Page 1

User Manual

TCM

High-Performance Tilt-Compensated Compass Module

Page 2

Table of Contents

1 COPYRIGHT & WARRANTY INFORMATION ................................................. 1

2 INTRODUCTION ......................................................................................... 2

3 SPECIFICATIONS ......................................................................................... 3

3.1 Characteristics & Requirements ........................................................... 3

3.2 Mechanical Drawings ............................................................................ 6

4 SET-UP ....................................................................................................... 8

4.1 Electrical Connections ........................................................................... 8

4.2 Installation Location .............................................................................. 9

4.2.1 Operate within the TCM’s dynamic range ................................... 9

4.2.2 Locate away from changing magnetic fields ............................... 9

4.2.3 Mount in a physically stable location .......................................... 9

4.2.4 Location-verification testing ........................................................ 9

4.3 Mechanical Mounting ......................................................................... 10

4.3.1 Pitch and Roll Conventions ........................................................ 10

4.3.2 Mounting Orientation ................................................................ 11

5 USER CALIBRATION .................................................................................. 12

5.1 Magnetic Calibration ........................................................................... 13

5.1.1 Full-Range Calibration ................................................................ 15

5.1.2 2D Calibration ............................................................................ 16

5.1.3 Limited Tilt Range Calibration .................................................... 17

5.1.4 Hard-Iron-Only Calibration ........................................................ 18

5.2 Accelerometer Calibration .................................................................. 18

5.2.1 Accelerometer-Only Calibration ................................................ 19

5.2.2 Mag-and-Accel Calibration ........................................................ 20

6 OPERATION WITH TCM STUDIO ............................................................... 21

6.1 Installation .......................................................................................... 21

6.2 Connection Tab ................................................................................... 22

6.2.1 Initial Connection ....................................................................... 22

6.2.2 Changing Baud Rate ................................................................... 22

6.2.3 Changing Modules ..................................................................... 23

6.3 Configuration Tab ............................................................................... 23

6.3.1 Mounting Options ...................................................................... 23

6.3.2 North Reference ......................................................................... 24

6.3.3 Endianess ................................................................................... 24

6.3.4 Output ........................................................................................ 25

6.3.5 Enable 3D Model ........................................................................ 25

6.3.6 Filter Setting (Taps) .................................................................... 25

6.3.7 Acquisition Settings .................................................................... 25

6.3.8 HPR During Calibration .............................................................. 26

6.3.9 Calibration Settings .................................................................... 26

PNI Sensor Corporation DOC#1014688 r07

TCM User Manual – July 2013 Page i

Page 3

6.3.10 Default ........................................................................................ 27

6.3.11 Retrieve ...................................................................................... 27

6.4 Calibration Tab .................................................................................... 28

6.4.1 Samples ...................................................................................... 28

6.4.2 Calibration Results ..................................................................... 29

6.4.3 Current Configuration ................................................................ 30

6.4.4 Options ....................................................................................... 30

6.4.5 Clear ........................................................................................... 30

6.5 Test Tab ............................................................................................... 31

6.5.1 Current Reading ......................................................................... 31

6.5.2 3D Model .................................................................................... 31

6.5.3 Acquisition Settings .................................................................... 31

6.5.4 Sync Mode .................................................................................. 32

6.6 Log Data Tab ....................................................................................... 33

6.7 Graph Tab ............................................................................................ 34

6.8 System Log Tab ................................................................................... 35

7 OPERATION WITH PNI BINARY PROTOCOL ............................................... 36

7.1 Datagram Structure ............................................................................ 36

7.2 Parameter Formats ............................................................................. 37

7.3 Commands & Communication Frames ............................................... 39

7.3.1 kGetModInfo (frame ID 1d) ........................................................ 40

7.3.2 kGetModInfoResp (frame ID 2d) ................................................ 40

7.3.3 kSetDataComponents (frame ID 3d) .......................................... 41

7.3.4 kGetData (frame ID 4d) .............................................................. 42

7.3.5 kGetDataResp (frame ID 5d) ....................................................... 42

7.3.6 kSetConfig (frame ID 6d) ............................................................ 43

7.3.7 kGetConfig (frame ID 7d) ............................................................ 47

7.3.8 kGetConfigResp (frame ID 8d) .................................................... 47

7.3.9 kSave (frame ID 9d) .................................................................... 48

7.3.10 kStartCal (frame ID 10d) ............................................................. 48

7.3.11 kStopCal (frame ID 11d) .............................................................. 50

7.3.12 kSetFIRFilters (frame ID 12d) ...................................................... 50

7.3.13 kGetFIRFilters (frame ID 13d) ..................................................... 52

7.3.14 kGetFIRFiltersResp (frame ID 14d) ............................................. 52

7.3.15 kPowerDown (frame ID 15d) ...................................................... 52

7.3.16 kSaveDone (frame ID 16d) .......................................................... 53

7.3.17 kUserCalSampleCount (frame ID 17d) ........................................ 53

7.3.18 kCalScore (frame ID 18d) ............................................................ 53

7.3.19 kSetConfigDone (frame ID 19d) .................................................. 54

7.3.20 kSetFIRFiltersDone (frame ID 20d) ............................................. 54

7.3.21 kStartContinuousMode (frame ID 21d) ...................................... 54

7.3.22 kStopContinuousMode (frame ID 22d) ...................................... 54

7.3.23 kPowerUpDone (frame ID 23d) .................................................. 55

PNI Sensor Corporation DOC#1014688 r06

TCM User Manual – July 2013 Page ii

Page 4

7.3.24 kSetAcqParams (frame ID 24d) ................................................... 55

7.3.25 kGetAcqParams (frame ID 25d) .................................................. 56

7.3.26 kSetAcqParamsDone (frame ID 26d) .......................................... 56

7.3.27 kGetAcqParamsResp (frame ID 27d) .......................................... 56

7.3.28 kPowerDownDone (frame ID 28d) ............................................. 56

7.3.29 kFactoryMagCoeff (frame ID 29 d) ............................................. 56

7.3.30 kFactoryMagCoeffDone (frame ID 30 d) ..................................... 56

7.3.31 kTakeUserCalSample (frame ID 31d) .......................................... 57

7.3.32 kFactoryAccelCoeff (frame ID 36 d) ............................................ 57

7.3.33 kFactoryAccelCoeffDone (frame ID 37 d) ................................... 57

7.3.34 kSetSyncMode (frame ID 46 d) ................................................... 57

7.3.35 kSetSyncModeResp (frame ID 47 d) ........................................... 58

7.3.36 kSyncRead (frame ID 49 d) .......................................................... 58

7.4 Code Examples .................................................................................... 59

7.4.1 Header File & CRC-16 Function .................................................. 59

7.4.2 CommProtocol.h File ................................................................. 62

7.4.3 CommProtocol.cpp File .............................................................. 64

7.4.4 TCM.h File .................................................................................. 68

7.4.5 TCM.cpp File ............................................................................... 69

PNI Sensor Corporation DOC#1014688 r06

TCM User Manual – July 2013 Page iii

Page 5

List of Tables

Table 3-1: Performance Characteristics1 3

Table 3-2: Absolute Maximum Ratings 4

Table 3-3: Electrical Operating Requirements 4

Table 3-4: I/O Characteristics 5

Table 3-5: Environmental Requirements 5

Table 3-6: Mechanical Characteristics 5

Table 4-1: TCM Pin Descriptions 8

Table 5-1: Magnetic Calibration Mode Summary 14

Table 5-2: 12 Point Full-Range Calibration Pattern 16

Table 5-3: 12 Point 2D Calibration Pattern 17

Table 5-4: 12 Point Limited-Tilt Calibration Pattern 17

Table 5-5: 6 Point Hard-Iron-Only Calibration Pattern 18

Table 6-1: Mounting Orientations 24

Table 7-1: UART Configuration 36

Table 7-2: TCM Command Set 39

Table 7-3: Component Identifiers 41

Table 7-4: Configuration Identifiers 44

Table 7-5: Sample Points 45

Table 7-6: Recommended FIR Filter Tap Values 51

List of Figures

Figure 3-1: TCM XB Mechanical Drawing 6

Figure 3-2: TCM XB Pigtailed Cable Drawing 6

Figure 3-3: TCM MB Mechanical Drawing 7

Figure 4-1: Positive & Negative Roll and Pitch Definition 10

Figure 4-2: Mounting Orientations 11

Figure 5-1: 12 Point Full-Range Calibration 15

Figure 5-2: Accelerometer Calibration Starting Orientations 20

Figure 7-1: Datagram Structure 36

PNI Sensor Corporation DOC#1014688 r06

TCM User Manual – July 2013 Page iv

Page 6

1 Copyright & Warranty Information

© Copyright PNI Sensor Corporation 2009

All Rights Reserved. Reproduction, adaptation, or translation without prior written permission is prohibited, except

as allowed under copyright laws.

Revised July 2013. For most recent version visit our website at www.pnicorp.com

PNI Sensor Corporation

2331 Circadian Way

Santa Rosa, CA 95407, USA

Tel: (707) 566-2260

Fax: (707) 566-2261

Warranty and Limitation of Liability. PNI Sensor Corporation ("PNI") manufactures its TCM products (“Products”)

from parts and components that are new or equivalent to new in performance. PNI warrants that each Product to be

delivered hereunder, if properly used, will, for one year following the date of shipment unless a different warranty

time period for such Product is specified: (i) in PNI’s Price List in effect at time of order acceptance; or (ii) on PNI’s

web site (www.pnicorp.com) at time of order acceptance, be free from defects in material and workmanship and will

operate in accordance with PNI’s published specifications and documentation for the Product in effect at time of

order. PNI will make no changes to the specifications or manufacturing processes that affect form, fit, or function of

the Product without written notice to the OEM, however, PNI may at any time, without such notice, make minor

changes to specifications or manufacturing processes that do not affect the form, fit, or function of the Product. This

warranty will be void if the Products’ serial number, or other identification marks have been defaced, damaged, or

removed. This warranty does not cover wear and tear due to normal use, or damage to the Product as the result of

improper usage, neglect of care, alteration, accident, or unauthorized repair.

THE ABOVE WARRANTY IS IN LIEU OF ANY OTHER WARRANTY, WHETHER EXPRESS, IMPLIED, OR

STATUTORY, INCLUDING, BUT NOT LIMITED TO, ANY WARRANTY OF MERCHANTABILITY,

FITNESS FOR ANY PARTICULAR PURPOSE, OR ANY WARRANTY OTHERWISE ARISING OUT OF ANY

PROPOSAL, SPECIFICATION, OR SAMPLE. PNI NEITHER ASSUMES NOR AUTHORIZES ANY PERSON

TO ASSUME FOR IT ANY OTHER LIABILITY.

If any Product furnished hereunder fails to conform to the above warranty, OEM’s sole and exclusive remedy and

PNI’s sole and exclusive liability will be, at PNI’s option, to repair, replace, or credit OEM’s account with an

amount equal to the price paid for any such Product which fails during the applicable warranty period provided that

(i) OEM promptly notifies PNI in writing that such Product is defective and furnishes an explanation of the

deficiency; (ii) such Product is returned to PNI’s service facility at OEM’s risk and expense; and (iii) PNI is satisfied

that claimed deficiencies exist and were not caused by accident, misuse, neglect, alteration, repair, improper

installation, or improper testing. If a Product is defective, transportation charges for the return of the Product to

OEM within the United States and Canada will be paid by PNI. For all other locations, the warranty excludes all

costs of shipping, customs clearance, and other related charges. PNI will have a reasonable time to make repairs or

to replace the Product or to credit OEM’s account. PNI warrants any such repaired or replacement Product to be

free from defects in material and workmanship on the same terms as the Product originally purchased.

