Page 1

C1500 ORP or pH Controller

120V/240V

O WNER’S MANUAL

Page 2

IMPORTANT SAFETY INFORMATION

When installing and using this electrical equipment, basic safety

precautions should always be followed including the following:

READ AND FOLLOW ALL INSTALLATION INSTRUCTIONS.

Installation of this equipment should be performed by a licensed

electrician and conform to all National Electric Code (NEC),

state and local codes. Installations in Canada must comply to

CEC requirements.

WARNING:To reduce the risk of electrical shock:

• Turn off or disconnect the power source before installing,

opening the door, or adjusting the internal workings of

the controller.

• Install all electrical equipment at least 10 feet (3 m) from

inside wall of pool or spa.

• Connect this device only to a grounding-type receptacle

protected by a ground-fault circuit interrupter (GFCI).

• Do not use an extension cord, connect the controller

directly into the outlet. Do not bury the cord.

WARNING:To reduce risk of injury, do not permit children to use

this product unless they are closely supervised at all times.

For proper operation, it is imperative that the system has proper

flow past the sensors when the pool filtration system is running.

When automating a body of water, size the feeders so desired

levels can be attained in short operating cycles. If feeders are

unable to keep up with demand within a short time frame,

automation becomes ineffective.

Always test and adjust sanitizer and pH to acceptable levels

before activating a new system. Automated chemical controllers

are designed to maintain water chemistry, not balance the pool.

While the system is feeding, inaccurate sanitizer/pH levels may

be displayed because the system is still circulating the chemical.

ve precautions for electrostatic

Obser

.

vices

sensitiv

VE THESE INSTRUCTIONS.

SA

e de

Page 3

Table of Contents

Specifications

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Optional FlowCell/Flow Switch . . . . . . . . . . . . . . . . . . . . . .3

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Feed Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

System Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Controller Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

System Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Cleaning the Sensor Tips . . . . . . . . . . . . . . . . . . . . . . . . .14

