Page 1

Page 2

Copyright Information

The copyright in this manual, the software and firmware in the printer described therein are

owned by the company.

Copyright © 2016-2017 All rights reserved

This product is manufactured, distributed, and sold by All ID Asia Pte Ltd. 67, Ayer Rajah

Crescent, #02-18, Singapore 139950

Product features, specifications and appearances are subject to change without notice.

CG Triumvirate is a trademark of Agfa Corporation. CG Triumvirate Bold Condensed font is

under license from the Monotype Corporation. Windows is a registered trademark of Microsoft

Corporation.

All other trademarks are the property of their respective owners.

PLR IP Holdings, LLC, its licensees and affiliates, fully supports all electronic waste initiatives.

As responsible stewards of the environment, and to avoid violating established laws, you should

properly dispose of this product in compliance with all applicable regulations, directives or other

governances in the area where you reside. Please check with local authorities or the retailer

where you purchased this product to determine a location where you can appropriately dispose

of the product.

You may also go to www.polaroid.com and reference Social Responsibility

http://www.polaroid.com/social-responsibility to learn more about the specific laws in your area

and to locate a collection facility near your home.

If your electronic device has internal memory on which personal or other confidential data may

be stored, you may want to perform a data sanitization process before you dispose of your

device to assure another party cannot access your personal data. Data sanitization varies by

the type of product and its software, and you may want to research the best sanitization process

for your device before disposal. You may also check with your local recycling facility to

determine their data sanitization procedures during the recycling process.

Polaroid, Polaroid & Pixel, Polaroid Classic Border Logo, and Polaroid Color Spectrum are

trademarks of PLR IP Holdings, LLC, used under license. All other trademarks are the property

of the respective owner, who has not sponsored, endorsed or approved this product. PLR IP

Holdings, LLC does not manufacture this product or provide any Manufacturer’s Warranty or

support.

For warranty information and technical support, please call +65-6778-0075 or visit

www.polaroid.com.

Information in this document is subject to change without notice and does not represent a

commitment on the part of the company. No part of this manual may be reproduced or

transmitted in any form or by any means, for any purpose other than the purchaser’s personal

use, without the expressed written permission of thecompany.

Page 3

Agency Compliance andApprovals

CE CLASSA

EN 55022

EN 55024

FCC CFR Title 47 Part 15Subpart B

ICES-003 ClassA

GB-4953

GB9254 (CLASS A)

GB27625

此为 A 级产品,在生活环境中,该产品可能会造成无线电干扰,在这种

情况下,可能需要用户对干扰采取切实可行的措施。

IEC 60950-1

Page 4

Page 5

Page 6

1. Introduction

1.1 Product Introduction

Congratulations on your purchase of a Polaroid P420T Barcode Printer.

This printer features two durable gear-driven motors that are capable of handling large

capacity 300 meter ribbons and large rolls of media within its sleek design. If the 5” interior

label capacity is not enough, simply add an external media roll mount and it can easily

handle 8.4” OD rolls of labels designed for expensive industrial label printers.

The adjustablesensor design accepts wide range of label media.Most of the frequently

used barcodeformats are included. Fonts and barcodes can be printed in any one of the

four directions.

This series of printer is built with the high quality, high performance MONOTYPE IMAGING

®

True Type font engine and one CG Triumvirate Bold Condensed smooth font. With flexible

firmware design, you may download any True Type Font to the printer’s memory. Other than

the scalable font, the printer also offers a choice of five different sizes of alphanumeric

bitmap font, OCR-A and OCR-B fonts. With its rich features, the P420T is the most costeffective and high performance printer in itsclass!

To print label formats, please refer to the instructions provided with your labeling software;

if you need to write custom programs, please refer to the programming manual that can be

found in the CD-ROM.

