Page 1

Record All Information and attach sales receipt

here for future reference:

Purchase Date:__________________________

Serial #: ________________________________

Questions? 1-888-895-4549

Learn more about your pressure washer,

get answers to frequently asked questions,

and register on line at

www.powermate.com

PRESSURE WASHER

OPERATION MANUAL

for model PWZ0142700.01

TABLE OF CONTENTS

Safety Guidelines/Denitions �������������������������������������2

Consumer Safety Information ������������������������������������2

Important Safety Instructions �������������������������������� 2-5

Specications ������������������������������������������������������������6

Carton Contents ��������������������������������������������������������6

Assembly Instructions ������������������������������������������� 6-7

Operating Instructions ����������������������������������������� 8-11

Maintenance ������������������������������������������������������������12

IMPORTANT: Please make certain that the person who is to use this equipment carefully reads and

understands these instructions before operating�

Storage ��������������������������������������������������������������������13

Repairs ��������������������������������������������������������������������13

Troubleshooting Guide ��������������������������������������������14

Parts List & Exploded View �������������������������������� 15-17

Warranty ������������������������������������������������������������������18

Français ������������������������������������������������������������� 20-37

Español �������������������������������������������������������������� 39-56

Part No� M100135 // Rev� 012/29/2010 PRINTED IN CHINA

Page 2

SAFETY GUIDELINES - DEFINITIONS

• SAVE ALL INSTRUCTIONS

This manual contains information that is important for you to know and understand� This information relates to protecting YOUR SAFETY and PREVENTING EQUIPMENT PROBLEMS� To help you recognize this information, we use the symbols below� Please read the manual and pay attention to these symbols�

DANGER

Indicates an imminently hazardous situation which, if not

avoided , WILL result in DEATH OR SERIOUS INJURY�

WARNING

Indicates a potentially hazardous situation which, if not

avoided, COULD result in DEATH OR SERIOUS INJURY�

CAUTION

Indicates a potentially hazardous situation which, if not

avoided, MAY result in MINOR OR MODERATE INJURY�

CAUTION

Used without the safety alert symbol indicates a potentially hazardous situation which, if not avoided, MAY result

in PROPERTY DAMAGE�

CONSUMER SAFETY INFORMATION

• SAVE ALL INSTRUCTIONS

WARNING

will be used around ammable materials, or on land covered with materials such as agricultural crops, forest, brush,

grass, or other similar items, then an approved spark arrester must be installed and is legally required by the state of

California� It is a violation of California statutes section 130050 and/or sections 4442 and 4443 of California Public Resources Code, unless the engine is equipped with a spark arrester, as dened in section 4442, and maintained in effective working order� Spark arresters are also required on some U�S� Forest Service land and may also be legally required

under other statutes and ordinances�

WARNING

This product contains chemicals known to the State of California to cause cancer, birth defects and/or reproductive

harm�

This product may not be equipped with a spark arresting mufer. If the product is not equipped and

CALIFORNIA PROPOSITION 65 WARNING

IMPORTANT SAFETY INFORMATION

• SAVE ALL INSTRUCTIONS

WARNING

Owners Manual for Safety, Operation, and Maintenance Instructions�

DANGER

• Spilled gasoline and it’s vapors can become ignited from cigarette sparks, electrical arcing, exhaust gases and hot engine

components such as the mufer.

• Heat will expand fuel in the tank, which could result in spillage

and possible re explosion.

• Operating the pressure washer in an explosive environment

could result in a re.

Do not operate this unit until you have read and understand this Operators Manual and the Engine

READ AND SAVE THESE INSTRUCTIONS

RISK OF EXPLOSION FOR FIRE

WHAT CAN HAPPEN HOW TO PREVENT IT

•

Shut off engine and allow it to cool before adding fuel to the tank�

• Use care in lling tank to avoid spilling fuel. Move pressure

washer away from fueling area before starting engine�

• Fill tank to ½˝ (12.7 mm) below bottom of ller neck to provide

space for fuel expansion�

• Operate and fuel equipment in well-ventilated areas free from

obstructions. Equip areas with re extinguisher suitable for gasoline res.

M100135Copyright © 2011 MAT Industries, LLC 2 - ENG

Page 3

IMPORTANT SAFETY INFORMATION (CONT.)

• SAVE ALL INSTRUCTIONS

DANGER

RISK OF EXPLOSION FOR FIRE (CONT.)

WHAT CAN HAPPEN HOW TO PREVENT IT

• Materials placed against or near the pressure washer can

interfere with its proper ventilation features causing overheating

and possible ignition of the materials�

• Mufer exhaust heat can damage painted surfaces, melt any

material sensitive to heat (such as siding, plastic, rubber, vinyl,

or the pressure hose, itself), and damage live plants.

• Improperly stored fuel could lead to accidental ignition. Fuel

improperly secured could get into the hands of children or other

unqualied persons.

• Use of acids, toxic or corrosive chemicals, poisons, insecticides, or any kind of ammable solvent with this product could

result in serious injury or death�

DANGER

RISK TO BREATHING (ASPHYXIATION)

WHAT CAN HAPPEN HOW TO PREVENT IT

• Breathing exhaust fumes will cause serious injury or death!

Engine exhaust contains carbon monoxide, an odorless and

deadly gas�

• Some cleaning uids contain substances which could cause

injury to skin, eyes or lungs�

• Never operate pressure washer in an area containing dry brush

or weeds�

• Always keep pressure washer a minimum of 4´ (1.2m) away

from surfaces (such as houses, automobiles or live plants) that

could be damaged form mufer exhaust heat.

• Store fuel in an OSHA-approved container, in a secure location

away from work area�

• Do not spray ammable liquids.

• Operate pressure washer in a well-ventilated area. Avoid en-

closed areas such as garages, basements, etc�

• Never operate unit in a location occupied by humans or animals.

• Use only cleaning uids specically recommended for high-pres-

sure washers� Follow manufacturers recommendations� Do not

use chlorine bleach or any other corrosive compound�

DANGER

RISK OF FLUID INJECTION AND LACERATION

WHAT CAN HAPPEN HOW TO PREVENT IT

• Your pressure washer operates at uid pressures and velocities high enough to penetrate human and animal esh, which

could result in amputation or other serious injury� Leaks caused

by loose ttings or worn or damaged hoses can result in injection injuries� DO NOT TREAT FLUID INJECTION AS A SIMPLE

CUT! See a physician immediately!

• Injuries can result if system pressure is not reduced before at-

tempting maintenance or disassembly�

• Inspect the high-pressure hose regularly. Replace the hose

regularly� Replace the hose immediately if it is damaged, worn,

has melted from contacting the engine, or shows any signs of

cracking, bubbles, pinholes, or other leakage� Never grasp a highpressure hose that is leaking or damaged�

• Never touch, grasp or attempt to cover a pinhole or similar water leak on the high-pressure hose� The stream of water IS under

high pressure and WILL penetrate skin�

• Never place hands in front of nozzle.

• Direct spray away from self and others.

•

Make sure hose and ttings are tightened and in good condition.

Never hold onto the hose or ttings during operation.

• Do not allow hose to contact mufer.

• Never attach or remove wand or hose ttings while system is

pressurized�

• To relieve system pressure, shut off engine, turn off water supply

and pull gun trigger until water stops owing.

•Use only hoses and accessories rated for pressure higher than

your pressure washer’s PSI.

Copyright © 2011 MAT Industries, LLCM100135 3 - ENG

Page 4

IMPORTANT SAFETY INFORMATION (CONT.)

• SAVE ALL INSTRUCTIONS

DANGER

RISK OF INJURY FROM SPRAY

WHAT CAN HAPPEN HOW TO PREVENT IT

• High-velocity uid spray can cause objects to break, propelling

particles at high speed�

• Light or unsecured objects can become hazardous projectiles.

DANGER

RISK OF FLUID INJECTION AND LACERATION

WHAT CAN HAPPEN HOW TO PREVENT IT

• Unsafe operation of your pressure washer could lead to serious injury or death to you or others�

• If proper starting procedure is not followed, engine can kickback causing serious hand and arm injury�

• The spray gun/wand is a powerful cleaning tool that could look

like a toy to a child�

• Reactive force of spray will cause gun/wand to kickback, and

could cause the operator to slip or fall or misdirect the spray�

Improper control of gun/wand can result in injuries to self and

others�

• Always wear ANSI-approved z87.1 safety glasses. Wear protective clothing to protect against accidental spraying�

• Never point wand at or spray people or animals.

• Always secure trigger lock when wand is not in service to pre-

vent accidental operation�

• Never permanently secure trigger in pull-back (open) position.

• Do not use chlorine bleach or any other corrosive compound.

• Become familiar with the operation and controls of the pressure

washer�

• Keep operating area clear of all persons, pets and obstacles.

• Do not operate the product when fatigued or under the inuence

of alcohol or drugs� Stay alert at all times�

• Never defect the safety features of this product.

• Do not operate machine with missing, broken or unauthorized

parts�

• Never leave wand unattached while unit is running.

• If engine does not start after two pulls, squeeze trigger of gun to

relieve pump pressure� Pull starter cord slowly until resistance is

felt� Then pull cord rapidly to avoid kickback and prevent hand or

arm injury�

• Keep children away from the pressure washer at all times.

• Do not overreach or stand on an unstable support.

• Do not use pressure washer while standing on a ladder.

• Grip gun/wand rmly with both hands. Expect the gun to kick-

back when triggered�

DANGER

RISK OF INJURY OR PROPERTY DAMAGE WHEN TRANSPORTING

OR STORING

WHAT CAN HAPPEN HOW TO PREVENT IT

• Fuel or oil leak or spill could result in re or breathing hazard.

Serious injury or death can result� Fuel or oil leaks will damage

carpet, paint or other surfaces in vehicles or trailers�

• If pressure washer is equipped with a fuel shut-off valve, turn

the valve to OFF position before transporting to avoid fuel leaks� If

pressure washer is not equipped with a fuel shut-off valve, drain

the fuel from tank before transporting� Only transport fuel in an

OSHA- approved container� Always place pressure washer on a

protective mat when transporting to protect against damage to

vehicle from leaks� Remove pressure washer from vehicle immediately upon arrival at your destination�

M100135Copyright © 2011 MAT Industries, LLC 4 - ENG

Page 5

IMPORTANT SAFETY INFORMATION (CONT.)

• SAVE ALL INSTRUCTIONS

WARNING

RISK OF BURSTING

WHAT CAN HAPPEN HOW TO PREVENT IT

• Over ination of tires could result in serious injury and property

damage�

WARNING

RISK OF HOT SURFACES

WHAT CAN HAPPEN HOW TO PREVENT IT

• Contact with hot surfaces, such as engines exhaust components, could result in serious burn�

WARNING

RISK OF CHEMICAL BURN

• Use a tire pressure gauge to check the tires pressure before

each use and while inating tires; see the tire sidewall for the cor-

rect tire pressure�

NOTE: Air tanks, compressors and similar equipment used to

inate tires can ll small tires similar to these very rapidly. Adjust

pressure regular on air supply to no more than the rating of the

tire pressure� Add air in small increments and frequently use the

tire gauge to prevent over ination.

• During operation, touch only the control surfaces of the pressure washer. Keep children away from the pressure washer at

all times� They may not be able to recognize the hazards of this

product�

WHAT CAN HAPPEN HOW TO PREVENT IT

• Use of acids, toxic or corrosive chemical, poisons, insecticides, or any kind of ammable solvent with this product could

result in serious injury or death�

WARNING

RISK OF ELECTRICAL SHOCK

WHAT CAN HAPPEN HOW TO PREVENT IT

• Spray directed at electrical outlets or switches, or objects

connected to an electrical circuit, could result in a fatal electric

shock�

WARNING

RISK OF INJURY FROM LIFTING

WHAT CAN HAPPEN HOW TO PREVENT IT

• Serious injury can result from attempting to lift too heavy an

object�

•Do not use acids, gasoline, kerosene, or any other ammable

materials in this product� Use only household detergents, cleaners

and degreasers recommended for use in pressure washers�

• Wear protective clothing to protect eyes and skin from contact

with spraying materials�

• Unplug any electrically operated product before attempting to

clean it� Direct spray away from electric outlets and switches�

•The pressure washer is too heavy to be lifted by one person.

