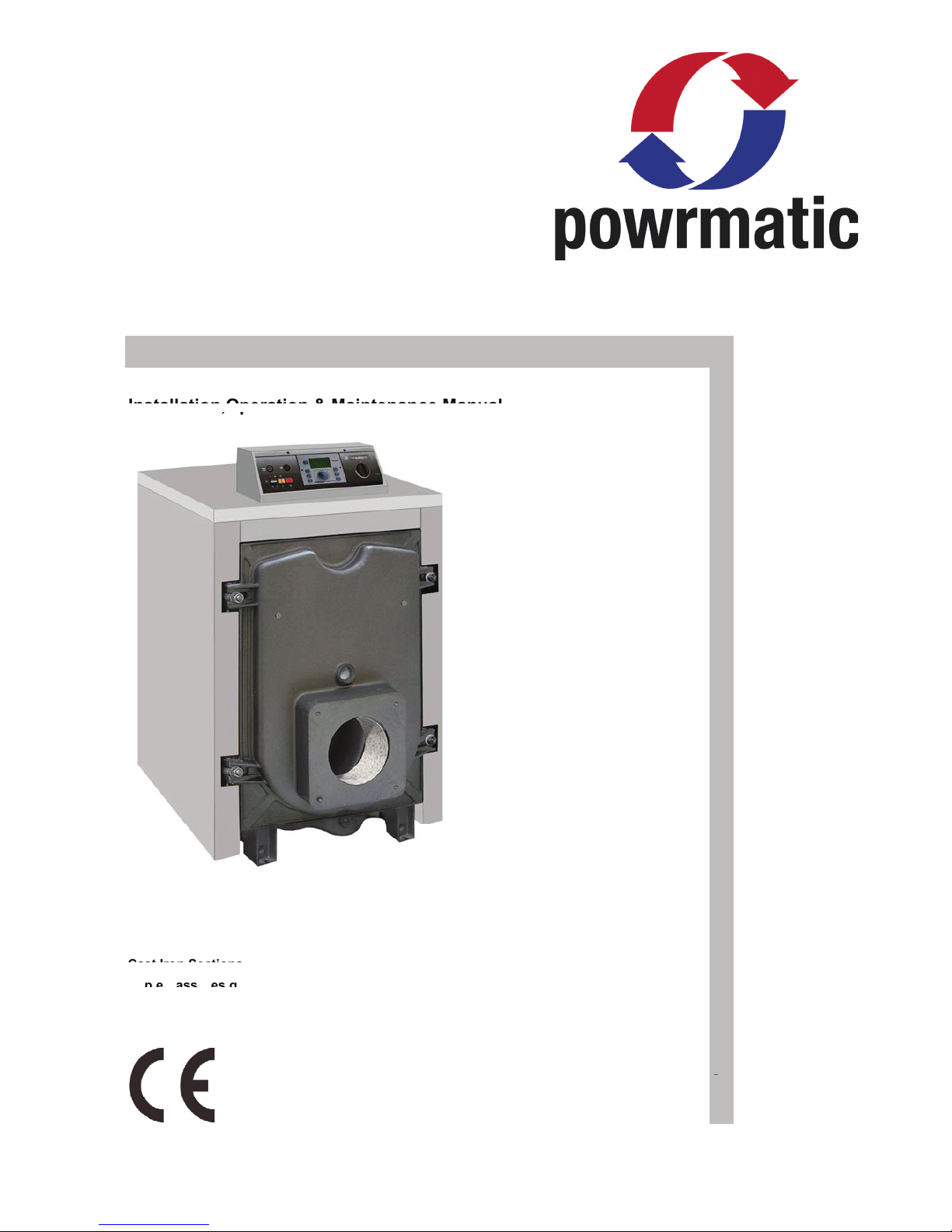

Powermatic PON Series, ON-05, ON-06, ON-07, ON-08 Installation, Operation & Maintenance Manual

...Page 1

PON Series Cast Iron Boilers

Installati

on,Operation & Maintenance Manua

l

,p

Cast Iron Sections

Triple P

ass Desig

n

Triple Pass Design

163 kW - 355 kW

-O

N

10

-

/ 2

0

02

/

EV.

0

R

E

Page 2

Contents :

