Page 1

BRUTUS™

BRUTUS™ HD

BRUTUS™ HD

Owner's Manual

for Maintenance and Safety

PTO

Page 2

WELCOME

Thank you for purchasing a POLARIS vehicle, and wel come to our world- wide family of POLARIS owners. We proudly produce

an exciting line of utility and recreational products.

• Snowmobiles

• All-terrain vehicles (ATVs)

• BRUTUS

• RANGER® utility vehicles

• Victory® motorcycles®

• Low Emission Vehicles (LEVs)

W e be lieve POLARIS sets a sta ndard of exce llence for all utility and recreat ional vehic les manufact ured in the worl d today. Many

years of experience have gone into the engineering, design, and development of your POLARIS vehicle, making it the finest

machine we’ve ever produced.

For safe and enjoyab le oper at ion of your vehicle, be su re to follow the instr uct io ns and recommendations i n th is owner’s manual .

Your manual contains instructions for minor maintenance, but information about major repairs is outlined in the POLARIS Service Manual and should be performed only by a Factory Certified Master Service Dealer® (MSD) Technician.

Your POLARIS dealer knows your vehicle best and is interes ted in your total satis fa ct ion . Be sure to return to your dealership for

all of your service needs during, and after, the warranty period.

We also take great pride in our complete line of apparel, parts and accessories, available through our online store at www.purepolaris.com. Have your accessories and clothing delivered right to your door!

™ utility vehicles

1

Page 3

POLARIS is registered trademark of and BRUTUS is a trademarks of POLARIS Industries Inc.

Copyright 2013 POLARIS Sales Inc. All information contained within this publication is based on the latest product information

at the time of publication. Due to constant improvements in the design and quality of production components, some minor discrepancies may result between the actual vehicle and the information presented in this publication. Depictions and/or procedures

in this publication are intended for reference use only. No liability can be accepted for omissions or inaccuracies. Any reprinting

or reuse of the depictions and/or procedures contained within, whether whole or in part, is expressly prohibited.

The original instructions for this vehicle are in English. Other languages are provided as translations of the original instructions.

Printed in U.S.A.

2013 BRUTUS Diesel Owner’s Manual

P/N 9924341

2

Page 4

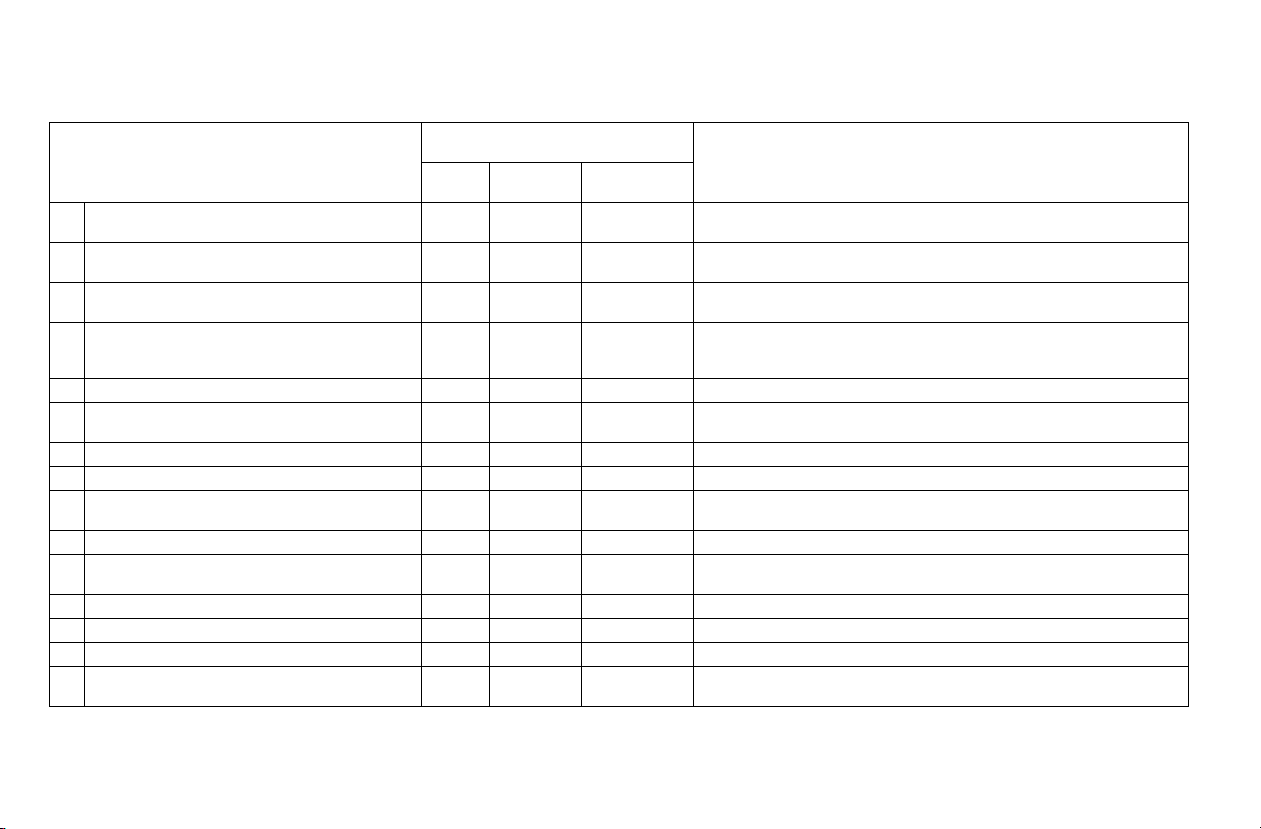

Table of Con tents

Introduction. . . . . . . . . . . . . . . . . . . . . . . . .4

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Features And Controls . . . . . . . . . . . . . . .18

Operation . . . . . . . . . . . . . . . . . . . . . . . . .34

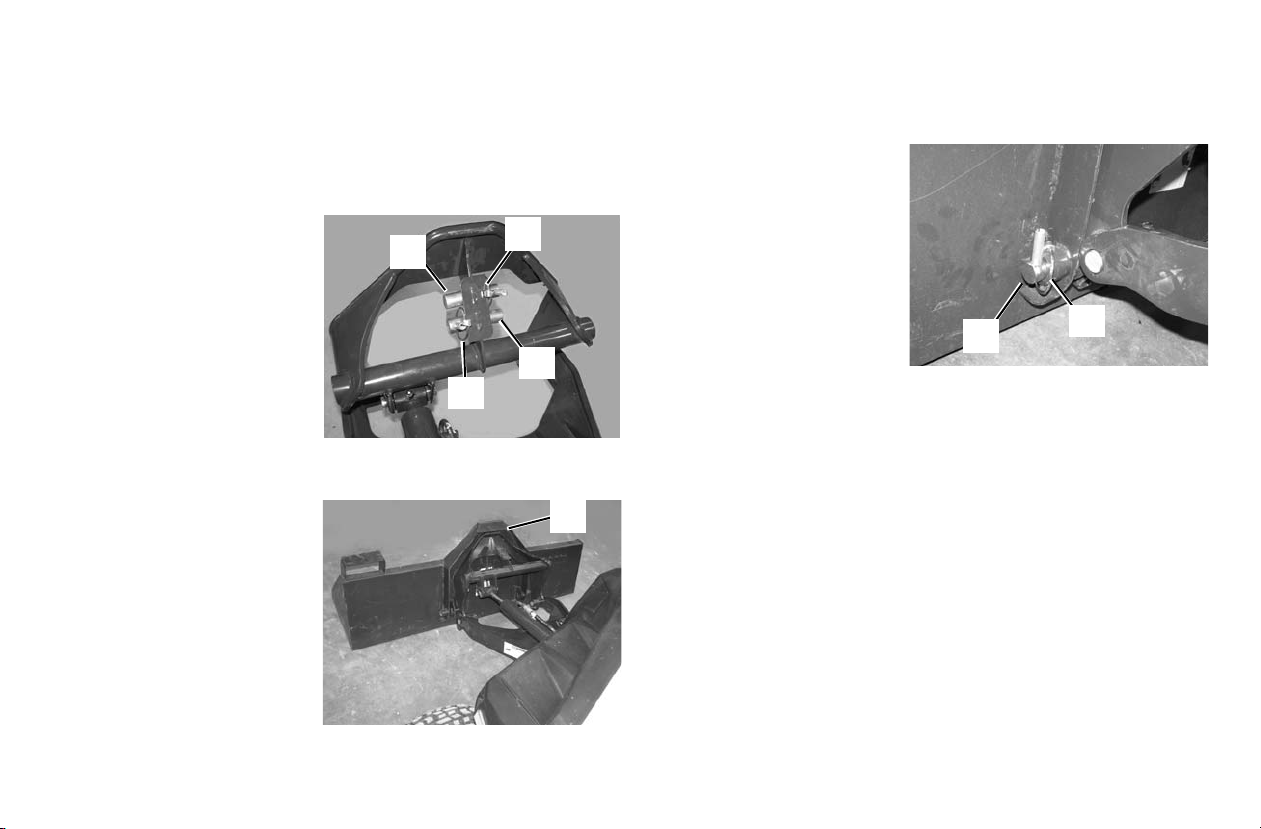

Attachment Arm . . . . . . . . . . . . . . . . . . . .70

PTO System . . . . . . . . . . . . . . . . . . . . . . .74

Emission Control Systems . . . . . . . . . . . .76

Maintenance . . . . . . . . . . . . . . . . . . . . . . .77

Specifications . . . . . . . . . . . . . . . . . . . . .125

Polaris Products . . . . . . . . . . . . . . . . . . .128

Troubleshooting . . . . . . . . . . . . . . . . . . .130

Warranties. . . . . . . . . . . . . . . . . . . . . . . .131

Maintenance Log . . . . . . . . . . . . . . . . . .136

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . .137

3

Page 5

INTRODUCTION

WARNING

Failure to follow the warnings contained in this manual can result in

severe injury or death.

A POLARIS BRUTUS is not a toy and can be hazardous to operate.

This vehicle handles differently than other vehicles, such as

motorcycles and cars. A collision or rollover can occur quickly, even

during routine maneuvers like turning, or driving on hills or over

obstacles, if you fail to take proper precautions.

• Read this owner’s manual. Understand all safety warnings,

precautions and operating procedures before operating the

vehicle. Keep this manual with the vehicle.

• Never permit a guest to operate this vehicle unless the guest has

read this manual and all product labels.

• Always keep hands and feet inside the vehicle at all times

• The Polaris BRUTUS is not intended for on-highway use. Driver

must be at least 16 years old with a valid driver’s license to

operate. Passengers m us t b e a t least 12 years ol d a nd tall enough

to sit with feet firmly on the floor. All SxS drivers should take a

safety training course. Polaris recommends that drivers and

passengers wear helmets, eye protection, and protective clothing,

especially for trail riding and other recreational use. Always wear

seat belts. Be particularly careful on difficult terrain. Never engage

in stunt driving, and avoid excessive speeds and sharp turns.

Riding and alcohol/drugs don’t mix. Check local laws before riding

trails.

The BRUTUS is an off-r oad vehicl e. Familiari ze yourse lf with

all laws and regulations concerning the operation of this vehicle in your area.

The following signal words and symbols appear throughout

this manual and on y our vehicle. Your safety is involved when

these words and symbols are use d. Become familiar with their

meanings before reading the manual.

Safety Symbols and Signal Words

The following signal words and symbols appear throughout

this manual. Your safety and the safety of others is involved

when these words and symbols are used. Become familiar with

their meanings before reading the manual.

The safety alert symbol indicates a potential personal injury hazard.

DANGER

A DANGER ind icates a hazardous situation that, if not avoided, will

result in death or serious injury.

WARNING

A WARNING indicates a hazardous situation that, if not avoided,

could result in death or serious injury.

CAUTION

A CAUTION indicates a hazar dous situat ion that, if not avoided, cou ld

result in minor or moderate injury.

NOTICE

A NOTICE indicates a situation that could result in property damage.

The Prohibition Safety Si gn indicates an ac tion NOT to tak e

in order to avoid a hazard.

The Mandatory Action Sign indicates an action that NEEDS

to be taken to avoid a hazard.

4

Page 6

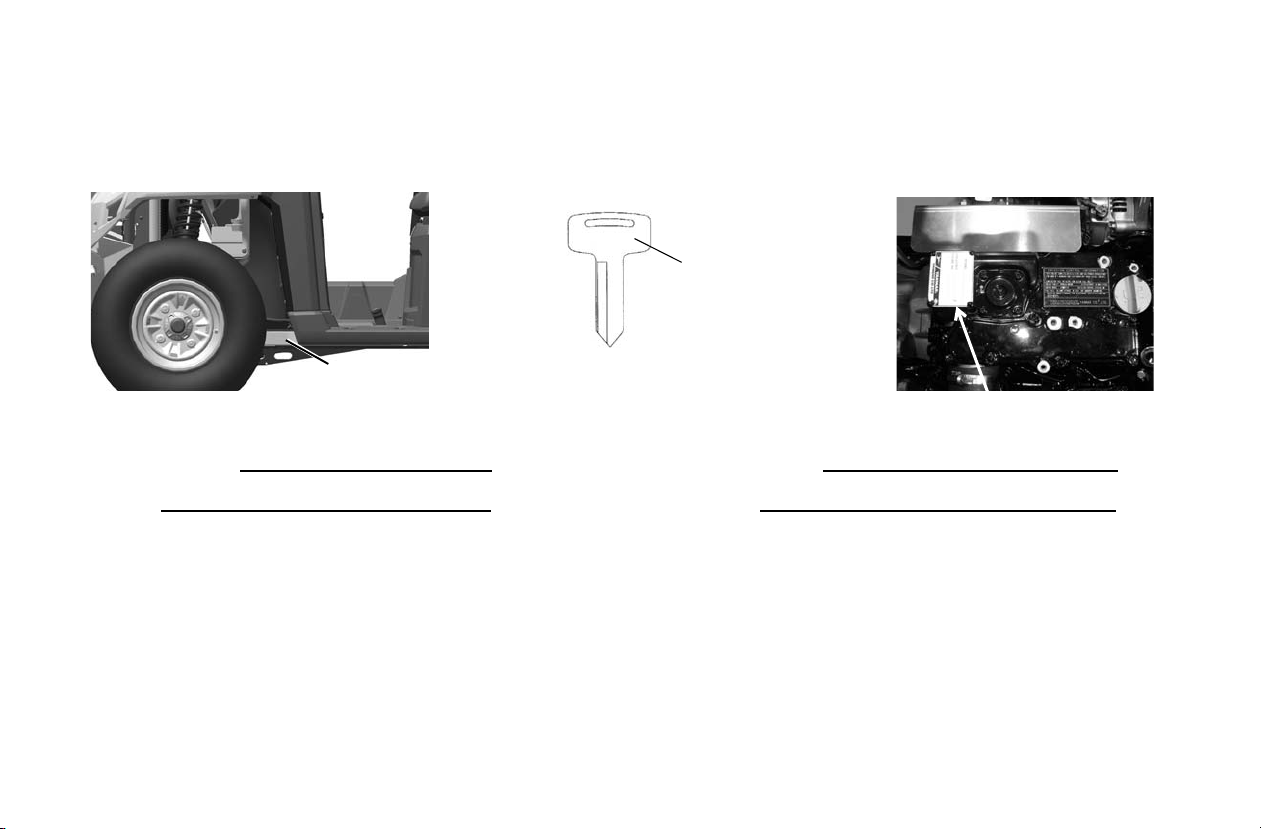

Vehicle Identification Numbers

Engine Serial Number

Key

Number

####

VIN

Record your vehicle's identification numbers and key number

in the spaces provided. Remove the spare key and store it in a

safe place. An ignit ion key can be duplicated only by orde ri ng

INTRODUCTION

a POLARIS key blank (using your key number) and mating it

with one of your existing keys. The ignition switch must be

replaced if all keys are lost

.

Vehicle Model Number:

Frame VIN:

European Vibration and Noise

The driver-perceived noise and hand/arm and whole body

vibration levels of this machinery is measured per prEN

15997.

The operating conditions of the machinery during testing:

The vehicles were i n like-new condition. Th e environ ment was

controlled as indicated by the test procedure(s).

The uncertainty of vibration exposure measurement is depen-

dent on many factors, including:

Engine Serial Number:

Key Number:

• Instrument and calibration uncertainty

• Variations in the machine such as wear of components

• Variation of machine operators such as experience or physique

• Ability of the worke r to reproduce typical work during mea surements

• Environmental factors such as ambient noise or temperature

5

Page 7

Safety

PTO Warning

(If Equipped)

Discretionary

Warning

Age 16

Warning

Shift

Caution

To Start Engine /

To Leave vehicle

Attachment Arm Warning

(If Equipped)

Seat Switch Warning

(If Equipped With PTO)

Towing Warning

Discretionary

Warning

Rotating Fan

Warning

Safety and Information Labels

Warning labels have been placed on the vehicle for your protection. Read and follow the instructions of the labels on the

vehicle carefully. If any of the labels depicted in this manual

differ from the labels on your vehicle, always read and follow

the instructions of the labels on the vehicle.

If any label becomes illegible or comes off, contact your

POLARIS dealer to purchase a replacement. Replacement

safety labels are provided by POLARIS at no charge. The part

number is printed on the label.

6

Page 8

Safety Labels and Locations

Age 16 Warn ing

WARNING

NO OPERATOR UNDER 16

Operating this vehicle if you are under the age of 16 increases your

chance of severe injury or death.

NEVER operate this vehicle if you are under age 16 and NEVER

operate this vehicle without a valid driver’s license.

7175566

To Start Engine / To Leave Vehicle

To Start Engine

• Gear Selector must be in PARK, NEUTRAL or travel control pedal

must be in NEUTRAL.

• PTO must be OFF (If Equipped).

To Leave Vehicle

• Put gear selector in PARK.

• STOP engine.

7179357

Shift Caution

CAUTION

To avoid transmission damage, shift only when vehicle is stationary

and at idle.

7172674

Seat Switch Warning

WARNING

• Check that seat switch is properly installed and functions correctly.

• Replace switch and components if damaged or missing.

7179343

SAFETY

Discretionary Warning

WARNING

Improper vehicle use can result in Serious Injury or Death.

NEVER Operate:

• At speeds too fast for your skills or the conditions.

• After or while using Alcohol or Drugs.

• On hills steeper than 15 degrees 15°.

• On public roads, a collision can occur with a another vehicle.

• With passengers under age twelve or who cannot comfortably

reach the floor and hand holds.

• With unapproved accessori es - they may seriously affect stability.

ALWAYS:

• Wear your seat belt. Vehicle rollover could cause severe injury or

death.

• Wear eye protection and keep hands and feet in vehicle at all

times.

• Reduce speed and use extra caution when carrying passengers.

• Avoid sharp turns or turns while applying heavy throttle.

• Operate slowly in reverse - avoid sharp turns or sudden braking.

• Make sure passenger reads and understands all safety signs.

• Watch for branches or other hazards that could enter vehicle.

LOCATE AND READ OWNER’S MANUAL. FOLLOW ALL

INSTRUCTIONS AND WARNINGS.

7179169

7

Page 9

SAFETY

Safety Labels and Locations

Attachment Arm Wa rning

WARNING

Avoid Serious Injury Or Death.

• Do not excee d attachment arm rated capacity.

• Keep bystanders away. No riders on attachment.

• Keep hands and body from under attachment.

• Do not modify the attachment arm o r use una pprove d att achme nts .

7179168

Rotating Parts Warning

Rotating Parts Can Cause serious Injury Or Death

• Keep PTO shield and all guards in place.

• Keep away from moving parts.

• Keep bystanders away.

• Do not exceed the PTO speed of 2000 RPM

See Owner’s Manual For More Instructions.

.

7179185

Rotating Fan Warning

WARNING

Avoid Serious Injury Or Death .

Do not operate with shields removed.

Do not modify.

7179166

Maximum Trailer Weight Warning

WARNING

Towing An Improperly Loaded Trailer Can Cause Loss Of Control

Resulting In Serious Injury Or Death.

Maximum Tongue Weight: 150 lbs. (68 kg)

Maximum Tow Weight: 2000 lbs. (907 kg)

See Owner’s Manual For More Instructions.

7179167

8

Page 10

Safety Labels and Locations

X

Load/Passenger/Tire Pressure Warning

WARNING

FALLING OFF CARGO BOX CAN CAUSE SERIOUS INJURY OR

DEATH

• Never carry riders in cargo box.

OVERLOADING OR IMPROPER TIRE PRESSURE CAN CAUSE

TIPPING OR LOSS OF CONTROL RESULTING IN SERIOUS

INJURY OR DEATH.

• Never exceed load capacities.