Except for the breach of warranty remedies set forth herein, or for personal injury, PNI shall have no liability for any

indirect or speculative damages (including, but not limited to, consequential, incidental, punitive and special

damages) relating to the use of or inability to use this Product, whether arising out of contract, negligence, tort, or

under any warranty theory, or for infringement of any other party’s intellectual property rights, irrespective of

whether PNI had advance notice of the possibility of any such damages, including, but not limited to, loss of use,

revenue or profit. In no event shall PNI’s total liability for all claims regarding a Product exceed the price paid for

the Product. PNI neither assumes nor authorizes any person to assume for it any other liabilities.

Some states and provinces do not allow limitations on how long an implied warranty lasts or the exclusion or

limitation of incidental or consequential damages, so the above limitations or exclusions may not apply to you. This

warranty gives you specific legal rights and you may have other rights that vary by state or province.

PNI Sensor Corporation DOC#1014688 r06

TCM User Manual – July 2013 Page 1

Page 7

2 Introduction

Thank you for purchasing PNI Sensor Corporation’s TCM XB (pn 12810) or TCM MB (pn

13095) tilt-compensated 3-axis digital compass. The TCM is a high-performance, low-power

consumption, tilt-compensated electronic compass module that incorporates PNI’s advanced

magnetic distortion compensation and calibration scoring algorithms to provide industry-leading

heading accuracy. The TCM combines PNI’s patented magneto-inductive sensors and

measurement circuit technology with a 3-axis MEMS accelerometer for unparalleled cost

effectiveness and performance.

PNI recognizes not all applications allow for significant tilt during calibration, so multiple

calibration methods are available to ensure optimized performance can be obtained in the real

world. These include Full-Range Calibration, when ≥45° of tilt is possible during calibration,

2D Calibration when constrained to calibration in a horizontal or near-horizontal plane, and

Limited-Tilt Calibration when tilt is constrained to <45° but >5° of tilt is possible.

PNI also recognizes conditions may change over time, and to maintain superior heading accuracy

it may be necessary to recalibrate the compass. So the TCM incorporates Hard-Iron-Only

Calibration to easily account for gradual changes in the local magnetic distorting components.

Plus, the accelerometer can be periodically recalibrated in the field to maintain maximum

accuracy.

These advantages make PNI’s TCM the choice for applications that require the highest accuracy

and performance anywhere in the world under a wide range of conditions. Applications for the

TCM include:

Unmanned vehicles – underwater (UUV), ground (UGV), & aerial (UAV)

Far target locaters and laser range finders

Dead reckoning systems

Systems in which the tilt angles used for calibration are physically constrained

With its many applications, the TCM incorporates a flexible and adaptable command set. Many

parameters are user-programmable, including reporting units, a wide range of sampling

configurations, output damping, and more.

We’re sure the TCM will help you to achieve the greatest performance from your system. Thank

you for selecting the TCM.

PNI Sensor Corporation DOC#1014688 r06

TCM User Manual – July 2013 Page 2

Page 8

Parameter

Value

Heading

Accuracy

≤65° of pitch after Full-Range

Calibration

<0.3° rms

≤80° of pitch after Full-Range

Calibration

<0.5° rms

≤5° of pitch after 2D calibration

<2.0° rms

≤2 times the calibration tilt angle when

using limited-tilt calibration2

<2.0° rms

Resolution

0.1°

Repeatability

0.05° rms

Attitude

Range

Pitch

± 90°

Roll

± 180°

Accuracy

Pitch

0.2° rms

Roll

≤65° of pitch

0.2° rms

≤80° of pitch

0.4° rms

≤86° of pitch

1.0° rms

Resolution

0.01°

Repeatability

0.05° rms

Maximum Operational Dip Angle3

85°

Magnetometers

Calibrated Field Range

± 125 µT

Resolution

0.05 µT

Repeatability

± 0.1 µT

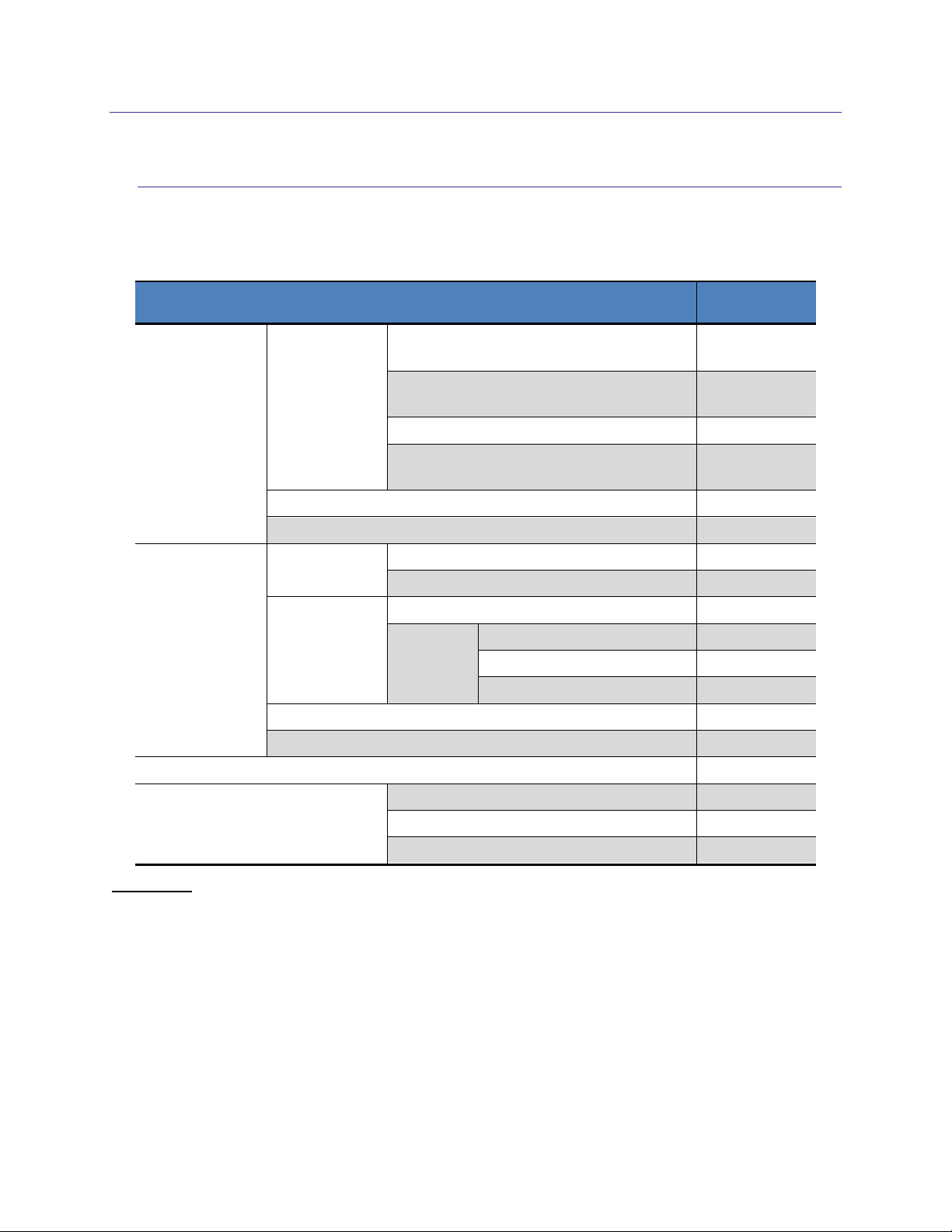

3 Specifications

3.1 Characteristics & Requirements

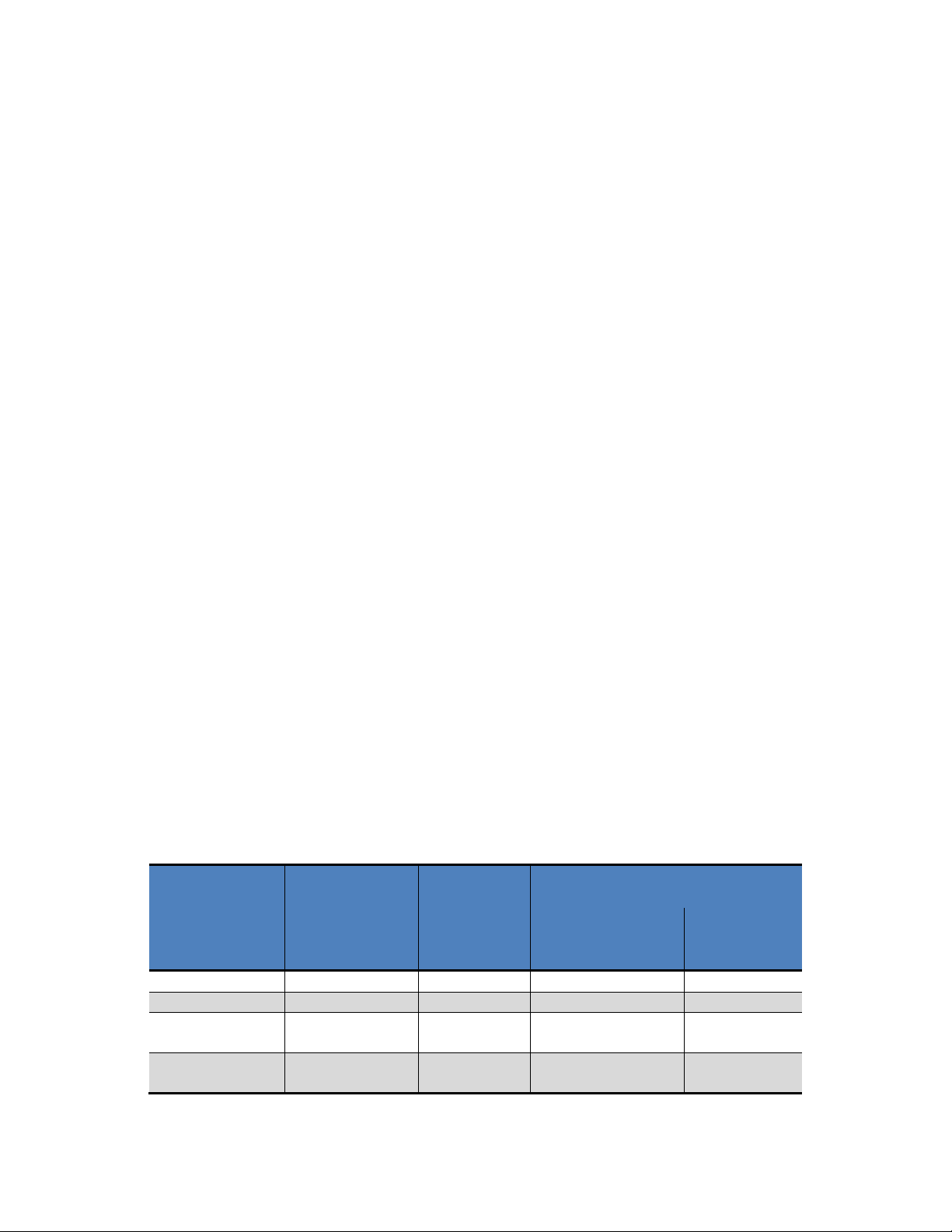

Table 3-1: Performance Characteristics1

Footnotes:

1. Specifications are subject to change. Assumes the TCM is motionless and the local magnetic

field is clean relative to the user calibration.

2. For example, if the calibration was performed over ±10° of tilt, then the TCM would provide <2°

rms accuracy over ±20° of tilt.