Description

3

Certifications , Symbols

3

Certifications

,

Symbols

General Warnings

4

g

Safety Inst

ructions

5

General Characteristics of 6PON series Boilers

6

Boiler Dimensions , Delivery Conditions

7

,y

Inf

ormation on the Boiler Plate

8

9

Technical Parameters

9

Recommended Minimum Distance for Installation

10

Recommended Minimum Distance for Installation

Important Instructions About Boiler Room

11

PO

N Series Cast Iron Boiler Parts and Spare Parts List

12

Cast Iron Sections with High Efficiency Design , Boiler Room Ventilation

13

Cast Iron Sections with High Efficiency Design

,

Boiler Room Ventilation

13

Plumbing Instructions

14

g

G

as

Side Resist

ance and Exit Flue Gas Temperature

15

16

Important Instructions About Flue and Connecting the Fuel Tank

16

Boiler Control Panels

17

oeCooaes

Standart Control Panel Electric Diagram

18

19

Operating Instructions

,

Loading and Unloading The Boiler Water

19

Checking and Starting the Boile

r

20

Checking and Starting the Boiler

Care Instructions , Cleaning the Boile

r

21

g

B

urner Door and Burner Connection

22

Instructions for Product Disposal , Positioning the Boile

r

23

Instructions for Product Disposal

,

Positioning the Boiler

23

2

Page 3

Description :

p

In this manualyou will find the instructions forRima threepass cast iron boilers suitable forbothgas and liquid fuel. ON

In

this

manual

you

will

find

the

instructions

for

Rima

three

pass

cast

iron

boilers

suitable

for

both

gas

and

liquid

fuel.

ON

series

hot

water

boilers

and

related

informaton

for

installation,operation

and

maintenance

of

the

boiler.For

high

efficiency

and

proper

working

conditions

please

read

this

manual

carefully

.

For

more

information

please

check

the

product

brochure

or

get in touch with Rima technical services.

Pl

easedo no

t

t

ouchorremove any partso

f

theboilerforstarti

ng,adjusting orrepairingtheboiler excep

t

th

e processes

written in this manual.

Please call Rima services and technical officials for installing the boiler.

Ourlicensed frenchisers and services willgiveyou instructions about workin

g

p

rincipals,conditions and care instructions afte

r

Our

licensed

frenchisers

and

services

will

give

you

instructions

about

working

principals,conditions

and

care

instructions

after

installing and starting the boiler

.

Our professionals

will be glad to answer all

your questions at any time

.

Our professionals will be glad to answer all your questions at any time

.

Certifications :

PON Series boilers are in compliance with ;p;

EC Directives :

(

90/396/EEC)Gas Appliances Directive

(90/396/EEC)

Gas Appliances Directive

(92/42/EEC) Efficiency Directive

(89/336/EEC)

Electromagnetic Compatability Directive

EN 303/1: Heating boilers with forced draught burners - Terminology, general

g g gy, g

requirements, testing and marking

-

-

EN 303/2:

Heating boilers

-

Part 2: Heating boilers with forced draught burners

-

Special

requirements for boilers atomizing oil burners

requirements for boilers atomizing oil burners

EN 303/3: Heating boilers-Part 3: Gas fired heating boilers-Assembly comprising a boiler

body and a forced draught burner

PON SERIES CE approved, No: CE-1015BR0261

Please

,

consider on the standards in installation

.

Symbols :

Caution , Dange

r

Important

p

Info

3

Page 4

General Warnings :

t l bi d ddith

ON series cast iron boilers are designed for working with hot water heating and/or hot water plumbing and produced with

the proper technology and materials suitable for this design.This design is restricted to use out of it's aim of use.p p gy gg

ON series boilers are delivered as sections and services assemble the boilers in the operation area The assembling of the

ON series boilers are delivered as sections and services assemble the boilers in the operation area.The assembling of the

b il t b d b Ri thil i Ri bli f th b il h ld l b db

boiler must be made by Rima technical services . Removing or re - assembling of the boiler should also be made byy g g y

licensed Rima services, if not the risk of damage is high.

licensed Rima services, if not the risk of damage is high.

In the assembling of the boiler; there must be a proper and safe concrete platform for to put the boiler on

.

Inth

e assem

bli

ng o

f

theboil

er,an empty space mus

t

beleft

f

rom sidesforsafety requirements an

d

for

fut

ure repairing

operations.

Starti

ng and first operation of the boiler must be made by authorized Rima technicians.

Do not add orpump waterto the boiler orplumbing system as it is working and hot . Foradding waterto the boiler orto the

system please wait for water temperature to reach 40ºC. Circulation pump must surely be started while adding water to the

ypp

ppyg

system . If not , the sections may crack.

system

. If

not

,

the sections may crack

.

If

the

boiler

willbekept

off

foralong

time

the

electric

system

mustbeshut

down

from

the

main

fuse.The

electric

mustbecut

off from the main shelter/fuse as the boiler is in repair,service or cleaning.

In

summer

months

,

when

the

boilerisoff

foralong

term,for

preventing

probable

problems

with

circulation

pumps

,

must

be

starte

d

1-2

ti

mes permon

th

for

5minut

es.

(Th

e waterw

ithchalk

can cause problems ,

if

th

e pumpis notuse

d

for

l

ongtime

period.)

.

The periodical controls of the boiler and the burner must be done. If not, the boiler may lose efficiency and the fuel amount

.

The

periodical

controls

of

the

boiler

and

the

burner

mustbedone.Ifnot,

the

boiler

may

lose

efficiency

and

the

fuel

amount

used may

incr

ease

.

used may increase

.

