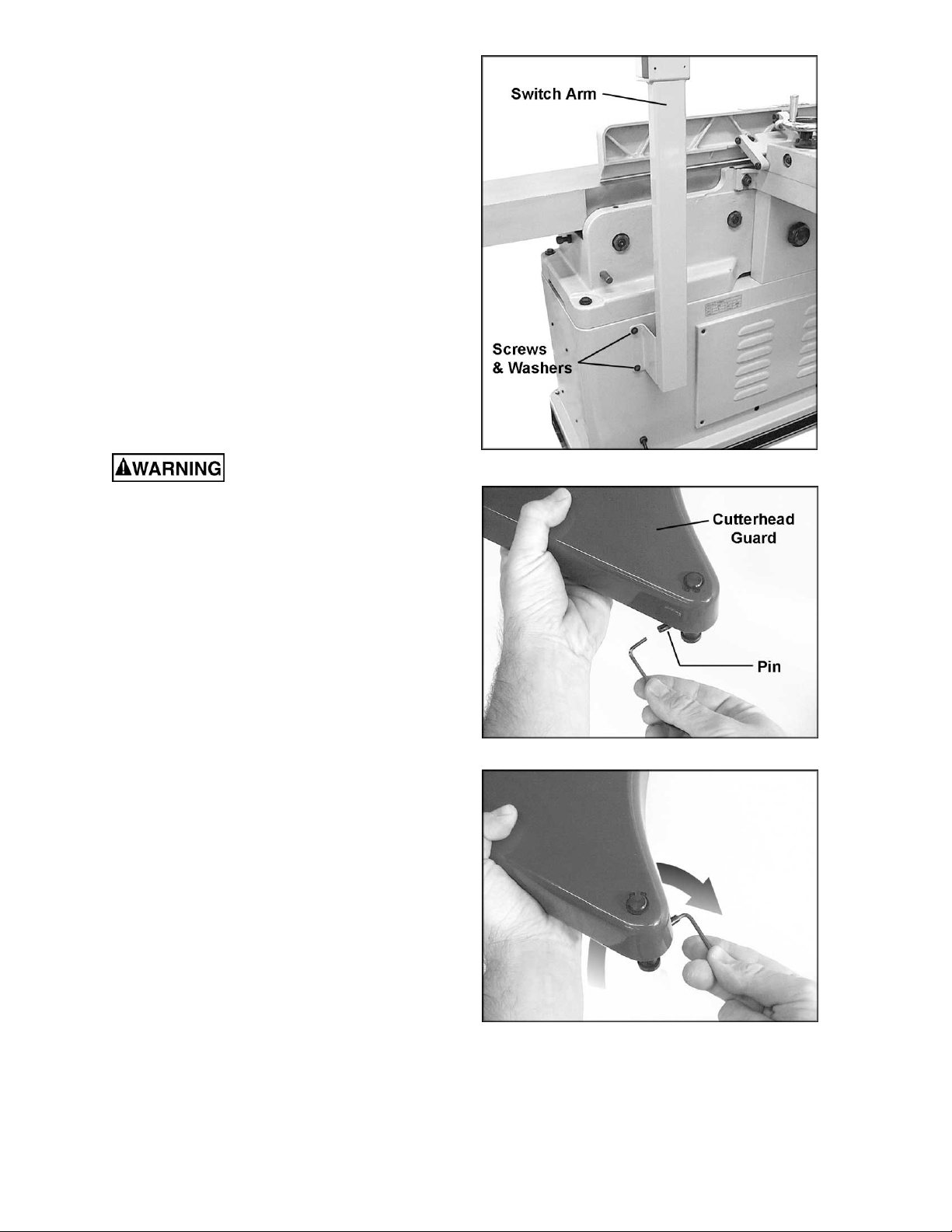

1. The switch arm was shipped in horizontal

position. Loosen and remove t he four socket

head cap screws and flat washers on the

bracket of the switch ar m (Figure 3) with a

5mm hex wrench. Hol d on t o the switch ar m

while doing this, to prevent the arm from

falling.

2. Place the switch arm in vertical positi on, as

shown in Fi gure 3, and align the f our holes

in the bracket with the four holes in the

jointer stand.

3. Re-insert the four socket head cap screws

with the four flat washers, as shown in

Figure 3.

4. Firmly tighten the four socket head cap

screws with the hex wrench.

Installing Cutterhead Guard

Jointer knives are extremely

sharp. Use caution when working with or

around the cutterh ead.

The cutterhead guard has a spring tension

mechanism which must be properly tensioned

when installing the cutterhead guard on the

machine.

To install the cutterhead guard:

1. Insert a small hex wrench, or similar obj ect,

into the pin on t he guard tension mec hanism

(Figure 4).

2. Twist the hex wrench and pi n clockwise, a s

shown in Figure 5, and hold them there.

3. Lower t he shaft of the guard int o the hole on

the jointer’s rabbeting ledge. See Figure 6.

The guard should be lowered into the hole

far enough that the groove in the guard’s

shaft will mate with the shaft of the locking

handle (Figure 6) .

4. After the guard has been inserted into the

hole, let go of the guard with your left hand the guard will swing toward the fence.

Figure 3

Figure 4

5. Completely tighten the locking handle

(Figure 6), whil e continuing to hold the hex

wrench and pin with your right hand.

6. When the guard is secured, rem ove the hex

wrench from the pin. Slightly loosen the

locking handl e (Figure 6) unti l the pin snaps

back against the r abbeting ledge.

7. Re-t ighten the locki ng handle ( Figure 6).

Figure 5

10

Page 11

The cutterhead guard should now have

sufficient spring tension. Test i t by swingi ng the

guard away from the fenc e and then releasing it.

The guard mu st always have

enough spring tension to cover the unused

part of the cutterhead during the cutting

operation, and to swing back to contact the

fence when the workpiece has cleared the

area.

If more spring tension on the guard is desired,

follow the abov e procedure with this exc eption:

tighten the locking handle without allowing the

pin to snap back to the rabbeting ledge. The

farther cl ockwise the pin i s situated, t he greater

will be the spring tension.

