Page 1

Operator’s Manual

Manuel de l'utilisateur

Manual del Usuario

Model: PW0501500

1500 PSI

Modèle : PW0501500

103,4 bar (1 500 PSI)

Modelo : PW0501500.NOM

10,34MPa ( 1500 PSI )

200-2657_Rev A_4-07

WARNING: Read and understand all safety precautions in this manual before operating. Failure to comply with

instructions in this manual could result in personal injury, property damage, and/or voiding of your warranty. The

manufacturer WILL NOT be liable for any damage because of failure to follow these instructions.

AVERTISSEMENT : Lisez et veillez à bien comprendre toutes les consignes de sécurité de ce manuel avant

d'utiliser l'appareil. Toute dérogation aux instructions contenues dans ce manuel peut entraîner l'annulation de la

garantie, causer des blessures et/ou des dégâts matériels. Le fabricant NE SAURA être tenu responsable de

dommages résultant de l'inobservation de ces instructions.

ADVERTENCIA: Lea y comprenda todas las precauciones de seguridad contenidas en este manual antes de

utilizar esta unidad. Si no cumple con las instrucciones de este manual podría ocasionar lesiones personales,

daños a la propiedad y/o la anulación de su garantía. El fabricante NO SERÁ responsable de ningún daño por

no acatar estas instrucciones.

This product is covered by US Patents and other international patents.

Ce produit est protégé par des brevets américains et d’autres brevets internationaux.

Este producto se encuentra cubierto por patentes de EE.UU. y otros patentes internacionales.

ENGLISH Pages 2-12

FRANCAIS Pages 13-23

ESPAÑOL Páginas 24-34

Page 2

2

INDEX

1.0 SAFETY AND OPERATION RULES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pages 4-6

PARTS DRAWING/PARTS LIST. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 7

2.0 SAFETY FEATURES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 8

3.0 OPERATING CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 8-9

3.1 HIGH PRESSURE HOSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 8

3.2 WATER CONNECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 8

3.3 POWER SUPPLY CONNECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 8

3.4 EXTENSION CORDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 9

4.0 OPERATING INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 9-10

4.1 START-UP PROCEDURE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 9

4.2 VARIO SPRAY NOZZLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 9

4.2.1 HAND BRUSH ASSY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 9

4.3 USE OF CHEMICAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 10

4.4 CLEANING TECHNIQUES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 10

4.5 END OF OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 10

5.0 MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 10-11

5.1 CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 10

5.2 NOZZLE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 10

5.3 LUBRICATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 11

5.4 WATER SCREEN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 11

5.5 COOLING SYSTEM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 11

6.0 SERVICING A DOUBLE INSULATED APPLIANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 11

7.0 MOVING AND STORAGE INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 11

8.0 TECHNICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 11

9.0 TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 12

Page 3

3

Safety precautions are essential when any mechanical

equipment is involved.

These precautions are necessary when using, storing and

servicing mechanical equipment. Using this equipment with

the respect and caution demanded will considerably lessen

the possibilities of personal injury. If safety precautions are

overlooked or ignored, personal injury or property damage

may occur.

The following symbols shown below are used extensively

throughout this manual.

Always heed these precautions, as they are essential when

using any mechanical equipment.

WARNING: This warning symbol identifies specific

instructions or procedures which if not correctly

followed could result in personal injury or death.

CAUTION: This caution symbol identifies specific

instructions or procedures which if not strictly

observed, could result in damage to, or destruction of

equipment.

This unit was designed for specific applications. It should not

be modified and/or used for any application other that that

which it was designed. If there are any questions regarding

its application, write or call. Do not use this unit until your

questions have been answered.

WARNING: When using this product basic

precautions should always be followed, including the

following:

1. Read this manual carefully - know your equipment.

Consider the applications, limitations, and the potential

hazards specific to your unit.

2. This product shall only be connected to a power supply

utilizing the power cord provided with the unit.

3. Do not touch plug or outlet with wet hands.

4. Avoid accidental starts. Move switch on unit to "OFF"

position before connecting or disconnecting cord to

electrical outlets.

5. Water spray must never be directed towards any

electric wiring or directly towards the pressure washer

machine itself or fatal electric shock may occur.

6. Never carry your pressure washer by the cord. Do not

pull on the cord to disconnect from the outlet.

7. To prevent damage, the cord should not be crushed,

placed next to sharp objects or near a heat source.

8. Stay alert, watch what you are doing.

9. Follow maintenance instructions specified in this

manual.

10. Check power cords before using. Damaged cords can

reduce performance of pressure washer or cause a

fatal electric shock.

11. Keep operating area clear of all persons.

12. To reduce the risk of injury, do not operate near

children

13. Always use both hands when operating pressure

washer to maintain complete control of the wand.

14. Do not touch nozzle or water spray while operating.

15. Wear safety goggles while operating.

16. Disconnect power plug from the outlet when not in use

and prior to detaching the high pressure hose.

17. Only pressure washer hoses and nozzles should be

used.

18. Never tie knots or kink the high pressure hose as

damage could result.

19. Carefully observe all chemical instructions and

warnings before using.

20. The pressure washer should not be used in areas

where gas vapors may be present. An electric spark

could cause an explosion or fire.

21. To minimize the amount of water getting into the

pressure washer, the unit should be placed as far as

possible from the cleaning site during operation.

22. To prevent accidental discharge, the spray gun should

be secured by locking the trigger when not in use.

23. Do not operate this product when fatigued or under the

influence of alcohol or drugs.

24. To allow free air circulation, the pressure washer

should NOT be covered during operation.

25. Know how to stop the product and bleed pressure

quickly. Be thoroughly familiar with the controls.

26. Do not over reach or stand on unstable support. Keep

good footing and balance at all times.

27. WARNING - Risk of injection or injury. Do not direct

discharge stream at persons.

28. See OPERATING CONNECTIONS Page 9 for

information on Extension Cords.

29. See SERVICING OF A DOUBLE INSULATED

PRODUCT, Section 6.0.

SAVE THESE INSTRUCTIONS

1.0 SAFETY AND OPERATION RULES

Page 4

456

Page 5

Page 6

Page 7

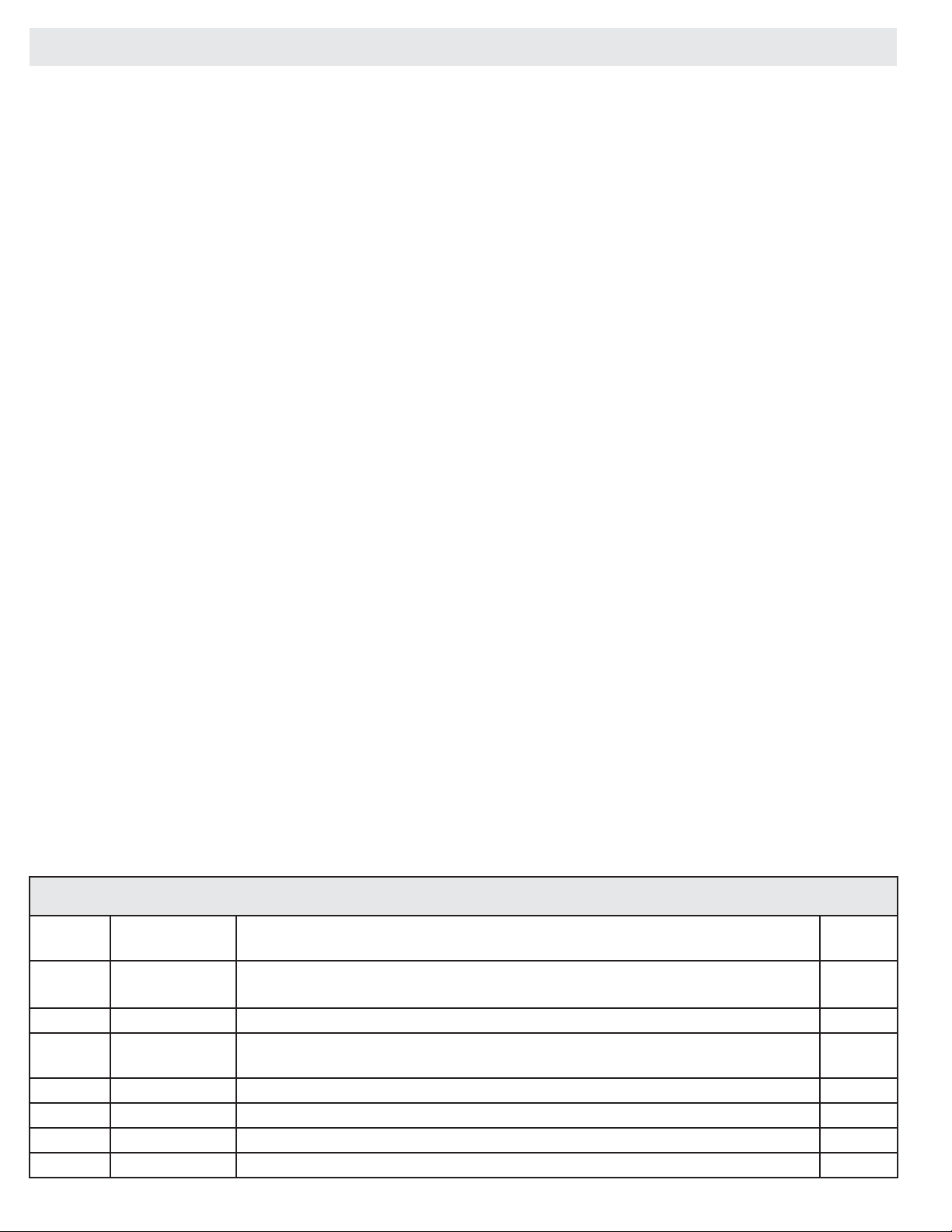

7

PARTS DRAWING

PARTS LIST

Ref. No. Part No. Description Qty.

