PI-2632-060200

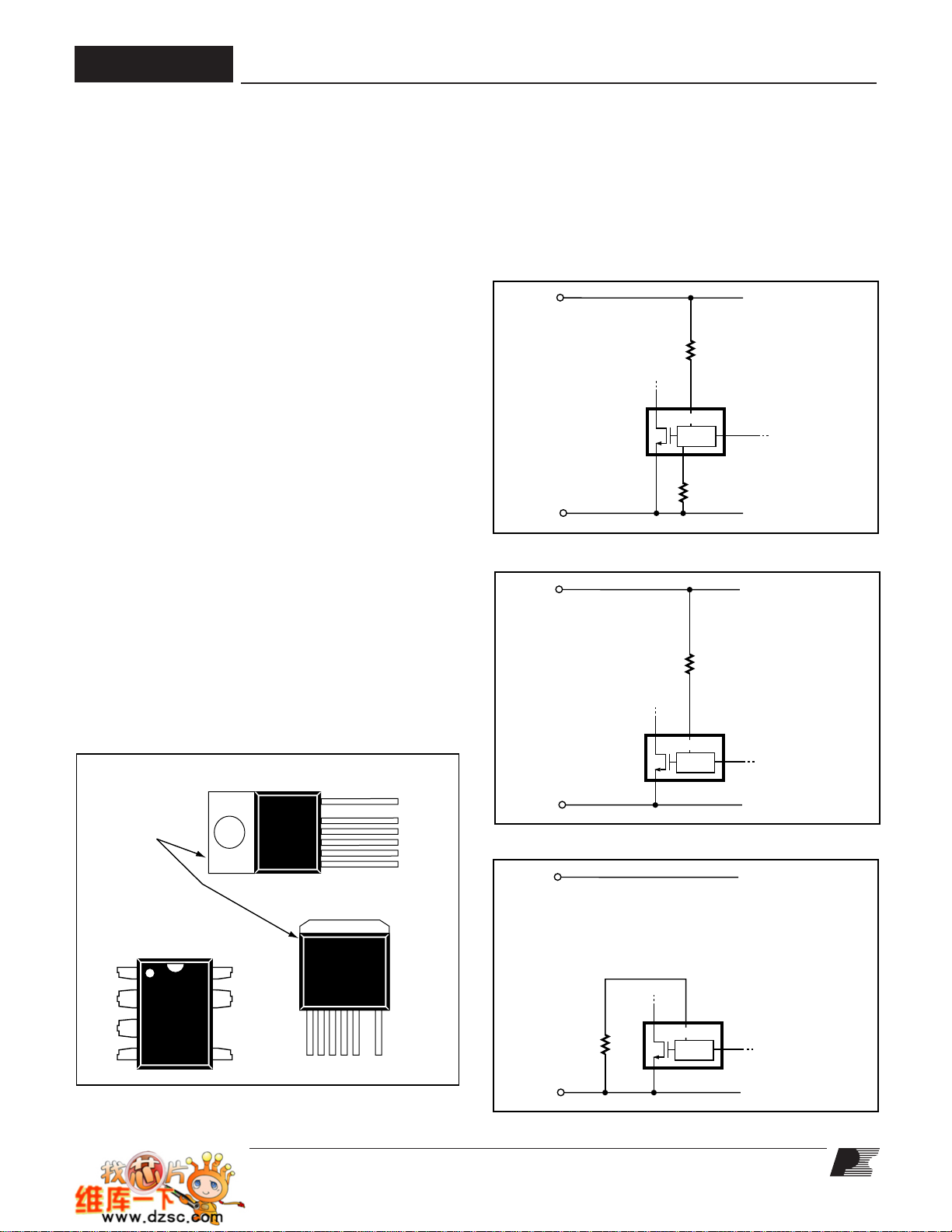

AC

IN

DC

OUT

D

S

C

TOPSwitch-GX

CONTROL

L

+

-

FX

查询TOP250Y/F供应商查询TOP250Y/F供应商

TOP242-250

TOPSwitch-GX Family

Extended Power, Design Flexible,

EcoSmart

Lower System Cost, High Design Flexibility

• Extended power range for higher power applications

• No heatsink required up to 34 W using P/G packages

• Features eliminate or reduce cost of external components

• Fully integrated soft-start for minimum stress/overshoot

• Externally programmable accurate current limit

• Wider duty cycle for more power, smaller input capacitor

• Separate line sense and current limit pins on Y/R/F packages

• Line under-voltage (UV) detection: no turn off glitches

• Line overvoltage (OV) shutdown extends line surge limit

• Line feed-forward with maximum duty cycle (DC

• Frequency jittering reduces EMI and EMI filtering costs

• Regulates to zero load without dummy loading

• 132 kHz frequency reduces transformer/power supply size

• Half frequency option in Y/R/F packages for video applications

• Hysteretic thermal shutdown for automatic fault recovery

• Large thermal hysteresis prevents PC board overheating

EcoSmart

• Extremely low consumption in remote off mode

• Frequency lowered with load for high standby efficiency

• Allows shutdown/wake-up via LAN/input port

Description

TOPSwitch-GX uses the same proven topology as TOPSwitch,

cost effectively integrating the high voltage power MOSFET,

PWM control, fault protection and other control circuitry onto

a single CMOS chip. Many

reduce system cost and improve design flexibility, performance

and energy efficiency.

Depending on package type, either 1 or 3 additional pins over

the TOPSwitch standard DRAIN, SOURCE and CONTROL

terminals allow the following functions: line sensing (OV/UV,

line feed-forward/DC

current limit, remote ON/OFF, synchronization to an external

lower frequency, and frequency selection (132 kHz/66 kHz).

All package types provide the following transparent features:

Soft-start, 132 kHz switching frequency (automatically reduced

at light load), frequency jittering for lower EMI, wider DC

hysteretic thermal shutdown, and larger creepage packages. In

addition, all critical parameters (i.e. current limit, frequency,

PWM gain) have tighter temperature and absolute tolerances

to simplify design and optimize system cost.

November 2005

®

®

, Integrated Off-line Switcher

Product Highlights

reduction rejects line ripple and limits DC

– Energy Efficient

(80 mW at 110 VAC, 160 mW at 230 VAC)

new functions are integrated to

reduction), accurate externally set

MAX

MAX

MAX

at high line

)

Figure 1. Typical Flyback Application.