• Reduce speed and allow greater distance for braking when

carrying cargo.

• Carrying tall, off-center, or un-secured loads will increase your risk

of losing control. Center and secure loads as low as possible in

box.

• Reduce speed and cargo on rough or hilly terrain.

• Check for proper tire pressure.

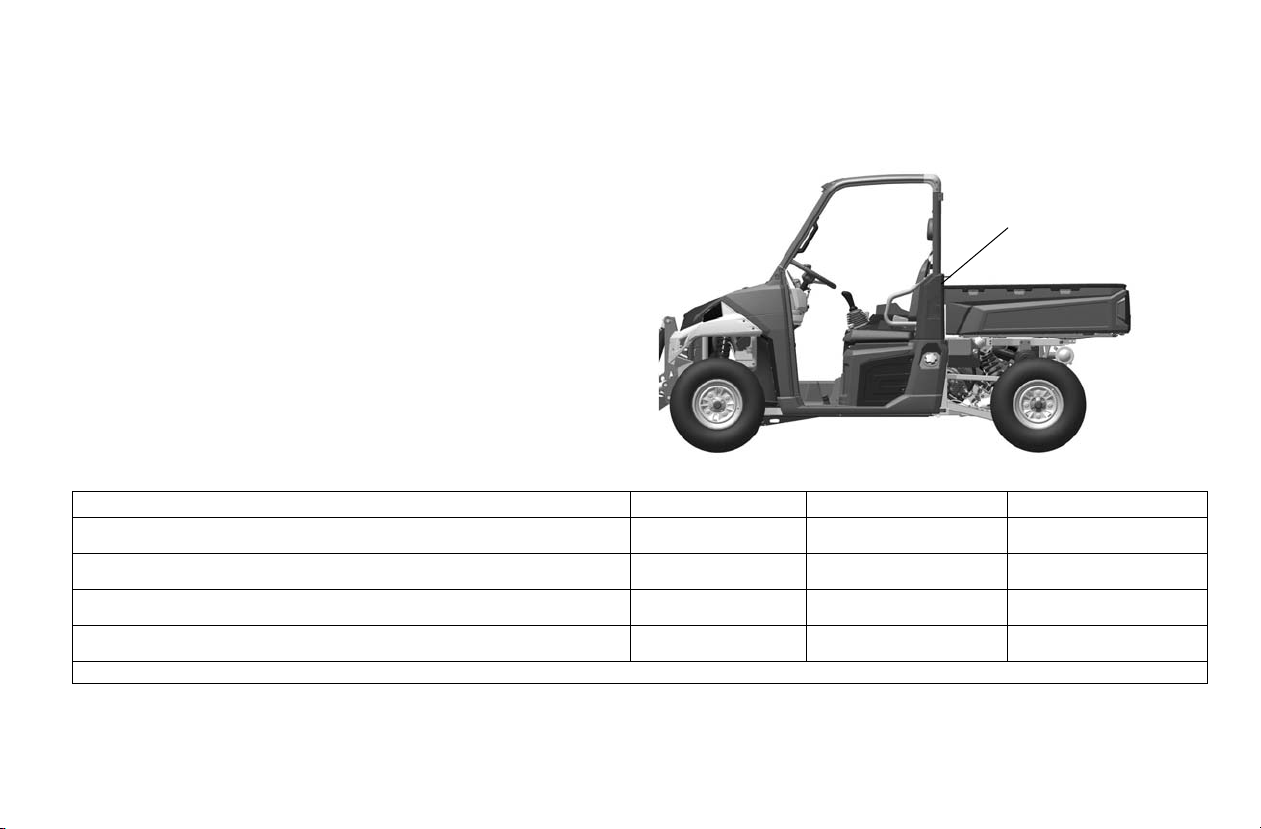

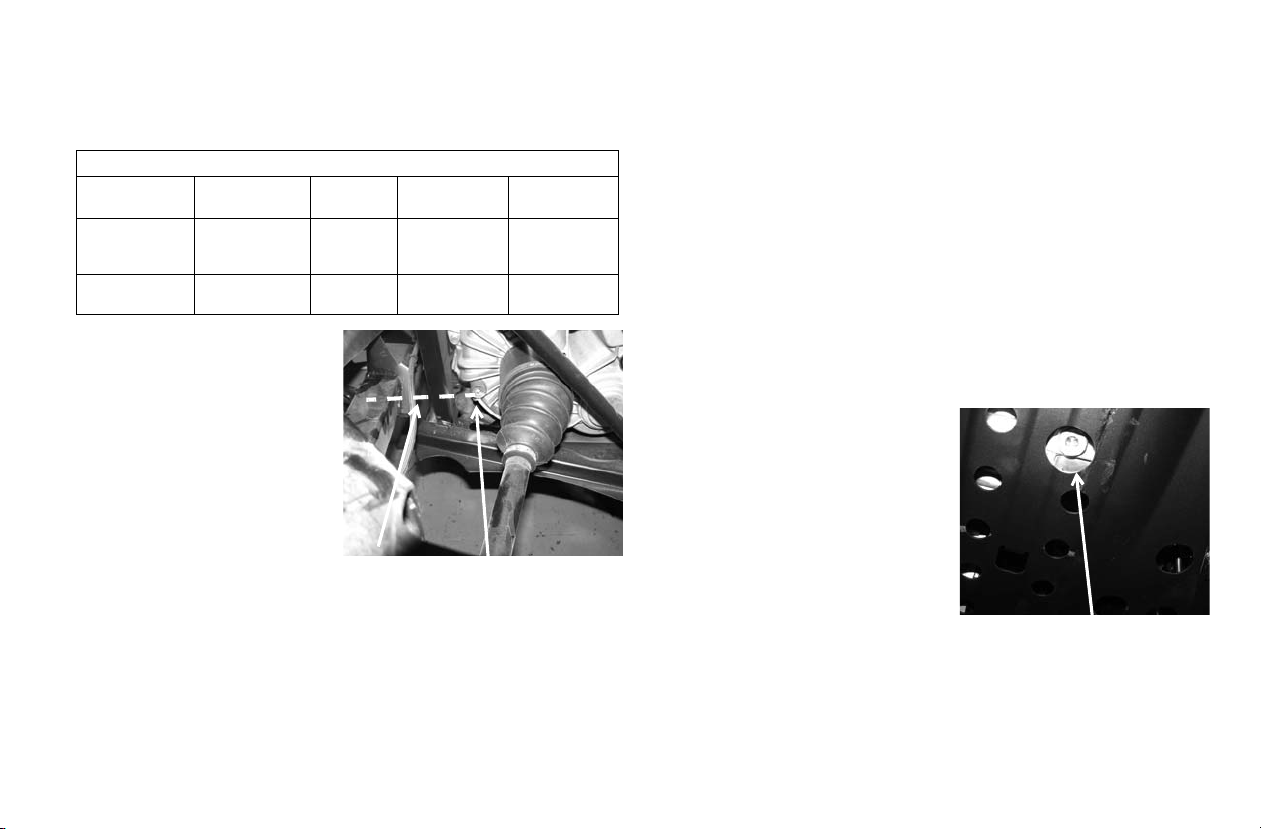

BRUTUS BRUTUS HD BRUTUS HDPTO

MAXIMUM CARGO BOX LOAD 1250 lbs.

ATTACHMENT ARM RATED CAPACITY 500 lbs.

TIRE PRESSURE IN PSI (KPa)

MAXIMUM WEIGHT CAPACITY INCLUDES WEIGHT OF OPERATOR,

PASSENGER, CARGO AND ACCESSORIES

Read Operation and Maintenance Manual for more detailed loading information.

(567 kg)

FRONT 10 (69)

REAR 20 (138)

1750 lbs.

(794 kg)

1250 lbs.

(567 kg)

(225 kg)

FRONT 20 (138)

REAR 20 (138)

2000 lbs.

(907 kg)

SAFETY

1250 lbs.

(567 kg)

500 lbs.

(225 kg)

FRONT 20 (138)

REAR 20 (138)

1750 lbs.

(794 kg)

9

Page 11

SAFETY

Safe Riding Gear

Always wear appropriate clothing when riding a POLARIS

vehicle. Wear protective clothing for comfort and to reduce the

chance of injury.

Eye Protection

Do not depend on eyeglasses or sunglasses for eye protection.

Whenever riding a POLARIS vehicle, always wear shatterproof goggles. POLARIS recommends wearing approved Personal Protective Equipment (PPE) bearing markings such as

VESC 8, V-8, Z87.1, or CE. Make sure protective eye wear is

kept clean.

Gloves

Wear gloves for comfort and for protection from sun, cold

weather and other elements.

Boots

Wear sturdy over-the-ankle boots. Do not ride a POLARIS

vehicle with bare feet.

Clothing

Wear long sleeves and long pants to protect arms and legs.

10

Page 12

Operator Safety

WARNING

SAFETY

Serious injury or death can result if you do not follow these

instructions and proc edures , which are outl ined i n further det ail within

your owner's manual.

• Read this manual and all labels carefully. Follow the operating procedures described.

• Never allow anyo ne unde r age 16 t o operat e this ve hicle an d

never allow anyone without a valid driver's license to operate this vehicle.

• Do not carry passengers until you have at least two hour s o f

driving experience with this vehicle.

• No person under the age of 12 may ride as a passenger in

this vehicle. Any passenger must be able to comfortably

reach the floor and hand holds.

• The driver and all passengers must wear eye protection and

seat belt at all times. All riders should also wear long

sleeves, long pants and sturdy over-the-ankle boots.

• Always keep hands and feet inside the vehicle at all times.

• Always keep both hands on t he ste ering whe el and b oth feet

on the floorboards of the vehicle during operation.

• Never permit a gu est to operate thi s vehicle unless the gue st

has read this manual and all product labels.

• To reduce tipover risk, be especially careful when encountering obstacles a nd slop es and when b raking on hills or during turns.

• This vehicle i s for of f road use onl y . Never operate on pub lic

roads. Always avoid paved surfaces.

• Never consume alcohol or drugs before or while operating

this vehicle.

• Never operate at exce ss ive speeds. Always travel at a speed

proper for the terrain, visibility and operating conditions,

and your experience.

• Never attempt jumps or other stunts.

• Always inspec t t he vehicle before each use to make sure it' s

in safe operating condition. Always follow the inspection

procedures described in this manual.

• Always travel slowly and use extra caution when operating

on unfamiliar terrain. Be alert to changing terrain.

• Never operate on excessively rough, slippery or loose terrain.

• Always follow proper procedures for turning. Practice turning at slow speeds before attempting to turn at faster speeds.

Never turn at excessive speeds.

• Always have this vehicle checked by an authorized

POLARIS dealer if it has been involved in an accident.

• Never operate this vehicle on hills too steep for the vehicle

or for your abilities. Practice on smaller hills before attempting larger hill s.

11

Page 13

SAFETY

Operator Safety

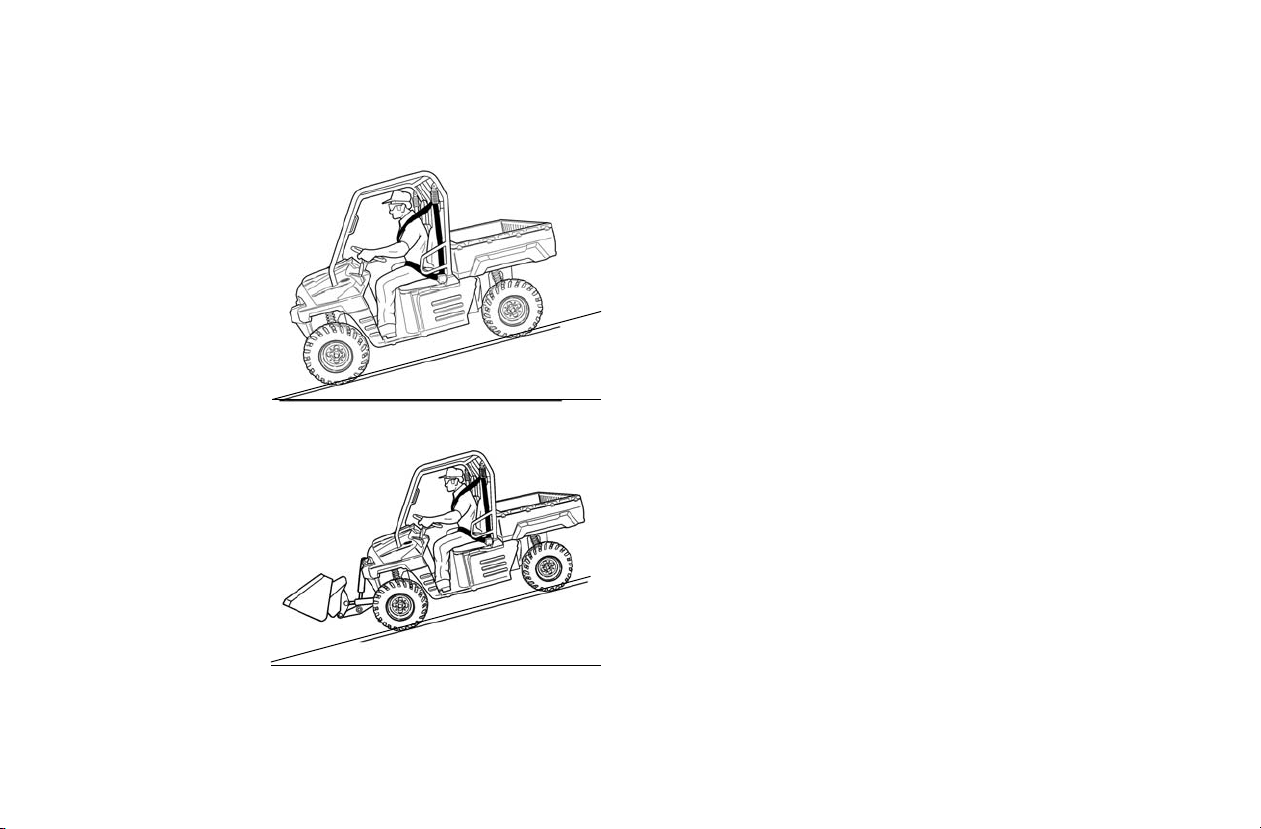

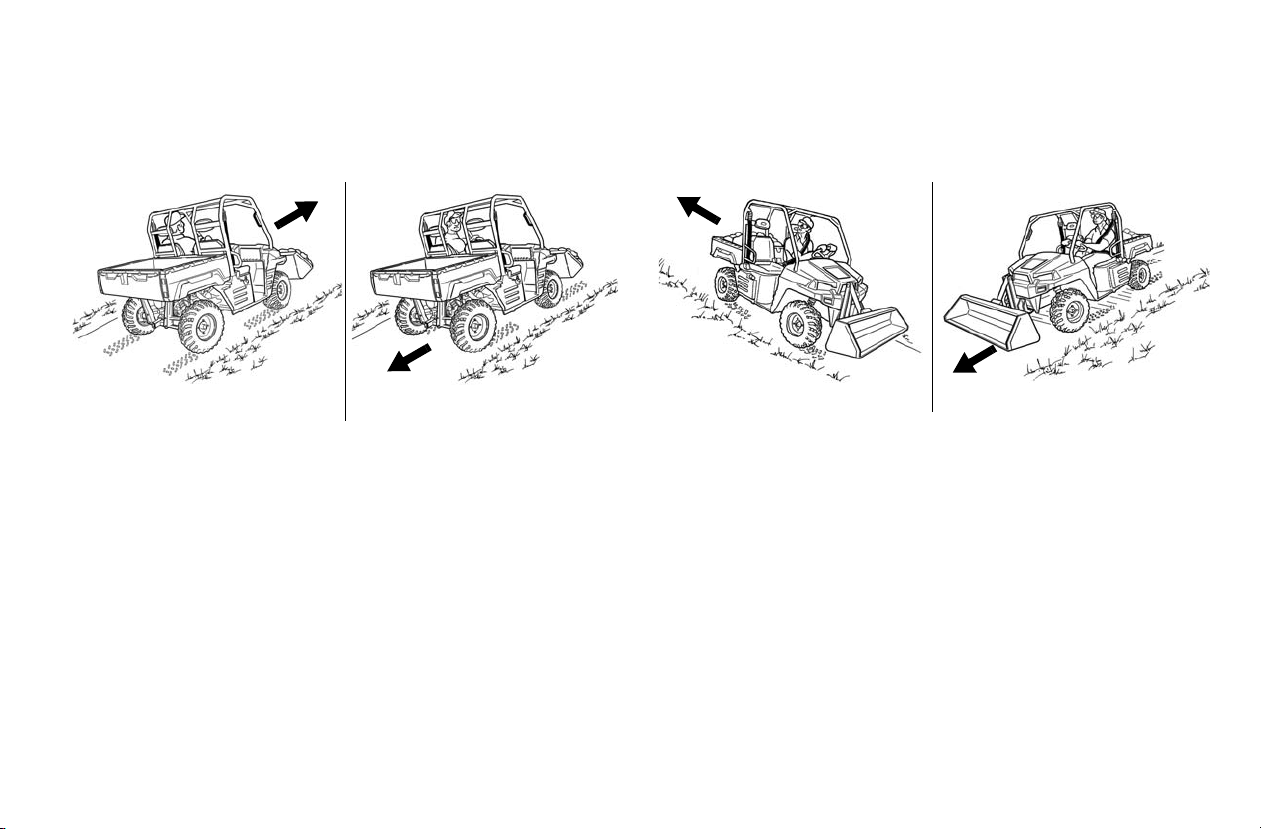

• Always follow proper procedures for climbing hills as

described in this manual. Check the terrain carefully before

attempting to climb a hill. Never climb hills with excessively slippery or loos e surf aces. Nev er mo ve the t ravel control pedal suddenly, make sudden changes of direction or

make sudden gear change s. Never go ove r the top o f a hill a t

high speed.

• Always follow the proper procedures outlined in this manual for traveling downhill and for braking on hills. Check

the terrain carefully before descending a hill. Never travel

downhill at high speed. Avoid going downhill at an angle,

which would cause the vehicle to lean sharply to one side.

Travel straight down the hill where possible.

• Always check for obstacles before operating in a new area.

Never atte mpt to operate over large o bstacles such as roc ks

or fallen trees. Always follow the proper procedures outlined in this manual when operating over obstacles.

• Always be careful of skidding or sliding. On slippery surfaces such as ice, travel slowly and exercise caution to

reduce the chance of skidding or sliding out of control.

• Never operate your ve hicle in f ast- flowin g water or i n water

deeper than that specified in this manual. Wet brakes may

have reduced stoppi ng abilit y. Test your brakes aft er leavi ng

water. If necessary, apply them lightly several times to let

friction dry out the pads.

• Always be sure there are no ob stacles or peopl e behi nd your

vehicle when opera ting i n reve rse. When it's safe to procee d

in reverse, move slowly. Avoid turning at sharp angles in

reverse.

• Always use the proper size and type of tires specified in this

manual. Alw ays maintain proper tire pressure as specified

on safety lab els.

• Never modify this vehicle through improper installation or

use of accessories.

• Never exceed the s tated load ca pacity for th is vehicle. Ca rgo

should be properly distributed and securely attached.

Reduce speed and follow the instructions in this manua l for

hauling cargo, with attach ments insta lled or pull ing a traile r.

Allow a greater distance for braking. Keep the attachment

arm low (if equipped) and slow down when turning.

• Disengage PTO (if equipped), put the gear selector in

PARK, stop the engine and make sure all rotating components are stopped before exiting utility vehicle.

• Always stop the engine before refueling. Remove flammable material co ntainers f rom the box before fi lling them wi th

fuel. Make sure the refueling area is well ventilated and free

of any source of flame or sparks. Fuel is extremely flammable. See page 38 for fuel safety warnings.

• Always remove the ignition key when the vehicle is not in

use to prevent unauthorized use or accidental starting.

FOR MORE INFORMATION ABOUT SAFETY, call

POLARIS at 1-800-342-3764.

12

Page 14

Operator Safety

WARNING

Equipment Modifications

We strongly recommend that consumers do not install on a

POLARIS BRUTUS any equipment that may increase the

speed or power of the ve hicle, or make any other modification s

to the vehicle for these purposes. Any modifications to the

original equipment of the vehicle create a substantial safety

hazard and increase the risk of bodily injury.

The warranty on your POLARIS BRUTUS is terminated if

any equipment has been added to the vehicle, or if any modifications have been made to the vehicle, that increase its speed

or power.

The addition of certain accessories, including (but not limited

to) mowers, blades, tires, spraye rs, or large racks, may change

the handling characteristics of the vehicle. Use only

POLARIS-approved accessories and attachments, and familiarize your self with their function and effect on the vehic l e.

