Page 1

Instruction Manual

CONTENT

COMMERCIAL GAS WATER HEATERS

POWER DIRECT VENT GAS MODELS

WITH DIRECT SPARK IGNITION

MODELS

PGC/SPC/BSS/BTS

Series 200, 201

NATURAL GAS & PROPANE

LOW LEAD

WARNING: If the information in these

instructions is not followed exactly, a fire

or explosion may result causing property

damage, personal injury or death.

Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS:

Do not try to light any appliance.

•

Do not touch any electrical switch; do

•

not use any phone in your building.

Immediately call your gas supplier

•

from a neighbor’s phone. Follow the

gas supplier’s instructions.

If you cannot reach your gas supplier,

•

call the fire department.

Installation and service must be

performed by a qualified installer,

service agency or the gas supplier.

Thank you for buying this energy efcient water heater.

We appreciate your condence in our products.

ALL TECHNICAL AND WARRANTY QUESTIONS: SHOULD BE DIRECTED TO THE LOCAL DEALER FROM WHOM THE WATER HEATER WAS

PURCHASED. IF YOU ARE UNSUCCESSFUL, CALL THE TECHNICAL SUPPORT PHONE NUMBER SHOWN ON THE WATER HEATER LABELING.

KEEP THIS MANUAL IN THE POCKET ON HEATER FOR FUTURE REFERENCE

WHENEVER MAINTENANCE ADJUSTMENT OR SERVICE IS REQUIRED.

PRINTED 1216 100277192

• For Your Safety •

AN ODORANT IS ADDED TO THE GAS USED

BY THIS WATER HEATER.

1

Page 2

TABLE OF CONTENTS

SAFE INSTALLATION, USE AND SERVICE.................................3

APPROVALS .................................................................................3

GENERAL SAFETY INFORMATION .............................................4

Precautions ..............................................................................4

Grounding Instructions .............................................................4

INSTALLATION REQUIREMENTS FOR MASSACHUSETTS

INTRODUCTION ...........................................................................8

Abbreviations Used ..................................................................8

Qualications ............................................................................8

Preparing For The Installation ..................................................8

DIMENSIONS AND CAPACITY DATA ...........................................9

Rough In Dimensions: All Models .............................................9

FEATURES AND COMPONENTS ..............................................11

34 Gallon Unit .........................................................................11

50 Gallon Unit .........................................................................12

Controls And Switches ...........................................................14

INSTALLATION CONSIDERATIONS ..........................................15

Locating The Water Heater ....................................................15

Insulation Blankets .................................................................16

Combustion Air And Ventilation ..............................................16

Corrosion and Water Quality ..................................................16

INSTALLATION REQUIREMENTS .............................................17

Gas Supply Systems ..............................................................17

Supply Gas Regulator ............................................................17

Power Supply .........................................................................17

Mixing Valves..........................................................................18

Circulation Pumps ..................................................................18

Dishwashing Machines ...........................................................18

Space Heating And Potable Water System ............................19

Storage Tank Installation ........................................................19

Solar Installation .....................................................................19

Closed Water Systems ...........................................................19

Thermal Expansion ................................................................19

Temperature-Pressure Relief Valve ........................................20

Condensate Drain ..................................................................21

VENTING INSTALLATION ..........................................................22

Vent Installation Considerations .............................................22

General Venting Instructions ..................................................22

Approved Vent/Intake Material ...............................................22

Polypropylene Installations .....................................................23

Vent Pipe Termination.............................................................23

Planning The Vent System .....................................................23

Integrated Filter Installation ....................................................24

Direct Vent Air Intake Moisture Protection ..............................25

Horizontal Vent Terminal Installation ......................................25

Vertical Vent Terminal Installation ...........................................26

Termination Clearances Sidewall Direct Vent .........................27

.........7

Direct Vent Installation Diagrams ...........................................28

Concentric Vent Installation ....................................................29

Venting Multiple Units .............................................................30

WATER HEATER INSTALLATION ...............................................31

Condensate Drain Installation ................................................31

Supply Gas Line Installation ...................................................31

Gas Line Leak Testing ............................................................32

Purging ...................................................................................32

Electrical Wiring ......................................................................33

Water Line Connections .........................................................33

T&P Valve Discharge Pipe .....................................................34

TEMPERATURE REGULATION .................................................35

High Temperature Limit Control (ECO)...................................35

Thermostat Control .................................................................35

CONTROL SYSTEM OPERATION .............................................36

Overview ................................................................................36

Control System Navigation .....................................................36

User Settings & Control System Menus .................................39

START UP ...................................................................................44

Start Up Conditions ................................................................44

Prior to Start Up ......................................................................44

Filling the Water Heater ..........................................................44

Initial Start Up .........................................................................45

LIGHTING THE WATER HEATER ..............................................46

Lighting & Operation Labels ...................................................46

Checking the Firing Rate ........................................................47

Gas Input Rate .......................................................................47

High Altitude Installations .......................................................47

TROUBLESHOOTING ................................................................48

Installation Checklist ...............................................................48

Sequence Of Operation ..........................................................48

Sequence Of Operation Flow Chart .......................................49

Operational Problems .............................................................50

Fault And Alert Conditions ......................................................51

LEAKAGE CHECKPOINTS .........................................................53

PERIODIC MAINTENANCE ........................................................54

Venting System Inspection .....................................................54

Ingegrated Filter Preventative Maintenance ...........................54

Temperature-Pressure Relief Valve Test ................................54

Draining and Flushing ............................................................55

Service ...................................................................................55

DIAGRAMS .................................................................................56

CCB-Central Control Board Layout ........................................56

Wiring Diagram .......................................................................57

Circulation Pump Wiring Diagrams ........................................58

Piping Diagrams .....................................................................59

NOTES ........................................................................................61

2

Page 3

SAFE INSTALLATION, USE AND SERVICE

CONTENT

The proper installation, use and servicing of this water heater is extremely important to your safety and the safety of others.

Many safety-related messages and instructions have been provided in this manual and on your own water heater to warn you and

others of a potential injury hazard. Read and obey all safety messages and instructions throughout this manual. It is very important

that the meaning of each safety message is understood by you and others who install, use, or service this water heater.

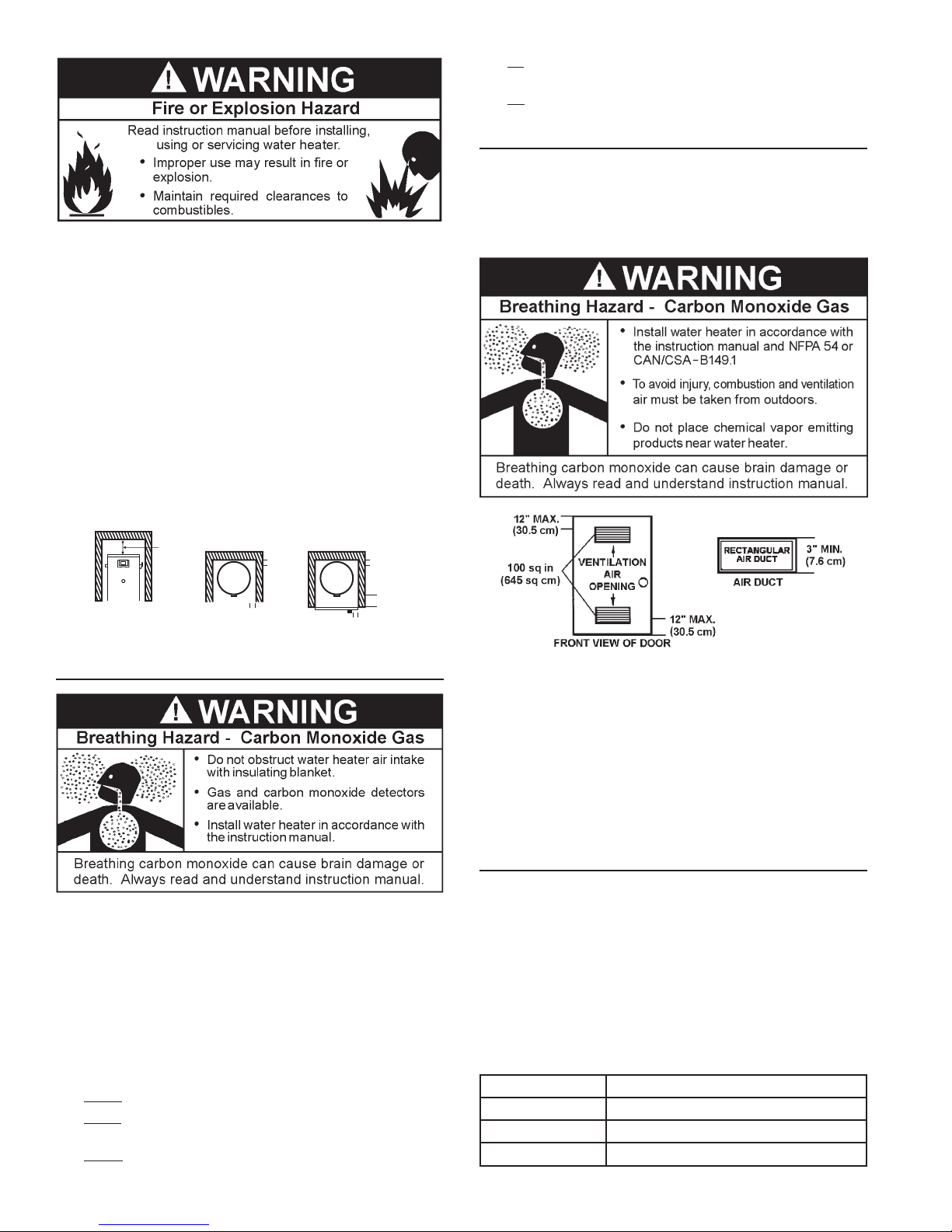

This is the safety alert symbol. It is used to alert you to

potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible

injury or death.

DANGER indicates an imminently

DANGER

WARNING

CAUTION

hazardous situation which, if not avoided,

will result in injury or death.

WARNING indicates a potentially hazardous

situation which, if not avoided, could result

in injury or death.

CAUTION indicates a potentially hazardous

situation which, if not avoided, could result in

minor or moderate injury.

CAUTION used without the safety alert

CAUTION

All safety messages will generally tell you about the type of hazard, what can happen if you do not follow the safety message, and

how to avoid the risk of injury.

symbol indicates a potentially hazardous

situation which, if not avoided, could result in

property damage.

APPROVALS

LOW LEAD

3

Page 4

CAUTION

GENERAL SAFETY INFORMATION

PRECAUTIONS

DO NOT USE THIS W ATER HE ATER IF ANY PART HAS

BEEN EXPOSED TO FLOODING OR WATER DAMAGE.

Immediately call a qualified service technician to inspect

the water heater and to make a determination on what steps

should be taken next.

If the unit is exposed to the following, do not operate heater

until all corrective steps have been made by a qualied service

technician.

1. External re.

2. Damage.

3. Firing without water.

Verify the power to the water heater is turned off before performing any service procedures.

The Enable/Disable switch at the base of the water heater disables the 24 volt gas control valve.

Electrical supply must be turned off at circuit breaker serving water heater.

GROUNDING INSTRUCTIONS

This water heater must be grounded in accordance with the National

Electrical Code and/or local codes. These must be followed in all

cases. Failure to ground this water heater properly may also cause

erratic control system operation.

This water heater must be connected to a grounded permanent

wiring system; or an equipment grounding conductor must be

run with the circuit conductors and connected to the equipment

grounding terminal or lead on the water heater.

Read and understand this instruction

manual and the safety messages

herein before installing, operating or

servicing this water heater.

Failure to follow these instructions and

safety messages could result in death

or serious injury.

This manual must remain with the

water heater.

Water temperature over 125°F (52°C)

can cause severe burns instantly

resulting in severe injury or death.

Children, the elderly and the

physically or mentally disabled are at

highest risk for scald injury.

Feel water before bathing or

showering.

Temperature limiting devices such as

mixing valves must be installed

when required by codes and to

ensure safe temperatures at fixtures.

Explosion Hazard

Overheated water can cause

water tank explosion.

Properly sized Te mperaturePressure Relief Valve must be

installed in the opening provided.

Improper installation, use and service may result

in property damage.

Do not operate water heater if exposed to flooding or water

•

damage.

Install in location with drainage.

•

Fill tank with water before operation.

•

Properly sized thermal expansion tanks are required on all

•

closed water systems.

Refer to this manual for installation and service.

