Power Integrations TOP227Y, TOP226Y, TOP221Y, TOP221P, TOP225Y Datasheet

...

®

TOP221-227

®

TOPSwitch-II Family

Three-terminal Off-line PWM Switch

Product Highlights

•Lowest cost, lowest component count switcher solution

•Cost competitive with linears above 5W

•Very low AC/DC losses – up to 90% efficiency

•Built-in Auto-restart and Current limiting

•Latching Thermal shutdown for system level protection

•Implements Flyback, Forward, Boost or Buck topology

•Works with primary or opto feedback

•Stable in discontinuous or continuous conduction mode

•Source connected tab for low EMI

•Circuit simplicity and Design Tools reduce time to market

Description

The second generation TOPSwitch-II family is more cost effective and provides several enhancements over the first generation TOPSwitchfamily. The TOPSwitch-IIfamily extends the power range from 100W to 150W for 100/115/230 VAC input and from 50W to 90W for 85-265 VAC universal input. This brings TOPSwitch technology advantages to many new applications, i.e. TV, Monitor, Audio amplifiers, etc. Many significant circuit enhancements that reduce the sensitivity to board layout and line transients now make the design even

AC |

|

IN |

|

|

D |

TOPSwitch |

CONTROL |

C |

|

|

|

|

S |

|

PI-1951-091996 |

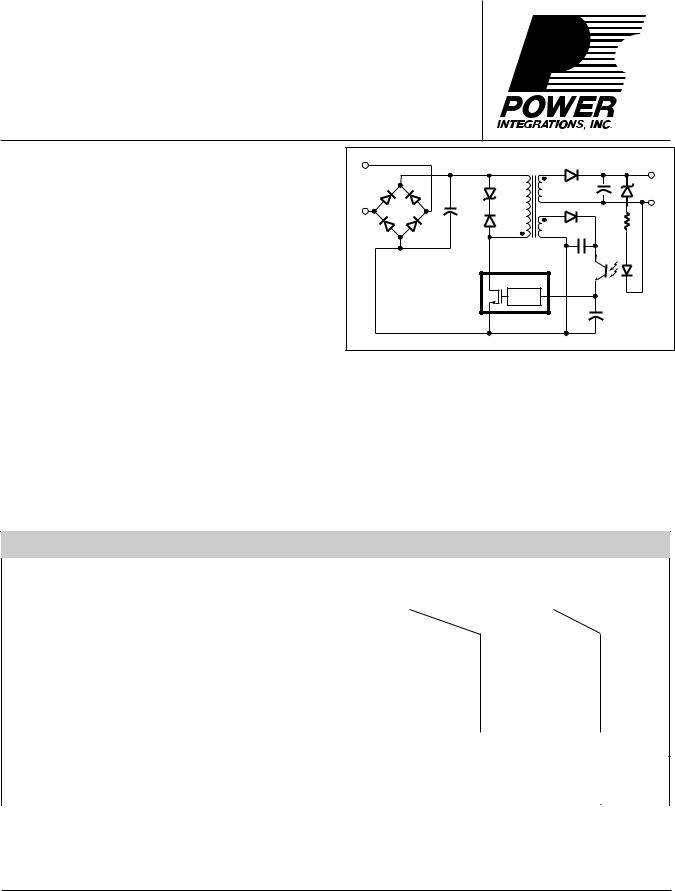

Figure 1. Typical Flyback Application.

easier. The standard 8L PDIP package option reduces cost in lower power, high efficiency applications. The internal lead frame of this package uses six of its pins to transfer heat from the chip directly to the board, eliminating the cost of a heat sink. TOPSwitch incorporates all functions necessary for a switched mode control system into a three terminal monolithic IC: power MOSFET, PWM controller, high voltage start up circuit, loop compensation and fault protection circuitry.

