Page 1

MX Immersion Circulator

Operator’s Manual

110-511 PSC/EN 06.08.11

Page 2

Table of Contents

Introduction .................................................................................................................................................2

General Information....................................................................................................................................3

General Safety Information....................................................................................................................... 3

Safety Recommendations.........................................................................................................................4

Regulatory Compliance and Testing ........................................................................................................5

Unpacking Your Immersion Circulator......................................................................................................5

Package Contents ....................................................................................................................................5

Controls and Components........................................................................................................................6

Quick-Start...................................................................................................................................................7

Installation and Startup..............................................................................................................................8

Normal Operation......................................................................................................................................10

Turning Your Circulator ON .................................................................................................................... 10

Main Operational Display........................................................................................................................10

Set-Up Sub-Menus .................................................................................................................................11

Adjusting the Temperature Set Point...................................................................................................... 11

Selecting the Temperature Unit..............................................................................................................12

Setting the Offset Calibration.................................................................................................................. 13

Setting the Low Limit Temperature......................................................................................................... 14

Setting the High Limit Temperature........................................................................................................15

Resetting the Factory Default Values ..................................................................................................... 15

Loss of Power Restart ............................................................................................................................ 16

Alarm Messages ..................................................................................................................................... 17

Routine Maintenance and Troubleshooting...........................................................................................18

Maintaining Clear Bath Water................................................................................................................. 18

Cleaning Your Immersion Circulator....................................................................................................... 18

ing the Over-Temperature Safety System.................................................................................... 19

Check

Troubleshooting Chart ............................................................................................................................ 20

Technical Information...............................................................................................................................21

Performance Specifications .................................................................................................................... 21

Reservoir Fluids......................................................................................................................................22

Application Notes....................................................................................................................................23

Equipment Disposal (WEEE Directive)...................................................................................................23

Replacement Parts and Accessories......................................................................................................25

PolyScience Circulating Bath Fluids ......................................................................................................25

Service and Technical Support ...............................................................................................................26

Warranty.....................................................................................................................................................26

110-511 PSC/EN 1

Page 3

Introduction

Thank you for choosing the MX Immersion Circulator. It is intended for the precise temperature control of

suitable liquids in a reservoir. Extremely easy to use and maintain, it combines design innovation with

highly intuitive operation to deliver convenient and versatile liquid temperature control for a wide range of

applications.

WARNING: PolyScience Circulating Baths are not intended for directly controlling the temperature of

foods, pharmaceuticals, medicines, or other objects which may be ingested by or injected in humans

or animals. Any such objects must be isolated from contact with the bath fluid and bath surfaces.

Here are some of the features that make the MX Immersion Circulator so user-friendly:

• Simple, intuitive operation

• Displays actual and set point temperature simultaneously

• Powerful pump, easy flow adjustment

• Attaches securely to both flat and rounded tank walls

• Converts any tank or vessel up to 28 liters into a reliable circulating bath

• Fully enclosed housing prevents direct contact with pump and heater, yet provides quick

access for inspection and cleaning

• Suitable for use with Class I non-flammable fluids per DIN 12876-1

It will take you very little time to get your new MX Immersion Circulator installed and running, This

Operator’s Manual is designed to guide you quickly through the process. We recommend that you read it

thoroughly before you begin.

110-511 PSC/EN 2

Page 4

General Information

General Safety Information

When installed, operated, and maintained according to the directions in this manual and common safety

procedures, your MX Immersion Circulator should provide safe and reliable liquid heating. Please ensure

that all individuals involved in the installation, operation, or maintenance of this unit read this manual

thoroughly prior to working with the unit.

This symbol alerts you to a wide range of potential dangers.

This symbol advises danger from electricity or electric shock.

This symbol indicates that a hot surface may be present.

/

This symbol marks information that is particularly important.

This symbol indicates alternating current.

These symbols on the Power Switch / Circuit Breaker indicate that they place the main power supply

ON / OFF.

This symbol on the Power Key indicates that it places the unit in a standby mode. It DOES NOT fully

disconnect the unit from the power supply.

This symbol indicates a protective conductor terminal.

Read all instructions pertaining to safety, set-up, and operation.

Proper operation is the user’s responsibility.

110-511 PSC/EN 3

Page 5

Safety Recommendations

To prevent injury to personnel and/or damage to property, always follow your workplace’s safety

procedures when operating this equipment. You should also comply with the following safety

recommendations:

WARNING:

• This Immersion Circulator is suitable only for use with Class I non-flammable fluids (per DIN

12876-1).

• Be aware of the chemical hazards that may be associated with the bath fluid used. Observe all

safety warnings for the fluids used as well as those contained in the material safety data sheet.

• Use only recommended bath fluids; see Technical Information in the rear of this manual for

recommendations.

• Use only non-acid bath fluids.

WARNING:

• Always connect the power cord on this Circulator to a grounded (3-prong) power outlet. Make

certain that the outlet is the same voltage and frequency as your unit.