4

Page 5

GENERAL SAFETY INFORMATION

5

Page 6

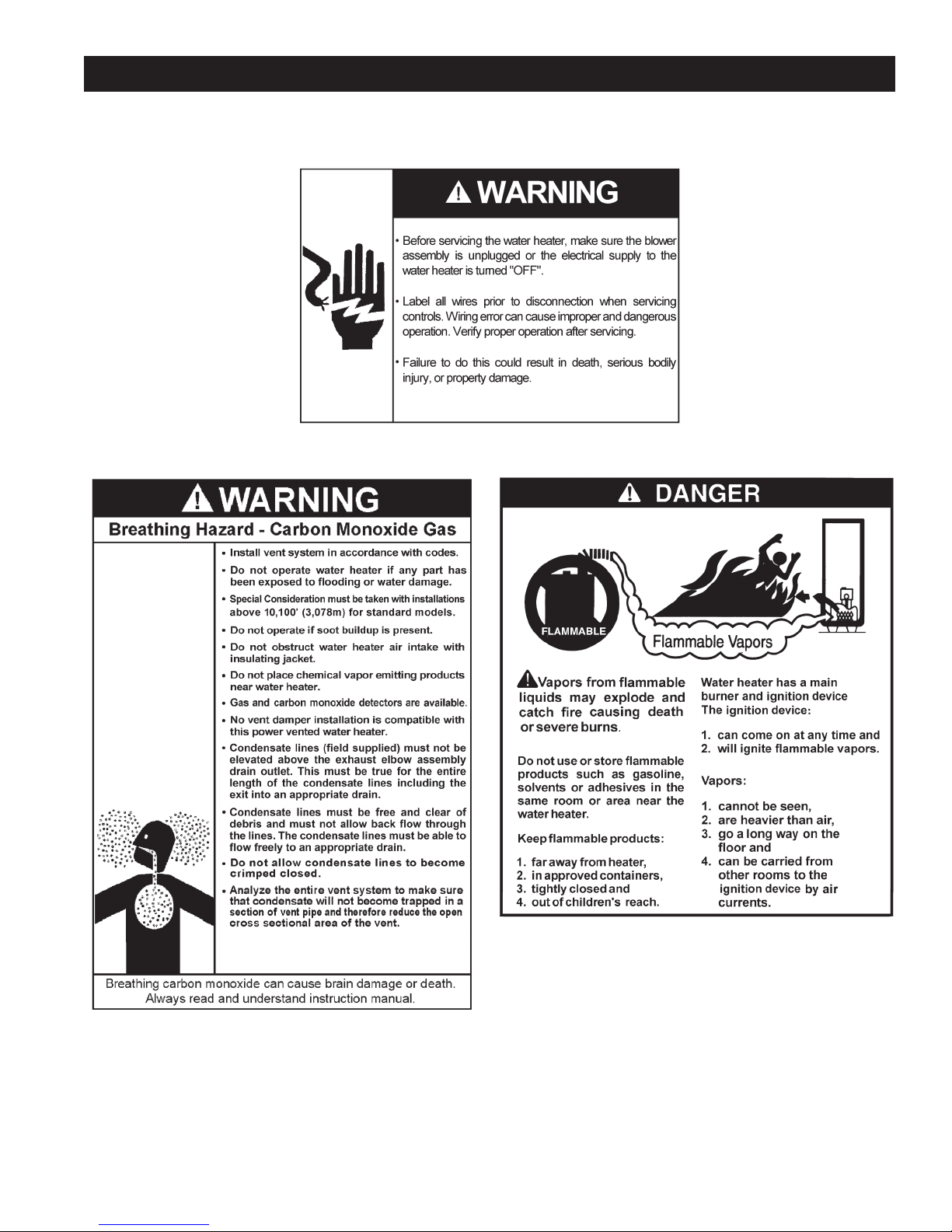

Fire or Explosion Hazard

Read instruction manual before

installing, using or servicing

water heater.

Avoid all ignition sources if you smell gas.

Do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance.

Use only the gas shown on the water heater rating plate.

Keep ignition sources away from faucets after extended

periods of non-use.

Maintain required clearances to combustibles.

Do not expose gas control valve/thermostat to excessive

gas pressure.

Do not obstruct water heater air intake

with insulating blanket.

Gas and carbon monoxide detectors

are available.

Install water heater in accordance with

the instruction manual.

Breathing carbon monoxide can cause brain damage or

death. Always read and understand instruction manual.

Breathing Hazard - Carbon Monoxide Gas

Property Damage Hazard

All water heaters eventually leak.

•

Do not install without adequate drainage.

•

CAUTION

GENERAL SAFETY INFORMATION

Fire Hazard

For continued protection against

risk of fire:

Do not install water heater on

carpeted floor.

Do not operate water heater if

exposed to flooding or water

damage.

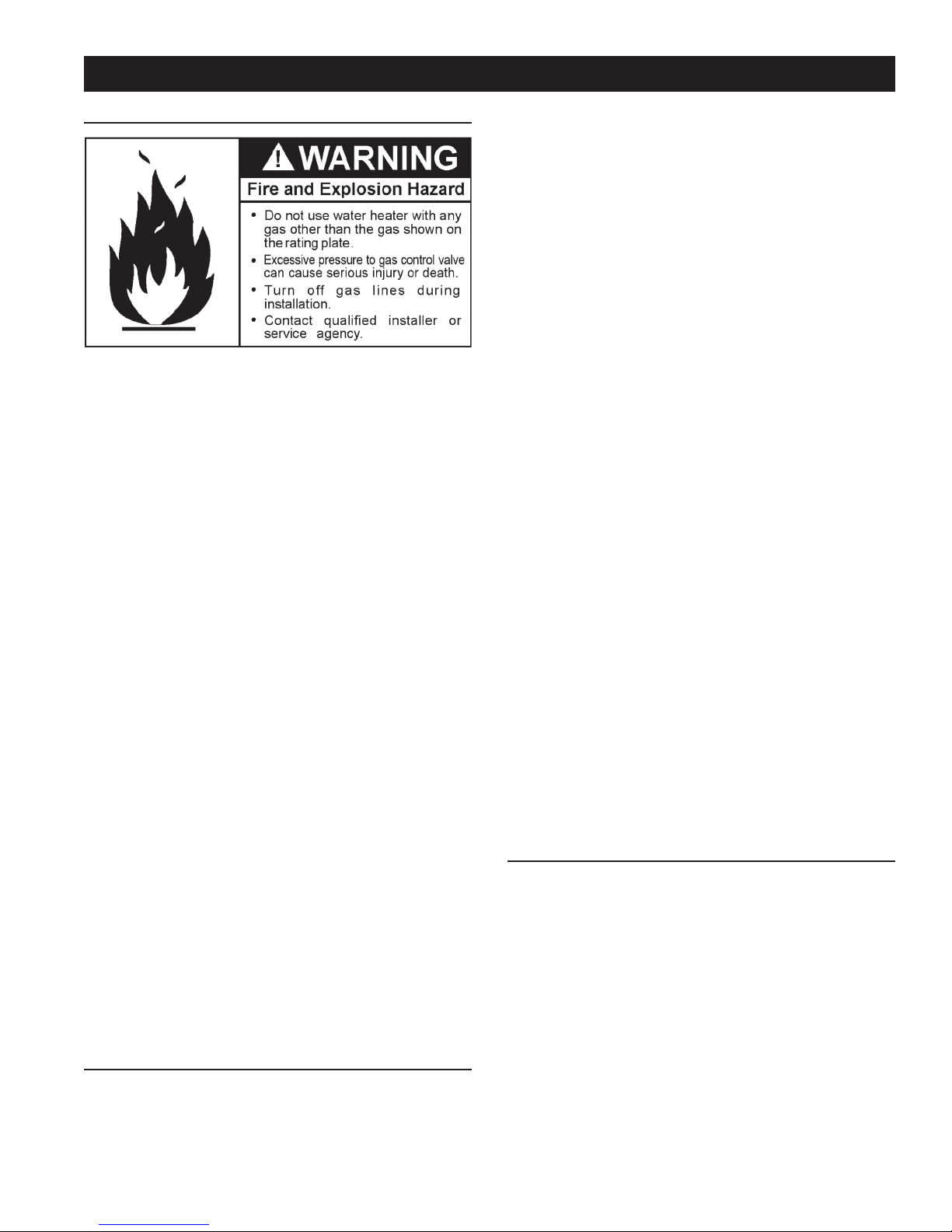

Fire and Explosion Hazard

Use joint compound or Teflon tape

compatible with propane gas.

Leak test gas connections

before placing the water heater in

operation.

Disconnect gas piping at main

gas shutoff valve before leak

testing.

Install sediment trap in accordance

with NFPA 54 or CAN/CSA B149.1.

Electrical Shock Hazard

Turn off power to the water heater

•

before performing any service.

Label all wires prior to disconnecting

•

when performing service. Wiring errors

can cause improper and dangerous

operation.

Verify proper operation after servicing.

•

Failure to follow these instructions can

•

result in personal injury or death.

Fire and Explosion Hazard

Do not use water heater with any gas

other than the gas shown on the rating

plate.

Excessive gas pressure to gas control

valve can cause serious injury or death.

Turn off gas lines during installation.

Contact a qualified installer or service

technician for installation and service.

6

Page 7

INSTALLATION REQUIREMENTS FOR THE COMMONWEALTH OF MASSACHUSETTS

For all side wall terminated, horizontally vented power vent, direct vent, and power direct vent gas fueled water heaters installed

in every dwelling, building or structure used in whole or in part for residential purposes, including those owned or operated by

the Commonwealth and where the side wall exhaust vent termination is less than seven (7) feet above nished grade in the

area of the venting, including but not limited to decks and porches, the following requirements should be satised:

INSTALLATION OF CARBON MONOXIDE DETECTORS At the time of installation of the side wall horizontal vented gas

fueled equipment, the installing plumber or gastter should observe that a hard wired carbon monoxide detector with an alarm

and battery back-up is installed on the oor level where the gas equipment is to be installed. In addition, the installing plumber

or gastter should observe that a battery operated or hard wired carbon monoxide detector with an alarm is installed on each

additional level of the dwelling, building or structure served by the sidewall horizontal vented gas fueled equipment. It should

be the responsibility of the property owner to secure the services of qualied licensed professionals for the installation of hard

wired carbon monoxide detectors.

In the event that the side wall horizontally vented gas fueled equipment is installed in a crawl space or an attic, the hard wired

carbon monoxide detector with alarm and battery back-up may be installed on the next adjacent oor level.

In the event that the requirements of this subdivision can not be met at the time of completion of installation, the owner should

have a period of thirty (30) days to comply with the above requirements provided that during said thirty (30) day period, a battery

operated carbon monoxide detector with an alarm should be installed.

APPROVED CARBON MONOXIDE DETECTORS Each carbon monoxide detector as required in accordance with the above

provisions should comply with NFPA 720 and be ANSI/UL 2034 listed and CSA certied.

SIGNAGE A metal or plastic identication plate should be permanently mounted to the exterior of the building at a minimum

height of eight (8) feet above grade directly in line with the exhaust vent terminal for the horizontally vented gas fueled heating

appliance or equipment. The sign should read, in print size no less than one-half (1/2) inch in size, GAS VENT DIRECTLY

BELOW. KEEP CLEAR OF ALL OBSTRUCTIONS.

INSPECTION The state or local gas inspector of the side wall horizontally vented gas fueled equipment should not approve the

installation unless, upon inspection, the inspector observes carbon monoxide detectors and signage installed in accordance

with the provisions of 248 CMR 5.08(2)(a) 1 through 4.

EXEMPTIONS: The following equipment is exempt from 248 CMR 5.08(2)(a)1 through 4:

1. The equipment listed in Chapter 10 entitled Equipment Not Required To Be Vented in the most current edition of NFPA

54 as adopted by the Board; and

2. Product Approved side wall horizontally vented gas fueled equipment installed in a room or structure separate from the

dwelling, building, or structure used in whole or in part for residential purposes.

MANUFACTURER REQUIREMENTS - GAS EQUIPMENT VENTING SYSTEM PROVIDED When the manufacturer of Product

Approved side wall horizontally vented gas equipment provides a venting system design or venting system components with

the equipment, the instructions provided by the manufacturer for installation of the equipment and the venting system should

include:

1. Detailed instructions for the installation of the venting system design or the venting system components; and

2. A complete parts list for the venting system design or venting system.

MANUFACTURER REQUIREMENTS - GAS EQUIPMENT VENTING SYSTEM NOT PROVIDED When the manufacturer

of a Product Approved side wall horizontally vented gas fueled equipment does not provide the parts for venting the

flue gases, but identifies special venting systems, the following requirements should be satisfied by the manufacturer:

1. The referenced special venting system instructions should be included with the appliance or equipment installation

instructions; and

2. The special venting systems should be Product Approved by the Board, and the instructions for that system should include a

parts list and detailed installation instructions.

A copy of all installation instructions for all Product Approved side wall horizontally vented gas fueled equipment, all venting

instructions, all parts lists for venting instructions, and/or all venting design instructions should remain with the appliance or

equipment at the completion of the installation.

7

Page 8

INTRODUCTION

Thank You for purchasing this water heater. Properly installed and

maintained, it should give you years of trouble free service.

ABBREVIATIONS USED

Abbreviations found in this Instruction Manual include :

• ANSI - American National Standards Institute

• ASME - American Society of Mechanical Engineers

• AHRI - Air-Conditioning, Heating and Refrigeration Institute

• NEC - National Electrical Code

• NFPA - National Fire Protection Association

• UL - Underwriters Laboratory

• CSA - Canadian Standards Association

QUALIFICATIONS

QUALIFIED INSTALLER OR SERVICE AGENCY

Installation and service of this water heater requires ability

equivalent to that of a Qualied Agency (as dened by ANSI below)

in the eld involved. Installation skills such as plumbing, air supply,

venting, gas supply and electrical supply are required in addition to

electrical testing skills when performing service.

