Page 1

PW0872400.01

Operator Manual

Manuel de L’opérateur

Manual del operador

0063665 02/06

STOP

¡PRIMERO LLÁMENOS!

ARRÊT

Coleman® Powermate® lea y

entienda todas las instrucciones

ALTO

DO NOT RETURN TO STORE!

CALL US FIRST!

CUSTOMER HOTLINE

1-800-445-1805

or 1-308-237-2181

FOR QUESTIONS OR

SERVICE INFORMATION

IMPORTANT - Please make

certain that everyone who uses

the Coleman® Powermate®

Pressure Washer thoroughly

reads and understands these

instructions prior to operation.

www.powermate.com

NE PAS RETOURNER AU MAGASIN!

APPELEZ–NOUS D’ABORD!

ASSISTANCE TELEPHONIQUE

A LA CLIENTELE

1-800-445-1805

ou 1-308-237-2181

POUR L'INFORMATION DE

QUESTIONS OU SERVICE

IMPORTANT - Veiller à ce que

toute personne amenée à utiliser cet

appareil de Coleman® Powermate®

lise soigneusement ces instructions

et les comprenne avant de procéder

à son utilisation.

NO LO DEVUELVA A LA TIENDA!

LÍNEA DIRECTA DE ATENCIÓN

AL CLIENTE

1-800-445-1805

o 1-308-237-2181

PARA la INFORMACION de

PREGUNTAS O SERVICIO

IMPORTANTE - Favor de

ceciorarse de que toda persona

que use el Lavador de presión

antes de la operación.

Page 2

TABLE OF CONTENTS

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

CUSTOMER SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Safety Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

General Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

SAFETY FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Thermal Relief Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Safety Lock Off Latch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Low Oil Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Spark Arresting Muffler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

SPRAY NOZZLE SELECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

BEFORE OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Pre-Start preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Hose and Gun Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

OPERATING CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

High Pressure Hose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Water Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

OPERATING INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Start-up Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

TABLE DES MATIÈRES

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

SERVICE CLIENTELE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

SÉCURITÉ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Symboles utilisés . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Précautions Générales de Sécurité . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

MESURES DE SÉCURITÉ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Soupape de surpression thermique . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Loquet de sécurité . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Arrêt suite au bas niveau d’huile . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Silencieux Pare-étincelles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

SPÉCIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

CHOIX DE BUSE DE PULVÉRISATION . . . . . . . . . . . . . . . . . . . . . . . .16

AVANT TOUTE UTILISATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Préparation précédant la mise en marche . . . . . . . . . . . . . . . . . . . . . .17

Montage du tuyau et du pistolet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Lubrification du moteur . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Carburant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

RACCORDEMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Tuyau haute pression . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Racordement d’eau . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

UTILISATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Procédure de lancement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Mise en marche du moteur . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Starting the Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

CHEMICAL INJECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

CLEANING TECHNIQUES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Application of Soap or Degreaser . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Application of Wax . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

END OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Nozzle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Water Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Engine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

STORAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Pump Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Engine Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

PERIODIC MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

ENGINE MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

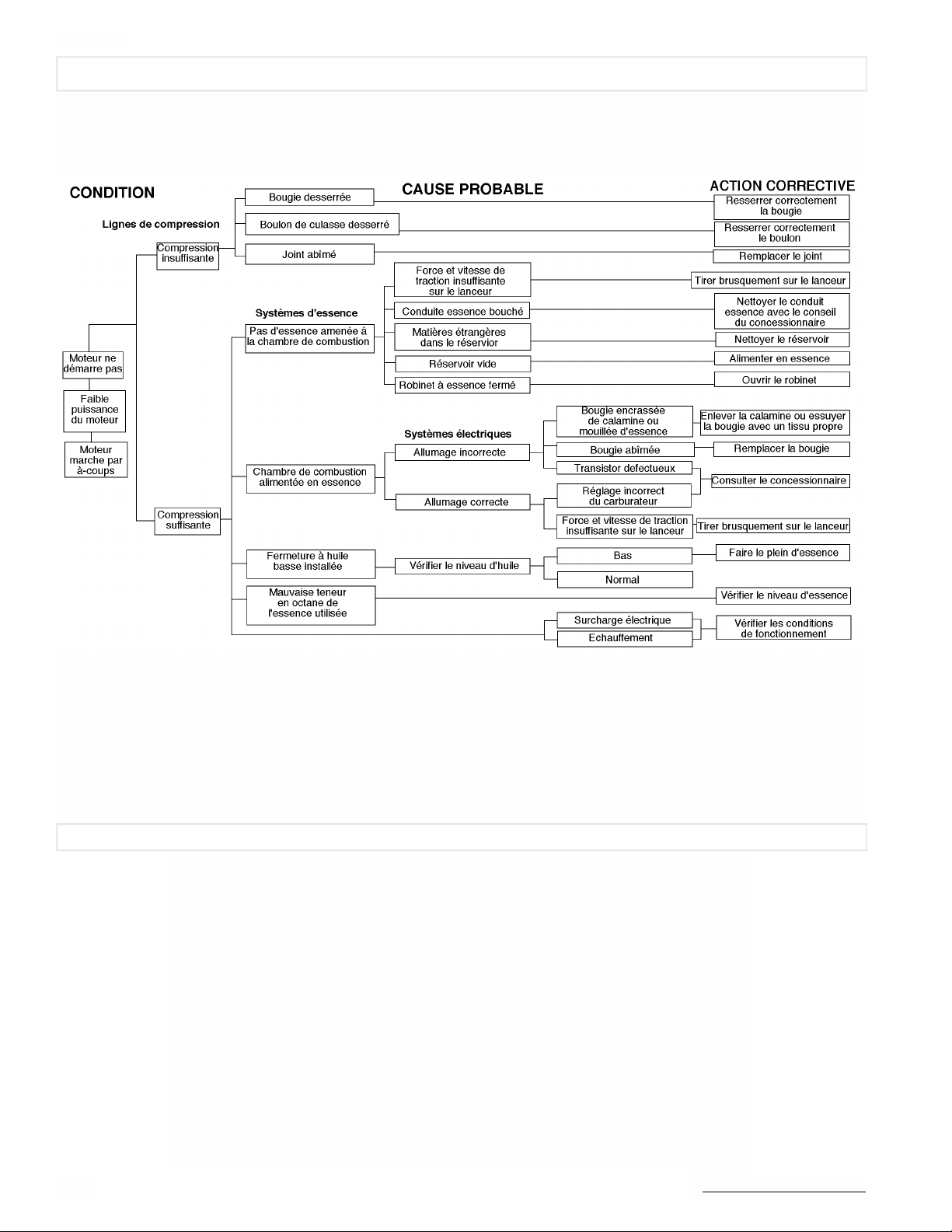

ENGINE TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

ENGINE SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

CALIFORNIA EMISSION CONTROL WARRANTY . . . . . . . . . . . . . .13

PARTS LIST AND PARTS DRAWING . . . . . . . . . . . . . . . . . . . . . . .38-42

UTILISATION DE PRODUITS CHIMIQUES . . . . . . . . . . . . . . . . . . . .18

TECHNIQUE DE NETTOYAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Application de Savon ou de Dégraissant . . . . . . . . . . . . . . . . . . . . . . .19

Application de Cire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

APRES UTILISATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

ENTRETIEN DE L'APPAREIL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Raccords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Ajutage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Filtre à eau . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Entretien du moteur . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

RANGEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Rangement de la pompe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Rangement du moteur . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

DÉPANNAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

GARANTIE LIMITÉE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

ENTRETIEN PÉRIODIQUE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

ENTRETIEN DU MOTEUR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

DÉPANNAGE DU MOTEUR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

CARACTERISTIQUES DU MOTEUR . . . . . . . . . . . . . . . . . . . . . . . . . .24

GARANTIE DE CONFORMITÉ AUX RÈGLEMENTS

ANTIPOLLUTION DE LA CALIFORNIE . . . . . . . . . . . . . . . . . . . . . . .25

LISTE DES PIÈCES ET SCHEMA DES PIÈCES . . . . . . . . . . . . . .38-42

INDICE

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

SERVICIO PARA LOS CLIENTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

SEGURIDAD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Símbolos de seguridad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Precauciones generales de seguridad . . . . . . . . . . . . . . . . . . . . . . . . . .27

CARACTERÍSTICAS DE SEGURIDAD . . . . . . . . . . . . . . . . . . . . . . . .28

Válvula de descarga de calor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Dispositivo de seguridad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Apagado por bajo nivel de aceite . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Silenciador apagachispas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

ESPECIFICACIONES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

SELECCIÓN DE BOQUILLA DE PULVERIZACIÓN . . . . . . . . . . . . .28

ANTES DE LA OPERACIÓN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Preparación incial . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Ensamblado de manguera y pistola . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Lubricación del motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Combustible . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

CONEXIONES DE OPERACIÓN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Manguera de alta presión . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Conexion de agua . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

INSTRUCCIONES DE OPERACIÓN . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Procedimiento de arranque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

2

Encendido del motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

INYECCION DE QUIMICOS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

TÉCNICAS DE LIMPIEZA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Aplicación de jabón y desgrasador . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Aplicación de cera . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

FIN DE LA APLICACIÓN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

MANTENIMENTO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Conexiones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Boquilla . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Rejilla de agua . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Mantenimiento del motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

ALMACENAMIENTO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Almacenamiento de la bomba . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Almacenamiento del motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

RESOLUCION DE PROBLEMAS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

GARANTIA LIMITADA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

MANTENIMIENTO PERIÓDICO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

MANTENIMIENTO DEL MOTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

DETECCION DE FALLOS DEL MOTOR . . . . . . . . . . . . . . . . . . . . . . .36

ESPECIFICACIONES DEL MOTOR . . . . . . . . . . . . . . . . . . . . . . . . . . .36

GARANTÍA DEL CONTROL DE EMISIÓN DE CALIFORNIA . . . . 37

LISTA DE PIEZAS Y DIAGRAMA DE PIEZAS . . . . . . . . . . . . . . .38-42

www.powermate.com

Page 3

Congratulations on purchasing a Coleman®

Powermate® Pressure Washer. Whether you are

doing light cleaning at home or are needing power

to do the tough jobs, Coleman® Powermate®

pressure washers are built to give you the power

you need. By following proper break-in

procedures, using recommended set-up and

operating procedures, and performing preventive

maintenance as specified in this manual, your

Coleman® Powermate® pressure washer will serve

you for years to come.