Obtain assistance from others before lifting�

Copyright © 2011 MAT Industries, LLCM100135 5 - ENG

Page 6

SPECIFICATIONS

• SAVE ALL INSTRUCTIONS

MODEL �������������������������������������������� PWZ0142700�01

PSI MAX ��������������������������������������������������������������2700

OPERATING PSI ������������������������������������������������2440

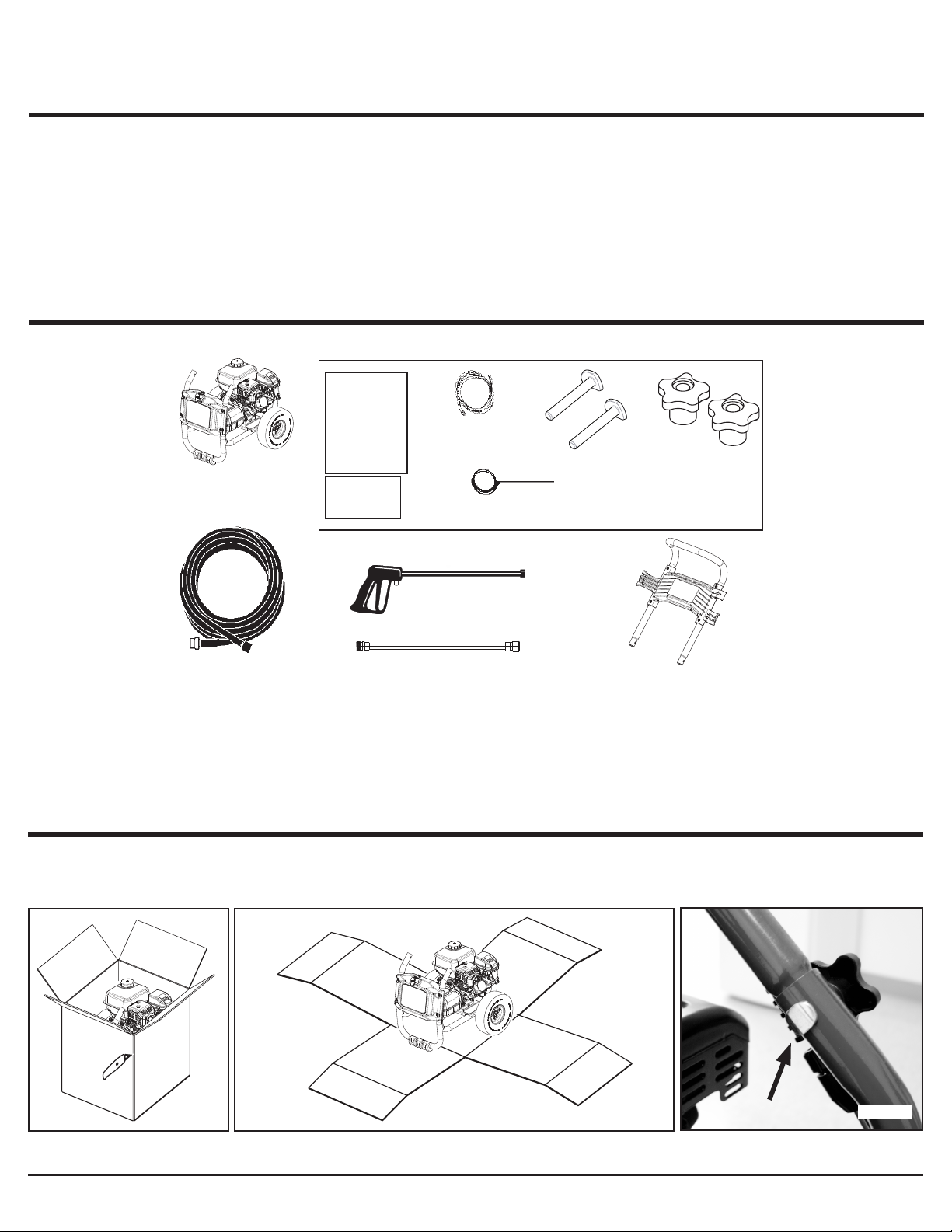

CARTON CONTENTS

• SAVE ALL INSTRUCTIONS

Engine Frame and

Wheel Assembly

Operation

Manual

Engine

Manual

Chemical

GPM MAX ��������������������������������������������������������������2�3

OPERATING GPM �������������������������������������������������2�1

Hose

Saddle Bolts

Cleaning Tool

Bagged Parts

Knobs

Spray Gun

High Pressure

Hose

Spray Wand

ASSEMBLY INSTRUCTIONS

• SAVE ALL INSTRUCTIONS

1. Locate and remove all loose parts from the carton. (Fig. 1)

2. Cut four corners of the carton from top and bottom and lay the panels at. (Fig. 2)

Handle

FIG. 1 FIG. 2

3. Remove handle from beneath unit. (Fig. 2)

FIG. 3

M100135Copyright © 2011 MAT Industries, LLC 6 - ENG

Page 7

ASSEMBLY INSTRUCTIONS (CONT.)

• SAVE ALL INSTRUCTIONS

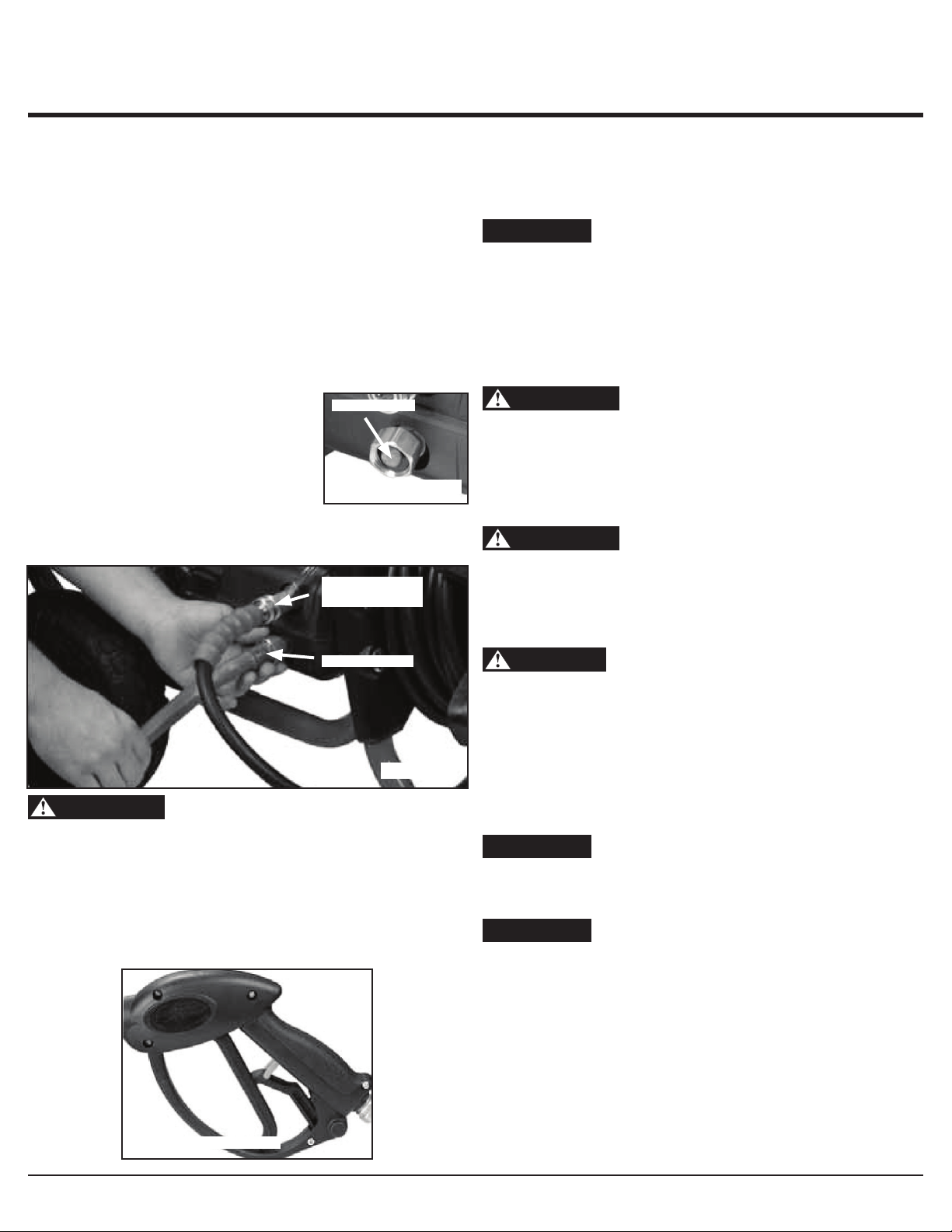

4� Slide handle onto bottom portion of frame assembly�

(Fig. 3)

5� Insert saddle bolts into appropriate hole location and

attach with knobs (both sides). Tighten securely. (Fig. 3)

6� Roll the unit off the carton and discard carton�

7� Connect high-pressure hose to pump outlet� Tighten

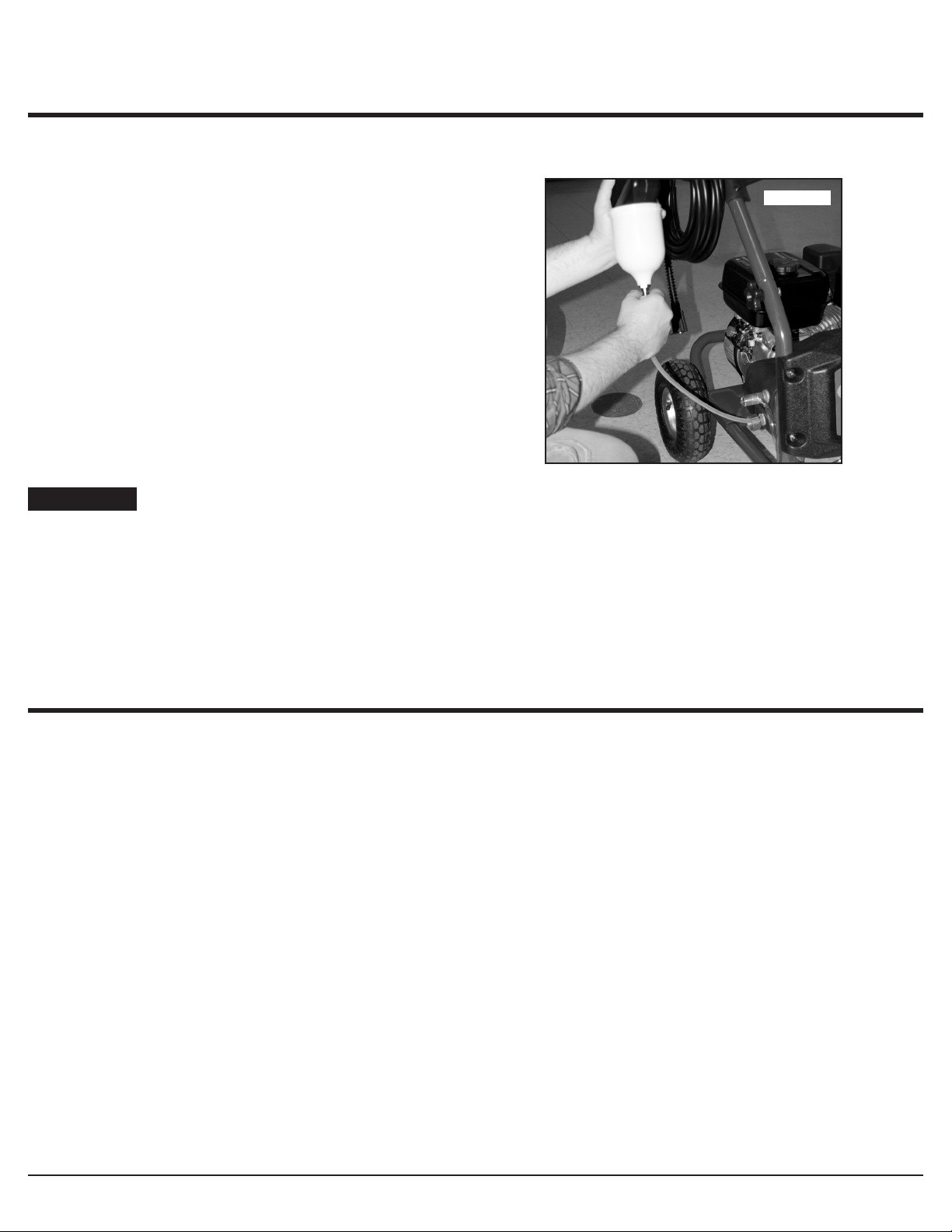

securely. (Fig. 4)

8. Connect wand to gun. Tighten securely. (Fig. 5)

9� Attach high-pressure hose to gun� Tighten securely�

(Fig. 6)

NOTE: The pump on this unit is maintenance free and

requires no oil, if there is a problem with the pump contact

an Authorized Service Center�

FIG. 5

WARNING

sure gauge to check the tires pressure before each use

and while inating tires; see the tire sidewall for the correct

tire pressure�

NOTE: Air tanks, compressors and similar equipment

used to inate tires can ll small tires similar to these very

rapidly� Adjust pressure regulator on air supply to no more

than the rating of the tire pressure� Add air in small increments and frequently use the tire gauge to prevent over

ination.

RISK OF BURSTING. Use a tire pres-

FIG. 4

FIG. 6

Copyright © 2011 MAT Industries, LLCM100135 7 - ENG

Page 8

OPERATING INSTRUCTIONS

• SAVE ALL INSTRUCTIONS

Compare the illustrations with your unit to familiarize yourself with the location of various controls and adjustments�

Save this manual for future reference�

Quick Connect Nozzles

stored in this panel

High-Pressure

Hose

Chemical

Tank

Spray Gun

Engine

BASIC ELEMENTS OF A

PRESSURE WASHER

High Pressure Pump (located inside the shroud,

not shown): Increases the pressure of the water supply�

Engine: Drives the high-pressure pump�

High Pressure Hose: Carries the pressurized water

from the pump to the run and spray wand�

Spray Gun: Connects with spray wand to control

water ow rate, direction, and pressure.

Chemical Hose: Feeds cleaning agents into the

pump to mix with the water� See How To Apply

Chemicals/Cleaning Solvents instructions in this section�

Quick Connect Nozzles: Allow the user to quickly

and easily change the degree of spray to t the job

at hand�

BASIC ELEMENTS OF AN ENGINE

Refer to the engine manual for location and operation of

engine controls�

Choke Control: Opens and closes carburetor choke

valve�

Chemical

Hose

Starter Grip: Pulling starter grip operates recoil starter to

crank engine�

Engine Switch: Enables and disables ignition system

PRESSURE WASHER TERMINOLOGY

PSI: Pounds per Square Inch� The unit of measure for water pressure� Also used for air pressure, hydraulic pressure, etc�

GPM: Gallons Per Minute. The unit of measure for the ow rate of water.

CU: Cleaning Units� GPM multiplied by PSI� GPM x PSI = CU

Bypass Mode: Allows water to re-circulate within the pump when the gun trigger is not pulled�

CAUTION

ing and damage to the pump�

Chemical Injection System: Mixes cleaners or cleaning solvents with the water to improve cleaning effectiveness�

Water Supply: All pressure washers must have a source of water� The minimum requirements for a water supply are

20 PSI and 5 gallons per minute�

Allowing the unit to run for more than two minutes without the gun trigger pulled could cause overheat-

M100135Copyright © 2011 MAT Industries, LLC 8 - ENG

Page 9

OPERATING INSTRUCTIONS (CONT.)