3. Performance at maximum operational dip angle will be somewhat degraded.

PNI Sensor Corporation DOC#1014688 r06

TCM User Manual – July 2013 Page 3

Page 9

Parameter

Minimum

Maximum

Units

Supply Voltage

-0.3

+10

VDC

Storage Temperature

-40

+85

°C

Parameter

Value

Supply Voltage

TCM XB

3.8 to 9 VDC

TCM MB

3.3 to 9 VDC

Communication

Lines

TCM XB

High Level Input

2.4 V minimum

Low Level Input

0.6 V maximum

Output Voltage Swing

±5.2 V typ., ±5.0 V min.

Tx Output Resistance

300 Ω

TCM MB

High Level Input

2.0 V minimum

Low Level Input

0.8 V maximum

Output Voltage Swing

0 – 3.3 V typical

Tx Output Resistance

330 Ω

Average

Current Draw

TCM XB

@ max. sample rate

20 mA typical

@ 8 Hz sample rate

16 mA typical

TCM MB

@ max. sample rate

17 mA typical

@ 8 Hz sample rate

13 mA typical

Peak Current

Draw

During application of external

power

120 mA pk, 60 mA avg

over 2 ms

During logical power up/down or

Sync Trigger

135 mA pk, 60 mA avg

over 4 ms

Sleep Mode

Current Draw

TCM XB

0.3 mA typical

TCM MB

0.1 mA typical

CAUTION:

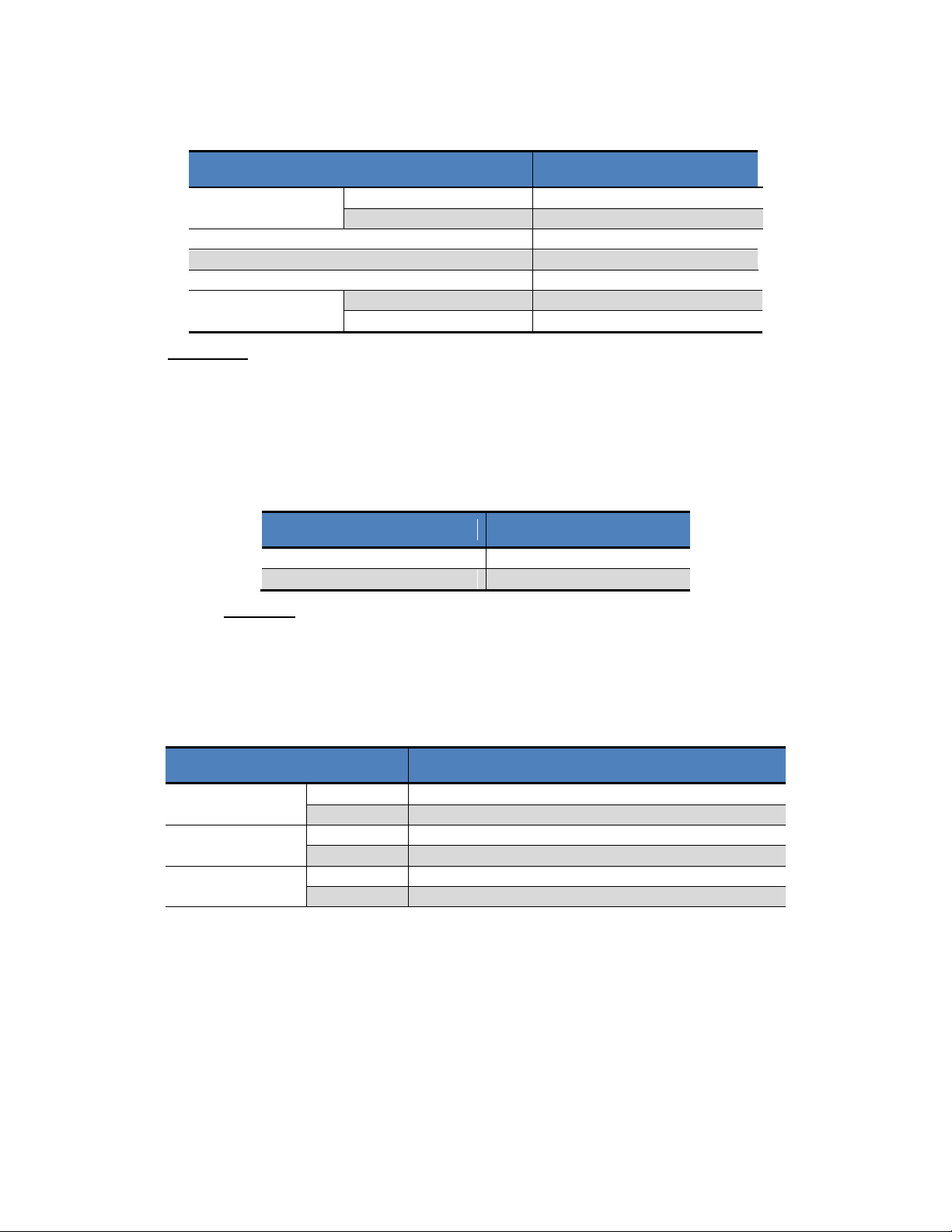

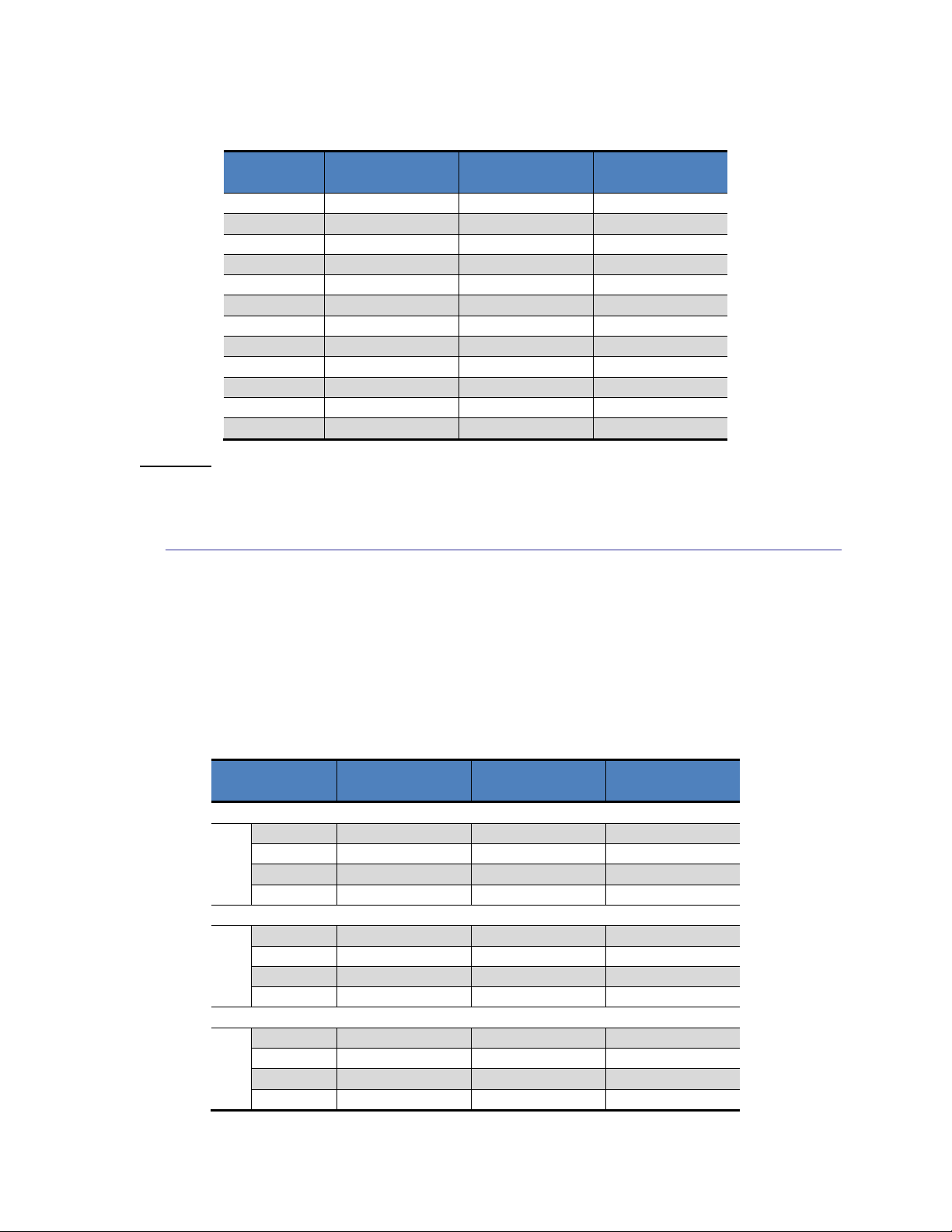

Table 3-2: Absolute Maximum Ratings

Stresses beyond those listed above may cause permanent damage to the device. These are

stress ratings only. Operation of the device at these or other conditions beyond those

indicated in the operational sections of the specifications is not implied.

Table 3-3: Electrical Operating Requirements

PNI Sensor Corporation DOC#1014688 r06

TCM User Manual – July 2013 Page 4

Page 10

Parameter

Value

Communication

Interface

TCM XB

RS232 UART

TCM MB

CMOS/TTL UART

Communication Protocol

PNI Binary

Communication Rate

300 to 115200 baud

Maximum Sample Rate1

~30 samples/sec

Time to Initial

Good Data2

Initial power up

<210 ms

Sleep Mode recovery

<80 ms

Parameter

Value

Operating Temperature1

-40C to +85C

Storage Temperature

-40C to +85C

Parameter

Value

Dimensions

(l x w x h)

TCM XB

35 x 43 x 13 mm

TCM MB

33 x 31 x 13 mm

Weight

TCM XB

6.8 gm

TCM MB

5.3 gm

Connector

TCM XB

9-pin Molex, pn 53780-0970

TCM MB

4-pin MIL-MAX, pn 850-10-004-10-001000

Table 3-4: I/O Characteristics

Footnotes:

1. The maximum sample rate is dependent on the strength of the magnetic

field, and typically will be from 25 to 32 samples/sec.

2. FIR taps set to “0”.

Table 3-5: Environmental Requirements

Footnote:

1. To meet performance specifications across this range,

recalibration will be necessary as the temperature varies.

Table 3-6: Mechanical Characteristics

PNI Sensor Corporation DOC#1014688 r06

TCM User Manual – July 2013 Page 5

Page 11

3.2 Mechanical Drawings

The default orientation is for the silk-screened arrow to point in the “forward” direction.

Figure 3-1: TCM XB Mechanical Drawing

Figure 3-2: TCM XB Pigtailed Cable Drawing

PNI Sensor Corporation DOC#1014688 r06

TCM User Manual – July 2013 Page 6

Page 12

The default orientation is for the silk-screened arrow to point in the “forward” direction.

Figure 3-3: TCM MB Mechanical Drawing

PNI Sensor Corporation DOC#1014688 r06

TCM User Manual – July 2013 Page 7

Page 13

Pin

Number1

TCM XB

TCM MB

9 Pin

Connector

Cable Wire

Color

4 Pin

Connector

1

GND

Black

GND

2

GND

Gray

Vin

3

GND

Green

UART Tx

4

NC

Orange

UART Rx

5

NC

Violet

6

NC

Brown

7

UART Tx

Yellow

8

UART Rx

Blue

9

Vin

Red

4 Set-Up

This section describes how to configure the TCM in your host system. To install the TCM into

your system, follow these steps:

Make electrical connections to the TCM.

Evaluate the TCM using TCM Studio or a binary terminal emulation program, such as

RealTerm or Tera Term, to ensure the compass generally works correctly.

Choose a mounting location.

Mechanically mount the TCM in the host system.

Perform a user calibration.