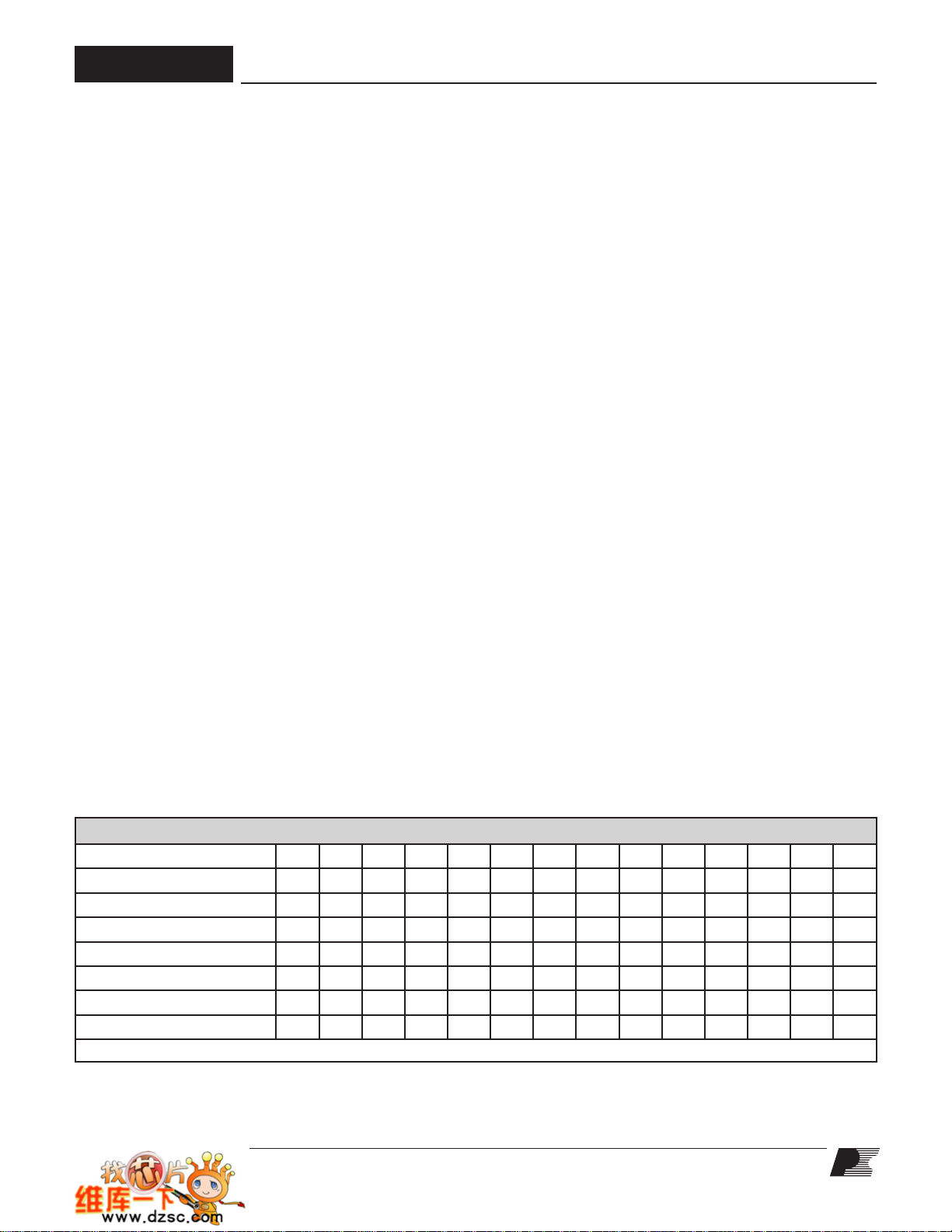

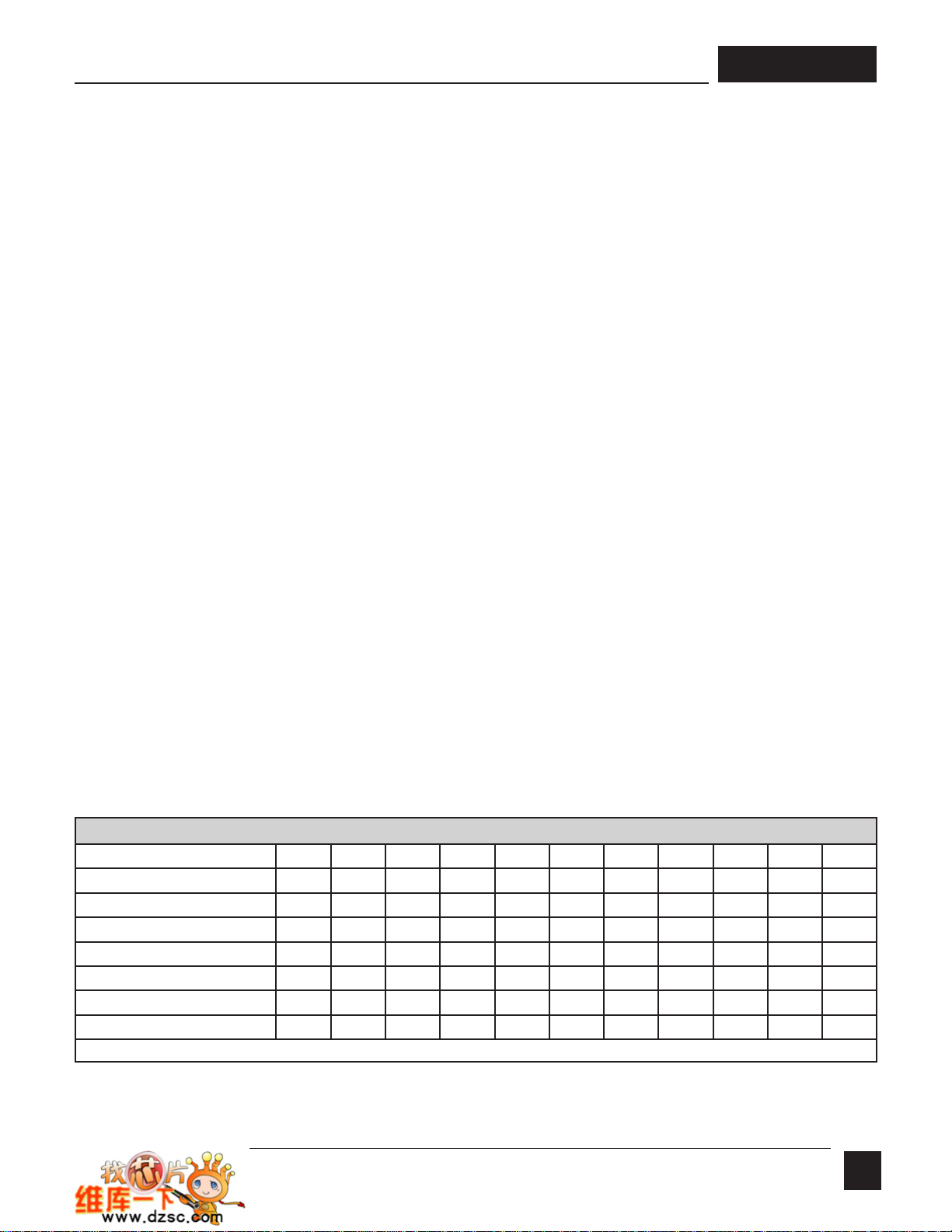

OUTPUT POWER TABLE

Open

Frame

15 W

22 W

22 W

25 W

45 W

45 W

28 W

50 W

65 W

30 W

57 W

85 W

34 W

64 W

125 W

70 W

165 W

75 W

205 W

79 W

250 W

82 W

290 W

4

Adapter

2

6.5 W

85-265 VAC

1

Frame

11 W

7 W

9 W

17 W

15 W

11 W

20 W

20 W

13 W

23 W

26 W

15 W

26 W

40 W

28 W

55 W

125 W

30 W

70 W

155 W

31 W

80 W

180 W

32 W

90 W

210 W

Open

2

10 W

14 W

14 W

15 W

23 W

30 W

20 W

28 W

45 W

22 W

33 W

60 W

26 W

38 W

90 W

43 W

48 W

53 W

55 W

MAX

230 VAC ±15%

PRODUCT

TOP242 P or G

TOP242 R

TOP242 Y or F

TOP243 P or G

TOP243 R

TOP243 Y or F

TOP244 P or G

TOP244 R

TOP244 Y or F

TOP245 P or G

TOP245 R

TOP245 Y or F

TOP246 P or G

TOP246 R

TOP246 Y or F

TOP247 R

TOP247 Y or F

TOP248 R

TOP248 Y or F

TOP249 R

TOP249 Y or F

TOP250 R

TOP250 Y or F

Table 1. Notes: 1. Typical continuous power in a non-ventilated enclosed

,

adapter measured at 50

power in an open frame design at 50 °C ambient. See Key Applications

for detailed conditions. 3. For lead-free package options, see Part

Ordering Information. 4. 230 VAC or 100/115 VAC with doubler.

3

Adapter

1

9 W

15 W

10 W

13 W

29 W

20 W

16 W

34 W

30 W

19 W

37 W

40 W

21 W

40 W

60 W

42 W

85 W

43 W

105 W

44 W

120 W

45 W

135 W

°C ambient. 2. Maximum practical continuous

TOP242-250

Section List

Functional Block Diagram ....................................................................................................................................... 3

Pin Functional Description ...................................................................................................................................... 4

TOPSwitch-GX

CONTROL (C) Pin Operation .................................................................................................................................. 6

Oscillator and Switching Frequency ........................................................................................................................ 6

Pulse Width Modulator and Maximum Duty Cycle .................................................................................................. 7

Light Load Frequency Reduction ............................................................................................................................ 7

Error Amplifier ......................................................................................................................................................... 7

On-Chip Current Limit with External Programmability ............................................................................................ 7

Line Under-Voltage Detection (UV) ......................................................................................................................... 8

Line Overvoltage Shutdown (OV) ........................................................................................................................... 8

Line Feed-Forward with DC

Remote ON/OFF and Synchronization ................................................................................................................... 9

Soft-Start ................................................................................................................................................................. 9

Shutdown/Auto-Restart ........................................................................................................................................... 9

Hysteretic Over-Temperature Protection ................................................................................................................. 9

Bandgap Reference .............................................................................................................................................. 10

High-Voltage Bias Current Source ........................................................................................................................ 10

Using Feature Pins ................................................................................................................................................... 10

FREQUENCY (F) Pin Operation ........................................................................................................................... 10

LINE-SENSE (L) Pin Operation ............................................................................................................................ 10

EXTERNAL CURRENT LIMIT (X) Pin Operation .................................................................................................. 11

MULTI-FUNCTION (M) Pin Operation .................................................................................................................. 11

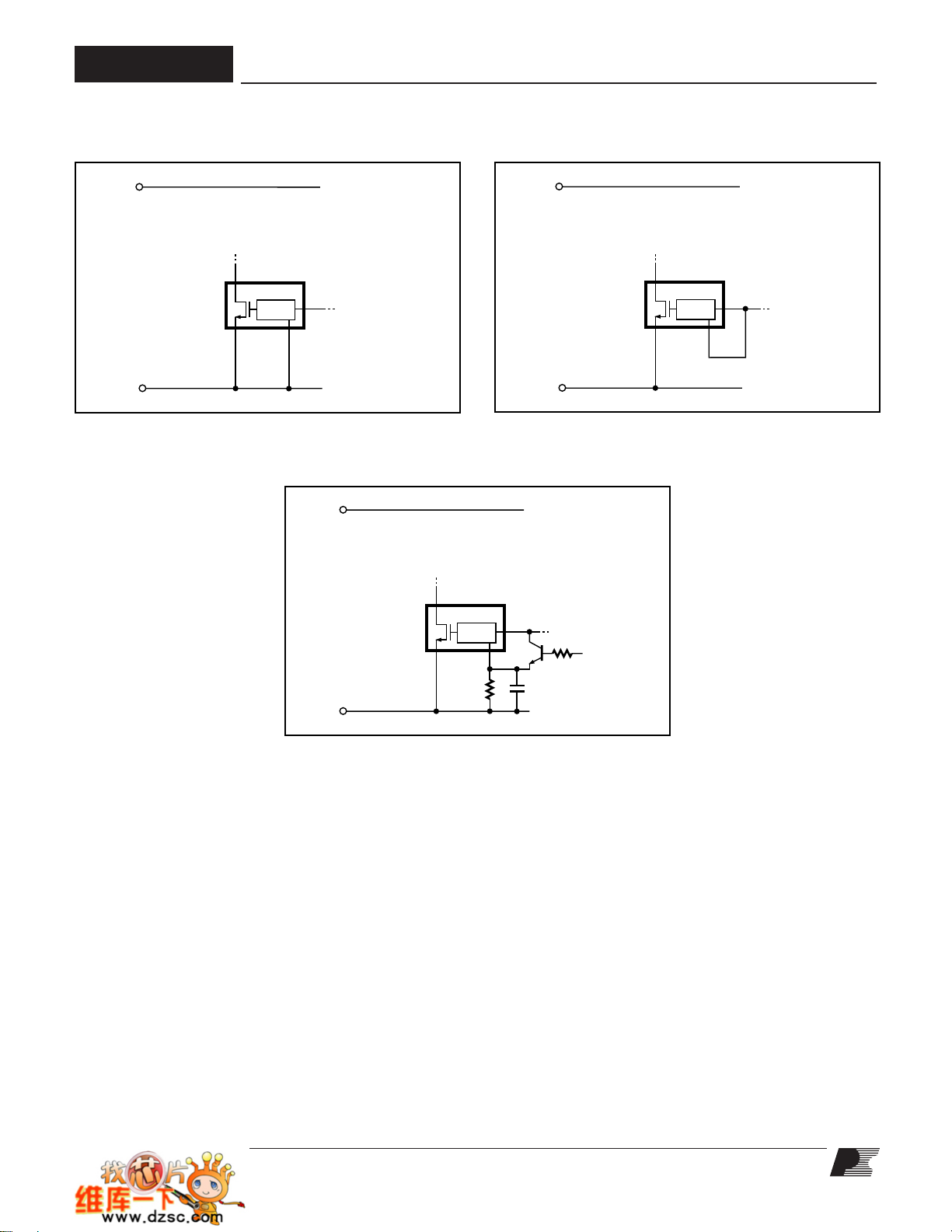

Typical Uses of FREQUENCY (F) Pin

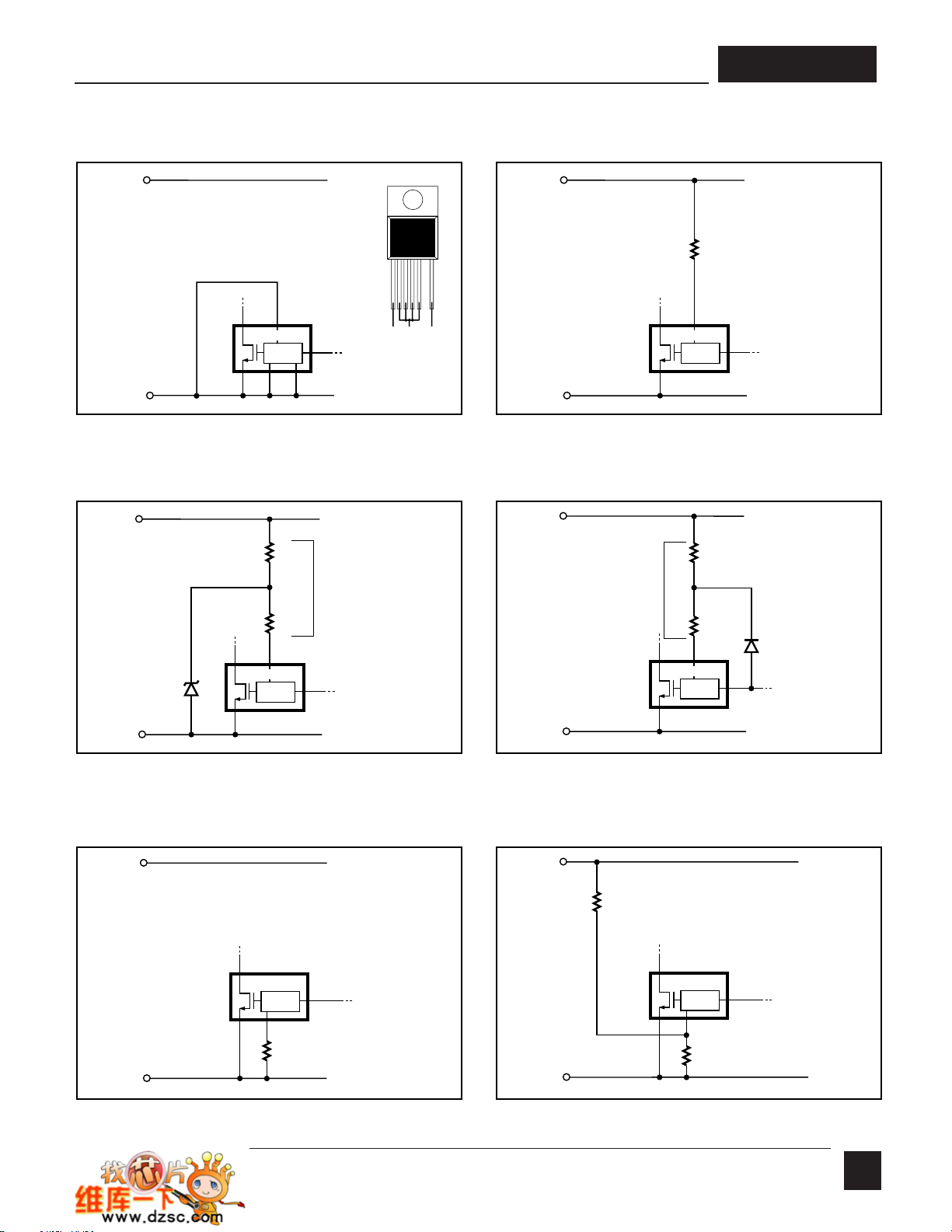

Typical Uses of LINE-SENSE (L) and EXTERNAL CURRENT LIMIT (X) Pins

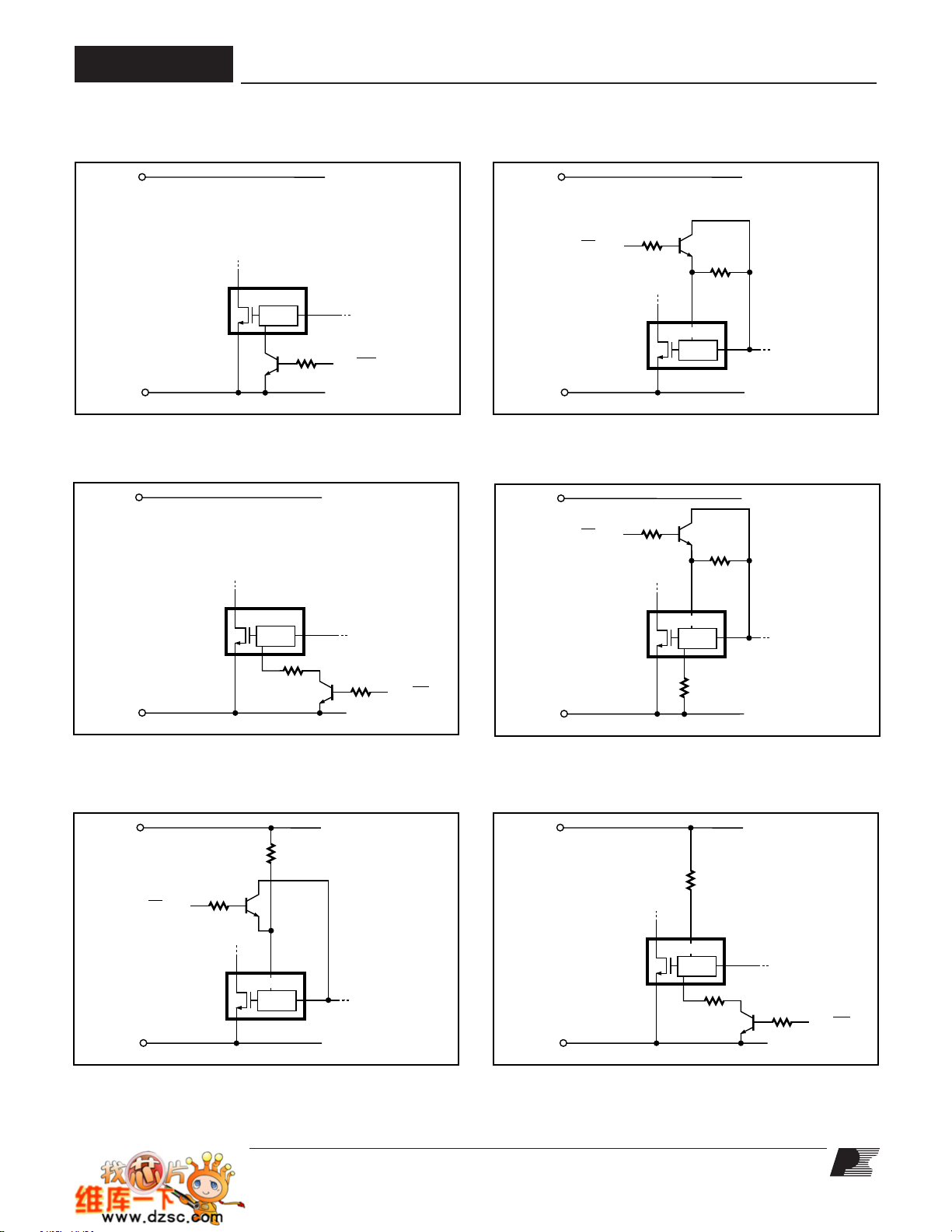

Typical Uses of MULTI-FUNCTION (M) Pin

Application Examples .............................................................................................................................................. 20