Most important is the safety of you and those

around you. Remember that while the Coleman®

Powermate® pressure washer gives you the power

you need to complete your job, safety rules should

always be followed.

Thank you for selecting our product.

English

Safety Symbols

The following symbols are used throughout this

manual. Follow listed instructions to ensure your

safety.

Indicates an imminently hazardous situation which,

if not avoided, will result in death or serious injury

Powermate Corporation

CUSTOMER SERVICE

Call our toll free number

1-800-445-1805

8 a.m. to 5 p.m. C.S.T.

or www.powermate.com

to obtain warranty service information or

order replacement parts or accessories.

Please have the following information available:

1.Model Number.

2.Serial Number.

3.Date and where purchased.

4.Replacement numbers if you are ordering parts.

Powermate Corporation

4970 Airport Road

P.O. Box 6001

Kearney, NE 68848

Attention: Warranty Service Department

Indicates a potentially hazardous situation which, if

not avoided, could result in death or serious injury.

Indicates a potentially hazardous situation exists,

which if not avoided, may result in minor or

moderate injury or product damage.

NOTE: Indicates operation or maintenance

information helpful to improve performance or

operation.

www.powermate.com

www.powermate.com

3

Page 4

English

The following Safety Precautions apply whenever using,

storing or servicing Coleman® Powermate® Pressure Washers

or their engines to reduce the possibility of personal injury.

Overlooking or ignoring these precautions can lead to personal

injury or product damage.

•Read this manual carefully. Know your equipment.

Consider applications, potential hazards and

limitations for your unit.

•Do not touch nozzle or water spray while operating.

•Wear safety goggles while operating.

•Only approved hoses and nozzles should be used.

•The trigger gun must not be jammed in position

during operation.

•Know your equipment. Consider the applications,

limitations, and the potential hazards specific to your

unit.

•Store the Pressure washer in a well ventilated area

with the fuel tank empty. Fuel should not be stored

near the pressure washer.

•Never operate under theses conditions:

a.A noticeable change in engine speed.

b.A noticeable loss of pressure.

c.The engine misfires.

d.Smoke or flames are present.

e.Enclosed compartment.

f.Excessive vibration.

g.Rain or inclement weather.

•Water spray must never be directed towards any

electric wiring or directly towards the pressure

washer.

•Do not allow the hose to come in contact with hot

muffler.

•Equipment must be placed on a firm, supporting

surface.

•Never tie knots or kink the high pressure hose.

•All hose connections must be properly sealed.

•Prior to starting the pressure washer in cold weather,

be sure ice has not formed in any part of the

equipment.

•Use only recommended chemicals.

•Outdoors use only.

•Place the pressure washer away from cleaning site

during operation.

•To prevent accidental discharge, the spray gun should

be secured by locking trigger when not in use.

•Do not run the pressure washer for more than five

minutes without depressing the trigger or damage to

the pump may result.

•Check the fuel system periodically for leaks or signs

of deterioration such as chafed or spongy hose, loose

or missing clamps, or damaged tank or cap. All

defects should be corrected before operation.

•Remove the spark plug or cable from the spark plug

to prevent accidental starting, when not in use, or

prior to detaching the high pressure hose.

•Keep the pressure washer clean and free of oil, mud

and other foreign matter.

•Do not wear loose clothing , jewelry, or anything that

may be caught in the engine.

•Never direct spray at people or pets.

•Never allow children to operate pressure washer at

any time.

•Use both hands to control the wand.

4

•Do not touch hot muffler.

•Service, operate and refuel under the following

conditions.

a.Good ventilation.

b.Refuel the pressure washer in a well lighted area.

c.Avoid fuel spills and never refuel while the

pressure washer is running.

d.Avoid an ignition source when refueling.

e.Use lead free fuel with a minimum of 85 octane.

•Do not smoke near the pressure washer.

•Do not use damaged high-pressure hoses.

www.powermate.com

Page 5

Up to 80°F

3/8” BSP

3/8” BSP

9 lbs.

4.7 fl. oz.

SAE 30W Nondetergent

The water stream discharged is

This is the nozzle used for

English

SAFETY FEATURES

THERMAL RELIEF VALVE

A thermal relief valve is provided to protect the pump

from overheating if the spray gun is closed for an extended

length of time or the nozzle becomes plugged. However, it is

intended to be used as a backup system and every effort

should be made to not permit the pump to heat up.

We recommend turning the pressure washer off if it will

not be used for more than five minutes. This saves wear on

the unit, reduces fuel consumption and extends the life of the

pump by avoiding heat.

SAFETY LOCK OFF LATCH

To prevent accidental discharge of high pressure water,

the safety latch on the trigger should be engaged whenever the

pressure washer is not in use. (Refer to Operating

Instructions.)

LOW-OIL SHUTDOWN

The unit is equipped with a low oil sensor. If the engine

oil level becomes lower than required, the pressure washer

will automatically shut off. This protects your pressure

washer engine from operating without proper lubrication.

If the pressure washer engine shuts off and the oil level is

according to specification, check to see if the pressure washer

is setting at an angle that forces oil to shift. Place on an even

surface to correct this. If the engine fails to start, the oil level

may not be sufficient to deactivate low oil level switch. Be

sure the sump is completely full of oil.

SPECIFICATIONS

Maximum Inlet Pressure . . . . . . . . . . . . . . . . . .Up to 90 PSIG

RPM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3600 RPM

Temperature of Pumped Fluids . . . . . . . . . . . . . . . .

Inlet Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Discharge Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Crankcase oil Capacity . . . . . . . . . . . . . . . . . . . . . . . .

Pump oil . . . . . . . . . . . . . . . . . . . . . . .

Consult the factory for special requirements that must be met

if the pump is to operate beyond one or more of the limits

specified above.

SPRAY NOZZLE SELECTION

Following is information concerning the four nozzles

provided with your pressure washer.

NOTE: The force of the spray on the surface you are

cleaning increases as you move closer to the surface.

0° High Pressure (Red):

very aggressive. Use with extreme caution to prevent damage

to the surface being cleaned or injury to persons or animals.

15° High Pressure (Yellow):

most cleaning applications. It provides wide coverage and a

powerful water stream.

40° High Pressure (White): This nozzle is used for

cleaning with a wider coverage over a larger area with a

powerful water stream.

65° Low Pressure (Black): Provides low pressure spray

and a wide coverage. Used primarily when operating the

chemical injector to apply chemicals.

The pump will overheat and may be damaged, or cause

damage if allowed to circulate more that five minutes.

SPARK ARRESTING MUFFLER

YOUR PRODUCT MAY NOT BE EQUIPPED WITH A SPARK

ARRESTING MUFFLER. If the product will be used around

flammable materials, such as agricultural crops, forests, brush, grass,

or other similar items, then an approved spark arrester should be

installed and is legally required in the State of California. The

California statutes requiring a spark arrester are Sections 13005(b),

4442 and 4443. Spark Arresters are also required on some U.S. Forest

Service land and may also be legally required under other statutes and

ordinances. An approved spark arrester is available from your

Coleman® Powermate® product dealer, or may be ordered from

Powermate Corporation, P.O. Box 6001, Kearney, Nebraska 68848.

1-800-445-1805.

www.powermate.com

5

Page 6

English

BEFORE OPERATION

NOTE: The engine and pump on your Coleman®

Powermate® Pressure Washer will often have improved

performance after a break-in period of several hours.

PRE-START PREPARATION

Before starting the pressure washer, check for loose or

missing parts and for any damage which may have occurred

during shipment.

HOSE AND GUN ASSEMBLY

NOTE: Align threaded connections carefully to

prevent damaging threads during assembly. Tighten

connections securely to prevent leaks during operation.