Checking the ORP Sensor . . . . . . . . . . . . . . . . . . . . . . . .14

Checking the pH Sensor . . . . . . . . . . . . . . . . . . . . . . . . . .15

Winterizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Page 4

Specifications

pH Control Range: 7.0 to 8.0

ORP Control Range: 200 to 900

Input Power: • 120 VAC 50/60 Hz, GFCI source required

• 240 VAC 50/60 Hz capable

• 8A fuse for 120V, 4A fuse for 240V

Controller Power: Less than .5 amp internally fused

Output Power: • 120 VAC 50/60 Hz

• 240 VAC 50/60 Hz capable

• 8A fuse for 120V, 4A fuse for 240V

Display: LCD, 2-line character display

Operating Temp: 40 - 120° F

Sensors: • pH: glass combination with 10' cable

• ORP: platinum combination with 10' cable

Inputs: ORP & pH sensors; BNC connectors

Flow detection

Outputs: • ORP/pH Feeder - High Voltage

120 VAC 50/60 Hz (with 120V input)

240 VAC 50/60 Hz (with 240V input)

8A fuse for 120, 4A fuse for 240 on-board

• ORP/pH Feeder – Low Voltage, 24V

Page 5

Introduction

O

R

P

p

H

2

3

ENTER

1

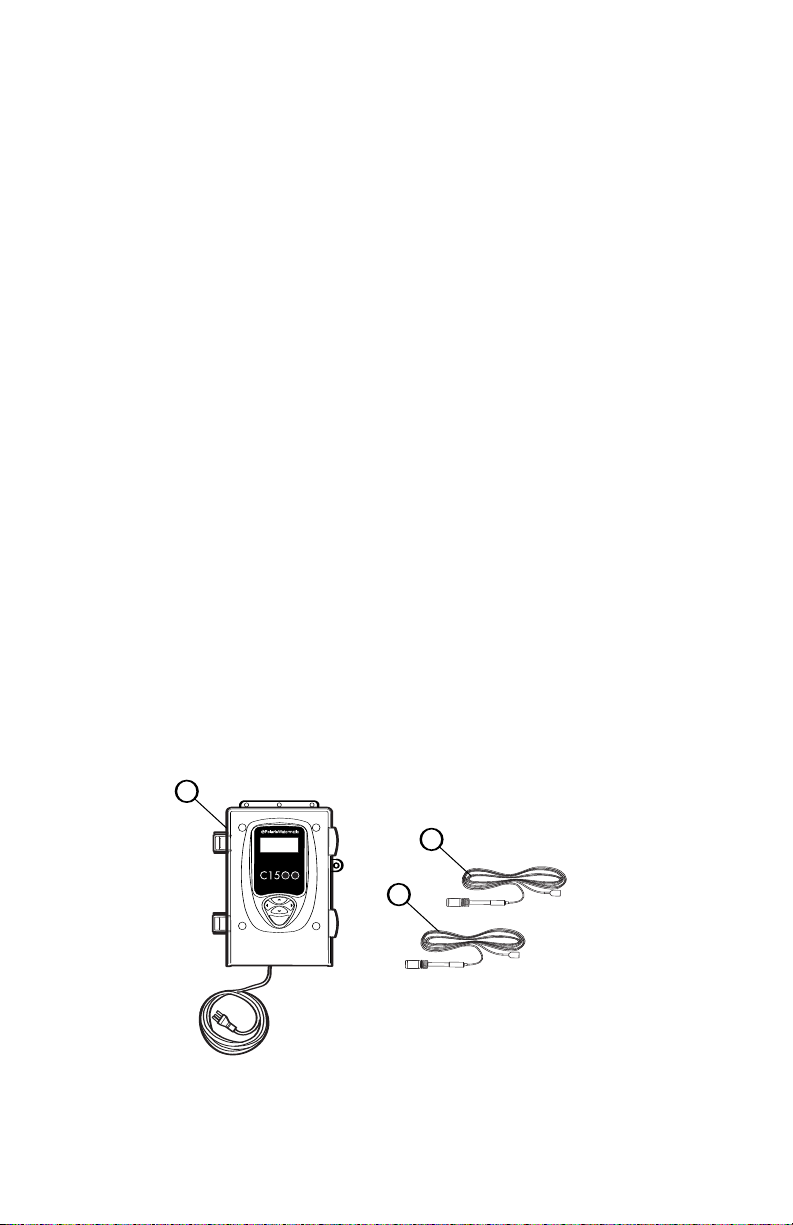

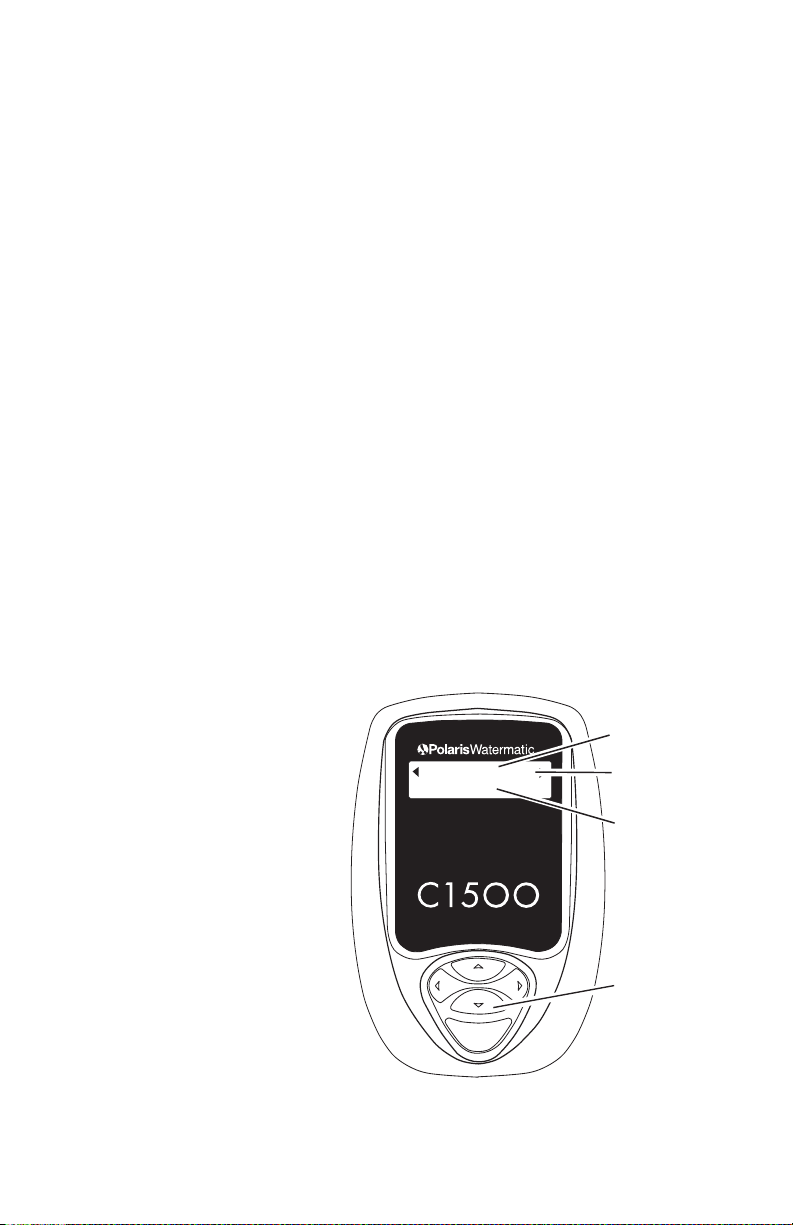

Chemical Automation System

Congratulations on the purchase of your new ORP/pH controller

and thank you for choosing Polaris. The Polaris Watermatic

C1500 Controller automatically monitors and maintains either

the sanitizer level or the pH balance in swimming pools, spas, or

any circulating water system that requires water chemistry

management. Designed for easy installation and simple

operation, it can be used with liquid feed pumps, granular

feeders, tablet erosion feeders, and ozone generators. It is not

warranted or recommended for use with chlorine gas systems.

