Porter-Cable 4210 User Manual

Part No. A05065 - 05-27-05

DOVETAIL JIG

INSTRUCTION

MANUAL

The Model and Serial No. plate is located on the main

housing of the tool. Record these numbers in the

spaces below and retain for future reference.

Model No. _____________________________________

Type __________________________________________

Serial No.______________________________________

IMPORTANT

Please make certain that the person who is

to use this equipment carefully reads and

understands these instructions before

starting operations.

ESPAÑOL: PÁGINA 27

FRANÇAISE : PAGE 51

To learn more about Porter-Cable

visit our website at:

http://www.porter-cable.com

Copyright © 2004 Porter-Cable Corporation

MODELS 4210 & 4212

Note: Rockler may not carry all products and/or sizes listed in this vendor's publication

(29550)

RTD10000210AA

2

TABLE OF CONTENTS

SAFETY GUIDELINES 3

IMPORTANT SAFETY INSTRUCTIONS 3

ADDITIONAL SPECIFIC SAFETY RULES 4

BACKGROUND INFORMATION

Dovetail and Box Joint Overview 5

Product Capabilities 6

4200 Series Dovetail Jig Overview 7

Carton Contents 7

Assembly 8

Additional Tools Required 8

Mounting Instructions 8

OPERATION

Clamps 9

Template Mounting 9

Template Support 10

Positioning the Wood 10

Half-Pins Vs. Half- Tails 11

Tearout Reduction 11

Aligning the Templates 11

Template Guides 12

Router Bit Depth 12

WOOD PREPARATION

Grain Direction 13

Board Thickness 13

Optimal Board Widths 13

Board Lengths 13

Project Layout 14

Drawers 14

BASIC JOINTS

Through Dovetails 15

Cutting the Tails 15

Cutting the Pins 16

Fitting and Troubleshooting 17

Half-Blind Dovetails 17

Cutting a Half-Blind Dovetail 17

Fitting and Troubleshooting 18

Half-Blind Dovetail with a Lipped Front 19

Cutting the Tails 19

Cutting the Pins 20

Fitting and Troubleshooting 20

Box Joints 21

Cutting the First workpiece 21

Cutting the Second Workpiece 22

Dovetail Dados (Sliding Dovetails) 23

Dado Board 23

Tenon Board 24

Fitting and Troubleshooting 24

MAINTENANCE 25

SERVICE 25

ACCESSORIES 25

WARRANTY 26

ESPAÑOL 27

FRANÇAISE 51

SERVICE CENTER LOCATIONS Back cover

3

Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

Used without the safety alert symbol indicates potentially hazardous situation which, if not avoided, may

result in property damage.

This manual contains information that is important for you to know and understand. This information relates to protecting YOUR SAFETY and PREVENTING EQUIPMENT PROBLEMS. To help you recognize this information, we use

the symbols to the left. Please read the manual and pay attention to these sections.

SAFETY GUIDELINES - DEFINITIONS

IMPORTANT SAFETY INSTRUCTIONS

Read and understand all instructions. Failure to follow all instructions listed below, may

result in electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS.

Technical Service Manager

Porter-Cable Corporation

4825 Highway 45 North

Jackson, TN 38305

There are certain applications for which this tool was designed. Porter-Cable strongly recommends that this

tool NOT be modified and/or used for any application other than for which it was designed. If you have any questions relative to

its application DO NOT use the tool until you have written Porter-Cable and we have advised you.

1. KEEP WORK AREA CLEAN. Cluttered areas and benches invite injuries.

2. AVOID DANGEROUS ENVIRONMENT. Don’t expose power tools to rain. Don’t use power tools in damp or wet

locations. Keep area well lit. Avoid chemical or corrosive environment. Do not use tool in presence of flammable

liquids or gases.

3. GUARD AGAINST ELECTRIC SHOCK. Prevent body contact with grounded surfaces. For example: pipes,

radiators, ranges, refrigerator enclosures.

4. KEEP CHILDREN AWAY. Do not let visitors contact tool or extension cord. All visitors should be kept away from

work area.