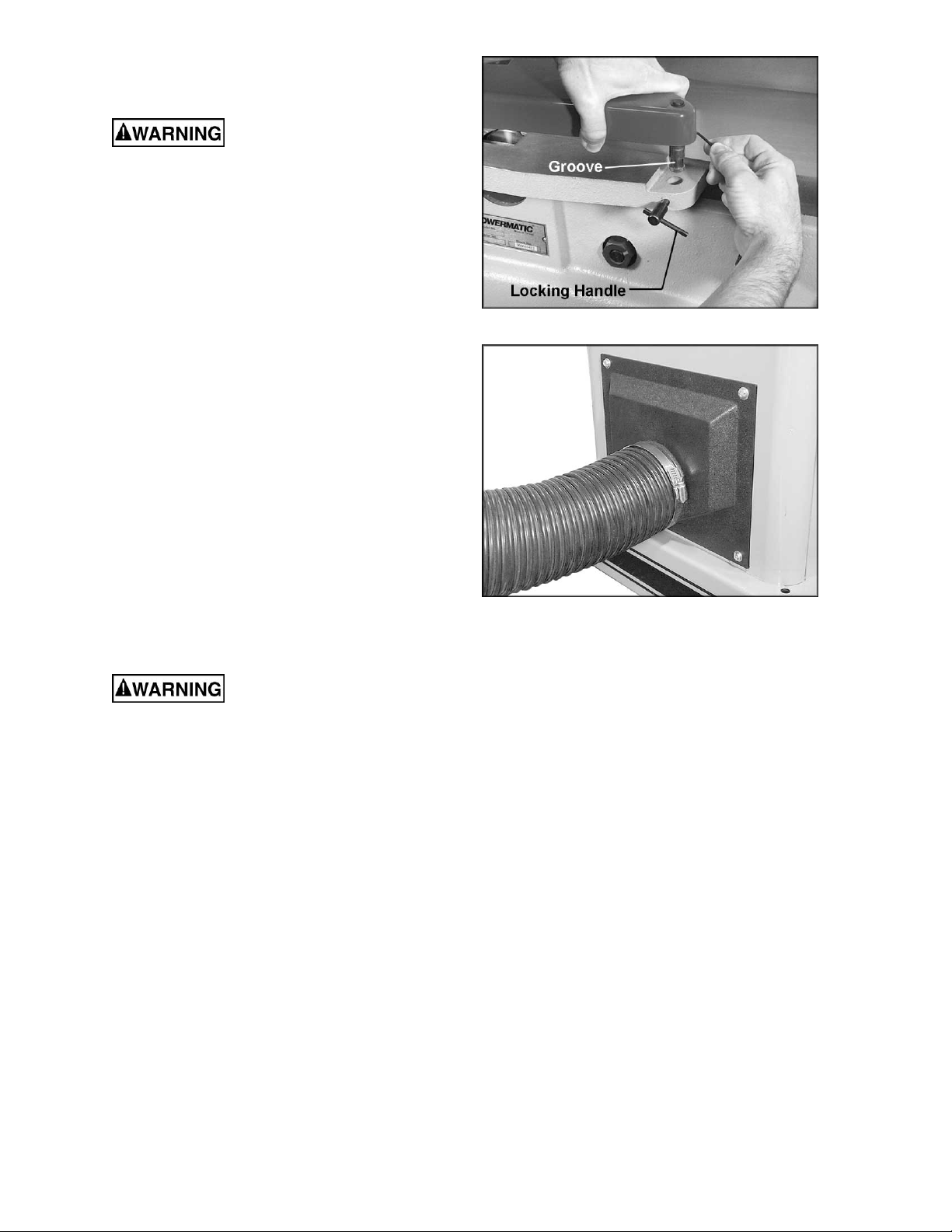

Dust Collection

It is strongly recomm ended that a dust collection

system (not provided) be connected to the

jointer. It will help keep your shop clean, and

reduce the ri sk of heal th problems due to wood

dust. The dust collector should have sufficient

capacity for this size jointer.

Figure 6

Connect the dust collection hose to the 4”

diameter dust por t on the jointer (Fi gure 7) and

secure it with a hose clamp or duct tape.

NOTE: Dryer v ent hose is not acceptabl e for this

purpose.

Grounding Instructions

Electrical connections must

be made by a qualified electrician in

compliance with all relevant codes. This

machine must be properly grounded to help

prevent electrical shock and possible fatal

injury.

This mac hine m ust be grounded. I n the event of

a malfuncti on or break down, groundi ng prov i des

a path of least resi stance f or electric current to

reduce the ri sk of el ectri c shock.

Improper connection of the equipmentgrounding conductor can result in a risk of

electric shock. The conductor with insulation

having an outer surface that is green with or

without yellow stripes, is the equipmentgrounding conductor. If repair or replacement of

the electric cord or plug is necessary, do not

connect the equi pment-grounding c onduc tor to a

live terminal.

Check with a qualified electrician or service

personnel if the grounding instructions are not

completely understood, or if in doubt as to

whether the tool is properly grounded.

Figure 7

(hose and clamp not prov ided)

11

Page 12

Use only three wire extension cords that have

three-prong grounding plugs and three-pole

receptacles that accept the tool’s plug.

Repair or replace a damaged or worn cord

immediately.

Make sure the voltage of your power supply

matches the specif ications on the m otor plate of

the Jointer.

Extens ion co rds

The use of an extension cord is not

recommended f or the PJ882 Joint er. But if one

is necessary, make sure the cord rating is

suitable for the amperage listed on the

machine’s motor plate. An undersized cord will

cause a drop in line volt age resulting in loss of

power and overheating.

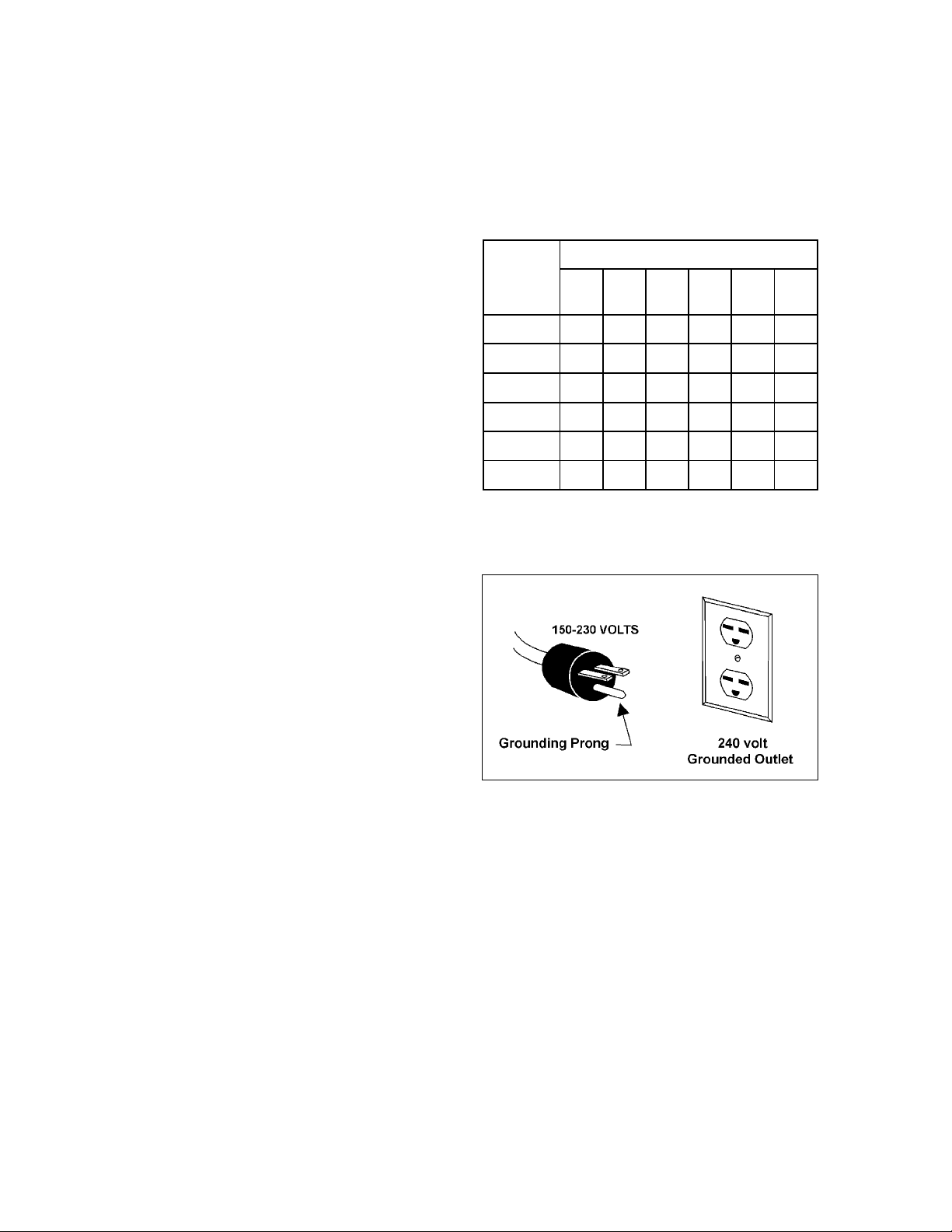

Use the chart in Fi gure 8 as a general guide in

choosing the cor rect size cord. If in doubt, use

the next heavi er gauge. The smaller the gauge

number, the heavier the cord.