• SAVE ALL INSTRUCTIONS

PRESSURE WASHER OPERATING FEATURES PRESSURE

ADJUSTMENTS

The pressure setting is present at the factory to achieve optimum pressure and cleaning� If you need a lower the pressure, it can be accomplished by these methods�

1� Back away from the surface to be cleaned� The further away you are, the less the pressure will be on the surface to

be cleaned�

2� Change to the 40° nozzle – this nozzle delivers a less powerful stream of water and a wider spray pattern�

CAUTION

DO NOT attempt to increase pump pressure� A higher pressure setting than the factory set pressure

may damage pump�

TO USE SPRAY WAND

The nozzles for the spray wand are stored on the top storage panel� See chart to choose the correct nozzle for the

job to be performed�

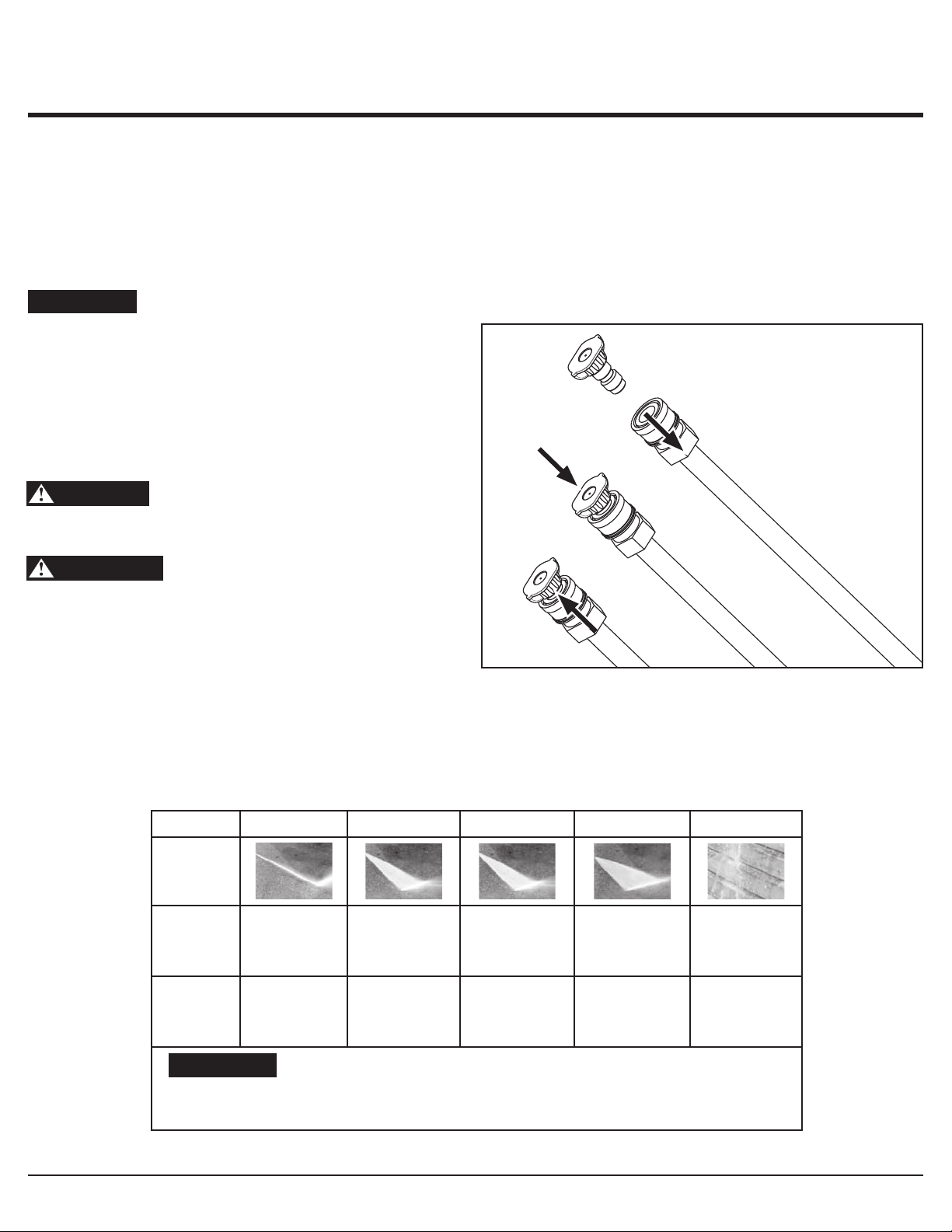

CHANGING NOZZLES ON SPRAY WAND

DANGER

direct discharge stream toward persons, unprotected skin,

eyes or any pets or animals� Serious injury will occur�

WARNING

attempt to change nozzles while pressure washer is running� Turn engine off before changing nozzles�

1� Pull back the quick connect collar on the spray wand

and hold it in place�

2�

Insert the desired quick connect nozzle and hold in place�

3� Slide the quick connect collar forward until it locks into

place�

4� Check that the quick connect nozzle is securely locked

into the spray wand�

RISK OF FLUID INJECTION. Do NOT

RISK OF FLUID INJECTION. Do NOT

FIG. 7

0° 15° 25° 40° Soap

Spray

Pattern

Uses

Surfaces*

CAUTION

*

damage to surfaces such as wood, glass, automotive paint, auto striping and trim, and delicate

objects such as owers and shrubs. Before spraying, check the item to be cleaned to assure

yourself that it is strong enough to resist damage from the force of the spray�

Powerful

pinpoint for

very intensive

cleaning

Metal or concrete

DO NOT use

on wood

The high pressure spray from your pressure washer is capable of causing

Intense cleaning of small

areas

Metal, concrete, or wood

Intense cleaning of medium

areas

Metal, concrete, or wood

Intense cleaning of larger

areas

Metal, concrete, or wood

Applies cleaning solutions

Metal, concrete, or vinyl

Copyright © 2011 MAT Industries, LLCM100135 9 - ENG

Page 10

OPERATING INSTRUCTIONS (CONT.)

• SAVE ALL INSTRUCTIONS

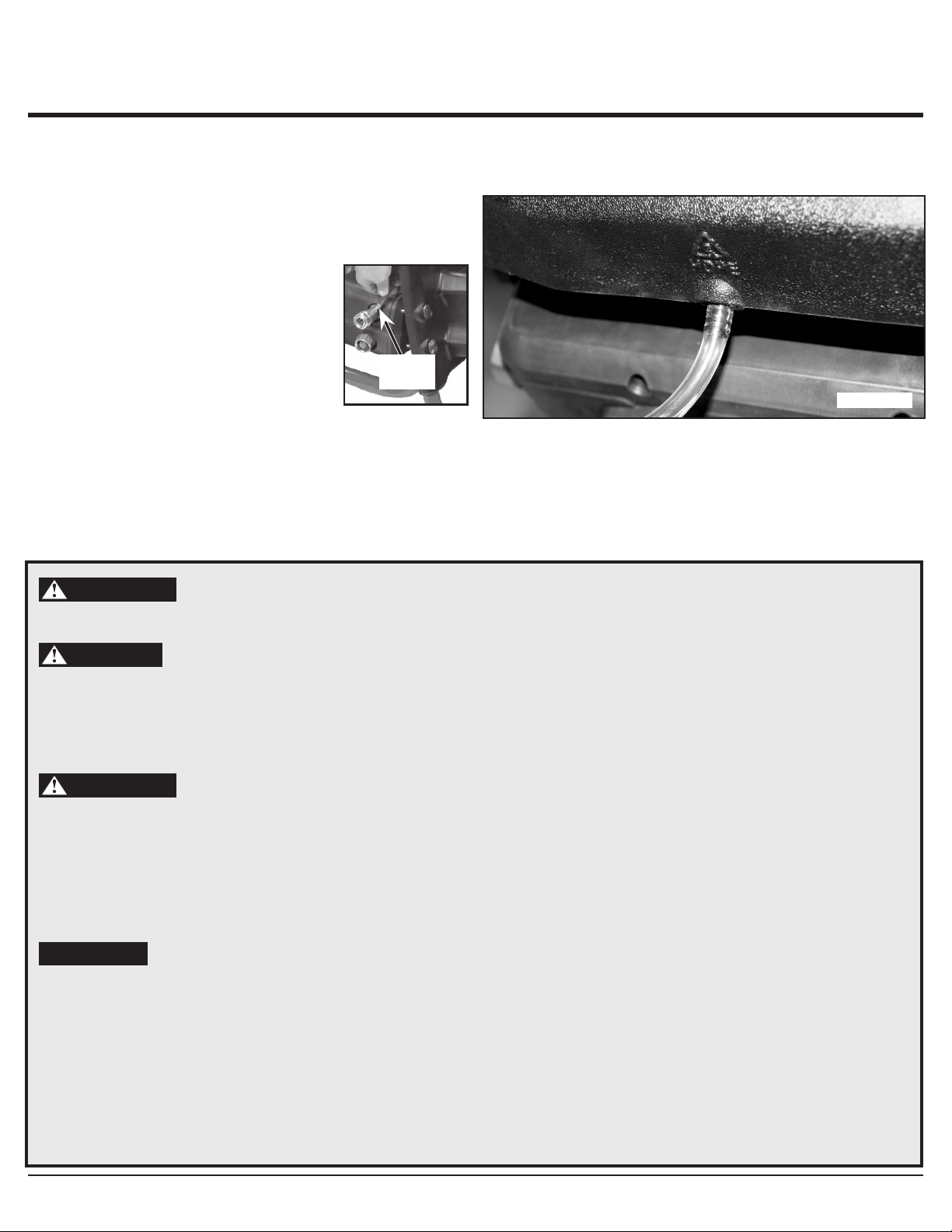

HOW TO APPLY CHEMICALS

AND CLEANING SOLVENTS

Applying chemicals or cleaning solvents is a low pressure

operation�

NOTE: Use only soaps and chemicals designed for pressure washer use� DO NOT USE BLEACH�

To Apply Chemicals:

1� Make sure the chemical hose is

pressed onto the barbed tting located

near high-pressure hose. (Fig. 8)

2�

The other end of the chemical hose

should be connected

the bottom of the chemical tank�

(Fig. 9)

NOTE: For every 7 gallons of water pumped 1 gallon of

chemical/cleaning solution will be used�

3� Fill chemical tank with appropriate cleaning solution�

4� Insert chemical nozzle into spray wand, see Use Spray

Wand paragraph in this section�

to the nipple on

Barbed

Fitting

FIG.8

NOTE: Chemicals and soaps will not siphon when us-

ing any quick connect nozzle other than the black soap

nozzle�

FIG. 9

WARNING

engine instruction manual before starting pressure washer.

DANGER

allow the high-pressure spray to come in contact with unprotected skin, eyes, or with any pets or animals� Serious

injury will occur�

• Your washer operates at uid pressures and velocities high enough to penetrate human and animal esh, which

could result in amputation or other serious injury. Leaks caused by loose ttings or worn or damaged hoses can

result in injection injuries. DO NOT TREAT FLUID INJECTION AS A SIMPLE CUT! See a physician immediately!

WARNING

Do not smoke when lling fuel tank.

• NEVER ll fuel tank completely. Fill tank to 1/2” below bottom of ller neck to provide space for fuel expansion.

Wipe any fuel spillage from engine and equipment before starting engine�

• NEVER run engine in doors or in enclosed, poorly ventilated areas. Engine exhaust contains carbon monoxide, an

odorless and deadly gas�

• DO NOT let hoses come in contact with very hot engine mufer during or immediately after use of your pressure

washer� Damage to hoses from contact with hot engine surfaces will NOT be covered by warranty�

CAUTION

could damage hose and/or pump inlet�

• DO NOT use hot water, use cold water only.

• NEVER turn water supply off while pressure washer engine is running or damage to

pump will result�

• DO NOT stop spraying water for more than two minutes at a time. Pump operates in bypass mode when spray

gun trigger is not pressed� If pump is left in bypass mode for more than two minutes internal components of the

pump can be damaged�

To reduce the risk of injury, read the pressure washer instruction manual and the

RISK OF FLUID INJECTION AND LACERATION. When using the high-pressure setting, DO NOT

RISK OF FIRE, ASPHYXIATION AND BURN. NEVER ll fuel tank when engine is running or hot.

RISK OF PROPERTY DAMAGE. NEVER pull water supply hose to move pressure washer� This

If you do not understand these precautions, please call 1-888-895-4549 to speak to a service representative for

further instructions

M100135Copyright © 2011 MAT Industries, LLC 10 - ENG

Page 11

OPERATING INSTRUCTIONS (CONT.)

• SAVE ALL INSTRUCTIONS

STARTING

Prior to starting, refer to your engine manual for

proper starting procedure.

1� In a well ventilated outdoor area add fresh, high

quality, unleaded gasoline with a pump octane rating

of 86 or higher. Do not overll. Wipe up spilled fuel

before starting the engine� Refer to Engine Owners

Manual for correct procedure�

2� Check engine oil level. See Engine Owners Manual

for correct procedure�

3� Connect the water hose to the water source. Turn

the water source on to remove all air from the hose�

When a steady stream of water is present, turn the

water source off�

4� Verify the lter screen is in water

inlet of pump. (Fig. 10)

NOTE: Cone side faces out�

5� Connect water source to pump inlet� NOTE: Water

source must provide a minimum of 5 gallons per minute

at 20 PSI. (Fig. 11)

Filter Screen

FIG. 10

High-Pressure

Hose Hook-up

8� Insert the quick connect nozzle for the task being

performed� See How To Use Wand instructions in this

section�

9� Turn water source on.

CAUTION

to do so could cause damage to the pump.

10� Remove all air from the pump and high pressure

hose by depressing trigger until a steady stream of

water is present�

11� Start engine. See Engine Owners Manual for correct

procedure�

WARNING

engine does not start after two pulls, squeeze trigger of gun to relieve pump pressure. Pull starter cord

slowly until resistance is felt. Then pull cord rapidly

to avoid kickback and prevent hand or arm injury.

12� Depress trigger on gun to start water ow.

WARNING

Stand on a stable surface and grip gun/spray wand

rmly with both hands. Expect the gun to kick when

triggered.

RISK OF PROPERTY DAMAGE. Failure

RISK OF UNSAFE OPERATION. If

RISK OF UNSAFE OPERATION.

