Porter-Cable 3812 User Manual

10" Bench Top Table Saw

Part No. 895558 (015)

The Model and Serial No. plate is located on the main

housing of the tool. Record these numbers in the

spaces below and retain for future reference.

Model No. _____________________________________

Type __________________________________________

Serial No.______________________________________

IMPORTANT

Please make certain that the person who is to

use this equipment carefully reads and

understands these instructions before starting

operations.

To learn more about Porter-Cable

visit our website at:

http://www.porter-cable.com

Copyright © 2001 Porter-Cable Corporation

Shown assembled with accessory stand model 38129

and accessory outfeed support model 38239.

ESPAÑOL: PÁGINA 19

FRANÇAISE : PAGE 37

Model 3812

Instruction

Manual

2

GENERAL SAFETY RULES

Woodworking can be dangerous if safe and proper operating procedures are not followed. As with all machinery, there

are certain hazards involved with the operation of the product. Using the machine with respect and caution will

considerably lessen the possibility of personal injury. However, if normal safety precautions are overlooked or ignored,

personal injury to the operator may result. Safety equipment such as guards, push sticks, hold-downs, featherboards,

goggles, dust masks and hearing protection can reduce your potential for injury. But even the best guard won’t make

up for poor judgment, carelessness or inattention. Always use common sense and exercise caution in the workshop.

If a procedure feels dangerous, don’t try it. Figure out an alternative procedure that feels safer. REMEMBER: Your

personal safety is your responsibility.

This machine was designed for certain applications only. Porter-Cable strongly recommends that this machine not be

modified and/or used for any application other than that for which it was designed. If you have any questions relative

to a particular application, DO NOT use the machine until you have first contacted Porter-Cable to determine if it can

or should be performed on the product.

Technical Service Manager

Porter-Cable Corporation

4825 Highway 45 North

Jackson, TN 38305

(IN CANADA: 505 SOUTHGATE DRIVE, GUELPH, ONTARIO N1H 6M7)

WARNING: FAILURE TO FOLLOW THESE RULES MAY RESULT IN SERIOUS PERSONAL INJURY

1. FOR YOUR OWN SAFETY, READ INSTRUCTION

MANUAL BEFORE OPERATING THE TOOL. Learn the

tool’s application and limitations as well as the specific

hazards peculiar to it.

2. KEEP GUARDS IN PLACE and in working order.

3. ALWAYS WEAR EYE PROTECTION.

Wear safety

glasses. Everyday eyeglasses only have impact resistant

lenses; they are not safety glasses. Also use face or dust

mask if cutting operation is dusty. These safety glasses

must conform to ANSI Z87.1 requirements. Note:

Approved glasses have Z87 printed or stamped on them.

4. REMOVE ADJUSTING KEYS AND WRENCHES. Form

habit of checking to see that keys and adjusting wrenches

are removed from tool before turning it “on”.

5. KEEP WORK AREA CLEAN. Cluttered areas and

benches invite accidents.

6. DON’T USE IN DANGEROUS ENVIRONMENT. Don’t

use power tools in damp or wet locations, or expose them

to rain. Keep work area well-lighted.

7. KEEP CHILDREN AND VISITORS AWAY. All children

and visitors should be kept a safe distance from work area.

8. MAKE WORKSHOP CHILDPROOF – with padlocks,

master switches, or by removing starter keys.

9. DON’T FORCE TOOL. It will do the job better and be

safer at the rate for which it was designed.

10. USE RIGHT TOOL. Don’t force tool or attachment to

do a job for which it was not designed.

11. WEAR PROPER APPAREL. No loose clothing, gloves,

neckties, rings, bracelets, or other jewelry to get caught in

moving parts. Nonslip footwear is recommended. Wear

protective hair covering to contain long hair.

12. SECURE WORK. Use clamps or a vise to hold work

when practical. It’s safer than using your hand and frees

both hands to operate tool.

13. DON’T OVERREACH. Keep proper footing and

balance at all times.

14. MAINTAIN TOOLS IN TOP CONDITION. Keep tools

sharp and clean for best and safest performance. Follow

instructions for lubricating and changing accessories.

15. DISCONNECT TOOLS before servicing and when

changing accessories such as blades, bits, cutters, etc.

16. USE RECOMMENDED ACCESSORIES. The use of

accessories and attachments not recommended by PorterCable may cause hazards or risk of injury to persons.