OUTPUT POWER TABLE

|

TO-220 (Y) Package1 |

|

8L PDIP (P) or 8L SMD (G) Package2 |

|||||

PART |

Single Voltage Input3 |

Wide Range Input |

PART |

|

Single Voltage. Input3 |

|

Wide Range Input |

|

100/115/230 VAC ±15% |

85 to 265 VAC |

|

100/115/230 VAC ±15% |

|

85 to 265 VAC |

|||

ORDER |

ORDER |

|

|

|||||

4,6 |

4,6 |

|

|

5,6 |

|

5,6 |

||

NUMBER |

NUMBER |

|

||||||

PMAX |

PMAX |

PMAX |

PMAX |

|||||

TOP221Y |

12 W |

7 W |

TOP221P or TOP221G |

9 W |

6 W |

|||

|

|

|

|

|

|

|

||

TOP222Y |

25 W |

15 W |

TOP222P or TOP222G |

15 W |

10 W |

|||

|

|

|

|

|

|

|

||

TOP223Y |

50 W |

30 W |

TOP223P or TOP223G |

25 W |

15 W |

|||

|

|

|

|

|

|

|

||

TOP224Y |

75 W |

45 W |

TOP224P or TOP224G |

30 W |

20 W |

|||

|

|

|

|

|

|

|

|

|

TOP225Y |

100 W |

60 W |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TOP226Y |

125 W |

75 W |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TOP227Y |

150 W |

90 W |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Notes: 1. Package outline: TO-220/3 2. Package Outline: DIP-8 or SMD-8 3. 100/115 VAC with doubler input 4. Assumes appropriate heat sinking to keep the maximum TOPSwitch junction temperature below 100 °C. 5. Soldered to 1 sq. in.( 6.45 cm2), 2 oz. copper clad (610 gm/m2) 6. PMAX is the maximum practical continuous power output level for conditions shown. The continuous power capability in a given application depends on thermal environment, transformer design, efficiency required, minimum specified input voltage, input storage capacitance, etc. 7. Refer to key application considerations section when using TOPSwitch-II in an existing TOPSwitch design.