1 012-0127 High pressure gun & hose assy. 1

2 118-0033 Water inlet filter screen 1

3 036-0055 Garden hose quick connect inlet nipple 1

4 005-0037 Variable nozzle with lance 1

5 010-0021 Soap lance assembly 1

6 095-0053 Wheel 2

7 024-0194 Utility brush 1

Page 8

8

2.1 AUTOMATIC TOTAL STOP

®

The pressure washer is equipped with a stop device which

will sense when the trigger on the gun is released. It will open

the power circuit to the motor and cause the pressure washer

to stop.

WARNING: If Automatic Total Stop® fails to

operate, DO NOT USE THE MACHINE. Contact our

Customer Service department. Further use will

damage the machine and/or cause personal injury.

WARNING: The pressure washer is also equipped

with a main power ON/OFF switch located on the

unit. It should always be moved to the OFF position

when the pressure washer is not being used to

prevent possible injury or damage.

2.2 MOTOR OVERLOAD

The electric motor in this pressure washer is equipped with

an overload protection device which will automatically shut

off the motor in the event the motor draws excessive current

or overheats.

3.1 HIGH PRESSURE HOSE

Attach the high pressure hose by carefully inserting the fitting

with the o-ring into the high pressure outlet and tightening the

threader nut by hand.

3.2 WATER CONNECTION

Before connecting, run water through the garden hose (not

supplied), to flush out any foreign matter. Attach garden hose

to the pressure washer water inlet connection (see Fig 1). If

your water source is a well, the garden hose length can only

be 30 ft. max.

3.3 POWER SUPPLY CONNECTION

The pressure washer is factory-equipped with an electrical

cord. This cord should only be connected to an electrical

outlet installed in accordance with local safety regulations.

NOTE: The power supply must be 120V, 60 Hz and a

minimum 15 amp circuit. (Dedicated)

A. Connect only to a properly grounded outlet.

B. Inspect cord before using. Do not use if cord

is damaged.

C. Keep all connections dry and off the ground.

D. Do not touch plug with wet hands.

If replacement of the plug or cord is needed, use only

identical replacement parts. Contact Customer Service for

proper replacement parts.

2.0 SAFETY FEATURES

3.0 OPERATING CONNECTIONS

ATTENTION:

Proper water connection.

Page 9

9

3.4 EXTENSION CORDS

Use only extension cords that are intended for outdoor use.

These extension cords are identified by a marking

"Acceptable for use with outdoor appliances: store indoors

while not in use". Use only extension cords having an

electrical rating not less that the rating of the product. Do not

use damaged extension cords. Examine extension cord

before using and replace if damaged. Do not abuse

extension cord and do not pull on any cord to disconnect.

Keep cord away from heat and sharp edges. Always

disconnect the product from the extension cord.

When using and extension cord, observe the specification

below:

Cable Length Wire Gauge

Up to 25 ft. 12 AWG Outdoor

WARNING: to reduce the risk of electrocution, keep

all connections dry and off the ground. Do not touch

plug with wet hands.

A. Inspect cord before using. Do not use if cord

is damaged.

B. Keep all connections dry and off the ground.

C. Do not touch plug with wet hands.

WARNING: risk of injury. Do not direct discharge

stream at anyone.

4.1 START-UP PROCEDURE

1. Make sure water supply is connected and turned on.

2. Make sure the unit is plugged in.

3. Release gun safety if locked. (Fig. 2)

4. To allow air to escape from the hose, squeeze trigger on

the gun until there is a steady stream of water coming

from the nozzle.

5. Remove any dirt or foreign matter from the gun outlet

and the male connector of the wand.

6. Insert the wand into the gun's quick connect coupling by

pushing firmly and twisting wand ¼ of a turn to lock into

place. (Fig 3)

NOTE: make sure wand is locked.

WARNING: if the wand is not securely locked into

place, it could be ejected under high pressure when

operating the gun.

7. Move the power on/off switch on the pressure washer to

the "ON" position.

8. Squeeze the gun trigger and the pressure washer motor

will start.

WARNING: make sure the wand is pointed in a safe

direction when starting the pressure washer. Do not

point at face or feet as serious injury could result.

4.2 VARIO SPRAY NOZZLE

The adjustable spray nozzle can adjust spray from fan to

pencil point. The spray is adjusted by turning the nozzle. (Fig.

4)

CAUTION: the pencil point spray adjustment is

very aggressive. We recommend that for most

cleaning applications, a twenty degree (20°) spray

angle be used to avoid damage to the surface being

sprayed.

NOTE: the pressure of the spray on the surface you are

cleaning increases as you move the wand closer to the

surface.

To increase angle to a fan spray, turn counterclockwise.

To decrease angle to pencil point spray, turn clockwise.

4.2.1 HAND BRUSH ASSEMBLY

Insert the hand brush into the gun (Fig. 3a). Push firmly and

twist clockwise 1/4 turn to lock into position.

3.0 OPERATING CONNECTIONS

4.0 OPERATING INSTRUCTIONS

Fig. 2

Fig. 3a

Fig. 3

Page 10

10

4.3 USE OF CLEANING CHEMICALS

1. Remove wand.

2. Install soap dispenser assembly. (Fig 5)

3. Remove bottle and check tube.

4. The soap or wax will automatically be mixed with the

water and discharged through the nozzle.

5. Use only approved pressure washer cleaners.

6. The soap lance assembly is designed to use low

pressure when dispensing detergents. The consumption

rate is up to 10:1.

4.4 CLEANING TECHINQUES

When cleaning with the Pressure Washer, many cleaning

tasks can be solved with water alone, but for most tasks it is

advantageous to use a detergent also. A detergent ensures a

quick soaking of the dirt allowing the high pressure water to

penetrate and remove the dirt more effectively.

4.4.1 APPLICATION OF SOAP DEGREASER

1. Apply the Pressure Washer Soap solution to a DRY work

surface. NOTE: WETTING THE SURFACE FIRST IS

NOT RECOMMENDED, AS IT DILUTES THE

DETERGENT AND REDUCES ITS CLEANING ABILITY.

On a vertical surface, apply soap horizontally from

side to side starting from the bottom to avoid streaking.

CAUTION: avoid working on hot surfaces or in

direct sunlight to minimize the chance of the soap

damaging painted surfaces.

2. Allow the soap to remain on the surface for a short time

before rinsing.

CAUTION: damage may occur to painted surface if

soap is allowed to dry on the surface. Wash and

rinse a small section at a time.

3. Rinse with clean water under high pressure. On a vertical

surface, first rinse from the bottom up, then rinse from the top

down. Hold nozzle 6 to 8 inches from the work surface at a

45° angle.

4.4.2 APPLICATION OF LIQUID VEHICLE WAX

1. Immediately after cleaning, apply liquid vehicle wax using

the soap dispenser assembly.

2. Apply the wax sparingly in an even layer. Apply to wet

surfaces from the bottom up for even distribution and to

avoid streaking.

3. Remove the suction tube from the wax bottle and rinse off

the surplus wax from your vehicle under low pressure. NOTE

- IF SURPLUS WAX IS NOT REMOVED, A HAZY FINISH

MAY RESULT.

4. Wipe dry to reduce water spotting.

4.5 END OF OPERATION

When you have completed use of the soap/wax application,

remove bottle and flush clean water through the tube until it

is thoroughly cleaned.

NOTE: Failure to clean properly will cause the injection system to

become clogged and inoperable.

1. Stop the machine by pressing the on/off button.

2. Disconnect electrical plug.

3. Turn off water and depressurize unit by squeezing

trigger.

WARNING: turn off water supply and squeeze trigger to

depressurize the unit. Failure to do so could result in

personal injury due to discharge of high pressure water.

4. Disconnect the high pressure discharge hose and

the water inlet hose.

5.1 CONNECTIONS

Connections on Pressure Washer hoses, gun and spray

wand should be cleaned regularly and lubricated with grease

to prevent leakage and damage to the o-rings.

5.2 NOZZLE

The spray nozzle should be lubricated regularly. Clogging of

the nozzle causes the pump pressure to be too high and

cleaning is immediately required. (Fig 6)

1. Separate the nozzle from the wand (Fig 6).

2. Clear the nozzle by forcing a stiff wire through center

hole.

3. Backflush the nozzle with water.

4. Reconnect the nozzle to the wand.

NOTE: Completely screw the nozzles on the wand up to the

complete lock. (See picture Fig. 6)

Restart the pressure washer and depress the trigger on the

spray gun. If the nozzle is still plugged, repeat above items 1

through 4.

4.0 OPERATING INSTRUCTIONS

Fig. 4

Fig. 5

5.0 MAINTENANCE

Page 11

11

5.3 LUBRICATION

The pressure washer is designed with a permanent lubrication

system. Conventional oil check and oil changes are not

necessary.