The capacity choice of the boiler must be made according to the projects that prepared properly in the terms of related

py

g

pj

pp

pp y

standards.If not , the boiler efficiency will be low.

standards.If not

,

the boiler efficiency will be low

.

ON series boilers are produced for heating only. For heating the sanitary water another equipment such as water heater or

pgygy

qp

heat exchanger is needed.For proper efficiency in this operation,correct water heater or heat exchanger must be selected.

heat exchanger is needed.For proper efficiency in this operation,correct water heater or heat exchanger must be selected

.

ON

seriesboilers aredeliveredw

ithout

b

urners.Forsuitableburnerselection please ge

t

int

ouchw

ith

Rimatechnici

ans.

Suitable burners must be selected for taking high efficiency.

gg y

If

theboilerisst

oppedautomaticallybecause ofoverheatingdo notaddcoldwate

r

totheboilerfor

re-starting.In

thi

s case

wait for the boiler to cool down and re- try starting.If it does not start ,please get in contact with technical services.

Incl

eaning, repairandothercare operationsthe originalspare partswhichapprovedandmanufacture

d

byRi

ma , mus

t

b

e

used.

'

Th

e periodicalandyearly controlso

f

theboil

er mus

t

bed

one properly andontime.Naturalgasisacleanfuelan

d

d

oesn

't

make a lot of dirt in the boiler.But the boilers that liquid fuels are used as fuels are much more easily get dirt. Controls and

care operations of the boiler is needed for keeping high efficiency and long life of the boiler.

ppg g y g

Repairingandperiodical controls of ON series boilers requiresprofession.In this manual the responsibilities and required

Repairing

and

periodical

controls

ofONseries

boilers

requires

profession.In

this

manual

the

responsibilities

and

required

information

for

usersofthe

boilerisdeclared

.

Besides

these

declared

operations

,

boiler

must

notbestarted

byaperson

rather than the user or one of our technicians.Please do not try to make adjustment or do not touch any parts of the boilers.

Theelectricit

yo

f

theb

urneran

d

boileri

s supplie

d

bycityelectri

c network.In

thi

s casetheelectric an

d

lighti

ng systems o

f

th

e

boiler room, burnerand boiler electrical connections, grounding line of control panel and boiler must be made by

professionals under the required and related standards.

pq

In this manualyou will find informations onlyforthe boilers. Please do not forget toget the instruction manual of the burne

r

In

this

manual

you

will

find

informations

only

for

the

boilers

.

Please

do

not

forgettoget

the

instruction

manual

of

the

burner

that

you

purchase

from

the

manufacturer

of

it.Burner

is

not

delivered

with

the

boiler.In

this

casewedo

not

give

any

guarantee for the burner that you purchase. Please get the guarantee cer

tificate f

or the burner from your supplier.

Please be sure that the front doo

r

(

burnerdoor)forthe boiler is strictlyclosed and burnerconnections areproperlymade as

Please

be

sure

that

the

front

door

(burner

door)

for

the

boilerisstrictly

closed

and

burner

connections

are

properly

made

as

the boiler is working

.

4

Page 5

Safety Inst

ructions :

Al

ways observe the following safety instructions and regulations.

A

lways perform the following steps prior to inspection work.

Always perform the following steps prior to inspection work

.

Cl

ose the gas shut-off valve.

Close the heating feed and return

.

Danger!

If you smell gas, risk of poisoning and explosion due to a malfunction!

If you smell gas, risk of poisoning and explosion due to a malfunction!

If you smell gas :

Do not switch lights on or off

.

Do not use any other electrical switches.

Do not use any other electrical switches.

Do not use a telephone in the area of the hazard.

Do not use naked flames (such as matches or cigarette lighters)

.

Do not smoke.

Do not smoke

.

Close the gas stop cock.

gp

O

pen the windows and doors.

Warn other residents

.

Get out of the house.

Notif

y your gas supplier or a suitably qua

lified h

eating engineer.

Danger!

Danger!

Inflammable mixtures of gas and air may explode

.

Do not use or store explosive or easily flammable substances such as petrol or paint in the same room as the applience.

Do not use or store explosive or easily flammable substances such as petrol or paint in the same room as the applience

.

Risk of poisoning and explosion due to a malfunction.

pgp

N

ever put the safety devices out of operation or tamper w

ith th

em so as to impair their function.

Safety Caution!

Safety Caution!

Inappropriate alterations can cause damage!

Under

no

circumstances

should

you

ever

attempt

to

make

alterations

to

the

gas

heating

boilerorother

partsofthe

system.Never try to carry out maintenance work or repairs on the appliance yourself.

Do not damage or remove seals on components.Only suitably qualified heating engineer or our customer service may

g

py

yqggy

removed sealed components.

removed sealed components.

Do not touch hot water connections or the flue outlet when the boiler is operating.

Do not touch hot water connections or the flue outlet when the boiler is operating.

Caution!

Risk of d

amage

!