During the filtration cycle, the controller maintains sanitizer

levels or pH balance by constantly measuring the OxidationReduction-Potential (ORP) and pH balance of the water. If the

sanitizer level (ORP) or pH falls below a predetermined set

point, the controller activates the chemical feeder.

Settings and measurements are displayed on an easy-to-read

LCD text screen and adjustments are made via a touch key pad.

Watermatic C1500 Components

1. C1500 ORP/pH Controller

2. ORP Sensor

3. pH Sensor

2

Page 6

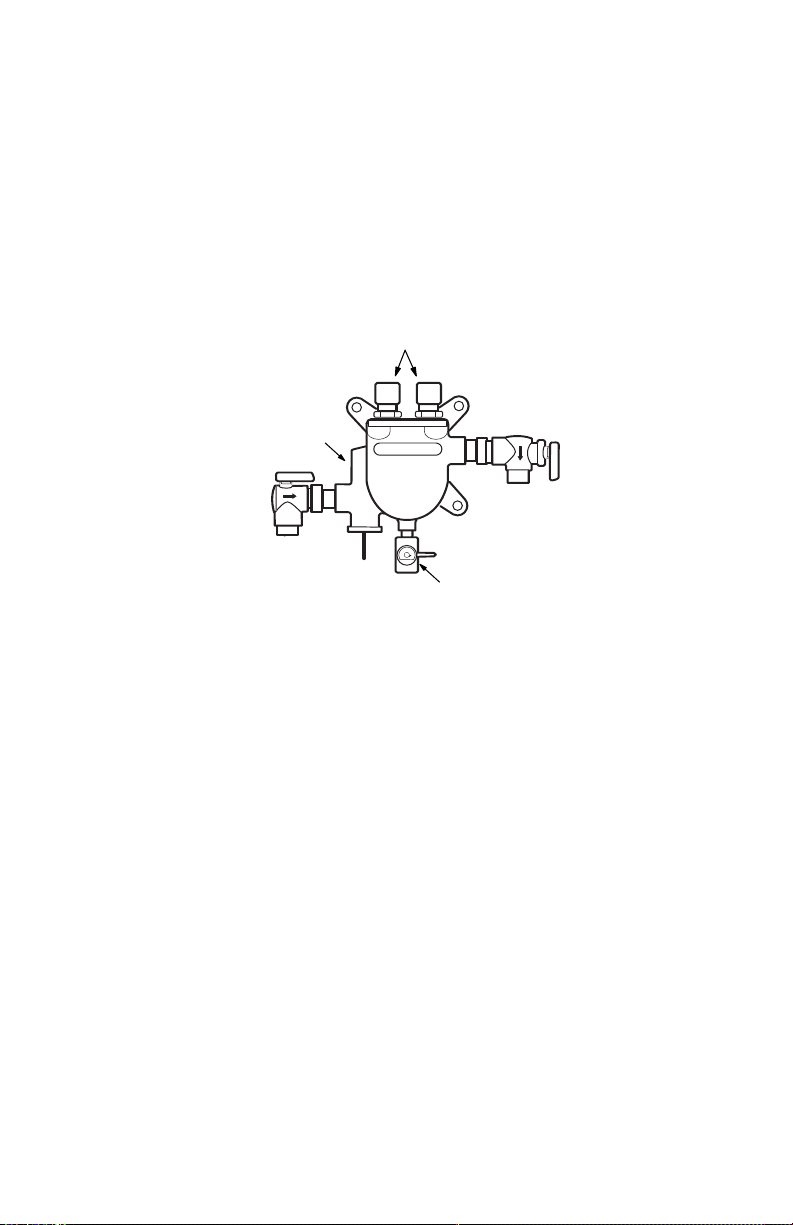

Optional Flow Cell/Flow Switch Assembly

Sample

Port

Compression Fittings

for Sensors

Flow Switch/

Flow Indicator

The flow cell houses the sensors and provides a sample port

for manual testing. It also contains an integrated flow switch/flow

indicator that prevents the feeder from feeding if there is

insufficient flow. If flow is insufficient, a warning message will

appear on the screen.

Contact an authorized Polaris dealer to order, part #9-700.