• Never operate the Circulator with a damaged power cord.

• Always turn the Circulator OFF and disconnect mains power before performing any maintenance

or service.

WARNING:

• Never operate the Circulator without bath fluid in the reservoir. Periodically check the reservoir to

ensure that the liquid depth is within acceptable levels. Always refill the reservoir using the same

bath fluid that is already in the reservoir. Bath oil must not contain any water contaminants and

should be preheated to the actual bath temperature before adding as there is an explosion hazard

at high temperatures.

• Turn electrical power to the unit OFF and remove Immersion Circulator from reservoir before

draining. Always drain all fluid from the reservoir before moving or lifting. Be sure to follow your

organization’s procedures and practices regarding the safe lifting and relocation of heavy objects.

WARNING:

• Always allow the bath fluid to cool to ambient temperature before draining.

• Always keep within the 85°C maximum operating temperature limit if using a polycarbonate open

bath tank

WARNING: It is the user’s responsibility to properly decontaminate the unit in the event hazardous

materials are spilled on exterior or interior surfaces. Consult manufacturer if there is any doubt

regarding the compatibility of decontamination or cleaning agents.

.

110-511 PSC/EN 4

Page 6

Regulatory Compliance and Testing

This equipment is compliant with the European Directive 2002/95/EC and its latest amendments on

Restrictions on Hazardous Substances (RoHS) and below the given limits of hazardous substances.

ETL Intertek (60 Hz units)

UL 61010-1 / CSA C22.2 No. 61010-1 — Safety Requirements for Measurement, Control, and

Laboratory Use; Part 1: General Requirements

UL 61010A-2-010 / CSA C22.2 No. 61010-2-010:04 — Safety Requirements for Measurement, Control,

and Laboratory Use; Part 2-010: Particular Requirements for Laboratory Equipment for the Heating of

Materials

UL 61010A-2-051 / CSA C22.2 No. 61010-2-051:04 — Safety Requirements for Measurement, Control,

and Laboratory Use; Part 2-051: Particular Requirements for Laboratory Equipment for the Mixing and

Stirring

CE (all units)

EC Low Voltage Directive 2006/95/EC

EC Electromagnetic Compatibility Directive 2004/108/EC

IEC 61010-1-2001

IEC 61010-2-2001

IEC 61326:2005 / EN 61326 : 2006

Unpacking Your Immersion Circulator

Your Immersion Circulator is packed in a special carton. You should keep this carton, along with all

packing materials, until the unit has been installed and you are certain it is working properly.

CAUTION: Remove any loose packing material that may have fallen into the heater/pump housing

during shipping. Before powering up, check that nothing remains around the heater or circulator pump.

We recommend that you begin using your Immersion Circulator immediately to confirm proper operation,

since beyond one week you may be eligible for warranty repair only (rather than replacement). You’ll find

complete warranty information in the back of this manual.

In the unlikely event that the unit was damaged or does not operate properly, immediately contact the

transportation company, file a damage claim, and contact the company where your Immersion Circulator

was purchased.

Package Contents

The following items are included in the shipping carton:

• MX Immersion Circulator

• Quick-Start Guide

• Resource Disk with Operator’s Manual

• Qualification Test Results

110-511 PSC/EN 5

Page 7

Controls and Components

Backlit

Display

Menu

Button

Up Arrow

Button

Down Arrow

Button

Front Flow

Adjuster

Power

Button

Safety Thermostat

(under plate)