Recommended Gauges (AWG) of Extension Cords

Extension Cord Length *

25

50

75

100

150

Amps

< 5 16 16 16 14 12 12

5 to 8 16 16 14 12 10 NR

8 to 12 14 14 12 10 NR NR

12 to 15 12 12 10 10 NR NR

15 to 20 10 10 10 NR NR NR

21 to 30 10 NR NR NR NR NR

feet

feet

feet

feet

feet

200

feet

230 Volt, Single Phase Operation

As receiv ed from the f actory, the single-phase

model of the PJ-882 Jointer i s designed to run

on 230 volt power only.

You may either connect a UL/CSA listed 230V

plug (similiar to the one shown in Figure 9) or

“hard-wire” the machine directly to a control

panel. If hard-wired to a panel, make sure a

disconnect is available for the operator. The

Jointer must comply with all local and national

codes after being wir ed.

If the Joi nter i s to be hard- wired, m ake sure the

fuses have been r emoved or the breakers hav e

been tripped in the circuit to which the Jointer

will be connected. Place a warning placard on

the fuse holder or circuit breaker to prevent it

being turned on while the machine is being

wired.

The Jointer with a 230 volt plug should onl y be

connected to an outlet having the same

configurati on. No adapter is av ailable or should

be used with the 230 volt pl ug.

Three Phase Operation

The three-phase model i s factory wired f or 230

volt, but can be converted to 460 volt if so

desired (see “Co nverti ng From 230 Volt to 460

Volt”).

*based on li miting th e lin e vol tage drop to 5V at 15 0% of th e

rated amp eres.

NR: Not Recommended.

Figure 8

Figure 9

You may either connect a UL/CSA listed plug, or

“hard-wire” the machine directly to a control

panel. If hard-wired to a panel, make sure a

disconnect i s available for the operator.

12

Page 13

If you are hard- wiri ng the Joi nt er, m ake sure the

fuses have been r emoved or the breakers hav e

been tripped in the circuit to which the Jointer

will be connected, and place a warni ng placard

on the fuse holder or ci rcuit br eaker t o prevent it

being turned on until wir ing is complete.

Converting from 230 Volt to 460 Volt

(Three Phas e Only)

Refer to the diagr am on page 46 for connecting

the motor leads for 460 volt power. If using a

plug, it must be a proper UL/CSA listed plug

suitable f or 460 volt operati on. T he Joi nter m ust

comply with all local and national codes after

being wired.

Three-Ph ase Test Run

On the three-phase unit, after wiring has been

completed, you should check that the wires

have been connected pr operly:

1. Connect machine to power source and

press the start butt on, shown in Figure 10.

(See “Operating Controls” on page 24 for

further inf ormation on the control switch.)

Figure 10

2. The cutterhead should rotate clockwise as

viewed from the front of the mac hine. If the

cutterhead rotation is incorrect, press the

stop button (Figure 10) and disconnect

machine from power.

3. Swit ch any two of the three wires at "R,S,T ".

4. Reconnect machine to power source.

Adjustments

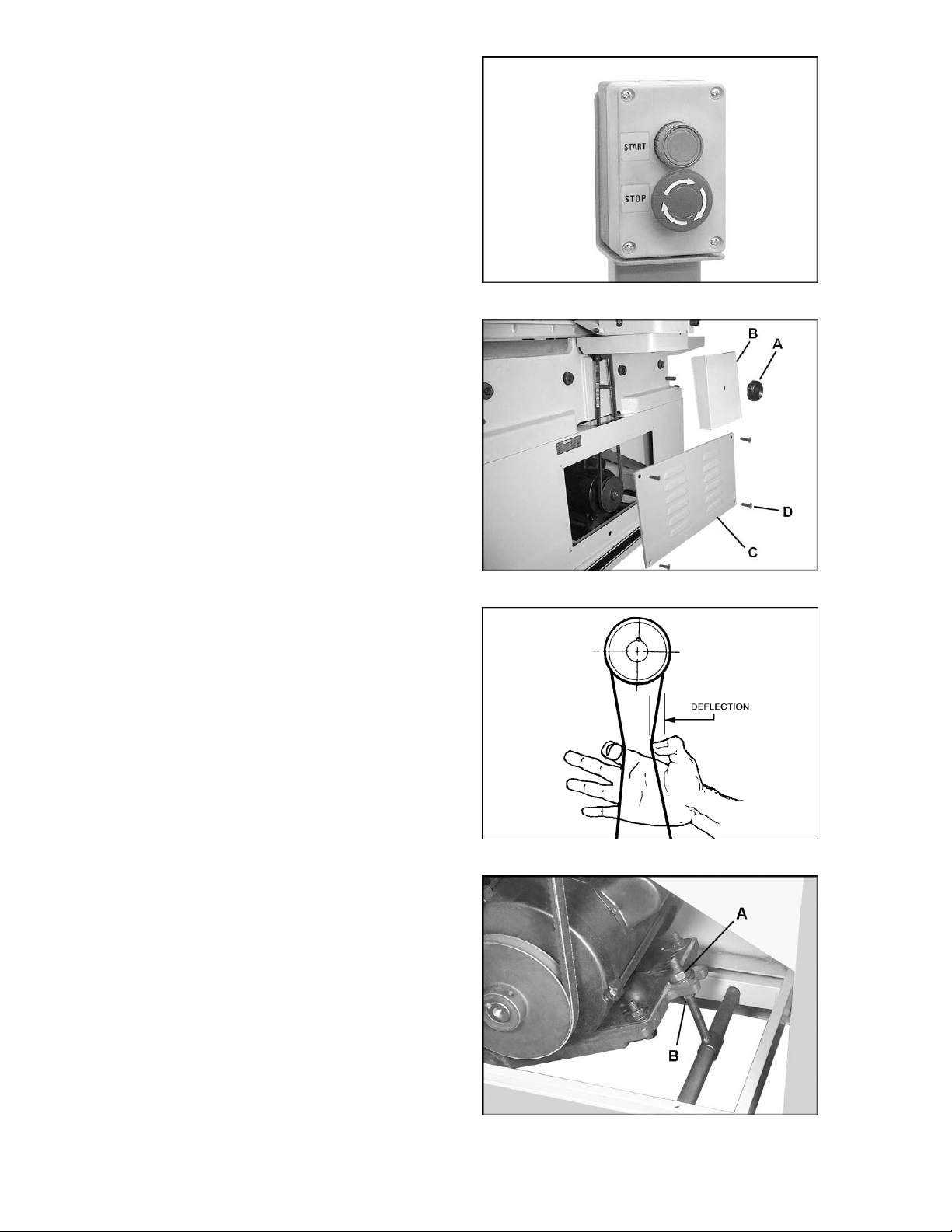

Drive Belt Tension

To check or adjust t he drive belt tension:

1. Unscrew the knob (A, Figure 11) and

remove the belt guar d ( B, Figure 11) .

2. Remove the rear panel (C, Figure 11) by

unscrewing the four flat head screws (D,

Figure 11) with a cr oss-point screwdriver.

3. Proper drive belt tension is achiev ed when

there is a small amount of deflecti on in the

drive belt midway between the pulleys,

when using moderate finger pressure

(Figure 12).

Figure 11

Figure 12

4. To increase the tension on the drive belt,

loosen the lower hex nut (B, Fi gure 13) with

a 17mm wrench, and ti ghten the top hex nut

(A, Figure 13) . When finished, ti ghten lower

hex nut (B, Figure 13).

5. Re-install rear panel and belt guard.

Figure 13

13

Page 14

NOTE: After operating the machine for a short

time, the drive belt tension should be rechecked, as the new drive belt may stretch

slightly duri ng the “breaking-in” period.