Water Source

FIG. 11

WARNING

tamination always protect against back ow when

connected to a potable water system.

6� Connect high pressure hose to pump outlet�

7� If applying a chemical or cleaning solution, see

How To Apply Chemicals/Cleaning Solvents instructions

in this section�

To reduce the possibility of con-

FIG. 12

13� Release trigger to stop water ow.

DANGER

ways engage the trigger lock when gun is not in use� Failure to do so could cause accidental spraying�

RISK OF INJURY FROM SPRAY. Al-

SHUTTING DOWN

1� After each use, if you have applied chemicals, ll the

chemical tank with clean water and draw clean water

through chemical injection system to rinse system

thoroughly�

CAUTION

to do so could cause damage to the pump.

2� Turn engine off. See Engine Owner’s Manual.

CAUTION

turn the water off with the engine running.

3� Turn water source off.

4� Pull trigger on spray gun to relieve any water

pressure in hose or spray gun�

5� See Storage section in this manual for proper storage

procedures�

RISK OF PROPERTY DAMAGE. Failure

RISK OF PROPERTY DAMAGE. NEVER

Trigger Lock Engaged

Copyright © 2011 MAT Industries, LLCM100135 11 - ENG

Page 12

MAINTENANCE

• SAVE ALL INSTRUCTIONS

WARNING

forming maintenance, you may be exposed to hot

surfaces, water pressure or moving parts that can

cause serious injury or death.

WARNING

disconnect, spark plug wire, let the engine cool and

release all water pressure before performing any

maintenance or repair. The engine contains ammable fuel. Do not smoke or work near open ames

while performing maintenance.

To ensure efcient operation and longer life of your pressure washer, a routine maintenance schedule should be

prepared and followed� If the pressure washer is used in

unusual conditions, such as high-temperatures or dusty

conditions, more frequent maintenance checks will be

required�

RISK OF BURN HAZARD. When per-

RISK OF FIRE HAZARD. Always

ENGINE

Consult the Engine Owners Manual for the manufacturer’s

recommendations for any and all maintenance� NOTE:

The frame is equipped with an oil drain hole to help make

changing the engine oil easier�

HOW TO CLEAN THE WATER

INLET FILTER

This screen lter should be checked periodically and

cleaned if necessary�

1� Remove lter by grasping end and

removing it from water inlet of pump

as shown. (Fig. 13)

2� Clean lter by ushing it with water on both sides.

3� Re-insert lter into water inlet of pump� NOTE: Cone

side faces out�

NOTE:

installed�

Do not operate pressure washer without lter properly

Filter Screen

FIG. 13

PUMP

The pump on this unit is maintenance free and requires no

oil, if there is a problem with the pump contact an Authorized Service Center�

NOZZLE CLEANING

If the nozzle becomes clogged with foreign materials, such

as dirt, excessive pressure may develop� If the nozzle becomes partially clogged or restricted, the pump pressure

will pulsate� Clean the nozzle immediately using the nozzle

kit supplied and the following instructions:

1�

Shut off the pressure washer and turn off the water supply�

2� Pull trigger on gun handle to relieve any water pressure�

3� Remove quick connect nozzle from the spray wand�

4� Remove any obstructions from the quick connect

nozzle with the nozzle cleaning tool provided and ush

with clean water�

5� Re-attach the quick connect nozzle to the spray wand

and turn on the water supply�

6� Start pressure washer and test�

M100135Copyright © 2011 MAT Industries, LLC 12 - ENG

Page 13

STORAGE

• SAVE ALL INSTRUCTIONS

ENGINE

Consult the Engine Owners Manual for the manufacturer’s

recommendations for storage�

PUMP

The manufacturer recommends using a pump protector/

winterizer when storing the unit for more than 30 days and/

or when freezing temperatures are expected� If a pump

protector/winterizer is not available, RV antifreeze or wind-

shield washer uid needs to be run through the pump as

outlined in the steps below�

NOTE: Using a pump protector/ winterizer, RV antifreeze

or windshield washer uid is to provide proper lubrication

to the internal seals of the pump regardless of temperature or environment�

1� Obtain a funnel, 6 oz� of RV antifreeze or windshield

washer uid, and 16–36” of garden hose with a male

hose connector attached to one end�

CAUTION

RV antifreeze. Any other an ti freeze is corrosive and

can damage pump.

2� Disconnect spark plug wire.

3�

Connect length of garden hose to water inlet of pump.

RISK OF PROPERTY DAMAGE. Use only

4� Add RV antifreeze or windshield washer uid to hose

as shown. (Fig. 14)

FIG. 14

5� Pull engine starter rope slowly several times until

antifreeze/ washer uid comes out of high-pressure

hose connection of pump�

6� Remove garden hose from water inlet of pump�

7� Reconnect spark plug wire.

REPAIRS

• SAVE ALL INSTRUCTIONS

To assure product SAFETY and RELIABILITY, repairs, maintenance and adjustment should be performed by an Authorized Warranty Service Center� Always use identical replacement parts� For the location of the nearest Authorized Warranty Service Center call 1-888-895-4549 or visit our website www�powermate�com�

Copyright © 2011 MAT Industries, LLCM100135 13 - ENG

Page 14

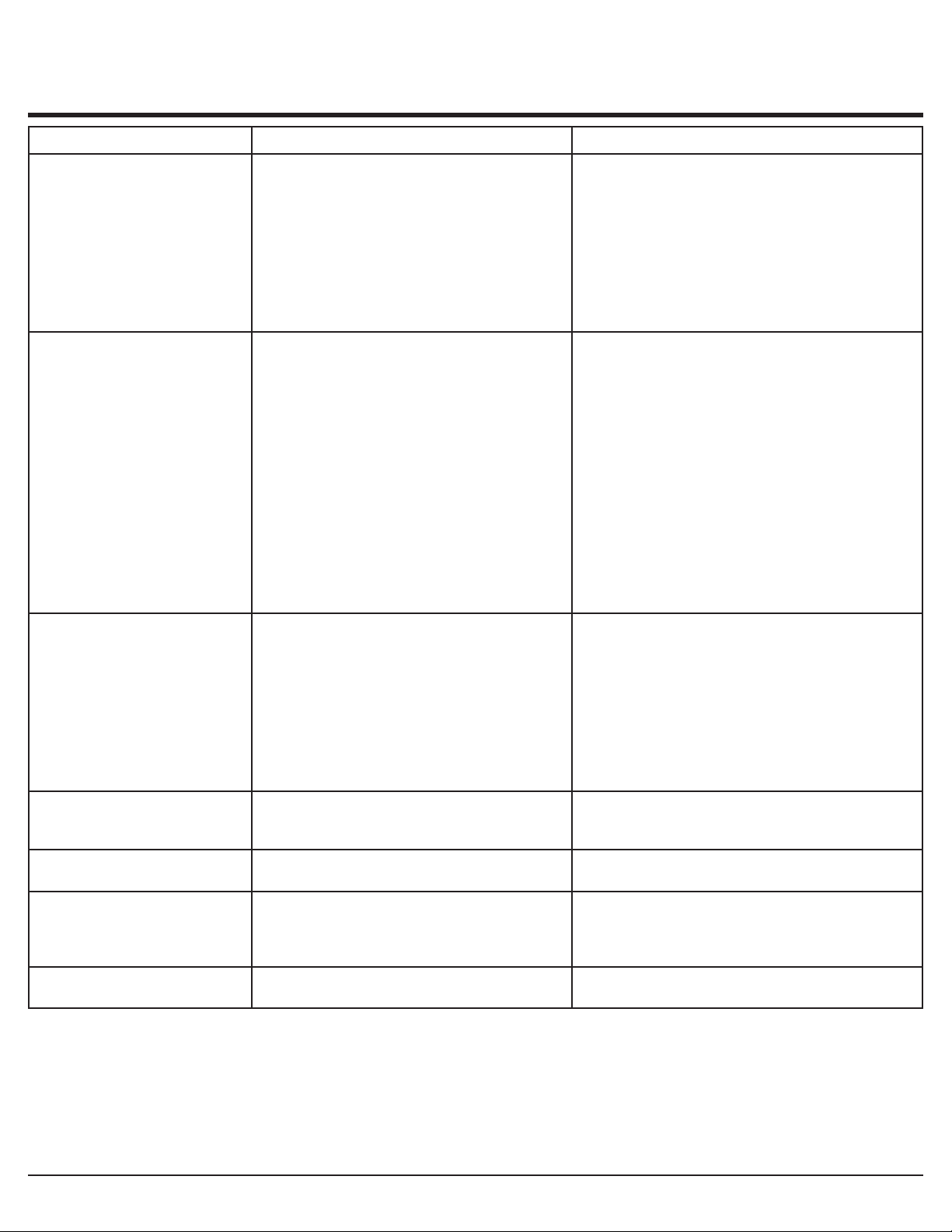

TROUBLESHOOTING GUIDE

• SAVE ALL INSTRUCTIONS

Problem Cause Correction

Engine will not start (see Engine Manual for further engine

troubleshooting)

No or low pressure (initial use) 1� High pressure nozzle is not installed�

Will not draw chemicals 1� Low pressure soap nozzle not installed�

No or low pressure (after period

of normal use)

Water leaking at gun/spray

wand connection

Water leaking at pump 1� Loose connections�

Pump Pulsates 1� Nozzle obstructed� 1� See Nozzle Cleaning paragraph in the Mainte-