July 2001

TOP221-227 |

|

|

|

|

|

|

|

VC |

|

|

|

|

|

|

|

CONTROL |

|

0 |

|

|

|

|

DRAIN |

|

|

|

|

|

|

|

|

ZC |

|

|

INTERNAL |

|

|

|

|

|

|

1 |

SUPPLY |

|

|

|

|

|

|

SHUTDOWN/ |

|

|

|

|

|

SHUNT REGULATOR/ |

|

AUTO-RESTART |

|

|

|

|

|

ERROR AMPLIFIER |

|

+ |

8 |

|

|

|

|

|

|

|

|

|

|

||

- |

5.7 V |

- |

|

|

|

|

|

|

4.7 V |

|

|

|

|

|

|

+ |

|

|

|

|

|

|

|

5.7 V |

|

|

|

|

|

|

|

|

|

|

|

|

|

+ |

|

IFB |

|

|

|

|

|

- |

VILIMIT |

THERMAL |

S |

Q |

|

|

|

||

|

SHUTDOWN |

|

|

|

|||

|

|

|

|

|

|

||

|

|

POWER-UP |

R |

Q |

|

CONTROLLED |

|

|

|

RESET |

|

||||

|

|

|

|

|

TURN-ON |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

GATE |

|

OSCILLATOR |

|

|

|

|

|

DRIVER |

|

|

|

|

|

|

|

|

|

DMAX |

|

|

|

|

|

|

|

CLOCK |

|

|

|

|

|

|

|

SAW |

|

- |

|

S |

Q |

LEADING |

|

|

|

|

|

|

|

|

|

|

|

+ |

|

R |

Q |

EDGE |

|

|

|

PWM |

|

|

|

BLANKING |

|

|

|

|

|

|

|

|

|

|

COMPARATOR |

|

|

|

MINIMUM |

||

|

|

|

|

|

|

||

|

|

|

|

|

|

ON-TIME |

|

|

|

|

|

|

|

|

DELAY |

RE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SOURCE |

|

|

|

|

|

|

|

PI-1935-091696 |

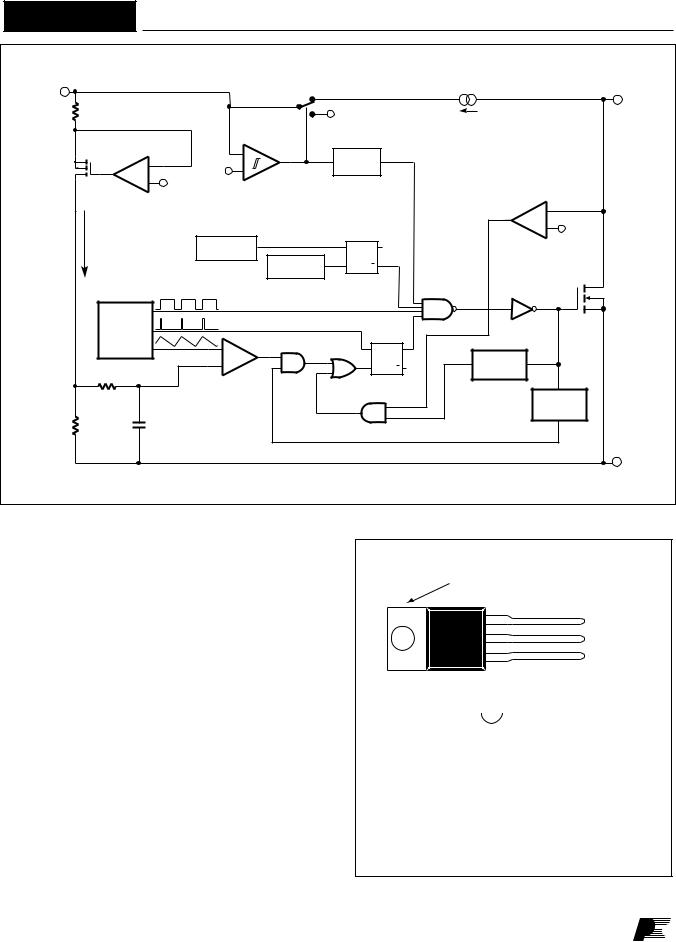

Figure 2. Functional Block Diagram.

Pin Functional Description

DRAIN Pin:

Output MOSFET drain connection. Provides internal bias current during start-up operation via an internal switched highvoltage current source. Internal current sense point.

CONTROL Pin:

Error amplifier and feedback current input pin for duty cycle control. Internal shunt regulator connection to provide internal bias current during normal operation. It is also used as the connection point for the supply bypass and auto-restart/ compensation capacitor.

SOURCE Pin:

Y package – Output MOSFET source connection for high voltage power return. Primary side circuit common and reference point.

P and G package – Primary side control circuit common and reference point.

SOURCE (HV RTN) Pin: (P and G package only)

Output MOSFET source connection for high voltage power return.

Tab Internally

Connected to SOURCE Pin

DRAIN

SOURCE

CONTROL

Y Package (TO-220/3)

|

|

|

|

|

|

|

SOURCE |

1 |

|

8 |

SOURCE (HV RTN) |

||

|

|

|

|

|

||

SOURCE |

|

2 |

|

7 |

SOURCE (HV RTN) |

|

SOURCE |

|

|

|

|

|

SOURCE (HV RTN) |

|

3 |

|

6 |

|||

CONTROL |

|

|

|

|

DRAIN |

|

|

4 |

|

5 |

|||

|

|

|

|

|

|

|

P Package (DIP-8)

G Package (SMD-8)

PI-2084-040401

Figure 3. Pin Configuration.

2 |

|

D |

7/01 |

||

|

|

|

TOP221-227

TOPSwitch-II Family Functional Description

TOPSwitch is a self biased and protected linear control current- to-duty cycle converter with an open drain output. High efficiency is achieved through the use of CMOS and integration of the maximum number of functions possible. CMOS process significantly reduces bias currents as compared to bipolar or discrete solutions. Integration eliminates external power resistors used for current sensing and/or supplying initial startup bias current.