ANSI Z223.1 2006 Sec. 3.3.83: “Qualied Agency” - “Any

individual, rm, corporation or company that either in person or

through a representative is engaged in and is responsible for (a)

the installation, testing or replacement of gas piping or (b) the

connection, installation, testing, repair or servicing of appliances

and equipment; that is experienced in such work; that is familiar

with all precautions required; and that has complied with all the

requirements of the authority having jurisdiction.”

is essential that all venting, water piping, gas piping and wiring

be installed as shown.

Particular attention should be given to the installation of

thermometers at the locations indicated in the piping diagrams

as these are necessary for checking the operation of the water

heater.

The principal components of the water heater are identied in

Features and Components beginning on Page 11 in this manual.

Use this reference to locate and identify various components on

the water heater.

See the Installation Checklist and Troubleshooting on page

48. By using this checklist the user may be able to make

minor operational adjustments and avoid unnecessary service

calls. However, service and diagnostic procedures should only

be performed by a Qualied Service Agency.

NOTE: Costs to correct installation errors are not covered

under the limited warranty.

2. Be sure to turn off power when working on or near the electrical

system of the water heater. Never touch electrical components

with wet hands or when standing in water.

3. The installation must conform to all instructions contained in

this manual and the local code authority having jurisdiction.

These shall be carefully followed in all cases. Authorities having

jurisdiction should be consulted before installation begins if

there are any questions regarding compliance with local, state

or national codes.

If you are not qualied (as dened by ANSI above) and licensed or

certied as required by the authority having jurisdiction to perform

a given task do not attempt to perform any of the procedures

described in this manual. If you do not understand the instructions

given in this manual do not attempt to perform any procedures

outlined in this manual.

PREPARING FOR THE INSTALLATION

1. Read the entire manual before attempting to install or operate

the water heater. Pay close attention to the General Safety

Information on Page 4 through Page 6. If you don’t follow the

safety rules, the water heater may not operate safely. It could

cause property damage, injury and/or death.

This manual contains instructions for the installation, operation,

and maintenance of the water heater. It also contains warnings

throughout the manual that you must read and be aware of.

All warnings and all instructions are essential to the proper

operation of the water heater and your safety. Detailed

installation diagrams are also found in this manual. These

diagrams will serve to provide the installer with a reference. It

In the absence of local codes, the installation must comply with

the current editions of the National Fuel Gas Code, ANSI Z223.1/

NFPA 54 and the National Electrical Code, NFPA 70 or CAN/

CSA-B149.1, the Natural Gas and Propane Installation Code

and CSA C22.1, the Canadian Electrical Code. All documents

are available from the Canadian Standards Association, 8501

East Pleasant Valley Road, Cleveland, OH 44131. NFPA

documents are also available from the National Fire Protection

Association, 1 Batterymarch Park, Quincy, MA 02269.

4. If after reading this manual you have any questions or do

not understand any portion of the instructions, call the toll

free number on the back cover of this manual for technical

assistance. In order to expedite your request, please have the

full Model, Serial and Series number of the water heater you

are working with available for the technician. This information is

located on the water heater’s rating plate.

5. Carefully plan the placement of the water heater. Examine

the location to ensure that it complies with the requirements

in Locating The Water Heater on Page 15 and the Rough In

Dimensions on Page 9.

8

Page 9

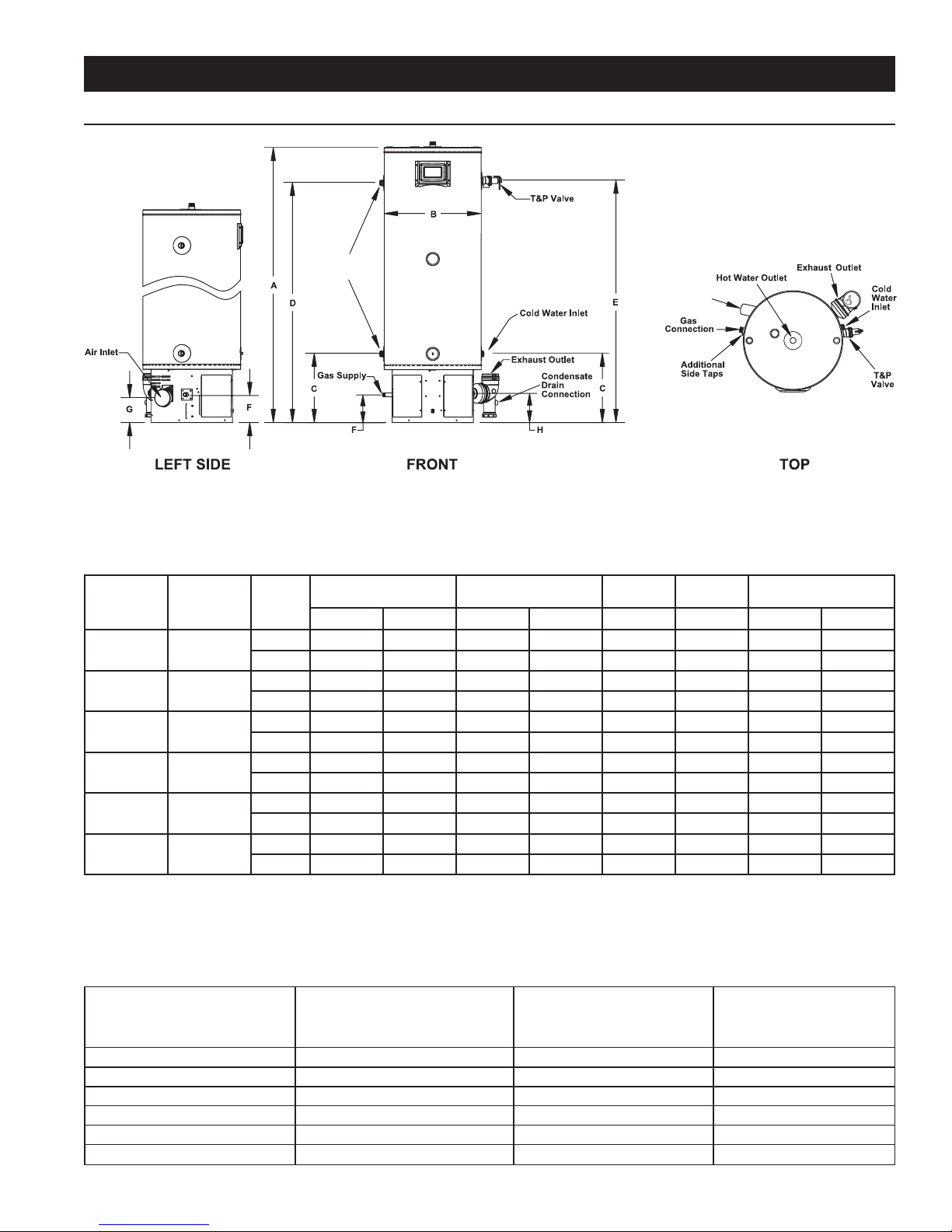

DIMENSIONS AND CAPACITY DATA

ROUGH IN DIMENSIONS: ALL MODELS

All Models

Additional

Side Taps

Figure 1 . DIMENSIONS FOR ALL MODELS

Air Inlet

U.S.

GALLONS

34 130

34 150

50 130

50 150

50 175

50 199

INPUT

(KBTU/HR)

UNITS

Inches

Inches

Inches

Inches

Inches

Inches

Top Outlet: 1” NPT

Side Inlet: 1” NPT

Gas Inlet: 1/2” NPT

Condensate drain outlet: 1/2” NPT

U.S. GALLONS

34 130 2 OR 3 150

34 150 2 OR 3 150

50 130 2 OR 3 176

50 150 2 OR 3 180

50 175 3 180

50 199 3 180

cm

cm

cm

cm

cm

cm

Table 1A - ROUGH-IN-DIMENSIONS

EXTERIOR WATER CONNECTIONS

T&P

HOT

A B C D E F G H

48-1/2 22 15-3/4 40-1/2 41 6-3/8 5-1/2 6-5/8

123.19 55.88 40 102.87 104.14 16.19 13.97 16.82

48-1/2 22 15-3/4 40-1/2 41 6-3/8 5-1/2 6-5/8

123.19 55.88 40 102.87 104.14 16.19 13.97 16.82

62-3/8 22 15-3/4 54-1/2 55 6-3/8 5-1/2 6-5/8

165.7 55.88 40 138.43 139.7 16.19 13.97 16.82

63-3/4 22 15-3/4 55-3/4 56-1/4 6-3/8 5-1/2 6-5/8

161.925 55.88 40 141.605 142.875 16.19 13.97 16.82

63-3/4 22 15-3/4 55-3/4 56-1/4 6-3/8 5-1/2 6-5/8

161.925 55.88 40 141.605 142.875 16.19 13.97 16.82

63-3/4 22 15-3/4 55-3/4 56-1/4 6-3/8 5-1/2 6-5/8

161.925 55.88 40 141.605 142.875 16.19 13.97 16.82

GAS

SUPPLY

AIR INLET/EXHAUST

Table 1B - ROUGH-IN-DIMENSIONS

INPUT

(KBTU/HR)

VENT

DIAMETER

(in.)

APPROX SHIP. WEIGHT

(lbs.)

9

Page 10

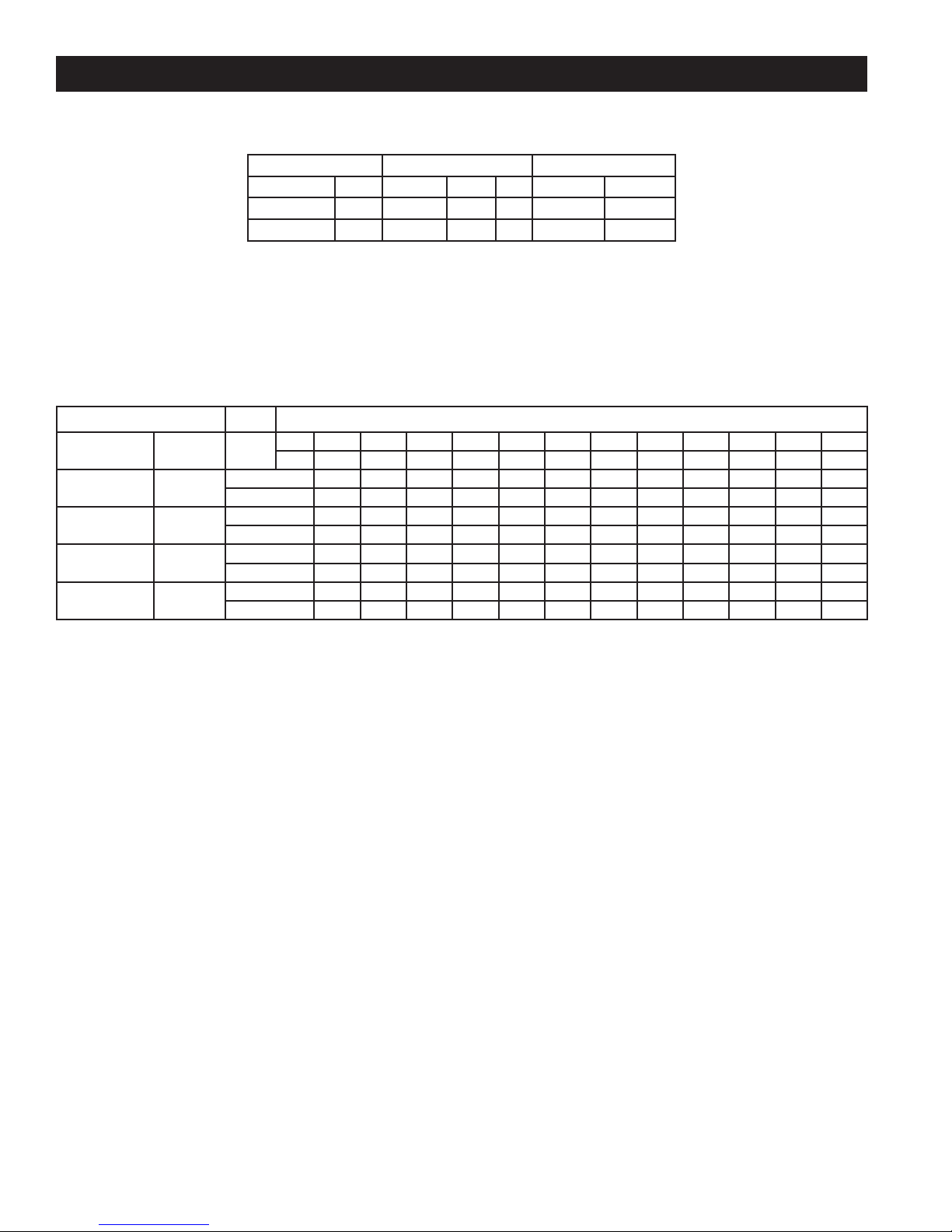

DIMENSIONS AND CAPACITY DATA

Table 2 – CAPACITY, GAS AND ELECTRICAL CHARACTERISTICS

Approximate Capacity *Manifold Pressure Electrical Characteristics

U.S. Gals. Liters Gas Type “WC kPA Volts/Hz Amperes

34 129 Nat./LP 0 0 120/60 <7

50 189 Nat/LP 0 0 120/60 <7

* The manifold pressure is the factory setting and is not adjustable. A negative pressure will be seen with just the blower running without

the Gas Control Valve open.