Failure to operate the BRU TUS properly can result in a collis ion , loss

of control, accident or overturn, which may result in serious injury or

death. Heed all safety w arnings outlin ed in this sec tion of the ow ner’s

manual. See the OPERATION section of the owner’s manual for

proper operating procedures.

SAFETY

Age Restrictions

This vehicle is an ADULT

VEHICLE ONL Y. NEVER operate

this vehicle if you are under age

16 and NEVER operate wi tho ut a

valid driver’s license.

No person under the age of 12

may ride as a passenger in this

vehicle. Any passenger must be

able to comfortably reach the

floor and hand holds.

Operating Without

Instruction

Operating this vehicle without

proper instruction increases the

risk of an accident. The operator

must understand how to operate

the vehicle properly in different

situations and on different types of

terrain.

All operators must read and

understand the Own er' s Ma nua l

and all warning and instruction labels before operating the vehicle.

13

Page 15

SAFETY

Operator Safety

Using Alcohol or Drugs

Operating the vehicle afte r

consuming alcohol or drugs could

adversely affect operator judgment,

reaction time, balance and

perception.

Never drink alcohol or use drugs or

medications before or while

operating this vehicle.

Seat Belts

Riding in this vehicle without wearing the seat belt increases the risk

of serious injury in the event of an accident or sudden stop. Riders

must wear seat belts at all times. Seat belts reduce the severity of

injury in the event of a sudden stop or accident. Always make sure

the seat belts are secured for both the operator and passengers

before riding.

Always follow these guidelines:

Under ANY of these conditions: Do ALL of these steps:

Passenger and/or cargo exceeds half the maximum weight capacity 1. Slow down.

Operating in rough terrain

Operating over obstacles

Climbing an incline

Towing

Operating with attachments installed

Protective Eyewear

Riding in this vehicle without wearing protective eye wear increases

the risk of a serious injuries in the event of an accident.

Operator and all passengers must always wear approved eye

protection (goggles).

Operating With a Load on the Vehicle

The weight of both cargo and passengers impacts vehicle operation.

For your safety and the safety of others, carefully consider how your

vehicle is loaded and how to safely operate the vehicle. Follow the

instructions in this manual for loading, tire pressure, gear selection

and speed.

• Do not exceed vehicle weight capacities. The vehi cle’ s maxim um

weight capacity is listed in the specifications section of this manual

and on a label on the vehicle. When more passenger weight is

added, cargo weight may need to be reduced accordingly.

• The recommended tire pressures are listed in the specifications

section of this manual and on a label on the vehicle.

2. Verify tire pressure.

3. Use extra caution when operating.

14

Page 16

Failure to Inspect Before Operating

Failure to inspect and verify that the vehicle is in safe operating

condition before operating increases the risk of an accident.

Always inspect your BRUTUS before each use to make sure it's in

safe operating condition.

Always follow all inspection and maintenance procedures and

schedules described in the owner's manual.

Exposure to Exhaust

Engine exhaust fumes are poisonous and can cause loss of

consciousness o r death i n a sh ort time . Nev er st art the engin e or let it

run in an enclosed area.

The engine exhaust from this product contains chemicals known to

cause cancer, birth defects or other reproductive harm. Operate this

vehicle only outdoors or in well-ventilated areas.

Operating a Damaged Vehicle

Operating a damaged vehicle can result in an accident. After any

overturn or accident, have a qualified service dealer inspect the entire

machine for possible damage, including (but not limited to) brakes,

throttle and steering systems.

Operating at Excess ive Speeds

Operating this vehicle at excessive speeds increases the operator's

risk of losing control. Alway s operat e at a speed that's appropria te for

the terrain, the visib ility and operating co ndi tio ns, your skills and your

passengers’ skills.

SAFETY

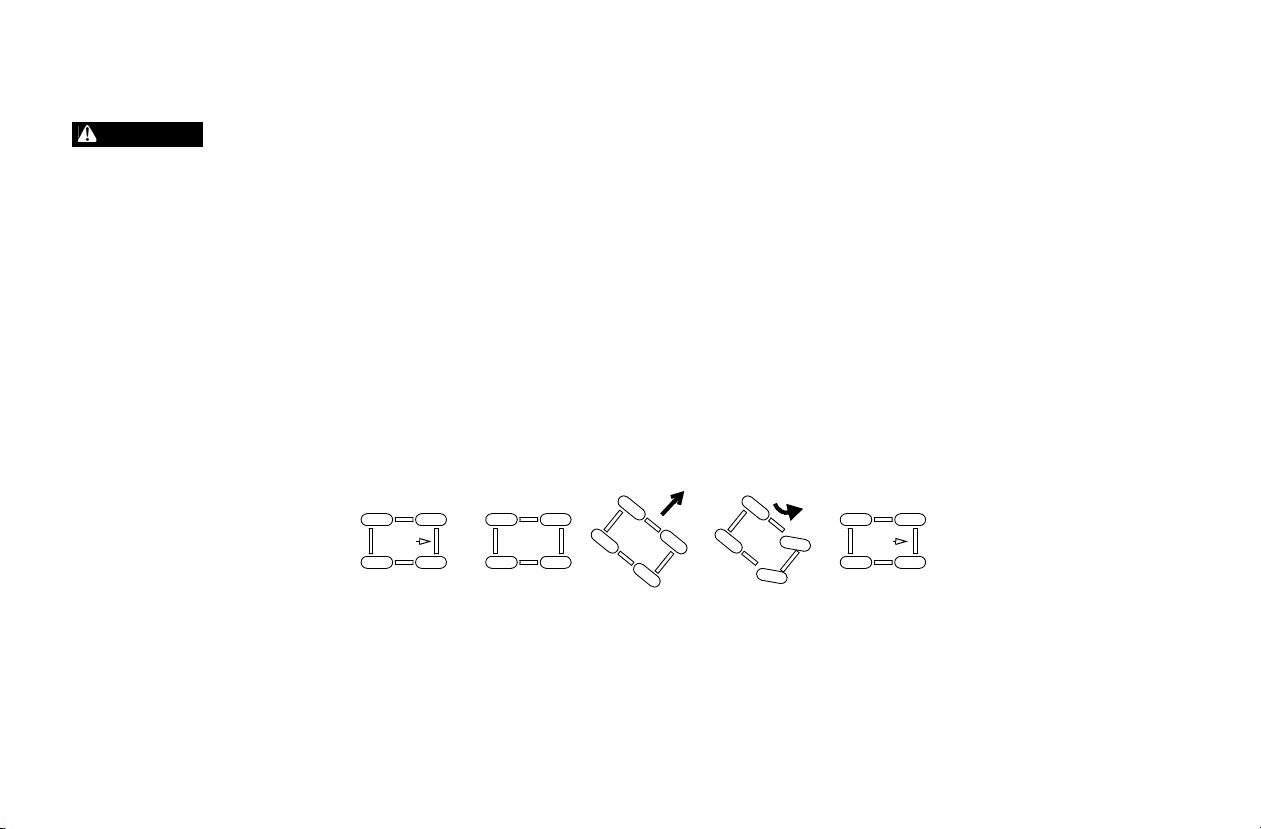

Turning Improperly

Turning improperly could cause loss of traction, loss of control,

accident or overturn. Always follow proper procedures for turning.

Never turn abruptly or at sharp angles. Never turn at high speeds.

Practice turning at slow speeds before attempting to turn at faster

speeds.

Operating on Pavement

This vehicle's tires are designed for off-road use only, not for use on

pavement. Operating this vehicle on paved surfaces (including

sidewalks, paths, parking lots and driveways) may adversely affect

the handling of the vehicle and could result in loss of control and

accident or overturn.

Avoid operating the vehicle on pavement. If it's unavoidable, travel

slowly and avoid sudden turns or stops.

15

Page 17

SAFETY

Operator Safety

Operating on Public Roads

Operating this vehicle on public streets, roads or highways could

result in a collision with another vehicle.

Never operate this vehicle on any public street, road or highway,

including dirt and gravel roa ds . In som e are as it' s unlaw fu l to ope rate

this vehicle on public streets, roads and highways.

Jumps and Stunts

Attempting wheelies, jumps and other stunts increases the risk of an

accident or overturn. Never attempt wheelies, jumps, or other stunts.

Avoid exhibition driving.

Operating in Unfamiliar Terrain

Failure to use extra caution when operating on unfamiliar terrain

could result in an ac ci den t or overturn. Unfamili ar te rrain may contain

hidden rocks, bumps, or holes that could cause loss of control or

overturn.

Travel slowly and use extra caution when operating on unfamiliar

terrain. Always be alert to changing terrain conditions.

Operating on Slippery Terrain

Failure to use extra caution when operating on excessively rough,

slippery or loose terrain could cause loss of traction, loss of control,

accident or overturn.

Do not operate on excessively slippery surfaces.

Always reduce speed and use additional caution when operating on

slippery surfaces.

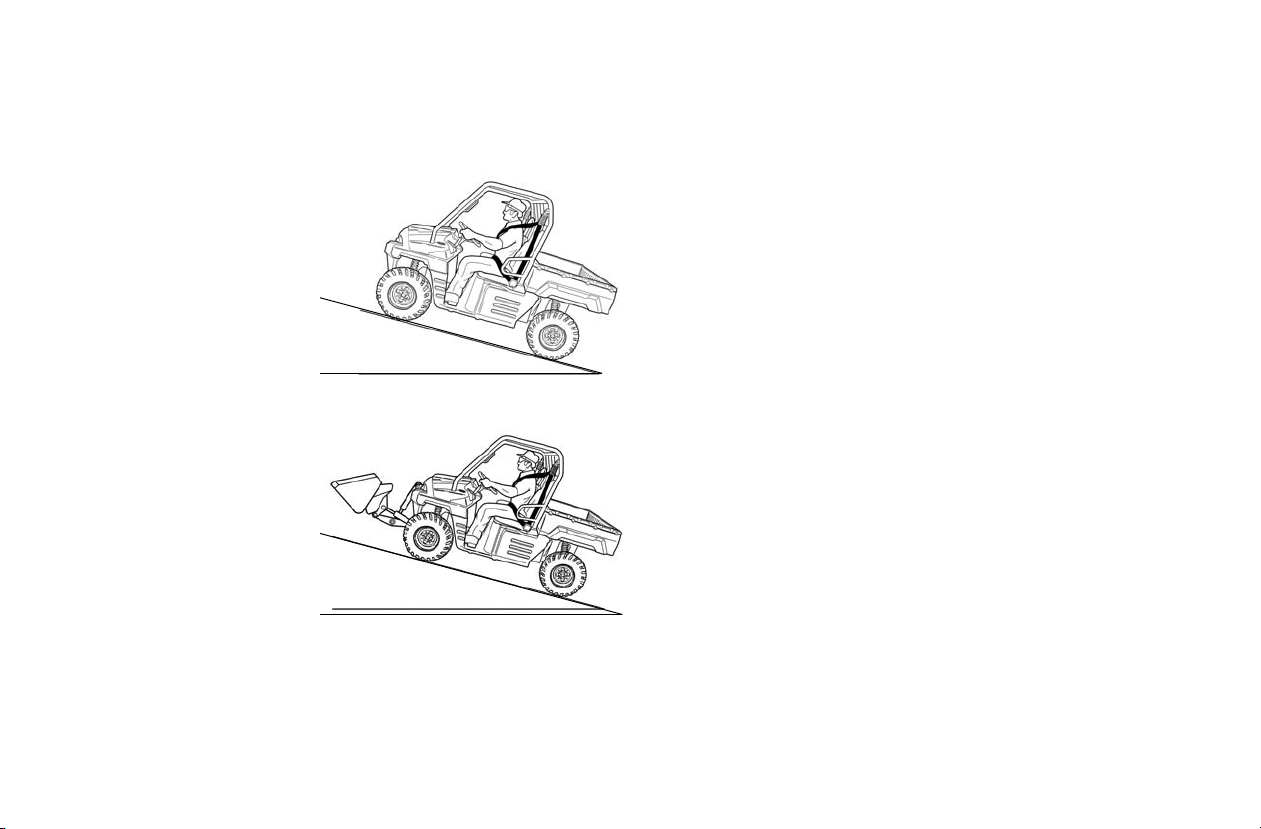

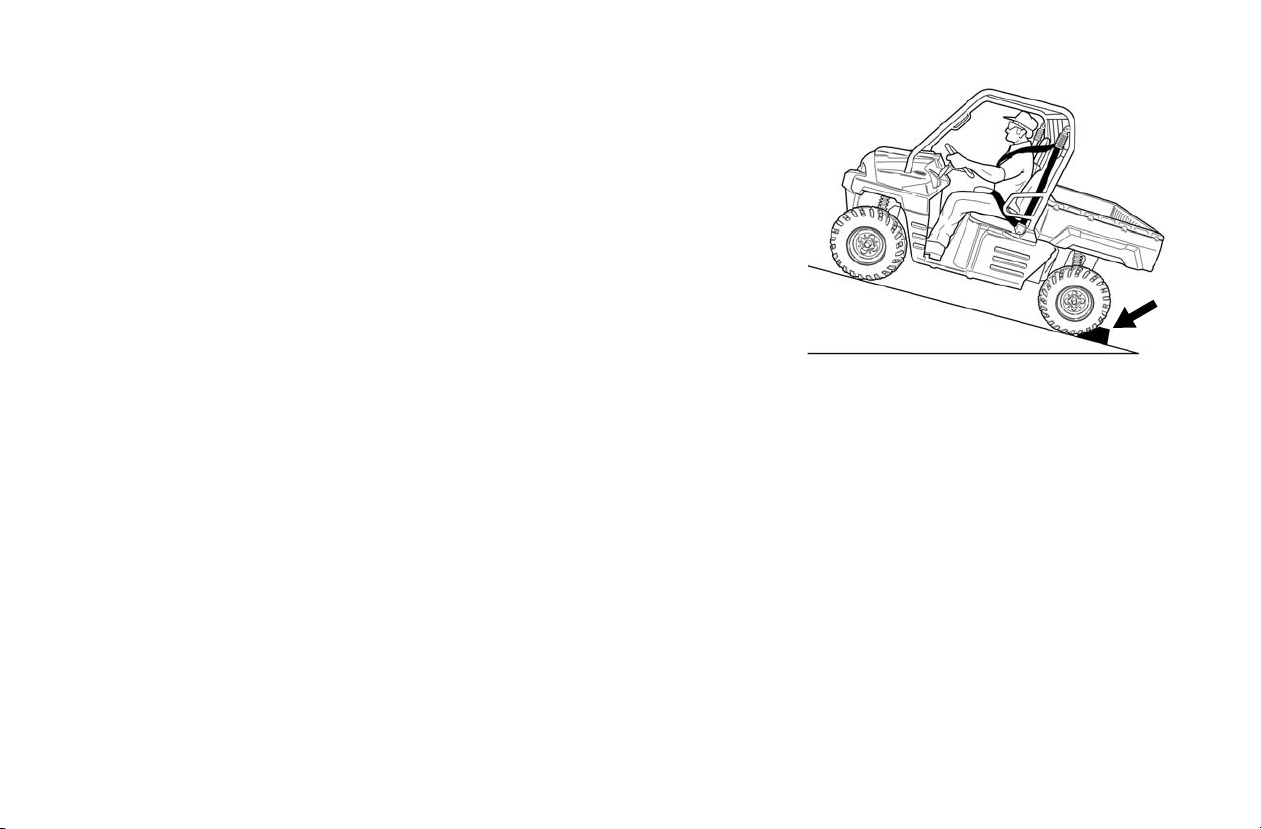

Improper Hill Climbing

Climbing hills imp roperly can ca use loss of co ntrol or vehicl e overturn.

Always follow proper procedures for clim bin g h ill s as described in the

owner's manual. See page 53.

Stalling While Climbing a Hill

Stalling or rolling backwards while climbing a hill could cause an

overturn. Always maintain a steady speed when climbing a hill.

If all forward speed is lost (engine running):

• Use the travel control pedal to slowly back the vehicle straight

downhill.

• If necessary, apply brake pressure to control speed.

If all forward speed is lost (engine not running):

• Apply the brakes and attempt to restart the engine.

• If engine will not restart, place transmission in neutral and slowly

allow the vehicle to roll straight downhill while applying brake

pressure to control speed.

16

Page 18

Operator Safety

Improper Tire Maintenance

Operating this vehicle with improper tires or with improper or uneven

tire pressure could cause loss of control or accident.

Always use the size and type of tires specified for your vehicle.

Always maintain proper tire pressure as described in the owner's

manual and on safety labels.

Operating on Frozen Bodies of Water

Severe injury or dea th c an re sul t i f th e vehicle and/or the op era tor fall

through the ice. Never operate the vehicle on a frozen body of water

unless you have first v erified that the i ce is suf fi cientl y thi ck t o sup port

the weight and moving force of the vehicle, yo u and your pass engers,

and your cargo, t ogether with any other v ehicl es in your party. Always

check with local authorities and residents to confirm ice conditions

and thickness over your entire route. Vehicle operators assume all

risk associated with ice conditions on frozen bodies of water.

Unauthorized Use of the Vehicle

Leaving the keys in the ignition can lead to unauthorized use of the

vehicle, which cou ld re sult in an accident o r ov ert urn. Always remove

the ignition key when the vehicle is not in use.

Hot Exhaust Systems

Exhaust system components are very hot during and after use of the

vehicle. Hot components can cause burns and fire. Do not touch hot

exhaust system components. Always keep combustible materials

away from the exhaust system. Use caution when traveling through

tall grass, especially dry grass.

SAFETY

Attachment Arm System (If Equipped)

The dealer explains the capabilities and restrictions of the BRUTUS

utility vehicle, attachment and accessories for each application. The

dealer demonstrates the safe operation according to Polaris

instructional materials, which are also available to operators. The

dealer can also identify unsafe modifications or use of unapproved

attachments and accessories. The attachments and buckets are

designed for an attachment arm Rated Capacity. They are designed

for secure fastening to the BRUTUS utility vehicle. The user must

check with the deale r, or POLARIS literature, to determine safe lo ads

of materials of specified densities for the vehicle - attachment

combination.

Safety Rules For Power Take-Off (PTO) Driven

Attachments (If Equipped)

• Keep PTO shields and all guards in place. Replace damaged or

missing shields and guards before operating.

• Follow warnings and instructions on machine signs (decals).

Replace damaged or missing decals.

• Do not wear loose or bulky clothing around the PTO or other

moving parts.

• Keep bystanders away from PTO driven equipment, and never

allow children near machines.

• Read and understand the manuals for the PTO driven equipment

and be aware of safe operating procedures and hazards that may

not be readily apparent.

• Always walk around equipment to avoid coming near a turning

PTO driveline. Stepping over, leaning across or crawling under a

turning PTO driveline can cause entanglement.

• Position the machine and attachment correc tl y to prevent driveline

stress.

• Use caution when raising PTO driven attachment. Excessive

driveline angle can reduce driveline service life.