17. REDUCE THE RISK OF UNINTENTIONAL STARTING.

Make sure switch is in “OFF” position before plugging in

power cord.

In the event of a power failure, move switch

to the “OFF” position.

18. NEVER STAND ON TOOL. Serious injury could occur if

the tool is tipped or if the cutting tool is accidentally

contacted.

19. CHECK DAMAGED PARTS. Before further use of the

tool, a guard or other part that is damaged should be

carefully checked to ensure that it will operate properly and

perform its intended function – check for alignment of

moving parts, binding of moving parts, breakage of parts,

mounting, and any other conditions that may affect its

operation. A guard or other part that is damaged should be

properly repaired or replaced.

20. DIRECTION OF FEED. Feed work into a blade or

cutter against the direction of rotation of the blade or cutter

only.

21. NEVER LEAVE TOOL RUNNING UNATTENDED.

TURN POWER OFF. Don’t leave tool until it comes to a

complete stop.

22.

STAY ALERT, WATCH WHAT YOU ARE DOING, AND

USE COMMON SENSE WHEN OPERATING A POWER

TOOL. DO NOT USE TOOL WHILE TIRED OR UNDER

THE INFLUENCE OF DRUGS, ALCOHOL, OR

MEDICATION. A moment of inattention while operating

power tools may result in serious personal injury.

23. MAKE SURE TOOL IS DISCONNECTED FROM

POWER SUPPLY while motor is being mounted,

connected or re-connected.

24. THE DUST GENERATED by certain woods and wood

products can be injurious to your health. Always operate

machinery in well ventilated areas and provide for proper

dust removal. Use wood dust collection systems whenever

possible.

25.

WARNING: SOME DUST CREATED BY

POWER SANDING, SAWING, GRINDING, DRILLING,

AND OTHER CONSTRUCTION ACTIVITIES contains

chemicals known to cause cancer, birth defects or other

reproductive harm. Some examples of these chemicals

are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other

masonry products, and

• arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how

often you do this type of work. To reduce your exposure

to these chemicals: work in a well ventilated area, and

work with approved safety equipment, such as those

dust masks that are specially designed to filter out

microscopic particles.

SAVE THESE INSTRUCTIONS.

Refer to them often and use them to instruct others.

3

ADDITIONAL SAFETY RULES FOR CIRCULAR SAWS

1. DO NOT operate your saw until it is completely

assembled and installed according to the instructions.

2. IF YOU ARE NOT thoroughly familiar with the

operation of circular saws, obtain advice from your

supervisor, instructor, or other qualified person.

3. ALWAYS use blade guard, spreader and anti-

kickback fingers for every operation for which it can be

used, including all through sawing.

4. ALWAYS hold the work firmly against the miter gage

or fence.

5. NEVER use the fence as a cut-off gage when cross-

cutting.

6. MOVE the rip fence out of the way when cross-

cutting.

7. NEVER perform any operation “free-hand” which

means using only your hands to support or guide the

workpiece. Always use either the fence or miter gage to

position and guide the work.

8. ALWAYS use a push stick for ripping narrow stock.

Refer to ripping applications in instruction manual where

the push stick is covered in detail.

9. AVOID KICKBACKS (work thrown back toward you)

by:

A. Keeping blade sharp.

B. Keeping rip fence parallel to the saw blade.

C. Keeping spreader and anti-kickback fingers and

guard in place and operating.

D. Not releasing the work before it is pushed all the

way past the saw blade.

E. Not ripping work that is twisted or warped or does

not have a straight edge to guide along the fence.

F. Making sure that the fence is properly aligned.

G. Always using the fence, miter gauge or fixture to

process work pieces.

H. Using feather boards or a fixture when the anti-

kickback device cannot be used.

I. Keeping control of the stock when manually

feeding.

J. Not attempting to saw stock that is too large to

safely control.

K. Not using the fence as a stop when crosscutting.

L. Not trying to saw stock with loose knots or other

flaws.

10. AVOID awkward operations and hand positions

where a sudden slip could cause your hand to move into

the cutting tool.

11. ALWAYS keep hands and fingers away from the

blade.

12. NEVER stand or have any part of your body in line

with the path of the saw blade.

13. NEVER reach behind or over the cutting tool with

either hand for any reason.

14. DIRECTION OF FEED. Feed work into blade or

cutter against the dir

ection of rotation of the blade or

cutter only.