3

Page 7

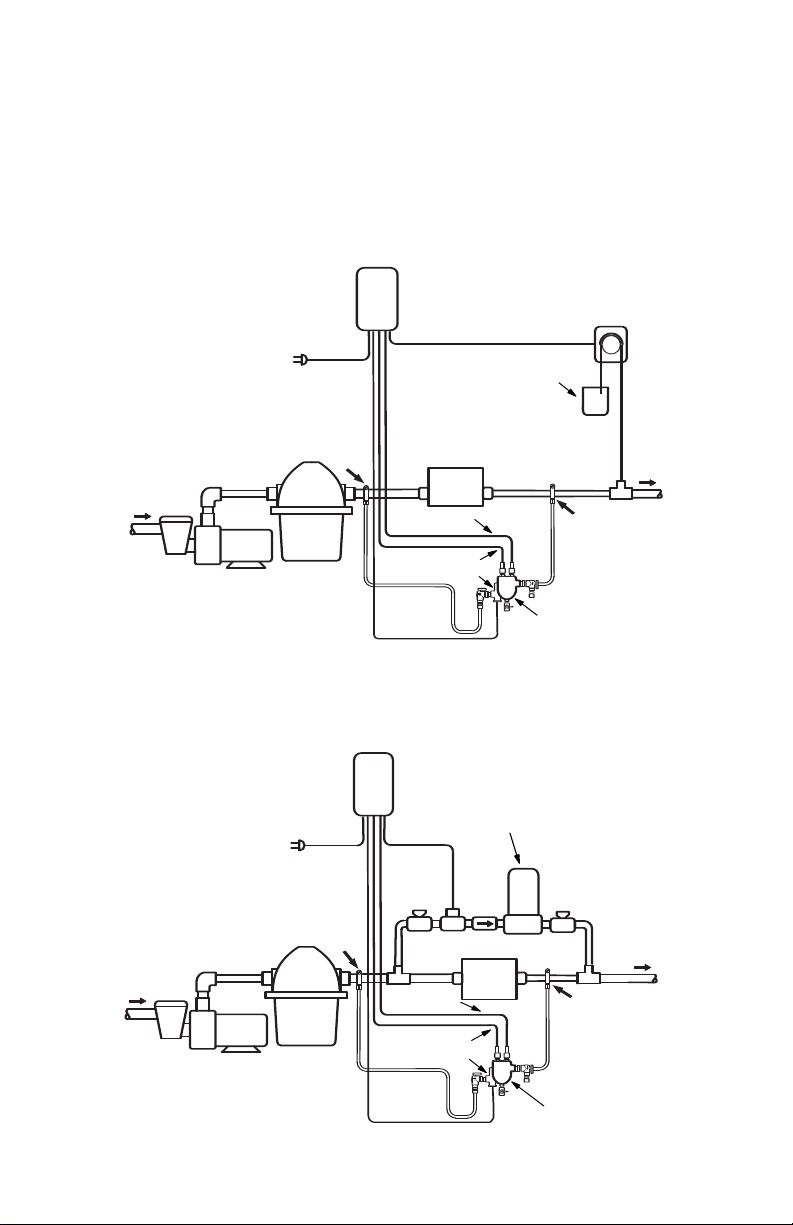

Installation

Feed Pump

B

A

From

Pool

Optional

Flow Cell

pH Sensor

ORP Sensor

Filter

Heater

Pump

120/240 VAC

GFCI Receptacle

To

Pool

Chemical

Tank

Controller

Flow Switch

B

A

From

Pool

Optional

Flow Cell

pH Sensor

ORP Sensor

Filter

Heater

Pump

To

Pool

Controller

Check

Valve

24V Solenoid

Valve

Flow Switch

Erosion

Feeder

120/240 VAC

GFCI Source

Install the chemical pump and erosion feed systems as shown.

If the model differs from these systems, refer to the installation

manual provided with it for the appropriate installation methods.

Liquid Feeder

If using an acid feed system, the insertion point must be down

stream of all equipment.