NOTE: IN CASE OF OIL LEAKAGE, CONTACT THE

CUSTOMER SERVICE DEPARTMENT CONCERNING

REPAIR. A SMALL AMOUNT OF LEAKAGE IS NORMAL.

5.4 WATER SCREEN

The pressure washer is equipped with a water inlet screen to

protect the pump.

CAUTION: if the screen is not kept clean, the flow of

water to the pressure washer will be restricted and

the pump may be damaged.

• To clean inner conical water screen, remove quick

connect and remove the plastic screen from the pump

inlet.

• Backflush screen to clean.

• Replace screen and quick connect immediately to

prevent any foreign matter from entering the pump.

CAUTION: do not damage the screen while

removing or cleaning. Any foreign particles entering

the pump may damage the pump.

5.5 COOLING SYSTEM

The air vents, located in and around the pressure washer,

must be kept clean and free of any obstructions to ensure

proper air cooling of the motor during operation.

WARNING: prevent water from penetrating the

vents of the pressure washer to minimize the risk of

damage to the machine and to reduce the risk of

shock to the operator.

In a double-insulated product, two systems of

insulation are provided instead of the grounding.

No grounding means is provided on a doubleinsulated product, nor should a means for

grounding be added to the pressure washer.

Servicing a double-insulated product requires

extreme care and knowledge of the system, and should be

done only by qualified service personnel. Replacement parts

for a double-insulated product must be identical to the parts

they replace. A double-insulated product is marked with the

words "DOUBLE-INSULATION" or "DOUBLE-INSULATED".

The following symbol may also be marked on the product.

C

AUTION: always store your pressure washer in a

location where the temperature will not fall below 40°F.

The pump in this machine is susceptible to permanent

damage if frozen. FREEZE DAMAGE IS NOT

COVERED BY THE WARRANTY.

In a continued commitment to improve quality, the

Manufacturer reserves the right to make component changes

or design changes when necessary.

5.0 MAINTENANCE

Fig. 6

6.0 SERVICING A DOUBLE-

INSULA TED APPLIANCE

7.0 MOVING AND STORAGE

INSTRUCTIONS

8.0 TECHNICAL DATA

Pump pressure

1500 PSI Max

*Operation pressure

Electrical requirement 120v, 15 amps, 60 Hz

Electrical cord 23 ft.

High pressure hose 19 ft.

Flow rate 1.5 GPM

Minimum amperage

source

15 amp

Pressure of inlet water 20 to 100 psi

Inlet water cold tap water

Soap consumption rate 10% Max

*Water flow and maximum pressure ratings determined in

accordance with PWMA. Standard PW101.

Page 12

12

9.0 TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE CORRECTION

Motor will not start or stops while

operating.

Extension cord length or gauge incorrect. Use proper extension cord. See Operator’s

Manual Section 3.3.

Loose or disconnected plug. Reconnect plug.

Tripped pressure washer thermal switch. Allow to cool and restart unit

Spray Gun Trigger not operating

properly.

Call Customer Service.

Defective gun. Remove gun, aim water stream away from

electrical source, and press ON. If machine

starts, replace gun assembly by contacting

Customer Service.

Circuit breaker trips or fuse

blown in fuse box.

Circuit overload. Check that the circuit is rated 15 amps or

greater.

Extension cord too long or wire size too

small.

Use proper extension cord as recommended in

Operator’s Manual Section 3.3.

Nozzle partially blocked. Clean nozzle as instructed in Section 5.2.

Excessive pressure. Clean nozzle as instructed in Section 5.2.

Water or oil leaking from bottom

of pump.

A small amount of leakage is normal. If excessive leaking occurs, call Customer

Service.

Trigger will not move. Spray gun safety lock engaged. Release safety lock.

Unit will not stop when trigger is

released.

Spray gun trigger system not operating

properly.

Call Customer Service.

Motor running but pump not

building mazimum pressure or

has irregular pressure

Faucet closed. Open faucet.

Water inlet screen clogged. Clean screen. See section 5.4.

Gun and hose failure. Replace gun and hose.

Kink in garden hose. Straighten hose.

Wand nozzle worn out Replace spray wand.

Air in pump. Let pressure washer run with gun open and

wand removed until steady stream of water is

released.

Clogged nozzle. Clean nozzle. See manual Section 5.2.

Page 13

13

TABLE DES MATIÈRES

1.0 RÈGLES DE SÉCURITÉ ET DE FONCTIONNEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pages 14

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pages 15-17

ILLUSTRATIONS DES PIÈCES/ LISTE DES PIÈCES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 18

2.0 CARACTÉRISTIQUES DE SÉCURITÉ. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 19

3.0 CONNEXIONS DE FONCTIONNEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 19-20

3.1 TUYAU À HAUTE PRESSION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 19

3.2 BRANCHEMENT À L'ALIMENTATION EN EAU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 19

3.3 CONNEXION À LA SOURCE D'ALIMENTATION ÉLECTRIQUE . . . . . . . . . . . . . . . . . . . . . . . page 19

RALLONGES ÈLECTRIQUES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 20

4.0 CONSIGNES D'UTILISATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 20-21

4.1 PROCÉDURE DE DÉMARRAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 20

4.2 BUSE POUR VAPORISATEUR VARIO. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 20

4.2.1 ASSEMBLAGE DE LA BROSSE À MAIN. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 20

4.3 USAGE DE NETTOYANTS CHIMIQUES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 21

4.4 TECHNIQUES DE NETTOYAGE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 21

4.5 APRÈS USAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 21

5.0 ENTRETIEN. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 21-22

5.1 RACCORDS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 21

5.2 BUSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 21

5.3 LUBRIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 22

5.4 PARAVENT À EAU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 22

5.5 SYSTÈME DE REFROIDISSEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 22

6.0 ENTRETIEN D'UN APPAREIL À ISOLATION DOUBLE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 22

7.0 DIRECTIVES POUR LEDÉPLACEMENT ET L'ENTREPOSAGE. . . . . . . . . . . . . . . . . . . . . . . . . . . . page 22

8.0 DONNÉES TECHNIQUES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 22

9.0 DÉPANNAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 23

Page 14

14

Il est essentiel de prendre des mesures de sécurité avec tout

équipement mécanisé.

Ces précautions s'avèrent nécessaires lorsque vous utilisez,

entreposez et faites l'entretien d'un équipement mécanisé.

Vous risquez moins de vous causer des blessures

corporelles si vous utilisez cet équipement selon les règles

de prudence et de respect que cela requiert. Vous pouvez

vous blesser ou causer des dommages à la propriété si vous

ne tenez pas compte ou ignorer les mesures de sécurité.

Les symboles ci-dessous sont utilisés fréquemment dans ce

manuel.

Tenez toujours compte de ces précautions parce qu'elles

sont essentielles lorsque vous utilisez un équipement

mécanisé.

AVERTISSEMENT: Ce symbole de mise en

garde identifie des directives et des procédures

particulières qui, si elles ne sont pas suivies

correctement, risquent de vous causer des

blessures corporelles ou entraîner la mort.

ATTENTION: Ce symbole d'avertissement

identifie des directives et des procédures qui, si

elles ne sont pas observées strictement, risquent

de provoquer des dommages ou de détruire

l'équipement.

Cet appareil a été conçu pour des applications particulières.

Il ne doit pas être modifié et/ou utilisé pour tout usage autre

que celui pour lequel il est conçu. Si vous avez des questions

concernant son utilisation, veuillez écrire ou appeler.

N'utilisez pas cet appareil tant que vous n'aurez pas obtenu

de réponses à vos questions.

AVERTISSEMENT: Vous devez toujours prendre

des précautions de base lorsque vous utilisez ce

produit, dont les suivantes :

1. Lisez ce manuel attentivement et apprenez à connaître

votre appareil; tenez compte de ses applications, de

ses limites et des risques éventuels qui lui sont

particuliers.

2. Ce produit ne doit être branché qu'à une source

d'alimentation en utilisant la corde d'alimentation qui

est fournie.

3. Ne touchez pas à la fiche ou à la prise électrique avec

des mains mouillées.

4. Évitez les démarrages accidentels; placez l'interrupteur

de l'appareil à la position ARRÊT (OFF) avant de le

brancher ou de débrancher la corde d'alimentation de

la prise électrique.

5. Ne dirigez jamais le jet d'eau vers un filage électrique

ou directement sur l'hydronettoyeur lui-même parce

qu'il y a risque de choc électrique mortel.

6. Ne tenez jamais votre hydronettoyeur par la corde; ne

tirez pas sur la corde pour la débrancher de la prise

électrique.

7. Afin de prévenir tout dommage, éviter d'écraser la

corde ou de la placer près d'objets tranchants ou d'une

source de chaleur.

8. Restez vigilant et surveillez ce que vous faites.

9. Suivez les directives d'entretien stipulées dans ce

manuel.

10. Vérifiez la corde d'alimentation avant de l'utiliser; une

corde d'alimentation endommagée peut réduire le

rendement de l'hydronettoyeur ou causer un choc

électrique mortel.

11. Assurez-vous qu'il n'y a personne là où vous nettoyez;

12. N'utilisez pas cet appareil à proximité d'enfants afin de

diminuer les risques de blessure.