A High Efficiency, 30 W, Universal Input Power Supply ........................................................................................ 20

A High Efficiency, Enclosed, 70 W, Universal Adapter Supply .............................................................................. 20

A High Efficiency, 250 W, 250-380 VDC Input Power Supply ............................................................................... 22

Multiple Output, 60 W, 185-265 VAC Input Power Supply .................................................................................... 23

Processor Controlled Supply Turn On/Off ............................................................................................................. 24

Key Application Considerations

TOPSwitch-II

TOPSwitch-FX

TOPSwitch-GX

TOPSwitch-GX

Quick Design Checklist .........................................................................................................................................

Design Tools ......................................................................................................................................................... 32

Product Specifications and Test Conditions

Typical Performance Characteristics

Part Ordering Information ....................................................................................................................................... 46

Package Outlines ..................................................................................................................................................... 47

Family Functional Description ....................................................................................................... 5

Reduction ..............................................................................................................8

MAX

...................................................................................................................... 14

...................................................... 15

........................................................................................................... 17

............................................................................................................................. 26

vs.

TOPSwitch-GX

vs.

TOPSwitch-GX

Design Considerations ............................................................................................................... 28

Layout Considerations ................................................................................................................. 30

.......................................................................................................................... 26

....................................................................................................................... 28

32

......................................................................................................... 33

.................................................................................................................... 40

O

11/05

2

TOP242-250

PI-2639-060600

SHUTDOWN/

AUTO-RESTART

PWM

COMPARATOR

CLOCK

SAW

HALF

FREQ.

CONTROLLED

TURN-ON

GATE DRIVER

CURRENT LIMI

T

COMPARATOR

INTERNAL UV

COMPARATOR

INTERNAL

SUPPLY

5.8 V

4.8

V

SOURCE (S

)

SRQ

D

MAX

STOP

SOFTSTART

-

+

CONTROL (C)

LINE-SENSE (L

)

EXTERNAL

CURRENT LIMIT (X)

FREQUENCY (F

)

-

+

5.8 V

1

V

I

FB

R

E

Z

C

V

C

+

-

LEADING

EDGE

BLANKING

÷ 8

1

HYSTERETIC

THERMAL

SHUTDOWN

SHUNT REGULATOR/

ERROR AMPLIFIER

+

-

DRAIN (D)

ON/OFF

SOFT

START

DC

MAX

V

BG

DC

MAX

V

BG

+ V

T

0

OV/UV

V

I (LIMIT)

CURRENT

LIMIT

ADJUST

LINE

SENSE

SOFT START

LIGHT LOAD

FREQUENCY

REDUCTION

STOP LOGIC

OSCILLATOR WITH JITTER

PI-2641-061200

SHUTDOWN/

AUTO-RESTART

PWM

COMPARATOR

CLOCK

SAW

CONTROLLED

TURN-ON

GATE DRIVE

R

CURRENT LIMI

T

COMPARATOR

INTERNAL UV

COMPARATOR

INTERNAL

SUPPLY

5.8 V

4.8

V

SOURCE (S

)

SRQ

D

MAX

STOP

SOFT-

START

-

+

CONTROL (C)

MULTI

-

FUNCTION (M

)

-

+

5.8 V

I

FB

R

E

Z

C

V

C

+

-

LEADING

EDGE

BLANKING

÷ 8

1

HYSTERETIC

THERMAL

SHUTDOWN

SHUNT REGULATOR/

ERROR AMPLIFIER

+

-

DRAIN (D)

ON/OFF

SOFT

START

DC

MAX

V

BG

DC

MAX

V

BG

+ V

T

0

OV/UV

V

I (LIMIT)

CURRENT

LIMIT

ADJUST

LINE

SENSE

SOFT START

LIGHT LOAD

FREQUENCY

REDUCTION

STOP LOGIC

OSCILLATOR WITH JITTER

Figure 2a. Functional Block Diagram (Y, R or F Package).

Figure 2b. Functional Block Diagram (P or G Package).

O

11/05

3

TOP242-250

PI-2724-010802

Tab Internally

Connected to

SOURCE Pin

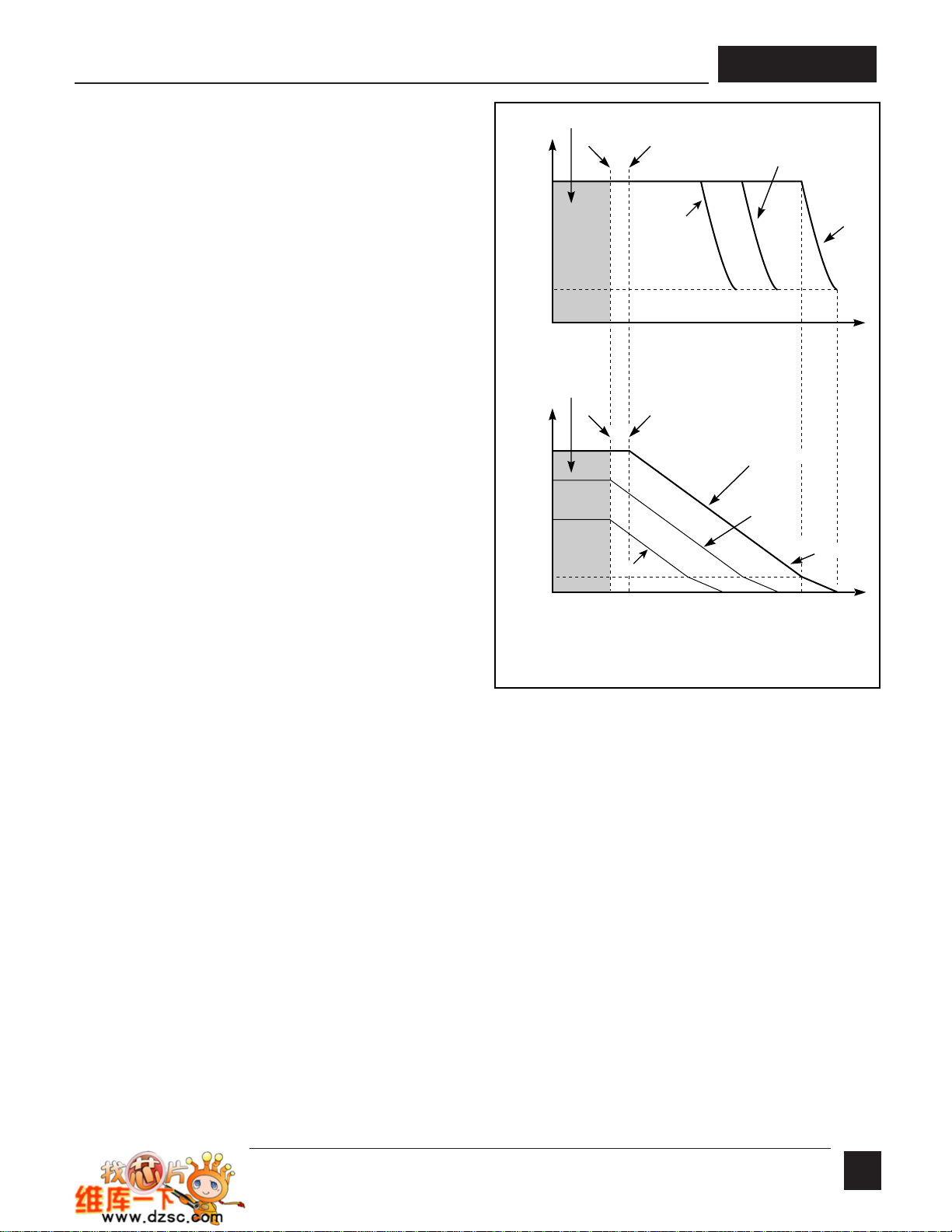

Y Package (TO-220-7C)

C

D

S

S

S

S

1 C

3 X

2 L

5 F

4 S

7 D

M

P Package (DIP-8B)

G Package (SMD-8B)

R Package (TO-263-7C)

F Package (TO-262-7C)

8

5

7

1

1 2 3 4 5 7

C L X S F D

4

2

3

X

PI-2629-092203

DC

Input

Voltage

+

-

D

S

C

CONTROL

L

R

IL

R

LS

12 kΩ

2

MΩ

VUV = IUV x R

LS

V

OV = IOV x RLS

For RLS = 2 MΩ

DC

MAX

@100 VDC = 78%

DC

MAX

@375 VDC = 38%

For

RIL = 12 kΩ

I

LIMIT

= 69%

See Figure 54b for

other resistor values

(R

IL

) to select different

I

LIMIT

values

VUV = 100 VDC

VOV = 450 VDC

PI-2509-040501

DC

Input

Voltage

+

-

D M

S

C

VUV = IUV x R

LS

V

OV = IOV x RLS

For RLS = 2 MΩ

VUV = 100 VDC

V

OV =

450 VDC

DC

MAX

@100 VDC = 78%

DC

MAX

@375 VDC = 38%

CONTROL

R

LS

2 MΩ

PI-2517-022604

DC

Input

Voltage

+

-

D M

S

C

For R

IL

= 12 kΩ

I

LIMIT

= 69%

CONTROL

R

IL

See Figures 54b, 55b

and 56b for other resistor

values (R

IL

) to select

different

I

LIMIT

values.

For R

IL

= 25 kΩ

I

LIMIT

= 43%

Pin Functional Description

DRAIN (D) Pin:

High voltage power MOSFET drain output. The internal

start-up bias current is drawn from this pin through a switched

high-voltage current source. Internal current limit sense point

for drain current.

CONTROL (C) Pin:

Error amplifier and feedback current input pin for duty cycle

control. Internal shunt regulator connection to provide internal

bias current during normal operation. It is also used as the

connection point for the supply bypass and auto-restart/

compensation capacitor.

LINE-SENSE (L) Pin: (Y, R or F package only)

Input pin for OV, UV, line feed forward with DC

remote ON/OFF and synchronization. A connection to SOURCE

pin disables all functions on this pin.

EXTERNAL CURRENT LIMIT (X) Pin: (Y, R or F package

only)

Input pin for external current limit adjustment, remote

ON/OFF, and synchronization. A connection to SOURCE pin

disables all functions on this pin.

reduction,

MAX

FREQUENCY (F) Pin: (Y, R or F package only)

Input pin for selecting switching frequency: 132 kHz if

connected to SOURCE pin and 66 kHz if connected to

CONTROL pin. The switching frequency is internally set for

fixed 132 kHz operation in P and G packages.

SOURCE (S) Pin:

Output MOSFET source connection for high voltage power

return. Primary side control circuit common and reference point.

Figure 4. Y/R/F Pkg Line Sense and Externally Set Current Limit.

MULTI-FUNCTION (M) Pin:

This pin combines the functions of the LINE-SENSE (L) and

EXTERNAL CURRENT LIMIT (X) pins of the Y package

into one pin. Input pin for OV, UV, line feed forward with

DC

reduction, external current limit adjustment, remote

MAX

ON/OFF and synchronization. A connection to SOURCE pin

disables all functions on this pin and makes TOPSwitch-GX

operate in simple three terminal mode (like TOPSwitch-II).

Figure 3. Pin Configuration (top view).

4

O

11/05

(P or G package only)

Figure 5. P/G Package Line Sense.

Figure 6. P/G Package Externally Set Current Limit.