4.1 Electrical Connections

The TCM XB incorporates a 9 pin Molex connector, part number 53780-0970, which mates

with Molex part 51146-0900 or equivalent. The TCM MB incorporates a 4 pin Mil-Max

connector, part number 850-10-004-10-001000, which mates with Mill-Max part 851-XX004-10-001000 or equivalent. The pin-out is given below in Table 4-1.

Table 4-1: TCM Pin Descriptions

Footnote:

1. For the TCM XB, pin #1 is indicated on Figure 3-1, while for the TCM MB, pin

#1 is the pin closest to the corner.

After making the electrical connections, it is a good idea to perform some simple tests to

ensure the TCM is working as expected. See Section 5 for how to operate the TCM with

TCM Studio, or Section 7 for how to operate the TCM using the PNI binary protocol.

PNI Sensor Corporation DOC#1014688 r06

TCM User Manual – July 2013 Page 8

Page 14

4.2 Installation Location

The TCM’s wide dynamic range and sophisticated calibration algorithms allow it to operate

in many environments. For optimal performance however, you should mount the TCM with

the following considerations in mind:

4.2.1 Operate within the TCM’s dynamic range

The TCM can be user calibrated to correct for static magnetic fields created by the host

system. However, each axis of the TCM has a calibrated dynamic range of ±125 µT. If

the total field exceeds this value for any axis, the TCM may not perform to specification.

When mounting the TCM, consider the effect of any sources of magnetic fields in the

host environment that, when added to Earth’s field, may take the TCM out of its dynamic

regime. For example, large masses of ferrous metals such as transformers and vehicle

chassis, large electric currents, permanent magnets such as electric motors, and so on.

4.2.2 Locate away from changing magnetic fields

It is not possible to calibrate for changing magnetic anomalies. Thus, for greatest

accuracy, keep the TCM away from sources of local magnetic distortion that will change

with time; such as electrical equipment that will be turned on and off, or ferrous bodies

that will move. Make sure the TCM is not mounted close to cargo or payload areas that

may be loaded with large sources of local magnetic fields.

4.2.3 Mount in a physically stable location

Choose a location that is isolated from excessive shock, oscillation, and vibration. The

TCM works best when stationary. Any non-gravitational acceleration results in a

distorted reading of Earth’s gravitational vector, which affects the heading measurement.

4.2.4 Location-verification testing

Location-verification testing should be performed at an early stage of development to

understand and accommodate the magnetic distortion contributors in a host system.

Determine the distance range of field distortion.

Place the compass in a fixed position, then move or energize suspect components

while observing the output to determine when they are an influence.

PNI Sensor Corporation DOC#1014688 r06

TCM User Manual – July 2013 Page 9

Page 15

Determine if the magnetic field is within the dynamic range of the compass.

With the compass mounted, rotate and tilt the system in as many positions as

possible. While doing so, monitor the magnetometer outputs, observing if the

maximum linear range is exceeded.

4.3 Mechanical Mounting

The TCM is factory calibrated with respect to its mounting holes. It must be aligned within

the host system with respect to these mounting holes. Ensure any stand-offs or screws used

to mount the module are non-magnetic. Refer to Section 3.2 for dimensions, hole locations,

and the reference frame orientation.

Note: Ensure that when attaching the TCM to the host system, the mounting method does not

introduce stresses on the board, as this can affect the performance of the accelerometer, and

therefore also negatively affect heading accuracy.

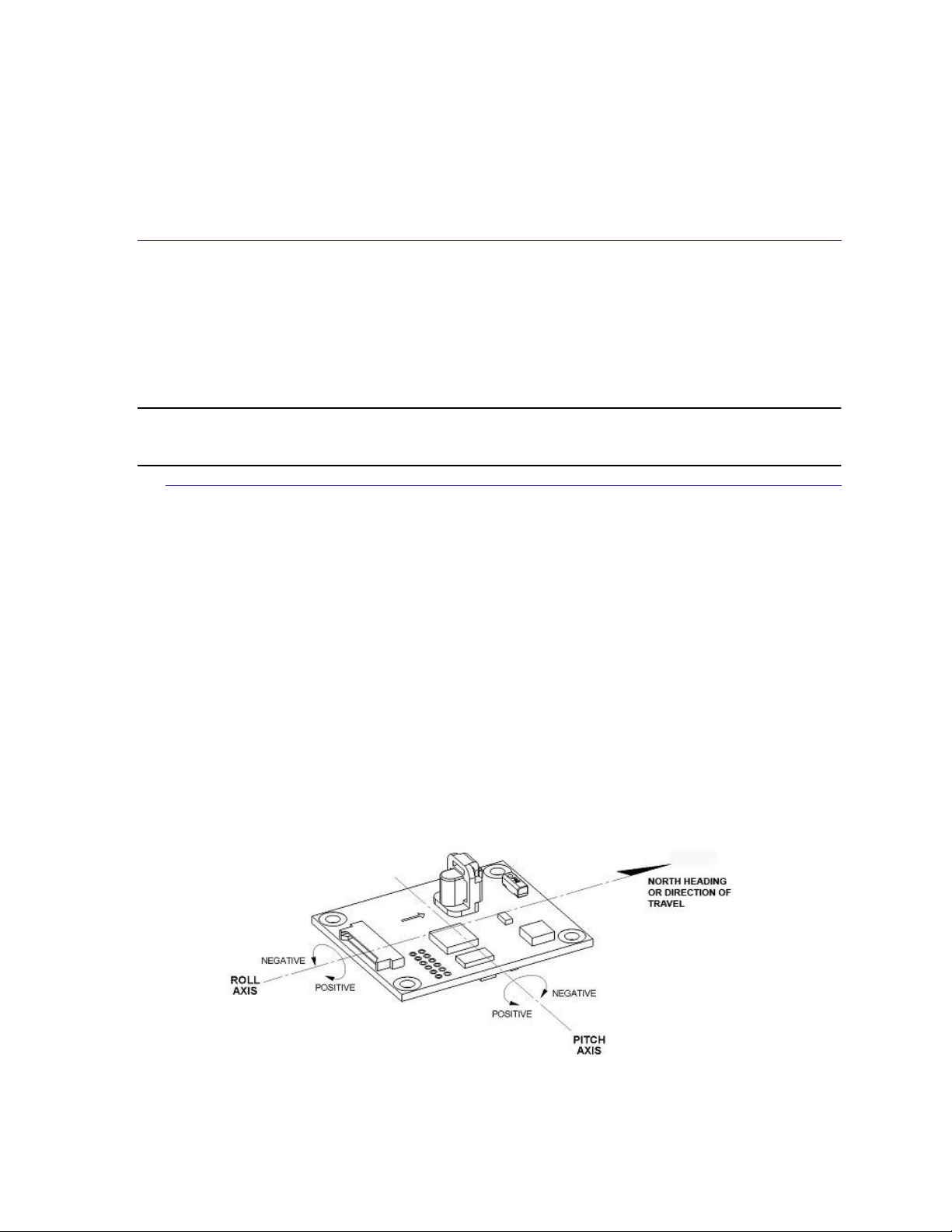

4.3.1 Pitch and Roll Conventions

The TCM uses a MEMS accelerometer to measure the tilt angle of the compass. This

data is output as pitch and roll data, and is also used in conjunction with the

magnetometers to provide a tilt-compensated heading reading.

The TCM utilizes Euler angles as the method for determining accurate orientation. This

method is the same used in aircraft orientation where the outputs are heading (also called

yaw or azimuth), pitch and roll. When using Euler angles, roll is defined as the angle

rotated around an axis through the center of the fuselage while pitch is rotation around an

axis through the center of the wings. These two rotations are independent of each other

since the rotation axes rotate with the plane body.

As shown in Figure 4-1, for the TCM a positive pitch is when the front edge of the board

is rotated upward and a positive roll is when the right edge of the board is rotated down.

Figure 4-1: Positive & Negative Roll and Pitch Definition

PNI Sensor Corporation DOC#1014688 r06

TCM User Manual – July 2013 Page 10

Page 16

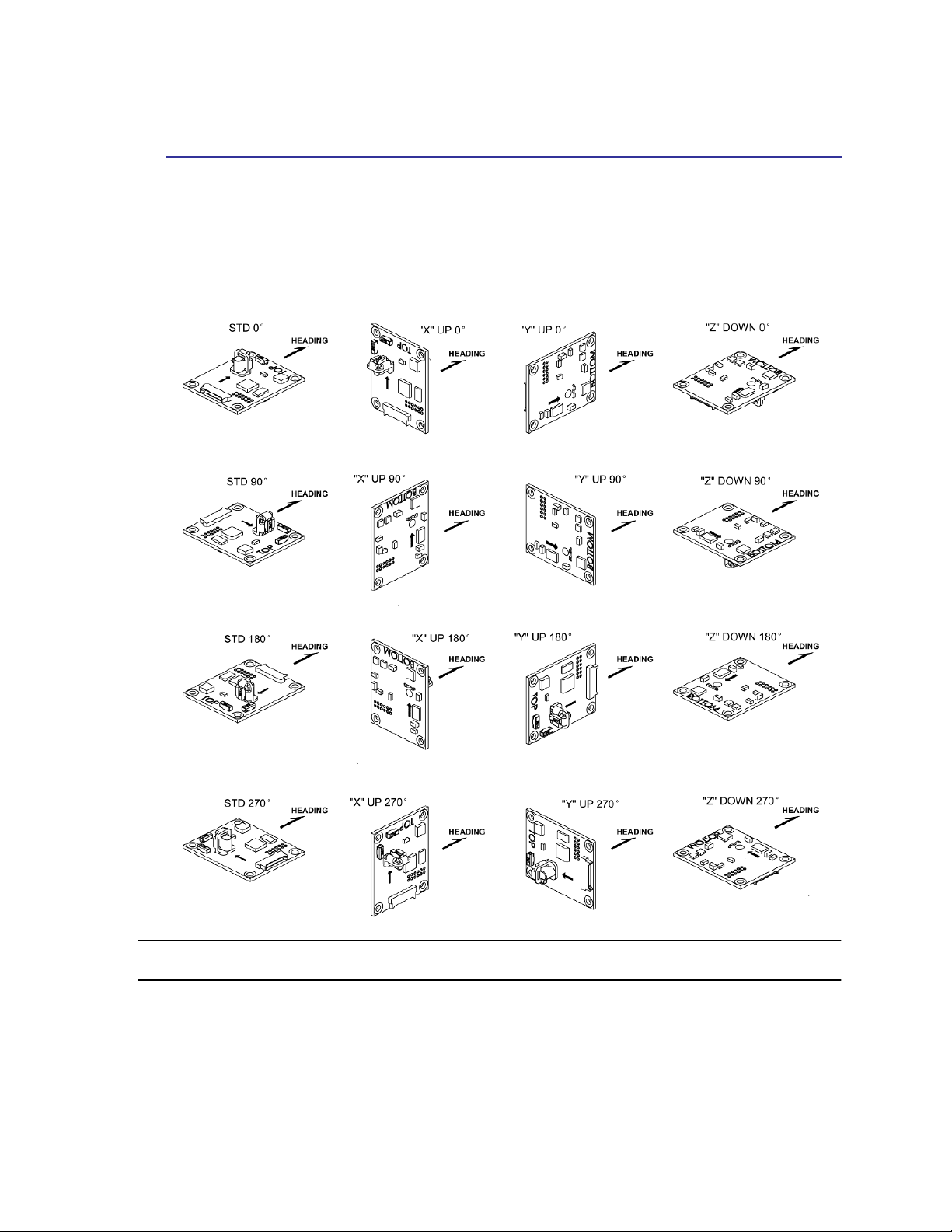

4.3.2 Mounting Orientation

The TCM can be mounted in various orientations, as shown for the TCM XB in Figure

4-2. All reference points are based on the white silk-screened arrow on the top side of the

board. The orientation should be programmed in the TCM using TCM Studio or the

kSetConfig command. The default orientation is “STD 0°”.