All models - Maximum Supply Pressure: 14 inches W.C. (3.48kPa)

Minimum Supply Pressure for Natural Gas: 3.50” (.87kPa)

Minimum Supply Pressure for Propane Gas: 8.00” (1.99kPa)

Minimum pressure must be maintained under both load and no load (dynamic and static) conditions.

Table 3 – RECOVERY CAPACITIES

Input Recovery Capacities

Rating

(Btu/hr)

130000 38.1

150000 44.0

175000 51.3

199000 58.3

Rating

(kW)

Temp.

Rise

F 30 40 50 60 70 80 90 100 110 120 130 140

C 17 22 28 33 39 44 50 56 61 67 72 78

GPH 495 371 297 248 212 186 165 149 135 124 114 106

LPH 1875 1406 1125 937 803 703 625 562 511 469 433 402

GPH 571 429 343 286 245 214 190 171 156 143 132 122

LPH 2163 1622 1298 1082 927 811 721 649 590 541 499 464

GPH 667 500 400 333 286 250 222 200 182 167 154 143

LPH 2524 1893 1514 1262 1082 946 841 757 688 631 582 541

GPH 758 569 455 379 325 284 253 227 207 190 175 162

LPH 2870 2152 1722 1435 1230 1076 957 861 783 717 662 615

Recovery capacity based on 95% thermal efciency.

10

Page 11

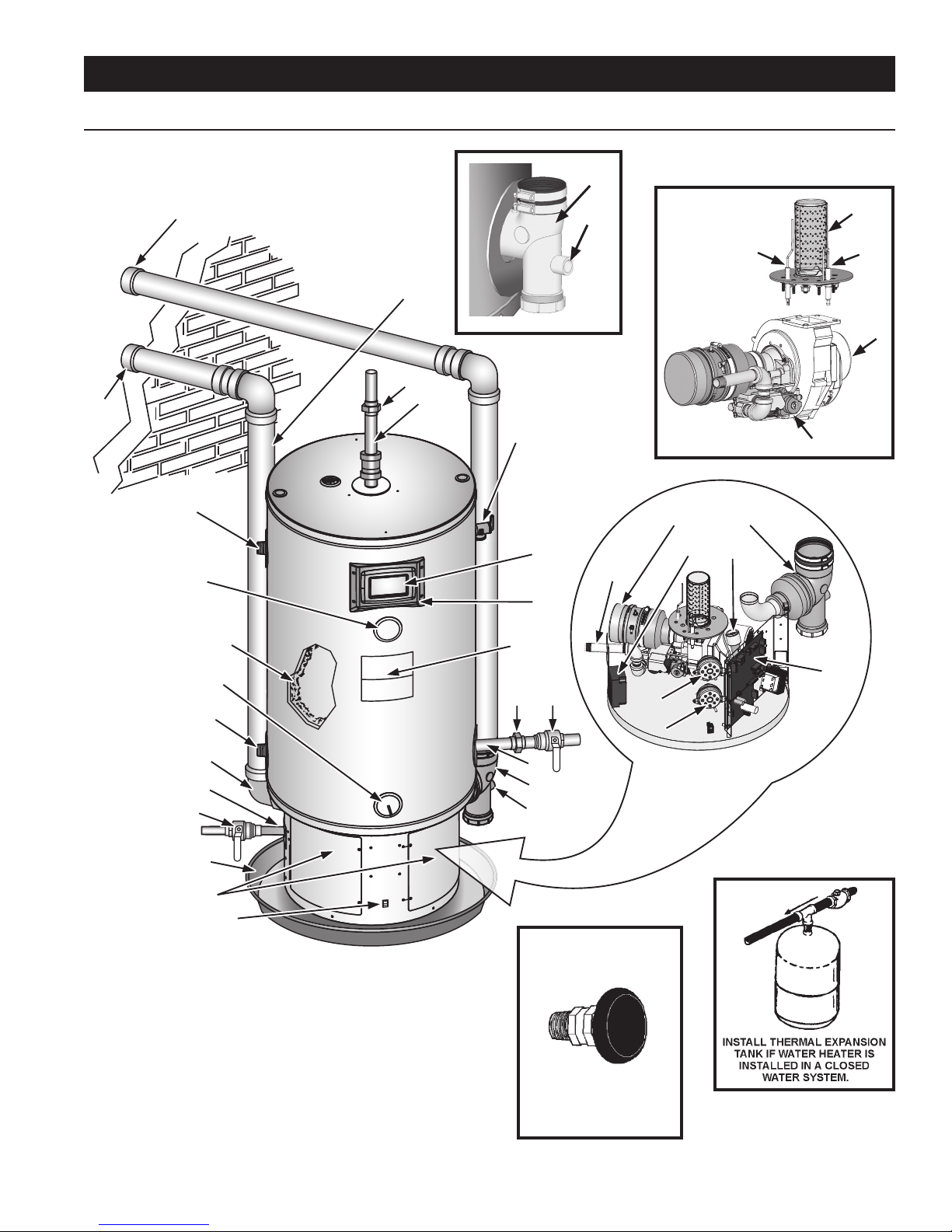

FEATURES AND COMPONENTS

34 GALLON UNIT

**11

**34

**25

32

24

27

31

17

14

20

21, 22

9

10

**12

15

33

30

23

11

5

6

7

4

8

28

32

**33

15

16

26

29

13

* CAUTION HARNESS HAS 120 VAC. IN OPERATION.

** See Venting Installation and Condensate Piping for more information.

17

19

**11

**12

18

VACUUM RELIEF

VALV E

*INSTALL PER

LOCAL CODES

1

2

3

This is a view of the area

at the bottom of

heater behind the

Access Doors.

Figure 2. 34 GALLON UNIT

11

Page 12

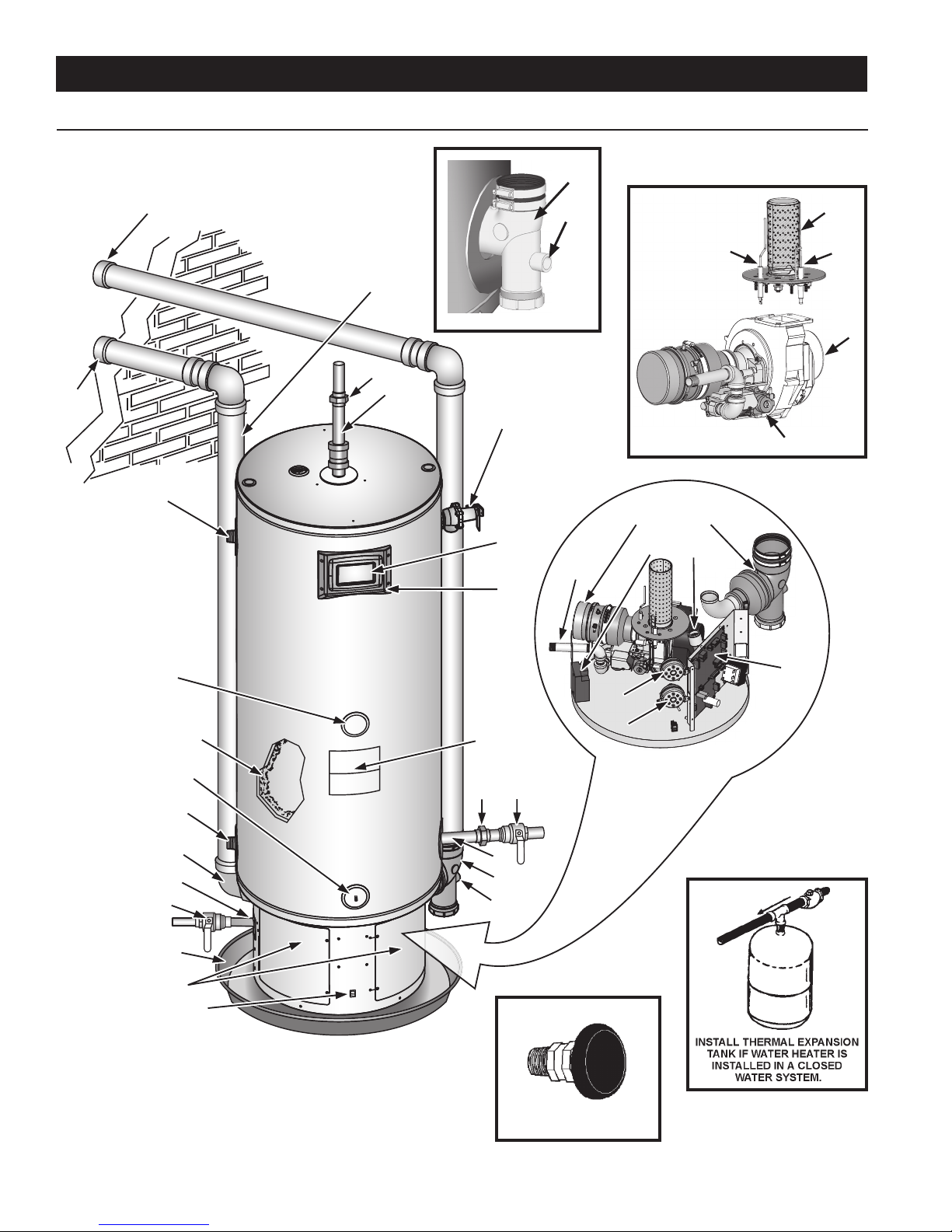

FEATURES AND COMPONENTS (CONT.)

50 GALLON UNIT

**11

**34

**25

32

31

17

14

20

9

10

**12

15

33

30

23

11

5

6

7

4

8

24

27

28

32

**33

15

16

26

29

13

* CAUTION HARNESS HAS 120 VAC. IN OPERATION.

** See Venting Installation and Condensate Piping for more information.

21, 22

18

17

19

**11

**12

VACUUM RELIEF VALVE

*INSTALL PER

LOCAL CODES

1

2

3

This is a view of the area

at the bottom of

heater behind the

Access Doors.

Figure 3. 50 GALLON UNIT

12

Page 13

FEATURES AND COMPONENTS (CONT.)