AWSC= Authorized Warranty Service Center

1� No fuel

2� Pressure builds up after two pulls on the

recoil starter or after initial use�

3. Choke lever in the “No Choke” position.

4� Spark plug wire not attached�

5� Engine ON/OFF switch in OFF position�

6. Choke lever in the “Choke” position on

a “hot” engine or an engine that has been

exposed to thermal heat for a long period of

time�

2� Low water supply�

3. Leak at high pressure hose tting.

4� Nozzle obstructed�

5. Water lter screen clogged.

6� Air in hose�

7. Choke lever in the “Choke” position.

8� High pressure hose is too long�

2. Chemical lter clogged.

3� Chemical screen not in cleaning solution�

4� Chemical too thick�

5� Pressure hose too long�

6� Chemical build up in chemical injector�

1� Worn seal or packing�

2� Worn or obstructed valves�

3� Warn unloaded piston�

1� Worn or broken O-ring�

2� Loose hose connection�

2� Piston packing worn�

3� Worn or broken O-rings�

4�

Pump head or tubes damaged from freezing�

1� Add fuel�

2� Squeeze gun trigger to relieve pressure�

3. Move choke to the “Choke” position.

4� Attach spark plug wire�

5� Place engine ON/OFF switch in ON position�

6. Move choke to the “No Choke” position.

1� See How to Use Spray Wand instructions in the

Operation Section�

2� Water supply must be at least 5 GPM @ 20 PSI�

3� Repair leak� Apply sealant tape if necessary�

4� See Nozzle Cleaning instructions in the Maintenance section�

5. Remove and clean lter.

6� Turn off the engine, then the water source�

Disconnect the water source from the pump inlet

and turn the water source on to remove all air

from hose� When there is a steady stream of water

present, turn water source off� Re-connect water

source to pump inlet and turn on water source�

Squeeze trigger to remove remaining water�

7. Move choke to the “No Choke” position.

8� Use high pressure hose under 100 feet�

1� See How to Use Spray Wand paragraph in the

Operation Section�

2. Clean lter.

3� Make sure end of chemical hose is fully submerged into cleaning solution�

4� Dilute chemical� Chemical should be in the

same consistency as water�

5� Lengthen water supply hose instead of high

pressure hose�

6� Have parts cleaned or replaced by AWSC�

1� Have replaced by AWSC�

2� Have replaced by AWSC�

3� Have replaced by AWSC�

1� Check and replace�

2� Tighten�

1� Tighten�

2� Have replaced by AWSC�

3� Have replaced by AWSC�

4� Have replaced by AWSC�

nance section for the correct procedure�

M100135Copyright © 2011 MAT Industries, LLC 14 - ENG

Page 15

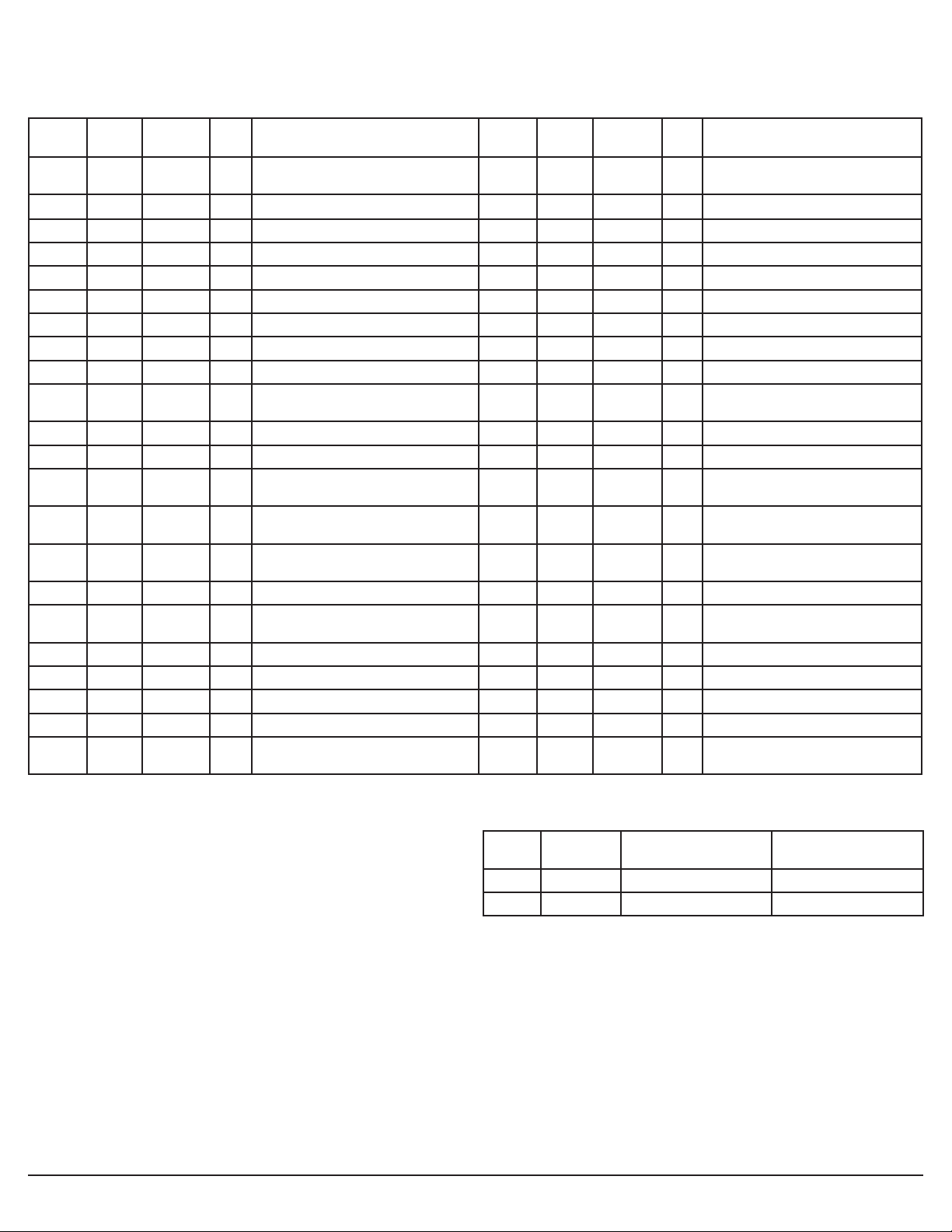

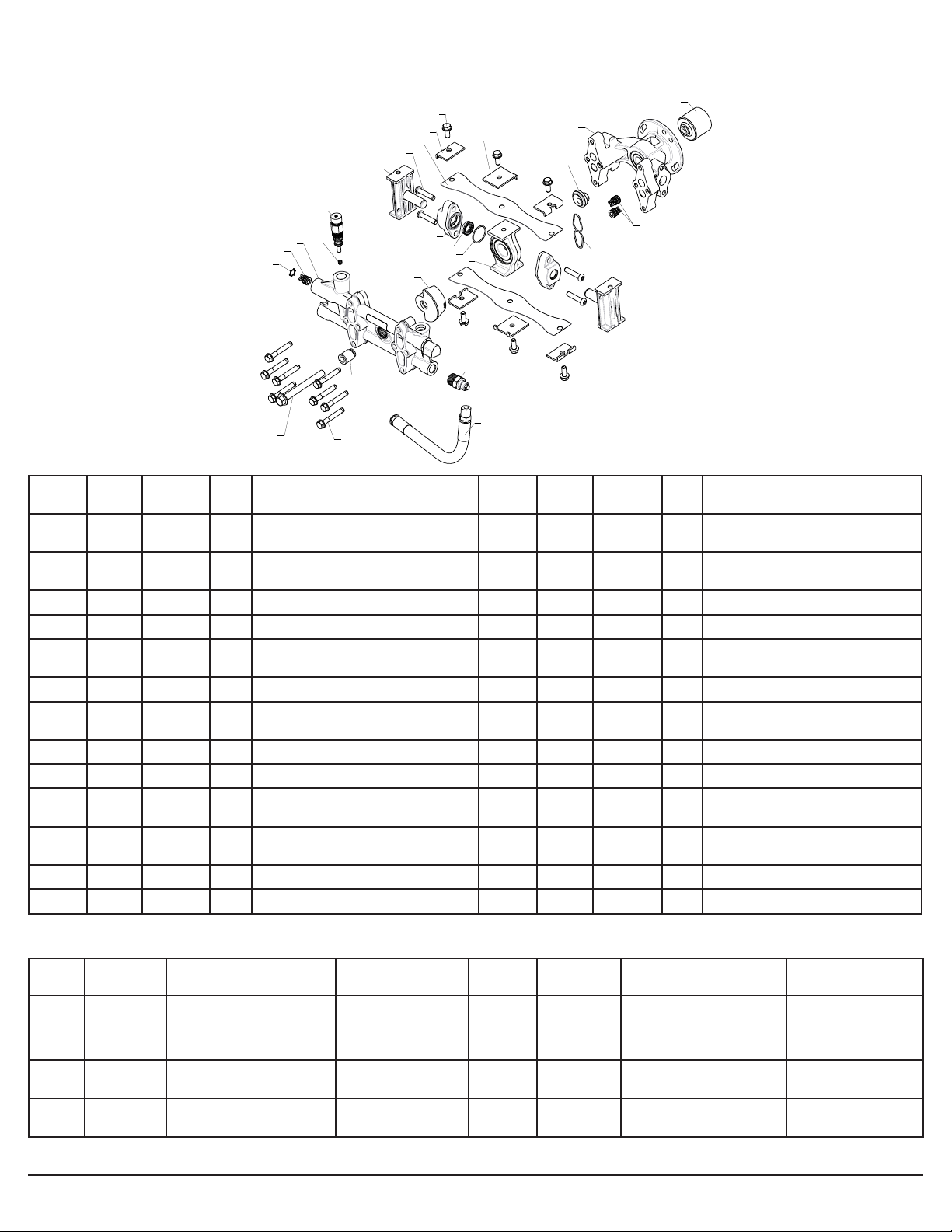

PARTS LIST & EXPLODED VIEW

PRESSURE WASHER ITEM # E104480

ITEM KIT #

1 E104107 1 Assm, Hose, 15 Foot, 20MPA

2 E104577 1 Panel, Accessory - Vette 24 E104573 1 Foot, Plastic - Vette

3 6 Screw, M6x1�0x16 SBHCS 25 E104574 1 Tank, Chemical - Vette

4 6 Washer, Lock M6 26 4 Bolt, M8x1�25x25 SBHCS

5 6 Washer, Flat 6MM - 18�5MM OD 27 4 Washer, Lock 8mm

6 E104126 5 Grommet, Nozzle 28 4 Washer, Flat 8mm X 19mm

7 E104112 1 Nozzle, 0 Degree Red 29 E104575 1 Cap, Chemical Tank - Vette

8 E104114 1 Nozzle, 15 Degree Yellow 30 E104063 2 Bolt, Saddle M8x45

9 E104115 1 Nozzle, 40 Degree White 31 E104064 2 Knob, Five Prong

10 E104598 1 Nozzle, 25 Degree - Green 32 6 Screw, #8-16x�75 Pan Head

11 E104113 1 Nozzle, Low Pressure Black 33 E104587 1 Cover, Pump Bottom - IC2

12 E104591 1 Assembly, Handle - Vette 34 1 1 Pump, IC2

13 E104430 1 Assembly, Engine, 180cc RATO,

14 E104811 1 Gun, Pressure Washer, BIT 101 36 1 1 Screw Set 5/16-24 X�438 SM DG

15 E104102 1 Assy, wand & quick connect,

16 2 Nut, M8x1�25 Nyloc 38 E104586 1 Cover, Pump Top - IC2

17 2 Washer, M8 - 30 OD 39 1 E104788 1 Injector, Chem, 1�8mm, Fixed,

18 E104611 2 Wheel, 10" Pneumatic 40 1,2 1 Nut, Swivel, Garden Hose

19 E104054 2 Spud, Wheel (Short) 41 1,2 1 Swivel, 3/8 NPT Male

20 4 Nut,M8X1,Serrated Flangehead 42 1 E104787 1 Screen, 3/4 Garden Hose

21 2 Screw, M6x1�0x10 Hex 43 E104141 1 Chemical Hose

22 4 Bolt, M8x1�25x35 Hex Serrated

PART

NO.

QTY DESCRIPTION ITEM KIT #

23 E104588 1 Weldmend, Tubing (Front, Base)

Pressure Rating

35 1 1 Shaft, Couple Spline

R180-3

37 4 Bolt, SHC, M8 X 1�25 X 20MM

15�125 inch

Flange

PART

NO.

QTY DESCRIPTION

- Vette

Plastite T20

PT

JE#4343

• Note: Any part number eld without a number listed is

not available

• Descriptions are provided for reference only.

KIT NUMBERS, DESCRIPTIONS, AND INCLUDED

COMPONENTS ARE LISTED BELOW:

KIT #

1 E104797 Kit, Assy IC2 34-36, 39-42

2 E104789 Kit, Swivel 40-41

ORDER

NO.