D

o notuse sprays, solvents, chlorinatedcleaning agents, paint,adhesives orsimilar substancesinthevicinityo

f

th

e

appliance. These substances can cause corrosion, including in the flue system.

5

Page 6

General Characteristics of PON series Boilers :

ON series boilers are, blowing burner, cast iron sectioned, between the capacities 163–355 kW with properburne

r

g

connection, works with gas or liquid fuel in 7 different ( 5 – 11 sections) type.

co ect o , o s t gas o qu d ue d e e t ( 5 sect o s) type

ON series boilers operating pressure is 6 bar maximum, and working temperature is 90 °C maximum.

ON series boilers operating pressure is 6 bar maximum, and working temperature is 90 C maximum

.

InONseries

boilers,heat

transfer

surface

areas

are

increased

by

the

special

wingsinthe

burning

room

and

chimney

ways.

This i

ncreases the heat transfer a

bilit

y of cast iron boiler to the maximum level.

ON

series

boilers

are

cast

iron

sectioned

boilers.This

brings

easy

assembling

and

easy

capacity

increasing

by

adding

sectionstotheboiler.Thetransportation an

d

installati

on o

f

theboileri

s easybecause o

f

theboileri

s assemble

d

inboil

er

rooms. It is easily to carry or shift position without breaking walls etc.

yy p g

ON

series

boilers

are

produced

from

special

cast

iron

alloyENGJL

200,which

gives

high

resistance

against

corrosion

and

thermal expansions

.

They are long life boilers according to this special cast iron alloy

.

With

the

helpofhorizontal

and

three

pass

specially

designed

sections

burning

gases

pass

three

timesinthe

boiler

and

t

ransmits burning energy to the water inside the sections at high level.

ON

series

boilers

are

high

efficiency

boilers

.

(

According

to

the

fuel

max.heating

value%91–93

).With

this

high

efficiency

and perfect isolation more energy is gained with less fuel. Heat loses are minimized on ON series boilers.

By appropriate burning room, heat transfersurface, turbulator, collectorand isolation high heat transferand optimum flue gas

emission results are provided.