17

Page 19

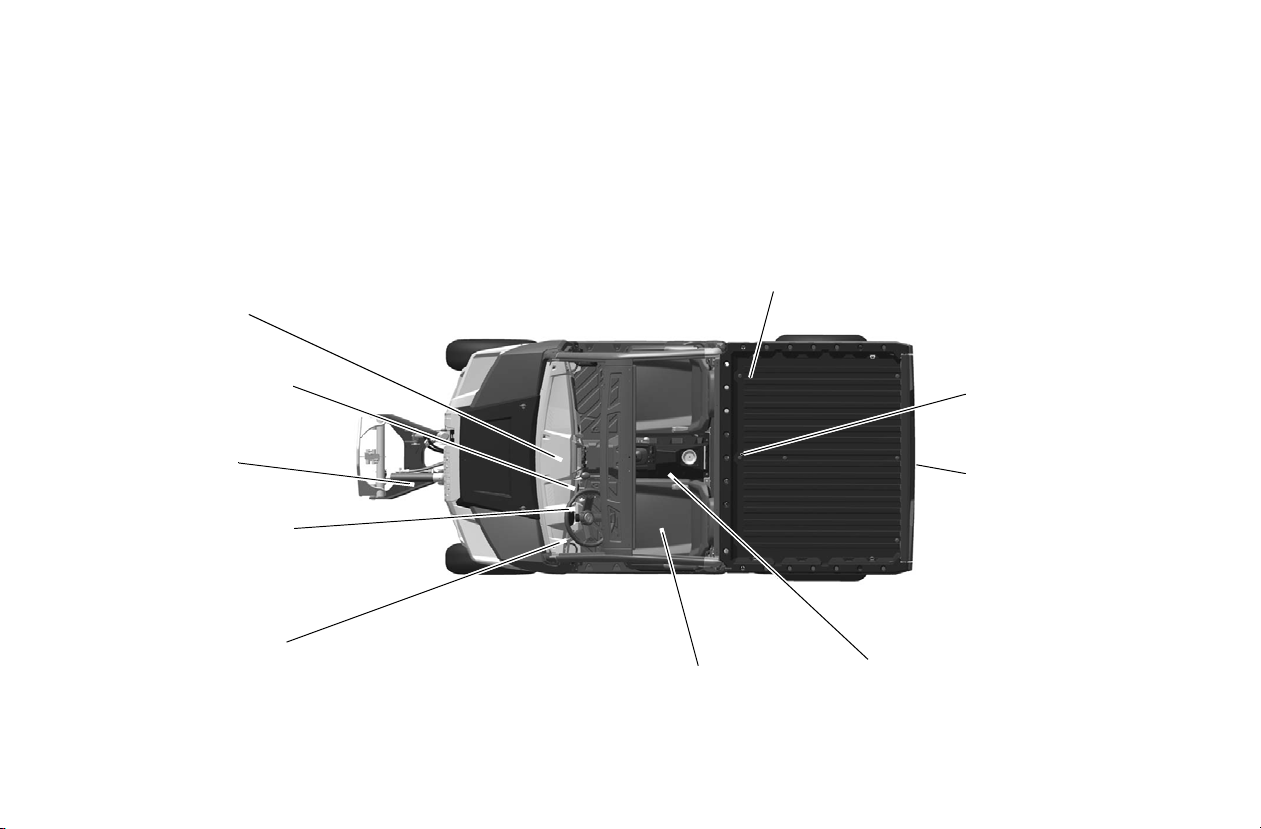

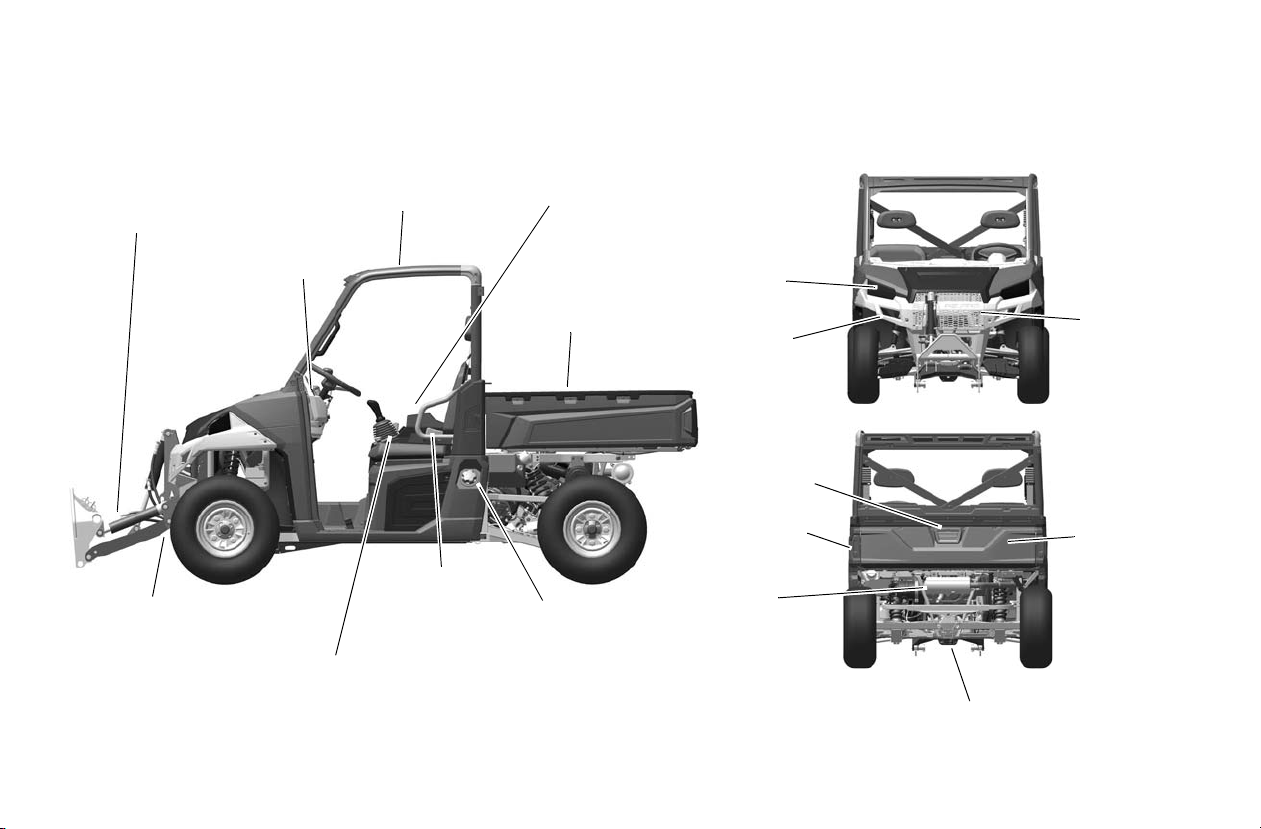

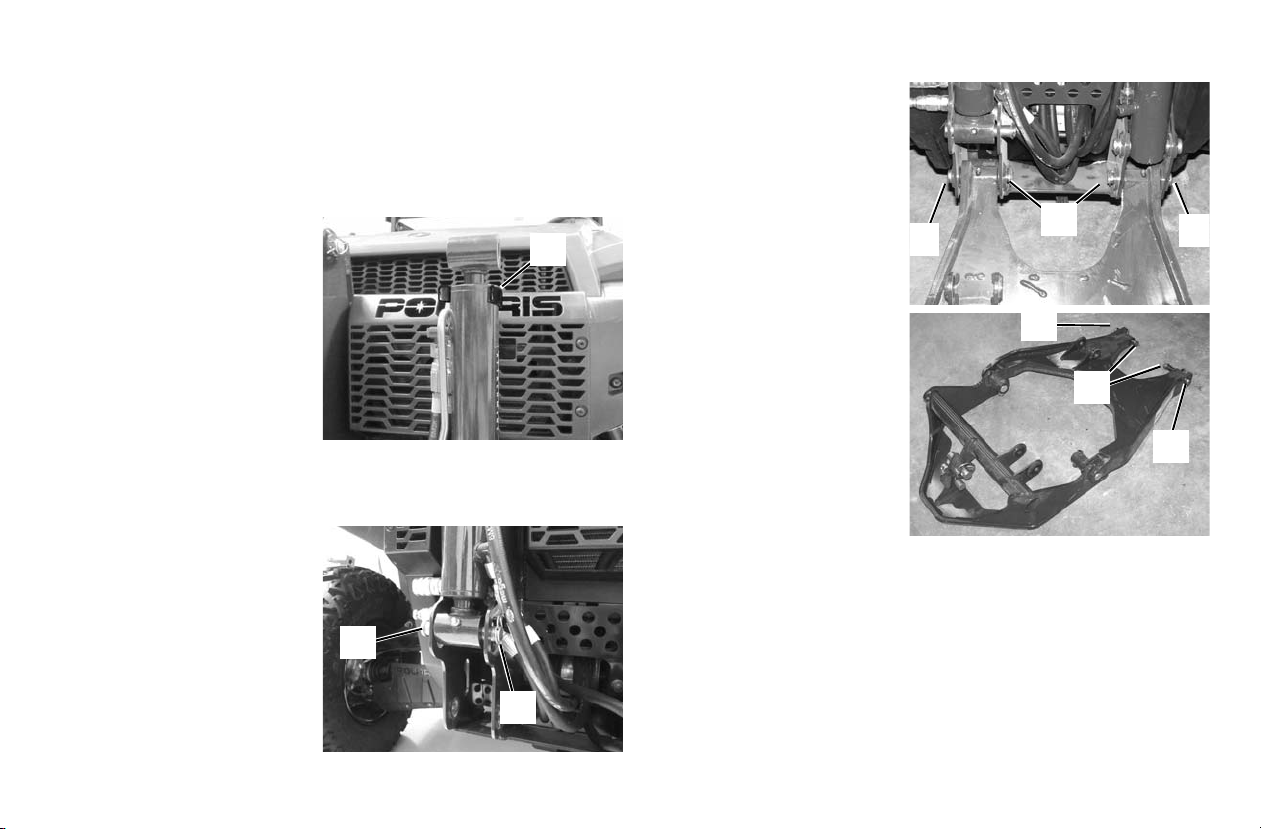

FEATURES AND CONTROLS

Front Bumper/

Brush Guard

Radiator

ROPS / OPS

Cab Frame

Console

Hip Bar

Cargo Box

Fuel Tank Cap

Tailgate Latch

Release

Receiver Hitch

Muffler

(Spark Arrester)

Tailgate

Storage Compartment

Under Seats

Headlights

Center Console

(Model HD and HD

PTO Only)

Attachment Arm

(Model HD and HDPTO Only)

PTO

(Model HDPTO Only)

Taillights

Component Locations

Not all models come with all features. Refer to the specifications section on page 125.

18

Page 20

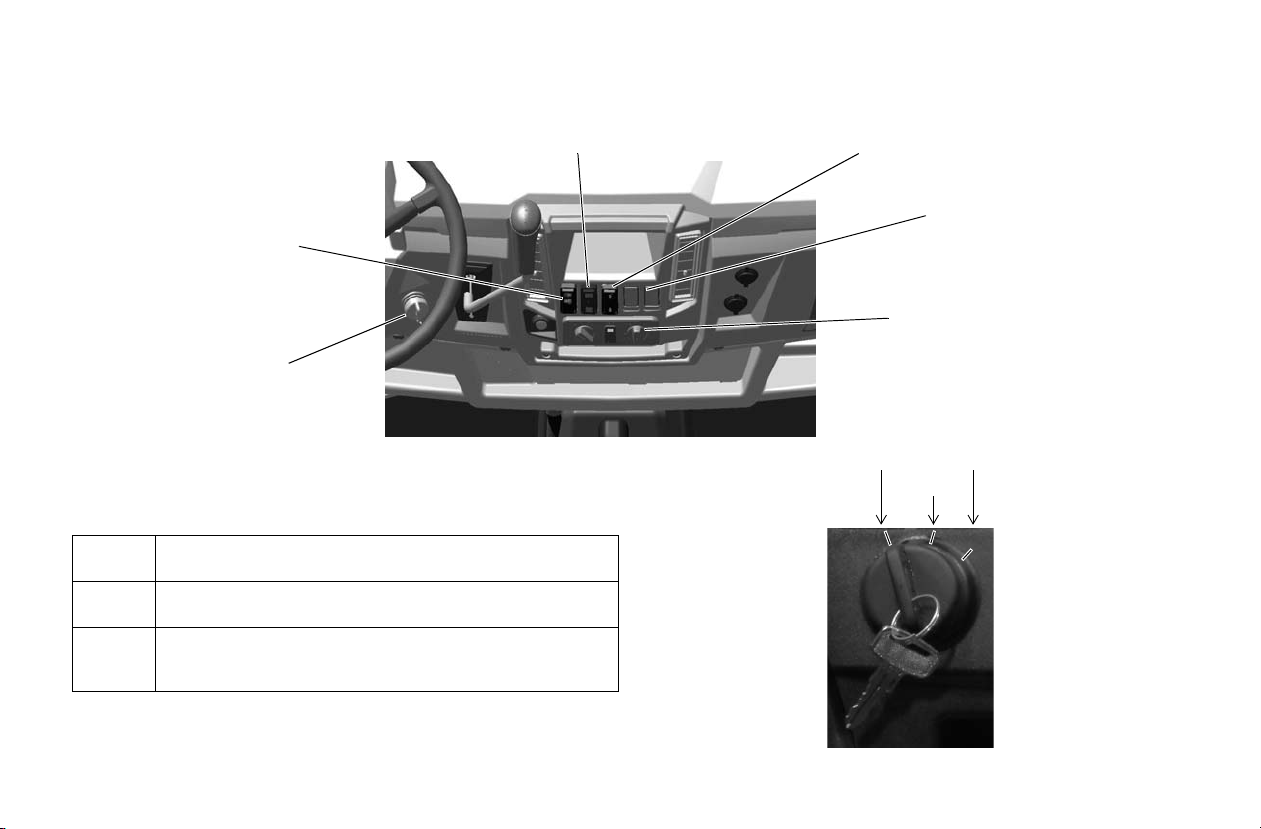

Switches and Indicator Lights

Ignition

Switch

Light Switch

AWD/Differential Switch

Power Lift Assist Switch

(If Equipped)

Blank Switch Op enings -

Available For Accessories

HVAC Switches

(If Equipped)

STARTOFF

ON

Ignition Switch

The ignition switch is a three-position, key-operated switch.

The key can be removed from the switch in the OFF position.

OFF The engine is off. Electrical circuits are off, except Acc,

ON Electrical circuits are on. Electrical equipment can be

START After the wait-to-start indicator turns off, turn the key to

12V.

used.

the START position to engage the electric starter. The

key returns to the ON position when released.

FEATURES AND CONTROLS

19

Page 21

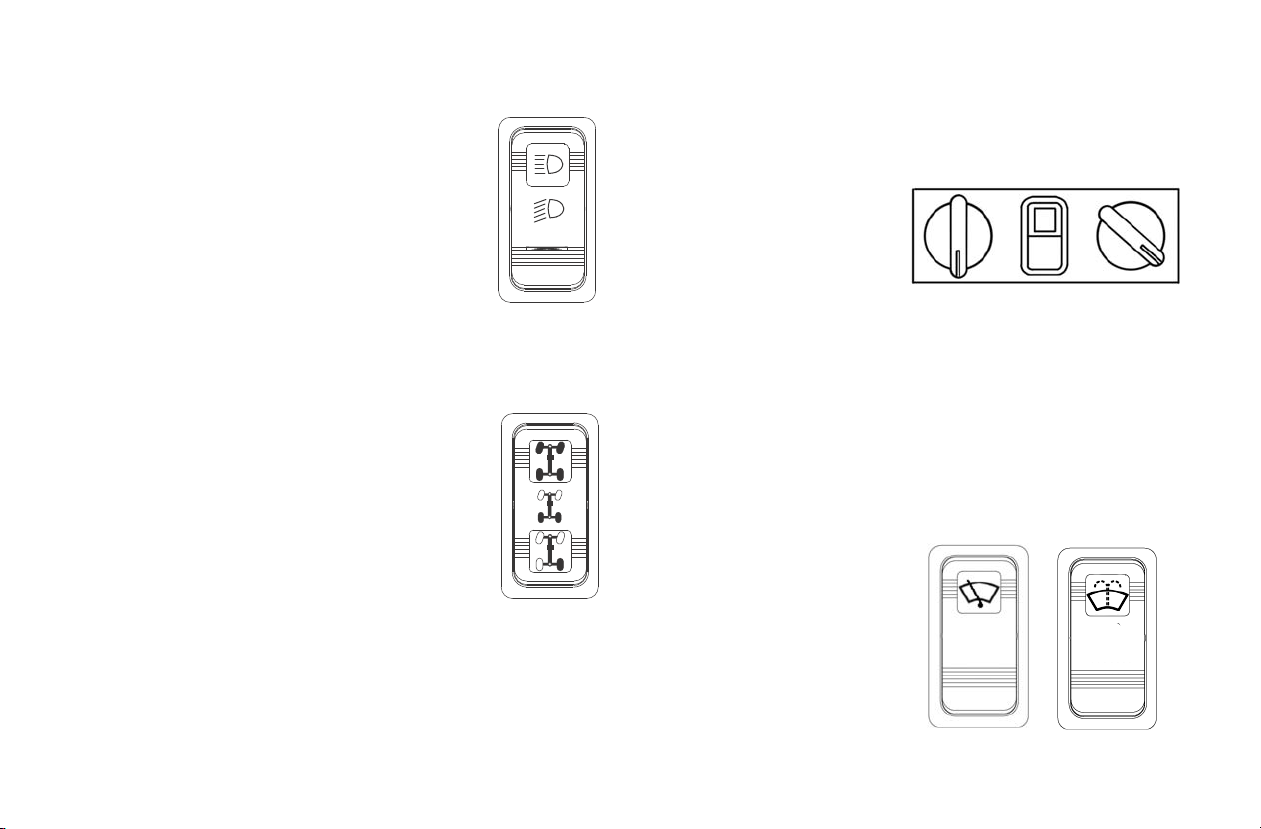

Switches and Indicator Lights

HIGH

OFF

LOW

AWD

Differential Lock

Differential Unlock

Fan

A/C

On-Off

Temp

Control

Wiper

Switch

Washer

Switch

Light Switch

The ignition switch must be in the ON

position to operate the headlights.

Press the top of the rocker switch

toward the dash to place the headlights

on high beam.

Move the rocker switch to the center

position to place the hea dl ights on low

beam.

Press the bottom of the rocker switch

to turn off the headlights.

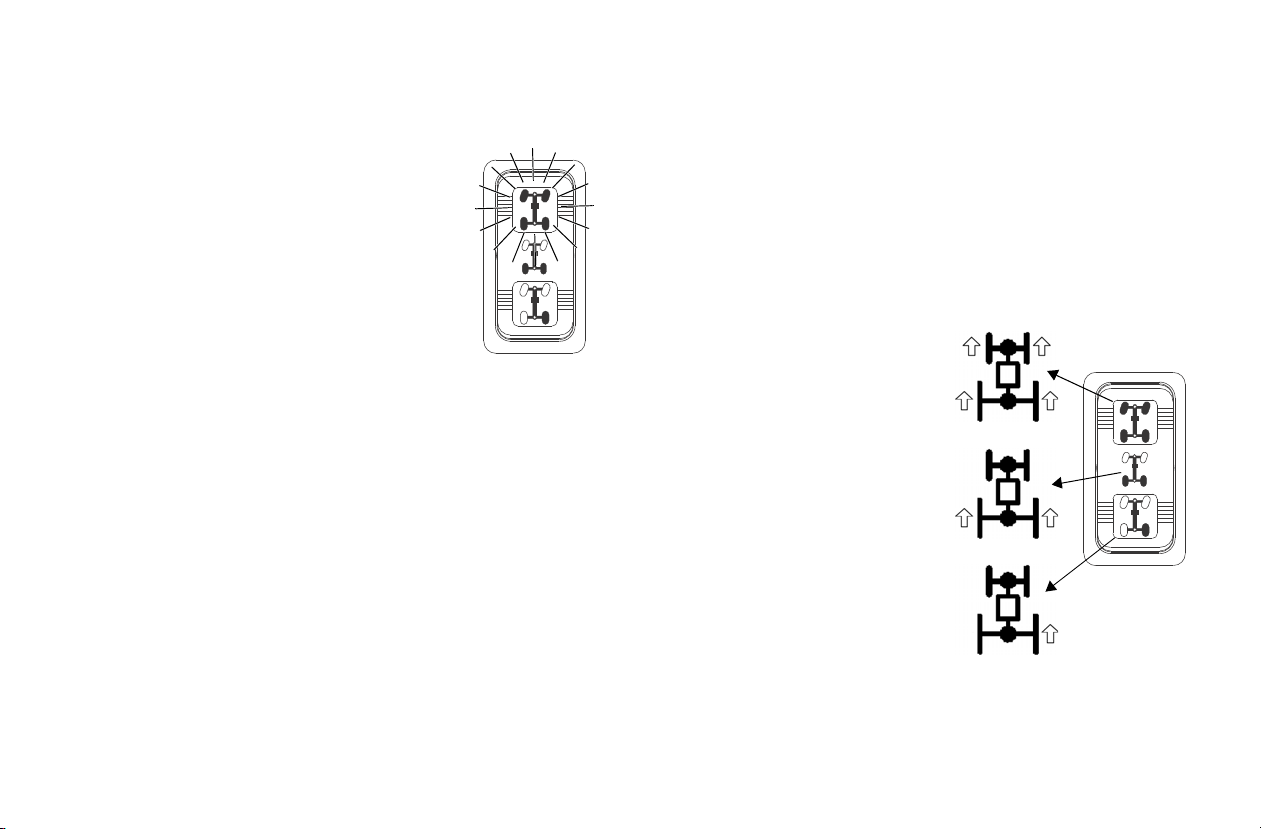

AWD/Differential Lock Switch

The AWD/Differential

Switch has three positions:

• All Wheel Drive (AWD)

• Differential Lo ck (2WD)

• Differential Unlock

Press the top of the rocker

switch to eng age All Wheel

Drive (AWD). See page 66

for operating instructions.

Move the rocker switch to the center position to lock the differential and operate in rear wheel drive. Press the bottom of

the switch to unlock the differential and allow the two rear

drive wheels to operate independently. See page 66 for differential lock operating instructions.