Note: TCM XB is shown. The Z axis sensor and the connector are on the module’s top surface,

regardless of model.

Figure 4-2: Mounting Orientations

PNI Sensor Corporation DOC#1014688 r06

TCM User Manual – July 2013 Page 11

Page 17

5 User Calibration

The magnetic sensors in the TCM are calibrated at PNI’s factory in a magnetically controlled

environment. However sources of magnetic distortion positioned near the TCM in the user’s

system will distort Earth’s magnetic field and should be compensated for in the host system with

a user calibration. Examples of such sources include ferrous metals and alloys (ex. iron, nickel,

steel, etc.), batteries, audio speakers, current-carrying wires, and electric motors. Compensation

is accomplished by mounting the TCM in the host system and performing a user calibration. It is

expected the sources of magnetic distortion remain fixed relative to the TCM’s position within

the host system. By performing a calibration, the TCM identifies the local sources of magnetic

distortion and negates their effects from the overall reading to provide an accurate heading.

As with the magnetic sensor, the accelerometer in the TCM is calibrated at PNI’s factory. But

the accelerometer will gradually change over time, and the user either will need to periodically

perform a user accelerometer calibration or return the unit to PNI for recalibration. As a general

rule-of-thumb, the accelerometer should be recalibrated every 6 to 12 months. Unlike a

magnetic calibration, the accelerometer may be calibrated outside the host system.

Accelerometer calibration is more sensitive to noise or hand jitter than magnetic calibration,

especially for subsequent use at high tilt angles. Because of this, ideally a stabilized fixture

would be used for accelerometer calibration, although resting the unit against a stable surface

often is sufficient.

Key Points:

Magnetic calibration:

o Requires incorporating the TCM into the host system to compensate for magnetic

sourcing and distorting components with the user’s system.

o Allows for 4 different methods of calibration. Full-Range Calibration provides

the highest heading accuracy, while 2D and Limited-Tilt Calibration support a

limited range of motion during calibration. Hard-Iron-Only Calibration updates

just the hard-iron coefficients with a relatively easy procedure.

Accelerometer calibration requires rotating the TCM through a full sphere of coverage,

but the TCM does not need to be incorporated into the user’s system during calibration.

If the TCM will experience different states during operation, such as operating with a

nearby shutter sometimes closed and sometimes open, or operating over a broad

temperature range, then different sets of calibration coefficients can be saved for the

various states. Up to 8 magnetic calibration coefficient sets and 3 accelerometer

calibration coefficient sets can be saved.

PNI Sensor Corporation DOC#1014688 r06

TCM User Manual – July 2013 Page 12

Page 18

5.1 Magnetic Calibration

Two fundamental types of magnetic distortion exist, hard-iron distortion and soft-iron

distortion. A given component can exhibit both hard-iron and soft-iron distortions. These

distortions are reviewed in the ensuing paragraphs, and are followed by discussions on

temperature effects and other considerations. For more information on magnetic distortion

and calibration, see PNI’s white paper “Local Magnetic Distortion Effects on 3-Axis

Compassing” at PNI’s website (http://www.pnicorp.com/technology/papers).

Hard-Iron Effects

Hard-iron distortions are caused by permanent magnets and magnetized objects in

close proximity to the sensors. These distortions add or subtract a fixed component to

each axis of the magnetic field reading. Hard-iron distortions usually are unchanging

and in a constant location relative to the sensors, for all heading orientations.

Soft-Iron Effects

Magnetically “soft” materials effectively bend the magnetic field near them. These

materials have a high magnetic permeability, meaning they easily serve as a path for

magnetic field lines. Unlike hard-iron effects, soft-iron effects do not increase or

decrease the total field in the area. However, the effect of the soft-iron distortion

changes as the host system’s orientation changes. Because of this, it is more difficult

to compensate for soft-iron materials.

Temperature Effects

While the hard-iron and soft-iron distortion of a system may remain quite stable over

time, normally the distortion signature will change over temperature. As a general

rule, the hard-iron component will change 1% per 10°C temperature change. Exactly

how this affects heading depends on several factors, most notably the hard-iron

component of the system and the inclination, or dip angle.

Consider the example of a host system with a 100 µT hard-iron component. This is a

fairly large hard-iron component, but not completely uncommon. A 10°C

temperature change will alter the magnetic field by ~1 µT in the direction of the hardiron component. Around San Francisco, with an inclination of ~60°, this results in up

to a couple of degrees of heading change over 10°C.

Consequently, no matter how stable a compass is over temperature, it is wise to

recalibrate over temperature since the magnetic signature of the host system will

change over temperature. The TCM helps accommodate this issue by allowing the

user to save up to 8 sets of magnetic calibration coefficient sets, so different

calibration coefficients can be generated and loaded at different temperatures.

PNI Sensor Corporation DOC#1014688 r06

TCM User Manual – July 2013 Page 13

Page 19

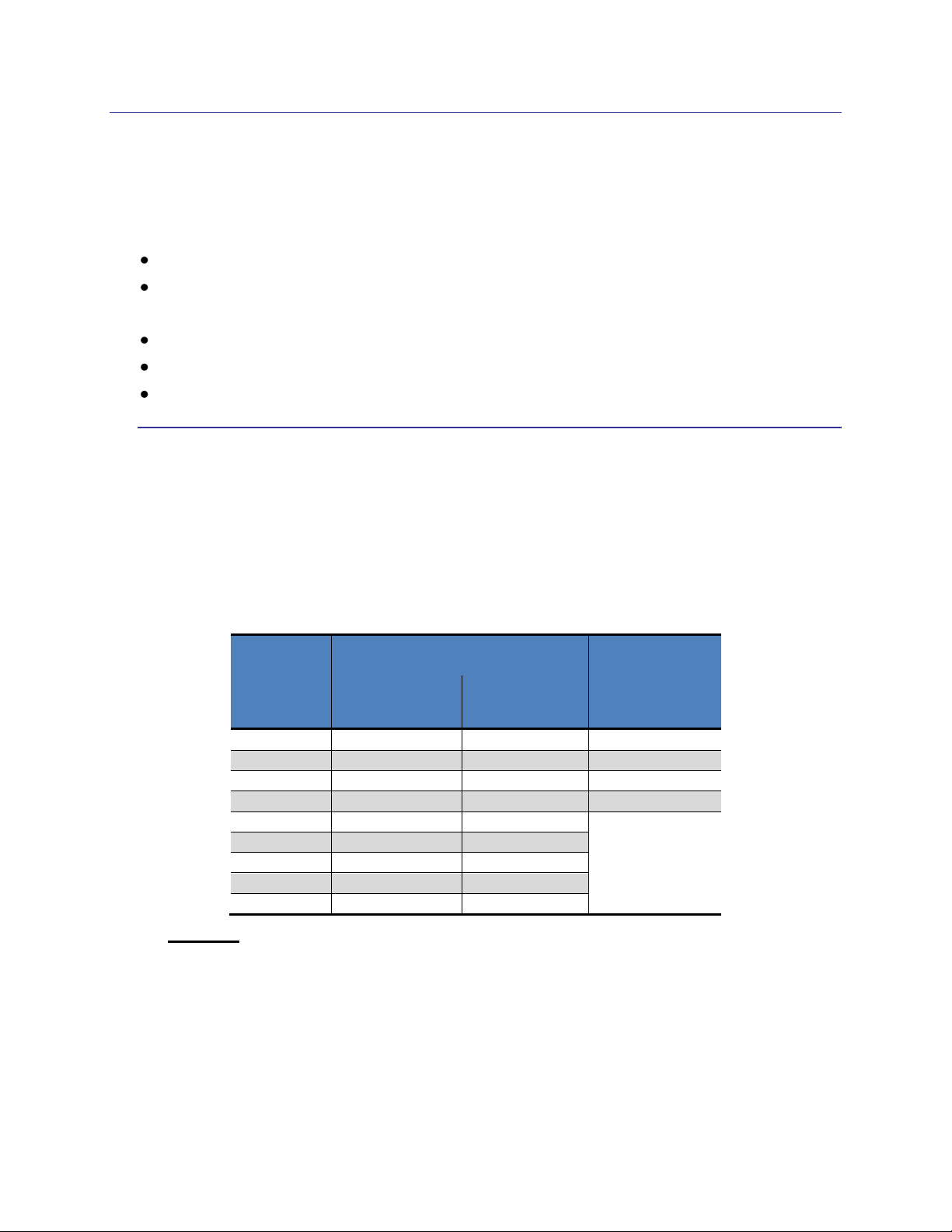

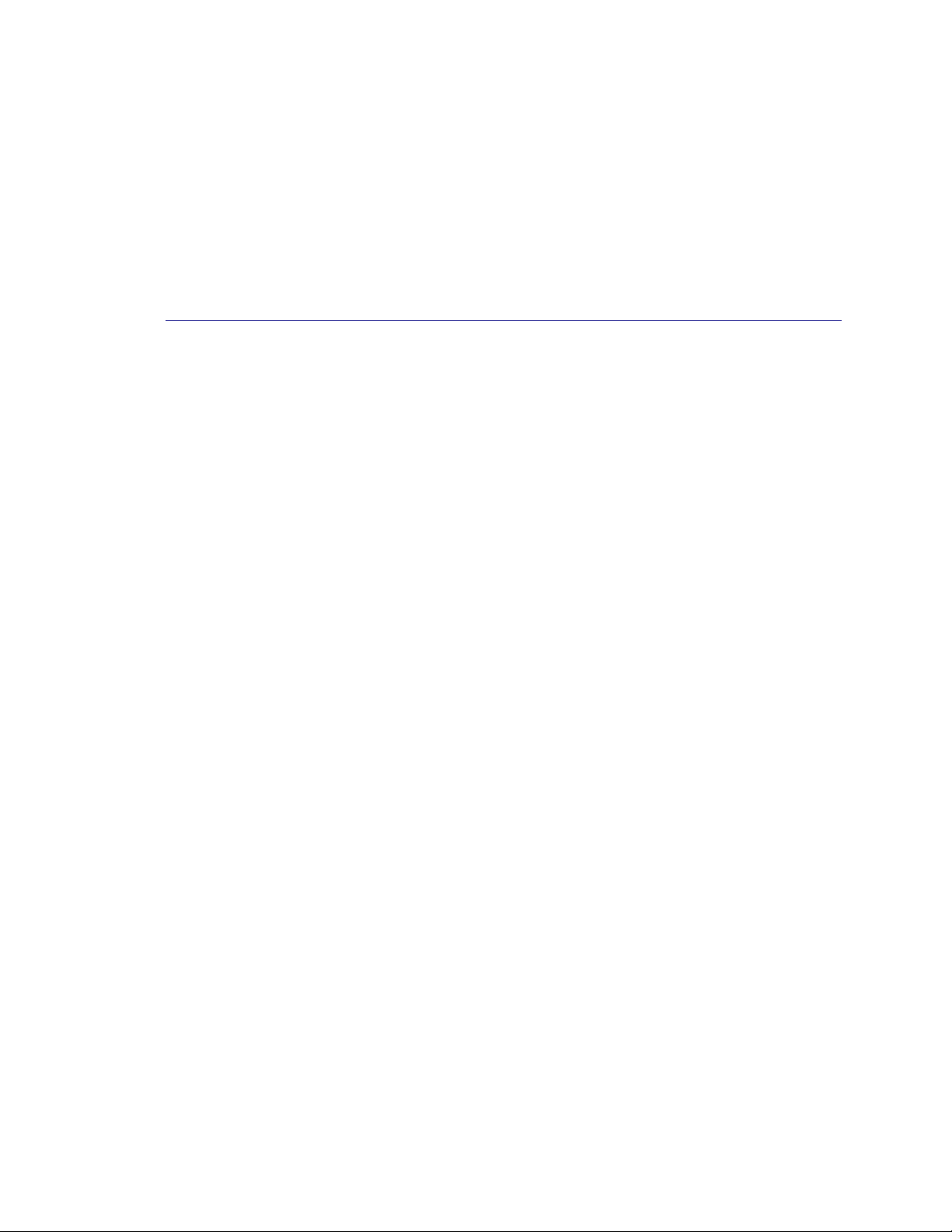

Calibration

Mode

Accuracy

Tilt Range

during Cal

Number of Samples

Minimum

Recommend

Allowable

Range

Full Range

0.3° rms

>±45°

12

10 – 18

2D Calibration

<2°

<±5°

12

10 – 18

Limited Tilt

Range

<2° over 2x tilt

range

±5° to ±45°

12

10 – 18

Hard Iron Only

Restores prior

accuracy

>±3°

6

4 - 18

Other Considerations

The TCM measures the total magnetic field within its vicinity, which is a

combination of Earth’s magnetic field and local magnetic sources and distortions.