LUBRICATION

DO NOT attempt to start the pressure washer engine

without filling the engine crank case with the proper amount

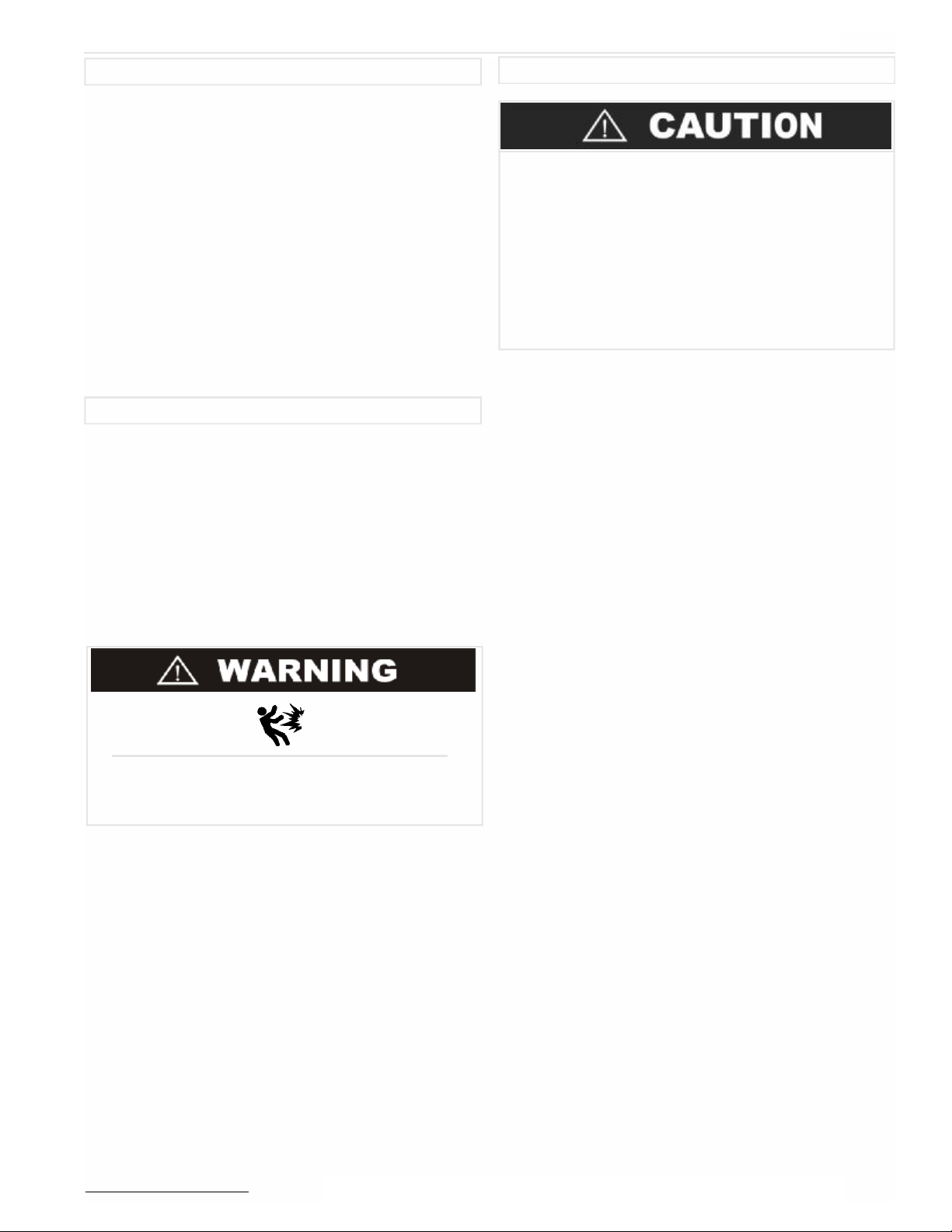

and type of oil (See pages 11 and 12 and Figure 2). Your

pressure washer engine has been shipped from the factory

without oil in the engine crankcase. Operating the unit without oil will ruin the engine.

The pump has been shipped with oil. Before operating

the pressure washer check the oil level of the pump to make

sure the oil level is to pump manufacturer’s required level.

(See Figure 2). Use oil that is recommended from the pump

manufacturer. DO NOT OVERFILL!

If the pump is not equipped with a dipstick or side glass

window check oil leaks from the pump. Pump oil is shipped

in the pump from factory. Follow pump manufacturer’s

maintenance schedule for proper care.

Attach the hose to the inlet of the trigger gun.

Handle Installation

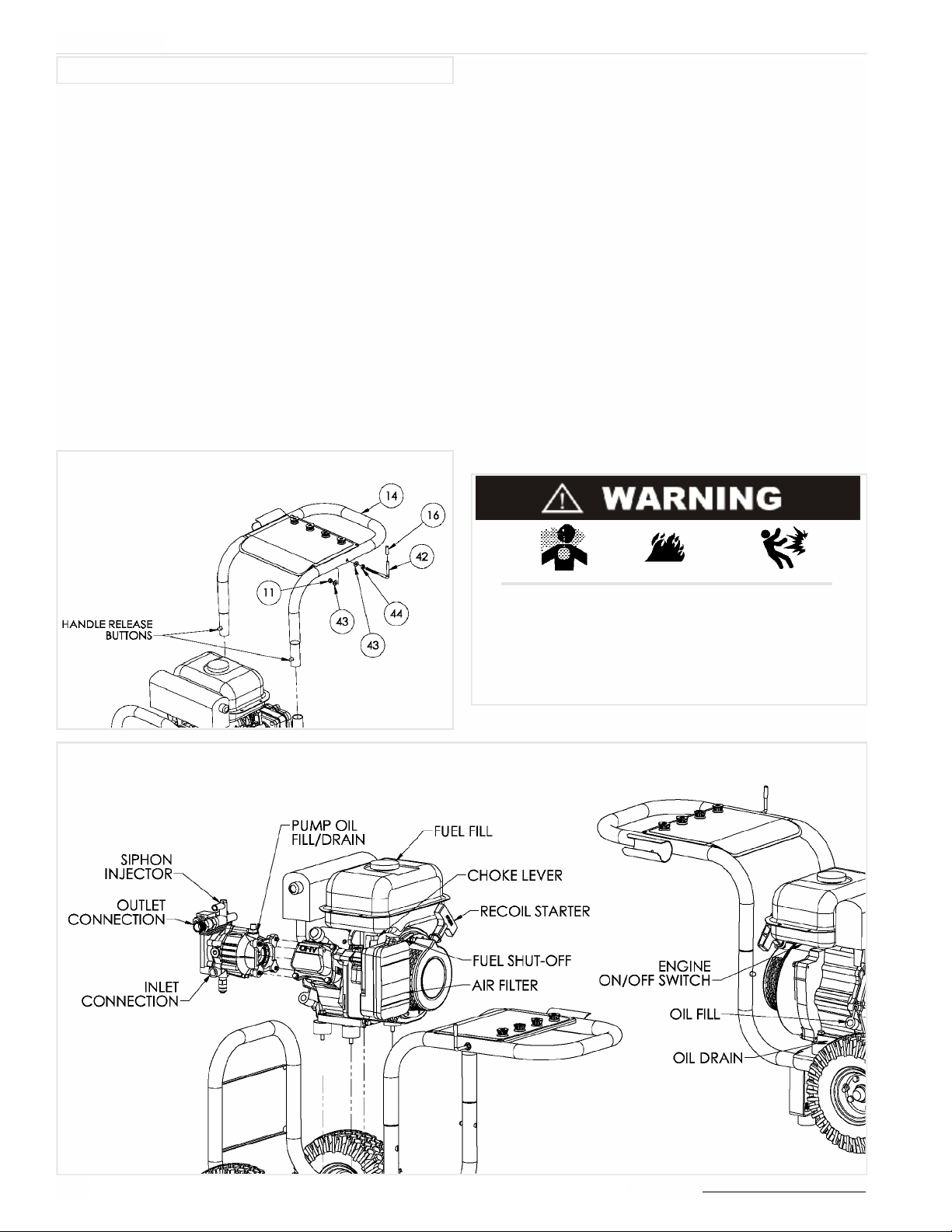

Install handle and hose hook as shown in Figure 1.

Figure 1

FUEL

Fill the tank with clean, fresh unleaded automotive

gasoline. (See Figure 2). Regular grade gasoline may be used

provided a high octane rating is obtained (at least 85 pump

octane).

Gasoline is very dangerous. Serious injury may result from

fire caused by gasoline contacting hot surfaces.

Do not overfill the tank. Keep maximum fuel level 1/2

inch below the bottom of the filler neck. This will allow

expansion in hot weather and prevent overflow.

Figure 2

www.powermate.com6

Page 7

when operating the chemical injector to apply chemicals.

When low pressure is required, grasp and slide the nozzle

English

OPERATING CONNECTIONS

HIGH PRESSURE HOSE

Attach the high pressure hose to the fitting located on the

pump. (See Figure 2, page 6).

NOTE: DO NOT use a high pressure hose from

another manufacturer.

WATER CONNECTION

Before connecting to unit, run water through the garden

hose (not supplied) to flush out any foreign matter. Check that

the screen is clean and is in the inlet of the pump. Attach

garden hose to the pressure washer water inlet. (See Figure 2,

page 6).

NOTE: The water supply must provide a minimum of

4 g.p.m. at 20 p.s.i. or the pump will be damaged.

OPERATING INSTRUCTIONS

START-UP PROCEDURE

1.Make sure water supply is connected and turned on.

2.Release gun safety if locked.

3.To allow air to escape from the hose, squeeze trigger on

the gun until there is a steady stream of water coming

from the nozzle.

4.Remove any dirt or foreign matter from the gun outlet and

the male connector of the wand.

5.Insert the nozzle wand into the gun wand and tighten the

twistfast fitting securely by hand.

CHEMICAL INJECTION

This pressure washer is intended for use only with

liquid car wash detergents, developed specifically for

pressure washer and with mild soaps. We recommend the

use of Coleman® Powermate® Pressure Washer Chemicals.

Only use chemicals compatible with the aluminum and brass

parts of the pressure washer. Powdered soaps may clog the

injection system. Always use chemicals according to

manufacturer directions. Powermate Corporation assumes

no responsibility for any damages caused by chemicals

injected through this pressure washer.

1.Attach injection tube assembly to the siphon injector on

the pump. (See Figure 2, page 6).

2.Open a container of Coleman® Powermate® Pressure

Washer Chemical and place next to the unit near the

injection tube.

3.Visually inspect strainer at the end of the injection tube to

verify that it is not clogged.

4.Insert the injection tube into the container all the way to

the bottom.

5.If chemical injection is adjustable, set injection rate by

turning valve clockwise until it is tight. Then turn valve

counterclockwise to increase injector rate and clockwise

to decrease injector rate.