Maximum

Liquid Level

Indicator

Heater /Pump

Access Cover

Rear Flow

Adjuster

Power Cord

Mounting

Clamp

Front View

Rear View

Heating

Circulating

Actual Bath

Temperature

Temperature

Set Point

Main Display

110-511 PSC/EN 6

Page 8

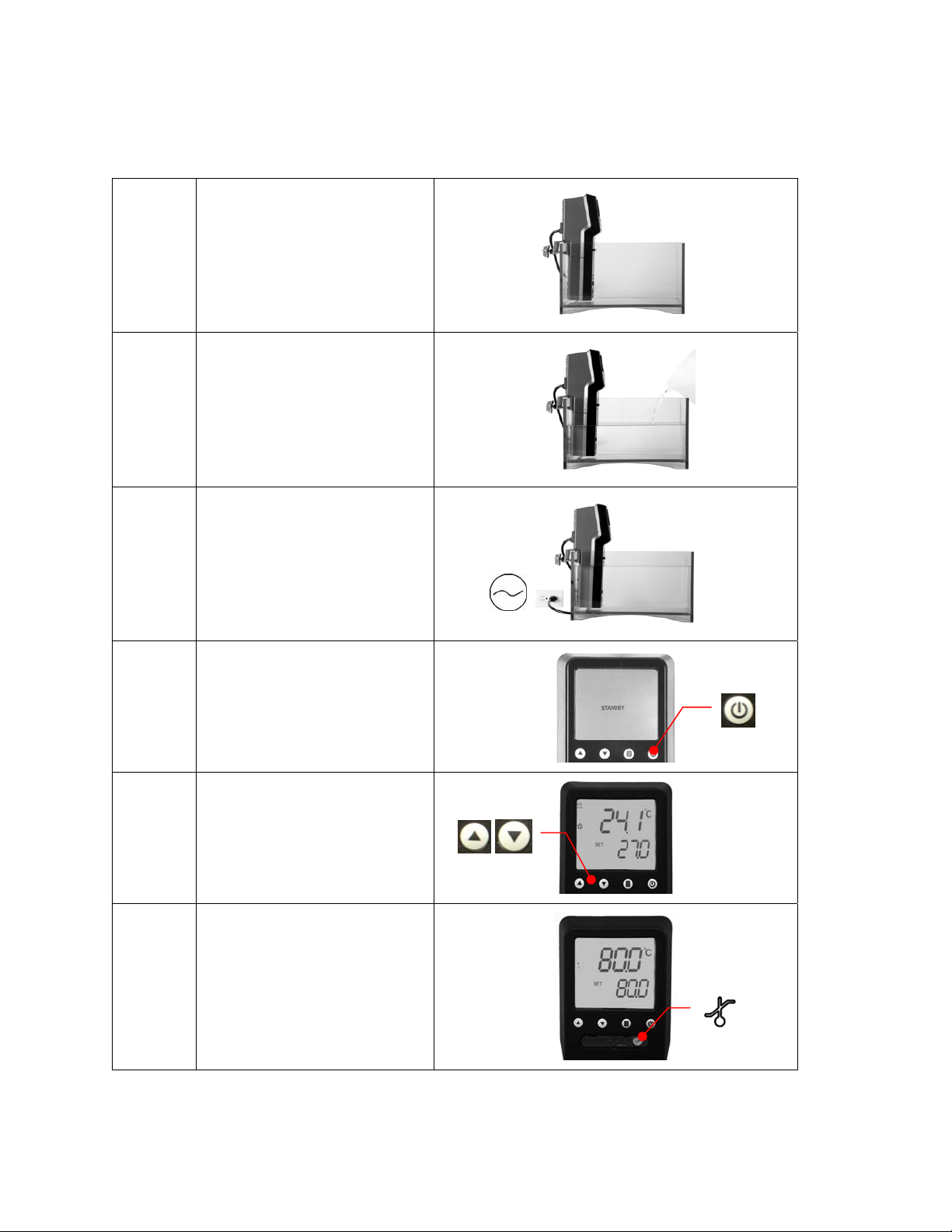

Quick-Start

See Installation and Startup for additional information.

1

2

3

Attach Immersion Circulator

to reservoir

Fill reservoir with fluid

Connect power cord to

electrical outlet

4

5

6

Turn Immersion Circulator “ON”

Enter temperature set point

Set safety thermostat once the

unit reaches set point

110-511 PSC/EN 7

Page 9

Installation and Startup

Your MX Immersion Circulator is easily installed. The only tools required are a flat-head screwdriver and a

container for adding water or another suitable fluid to the user-supplied reservoir.

1. Place the flow adjusters in the desired position. These slide controls allow you to easily adjust

the force with which liquid will circulate in the reservoir. You’ll achieve maximum circulation by

placing both the front and rear flow adjusters in the fully open position.

WARNING: To avoid the potential for burns, do not change the position of the flow adjusters

while your Immersion Circulator is immersed in hot liquid. For safety, turn power to the unit

off, remove from reservoir, and allow to cool before making adjustments.

2. Attach the Immersion Circulator to the reservoir (user-

supplied). A mounting clamp is provided that mounts securely to

both flat and rounded tank walls. Allow a minimum of 1.3 cm /

0.5 inch clearance between the bottom of the Circulator’s

housing and the bottom of the reservoir.

Maximum

liquid level

3. Add liquid to

the reservoir. The liquid in the reservoir should

be maintained somewhere between the “Maximum” and

Minimum

liquid level

“Minimum” liquid level lines embossed on the heater/pump

housing.

WARNING: See Technical Information in the rear of this manual for a list of compatible

liquids.

WARNING: Read the safety data sheet for the bath fluid being used carefully before filling

reservoir.

WARNING: If the proper fluid level is not maintained, the heater coil may become exposed

and possibly damaged (fluid level too low) or the bath may overflow (fluid level too high).

4. Plug the power cord into a properly grounded electrical outlet. The LCD will light and

“Standby” will appear on the display

WARNING: The correct voltage and frequency for your Immersion Circulator are indicated

on the identification label on the back of the unit. The use of an extension cord is not

recommended. If one is necessary, it must be properly grounded and capable of handling

the total wattage of the unit. The extension cord must not cause more than a 10% drop in

voltage to the unit.

.

WARNING: Make certain that the electrical outlet is the same voltage and frequency as

your Immersion Circulator.