p

6

Page 7

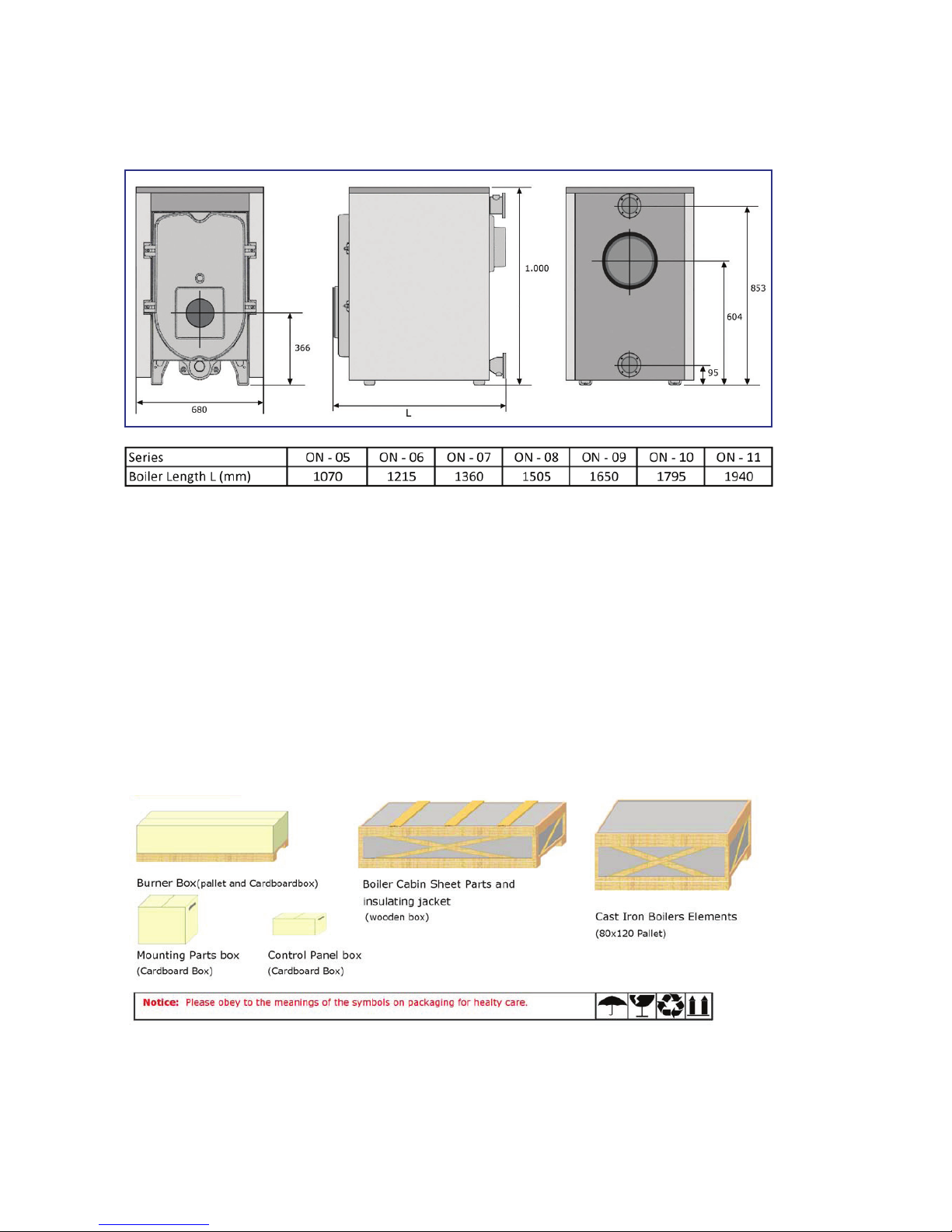

Boiler Dimensions :

Delivery Conditions :

Boiler sections are delivered as not - assembled according to the boiler room specifications and dimensions.In not

assembled deliveries, sections and assembling aparats are delivered on a pallet, cabins,isolation and other elements are

delivered in a box. Rima technicians make the assembling of the boiler.

7

Page 8

Information on the Boiler Plate :

The identification plate is mounted on the back side of the boiler cabin.

PON-05 , P0N-06,PON-07 …

8

Page 9

Technical Parameters :

9

Page 10

Recommended Minimum Distance for Installation:

Do not put flammable materials on top of the boiler or near the boiler than specified safety distance.

There must be space for the tools that will be

used in boiler room.

The measurements of the boiler room and the empty spaces must be arranged properly for future assembling repairing, reassembling, burner connecting issues.

* The concrete platform must be in the mentioned dimensions.

* Concrete platfrom must not be coated with slipper materials such as ceramics etc.

* If sound isolaton will be made , first do the sound isolation than make the concrete for platform.

* Platfroms must be made of BS 25 concrete and scales.

In ON series boilers burner doors can be opened to

both sides. According to this the required empty

spaces for the both sides are given equal

(min. 700 mm). This will gives advantages for operations.

If the boiler room area is not enough for this

you can choose one side and leave the big empty

space there. Half of this empty space will be enough

for the other side in these conditions.

10

Page 11

Important Instructions About Boiler Room:

The ceiling of the boiler room can be isolated for sound and heat isolation. The position and place of the boiler is important

for sound isolation of the boiler.

Boiler room must have a good lighting and control switches of lighting must be outside of the boiler room.

There must not be any other equipments such as aspirator, air condition central etc. in the boiler rooms. These kind of

equipments can make vacuum effect and defect boilers pull force. This can cause burner failures.

Children must not enter to the boiler room. A second key must be kept in safe place for urgent matters.

Gas alarm equipments must be placed to the proper highth as mentioned on standards.

No one except the responsible person should get in to the boiler room.

There must not be equipments like water pump,contactor etc.. in the boiler room.

Fuel tanks must be put in another place which is rounded by walls.Natural air conditioning is needed for this place.

There must not be any kind of explosive , burning and flammable materials in the boiler room.

Boiler room must be air conditioned by natural or other ways.

Humidity must be prevented in boiler room.

Boiler room must have the requested dimensions .

Th

ere must notbe any kind of explosive , burning an

d fl

ammable gases intheboiler room atmosphere.

For feeding water to the boiler,water line must be arranged near the boiler. And for filling out the water of the boiler in

necesarry conditions, there must be a connection to drainage in the system.

For the efficiency of the burner and the boiler,boiler room must be kept clean and dry.

If there are any electric keys, cables etc. Which can cause short circuits must be fixed, renewed as soon as possible.

In Natural Gas or LPG use ; boiler room,flue,system and plumbing issues must be under parameters of EN standarts and

gas offices orders. Rima is not responsible for any failure or problems that will be occured because of inadequate or not

sufficiently qualified conditions of boiler room, plumbing and other systems.

The instructions of local gas delivery must be applied.

Before painting , keep flammable materials out.

Boiler must not be installed on carpet.

Before any welding operation in boiler room, boiler must be stopped and the gas flow must be stopped by turning of the gas

valve.

Do not touch the boiler when it is hot.

Switch off the boiler immediately if there is danger of burning or explosion ( elecricity problem, gas leakage, liquid gas , etc.).

11

Page 12

PON Series Cast Iron Boiler Spare Parts List :

PON Series Cast Iron Boiler Parts :

12

Page 13

If the fuel is natural gas

* If natural ventilation system is used.

** Ventilated airing system is used.

*** Bottom value shows the clean

air input up shows the air output.

Cast Iron Sections with High Efficiency Design :

3 draught design forces the flue gas to circulate inside the body of the boiler three times before the chimney exit, transferring

all usefull energy to the water inside the sections. The optimized combustion chamber combined with perfect heat insulation

provides maximum fuel efficiency.