Applications

o Manufacturing & Warehousing

Work inProgress

ItemLabels

Instructionlabels

Agencylabels

o Healthcare

PatientIdentification

Pharmacy

SpecimenIdentification

o Parcel Post

Shipping/ Receiving

Labels

o Small Office/ HomeOffice

o RetailMarking

Pricetags

Shelflabels

Jewelrytags

1

Page 7

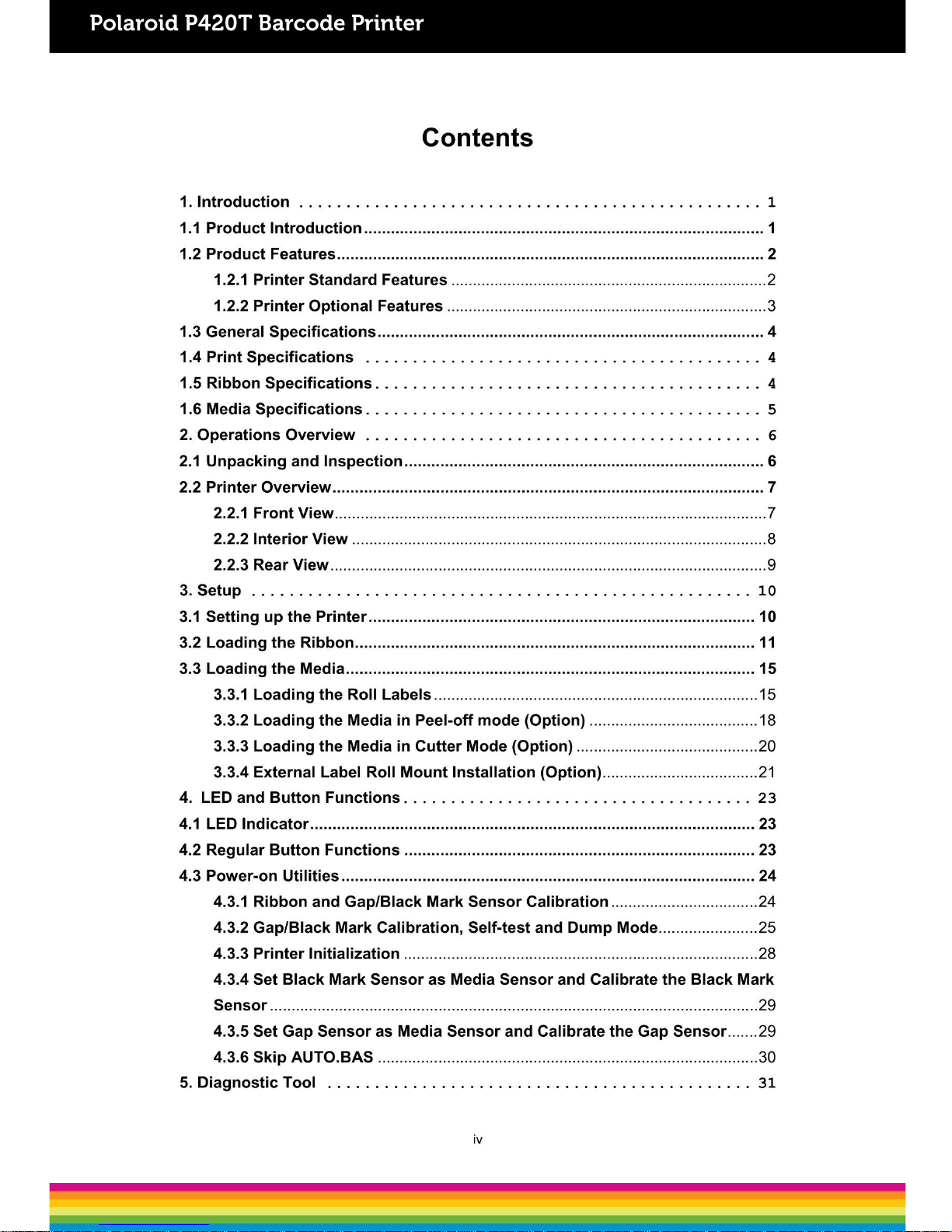

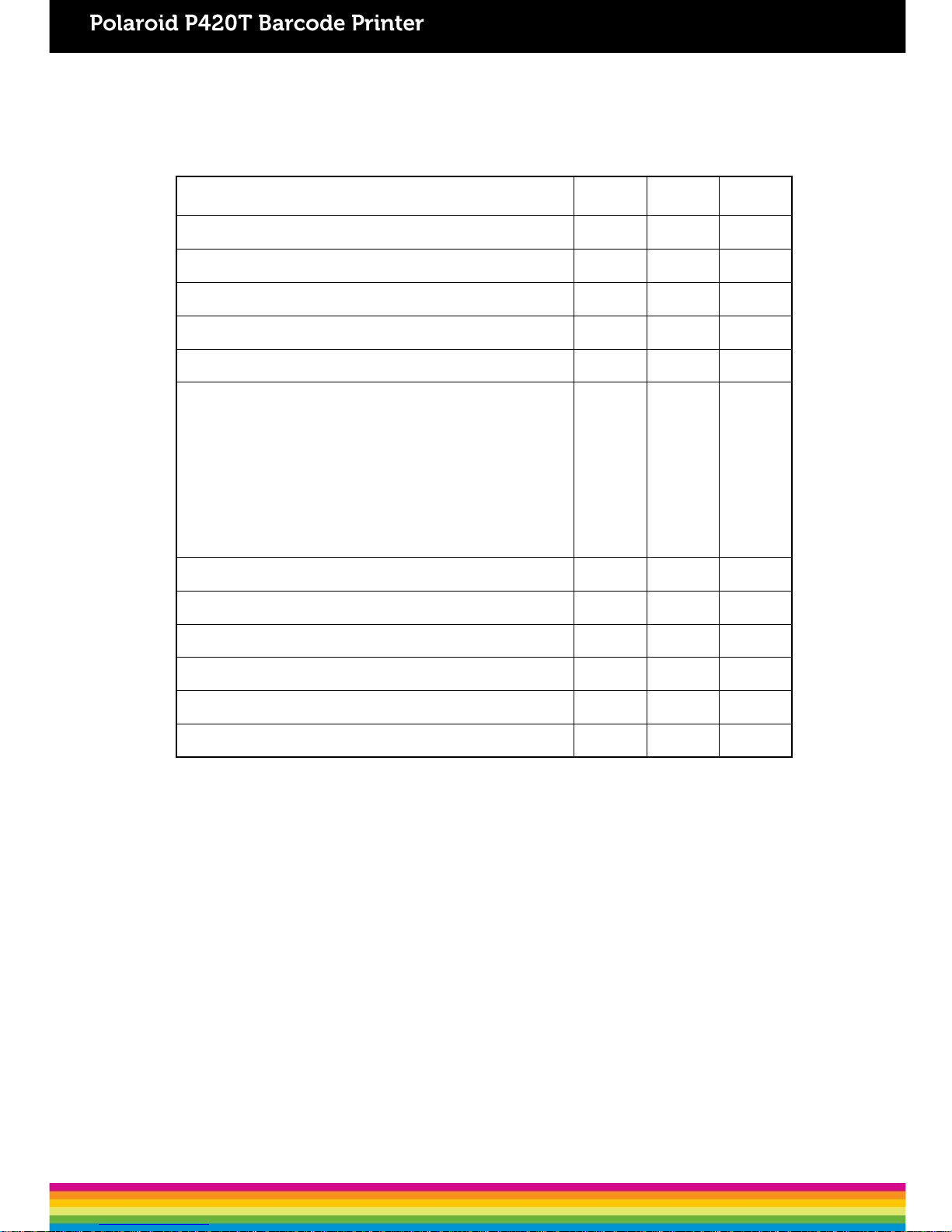

Standard Features

P420T

Thermal transferprinting ○

Direct thermalprinting ○

ABS plasticenclosure ○

Position adjustable gapsensor ○

Position adjustable black marksensor ○

Ribbonsensor ○

Head opensensor ○

USB 2.0 (full speed)interface ○

8 MB SDRAMmemory ○

4 MB FLASHmemory ○

micro SD memorycard reader for memoryexpansion up to 4 GB

○

Real timeclock ○

One power switch, one feed button andLED ○

Standard industry emulations right out of the box including Eltron® and Zebra

®

languagesupport

○

Internal 8 alpha-numeric bitmapfonts ○

Fonts and barcodes can be printed in any one of the four directions (0, 90,180,

270 degree)

○

Internal Monotype Imaging® true type font engine with one

CG Triumvirate Bold Condensed scalablefont

○

Downloadable fonts from PC to printer memory ○

Downloadable firmwareupgrades ○

Text, barcode, graphics/image printing (Please refer to the TSPL/TSPL2

programming manual for supportingcode page)

○

Supported barcode Supportedimage

1D barcode 2D barcode

BITMAP, BMP,

PCX

(Max. 256colors

graphics)

Code39,

Code 93,

Code128UCC,

Code128 subsets

A,B,C, Codabar, Interleaved

2 of 5, EAN-8, EAN-13,

EAN-128,

UPC-A, UPC-E, EAN and

UPC2(5)

digits add-on, MSI, PLESSEY,

POSTNET,

China POST, GS1

DataBar, Code11

PDF-417,

Maxicode,

DataMatrix, QR

code, Aztec,

GS1 DataBar Composite

code

2

1.2 Product Features

1.2.1 Standard Features

The printer offers the following standardfeatures.

Page 8

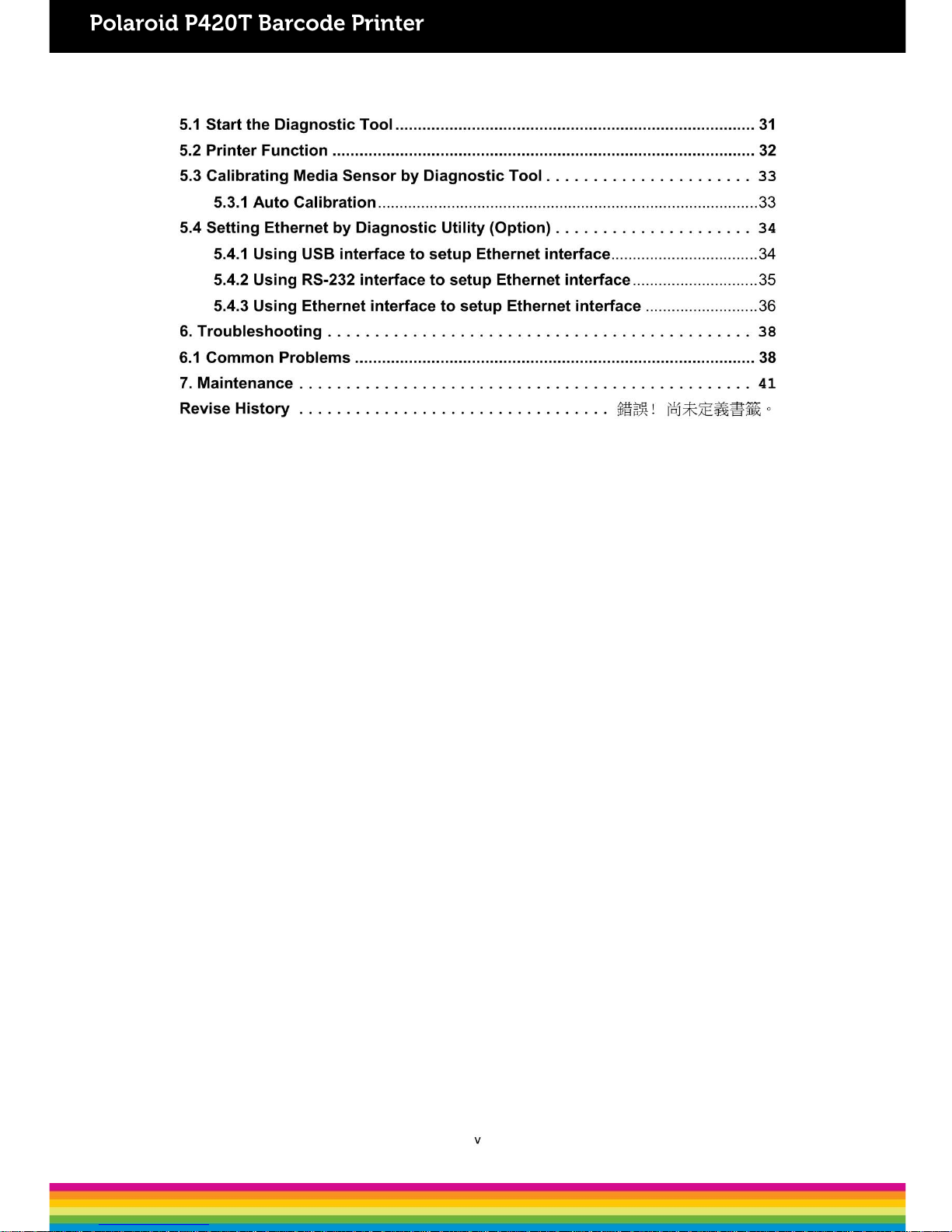

1.2.2 Optional Features

The printer offers the following optionalfeatures.

Optional Features

User

options

Dealer

options

Factory

options

LCD display (graphic type, 128x64 pixel) with back light

- - ○

Internal Ethernet print server (10/100 Mbps)interface - - ○

Serial RS-232C (2400-115200 bps) interface - - ○

Centronicsinterface - - ○

Peel-offmodule - ○ Guillotine cutter module (Full cut and partial cut)

Paper thickness: 0.06~ 0.19mm, 500,000 cuts

0.20~ 0.25mm, 200,000 cuts

Note:

Except for the linerless cutter, all regular/heavy duty/care

label cutters DO NOT cut on media withglue.