5. STORE IDLE TOOLS. When not in use, tools should be stored in dry, and high or locked-up place – out of reach

of children.

6. DON’T FORCE TOOL. It will do the job better and safer at the rate for which it was intended.

7. USE RIGHT TOOL. Don’t force small tool or attachment to do the job of a heavy duty tool. Don’t use tool for

purpose not intended – for example – do not use a circular saw for cutting tree limbs or logs.

8. DRESS PROPERLY. Do not wear loose clothing or jewelry. Loose clothing, draw strings and jewelry can be

caught in moving parts. Rubber gloves and non-skid footwear are recommended when working outdoors. Wear

protective hair covering to contain long hair.

9. USE ANSI Z87.1 SAFETY GLASSES. Wear safety glasses or goggles while operating power tools. Also face or

dust mask if operation creates dust. All persons in the area where power tools are being operated should also

wear safety glasses and face or dust mask.

10. DON’T ABUSE CORD. Never carry tool by cord or yank it to disconnect from receptacle. Keep cord from heat,

oil, and sharp edges. Have damaged or worn power cord and strain reliever replaced immediately. DO NOT

ATTEMPT TO REPAIR POWER CORD.

11. SECURE WORK. Use clamps or a vise to hold work. It’s safer than using your hand and it frees both hands to

operate tool.

12. DON’T OVERREACH. Keep proper footing and balance at all times.

13. MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for better and safer performance. Follow

instructions for lubricating and changing accessories. Inspect tool cords periodically and if damaged, have

repaired by authorized service facility. Inspect extension cords periodically and replace if damaged. Have all

worn, broken or lost parts replaced immediately. Keep handles dry, clean and free from oil and grease.

14. DISCONNECT TOOLS when not in use, before servicing, and when changing accessories such as blades, bits, cutters,

etc.

15. REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of checking to see that keys and adjusting

wrenches are removed from the tool before turning it on.