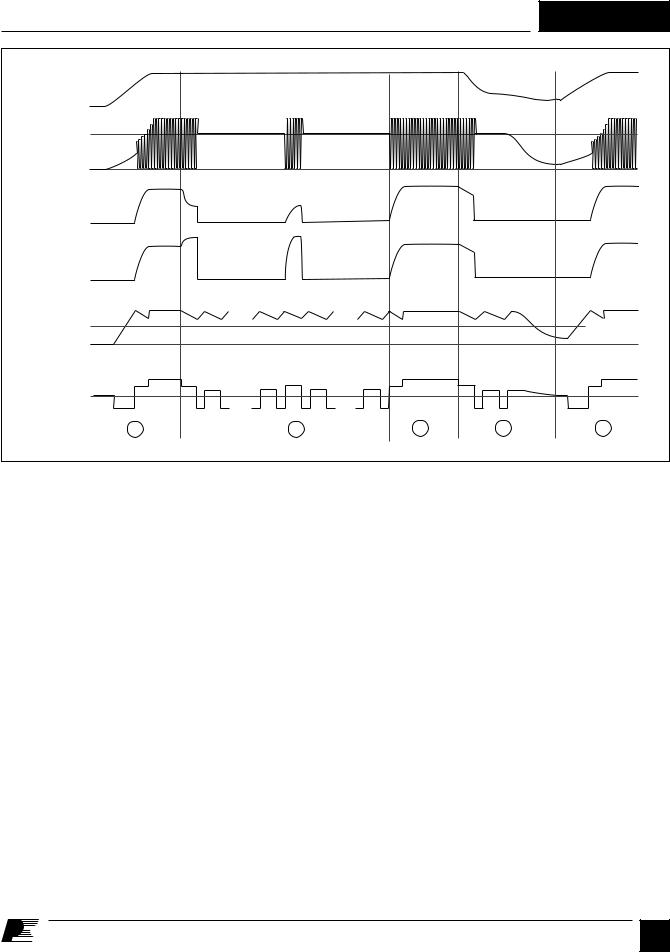

During normal operation, the duty cycle of the internal output MOSFET decreases linearly with increasing CONTROL pin current as shown in Figure 4. To implement all the required control, bias, and protection functions, the DRAIN and CONTROL pins each perform several functions as described below. Refer to Figure 2 for a block diagram and to Figure 6 for timing and voltage waveforms of the TOPSwitch integrated circuit.

Auto-restart |

|

|

DMAX |

IB |

|

Slope = PWM Gain |

||

|

||

Duty Cycle (%) |

|

|

DMIN |

|

|

ICD1 2.0 |

6.0 |

|

|

IC (mA) |

|

|

PI-2040-050197 |

Figure 4. Relationship of Duty Cycle to CONTROL Pin Current.

IC |

|

|

Charging CT |

|

|

5.7 V |

|

|

4.7 V |

|

|

VC |

|

|

0 |

|

|

Off |

|

|

VIN |

|

|

DRAIN |

|

|

0 |

|

|

|

Switching |

|

(a) |

|

|

|

|

ICD2 |

IC |

ICD1 |

Discharging CT |

Charging CT |

Discharging CT |

|

5.7 V |

|

|

4.7 V |

|

|

VC |

8 Cycles |

|

0 |

|

|

95% |

|

|

|

5% |

|

|

|

|

Off |

Off |

Off |

VIN |

|

|

DRAIN |

|

|

0 |

|

|

Switching |

|

Switching |

(b)

CT is the total external capacitance connected to the CONTROL pin

PI-1956-092496

Figure 5. Start-up Waveforms for (a) Normal Operation and (b) Auto-restart.

D 3 7/01

TOP221-227

TOPSwitch-II Family Functional Description (cont.)

Control Voltage Supply

CONTROL pin voltage VC is the supply or bias voltage for the controller and driver circuitry. An external bypass capacitor closely connected between the CONTROL and SOURCE pins is required to supply the gate drive current. The total amount of capacitance connected to this pin (CT) also sets the autorestart timing as well as control loop compensation. VC is regulated in either of two modes of operation. Hysteretic regulation is used for initial start-up and overload operation. Shunt regulation is used to separate the duty cycle error signal from the control circuit supply current. During start-up, CONTROL pin current is supplied from a high-voltage switched current source connected internally between the DRAIN and CONTROL pins. The current source provides sufficient current to supply the control circuitry as well as charge the total external capacitance (CT).