TOPSwitch-GX Family Functional

PI-2633-011502

Duty Cycle (%)

IC (mA)

TOP242-5 1.6 2.0

TOP246-9 2.2 2.6

TOP250 2.4 2.7

5.2 6.0

5.8 6.6

6.5 7.3

I

CD1

I

B

Auto-restart

IL = 125 µA

IL < I

L(DC)

IL = 190 µA

78

10

38

Frequency (kHz)

IC (mA)

30

I

CD1

I

B

Auto-restart

132

Note: For P and G packages IL is replaced with IM.

IL < I

L(DC)

IL = 125 µA

Slope = PWM Gain

IL = 190 µA

Description

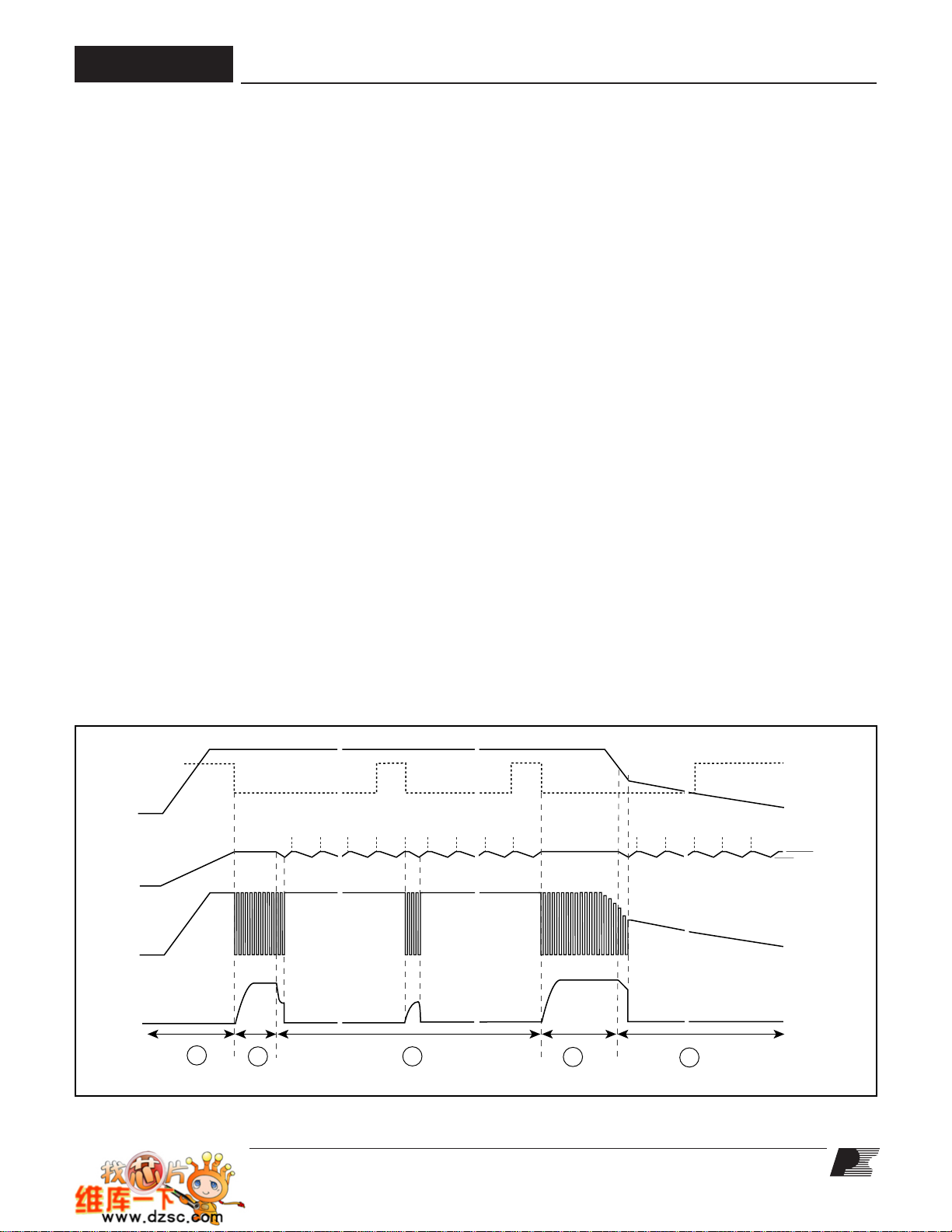

Like TOPSwitch, TOPSwitch-GX is an integrated switched

mode power supply chip that converts a current at the control

input to a duty cycle at the open drain output of a high voltage

power MOSFET. During normal operation the duty cycle

of the power MOSFET decreases linearly with increasing

CONTROL pin current as shown in Figure 7.

In addition to the three terminal TOPSwitch features, such as

the high voltage start-up, the cycle-by-cycle current limiting,

loop compensation circuitry, auto-restart, thermal shutdown,

the TOPSwitch-GX incorporates many additional functions that

reduce system cost, increase power supply performance and

design flexibility. A patented high voltage CMOS technology

allows both the high voltage power MOSFET and all the low

voltage control circuitry to be cost effectively integrated onto

a single monolithic chip.

Th ree ter min als , FR EQU ENC Y, LIN E-S ENS E, a nd

EXTERNAL CURRENT LIMIT (available in Y, R or F

package) or one terminal MULTI-FUNCTION (available in P

or G package) have been added to implement some of the new

functions. These terminals can be connected to the SOURCE

pin to operate the TOPSwitch-GX in a TOPSwitch-like three

terminal mode. However, even in this three terminal mode, the

TOPSwitch-GX offers many new transparent features that do

not require any external components:

TOP242-250

1. A fully integrated 10 ms soft-start limits peak currents

and voltages during start-up and dramatically reduces or

eliminates output overshoot in most applications.

2. DC

input voltage requirement and/or higher power capability.

3. Frequency reduction at light loads lowers the switching

losses and maintains good cross regulation in multiple output

supplies.

4. Higher switching frequency of 132 kHz reduces the

transformer size with no noticeable impact on EMI.

5. Frequency jittering reduces EMI.

6. Hysteretic over-temperature shutdown ensures automatic

recovery from thermal fault. Large hysteresis prevents

circuit board overheating.

7. Packages with omitted pins and lead forming provide large

drain creepage distance.

8. Tighter absolute tolerances and smaller temperature

variations on switching frequency, current limit and PWM gain.

The LINE-SENSE (L) pin is usually used for line sensing by

connecting a resistor from this pin to the rectified DC high

voltage bus to implement line overvoltage (OV), under-voltage

(UV) and line feed-forward with DC

mode, the value of the resistor determines the OV/UV thresholds

and the DC

above the under-voltage threshold. See Table 2 and Figure 11.

of 78% allows smaller input storage capacitor, lower

MAX

is reduced linearly starting from a line voltage

MAX

reduction. In this

MAX

Figure 7. Relationship of Duty Cycle and Frequency to CONTROL

Pin Current.

The pin can also be used as a remote ON/OFF and a

synchronization input.

The EXTERNAL CURRENT LIMIT (X) pin is usually used

to reduce the current limit externally to a value close to the

operating peak current, by connecting the pin to SOURCE

through a resistor. This pin can also be used as a remote

ON/OFF and a synchronization input in both modes. See

Table 2 and Figure 11.

For the P or G packages the LINE-SENSE and EXTERNAL

CURRENT LIMIT pin functions are combined on one MULTIFUNCTION (M) pin. However, some of the functions become

mutually exclusive as shown in Table 3.

The FREQUENCY (F) pin in the Y, R or F package sets the

switching frequency to the default value of 132 kHz when

connected to SOURCE pin. A half frequency option of

66 kHz can be chosen by connecting this pin to CONTROL pin

instead. Leaving this pin open is not recommended.

11/05

O

5

TOP242-250

PI-2545-082299

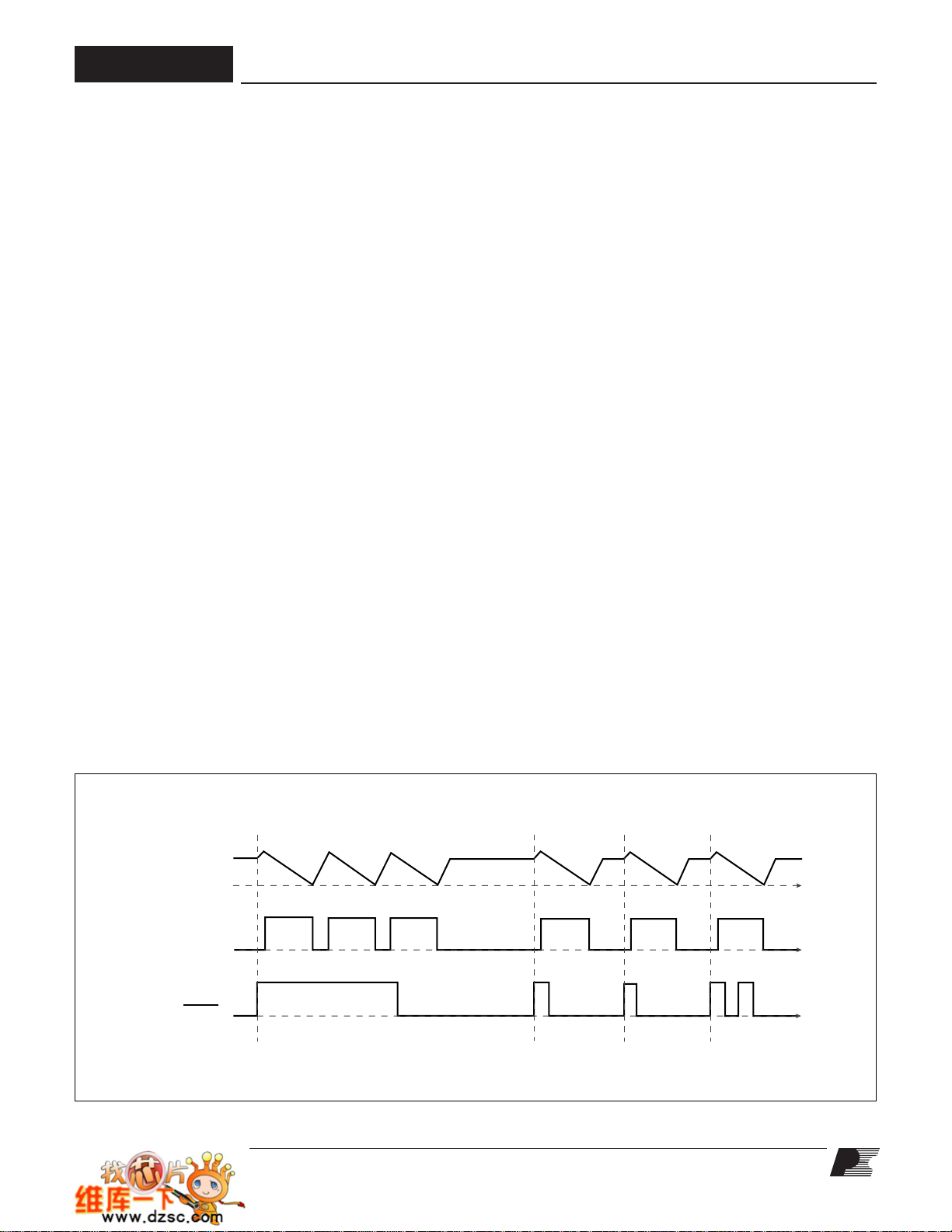

S1 S2 S6 S7 S1 S2 S6 S7S0

S1 S7

S0

S0

5.8 V

4.8

V

S7

0 V

0 V

0 V

V

LINE

V

C

V

DRAIN

V

OUT

Note: S0 through S7 are the output states of the auto-restart counter

2

1

2

3

4

0 V

~

~

~

~

~

~

~

~

~

~

S6 S7

~

~

~

~

~

~

~

~

V

UV

~

~

~

~

~

~

~

~

S2

~

~

CONTROL (C) Pin Operation

The CONTROL pin is a low impedance node that is capable

of receiving a combined supply and feedback current. During

normal operation, a shunt regulator is used to separate the

feedback signal from the supply current. CONTROL pin voltage

VC is the supply voltage for the control circuitry including the

MOSFET gate driver. An external bypass capacitor closely

connected between the CONTROL and SOURCE pins is required

to supply the instantaneous gate drive current. The total amount

of capacitance connected to this pin also sets the auto-restart

timing as well as control loop compensation.

When rectified DC high voltage is applied to the DRAIN

pin during start-up, the MOSFET is initially off, and the

CONTROL pin capacitor is charged through a switched high

voltage current source connected internally between the DRAIN

and CONTROL pins. When the CONTROL pin voltage VC

reaches approximately 5.8 V, the control circuitry is activated

and the soft-start begins. The soft-start circuit gradually

increases the duty cycle of the MOSFET from zero to the

maximum value over approximately 10 ms. If no external

feedback/supply current is fed into the CONTROL pin by the

end of the soft-start, the high voltage current source is turned

off and the CONTROL pin will start discharging in response

to the supply current drawn by the control circuitry. If the

power supply is designed properly, and no fault condition

such as open loop or shorted output exists, the feedback loop

will close, providing external CONTROL pin current, before

the CONTROL pin voltage has had a chance to discharge to

the lower threshold voltage of approximately 4.8 V (internal

supply under-voltage lockout threshold). When the externally

fed current charges the CONTROL pin to the shunt regulator

voltage of 5.8 V, current in excess of the consumption of the

chip is shunted to SOURCE through resistor R

E

Figure 2. This current flowing through RE controls the duty cycle

of the power MOSFET to provide closed loop regulation. The

shunt regulator has a finite low output impedance ZC that sets

the gain of the error amplifier when used in a primary feedback

configuration. The dynamic impedance ZC of the CONTROL

pin together with the external CONTROL pin capacitance sets

the dominant pole for the control loop.