If the wand is not securely locked into place, it could be

ejected under high pressure when operating the gun,

possibly causing injury or damage.

STARTING THE ENGINE (See Figure 2, page 6)

1.Check oil and fuel level.

2.Adjust choke prime as necessary.

3.Set the engine switch to the “ON” position.

4.Squeeze trigger on pressure washer to release pressure

while pulling on the engine starter rope with a fast steady

pull. Pressure may otherwise build up making starting the

unit difficult.

5.As the engine warms up, readjust the choke.

6.If your pressure washer is equipped with removable

nozzles, remove the high-pressure nozzle from the wand

and install the black injection nozzle. The solution will

automatically be mixed with the water and discharged

through the nozzle.

7.If your pressure washer is equipped with an adjustable

nozzle, the low pressure nozzle position should be used

cover away from the gun.

NOTE:For certain models, if the engine throttle is not in

the “fast” position, the injection of the solution

may be decreased or stopped.

www.powermate.com

7

Page 8

English

CLEANING TECHNIQUES

Cleaning Techniques

When cleaning with the pressure washer, many cleaning

tasks can be solved with water alone, but for most tasks it is

advantageous to use a detergent also. A detergent ensures a

quick soaking of the dirt allowing the high pressure water to

penetrate and remove the dirt more effectively.

Coleman® Powermate® Pressure Washer Chemicals are

specially formulated to be used with your pressure washer.

APPLICATION OF SOAP OR DEGREASER

1.Apply the solution to a DRY work surface.

On a vertical surface, apply horizontally from side to side

starting from the bottom to avoid streaking.

NOTE: Wetting the surface first is not recommended, as it

dilutes the detergent and reduces its cleaning ability.

Avoid working on hot surfaces or in direct sunlight to

minimize the chances of the chemical damaging painted

surfaces. Damage may occur to painted surface if

chemical is allowed to dry on the surface. Hold nozzle far

enough away from surface to prevent damage to the

surface.

MAINTENANCE

CONNECTIONS

Connections on pressure washer hoses, gun and spray

wand should be cleaned regularly and lubricated with the

manufacturer’s recommended grease to prevent leakage and

damage to the o-rings.

NOZZLE

If the high pressure/low pressure adjustment of the nozzle

becomes difficult, please contact Coleman® Powermate®

Customer Service Department for proper cleaning and

lubrication procedures.

Clogging of the nozzle causes the pump pressure to be too

high and cleaning is immediately required.

A nozzle cleaner must only be used when the spray wand is

disconnected from the gun or personal injury could result.

2.Allow chemical to remain on the surface for a short time

before rinsing.

3.Rinse with clean water under high pressure. On a vertical

surface, first rinse from the bottom up, then rinse from the top

down. Hold nozzle 6 to 8 inches from the work surface at a

45° angle using the flat spray as a peeling tool rather than a

scrub brush.

APPLICATION OF WAX

1.Immediately after cleaning, apply Coleman®

Powermate® Pressure Washer Wax. Place injection tube

in container of wax.

2.Apply the wax sparingly in an even layer. Apply to wet

surfaces from the bottom up for even distribution and to

avoid streaking.

3.Remove the suction tube from the wax bottle and rinse off

the surplus wax.

NOTE: IF SURPLUS WAX IS NOT REMOVED, A

HAZY FINISH MAY RESULT.

4.Wipe dry to reduce water spotting.

END OF OPERATION

End of Operation

When you have completed use of the chemical injection

system, remove tube from container. Continue to run in low

pressure position and inject clean water through the tube and

injection system by placing end of tube in a container of clean

water. Continue to run until it is thoroughly cleaned.

1.Separate the wand from the gun.

2.Clear the nozzle with a small rigid piece of wire such as a

paper clip.

3.Flush the nozzle backwards with water.

4.Reconnect the wand to the gun.

Restart the pressure washer and depress the trigger on the

spray gun. If the nozzle is still plugged or partially plugged,

repeat above items 1-4.

If the previous procedure does not clear the nozzle,

replace with a new nozzle.

WATER SCREEN

The pressure washer is equipped with a water inlet screen

to protect the pump. If the screen is not kept clean, it will

restrict the flow of water to the pressure washer and may

cause damage to the pump. Do not damage the screen while

removing or cleaning screen. Any foreign particles entering

the pump may damage the pump. Do not operate pressure

washer without the screen in place.

Remove the screen and back flush to remove impurities

from screen. Replace immediately.

ENGINE MAINTENANCE

During the winter months, rare atmospheric conditions

may develop which will cause an icing condition in the

carburetor. If this develops, the engine may run rough, lose

power, and may stall. This temporary condition can be

overcome by deflecting some of the hot air from the engine

over the carburetor area.

NOTE: Refer to pages 11 and 12 for service and

maintenance of the engine.

www.powermate.com8

Page 9

Engine may be covered exclusively by a separate warranty from

Warranty applies only if the product is used solely for consumer

STORAGE LIMITED WARRANTY

English

PUMP STORAGE

If you must store your pressure washer in a location where the

temperature is below 32°F, you can minimize the chance of damage

to your machine by utilizing the following procedure:

1.Shut off water supply and relieve pressure in the spray gun

by depressing the trigger. Disconnect the garden hose

from the pressure washer, but leave the high-pressure hose

connected.

2.Tip the unit on its side with the inlet connection pointing up.

3.Insert a small funnel (to prevent spilling) into the inlet

and pour in approximately 1/4 cup of RV antifreeze.

4.Disconnect spark plug wire.

5.Without connecting garden hose pull the recoil several

times to circulate the antifreeze in the pump system.

Continue to add antifreeze and pull the recoil until the

antifreeze is expelled when the trigger is pulled.

6.Turn the unit upright.

Prior to restarting, thaw out any possible ice from the

pressure washer hoses, spray gun and wand.

Another method of reducing risks of freeze damage is to drain

your pressure washer as follow:

1.Stop the pressure washer and detach supply hose and high

pressure hose. Squeeze the trigger of the discharge gun to

drain all water from the wand and hose.

2.Restart the pressure washer and let it run briefly (about 5

seconds) until water no longer discharges from the high

pressure outlet.

ENGINE STORAGE

When the pressure washer is not being operated or is being

stored more than one month, follow these instructions:

1.Replenish engine oil to upper level.

2.Drain gasoline from fuel tank, fuel line, fuel valve and

carburetor.

3.Pour about one teaspoon of engine oil through the spark

plug hole, pull the recoil starter several times and replace

the plug. Then pull the starter slowly until you feel

increased pressure which indicates the piston is on its

compression stroke and leave it in that position. This

closes both the intake and exhaust valves to prevent the

inside of the cylinder from rusting.

Warranty Coverage: Powermate Corporation (the Company)

warrants to the original retail customer in North America that it will

repair or replace, free of charge, any parts found by the Company or

its authorized service representative to be defective in material or

workmanship. This warranty covers the cost of replacement parts

and labor for defects in material or workmanship.

Not Covered:

· Transportation charges for sending the product to the Company

or its authorized service representative for warranty service, or

for shipping repaired or replacement products back to the

customer; these charges must be borne by the customer.

·

the engine manufacturer as set forth in the engine Manual (if

included).

· Damages caused by abuse or accident, and the effects of

corrosion, erosion and normal wear and tear.

· Warranty is void if the customer fails to maintain and operate

the product as instructed and recommended by the Company in

the owner's manual.

·

applications, and does not apply if the product is used for

commercial or business applications, or as rental equipment.

· The Company will not pay for repairs or adjustments to the

product, or for any costs or labor, performed without the

Company's prior authorization.

Warranty Period: One (1) year from the date of purchase. For

warranty service, the customer must provide dated proof of purchase

and must notify the Company within the warranty period.

For warranty service: Call toll free 800-445-1805, or write to

Powermate Corporation, Product Services, 4970 Airport Road, P. O.

Box 6001, Kearney, NE 68848.

EXCLUSIONS AND LIMITATIONS: THE COMPANY MAKES

NO OTHER WARRANTY OF ANY KIND, EXPRESS OR

IMPLIED. IMPLIED WARRANTIES, INCLUDING

WARRANTIES OF MERCHANTABILITY AND OF FITNESS FOR

A PARTICULAR PURPOSE, ARE HEREBY DISCLAIMED. THE

WARRANTY SERVICE DESCRIBED ABOVE IS THE

EXCLUSIVE REMEDY UNDER THIS WARRANTY; LIABILITY

FOR INCIDENTAL AND CONSEQUENTIAL DAMAGES IS

EXCLUDED TO THE EXTENT PERMITTED BY LAW.

This warranty gives you specific legal rights, and you may also have

other rights which vary from state to state. Some states do not allow

a disclaimer of implied warranties, or the exclusion or limitation of

incidental and consequential damages, so the above disclaimers and

exclusions may not apply to you.

4.Cover the pressure washer and store in a clean, dry place

that is well ventilated away from open flame or sparks.