The first time VC reaches the upper threshold, the high-voltage current source is turned off and the PWM modulator and output transistor are activated, as shown in Figure 5(a). During normal operation (when the output voltage is regulated) feedback control current supplies the VC supply current. The shunt regulator keeps VC at typically 5.7 V by shunting CONTROL pin feedback current exceeding the required DC supply current through the PWM error signal sense resistor RE. The low dynamic impedance of this pin (ZC) sets the gain of the error amplifier when used in a primary feedback configuration. The dynamic impedance of the CONTROL pin together with the external resistance and capacitance determines the control loop compensation of the power system.

If the CONTROL pin total external capacitance (CT) should discharge to the lower threshold, the output MOSFET is turned off and the control circuit is placed in a low-current standby mode. The high-voltage current source turns on and charges the external capacitance again. Charging current is shown with a negative polarity and discharging current is shown with a positive polarity in Figure 6. The hysteretic auto-restart comparator keeps VC within a window of typically 4.7 to 5.7 V by turning the high-voltage current source on and off as shown in Figure 5(b). The auto-restart circuit has a divide-by-8 counter which prevents the output MOSFET from turning on again until eight discharge-charge cycles have elapsed. The counter effectively limits TOPSwitch power dissipation by reducing the auto-restart duty cycle to typically 5%. Autorestart continues to cycle until output voltage regulation is again achieved.

Bandgap Reference

All critical TOPSwitch internal voltages are derived from a temperature-compensated bandgap reference. This reference is also used to generate a temperature-compensated current source which is trimmed to accurately set the oscillator frequency and MOSFET gate drive current.

Oscillator

The internal oscillator linearly charges and discharges the internal capacitance between two voltage levels to create a sawtooth waveform for the pulse width modulator. The oscillator sets the pulse width modulator/current limit latch at the beginning of each cycle. The nominal frequency of 100 kHz was chosen to minimize EMI and maximize efficiency in power supply applications. Trimming of the current reference improves the frequency accuracy.

Pulse Width Modulator

The pulse width modulator implements a voltage-mode control loop by driving the output MOSFET with a duty cycle inversely proportional to the current into the CONTROL pin which generates a voltage error signal across RE. The error signal across RE is filtered by an RC network with a typical corner frequency of 7 kHz to reduce the effect of switching noise. The filtered error signal is compared with the internal oscillator sawtooth waveform to generate the duty cycle waveform. As the control current increases, the duty cycle decreases. A clock signal from the oscillator sets a latch which turns on the output MOSFET. The pulse width modulator resets the latch, turning off the output MOSFET. The maximum duty cycle is set by the symmetry of the internal oscillator. The modulator has a minimum ON-time to keep the current consumption of the TOPSwitchindependent of the error signal. Note that a minimum current must be driven into the CONTROL pin before the duty cycle begins to change.

Gate Driver

The gate driver is designed to turn the output MOSFET on at a controlled rate to minimize common-mode EMI. The gate drive current is trimmed for improved accuracy.

Error Amplifier

The shunt regulator can also perform the function of an error amplifier in primary feedback applications. The shunt regulator voltage is accurately derived from the temperature compensated bandgap reference. The gain of the error amplifier is set by the CONTROL pin dynamic impedance. The CONTROL pin clamps external circuit signals to the VC voltage level. The CONTROL pin current in excess of the supply current is separated by the shunt regulator and flows through RE as a voltage error signal.

Cycle-By-Cycle Current Limit

The cycle by cycle peak drain current limit circuit uses the output MOSFET ON-resistance as a sense resistor. A current limit comparator compares the output MOSFET ON-state drain-

source voltage, VDS(ON) with a threshold voltage. High drain current causes VDS(ON) to exceed the threshold voltage and turns the output MOSFET off until the start of the next clock cycle.