13. Utilisez toujours vos deux mains lorsque vous faites

fonctionner l'hydronettoyeur afin d'assurer un plein

contrôle du tuyau-rallonge.

14. Ne touchez pas au pistolet ou à la buse lorsque vous

nettoyez.

15. Portez des lunettes de sécurité lorsque vous nettoyez.

16. Débranchez la fiche d'alimentation sur la prise

électrique lorsque vous ne l'utilisez pas ou avant de

détacher le tuyau à haute pression.

17. Vous ne devriez utiliser que des tuyaux à haute

pression et des pistolets.

18. Ne pas faire de nœuds ou plier le tuyau à haute

pression, car vous risquez de l'endommager.

19. Suivez attentivement toutes les directives relatives aux

produits chimiques et les mises en garde avant usage.

20. L'hydronettoyeur ne devrait pas être utilisé dans des

endroits où il pourrait y avoir des émanations de gaz;

une étincelle électrique peut causer une explosion ou

un incendie.

21. Afin de minimiser la quantité d'eau dans .

l'hydronettoyeur, placez celui-ci le plus loin possible de

l'endroit nettoyé pendant usage.

22. Afin de prévenir toute décharge accidentelle, le pistolet

vaporisateur devrait être bien fixé en verrouillant la

détente lorsqu'il n'est pas utilisé.

23. Ne faites pas fonctionner cet appareil lorsque vous

êtes fatigué ou sous l'influence d'alcool ou de drogues;

24. Ne recouvrez PAS l'hydronettoyeur lorsque vous

l'utilisez afin que l'air circule librement.

25. Apprenez comment arrêter cet appareil et purger la

pression rapidement; familiarisez-vous pleinement

avec les commandes.

26. N'essayez pas d'étendre votre portée ou de vous tenir

debout sur objet instable; soyez ferme sur vos pieds et

restez en équilibre en tout temps.

27. AVERTISSEMENT - Risque d'injection ou de blessure.

Ne dirigez pas le jet directement sur des personnes.

28. Voir les CONNEXIONS DE FONCTIONNEMENT à

la page 20 pour des renseignements sur les rallonges.

29. Voir ENTRETIEN D'UN APPAREIL À ISOLATION

DOUBLE à la section 6.0.

CONSERVEZ CES INSTRUCTIONS

1.0 RÈGLES DE SÉCURITÉ ET DE FONCTIONNEMENT

Page 15

151617

Page 16

Page 17

Page 18

18

ILLUSTRATIONS DES PIÈCES

LISTE DES PIÈCES

Ref.

No.

No/ P Description Qté.

1 012-0127 Assemblage du pistolet à haute pression et du tuyau 1

2 118-0033 Paravent à eau 1

3 036-0055 Branchement rapide du tuyau d'arrosage au raccord fileté d'admission 1

4 005-0037 Buse variable avec jet 1

5 010-0021 Dispositif dispensateur de savon 1

6 095-0053 Roue 2

7 024-0194 Nettoyeur à pression brosse utilitaire 2

Page 19

19

AUTOMATIC TOTAL STOP®

L'hydronettoyeur est doté un dispositif d'arrêt qui détecte

lorsqu'on relâche la détente du pistolet. Il ouvrira le circuit

électrique du moteur et arréte le pulvérisateur.

AVERTISSEMENT: Si l'Automatic Total

Stop® ne fonctionne pas, N'UTILISEZ PAS

L'APPAREIL. Communiquez avec notre

service à la clientèle. Vous risquez

d'endommager l'appareil et/ou causer des

blessures corporelles si vous continuez de

l'utiliser.

AVERTISSEMENT: L'hydronettoyeur est

également équipé d'un interrupteur

d'alimentation principal ON/OFF (EN

MARCHE/ARRÊT). L'interrupteur devrait

toujours être à la position OFF (ARRÊT)

lorsque l'hydronettoyeur n'est pas utilisé afin

de prévenir d'éventuelles blessures ou des

dommages.

SURCHARGE DU MOTEUR

Le moteur électrique de l'hydronettoyeur est doté d'un

dispositif de protection contre les surcharges qui le fermera

automatiquement advenant qu'il tire trop de courant ou qu'il

surchauffe.

3.1 TUYAU À HAUTE PRESSION

Attachez le tuyau à haute pression en insérant posément la

fixation avec le joint torique dans la prise à haute pression et

en serrant l'écrou fileté à la main.

3.2 BRANCHEMENT À L'ALIMENTATION EN EAU

Avant de brancher, faites circuler l'eau dans le tuyau

d'arrosage (non fourni) pour évacuer tout corps étranger.

Attachez le tuyau d'arrosage à l'entrée d'alimentation en eau

de l'hydronettoyeur. Si votre source d'alimentation en eau est

un puits, la longueur maximale du tuyau d'arrosage ne doit

pas dépasser 9,1 m (30 pi).

3.3 CONNEXION À LA SOURCE D'ALIMENTATION

ÉLECTRIQUE

L'hydronettoyeur vient équipé d'une corde d'alimentation.

Celle-ci devrait être branchée uniquement sur une prise de

courant installée conformément à la réglementation locale en

matière de sécurité.

REMARQUE : la source d'alimentation doit être de 120 V, 60

Hz avec un circuit minimal de 15 A. (Réservé)

A. Ne branchez qu'à une prise avec mise à

la terre.

B. Inspectez la corde d'alimentation avant

de l'utiliser. Ne l'utilisez pas si elle est

endommagée.

C. Gardez toutes les connexions sèches et au-

dessus du sol.

D. Ne touchez pas à la fiche avec des mains

mouillées.

Si vous devez remplacer la fiche ou la corde d'alimentation,

utilisez uniquement des pièces semblables. Communiquez

avec le service à la clientèle pour les bonnes pièces de

remplacement.

2.0 CARACTÉRISTIQUES DE SÉCURITÉ

ATTENTION:

Un branchement en eau approprié.

3.0 CONNEXIONS DE FONCTIONNEMENT

Page 20

20

3.4 RALLONGES ÉLECTRIQUES

Utilisez uniquement des rallonges destinées à un usage

externe. Ces rallonges sont identifiées d'une marque "

Acceptable pour usage avec des appareils extérieurs :

entreposez à l'intérieur lorsque non utilisé ". Utilisez

uniquement des rallonges qui possèdent un coefficient

électrique qui n'est pas inférieur à celui du produit. N'utilisez

pas de rallonges endommagées. Examinez la rallonge

électrique avant de l'utiliser et remplacez-la si elle est

endommagée. N'utilisez pas trop de rallonges et ne tirez pas

sur elles pour les débrancher. Gardez la corde éloignée de la

chaleur et des rebords tranchants. Débranchez toujours

l'appareil de la rallonge.

Suivez les caractéristiques techniques ci-dessous lorsque

vous utilisez une rallonge :

Longueur du câble Calibre du filage

Jusqu'à 7,6 m (25 pi) 12 AWG extérieur

AVERTISSEMENT: gardez toutes les

connexions sèches et au-dessus du sol afin de

réduire les risques d'électrocution. Ne touchez

pas à la fiche avec des mains mouillées.

A. Inspectez la corde d'alimentation avant de

l'utiliser. Ne l'utilisez pas si elle est

endommagée.

B. Gardez toutes les connexions sèches et

au-dessus du sol.

C. Ne touchez pas à la fiche avec des mains

mouillées.

AVERTISSEMENT: risque de blessure. Ne

dirigez pas le jet directement sur des personnes.

4.1 PROCÉDURE DE DÉMARRAGE

1. Assurez-vous que l'approvisionnement en eau soit

branché et ouvert.

2. Assurez-vous que l'appareil soit branché.

3. Relâchez le dispositif de sécurité du pistolet s'il est

verrouillé. (Fig. 2)

4. Afin de laisser l'air s'échapper du tuyau, appuyez sur la

détente du pistolet jusqu'à ce que le flot d'eau soit

régulier.

5. Enlevez toute saleté ou corps étranger de la sortie de la

buse et de la fiche mâle du tube-rallonge.

6. Insérez le tube-rallonge dans le raccord à branchement

rapide de la buse en poussant fermement et en le

tournant d'un quart (¼) de tour pour le verrouiller en

place. (Fig. 3)

REMARQUE : assurez-vous que le tube rallonge soit bien

verrouillé.

AVERTISSEMENT: si le tube-rallonge n'est pas

bien verrouillé en place, la forte pression

pourrait l'éjecter lorsque vous actionnez le

pistolet.

7. Placez l'interrupteur de l'hydronettoyeur à la position "

ON " (EN MARCHE).

8. Appuyez sur la détente du pistolet pour démarrer le

moteur de l'hydronettoyeur.

AVERTISSEMENT: assurez-vous que le tuberallonge soit pointé vers un endroit sécuritaire

lorsque vous démarrez l'hydronettoyeur. Ne

pointez pas vers un visage ou aux pieds, car

vous risquez d'infliger des blessures graves.

4.2 BUSE POUR VAPORISATEUR VARIO

La buse peut ajuster le jet en éventail ou en pointe. Vous

ajustez le jet en la tournant. (Fig 4)

ATTENTION: le jet en pointe est très puissant.

Pour la plupart des cas de nettoyage, nous

recommandons un jet d'angle de vingt degrés

(20°) afin de ne pas endommager la surface

ciblée.