4

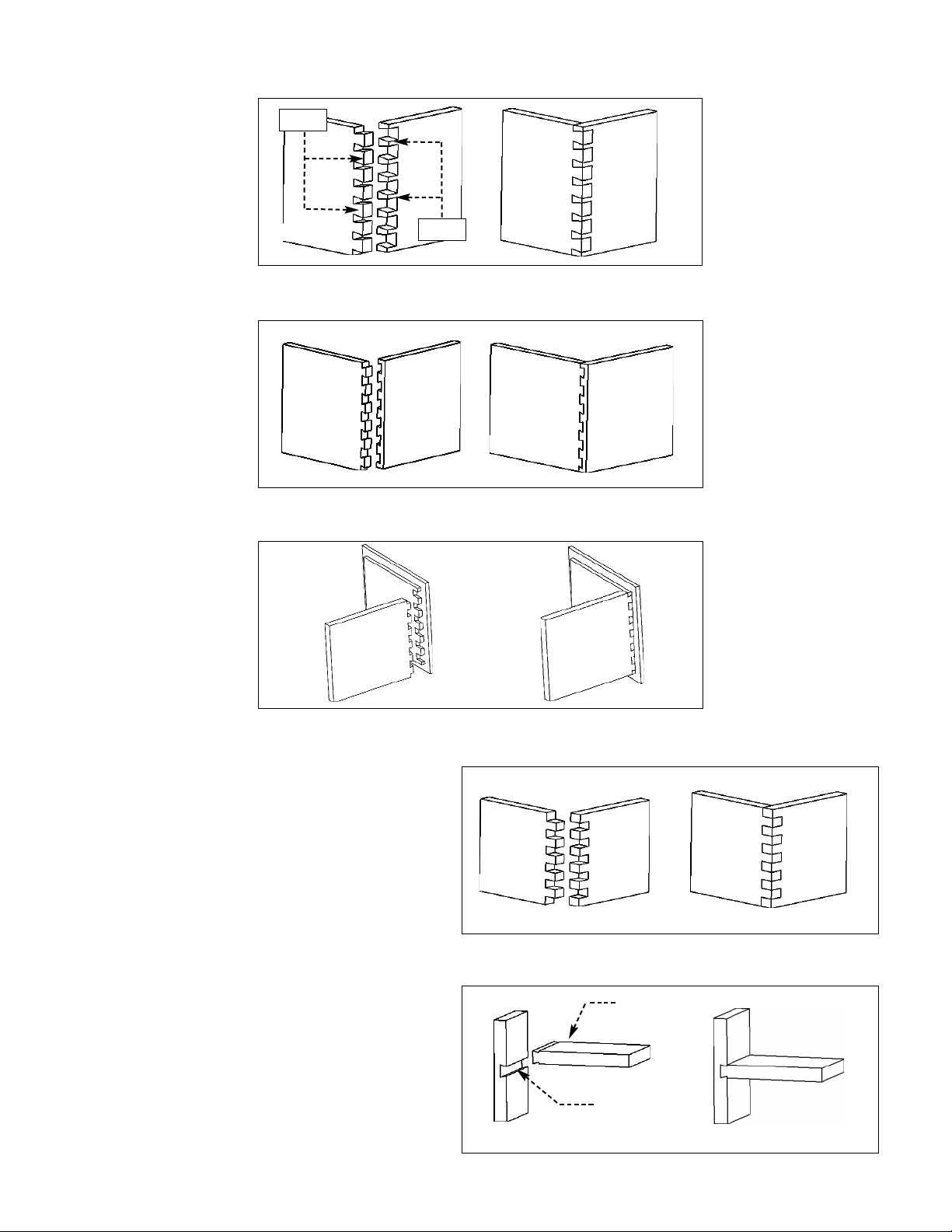

Types of dovetails include through dovetails, half-blind dovetails, rabbeted half-blind dovetails, mitered-through

dovetails, blind dovetails, and mitered dovetails. Of these joints, the through, half-blind, and rabbeted half-blind are

the most common.

DOVETAIL AND BOX JOINT OVERVIEW

The dovetail joint is a traditional joint that is both strong and visually appealing. This joint has flared protrusions (tails)

that are cut into one board (drawer side) and protrusions with slanted sides (pins) that are cut in the other board

(drawer front or back). When the two pieces are joined, the tails and pins lock together mechanically, so that pulling

on the drawer front will pull the drawer side as well without the need for fasteners (screws, nails, etc.). Since the pins

and tails have a sufficient amount of surface, the joint is even made stronger by glue.

FAILURE TO FOLLOW THESE RULES MAY RESULT IN SERIOUS PERSONAL INJURY.

ADDITIONAL SAFETY RULES

1. READ AND FOLLOW ALL SAFETY INSTRUCTIONS in the instruction manual supplied with your router.

2. SECURE WORK. Be sure Dovetail Fixture/Jig and work is anchored securely to prevent movement.

3. BE SURE CORD SET IS FREE and will not hang up during routing operations.

4. KEEP HANDS CLEAR of cutter when motor is running to prevent personal injury.

5. MAINTAIN FIRM GRIP on router when starting motor to resist starting torque.

6. STAY ALERT and keep cutter free, clear of all foreign objects while motor is running.

7. BE SURE MOTOR HAS COMPLETELY STOPPED before removing router from Dovetail Fixture/Jig and setting

Dovetail Fixture/Jig down between operations.

8. NEVER REMOVE ROUTER MOTOR from router base while template guide and dovetail bit are installed. dovetail

bit may not fit through hole in template guide.

9. TIGHTEN TEMPLATE GUIDE LOCKNUT SECURELY.

10. SOME WOOD CONTAINS PRESERVATIVES WHICH CAN BE TOXIC. Take extra care to prevent inhalation and

skin contact when working with these materials. Request, and follow, any safety information available from your

material supplier.

REPLACEMENT PARTS

When servicing use only identical replacement parts.