20

HVAC Switches (If Equipped)

If equipped with a Cab with

HVAC (Heat and Air Conditioning):

• Fan Switch (OFF-LowMed-High)

• Air Conditioning (Press

top of switch to turn Air

Conditioning ON, bottom

for OFF)

• Temperature Control

Switch (Rotate clockwise to increase temperature, counterclockwise to decrease)

Wiper Switch (If Equipped)

If equipped with a cab with a

wiper, the front wiper swit ch

is located on the wiper motor

cover at the top of the front

window:

• Wiper Switch (OFF-LowHigh)

• Washer Switch (Press and

hold top of switch to activate window washer)

Page 22

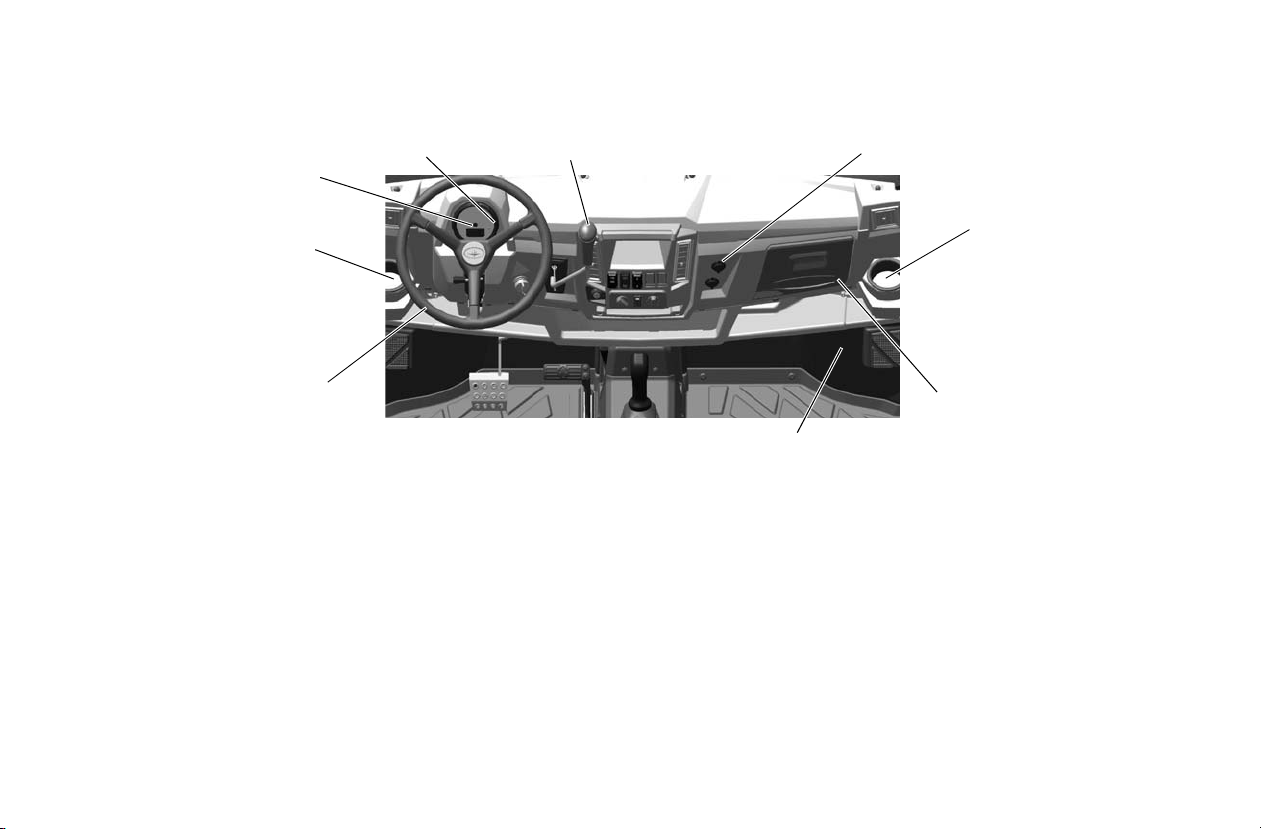

Console

Cup Holder

12V Auxiliary

Outlet

Mode

Button

Storage

Tray

Instrument

Cluster

Gear Selector

(Shifter)

Steering

Wheel

Storage

Compartment

Cup Holder

FEATURES AND CONTROLS

Auxiliary Outlet

The 12-volt receptacles have spade connections on the back

that may be used to power an auxiliary light or other optional

accessories or lights. The connections are behind the console,

under the dash.

Mode Button

The button located on the instrument cluster is used to toggle

through mode options. See pages 27-33.

Gear Selector

Use the gear selector to shift gears. Low gear is the primary

driving range for the BRUTUS. High gear is intended for use

on hard-packed surfaces with light loads. To shift gears, brake

to a complete stop. When the engine is idling, move the lever

to the desired gear.

NOTICE: Shifting gears with the engine speed above idle or while

Tip: Maintaining shift linka ge adjustmen t is important to assure proper

the vehicle is moving could cause transmission damage.

Always shift when the vehicle is stationary and the engine

is at idle.

transmission function. See your dealer if you experience any

shifting prob lems.

21

Page 23

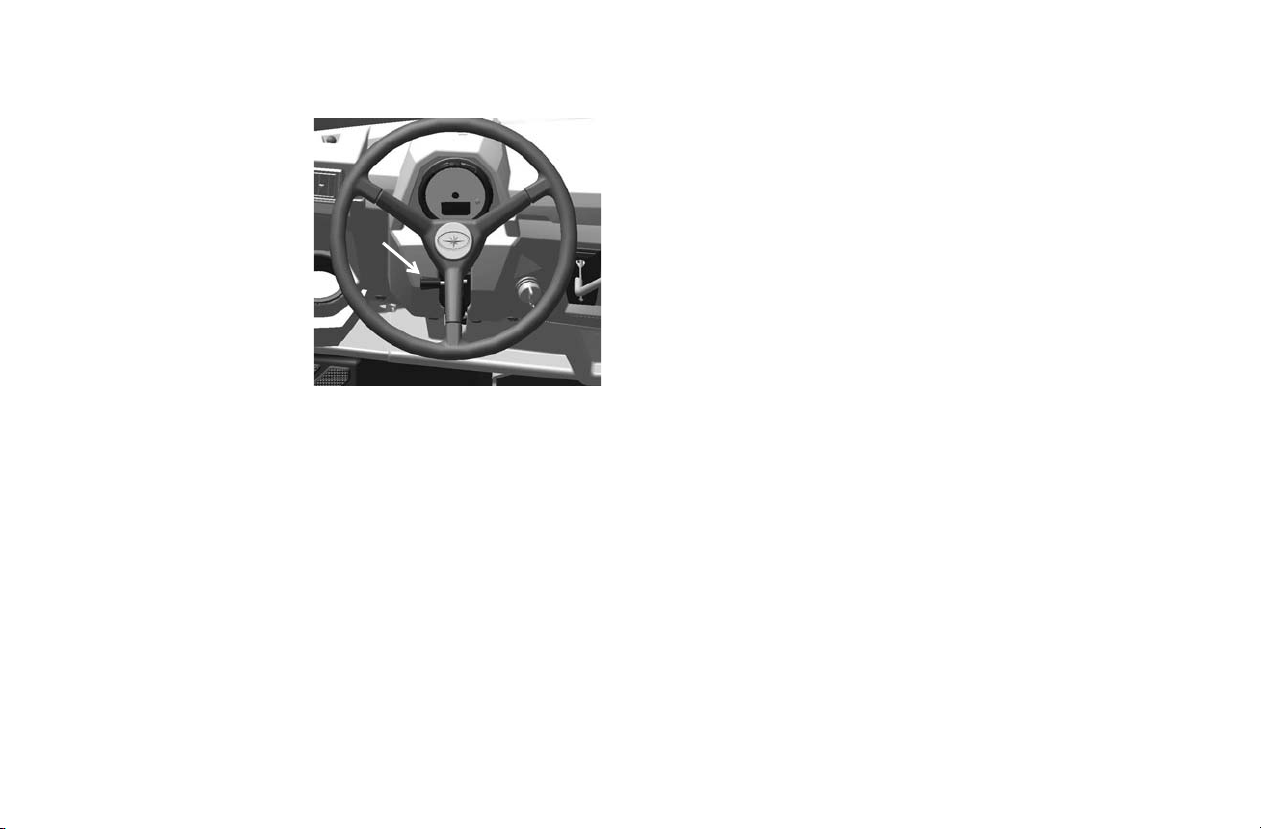

FEATURES AND CONTROLS

Console

Adjustable Steering

Wheel

The steering wheel can be

tilted upward or downward

for rider preference .

Lift and hold th e adjust ment

lever toward you while

moving the steering wheel

upward or downward.

Release the lever when the

steering wheel is at the

desired position.

22

Page 24

Center Console (For Models HD and

1

2

3

4

5

6

HD

PTO Only)

Joystick - Attachment

Arm

Movement of the joystick

(Item 1) controls the lift and

tilt functions of the attachment arm and the PROTACH attachment system.

See Page 44.

Engine Speed Control

Lever

The engine speed control lever (Item 2)controls engine RPM.

This is used to set engine RPM separately from the travel

speed when using attachments. See Page 47.

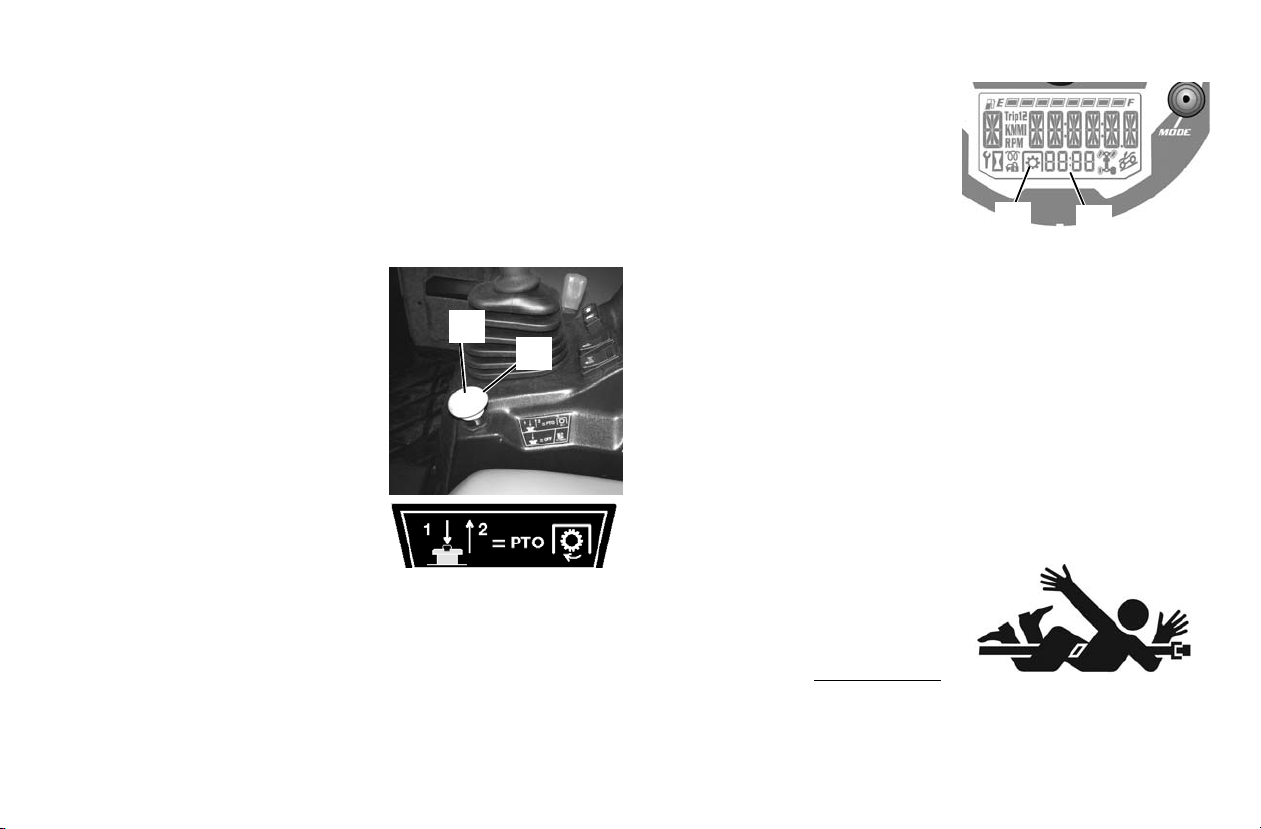

Power T ake-Off (PTO)

The front PTO (Item 3) is available on model HDPTO only.

The PTO has a rated speed of 2000 RPM. The PTO is used to

power some attachments. See page 68.

WARNING! Do NOT exceed the rated attachment PTO speed. Stay

clear of rotating driveline. Keep bystanders away. Keep PTO shields

and all guards in place. Disengage PTO, put the gear selector in

PARK, stop the engine and make sure all rotating components are

stopped before exiting utility vehicle. Do NOT service the utility

vehicle or attachment with the PTO engaged. Do NOT service the

attachment in a raised position unless properly blocked and with all

rotating components stopped. Disengage PTO for road travel.

FEATURES AND CONTROLS

Joystick Lock Switch

The joystick lockout switch (Item 4) is used to active or lockout the joystick functions. The joystick should be lockout

when no attachments are instal led. This will keep the joystick

from accidentally being activated. See Page 44.

Tilt Lock Switch

The tilt lockout switch (Item 5) locks out the tilt function. See

Page 44.

Tip: When operating PTO driven attachments, the tilt lockout switch

will automatically activate. Using the attachment with the tilt

locked out will limit the possibility of tilting the attachment while

the PTO shaft is turning and putting stress on the PTO driveline

u-joints. Before engaging the PTO system, tilt the attachment to

the desired operating position. See your attachment Owner’s

Manual for detailed information.

Front Auxiliary Hydraulic Switch

The front auxiliary hydraulic switch (Item 6) controls hydraulic flow to the front male and female coupler for attachment

operation. See Page 45.

23

Page 25

FEATURES AND CONTROLS

ROPS / OPS

Travel Control

Pedal

Brake

Pedal

Rollover Protective Structure (ROPS) /

Occupant Protective Structure (OPS)

The Rollover Protective Structure (ROPS) on this vehicle

meets OSHA 1928.53 rollover

performance requirements. The

Occupant Protective S t ruc tur e

(OPS) on this vehicle meets

ANSI/OPEI B71.9-2012 occupant requirements. Always have

your authorized POLARIS

dealer thoroughly inspect the

ROPS / OPS if it ever becomes

damaged in any way.

No device can assure occupant protection in the event of a

rollover . Always follow all safe operating practi ces out li ned in

this manual to avoid vehicle rollover.

WARNING! Vehicle rollover could cause severe injury or death.

Always avoid operating in a manner that could result in vehicle

rollover.

Storage Compartments

A storage compartment is located under both the driver’s and

operator’s seat.

Trailer Hitch Bracket

This vehicle is equipped with a receiver hitch bracket for a

trailer hitch. To avoid injury and property damage, always

heed the warnings and towing capacities outlined on pages 61.

Brake Pedal

Depress the brake pedal to

slow or stop the vehicle.

Apply the brakes while

starting the engine.

Travel Control

Pedal

The travel control pedal is

used to control the forward

and backward movement of

the utility vehicle. The farther the pedal is pressed, the

faster the travel speed.

Press the toe of the pedal for

forward travel, press the heel of the pedal for backward travel.

24

Page 26

Seat Removal

Seat

Switch

Harness

Model HD

PTO Only

Buckle

Latch Plate

Pull up on the rear of the seat and tilt it

toward the front of the vehicle. In stall

the seat by sliding the tabs into the

front of the seat base. Push down

firmly on the rear of the seat until the

pins are full y s eat ed into the gro mmets .

Tip: For Model HDPTO; a seat switch is

located under the operator’s seat. Set

the seat aside if possible to avoid disconnecting the seat switch. If the seat

switch is disconnected, the harness

must be secured in it’ s origin al positio n

to avoid harness damage.

Seat Belt s

This POLARIS vehicle is

equipped with three-point

lap and diagonal seat belts

on all external seats.The

center seat is equipped

with a lap-style seat belt.

Always make sure the se at

belts are secured for all

riders befo re operating.

WARNING! Falling from a

moving vehicle c ould resu lt in

serious injury or death.

Always fasten your seat belt

securely before operating or

riding in the BRUTUS.

FEATURES AND CONTROLS

To wear the seat belt properly, follow this procedure:

1. For 3-point belts, pull the seat belt latch downward and

across your chest toward the buckle at the inner edge of

the seat. The belt should fit snugly across your hips and

diagonally across your chest. Make sure the belt is not

twisted. For lap style belts, place the belt across your lap

as low on your hips as possible. Make sure that the belt is

not twisted.

2. Push the latch plate into the buckle until it clicks.

3. Release the strap, it will self-tighten.

Tip: The center belt must be tightened manually by pulling on the

strap.

4. To release the seat belt, press the square red button in the

buckle's center.

25

Page 27

FEATURES AND CONTROLS

Seat Belt s

Seat Belt Inspection

Inspect all seat belts for proper operation before each use of

the vehicle.

1. Push the latch plate into the buckle until it clicks. The

latch plate must slide smoothly into the buckle. A click

indicates that it's securely latched.

2. Push the red release latch in the middle of the buckle to

make sure it releases freely.

3. Pull each seat belt completely out and inspect the full

length for any damage, including cuts, wear, fraying or

stiffness. If any damage is found, or if the seat belt does

not operate properly, have the seat belt system checked

and/or replaced by an authorized POLARIS dealer.

4. To clean dirt or debris from the seat belts, sponge the

straps with mild soa p and wate r. Do not use bleach, dye or

household detergents.

26

Page 28

1

20

10

11

12

13

14

15

16

17

18

19

2

3

3

4

5

6

7

8

9

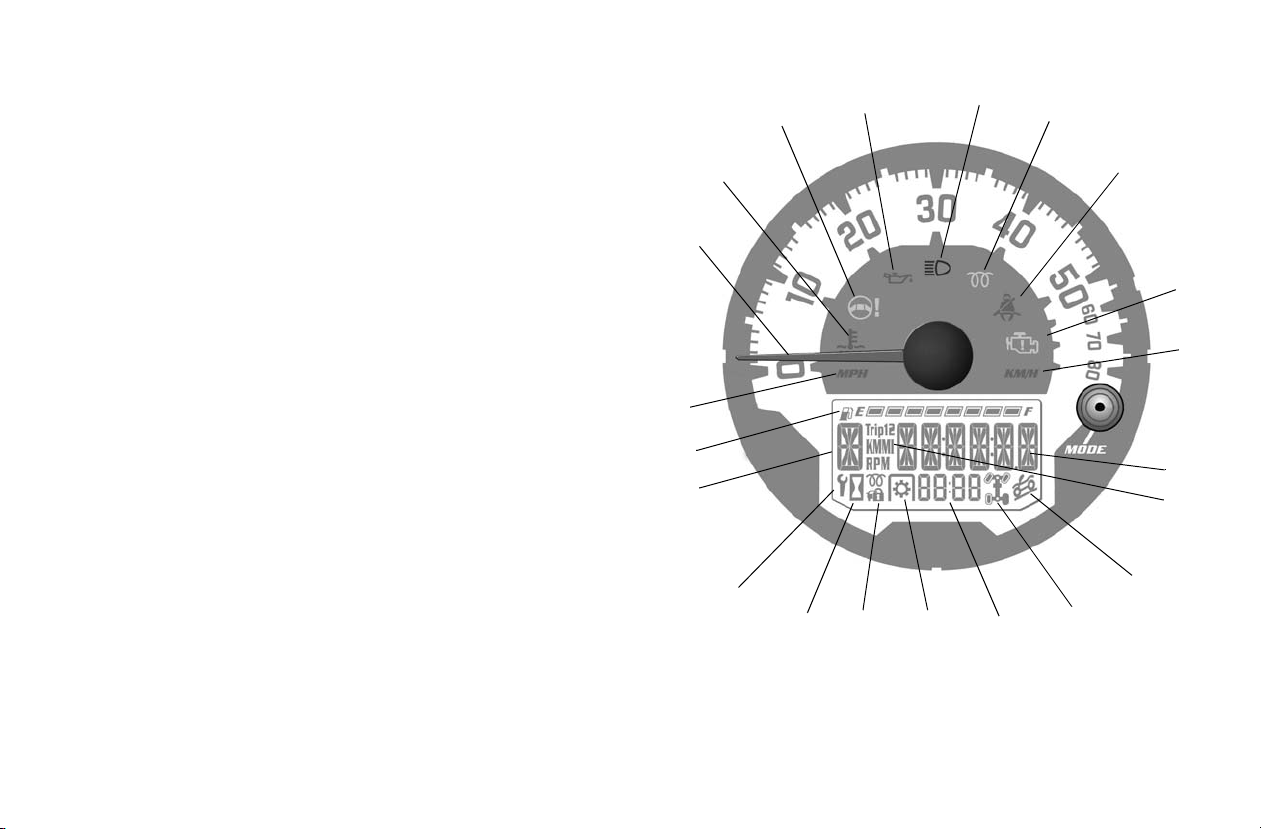

Instrument Cluster

Your vehicle is equipped with an instr ument clus ter that senses

vehicle speed from the transmission. In addition to showing

vehicle speed, the s peedometer needle fl as hes when a warning

condition exists.