Erosion Feeder

4

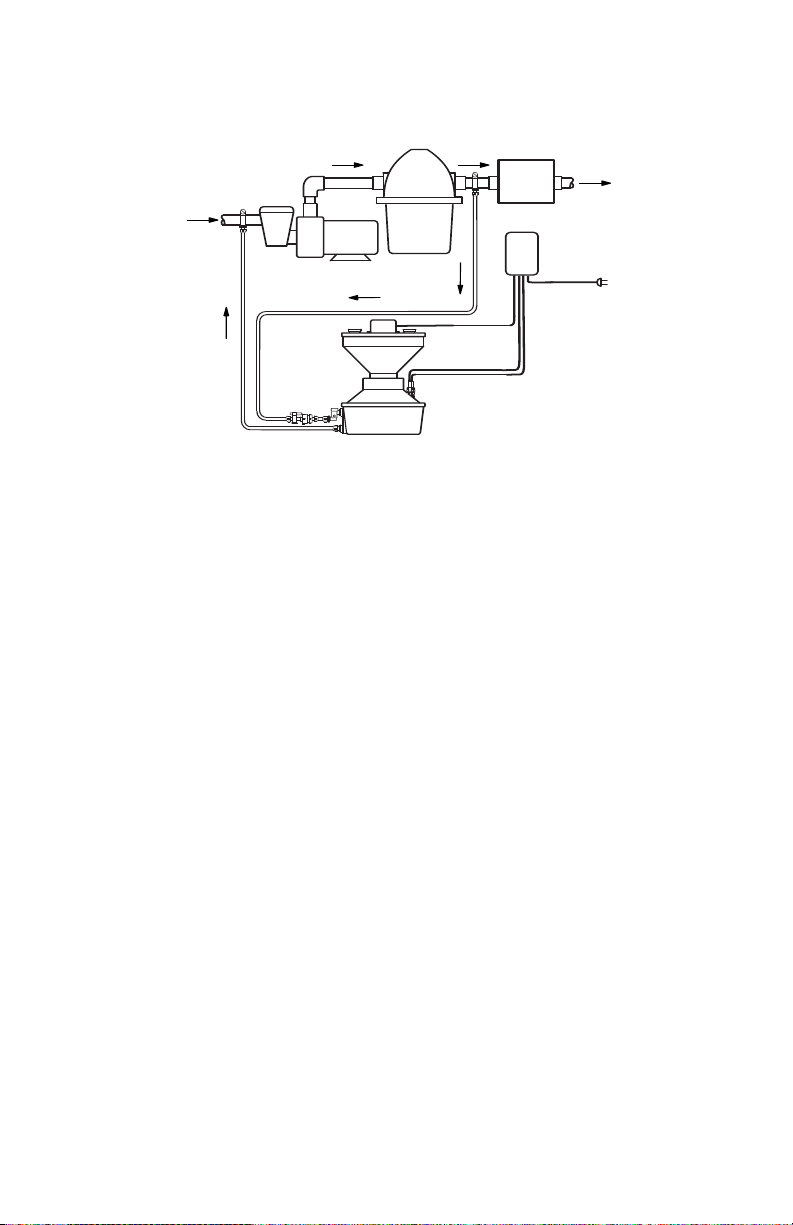

Page 8

ORP

pH

Pump

Hopper

Tank

Heater

Controller

Filter

To

Pool

From

Pool

WATERMATIC

G1000

Heater

120/240 VAC

G

FCI Source

Granular Feeder

Do not install granular feeders below the pool water level.

Controller Installation

Before installing the controller, do a site assessment to consider

where and how you will mount the unit. The controller should be

mounted on a wall or other flat surface within eight feet of the

feeder, at least ten feet away from the edge of the water and

within six feet of the GFCI power source. Use mounting screws

or anchors to mount the controller.

5

Page 9

Sensor Installation

Controller

Compression

Fitting

Sensor Tip

ENTER

Chemical Automation System

ORP

OR

P

OR

P

Sensors

with

O-rings

Controller

Compression

Fitting

PVC Tee

Sensor Tip

ORP

ENTER

C

hemical Automation System

Unpack the sensors and remove the protective bottle and

o-rings. Set aside the o-rings. Save the bottles for winterizing

or reshipping.

Flow Cell

Remove the compression fitting

nut from the flow cell and slide it up

onto the sensor. Slide o-ring from

the bottle onto the sensor. Insert

the sensor into the compression

fitting on the flow cell assembly.

The sensor tip should extend below

the water line in the flow cell.

Granular Feeder

Insert the sensors with the o-rings

into the holes on the feeder tank.

The sensor tips should be covered

with at least 1" of water.

In-line

Install 1/2" female threaded PVC

tee into the return line. Screw the

compression fitting into the tee.

Slide an o-ring onto the sensor.

Insert sensor with o-ring into the

fitting. Sensor tip should be below

the water line in the pipe.

Hand-tighten the nuts of the compression fittings, do not use

a wrench. Route sensor cables to the controller, coiling extra

cable externally, not in the controller box.

6

Page 10

Electrical Connections

Grommets

Wire Clamp

For SMALL

Diameter

Cables:

Bend grommet

to open slot

For LARGE

Diameter

Cables:

Tear out grommet center

Controller

Housing

Sensors

BNC Connections

Flow

Switch

Wire

Clamp

Grommet

120/240V Output

to Feeder

24V Output

to Feeder

To complete electrical connects:

1. Ensure power is disconnected. Open the controller door.

2. Remove the wire clamp.

3. Strip wire leads (maximum of 3/8") from ORP and pH

feeders. To facilitate wire hook-up, remove output terminal

block from circuit board. Attach feeder AC output leads to

terminal block. Note the orientation of the leads (ground, line

and neutral). Reinstall terminal block.