16. AVOID UNINTENTIONAL STARTING. Do not carry a plugged-in tool with finger on switch. Be sure switch is off

when plugging in. Keep hands, body and clothing clear of blades, bits, cutters, etc. when plugging in the tool.

17. OUTDOOR USE EXTENSION CORDS. When tool is used outdoors, use only extension cords marked “Suitable

for use with outdoor appliances – store indoors when not in use.” If an extension cord is to be used outdoors it

must be marked with the suffix W-A or w following the cord type designation.

18. STAY ALERT. Watch what you are doing. Use common sense. Do not operate tool when you are tired or while

under the influence of medication, alcohol or drugs.

19. CHECK DAMAGED PARTS. Before further use of the tool, a guard or other part that is damaged should be

carefully checked to determine that it will operate properly and perform its intended function. Check for alignment

of moving parts, binding of moving parts, breakage of parts, mounting, and any other conditions that may affect

its operation. A guard or other part that is damaged should be properly repaired or replaced by an authorized

service center unless otherwise indicated elsewhere in this instruction manual. Have defective switches replaced

by authorized service center. Do not use tool if switch does not turn it on and off.

20. WEAR ANSI

S3.19 EAR PROTECTION to safeguard against possible hearing loss.

BACKGROUND INFORMATION

NOTE: This manual includes instruction for the basic dovetail jig operations. Please visit our Web Site at

www.porter-cable.com/jigs for the supplementary manual that gives instruction for more advanced procedures.

5

THROUGH DOVETAILS

RABBETED HALF-BLIND DOVETAILS

Tails

Pins

BOX (FINGER) JOINT

A similar joint, called a box or finger joint, has

straight protrusions called fingers on both boards.

This joint is used on jewelry boxes and other small

boxes. The box joint is strong because it has a large

surface area for glue.

The Dovetail Dado, or Sliding Dovetail,

consists of a dovetail-shaped dado in one

board and a dovetail-shaped tenon in the

other board. This method is a strong way of

connecting fixed shelves to walls.

DOVETAIL DADO (SLIDING DOVETAIL)

HALF-BLIND DOVETAILS

Tenon

Dado

6

JIG OVERVIEW

The 4200 series dovetail jigs come equipped with an easy-to-mount, heavy-duty steel base (A) Fig. A1 featuring a

clamping system designed to hold wood and minimize board slippage during cuts. Troubleshooting tips (B) are

provided on each side of the base. Three different machined aluminum templates (Fig. A2) can be used on the jig

system to create all joints described in this manual. The fingers on each template are used in combination with the

template guides (Fig. A3) to guide the router in the proper motion. Additionally, each template aids in setting proper

board alignment and router bit depth. Dovetail bits and straight bits (Figs. A4 and A5) are used with this jig system.

A1 A2

A3

A4

A5

A

B

The Porter-Cable 4200 series dovetail jig will help you cut these joints efficiently. An accessory kit will enable you to

cut miniature versions of these joints for small gift boxes or cubbyhole drawers on a roll-top desk. The 4200 series

also has the capability to cut more advanced joints (dovetails that skip pins, wood hinges, end-to-end joints, various

types of angle joints, and joints with inlays).

PRODUCT CAPABILITIES

The specific model capabilities are:

Jigs

4210 Dovetail Jig - half-blind, half-blind with a lipped front, and dovetail dados.

4212 Deluxe Dovetail Jig - through dovetail, box joint, half-blind, half-blind with a lipped front, and

dovetail dados.

Accessories

4211 Accessory Kit - includes the template, router bit, and templet guide included with the model 4210.

4213 Accessory kit - incudes all items necessary to provide the 4210 jig with the same capabilities as the

4212 deluxe dovetail jig.

4215 Accessory kit - contains the template, router bits, and templet guides to make miniature through

dovetails and half-blind dovetails.