REMARQUE : la pression du jet sur la surface que vous

nettoyez augmente au fur et à mesure que vous rapprochez

le tube-rallonge de celle-ci.

Pour augmenter l'angle afin d'obtenir un jet en éventail,

tournez la buse dans le sens contraire des aiguilles.

Pour diminuer l'angle afin d'obtenir un jet de pointe, tournez

la buse dans le sens des aiguilles.

4.2.1 ASSEMBLAGE DE LA BROSSE À MAIN

Insérez la brosse à main dans le pistolet (Illust. 3a). Poussez

fermement et tournez 1/4 de tour dans le sens des aiguilles

d'une montre pour verrouiller en place.

3.0 CONNEXIONS DE FONCTIONNEMENT

4.0 CONSIGNES D'UTILISATION

Fig. 3

Fig. 3a

Fig. 2

Page 21

21

4.3 USAGE DE NETTOYANTS CHIMIQUES

1. Retirez le tube-rallonge.

2. Installez le dispensateur de savon. (Fig. 5)

3. Enlevez la bouteille et vérifiez le tube.

4. Le savon ou la cire se mélangeront automatiquement à

l'eau et seront évacués par la buse.

5. Utilisez uniquement des nettoyants pour hydronettoyeur

autorisés.

6. Le dispositif dispensateur de savon est conçu pour

utiliser une basse pression lorsqu'il mélange les détersifs

à l'eau. Le coefficient de consommation peut atteindre 10:1.

4.4 TECHNIQUES DE NETTOYAGE

Lorsque vous nettoyez avec l'hydronettoyeur, plusieurs

tâches peuvent être accomplies avec de l'eau seulement,

mais, dans la plupart des cas, il est préférable d'utiliser

également un détersif. Un détersif permet d'imbiber

rapidement la saleté et à l'eau sous haute pression de

pénétrer et d'enlever celle-ci plus efficacement.

4.4.1 APPPLICATION D'UN SAVON DE

DÉGRAISSAGE

1. Appliquez la solution savonneuse de l'hydronettoyeur sur

une surface de travail SÈCHE. REMARQUE : IL N'EST

PAS RECOMMANDÉ DE MOUILLER LA SURFACE EN

PREMIER. CELA DILUE LE DÉTERSIF ET RÉDUIT LA

CAPACITÉ DE NETTOYAGE. Sur une surface verticale,

appliquez le savon horizontalement d'un côté à l'autre en

partant du bas afin d'éviter les stries.

ATTENTION: évitez de travailler sur des surfaces

chaudes ou sous un ensoleillement direct afin de

réduire les risques que le savon endommage les

surfaces peintes.

2. Laissez le savon reposer pendant un court moment

avant de rincer.

ATTENTION: vous pouvez endommager les

surfaces peintes si vous laissez le savon sécher.

Lavez et rincez une petite section à la fois.

3. Rincez avec de l'eau propre à haute pression. Sur une

surface verticale, rincez en premier du bas vers le haut

puis du haut vers le bas. Maintenez la buse à environ 15

à 20 cm (6 à 8 po) de la surface de travail à un angle de 45°.

4.4.2 APPLICATION D'UNE CIRE LIQUIDE POUR

VÉHICULE

1. Dès que vous avez terminé de nettoyer, appliquez la cire

liquide pour véhicule en vous servant du dispensateur de

savon.

2. Appliquez la cire modérément de façon uniforme.

Appliquez sur les surfaces mouillées du bas vers le haut

pour une diffusion égale et pour éviter les stries.

3. Retirez le tube à succion de la bouteille de cire et rincez

à basse pression le surplus de votre véhicule.

REMARQUE - SI VOUS N'ENLEVEZ PAS LE SURPLUS

DE CIRE, VOUS RISQUEZ D'OBTENIR UN FINI VOILÉ.

4. Séchez avec un chiffon pour éliminer les taches d'eau.

4.5 APRÈS USAGE

Une fois que vous avez terminé d'appliquer le savon ou la

cire, retirez la bouteille et faites couler l'eau à travers le tube

jusqu'à ce qu'il soit complètement nettoyé.

REMARQUE : à défaut de bien le nettoyer, vous risquez que

le système d'injection se bouche et cesse de fonctionner.

1. Arrêtez l'appareil en appuyant sur le bouton On/Off

(En marche/Arrêt).

2. Débranchez la fiche électrique.

3. Fermez l'eau et dépressurisez l'appareil en appuyant

sur la détente.

AVERTISSEMENT: fermez l'alimentation en

eau et appuyez sur la détente pour

dépressuriser l'appareil. À défaut de quoi vous

risquez de vous blesser par suite d'un

écoulement d'eau sous haute pression.

4) Débranchez le tuyau d'écoulement à haute pression et le

tuyau d'entrée d'eau.

5.1 RACCORDS

Les connexions des tuyaux de l'hydronettoyeur, du pistolet et

du tube-rallonge devraient être nettoyées et lubrifiées

régulièrement afin de prévenir les fuites et les dommages

aux joints toriques.

5.2 BUSE

On doit lubrifier la buse régulièrement. L'obstruction de celleci peut augmenter la pression de la pompe et un nettoyage

immédiat s'impose. (Fig. 6)

1. Retirez la buse de la lance (Fig. 6).

2. Nettoyez la buse.

3. Nettoyez la buse en insérant un filin rigide dans le centre

du trou.

4. Faites un refoulement d'eau dans la buse.

REMARQUE : vissez complètement la buse au tube-rallonge

jusqu'à verrouillage complet. (Voir photo à Fig. 6)

Redémarrez l'hydronettoyeur et relâchez la détente du

pistolet. Si la buse est toujours bouchée, répétez les points 1

à 4 ci-dessus.

4.0 CONSIGNES D'UTILISATION

Fig. 4

Fig. 5

5.0 ENTRETIEN

Page 22

22

5.3 LUBRIFICATION

L'hydronettoyeur est conçu avec un système de lubrification

permanent. Il n'est pas nécessaire d'effectuer une vérification

ou une vidange d'huile conventionnelle.

REMARQUE : ADVENANT UNE FUITE D'HUILE,

COMMUNIQUEZ AVEC LE SERVICE À LA CLIENTÈLE

AFIN DE LE FAIRE RÉPARER. UNE LÉGÈRE FUITE

D'HUILE EST NORMALE.

5.4 PARAVENT À EAU

L'hydronettoyeur est équipé d'un paravent d'entrée d'eau

pour protéger la pompe.

ATTENTION : si le paravent à eau n'est pas

nettoyé régulièrement, le débit d'eau vers

l'hydronettoyeur s'affaiblira et la pompe pourra

s'endommager.

• Pour nettoyer l'intérieur du paravent conique, enlevez le

raccord rapide et l'écran de plastique de l'entrée de la

pompe.

• Effectuez un refoulement d'eau à travers le paravent.

• Remplacez le paravent d'eau et mettez en place de

raccord rapide immédiatement afin de prévenir des

objets étrangers d'entrer dans la pompe.

ATTENTION : n'endommagez pas le paravent

lorsque vous l'enlevez et le nettoyez. Tout corps

étranger qui pénètre dans la pompe peut

endommager celle-ci.

5.5 SYSTÈME DE REFROIDISSEMENT

Les conduits d'aération situés dans et autour de

l'hydronettoyeur doivent être maintenus propres et exempts

de toute obstruction afin d'assurer un refroidissement

approprié du moteur pendant qu'il fonctionne.

AVERTISSEMENT : évitez que de l'eau pénètre

dans les conduits d'aération de l'hydronettoyeur

afin de réduire les risques de dommage à

l'appareil et de chocs à l'opérateur.

Dans un système à isolation double, il y a deux

systèmes d'isolation au lieu d'une mise à la terre.

Aucun moyen de mise à la terre n'est fourni sur

un produit à isolation double et il en est de

même pour l'hydronettoyeur. L'entretien d'un

produit à isolation double exige de prendre des précautions

extrêmes et de bien connaître le système et il ne devrait être

effectué que par une personne qualifiée. Les pièces de

rechange pour un produit à isolation double doivent être

semblables à celles qu'elles remplacent. Un produit à

isolation double est marqué par les mots " ISOLATION

DOUBLE " ou " DOUBLE ISOLATION ". On peut également

retrouver le symbole suivant sur le produit.

ATTENTION : entreposez toujours votre

hydronettoyeur dans un endroit où la température

ne sera pas inférieure à 4,5 °C (40 °F). Vous

pourriez endommager la pompe de façon

permanente. LA GARANTIE NE COUVRE PAS

LES DOMMAGES CAUSÉS PAR LE GEL.

Dans le cadre de son engagement à améliorer la qualité de

ses produits, le fabricant se réserve le droit de modifier ses

composantes ou ses modèles, s'il y a lieu.

5.0 ENTRETIEN

Fig. 6

6.0 ENTRETIEN D'UN APPAREIL À

ISOLATION DOUBLE

7.0 DIRECTIVES POUR LE

DÉPLACEMENT ET L'ENTREPOSAGE

8.0 DONNÉES TECHNIQUES

Pression de la pompe

103,4 bar (1500 PSI) max.