15. DO NOT feed the material too fast while cutting.

Feed the material just fast enough so that the blade will

cut.

16. NEVER attempt to free a stalled saw blade without

first turning the saw “OFF.”

17. NEVER start the saw with the workpiece pressed

against the blade.

18. MAKE sure table is clear of all objects before turning

saw “ON”.

19. ALWAYS turn the saw “OFF” and wait for the blade

to stop before removing scarp pieces.

20. NEVER perform layout, assembly or set-up work on

the table while the saw is operating.

21. PROVIDE adequate support to the rear and sides of

the saw table for wide or long workpieces.

22. NEVER use solvents to clean plastic parts. Solvents

could possibly dissolve or otherwise damage the

material. Only a soft damp cloth should be used to clean

plastic parts.

23. SHOULD any part of your circular saw be missing,

damaged, or fail in any way, or any electrical

components fail to perform properly, shut off switch and

remove plug from power supply outlet. Replace missing,

damaged or failed parts before resuming operation.

24. THE USE of attachments and accessories not

recommended by Porter-Cable may result in the risk of

injuries.

25. ADDITIONAL INFORMATION regarding the safe

and proper operation of this product is available from

the National Safety Council, 1121 Spring Lake Drive,

Itasca, IL 60143-3201, in the Accident Prevention

Manual for Industrial Operations and also in the Safety

Data Sheets provided by the NSC. Please also refer to

the American National Standards Institute ANSI 01.1

Safety Requirements for Woodworking Machinery and

the U.S. Department of Labor OSHA 1910.213

Regulations.

UNPACKING

Your new saw is shipped complete in one container.

Carefully unpack the saw and all loose items from the

shipping container. Fig. 2 illustrates the saw removed

from the container and Fig. 3, illustrates all the loose

items packed with the saw.

Fig. 2

Fig. 3

1 - Handle

2 - 1/4"-20x1-3/4" screw

3 - Fence

4 - Miter Gage

5 - Blade Guard and

Spreader Assembly

6 - Anchor Block Shim (3)

7 - Table Insert

8 - Blade Wrench (2)