NOTICE: High water pressure may damage components. Wash the

Rider Information Center

vehicle by hand or with a garden hose using mild soap.

Certain products, including insect repellents and

chemicals, will damage the instrument cluster lens and

other plastic surfaces. Do not use alcohol to clean the

instrument cluster. Do not allow insect sprays to contact

the lens. Immediately clean off any fuel that splashes on

the instrument cluster.

The rider information display is located in the instrument cluster. All segments will light up for 1 second at start-up. If the

instrument cluster fails to illuminate, a battery over-voltage

may have occurred and the instrument cluster may have shut

off to protect the electronic speedometer. If this occurs, take

the vehicle to your Polaris dealer for proper diagnosis.

1. Vehicle Speed Display - Analog display of vehicle speed

in MPH or km/h.

2. Information Display Area - Odometer / Tri p Meter /

Tachometer / Engine Temperature / Engine Hours /

Service Info - LCD display of the service hour interval,

total vehicle miles or km., total engine hours, a trip meter,

engine RPM and engine temperature.

FEATURES AND CONTROLS

27

Page 29

FEATURES AND CONTROLS

Instrument Cluster

3. MPH / KM/H Display - MPH is displayed when the

instrument cluster is in the Standard mode. KM/H is dis-

played when the instrument cluster is in the Metric mode.

4. High Beam Indicator - LED icon illuminates whenever

the Headlam p switch is in the high beam position.

5. Fuel Level Indicator - LCD bar graph indicating current

fuel level. All segments will flash when the last segment is

cleared indicating a low fuel warning.

6. Clock / PTO RPM - Displays current time in either 12hour or 24-hour formats. When the PTO is engaged, PTO

RPM will be indicated instead of the clock.

7. Engine / Hydraulic Fluid Temperature Indicator - LED

icon illuminates when the ECM determines the engine is

overheating. The indicators will initially flash to indicate

the engine is overheating. The indicators will stay lit and

not flash if a severe overheating condition exists.

8. PTO Indicator - PTO is engaged when this is illuminated.

PTO RPM will be displayed in the Clock field (6) ONLY

when engine RPM is displayed in the Information Display

Area (2).

9. Check Engine MIL - Illuminated when the ECM has

detected a Diagnostic Trouble Code in the engine management system.

10. Unit Lock - N/A on this model.

11. Hour Meter - Illuminates when the dis play (2) i s showing

hours.

12. Low Oil Pressure Indicator - LED icon illuminates low

engine oil or hydraulic fluid pressure is sensed.

13. Gear Position Indicator - Displays gear selector position.

H = High

L = Low

N = Neutral

P = Park

-- = Gear Signal Error (shifter stuck between gears)

14. Power Steering System MIL - N/A on this model.

15. Glow Plug Indicator - Illuminated when the glow plugs

are active. Light goes out when the engine is ready to start.

16. Seat Belt Indicator - LED ic on illuminate s for 10 secon ds

when the key is turned to the ON position. The lamp is a

reminder to the operator to ensure all riders are wearing

seat belts before operating the vehicle.

17. AWD/TURF Indicator - Illuminate to ind icate how many

drive wheels are active. This will tell you if you are in

AWD, 2WD, or Turf.

18. ADC Indicator - N/A on this model.

19. Service Interval Indicato r - Preset at the factory and

adjustable by the user, a flashing wrench symbol alerts the

operator that the preset service interval has been reached

and maintenance should be performed. The wrench icon

will flash for 10 seconds upon start-up once it reaches 0.

20. Unit of Measurement - Indicates the measurement (Trip

1, Trip 2, KM, MI, RPM) being displayed in the Informa-

tion Display Area (2).

28

Page 30

Instrument Cluster

Information Display Area

The LCD portion of the instrument cluster is the information

display area which displ ays the f ollowi ng infor mat ion: odometer, trip meter, RPM, battery voltage, engine temperature, air

temperature, engine hours , tro ubl e code s, service interval, and

clock.

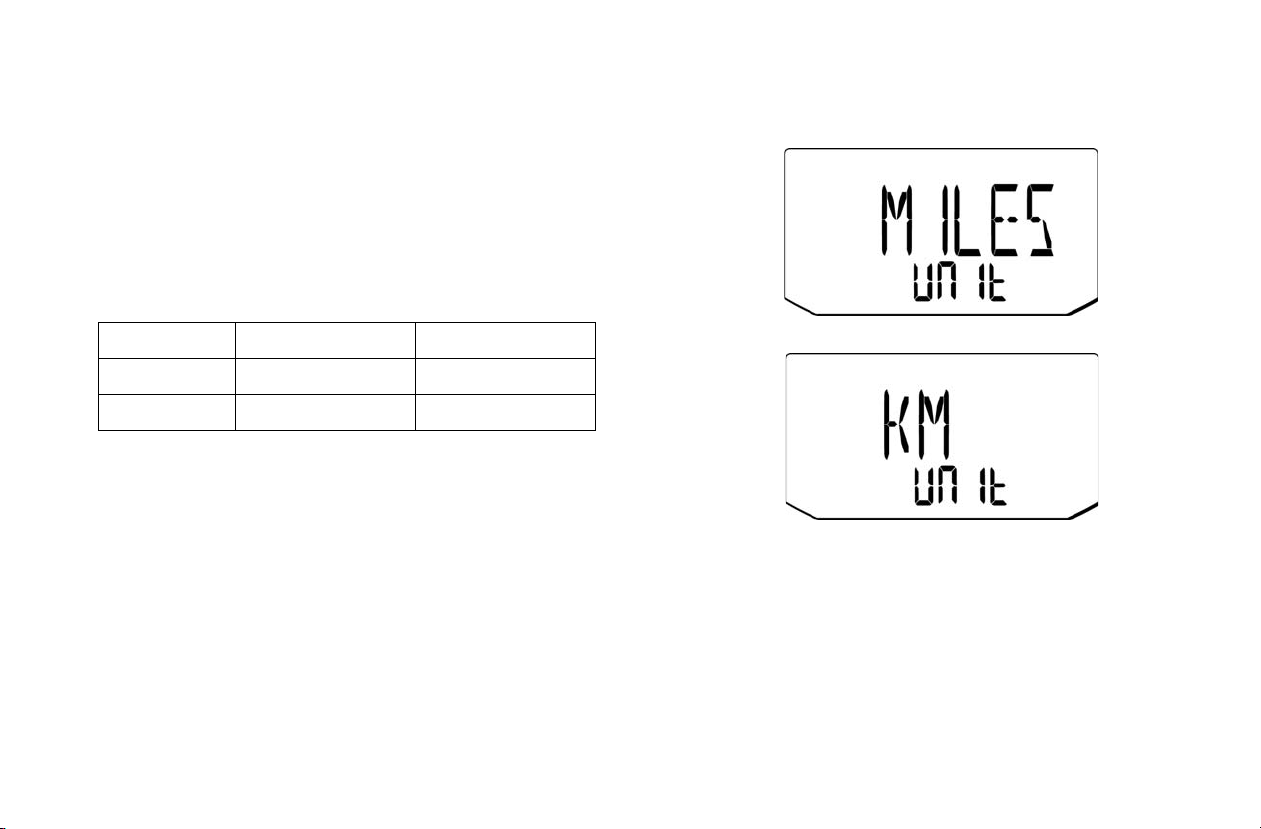

Units of Measurement

Distance Miles (MPH) Kilometers (KM/H)

Temperature Fahrenheit Celsius

Time 12-Hour Clock 24-Hour Clock

T o change bet ween S tandard and Metri c units of mea surement,

follow these steps:

1. Turn the key to the OFF position.

2. Press and hold the MODE button while turning the key to

the ON position.

3. When the display flashes the distance setting, tap the

MODE button to advance to the desired setting.

FEATURES AND CONTROLS

4. Press and hold the MODE button to save the setting and

advance to the next display option.

5. Repeat the procedure to change rema ining displ ay setting s.

29

Page 31

FEATURES AND CONTROLS

Instrument Cluster

Odometer

Engine Hours

The odometer records and displays the total distance traveled

by the vehicle. The odometer can not be reset.

Trip Meter

The trip meter records the miles tr aveled by the vehicle on

each trip. To reset the t rip meter:

1. Toggle the MODE button to TRIP 1.

2. To reset to 0, push and hold the MODE button until the

distance display changes to 0.

30

Engine hours are logged anytime the engine is running. Total

hours can not be reset.

Tachometer (RPM)

Engine RPM can be displayed digitally.

PTO RPM, when engaged, is indicated after the PTO icon.

Page 32

Instrument Cluster

Engine Temperature

FEATURES AND CONTROLS

Clock

Engine temperature can be displayed in F° or ° C. Refer to

“Units of Measurement” to change the format.

The clock displays the time in a 12-hour or 24-hour format.

Refer to “Units of Measurement” to change the format (Standard 12-hour / Metric-24 hour). To set the clock, follow these

steps:

1. Toggle the MODE button until the odometer is displayed.

2. Press and hold the MODE button until the hour segment

flashes. Release the button.

3. With the segment flashing, tap the MODE button to

advance to the desired setting.

4. Press and hold the MODE button until the next segment

flashes. Release the button.

5. Repeat steps 3-4 twice to set the 10 minute and 1 minute

segments. After completing the 1-minute segment, step 4

will save the new settings and exit the clock mode.

31

Page 33

FEATURES AND CONTROLS

Instrument Cluster

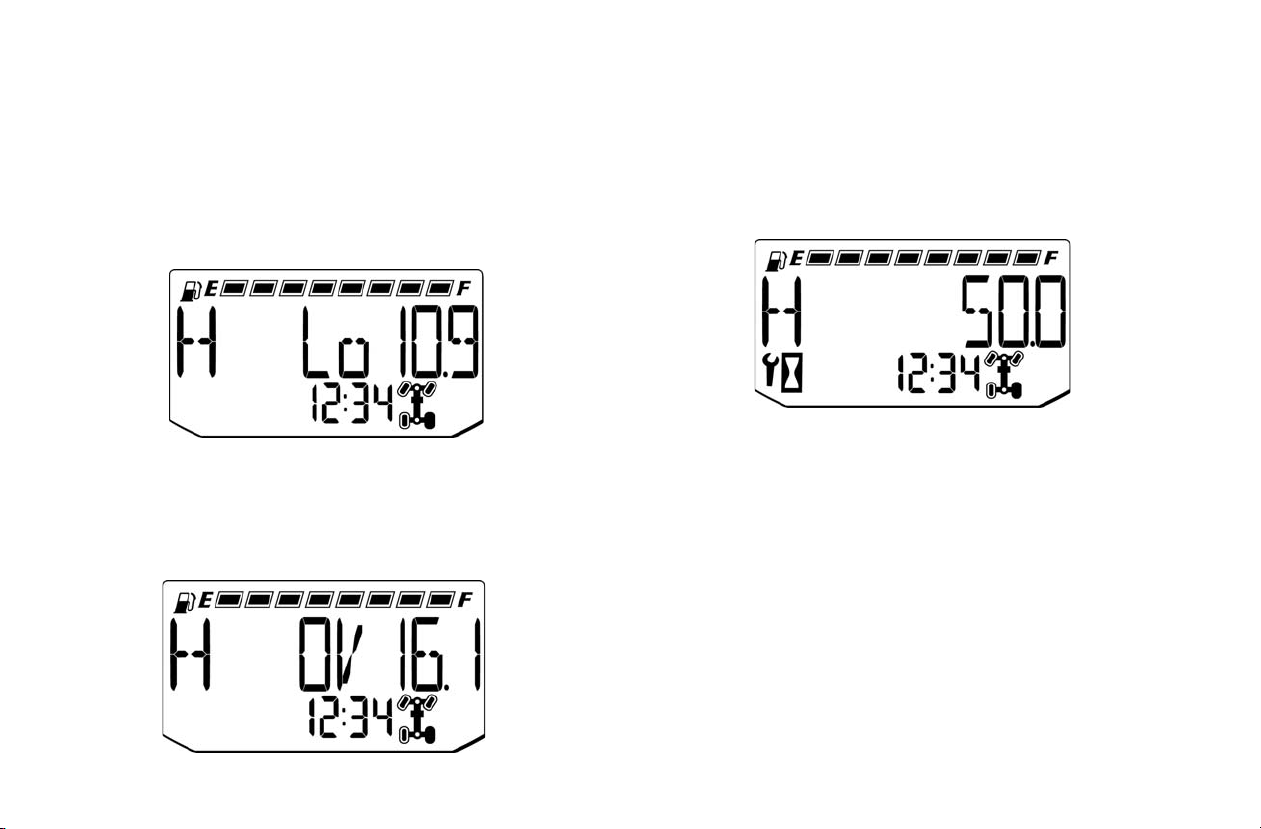

Battery Under / Over Voltage

This warning usually indicates that the vehicle is operating at

an RPM too low to keep the battery charged. It may also occur

when the engine is at idle and a high electrical load is applied

(lights, cooling fan or other accessories).

Battery Voltage Low

If battery voltage drops below 11 volts, a warning screen will

display “Lo” and provide the present battery voltage. If voltage drops below 8.5 volts, LCD backlighting and icons will

turn off.

Battery Voltage High

If battery voltage rises above 15 volts, a warning screen will

display “OV” and provide the present battery voltage. If voltage rises above 16.5 volts, LCD backlighting and icons will

turn off.

Programmed Service Interval

The initial factory service interval setting is 50 hours. Each

time the engine is start ed, the engine hours are sub tracted from

the service interva l hours. When the ser vice inter val reaches 0,

the LCD wrench icon will flash for approximately 10 seconds

each time the engine is started.

To change the hour setting or reset the function, follow these

steps:

1. Toggle the MODE button until the wrench icon is displayed in the information area.

2. Press and hold the MODE button unti l the i nformat ion dis play area begins to flash.

3. Toggle the MODE button to increase the service interval

hours in 5 hour increments to a maximum of 100 hours.

4. To turn off the service interval function, toggle the MODE

button until “OFF” is displayed.

32

Page 34

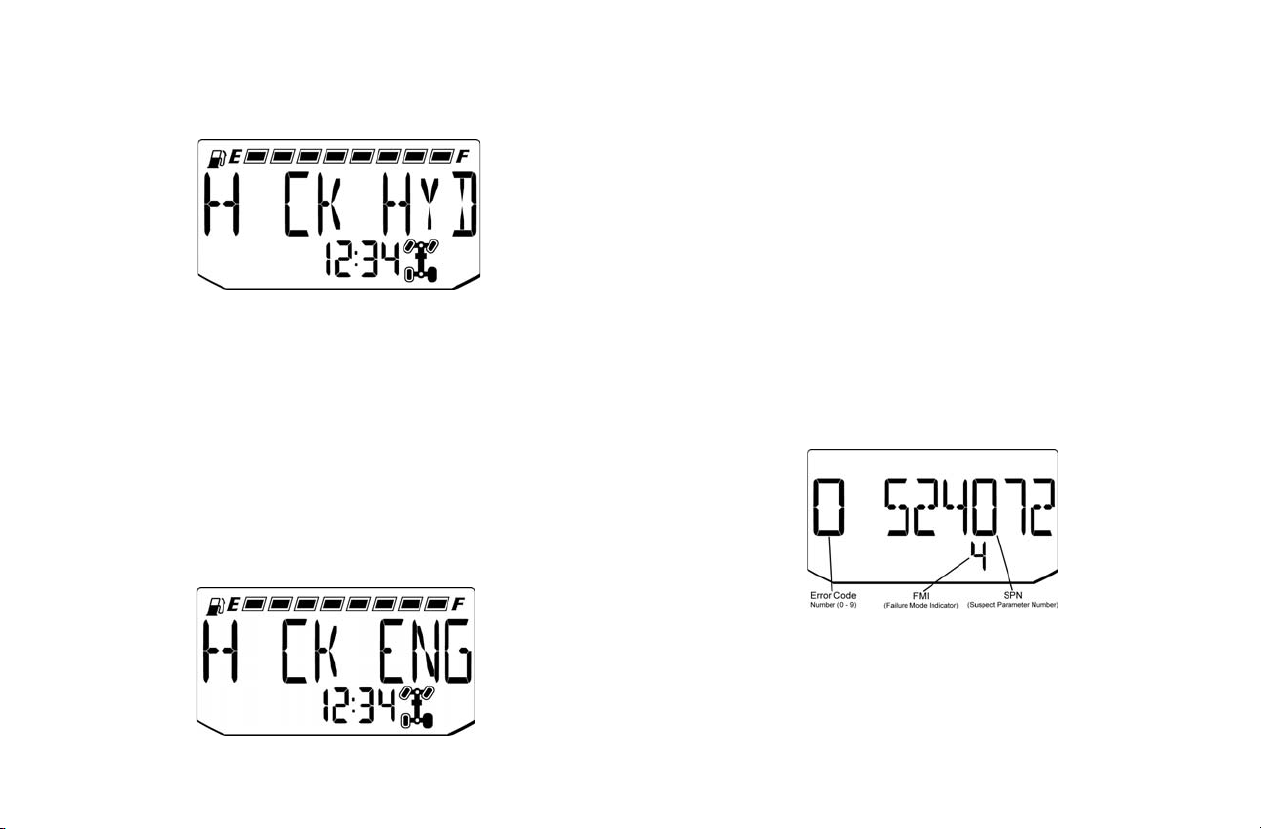

Instrument Cluster

Check Hydraulic

Indicates too low of hydraulic oil pressure which is likely

caused by a plugged or too high of hydraulic oil temperature.

The Oil or Temperature l ight will illuminate along with this

message.

Check Engine / Trouble Code Display

The diagnostic mode i s acces sible only when the che ck engi ne

MIL has been activated

Use the following procedure to display diagnostic trouble

codes that were acti vated durin g curr en t ign ition cycl e caus ing

the MIL to illuminate. Diagnostic trouble codes will remain

stored in the gauge (even if MIL turns off) until the key is

turned off.

FEATURES AND CONTROLS

1. If the trouble codes are not displayed, use the MODE button to toggle until “CK ENG” displays on the information

display area.

2. Press and hold the MODE button to enter the diagnostics

code menu.

3. A set of three numbers will appear in the information area.

4. The first number (located far left) can range from 0 to 9.

This number represents the total number of trouble codes

present (example: 2 means there are 3 codes present).

5. The second number (located top right) can be 2 to 6 digits

in length. This number equates to the suspected area of

fault (SPN).

6. The third number (located bottom right) can be 1 to 2 digits in length. This number equates to t he f au lt mode (FMI).

7. See your dealer for Diagnostic Trouble Codes.

8. If more than one code exists, press the MODE button to

advance to the next trouble code.

9. To exit the diagnostic mode, press and hold the MODE

button or turn the ignition key OFF once the codes are

recorded.

33

Page 35

OPERATION

WARNING

Failure to operate the v ehi cl e properly can resul t in a collision , lo ss o f

control, accident or overturn, which may result in serious injury or

death. Read and understand all safety warnings outlined in this

owner’s manual.

Break-In Period

The break-in period for your new vehicle is the first 50 hours

of operation. No single a ct ion on your part is as impor ta nt as a

proper break-in per iod . Car ef ul treatment of a new e ngi ne wi ll

result in more efficient performance and longer life for the

engine.

New Engine Break-In

1. Fill the fuel tank with the recommended fuel. See page 36.

2. On the in itial engine start-up, allow the engine to idle for

approximately 15 minutes. Check for proper engine oil

pressure, diesel fuel leaks, engine oil leaks, coolant leaks,

hydraulic leaks and proper operation of the indicators and

gauges.

3. During the first hour of operation, vary engine speed and

the load on the engine. Short periods of maximum engine

speed and load are de sirable. Avoid prolonged operatio n at

minimum or maximum engine speeds and loads for the

next 4 to 5 hours.

4. During the break-in period, carefully observe the engine

oil pressure, engine temperature and hydraulic fluid temperature.

5. Check the engine oil, engine coolant and hydraulic fluid

level frequently during the break-in period. Perform regular checks on areas outlined on the daily pre-ride inspection checklist. See page 35.

6. Change both the engine oil and the filter at 50 hours.

7. Check fluid levels of transmission and all gearcases after

the first 25 hours of operation and every 100 hours thereafter.