The current limit comparator threshold voltage is temperature

4 |

|

D |

7/01 |

||

|

|

|

|

|

|

|

|

|

|

|

|

TOP221-227 |

VIN |

|

|

|

|

|

|

|

|

|

DRAIN |

VIN |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

|

|

|

|

|

|

|

|

VOUT |

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

IOUT |

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

2 |

8 |

1 |

2 |

8 |

1 |

|

|

VC |

|

• • • |

|

|

|

• • • |

|

|

VC(reset) |

0 |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

1 |

2 |

8 |

1 |

2 |

8 |

1 |

|

|

IC |

0 |

• • • |

|

|

|

• • • |

|

|

|

|

1 |

|

|

2 |

|

|

1 |

3 |

1 |

|

|

|

|

|

|

|

|

|

PI-2030-042397 |

Figure 6. Typical Waveforms for (1) Normal Operation, (2) Auto-restart, and (3) Power Down Reset.

compensated to minimize variation of the effective peak current limit due to temperature related changes in output MOSFET

RDS(ON).

The leading edge blanking circuit inhibits the current limit comparator for a short time after the output MOSFET is turned on. The leading edge blanking time has been set so that current spikes caused by primary-side capacitances and secondary-side rectifier reverse recovery time will not cause premature termination of the switching pulse.

The current limit can be lower for a short period after the leading edge blanking time as shown in Figure 12. This is due to dynamic characteristics of the MOSFET. To avoid triggering the current limit in normal operation, the drain current waveform should stay within the envelope shown.

Shutdown/Auto-restart

To minimize TOPSwitch power dissipation, the shutdown/ auto-restart circuit turns the power supply on and off at an autorestart duty cycle of typically 5% if an out of regulation condition persists. Loss of regulation interrupts the external current into the CONTROL pin. VC regulation changes from shunt mode to the hysteretic auto-restart mode described above. When the fault condition is removed, the power supply output

becomes regulated, VC regulation returns to shunt mode, and normal operation of the power supply resumes.

Overtemperature Protection

Temperature protection is provided by a precision analog circuit that turns the output MOSFET off when the junction temperature exceeds the thermal shutdown temperature (typically 135 °C). Activating the power-up reset circuit by removing and restoring input power or momentarily pulling the CONTROL pin below the power-up reset threshold resets the latch and allows TOPSwitch to resume normal power supply operation. VC is regulated in hysteretic mode and a 4.7 V to 5.7 V (typical) sawtooth waveform is present on the CONTROL pin when the power supply is latched off.

High-voltage Bias Current Source

This current source biases TOPSwitch from the DRAIN pin and charges the CONTROL pin external capacitance (CT) during start-up or hysteretic operation. Hysteretic operation occurs during auto-restart and overtemperature latched shutdown. The current source is switched on and off with an effective duty cycle of approximately 35%. This duty cycle is determined by the ratio of CONTROL pin charge (IC) and discharge currents (ICD1 and ICD2). This current source is turned off during normal operation when the output MOSFET is switching.