1: Control Assembly

2: Blocked Intake Switch

3: Blocked Outlet Switch

4: Blower Assembly

5: Burner Assembly

6: Flame Sensor

7: Igniter Assembly

8: Gas Control Valve Assembly

9: Display Board

10: Display Enclosure

** 11: Exhaust Elbow Assembly

** 12: Condensate Drain Outlet

13: Enable / Disable Switch

14: Hot Water Outlet

15: Gas Supply

16: Main Manual Gas Shutoff Valve

17: Union

18: Inlet Water Shutoff Valve

19: Cold Water Inlet

20: T & P Relief Valve

21: Rating Plate

22: Labels

23: Drain Valve

24. Upper Temperature Probe (ECO)

** 25: Exhaust Vent Terminal

26: Drain Pan

27: Insulation

28: Lower Temperature Probe

29: Access Door

30: Spark Module

31. Air Intake Pipe

32. Additional Side Taps

33. Intake Air Connection

**34. Intake Vent Terminal

13

Page 14

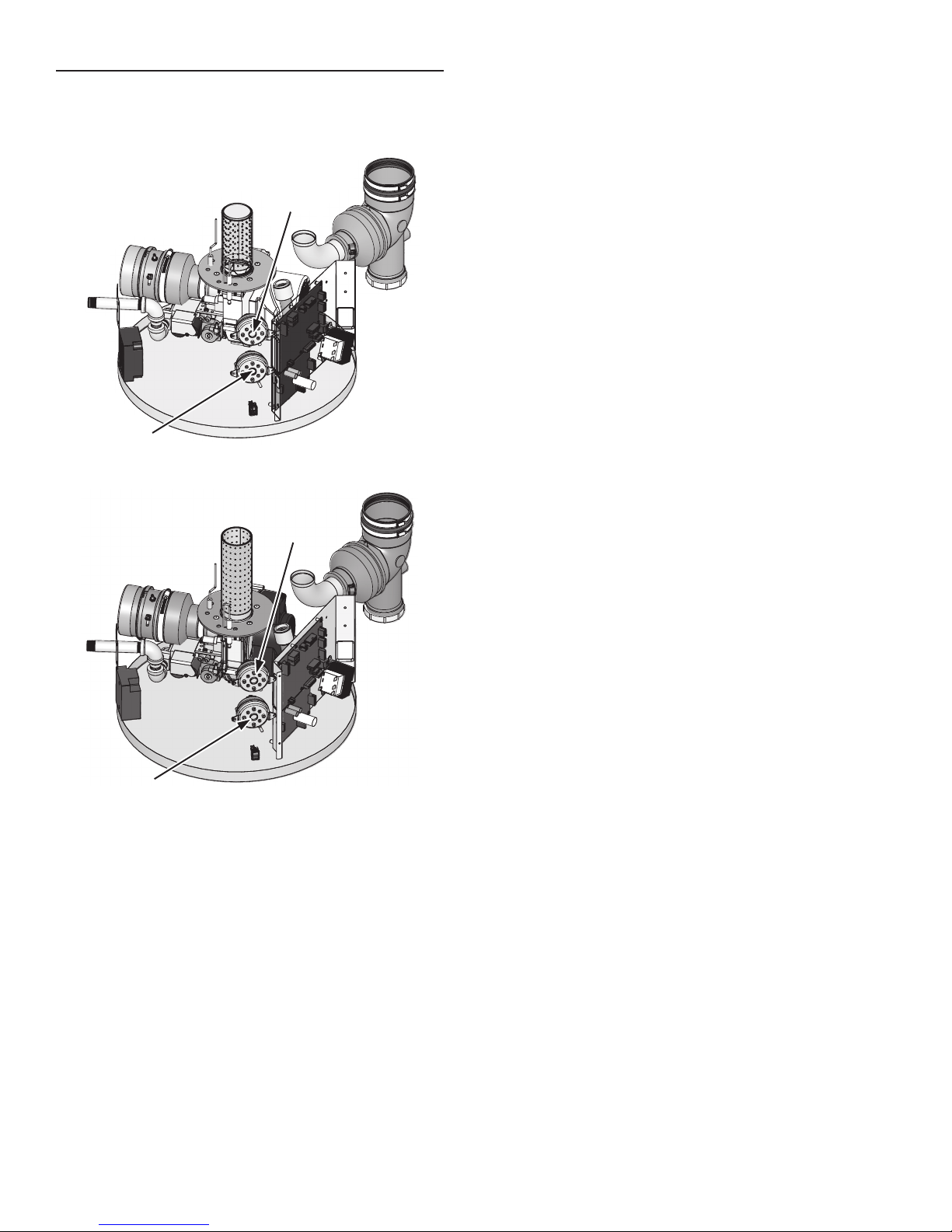

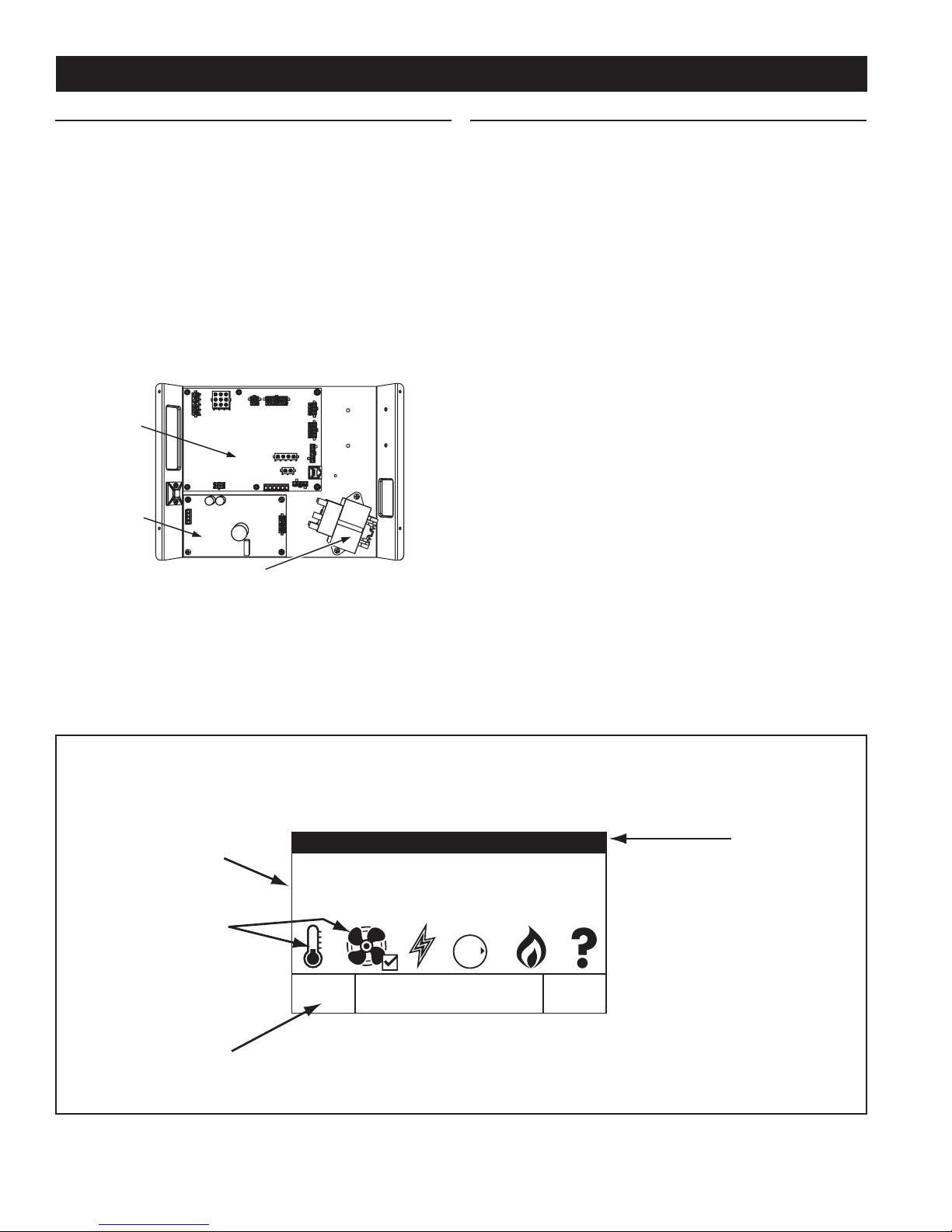

CONTROLS AND SWITCHES

Switch

Switch

This model is provided with two pressure switches. These switches

are essential to the safe and proper operation of the unit. All switches

are wired in series. The controller is set up to shut the unit down

whenever there is a failure of any of the switches. It is important to

understand the purpose of each switch.

Blocked Outlet

Switch

Blocked Intake

34 GALLON UNIT

Blocked Outlet

Switch

BLOCKED OUTLET SWITCH

The Blocked Outlet Switch is set up to shut the unit off when a buildup of positive pressure in the exhaust vent pipe occurs. This switch

is a positive pressure switch that requires an increase in pressure to

change the electrical contacts from normally closed to open. When

this switch prevents the unit from igniting, most likely the exhaust is

blocked by some means. Check to see if the condensate is allowed

to ow freely from the exhaust elbow and for obstructions in the

exhaust venting and exhaust vent terminal. Also verify that the vent

length does not exceed the maximum allowed as shown in Planning

the Vent System beginning on page 23.

BLOCKED INTAKE SWITCH

The Blocked Intake Switch is set up to shut the unit off when a buildup of negative pressure in the intake air pipe occurs. This switch

is a negative pressure switch that requires an increase in negative

pressure to change the electrical contacts from normally closed to

open. The switch is connected to the pressure tap on the PVC pipe

connected to the inlet of the blower. When this switch prevents the

unit from igniting, most likely the intake is blocked. Verify that the

integrated lter on the intake air connection, the intake air pipe,

and the intake air termination are free of obstructions that may

prevent air from entering the unit. Also Verify the intake air pipe

length does not exceed the maximum allowed in Planning the Vent

System beginning on page 23.

WATER HEATING ENABLE/DISABLE SWITCH

IMPORTANT: The Enable/Disable switch listed in this manual is

NOT an “on/off” switch and does not disconnect 120 volt power to

the CCB and other heater components.

When in the “Disabled” position the switch removes electrical power

from the gas control valve so that water heating is disabled. The

display, CCB, and other electrical components will still be energized

and the display will read “Water Heating Disabled”.

Blocked Intake

50 GALLON UNIT

Figure 4

SPARK IGNITER

The Spark Igniter is a device that ignites the main burner by spark.

When high voltage is applied to the igniter, spark is generated to

ignite the main burner.

CONFIGURATION KEY

The configuration key is located inside the control box. It

provides for the ability of the heater to retain information

collected over its lifetime, even if the control board is replaced

because of failure.

The conguration key should stay with the heater.

14

Page 15

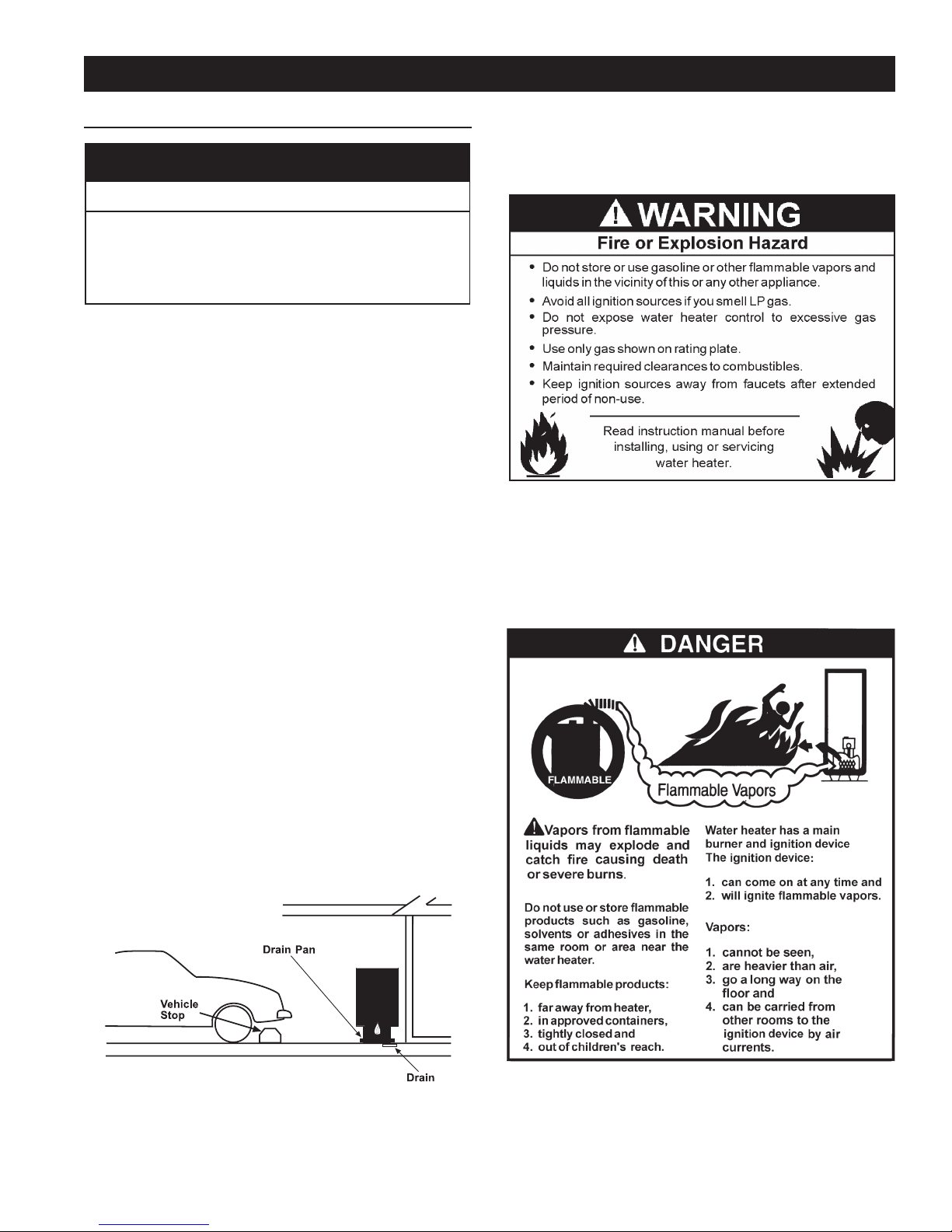

CAUTION

INSTALLATION CONSIDERATIONS

LOCATING THE WATER HEATER

Property Damage Hazard

All water heaters eventually leak.

•

Do not install without adequate drainage.

•

Carefully choose a location for the new water heater. The placement

is a very important consideration for the safety of the occupants in

the building and for the most economical use of the water heater.

Whether replacing an existing water heater or installing the water

heater in a new location observe the following critical points:

1. The water heater must be located indoors.

2. The water heater must not be located in an area where it will

be subject to freezing temperatures.

3. Locate the water heater so it is protected and not subject to

physical damage by a moving vehicle. In garage installation

avoid damage to your water heater by installing a vehicle

stop as shown in Figure 5. Check state and local codes for

requirements prior to installation.

4. Locate the water heater on a level surface.

5. Locate the water heater near a oor drain. The water heater

should be located in an area where leakage of the tank or

connections will not result in damage to the area adjacent

to the water heater or to lower oors of the structure. When

such locations cannot be avoided, it is recommended that a

metal drain pan, piped to adequate drain, be installed under

the water heater. Drain pan should be fabricated with sides

at least 1-3/4” deep with diameter at least 2” greater than

diameter of heater. Pan must not restrict combustion air ow.

6. Locate the water heater close to the point of major hot

water usage.

7. Locate the water heater close to a 120 VAC power supply.

See Power Supply on Page 18 for requirements.

8. Locate the water heater where an adequate supply of fresh

air for combustion and ventilation can be obtained. See

Combustion Air and Ventilation on Page 16.