NOTE: The use of a fuel additive, such as Coleman®

Powermate® Generator Fuel Additive, or an equivalent, will

minimize the formulation of fuel gum deposits during storage,

Such an additive may be added to the gasoline in the fuel tank of

the engine, or to the gasoline in a storage container.

www.powermate.com

9

Page 10

English

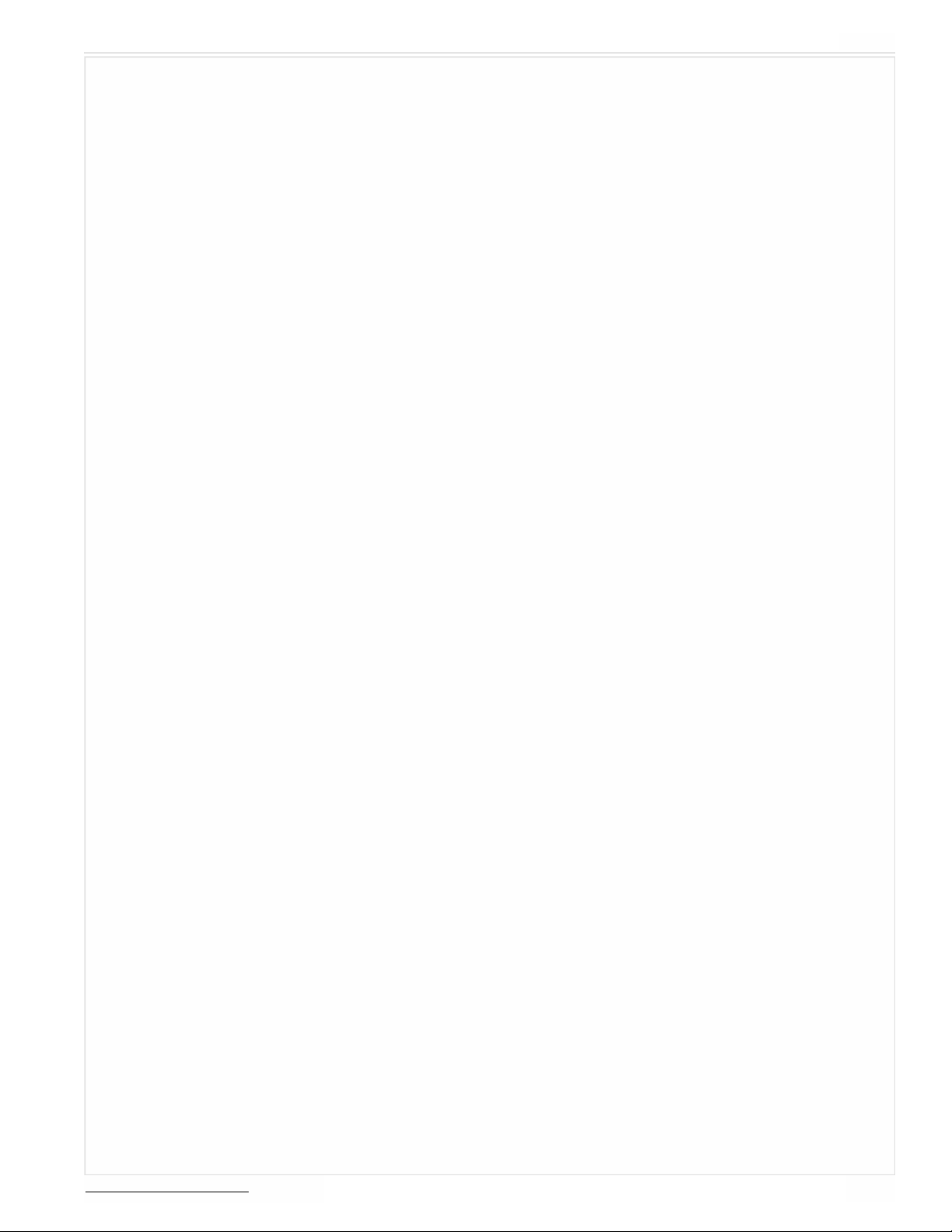

PROBLEM

POSSIBLE CAUSE

CORRECTION

Engine will not start or stops while

operating.

Engine is overloaded.

Water or oil leaking from bottom of pump.

Pressure increases when gun is closed.

Engine running but pump not building

maximum pressure or has irregular

pressure.

Low-oil shutdown.

Engine switch not in the “ON” position.

Pressure build up in hose.

Nozzle partially blocked.

Excessive pressure.

A small amount of leakage is normal.

Bypass valve not operating properly.

Faucet closed

Unit has been stored in freezing

temperatures.

Inadequate water supply.

Water inlet screen clogged.

Kink in garden hose.

Wand nozzle worn or damaged.

Air in pump.

Adjustable pressure knob not set to

maximum position.

Suction or discharge valves clogged or

worn out.

By-pass valve not operating effectively.

Fill engine with oil.

Turn switch “ON”.

Squeeze trigger.

Clean nozzle.

Reduce pressure by using pressure

adjustment knob

If excessive leaking occurs call the

Customer Service Department.

Call the Customer Service Department.

Open faucet.

Thaw out unit completely including hose,

gun and wand.

Provide a minimum of 4 gpm at 20 psi.

Clean screen.

Straighten hose

Replace nozzle,

Let run with gun open and wand removed

until steady stream of water is released.

Set to maximum position.

Call the Customer Service Department.

Call the Customer Service Department.

No intake of chemicals

Trigger will not move.

Water in crankcase.

Noisy operation.

Rough/pulsating operation with pressure

drop.

Injection tube not securely inserted into

unit.

Tube cracked or split.

Wrong nozzle.

Injector turned off.

Injection tube strainer clogged.

Nozzle blocked.

Dried chemicals injector.

Gun safety lock engaged.

High humidity.

Worn seals.

Worn bearings

Air mixed with water.

Worn packing.

Inlet restriction.

Unloader.

Air mixed in water.

Push firmly into injector.

Replace tubing.

Switch to low pressure nozzle.

Turn collar counter clockwise.

Clean strainer.

Clean nozzle.

Dissolve by running warm water trough the

injection tube.

Release safety lock.

Change oil more frequently.

Call the Customer Service Department.

Call the Customer Service Department.

Check inlet lines for restrictions and /or

proper sizing.

Call the Customer Service Department.

Check system for stoppage, air leaks,

correctly sized inlet plumbing to pump.

Check unloader for proper operation.

Check inlet lines for restrictions and/or

proper sizing.

High crankcase temperatures.

Wrong grade of oil.

Improper amount of oil in crankcase.

Use recommended oil.

Adjust oil level to proper amount.

www.powermate.com10

Page 11

Open the oil drain plug and let oil drain completely into a

PERIODIC MAINTENANCE

English

ITEM NOTES

Spark Plug

Engine Oil Check oil level.

Air Filter Clean, replace if necessary.

Fuel Filter

Fuel Line

Exhaust

System

Carburetor Check choke operation.

Starting

System

Fittings/

Fasteners

Check condition. Adjust gap and

clean. Replace if necessary.

Replace.

Clean fuel filter and fuel tank strainer.

Replace if necessary.

Check fuel hose for cracks or other

damage. Replace if necessary.

Check for leakage. Retighten or

replace gasket if necessary.

Check muffler screen. Clean/replace

if necessary.

Check recoil starter operation.

Check. Replace if necessary.

Daily (Before

operation)

ü

ü

ü

ü

ü

Initial

20 hours

Every

50 hours

ü

ü ü

ü

Every

100 hours

ü

ü

ü

ENGINE MAINTENANCE

SPARK PLUG

Remove the spark plug and clean the electrodes section

with a wire brush or sandpaper. Next, set the gap at .028/.031

inches (0.7-0.8 mm) by adjusting the negative electrode.

Replace the spark plug with correct torque: 14 ft-lb (20 N.m)

Replace with only the same type of spark plug which

was removed. An improper spark plug can cause the

engine to overheat, emit smoke, or otherwise perform

poorly.

OIL TYPE

Use new good quality oil, SE, SF, or SD grade. The oil to

be used depends upon the temperature at which the engine is

operated:

Below 32° F (0° C) . . . . . . . . .SAE 10W, 10W-30, or 10W-40

32 to 80° F (0 to 25° C) . . . . . .SAE 20W, 10W-30, or 10W-40

80 to 95° F (25 to 35° C) . . . . .SAE 30W, 10W-30, or 10W-40

Above 95° F (35° C) . . . . . . . . . . . . . . . . . . . . . . . . .SAE 40W

OIL REPLACEMENT

1.Change oil while engine is warm.

2.Place the generator unit on a level surface.

3.Remove the oil filler cap.

4.

pan placed under the engine.

5.Check gaskets. Replace if required.

6.Reinstall the oil drain plug and refill engine with clean

oil.

7.Replace the oil filler cap.

AIR FILTER CLEANING

1.Unscrew the air filter cover.

2.Remove filter element and wash well in solvent.

3.Pour a small amount of oil onto the filter element and

gently squeeze out any excess oil.

4.Replace the filter element and air filter cover.

5.Be sure the filter cover seals properly all around.

FUEL VALVE FILTER CLEANING

1.Remove the cup at the bottom of the fuel valve with a

small wrench.

2.Remove the fuel valve filter.

3.Clean and wash out the filter and cup and replace.

FUEL STRAINER CLEANING

1.Remove the plastic fuel strainer, located below the fuel

tank cap.

2.Wash the strainer in solvent and replace.

11www.powermate.com

Page 12

English

ENGINE TROUBLESHOOTING

ENGINE SPECIFICATIONS

Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-stroke, single cylinder, gasoline, OHV

Displacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .171 cc, 10.44 cubic inches

Maximum HP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5.5 HP @ 3600 rpm

Starting System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Recoil (electronic ignition)

Driving System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Direct coupling, tapered crank

Oil Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . 20 oz.

Spark Plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Champion RN14YC or equivalent

Governor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Mechanical (adjustable)

Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Forced air cooling

Bore x Stroke . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66.0 X 50.0 mm (2.60 x 1.97 in.)