34

Page 36

OPERATION

Pre-Ride Inspection

Failure to inspect and verify that the vehicle is in safe operating condition before operating increases the risk of an accident.

Always inspect the vehicle before each use to make sure it's in safe operating condition.

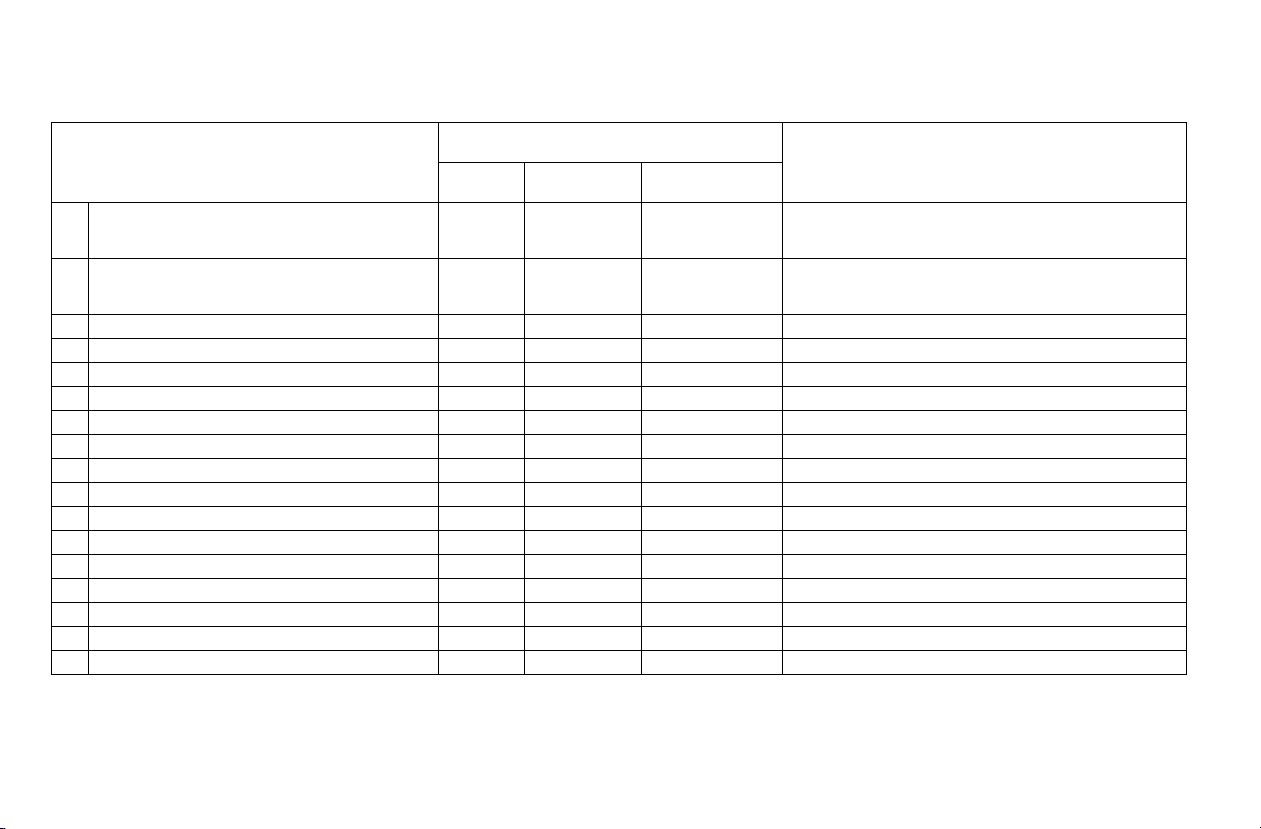

Item Remarks Page

Brake system/pedal travel Ensure proper operation. 24, 101

Brake fluid Ensure proper level. 101

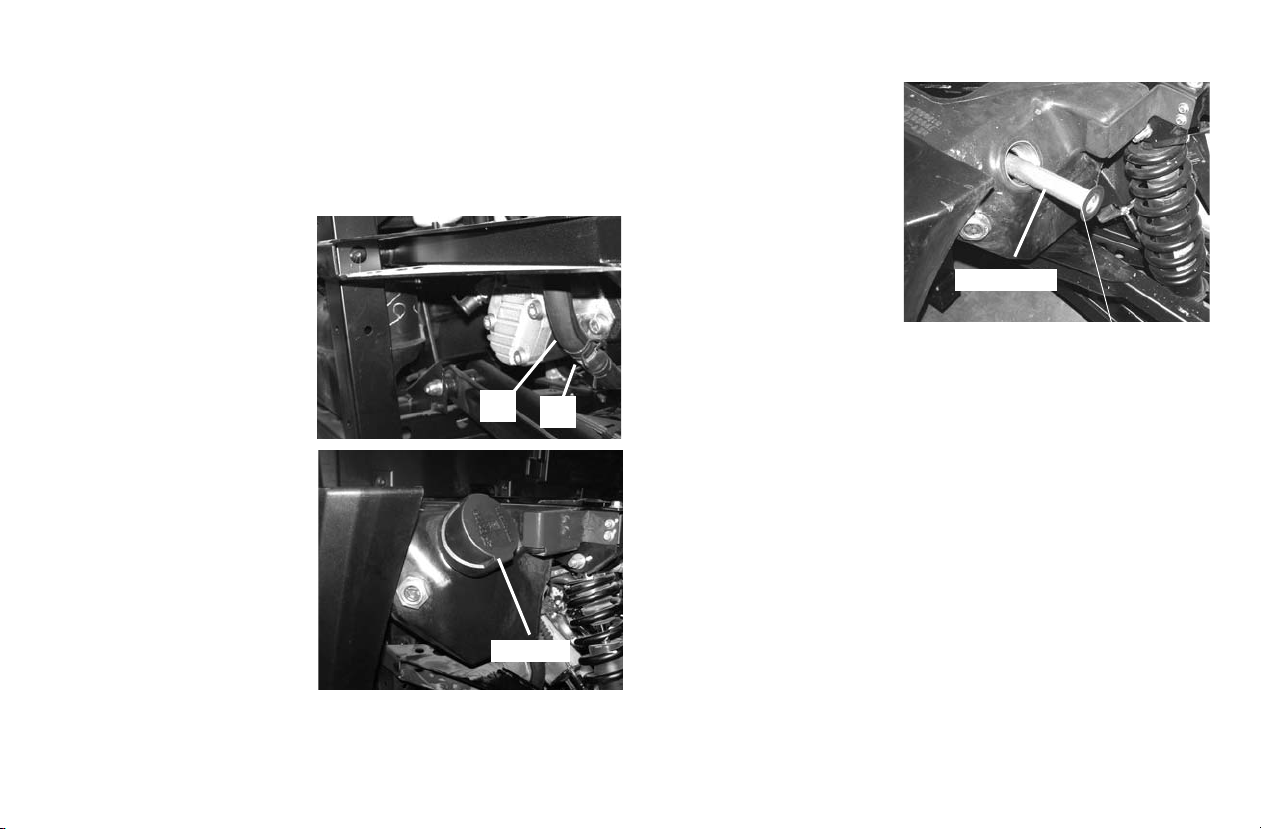

Front and Rear suspension Inspect, lubricate if necessary. 119

Seat Belts Check length of belt for damage, check latches for proper operation. 26

ROPS/OPS Check condition of ROPS/OPS and mounting hardware. 26

Steering Ensure free operation. 103

Tires/wheels/fasteners Inspect condition and pressure. Inspect, ensure fastener tightness. 112

Safety Signs (Decals) Check for damaged or missing signs (decals). Replace any signs that are damaged or missing.

Frame nuts, bolts, fasteners Inspect, ensure tightness. Fuel and oil Ensure proper levels. 39, 88

Coolant level Ensure proper level. 92

Coolant hoses Inspect for leaks. Travel Control Pedal Ensure proper operation. 24

Indicator lights/switches Ensure operation. 19

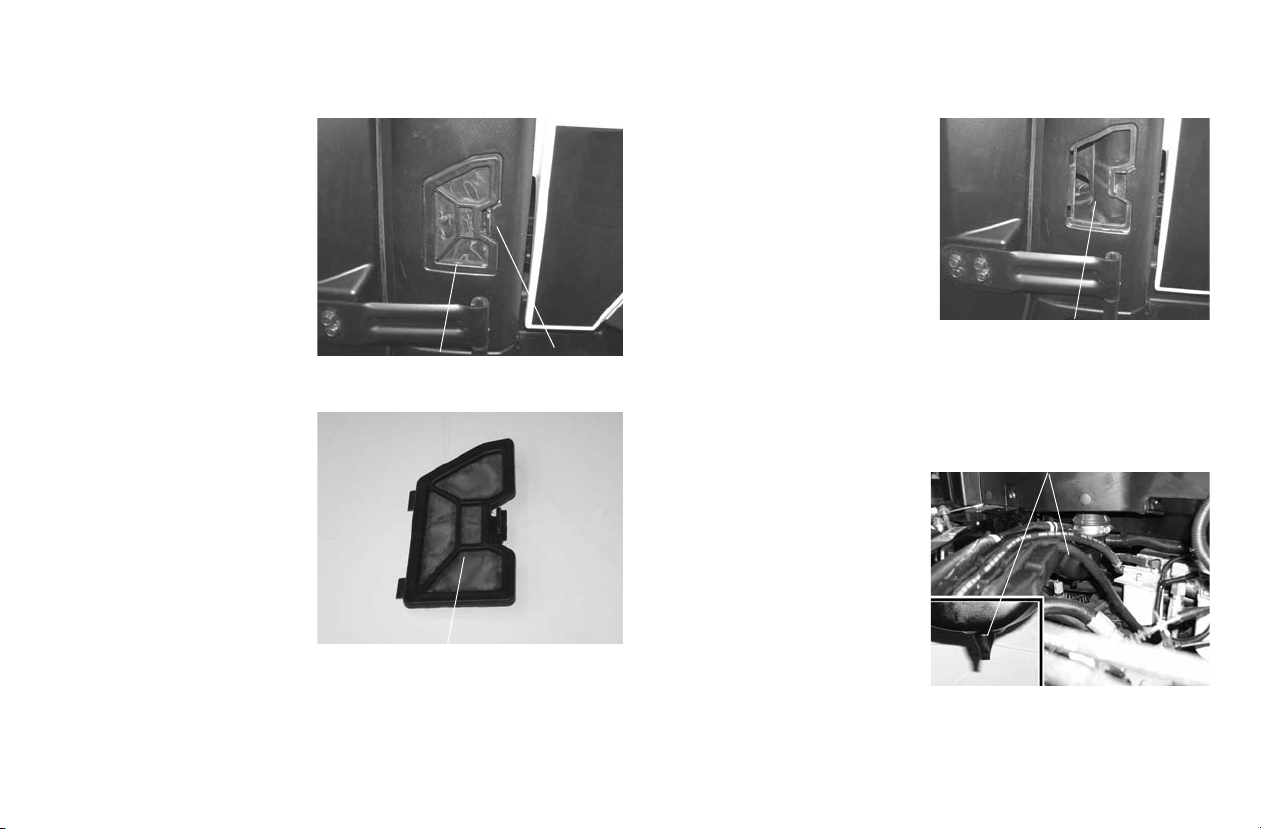

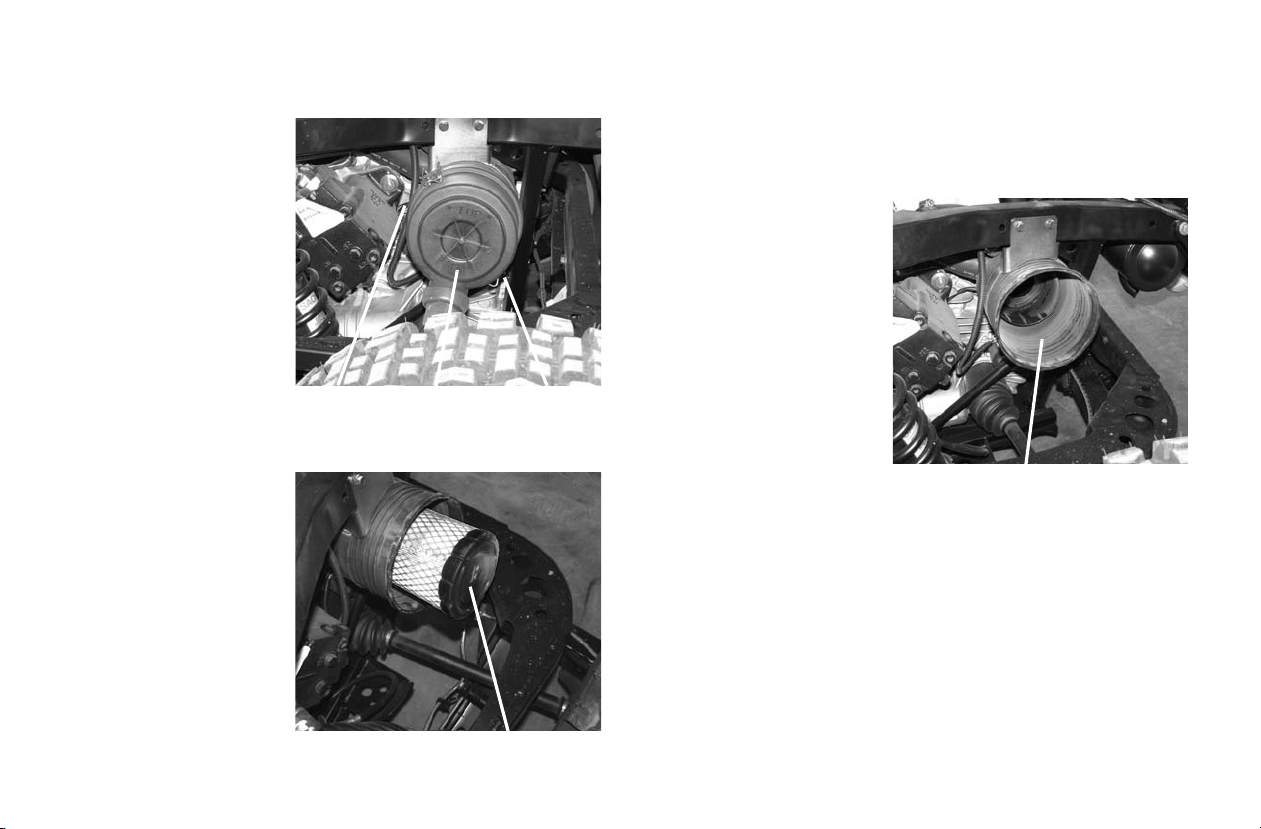

Air filter, pre-filter Inspect, clean and replace as needed. 95

PTO (If Equipped) Inspect splines, guards, shields and hardware, ensure tightness, replace damaged parts. 51

Brake light/tail lamp /Headlamp Check operation, apply POLARIS dielectric grease when lamp is replaced. 102, 114

Heater/Air Conditioning Filter Clean and replace filter as needed during heating and cooling season. 106

35

Page 37

OPERATION

Fuel Recommendations

NOTICE: For the best engine performance, to prevent engine

POLARIS recommends the follow ing diesel fuels for use in

this vehicl e:

•Low Sulfur

• Ultra Low Sulfur #2

• #1 Diesel Fuel containing no more than 5% bio-diesel (see

page 37)

See page 39 for cold we ather fu el blend recommendati ons. For

more information about recommended diesel fuels and the

consequences of using bio-diesel fuel exceeding 5% bio-diesel, see Additional Technical Fuel Requirements below.

Diesel fuel should comply with the following world-wide

specifications.

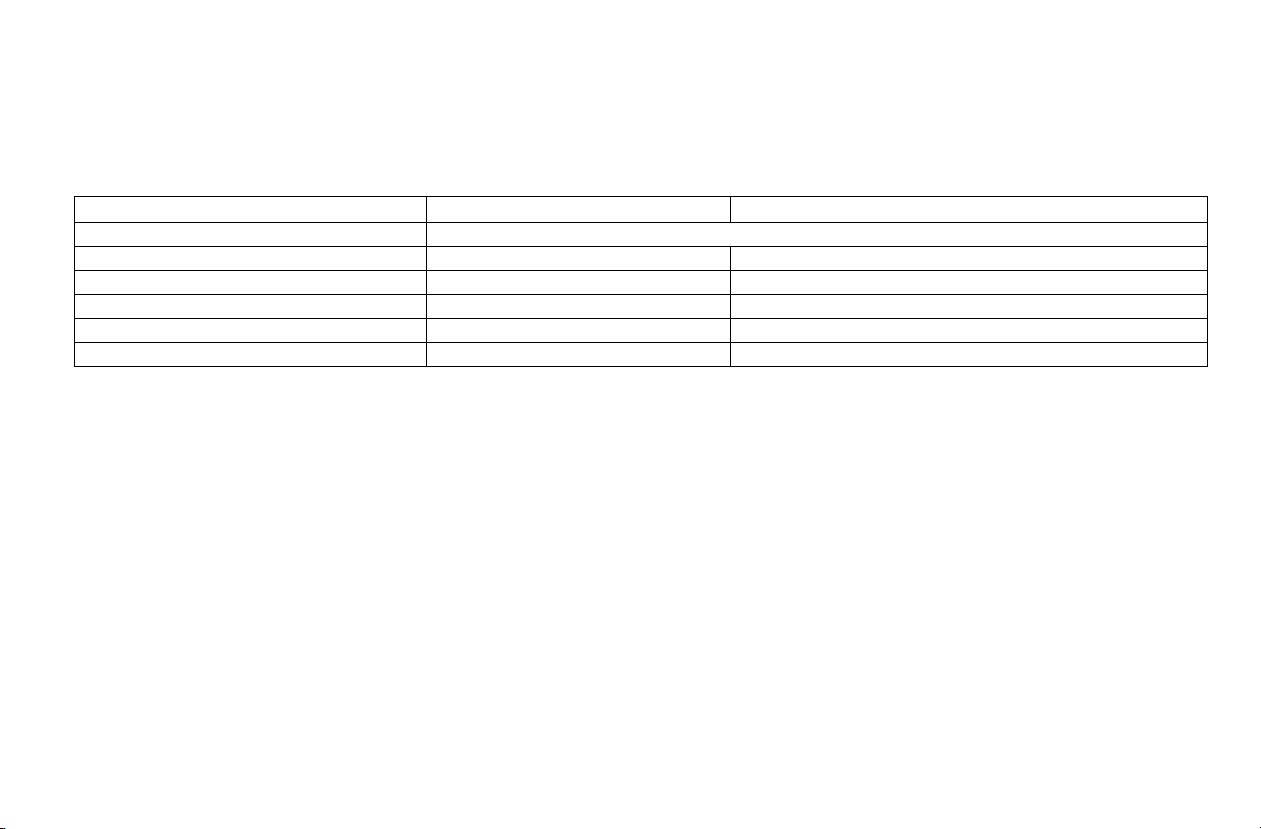

Diesel Fuel Specification Location

ASTM D975

No. 1D S15, S500

No. 2D S15, S500

EN590:96 European Union

ISO 8217 DMX International

BS 2869-A1 or A2 United Kingdom

JIS K2204 Grade No. 2 Japan

KSM-2610 Korea

GB252 China

damage and to comply with EPA/CARB warranty

requirements, use ONLY the recommended diesel fuels.

Use only CLEAN diesel fuel.

USA

Additional Technica l Fuel Requirements

• The fuel cetane number should be equal to 45 or higher.

• The sulfur content must not exceed 0.5% by volume. Less

than 0.5% is preferred. Espe cially in th e U.S.A. and Canada,

Low Sulfur (300 to 500 ppm (mg/kg) or Ultra Low Sulfur

fuel should be used.

• Bio-Diesel fuels: see pages 37-38.

• NEVER mix ker osene, used engin e oil or residual fuels with

diesel fuel.

• Water and sediment in the fuel should not exceed 0.05% by

volume.

• Keep the fuel tank and fuel-handling equipment clean at all

times.

• Poor quality fuel can reduce engine performance and/or

cause engine damage.

• Fuel additives are not recommended. Some fuel additives

may cause poor engine performance.

• Ash content must not exceed 0.01% by volume.

• Carbon residue content must not exceed 0.35% by volume.

Less than 0.1% is preferred.

• Total aromatics content should not exceed 35% by volume.

Less than 30% is preferred.

• PAH (polycyclic aromatic hydrocarbons) content should be

below 10% by volume.

• Metal content of Na, Mg, Si and Al should be equal to or

lower than 1 mass ppm (test analysis method JPI-5S-44-95) .

• Lubricity: Wear mark of WS1.4 should be Max. 0.018 in.

(460µm) at HFRR test.