*Pression de fonctionnement

Exigences électriques 120 V, 15 A, 60 Hz

Corde électrique 7 m (23 pi)

Tuyau à haute pression 5,8 m (19 pi)

Débit d'eau 5,68 lpm

Source d'intensité

minimale

15 A

Pression dans l'entrée

d'eau

1,4 à 6,9 bar (20 à 100 PSI)

Entrée d'eau Eau froide du robinet

Coefficient de

consommation de savon

10 % max.

*Le débit d'eau et le coefficient maximal de la pression sont

établis conformément aux normes de la PWMA (Pressure

Washer Manufacturers Association). Standard PW101

Page 23

23

9.0 DÉPANNAGE

PROBLÈME CAUSE PROBABLE CORRECTIF

Le moteur de démarre pas ou

s'arrête en cours de

fonctionnement

Longueur de la rallonge ou jauge

défectueuse

Utilisez une bonne rallonge. Voir le Manuel de

l'utilisateur à la section 3,3

Fiche lâche ou débranchée Rebranchez la fiche

L'interrupteur thermique de

l'hydronettoyeur a sauté

Laissez l'appareil refroidir et redémarrez-le

La détente du pistolet ne fonctionne pas

bien

Appelez le service à la clientèle.

Pistolet défectueux Retirez le pistolet, orientez le jet d'eau dans une

direction opposée à la source d'électricité et

appuyez sur ON (EN MARCHE). Si l'appareil

redémarre, remplacez le pistolet en

communiquant avec le service à la clientèle.

Le disjoncteur ou un fusible a

sauté

Surcharge du circuit Vérifiez que le circuit a un coefficient de 15 A ou

plus

La rallonge est trop longue ou le filage

trop petit

Utilisez une bonne rallonge comme il est

recommandé à la section 3.3 du Manuel de

l'utilisateur

La buse partiellement bouchée Nettoyez la buse comme indiqué à la section 5.2

Pression trop forte Nettoyez la buse comme indiqué à la section 5.2

Fuite d'eau ou d'huile au bas de

la pompe

Une légère fuite d'huile est normale Si la fuite est importante, communiquez avec le

service à la clientèle.

La détente ne bouge pas Le cran de sûreté du pistolet est en

place

Relâchez le cran de sûreté

L'appareil ne veut pas s'arrêter

lorsque la détente est relâchée

La détente du pistolet ne fonctionne pas

bien

Appelez le service à la clientèle

Le moteur tourne, mais la pompe

ne développe pas une pression

maximale ou celle-ci est

irrégulière

Le robinet est fermé Ouvrez le robinet

Le paravent à eau est bouché Nettoyez le paravent. Voir la section 5.4.

Le pistolet et le tuyau sont défectueux Remplacez le pistolet et le tuyau.

Le tuyau d'arrosage est plié Redressez le tuyau.

La buse du tube-rallonge est usée Remplacez la buse du tuyau-rallonge.

Il y a de l'air dans la pompe Laissez l'hydronettoyeur fonctionner avec le

pistolet ouvert et le tube-rallonge enlevé jusqu'à

ce que l'écoulement d'eau soit régularisé.

Buse bouchée Nettoyez la buse. Voir la section 5.2 du Manuel

d'utilisateur

Page 24

24

ÍNDICE

1.0 NORMAS OPERATIVAS Y DE SEGURIDAD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . páginas 25

INSTALACIÓN. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . páginas 26-28

LISTADO DE PARTES Y DIAGRAMAS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . página 29

2.0 CARACTERÍSTICAS DE SEGURIDAD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . página 30

3.0 CONEXIONES OPERATIVAS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . página 30-31

3.1 MANGUERA DE ALTA PRESIÓN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . página 30

3.2 CONEXIÓN DEL AGUA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . páginas 30

3.3 CONEXIÓN DE SUMINISTRO ELECTRICO. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . página 30

3.4 EXTENSIONES ELÉCTRICAS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . página 31

4.0 INSTRUCCIONES DE USO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . página 31-32

4.1 PROCEDIMIENTO DE ARRANQUE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . página 31

4.2 BOQUILLA DE CHORRO REGULABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . página 31

4.2.1 UNIDAD DE CEPILLO MANUAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . página 31

4.3 USO DE PRODUCTOS QUÍMICOS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . página 32

4.4 TÉCNICAS DE LIMPIEZA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . página 32

4.5 TERMINO DE LA OPERACIÓN. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . página 32

5.0 MANTENIMIENTO. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . página 32-33

5.1 CONEXIONES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . página 32

5.2 BOQUILLA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . página 32

5.3 LUBRICACIÓN. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . página 33

5.4 FILTRO AGUA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . página 33

5.5 SISTEMA DE REFRIGERACIÓN ENFRIAMIENTO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . página 33

6.0 MANTENIMIENTO DE UN EQUIPO CON AISLANTE DOBLE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . página 33

7.0 MANEJO Y ALMACENAMIENTO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . página 33

8.0 DATOS TÉCNICOS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . página 33

9.0 LOCALIZACIÓN Y SOLUCIÓN DE PROBLEMAS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . página 34

Page 25

25

Cuando se trata de un equipo mecánico, las precauciones

inherentes a la seguridad son esenciales. Por ello, es

necesario adoptar dichas precauciones durante el uso,

almacenamiento y mantenimiento del equipo mecánico. El

utilizar los aparatos con el respeto y la cautela requeridos

disminuye notablemente las posibilidades de provocar

lesiones personales. Si se descuidan o ignoran estas

precauciones de seguridad entonces se corre el riesgo de

lesiones personales o daño al equipo.

Los siguientes símbolos son utilizados frecuentemente en

este manual.

Tenga siempre presente dichas precauciones puesto que

son esenciales cuando se opera equipo mecánico.

ADVERTENCIA: Este símbolo identifica

instrucciones o procedimientos específicos que si

no se siguen adecuadamente pueden provocar

daños personales o la muerte.

PRECAUCIÓN: Este símbolo identifica las

instrucciones o procedimientos específicos que si

no son observadas rigurosamente pueden

provocar daños o incluso la destrucción del

equipo.

Esta unidad ha sido diseñada para aplicaciones específicas.

No debe de ser modificada y/o utilizada para otra aplicación

diferente para la que fue diseñada. Si tiene preguntas en

sobre su aplicación, escriba o llame por teléfono. No utilicen

la máquina hasta haber clarificado sus dudas.

ADVERTENCIA: Cuando utilice el equipo

siempre es necesario seguir las siguientes

precauciones básicas para el producto,

incluyendo las que se incluyen a continuación:

1. Lea cuidadosamente este manual - familiarícese con

su equipo. Tenga presente las aplicaciones,

limitaciones y los peligros potenciales relacionados

con su unidad.

2. Este producto deberá de conectarse únicamente a un

suministro de electricidad mediante el cable de

electricidad proporcionado con la unidad.

3. No toque el enchufe o la toma con las manos mojadas.

4. Eviten arranques accidentales. Coloquen el interruptor

en OFF antes de conectar o desconectar el cable

eléctrico a una toma.

5. No dirijan nunca el chorro del agua sobre instalaciones

eléctricas o sobre la misma hidrolimpiadora de alta

presión, el hacerlo puede ocasionar fatales sacudidas

eléctricas.

6. Nunca cargue la hidrolimpiadora de alta presión por el

cable. No tire del cable para desconectar elequipo de

la toma.

7. Con el fin de evitar daños, el cable no debe ser

aplastado, no debe colocarse cerca de objetos

cortantes ni de fuentes de calor.

8. Siempre este atento y ponga atención en lo que se

está haciendo.

9. Siga las instrucciones de mantenimiento presentadas

en este manual.

10. Verifique los cables eléctricos antes de su uso. Los

cables dañados pueden reducir el desempeño del

equipo o de la hidrolimpiadora de alta presión o bien

provocar una sacudida eléctrica fatal.

11. Retire a la gente del área de trabajo.

12. Para reducir el riesgo de lesiones, no opere el aparato

cerca de niños.

13. Sujete con ambas manos la hidrolimpiadora de alta

presiónpara mantener el control completo del

lanzador.

14. No toque el lanzador o el chorro de agua cuando esté

en funcionamiento.

15. Utilice lentes de seguridad durante su uso.

16. Desconecten el enchufe eléctrico de la toma cuando

no esté en uso y antes de quitar la manguera de alta

presión.

17. Solamente debe de utilizar las mangueras y los

lanzadores de la hidrolimpiadora de alta presión.

18. Nunca haga nudos ni pliegue la manguera de alta

presión puesto que podría dañarla.

19. Observe cuidadosamente todas las instrucciones

sobre productos químicos y las advertencias antes del

uso.

20. La hidrolimpiadora no debe de utilizarse en áreas

donde existan vapores gaseosos. Una chispa eléctrica

podría provocar una explosión o un incendio.

21. Para minimizar la cantidad de agua que podría entrar

en la hidrolimpiadora de alta presión durante el uso, la

unidad debe de colocarse lo más lejos posible de la

zona a ser limpiada.

22. Para evitar descargas accidentales, la pistola de

chorro debe estar asegurada con el candado de

bloqueo.

23. No utilice el equipo cuando esté fatigado o bajo la

influencia de alcohol o de drogas.

24. Para permitir la libre circulación del aire, la

hidrolimpiadora de alta presión NO debe de estar

cubierta durante su operación.

25. Aprenda como detener el producto o purgar la presión

rápidamente. Familiarícese a fondo con los controles.