Carburetor Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Float

Air Cleaner Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Foam element

www.powermate.com12

Page 13

English

CALIFORNIA EMISSION CONTROL WARRANTY STATEMENT

YOUR WARRANTY RIGHTS AND OBLIGATIONS

The California Air Resources Board and Powermate Corporation (herein "Powermate") are pleased to explain the evaporative emission

control system (EECS) warranty on your 2006 pressure washer. In California, new pressure washers must be designed, built and equipped

to meet the State's stringent anti-smog standards. Powermate must warrant the EECS on your pressure washer for the periods of time

listed below, provided there has been no abuse, neglect or improper maintenance of your pressure washer.

Your EECS includes parts such as: fuel hoses.

MANUFACTURER'S WARRANTY COVERAGE:

This evaporative emission control system is warranted for two years. The warranty period begins on the date the pressure washer is

delivered to an ultimate purchaser.

Powermate warrants to the ultimate purchaser and any subsequent owner that the pressure washer is (i) designed, built and equipped so as

to conform with all applicable regulations; and (ii) free from defects in materials and workmanship that cause the failure of a warranted

part to be identical in all material respects to that part as described in Powermate's application for certification.

If any evaporative emission-related part on your pressure washer is defective, the part will be repaired or replaced by Powermate.

OWNER'S WARRANTY RESPONSIBILITIES:

As the pressure washer owner, you are responsible for performance of the required maintenance listed in your owner's manual.

Powermate recommends that you retain all receipts covering maintenance on your pressure washer, but Powermate cannot deny warranty

solely for the lack of receipts. You should, however, be aware that Powermate may deny you warranty coverage if your pressure washer

or a part has failed due to abuse, neglect or improper maintenance or unapproved modifications.

You are responsible for presenting your pressure washer to an authorized Powermate warranty service center as soon as the problem

exists. The warranty repairs should be completed in a reasonable amount of time, not to exceed 30 days. If you have a question regarding

your warranty coverage, you should call Powermate Product Service at 1-800-445-1805.

DETAILS OF YOUR WARRANTY

Subject to certain conditions and exclusions as stated below, the warranty on emission-related parts is as follows:

(1)Any warranted part that is not scheduled for replacement as required maintenance in the written instructions supplied, is warranted

for the period stated above. If the part fails during the period of warranty coverage, the part will be repaired or replaced by

Powermate according to Subsection (4) below. Any such part repaired or replaced under warranty will be warranted for the

remainder of the period.

(2)Any warranted part that is scheduled only for regular inspection in the written instructions supplied, is warranted for the warranty

period stated above. Any such part repaired or replaced under warranty will be warranted for the remaining warranty period.

(3)Any warranted part that is scheduled for replacement as required maintenance in the written instructions supplied, is warranted for

the period of time before the first scheduled replacement date for that part. If the part fails before the first scheduled replacement

date, the part will be repaired or replaced by Powermate according to Subsection (4) below. Any such part repaired or replaced under

warranty will be warranted for the remainder of the period prior to the first scheduled replacement date for the part.

(4)Repair or replacement of any warranted part under the warranty provisions herein must be performed at an authorized Powermate

warranty service center at no charge to the owner.

(5)The pressure washer owner will not be charged for diagnostic labor that is directly associated with diagnosis of a defective,

emission-related warranted part, provided that such diagnostic work is performed at an authorized Powermate warranty service

center.

(6)Powermate is liable for damages to other engine or pressure washer components proximately caused by a failure under warranty of

any warranted part.

(7)Throughout the pressure washer warranty period stated above, Powermate will maintain a supply of warranted parts sufficient to

meet the expected demand for such parts.

(8)Any replacement part may be used in the performance of any warranty maintenance or repairs and must be provided without charge

to the owner. Such use will not reduce the warranty obligations of Powermate.

(9)Add-on or modified parts that are not exempted by the Air Resources Board may not be used. The use of any non-exempted add-on

or modified parts by the ultimate purchaser will be grounds for disallowing a warranty claims. Powermate will not be liable to

warrant failures or warranted parts caused by the use of a non-exempted add-on or modified part.

(10)The repair or replacement of any warranted part otherwise eligible for warranty coverage may be excluded from such warranty

coverage if the pressure washer has been abused, neglected or improperly maintained, and such abuse, neglect or improper

maintenance was the direct cause of the need for repair or replacement of the part.

WARRANTED PARTS:

The following emission warranty parts list is covered:

Fuel Hose.

13www.powermate.com

Page 14

Français

Félicitations pour votre achat de nettoyeur haute

pression Coleman® Powermate®. Que ce soit pour

des travaux de nettoyage ordinaire à la maison ou

pour des travaux plus difficiles, les laveuses

Coleman® Powermate® ont été conçues pour vous

offrir la puissance dont vous avez besoin. Votre

laveuse à pression Coleman® Powermate® vous

rendra service pendant des années. Pour cela, suivre

les procédures de rodage, les procédures de

préparation et d'utilisation, et effectuer l'entretien

préventif selon les indications de ce document, ainsi

que du manuel relatif au moteur, qui l'accompagne.

Le plus important, c'est votre propre sécurité et

celle de votre entourage. Ne pas oublier que, si la

laveuse à pression Coleman® Powermate® vous

offre toute la puissance dont vous avez besoin, il ne

faut pas pour autant mettre de côté les règles de

sécurité.

Symboles Utilisés

Les symboles suivants sont utilisés dans ce

manuel. Pour votre sécurité, suivre les consignes

indiquées.

Indique une situation présentant un danger imminent

et qui, en l'absence d'intervention, peut conduire à la

mort ou entraîner de graves blessures.

Merci d'avoir choisi notre produit.

Powermate Corporation

SERVICE CLIENTELE

Appeler notre numére numéro gratuit

1-800-445-1805

ou www.powermate.com

pour tous renseignements concernant la garantie ou

pour commander des pièces de rechange ou des

accessoires.

Veuillez être prêt a donner les renseignements

suivants:

1.Numéro de modèle

2. Numéro de série.

3. Date et lieu d’achat.

4. Référence des pièces en cas de commande de

pièces de rechange.

Indique une situation présentant un danger potentiel

et qui, en l'absence d'intervention, pourrait conduire

à la mort ou entraîner de graves blessures.

Indique une situation présentant un danger potentiel

et qui, en l'absence d'intervention, pourrait entraîner

des blessures légères ou endommager le produit.

NOTE : indique des renseignements sur l'utilisation

ou l'entretien, qui peuvent améliorer les

performances ou le fonctionnement.

Powermate Corporation

4970 Airport Road

P.O. Box 6001

Kearney, NE 68848

Attention: Warranty Service Department

www.powermate.com

www.powermate.com14

Page 15

Les mesures de sécurité ci-après doivent être prises lors

de l'utilisation, du stockage ou de l'entretien d'une nettoyeur

haute pression Coleman® Powermate® ou de son moteur, afin

de réduire le risque de blessures corporelles. En ne suivant pas

ou en ignorant ces précautions, il peut y avoir blessures ou

endommagement du produit.

Français

•Ne pas toucher à la buse ou au jet d'eau, lorsque l'appareil

fonctionne.

•Porter des lunettes de protection en travaillant.

•N'utiliser que des flexibles et des buses approuvées.

•Lire attentivement ce manuel. Apprenez à bien

connaître votre équipement. Examiner les utilisations

possi bles, les dangers potentiels et les limitations de

votre machine.

•Se familiariser avec l'appareil et tenir compte des

domaines d'usage, des restrictions et des risques

potentiels qui découlent de son utilisation.

•Stocker le nettoyeur dans un endroit bien ventilé,

avec le réservoir de carburant vide. Ne pas stocker

de carburant près de la génératrice.

•Ne jamais utiliser dans les conditions suivantes :

a.Une variation importante du régime moteur.

b.Une perte de pression notable.

c.Le moteur a des ratés.

d.Présence de fumée ou de flammes.

e.Compartiment fermé.

f.Vibration excessive.

g.Pluie ou mauvais temps.

•Ne jamais diriger le jet d'eau vers des câbles

électriques ou directement sur le nettoyeur.

•Le pistolet à gâchette ne doit pas rester bloqué en

position lors de l'utilisation.

•Ne jamais faire de nœuds dans le flexible haute pression,

ni le pincer.

•Les raccords de flexible doivent être étanches.

•Par temps froid, avant de faire démarrer le nettoyeur,

s'assurer qu'il n'y a pas de glace en aucun endroit de

l'équipement.

•N'utiliser que des produits chimiques recommandés.

•Pour usage extérieur seulement.

•Éloigner le nettoyeur haute pression de la surface de

nettoyage durant le fonctionnement.

•Afin d'éviter toute décharge accidentelle, bloquer la

gâchette du pistolet de pulvérisation, lorsqu'il n'est pas

utilisé.

•Pour éviter d'endommager la pompe, ne pas faire

fonctionner le nettoyeur plus de cinq minutes sans appuyer

sur la gâchette.

•Éviter tout contact du flexible avec le silencieux

chaud.

•Placer l'équipement sur une surface plane et ferme.

•Retirer la bougie ou le fil de bougie, afin

d'empêcher tout démarrage accidentel, lorsque

l'appareil n'est pas en service ou avant de débrancher

le flexible haute pression.

•Le nettoyeur doit rester propre, sans traces d'huile, de

boue et d'autres corps étrangers.

•Ne pas porter de vêtements amples, de bijoux ou

quoi que ce soit qui pourrait se prendre dans le

moteur.

•Ne jamais diriger le jet sur des personnes ou des

animaux domestiques.

•Ne jamais autoriser un enfant à se servir d'un

nettoyeur haute pression.

•Tenir la lance à deux mains.

•Vérifier de temps en temps le circuit de carburant, à la

recherche de fuites ou de signes de détérioration :

flexible usé par frottement ou spongieux, colliers

desserrés ou manquants, réservoir ou bouchon

endommagé. Corriger les défauts avant utilisation de la

machine.