110-511 PSC/EN 8

Page 10

5. Turn power ON. Press ;

Immersion Circulator will begin running, actual and set point temperatures will be displayed, and

the word “SET” will be continuously lit. The circulating symbol will also be lit and the heating

symbol will also be flashing if the actual bath temperature is below the set point temperature

6. Set the Sa

Circulator and is the temperature at which the heater will be turned OFF in the event that the

liquid level in the bath drops too low or the Circulator malfunctions. It is normally set about 5°

higher than the desired operating temperature. Setting the Safety Set temperature is a four-step

process.

Using a flat blade screwdriver, rotate the Safety

A.

Thermostat (located beneath the cover plate on the

front of the unit’s housing) clockwise until it stops.

B. Press

Continue pressing the

point temperature is equal to your desired Safety

Set temperature. “SET” will stop flashing

approximately 10 seconds after the desired

temperature has been entered. Allow the Circulator

to stabilize at this temperature.

fety Set temperature. This is a “Do Not Exceed” temperature setting for your

the

or key; “SET” will begin flashing.

all characters and symbols on the LCD will momentarily light. The

Heating Symbol

Circulating

Symbol

and keys until the set

.

C.

Once the bath temperature has stabilized, slowly rotate the Safety

Thermostat counter-clockwise until you hear a soft “click;” the

OVERTEMP or LOW FLUID alarm symbol will appear on the display

approximately 5-10 seconds later. At this point, the heater will also turn

OFF.

D. Slowly rotate the Safety Thermostat clockwise until the alarm symbol

extinguishes. The heater should also turn back ON. You are now ready

to start normal operation.

Over-Temperature/Low Liquid Level alarm

WARNING: The Safety Thermostat is user-adjustable from approximately 40° to 210°C. Do not force

the indicator dial beyond the stops at either end of the dial’s range.

110-511 PSC/EN 9

Page 11

Normal Operation

Keys and Controls

Power

Turns the Immersion Circulator ON.

Accesses the Temperature Controller’s set-up sub-menus. The items in

Menu

Up Arrow

these sub-menus are used to configure the Controller’s general

operational parameters (temperature unit, upper and lower temperature

limits, offset calibration, etc.).

Used to increase temperature set point and other operational

settings/values.

Down Arrow

Used to decrease temperature set point and other operational

settings/values.

Turning Your Circulator ON

Press the key.

All characters/symbols on the LCD will momentarily light. When the Circulator begins running, the actual

and set point temperatures will be displayed and the circulating symbol will be lit.

If the actual bath temperature is lower than the set point temperature, the heat symbol will also be lit.

Main Operational Display

Heating

Circulating

Actual Bath

Temperature

Set Point

Temperature

110-511 PSC/EN 10

Page 12

Set-Up Sub-Menus

Press the

to change the current setting / value in the sub-menu.

Sub-Menu Selection / Range

Temperature unit °C or °F

Offset Calibration -3.0°C to +3.0°C Press

Low Limit -55° to +10°C / -65° to +50°F Press

High Limit +40° to +155°C / +100 to +305°F Press

To accept a value in a sub-menu, press

key to access the Temperature Controller’s set-up sub-menus. The or

To Change

Current Value

Press

Press

or allow the display to ‘time out’ (approximately 10 seconds).

for °C

for °F

keys are used

or

or

or

Adjusting the Temperature Set Point

This is the temperature at which the fluid in your circulating bath will be maintained. It may be set to one-

tenth of a degree over a range of -50° to +135°C / -60° to +275°F. The factory default is 20°C / 68°F.

Flashes when set point

is being changed

To Change: Press the

or repeatedly press

To Accept: Press

(approximately 10 seconds).

or key. The word “SET” will begin flashing. Continue holding

or

until the desired set point temperature is displayed.

or allow the LCD to return to the main operational display

110-511 PSC/EN 11

Page 13

Selecting the Temperature Unit

The temperature units sub-menu (°C / °F) allows you to select the temperature unit in which the actual

bath temperature and set point temperature are displayed. The factory default is °C.

Appears when in

Temperature Units

sub-menu

To Access: Press the

To Change: Press

To Accept: Press

key until the °C/°F appears on the display.

to select °C; press

or allow the LCD to return to the main operational display

(approximately 10 seconds).

to select °F.

110-511 PSC/EN 12

Page 14

Setting the Offset Calibration

This sub-menu allows you to match the Circulator’s temperature display to an external reference

thermometer. A value from -3.0° to +3.0°C may be entered; the factory default is 0.0°C.

IMPORTANT: To prevent the Offset Calibration value from being changed unintentionally, the following

power down/power up sequence is required to enable the Offset Calibration function.

1. Turn Mains power OFF by disconnecting the electrical cord from the outlet.

2. Turn Mains power ON while pressing and holding the

When STANDBY appears on the display, release the key and press . You can now

3.

proceed as outlined below.

The Offset Calibration function will remain enabled until the electrical power is turned OFF by pressing

the

key.

key.

Appears when in

Offset Calibrate sub-menu

To Acc

ess: Press the

To Change: Press

key until OFFSET CALIBRATE appears on the display.

or .