1

2

3

4

5

6

7

8

4

ASSEMBLY INSTRUCTIONS

ASSEMBLING BLADE

RAISING AND LOWERING

HANDWHEEL

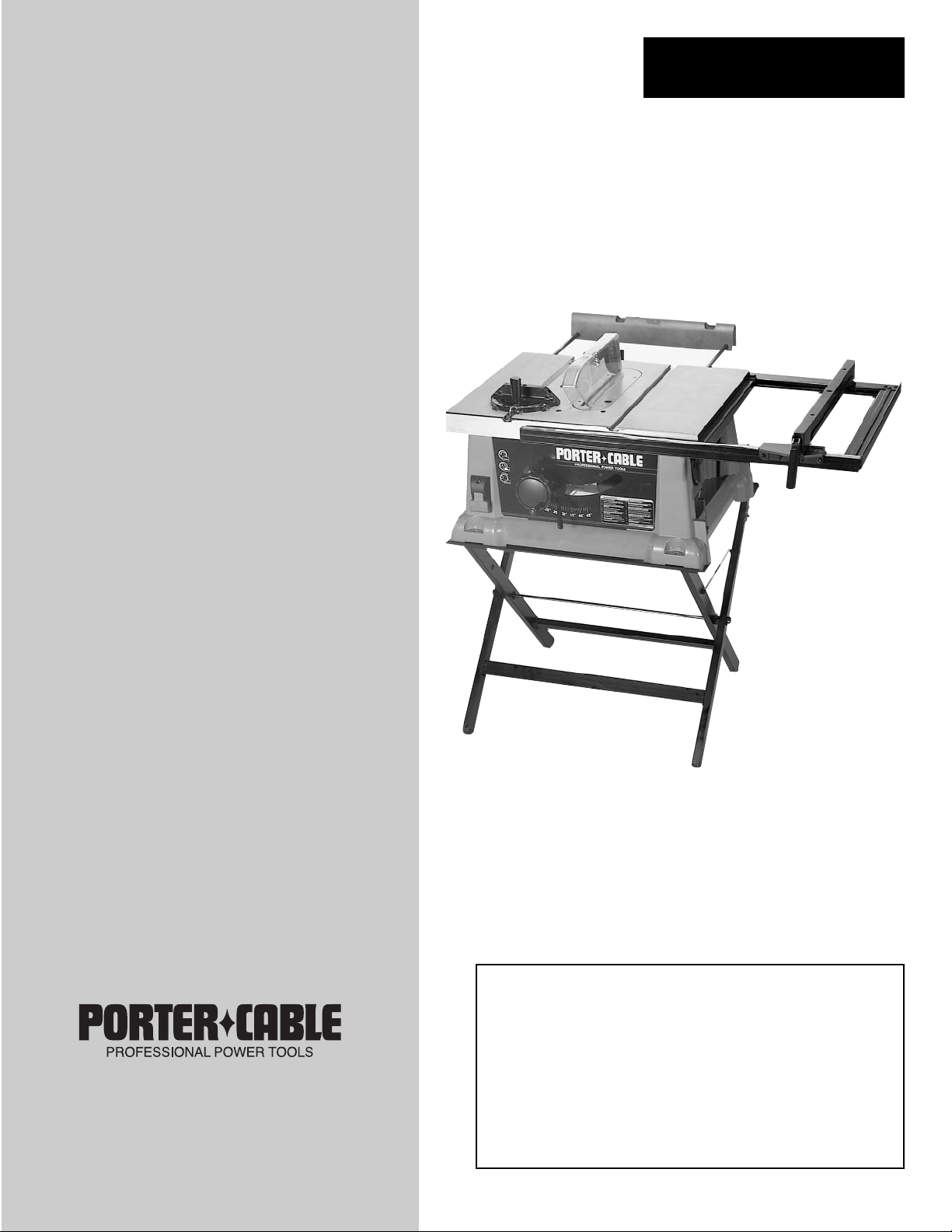

1. Insert the 1-3/4" screw (D) Fig. 4, through handle

(E). Assemble handle (E) to handwheel (A) by threading

screw (D) clockwise into handwheel as shown in Fig. 5.

Handle (E) should rotate freely on screw (D).

Fig. 4

Fig. 5

ASSEMBLING BLADE

GUARD AND SPREADER

ASSEMBLY

1. WARNING: WHEN ASSEMBLING THE BLADE

GUARD AND SPREADER ASSEMBLY, MAKE

CERTAIN THE SAW IS DISCONNECTED FROM THE

POWER SOURCE.

2. IMPORTANT: THE BLADE GUARD AND SPREADER

ASSEMBLY MUST BE PROPERLY ALIGNED TO THE

SAW BLADE IN ORDER TO HELP PREVENT

KICKBACK.