Drive Belt Replacement

1. Unscrew the knob (A, Figure 11) and

remove the belt guar d ( B, Figure 11) .

2. Remove the rear panel (C, Figure 11) by

removing the four flat head screws with a

cross-point screwdriver.

3. On the mot or base pl ate, loosen the top hex

nut (A, Figure 13), and lift up on the motor to

create slack in the drive belt. Remove the

drive belt from both pulleys.

4. Install the new drive belt around top and

bottom pulleys, and tension it appropriately

(see “Drive Belt Tension”).

5. Re-install rear panel and belt guard (Fi gure

11).

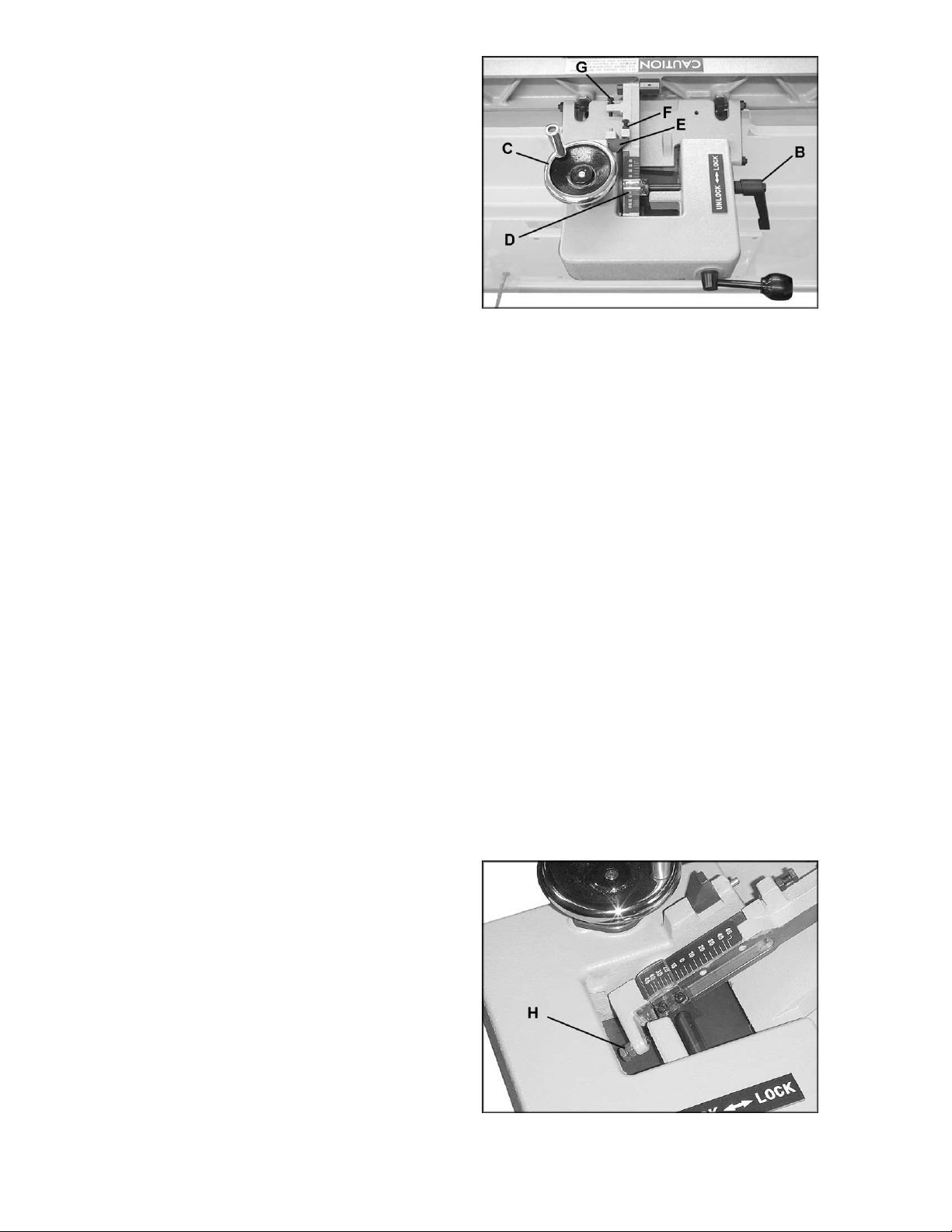

Fence Movement

The fence can be moved forward or backward

across the widt h of the table. It also tilts up to 45

degrees forward and backward, and contains

positive stops at bot h the se angl e s, as well as a

positive stop at 90 degrees.

To slide fence forward or backward:

1. Loosen locking handle (A, Figure 14).

2. Push the entire fence assembly to the

desired posit ion, and tighten loc king handle

(A, Figure 14). A plastic buffer piece is

mounted to t he fr ont of t he fence to prev ent

scratching the table when the fence is

moved.

NOTE: If the lock handle (A, Figure 14) i s in an

inconvenient position, it can be adjusted.

Loosen the two hex nuts underneath the slide

bracket (Figure 15). Flip the handle to the

desired posit ion, and re-ti ghten t he hex nut s. Do

not overti ghten the hex nuts, as thi s can make

the fence difficult to move on the slide bracket.

To tilt fence forward:

The fence can be tilted forward to any angle

down to 45 degrees.

1. Loosen locking handle (B, Figure 14).

2. Rotate handwheel (C, Figure 14) until the

desired angle i s indicated on the scale (D,

Figure 14). Or you can place your beveled

workpiece on the table and against the

fence, and rotate t he handwheel (C, Fi gure

14) until the angle of the f ence matches the

bevel of your workpiec e.

Figure 14

Figure 15

14

Page 15

3. Tighten locking handle (B, Figure 14).

To tilt fence backw ard:

The fence can be tilt ed back ward up to 45° (t hat

is, for a total angle of 135° from table surface).

1. Loosen locking handle (B, Figure 16).

2. Flip the 90° stop bl ock (E, Figure 16) out of

the way.

3. Rotate handwheel (C, Figure 16) until the

desired angle i s indicated on the scale (D,

Figure 16). Or you can place your beveled

workpiece on the table and against the

fence, and rotate t he handwheel (C, Fi gure

16) until the angle of the f ence matches the

bevel of your workpiec e.

4. Tighten locking handle (B, Figure 16).

IMPORTANT: When the tilted operation is

finished and the f ence is ret urned to 90°, do not

forget to flip the 90° stop block (F, Figure 16)

back to its origi nal posi tion.

Figure 16

Fence Stops

Periodic ally check the 90° and 45° til t accuracy

of the fence with an angle measuring device,

such as an adjustable square or machinist’s

protractor. If adjustments are necessary,

proceed as follows:

Setting the 90° Stop

1. The 90° stop is contr olled by the screw (F,

Figure 16) and the stop block (E, Figure 16).

2. Loosen the locking handle (B, Figure 16)

and loosen the hex nut on the screw (F,

Figure 16).

3. Set your angle measuring device to 90

degrees, and place it on the table and

against the fence.

4. Move t he fence until it fit s flush against the

angle measuri ng device. Turn t he screw (F,

Figure 16) until t he screw contacts the stop

block (E, Figure 16).

5. Ti ghten the hex nut on the screw (F, Figure

16) and the lock handl e (B, Figure 16) .

Setting the 45° Forward Sto p

1. The 45° forward stop is controlled by the

screw (H, Figure 17).

2. Loosen the locking handle (B, Figure 16)

and loosen the hex nut on the screw (H,

Figure 17).

3. Set your angle measuring device at 45°.

Place it on t he table and against the fence,

and tilt t he fence until it is flush against t he

45° angle.