When a fault condition such as an open loop or shorted output

prevents the flow of an external current into the CONTROL

pin, the capacitor on the CONTROL pin discharges towards

4.8 V. At 4.8 V, auto-restart is activated which turns the output

MOSFET off and puts the control circuitry in a low current

standby mode. The high-voltage current source turns on and

charges the external capacitance again. A hysteretic internal

supply under-voltage comparator keeps V

within a window

C

of typically 4.8 V to 5.8 V by turning the high-voltage current

source on and off as shown in Figure 8. The auto-restart

circuit has a divide-by-eight counter which prevents the output

MOSFET from turning on again until eight discharge/charge

cycles have elapsed. This is accomplished by enabling the

output MOSFET only when the divide-by-eight counter reaches

full count (S7). The counter effectively limits TOPSwitch-GX

power dissipation by reducing the auto-restart duty cycle

to typically 4%. Auto-restart mode continues until output

voltage regulation is again achieved through closure of the

feedback loop.

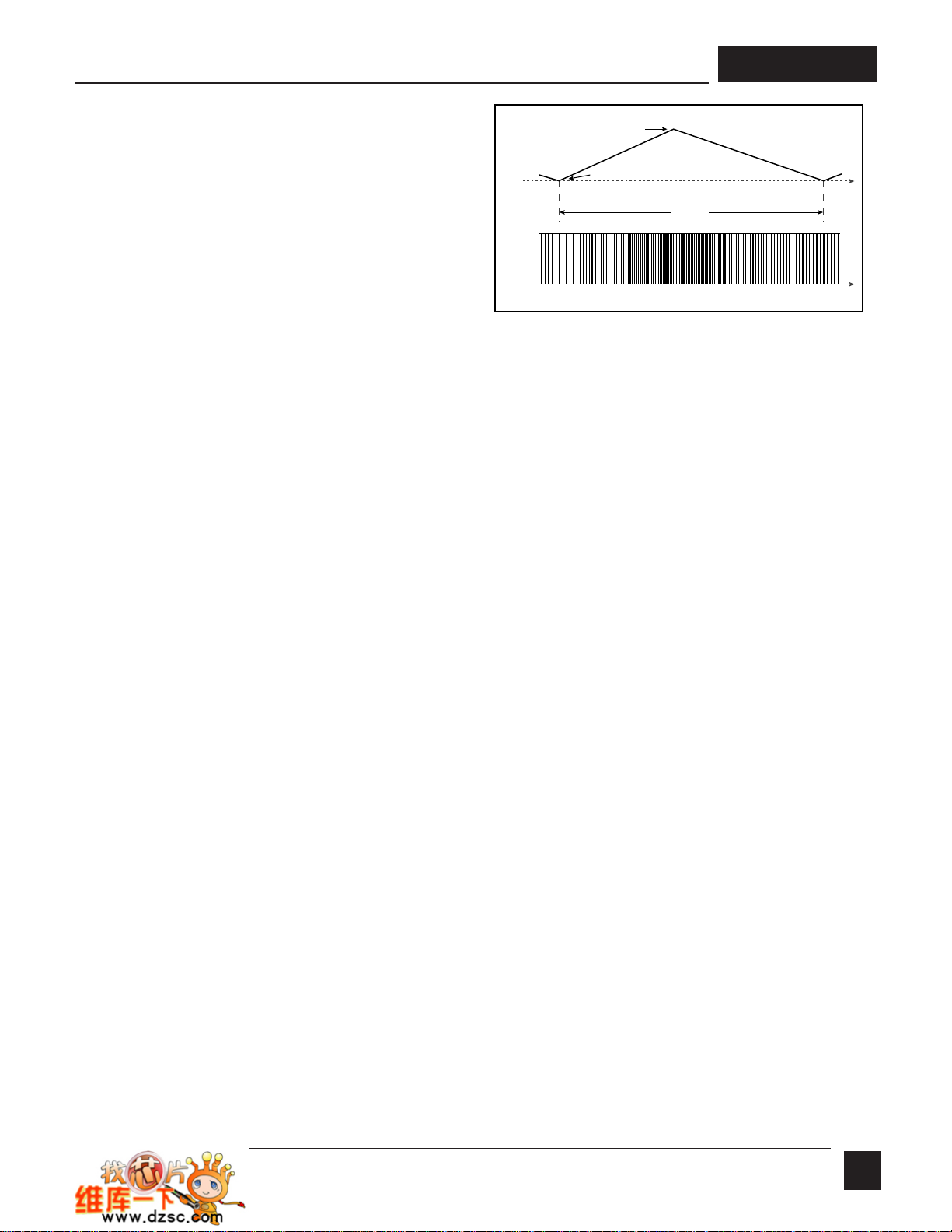

Oscillator and Switching Frequency

The internal oscillator linearly charges and discharges an

as shown in

Figure 8. Typical Waveforms for (1) Power Up (2) Normal Operation (3) Auto-Restart (4) Power Down.

O

11/05

6

internal capacitance between two voltage levels to create

PI-2550-092499

128 kHz

4 ms

Time

Switching

Frequency

V

DRAIN

136 kHz

a sawtooth waveform for the pulse width modulator. This

oscillator sets the pulse width modulator/current limit latch at

the beginning of each cycle.

The nominal switching frequency of 132 kHz was chosen to

minimize transformer size while keeping the fundamental EMI

frequency below 150 kHz. The FREQUENCY pin (available

only in Y, R or F package), when shorted to the CONTROL pin,

lowers the switching frequency to 66 kHz (half frequency) which

may be preferable in some cases such as noise sensitive video

applications or a high efficiency standby mode. Otherwise, the

FREQUENCY pin should be connected to the SOURCE pin

for the default 132 kHz.

TOP242-250

Figure 9. Switching Frequency Jitter (Idealized V

Waveforms).

DRAIN

To further reduce the EMI level, the switching frequency is

jittered (frequency modulated) by approximately ±4 kHz at

250 Hz (typical) rate as shown in Figure 9. Figure 46 shows

the typical improvement of EMI measurements with frequency

jitter.

Pulse Width Modulator and Maximum Duty Cycle

The pulse width modulator implements voltage mode control

by driving the output MOSFET with a duty cycle inversely

proportional to the current into the CONTROL pin

that

is in excess of the internal supply current of the chip (see

Figure 7). The excess current is the feedback error signal that

appears across RE (see Figure 2). This signal is filtered by an RC

network with a typical corner frequency of 7 kHz to reduce the

effect of switching noise in the chip supply current generated

by the MOSFET gate driver. The filtered error signal is

compared with the internal oscillator sawtooth waveform to

generate the duty cycle waveform. As the control current

increases, the duty cycle decreases. A clock signal from the

oscillator sets a latch which turns on the output MOSFET. The

pulse width modulator resets the latch, turning off the output

MOSFET. Note that a minimum current must be driven into

the CONTROL pin before the duty cycle begins to change.

The maximum duty cycle, DC

is set at a default maximum

MAX,

value of 78% (typical). However, by connecting the LINESENSE or MULTI-FUNCTION pin (depending on the

package) to the rectified DC high voltage bus through a

resistor with appropriate value, the maximum duty cycle can

be made to decrease from 78% to 38% (typical) as shown in

Figure 11 when input line voltage increases (see line feed

forward with DC

reduction).

MAX

Light Load Frequency Reduction

The pulse width modulator duty cycle reduces as the load at

the power supply output decreases. This reduction in duty

cycle is proportional to the current flowing into the CONTROL

pin. As the CONTROL pin current increases, the duty cycle

decreases linearly towards a duty cycle of 10%. Below 10%

duty cycle, to maintain high efficiency at light loads, the

frequency is also reduced linearly until a minimum frequency

is reached at a duty cycle of 0% (refer to Figure 7). The

minimum frequency is typically 30 kHz and 15 kHz for

132 kHz and 66 kHz operation, respectively.

This feature allows a power supply to operate at lower

frequency at light loads thus lowering the switching losses

while maintaining good cross regulation performance and low

output ripple.

Error Amplifier

The shunt regulator can also perform the function of an error

amplifier in primary side feedback applications. The shunt

regulator voltage is accurately derived from a temperaturecompensated bandgap reference. The gain of the error

amplifier is set by the CONTROL pin dynamic impedance.

The CONTROL pin clamps external circuit signals to the V

voltage level. The CONTROL pin current in excess of the

supply current is separated by the shunt regulator and flows

through RE as a voltage error signal.

On-Chip Current Limit with External Programmability

The cycle-by-cycle peak drain current limit circuit uses the

output MOSFET ON-resistance as a sense resistor. A current

limit comparator compares the output MOSFET on-state drain

to source voltage, V

current causes V

DS(ON)

with a threshold voltage. High drain

DS(ON)

to exceed the threshold voltage and turns

the output MOSFET off until the start of the next clock cycle.

The current limit comparator threshold voltage is temperature

compensated to minimize the variation of the current limit due

to temperature related changes in R

of the output MOSFET.

DS(ON)

The default current limit of TOPSwitch-GX is preset internally.

However, with a resistor connected between EXTERNAL

CURRENT LIMIT (X) pin (Y, R or F package) or MULTIFUNCTION (M) pin (P or G package) and SOURCE pin,

current limit can be programmed externally to a lower level

between 30% and 100% of the default current limit. Please

refer to the graphs in the typical performance characteristics

section for the selection of the resistor value. By setting current

limit low, a larger TOPSwitch-GX than necessary for the power

C

11/05

O

7

TOP242-250

PI-2637-060600

Oscillator

(SAW)

D

MAX

Enable from

X, L or M Pin (STOP)

Time

required can be used to take advantage of the lower R

DS(ON)

for

higher efficiency/smaller heat sinking requirements. With

a second resistor connected between the EXTERNAL

CURRENT LIMIT (X) pin (Y, R or F package) or MULTIFUNCTION (M) pin (P or G package) and the rectified DC

high voltage bus, the current limit is reduced with increasing

line voltage, allowing a true power limiting operation against

line variation to be implemented. When using an RCD clamp,

this power limiting technique reduces maximum clamp

voltage at high line. This allows for higher reflected voltage

designs as well as reducing clamp dissipation.

The leading edge blanking circuit inhibits the current limit

comparator for a short time after the output MOSFET is turned

on. The leading edge blanking time has been set so that, if a

power supply is designed properly, current spikes caused by

primary-side capacitances and secondary-side rectifier reverse

recovery time should not cause premature termination of the

switching pulse.

The current limit is lower for a short period after the leading

edge blanking time as shown in Figure 52. This is due to

dynamic characteristics of the MOSFET. To avoid triggering

the current limit in normal operation, the drain current waveform

should stay within the envelope shown.

Line Under-Voltage Detection (UV)

At power up, UV keeps TOPSwitch-GX off until the input line

voltage reaches the under-voltage threshold. At power down,

UV prevents auto-restart attempts after the output goes out

of regulation. This eliminates power down glitches caused

by slow discharge of the large input storage capacitor present

in applications such as standby supplies. A single resistor

connected from the LINE-SENSE pin (Y, R or F package) or

MULTI-FUNCTION pin (P or G package) to the rectified DC

high voltage bus sets UV threshold during power up. Once the

power supply is successfully turned on, the UV threshold is

lowered to 40% of the initial UV threshold to allow extended

input voltage operating range (UV low threshold). If the UV

low threshold is reached during operation without the power

supply losing regulation, the device will turn off and stay off

until UV (high threshold) has been reached again. If the power

supply loses regulation before reaching the UV low threshold,

the device will enter auto-restart. At the end of each autorestart cycle (S7), the UV comparator is enabled. If the UV

high threshold is not exceeded the MOSFET will be disabled

during the next cycle (see Figure 8). The UV feature can

be disabled independent of the OV feature as shown in

Figures 19 and 23.

Line Overvoltage Shutdown (OV)

The same resistor used for UV also sets an overvoltage threshold

which, once exceeded, will force TOPSwitch-GX output into

off-state. The ratio of OV and UV thresholds is preset at 4.5

as can be seen in Figure 11. When the MOSFET is off, the

rectified DC high voltage surge capability is increased to the

voltage rating of the MOSFET (700 V), due to the absence

of the reflected voltage and leakage spikes on the drain. A

small amount of hysteresis is provided on the OV threshold to

prevent noise triggering. The OV feature can be disabled

independent of the UV feature as shown in Figures 18 and 32.

Line Feed-Forward with DC

Reduction

MAX

The same resistor used for UV and OV also implements line

voltage feed-forward, which minimizes output line ripple and

reduces power supply output sensitivity to line transients.

This feed-forward operation is illustrated in Figure 7 by the

different values of IL (Y, R or F package) or IM (P or G package).

Note that for the same CONTROL pin current, higher line

voltage results in smaller operating duty cycle. As an added

Figure 10. Synchronization Timing Diagram.