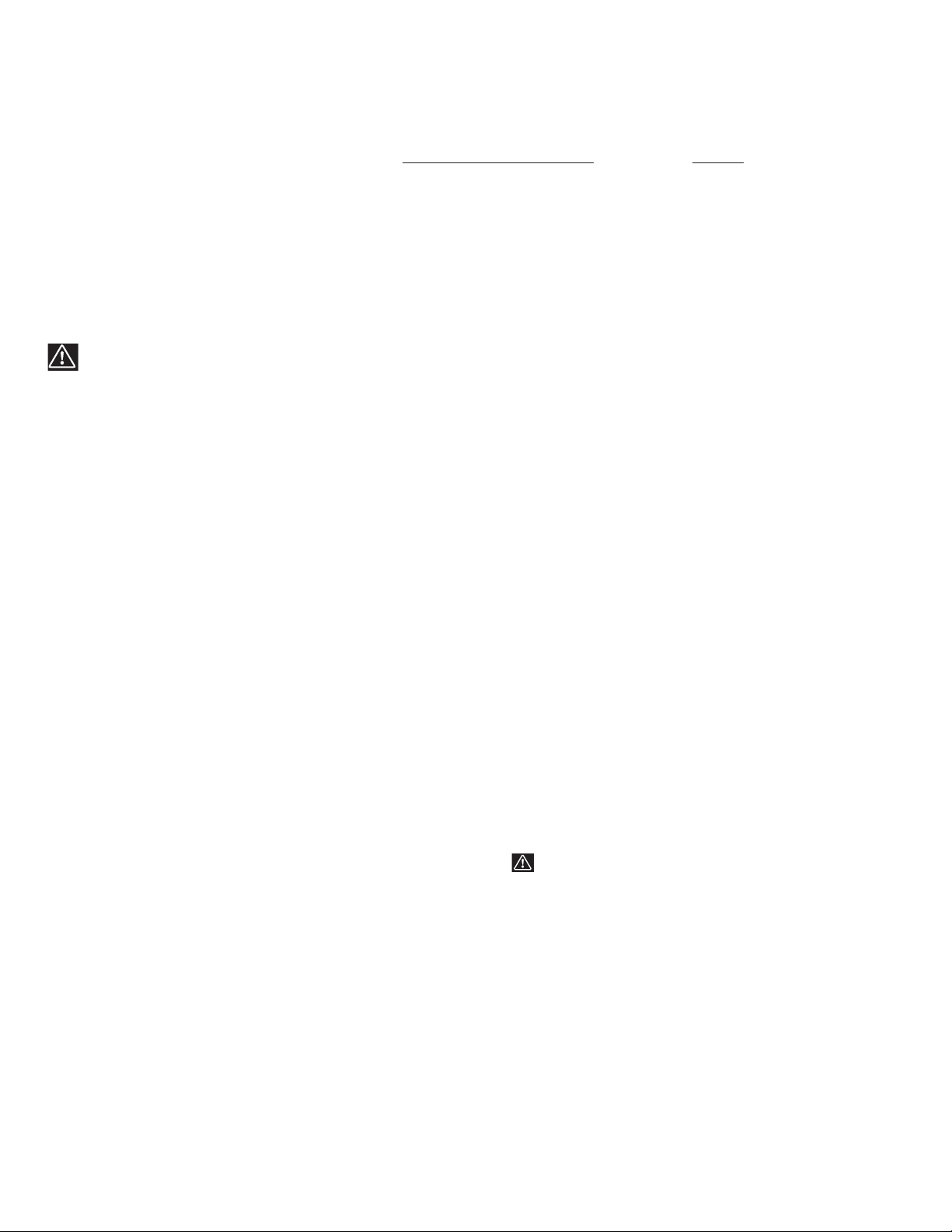

3. Position the blade 90 degrees to the table and lock

in place.