Figure 17

15

Page 16

4. Rotate the screw (H, Figure 17) until it

contacts the casting in front of it.

5. Tighten t he hex nut on the scre w (H, Fi gure

17) and tighten locking handle (B, Figure

16).

Setting the 45° Backward Stop

1. The 45° backward stop is cont rolled by the

screw (G, Figure 18), which will contact the

back of the fence when the fence is tilted

backward.

2. Fli p the stop block (E, Figur e 18) out of t he

way.

3. Loosen the locking handle (B, Figure 18)

and loosen the hex nut on the screw (G,

Figure 18).

4. Tilt the fence backward. Set your angle

measuring device at 135° and place it on

the table and against the fence.

5. If necessary, turn the screw (G, Figur e 18),

until the fence lies flush against the angle

measuring devic e.

6. Re-tighten the hex nut on the screw (G,

Figure 18) and tighten locking handle (B,

Figure 18).

Fence Removal

To remove the fence assembly from the

machine, r emove the two hex nuts and one flat

washer that secure it to the slide bracket (see

Figure 15). Lift the fence strai ght up and off the

Jointer.

When re-installing the fence assembly, make

sure the cutout in t he fence assembly sits ov er

the key in the slide br ac k et.

Figure 18

Locking Handles

All locking handles of the type shown in B,

Figure 18, c an be rotated if they are i n the way

of other m ac hi ne par ts. Simply lif t straight out on

the locking handle and rotate it, then release,

making sure it seats properly.

Table and Knife Adjustments

For accurat e jointing, at least three t hings must

be true:

1. Infeed and outf eed tables must be parall el,

or “coplanar” .

16

Page 17

2. Knives m ust be set i n the c utt erhead so that

P

s

the highest point of thei r arc is level wit h the

the outfeed table.

3. Knives must be parallel with the outfeed

table across the entire length of the knives.

These alignments are explained below.

Setting Tables Parallel

For optimum performance of the jointer, the

infeed and outf eed tables must be parall el frontto-back with eac h other. If they are not paral lel,

the finished workpiece may have a slight taper

across its width or length.

The tables hav e been set parall el at the f actory,

but they should be double-checked by the

operator. Also, as the machine receives use,

this parallel setting should be checked

occasionally and adjusted if necessary.

The following procedure uses a steel straight

edge to set the t ables, which should be accurate

enough for most pur poses.

This procedure demonstrates how to set the

parallelism of the outfeed table; the procedure

for the infeed tabl e wil l be identical.

1. Di sconnect jointer from power source.

2. Remove the cutterhead guar d by loosening

the locking handl e (see Figure 6) an d lifti ng

the guard shaft out of the hol e.

3. Slide the fence assembly back as far as it

will go, or remove it from the machine

entirely.

4. Loosen the locking handle on the outfeed

table (see A, Figure 23). Use the lifting

handle (B, Figure 23) to raise the outfeed

table higher than the cutterhead.

lace a straight edge ac ross the front of the

5.

outfeed tabl e and extending ov er the infeed

table. See Figur e 19.

6. Raise the infeed table until it contacts the

traight edge. To raise the infeed table,

loosen the locki ng handle ( see A, Figure 28)

and lift the adjustment arm (B, Figure 28).

When it contacts the straight edge, tighten

the locking handle (A, Figure 28).

7. The straight edge should lie level across

both tables. Move the straight edge to the

back of the outfeed table, and perf orm the

same test. See Figure 20.

8. If the straight edge does not lie level, the

front or back of the t able must be adjusted

to make the tables paral lel with each other.

Proceed as follows.

Figure 19

Figure 20

17

Page 18

9. Each table has four cam adjustment

devices; two in front and two in back.

NOTE: On the front of the Jointer, the two

outside cams are concealed by the hubs.

You must remove the hub to expose the

cam adjustment dev ice. Remove the socket

head cap screw and flat washer at the

center with a 6mm hex wrench, and loosen

the two setscrews in the hub (Figure 21

shows one of the two set scre w holes). Pull

the hub straight out to expose the cam

adjustment device.

10. At the area of the table where the

adjustment must be made, pry out the cap

(A, Figure 22) fr om the hole.

11. T here are two set screws in the hol e. Insert

a 4mm hex wrench (B, Figure 22) into the

hole and loosen the upper set screw by

turning the hex wrench counterclockwise.

Remove the upper set screw fr om the hole.

12. Loos en the lower set screw (do not rem ove

it) by turning c ounterclockwise with the hex

wrench.

13. Turn the hex nut (C, Fi gur e 22) with a 1-1/4"

wrench. T his adjustment i s sensitive and

should be made in small increment s.

NOTE: The rotation is different for left and

right hex nuts; the right hex nut being turned

in Figure 22 will be turned clockwise to raise

that area of the tabl e, or c ounterclockwise to

lower that area of the table. The left hex nut

shown in Fi gure 22 would be rotated i n the

opposite manner.

14. Use the straight edge upon the table and

across the cutterhead to check the

adjustment until the tabl e is parallel wit h the

cutterhead.

15. When the adjustment is satisfactory, with

the tables now parallel to the cutterhead,

tighten the lower set screw with the hex

wrench (B, Figure 22).

16. Insert and tighten the upper set screw.

17. Re-insert the cap (A, Figure 22) to keep

dust and debris out of t he hole.

Setting Knives at Correct Height and Parallel To Outfeed Table

Figure 21

Figure 22

(back of outfeed table shown)

For accurate jointing, the outfeed table surface

must be level with the kniv es at the hi gh point of

their arc. Al so, the knives must be parall el with

the outf eed table along the enti re length of the

knives.

18

Page 19

When you receive the jointer, the knives have

been pre-set at t he factor y. However, the height

and parallelism of the knives with the outfeed

table should be checked, and any needed

adjustment s made, before put ting the j ointer into

operation.

Proceed as follows:

1. Di sconnect jointer from power source.

2. Place a straight edge upon the outfeed table

and extending over the center of the

cutterhead as shown in Figures 23 and 24.

3. Rotate the cutterhead, using the belt or

pulley, until one k nife is at its highest point.

Do not grab the cutterhead it self to rotate it.

4. Lower the outfeed table until the straight

edge contacts the knif e, as shown in Figure

24. Using the driv e belt, r ock the cutterhead

slightly t o make sure t he apex of the knif e is

contacti ng the str aight edge.

5. Lock the outfeed table at that setting by

tightening t he l oc ki ng handle (A, Figure 23).

Figure 23

The importance of the knives being level with

the outfeed tabl e are shown by these ex amples

of incorrect settings:

If the outfeed table is too high, the finished

surface of the workpiece will be curved. See

Figure 25.

If the outf eed table i s too l ow, the work will have

a gouge, or snipe, at the end of the cut. See

Figure 26.

Figure 24

Figure 25

Figure 26

19

Page 20

Figure 27 illustrates the correct setting of

outfeed table level with the knives. The

workpiece will rest firmly on both tables with no

open space under the finished cut.

The outfeed table has now been locked at a

standard height, l ev el with the arc of t he knives.

NOTE: After the outfeed table has been set at

the correct height, it should not be changed

except for special operations or after replacing

knives.

Further fi ne adjustments will now be achieved by

adjusting the k nives in the cutt erhead. Proceed

as follows.

Figure 27

Jointer knives are extremely

sharp; use cau tion and p roceed slowly wh en

setting them.

6. Lower the infeed table out of the way, by

loosening the l ocking handl e (A, Figure 28)

and pushing down on the adjustment arm

(B, Figure 28).

7. An aluminum knif e setting gauge, shown in

Figure 29, is provi ded with the jointer. If you

require very fine tolerances when setting the

knives, a knife setting gauge with a dial

readout can be purchased (see “Optional

Accessories” on page 32). The provided

aluminum gauge should, however, be

accurate enough for most woodworking

needs.