O

11/05

8

TOP242-250

feature, the maximum duty cycle DC

is also reduced

MAX

from 78% (typical) at a voltage slightly higher than the UV

threshold to 30% (typical) at the OV threshold (see Figure 11).

Limiting DC

at higher line voltages helps prevent transformer

MAX

saturation due to large load transients in TOP248, TOP249 and

TOP250 forward converter applications. DC

of 38% at

MAX

high line was chosen to ensure that the power capability of the

TOPSwitch-GX is not restricted by this feature under normal

operation.

Remote ON/OFF and Synchronization

TOPSwitch-GX can be turned on or off by controlling the

current into the LINE-SENSE pin or out from the EXTERNAL

CURRENT LIMIT pin (Y, R or F package) and into or out

from the MULTI-FUNCTION pin (P or G package) (see

Figure 11). In addition, the LINE-SENSE pin has a 1 V

threshold comparator connected at its input. This voltage

threshold can also be used to perform remote ON/OFF

control. This al lo ws easy implementation of remote

ON/OFF control of TOPSwitch-GX in several different ways.

A transistor or an optocoupler output connected between

the EXTERNAL CURRENT LIMIT or LINE-SENSE pins

(Y, R or F package) or the MULTI-FUNCTION pin (P or G

package) and the SOURCE pin implements this function with

“active-on” (Figures 22, 29 and 36) while a transistor or an

optocoupler output connected between the LINE-SENSE pin

(Y, R or F package) or the MULTI-FUNCTION (P or G package)

pin and the CONTROL pin implements the function with

“active-off” (Figures 23 and 37).

When a signal is received at the LINE-SENSE pin or the

EXTERNAL CURRENT LIMIT pin (Y, R or F package) or

the MULTI-FUNCTION pin (P or G package) to disable the

output through any of the pin functions such as OV, UV and

remote ON/OFF, TOPSwitch-GX always completes its current

switching cycle, as illustrated in Figure 10, before the output is

forced off. The internal oscillator is stopped slightly before the

end of the current cycle and stays there as long as the disable

signal exists. When the signal at the above pins changes state

from disable to enable, the internal oscillator starts the next

switching cycle. This approach allows the use of these pins

to synchronize TOPSwitch-GX to any external signal with a

frequency between its internal switching frequency and 20 kHz.

cycles between 4.8 V and 5.8 V (see CONTROL pin operation

section above) and runs entirely off the high voltage DC input,

but with very low power consumption (160 mW typical at

230 VAC with M or X pins open). When the TOPSwitch-GX

is remotely turned on after entering this mode, it will initiate

a normal start-up sequence with soft-start the next time the

CONTROL pin reaches 5.8 V. In the worst case, the delay from

remote on to start-up can be equal to the full discharge/charge

cycle time of the CONTROL pin, which is approximately

125 ms for a 47

µF CONTROL pin capacitor. This

reduced consumption remote off mode can eliminate

expensive and unreliable in-line mechanical switches. It also

allows for microprocessor controlled turn-on and turn-off

sequences that may be required in certain applications such as

inkjet and laser printers.

Soft-Start

Two on-chip soft-start functions are activated at start-up with a

duration of 10 ms (typical). Maximum duty cycle starts from

0% and linearly increases to the default maximum of 78% at

the end of the 10 ms duration and the current limit starts from

about 85% and linearly increases to 100% at the end of the

10 ms duration. In addition to start-up, soft-start is also

activated at each restart attempt during auto-restart and when

restarting after being in hysteretic regulation of CONTROL

pin voltage (V

), due to remote OFF or thermal shutdown

C

conditions. This effectively minimizes current and voltage

stresses on the output MOSFET, the clamp circuit and the

output rectifier during start-up. This feature also helps

minimize output overshoot and prevents saturation of the

transformer during start-up.

Shutdown/Auto-Restart

To minimize TOPSwitch-GX power dissipation under fault

conditions, the shutdown/auto-restart circuit turns the power

supply on and off at an auto-restart duty cycle of typically 4%

if an out of regulation condition persists. Loss of regulation

interrupts the external current into the CONTROL pin. V

regulation changes from shunt mode to the hysteretic autorestart mode as described in CONTROL pin operation section.

When the fault condition is removed, the power supply output

becomes regulated, V

regulation returns to shunt mode, and

C

normal operation of the power supply resumes.

C

As seen above, the remote ON/OFF feature allows the

TOPSwitch-GX to be turned on and off instantly, on a cycleby-cycle basis, with very little delay. However, remote

ON/OFF can also be used as a standby or power switch to

turn off the TOPSwitch-GX and keep it in a very low power

consumption state for indefinitely long periods. If the

TOPSwitch-GX is held in remote off state for long enough

time to allow the CONTROL pin to discharge to the internal

supply under-voltage threshold of 4.8 V (approximately 32 ms

for a 47

µF CONTROL pin capacitance), the CONTROL pin

goes into the hysteretic mode of regulation. In this mode, the

CONTROL pin goes through alternate charge and discharge

Hysteretic Over-Temperature Protection

Temperature protection is provided by a precision analog

circuit that turns the output MOSFET off when the junction

temperature exceeds the thermal shutdown temperature

(140 °C typical). When the junction temperature cools to

below the hysteretic temperature, normal operation resumes

providing automatic recovery. A large hysteresis of 70

(typical) is provided to prevent overheating of the PC board due

to a continuous fault condition. V

is regulated in hysteretic mode

C

and a 4.8 V to 5.8 V (typical) sawtooth waveform is present on

the CONTROL pin while in thermal shutdown.

11/05

°C

O

9

TOP242-250

Bandgap Reference

All critical TOPSwitch-GX internal voltages are derived from

a temperature-compensated bandgap reference. This reference

is also used to generate a temperature-compensated current

reference, which is trimmed to accurately set the switching

frequency, MOSFET gate drive current, current limit, and the

line OV/UV thresholds. TOPSwitch-GX has improved circuitry

to maintain all of the above critical parameters within very tight

absolute and temperature tolerances.

High-Voltage Bias Current Source

This current source biases TOPSwitch-GX from the DRAIN

pin and charges the CONTROL pin external capacitance

during start-up or hysteretic operation. Hysteretic operation

occurs during auto-restart, remote OFF and over-temperature

shutdown. In this mode of operation, the current source

is switched on and off with an effective duty cycle of

approximately 35%. This duty cycle is determined by the

ratio of CONTROL pin charge (IC) and discharge currents

(I

CD1

and I

). This current source is turned off during normal

CD2

operation when the output MOSFET is switching. The effect of

the current source switching will be seen on the DRAIN voltage

waveform as small disturbances and is normal.

Using Feature Pins

FREQUENCY (F) Pin Operation

The FREQUENCY pin is a digital input pin available in the

Y, R or F package only. Shorting the FREQUENCY pin to

SOURCE pin selects the nominal switching frequency of

132 kHz (Figure 13), which is suited for most applications.

For other cases that may benefit from lower switching

frequency such as noise sensitive video applications, a

66 kHz switching frequency (half frequency) can be selected by

shorting the FREQUENCY pin to the CONTROL pin

(Figure 14). In addition, an example circuit shown in Figure 15

may be used to lower the switching frequency from 132 kHz in

normal operation to 66 kHz in standby mode for very low

standby power consumption.

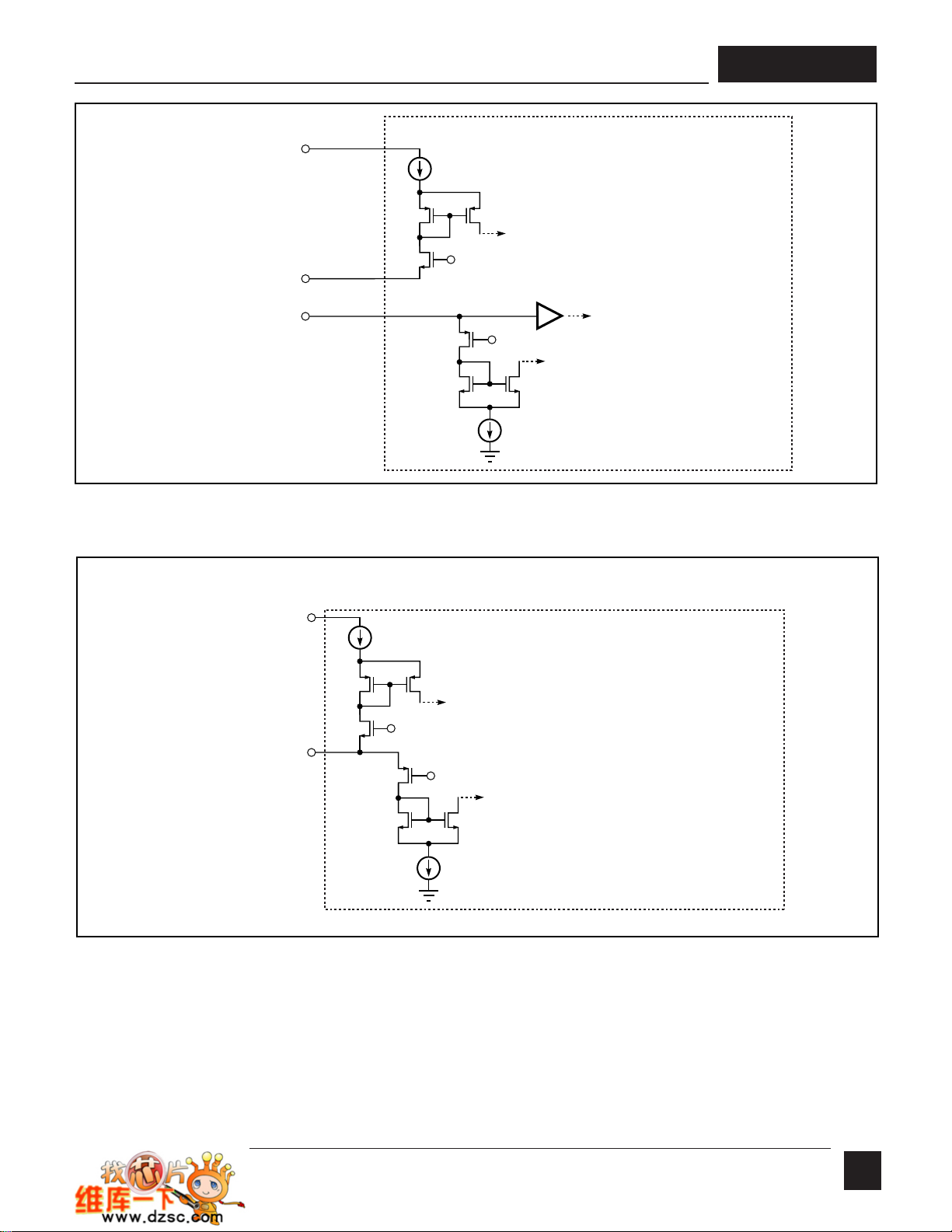

LINE-SENSE (L) Pin Operation (Y, R and F Packages)

When current is fed into the LINE-SENSE pin, it works as

a voltage source of approximately 2.6 V up to a maximum

current of +400 µA (typical). At +400 µA, this pin turns into

a constant current sink. Refer to Figure 12a. In addition, a

comparator with a threshold of 1 V is connected at the pin and

is used to detect when the pin is shorted to the SOURCE pin.

There are a total of four functions available through the use of

the LINE-SENSE pin: OV, UV, line feed-forward with DC

reduction, and remote ON/OFF. Connecting the LINE-SENSE

pin to the SOURCE pin disables all four functions. The LINESENSE pin is typically used for line sensing by connecting a

resistor from this pin to the rectified DC high voltage bus to

implement OV, UV and DC

reduction with line voltage. In

MAX

this mode, the value of the resistor determines the line OV/UV

thresholds, and the DC

is reduced linearly with rectified DC

MAX

high voltage starting from just above the UV threshold. The pin

can also be used as a remote ON/OFF and a synchronization

input. Refer to Table 2 for possible combinations of the functions

with example circuits shown in Figure 16 through Figure 40. A

description of specific functions in terms of the LINE-SENSE

pin I/V characteristic is shown in Figure 11 (right hand side).

The horizontal axis represents LINE-SENSE pin current with

positive polarity indicating currents flowing into the pin. The

meaning of the vertical axes varies with functions. For those

that control the ON/OFF states of the output such as UV, OV

and remote ON/OFF, the vertical axis represents the enable/

disable states of the output. UV triggers at IUV (+50 µA typical

with 30 µA hysteresis) and OV triggers at IOV (+225 µA

typical with 8 µA hysteresis). Between the UV and OV

thresholds, the output is enabled. For line feed-forward with

MAX

LINE-SENSE AND EXTERNAL CURRENT LIMIT PIN TABLE*

Figure Number 16 17 18 19 20 21 22 23 24 25 26 27 28 29

Three Terminal Operation

Under-Voltage

Overvoltage

Line Feed-Forward (DC

Overload Power Limiting

External Current Limit

Remote ON/OFF

*This table is only a partial list of many LINE-SENSE and EXTERNAL CURRENT LIMIT pin configurations that are possible.

Table 2. Typical LINE-SENSE and EXTERNAL CURRENT LIMIT Pin Configurations.