To Accept: Press

or allow the LCD to return to the main operational display

(approximately 10 seconds).

CAUTION: The Offset Calibration value is always shown in degrees C, even if degrees F is selected as

the temperature unit in which the control and actual bath temperatures are displayed. Your Immersion

Circulator will automatically convert the °C offset calibration value to the correct °F display offset value.

110-511 PSC/EN 13

Page 15

Setting the Low Limit Temperature

This sub-menu allows you to limit how low the temperature set point may be set. It also serves as a low

limit safety, alerting you if bath temperature falls below the low limit temperature setting. The Low Limit

value may be set from -55° to +10°C / -65° to +50°F; the factory default is -50°C / -60°F.

To avoid an unwanted alarms or shutdown during regular operation, the Low Limit value should be set at

least 5° lower than the selected control temperature.

Appears when in the

Low Limit sub-menu

To Access: This Press the

key until LOW LIMIT appears on the display.

To Change: Press

To Accept: Press

(approximately 10 seconds).

or .

or allow the LCD to return to the main operational display

110-511 PSC/EN 14

Page 16

Setting the High Limit Temperature

This sub-menu allows you to limit how high the temperature set point may be set. It also serves as a high

limit safety, alerting you if bath temperature rises above the high limit temperature setting. The High Limit

value may be set from +40° to +155°C / +100° to +305°F; the factory default is +150°C / +300°F.

To avoid an unwanted shutdown during regular operation, the High Limit value should be set at least 5°

higher than the selected control temperature.

Appears when in the

High Limit sub-menu

To Access: This Press the

key until HIGH LIMIT appears on the display.

To Change: Press

To Accept: Press

or .

or allow the LCD to return to the main operational display

(approximately 10 seconds).

Resetting the Factory Default Values

You can return your Circulator to all factory-set default as follows:

1. Press the

2. Unplug the power cord from the electrical outlet.

3. Plug the power cord back into the electrical outlet while pressing either the

The factory default values are:

Operational Parameter Factory Default Value

Temperature Scale °C

Temperature Set Point 20°C / 68°F

Calibration Offset 0.0°C

Low Limit -50°C / -60°F

key to turn the Circulator OFF.

or .button.

High Limit +150°C / +300°F

110-511 PSC/EN 15

Page 17

Loss of Power Restart

WARNING: The unit will start automatically after a disruption in electrical power.

In the event that electrical power lost while your Circulator is in use, it will begin operating automatically

once power is restored. FAIL POWER will appear on the display to alert you that there was a power

disruption. To clear the message, turn the Circulator OFF and then back ON again using the

FAIL POWER

Indicates electrical power was

disrupted during operation

key.

110-511 PSC/EN 16

Page 18

Alarm Messages

Alarm

Symbol

FAIL POWER

(flashing)

(flashing)

Description Corrective Action

Informational Message:

Indicates that electrical power

was lost during operation.

Warning: The temperature set

point is below the Low Limit

temperature value.

Warning: The temperature set

point is above the High Limit

temperature value.

Alarm: The bath temperature

has fallen below the Low Limit

temperature value. Power to

the pump and heater will

remain OFF until the problem

is corrected.

Alarm: The bath temperature

has risen above the High Limit

temperature value. Power to

the heater and pump will

remain OFF until the problem

is corrected.

Fault: The liquid in the bath

has dropped too low or the

temperature of the bath fluid

has exceeded the Safety Set

temperature. Power to the

heater will remain OFF until the

problem is corrected.

Using the key, turn the Circulator OFF and then back ON.

This will clear the message.

Decrease the Low Limit temperature value or increase the

temperature set point.

Increase the High Limit temperature value or decrease the set

point temperature.

Allow bath to warm or add heat load.

Decrease the Low Limit temperature value.

Allow bath to cool or increase High Limit temperature value.

Replace fluid.

Fluid level in reservoir has fallen below minimum level;

add fluid as required.

Fluid temperature is higher than Safety Set temperature;

increase Safety Set temperature setting.

Controller failure; consult factory.

Fault: The Circulator’s

temperature sensor has failed.

Fault: The Circulator’s heater

has failed.

Consult factory.

Consult factory.

110-511 PSC/EN 17

Page 19

Routine Maintenance and Troubleshooting

WARNING: Always turn your Circulator OFF and disconnect it from the electrical power outlet before

performing any maintenance or service.

WARNING: To avoid the potential for burns, allow the Immersion Circulator to cool completely before

cleaning or performing any maintenance.

WARNING: Turn electrical power to the unit OFF and remove Immersion Circulator from reservoir

before draining. Always drain all fluid from the reservoir before moving or lifting. Be sure to follow

your organization’s procedures and practices regarding the safe lifting and relocation of heavy

objects.

CAUTION: Always clean and dry your MX Immersion Circulator thoroughly before storing.

Maintaining Clear Bath Water

Optimum temperature and moisture conditions for algae growth existing when using water as a bath fluid.