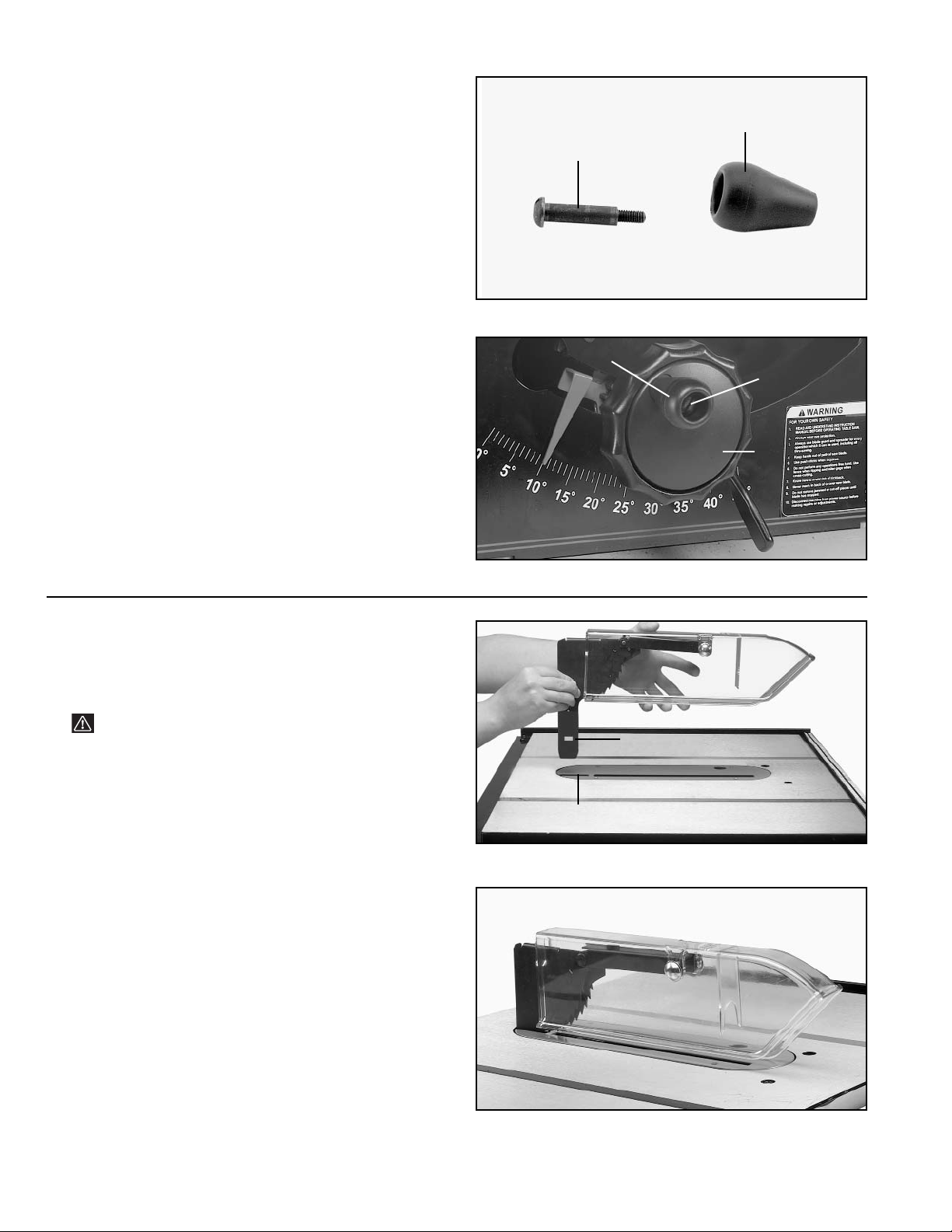

4. Insert spreader end (A) Fig. 6, of blade guard into

anchor block (B). Push spreader (A) down into holder

until you hear a click, indicating that the spreader is

secured. NOTE: It is important that the spreader (A) be

in the vertical position and pushed straight down into the

spreader anchor block (B) during the assembly

procedure.