•Ne pas toucher au silencieux, lorsqu'il est chaud.

•Pour les interventions d'entretien, l'utilisation et le rem

plissage de carburant, respecter les conditions suivantes.

a.Bonne ventilation.

b.Faire le plein de carburant du nettoyeur dans un endroit

bien éclairé.

c.Éviter tout déversement de carburant et ne jamais faire

le plein lorsque la machine est en marche.

d.Ne pas faire de plein en présence d'une source

d'inflammation.

e.Utiliser un carburant sans plomb, avec indice d'octane

de 85 au minimum.

•Ne pas fumer à proximité de la laveuse.

•Ne pas se servir d'un flexible haute pression endommagé.

15www.powermate.com

Page 16

Français

MESURES DE SÉCURITÉ

SOUPAPE DE SURPRESSION THERMIQUE

La soupape de surpression thermique a pour but de

protéger la pompe de toute surchauffe si le pistolet de

pulvérisation est fermé durant une longue période ou si la buse

s’engorge. Toutefois, elle est conçue comme système

auxiliaire et l’on doit faire tous les efforts possibles pour

empêcher la pompe de surchauffer.

Nous recommandons d’arrêter le nettoyeur haute pression

si l’on ne prévoit pas de l'utiliser durant plus de cinq minutes.

Ceci évite l’usure de l’appareil, réduit la consommation de

carburant et prolonge la vie de la pompe en évitant la

surchauffe.

LOQUET DE SÉCURITÉ

Pour éviter tout déversement accidentel d’eau sous haute

pression, le loquet de sécurité sur la gâchette devrait être en

place lorsque le nettoyeur haute pression n’est pas utilisé.

(Reportez-vous aux instructions d’utilisation.)

ARRÊT SUITE AU BAS NIVEAU D’HUILE

Le système est équipé d'un détecteur de bas niveau

d'huile. Si le niveau d’huile du moteur est plus bas que celui

exigé, le nettoyeur haute pression s’arrêtera automatiquement.

Ceci portège le moteur de votre nettoyeur haute pression en

l’empêchant de fonctionner sans le niveau de lubrification

voulu.

Si le moteur de votre nettoyeur haute pression s’arrête et

si le niveau d’huile respecte les spécifications, vérifiez si le

nettoyeur haute pression n’est pas installé à un angle qui force

l’huile à se déplacer. Installez sur une surface plane pour

corriger ce problème. Si le moteur refuse de démarrer, le

niveau d’huile n’est peut-être pas suffisant pour désactiver

l’interrupteur de bas niveau d’huile. Assurez-vous que le

carter est rempli d'huile.

SPÉCIFICATIONS

Pression maximale d'entrée . . . . . . .Jusqu'à 90 psig (620 kPa)

R/MIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3600 R/MIN

Température des fluides pompés . . . . . .Jusqu'à 80 °F (27 °C)

Orifices d'entrée . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3/8² BSP

Orifices de refoulement . . . . . . . . . . . . . . . . . . . . . . . .3/8² BSP

Poids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 lb (4 kg)

Capacité du carter en huile . . . . . . . . . .4.7 oz fluides (0,14 L)

Vérifier le facteur de correction à utiliser en cas d'exigences spéciales à satisfaire par la pompe, lorsqu'elle doit

fonctionner au-delà d'une ou plusieurs des limites indiquées

ci-dessus.

CHOIX DE BUSE DE PULVÉRISATION

Voici les renseignements concernant les quatre buses fournies

avec votre nettoyeur haute pression.

Remarque: La force du jet sur la surface à nettoyer

augmente lorsque vous rapprochez kde la surface avec la

baguette.

0° Haute Pression (Rouge): Le jet d’eau déchargé est

très agressif. Utilisez avec soin pour ne pas endommager la

surface nettoyée ou blesser les personnes ou les animaux.

15° Haute Pression (Jaune): Voici la buse utilisée pour

la plupart des applications de nettoage. Elle offre une vaste

couverture et un et d’eau puissant.

40° Haute Pression (Pâle): Voici la buse utilisée pour la

plupart des applications de nettoage une grand la zone. Elle

offre une vaste couverture et un et d’eau puissant.

65° Basse Pression (Noir): Offre un jet de basse pression et une vaste couverture. Utilisé principalemetn avec l’injecteur chimique pour appliquer des produits chimiques.

La pompe surchauffera et peut être endommagée si on la

laisse recycler pendant plus de cinq minutes.

SILENCIEUX PARE-ÉTINCELLES

VOTRE PRODUIT PEUT NE PAS ÊTRE MUNI D'UN

SILENCIEUX PARE-ÉTINCELLES. S’il doit être utilisé à proximité

de matériaux inflammables, tels que des récoltes, des forêts, des

broussailles, des herbes ou autres, il est fortement recommandé

d’installer un pare-étincelles, par ailleurs obligatoire en Californie.

L’usage d’un pare-étincelles pourrait également être exigé par

d’autres lois et règlements. Un pare-étincelles homologué est

disponible auprès de votre concessionnaire Coleman® Powermate®

ou peut être commandé à Powermate Corporation, P. O. Box 6001,

Kearney, Nebraska 68848. Téléphone : 1-800-445-1805.

www.powermate.com16

Page 17

Si la pompe ne possède pas de jauge d'huile ou de voyant

pompe. La pompe est expédiée de l'usine avec son huile. Pour

AVANT TOUTE UTILISATION

REMARQUE: Le moteur et la pompe de votre

nettoyeur haute pression Coleman® Powermate®

fonctionneront beaucoup mieux après une période de

rodage de plusieurs heures.

PRÉPARATION PRECEDANT LA MISE EN MARCHE

Avant de mettre en marche le nettoyeur haute pression,

vérifiez qu’il n’y a aucune pièce desserrée et manquante ainsi

que pour tout dommage survenu lors de l’expédition.

Français

LUBRIFICATION DU MOTEUR

N’essayez PAS de faire démarrer le moteur du nettoyeur

sans remplir l’arbre coudé du moteur de la bonne quantité et

sorte d’huile (Voir pages 22 et 23 et Figure 2). On a expédié

le moteur de votre nettoyeur de l’usine sans huile dans l'arbre

coudé du moteur. Vous pouvez détruire le moteur en faisant

fonctionner l’appareil sans huile.

La pompe a été livrée avec le plein d'huile. Avant

d'utiliser la laveuse à pression, vérifiez le niveau d'huile de la

pompe afin qu'il corresponde aux directives du fabricant.

(Voir Figure 2). Utilisez l'huile recommandée par le fabricant

de la pompe. NE PAS LA REMPLIR À L'EXCÈS.

MONTAGE DU TUYAU ET DU PISTOLET

REMARQUE: Alignez les raccords filetés avec soin

pour ne pas endommager les fils en assemblant. Resserrez

bien tous les raccords afin d’éviter toute fuite lorsque

l’appareil est en marche.

Fixez le tuyau à l’arrivée de la gâchette du pistolet.

MONTAGE DE LA POIGNÉE

Installer la poignée et le crochet de tuyau selon la Figure 1.

Figure 1

BOUTONS DE

DÉCLENCHEMENT

DE POIGNÉE

latéral à glace, vérifier s'il n'y a pas de fuites d'huile par la

un bon entretien, suivre le programme recommandé par le

fabricant de la pompe.

CARBURANT

Remplissez le réservoir avec de l’essence d'automobile

propre, fraîche sans plomb. (Voir Figure 2). On peut utiliser

l’essence régulière si l’on a un indice d’octane élevé (au

moins d’indice 85).

L’essence est très dangereuse. De sérieuses blessures peuvent résulter d'un feu causé par l’esence entrant en contact

avec des surfaces chaudes.

Ne pas trop remplir le réservoir. Maintenir le niveau

d’essence maximum à deux centimètres au-dessous du haut

du goulot de remplissement. Ceci permet l’expansion du

carburant pendant les périodes de chaleur et empêche

l’essence de déborder.

Figure 2

17www.powermate.com

Page 18

Français

RACCORDEMENTS

TUYAU HAUTE PRESSION

Fixer les tuyaux haute pression à l'endroit prévu qui se

trouve en pompe. (Voir Figure 2, page 16).

REMARQUE: Ne PAS utiliser un haut tuyau de pression d'un

autre fabricant.

RACCORDEMENT D’EAU

Avant de raccorder l’appareil, faites couler l’eau dans le tuyau

d'arrosage (non compris) pour évacuer toute matière étrangère.

Vérifiez que la grille soit propre et dans l’arrivée de la pompe. Fixez

le tuyau à la prise d’eau du nettoyeur haute pression. (Voir Figure

2, page 16).

REMARQUE: L’alimentation en eau doit fournir un minimum

de 4 g.p.m. à 20 p.s.i. sinon la pompe pourrait être

endommagée.

UTILISATION

PROCÉDURE DE LANCEMENT

1.Assurez-vous que l'alimentation d’eau soit raccordée et

en marche.

2.Dégagez le dispositif de verrouillage du pistolet, au

besoin.

3.Pour permettre à l'air de s’échapper du tuyau, appuyez

sur la gachette du pistolet jusqu'à ce qu’il y ait un jet

d’eau uniforme s'échappant de l'embout.

4.Retirez toute poussière ou matière étrangère de l’orifice

de sortie du pistolet ainsi que du raccord de la baguette.

5.Insérez la baguette-buse dans la baguette du pistolet et

resserrez le raccord en tournant manuellement.