4. If using a Flow Cell, remove the jumper on the Flow terminal

block and attach leads from the Flow Switch to the terminal.

5. Attach the pH and ORP sensor BNC connectors to the board.

6. Route connections through housing grommets using the

appropriate grommet for the wire size.

7. Reinstall wire clamp and close the door.

7

Page 11

Operation

ENTER

Key Pad

Current ORP

Chemical Automation System

ORP 600 OK

pH 7.8

Current pH

Status

System Startup

Do not add chemicals to the feeder until completing the following

startup operations.

1. Use a DPD test kit and fresh phenol red solution to test the

water’s sanitizer level and pH, then manually adjust the

water to acceptable levels.

2. With the controller power off, turn on the filter pump to check

for leaks and proper flow.

3. Plug controller power cord into GFCI receptacle. The LCD

display screen should illuminate.

3. Review controller displays and set the controller functions.

Adjust the defaults, if necessary, to match the application.

Controller Displays

ORP and pH measurements and settings are displayed on the

controller’s LCD screen. Adjustments to settings are made with

the key pad. Use the left and right arrow keys to move through

the screens and the up or down keys to adjust the settings.

Main Screen

The Main screen shows

the current ORP and pH

readings, and a status

message.

The status messages

are: “Feeding” when

chemical is being

dispensed, “OK” when

sensor readings match

the desired levels, no

display or blank during

a feed delay cycle or

an alert notice.

8

Page 12

Feed ORP or pH

Feed ORP or pH

ORP

Feeder Type

Granular

Feed Time

5 sec

Feed Delay

10 min

Configures the controller as

either an ORP feeder or a

pH feeder. Only one may

be selected.

Feeder Type

Specifies the type of feeder

being used. Depending on the

feeder selected, Feed Time and

Feed Delay settings will change

to the feeder specific defaults

outlined in the Appendix.

Types of feeders available:

• Granular

• Liquid (Use for Ozone generators)

• Erosion HP (line voltage) solenoid

• Erosion LP (24V) solenoid

Acid/Base

Displayed only if ”Feed pH” is chosen. Designates whether the

controller maintains the pH below the set point (acid) or above

the set point (base).

Feed Time

Designates the amount of time

the feeder is activated.The

preset defaults for specific

feeder types (see Appendix)

can be adjusted as necessary.

Feed Delay

Designates a minimum time

between feeding. This option is

ed if “Continuous”

not displa

feed is selected. All feeders

def

be adjusted from 1-99 min

y

ault to 10 minutes but can

utes

.

9

Page 13

Overfeed

Overfeed

99 min

Manual Feed

Press Enter

ORP 600 Feeding

pH 7.8

Audible Alarm

On

Displays only when Feed Time

is set to "Continuous." Sets a

maximum feed time to prevent

overfeeding caused by an

empty chemical tank or tubing

leak. Defaults to 99 minutes, but

is selectable from 1-99 minutes.

Manual Feed

Activates either the ORP or

pH feeder to facilitate testing

of connections and feed cycles.

To manually feed, press the

<Enter> key.

When manually feeding, the

Main screen will display a

“feeding” status message.

Audible Alarm

Toggles the controller’s

internal audible alarm

on or off.

The alarm sounds and an

alert message is displayed

on the screen for the following

circumstances:

High Alert - When ORP is above 900 or pH is above 8.0 for ten

consecutive minutes.

Low Alert - When ORP is below 200 or pH below 7.0 for ten

consecutive minutes.

When the alert condition is corrected, the controller will wait ten

minutes then automatically clear the alert. After a two-minute

delay, it will activate the feeder as needed.

witch is installed and there is insufficient flow

w cell/flo

If a flo

er the sensors

v

o

w s

, a

No Flowaler

t will be signaled on the screen.

10

Page 14

ORP or PH Setpoint

ORP Setpoint

600

PH Calibration

7.5 Press Enter

PH Setpoint

7.5

Designates the desired level of sanitizer (ORP) or pH depending

on feeding system.

Feed ORP

Set ORP to any value between

200 and 800, in increments of

10. The default is 600.

Feed pH

Set pH to any value between

7.0 and 8.2, in increments of

0.1 pH. The default is 7.5.

The controller displays direct ORP readings and the control is

based on this reading, not parts per million (ppm). While ORP

indicates the effectiveness of the sanitizer, it does not directly

correlate to a ppm reading. Use a DPD test kit to measure the

free chlorine. If you need more or less sanitizer, adjust the set

point up or down accordingly.