9. Locate the water heater where the vent and intake air piping,

when installed, will remain within the maximum equivalent

lengths allowed. See Planning the Vent System on page 24.

11. Do not locate the water heater where the subsequent

installation of the vent (exhaust) or intake air terminations

would be objectionable due to noise at the termination(s).

This includes locations close to or across from windows and

doors. See Venting Installation beginning on page 22.

Do not locate water heater areas where ammable liquids (vapors)

are likely to be present or stored (garages, storage and utility

areas, etc.): Flammable liquids (such as gasoline, solvents,

propane (LP or butane, etc.) and other substances (such as

adhesives, etc.) emit ammable vapors which can be ignited by

a gas water heater’s ignition device or main burner. The resulting

ashback and re can cause death or serious burns to anyone

in the area.

10. Do not locate the water heater where noise (such as

the Combustion Blower) during normal operation will be

objectionable in adjacent areas.

Figure 5. GARAGE INSTALLATION

When the water heater is installed directly on carpeting, the water

heater shall be installed on a metal or wood panel extending beyond

the full width and depth of the water heater by at least 3″ (7.62 cm) in

any direction or, if the water heater is installed in an alcove or closet,

the entire oor shall be covered by the panel. The panel must be

strong enough to carry the weight of the heater when full of water.

15

Page 16

Minimum clearances from combustible materials are stated on the data

plate located on the front of the water heater. Standard clearances

are 0” (0 cm) at the sides and rear, 0” (0 cm) from the front, and 0” (0

cm) from the top. If the clearances from combustible material stated

on the water heater differ from the standard clearances, install the

water heater according to the clearances stated on the water heater.

Adequate clearance for inspection and service should be considered

before installation. A minimum of 24” (61 cm) of front clearance and 4”

(10.2 cm) on each side should be provided for access to replaceable

and/or serviceable parts such as thermostats, drain valve, condensate

drain, temperature-pressure relief valve, and the vent connection

(exhaust elbow).

Figure 6 may be used as a reference guide to locate the specic

clearance locations. When installing the water heater, consideration

must be given to proper location. The location selected should be

as close to the wall as practicable and as centralized with the water

piping system as possible.

CEILING

LEFT

WALL

FRONT VIEW

*For service access

0"

RIGHT

WALL

WITHOUT DOOR

MIN.

TOP VIEW

OF CLOSET

WATER

HEATER

0" MIN.

*4" MIN.

TOP VIEW

OF CLOSET

WITHOUT DOOR

WATER

HEATER

0" MIN.

*24" MIN. (61 c m)

0" MIN.

Figure 6: MINIMUM CLEARANCE LOCATIONS

INSULATION BLANKETS

• Do obtain new warning and instruction labels from the manufacturer

for placement on the blanket directly over the existing labels.

• Do inspect the insulation blanket frequently to make certain it

does not sag, thereby obstructing combustion air ow.

COMBUSTION AIR AND VENTILATION

A gas water heater cannot operate properly without the correct

amount of air for combustion. Never obstruct the ow of ventilation

air. If you have any doubts or questions at all, call your gas supplier.

Failure to provide the proper amount of combustion air can result

in a re or explosion and cause death, serious bodily injury, or

property damage.

Figure 7: COMBUSTION AIR AND VENTILATION

It is imperative that the water heater(s) be installed direct vent so

that all air for combustion and ventilation is taken from outdoors.

Propellants of aerosol sprays and volatile compounds, (cleaners,

chlorine based chemicals, refrigerants, etc.) in addition to being

highly ammable in many cases, will also react to form corrosive

acids when exposed to the combustion products of the water heater.

The results can be hazardous, and also cause product failure. Air

for combustion and ventilation must not come from a corrosive

atmosphere. Any failure due to corrosive elements in the atmosphere

is excluded from warranty coverage.

Insulation blankets are available to the general public for external use

on gas water heaters but are not necessary with these products. The

purpose of an insulation blanket is to reduce the standby heat loss

encountered with storage tank heaters. Your water heater meets or

exceeds the Energy Policy Act standards with respect to insulation and

standby loss requirements, making an insulation blanket unnecessary.

Should you choose to apply an insulation blanket to this heater, you

should follow these instructions (For identication of components

mentioned below. See Figures 1, 2, 3 and 4. Failure to follow these

instructions can restrict the air ow required for proper combustion,

potentially resulting in re, asphyxiation, serious personal injury or death.

• Do not cover the control system LCD on top of the water heater.

• Do not cover the outer door, thermostat or temperature-pressure

relief valve.

• Do not cover the instruction manual. Keep it on the side of the

water heater or nearby for future reference.

CORROSION AND WATER QUALITY

Water quality will vary from location to location and may contain

contaminates that may reduce the life or performance of the water heater.

Contaminates which can reduce the life or performance of the water

heater if present in high quantities include those which contribute to

hardness (dissolved minerals such as sodium, calcium and magnesium);

plus chlorides and sulfates. Additionally, water that is too acidic or basic

(measured as pH) can reduce the life of the water heater. Water treatment

systems (such as water softeners for hardness) should be used and

maintained properly if the contaminate levels exceed the following:

Warranty is void in applications which exceed the

water quality requirements listed below.

Total Hardness: 12 grains per gal. (205 mg/liter) max.

Chloride: 200 mg/liter max.

pH: 6.5-8.0

Alkalinity: 200 mg/liter max.

16

Page 17

INSTALLATION REQUIREMENTS

GAS SUPPLY SYSTEMS

Low pressure building gas supply systems are dened as those

systems that cannot under any circumstances exceed 14”

W.C. (1/2 PSI Gauge). These systems do not require pressure

regulation. Measurements should be taken to insure that gas

pressures are stable and fall within the requirements stated on

the water heater rating plate. Readings should be taken with

all gas burning equipment off (static pressure) and with all gas

burning equipment running at maximum rate (dynamic pressure).

The gas supply pressure must be stable within 1.5” W.C.

from static to dynamic pressure to provide good performance.

Pressure drops that exceed 1.5” W.C. may cause rough starting,

noisy combustion or nuisance outages. Increases or spikes in

static pressure during off cycles may cause failure to ignite or in

severe cases damage to water heater gas control valves. If your

low pressure system does NOT meet these requirements, the

installer is responsible for the corrections.

High pressure building supply systems use pressures that exceed

14” W.C. (1/2 PSI Gauge). These systems must use eld supplied

regulators to lower the gas pressure to less than 14” W.C. (1/2

PSI Gauge). Water heaters require gas regulators that are properly

sized for the water heater input and deliver the rating plate specied

pressures. Gas supply systems where pressure exceeds 5 PSI

often require multiple regulators to achieve desired pressures.

Systems in excess of 5 PSI building pressure should be designed

by gas delivery professionals for best performance. Water heaters

connected to gas supply systems that exceed 14” W.C. (1/2 PSI

Gauge) at any time must be equipped with a gas supply regulator.

All models require a minimum gas supply pressure of 3.5”

W.C.(0.87 kPa) for natural gas and 8.0” W.C. (1.99 kPa) for

propane. The minimum supply pressure is measured while gas

is not owing (static pressure) AND while gas is owing (dynamic

pressure). The supply pressure (static and dynamic) should never

fall below 3.5” W.C.(0.87 kPa) for natural gas or 8.0” W.C. (1.99

kPa) for propane. The supply pressure should be measured with

all gas red water heaters connected to the common main ring

at full capacity. If the supply pressure drops more than 1.5” W.C.

(0.37 kPa) as gas begins to ow to the water heater then the supply

gas system including the gas line and/or the gas regulator may

be restricted or undersized. See Supply Gas Regulator on page

17 and Supply Gas Line Installation on page 31. The gas control

valve on all models has a maximum gas supply pressure limit of

14” W.C.(3.48 kPa) The maximum supply pressure is measured

while gas is not owing (static pressure) AND while gas is owing

(dynamic pressure).

SUPPLY GAS REGULATOR

The maximum allowable gas supply pressure for this water heater

is 14 inches W.C. (3.5 kPa). Install a positive lock-up gas pressure

regulator in the gas supply line if inlet gas pressure can exceed 14

inches W.C. (3.5 kPa) at any time. Regulators must be sized/used

according to manufacturer’s specications.

If a positive lock-up regulator is required follow these instructions:

1. Positive lock-up gas pressure regulators must be rated at or

above the input Btu/hr rating of the water heater they supply.

2. Supply gas regulators shall have inlet and outlet connections not

less than the minimum supply gas line size for the water heater

they supply

3. Positive lock-up gas pressure regulator(s) should be installed

no closer than 3 feet (1 meter) and no farther than 8 feet (2.4

meters) from the water heater’s inlet gas connection.

4. After installing the positive lock-up gas pressure regulator(s) an

initial nominal supply pressure setting of 7.0” W.C.(1.74 kPa) for

Natural Gas and 11.0” W.C. (2.74 kPa) for Propane (LP) while

the water heater is operating is recommended and will generally

provide good water heater operation. Some additional adjustment

may be required later to maintain a steady gas supply pressure.

5. When installing multiple water heaters in the same gas supply

system it is recommended that individual positive lock-up gas

pressure regulators be installed at each unit.

All gas piping must comply with local codes and ordinances or with

the current editions National Fuel Gas Code (ANSI Z223.1/ NFPA-

54) or the Natural Gas and Propane Installation Code (CAN/CSA

B149.1) whichever applies. Copper or brass tubing and ttings

(except tin lined copper tubing) shall not be used.

If the gas control valve is subjected to pressures exceeding 1/2 psi

(3.5 kPa), the damage to the gas control valve could result in a re

or explosion from leaking gas.

If the main gas line Shut-off serving all gas water heaters is used,

also turn off the gas at each water heater. Leave all gas appliances

shut off until the water heater installation is complete.

A gas line of sufcient size must be run to the water heater. Consult

the current edition of National Fuel Gas Code (ANSI Z223.1/NFPA

54) or the Natural Gas and Propane Installation Code (CAN/CSA

B149.1) and your gas supplier concerning pipe size.

There must be:

• A readily accessible manual shut off valve in the gas supply

line serving the water heater, and

• A sediment trap ahead of the gas control valve to help prevent

dirt and foreign materials from entering the gas control valve.

• A ground joint union of proper size between the manual shut

off valve and gas control valve to permit servicing of the unit.

Be sure to check all the gas piping for leaks before lighting the

water heater. Use a soapy water solution, not a match or open

ame. Rinse off soapy solution and wipe dr y.

POWER SUPPLY

The water heaters covered in this manual require a 120 VAC,

1Ø (single phase), 60Hz, 7 amp power supply and must also be

electrically grounded in accordance with local codes or, in the

absence of local codes, with the National Electrical Code, ANSI/

NFPA 70 or the Canadian Electrical Code, CSA C22.1.

If any of the original wire as supplied with the water heater must

be replaced, it must be replaced with 105°C rated wiring or its

equivalent, except in the burner housing. In this case 200°C

rated wire must be used.

DEDICATED POWER WIRING AND BREAKERS

Dedicated power supply wires, ground wiring and dedicated

circuit breakers often prevent electrical line noise and

should be considered when installing the water heater.

POWER FLUCTUATIONS AND ELECTRICAL NOISE

The water heater’s control system requires a source of stable

clean electricity for proper operation. Connecting the water heater

to a branch circuit that is subject to uctuations in voltage level or

17

Page 18

electrical line noise such as EMI (electro magnetic interference) or

RFI (radio frequency interference) may cause erratic control system

operation and malfunction.

A high quality power supply lter/suppressor must be installed if the

above conditions exist. Call the technical support phone number for

more information.

NOTE: Malfunctions caused by the power supply and the costs

to install power supply lters are not covered under the limited

warranty.

MIXING VALVES

Water temperature over 125°F (52°C)

can cause severe burns instantly

resulting in severe injury or death.

Children, the elderly and the

physically or mentally disabled are at

highest risk for scald injury.

Feel water before bathing or

showering.

Temperature limiting devices such as

mixing valves must be installed

when required by codes and to

ensure safe temperatures at fixtures.

CIRCULATION PUMPS

A circulating pump is used when a system requires a circulating loop or

there is a storage tank used in conjunction with the water heater. The tank

is provided with a 1” NPT recirculation loop return connection. See the

Piping Diagrams section beginning on Page 59 for the installation location

of circulating pumps.

See Circulation Pump Wiring Diagrams on page 58 for electrical hookup

information. Install in accordance with the current edition of the National

Electrical Code, NFPA 70 or the Canadian Electrical Code, CSA C22.1.

Stainless Steel circulating pumps are recommended for use with

commercial water heaters.

Re f e r to th e circula t i n g pump ma nufactu r e r ’s in s t r u c t i ons fo r it s opera t i o n ,

lubrication and maintenance instructions.

DISHWASHING MACHINES

All dishwashing machines meeting the National Sanitation

Foundation requirements are designed to operate with water ow

pressures between 15 and 25 pounds per square inch (103 kPa

and 173 kPa). Flow pressures above 25 pounds per square inch

(173 kPa), or below 15 pounds per square inch (103 kPa), will

result in improperly sanitized dishes. Where pressures are high,

a water pressure reducing or ow regulating control valve should

be used in the 180°F (82°C) line to the dishwashing machine and

should be adjusted to deliver water pressure between these limits.