While the TCM’s calibration algorithms can compensate for local static magnetic

sources, it is not possible to compensate for dynamic changes in the magnetic field.

Consequently, it is recommended to keep the TCM away from dynamic magnetic

fields. If this is not possible, then take measurements only when the state of the

magnetic field is known. For example, if an electric motor is nearby take

measurements only when the motor is off. Alternatively, different sets of magnetic

calibration coefficients can be generated in advance for various states and then called

when appropriate. Using the prior example, generate and use one set of coefficients

for when the motor is off and another set for when the motor is on.

The main objective of a magnetic user calibration is to compensate for hard-iron and soft-

iron distortions to the magnetic field caused by components within the user’s host system.

To that end, the TCM needs to be mounted within the host system and the entire host system

needs to be moved as a single unit during a user calibration. The TCM allows the user to

perform a calibration only in a 2D plane or with limited tilt, but provides the greatest

accuracy if the user can rotate through 360° of heading and at least ±45°of tilt.

The following subsections provide instructions for performing a magnetic calibration of a

TCM system. Several calibration mode options exist, as summarized in Table 5-1. To meet

the accuracy specification, the number of samples should be the “Minimum Recommended”

value, or greater. Calibration may be performed using Studio or using the PNI binary

protocol, and up to 8 sets of magnetic calibration coefficients may be saved. The

recommended calibration patterns described in the following sub-sections provide a good

distribution of sample points. Also, PNI recommends the location of the TCM remain fairly

constant while only the orientation is changed.

Table 5-1: Magnetic Calibration Mode Summary

PNI Sensor Corporation DOC#1014688 r06

TCM User Manual – July 2013 Page 14

Page 20

Before proceeding with a calibration, ensure the TCM is properly installed in the host

system, as discussed in Section 4. Also, the software should be properly configured with

respect to the mounting orientation, Endianness, north reference, etc.

Section 6.4 outlines how to perform a calibration using Studio, while Section 7.3.10 provides

a step-by-step example of how to perform a calibration using the PNI protocol.

5.1.1 Full-Range Calibration

A Full-Range Calibration is appropriate when the TCM can be tilted ±45° or more. This

method compensates for hard and soft iron effects in three dimensions, and allows for the

highest accuracy readings. The recommended 12 point calibration pattern is a series of 3

circles of evenly spaced points, as illustrated in Figure 5-1 and listed in Table 5-2. The

pitch used in the second and third circles of the calibration should at least match the

maximum and minimum pitch the device is expected to encounter in use.

Figure 5-1: 12 Point Full-Range Calibration

Note: While Figure 5-1 shows the location of the device changing, this is for illustration purposes and

it is best for the location of the device to remain constant while only the orientation is changed.

PNI Sensor Corporation DOC#1014688 r06

TCM User Manual – July 2013 Page 15

Page 21

Sample #

Yaw1

Pitch

Roll

First Circle

1

0°

±5°

30° to 40°

2

90°

±5°

-30° to -40°

3

180°

±5°

30° to 40°

4

270°

±5°

-30° to -40°

Second Circle

5

30°

> +45°

30° to 40°

6

120°

> +45°

-30° to -40°

7

210°

> +45°

30° to 40°

8

300°

> +45°

-30° to -40°

Third Circle

9

60°

< -45°

30° to 40°

10

150°

< -45°

-30° to -40°

11

240°

< -45°

30° to 40°

12

330°

< -45°

-30° to -40°

Table 5-2: 12 Point Full-Range Calibration Pattern

Footnote:

1. Yaw listings are not absolute heading directions but rather relative heading

referenced to the first sample.

5.1.2 2D Calibration

A 2D Calibration is intended for very low tilt operation (<5°) where calibrating the TCM

with greater tilt is not practical.

This procedure calibrates for hard and soft iron effects in only two dimensions, and in

general is effective for operation and calibration in the tilt range of -5° to +5°. The

recommended 12 point calibration pattern is a circle of evenly spaced points, as given in

Table 5-3.

PNI Sensor Corporation DOC#1014688 r06

TCM User Manual – July 2013 Page 16

Page 22

Sample #

Yaw

Pitch1

Roll1

1

0°

0°

0° 2 30°

max. negative

max. negative

3

60°

0°

0°

4

90°

max. positive

max. positive

5

120°

0°

0°

6

150°

max. negative

max. negative

7

180°

0°

0° 8 210°

max. positive

max. positive

9

240°

0°

0°

10

270°

max. negative

max. negative

11

300°

0°

0°

12

330°

max. positive

max. positive

Sample #

Yaw

Pitch

Roll

First Circle

1

0°

0°

0°

2

90°

0°

0°

3

180°

0°

0°

6

270°

0°

0°

Second Circle

7

45°

> +5°

> +5°

8

135°

> +5°

> +5°

11

225°

> +5°

> +5°

12

315°

> +5°

> +5°

Third Circle

13

45°

< -5°

< -5°

14

135°

< -5°

< -5°

17

225°

< -5°

< -5°

18

315°

< -5°

< -5°

Footnote:

Table 5-3: 12 Point 2D Calibration Pattern

1. For best results, the tilt experienced during calibration should match that experienced

in service. For example, if the TCM is restrained to a level plane in service, then

calibration should be in a plane, where “max. positive” and “max. negative” are 0°.

5.1.3 Limited Tilt Range Calibration

A Limited Tilt Range Calibration is recommended when 45° of tilt isn’t feasible, but >5°

of tilt is possible. It provides both hard-iron and softiron distortion correction. The

recommended 12 point calibration pattern given below is a series of 3 circles of evenly

spaced points, with as much tilt variation as expected during use.

Table 5-4: 12 Point Limited-Tilt Calibration Pattern

PNI Sensor Corporation DOC#1014688 r06

TCM User Manual – July 2013 Page 17

Page 23

Sample #

Yaw

Pitch1

Roll1

1

0°

max. negative

max. negative

2

60°

max. positive

max. positive

3

120°

max. negative

max. negative

4

180°

max. positive

max. positive

5

240°

max. negative

max. negative

6

300°

max. positive

max. positive

Note that a similar and acceptable alternative pattern would be to follow the

recommended 12 point Full-Range Calibration pattern, but substituting the >±45° of pitch

with whatever pitch can be achieved and the ±10° to ±20° or roll with whatever roll can

be achieved up to these limits.

5.1.4 Hard-Iron-Only Calibration

It is not uncommon for the hard-iron magnetic distortions around the TCM to change.

Some reasons for this include significant temperature change or temperature shock to a

system, as well as gradual aging of components. A Hard-Iron-Only Calibration allows

for quick recalibration of the TCM for hard-iron effects, and generally is effective for

operation and calibration in the tilt range of 3° or more (≥45° is preferred). The

recommended 6 point calibration pattern given below is a circle of alternately tilted,

evenly spaced points, with as much tilt as expected during use.

Table 5-5: 6 Point Hard-Iron-Only Calibration Pattern

Footnote:

1. For best results, the tilt experienced during calibration should match that experienced

in service. For example, if the TCM will be subject to ±45° of pitch and roll when in

service, then “max negative” should be -45° and “max positive” should be +45°.

5.2 Accelerometer Calibration

The TCM uses a MEMS accelerometer to measure the attitude of the compass. This data is

output as pitch and roll data. Additionally, the accelerometer data is critical for establishing

an accurate heading reading when the TCM is tilted, as discussed in the PNI white paper

“Tilt-Induced Heading Error in a 2-Axis Compass”, which can be found on PNI’s web site

(http://www.pnicorp.com/technology/papers).

The TCM algorithms assume the accelerometer only measures the gravitational field. If the

TCM is accelerating, this will result in the TCM calculating an inaccurate gravitational

PNI Sensor Corporation DOC#1014688 r06

TCM User Manual – July 2013 Page 18

Page 24

vector, which in turn will result in an inaccurate heading reading. For this reason, the TCM

should be stationary when taking a measurement.

As previously mentioned, PNI calibrates the accelerometer in its factory prior to shipment.

But over time the bias and offset of the accelerometer will drift. For this reason PNI

recommends the accelerometer be recalibrated every 6 to 12 months. The user may return

the TCM to PNI for accelerometer calibration, or the user may perform a user accelerometer

calibration. The remainder of this section covers the user accelerometer calibration.

5.2.1 Accelerometer-Only Calibration

The requirements for a good user accelerometer calibration differ significantly from the

requirements for a good magnetic calibration. Specifically, a good accelerometer

calibration involves the TCM experiencing a wide range of pitch and roll values,

preferably seeing both ±180° of pitch and ±180° of roll. Also, it is necessary for the

TCM to be very still during an accelerometer calibration. If possible, PNI recommends

using a fixture to hold the device during calibration, although resting the TCM on a hard

surface normally is sufficient.

The accelerometer either can be calibrated while mounted in the host system or it may be

removed and calibrated outside the system. The advantage of performing the calibration

while mounted in the host system is the user does not need to remove the TCM from the

system, which can be burdensome, and a simultaneous Mag-and-Accel Calibration may

be appropriate. The advantage of performing the calibration outside of the system is it

may be much simpler to obtain the desired range of pitch and roll.

Figure 5-2 shows the two basic starting positions for the recommended 18-point

calibration pattern. Starting with the TCM as shown on the left in Figure 5-2, rotate the

device about its z axis such that it sits on each of its 4 edges, taking one calibration

sample on each edge. Then place the TCM flat on the surface and take a calibration

sample, then flip it over (roll it 180°) and take another sample. Next, starting with the

TCM as shown on the right, take a calibration point with it being vertical (0°). Now tilt

the TCM back 45° and take another calibration point (+45°), then tilt the device forward

45° and take another calibration point (-45°). Repeat this 3-point calibration process for

the TCM with it resting on each of its 4 corners. Note that it is possible to perform an

Accelerometer Calibration with as few as 12 sample points, although it generally is more

difficult to obtain a good calibration with just 12 sample points. Also, the maximum

number of calibration points is 18.

PNI Sensor Corporation DOC#1014688 r06

TCM User Manual – July 2013 Page 19

Page 25

Note: While the TCM is shown removed from the host system, the Accelerometer

Calibration may be performed with the TCM mounted in the host system.