To prevent algae contamination and minimize the frequency of draining the reservoir, an algaecide such

as polyclean Algaecide (004-300040) should be used.

WARNING: Do not use chlorine bleach.

Cleaning Your Immersion Circulator

WARNING: It is the user’s responsibility to properly decontaminate the unit in the event hazardous

materials are spilled on exterior or interior surfaces. Consult the manufacturer if there is any doubt

regarding the compatibility of decontamination or cleaning agents.

Temperature Controller

Turn the Temperature Controller OFF by pressing

and unplug power cord from the electrical outlet.

Remove Temperature Controller from bath reservoir and, keeping it upright, wipe the housing with a clean

cloth dampened with a mild detergent and water or mild all-purpose cleaner.

CAUTION: Do not spray cleaning liquids directly onto the Temperature Controller or allow them to

enter the Controller’s vents. Do not use abrasives as these could scratch the housing or the digital

display.

CAUTION: Never immerse the Circulator’s controls or display in water or other liquids or place under

running water. Do not clean the unit in a glassware washer.

110-511 PSC/EN 18

Page 20

Bath Reservoir and Wetted Components

A concentrated bath cleaner (polyclean Bath Cleaner, part number 004-300050) is available to remove

mineral deposits from the Temperature Controller’s wetted parts. The cleaner should be added to the

bath reservoir at the prescribed dosage and circulated at 60°C / 140°F until the scale is removed.

Pump Impeller

In the unlikely event that debris becomes lodged in the pump impeller, a soft brush can be used to

remove any lodged particles. If necessary, soak in a solution of distilled water and polyclean Bath Cleaner

to soften before brushing.

CAUTION: Do not use hard utensils or abrasive pads to remove trapped debris.

Checking the Over-Temperature Safety System

Your Circulator incorporates over-temperature protection according to IEC 61010. For optimum safety,

this system should be checked for proper operation at least every six months. This check must be

performed with the unit running.

Enter a temperature set point of approximately 50°C and then allow the bath to stabilize at that

1.

temperature. The amount of time this will take will depend on the size of the bath and the difference

between the initial bath temperature and the Safety Set temperature.

2. Once the bath temperature has stabilized, slowly rotate the Safety Thermostat

counter-clockwise until you hear a soft “click;” the OVERTEMP or LOW FLUID

alarm symbol will appear on the display approximately 5-10 seconds later. At

this point, the heater will also turn OFF.

3. Slowly rotate the Safety Thermostat clockwise until the alarm symbol

extinguishes (you may also hear a soft “click”). The heater should turn back

ON.

4.

Reset the Safety Set temperature to the desired temperature value

(see Installation and Startup).

110-511 PSC/EN 19

Page 21

Troubleshooting Chart

Problem Possible Causes Corrective Action

Unit does not run

(Digital Display is

blank)

Unit does not run

(STANDBY appears

on Digital Display)

No fluid circulation Insufficient fluid in reservoir

Insufficient circulation Fluid viscosity too high

Unit does not heat Insufficient fluid in reservoir

Insufficient heating Insufficient circulation

No power to unit Check that the electrical cord is secure and

Unit in Standby mode Press Power Key on front panel.

Pump impeller jammed

Low line voltage

Temperature set point too

low

Safety Set Temperature too

low

Low line voltage

Ambient temperature too

cool

Excessive heat loss

connected to an operating electrical outlet.

Add fluid to reservoir.

Inspect pump and remove debris as required.

Replace with lower viscosity bath fluid.

Check and correct as required.

Add fluid to reservoir.

Increase temperature set point.

Increase Safety Set temperature.

See Insufficient circulation, above.

Check and correct as required.

Increase ambient temperature or relocate unit.

Check for vapor/heat loss from internal

reservoir.

Temperature

unstable

Insufficient circulation

Debris or mineral build-up

on pump, heater, or

temperature sensor.

Check pump flow and operation.

Clean as required.

110-511 PSC/EN 20

Page 22

Technical Information

Performance Specifications

Operating Temperature Range: Ambient +10° to 135°C

Ambient +20° to 275°F

Temperature Stability: ±0.07°C / ±0.13°F

Heater Wattage: 1100 watts

Electrical Requirements: 120V, 60Hz, 10 amps or

240V, 50Hz, 6 amps

Environmental Conditions Indoor use only

Maximum Altitude: 2000 meter

Operating Ambient: 5° to 35°C (41° to 95°F)

Relative Humidity: 80%, non-condensing

Installation Category: II

Pollution Degree: 2

Ingress Protection: IP 31

Climate Class: SN

Software Class: B

Output Waveform: Sinusoidal

Specifications subject to change without notice.

Attainable Temperatures:

Your MX Immersion Circulator can be used with reservoirs of various capacities and shapes as well as

different fluids. These variables may adversely affect temperature accuracy and stability. For example, a

reservoir with a large surface area loses heat more quickly, which may prevent the Circulator from

attaining the desired temperature.