DESCRIPTION

Copyright © 2011 MAT Industries, LLCM100135 15 - ENG

COMPONENT

REFERENCE #

Page 16

PARTS LIST & EXPLODED VIEW

PRESSURE WASHER ITEM # E104480

5

4

3

1

2

8

7

6

9

10

11

12

13

38

27

39

40

41

42

43

29

28

27

26

25

37

30

28

36

35

34

33

32

31

20

15

14

16

21

23

24

5

4

3

22

19

18

17

M100135Copyright © 2011 MAT Industries, LLC 16 - ENG

Page 17

19

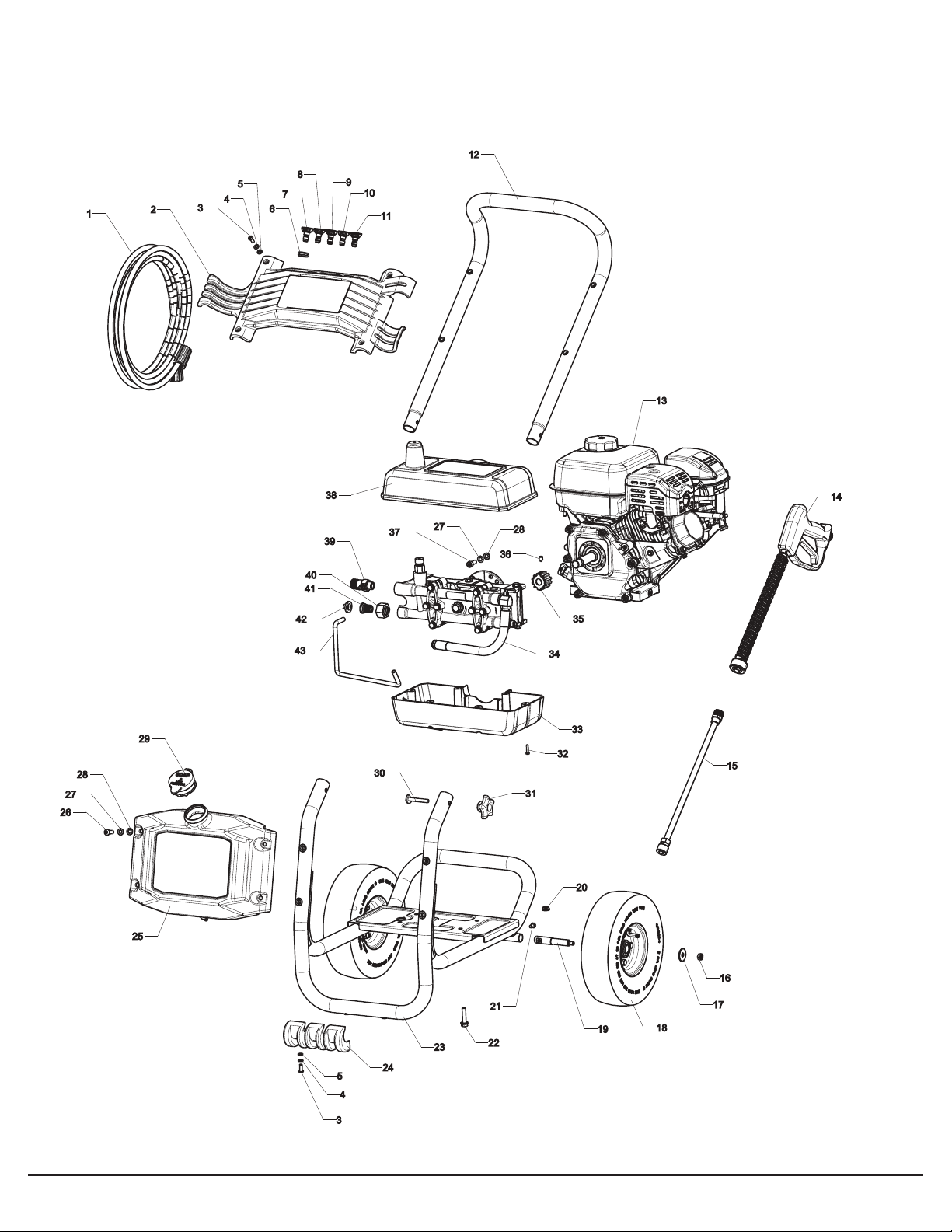

PARTS LIST & EXPLODED VIEW

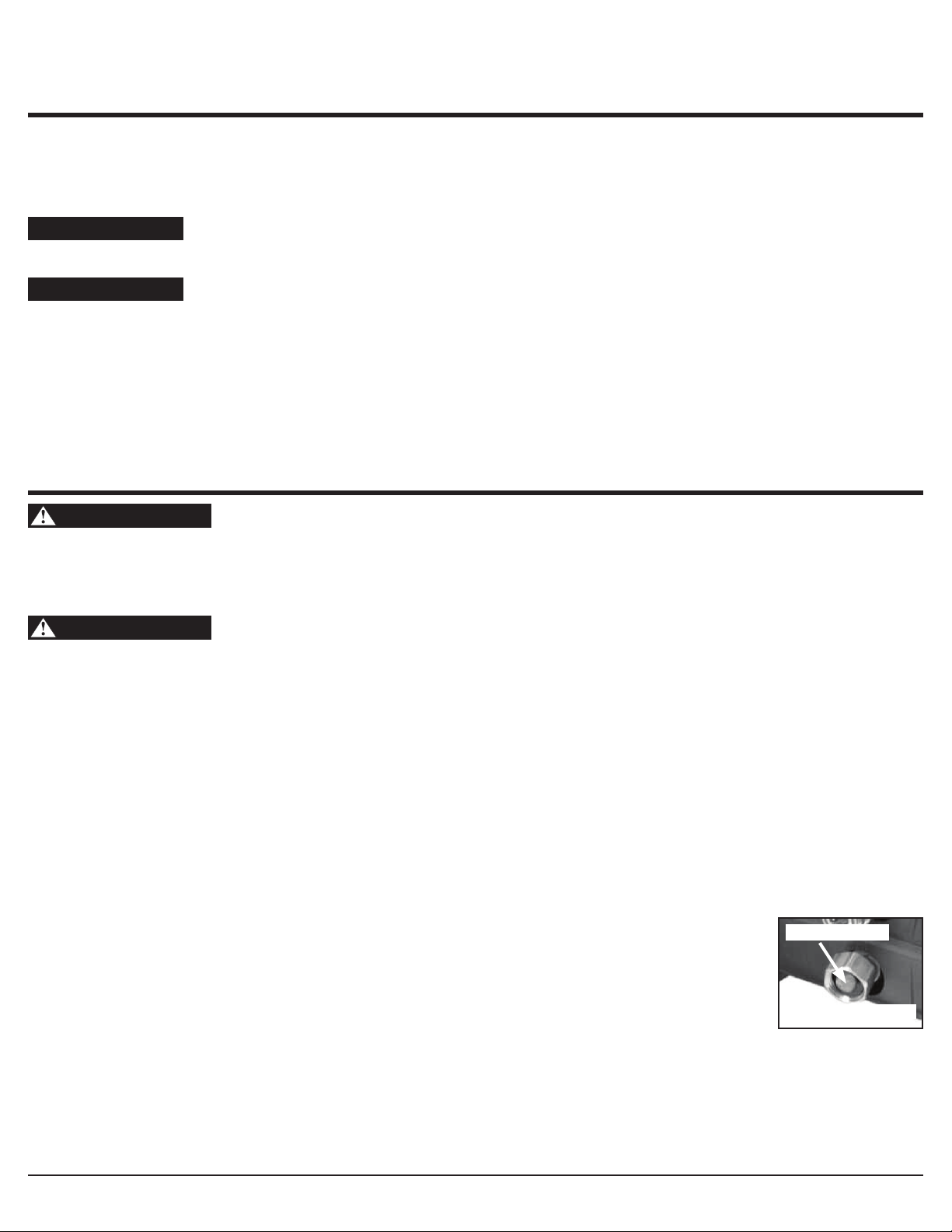

PRESSURE WASHER ITEM # E104579 - PUMP

15

14

13

12

11

16

18

17

5

4

3

2

ITEM KIT #

PART

NO.

1

23

25

24

QTY DESCRIPTION ITEM KIT #

6

1 5 1 Ring, Retaining, Internal, �600,

10

9

8

7

21

22

14 4 Clamp, Block End

20

PART

NO.

2

QTY DESCRIPTION

IC2

2 1,5 5 Assembly, Valve, IC2 15 6 Screw, IHW 5/16 - 18 X �75

GRD 8

3 1 Assembly, Head IC2 16 2 Clamp, Block Mid-Strap

4 2 1 Seat, Unloader, IC2 17 1 Coupler, Shaft Bearing IC2

5 2 1 Unloader, IC2 18 1 Assembly, Pump Body Radial,

IC2

6 1 Shaft, Counterweight 2�5GPM 19 1 Spline, Bearing Coupler

7 1 Assembly, Ring Radial 20 1,5 2 O-ring, Custom, Head Pump

Body, IC2

8 3 2 O-ring, Journal Body, IC2 21

9 3 2 Seal, 16mm, IC2 22

10 2 Assembly, Journal Body and

23 1 Assembly, Shaft Inner Ring

E104812

E105544

1 Thermal Relief, IC2

1 Pulse Hose, IC2

Bushing, IC2

11 4 2 Assembly, Piston and Cap 24 8 Screw, 5/16 - 18 X 2�125 THD

FRM

12 4 Screw, 5/16 - 18 X 1�5 THD FRM 25 1 Bolt, 7/16 - 14 X 4�00 GRD 8

13 2 Strap, IC2

KIT NUMBERS, DESCRIPTIONS, AND INCLUDED COMPONENTS ARE LISTED BELOW:

KIT #

ORDER

NO.

DESCRIPTION

1 E104784 Kit, Valve, In/Out 2,20 4 E104785 Kit, Piston w/Cap

2 E104782 Kit, Unloader 4,5 5 E104783 Kit, Valves All

3 E104786 Kit, Seals w/O-ring

(repairs both pistons)

• Note: Any part number eld without a number listed is not available • Descriptions are provided for reference only.

COMPONENT

REFERENCE #

8,9

KIT #

ORDER

NO.

DESCRIPTION

(replaces both pistons)

• NOTE: Order Kit E104786

when replacing pistons

(replaces all 5)

Copyright © 2011 MAT Industries, LLCM100135 17 - ENG

COMPONENT

REFERENCE #

11

1,2,20

Page 18

LIMITED WARRANTY

• SAVE ALL INSTRUCTIONS

WARRANTY COVERAGE: MAT Industries, LLC (the Company)

Warrants to the original retail customer in North America that it will repair or replace, free of charge, any parts found

by the Company or its authorized service representative to be defective in material or workmanship� This warranty

covers the cost of replacement parts and labor for defects in material or workmanship�

NOT COVERED

· Transportation charges for sending the product to the

Company or its authorized service representative for

warranty service, or for shipping repaired or replacement

products back to the customer; these charges must be

borne by the customer�

· Engine may be covered exclusively by a separate warranty from the engine manufacturer as set forth in the

engine Manual (if included).

· Damages caused by abuse or accident, and the effects

of corrosion, erosion and normal wear and tear�

WARRANTY PERIOD

Two (2) year from the date of purchase. For warranty service, the customer must provide dated proof of purchase and

must notify the Company within the warranty period�

For warranty service: Call toll free 888-895-4549, or write to Sanborn Manufacturing Co., Product Servic-

es, 118 West Rock Street, P. O. Box 206, Springeld, MN 56087.

· Warranty is void if the customer fails to maintain and

operate the product as instructed and recommended by

the Company in the owner’s manual.

· Warranty applies only if the product is used solely for

consumer applications, and does not apply if the product

is used for commercial or business applications, or as

rental equipment�

· The Company will not pay for repairs or adjustments to

the product, or for any costs or labor, performed without

the Company’s prior authorization.

EXCLUSIONS AND LIMITATIONS

THE COMPANY MAKES NO OTHER WARRANTY OF ANY KIND, EXPRESS OR IMPLIED. IMPLIED WARRANTIES,

INCLUDING WARRANTIES OF MERCHANTABILITY AND OF FITNESS FOR A PARTICULAR PURPOSE, ARE HEREBY

DISCLAIMED. THE WARRANTY SERVICE DESCRIBED ABOVE IS THE EXCLUSIVE REMEDY UNDER THIS WARRANTY;

LIABILITY FOR INCIDENTAL AND CONSEQUENTIAL DAMAGES IS EXCLUDED TO THE EXTENT PERMITTED BY LAW�

This warranty gives you specic legal rights, and you may also have other rights which vary from state to state. Some

states do not allow a disclaimer of implied warranties, or the exclusion or limitation of incidental and consequential

damages, so the above disclaimers and exclusions may not apply to you�

M100135Copyright © 2011 MAT Industries, LLC 18 - ENG

Page 19

Page 20

Inscrivez tous les renseignements et agrafez le

reçu de caisse ici pour références futures :

Date d’achat :__________________________

N° de série : ________________________________

Questions? 1-888-895-4549

Apprenez encore plus en ce qui concerne votre

laveuse à pression, obtenez des réponses aux

questions les plus fréquentes et enregistrez votre

produit en ligne à

www.powermate.com

LAVEUSE À PRESSION

GUIDE D’UTILISATION

pour modèle PWZ0142700.01

TABLE DES MATIÈRES

Mesures de sécurité/Dénitions ������������������������������21

Renseignements sur la sécurité

du consommateur ���������������������������������������������������21

Mesures de sécurité importantes ��������������������� 21-24

Fiche Technique ������������������������������������������������������25

Contenu de la boîte �������������������������������������������������25

Instructions d’assemblage �������������������������������� 25-26

Instructions d’utilisation ������������������������������������� 27-31

IMPORTANT: Assurez-vous que toute personne qui utilisera cet équipement lise attentivement ces instruc-

tions avant de l’utiliser.

Entretien ������������������������������������������������������������������31

Entreposage ������������������������������������������������������������32

Réparations �������������������������������������������������������������32

Guide de dépannage ����������������������������������������� 32-33

Liste - Pèces et Diagramme Éclaté ������������������ 34-36

Garantie �������������������������������������������������������������������37

English ����������������������������������������������������������������� 1-18

Español �������������������������������������������������������������� 39-56

N° de pièce M100135 // Rev� 012/29/2010 IMPRIMÉ EN CHINE

Page 21

MESURES DE SÉCURITÉ – DÉFINITIONS

• CONSERVER TOUTES LES INSTRUCTIONS

Ce guide contient des renseignements importants que vous deviez bien saisir� Cette information porte sur VOTRE

SÉCURITÉ et sur LA PRÉVENTION DE PROBLÈMES D’ÉQUIPEMENT. A n de vous aider à identi er cette information,

nous avons utilize les symboles ci-dessous� Veuillez lire attentivement ce guide en portant une attention particulière à

ces symboles�

DANGER

Indique un danger imminent qui, s’il n’est pas évité,

CAUSERA DE GRAVES BLESSURES OU LA MORT�

AVERTISSEMENT

Indique la possibilité d’un danger qui, s’il n’est pas évité,

POURRAIT CAUSER DE GRAVES BLESSURES OU LA

MORT�

ATTENTION

Indique la possibilité d’un danger qui, s’il n’est pas évité,

PEUT causer DES BLESSURES MINEURES OU MOYENNES�

ATTENTION

Sans le symbole d’alerte. Indique la possibilité d’un danger qui, s’il n’est pas évité, PEUT causer DES DOMMAG-

ES À LA PROPRIÉTÉ�

RENSEIGNEMENTS SUR LA SÉCURITÉ DU CONSOMMATEUR

• CONSERVER TOUTES LES INSTRUCTIONS

AVERTISSEMENT

n’en est pas équipé, et s’il est utilisé près de matériaux inammables ou sur de la terre couverte de produits agricoles,

forêts, broussailles, gazon ou autres articles semblables, un pare-étincelles approuvé doit être posé, et est exigé

par la loi en Californie� Selon la section 130050 de la loi de la Californie, et les sections 4442 et 4443 du Code sur les

ressources publiques de la Californie, ce produit ne peut pas être utilisé en Californie, à moins que le moteur ne soit

équipé d’un pare-étincelles, tel que décrit dans la section 4442, et à moins que l’appareil ne soit maintenu en bon état

de fonctionnement� Des pare-étincelles sont également requis sur certaines terres forestières des États-Unis et peuvent être exigés légalement sous certains autres lois et arrêtés�

AVERTISSEMENT

Ce produit contient des produits chimiques connus de l’État de Californie comme causant des cancers, des anomalies

congénitales et/ou présentant des dangers pour la reproduction�

Il se peut que ce produit ne soit pas équipé d’un silencieux à pare-étincelles. Si le produit

CALIFORNIE PROPOSITION 65 AVERTISSEMENT

MESURES DE SÉCURITÉ IMPORTANTES

• CONSERVER TOUTES LES INSTRUCTIONS

AVERTISSEMENT

l’utilisation et l’entretien de ce Guide de l’utilisateur et du Guide du propriétaire du moteur.

DANGER

• Les cigarettes, étincelles, arc électrique, gaz d’échappement

et des parties chaudes du moteur telles qu’un silencieux peuvent enammer l’essence déversée et ses vapeurs.

• Le combustible du réservoir se dilate sous l’effet de la chaleur

et pourrait se solder par un déversement et un incendie ou une

explosion�

• Le fonctionnement de la laveuse haute pression dans un milieu explosif pourrait se solder par un incendie�

RISQUE D’EXPLOSION OU D’INCENDIE

CE QUI PEUT SE PRODUIRE COMMENT L’ÉVITER

N’utilisez pas cet appareil avant d’avoir lu et compris les instructions sur la sécurité,

LISEZ ET CONSERVEZ CES INSTRUCTIONS

•

Éteindre le moteur et le laisser refroidir avant de remplir le réser-

voir d’essence.

• Être attentif et éviter de déverser de l’essence lors du remplis-

sage du réservoir� Éloigner la laveuse haute pression de la zone

de ravitaillement avant de démarrer le moteur�

• Laisser environ 127 mm (1/2 po) de dégagement sous le bord du

goulot de remplissage pour permettre l’expansion de l’essence.

• Utiliser et faire le plein d’essence de l’équipement dans des

zones bien dégagées de tout obstacle� Installer un extincteur

adéquat dans les zones de travail pour combattre les incendies à

base d’essence.

Copyright © 2011 MAT Industries, LLCM100135 21 - FR

Page 22

MESURES DE SÉCURITÉ IMPORTANTES (SUITE)

• CONSERVER TOUTES LES INSTRUCTIONS

DANGER

RISQUE D’EXPLOSION OU D’INCENDIE (SUITE)

CE QUI PEUT SE PRODUIRE COMMENT L’ÉVITER

• Du matériel déposé contre ou près de la laveuse haute

pression peut interférer avec les fonctionnalités d’aération de

l’équipement et provoquer une surchauffe et l’allumage du materiel (risque d’incendie).

• La chaleur de l’échappement du silencieux peut endommager

des surfaces peintes, faire fondre tout type de matériel sensible

à la chaleur (comme du revêtement extérieur, plastique, caoutchouc, vinyle ou meme le tuyau haute pression) et nuire aux

plantes vivantes�

• De l’essence mal entreposée pourrait provoquer un allumage (incendie) accidentel. Ranger l’essence de façon sécuritaire

pour en empêcher l’accès aux enfants et à toutes autres personnes non qualiées.