- ○ -

External roll mount with 3” core (8.4 OD) label spindle ○

Extended plate for external rollmount ○

Bluetooth module (RS-232C interface) ○ - KP-200 Plus keyboard displayunit ○ - KU-007 Plus programmable smart keyboard display unit

○ - -

HCS-200 long rangeCCD scanner ○ - -

3

Page 9

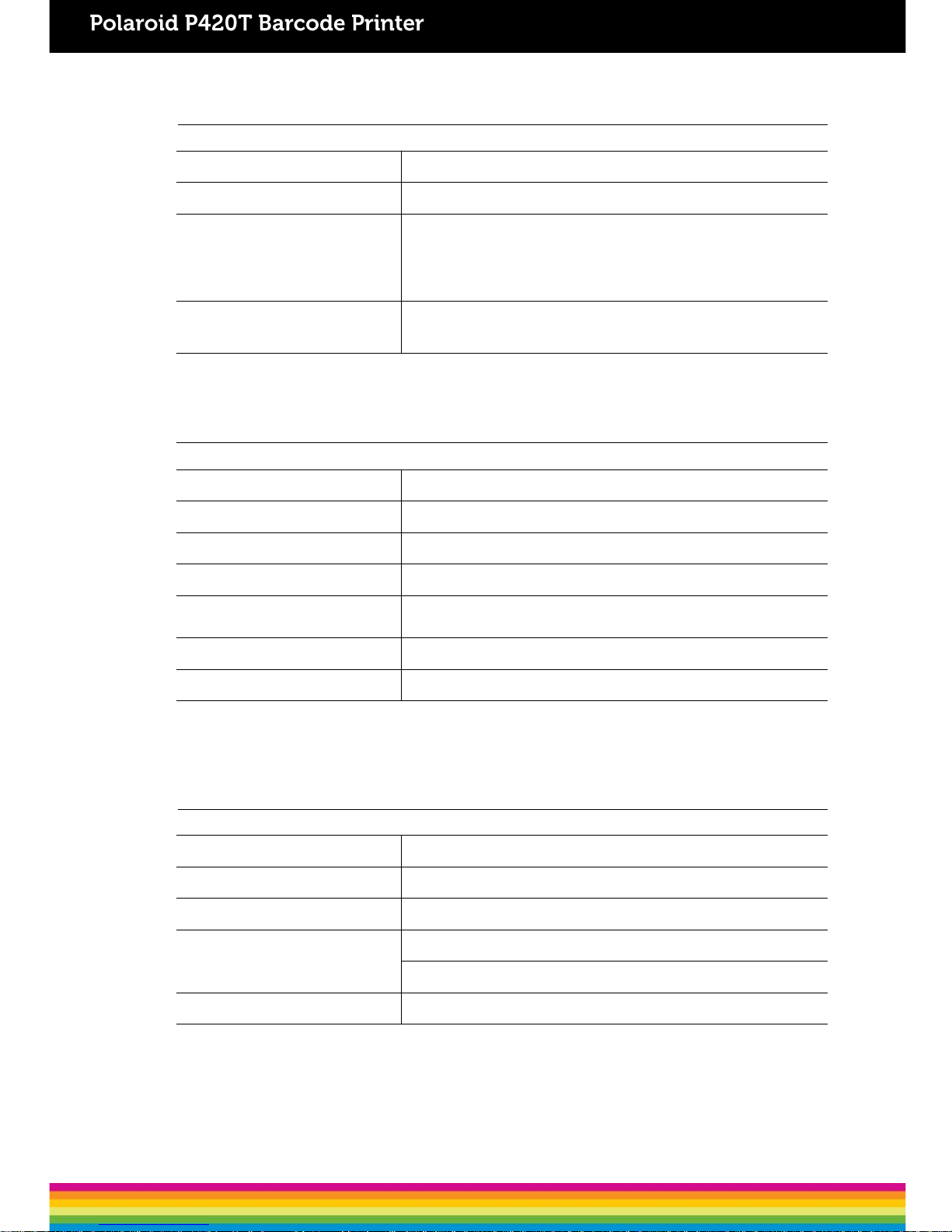

1.3 General Specifications

General Specifications

Physicaldimensions

224 mm

(W) x 186 mm (H) x 294 mm (D)

Weight

2.45

kg

Electrical

External universal

switching powersupply

Input:

AC 100-240V

Output:

DC 24V 2.5A,

60W

Environmentalcondition

Operation:

5 ~ 40˚C (41 ~ 104˚F), 25~85% non-condensing

Storage:

-40 ~ 60 ˚C (-40 ~ 140˚F), 10~90% non-condensing

1.4 Print Specifications

Print Specifications

Print headresolution 203 dots/inch (8 dots/mm)

Printingmethod Thermal transfer and directthermal

Dotsize (width xlength) 0.125 x 0.125mm (1 mm = 8dots)

Printspeed (inches persecond) 5ips

Print speed forpeel

mode & cuttermode

2, 3ips

Max. printwidth 108 mm(4.25”)

Max. printlength 2,794 mm(110”)

1.5 Ribbon Specifications

Ribbon Specifications

Ribbon outsidediameter

Max. 67

mm

Ribbonlength

300

meter

Ribbon core insidediameter

1 inch

(25.4mm)

Ribbonwidth

Max. 110

mm

Min. 40

mm

Ribbon woundtype

Outside

wound

4

Page 10

1.6 Media Specifications

Media Specifications

Label rollcapacity

127 mm (5”)

OD

Mediatype Continuous, die-cut, black mark, fan-fold, notch

Media woundtype

Printing

face outside wound & Printing face insidewound

Media width

(label+ liner)

Max. 118 mm

(4.6”)

Min. 25.4 mm

(1.0”)

Media thickness

(label +liner)

Max.

0.254 mm (10mil)

Min. 0.06 mm (2.36

mil)

Media corediameter

25.4 mm~38 mm

(1”~1.5”)

Labellength

10~2,794 mm

(0.39”~110”)

Note:

If your label length

is less than 25.4mm (1”), we

recommend

you to use the perforation at the gap for

easier

tearaway.

Label length

(peeler mode)

Max.

152.4 mm(6”)

Min. 25.4 mm

(1”)

Label length

(cutter mode)

Max.

2,794 mm(110”)

Min. 25.4 mm

(1”)

Gapheight

Min.

2 mm(0.09”)

Black markheight

Min.

2 mm(0.09”)

Black markwidth

Min.

8 mm(0.31”)

5

Page 11

2. Operations Overview

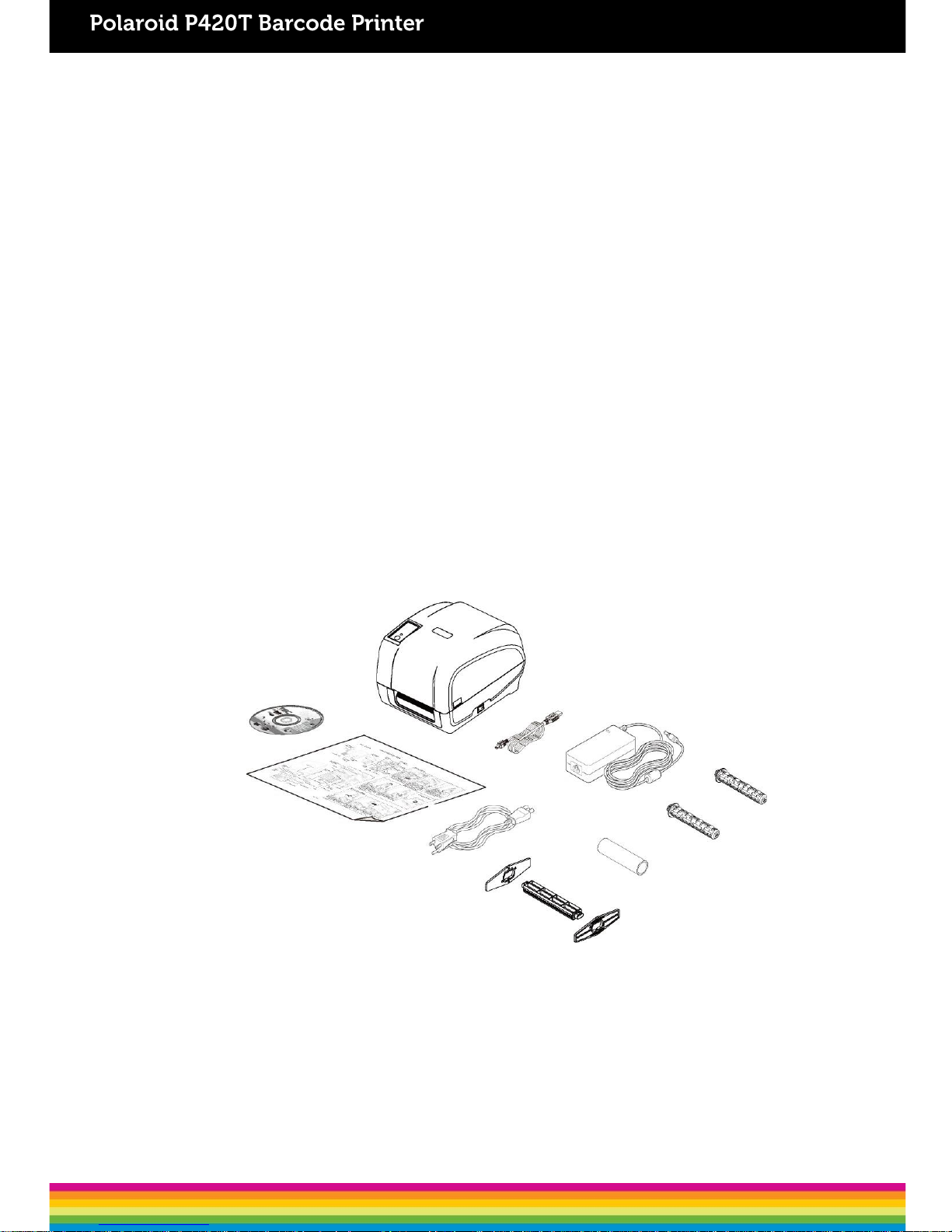

2.1 Unpacking and Inspection

This printer has been specially packaged to be protected from damage during shipping. Upon

receiving, please inspect the packaging and printer carefully. Please retain the packaging

materials, in case you need to re-shipthe printer.