Figure 5-2: Accelerometer Calibration Starting Orientations

5.2.2 Mag-and-Accel Calibration

The TCM allows for a simultaneous magnetometer and accelerometer calibration. This

requires a full-coverage calibration pattern, physically stable measurements, and

installation in the user’s system so the host system’s magnetic signature is present. PNI

recommends 18 to 32 calibration points for a Mag-and-Accel Calibration. The

Accelerometer-Only Calibration pattern discussed in Section 5.2 will work for a Magand-Accel Calibration. Optimal performance is obtained when all rotations of the TCM

are performed towards magnetic north to achieve the widest possible magnetic field

distribution.

Note that combining calibrations only makes sense if all the host system’s magnetic

distortions (steel structures or batteries, for instance) are present and fixed relative to the

module when calibrating. If an Accelerometer-Only Calibration is performed, the user’s

system distortions are not relevant, which allows the TCM to be removed from the host

system in order to perform the Accelerometer-Only Calibration.

PNI Sensor Corporation DOC#1014688 r06

TCM User Manual – July 2013 Page 20

Page 26

6 Operation with TCM Studio

TCM Studio puts an easy-to-use, graphical-user interface (GUI) onto the binary command

language used by the TCM. TCM Studio is intended for evaluating, demonstrating, and

calibrating the TCM module. The program includes the ability to log and save the outputs from

the TCM to a file for off-line evaluation. Check the PNI website for the latest TCM Studio

updates at www.pnicorp.com.

Note: TCM Studio v3.X and higher is compatible with the TCM XB, TCM MB and legacy TCM 6, but not

other legacy TCM models. The TCM XB also will work with TCM Studio v3 and higher, while the TCM

MB will work with TCM Studio v4 and higher. The version of Studio is identified in the upper left corner of

the GUI.

The TCM Studio evaluation software communicates with the TCM through the RS232 serial port

of a computer. The TCM MB requires a user-supplied level shifter to make it compatible with

the computer’s RS232 interface.

6.1 Installation

TCM Studio is provided as an executable program which can be downloaded from PNI’s

website. It will work with Windows XP, Windows Vista, Windows 7, and Mac OS X

operating systems. Check the PNI web page at www.pnicorp.com for the latest version.

For Windows computers, copy the TCMStudio.msi file onto your computer. Then, open the

file and step through the Setup Wizard.

For Mac computers, copy the TCMStudio.zip file onto your computer. This automatically

places the application in the working directory of your computer. The Quesa plug-in, also in

the .zip file, needs to be moved to /Library/CFMSupport, if it is not already there.

PNI Sensor Corporation DOC#1014688 r06

TCM User Manual – July 2013 Page 21

Page 27

6.2 Connection Tab

6.2.1 Initial Connection

If using the PNI dual-connectorized cable, ensure the batteries are well-charged.

Select the serial port the module is plugged into, which is generally COM 1.

Select 38400 as the baud rate.

Click the <Connect> button if the connection is not automatic.

Once a connection is made the “Connected” light will turn green and the module’s

firmware version, serial number, and PCA version will be displayed in the header section.

6.2.2 Changing Baud Rate

To change the baud rate:

In the Module window, select the new baud rate for the module.

Click the <Power Down> button. The button will change to read <Power Up>.

In the Computer window, select same baud rate for the computer.

Click the <Power Up> button. The button will revert back to <Power Down>.

Note: While the TCM can operate at a baud rate of 230400, a PC serial port normally will not

operate this fast.

PNI Sensor Corporation DOC#1014688 r06

TCM User Manual – July 2013 Page 22

Page 28

6.2.3 Changing Modules

Once a connection has been made, TCM Studio will recall the last settings. If a different

module is used, click the <Connect> button once the new module is attached. This will

reestablish a connection, assuming the module baud rate is unchanged.

6.3 Configuration Tab

Note: No settings will be changed in the module until the <SAVE> button has been selected.

6.3.1 Mounting Options

TCM Studio supports 16 mounting orientations, as illustrated previously in Figure 4-2.

The descriptions in TCM Studio are slightly different from those shown in Figure 4-2,

and the relationship between the two sets of descriptions is given below.

PNI Sensor Corporation DOC#1014688 r06

TCM User Manual – July 2013 Page 23

Page 29

TCM Studio

Description

Figure 4-2

Description

TCM Studio

Description

Figure 4-2

Description

Standard

STD 0°

Y Sensor Up

“Y” Up 0°

Standard 90

Degrees

STD 90°

Y Sensor Up Plus

90 Degrees

“Y” Up 90°

Standard 180

Degrees

STD 180°

Y Sensor Up Plus

180 Degrees

“Y” Up 180°

Standard 270

Degrees

STD 270°

Y Sensor Up Plus

270 Degrees

“Y” Up 270°

X Sensor Up

“X” Up 0°

Z Sensor Down

“Z” Down 0°

X Sensor Up Plus

90 Degrees

“X” Up 90°

Z Sensor Down

Plus 90 Degrees

“Z” Down 90°

X Sensor Up Plus

180 Degrees

“X” Up 180°

Z Sensor Down

Plus 180 Degrees

“Z” Down 180°

X Sensor Up Plus

270 Degrees

“X” Up 270°

Z Sensor Up Plus

270 Degrees

“Z” Down 270°

Table 6-1: Mounting Orientations

6.3.2 North Reference

Declination, also called magnetic variation, is the difference between true and magnetic

north. It is measured in degrees east or west of true north. Correcting for declination is

accomplished by storing the correct declination angle, and then changing the heading

reference from magnetic north to true north. Declination angles vary throughout the

world, and change very slowly over time. For the greatest possible accuracy, go to the

National Geophysical Data Center web page below to get the declination angle based on

your latitude and longitude:

http://www.ngdc.noaa.gov/geomagmodels/Declination.jsp

Magnetic

When the <Magnetic> button is selected, heading will be relative to magnetic north.

True

When the <True> button is selected, heading will be relative to true north. In this

case, the declination needs to be set in the “Declination” window.

6.3.3 Endianess

PNI Sensor Corporation DOC#1014688 r06

TCM User Manual – July 2013 Page 24

Select either the <Big> or <Little> Endian button. The default setting is <Big>. See

Sections 7.2 and 7.3 for additional information.

Page 30

6.3.4 Output

The TCM module can output heading, pitch, and roll in either degrees or mils. Click

either the <Degrees> or <Mils> button. The default is <Degrees>. (There are 6400 mils

in a circle, such that 1 degree = 17.7778 mils and 1 mil = 0.05625 degree.)

6.3.5 Enable 3D Model

TCM Studio’s Test tab includes a live-action 3-D rendering of a helicopter. Some

computer systems may not have the graphics capability to render the 3D Model, for this

reason it may be necessary to turn off this feature.

6.3.6 Filter Setting (Taps)

The TCM incorporates a finite impulse response (FIR) filter to effectively provide a more

stable heading reading. The number of taps (or samples) represents the amount of

filtering to be performed. The user should select either 0, 4, 8, 16, or 32 taps, with zero

taps representing no filtering. Note that selecting a larger number of taps can

significantly slow the time for the initial sample reading and, if “Flush Filters” is

selected, the rate at which data is output. The default setting is 32.

6.3.7 Acquisition Settings

Mode

When operating in Continuous Acquisition Mode, the TCM continuously outputs data

to the host system. The rate is set by the Sample Delay. When operating in Poll

Mode, TCM Studio simulates a host system and polls the TCM for a single

measurement; but TCM Studio makes this request at a fixed rate which is set by the

Poll Delay. In both cases data is continuously output, but in Continuous Mode the

TCM controls the data rate while in Poll Mode the TCM Studio program controls the

data rate. Poll Mode is the default.

Poll Delay

The Poll Delay is relevant when Poll Mode is selected. It represents the time delay,

in seconds, between the completion of TCM Studio receiving one set of sampled data

and requesting the next sample set. If the delay is set to 0, then TCM Studio requests

new data as soon as the previous request is fulfilled. Note that the inverse of the Poll

Delay is greater than the sample rate, since the Poll Delay does not include the actual

measurement acquisition time. The default is 0.

PNI Sensor Corporation DOC#1014688 r06

TCM User Manual – July 2013 Page 25

Page 31

Acquire Delay

The Acquire Delay sets the time between samples taken by the module, in seconds.

This is an internal setting that is NOT tied to the time with which the module

transmits data to TCM Studio or the host system. Generally speaking, the Acquire

Delay is either set to 0, in which case the TCM is constantly sampling or set to equal

either the Poll Delay or Sample Delay values. The advantage of running with an

Acquire Delay of 0 is that the FIR filter can run with a relatively high Tap value to

provide stable and timely data. The advantage of using a greater Acquire Delay is

that power consumption can be reduced, assuming the Sample or Poll Delay are no

less than the Acquire Delay.

Sample Delay

The Sample Delay is relevant when Continuous Mode is selected. It is the time

delay, in seconds, between completion of the TCM sending one set of data and the

start of sending the next sample set. If the delay is set to 0, then the TCM will begin

sending new data as soon as the previous data set has been sent. Note that the inverse

of the Sample Delay is greater than the sample rate, since the Sample Delay does not

include the actual measurement acquisition time. The default is 0.

Flush Filters

Flushing the FIR filter clears all the filter values so it is necessary to fully repopulate

the filter before a good reading can be given. For example, if 32 FIR taps is set, then

32 new samples must be taken to provide a good reading. It is particularly prudent to

flush the filter if the Sample Delay is set to a non-zero value as this will purge old

data. Note that flushing the filters increases the delay until data is output, with the

length of the delay being directly correlated to the number of FIR taps. The default is

not to Flush Filters.

6.3.8 HPR During Calibration

When the <On> button is selected, heading, pitch, and roll will be output on the

Calibration tab during a calibration.

6.3.9 Calibration Settings

Automatic Sampling

When selected, the module will take a sample point once the minimum change and

stability requirements have been satisfied. If the user wants to have more control

over when the point will be taken, then Auto Sampling should be deselected. Once

deselected, the <Take Sample> button on the Calibration tab will be active. Selecting

PNI Sensor Corporation DOC#1014688 r06

TCM User Manual – July 2013 Page 26

Page 32

the <Take Sample> button will indicate to the module to take a sample once the

minimum change and stability requirements are met.

Calibration Points

Select the number of points to take during a calibration. The minimum recommended

number of points for an initial magnetic calibration is 12, although a Hard-Iron-Only

(re)Calibration can be performed with only 6 recommended samples. The TCM will

need to be rotated through at least 180° in the horizontal plane with a minimum of at

least 1 positive and 1 negative Pitch and at least 1 positive and 1 negative Roll as part

of the 12 points.

Calibration Method Buttons

Full Range Calibration - recommended calibration method when >45° of tilt is

possible. The minimum recommended number of calibration points is 12.

HI Only Calibration - serves as a hard iron recalibration to a prior calibration. If the

hard iron distortion around the module has changed, this calibration can bring the

module back into specification. The minimum recommended number of calibration

points is 6.

Limited Tilt Range Calibration - recommended calibration method when >5° of tilt

calibration is available, but tilt is restricted to <45°. (i.e. Full-Range Calibration is

not possible.) The minimum recommended number of calibration points is 12.

2D Calibration - Recommended when the available tilt range is limited to ≤5°. The

minimum recommended number of calibration points is 12.

Accel Only Calibration – Select this when only an accelerometer calibration will be

performed. The minimum recommended number of calibration points is 18.

Accel Calibration with Mag – The user should select this when magnetometer and

accelerometer calibration will be performed simultaneously. The minimum

recommended number of calibration points is 18.

6.3.10 Default

Clicking this button restores the TCM Studio program to the factory default settings.

6.3.11 Retrieve

Clicking on this button causes TCM Studio to read the settings from the module and

display them on the screen.