UTILISATION DE PRODUITS CHIMIQUES

Ce nettoyeur est conçu seulement pour les détergents

liquides de lave-auto, formulés spécialement pour les

nettoyeurs haute pression, et pour les savons doux. Nous

recommandons d’utiliser les produits chimiques de nettoyeurs

haute pression Coleman® Powermate®. N’utilisez que des

produits chimiques compatibles avec les pièces d’aluminium

et de cuivre du nettoyeur. Les savons en poudre peuvent

bloquer le système d’injection. Utilisez toujours les produits

chimiques conformément aux directives des fabricants.

Powermate Corporation n’accepte aucune responsabilité pour

tout dommage causés par des produits chimiques

injectés par ce nettoyeur haute pression.

1.Fixez le tube d’injection à l’injecteur du siphon sur la

pompe. (Voir Figure 2, page 16).

2.Ouvrez le contenant de produits chimiques de nettoyeur à

haute pression Coleman® Powermate® et placez-le à côté

de l’appareil près du tube d’injection.

3.Regardez le filtre au bout du tube d’injection afin de vous

assurer qu’il ne soit pas bloqué.

4.Insérez le tube d’injection dans le contenant jusqu’au

fond.

Si la baguette n’est pas bien verrouillée en place, elle peut

être éjectée sous la haute pression lorsqu’on utilise le

pistolet ce qui peut provoquer des blessures ou des

dommages.

MISE EN MARCHE DU MOTEUR: (Voir Figure 2, page 16)

1.Vérifiez les niveaus d’huile et de carburant.

2.Ajustez le volet de départ si nécessaire.

3.Réglez le démarreur en position “ON”.

4.Appuyez sur la gâchette du nettoyeur haute pression pour

dégager la pression tout en tirant sur la corde du démarreur d’un

coup rapide et égal sinon la pression peut s’accumuler

rendant la mise en marche plus difficile.

5.Ajustez le volet de départ pendant que le moteur se réchauffe.

5.Si l'injection de produits chimiques est réglable, fixez-en

le débit en tournant à fond le robinet dans le sens des

aiguilles d'une montre. Tournez ensuite le robinet dans le

sens contraire des aiguilles d'une montre pour augmenter

le débit d'injection ou dans le sens des aiguilles d'une

montre pour le diminuer.

6.Si la laveuse à pression est équipée de buses amovibles,

retirez la buse haute pression de la tige et installez la buse

d'injection noire. La solution se mélangera

automatiquement à l'eau et refluera alors par la buse.

7.Si la laveuse à pression est munie d'une buse réglable, il

faut la mettre en position basse pression lors de

l'utilisation de l'injecteur aux fins d'application des

produits chimiques. Pour passer en mode basse pression,

saisissez la buse et éloignez sa bague coulissante du

pistolet en la faisant glisser.

REMARQUE:

Si la vitesse du moteur n’est pas en position “fast”,

l’injection de la solution peut diminuer ou s’arrêter.

18 www.powermate.com

Page 19

atmosphériques rares qui pourrait geler le carburateur. Si ceci

TECHNIQUE DE NETTOYAGE ENTRETIEN DE L'APPAREIL

Français

TECHNIQUE DE NETTOYAGE

Lorsque vous nettoyez avec le nettoyeur à haute pression,

on peut acomplir de nombreuse tâches de nettoyage en

utilisant seulement de l'eau, mais pour la plupart des tâches il

est préférable d’utiliser aussi un nettoyant ce qui assure un

trempage ragide de la saleté et par conséquent permet à l’eau à

haute pression de pénétrer et de retirer la saleté plus

efficacement.

Les produits chimiques de nettoyeur à haute pression

Coleman® Powermate® sont spécialement formulés pour

votre nettoyeur à haute pression.

APPLICATION DE SAVON OU DE DEGRAISSANT

1.Appliquez la solution sur une surface de travail SÈCHE.

Sur une surface verticale, appliquez horizontalement d’un

côté à l’autre en commençant par le bas pour éviter des

coulées.

NOTE: Il n’est pas recommandé de mouiller la surface

d’abord parce que cela dilue le detergeant et réduit sa

capacité de nettoyage. Évitez de travailler sur des

surfaces chaudes ou sous les rayons directs du soleil

afin de réduire les risques que le produit chimique

n'abîme les surfaces peintes. Les dommages à la

surface peinte peuvent survenir après séchage du

produit chimique sur la surface en question. Tenez la

buse suffisamment éloignée de cette dernière pour

empêcher que la surface ne s'abîme.

2.Laissez le produit chimique sur la surface un peu avant de

le rincer.

3.Rincez à l’eau propre sous une haute pression. Sur les

surfaces verticales, rincez d’abord de bas en haut, puis

rincez de haut en bas. Tenez l’ajutage de 6 à 8 pouces de

la surface de travail à un angle de 45° en utilisant un jet

plat comme un outil pour peler plutôt que comme une

brosse pour frotter.

APPLICATION DE CIRE

1.Immédiatement après le nettoyage, appliquez la cire du

nettoyeur à haute pression Coleman® Powermate®.

Placez le type d’injection dans le contenant de cire.

2.Appliquez la cire en petite quantité en une couche uni

forme. Appliquez aux surfaces mouillées de bas en haut

haut uniformément pour éviter les coulées.

3.Retirez le tube de succion de la bouteille de cire et rincez

le surplus de cire.

NOTE: SI L’EXCÉDENT DE CIRE N’EST PAS

ENLEVE, ON PEUT AVOIR UN FINI BROUILLÉ.

4.Essuyez pour réduire les tâches d’eau.

RACCORDS

Les raccords des tuyaux, pistolet et baguette du nettoyeur

à haute pression doivent être nettoyés régulièrement et

lubrifiés avec de la graisse pour éviter les fuites et les

dommages aux joints toriques.

AJUTAGE

S’il est difficile d’ajuster la haute/basse pression de la

buse, veuillez communiquer avec le service à la clientèle de

Coleman® Powemate® pour obtenir les procédures

appropriées pour nettoyer et lubrifier.

Si l’ajutage est bloqué cela peut provoquer une pression

trop forte de la pompe et il faut le nettoyer immédiatement.

On ne doit utiliser le nettoyeur d’ajutage que lorsque la

baguette est débranchée du pistolet sinon des blessures

personnelles pourraient en résulter.

1.Séparez la baguette du pistolet.

2.Nettoyer la buse avec un petit morceau de fil rigide

comme un trombone.

3.Vidangez l’ajutage en sens inverse avec de l’eau.

4.Replacez la baguette au pistolet.

Remettez en marche le nettoyeur à haute pression et

dégagez la gachette du pistolet vaporisateur. Si l’ajutage est

encore bloqué ou l’est partiellement, reprenez les étapes 1 à 4

précédentes.

Si la marche à suivre précédente ne permet pas de

dégager la buse, remplacez-la par une nouvelle buse.

FILTRE A EAU

Votre nettoyeur haute pression est muni d’une grille pour

la prise d’eau afin de protéger la pompe. Si la grille n’est pas

bien entretenue, cela réduira le débit d'eau du nettoyeur haute

pression et pourra endommager la pompe. En retirant ou

nettoyant la grille, ne l’endommagez pas. Toute particule

étrangère pénétrant dans la pompe peut l’endommager. Ne

faites PAS fonctionner le nettoyeur haute pression sans grille.

Enlevez le filtre à tamis et procédez à son rinçage par

circulation inverse afin d'en déloger les impuretés.

Replacez-le immédiatement.

APRES UTILISATION

Lorsque vous avez fini d'utiliser le système d'injection de

produits chimiques, retirez le tube du récipient. Laissez la

machine fonctionner à basse pression et injectez de l'eau

propre par le tube et le système d'injection, en plongeant

l'extrémité du tube dans un récipient d'eau propre. Laissez la

machine en marche jusqu'à ce que le nettoyage soit terminé.

ENTRETIEN DU MOTEUR

Durant les mois d’hiver, il peut y avoir des conditions.

se produit, le moteur peut mal tourner, perdre de la puissance

et s’arrêter. Ce problème passager peut être solutionné en

dirigeant un peu d’air chaud du moteur vers le carburateur.

REMARQUE: Reportez-vous au page 22 et 23 pour

l'utilisation et l'entretien du moteur.

19www.powermate.com

Page 20

Français

RANGEMENT

RANGEMENT DE LA POMPE

Si vous devez ranger votre nettoyeur à haute pression

dans un endroit où la température est sous 0°C, vous pouvez

réduire les risques de dommages en utilisant la démarche

suivante:

1.Coupez l'alimentation en eau et relâchez la pression dans

le pistolet pulvérisateur en appuyant sur la gâchette.

Débranchez le tuyau d'arrosage de la laveuse à pression

tout en assurant le raccordement du flexible haute

pression.

2.Mettez l’appareil sur le côté, la connexion d’entrée vers le

haut.

3.Insérez un petit entonnoir (pour éviter les fuites) dans

l’orifice d’entrée et versez-y environ 1/4 tasse d’antigel.

4.Débranchez le fil de la bougie.

5.Sans raccorder le tuyau d’arrosage, tirez sur le mécanisme

de rappel plusieurs fois afin de faire circuler l'antigel

dans le système de la pompe. Continuez à ajouter de

l’anti-gel et de tirer sur le mécanisme de rappel jusqu’à ce

que l’anti-gel sorte en tirant sur la gâchette. Débranchez

le tuyau haute pression. L’anti-gel servira à empêcher la

rouille durant l’entreposage et aidera à empêcher les

pistons de coller.

6.Mettez l'appareil debout.

3.Versez environ une cuillerée à café d’huile à moteur dans

le trou de la bougie, tirez sur le lanceur à rappel plusieurs

fois et replacez la bougie. Puis tirez sur le démarreur

lentement jusqu'à ce que vous sentiez une pression accrue