See Figure 8.

Water heated to a temperature which will satisfy clothes washing,

dish washing, and other sanitizing needs can scald and cause

permanent injury upon contact. Short repeated heating cycles

caused by small hot water uses can cause temperatures at the point

of use to exceed the water heater’s temperature setting by up to

20°F (11°C).

Some people are more likely to be permanently injured by hot water

than others. These include the elderly, children, the inrm and the

physically/mentally disabled. Table 4 shows the approximate timeto-burn relationship for normal adult skin. If anyone using hot water

provided by the water heater being installed ts into one of these

groups or if there is a local code or state law requiring a certain water

temperature at the point of use, then special precautions must be taken.

In addition to using the lowest possible temperature setting that

satises the demand of the application a Mixing Valve should be

installed at the water heater or at the hot water taps to further

reduce system water temperature. See Figure 8 in Dishwashing

Machines and Figures 52 through 54 in Piping Diagrams beginning

on Page 59.

Mixing valves are available at plumbing supply stores. Consult

a Qualied Installer or Service Agency. Follow mixing valve

manufacturer’s instructions for installation of the valves.

In all cases, the following burn table must be used.

Table 4

Water Temperature

°F (°C)

Time for 1st Degree Burn

(Less Severe Burns)

110 (43.3) (normal shower temp.)

116 (46.7) (pain threshold)

116 (46.7) 35 minutes 45 minutes

122 (50) 1 minute 5 minutes

131 (55) 5 seconds 25 seconds

140 (60) 2 seconds 5 seconds

149 (65) 1 second 2 seconds

154 (67.8) instantaneous 1 second

(U.S. Government Memorandum, C.P.S.C., Peter L. Armstrong, Sept. 15, 1978)

Time for Permanent

Burns

2nd & 3rd Degree

(Most Severe Burns)

HOT WATER

OUTLET

12” TO 15”

(30-38 cm)

TEMPERED WATER

OUTLET

TO TANK

INLET

MIXING

VALVE

CHECK

VALVE

COLD

WATER

INLET

CHECK

VALVE

Figure 8

The National Sanitation Foundation also recommends circulation of

180°F (82°C) water. The circulation should be just enough to provide

180°F (82°C) water at the point of take-off to dishwashing machine.

Adjust ow by throttling a full port ball valve installed in the circulating

line on the outlet side of the pump. Never throttle ow on the suction

side of a pump.

NOTE: To comply with NSF Standard 5 installation requirements the

bottom of the water heater must be sealed to the oor with a silicone

based sealant or elevated 6 inches above the oor.

18

Page 19

SPACE HEATING AND POTABLE WATER SYSTEM

ater

Hot

W

O

Your water heater is equipped with additional side taps for use in

space heating applications. See Features and Components on

Page 11 for locations. If this water heater is to be used to supply

both space heating and potable (drinking) water, the instructions

listed below must be followed:

• Be sure to follow the manual(s) shipped with the air handler

or other type heating system.

• Th i s water he a ter cann o t be used in spa c e he ating ap p licat i o ns

only.

• This water heater is not to be used as a replacement for an

existing boiler installation.

• Do not use with piping that has been treated with chromates,

boiler seal or other chemicals and do not add any chemicals

to the water heater piping

• If the space heating system requires water temperatures in

excess of 120°F, a mixing valve must be installed per the

manufacturer’s instructions in the potable hot water supply to

devices such as pressure reducing valves, check valves, and back

ow preventers. Devices such as these cause the water system to

be a closed system.

THERMAL EXPANSION

As water is heated, it expands (thermal expansion). In a closed

system the volume of water will grow when it is heated. As the

volume of water grows there will be a corresponding increase in

water pressure due to thermal expansion. Thermal expansion can

cause premature tank failure (leakage). This type of failure is not

covered under the limited warranty. Thermal expansion can also

cause intermittent temperature-pressure relief valve operation:

water discharged from the valve due to excessive pressure build

up. This condition is not covered under the limited warranty. The

temperature-pressure relief valve is not intended for the constant

relief of thermal expansion.

A properly sized thermal expansion tank should be installed

on all closed systems to control the harmful effects of thermal

expansion. Contact a local plumbing service agency to have a

thermal expansion tank installed.

limit the risk of scald injury. See Mixing Valves on Page 18.

• Pumps, valves, piping and fittings must be compatible with

potable water.

• A properly installed ow control valve is required to prevent

thermosiphoning. Thermosiphoning is the result of a continuous

ow of water through the air handler circuit during the off cycle.

Weeping (blow off) of the temperature-pressure relief valve (T &

P relief valve) or higher than normal water temperatures are the

rst signs of thermosiphoning.

• The hot water line from the water heater should be vertical past

any mixing valve or supply line to the heating system to remove

air bubbles from the system. Do not connect the water heater to

any system or components previously used with non-potable water

NOTE: To protect against untimely corrosion of hot and cold

water fittings, it is strongly recommended that di-electric unions

or couplings be installed on this water heater (see Figure 9) when

connected to copper pipe.

heating appliances when used to supply potable water.

STORAGE TANK INSTALLATION

When installing the water heater with a storage tank, see Figure

ater

utlet

Union

Sweat

Fittings

55 on page 60 in Piping Diagrams for suggestions.

NOTE: If ta nk temperatur e is set ab o v e 120°F and wat e r is su p p l i e d

for domestic use (hand washing, showering, etc.) a mixing valve

should be installed in the hot water line to domestic xtures.

Installation must conform to local code requirements. If a check

valve is installed in the cold water supply line, an expansion tank

must be installed between the check valve and the water heater’s

Temperature-

Pressure

Relief Valve

cold water inlet. Set storage tank temperature ve degrees lower

than the water heater’s temperature setting. Using the plug valve,

adjust the ow in the recirculating line to ve gallons per minute.

Sweat

SOLAR INSTALLATION

If this water heater is used as a solar storage heater or as a

backup for the solar system, the water supply temperatures to the

water heater tank may be in excess of 120°F (48.9°C). A mixing

valve must be installed in the water supply line to limit the supply

temperature to 120°F (48.9°C).

Fittings

Shutoff

Valve

Union

Cold

W

Inlet

NOTE: Solar water heating systems can often supply water with

temperatures exceeding 180°F (82.2°C) and may result in water

heater malfunction.

Figure 9

CLOSED WATER SYSTEMS

Water supply systems may, because of code requirements or such

conditions as high line pressure, among others, have installed

19

Page 20

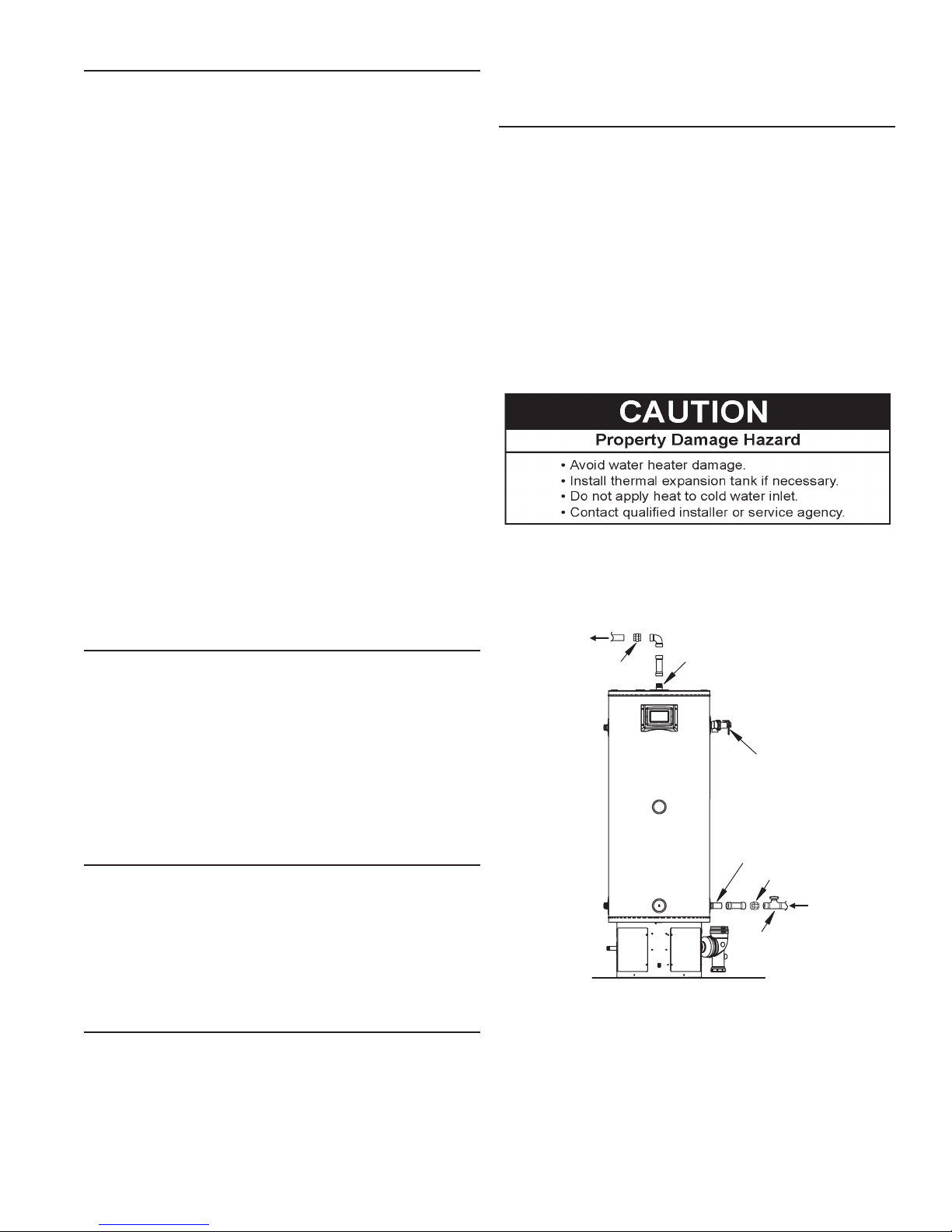

Figure 9 also shows the typical attachment of the water piping

CAUTION

to the water heater. The water heater is equipped with 1” NPT

connections for all models.

NOTE: If using copper tubing, solder tubing to an adapter before

attaching the adapter to the water heater connections. Do not

solder the water lines directly to the water heater connections. It

will damage the tank, T & P Valve and Pipe Insulation (if supplied).

Fit pipe insulation over the incoming cold water line and the hot

water line. Make sure that the insulation is against the top cover

of the heater. Fit T & P valve insulation over valve. Make sure that

the insulation does not interfere with the lever of the T & P valve.

Secure all insulation using tape.

TEMPERATURE-PRESSURE RELIEF VALVE

Explosion Hazard

Temperature-Pressure Relief Valve

must comply with ANSI Z21.22CSA 4.4 and ASME code.

Properly sized temperaturepressure relief valve must be

installed in opening provided.

Can result in overheating and

excessive tank pressure.

Can cause serious injury or death.

Explosion Hazard

Temperature-Pressure Relief Valve

must comply with ANSI Z21.22CSA 4.4 and ASME code.

Properly sized temperaturepressure relief valve must be

installed in opening provided.

Can result in overheating and

excessive tank pressure.

Can cause serious injury or death.

This water heater is provided with a properly rated/sized and

certied combination Temperature-Pressure Relief Valve (T&P

relief valve) by the manufacturer. The valve is certied by a

nationally recognized testing laboratory that maintains periodic

inspection of production of listed equipment of materials as

meeting the requirements for Relief Valves for Hot Water Supply

Systems, ANSI Z21.22 • CSA 4.4, and the code requirements

of ASME.

If replaced, the new T&P valve must meet the requirements

of local codes, but not less than a combination TemperaturePressure Relief Valve rated/sized and certied as indicated in

the previous paragraph. The new valve must be marked with a

maximum set pressure not to exceed the marked hydrostatic

working pressure of the water heater (150 psi = 1,035 kPa) and

a discharge capacity not less than the water heater Btu/hr or

kW inp ut rate as sh o wn on the wate r he ate r ’s mode l ra t ing pla te.

NOTE: In addition to the factory installed Temperature-Pressure

Relief Valve on the water heater, each remote storage tank

that may be installed and piped to a water heating appliance

must also have its own properly sized, rated and approved

Temperature-Pressure Relief Valve installed.

For safe operation of the water heater, the Temperature-Pressure

Relief Valve must not be removed from its designated opening

nor plugged. The Temperature-Pressure Relief Valve must be

installed directly into the tting of the water heater designed for the

Temperature-Pressure Relief Valve. Install discharge piping so that

any discharge will exit the pipe within 6 inches (15.2 cm) above an

adequate oor drain, or external to the building. In cold climates it is

recommended that it be terminated at an adequate drain inside the

building. Be certain that no contact is made with any live electrical

part. The discharge opening must not be blocked or reduced in size

under any circumstances. Excessive length, over 30 feet (9.14 m),

or use of more than four elbows can cause restriction and reduce

the discharge capacity of the valve.