5. Fig. 7 illustrates the blade guard in place.

Fig. 6

Fig. 7

D

E

D

A

E

A

B

5

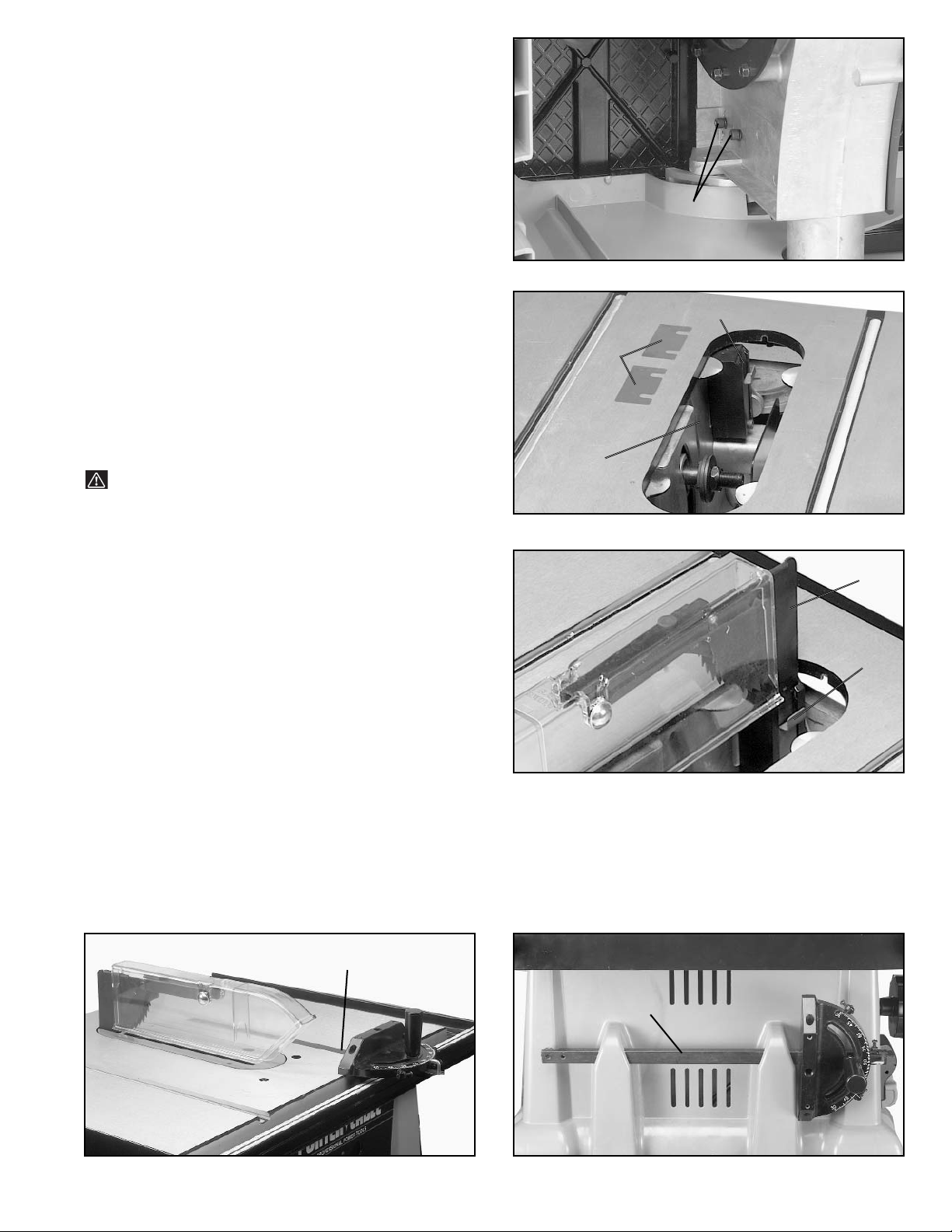

6. NOTE: The anchor block (B) Fig. 6, has been adjusted

at the factory so that the spreader will be aligned with the

saw blade which is supplied with the saw. When

changing to blades with different widths it may be

necessary to adjust the anchor block (B) Fig. 9, as

follows:

7. Remove table insert and saw blade.

8. Loosen the two screws (C) Fig. 8 (under saw table),

that attach the anchor block (B) Fig. 9, to the saw frame

(E).

9. Three additional shims, two of which are shown at (D)

Fig. 9, are supplied with your saw and can be used as

required between the anchor block (B) and the frame (E)

in order to align the spreader with the saw blade.

10. After adjustment is completed, tighten the two

screws (C) Fig. 8.

REMOVING BLADE

GUARD/SPREADER

ASSEMBLY

WARNING: MAKE SURE THE SAW IS DISCON-

NECTED FROM THE POWER SOURCE.

The blade must be in the 90 degree position to the table

for the blade guard and spreader assembly to be

removed. Remove the table insert, pull out on the

spreader release spring (A) Fig. 9A, while pulling up on

the blade guard/spreader assembly (B). NOTE: STORE

THE BLADE GUARD AS SHOWN IN FIG. 31A, WHEN

THE BLADE GUARD IS NOT IN USE.

MITER GAGE

The miter gage is shipped completely assembled and is

supplied with a T-slot miter gage bar (A) Fig. 10, that can

be inserted into either one of the two T-slotted miter

gage grooves located in the table top, as shown. The Tslot miter gage can be extended beyond the front of the

table for cross-cutting wide workpieces.

MITER GAGE HOLDER

Fig. 11, illustrates the miter gage (D) inserted into the

miter gage holder when not in use.