The following items are included in thecarton:

One P420T printer

One Windows labeling software/Windows driver CD

One quick installationguide

One powercord

One auto switching power supply

One USB interfacecable

Two ribbonspindles

One ribbon papercore

One labelspindle

If any items are missing, please contact the Customer Service department of the

reseller/distributor that you purchased the printer from.

6

Page 12

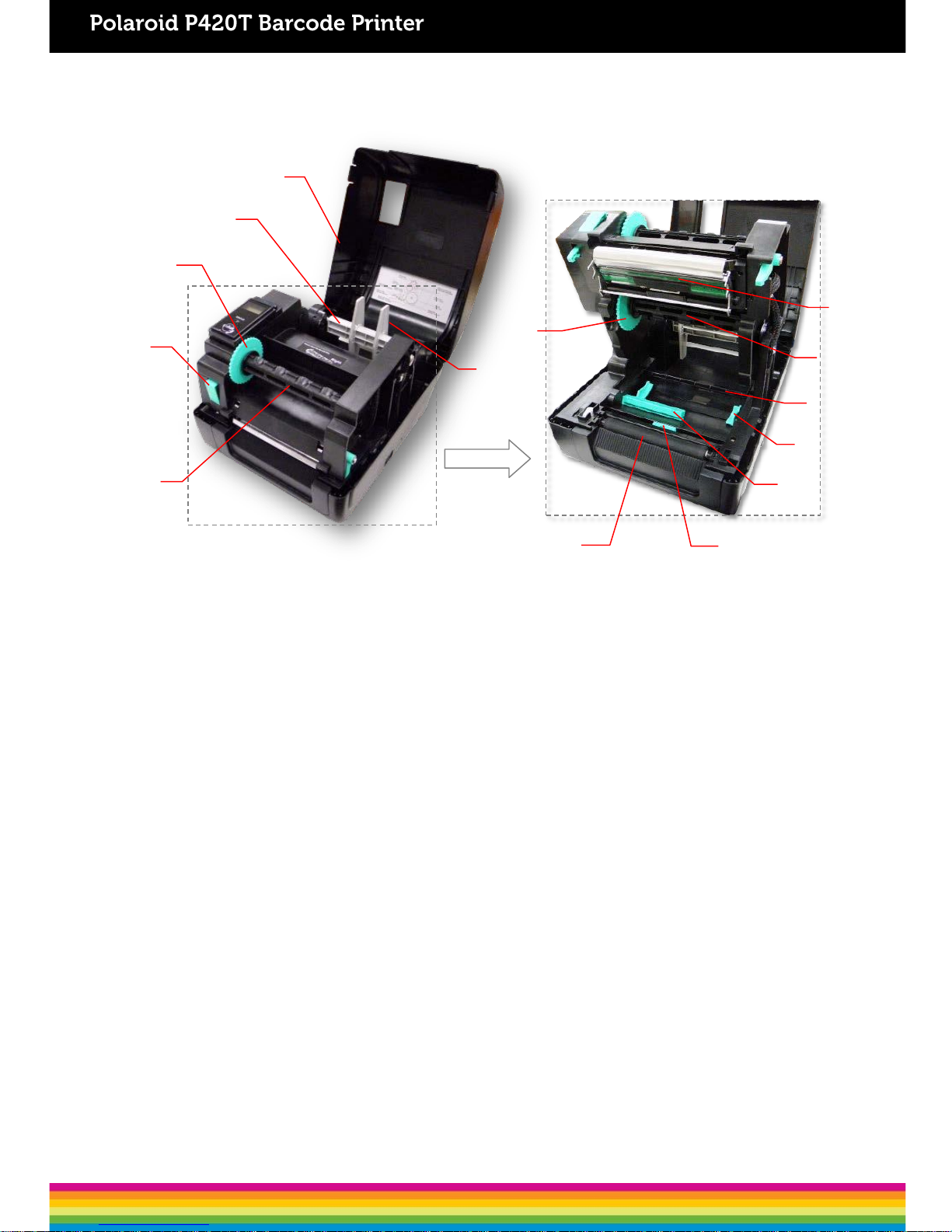

1. LED indicator

2. FEED Button

3. LCD display (Option)

4. Paper exit chute

5. Top cover opentab

6. Power switch

2.2 Printer Overview

2.2.1 FrontView

1

2

3

4

6

5

7

Page 13

2.2.2 InteriorView

1. Printer topcover

2. Media supplyspindle

3. Ribbon rewindhub

4. Print head releasebutton

5. Ribbon rewindspindle

6. Fixing tab

7. Ribbon supplyhub

8. Platen roller

9. Black mark sensor

10. Gap sensor

11. Media guide

12. Media bar

13. Ribbon supplyspindle

14. Print head

13

9

5

6

4

OPEN

10

12

8

11

1

2

3

14

7

8

Page 14

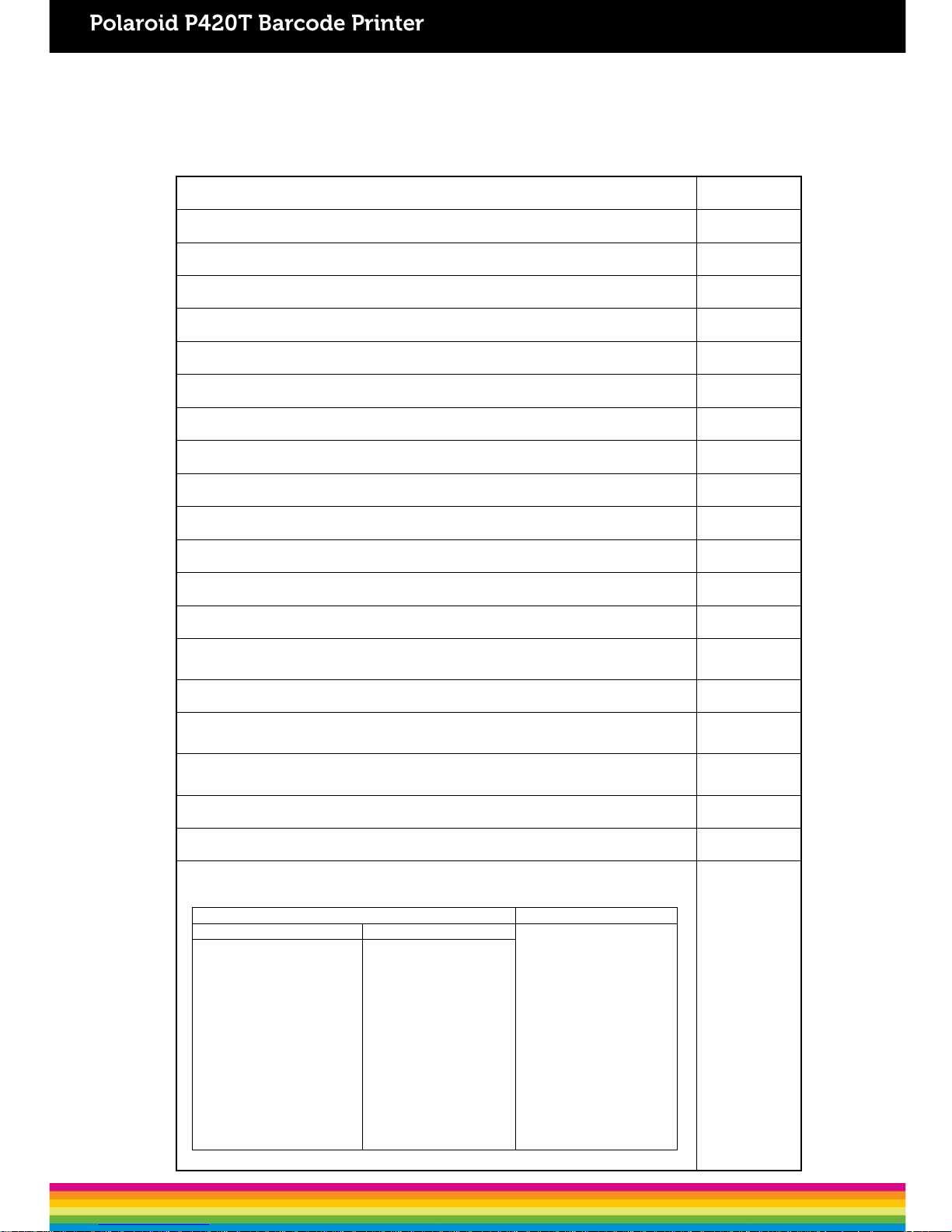

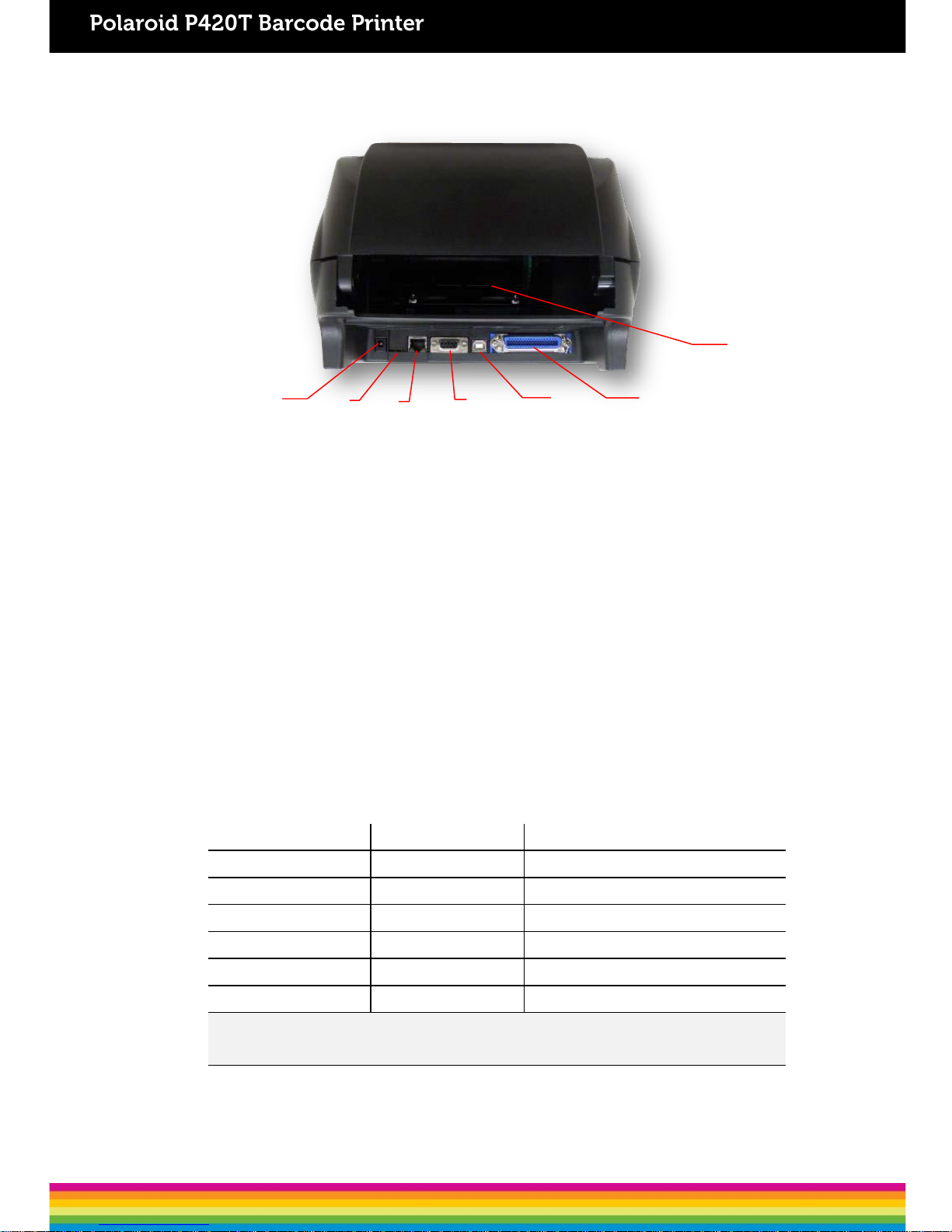

2.2.3 RearView

1. Power jack socket

2. *micro SD cardslot

3. Internal Ethernet interface (Option)

4. RS-232C interface (Option)

5. USB interface (USB 2.0/ Full speedmode)

6. Centronics interface (Option)

7. Rear external label entrancechute

Note:

The above interface is only for reference. Please refer to the product specifications for

the interface options.

* Recommended micro SD cardspecification

SD cardspec

SD

cardcapacity

Approved

SD card manufacturer

V1.0,V1.1

microSD 128

MB

Transcend,

Panasonic

V1.0,V1.1

microSD 256

MB

Transcend,

Panasonic

V1.0,V1.1

microSD 512

MB

Panasonic

V1.0,V1.1

microSD 1

GB

Transcend,

Panasonic

V2.0 SDHC CLASS4

microSD 4

GB

Panasonic

V2.0 SDHC CLASS6

microSD 4

GB

Transcend

- The DOS FAT file system is supported for the SD card.

- Folders/files stored in the SD card should be in the 8.3 filename format.

2

1

6

4

5

3

7

9

Page 15

3. Setup

3.1 Setting up the Printer

1. Place the printer on a flat surface.

2. Ensure thatthe power is switched off.

3. Connect the printer to the computer with

the provided USB cable.

4. Insert the power cord into theAC power

cord socket of the printer. Then, insert

the other end of the cord into a properly

grounded AC electrical outlet.

Note:

* The printer power should be turned off before connecting or disconnecting the communications and power cables.

* The above interface is only for reference. Please refer to the product specifications for the interface options.

10

Page 16

3.2 Loading the Ribbon

1. Open the printer‘s top cover by

pulling the latches located on each

side of theprinter.

2. Insert the paper core into the ribbon

rewindspindle.