110-511 PSC/EN 21

Page 23

Reservoir Fluids

Depending on your needs, a variety of fluids can be used with your Immersion Circulator. No matter what

bath fluid is selected, it must be chemically compatible with the reservoir and the materials in your

Immersion Circulator. It must also be suitable for the desired temperature range.

WARNING: Do not use a flammable liquid as a bath fluid as a fire hazard may result.

WARNING: Always use fluids that satisfy safety, health, and equipment compatibility requirements.

For optimum temperature stability, the fluid’s viscosity should be 50 centistokes (cSt) or less at its lowest

operating temperature. This permits good fluid circulation and minimizes heating from the pump.

For temperatures from 10°C to 90°C, distilled water is recommended. For temperatures below 10°C, a

mixture of laboratory grade ethylene glycol and water should be used. Do not use deionized water.

The following chart is intended to serve as a guide in selecting a bath fluid for your application. For

optimum temperature stability and low vaporization, be sure to stay within the fluid's normal temperature

range.

You are responsible for proper selection and use of the fluids. Avoid extreme range operation.

Viscosity

Fluid Description

distilled water 1 50°C 1.00 4.18 10° to 90°C 2° to 100°C

polyclear MIX 30 1 50°C 1.00 4.18 15° to 90°C 2° to 100°C

polytherm S150 50 100°C 0.41 1.71 50° to 150°C 5° to 270°C*

polytherm S200 125 150°C 0.40 1.67 100° to 200°C 80° to 232°C*

polytherm S250 500 200°C 0.39 1.63 150° to 250°C 125° to 260°C*

polytherm M170 40 85°C 0.40 1.67 50° to 170°C 25° to 190°C

polycool HC -50 3 -30°C 0.62 2.59 -50° to 100°C -62° to 118°C

polycool EG -25

(50/50 mix with distilled H

polycool EG -25

(30/70 mix with distilled H

polycool PG -20

(50/50 mix with distilled H

polycool PG -20

(30/70 mix with distilled H

polycool MIX -25

(50/50 mix with distilled H

polycool MIX -25

(30/70 mix with distilled H

2

2

2

2

2

2

O)

O)

O)

O)

O)

O)

(cSt)

@ 25°C

20 -20°C 0.78 3.26 -25° to 100°C -30° to 115°C

12 0°C 0.89 3.72 0° to 95°C -15° to 107°C

20 -10°C 0.83 3.47 -20° to 100°C -30° to 115°C

12 5°C 0.92 3.85 5° to 90°C -10° to 107°C

20 -20°C 0.78 3.26 -25° to 100°C -30° to 115°C

12 0°C 0.89 3.72 0° to 95°C -15° to 107°C

@ Fluid

Temperature

Specific Heat

BTU/lb°F KJ/Kg°C

Normal

Temperature

Range

Extreme

Temperature

Range

*WARNING: This is the fluid’s flash point temperature.

110-511 PSC/EN 22

Page 24

WARNING: DO NOT USE THE FOLLOWING LIQUIDS:

• Automotive antifreeze with additives**

• Hard tap water**

• Deionized water with a specific resistance > 1 meg ohm

• Any flammable fluids

• Concentrations of acids or bases

• Solutions with halides: chlorides, fluorides, bromides, iodides or sulfur

• Bleach (Sodium Hypochlorite)

• Solutions with chromates or chromium salts

• Glycerine

• Syltherm fluids

At temperatures above 40°C, additives or mineral deposits can adhere to the heater. If deposits are allowed

**

to build up, the heater may overheat and fail. Higher temperatures and higher concentrations of additives

will hasten deposit build up.

Application Notes

At a fluid's low temperature extreme:

• The presence of ice or slush adversely affects temperature stability.

• A viscosity above 10 centistokes adversely affects temperature uniformity.

• A high fluid viscosity and high pump speed adds heat to the fluid being pumped.

At a fluid's temperature above ambient without refrigeration:

• If your set point temperature is less than 15°C above the ambient temperature, the

viscosity of the fluid should be 10 centistokes or less to minimize friction heating of the fluid.

• Heat loss should be encouraged by uncovering the fluid and lowering the pump speed.

At fluid's high temperature extreme:

• Heat loss from vapor adversely affects temperature stability.

• To prevent the accumulation of vapors inside the room, the reservoir may need to be

placed in a fume hood.

• Use a cover and/or floating hollow balls to help prevent heat and vapor loss.

• Replenish fluid lost from vapor frequently.

110-511 PSC/EN 23

Page 25

Equipment Disposal (WEEE Directive)

or

This equipment is marked with the crossed out wheeled bin symbol to indicate it is covered by the Waste

Electrical and Electronic Equipment (WEEE) Directive and is not to be disposed of as unsorted municipal

waste. Any products marked with this symbol must be collected separately, according to the

regulatory guidelines in your area.

It is your responsibility to correctly dispose of this equipment at lifecycle-end by handing it over to an

authorized facility for separate collection and recycling. It is also your responsibility to decontaminate the

equipment in case of biological, chemical and/or radiological contamination, so as to protect the persons

involved in the disposal and recycling of the equipment from health hazards. By doing so, you will help to

conserve natural and environmental resources and you will ensure that your equipment is recycled in a

manner that protects human health.