26. No se extienda o suba sobre una superficie inestable.

Mantenga una posición firme y buen balance durante

todo el tiempo. .

27. ADVERTENCIA - Riesgo de inyección o lesión. No

apunte el flujo del chorro directamente a las personas.

28. Vea la sección CONEXIONES OPERATIVAS en la

página 31 para obtener información sobre extensiones

eléctricas.

29. Ver la sección 6: MANTENIMIENTO DE UN EQUIPO

CON AISLANTE DOBLE

30. Nunca opere el equipo, si el cordón de alimentación

y/o la clavija, se encuentran dañados, lleve el equipo

al centro de servicio autorizado Powermate, más

cercano a su domicilio, para que un técnico

especializado lo reemplace.

"GUARDE ESTAS INSTRUCCIONES"

1.0 NORMAS OPERATIVAS Y DE SEGURIDAD

Page 26

262728

Page 27

Page 28

Page 29

29

DIAGRAMA DE PIEZAS

LISTA DO DE PIEZAS

Ref.

No.

No. de parte Descripción Qty.

1 012-0127 Pistola de alta presión y ensamble de la manguera 1

2 118-0033 Filtro de agua de entrada 1

3 036-0055 Entrerrosca de entrada para la manguera 1

4 005-0037 Tubo con boquilla variable 1

5 010-0021 Unidad de la lanza de jabón 1

6 095-0053 Ruedas 2

7 024-0194 Unidad de cepillo manual 1

Page 30

30

2.1 AUTOMATIC TOTAL STOP

®

La máquina de lavar a presión cuenta con un dispositivo de

detección que detecta cuándo se libera el gatillo de la

pistola. Abrirá el circuito eléctrico al motor y parará la

máquina de lavar a presión.

ADVERTENCIA: Si la opción de Automatic

Total Stop® no funciona, NO UTILICE LA

MAQUINA. Póngase en contacto con el

Departamento de Atención al Cliente. Si, por

el contrario, continua utilizando la máquina

pueden resultar lesiones o daño a la máquina.

ADVERTENCIA : La máquina de lavar a

presión cuenta también con un interruptor

eléctrico principal de encendido y apagado.

Cuando la hidrolimpiadora no esté en uso, es

necesario que dicho interruptor esté colocado

siempre en apagado (OFF) para prevenir

posibles accidentes o daños.

2.2 SOBRECARGA DEL MOTOR

El motor eléctrico de la hidrolimpiadora posee un dispositivo

de protección contra sobrecarga que bloquea

automáticamente el motor en el caso de exceso de corriente

o en el caso de recalentamiento.

3.1 MANGUERA DE ALTA PRESIÓN

Conecte la manguera de alta presión introduciendo con

cautela la conexión con el empaque en la toma de alta

presión y apriete la tuerca con la mano.

3.2 CONEXIÓN DELAGUA

Antes de efectuar la conexión, haga correr el agua por la

manguera jardín (no incluida en el suministro) para hacer

librarla de cualquier material extraño. Conecte la manguera

del jardín a la conexión de entrada de la hidrolimpiadora de

alta presión (ver figura 1). Si su suministro de agua es de

pozo entonces la longitud de su manguera puede ser de un

máximo de 30 ft.

3.3 CONEXIÓN DEL SUMINISTRO ELÉCTRICO

La lavadora a presión está equipada con un cable eléctrico

de fábrica. Este cable deberá ser conectado únicamente a

una toma eléctrica instalada en conformidad con las

normativas locales de seguridad.

NOTA: La corriente eléctrica deberá ser de 120V, 60 Hz con

un circuito de por lo menos 15 amp. (exclusivo)

A. Conecte sólo a una toma eléctrica con

una puesta a tierra idónea.

B. Inspeccione el cable antes de su uso. Si

está dañado, no utilice el aparato..

C. Mantengan secas y en alto todas las

conexiones.

D. No toquen el enchufe con las manos mojadas.

Si es necesario sustituir el enchufe o la toma, utilice sólo

piezas de repuesto del mismo tipo. Póngase en contacto con

el Departamento de Asistencia Clientes para obtener los

repuestos adecuados.

2.0 CARACTERÍSTICAS DE SEGURIDAD

Fig. 1

ATENCIÓN:

Conexión apropiada del agua.

3.0 CONEXIONES OPERA TIVAS

Page 31

31

3.4 EXTENSIONES ELÉCTRICAS

Utilice exclusivamente extensiones para uso exterior. Dichas

extensiones están marcadas con la frase "Aptas para uso

exterior: si no las utilizan, colóquenlas en un lugar bajo

techo".

Utilice solamente extensiones con una potencia eléctrica

superior a la potencia nominal del equipo.

No utilicen extensiones dañadas. Antes del uso, inspeccione

la extensión y si está dañada substitúyanla.

No utilice la extensión de manera incorrecta y no jale del

cable para desconectarla Mantenga las extensiones

eléctricas lejos de fuente de calor y objetos filosos.

Desenchufe siempre el equipo de la extensión eléctrica.

Cuando utilice extensiones eléctricas tenga presente las

siguientes características:

Longitud del cable Calibre del alambre

Hasta 25 pies 12 AWG exterior

ADVERTENCIA: Mantengan secas y en alto

todas las conexiones. No toquen el enchufe

con las manos mojadas.

A. Inspeccione el cable antes de su uso. Si

está dañado, no utilice el aparato..

B. Mantengan secas y en alto todas las

conexiones.

C. No toquen el enchufe con las manos

mojadas.

ADVERTENCIA: Riesgo de lesión. NO apunte el

flujo de descarga sobre cualquier persona.

4.1 PROCEDIMIENTO DE ARRANQUE

1. Asegúrense de que la alimentación del agua esté

conectada.

2. Asegúrense de que el equipo esté conectado.

3. Libere el candado de la pistola, si está bloqueada. (Fig.

2)

4. Con el fin de permitir la salida de aire de la manguera,

apriete el gatillo de la pistola hasta que salga un flujo

regular de agua por la boquilla.

5. Extraigan cualquier objeto extraño de la salida de la

pistola y del conector macho del lanzador.

6. Introduzcan el lanzador en la unión rápida empujando

enérgicamente y luego girando el lanzador d ¼ de vuelta

para bloquearlo en su lugar. (Fig. 3)

NOTA : Asegúrense de que el lanzador esté enganchado.

ADVERTENCIA: Si el lanzador no está bien

enganchado en su lugar, cuando utilice la

pistola podría ser expulsada debido a la alta

presión.

7. Coloquen el interruptor ON/OFF de la hidrolimpiadora en

la posición ON.

8. Aprieten el gatillo de la pistola; ahora, el motor de la

hidrolimpiadora se pondrá en marcha.

ADVERTENCIA : Asegúrese de que el

lanzador esté apuntando hacia un lugar seguro

cuando arranque la hidrolimpiadora. No lo

apunte hacia la cara o pies, esto puede

ocasionar serias lesiones.

4.2 BOQUILLA DE CHORRO REGULABLE

La boquilla de chorro ajustable puede ajustar el chorro desde

una modalidad de abanico hasta una de punta de lápiz. Para

ajustar el chorro se debe girar la boquilla. (Fig. 4)

PRECAUCIÓN: Utilizar el chorro de punta del

lápiz puede dar resultados muy agresivos.

Aconsejamos utilizar para la mayor parte de las

aplicaciones de limpieza, un ángulo de chorro de

veinte grados (20°) para no dañar las superficies

rociadas.

NOTA: La presión del chorro sobre la superficie que está

limpiando aumenta en proporción al acercamiento de la

boquilla sobre la superficie misma.

Para aumentar el ángulo de un chorro a la forma de abanico,

gire hacia la izquierda.

Para disminuir el ángulo del chorro a la forma de punta de

"lápiz", gire hacia la derecha.

4.2.1 UNIDAD DEL CEPILLO MANUAL

Introduzca el cepillo manual en la pistola (Fig. 3a). Empuje

con firmeza y gire en sentido de las manecillas del reloj

girándolo un 1/4 para asegurarlo en su posición.

3.0 CONEXIONES OPERA TIVAS

4.0 INSTRUCCIONES DE USO

Fig. 3

Fig. 2 Fig. 3a

Page 32

32

4.3 USO DE PRODUCTOS QUÍMICOS DE

LIMPIEZA

1. Retire el vástago.

2. Instale la unidad del dispensador de jabón. (Fig. 5)

3. Retire el recipiente e inspeccione el tubo.

4. El jabón o la cera se mezclarán automáticamente con el

agua y se descargarán a través de la boquilla.

5. Utilice únicamente productos de limpieza aprobados

para lavadoras a presión.

6. La unidad de lanza de jabón está diseñada para el uso a

baja presión al dispensar detergentes. La tasa de

consumo es de hasta de 10:1.

4.4 TÉCNICAS DE LIMPIEZA

Cuando se limpia con la máquina de lavar a presión muchas

de las tareas se pueden realizar efectivamente con pura

agua, pero para muchas tareas, también es conveniente

utilizar detergente. El uso de detergente asegura un

remojado inmediato del área a limpiar, permitiendo que el

agua a alta presión penetre y elimine eficazmente la

suciedad.