3. Insert the left side of the spindle into

the ribbon rewind hub first. Then, insert

the right side into the hole at the right

side of ribbonmechanism.

11

Page 17

4. Push the release button to lift up the

print headmechanism.

5. Insert the ribbon into the ribbon spindle.

6. Insert the left side of ribbon supply

spindle into the ribbon supply hub first.

Then, insert the right side of ribbon

supply spindle into the hole at theright

side of ribbonmechanism.

12

Page 18

7

. Lead the ribbonthrough the print

head

and

stick the ribbon’s clear front onto

the

r

ibbon rewind paper core.

8.

Wind up the ribbon rewind hub until

t

he clear front part is thoroughly wound

up

and the black ribbon covers the print

head.

9.

Close the print head mechanismwith

both

hands and ensurethat it is latched

securely

.

13

Page 19

Ribbon loading path

Print head

Ribbon

rewind hub

Ribbon

Paper core

14

Page 20

3.3 Loading the Media

3.3.1 Loading the RollLabels

1. Open the printer‘s top cover by

pulling the latches located on each side

of theprinter.

2. Insert thelabel roll into the media

supply spindle and use the two fixing

tabs to centralise the paper roll onto the

spindle. (If the width of your label is 4",

you can remove the fixing tabsfrom the

supplyspindle.)

3. Place the label roll onto the media

rollmount.

15

15

Page 21

4. Push the release button to lift up the

print head mechanism.

5. Pull the label (printingside faced up),

through the media bar, media sensor and

place the label‘s leading edge onto the

platen roller. Move the media guides to fit

the label.

Gapsensor Black marksensor

Gap sensor

Black mark

sensor

Media guide

Platen roller

Note: The media guide is adjustable. Please ensure that the gap or black mark is

at the location where media gap/black mark will pass through for sensing.

16

Page 22

Note: Please calibrate the gap/ black mark sensor when changing media.

Media loading path

Media

Media bar

Media guide

Gap sensor

Platen roller

Black mark sensor

6.

Close the print head mechanismwith

both hands and ensure

that it is latched

securely.

1

2

7

. Use “Diagnostic Tool” to set the

media

sensor type and

calibratethe selected

sensor. (Start

the “Diagnostic tool”

Select

the “Printer Configuration” tab

Click

the “Calibrate Sensor” button )

Please refer

to section5.3.

Path for outside wound

Path for inside wound

17

Page 23

3.3.2 Loading the Media in Peel-off mode (Option)

1. Refer to Chapter 3.3.1 to load the

label roll. Use “Diagnostic Tool” to set

the media sensor type and calibrate the

selectedsensor.

2. Pull the label through thefront of the

printer and peel some labels off theliner.

3. Open the peel-off cover. Feed the

liner into peel-off coverslot.