8. Place the provided knife setting gauge at

the back of the outfeed table (toward the

fence support si de) and extending over the

cutterhead as shown i n Fi gure 29. Place t he

gauge so that the right mark lines up with

the edge of the outfeed t able, as shown.

9. Rotate the cutterhead clockwise (by using

the pulley). If table and knives are set

correctly, the knife will contac t the al umi num

gauge and move the gauge until the left

mark now lines up with the edge of the

outfeed tabl e, as shown in Fi gur e 30.

Figure 28

Figure 29

20

Page 21

10. Plac e the alumi num knife gauge at t he fr ont

of the outfeed table (toward the rabbet

ledge) and repeat the process.

11. This test should be performed on all three

knives in the cutter head, using the provi ded

gauge.

12. If any knife is either too high or too low at

one of its ends to corr ectly move the gauge

as described abov e, then the height and/or

parallelism of that knife in the cutterhead

needs to be adjusted. Proceed as follows.

13. Slightly loosen the five gib screws (see

Figure 31) with an 8mm wrench. (NOTE:

The springs below the knife will cause the

knife to ris e .)

14. Turn the jack screw(s) with a hex wrench;

clockwise to l ower the setting of the knif e i n

the cutterhead, counterclockwise to raise

the setting of the knife.

15. Use the edge of a board to push the knife

back down so that it is fl ush against the j ack

screws. See Figure 32. Tighten the gib

screws only enough to keep the knife in

position in the cutterhead. Do not fully

tighten.

16. Check t he height of t he knif e agai n by usi ng

the gauge at front and back of the outfeed

table. Make further adjustments to the jack

screw(s) as needed.

17. Repeat this process for each of the other

two knives in turn. Do not fully tighten gib

screws, only tighten them enough to keep

the knife in positi on.

18. For best results, knives should be set at

approximately .015" above the cutterhead.

Knife height shoul d not vary more t han .002.003" across the length of the cutterhead. All

three knives must be set at equal height in

the cutterhead and parallel to the outfeed

table across thei r length.

Figure 30

Figure 31

19. Aft er all three kniv es are po sit ioned pr operl y

in the cutterhead and m ade snug, continue

tightening the gib screws. The gib screws

should be tightened in increments, to

prevent any distortion to the cutterhead or

buckling of knives. Begin tightening t he gib

screws a lit tle more on one knif e. Star t with

the center screw and work your way to the

ends. Do not fully tighten yet.

20. Rotate the cutterhead to the other two

knives in turn. Repeat step 20 for each

knife.

Figure 32

21

Page 22

21. The tightening process should continue at

least two more times, each time tightening

the gib screws furt her on all three knives in

turn. On the third time, the gib screws

should all be firml y tight ened.

Before operating the jointer,

make sure all gib screws are firmly

tightened. A loose knife thrown from the

cutterhead can cau se severe or fatal injury.

22. After all knife adjustments are completed,

the guards and fence assembly should be

placed back on the machine before

operating.

Outfeed Table Stop Screws

The stop scre w (B, Figur e 33) limi ts the am ount

of fall of the outfeed t able. The stop screw has

been pre-set at the factory, but if future

adjustment is ever needed, simply loosen the

hex nut (A, Figure 33) and turn the screw (B,

Figure 33) as needed with a 14mm wrench.

When satisf ied, re-ti ghten t he hex nut ( A, Fi gure

33).

The screw (C, Figure 33) limits the rise of the

outfeed table. If adjustment is needed, loosen

the hex nut (D, Figur e 33) and turn the screw (C,

Figure 33) as needed with a 9mm hex wrench.

When satisfi ed, re- tight en the hex nut (D, Figur e

33).

Figure 33

Setting Infeed Table (Depth of Cut)

1. Loosen locking handle (A, Figure 34).

2. Move tabl e adjustment arm (B, Figure 34) t o

raise or lower infeed table to the desired

depth of cut , which is shown on the gauge

via the pointer (C, Fi gur e 34) .

NOTE: Do not exceed 1/8” maximum depth of

cut. For deeper cuts, make several passes.

3. Re-t ighten locking handle (A, Figure 34).

Infeed Table Depth Stop

The knob (Figure 35) controls a depth stop.

When the i nfeed table is lowered, i t will stop at

the 1/8” depth mark.

To further lower the infeed table, such as for

rabbeting operat ions, disengage the depth stop

by pulling out on the k nob, rot ati ng t he knob 90°

and then releasing i t. The i nfeed table can then

be lowered all the way.

To re-engage the depth stop, rotate the knob

90° until the knob snaps back in.

Figure 34

Figure 35

22

Page 23

Infeed Table Stop Screws

The stop screws below the infeed table have the

same function as those for the outfeed table.

See “Outfeed Table Stop Screws” for

instructions on adjustment.

Replacing Knives in the Cutterhead

Jointer knives are extremely

sharp. Use caution and p roceed slowly wh en

working with or around the cu t t erhead.

1. Di sconnect jointer from power source.

2. Remove the belt guard so that you can

rotate the cutterhead by turning the motor

pulley or by moving the drive belt. Do not

grab the cutter head itself to rotate it.

3. Remove the old knives by loosening the

square head gib screws with an 8mm

wrench. See Figure 36. The springs in the

cutterhead will raise the knife for easy

removal. Remove knife and gib.

4. Clean the gib and the knif e slot. Sandwich

the new knife and gi b toget her and drop int o

slot. Make sure t he k nife is oriented properly

in the cutterhead, as shown in Figure 36.

Figure 36

IMPORTANT: T o position the knives for rabbet

cuts, take a shop scale with 1/32” graduations

and place it against the end of the cutterhead.

Slide the knif e out until it i s at the 1/ 32” m ark on

the scale; that is, the knife will now be 1/32”

beyond the edge of the cutterhead. The gib

should remai n in normal posit ion, even with the

edge of the cutterhead. See Figure 37. This

adjustment will ensure that the knife clears the

end of the gib and cutterhead, and has good

contact with the workpiece. (See under

“Operation” for further i nformation on rabbeting

procedures.)

5. The height and paral lelism of the k nife in the

slot, both for rabbeting and normal jointer

work, must now be set properly, to ensure

correct operation as well as minimize the

hazard of kic kback. Refer to “S etting Knives

at Correct Height and Parallel to Outfeed

Table” on page 18 for information on

adjustment and tightening procedures for

the knives.

Before starting the jointer,

make sure all gib screws are firmly

tightened. A loose knife thrown from the

cutterhead can cau se severe or fatal injury.

Figure 37

23

Page 24

Eliminating “Play” in Tables

There are four set screws at the front of the

jointer – two on the outfeed table and t wo on the

infeed table – that will allow you to prevent

“play” in the tables. (Figure 38 shows a set

screw for the outfeed table.)

After a period of use, the copper tip (see item

#27, page 37) which is attached to the end of

the set screw (A, Fi gure 38) may becom e l oose.

Resolve this as follows.

1. Loosen the hex nut (B, Figure 38) with a

14mm wrench.

2. Tight en the set screw (A, F igure 38) with a

5mm hex wrench. Do not over tighten the set

screw, as it may prevent the table from

being raised and l owered easily.

3. Tighten hex nut (B, Figure 38).

4. Repeat for the other set screws as needed.

NOTE: The outfeed table is pre-set at the

factory tighter than the infeed table. If you find

the outf eed table diffi cult t o move with t he lifti ng

handle, loosen the two set screws on the

outfeed tabl e, as j ust described.

Operating Controls

Press the start switch, shown in Figure 39, to

begin rotation of the cutter head. T he stop butt on

is a mushroom style button which i s conveni ent

for "emergency " shut-downs.