O

11/05

10

▼

MAX

✓

✓ ✓ ✓ ✓ ✓

✓ ✓ ✓ ✓ ✓

)

✓ ✓ ✓ ✓

✓

✓ ✓ ✓ ✓ ✓ ✓

✓ ✓ ✓ ✓ ✓ ✓ ✓

TOP242-250

DC

reduction, the vertical axis represents the magnitude of

MAX

the DC

maximum duty cycle from 78% at I

. Line feed-forward with DC

MAX

reduction lowers

MAX

(+60 µA typical) to

L(DC)

38% at IOV (+225 µA).

EXTERNAL CURRENT LIMIT (X) Pin Operation

(Y, R and F Packages)

When current is drawn out of the EXTERNAL CURRENT

LIMIT pin, it works as a voltage source of approximately

1.3 V up to a maximum current of -240 µA (typical). At

-240 µA, it turns into a constant current source (refer to

Figure 12a).

There are two functions available through the use of the

EXTERNAL CURRENT LIMIT pin: external current limit

and remote ON/OFF. Connecting the EXTERNAL CURRENT

LIMIT pin to the SOURCE pin disables the two functions. In

high efficiency applications, this pin can be used to reduce the

current limit externally to a value close to the operating peak

current by connecting the pin to the SOURCE pin through

a resistor. The pin can also be used for remote ON/OFF.

Table 2 shows several possible combinations using this pin. See

Figure 11 for a description of the functions where the horizontal

axis (left hand side) represents the EXTERNAL CURRENT

LIMIT pin current. The meaning of the vertical axes varies

with function. For those that control the ON/OFF states of the

output such as remote ON/OFF, the vertical axis represents the

enable/disable states of the output. For external current limit,

the vertical axis represents the magnitude of the I

LIMIT

. Please

see graphs in the Typical Performance Characteristics section

for the current limit programming range and the selection of

appropriate resistor value.

MULTI-FUNCTION (M) Pin Operation (P and G

Packages)

The LINE-SENSE and EXTERNAL CURRENT LIMIT pin

functions are combined to a single MULTI-FUNCTION pin

for P and G packages. The comparator with a 1 V threshold

at the LINE-SENSE pin is removed in this case as shown in

Figure 2b. All of the other functions are kept intact. However,

since some of the functions require opposite polarity of input

current (MULTI-FUNCTION pin), they are mutually exclusive.

For example, line sensing features cannot be used simultaneously

with external current limit setting. When current is fed into

the MULTI-FUNCTION pin, it works as a voltage source of

approximately 2.6 V up to a maximum current of +400 µA

(typical). At +400 µA, this pin turns into a constant current

sink. When current is drawn out of the MULTI-FUNCTION

pin, it works as a voltage source of approximately 1.3 V up to

a maximum current of -240 µA (typical). At -240 µA, it turns

into a constant current source. Refer to Figure 12b.

There are a total of five functions available through the use

of the MULTI-FUNCTION pin: OV, UV, line feed-forward

with DC

reduction, external current limit and remote

MAX

ON/OFF. A short circuit between the MULTI-FUNCTION

pin and SOURCE pin disables all five functions and forces

TOPSwitch-GX to operate in a simple three terminal mode

like TOPSwitch-II. The MULTI-FUNCTION pin is typically

used for line sensing by connecting a resistor from this pin to

the rectified DC high voltage bus to implement OV, UV and

DC

reduction with line voltage. In this mode, the value

MAX

of the resistor determines the line OV/UV thresholds, and the

DC

is reduced linearly with increasing rectified DC high

MAX

voltage starting from just above the UV threshold. External

current limit programming is implemented by connecting the

MULTI-FUNCTION pin to the SOURCE pin through a resistor.

However, this function is not necessary in most applications

since the internal current limit of the P and G package devices

has been reduced, compared to the Y, R and F package

devices, to match the thermal dissipation capability of the P

and G packages. It is therefore recommended that the MULTIFUNCTION pin is used for line sensing as described above and

not for external current limit reduction. The same pin can also

MULTI-FUNCTION PIN TABLE*

Figure Number 30 31 32 33 34 35 36 37 38 39 40

Three Terminal Operation

Under-Voltage

Overvoltage

Line Feed-Forward (DC

Overload Power Limiting

External Current Limit

Remote ON/OFF

*This table is only a partial list of many MULTI-FUNCTION pin configurations that are possible.

Table 3. Typcial MULTI-FUNCTION Pin Configurations.

▼

MAX

✓

✓ ✓ ✓

✓ ✓ ✓

)

✓ ✓

✓

✓ ✓ ✓ ✓

✓ ✓ ✓ ✓ ✓

O

11/05

11

TOP242-250

-250 -200 -150 -100 -50 0 50 100 150 200 250 300 350 400

PI-2636-010802

Output

MOSFET

Switching

(Enabled)

(Disabled)

I

LIMIT

(Default)

DC

MAX

(78.5%)

Current

Limit

M Pin

L PinX Pin

Maximum

Duty Cycle

V

BG

-22 µA

-27 µA

V

BG

+ V

TP

I

I

I

I

I

UV

I

REM(N)

I

OV

Pin Voltage

Note: This figure provides idealized functional characteristics with typical performance values. Please refer to the parametric

table and typical performance characteristics sections of the data sheet for measured data.

X and L Pins (Y, R or F Package) and M Pin (P or G Package) Current (µA)

Disabled when supply

output goes out of

regulation

Figure 11. MULTI-FUNCTION (P or G package), LINSE-SENSE, and EXTERNAL CURRENT LIMIT (Y, R or F package) Pin Characteristics.

be used as a remote ON/OFF and a synchronization input in

both modes. Please refer to Table 3 for possible combinations

of the functions with example circuits shown in Figure 30

through Figure 40. A description of specific functions in terms

of the MULTI-FUNCTION pin I/V characteristic is shown in

Figure 11. The horizontal axis represents MULTI-FUNCTION

pin current with positive polarity indicating currents flowing into

the pin. The meaning of the vertical axes varies with functions.

For those that control the ON/OFF states of the output such

as UV, OV and remote ON/OFF, the vertical axis represents

the enable/disable states of the output. UV triggers at IUV

(+50 µA typical) and OV triggers at IOV (+225 µA typical with

30 µA hysteresis). Between the UV and OV thresholds, the

output is enabled. For external current limit and line feedforward with DC

magnitude of the I

DC

reduction lowers maximum duty cycle from 78% at I

MAX

(+60 µA typical) to 38% at IOV (+225 µA). External current

reduction, the vertical axis represents the

MAX

LIMIT

and DC

MAX

. Line feed-forward with

M(DC)

limit is available only with negative MULTI-FUNCTION

pin current. Please see graphs in the Typical Performance

Characteristics section for the current limit programming

range and the selection of appropriate resistor value.

O

11/05

12

VBG + V

T

1 V

V

BG

240 µA

400 µA

CONTROL (C)

Y, R and F Package

(Voltage Sense)

(Positive Current Sense - Under-Voltage,

Overvoltage, ON/OFF Maximum Duty

Cycle Reduction)

(Negative Current Sense - ON/OFF,

Current Limit Adjustment)

PI-2634-022604

TOPSwitch-GX

LINE-SENSE (L)

EXTERNAL CURRENT LIMIT (X)

VBG + V

T

V

BG

240 µA

400 µA

CONTROL (C)

MULTI-FUNCTION (M)

(Positive Current Sense - Under-Voltage,

Overvoltage, Maximum Duty

Cycle Reduction)

(Negative Current Sense - ON/OFF,

Current Limit Adjustment)

PI-2548-022604

TOPSwitch-GX

P and G Package

Figure 12a. LINE-SENSE (L), and EXTERNAL CURRENT LIMIT (X) Pin Input Simplified Schematic.

TOP242-250

Figure 12b. MULTI-FUNCTION (M) Pin Input Simplified Schematic.

11/05

O

13

TOP242-250

PI-2654-071700

DC

Input

Voltage

+

-

D

S

C

CONTROL

F

PI-2655-071700

DC

Input

Voltage

+

-

D

S

C

CONTROL

F

PI-2656-040501

DC

Input

Voltage

+

-

D

S

C

STANDBY

QS can be an optocoupler output.

CONTROL

F

20

kΩ

R

HF

1 nF

Q

S

47 kΩ

Typical Uses of FREQUENCY (F) PIN

Figure 13. Full Frequency Operation (132 kHz). Figure 14. Half Frequency Operation (66 kHz).

14

O

11/05

Figure 15. Half Frequency Standby Mode (For High Standby

Efficiency).

TOP242-250

X F

PI-2617-050100

DC

Input

Voltage

+

-

D

C S

D

S

C

CONTROL

L

C L X S F D

PI-2618-081403

DC

Input

Voltage

+

-

D

S

C

CONTROL

L

2 MΩR

LS

VUV = IUV x R

LS

V

OV = IOV x RLS

For RLS = 2 MΩ

V

UV

= 100 VDC

V

OV =

450 VDC

DC

MAX

@100 VDC = 78%

DC

MAX

@375 VDC = 38%

PI-2510-040501

DC

Input

Voltage

+

-

D M

S

C

VUV = RLS x I

UV

For Value Shown

VUV = 100 VDC

R

LS

6.2 V

2

MΩ

22

kΩ

CONTROL

PI-2620-040501

DC

Input

Voltage

+

-

D

S

C

CONTROL

L

2 MΩ

30 kΩ

R

LS

1N4148

V

OV

= I

OV x RLS

For Values Shown

VOV = 450 VDC

X

PI-2623-092303

DC

Input

Voltage

+

-

D

S

C

R

IL

For R

IL

= 12 kΩ

I

LIMIT

= 69%

See Figure 54b for

other resistor values

(R

IL

)

For

R

IL

= 25 kΩ

I

LIMIT

= 43%

CONTROL

X

PI-2624-040501

DC

Input

Voltage

+

-

D

S

C

2.5 MΩ

R

LS

6 kΩ

R

IL

100% @ 100 VDC

63% @ 300 VDC

I

LIMIT

=

I

LIMIT

=

CONTROL

Typical Uses of LINE-SENSE (L) and EXTERNAL CURRENT LIMIT (X) P ins

Figure 16. Three Terminal Operation (LINE-SENSE and

EXTERNAL CURRENT LIMIT Features Disabled.

FREQUENCY Pin Tied to SOURCE or CONTROL Pin).

Figure 18. Line-Sensing for Under-Voltage Only (Overvoltage

Disabled).

Figure 17. Line-Sensing for Under-Voltage, Overvoltage and Line

Feed-Forward.

Figure 19. Linse-Sensing for Overvoltage Only (Under-Voltage

Disabled). Maximum Duty Cycle Reduced at Low Line

and Further Reduction with Increasing Line Voltage.

Figure 20. Externally Set Current Limit.

Figure 21. Current Limit Reduction with Line Voltage.

O

11/05

15

TOP242-250

X

PI-2625-040501

DC

Input

Voltage

+

-

D

S

C

ON/OFF

47 KΩ

QR can be an optocoupler

output or can be replaced by

a manual switch.

Q

R

CONTROL

PI-2621-040501

DC

Input

Voltage

+

-

D

S

C

CONTROL

L

47 kΩ

Q

R

R

MC

45 kΩ

QR can be an

optocoupler output or

can be replaced

by a manual switch.

ON/OFF

X

ON/OFF

47 kΩ

PI-2626-040501

DC

Input

Voltage

+

-

D

S

C

R

IL

Q

R

12 kΩ

For

R

IL

=

I

LIMIT

= 69%

25

kΩ

For

R

IL

=

I

LIMIT

= 43%

QR can be an optocoupler

output or can be replaced

by a manual switch.

CONTROL

PI-2627-040501

DC

Input

Voltage

+

-

D

S

C

CONTROL

L

47 kΩ

Q

R

R

MC

45 kΩ

QR can be an

optocoupler output

or can be replaced

by a manual switch.

ON/OFF

X

R

IL

PI-2622-040501

DC

Input

Voltage

+

-

D

S

C

CONTROL

L

47 kΩ

2

MΩ

Q

R

R

LS

ON/OFF

For RLS = 2 MΩ

V

UV

= 100 VDC

V

OV

= 450 VDC

QR can be an optocoupler

output or can be replaced

by a manual switch.

X

ON/OFF

47 kΩ

PI-2628-040501

DC

Input

Voltage

+

-

D

S

C

CONTROL

L

R

IL

R

LS

Q

R

2 MΩ

VUV = IUV x R

LS

V

OV = IOV x RLS

DC

MAX

@100 VDC = 78%

DC

MAX

@375 VDC = 38%

12 kΩ

For

R

IL

=

I

LIMIT

= 69%

QR can be an optocoupler

output or can be replaced

by a manual switch.

Typical Uses of LINE-SENSE (L) and EXTERNAL CURRENT LIMIT (X) Pins (cont.)

Figure 22. Active-on (Fail Safe) Remove ON/OFF. Figure 23. Active-off Remote ON/OFF. Maximum Duty Cycle

Reduced.

Figure 24. Active-on Remote ON/OFF with Externally Set Current

Limit.

Figure 26. Active-off Remote ON/OFF with LINE-SENSE. Figure 27. Active-on Remote ON/OFF with LINE-SENSE and

16

O

11/05

Figure 25. Active-off Remote ON/OFF with Externally Set Current

Limit.

EXTERNAL CURRENT LIMIT.