Note: The ORP reading is not linear. An adjustment from 700

to 750 could increase the sanitizer level by several ppm. The

World Health Organization suggests maintaining an ORP at

or above 650.

Calibration

Allows user to adjust the pH

sensor reading to match the

actual pH of the water.

To calibrate the pH, check

the pH of the water at the

probe location using a high-quality manual test kit with fresh

phenol red solution. If the pH reading on screen is different

than the actual, use the up/down curser to select the proper pH.

Press <Enter> to save the entry. Using the left/right arrow key,

return to the Main screen and verify that pH displays accurately.

11

Page 15

System Operation

When system setup is complete:

1. Fill feeder with chemical.

2. Turn on the pool circulation system. A 2-minute delay at

startup allows air to be purged from the feeders and the

sensors to stabilize.

3. Manually feed one cycle to ensure proper operation. ORP

or pH feed messages (“Feeding,” “OK,” blank or an alert) will

display under Status.

4. Allow the system to operate for a few days. With the filtration

system running, retest the levels and adjust the set points

if necessary.

To place the controller in

control, sensing, etc. but power is still on) press and hold the

<Enter> key for five seconds. Press any key to reactivate.

To service the controller, unplug the controller to disconnect

the power.

Standby Mode (disables feeder

12

Page 16

13

Page 17

Maintenance

Cleaning the Sensor Tips

Clean the sensor tips once a month to ensure accurate

readings. When dirty, the sensors can read a lower than actual

sanitizer/pH level and can cause too much sanitizer/pH to

be dispensed.

Note: A sensor tip coated with calcium scale will not look dirty.

To clean the sensor tip.

1. Turn off the controller. Turn off the filtration system or close

the valves to isolate the sensor.

2. Remove the sensor from the compression fitting.

3. Swirl the tip for five seconds in muriatic acid (diluted 5 to 1)

or white vinegar and rinse it in water. Do not touch, wipe or

brush the end of the sensor. For commercial pools and

spas, every third cleaning, swirl the sensor tip in a solution

of liquid soap and water. Rinse with water.

4. Reinstall the sensor and turn on the controller.

5. Allow the controller to operate for a few minutes to get an

accurate reading. Adjust the setting if necessary.

Checking the ORP Sensor

The ORP sensor should be checked every six months or

anytime the feeder oversanitizes the water.

1. Clean the sensor tip.

2. Put the sensor in a clean glass of tap water.This should give

a reading of between 200 and 400. Adding a pinch of

Dichlor or Trichlor should cause the ORP level to jump

to between 750 and 800. If Dichlor or Trichlor are not

available and a sanitizer with a high pH such as calcium

hypochlorite or liquid chlorine (sodium hypochlorite) is used,

the ORP level may only rise to between 650 and 750.

3. If the sensor does not respond as indicated, the sensor

should be replaced.

14

Page 18

Checking the pH Sensor

The pH sensor should be checked every six months or anytime

the pH goes out of range.

1. Clean the sensor.

2. Place the sensor in a clean glass of tap water. Add a small

amount of acid to the glass. The pH reading should drop.

Place the sensor in any solution with a pH above 7.5.The

pH reading should rise.

3. If the sensor does not respond as indicated, the sensor

should be replaced.

Winterizing

If the system is subject to extended shutdowns or is located in

colder climates, it is important to winterize the system.

1. Turn off the main power to the controller.

2. Gently remove the sensors and store them in a protective

cap or bottle filled with a liquid solution of one teaspoon salt

and three teaspoons water. Mix the solution thoroughly and

make sure the solution completely covers the tip of the

sensors. Store the sensors in a warm place. Do not expose

sensors to freezing temperatures.

3. If installed, drain the water from the flow cell/flow switch.

15

Page 19

Warranty

Polaris Watermatic C1500 ORP or pH Controller

This limited warranty is extended to the original consumer

purchaser of this Polaris Watermatic Controller manufactured by

Polaris Pool Systems, Inc. ("Polaris"), 2620 Commerce Way,

Vista, CA 92081-8438, USA.

Polaris warrants the Watermatic Controller, including all parts

and components thereof, to be free of defects in material and

workmanship. For questions regarding your Polaris Watermatic

Controller, please call or write us. Be sure to provide the serial

number of your unit.

The warranty commences on the date of installation of the

controller and shall remain in effect for a period of one (1) year

from the date of purchase as established by proof of purchase or

two (2) years from the date of manufacture of the controller as

established by the serial number, whichever is earlier.

This limited warranty does not apply if the failure is caused or

contributed by any of the following: improper handling, improper

storage, abuse, unsuitable application of the unit, lack of

reasonable and necessary maintenance, winter freezing or

repairs made or attempted by other than Polaris or one of its

Authorized Service Centers. Polaris will repair or replace, at its

option, a unit, part or component proved to be defective within

the warranty period and under the conditions of the warranty.