After being pushed, the stop button remains

engaged. To re-start the Jointer, twist the stop

button clockwise until it pops back out.

Figure 38

Operation

NOTE: If y ou are inexperienced at jointing, use

scrap pieces of lumber t o c hec k settings and get

the feel of operati ons before att empting regul ar

work.

Stabilize l ong workpieces by using a n assistant ,

or roller stands set level with the outfeed or

infeed table surf ac e.

The fence should be adjusted to create

minimum exposure t o the cutterhead during the

jointing operation.

Check the following before operating the j ointer:

1. Outfeed table must be set level with the hi gh

point of the knives.

2. Fence adjusted for minimum exposure of

cutterhead, and locked at desired angle.

Figure 39

24

Page 25

3. The cutterhead guar d must be in place and

operating proper ly (except when rabbeting) .

4. Infeed table set for desir ed depth of cut.

5. Stand away from the cutterhead and turn

the machine on for a f ew moments. Listen

for any odd noises, rubbi ngs, vi brati ons, etc.

Correct such problems before attempting

operations on the jointer.

6. Carefully check your workpiece for knots,

holes, staples or any foreign material that

might damage knives or pose a risk of

kickback. A lso check the workpiece for gr ain

orientation.

Hand Placement

At the start of the cut, the left hand holds the

workpiece firmly against the infeed table and

fence while the ri ght hand pushes the workpi ece

in a smooth, even motion t oward the cutterhead.

After the c ut is under way, the new surface rests

firmly on the outfeed table. The left hand is

transferred to the outfeed side and presses

down on this part of t he workpiece, at the same

time maintaining flat c ontact with the fence. The

right hand presses the workpiece forward and

before the right hand reaches the cutterhead it

should be moved to the work on the outfeed

table. Never pass hands directly over the

cutterhead.

Surfacing

Always use a hold down or

push block when surfaci ng stock.

Jointing the f ace of stock, or surf acing, i s shown

in Figure 40. Adjust the infeed tabl e for depth of

cut. Cuts of approximately 1/16” at a time are

recommended, as this allows better control over

the material being surfaced. More passes can

then be made to reach the desir ed depth.

Figure 40

Edge Jointing

This is the most common operation for the

jointer. Set fence square with the t able. Depth of

cut should be the m inimum requi red to obtain a

straight edge. Do not make cuts deeper than

1/8" in a single pass. Hol d the best face of the

workpiece firmly against the fence throughout

the feed. See Figure 41.

Figure 41

25

Page 26

Rabbeting

A rabbet cut requires

removal of the guard. Use extreme caution

and keep hands cl ear of cutterhead. Alw ays

re-install guard immediately after rabbeting

operation is completed.

A rabbet is a groove cut along the edge of a

board. See Figure 42. The width and thick ness

of the wood to be rabbeted depends upon the

width and length of the rabbet. Ho wever, never

rabbet a piece of wood less than 12” l ong.

Use push blocks to rabbet cut whenever

possible. The rabbeting capacity is 1/2”.

1. Di sconnect jointer from power source.

2. Set fence for desired width of rabbet .

3. Check width of the rabbet by measuring t he

distance from the end of a knife in the

cutterhead to t he fence. NOTE: The kniv es

must be extended beyond t he cut ter head by

1/32”. (see “Replacing Knives in the

Cutterhead” for this procedure).

Figure 42

4. Re-connect power. It is easier and safer t o

take a series of shallow cuts. Lower the

infeed table 1/32” at a time and make

successive cuts until the desired depth of

rabbet has been obtained. See Figure 42.

Jointing Short or Thin Work

When jointing short or thin work pieces, use a

push block to elim inate all danger to t he hands.

Two push blocks are shipped with your jointer.

You can also mak e your own easily from scrap

material. Ex am ples are shown in Figure 43.

Jointing Warped Surfaces

If the wood to be jointed is cupped or bowed,

place the concave side down, and take light cuts

until the surfac e i s flat.

Avoid forcing such material down against the

table – excessive pressure will spring it while

passing the kniv es, and it will spring back and

remain curv ed aft er the c ut is completed.

Beveling

To cut a bevel, lock the fence at the required

angle and run the work piece acros s the knives

while keeping it firmly against the fence and

tables. Several passes may be necessary to

achieve the desi r ed r esul t.

Figure 43

26

Page 27

Although the fence may be

tilted in or out for a bevel cut, it is

recommended for safety reasons that the

fence be tilted in toward the operator,

making a cradled cut.

Direction of Grain

Avoid feeding work into the jointer against the

grain. Thi s may r esult in c hipped and spl i ntered

edges. See Figure 44. Feed with the grain to

obtain a smooth surfac e, as shown in Figure 45.

Skewing (Shear Cutting)

When edging or facing material such as burl or

birds-eye maple, it is not unusual to deface or

mar the surface being finished. This is caused

by the cutterhead kniv es at tim es cutti ng against

the grain. In order to prevent the defacing or

marring of this type wood, it is necessary to

skew the material being worked so that it

crosses the knives at an angle.

The fence will all ow for this type of cut:

Figure 44

Figure 45

1. Release the fenc e locking handl e (A, Figure

46) and remove the two hex nuts and

washer (B, Figure 46) holding the fence to

the slide bracket. Remove the fence

assembly.

2. Remove the key (C, Figure 46) from the

fence support. If necessary, use a flat head

screwdriv er to pry up one end of the key .

3. Replace the f ence assembly at the desi red

angle across t he cut terhead. See F igur e 47.

Secure the fence to the slide bracket with

the hex nuts and washer (B, Figure 46),

then tighten the fence locking handle (A,

Figure 46).

NOTE: When placing the fence assembly back

into normal position, be sure to first install the

key into its slot.

Figure 46

27

Page 28

Maintenance

t

Disconnect machine from

power source before doing any

maintenance. Failure to comply may cause

serious injury.

The table and fence surfaces must be kept

clean and free of rust for best results. Some

users apply a thin coat of paste wax. Avoid

waxes or protectiv e sprays that contain si licone,

as this can transf er to the workpiece and make it

difficult for later finishes to adhere to the wood.

Another opti on is talcum powder appli ed with a

blackboard eraser rubbed in vigorously once a

week; this will fill casting pores and form a

moisture barrier. This method provides a table

top that is slick and all ows rust rings to be easi ly

wiped from the surface. Important also is the

fact that talcum powder will not stain wood or

mar finishes as some ot her pr oduc ts.

Gum and pitch which collect on the knives

cause excessiv e friction as the work cont inues,

resulting in overheating of the knives, less

efficient cutting, and consequent reduc tion in t he

life of t he kniv es. Use ov en cl eaner or “gum and

pitch remover” to wipe this off the knives. Use

caution when working around knives!

Figure 47

(skewing t he fence)

The bearings in the cutterhead are sealed for life

and do not require lubri c ation.

The fence assem bly should sli de easil y ov er t he

slide bracket . Keep the slide bracket, shown in

Figure 48, l ubricated with a good quality multipurpose grease. Do not get gr ease on the drive

belt.

Do not place he avy objec ts on the tables, or use

the jointer as a storage table.

Sharpening Knives

Knives should be kept sharp. Thi s will cont ribut e

to better stock finish, longer machine life, and

safer operation.

A jointer knife hone provides a simple way to

sharpen kniv es. Hones are avail able from many

woodworking supply stores. Carefully read any

instructions that accompany the hone.

Use caution and proceed

slowly when sharpening knives. Disconnect

jointer from power source, and wear

approved eye protect io n.

When finished sharpening knives, they should

be re-set level with and parallel to the outfeed

able. See “Setti ng Kniv es at Corr ect Hei ght and

Parallel to Outfeed Table” on page 18.