TOP242-250

X

PI-2629-092203

DC

Input

Voltage

+

-

D

S

C

CONTROL

L

R

IL

R

LS

12 kΩ

2

MΩ

VUV = IUV x R

LS

V

OV = IOV x RLS

For RLS = 2 MΩ

DC

MAX

@100 VDC = 78%

DC

MAX

@375 VDC = 38%

For

RIL = 12 kΩ

I

LIMIT

= 69%

See Figure 54b for

other resistor values

(R

IL

) to select different

I

LIMIT

values

VUV = 100 VDC

VOV = 450 VDC

PI-2640-040501

DC

Input

Voltage

+

-

D

S

C

CONTROL

L

ON/OFF

47 kΩ

QR can be an optocoupler

output or can be replaced by

a manual switch.

300 kΩ

Q

R

PI-2508-081199

DC

Input

Voltage

+

-

D

S

C

CONTROL

M

C

D S

C D

S

S

S S

M

PI-2509-040501

DC

Input

Voltage

+

-

D M

S

C

VUV = IUV x R

LS

V

OV = IOV x RLS

For RLS = 2 MΩ

VUV = 100 VDC

V

OV =

450 VDC

DC

MAX

@100 VDC = 78%

DC

MAX

@375 VDC = 38%

CONTROL

R

LS

2 MΩ

PI-2510-040501

DC

Input

Voltage

+

-

D M

S

C

VUV = RLS x I

UV

For Value Shown

VUV = 100 VDC

R

LS

6.2 V

2

MΩ

22

kΩ

CONTROL

PI-2516-040501

DC

Input

Voltage

+

-

D M

S

C

V

OV

= I

OV x RLS

For Values Shown

V

OV

= 450 VDC

CONTROL

R

LS

1N4148

2

MΩ

30

kΩ

Typical Uses of LINE-SENSE (L) and EXTERNAL CURRENT LIMIT (X) Pins (cont.)

Figure 28. Line-Sensing and Externally Set Current Limit. Figure 29. Active-on Remote ON/OFF.

Typical Uses of MULTI-FUNCTION (M) Pin

Figure 30. Three Terminal Operation (MULIT-FUNCTION Features

Disabled).

Figure 32. Line-Sensing for Under-Voltage Only (Overvoltage

Disabled).

Figure 31. Line-Sensing for Undervoltage, Over-Voltage and Line

Feed-Forward.

Figure 33. Line-Sensing for Overvoltage Only (Under-Voltage

Disabled). Maximum Duty Cycle Reduced at Low Line

and Further Reduction with Increasing Line Voltage.

O

11/05

17

TOP242-250

PI-2517-022604

DC

Input

Voltage

+

-

D M

S

C

For R

IL

= 12 kΩ

I

LIMIT

= 69%

CONTROL

R

IL

See Figures 54b, 55b

and 56b for other resistor

values (R

IL

) to select

different

I

LIMIT

values.

For R

IL

= 25 kΩ

I

LIMIT

= 43%

PI-2518-040501

DC

Input

Voltage

+

-

D M

S

C

CONTROL

R

IL

RLS2.5 MΩ

6

kΩ

100% @ 100 VDC

63% @ 300 VDC

I

LIMIT

=

I

LIMIT

=

PI-2519-040501

DC

Input

Voltage

+

-

D

S

C

Q

R

ON/OFF

M

CONTROL

QR can be an optocoupler

output or can be replaced

by a manual switch.

47 kΩ

PI-2522-040501

DC

Input

Voltage

+

-

D

S

C

R

MC

45 kΩ

M

CONTROL

Q

R

QR can be an optocoupler

output or can be replaced

by a manual switch.

ON/OFF

47 kΩ

Typical Uses of MULTI-FUNCTION (M) Pin (cont.)

Figure 34. Externally Set Current Limit (Not Normally Required-See

M Pin Operation Description).

Figure 36. Active-on (Fail Safe) Remote ON/OFF.

Figure 35. Current Limit Reduction with Line Voltage (Not Normally

Required-See M Pin Operation Description).

Figure 37. Active-off Remote ON/OFF. Maximum Duty Cycle

Reduced.

18

O

11/05

Typical Uses of MULTI-FUNCTION (M) Pin (cont.)

PI-2520-040501

DC

Input

Voltage

+

-

D

S

C

Q

R

R

IL

M

CONTROL

12 kΩ

For

R

IL

=

I

LIMIT

= 69%

QR can be an optocoupler

output or can be replaced

by a manual switch.

ON/OFF

47 kΩ

25 kΩ

For

R

IL

=

I

LIMIT

= 43%

PI-2521-040501

DC

Input

Voltage

+

-

D

S

C

R

IL

R

MC

24 kΩ

12

kΩ

M

CONTROL

Q

R

2R

IL

R

MC

=

QR can be an optocoupler

output or can be replaced

by a manual switch.

ON/OFF

47 kΩ

PI-2523-040501

DC

Input

Voltage

+

-

D

S

C

R

LS

M

For RLS = 2 MΩ

VUV = 100 VDC

VOV = 450 VDC

CONTROL

Q

R

2 MΩ

QR can be an optocoupler

output or can be replaced

by a manual switch.

ON/OFF

47 kΩ

TOP242-250

Figure 38. Active-on Remote ON/OFF with Externally Set Current

Limit (See M Pin Operation Description).

Figure 40. Active-off Remote ON/OFF with LINE-SENSE.

Figure 39. Active-off Remote ON/OFF with Externally Set Current

Limit (See M Pin Operation Description).

O

11/05

19

TOP242-250

12 V @

2.5

A

D2

1N4148

T1

C5

47 µF

10 V

U2

LTV817A

VR2

1N5240C

10 V, 2%

R6

150 Ω

R15

150 Ω

C14

1 nF

D1

UF4005

R3

68 kΩ

2 W

C3

4.7 nF

1 kV

CY1

2.2 nF

U1

TOP244Y

D L

S X

F

C

R8

150 Ω

C1

68 µF

400 V

C6

0.1

µF

D8

MBR1060

C10

560 µF

35 V

C12

220 µF

35 V

C11

560 µF

35 V

RTN

R5

6.8

Ω

R1

4.7 MΩ

1/2 W

R4

2 MΩ

1/2 W

R2

9.09 kΩ

PI-2657-081204

L3

3.3

µH

BR1

600 V

2A

F1

3.15 A

J1

L1

20 mH

L

N

CX1

100 nF

250 VAC

CONTROL

CONTROL

TOPSwitch-GX

PERFORMANCE SUMMARY

Output Power: 30 W

Regulation: ± 4%

Efficiency: ≥ 79%

Ripple: ≤ 50 mV pk-pk

Application Examples

A High Efficiency, 30 W, Universal Input Power Supply

The circuit shown in Figure 41 takes advantage of several of

the TOPSwitch-GX features to reduce system cost and power

supply size and to improve efficiency. This design delivers

30 W at 12 V, from an 85 VAC to 265 VAC input, at an ambient

of 50 °C, in an open frame configuration. A nominal efficiency

of 80% at full load is achieved using TOP244Y.

The current limit is externally set by resistors R1 and R2 to a

value just above the low line operating peak DRAIN current

of approximately 70% of the default current limit. This

allows use of a smaller transformer core size and/or higher

transformer primary inductance for a given output power,

reducing TOPSwitch-GX power dissipation, while at the same

time avoiding transformer core saturation during startup and

output transient conditions. The resistors R1 & R2 provide a

signal that reduces the current limit with increasing line voltage,

which in turn limits the maximum overload power at high input

line voltage. This function in combination with the built-in

soft-start feature of TOPSwitch-GX, allows the use of a low cost

RCD clamp (R3, C3 and D1) with a higher reflected voltage,

by safely limiting the TOPSwitch-GX drain voltage, with

adequate margin under worst case conditions. Resistor R4

provides line sensing, setting UV at 100 VDC and OV at

450 VDC. The extended maximum duty cycle feature of

TOPSwitch-GX (guaranteed minimum value of 75% vs. 64%

for TOPSwitch-II) allows the use of a smaller input capacitor

(C1). The extended maximum duty cycle and the higher

reflected voltage possible with the RCD clamp also permit

the use of a higher primary to secondary turns ratio for T1,

which reduces the peak reverse voltage experienced by the

secondary rectifier D8. As a result a 60 V Schottky rectifier

can be used for up to 15 V outputs, which greatly improves

power supply efficiency. The frequency reduction feature of the

TOPSwitch-GX eliminates the need for any dummy loading

for regulation at no load and reduces the no-load/standby

consumption of the power supply. Frequency jitter provides

improved margin for conducted EMI, meeting the CISPR 22

(FCC B) specification.

Output regulation is achieved by using a simple Zener sense

circuit for low cost. The output voltage is determined by the

Zener diode (VR2) voltage and the voltage drops across the

optocoupler (U2) LED and resistor R6. Resistor R8 provides

bias current to Zener VR2 for typical regulation of ±5% at

the 12 V output level, over line and load and component

variations.

A High Efficiency, Enclosed, 70 W, Universal Adapter Supply

The circuit shown in Figure 42 takes advantage of several of the

TOPSwitch-GX features to reduce cost, power supply size and

O

11/05

Figure 41. 30 W Power Supply using External Current Limit Programming and Line Sensing for UV and OV.

20

TOP242-250

19 V

@ 3.6 A

TOP249Y

U1

U3

TL431

U2

PC817A

D L

S X

F

C

RTN

L2

820 µH

2A

C6

0.1 µF

X2

F1

3.15 A

85-265 VAC

BR1

RS805

8A 600 V

L3

75 µH

2A

t°

T1

C13

0.33 µF

400 V

C12

0.022 µF

400 V

C11

0.01 µF

400 V

RT1

10 Ω

1.7 A

PI-2691-042203

All resistors 1/8 W 5% unless otherwise stated.

J1

L

N

CONTROL

CONTROL

TOPSwitch-GX

C1

150 µF

400 V

PERFORMANCE SUMMARY

Output Power: 70 W

Regulation: ± 4%

Efficiency: ≥ 84%

Ripple: ≤ 120 mV pk-pk

No Load Consumption: < 0.52 W @ 230 VAC

C5

47 µF

16 V

C3

820 µF

25 V

L1

200 µH

C2

820 µF

25 V

C14

0.1 µF

50 V

C4

820 µF

25 V

C10

0.1 µF

50 V

C9

4.7 nF 50 V

C8

0.1 µF

50 V

VR1

P6KE200

D2

MBR20100

C7 2.2 nF

Y1 Safety

D3

MBR20100

D4

1N4148

R11

2 MΩ

1/2 W

R9

13 MΩ

R8

4.7 Ω

R1

270 Ω

R2

1 kΩ

R5

562 Ω

1%

R4

31.6 kΩ

1%

R7

56 kΩ

R10

20.5 kΩ

R3

6.8 Ω

R6

4.75 kΩ

1%

C15

1 µF

50 V

D1

UF4006

increase efficiency. This design delivers 70 W at 19 V, from an

85 VAC to 265 VAC input, at an ambient of 40 °C, in a small

sealed adapter case (4” x 2.15” x 1”). Full load efficiency is

85% at 85 VAC rising to 90% at 230 VAC input.

Due to the thermal environment of a sealed adapter, a TOP249Y

is used to minimize device dissipation. Resistors R9 and R10

externally program the current limit level to just above the

operating peak DRAIN current at full load and low line. This

allows the use of a smaller transformer core size without

saturation during startup or output load transients. Resistors

R9 and R10 also reduce the current limit with increasing line

voltage, limiting the maximum overload power at high input

line voltage, removing the need for any protection circuitry on

the secondary. Resistor R11 implements an under-voltage and

overvoltage sense as well as providing line feed-forward for

reduced output line frequency ripple. With resistor R11 set at

2 MΩ, the power supply does not start operating until the DC

rail voltage reaches 100 VDC. On removal of the AC input,

the UV sense prevents the output glitching as C1 discharges,

turning off the TOPSwitch-GX when the output regulation is

lost or when the input voltage falls to below 40 V, whichever

occurs first. This same value of R11 sets the OV threshold to

450 V. If exceeded, for example during a line surge,

TOPSwitch-GX stops switching for the duration of the surge,

extending the high voltage withstand to 700 V without device

damage. Capacitor C11 has been added in parallel with VR1 to

reduce Zener clamp dissipation. With a switching frequency of

132 kHz, a PQ26/20 core can be used to provide 70 W. To

maximize efficiency, by reducing winding losses, two output

windings are used each with their own dual 100 V Schottky

rectifier (D2 and D3). The frequency reduction feature of the

TOPSwitch-GX eliminates any dummy loading to maintain

regulation at no load and reduces the no-load consumption of

the power supply to only 520 mW at 230 VAC input. Frequency

jittering provides conducted EMI meeting the CISPR 22

(FCC B) / EN55022B specification, using simple filter components

(C7, L2, L3 and C6), even with the output earth grounded.

To regulate the output, an optocoupler (U2) is used with a

secondary reference sensing the output voltage via a resistor

divider (U3, R4, R5, R6). Diode D4 and C15 filter and smooth

the output of the bias winding. Capacitor C15 (1 µF) prevents

the bias voltage from falling during zero to full load transients.

Resistor R8 provides filtering of leakage inductance spikes,