Liner

Label

Liner

Peel-off

cover slot

18

Page 24

4. Close the peel-off cover.Use the

DiagTool to set the peel-off mode by

selecting “PEEL” option for Post-Print

Action setting. Then,click “Set” button

to enable the peel-off mode.

6. Press the FEED button to test.

Note:

Please calibrate the gap/black mark sensor when changing media.

Liner

5. Close the printhead mechanism

and printer cover. Printer is ready for

peel-offmode.

Liner

Label

19

Page 25

3.3.3 Loading the Media in Cutter Mode (Option)

Note:

Please calibrate the gap/black mark sensor when changing media.

1. Refer

to Chapter 3.3.1 to load the

label roll.

2

. Pull the label through thecutter

paper

opening.

3.

Close the print headmechanism and

printer

cover. Use theDiagTool to set

the

printer

for cutter mode by selecting

“CUTTER” option

for Post-Print Action

setting

then click “Set” button to enable

the

cutter mode. Press

the FEED button

to

test.

20

Page 26

3.3.4 External Label Roll Mount Installation (Option)

Extended

External label

plate

rollmount

1.

Installthe extended plate onto the

external

label rollmount with 2 screws.

2.

Attach the extended plate onthe

bottom

of the printer. If you

purchase the

external label roll

mount only, you’d just

need to put

it on the rear of printer.

3.

Insert a 3” (or 1”) label spindle intoa

paper

roll. And install it ontothe external

paper roll

mount.

21

1” label

spindle

3” label

spindle

Page 27

4. Feed the media through the rear

external label entrancechute.

5. Refer to chapter 3.3.1 to install the

label. Use “Diagnostic Tool” to set

the media sensor type and calibrate

the selectedsensor.

Note:

Please calibrate the gap/black mark sensor when changing media.

22

Page 28

4. LED and Button Functions

This printer has one button and one three-color LED indicator. By indicating the LED with

different colors and pressing the button, printer can feed labels, pause the printing job, select

and calibrate the media sensor, print printer self-test report and reset printer to default

settings (initialization). Please refer to below table for the different functions.

4.1 LED Indicator

LEDColor Description

Green/Solid

This indicatesthat the power is on and the device is ready to

be used.

Green/Flash

This indicatesthat the system is downloading data from the

PCto the printer’s memory, or the printer isbeing paused.

Amber This indicatesthat the system is clearing data from printer.

Red /Solid This indicates that the printer head is open/ cutter error.

Red /Flash

This indicatesa printing error, such as printer head is open,

no paper, paper jam, no ribbon, or memory error etc.

4.2 Regular Button Functions

1. Feedlabels

When the printer is at ready mode (Green/Solid), press the button to feed one label to the

beginningof next.

2. Pause the printingjob

When the printer is at printing mode, press the button to pause a print job. When the printer is

paused, the LED will be blink in green. Press the button again to continue the printing job.

23

Page 29

4.3.1 Ribbon and Gap/Black Mark Sensor Calibration

Gap/black mark sensor sensitivity calibration should be performed for the following conditions:

1. A brand new printer

2. Change label stock

3. Printer initialization

Please follow the steps below to calibrate the ribbon and gap/black mark sensor:

1. Switch off the printer

2. Press the button while you switch on the printer

3. Release the button when LEDis red and blinking.

4.3 Power-on Utilities

There are six power-on utilities to set up and test the printer. These utilities are activated by

pressing the FEED buttonand then, switching on the printer simultaneously and releasingthe

button at different color ofLED.

Please follow the steps below for different power-on utilities:

1. Switch off the printer

2. Press the button while you switchon the printer

3. Release the button when LED indicates accordingly

Power onutilities The LED color will change as follows:

LEDcolor

Functions

Amber

Red

(5

blinks)

Amber

(5blinks)

Green

(5

blinks)

Green/Amber

(5blinks)

Red/Amber

(5blinks)

Solidgreen

1. Ribbon sensor calibration and gap /

black mark sensorcalibration

Release

2. Gap / black mark sensor calibration,

Self-test and enter dumpmode

Release

3. Printerinitialization

Release

4. Set black mark sensor as media

sensor and calibrate the black mark

sensor

Release

5. Set gap sensor as media sensorand

calibrate the gapsensor

Release

6. SkipAUTO.BAS

Release

24

Page 30

It will calibrate the ribbon sensor and gap/black mark sensor sensitivity.

The LED color will change according to the following order:

Amber red (5 blinks) amber (5 blinks) green (5 blinks) green/amber (5 blinks)

red/amber (5 blinks) solid green

Note:

Please select gap or black mark sensor by sending GAP or BLINE command to printer prior to

calibrating the sensor.For more information about GAP and BLINE command, please refer to

TSPL2 programming manual.

4.3.2 Gap/Black Mark Calibration, Self-test and Dump Mode

While calibratingthe gap/black mark sensor, printer will measure the label‘s length, print the

internal configuration (self-test) on label and then, enter the dump mode. To calibrate gap or

black mark sensor, it depends on the sensor setting from the last print job.

Please follow the steps below to calibrate thesensor:

1. Switch off the printer

2. Press the button while you switch on the printer

3. Release the button when LED becomes amber and blinking.

The LED color will change according to the following order:

Amber red (5 blinks) amber (5 blinks) green (5 blinks) green/amber (5 blinks)

red/amber (5 blinks) solid green

4. Printer will calibrate the sensor, measure the label‘s length, print internal settings, andthen

enter the dump mode.

Note:

Please select gap or black mark sensor by Diagnostic Tool or by GAP or BLINE command prior to

calibrate thesensor. For more information about GAP and BLINE command, please refer to TSPL2

programming manual.

25

Page 31

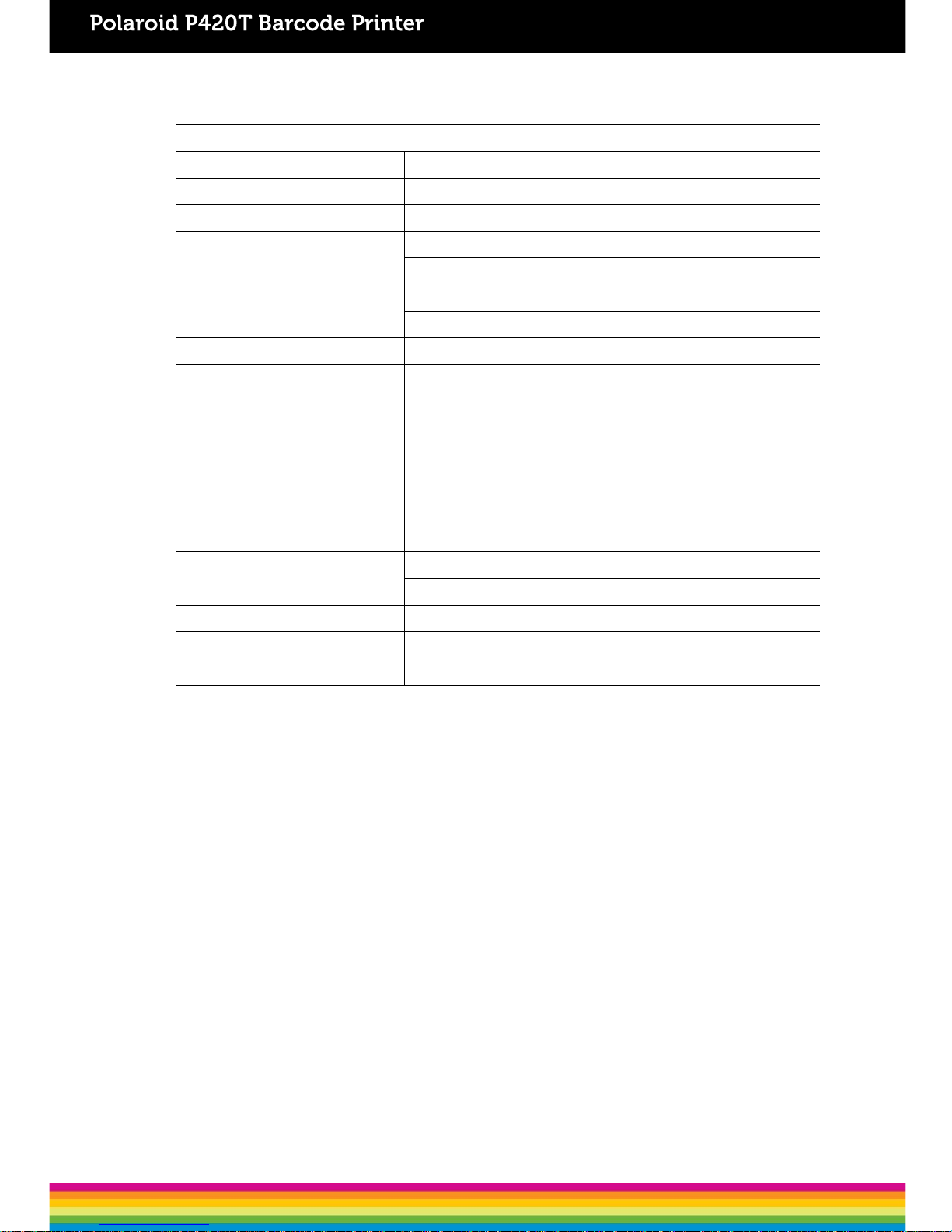

Self-test

Printer will print its configuration after gap/black mark sensor calibration. Self-test printout

can be used to check if there is any dot damage on the heater element, printer

configurations and available memory space.