Figure 48

28

Page 29

Knives can usually be whetted several tim es in

the cutterhead bef ore hav ing to be rem oved and

re-ground.

TIP: If the joint er is used f requently, keeping a

spare set of knives on hand is recommended.

Extra knives (stock no. 6296046, set of 3) may

be obtained from your distributor, or by calling

customer service at 1-800-274-6848.

Cutterhead Repairs

The entire cutterhead assembly may be

removed from the Jointer for bearing

replacement or other m aintenance procedures.

Use caution when working

around sharp knives.

To remove the cutterhead, proceed as follows:

1. Di sconnect jointer from power source.

2. Remove fence assembly from jointer.

3. Lower bot h infeed and outf eed table.

4. Remove belt guard, and remove drive belt

from around cutter head pulley.

Figure 49

5. Remove knives from cutterhead.

6. Remove rabbeting ledge by loosening and

removing the two hex cap screws and

washers which secure it to the infeed table.

7. Loosen the two bolts that secure the

cutterhead to t he base; the se are accessed

through the gap below the j oint er base. See

Figures 49 and 50. Pl ace a wrench on each

of the bolt heads and turn each bol t until t he

cutterhead i s loosened.

8. Lift cutterhead strai ght up from base.

9. Remove pulley and both bearing housings.

IMPORTANT:

this should be done by qualified service

personnel. Bearings are press fitted and must

be removed or installed with an “arbor press”.

10. To re-install cutterhead, reverse the above

procedure. Before re-installing, make sure

the machine's curved seats of the base

casting are free of dirt, dust or grease, to

help ensure a tight fi t.

11. After the cutterhead has been installed,

check the infeed and outf eed table settings

in relationship to the cutterhead.

TIP: You may wish to keep an ext ra cutterhead

on hand to maintain shop produc tivity.

If the bearings need replacem ent,

Figure 50

29

Page 30

Troubleshooting – Operating Problems

Trouble Probable Cause Remedy

Finished stock i s

concave on back

end.

Finished stock i s

concave on front end.

Finished stock i s

concave in the

middle.

Ends of finished

stock are cut more

than the middle.

Chip out.

Fuzzy grain.

Knife is higher than outfeed table.

Outfeed table is higher than knife.

Both tables have t oo much end fall.

Table ends are rai sed hi gher than t he

middle.

Cutting against the grain. Cut with the grain whenev er possible.

Dull knives/i nsert s. Sharpen or replac e k niv es/inserts.

Feeding workpiec e too fast. Use slower rate of feed.

Cutting too deepl y. Make shallower cuts.

Knots, imperfections in wood.

Wood has high moistur e c ontent. Allow wood to dry or use diff er ent stock.

Dull knives. Sharpen or replac e k niv es/inserts.

Raise outfeed table until it aligns with

tip of knife. See page 19.

Lower outfeed table until it aligns with

tip of knife. See page 19.

Raise both table ends using the cam

adjustment devices. See pages 17-18.

Lower both table ends using the cam

adjustment devices. See pages 17-18.

Inspect wood closely for imperfections;

use different stock if necessary.

Cutterhead slows

while operating.

“Chatter” marks on

workpiece.

Uneven knife marks

on workpiece.

Feeding workpiec e too quickly, or

applying too much pressure to

workpiece.

Knives incorr ectly set.

Feeding workpiec e too fast.

Knives are nicked, or out of

alignment.

Feed more slowly, or appl y l ess

pressure to workpiece.

Set knives properl y usi ng pr ov ided k nife

setting gauge. Check that knife slots

are clean and free of dust or debri s.

Feed workpiece slowly and

consistently.

Replace nick ed knives; align knives

properly using k nife-setting gauge. See

page 20.

30

Page 31

Troubleshooting – Mechanical and Electrical Problems

Trouble Probable Cause Remedy

Machine will not

start/restart or

repeatedly t rips

circuit breaker or

blo ws fuses.

No incoming power.

Overload aut omatic reset has not

reset.

Jointer frequently trips.

Verify unit is connected to power, onbutton is pushed in com pletely, and

stop-button is disengaged. See page

24.

When jointer overloads on the circuit

breaker built into the motor starter, it

takes time for the machine to cool

down before restar t. Allow unit to

adequately cool bef ore attempting

restart. If pr oblem persists, check

amp setting on the mot or start er

inside the electrical enclosure.

One cause of overl oading trips which

are not electric al in nature is too

heavy a cut. The solution is to take a

lighter cut. If too deep a c ut is not t he

problem, then chec k the amp setting

on the overload rel ay . Match the full

load amps on the motor as noted on

the mo tor pl ate. If amp s etti ng is

correct then ther e is probably a loose

electric al lead. Check amp setting on

motor starter.

Building circuit breaker trips or fuse

blows.

Switch or motor f ailur e ( how to

distinguish).

Motor overheat ed.

Motor failure.

Verify that jointer is on a circuit of

correct size. If circuit size is correct,

there is probabl y a loose el ectr ic al

lead. Check amp setting on motor

starter.

If you have access to a voltmeter, you

can separate a starter f ailure from a

motor fai lu re by fi r st, verifying

incoming voltage at 220+/-20 and

second, checking the voltage

between starter and motor at 220+/-

20. If incoming voltage is incorrect,

you have a power supply problem. If

voltage between start er and m otor is

incorrect, y ou hav e a starter pr oblem.

If voltage bet ween start er and m otor

is correct, you hav e a motor pr oblem .

Clean motor of dust or debri s to allow

proper air circulation. Allow motor to

cool down before r estar ting.

If electri c mot or i s suspect, you have

two options: Have a qualified

electrician test the motor for function

or remove the motor and take it t o a

qualified elec tric motor repair shop

and have it tested.

31

Page 32

Trouble Probable Cause Remedy

Machine will not

start/restart or

repeatedly t rips

circuit breaker or

blo ws fuses.

Miswiring of the unit.

On/off switch failure.

Optional Accessories

6296046 .......... Knives (set of 3)

2230035 .......... Knife Setting Gauge

6285917 .......... Push Block

Double check to confirm all electrical

connections are cor r ec t. Refer to

appropriate wir ing diagrams on pages

44 through 46 to make any needed

corrections.

If the on/off switch is suspect, you

have two options: Hav e a qualified

electrician test the switch for function,

or purchase a new on/off switc h and

establish if that was the pr oblem on

changeout.

Replacement Parts

Replacement part s are li sted on the f ollowing page s. To order par ts or reac h our servi ce depar tment, call

1-800-274-6848 between 7:30 a.m. and 6:00 p.m. (CST), Monday through Friday. Having the Model

Number and Serial Number of your machine available when you call will allow us to serve y ou quickly and

accurately.

32

Page 33

Parts List: Cutterhead Assembly

Index No. P art No. Description Size Qty

................. PJ882-CHA............. Cutterhead Assembly (Items 1 thru 5, and 10 thru 13)..............................

1...............6296046.................. Knife.................................................................. ...................................3

2...............6296153.................. Knife Gib............................................................ ...................................3

3...............6296048.................. Key.................................................................... 5x5x25........................1

4...............BB-6204VV............. Ball Bearing....................................................... 6204-2NSE.................2

5...............PJ882-405 ..............Bearing Housing................................................ ...................................2

6...............TS-0267021............ Socket Set Screw.............................................. 1/4”-20x1/4”................2

7...............PJ882-407 ..............Pulley................................................................ ...................................1

8...............PJ882-408 ..............Bolt.................................................................... ...................................2

9...............TS-0720091............ Lock Washer......................................................3/8”.............................2

10.............6296154.................. Square Head Scr ew........................................... .................................15

11.............PJ882-411 .............. Cutterhead......................................................... ...................................1