The combustion room of the boiler is positive pressure. Boiler is working under horizontal 3 pass principal.

Boiler Room Ventilation :

There are three reasons for fresh air in boiler rooms.

1.The air needed for the burning in the boiler.

2.The air needed for prevention of dirt and dust,for releasing the gases and fuel to put out.

3.The air needed for overheating in the boiler room.

Ventilation for first two reasons are continously needed.The third one is needed especially for the boilers which

are working on summer time.

Maximum temperature for the boiler room must be 32 °C and boiler room must be protected against freezing.

13

Page 14

Plumbing Instructions :

Fresh water must be added periodically to the plumbing. The chalk and other chemicals will connect with the system and

become solid . For avoiding this , closed expansion tank must be used in the system.In the systems that closed expansion

tanks are used, water will flow in closed system so it will not evaporate and lost.So in this kind of systems the water level wiill

stay same and fresh water addition will not be necessary. This will prevent chalk and dust and the life of the sytem will be

long.

The water in the radiator or heating system is not healthy.Do not use this water as drinking or cleaning water.Do not take

water from the system.If the water level is low , water addition is needed.

For avoiding chalk and other chemical dust problems soft water must be used in the system.Plumbing system water quality :

Ph 7,2 Th 25 °Fr

If the city sanitary water is not in requested quality water addition from wells or other sources must be made after testing

it.For reaching the requested quality additional processes must be applied to the water if needed.

For avoiding the chalk and other dust to get in to the boiler, or from boiler to plumbing system dust holders must be placed in

and out line of the system.

Circulation pump must be connected to the water output of the boiler and the capacity of the pump must be suitable to the

boiler capacity. If not,problems may occur in flowing of the water and heating efficiency of the boiler.

There must be water inside of the boiler every time. If not , corrosion can occur in the boiler and the plumbing system. If the

Forworking the system properly4 waymixture valve orthermostatic control by-pass pump must be used forincreasing

return water temperature.

By connecting a three way motor valve between the forward and return line of heating system,the water that flows to the

system can be controlled in ratios.

boil

er w

ill

not be used in winter season, for avoid freezing , anti-freeze solution must be used.

14

Page 15

*** ON series boiler is designed,forced circulation hot water heating systems only.

For healthy working conditions of the boiler,temperature difference between water forward and water return must not be more

than 20 °C.And boiler must not be started or work under the water volumes which is mentioned in the below table.

Gas Side Resistance and Exit Flue Gas Temperature :

15

Page 16

The platform of the fuel tank must be strong to carry the tank. If the fuel tank is outside tank , connection pipes must be

isolated. Fuel tank must be placed in higher level than the burner.The height difference between the burner and fuel tank ( H

) must be more than 4 m. In the seasons that the boiler is not used,fuel tank must be empty for avoiding corrosion.

Important Instructions About Connecting the Fuel Tank :

Important Instructions About Flue :

16

Page 17

Standart Control Panel (Single Stage): (Dual Stage) :

1- Main ON/OFF Switch 1- Main ON/OFF Switch

2- Boiler Thermostat ( 30-60-90 °C) 2- Boiler (TRZ)Thermostat ( 60-75-90 °C):

3- Boiler Thermometer 3- Boiler Thermometer

5- Defect Indicator 5- Defect Indicator

6- Working Indicator 6- Working Indicator

7- Reset Button 7- Reset Button

8- Fuse 8- Fuse

9- Water pressure defect indicator 9- Water pressure defect indicator

10- Ecopanel mounting place 10- Ecopanel mounting place

Eco Control Panel :

1- Manual mode key / Emission Measurement key (not applicable for district heating controllers)

2- Operating mode key for permanent and temporary operating modes (Basic display)

3- Heating characteristics key

4- Information key for the display of temperatures and operating status

5- Multi-functional Display

6- Cover clip for the service jack

7- Daytime room temperature setpoint key

8- Night-time room temperature setpoint key

9- DHW daytime temperature setpoint key

10- Rotary pushbutton (push and turn)

11- Operating modes symbols

Boiler Control Panels :

4- Safety Thermostat with manual reset (set to 100 °C) 4- Safety Thermostat with manual reset (set to 100 °C).

17

Page 18

Single Stage :

Dual Stage :

Standard Control Panel Electric Diagram :

18

Page 19

Heating System :

Fuel and Electrical Connections :

Unloading Water of the boiler :

Loading Water of the boiler :

Operating Instructions :

These connections must be made by certified professionals under the terms of EN standards.EN approved materials must be

used in the system.Burner,control panel, ecopanel etc. Manufacturer or distrubutor warnings, instruction manuals must be

read .Burner must not be started before boiler circulation starts.If circulation or protection pump has a failure burner must be

switched off. This system must work coordinate. Turning the pumps on when the water heat reachs over 40 °C is completely

wrong. Circulation pump and burner must work simultaneously.