Requirements for waste collection, reuse, recycling, and recovery programs vary by regulatory authority

at your location. Contact your local responsible body (e.g., your laboratory manager) or authorized

representative for information regarding applicable disposal regulations.

110-511 PSC/EN 24

Page 26

Replacement Parts and Accessories

Description

Housing Assembly, rear bottom with slider 530-134

Pump Blades 702-894

Tank Mounting Bracket /Clamp 300-688

Tank Mounting Knob/Screw 400-874

Bumper for tank mounting knob/screw 400-872

Safety Thermostat Cover Plate 300-717

Resource Disk (with Operator’s Manual) 110-815

Part

Number

PolyScience Circulating Bath Fluids

Circulating Bath Fluids Quantity Part Number

polyclean Algaecide 8 oz / 236 ml 004-300040

polyclean Algaecide Twelve 8 oz / 236 ml bottles 004-300041

polyclean Bath Cleaner 8 oz / 236 ml 004-300050

polyclean Bath Cleaner Twelve 8 oz / 236 ml bottles 004-300051

polycool EG -25 (ethylene glycol) 1 gal / 4.5 liter 060340

polycool PG -20 (propylene glycol) 1 gal / 4.5 liter 060320

polycool HC -50 (water-based heat transfer fluid) 1 gal / 4.5 liter 060330

polytherm S150 (silicone oil) 1 gal / 4.5 liter 060326

polytherm S200 (silicone oil) 1 gal / 4.5 liter 060327

polytherm S250 (silicone oil) 1 gal / 4.5 liter 060328

polytherm M170 (mineral oil) 1 gal / 4.5 liter 060321

polycool MIX -25

(50/50 blend polycool EG -25 / H

O plus polyclean

2

algaecide)

polyclear MIX 30

(distilled water plus polyclean algaecide)

0.5 gal / 2.27 liter bottles

0.5 gal / 2.27 liter bottles

Five

Five

004-300060

004-300062

110-511 PSC/EN 25

Page 27

Service and Technical Support

If you have followed the troubleshooting steps outlined previously and your Circulator still fails to operate

properly, contact the supplier from whom the unit was purchased. Have the following information

available for the customer service person:

• Model, Serial Number, and Voltage (from back panel label)

• Date of purchase and purchase order number

• Supplier’s order number or invoice number

• A summary of the problem

Warranty

The manufacturer agrees to correct for the original user of the product, either by repair (using new or

refurbished parts), or at the manufacturer’s election, by replacement (with a new or refurbished product),

any defects in material or workmanship which develop during the warranty period. The standard warranty

is twenty-four (24) months after delivery of the product. In the event of replacement, the replacement unit

will be warranted for the remainder of the original warranty period or ninety (90) days, whichever is

longer. For purposes of this limited warranty, “refurbished” means a product or part that has been

returned to its original specifications. In the event of a defect, these are your exclusive remedies.

If the product should require service, contact the manufacturer’s/supplier’s office for instructions. When

return of the product is necessary, a return authorization number is assigned and the product should be

shipped, transportation charges pre-paid, in either its original packaging or packaging affording an equal

degree of protection to the indicated service center. To insure prompt handling, the return authorization

number must be placed on the outside of the package. A detailed explanation of the defect should be

enclosed with the item.

The warranty shall not apply if the defect or malfunction was caused by accident, neglect, unreasonable

use, improper service, acts of God, modification by any party other than PolyScience, or other causes not

arising out of defects in material or workmanship.

EXCLUSION OF IMPLIED WARRANTIES. THERE ARE NO WARRANTIES, EXPRESSED OR

IMPLIED, INCLUDING, BUT NOT LIMITED TO, THOSE OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE WHICH EXTEND BEYOND THE DESCRIPTION AND PERIOD AS STATED

IN THE OPERATOR’S MANUAL INCLUDED WITH EACH PRODUCT.

LIMITATION ON DAMAGES. THE MANUFACTURER’S SOLE OBLIGATION UNDER THE WARRANTY

IS LIMITED TO THE REPAIR OR REPLACEMENT OF A DEFECTIVE PRODUCT AND POLYSCIENCE

SHALL NOT, IN ANY EVENT, BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES

OF ANY KIND RESULTING FROM USE OR POSSESSION OF THIS PRODUCT.

Some states do not allow: (A) limitations on how long an implied warranty lasts; or (B) the exclusion or

limitation of incidental or consequential damages, so the above limitations or exclusions may not apply to

you. This warranty gives you specific legal rights and you may have other rights that vary from state to

state.

Manufactured by:

PolyScience

6600 W. Touhy Avenue Niles, IL 60714 U.S.A.

1-800-229-7569 ● 1-847-647-0611

www.polyscience.com

110-511 PSC/EN 26

Loading...

Loading...