Self-test printout

Printer model name & Main board firmware version

Printer serialnumber

Printedmileage

Main board firmware checksum

Serial portsetting

Code page

Country code

Print speed

Printdarkness

Label size (width, height)

Black mark or gap size (vertical gap, offset)

Sensorsensitivity

Ethernet settings information(option)

File managementinformation

Print head testpattern

Self-test printout (with printer firmware V7.0 and later version)

Modelname

F/Wversion

Firmwarechecksum

Printer S/N

Configurationfile

Systemdate

Systemtime

Printed mileage (meter)

Cuttingcounter

26

Page 32

Print speed (inch/sec)

Printdarkness

Label size (inch)

Gap distance(inch)

Gap/black mark sensorintension

Code page

Countrycode

ZPL setting information

Printdarkness

Print speed(inch/sec)

Label size

Control prefix

Format prefix

Delimiterprefix

Printer power up motion

Printer head close motion

Note:

ZPL is emulating for Zebra

®

language.

RS232 serialport

configuration

Numbers of download files

Total & available memory

space

Print head check pattern

27

Page 33

4.3.3 PrinterInitialization

Printer initialization is used to clear DRAM and restore its settings to default. The only exception

is ribbon sensitivity, which will not be restored to default.

Printer initialization is activated by the following procedures.

1. Switch off the printer

2. Press the button while you switch on the printer

3. Release the button when LED turns green after 5 amber blinks.

The LED color will be changed asfollowing:

Amber red (5 blinks) amber (5 blinks) green (5 blinks) green/amber (5 blinks)

red/amber (5 blinks) solid green

Dumpmode

Printer will enter dump mode after printing its configuration. In the dump mode, all characters

will be printed in 2 columns as follows. The left side characters are received from your system

and the right side data are the corresponding hexadecimal value of the characters. It allows

users or engineers to verify and debug theprogram.

Note:

1. Dump mode requires 4” wide paper width.

2. Turn off / on the power to resume printer for normal printing.

ASCIIData

Hex decimal data related to left

column of ASCIIdata

28

Page 34

4.3.4 Set Black Mark Sensor as Media Sensor and Calibrate the Black Mark Sensor

Please follow the steps asbelow.

1. Switch off the printer

2. Press the button while you switch on the printer

3. Release the button when LED turns green/amber after 5 green blinks. (Any green/amber will

do during the 5blinks).

The LED color will change according to the following order:

Amber red (5 blinks) amber (5 blinks) green (5 blinks) green/amber (5 blinks)

red/amber (5 blinks) solid green

4.3.5 Set Gap Sensor as Media Sensor and Calibrate the Gap Sensor

Please follow the steps asbelow.

1. Switch off the printer

2. Press the button while you switch on the printer

Printer configuration will be restored to defaults as below after initialization.

Parameter Default setting

Speed

101.6

mm/sec (4 ips)(203DPI)

76

mm/sec (3 ips)(300DPI)

Density

8

Label

Width

4” (101.5

mm)

Label

Height

4” (101.5

mm)

Sensor

Type

Gap

sensor

Gap

Setting

0.12”

(3.0mm)

Print

Direction

0

Reference

Point

0,0

(upper leftcorner)

Offset

0

Tear

Mode

On

Peel

offMode

Off

Cutter

Mode

Off

Serial Port

Settings

9600

bps, none parity, 8 data bits, 1 stop bit

Code

Page

850

Country

Code

001

Clear

FlashMemory

No

IP

Address

DHCP

29

Page 35

3. Release the button when LED turns red/amber after 5 green/amber blinks.

The LED color will change according to the following order:

Amber red (5 blinks) amber(5 blinks) green(5 blinks) green/amber(5 blinks)

red/amber (5 blinks) solid green

4.3.6 SkipAUTO.BAS

TSPL2 programming language allows user to download an auto execution file to flash memory.

Printer will run the AUTO.BAS program immediately when switching on the printer. The

AUTO.BAS program can be interrupted without running the program by the power-on utility.

Please follow the procedures below to skip an AUTO.BAS program.

1. Switch off the printer

2. Press the FEED button while you switch on the printer

3. Release the FEED button when LED becomes solid green.

The LED color will change according to the following order:

Amber red (5 blinks) amber(5 blinks) green(5 blinks) green/amber(5 blinks)

red/amber (5 blinks) solid green

4. Printer will be interrupted to run the AUTO.BAS program.

30

Page 36

5. Diagnostic Tool

This Diagnostic Utility is an integrated tool incorporating features that enable you to explore a

printer’s settings/status; change a printer’s settings; download graphics, fonts and firmware;

create a printer bitmap font; and send additional commands to a printer. With this powerful

tool, you can review printer status and settings in an instant, which makes it much easier to

troubleshoot problems or issues.

5.1 Start the Diagnostic Tool

1. Double click on the Diagnostic tool icon to start thesoftware.

2. There are four features (Printer Configuration, File Manager, Bitmap Font Manager,

Command Tool) included in the Diagnostic utility.

Printerfunctions

Featurestab

Interface

PrinterStatus

Printersetup

31

Page 37

5.2 Printer Function

1. Select the PC‘s interface connected to the printer.

2. Click the “Printer Function” button to setup.

3. The detailed functions in the Printer Function Group are listed asbelow.

Function Description

Calibrate

Sensor

Calibrate

the

sensor specified in the Printer Setup

group

media sensorfield

Ethernet

Setup

Setup the

IP address, subnet mask, gateway for

the

on boardEthernet

RTC

Setup

Synchronize printer

Real Time Clock with PC

Print

TestPage

Print a

testpage

Reset

Printer

Reboot

printer

Factory

Default

Initialize the printer and restore the settings

to

factory

default. (Please refer section4.3.3)

Dump

Text

To

activate the printer dumpmode.

Ignore

AUTO.BAS

Ignore the

downloaded AUTO.BAS program

Configuration

Page

Print printer configuration

(Please refer section

4.3.2)

Password

Setup

Set

the password to protect the settings

For more information about Diagnostic Tool, please refer to the diagnostic utility quick start

guide in the CD disk \ Utilities directory.

2

1

The

default interface settingis

USB. If

printer is connected via

USB

interface, no changes is

needed

32

Page 38

5.3 Calibrating Media Sensor by Diagnostic Tool

5.3.1 Auto Calibration

1. Make sure the media is install ready and print head mechanism is closed. (Please refer to

section3.3.)

Note: The media sensor position is adjustable. Please ensure that the gap (▽) or

black mark is at the location where media gap/black mark will pass through for

sensing.

Gapsensor Black marksensor

2. Switch on the printer

3. Open Diagnostic tool and set the interface. (The default setting is USB.)

4. Click the “Calibrate Sensor” button.

5. Select the media type and click the “Calibrate” button.

1

2

2

1

The

default interface settingis

USB interface. If USB

interface

is

connected with printer,no

other settings need to

be

changed

in the interfacefield.

33

33

Page 39

5.4 Setting Ethernet by Diagnostic Utility (Option)

The Diagnostic Utility is enclosed in the CD disk \Utilities directory. Users can use Diagnostic Tool to

set up the Ethernet by RS-232, USB and Ethernet interfaces. The following contents will guide users

on how to configure the Ethernetsettings via these three interfaces.

5.4.1 Using USB interface to setup Ethernetinterface

1. Connect the USB cable between the computer and the printer.

2. Switch on the printer.

3. Start the Diagnostic Utility by double clicking onthe

icon.

4. The Diagnostic Utility defaultinterface setting is USB. If USBinterface is connected with

printer, no other settings need to be changed in the interface field.

5. Click on the “Ethernet Setup” button from “Printer Function” group in Printer Configuration

tab to setup the IP address, subnet mask and gateway for the on board Ethernet.

34

Page 40

5.4.2 Using RS-232 interface to setup Ethernet interface

1. Connect the computer to the printer with a RS-232 cable.

2. Switch on the printer.

3. Start the Diagnostic Utility by double-clicking on the

icon.

4. Select “COM” as interface then click on the “Setup” button to setup the serial port baud rate,

parity check, data bits, stop bit and flow controlparameters.

5. Click on the “Ethernet Setup” button from printer function of Printer Configuration tab,to

setup the IP address, subnet mask and the gateway for the on board Ethernet.

35

Page 41

5.4.3 Using Ethernet interface to setup Ethernet interface

1. Connect the computer and the printer to the LAN.

2. Switch on the printer.

3. Start the Diagnostic Utility by double-clicking on the

icon.