Protection pump must be chosen properly accoridng to the capacity of the boiler.The connection of the pump to the collectors

must be done correctly with valve and thermostat connection. This way,system may stop in adjusted temperature.In any

failure situation (contactor,thermic failure,electricity cut ,other failures.) when the pumps are not working ( heating and

protection pumps etc..) burner must not start. System must do this automatically.Electrical system must be made according

to all above information.

In the system , the difference between direct flow temperature and the return temperature of the water must not be over 20

°C. The return water temperature must be over 50-55 °C. Boiler protection pump must be used for increasing the return water

temperature. The water level of the system must be measured every day (if it is open system by hydrometer,if it is closed

system by manometer) and water must be added if the level is measured low. But this water addition must not be made while

the system is hot. If there are problems that cause water leakages they must be fixed as soon as possible. Plumbing system

must be made by certificated professionals, under the terms of EN standards. EN approved materials must be used in the

system.

Loading and Unloading the Boiler Water :

Plumbing and all radiator valves must be opened if the boilers water will be unloaded. All the systems water can be unloaded

by boilers drainage as if the boiler is in the bottom of the system.If some part of heating system is under the boiler

room,unloading the water process can be made at a point at the bottom of the system.

Water must be loaded from the tap over the plumbing system to the boiler.During the loading process all valves of the

plumbing system and the radiators must be opened.For preventing air fill to the system this operation must be made slowly

and the stopper in the top must be opened. When water comes from this stopper it means that the process is finished. Air

must be taken from every radiator.

Water must be in quality which mentioned on ''plumbing instructions''.

Boiler must not be filled up with water when it is hot. This can cause cracks in sections.

19

Page 20

Checking Before Started :

Getting Started :

Stopping the Boiler :

Failure First Controls :

Checking and Starting the Boiler :

Following controls must be done before starting the boiler.If there are any problems or failure, boiler must not be started.

Water level of the boiler must be controlled. Water must be added to the boiler if the water level is low.

Please call rima technicians if there is a water leakage. Leakage must be prevented before starting the boiler. If there is a

leakage in the plumbing system,boiler must be started after repair.

Flue connections must be controlled. Boiler must not be started before repairing the connection if there is a problem.

Area must be properly air conditioned.

Gas valves must be checked as if they are on if gas fuel is used in the boiler.

Liquid fuel level of the tank must be controlled and fuel valve must be opened if liquid fuel is used in the boiler. Fuel - burner

connection must be controlled.If there are any problems , filters must be cleaned.

Working and the directions of the pumps must be controlled.

Electric system of the control panel must be controlled.

All water and gas valves of the boiler must be opened.

*** All other connections must be checked according to the system options.

Turn off the main fuse switch of the boiler room.

Turn the main electric switch of the boiler room on. Working lamp will be on.

Start the circulation pump.

Turn the ''on / off '' switch of the burner to the mode ''on'' (Check the burner instruction manual.) The indicator light will be on

.

Adjust the boiler temperature from the thermostat.If the burner is dual level, adjust the boiler temperature same the single

stage.Dual stage (TRZ) thermostat adjust the temperature changes own by own ( + 8 °C ).

If the burner does not start , follow the instructions written on the manual of the burner.If the burner does not start after

applying the written operations in the manual,call the technical service of the burner.

Turn the ''on / off'' switch of the burner to the '' off '' position

Turn the ''on / off'' switch of the control panel to the '' off '' position.

Turn of the circulation pump.

Turn of the fuel valves.

Burner must start.

If the boiler doesn't start or if the safety thermostate stop the boiler again please call Rima technical services.

If the burner safety light is on ; Please check the burner instruction manual or get in contact with the burner manufacturer or

distrubutor services.

When a problem or failure occurs in the boiler or the burner,please make the following first controls before calling technical

services. Don't do anything rahter than mentioned controls. After these controls call Rima technical services.

If boiler stops working and doesn't start again ; Safety thermostate may have stopped the boiler because of overheating at

boiler water.In this case wait for the boiler to cool down and please make the following controls.

Check if fuel is coming to the burner or not. If not , make fuel to come to the burner.

Check if pump is working or not. If not , this could be the reason of overheating.Please get in touch with pump manufacturer

or distributor.

Check if the valves are on or off.Open the valves if they are closed.

Please push the safety thermostate switch after the boiler is cold enough.

20

Page 21

Daily Controls :

Periodic Controls :

Yearly Controls :

Smoke Channels Cleaning :

These are the processes that the user must apply every day in season of everyday use. Please read and apply the

instructions and controls mentioned in ''Pre Control'' section of the manual for daily controls.

Care Instructions :

Boiler and burner controls are made in three programs.Daily (in everyday use ),periodic and yearly.

For efficient use, preventing the possible failures and optimum life of the boiler periodic controls are important.It is

recommended that periodical controls for the boiler must be made by once in every three months.These periodical controls

are made by rima technicians by applying following processes.