36

Page 38

Fuel Recommendations

Bio-Diesel Fuels

In Europe and in the United States, as well as some other countries, non-mineral oil based fuel resources such as RME

(Rapeseed Methyl Ester) and SOME (Soybean Methyl Ester),

collectively known as FAME (Fatty Acid Methyl Esters), are

being used as extenders for mineral oil derived diesel fuels.

YANMAR approves the use of bio-diesel fuels that do not

exceed a blend of 5% (by vol ume) of FAME with 95% (by volume) of approved mineral oil deriv ed die sel fu el. Suc h bio- diesel fuels are known in the marketplace as B5 diesel fuels.

These B5 diesel fuels must meet certain requirements:

1. The bio-fuels must meet the minimum specifications for

the country in which they are used.

• In Europe, bio-diesel fuels must comply with the European

Standard EN14214.

• In the United States, bio-diesel fuels must comply with the

American Standard ASTMD-6751.2.

2. Bio-fuels should be purchased only from recognized and

authorized diesel fuel suppliers.

OPERATION

Precautions and concerns regarding the use of bio-fuels:

1. Free methanol in FAME may result in corrosion of aluminum and zinc FIE components.

2. Free water in FAME may result in plugging of fuel filters

and increased bacterial growth.

3. High viscosity at low temperatures may result in fuel

delivery problems, injection pump seizures and poor

injection nozzle spray atomi za ti on.

4. FAME may have adverse effects on some elastomers (s eal

materials) and may result in fuel leakage and dilution of

the engine lubricating oil.

5. Even bio-diesel fuels that comply with a suitable standard

as delivered will require additional care and attention to

maintain the quality of the fuel in the equipment or other

fuel tanks. It is important to maintain a supply of clean,

fresh fuel. Regular flushing of the fuel system and/or fuel

storage containers may be necessary.

6. The use of bio-diesel fuels that do not comply with the

standards as agreed to by the diesel engine manuf acturers

and the diesel fuel injection equipment manufacturers, or

bio-diesel fuels that have degraded as per the precautions

and concerns above, may affect the warranty coverage of

your engine.

37

Page 39

OPERATION

Fuel Recommendations

Bio-Diesel Fuels

B6 To B20 Bio-diesel Fuel Blend Usages

B6 to B20 bio-diesel is not approved for this POLARIS application.

Approved Engines

Only the YANMAR TNM engine series listed below may

operate with bio-diesel fuel concentrations up to B5 for

POLARIS applications

NOTICE: Do not exceed bio-diesel fuel ble nd B5 for thi s POLARIS

application.

•3TNM72

Approved Fuel

NOTICE: Raw pressed vegeta ble oils are no t con si dere d bi o-di es el,

and are unacceptable for use as fuel in any concentration

in YANMAR engines.

Bio-diese l fuel blends up to B5 must comply with the following standards:

• EN14214 (European standard) and/or ASTM D-6751

(American standard).

• All applicable engines may operate with bio-diesel fuel up

to a maximum B5 (5% bio-diesel blend) concentration.

Operating Conditions with B5 Bio-diesel Fuel Blends

Engine Warranty

Damages, performance or service concerns determined to be

caused by the use of bio-diesel fuel not meeting the specifications outlined above are not considered to be defects in material or factory workmanship and are not covered under

warranty. The same applies to damages or other concerns

induced by not complying with the recommended operating

conditions of YANMAR engines with bio-diesel fuel.

Handling Fuel

WARNING! Diesel fuel is flammable and explosive under certain

conditions.

• NEVER refuel with the engine running.

• Always refuel outdoors or in a well ventilated area.

• Fill the fuel tank with diesel fuel ONLY. Filling the fuel tank with

gasoline may result in a fire and will damage the engine.

• Remove flammable material containers from the box before filling

them with fuel.

• Do not smoke or allow open flames or sparks in or near the area

where refueling is performed or where fuel is stored.

• Wipe up all spills immediately.

• Keep sparks, open flames or any other form of ignition (match,

cigarette, static electricity source) well away when refueling.

• NEVER remove the fuel cap while the engine is running.

• NEVER overfill the fuel tank. Do not fill the tank neck.

• If fuel spills on your skin or clothing, immediately wash it off with

soap and water and change clothing.

38

Page 40

Fuel Recommendations

Refueling

The fuel tank filler cap is located on

the outside left side of the vehicle

near the operator seat. Remove the

cap and add the recommended fuel

to the bottom of the filler neck. Do

not overfill.

Cold Weather Operation

Cold weather operation can result in fuel gelling if the incorrect fuel type is used. Use the following fuel blending guideline to prev ent this from occurring.

Fuel Blending Guideline

Temperature No. 2 No. 1

+15° F (9° C) 100% 0%

Down to -20° F (-29° C) 50% 50%

Below -20° F (-29° C) 0% 100%

Block Heater Use

If this vehicle will be operated when temperatures are in the

+5° to -25° F. (-15° to -32° C) range, a block heater must be

installed. Please see your dealer to purchase a block heater kit.

OPERATION

Bio-Diesel Blended Fuel

NOTICE: Never use bio-diesel blended fuel containing more than

5% bio-diesel in this vehicle. See page 37.

Bio-diesel blended fuel has unique qualities that should be

considered before using it in this vehicle:

• Cold weather conditions can lead to plugged fuel system

components and hard starting.

• Bio-diesel blended fuel is an excellent medium for micro-

bial growth and contamination which can cause corrosion

and plugging of fuel system components.

• Use of bio-diesel blended fuel may result in premature fail-

ure of fuel system components, such as plugged fuel filters

and deteriorated fuel lines.

• Shorter maintenance intervals may be required, such as

cleaning the fuel system and replacing fuel filters and fuel

lines.

• Using bio-diesel blended fuels containing more than five

percent (5%) bio-diesel can affect engine life and cause

deterioration of hoses, tubes, injectors, injector pump and

seals.

39

Page 41

OPERATION

Cold Weather Operation

Bio-Diesel Blended Fuel

Use the following guidelines if bio-diesel blended fuel is used:

• Never use bio-diesel blended fuel containing more than 5%

bio-diesel in this vehicle.

• Ensure the fuel tank is as full as possible at all times to prevent moisture from collecting in the fuel tank.

• Ensure that the fuel tank cap is securely tightened.

• Clean up any spilled fuel immediately to prevent damage to

painted surfaces.

• Drain all water from the fuel filter daily before operating the

vehicle.

• Do not exceed the engine oil change interval. Extended

intervals can result in engine damage.

• Before vehicle storage, drain the fuel tank, refill with 100%

petroleum diesel fuel, add fuel stabilizer and run the engine

for at least 30 minutes.

NOTICE: Bio-diesel blended fuel does not have long term stability

and should not be stored for more than three months.

Operating Conditions

NOTICE: Observe the following environmental operating conditions

to maintain engine performance and avoid premature

engine wear.

• Avoid operating in the presence of chemical gases or fumes.

• Avoid operating in a corr osive atmosphe re such as s alt water

spray.

• NEVER operate the engine in a floodplain unless proper

precautions are taken to avoid being subject to a flood.

• NEVER expose the engine to the rain.

• The standard range of ambient temperatures for the normal

operation of YANMAR engines is from +5° F (-15° C) to

+104° F (+40° C).

• If the ambient temperature exceeds +104° F (+40° C), the

engine may overheat and cause the engine oil to break

down.

• If the ambient temperature is between +5° F (-15° C) and 25° F (-32° C), POLARIS recommends the use of a block

heater. See page 39.

40

Page 42

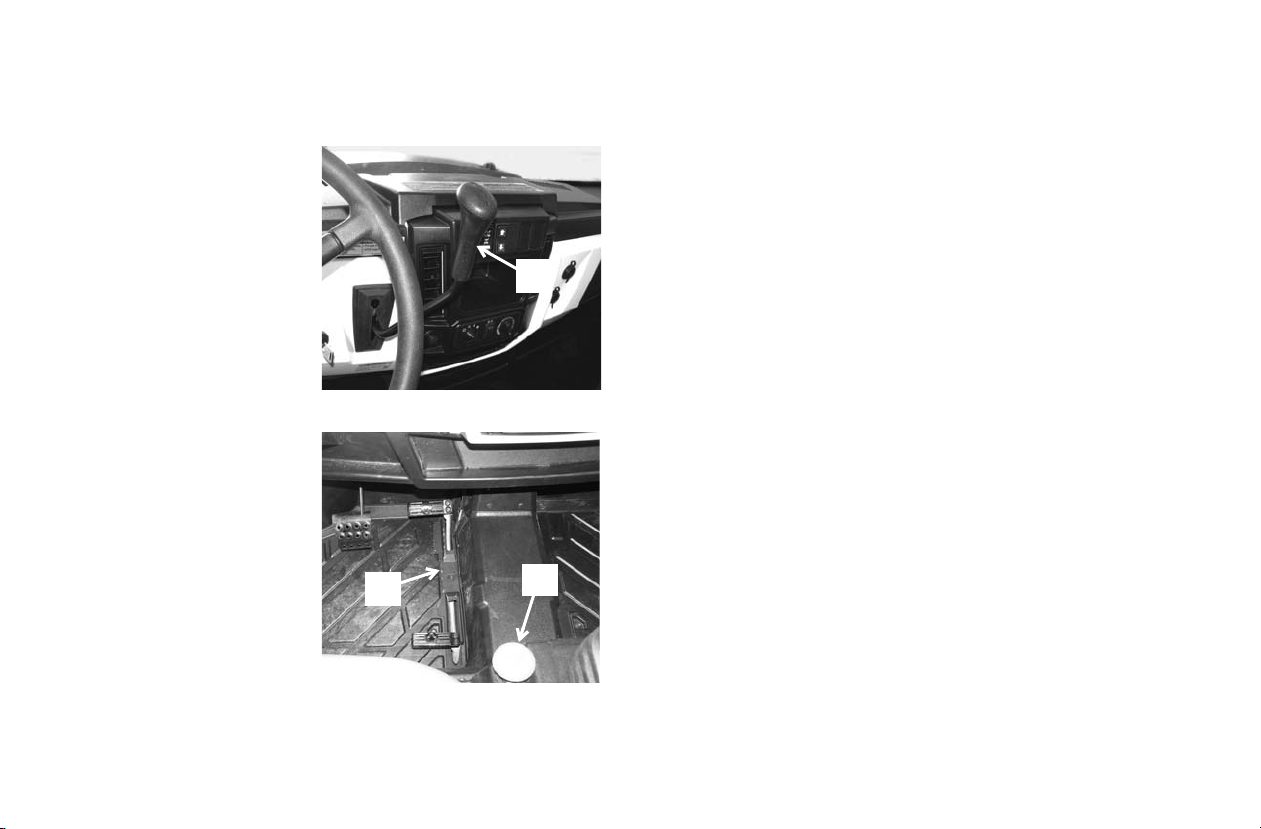

Starting the Engine

START

HELP

NOTICE: NEVER use an engine

Before operating this vehicle in

cold weather, review the cold

weather operation infor mat ion

beginning on page 39.

Always wait for the glow pl ug indi cator light to turn off before cranking the engine.

Tip: Engine will not start unless: Gear selector is in Park or Neutral,

1. Always start the engine outdoors or in a well-ventilated

2. Sit in the driver's seat and fasten the seat belt.

3. Apply the brakes.

4. Put the gear selector lever in the Park position.

5. Turn the ignition switch to the ON position and wait for

6. Turn the ignition switch past the ON position to START.

7. If the engine does not start withi n five second s, rele as e the

starting aid such as ether.

Engine damage will result.

travel control pedal is in neutral and PTO (if equipped) is OFF.

area.

the glow plug indicator light to turn off before cranking

the engine.

Engage the starter f or a maximum of fi ve seconds. Rel ease

the key when the engine starts.

ignition switch and wai t five second s. Repeat steps 5 an d 6

until the engine starts.

OPERATION

8. Allow the engine to warm to operating temperature. (For

Models HD and HD

with the engine speed control lever to aid in warm up unt il

the engine idles smoothly.)

NOTICE: Operating the vehicle immediately after starting could

cause engine and hydraulic compo nent damage . Allow the

engine to warm up for several minutes before operating

the vehicle.

Stopping the Engine

For maximum engine life, allow the engine to idle, without

load, for 5 minutes. This will allow the engine components

that operate at high temperatures, such as the exhaust system,

to cool slightly before the engine is shut down.

1. Press the brake pedal until the utility vehicle comes to a

complete stop.

2. For models HD and HD

arm and put the attachment flat on the ground.

3. Move the gear selector lever to Park.

4. For models HD and HD

control lev er to low idle. Disengage the PTO and make

sure all rotating components are completely stopped.

5. Turn the engine off and remove the key to prevent unau-

thorized use.

WARNING! A rolling vehicle can cause serious injury. Always place

the gear selector lever in PARK before stopping the engine.

PTO; Vary the engine RPM slightly

PTO only: Lower the attachment

PTO only: Move the engine speed

41

Page 43

OPERATION

Braking

1. Release the travel control pedal completely.

2. Press the brake pedal evenly and firmly.

3. Practice starting and stopping (using the brakes) until

you're familiar with the controls.

Tip: When the travel control pedal is released, the vehicle hydraulic

system will slow the vehicle to a stop. Use the brake pedal to

assist the stopping distance.

Driving Procedure

4. Start the engine and allow it to warm up.

5. For Model HD; Raise the attachment arm. See page 44.

6. Apply the service brakes and shift the transmission into

gear.

7. Check your surroundings and determine your path of

travel.

8. Keeping both hands on the steering wheel, slowly release

the brakes and depress the travel control pedal with your

right foot to begin driving. (Press the toe of the travel control pedal for forward travel, press the heel of the travel

control pedal for backward travel.)

9. Drive slowly. Practice maneuvering and using the travel

control pedal and brakes on level surfaces.

Tip: Allow the utility vehicle to come to a stop before changing direc-

tions with the travel control pedal.

10. Do not carry a passenger until you have at least two hours

of driving experience with this vehicle.

1. Wear eye protection.

2. Perform the pre-ride inspection. See page 35.

3. Sit in the driver's seat and fasten the seat belt.

42

Page 44

Driving with a Passenger

1. Perform the pre-ride inspection. See page 35.

2. Make sure all passengers are at least 12 years of age and

tall enough to comfortably and safely sit in a passenger

seat with the seat belt secured, put both feet on the floor

and grasp the hand hold.

3. Make sure all passengers are wearing eye protection.

4. Make sure all passengers secure their seat belt.

5. Do not carry more than two passengers in the BRUTUS

utility vehicle. Do not carry more than one passenger in

models HD and HD

6. Allow a passenger to ride only in a passenger seat.

7. Slow down. Always travel at a speed appropriate for your

skills, your passengers’ skills, and operating conditions.

Avoid unexpected or aggressive maneuvers that could

cause discomfort or injury to a passenger.

8. Vehicle handling may change with a passenger and/or

cargo on board. All ow more time and distance f or braking.

9. Always follow all operating guidelines as outlined on

safety labels and in this manual.

PTO.

OPERATION

43

Page 45

OPERATION

2

1

3

4

5

5

4

6

7

8

8

7

Hydraulic Controls (Models HD and

HD

PTO)

Joystick Operation

Start the engine. See page 41.

Allow the hydraulic system to warm to operating temperature.

Tip: The utility vehicle has both a joystick lockout switch (Item 1) and

a tilt lockout switch (Item 2). When operating PTO driven attachments, the tilt lockou t switch wil l automatica lly activ ate. Using th e

attachment with the til t lo ck ed out w ill lim it the pos s ibi lity of tilting

the attachment while the PTO shaft is turning and putting stress

on the PTO dri veline u-joints.

Tip: Before engaging the PTO sys-

tem, tilt the attachment to the

desired operating position.

See your attachment Owner’s

Manual for detailed informa-

tion.

To lockout joystick functions;

press the fr ont of the attachment joystick lock switch (Item

1) to enable th e joystick (Item

3) lockout feature. All functions of the joystick will be locked out.

T o lockout the tilt function; press the front of the attachm ent tilt

lock switch (Item 2) to lockout the j oystick (Item 3) tilt function.

Tip: The utility vehicle engine must be running for the hydraulic sys-

44

tem to be activated.

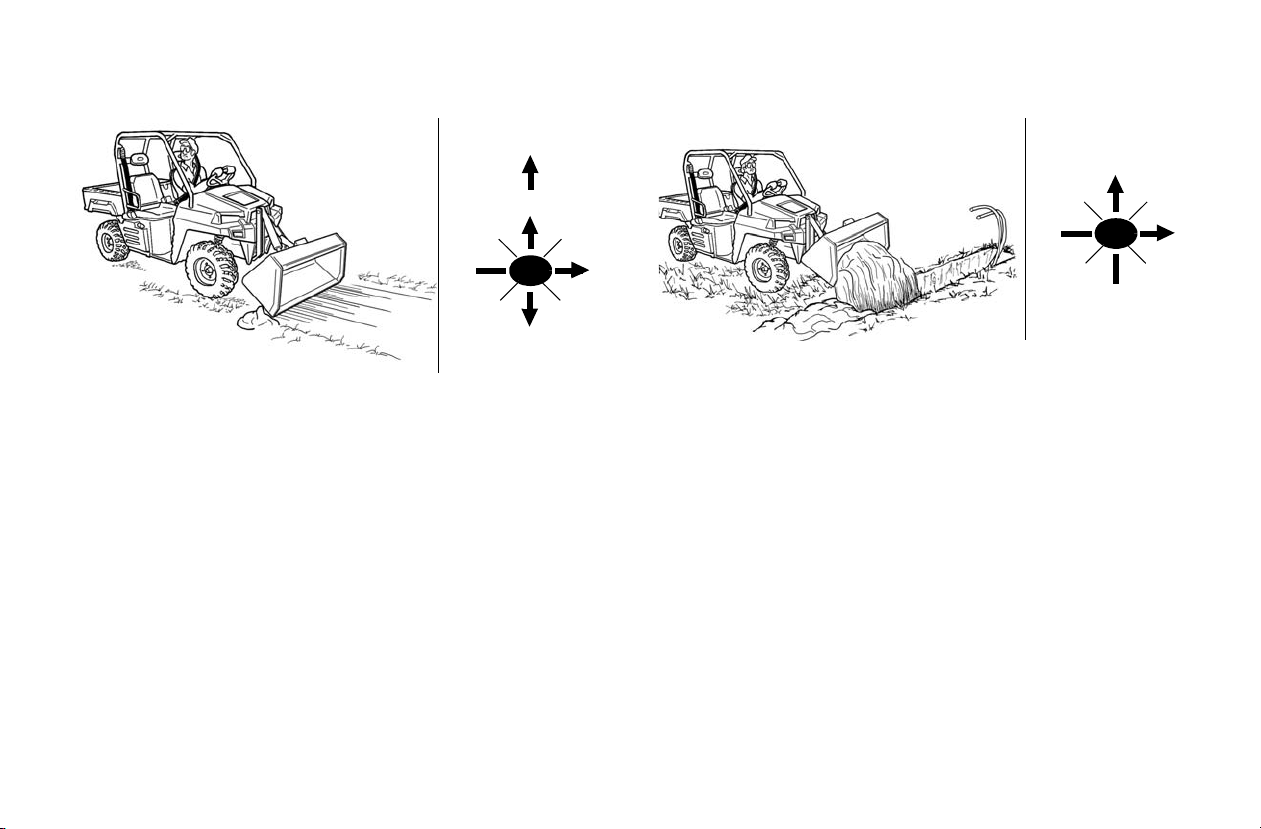

Attachment Arm Operation

Movement of the joystick

controls the hydraulic cylinders for the lift and tilt

functions.

Pull the joystick backward

to raise the attachment arm

(Item 4).

Push the joystick forward to

lower the attachment arm

(Item 5).

Attachment Arm Float Position

Move the joystick fully forward (Item 6) until the joystick

locks in the float position.

Use the float position of the attachment arm to level loose

material ONLY while driving backward.

Pull the joystick backward

(Item 4) to raise the attachment arm and release from

the float position.

Tilt Operation

Move the joystick to the

right to tilt the bucket forward (Item 7).

Move the joystick left to

tilt the buc ket backward

(Item 8).

Page 46

Hydraulic Controls (Models HD and

1

2 3

HD

PTO)

Front Auxiliary Hydraulic Operation

WARNING!

Avoid Injury Or Death.

Diesel fuel or hydraulic fluid under

pressure can penetrate skin or

eyes, causing serious injury or

death. Fluid leaks under pressure

may not be visible. Use a piece of

cardboard or wood to find lea ks. Do

not use your bare hand. Wear

safety goggles. If fluid enters skin

or eyes, get immediate medical

attention from a physician fam iliar

with this injury.

Tip: The utility vehicle engine must be running for the auxiliary