4.4.1 APLICACIÓN DE JABÓN

DESENGRASANTE

1. Aplique la solución de jabón de la hidrolimpiadora sobre

una superficie de trabajo seca. NOTA: NO SE

ACONSEJA MOJAR LA SUPERFICIE ANTES, PUESTO

QUE DILUYE EL DETERGENTE Y REDUCE SU

CAPACIDAD DE LIMPIEZA. Ante la presencia de una

superficie vertical, aplique el jabón horizontalmente de

lado a lado empezando desde abajo para evitar rayas.

PRECAUCIÓN: Evite trabajar sobre superficies

calientes o directamente sobre la luz solar para

minimizar así la posibilidad de que el jabón dañe la

pintura de la superficie.

2. Antes de enjuagar, deje que el jabón permanezca sobre

la superficie por un breve lapso de tiempo.

PRECAUCIÓN: Si deja que el jabón se seque

sobre superficies pintadas, éste puede dañar dicha

superficie. Lave y seque una sección a la vez.

3. Enjuague con agua limpia bajo alta presión. Sobre

superficies verticales, comiencen a enjuagar primero

desde la parte de abajo, luego enjuague desde la parte

de arriba hacia abajo. Sujete la boquilla entre 6 y 8

pulgadas de la superficie de trabajo con un ángulo de

45°.

4.4.2 APLICACIÓN DE LA CERA LÍQUICA

1. Inmediatamente después de la limpieza, aplique cera

líquida para vehículos utilizando la unidad dispensadora

de jabón.

2. Aplique la cera con moderación en una capa uniforme.

Aplique a las superficies húmedas desde abajo hacia

arriba para una distribución uniforme y para evitar la

aparición de rayas.

3. Retire el tubo de succión del recipiente de cera y

enjuague el exceso de cera de su vehículo a baja

presión. NOTA: LA CONSECUENCIA DE NO RETIRAR

EL EXCESO DE CERA PODRÍA SER UN ACABADO

EMPAÑADO.

4. Seque para reducir las manchas de agua.

4.5 TERMINO DE LA OPERACIÓN

Cuando haya finalizado de utilizar la aplicación de

jabón/cera, retire el recipiente y enjuague el tubo con agua

limpia hasta que quede completamente limpio.

NOTA: La falta de limpieza adecuada provocará que el

sistema de inyección se obstruya y sea imposible ponerlo en

funcionamiento.

1. Pare el equipo presionando el botón on/off.

2. Desconecte el aparato.

3. Cierre el agua y despresurice el equipo presionando el

gatillo.

ADVERTENCIA: Cierre la alimentación del agua y

presione el gatillo para despresurizar el equipo. El

no realizar estos pasos puede provocar daños a

las personas debido a la descarga del agua a alta

presión.

4. Desconecten la manguera de descarga de alta presión

y la manguera de agua de entrada.

5.1 CONEXIONES

Las conexiones de las mangueras, la pistola y el lanzador de

chorro de la hidrolimpiadora, deben ser limpiados con

regularidad y lubricados con grasa para evitar fugas y el

daño a los empaques.

5.2 BOQUILLA

El dispositivo de regulación de la boquilla debe lubricarse

con regularidad.

La obstrucción de la boquilla provoca que el aumento de la

presión de la bomba sea muy alto y esto requiere una

limpieza inmediata.

1. Separe la boquilla del vástago (Fig. 6).

2. Limpie la boquilla pasando un alambre por el orificio

central.

3. Laven a reflujo con agua.

4. Reconecte la boquilla al vástago.

4.0 INSTRUCCIONES DE USO

Fig. 4

Fig. 5

5.0 MANTENIMIENTO

Page 33

33

NOTA: atornille completamente las boquillas en el vástago

hasta que queden completamente firmes. (Consulte la Fig. 6)

Reinicie la hidrolimpiadora y presione el gatillo de la pistola

de esperado. Si la boquilla está tapada, repita los pasos 1 y

4.

5.3 LUBRICACIÓN

La hidrolimpiadora está diseña con un sistema de lubricación

permanente. No son necesarios controles convencionales ni

cambio de aceites.

NOTA : EN EL CASO DE FUGAS DE ACEITE,

CONTACTEN AL DEPARTAMENTO DE SERVICIO AL

CLIENTE, DEPARTAMENTO DE REPARACIONES. UNA

PEQUEÑA PÉRDIDA DE ACEITE ES NORMAL.

5.4 FILTRO AGUA

La hidrolimpiadora está dotada de un filtro de entrada de

agua para proteger la bomba.

PRECAUCIÓN : Si no se mantiene limpio el filtro,

el flujo del agua hacia la hidrolimpiadora se ve

limitado y la bomba puede dañarse.

1. Para limpiar la pantalla de agua cónica interna, retire la

conexión rápida y retire la pantalla plástica de la entrada

de la bomba.

2. Realice el retrolavado de la pantalla para limpiarla.

3. Reemplace la pantalla y conecte rápidamente la

conexión para impedir que todo material externo ingrese

en la bomba.

PRECAUCIÓN: Tenga cuidado de no dañar el filtro

cuando lo quite para limpiarlo . Cualquier partícula

extraña que pudiera entrar en la bomba puede

dañarla.

5.5 SISTEMA DE ENFRIAMIENTO

Los respiraderos de aire colocados alrededor de la

hidrolimpiadora , deben mantenerse limpios y libres de

cualquier obstrucción para garantizar el enfriamiento del

motor con aire fresco.

PRECAUCIÓN: Evite que el agua penetre en los

respiraderos de la hidrolimpiadora para que el

riesgo de dañar la máquina sea mínimo y para

reducir el peligro de sacudida eléctrica al operador.

Un equipo con doble aislamiento cuenta con dos

sistemas de aislamiento en lugar de la tierra. El

no tener tierra quiere decir es un producto con

doble aislamiento, ni se tiene que agregar una

tierra a la hidrolimpiadora. El dar mantenimiento a este tipo

de instalación requiere mucho cuidado, un buen

conocimiento del sistema y debe ser efectuada solamente

por personal calificado. Las piezas de repuesto de una

instalación de doble aislamiento deben ser idénticas a la

piezas que hay que cambiar. Estos equipos están

identificados por las palabras "DOBLE AISLAMIENTO"

(DOUBLE-INSULATION o DOUBLE-INSULATED). El equipo

puede estar identificado también con el siguiente símbolo.

PRECAUCIÓN: Almacene la hidrolimpiadora en un

lugar cuya temperatura no descienda por debajo de

los 40°F. En el caso de congelamiento, la bomba

del equipo está sujeta a daño permanente. LOS

DAÑOS PROVOCADOS POR EL HIELO NO

ESTÁN CUBIERTOS POR LA GARANTÍA.

Con el fin de perfeccionar la calidad, el Fabricante se reserva

el derecho de efectuar las modificaciones a los proyectos o

componentes, si lo considera oportuno.

5.0 MANTENIMIENTO

Fig. 6

6.0 MANTENIMIENTO DEL EQUIPO

CON DOBLE AISLAMIENTO

7.0 INSTRUCCIONES DE MANEJO Y

ALMACENAMIENTO

8.0 DATOS TÉCNICOS

Presión de bomba

1500 PSI Max

*Presión de uso max.

Sistema eléctrico

necesario

120 V, 15 Amp., 60 Hz

Cable eléctrico 23 pies

Manguera alta presión 19 pies

Velocidad de flujo 1.5 gpm

Fuente mínima de

amperaje

15 Amp.

Presión del agua de

entrada

de 20 a 100 psi

Agua de entrada Agua fría de la llave

Porcentaje de consumo

de jabón

10 % Max.

*Flujo de agua y tasa de máxima presión determinado del

acuerdo y PWMA. Standard PW101.

Page 34

34

9.0 LOCALIZACIÓN Y SOLUCIÓN DE PROBLEMAS

PROBLEMAS CAUSAS PROBABLES SOLUCIÓN

El motor no arranca o se detiene

durante el funcionamiento

Cable de corriente eléctrica incorrecto Utilizar el cable correcto. Ver manual de

operaciones sección 3.3.

Clavija floja ó desconectada Conectar nuevamente la clavija.

Sobrecarga del breaker Permita que se enfríe la unidad y volver a

arrancarla .

Gatillo de la pistola rociadora no

funciona

Póngase en contacto con un técnico del

Cuidado al Cliente.

Pistola defectuosa Quite la pistola, drenar el agua lejos de la

corriente eléctrica, presionar ON. Si la

maquina arranca, reemplace el ensamblaje de

la pistola poniéndose en contacto un técnico

de cuidado al Cliente.

El interruptor del circuito se zafa

o están quemados los fusibles de

la caja de fusibles

Sobrecarga eléctrica Verificar que el circuito tenga 15 amperes o

más.

Cable eléctrico muy largo o medida del

cable chica

Utilizar el cable correcto como se recomienda

en el manual de operaciones sección 3.3.

Boquilla bloqueada Limpie la boquilla como se indica en la sección

5.2.

Demasiada presión Limpie la boquilla como se indica en la sección

5.2.

Hay pérdidas de agua y aceite

en el fondo de la bomba

Una fuga pequeña es normal Si se trata de una fuga grande, póngase en

contacto con un técnico de Cuidado al Cliente.

El gatillo no se mueve . Seguro de la pistola activado Desactive el candado.

El equipo no se detiene cuando

se suelta el gatillo