Boilers burning room and smoke channels check and cleaning if needed.

Leakage controls of water input - water output of the boiler and flue connections.

Valves check

Pumps check

Fuel filter control and cleaning if needed

Burning control (with eye).Burning and flame adjustments if needed.

Control of the liquid fuel sensor.Cleaning if needed.

Working and safety controls of burner and the boiler.

Sensor of the burner liquids tests.Cleaning or renewing if needed .

Working and safety controls of burner and the boiler.

Yearly controls of the boiler must be made by rima technicians before the season starts. Flue and flue lines must be cleaned

before calling technicians for yearly controls. In yearly controls rima technicians apply the following processes.

Situation and the leakproof of the sections and rope isolations controls.

Working pressure test for burning adjustment with the flue gas measurement system if needed.

Sensors and connection of the sensors test.

Boiler burning room and possible soot layers on smoke channels are checks and cleanings.

Connection and the leakproof of the boilers door test.

Leakproof of the connections of the boiler test.

Valves test for proper opening and closing.

Fuel filter test. Cleaning if needed.

Cleaning the Boiler :

The time period for cleaning service is variable according to the fuel type of the boiler and period of use.In boiler cleaning

operation ceramic ropes that isolate front door with front section and flue with back section must be controlled and must be

renewed if needed.

Before applying mentioned services to the boiler;electric must be cut off from the main switch,fuel valves must be closed,

control panel and the burner must be protected for avoiding any possible damage.

Because of the soot layer on heating surfaces, 100 °C increase on flue temperature brings out a % 5 decrease on

efficiency.By pulling out the M16 screws and stamps on the 4 hinges which connects door to the front section,open the

burner door. Clean the burning room, take turbulators out and clean horizontal smoke channels (2nd and 3rd pass). Than

clean the turbulator and put them in to the channels. Close the burner door strictly.In this cleaning operation soot layer may

occur in flue area.This soot particules can be cleaned by seperating horizontal smoke channels from boiler flue. After this

operation these two screws must be connected again and must be tested for leakage.

21

Page 22

Burner Door and Burner Connection :

In burner connection process there must not be any

empty space left between the front door and the

burner barrel.All connection points must be covered

with isolation material for avoiding any air leakage

possibility.

A metal sheet is used for easier assembling of the

burner to the door. This metal sheet is made of 10

mm thickness and in the dimensions of 255x255 mm ,

and burner hole dimension 132 mm (1).

The isolation of the burner door is made of a special

thermal ceramic which is durable up to 1250ºC and

has no defections on human health (2). Please be

sure that this isolation plate is carried carefully and

intensivly during transportation.

There is a ceramic rope fit in to the channels of isolation

door.This prevents leakages between isolation

door and front section of the boiler. After repairing

or cleaning service the doors connection with the

o c ea g se ce t e doo s co ect o t t e

front section must be done properly,strictly.

ON series boilers doors are available for opening to

both sides. This brings advantages of assembling,

reparing and other operations.

A tempered ceramic glass is placed on to the burner

door for watching flame inside (3).

22

Page 23

Instructions For Product Disposal

Cast iron heating boilers are used for long years according to the specifications of its materials and they are long

term equipments.

Life time period for these equipments which is declared in the legal documents is 15 years .

According to this situation renewing of these items are generally done because of technological reasons.

Cast iron boilers, which are produced with human-kind materials can be disposed of as follows .

Cast Iron Body (Gray Cast Iron ) Through iron scrap dealers and cast iron melting companies

Pipes and Cabin Steels Through iron scrap dealers

Other Metal Parts Through iron scrap dealers

Thermal Ceramic and other Isolation Materials Through common waste system

***For more information please get in contact with Rima licensed services.

Positioning the Boiler

Rima boilers must be positioned and placed in the terms of fine protection laws with caution.

pp p

When installing and operating the boilers it is necessary to keep a safe 200 mm distance from combustible

materials with combustibility degrees B,C1,C2

For easily flammable materials with combustibility degree C3 ,which burn quickly and by themselves also after

the ignition source removal the safe distance is doubled it means 400 mm.

The safe distance is to be doubled also in case that the combustibility degree of building material wasn't proved.

Combustibility degrees of building Building materials and products ranked in combustibility degrees

materials and products

A- incombustible Granite,sandstone,bricks,ceramic tiles,mortars,fireproof plasters,…

B- hardly combustible acumin,izumin,heraklit,lignos,boards and basalt felt,fiberglass boards,…..

C

1-combustible with difficulties

Beech and oak wood, hobrex board, plywood,werzalit,……………..

C

2-medium combustible

Pine wood,larch,white wood, chipboard and cork boards, rubber flooring,…….

C

3-easily combustible

Asphalt board,fireboards,polyurethane,polystyrenbe,polyethylene , PVC , ………

***For more information please get in contact with Rima licensed services.

23

Loading...

Loading...