• L’utilisation d’acides, de produits chimiques toxiques ou corrosifs, de poisons, d’insecticides ou de toute sorte de solvant

inammable dans ce produit pourrait provoquer des blessures

graves ou la mort�

DANGER

RISQUE D’ASPHYXIE

CE QUI PEUT SE PRODUIRE COMMENT L’ÉVITER

•

Respirer les vapeurs d’échappement provoquera de graves

blessures voire, un décès ! Les gaz d’échappement des moteurs

contiennent du monoxyde de carbone, un gaz inodore et mortel�

• Certains liquides nettoyants contiennent des substances

pouvant provoquer des blessures à la peau, aux yeux ou au

système respiratoire�

• Ne jamais utiliser la laveuse haute pression dans une zone avec

arbustes ou broussailles secs�

• Toujours éloigner la laveuse haute pression d’au moins 1,2 m

(4 pi) de toutes surfaces (telles que desmaisons, voitures, ou des

plantes vivantes) qui pourraient

être endommagées par la chaleur s’échappant du silencieux.

• Entreposer l’essence dans un contenant homologué par la Loi

sur la santé et la sécurité du travail dans un emplacement sécuritaire loin de la zone de travail�

• Ne pas vaporiser des liquids inammables.

• Utiliser la laveuse haute pression dans une zone bien aérée.

Éviter les endroits clos comme les garages, les sous-sols, etc�

• Ne jamais utiliser l’appareil dans un endroit habité par des hommes ou des an maux�

• Utiliser uniquement des liquids nettoyants spécialement recommandés

pour les laveuses haute pression� Suivre les recommandations

des fabricants�

Ne pas utiliser de produit à blanchir au chlore ou tout autre composé corrosif�

DANGER

RISQUE D’INJECTION ET DE LACÉRATION

CE QUI PEUT SE PRODUIRE COMMENT L’ÉVITER

• Votre laveuse haute pression fonctionne à des pressions de

liquides et des vitesses sufsamment élevées pour pénétrer la

peau de l’homme et animale, ce qui pourrait se solder par une

amputation ou autre blessure grave� Des fuites provoquées par

des raccords lâches ou des tuyaux usés ou endommagés peuvent se solder par des blessures par injection� NE PAS TRAITER

UN INJECTION DE LIQUIDE COMME UNE SIMPLE COUPURE !

Consulter un médecin immédiatement !

• Il y a risque de blessures si la pression n’est pas réduite avant

d’essayer de procéder à un entretien ou un démontage.

• Inspecter périodiquement le tuyau haute pression. Remplacer

immédiatement le tuyau s’il est endommagé, usé, s’il a fondu en

contact avec le moteur ou s’il démontre un signe de ssure, des

bulles, des trous d’épingle ou tout autre fuite. Ne jamais saisir

untuyau haute pression quifuit ou est endommagé�

• Ne jamais toucher, saisir ou essayer de couvrir un trou minuscule ou tout autre fuite similaire sur le tuyau haute pression�

• Le jet d’eau EST sous haute pression et PÉNÈTRERA la peau.

• Ne jamais mettre les mains devantl’embouchure.

• Éloigner le jet, ne pas le diriger vers soimême ou autrui.

• S’assurer que le tuyau et les raccords sont serrés et en bon

état. Ne jamais s’agripper au tuyau ou aux raccords en cours de

fonctionnement�

• Ne pas mettre le tuyau en contact avec le silencieux.

• Ne jamais attacher ou retirer le tube ou les raccords du tuyau

avec le système sous pression�

• Pour décompresser le système, éteindre le moteur, fermer

l’approvisionnement en eau et enclencher la détente du pistolet

jusqu’à l’arrêt complet de l’écoulement d’eau.

• Utiliser uniquement des tuyaux et accessoires classés pour des

pressions plus élevées que le PSI de la laveuse haute pression�

M100135Copyright © 2011 MAT Industries, LLC 22 - FR

Page 23

MESURES DE SÉCURITÉ IMPORTANTES (SUITE)

• CONSERVER TOUTES LES INSTRUCTIONS

DANGER

RISQUE DE BLESSURE PAR JET

CE QUI PEUT SE PRODUIRE COMMENT L’ÉVITER

• Un jet de liquide à haute vitesse peut briser des objets et projeter les éclats à haute vitesse�

• Des objets légers ou mal xés peuvent se transformer en projectiles dangereux�

DANGER

RISQUE D’UTILISATION DANGEREUSE

CE QUI PEUT SE PRODUIRE COMMENT L’ÉVITER

• Toujours porter des lunettes de sécurité conformes à la norme

ANSI Z87�1 Porter des vêtements protecteurs pour se protéger

de jets accidentels�

• Ne jamais diriger la lance ou le jet vers une personne ou des

animaux�

• Toujours xer solidement le verrou de la détentelorsque le tube

pulvérisateur est inutilisé pour empêcher tout fonctionnement accidentel�

• Ne jamais xer, de façon permanente, la détente en position

arrière (ouverte).

DANGER

RISQUE DE BLESSURE OU DE DOMMAGE À LA PROPRIÉTÉ LORS

DU TRANSPORT OU DU RANGEMENT

CE QUI PEUT SE PRODUIRE COMMENT L’ÉVITER

• Il y a risque de fuite ou de déversement d’essence ou d’huile

qui pourrait se solder par un incendie ou des problèmes respira-

toires, des blessures graves, voire la mort. Des fuites d’essence

ou d’huile endommageront les tapis, peinture ou toutes autres

surfaces de véhicules ou de remorques�

• Si la laveuse haute pression est dotée d’une soupape d’arrêt,

FERMER la soupape d’arrêt avant le transport pour éviter

toute fuite d’essence. S’il n’y a pas de soupape d’arrêt, purger

l’essence du réservoir avant le transport. Transporter l’essence

uniquement dans un contenant homologué par la Loi sur la santé

et la sécurité du travail � Toujours installer la laveuse haute pression sur un revêtement protecteur lors du transport pour protéger

le véhicule de tout dommage de fuites� Retirer immédiatement la

laveuse haute pression du véhicule dès l’arrivée à destination.

Copyright © 2011 MAT Industries, LLCM100135 23 - FR

Page 24

MESURES DE SÉCURITÉ IMPORTANTES (SUITE)

• CONSERVER TOUTES LES INSTRUCTIONS

AVERTISSEMENT

RISQUE D’ÉCLATEMENT

CE QUI PEUT SE PRODUIRE COMMENT L’ÉVITER

• Des pneus surgonés pourraient provoquer des blessures

graves et des dommages à la propriété�

AVERTISSEMENT

ATTENTION SURFACES CHAUDES

CE QUI PEUT SE PRODUIRE COMMENT L’ÉVITER

• Le contact de surfaces chaudes comme les composants

d’échappement moteur, pourrait provoquer des brûlures graves

AVERTISSEMENT

RISQUE DE BRÛLURE CHIMIQUE

• Utiliser un manomètre pour vérier la pression des pneus avant

chaque utilization et lors du gonage; consulter le anc de pneu

pour obtenir la pression correcte� REMARQUE : des réservoirs

d’air, des compresseurs et d’autres appareils similaires

utilisés pour goner les pneus peuvent remplir de petits pneus

à ces pressions très rapidement� Régler le régulateur de pres-

sion d’air à une pression moindre que celle indiquée sur le

pneu. Ajouter l’air par petite quantité et utiliser fréquemment le

manomètre pour empêcher un surgonage

• En cours de fonctionnement, ne toucher que les surfaces de

commande de la laveuse haute pression� Tenir en tout temps les

enfants à l’écart de la laveuse haute pression. Ils n’ont pas assez

de jugement pour reconnaître les dangers inhérents au produit�

CE QUI PEUT SE PRODUIRE COMMENT L’ÉVITER

• L’utilisation d’acides, de produits chimiques toxiques ou corrosifs, de poisons, d’insecticides, ou de tout type de solvant

inammable avec le produit risque de se solder par des bles-

sures graves, voire la mort�

AVERTISSEMENT

RISQUE DECHOC ÉLECTRIQUE

CE QUI PEUT SE PRODUIRE COMMENT L’ÉVITER

• Un jet en direction de prises électriques ou d’interrupteurs ou

tout objet branché à un circuit électrique pourrait se solder par

un choc électrique�

AVERTISSEMENT

RISQUE DE BLESSURE EN SOULEVANT LE PRODUIT

CE QUI PEUT SE PRODUIRE COMMENT L’ÉVITER

• Essayer de soulever un objet trop lourd peut se solder par de

graves blessures�

•Ne pas utiliser d’acides, d’essence, de kérosène ou tout autre

materiel inammable avec ce produit. Utiliser uniquement des

detergents domestiques, des nettoyants et

dégraissants recommandés pour les laveuses haute pression�

and degreasers recommended for use in pressure washers�

• Porter des vêtements protecteurs pour protéger les yeux et la

peau contre le

contact avec les matériaux sous pression�

• Débrancher tout produit fonctionnant à l’électricité avant

d’essayer de le nettoyer. Éloigner le jet des prises électriques et

interrupteurs�

• La laveuse haute pression est trop lourde pour être soulevée

par une seule personne. Demander de l’aide avant de la soulever.

M100135Copyright © 2011 MAT Industries, LLC 24 - FR

Page 25

FICHE TECHNIQUE

• CONSERVER TOUTES LES INSTRUCTIONS

MODÈLE ������������������������������������������ PWZ0142700�01

PSI MAX ��������������������������������������������������������������2700

PSI EN FONCTIONNEMENT ����������������������������2440

CONTENU DE LA BOÎTE

• CONSERVER TOUTES LES INSTRUCTIONS

Ensemble de

châssis de moteur

avec roues

Guide de

l’utilisateur

Guide du

moteur

Boyau de

produit chimique

GPM MAX ��������������������������������������������������������������2�3

GPM EN FONCTIONNEMENT ����������������������������2�1

Boulons de serrage

Outil de nettoyage

Pièces dans un sac

Boutons

Pistolet de

vaporisation

Boyau à haute

pression

Tube de pulvérisation

Poignée

D’ASSEMBLAGE

• CONSERVER TOUTES LES INSTRUCTIONS

1. Identier et retirer toutes les pieces détachées de la boîte pliante. (Fig. 1)

2. Couper les quatre coins de la boîte, du haut vers le bas, et mettre les côtés à plat sur le sol. (Fig. 2)

FIG. 1 FIG. 2

3. Retirez la poignée d’en dessous de l’équipement. (Fig. 2)

FIG. 3

Copyright © 2011 MAT Industries, LLCM100135 25 - FR

Page 26

D’ASSEMBLAGE (SUITE)

• CONSERVER TOUTES LES INSTRUCTIONS

4� Faites glisser la poignée sur la partie inférieure de

l’ensemble du cadre. (Fig. 3)

5� Insérez les boulons de serrage dans les trous appro

priés et attachez-les avec les boutons (des deux côtés).

Serrez à fond. (Fig. 3)

6. Sortez l’équipement du carton en le faisant rouler, puis

jetez le carton�

7. Connectez le tuyau exible haute pression à l’orice de

sortie de la pompe. Serrez à fond. (Fig. 4)

8� Connectez la lance de vaporisation au pistolet� Serrez à

fond. (Fig. 5)

9. Attachez le tuyau exible haute pression au pistolet.

Serrez à fond. (Fig. 6)

REMARQUE : la pompe de cet appareil ne nécessite pas

de maintenance ni de lubri ant. En cas de problème avec

la pompe, contacter un centre de réparation agréé�

FIG. 5

FIG. 4

AVERTISSEMENT

Risque d’éclatement. Utiliser un manomètre pour verier

la pression des pneus avant chaque utilisation et lors du

gonage; consulter le anc de pneu pour obtenir la pression correcte�

REMARQUE : des réservoirs d’air, des compresseurs

et d’autres appareils similaires utilisés pour goner les

pneus peuvent remplir de petits pneus à ces pressions

très rapidement. Régler le régulateur de pression d’air

à une pression moindre que celle indiquée sur le pneu�

Ajouter de l’air par petite quantité et utiliser fréquemment

le manomètre pour empêcher un surgonage

RISQUE D’ÉCLATEMENT.

FIG. 6

M100135Copyright © 2011 MAT Industries, LLC 26 - FR

Page 27

UTILISATION

• CONSERVER TOUTES LES INSTRUCTIONS

Comparez les illustrations avec votre appareil a n de vous familiariser avec l’emplacement des commandes et des

réglages� Conservez ce guide pour les références futures�

Buses à connexion rapide

rangées sur ce panneau

Boyau à haute

pression

Réservoir

de produits

chimiques

Pistolet de Vaporization

Moteur

ÉLÉMENTS DE BASE D’UNE

LAVEUSE À PRESSION

Pompe à haute pression (située à l’intérieur du

bouclier, N’est pas montré sur le schéma) : Augmente la pression de la source d’eau.

Moteur : Entraîne la pompe à haute pression�

Boyau à haute pression : Achemine l’eau sous

pression de la pompe vers le pistolet et la lance de

vaporisation�

Pistolet de vaporisation : S’attache à la lance

pour régler le débit d’eau, la direction et la pression.

Boyau de produit chimique : Alimente es agents

de nettoyage dans la pompe pour les mélanger avec

l’eau. Consultez la partie intitulée « Application des

produits chimiques/solvants de nettoyage » de cette

section�

Buses à connexion rapide : Permettent à

l’utilisateur de changer rapidement et facilement le

degré de concentration du jet en fonction du travail

concret à effectuer�

ÉLÉMENTS DE BASE DU MOTEUR

Consultez le guide du moteur pour connaître

l’emplacement et l’utilisation des commandes du moteur.

Commande d’étrangleur : Ouvre et ferme la soupape

de l’étrangleur dans le carburateur.

Boyau de

produit

chimique

Poignée du démarreur : Tirer sur la poignée du démar-

reur fait fonctionner le démarreur à rappel pour démarrer

le moteur�

Interrupteur du moteur : Met en fonction ou hors fonc-

tion le système d’allumage

PRETERMINOLOGIE DES LAVEUSES À PRESSION

PSI : livres par pouce carré. Une unite de mesure de pression d’eau. Également utilisé pour la pression d’air, la pression

hydraulique, etc�

GPM : Gallons par minute. L’unité de mesure du débit d’eau.