4. Select “Ethernet” as the interface then click on the “Setup” button to setup the IP address,

subnet mask and gateway for the on board Ethernet.

5. Click the “Discover Device” button to explore the printers that exist on the network.

6. Select the printer in the left side of listed printers, the correspondent IP address will be

shown in the right side “IP address/Printer Name” field.

7. Click “Change IP Address” to configure the IP address obtained by DHCP or static.

The default IP address is obtained by DHCP. To change the setting to static IP address,

click “Static IP” radio button then enter the IP address, subnet mask and gateway. Click “Set

IP” to take effect thesettings.

36

Page 42

Users can also change the “Printer Name” by another model name in this field, then click

“Set Printer Name” to take effect thischange.

Note: After clicking the “Set Printer Name” or “Set IP” button, printer will reset for the

settings to take effect.

8. Click “Exit” button to exit the Ethernet interface setup and go back to Diagnostic Tool main

screen.

Factory Defaultbutton

This function will reset the IP, subnet mask, gateway parameters obtained by DHCP and

reset the printername.

Web setupbutton

Except to use the Diagnostic Utility to setup the printer, you can also explore and configure

the printer settings and status or update the firmware with the IE or Firefox web browser.

This feature provides a user friendly setup interface and the capability to manage the printer

remotely over anetwork.

37

Page 43

6. Troubleshooting

6.1 Common Problems

The following guide lists out the most common problems that you may encounter when using this

barcode printer. If the printer still does not function after applying the suggested solutions, please

contact the Customer Service Department of the reseller or distributor that you purchased the printer

from, for assistance.

Problem

Possible Cause

Suggested

Solution

Power indicator

doesnot

illuminate

*

The power cord isnot

properlyconnected.

* Plug in the power cord to printer and outlet.

* Switch on the printer.

- The printer statusfrom

DiagTool indicates

“Head Open”.

- The LCD shows“Carriage

Open”.

*

The printer coveris open.

* Please close the print

cover.

- The printer statusfrom

DiagTool indicates “Ribbon

End Err.” Or “

Ribbon Encoder

Err.”

- The LCD shows “No Ribbon”.

* Running out of ribbon.

* The ribbon isinstalled

incorrectly.

* Installa new ribbonroll.

* Please refer to the steps on section 3.2 to

re-install theribbon.

- The printer statusfrom

DiagTool shows “Out

of Paper”.

- The LCD shows “NoPaper”.

* Running out oflabel.

* The label isinstalled

incorrectly.

* Gap/black mark sensor is not

calibrated.

* Install a new label roll.

* Please refer to the steps on section 3.3 to

re-install the labelroll.

* Calibrate the gap/black mark sensor.

- The printer status from

DiagTool shows “Paper Jam”.

- The LCD shows “PaperJam”.

* Gap/black mark sensor is not

setproperly.

* Make sure label size is set

properly.

* Labels may be stuckinside

the printermechanism.

* Calibrate the gap/black mark sensor.

* Set label sizecorrectly.

-

The LCD shows “Take Label”.* Peel-off function is enabled.

* If the peel-off module is installed, please

remove thelabel.

* If there is no peel-off module in front of the

printer, please switch off the printer and

installit.

* Check if the connector is plugging

correctly.

38

Page 44

Problem

Possible Cause

Suggested

Solution

Not

Printing

* Cable is not connected to

serial or USB interface or

parallelport correctly.

* The serial port cablepin

configuration is not pin to pin

connected.

* Re-connect cable to interface.

* If using serialcable,

- Please replace the cable with pin to pin

connected.

- Check the baud rate setting. The default baud

rate setting of printer is 9600,n,8,1.

* If using the Ethernet cable,

- Check if the Ethernet RJ-45 connector

green LED is lit on.

- Check if the Ethernet RJ-45 connector

amber LED is blinking.

- Check if the printer gets the IP address when

using DHCPmode.

- Check if the IP address is correct when using

the static IP address.

- Wait a few seconds let the printer get the

communication with the server then check the

IP

address setting again.

* Change a newcable.

* Ribbon and media are not compatible.

* Verify the ribbon-inkedside.

* Reload the ribbonagain.

* Clean the printhead.

* The print density setting isincorrect.

* Print head’s harness connector is not well

connected with printheat. Turn off the printer and

plug the connector again.

* Check your program if there is a command PRINT

at the end of the file and theremust have CRLF at

the end of each command line.

Memory

full

( FLASH / DRAM

)

*

The space of FLASH/DRAM

isfull.

* Delete unused files in the FLASH/DRAM.

* The max. numbers of DRAM is 256 files.

* The max. user addressable memoryspace of

DRAM is256KB.

* The max. numbers of file of FLASH is 256 files.

* The max. user addressable memoryspace of

FLASH is 2560KB.

microSD card

is unableto use

* microSD card isdamaged.

* microSD card doesn’t insert

correctly.

* Use the non-approved

microSD cardmanufacturer.

* Use the supported capacity microSDcard.

* Insert the microSD cardagain.

* The supported microSD card spec and the

approved microSD card manufacturers, please

refer to section2.2.3.

Poor Print

Quality

* Ribbon and media is loaded

incorrectly

* Dust or adhesive

accumulation on the print

head.

* Print density is notset

properly.

* Printhead element

is damaged.

* Ribbon and media are

incompatible.

* The printhead pressure is not

setproperly.

* Reload the supply.

* Clean the printhead.

* Clean the platenroller.

* Adjust the print density and print speed.

* Run printer self-test and check the print head

test pattern if there is dot missing in thepattern.

* Change proper ribbon or proper label

media.

* The print head mechanism does not latch the

print headproperly.

39

Page 45

Problem

Possible Cause

Suggested

Solution

Cutter is not

working

* The connector isloose.

* Cutterjam.

* Cutter PCB isdamaged.

* Plug in the connect cable correctly.

* Remove thelabel.

* Make sure the thickness of label is less

than 0.19mm.

* Replace a cutter driver ICboard.

Skip

labels whenprinting

* Label size is not specified

properly.

* Sensor sensitivity is not set

properly.

* The media sensor is covered

withdust.

* Check if label size is setup correctly.

* Calibrate the sensor by Auto Gap or

Manual Gapoptions.

* Clear the GAP/Black mark sensor by

blower.

The printing position of small

label isincorrect

* Media sensor sensitivity isnot

setproperly.

* Label size isincorrect.

* The parameter Shift Y in the

LCD menu isincorrect.

* The vertical offset setting in

the driver is incorrect.

* Calibrate the sensor sensitivity again.

* Set the correct label size and gap size.

* If using the software BarTender, pleaseset

the vertical offset in the driver.

Missing printing on the left

or

right side of

label

*

Wrong label sizesetup.

* Set the correct label

size.

RTC

time is incorrectwhen

reboot the

printer

*

The battery has run down.

* Check if there is a

battery on the main

board.

Wrinkle

problem

* Ribbon installation

is incorrect.

* Media installation is incorrect.

* Print density isincorrect.

* Media feeding isincorrect.

* Please set the suitable density to have

good print quality.

* Make sure the label guide touch the edge of

the mediaguide.

Gray

line on the blanklabel

* The print head isdirty.

* The platen roller is dirty.

* Clean the printhead.

* Clean the platenroller.

Irregular

printing

* The printer is in Hex Dump

mode.

* The RS-232 settingis

incorrect.

* Turn off and on the printer to skip the

dumpmode.

* Re-set the Rs-232setting.

40

Page 46

7. Maintenance

This section provides routine cleaning and maintenance procedures.

1. Please use one of following material to clean theprinter.

Cottonswab

Lint-freecloth

Vacuum / Blowerbrush

100%ethanol

2. The cleaning process is described asfollowing,

PrinterPart Method Interval

PrintHead

1.

Always switchoff the printer

before cleaning the printhead.

2.

Allow the print head to cool forat

least oneminute.

3.

Use a cotton swab and 100%

ethanol to clean the print head

surface.

Clean

the print head when changing anew

label

roll.

PlatenRoller

1.

Switch off the printer.

2.

Rotate the platen roller and wipe it

thoroughly with 100% ethanol and a

cotton swab, or lint-freecloth.

Clean

the platen roller when changing a

new label

roll

Tear Bar/PeelBar

Use

the lint-free cloth with 100%

ethanol to

wipeit.

As

needed

Sensor

Compressed

air orvacuum

Monthly

Exterior

Wipe it

with water-dampenedcloth

As

needed

Interior

Brush or

vacuum

As

needed

Note:

Do not touch printer head by hand. If you touch it, please use ethanol to clean it.

Please use 100% Ethenol. DO NOT use medical alcohol, which may damage the printerhead.

Regularly clean the print head and supply sensorsonce you change to a new ribbon, in order

to maintainthe printer‘s performance and extend the printer‘s life.

41

Page 47

Loading...

Loading...