No valve or other obstruction is to be placed between the

Temperature-Pressure Relief Valve and the tank. Do not connect

discharge piping directly to the drain unless a 6” (15.2 cm) air gap

is provided. To prevent bodily injury, hazard to life, or property

damage, the temperature-pressure relief valve must be allowed

to discharge water in adequate quantities should circumstances

demand. If the discharge pipe is not connected to a drain or other

suitable means, the water ow may cause property damage.

Water Damage Hazard

Temperature-Pressure Relief Valve discharge

•

pipe must terminate at adequate drain.

T&P VALVE DISCHARGE PIPE REQUIREMENTS:

• Shall not be smaller in size than the outlet pipe size of the

valve, or have any reducing couplings or other restrictions.

• Shall not be plugged or blocked.

• Shall not be exposed to freezing temperatures.

20

Page 21

• Shall be of material listed for hot water distribution.

• Shall be installed so as to allow complete drainage of both

the Temperature-Pressure Relief Valve and the discharge

pipe.

• Must terminate a maximum of six inches (15.2 cm) above a

oor drain or external to the building. In cold climates, it is

recommended that the discharge pipe be terminated at an

adequate drain inside the building.

• Shall not have any valve or other obstruction between the

temperature-pressure relief valve and the drain.

Burn hazard.

Hot water discharge.

Keep clear of TemperaturePressure Relief Valve

discharge outlet.

The Temperature-Pressure Relief Valve must be manually

operated at least twice a year. Caution should be taken to ensure

that (1) no one is in front of or around the outlet of the TemperaturePressure Relief Valve discharge line, and (2) the water manually

discharged will not cause any bodily injury or property damage

because the water may be extremely hot. If after manually

operating the valve, it fails to completely reset and continues to

release water, immediately close the cold water inlet to the water

heater, follow the draining instructions in this manual, and replace

the Temperature-Pressure Relief Valve with a properly rated/sized

new one.

NOTE: The purpose of a Temperature-Pressure Relief Valve

is to prevent excessive temperatures and pressures in the

storage tank. The T&P valve is not intended for the constant

relief of thermal expansion. A properly sized thermal expansion

tank must be installed on all closed systems to control thermal

expansion, see Closed Water Systems and Thermal Expansion

on Page 19.

If you do not understand these instructions or have any

questions regarding the Temperature-Pressure Relief Valve call

the toll free number listed on the back cover of this manual for

technical assistance.

CONDENSATE DRAIN

The water heaters covered in this manual are condensing water

heaters and require a building drain to be located in close proximity

to allow the condensate to drain safely.

Condensate drains from the water heater at the exhaust elbow

located at the bottom. The eld installed condensate drain line

must not be elevated above the condensate drain connection on

the condensate trap, see Figure 10. If the condensate does not

drain properly it will build up in the exhaust (vent) elbow. This will

restrict the ow of ue gases and cause the Blocked Exhaust

pressure switch to open its contacts. The control system monitors

all pressure switches, if the Blocked Exhaust Switch contacts are

open the control system will lock out and disable heating operation.

The “Blocked Exhaust” Fault message will be displayed on the

control system’s LCD.

The Condensate Cleanout Cap must be on and tight when unit is

in operation.

NOTE: If the “Blocked Exhaust “ Fault message is ever displayed

on the control system LCD, check the condensate drain rst and

ensure it is not blocked.

Old trap piping is not compatible with

new trap piping.

EXHAUST (VENT)

ELBOW

CONDENSATE

DRAIN LINE

CONNECTION

DRAIN LINE TO TERMINATE NO

MORE THAN 6 INCHES (15.2cm)

CONDENSATE

CLEANOUT CAP

CONDENSATE DRAIN

LINE - FIELD INSTALLED

BUILDING

DRAIN

Figure 10

DO NOT remove the factory installed exhaust/condensate elbow

for any reason, see Figure 10. The water heater’s vent pipe is

under a slight positive pressure while unit is in operation. The

water trap inside of the exhaust/condensate elbow prevents ue

gases from escaping into the installed space.

Do not install any external condensate trap. The exhaust elbow

assembly has an internal condensate trap.

Installation must conform with these instructions and local

building codes.

Field supplied materials required for installation include:

• Approved PVC cement and PVC primer.

• 1/2 inch PVC pipe - minimum length to equal the distance

between the water heater and a suitable building drain.

• 1/2 inch PVC ttings (elbows, couplings, and adapters)

necessary to install a condensate drain line between the

Exhaust/Condensate Elbow Assembly and a suitable

building drain.

• Floor mounted standoffs to brace the drain line.

NOTES:

1. The condensate drains from the water heater’s covered by

this instruction have PH levels between 4.3 and 5.0. Install

a commercially available neutralizing kit if required by local

codes. Lower PH levels are acidic. Do not connect a metal

condensate drain line, such as copper pipe, to the water

heater for this reason.

2. The eld installed condensate drain line must not be less than

1/2 inch PVC in size.

3. DO NOT remove, modify or alter the factory condensate trap.

THIS SIDE VIEW

OF EXHAUST

ELBOW AND

ARROW INDICATE

THE LOCATION OF

THE PRESSURE

PORT

ABOVE DRAIN

21

Page 22

VENTING INSTALLATION

VENT INSTALLATION CONSIDERATIONS

This water heater has a direct vent system in which all air for

combustion is taken from the outside atmosphere and all

combustion products are discharged to the outdoors.

This water heater must be properly vented for removal of exhaust

gases to the outside atmosphere. Correct Installation of the vent

pipe system is mandatory for the safe and efcient operation of

this water heater and is an important factor in the life of the unit.

Vent pipe installation must be performed in accordance with state

and local codes, or in the absence of such, the National Fuel

Gas Code, NFPA 54, ANSI Z223.1-current edition. Canadian

installations must be performed in accordance with CAN/CSAB149.1-current edition.

Either 2 inch or 3 inch pipe may be used on the vent termination

for 130,000 & 150,000 Btu/hr models. When concentric venting

130,000 & 150,000 Btu/hr, use only 2 inch concentric vent on the

vent termination. When concentric venting 130,000 & 150,000

Btu/hr models, 3 inch pipe must be reduced to 2 inch concentric

vent at the termination. Use only 3 inch pipe or 3 inch concentric

vent on the vent termination for 175,000 & 199,000 Btu/hr models.

When replacing an existing Polaris unit, it is recommended

that the venting system be reviewed for compliance with the

requirements contained in this instruction manual. If the venting

is not in compliance, it is recommended that the appropriate

changes be made to bring it into compliance. Never operate the

water heater unless it is vented to the outdoors.

Note: It is important that the factory-installed air inlet lter be

inspected periodically and cleaned if necessary. See Integrated

Filter Preventative Maintenance on Page 54 in the Periodic

Maintenance section.

Note: If vent system is not in compliance with the current installation

manual, the manufacturer reserves the right to evaluate installation

prior to granting any warranty on service claims.

Important: Check to make sure the vent pipe is not blocked in

any way.

Note: Do not common vent this water heater with any other

appliance. Do not install in the same chase or chimney with

a metal or high-temperature plastic from another gas or fuel

burning appliance.

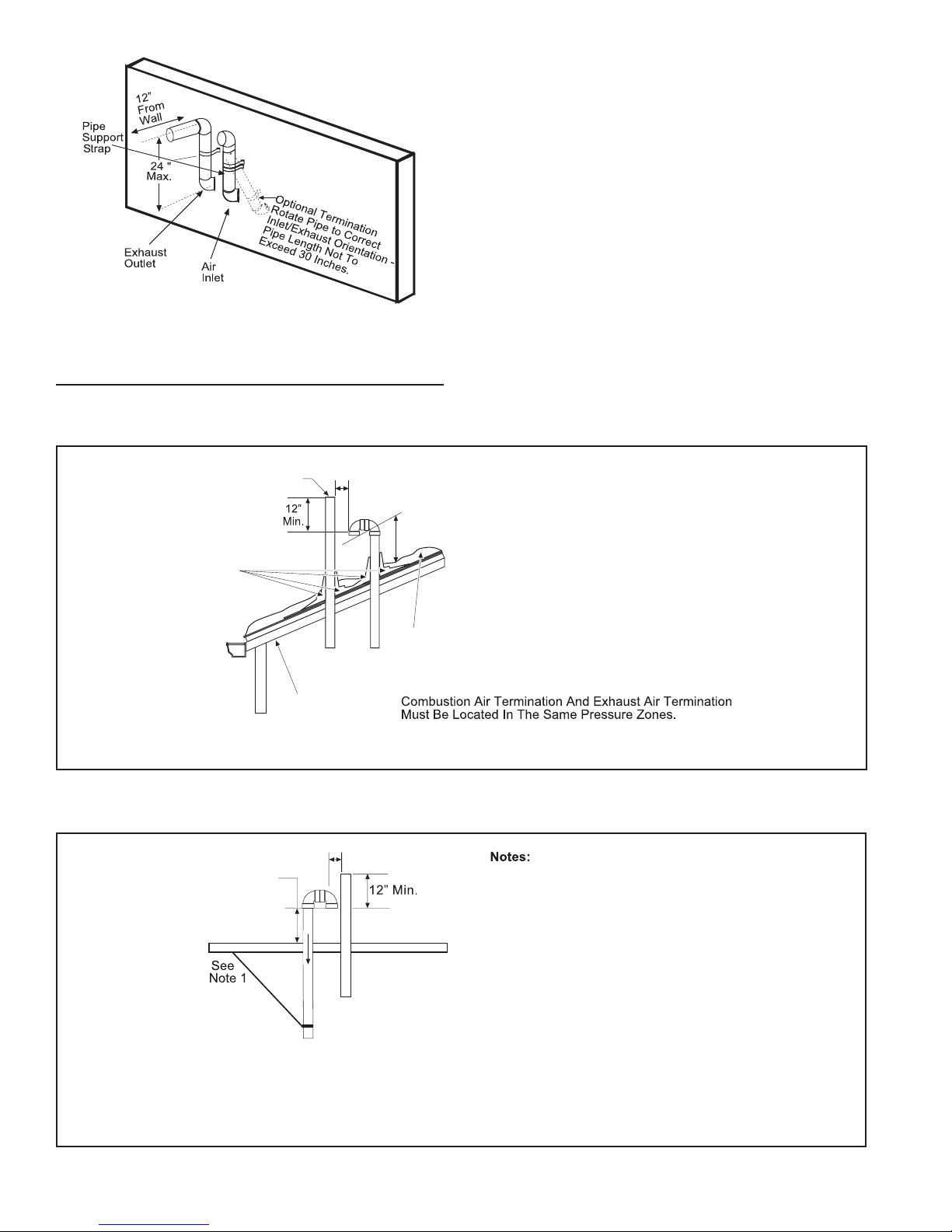

In cold climates any water vapor remaining in the ue gases

will condense into a cloud of vapor at the point where the vent

system exits the building. Special consideration is recommended,

before locating the vent termination near walkways, windows and

building entrances.

Direct venting into dead spaces such as alleys, atriums, and

inside corners can cause recirculation of ue gases. Recirculation

of ue gases will cause sooting, and icing of the combustion air

intake during severe cold weather. To prevent the recirculation

of ue gases, maintain as much distance as possible between

the combustion air intake and the exhaust vent terminal. Refer

to Horizontal Vent Terminal Installation on Page 25 and Vertical

Vent Terminal Installation on Page 26.

GENERAL VENTING INSTRUCTIONS

The following guidelines should be followed when installing the

air inlet and exhaust outlet piping:

• Venting should be as direct as possible with a minimum

number of pipe ttings.

• Vent diameter must not be reduced unless specically noted in

the installation instructions.

• All 2” horizontal inlet vent piping must be sloped downward

1/4 inch per foot (3” Piping must slope downward 1/8” per foot)

toward the water heater so that moisture in the inlet air will exit

through the air intake moisture drain trap.

• All 2” horizontal exhaust vent piping must be sloped upward

1/4 inch per foot (3” Piping must slope upward at 1/8” per foot)

so that condensate will run back to the heater and exit through

the condensate trap.

• Support all horizontal pipe runs every four feet and and all

vertical pipe runs every six feet or according to local codes.

• All venting systems (except Polypropylene vent systems)

run through unconditioned spaces where below freezing

temperatures are expected should be properly insulated

to prevent freezing. For horizontal runs, wrap the vent pipe

with nationally recognized/listed heat tape and/or approved

insulation for freeze protection. Install per the manufacturer’s

instructions.

• An air intake lter is included with the unit and must be installed

according to the installation instructions supplied with the lter.

• It is important to select the proper pipe cement for the type

of plastic pipe being used. All joints in the vent system piping

(except Polypropylene vent systems) must be properly

cemented. Polypropylene vent systems do not use cement to

connect the pipe and elbow sections but use a push together

gasket seal method. Do not attempt to connect Polypropylene

with sealant cement.

• Piping must be sized and cut before cementing. Cut the pipe

end square and remove all ragged edges and burrs. Make sure

the inside of the pipe is clean and free of cuttings and loose dirt.

Chamfer the end and apply primer to the tting and pipe. Apply

a moderate even coat of pipe cement inside the tting. Apply

a liberal amount of cement to the outside of the pipe to socket

depth. Assemble the parts quickly while cement is still wet. Twist

the pipe 1/4 turn during insertion and hold for 30 seconds.