CU : Unités de nettoyage� GAL� PAR MIN� x PSI = CU

Mode de dérivation : Permet à l’eau de recirculer dans la pompe lorsque la détente n’est pas actionnée.

ATTENTION

risque de surchauffer et d’endommager la pompe.

Système d’injection de produit chimique : Mélange les nettoyants ou les solvants de nettoyage avec l’eau pour

augmenter l’ef cacité de nettoyage.

Si vous laissez l’appareil en marche pendant plus de deux minutes sans actionner la détente, cela

Source d’eau : Toutes les laveuses à pression ont besoin d’une source d’eau. Les exigences minimums pour la

source d’eau sont de 20 PSI et de 19 litres (5 gallons) à la minute.

Copyright © 2011 MAT Industries, LLCM100135 27 - FR

Page 28

UTILISATION (SUITE)

• CONSERVER TOUTES LES INSTRUCTIONS

CARACTÉRISTIQUES DE FONCTIONNEMENT DE LA LAVEUSE À

PRESSION RÉGLAGE DE LA PRESSION

La pression est préréglée à l’usine a n d’obtenir une pression ainsi qu’un nettoyage optimums. La pression peut être

diminuée de la façon suivante�

1� Éloignez-vous de la surface à nettoyer� Plus vous êtes éloigné, moins sera la pression sur la surface à nettoyer�

2. Utiliser la buse de 40° – Cette buse produit un jet d’eau moins puissant et pulvérise sur une plus grande surface.

ATTENTION

NE tentez PAS d’augmenter la pression de la pompe. Une pression plus élevée que celle réglée à

l’usine peut endommager la pompe.

FIG. 7

POUR UTILISER LE TUBE DE

PULVÉRISATION

Les buses pour la lance de vaporisation sont rangées sur

le panneau de rangement du haut� Consulter le tableau

pour choisir la buse appropriée pour le travail concret à

effectuer�

CHANGEMENT DES BUSES SUR LE

TUBE DE PULVÉRISATION

DANGER

Ne pas diriger le jet en direction de personnes, sur la peau

et les yeux sans rotection ou sur des animaux� Une blessure grave se produira�

AVERTISSEMENT

PAS essayer de changer de buse lorsque la laveuse haute pression est en fonctionnement� Éteindre le moteur avant de

changer de buse

1. Tirez vers l’arrière le collier à connexion rapide sur la lance de vaporisation et maintenez-le dans cette position.

2� Insérez la buse à connexion rapide désirée et maintenez-le en place�

3. Faites glisser le collier à connexion rapide vers l’avant jusqu’à ce qu’il se verrouille en place.

4� Assurez-vous que la buse à connexion rapide est solidement verrouillée dans la lance de vaporisation�

RISQUE D’INJECTION DE LIQUIDES.

lA PROJECTION D’OBJETS POURRAIT PROVOQUER DE GRAVES BLESSURES. NE

0° 15° 25° 40° Soap

Type de

jet

Usages

Surfaces*

ATTENTION

*

d’endommager les surfaces fragiles telles que le bois, le verre, la peinture d’automobiles, les

garnitures d’auto ainsi que les objets délicats tells que les eurs et arbustes. Avant de vaporiser, vériez l’objet à nettoyer an de vous assurer qu’il est assez robuste pour résister à la

puissance du jet sans subir des dommages�

jet étroit puissant pour le

nettoyage

intense

métal ou bé-

ton; NE PAS

utiliser sur le

bois

nettoyage

intense de petites surfaces

métal, béton

ou bois

Le jet à haute pression de la laveuse à pression est capable

Nettoyage intensif de zones

moyennement

sales

métal, béton

ou bois

couvre une

surface plus

grande

métal, béton

ou bois

applique des

solutions de

nettoyage

métal, béton,

bois ou vinyle

M100135Copyright © 2011 MAT Industries, LLC 28 - FR

Page 29

UTILISATION (SUITE)

• CONSERVER TOUTES LES INSTRUCTIONS

APPLICATION DES PRODUITS

CHIMIQUES/SOLVANTS DE

NETTOYAGE

L’application des solutions de nettoyage

devrait être effectuée à basse pression�

REMARQUE : Utilisez seulement des savonsou des

produits chimiques qui sont conçus spécialement pour

une laveuse à pression. Ne pas utiliser de l’eau de Javel.

Application de produits chimiques

1. Vérier que le tuyau pour produits

chimiques est solidement appuyé sur

le raccord cannelé situé près du

raccord du tuyau haute pression de

la pompe, comme indiqué. (Fig. 8)

2�

L’autre bout du tuyau de produit

chimique doit être connecté au

mamelon du fond du réservoir de

produits chimiques. (Fig. 9)

REMARQUE : Pour chaque quantité de 26,5 litres (7 gallons) d’eau pompée, 3,8 litres (1 gallon) de produit chi-

mique/ solution de nettoyage seront utilisés�

AVERTISSEMENT

sion avant de la mettre en marche.

An de réduire le risque de blessures, lire le monde d’emploi de la laveuse haute pres-

Barbed

Raccord

Fitting

cannelé

FIG.8

3� Remplissez le réservoir de produits chimiques avec la

solution de nettoyage appropriée�

4. Insérez la buse d’injection de produits chimiques dans

la lance de vaporisation� Voir le paragraphe consacré à

la lance de vaporisation dans cette section�

REMARQUE : Les produits chimiques et les savons ne seront pas siphonnés si une buse à connexion rapide quelconque autre que la buse à savon noire est utilisée�

FIG. 9

DANGER

PAS laisser le jet à haute pression en contact avec la peau et les yeux sans protection ou avec des animaux� Une blessure grave

se produira�

•La laveuse haute pression fonctionne à des pressions de liquides et des vitesses sufsamment élevées pour pénétrer la peau

humaine et animale, ce qui pourrait se solder par une amputation ou autres blessures graves� Des fuites provoquées par des

raccords lâches ou des tuyaux usés ou endommagés peuvent se solder par des blessures par injection� NE PAS TRAITER UNE

INJECTION DE LIQUIDE COMME UNE SIMPLE COUPURE ! Consulter un médecin immédiatement !

AVERTISSEMENT

avec le moteur en marche ou chaud. Ne pas fumer lors du plein d’essence.

•

NE JAMAIS remplir le réservoir au complet. Laisser environ 127 mm (1/2 po) de dégagement sous le bord du goulot de remplissage

pour permettre l’expansion de l’essence. Essuyer toute trace d’essence du moteur et de l’équipement avant de démarrer le moteur.

• NE JAMAIS utiliser le moteur à l’intérieur ou dans un espace clos peu aéré. Les gaz d’échappement des moteurs contiennent du

monoxyde de carbone, un gaz inodore et mortel�

• NE PAS laisser les tuyaux en contact avec le silencieux chaud en cours de fonctionnement ou immédiatement près l’utilisation

de la laveuse haute pression� Les dommages aux tuyaux, suite à un contact avec les surfaces chaudes du moteur, NE sont PAS

couverts par la garantie�

ATTENTION

pour déplacer la laveuse haute pression. Cette action risque d’endommager le tuyau ou l’arrivée d’eau de la pompe.

• NE PAS utiliser d’eau chaude. Utiliser uniquement de l’eau froide.

• NE JAMAIS fermer l’arrivée d’eau lors du fonctionnement de la laveuse haute pression, cela endommagera la pompe.

• NE PAS cesser la pulvérisation d’eau pour une période de plus de deux minutes à chaque fois. La pompe fonctionne en mode

de dérivation lorsque la détente du pistolet de pulvérisation n’est pas engagée. Il y a risque d’endommagement des composants

internes de la pompe si elle demeure en mode de dérivation pour plus de deux minutes�

RISQUE D’INJECTION DE LIQUIDE ET DE LACÉRATION. Lors du fonctionnement à pression élevée, NE

RISQUE D’INCENDIE, ASPHYXIE ET DE BRÛLURES. NE JAMAIS faire le plein du réservoir

RISQUE DES DOMMAGES À LA PROPRIÉTÉ. NE JAMAIS tirer sur le tuyau d’approvisionnement en eau

Si vous ne comprenez pas ces mises en garde, veuillez téléphoner le 1-888-895-4549 et communiquer avec un représentant du

service à la clientèle pour obtenir de plus amples instructions�

Copyright © 2011 MAT Industries, LLCM100135 29 - FR

Page 30

UTILISATION (SUITE)

• CONSERVER TOUTES LES INSTRUCTIONS

DÉMARRAGE

Avant de démarrage, l’appareil, consultez le guide

du moteur pour connaître la procédure de démarrage appropriée.

1� Dans un endroit extérieur bien aéré, ajoutez de

l’essence pure, sans plomb, de haute qualité et ayant

un indice d’octane de 86 ou plus. Ne pas trop remplir.

Essuyez l’essence déversée avant de démarrer le

moteur� Consultez le guide du moteur pour connaître la

procedure appropriée�

2� Vériez le niveau d’huile. Consultez le guide du

moteur pour connaître la procédure appropriée�

3� Raccorder le tuyau d’eau à l’approvisionnement

d’eau. Faire couler de l’eau dans le tuyau pour retirer

toute bulle d’air. Dès que le jet d’eau est constant,

fermer l’approvisionnement d’eau.

4� Assurez-vous que l’écran ltrant

est dans l’ori ce d’entrée d’eau

de la pompe. (Fig. 10)

REMARQUE : Le côté conique doit

être dirigé vers l’extérieur.

5� Branchez la source d’eau à l’ori ce d’entrée de la

pompe� REMARQUE : La source d’eau doit fournir un

minimum de 19 litres (5 gallons) par minute à 20 PSI.

at 20 PSI. (Fig. 11)

Écran ltrant

FIG. 10

Boyau à haute

pression

Source d’eau

FIG. 12

Dispositif de blocage de la

détente engagé

8� Insérez la buse à connexion rapide appropriée

pour la tâche à accomplir. Consulter les directives sur

l’utilisation de la lance dans cette section.

9� Ouvrez le robinet de la source d’eau.

ATTENTION

PROPRIÉTÉ. Négliger de suivre cette directive pourrait endommager la pompe.

10� Retirer toute trace de bulles d’air de la pompe et

du tuyau haute pression en appuyant sur la détente

jusqu’à l’obtention d’un jet d’eau constant.

11� Démarrez le moteur. Consultez le guide du moteur

pour connaître la procédure appropriée�

AVERTISSEMENT

DANGEREUSE. Si le moteur ne démarre pas après

deux tentatives, appuyer sur la détente du pistolet

pour décompresser la pompe. Tirer lentement la

corde du démarreur jusqu’à obtention d’une résistance. Puis tirer rapidement surcelui-ci pour éviter

l’effet de rebond moteur et empêcher toute blessure

à la main ou au bras.

RISQUE DES DOMMAGES À LA

RISQUE D’UTILISATION

FIG. 11

AVERTISSEMENT

de contamination, toujours protéger le système

contre les refoulements s’il est raccordé au système

d’apport en eau potable.

6� Attachezle boyau à haute pression à la sortie de la

pompe�

7� Si vous appliquez un produit chimique ou une

solution de nettoyage. Si vous voulez appliquer un

produit chimique ou une solution de nettoyage, con

sultez la partie intitulée « Application des produits

chimiques/solvants de nettoyage » de cette section�

Pour réduire la possibilité

12� Appuyez sur la détente du pistolet pour com

mencer la vaporisation d’eau.

AVERTISSEMENT

DANGEREUSE

saisir solidement le pistolet/la lance avec les deux

mains. S’attendre à un effet de rebond lorsque la

détente du pistolet de pulvérisation est engagée.

13� Relâchez la détente pour arrêter le débit d’eau.

DANGER

rouiller la détente lorsque le pistolet n’est pas utilisé

pour empêcher une pulverization accidentelle.

. Se tenir sur une surface stable et

RISQUE DE BLESSURE PAR JET. Ver-

RISQUE D’UTILISATION

M100135Copyright © 2011 MAT Industries, LLC 30 - FR

Page 31

UTILISATION (SUITE)

• CONSERVER TOUTES LES INSTRUCTIONS

ARRÊT DE L’APPAREIL

1� Après chaque emploi, si vous avez appliqué des produits chimiques, remplissez le réservoir de produits chimiques

avec de l’eau propre et aspirez l’eau à travers le système d’injection de produits chimiques an de rincer complètement le système�

ATTENTION

que d’endommager la pompe.

2� Arrêtez le moteur. Consultez le Guide du moteur�

ATTENTION

3� Fermez le robinet de la source d’eau.

4�

Appuyez sur la détente du pistolet de vaporisation pour dégager l’eau sous pression dans le boyau ou dans le pistolet.

5� Consultez la section sur l’entreposage de ce guide pour connaître les procédures d’entreposage appropriées.

RISQUE DES DOMMAGES À LA PROPRIÉTÉ. Si vous n’exécutez pas cette étape, cela ris-

NE fermez JAMAIS le robinet d’eau lorsque le moteur tourne.

ENTRETIEN

• CONSERVER TOUTES LES INSTRUCTIONS

AVERTISSEMENT

Lors d’un entretien, il y a présence de surfaces

d’eau chaudes, à pression élevée et de pièces mobiles qui peuvent provoquer des blessures graves ou

un décès.

AVERTISSEMENT

Avant tout entretien ou réparation, toujours débrancher le l de la bougie, laisser refroidir le moteur et décompresser toute pression d’eau. Le mo-

teur contient un combustible in ammable. Ne pas

fumer ou travailler près de ammes nues lors d’un

entretien.

An d’assurer le bon fonctionnement et une durée de vie

prolongée de votre laveuse à pression, vous devez pré-

parer et suivre un calendrier d’entretien régulier. Si votre

laveuse à pression est utilisée dans un environnement

défavorable, tel qu’à des temperatures élevées ou des

conditions poussiéreuses, les vérications d’entretien doi-

vent être exécutées plus souvent�

RISQUE DE BRÛLURE.

RISQUE D’INCENDIE.

NETTOYAGE DE LA BUSE

Si la buse devient obstruée par des matériaux étrangers comme la poussière, une pression excessive peut se