Fig. 8

Fig. 9

Fig. 10

Fig. 11

A

C

D

Fig. 9A

A

B

D

E

B

6

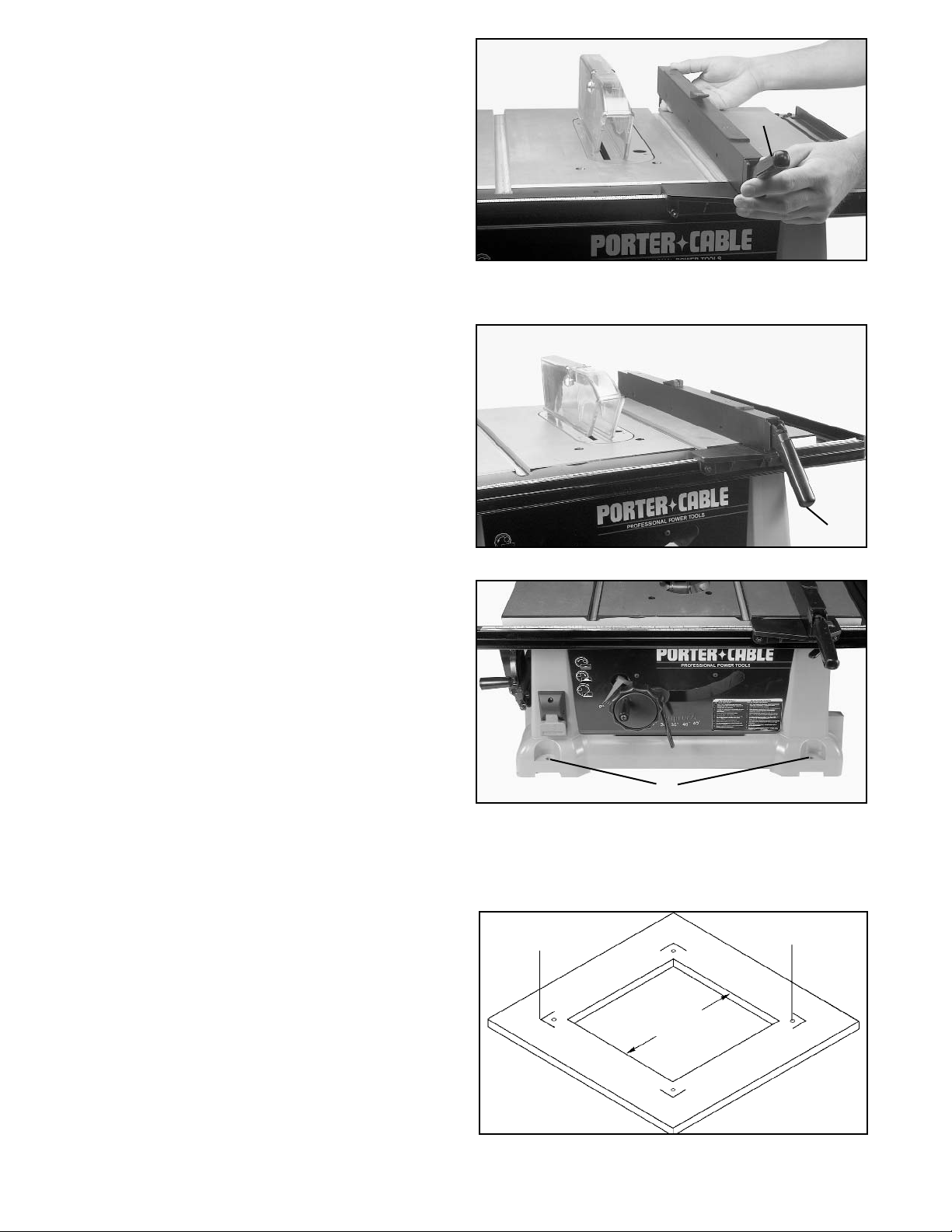

ASSEMBLING RIP FENCE

TO SAW TABLE

1. The rip fence may be used on the right or left hand

side of the saw table. Lift locking handle (A) Fig. 12, and

position the front end of the fence on the front fence rail

as shown.

2. While pressing front end of fence firmly against front

fence rail, place rear end of fence down on the rear

fence rail and push down on locking handle (A) Fig. 13,

to lock fence in place.

Fig. 12

Fig. 13

FASTENING SAW TO A

SUPPORTING SURFACE

The saw MUST be properly secured to a supporting

surface using the four mounting holes, two of which are

shown at (A) Fig. 14.

CAUTION: THE SUPPORTING SURFACE MUST BE

ABLE TO SUPPORT 300LBS.

IMPORTANT: A HOLE MUST BE PROVIDED IN THE

SUPPORTING SURFACE TO FACILITATE SAWDUST

FALL-THRU AND REMOVAL. Square the saw on the

supporting surface and mark the location of the four

5/16 inch holes to be drilled, as shown in Fig. 15. Locate

and mark an 11 or 12 inch square centered between the

four mounting holes and cut out and remove the square,

as shown in Fig. 15. This opening will allow sawdust to

fall through the saw base. Fasten the saw to the

workbench utilizing the mounting holes that were just

drilled.

IMPORTANT: FAILURE TO PROVIDE THIS SAW

DUST FALL-THRU AND REMOVAL HOLE WILL

ALLOW SAW DUST TO BUILD-UP AROUND THE

MOTOR WHICH MAY RESULT IN A FIRE HAZARD OR

CAUSE MOTOR DAMAGE.

Fig. 14

Fig. 15

A

A

SAW PLACEMENT

MARKS

5/16" HOLES

11" OR 12"

SQUARE

CUTOUT

A

Loading...

Loading...