Unless local repair is authorized, the consumer must deliver or

ship the unit or the warranted parts or components, freight

prepaid to the nearest Polaris Authorized Service Center or

return it freight prepaid (after proper authorization) to the plant of

manufacture. Authorization to return a unit to the plant of

manufacture must be obtained from the Polaris Customer

Service Department. For your convenience, please check with

your dealer for the local procedure before exercising this

If further directions or instructions should be required,

.

anty

arr

w

contact the Customer Service Department at 1-800-VACSWEEP (USA and Canada only) or 760-599-9600. Be sure to

insure y

our shipments against loss or damage during transit.

16

Page 20

Polaris is not responsible for the cost of removal of the unit,

damages occurring during removal or due to removal, any other

expenses incurred in shipping the unit or parts to or from the

factory or its Authorized Service Centers, or the installation of

the repaired or replacement unit. The consumer must bear these

expenses. This warranty does not cover repair of a unit except at

our factory or a Polaris Authorized Service Center.

REPAIR OR REPLACEMENT AS PROVIDED UNDER THIS

LIMITED WARRANTY IS THE EXCLUSIVE REMEDY OF THE

CONSUMER. THIS LIMITED WARRANTY IS IN LIEU OF ALL

OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING

THE IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE, AND ALL SUCH

OTHER WARRANTIES ARE DISCLAIMED EXCEPT TO THE

EXTENT ANY IMPLIED WARRANTY MAY BE IMPOSED BY

STATE CONSUMER LAW. ANY SUCH IMPLIED WARRANTY

IMPOSED BY STATE CONSUMER LAW IS LIMITED IN

DURATION TO ONE (1) YEAR FROM DATE OF PURCHASE. IN

NO EVENT SHALL POLARIS BE LIABLE FOR INCIDENTAL

OR CONSEQUENTIAL DAMAGES OF ANY NATURE OR KIND

OR FOR DAMAGES TO PERSONS OR PROPERTY,

INCLUDING ANY DAMAGE RESULTING FROM THE USE OF

THE POLARIS WATERMATIC CONTROLLER. THE ONLY

REMEDY PROVIDED TO YOU UNDER AN APPLICABLE

IMPLIED WARRANTY AND THE LIMITED WARRANTY SET

FORTH ABOVE SHALL BE THE REMEDIES EXPRESSLY

PROVIDED FOR UNDER THIS LIMITED WARRANTY.

This limited warranty gives you specific legal rights. You may

also have other rights that may vary from state to state. Some

states do not allow limitations on how long an implied warranty

lasts, or the exclusion or limitation of incidental or consequential

damages, so the above limitations may not apply to you.

This limited warranty is valid only in the United States of

America and Canada, and it does not apply to Polaris

Watermatic Controllers sold or installed in any other country.

17

Page 21

Appendix

Feed Times and Delay Times

When the ORP or pH feeder type is specified during setup, the

Feed Time and Delay Time settings change to the feeder

specific defaults listed below. The options listed are available to

customize for the specific application.

After allowing the system to run for a few days, adjust the ORP

or pH settings as needed. Lengthen the feed cycle if the water is

undersanitized or shorten it if the water is oversanitized. Shorten

the delay time if the feeder cannot keep up with demand.

ular Feeder

Gran

Feed Time Delay Time Overfeed

(Min.) (Min.)

Options 0.5, 1, 2, 3, 4, 5 Sec. 1 – 99 N/A

Defaults 5 Sec. 10

Liquid Feeder (Use for ozone generators)

Feed Time Delay Time Overfeed

(Min.) (Min.)

Options Continuous Off 1 - 99

5, 10, 15, 20, 30 Sec. 1 - 99 Off

1, 2, 3, 4, 5, 10, 15 Min.

Defaults 10 Min. 10 Off

Erosion Feeder

Feed Time Delay Time Overfeed

(Min.) (Min.)

Options: Continuous Off 1 - 99

5, 10, 15, 20, 30 Sec. 1 - 99 Off

1, 2, 3, 4, 5, 10, 15 Min.

Default 10 Min 10 Off

Erosion LP = Low power (24V) solenoid

Erosion HP = High po

wer (line voltage) solenoid

18

Page 22

Alerts and Alarms

The following alert conditions will sound the audible alarm:

• High PH Alert

• Low PH Alert

• High ORP Alert

• Low ORP Alert

• PH Overfeed

• ORP Overfeed

The following alert conditions will not sound the Alarm:

• No Flow

• 2-Minute Flow Delay

19

Page 23

Page 24

©2006 Polaris Pool Systems, Inc. All rights reserved. TL-448 6/06

Loading...

Loading...