D 5 7/01

TOP221-227

|

|

|

|

D2 |

|

L1 |

|

|

|

|

|

|

UF5401 |

|

3.3 |

µH |

|

|

|

|

|

|

|

|

|

+5 V |

+ |

|

|

|

C2 |

|

|

C3 |

|

|

C1 |

|

330 µF |

VR1 |

100 |

µF |

||

R3 |

|

|

10 V |

|

10 V |

|||

47 kΩ |

|

2.2 nF |

|

|

|

|||

|

|

|

|

|

|

RTN |

||

|

|

1 kV |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

D1 |

|

|

|

|

R2 |

|

|

|

UF4005 |

|

|

|

|

|

||

|

|

|

|

|

|

100 |

Ω |

|

|

|

|

|

D3 |

|

|

|

|

Wide-Range |

|

|

|

1N4148 |

R1 |

|

|

|

|

|

T1 |

|

10 Ω |

|

|

|

|

DC Input |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

||

|

|

U1 |

|

C4 |

|

|

|

+ |

|

D |

|

|

|

|

|

||

|

TOP221P |

|

|

|

|

|

||

|

TOPSwitch-II |

100 µF |

|

|

|

|

||

|

|

|

|

|

|

|||

|

|

CONTROL |

16 V |

|

|

|

|

|

|

|

C |

|

|

|

|

||

|

|

|

|

U2 |

|

|

12 V Non-Isolated |

|

|

|

|

|

|

|

|

||

|

|

|

|

C5 |

PC817A |

|

|

|

|

S |

|

|

|

|

|

|

|

|

|

|

47 µF |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

- |

|

|

|

10 V |

|

|

|

- |

PI-2115-040401

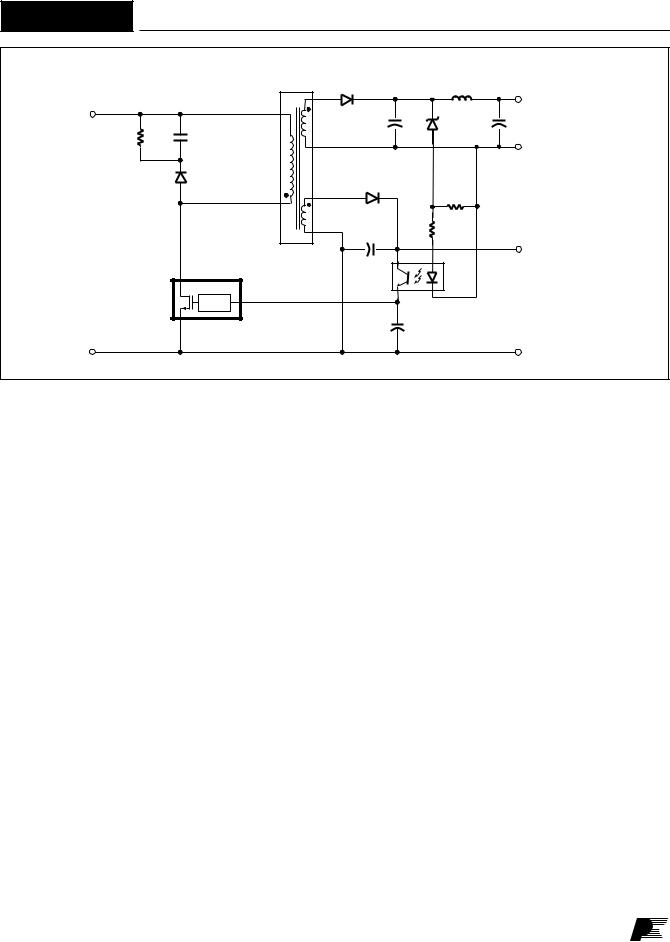

Figure 7. Schematic Diagram of a 4 W TOPSwitch-II Standby Power Supply using an 8 lead PDIP.

Application Examples

Following are just two of the many possible TOPSwitch implementations. Refer to the Data Book and Design Guide for additional examples.

4 W Standby Supply using 8 Lead PDIP

Figure 7 shows a 4 W standby supply. This supply is used in appliances where certain standby functions (e.g. real time clock, remote control port) must be kept active even while the main power supply is turned off.

The 5 V secondary is used to supply the standby function and the 12 V non-isolated output is used to supply power for the PWM controller of the main power supply and other primary side functions.

For this application the input rectifiers and input filter are sized for the main supply and are not shown. The input DC rail may

vary from 100 V to 380 V DC which corresponds to the full universal AC input range. The TOP221 is packaged in an 8 pin power DIP package.

The output voltage (5 V) is directly sensed by the Zener diode (VR1)andtheoptocoupler(U2). Theoutputvoltageis determined by the sum of the Zener voltage and the voltage drop across the LED of the optocoupler (the voltage drop across R1 is negligible). The output transistor of the optocoupler drives the CONTROL pin of the TOP221. C5 bypasses the CONTROL pin and provides control loop compensation and sets the auto-restart frequency.

The transformer’s leakage inductance voltage spikes are snubbed by R3 and C1 through diode D1. The bias winding is rectified and filtered by D3 and C4 providing a non-isolated 12 V output which is also used to bias the collector of the optocoupler’s output transistor. The isolated 5 V output winding is rectified by D2 and filtered by C2, L1 and C3.

6 |

|

D |

7/01 |

||

|

|

|

Loading...

Loading...