7

CARTON CONTENTS

1. Base

2. Half-blind & Dado Template

3. Dovetail Bit

4. Template Guide

5. Lock nut

6. T-handle Hex Wrench

4210

4212

1. Base

2. Half-blind & Dado Template

3. Through & Box Template

4. Dovetail Bit

5. Straight Bit

6. Template Guide (2)

7. Lock Nuts (2)

8. T-handle Hex Wrench

DOVETAIL JIGS

ACCESSOR

Y KITS

1. Half-blind & Dado Template

2. Brackets (2)

3. Dado Depth Bracket

4. Half-blind Depth Bracket

5. Dovetail Bit

6. Depth Knob

7. Screws (8)

8. Hex Nuts (1)

9. Wrench

10. Template Guide and Lock Nut

1. Through and Box Joint

Template

2. Brackets (2)

3. Half-Blind Depth Bracket

4. Straight Bit

5. Template Guide and Lock Nut

6. Hex Nuts (1)

7. Screws (6)

8. Depth Knob

9. Wrench

1. Miniature Half-blind, Through, &

Box Template

2. Brackets (2)

3. Template Guide and Lock Nut (2)

4. Half-blind Depth Bracket

5. Offset Guide (2)

6. Depth Knob

7. Dovetail Bit

8. Straight Bit

9. Hex Nuts (1)

10.Screws (6)

11.Wrench

4211 4213 4215

1

2

3

4

5

6

1

2

4

3

5

6

7

8

1

23

5

4

6

7

8

9

10

1

23

5

4

6

7

8

9

1

23

5

4

6

7

8

9

10

11

8

ADDITIONAL TOOLS REQUIRED

The router that you use with this jig

NOTE: While the jigs and accessory kits include the router bits and template guides to make the basic dovetail

joints, additional router bits are required to make box joints.

MOUNTING INSTRUCTIONS

NOTE: Always mount your jig to a solid work surface.

You can mount your jig permanently (Fig. B1) by using the pre-drilled holes (A) Fig B1) on each side of the base, or

you can mount the base to your work surface using clamps (Fig. B2).

B1

B2

u

must accept the Porter-Cable template guides supplied with the

jig. (Adapters and sub-bases are available for most routers.)

must have a 1/2" collet for use with 4210 and 4212 jigs and the

4211 and 4213 accessory kits.

must have a 1/4" collet for use with the 4215 accessory kit.

u

u

A

ASSEMBLY

The 4200 series dovetail jigs come fully assembled from the factory. However, the accessory templates (4211, 4213,

4215) require assembly. The supplied hex wrench can be used to attach the brackets and router bit depth guides

to the template. A 3/8" wrench is required to adjust the height of the router bit depth guide.

HEIGHT ADJUSTMENT

ASSEMBLED JIG

3/8"

9

Mount your workpiece in the jig properly. If the workpiece is not secure, it can be damaged when it moves.

The jigs utilize two mounting positions for workpieces - horizontal and vertical. Some joints require both, while

others require the use of a scrap board in the horizontal position (upper clamp) and the workpiece in the vertical

position (lower clamp).

Position your workpiece correctly left-to-right to produce symmetrical and tight-fitting joints.

Tear-out from the router bit can be reduced when scrap wood is positioned properly against the workpiece.

CLAMPS

The 4200 series jigs are equipped with two cam-action clamps (A) Fig. C1 with knobs (B) to adjust for workpiece

thickness, and levers (C) for quick clamping and releasing of workpieces.

NOTE: Use a scrap board (A) Fig. C2 to prevent misalignment (A) Fig. C3.

TEMPLATE MOUNTING

You can mount the templates in two positions on the jig(s) which allows the production of multiple types of joints

with each template. To reverse a template, loosen the template knobs (C) Fig. D1, remove the template (B) from the

base, rotate it 180 degrees horizontally, replace it on the base, and tighten the template knobs.

NOTE: Secure the templates by inserting the template brackets (A) Fig. D2 between the large template knobs (B)

Fig. D2 and the brass adjustment knobs (C). You can then make front-to-back adjustments by loosening the large

template knobs (B) and rotating the brass adjustment knobs (C).

A

B

C

A

A

B

C

A

C1

C2 C3

D1

D2

C

OPERATION

A

ROTATE

Loading...

Loading...