PNI Sensor Corporation DOC#1014688 r06

TCM User Manual – July 2013 Page 27

Page 33

6.4 Calibration Tab

Note: The default settings are recommended for the highest accuracy and quality of calibration.

6.4.1 Samples

Before proceeding, refer to Section 5 for the recommended calibration procedure

corresponding to the calibration method selected on the Configuration tab.

Clicking the <Start> button begins the calibration process.

If “Automatic Sampling” is not checked on the Configuration tab, it is necessary to click

the <Take Sample> button to take a calibration sample point. This should be repeated

until the total number of samples, as set on the Configuration tab, is taken while changing

the orientation of the module between samples as discussed in Section 5.

If “Automatic Sampling” is checked, the module will need to be held steady for a short

time and then a sample automatically will be taken. Once the window indicates the next

number, the module’s orientation should be changed and held steady for the next sample.

Once the pre-set number of samples has been taken (as set on the Configuration tab) the

calibration is complete.

PNI Sensor Corporation DOC#1014688 r06

TCM User Manual – July 2013 Page 28

Page 34

6.4.2 Calibration Results

Once a calibration is complete, the “Calibration Results” window will indicate the quality

of the calibration. This may take a minute or more to populate. The primary purpose of

these scores is to confirm the calibration was successful, as indicated by a low Mag

and/or Accel CalScore. The other scores provide information that may assist in

improving the CalScore, should it be unacceptably high. If either CalScore is too high,

click the <Start> button to begin a new calibration. If the calibration is acceptable, click

the <Save> button to save the calibration to the module’s flash. If the <Save> button is

not selected then the module will need to be recalibrated after a power cycle.

Note: If a calibration is aborted, all the score’s will read “179.80”, and the calibration coefficients

will not be changed. (Clicking the <Save> button will not change the calibration coefficients.)

Mag CalScore

Represents the over-riding indicator of the quality of the magnetometer calibration.

Acceptable scores will be <1 for Full-Range Calibration, <2 for other methods. Note

that it is possible to get acceptable scores for Dist Error and Tilt Error and still have a

rather high Mag CalScore value. The most likely reason for this is the TCM is close

to a source of local magnetic distortion that is not fixed with respect to the module.

Dist Error

Indicates the quality of the sample point distribution, primarily looking for an even

yaw distribution. Significant clumping or a lack of sample points in a particular

section can result in a poor score. The score should be <1 and close to 0.

Tilt Error

Indicates the contribution to the Mag CalScore caused by tilt or lack thereof, and

takes into account the calibration method. The score should be <1 and close to 0.

Tilt Range

This reports the larger of either half the full pitch range or half the full roll range of

sample points. For example, if the module is pitched +10° to -20º, and rolled +25º to

-15º, the Tilt Range value would be 20º, as derived half the full roll range. For FullRange Calibration and Hard-Iron-Only Calibration, this should be ≥45°. For 2D

Calibration, this ideally should be ≈2°. For Limited Tilt Range Calibration the value

should be as large a possible given the user’s constraints.

Accel CalScore

Represents the over-riding indicator of the quality of the accelerometer calibration.

Acceptable scores will be <1.

PNI Sensor Corporation DOC#1014688 r06

TCM User Manual – July 2013 Page 29

Page 35

6.4.3 Current Configuration

These indicators mimic the pertinent selections made on the Configuration tab.

6.4.4 Options

This window indicates how many samples are to be taken and provides real time heading,

pitch, and roll information if “HPR During Calibration” is set to <On>, both as defined

on the Configuration tab.

Audible Feedback

If selected TCM Studio will give an audible signal once a calibration point has been

taken. Note that an audible signal also will occur when the <Start> button is clicked,

but no data will be taken.

6.4.5 Clear

Clear Mag Cal to Factory

This button clears the user’s calibration of the magnetometers. Once selected, the

module reverts to its factory magnetometer calibration. To save this action in

nonvolatile memory, click the <Save> button. It is not necessary to clear the current

calibration in order to perform a new calibration.

Clear Accel Cal to Factory

This button clears the user’s calibration of the accelerometer. Once selected, the

module reverts back to its factory accelerometer calibration. To save this action in

non-volatile memory, click the <Save> button. It is not necessary to clear the current

calibration in order to perform a new calibration.

PNI Sensor Corporation DOC#1014688 r06

TCM User Manual – July 2013 Page 30

Page 36

6.5 Test Tab

6.5.1 Current Reading

Once the <Go> button is selected the module will begin outputting heading, pitch and roll

information. Selecting the <Stop> button or changing tabs will halt the output of the

module.

Contrast

Selecting this box sets the “Current Readings” window to have yellow lettering on a

black background, rather than black lettering on a white background.

6.5.2 3D Model

The helicopter will follow the movement of the TCM and give a visual representation of

the module’s orientation, assuming the “Enable 3D Model Display” box is selected on the

Configuration tab.

6.5.3 Acquisition Settings

These indicators mimic the pertinent selections made on the Configuration tab.

PNI Sensor Corporation DOC#1014688 r06

TCM User Manual – July 2013 Page 31

Page 37

6.5.4 Sync Mode

Sync Mode enables the module to stay in Sleep Mode until the user’s system sends a

trigger to report data. When so triggered, the TCM will wake up, report data once, then

return to Sleep Mode. One application of this is to lower power consumption. Another

use of the Sync Mode is to trigger a reading during an interval when local magnetic

sources are well understood. For instance, if a system has considerable magnetic noise

due to nearby motors, the Synch Mode can be used to take measurements when the

motors are turned off.

Enter Sync Mode

On the Test tab, above the tabs and 3D model, click the “Sync Mode” check box to

enter Sync Mode.

Sync Mode Output

To retrieve the first reading, click the <Sync Read> button. Heading, pitch and roll

information will be displayed on Current Reading window. If the “Enable 3D Model

Display” box is selected on the Configuration tab, then the helicopter will follow the

movement as well. The module will enter Sleep Mode after outputting the heading,

pitch, and roll information. To obtain subsequent readings, the user should first click

on the <Sync Trigger> button to wake up the module and then click on the <Sync

Read> button to get the readings, after which the module will return to sleep.

Exit Sync Mode

Click on the <Sync Trigger> button and then uncheck the “Sync Mode” check box to

exit Sync Mode.

Note that <Sync Trigger> sends a 0xFF signal as an external interrupt to wake up the

module. This is not done for the first reading as the module is already awake.

PNI Sensor Corporation DOC#1014688 r06

TCM User Manual – July 2013 Page 32

Page 38

6.6 Log Data Tab

TCM Studio can capture measurement data and then export it to a text file. To acquire data

and export it, follow the procedure below:

Select the parameters you wish to log in the “Data” window. Use Shift -Click and

Ctrl-Click to select multiple items. In the screen shot above, “Heading”, “Pitch”, and

“Roll” were selected.

Click the <Go> button to start logging. The <Go> button changes to a <Stop> button

after data logging begins.

Click the <Stop> button to stop logging data.

Click the <Export> button to save the data to a file.

Click the <Clear> button to clear the data from the window.

Note: The data logger use ticks for time reference. A tick is 1/60 second.

PNI Sensor Corporation DOC#1014688 r06

TCM User Manual – July 2013 Page 33

Page 39

6.7 Graph Tab

The graph provides a 2-axis (X,Y) plot of the measured field strength. If “w/o User Cal”

graph data is selected, the plot and data provide magnetic field strength measurements after

the FIR taps are applied, but prior to applying the user calibration coefficients. If “with User

Cal” graph data is selected, the plot and data provide data after applying the FIR filter and the

user calibration coefficients. The sample plot shows a 360° rotation in the horizontal plane,

with both “w/o User Cal” and “with User Cal” selected. The offset between these two plots

represents the effect of the calibration coefficients. The graph can be used to visually see

hard and soft iron effects within the environment measured by the TCM, as well as corrected

output after a user calibration has been performed.

PNI Sensor Corporation DOC#1014688 r06

TCM User Manual – July 2013 Page 34

Page 40

6.8 System Log Tab

The System Log tab shows all communication between TCM Studio and the TCM module

since launching TCM Studio. Closing TCM Studio will erase the system log. Select the

<Export> button, at the bottom right of the screen, to save the system log to a text file.

PNI Sensor Corporation DOC#1014688 r06

TCM User Manual – July 2013 Page 35

Page 41

Parameter

Value

Number of Data Bits

8

Start Bits

1

Stop Bits

1

Parity

none

ByteCount

(UInt16)

Packet Frame

(1 - 4092 UInt8)

CRC-16

(UInt16)

Payload

(1 - 4091 UInt8)

Frame

ID

(UInt8)

00 09

Frame ID

0A

ByteCount

00 00

CalOption

CalOption

(2D Calibration)

00 14

5C F9

Checksum

00 05

Frame ID

01

ByteCount

EF D4

Checksum

7 Operation with PNI Binary Protocol

The TCM utilizes a binary communication protocol, where the communication parameters

should be configured as follows:

Table 7-1: UART Configuration

7.1 Datagram Structure

The data structure is shown below:

Figure 7-1: Datagram Structure

The ByteCount is the total number of bytes in the packet including the CRC-16 checksum.

CRC-16 is calculated starting from the ByteCount to the last byte of the Packet Frame. The

ByteCount and CRC-16 are always transmitted in big Endian. Two examples follow.

Example: The complete packet for the kGetModInfo command, which has no payload is:

Example: Below is a complete sample packet to start a 2D Calibration (kStartCal):

PNI Sensor Corporation DOC#1014688 r06

TCM User Manual – July 2013 Page 36

Page 42

ExponentS Mantissa

63 62 5251 0

ExponentS Mantissa

3130 2322 0

msb

31 2423 16 15 8

lsb

7 0

Big Endian

lsb

7 0 15 8 23 16

msb

31 24

Little Endian

7.2 Parameter Formats

Note: Floating-point based parameters conform to ANSIring/IEEE Std 754-1985. Please refer to the

Standard for more information. PNI also recommends refer to the user’s compiler instructions to

understand how the compiler implements floating-point format.

64-Bit Floating Point (Float64)

The 64-bit float format is given below in big Endian. In little Endian, the bytes are in

reverse order in 4 byte groups. (eg. big Endian: ABCD EFGH; little Endian:

DCBA HGFE).

The value (v) is determined as: “if and only if” 0 < Exponent < 2047, then

v = (-1)*S*2(Exponent-1023)*1.Mantissa

32-Bit Floating Point (Float32)

Shown below is the 32-bit float format in big Endian. In little Endian format, the 4

bytes are in reverse order, with LSB first.

The value (v) is determined as: “if and only if” 0 < Exponent < 255, then

v = (-1)*S*2(Exponent-127)*1.Mantissa

Signed 32-Bit Integer (SInt32)

SInt32-based parameters are signed 32-bit numbers, in 2’s compliment. Bit 31

represents the sign of the value, where 0=positive and 1=negative.

PNI Sensor Corporation DOC#1014688 r06

TCM User Manual – July 2013 Page 37

Page 43

Big Endian

msb

15 8

lsb

7 0

Little Endian

lsb

7 0

msb

15 8

byte

7 0

msb

31 24 23 16 15 8

lsb

7 0

Big Endian

lsb

7 0 15 8 23 16

msb

31 24

Little Endian

Big Endian

msb

15 8

lsb

7 0

Little Endian

lsb

7 0

msb

15 8

Signed 16-Bit Integer (SInt16)

SInt16-based parameters are signed 16-bit numbers, in 2’s compliment. Bit 15

represents the sign of the value, where 0=positive and 1=negative.

Signed 8-Bit Integer (SInt8)

UInt8-based parameters are unsigned 8-bit numbers. Bit 7 represents the sign of the

value, where 0=positive and 1=negative.

Unsigned 32-Bit Integer (UInt32)