Page 1

Item

Part #

Quantity

Package

SENtral

13658P

<4000

Cut-Tape

SENtral

13658

4000

Tape & Reel

SENtral

Motion Coprocessor

General Description

The SENtral Motion Coprocessor is a

custom integrated circuit that makes it easy

to quickly incorporate, optimize and operate

multiple motion sensors on mobile

consumer electronics devices. SENtral

employs and manages a user-specified

3-axis magnetometer, 3–axis accelerometer,

and 3–axis gyroscope to provide reliable

motion tracking, and accurate heading and

orientation data. SENtral gathers data from

the individual sensors, then integrates and

fuses this data using PNI’s proprietary

Kalman filtering and heuristic algorithms.

Features

Heading Accuracy of 2° rms.

Ultra Low Power Consumption

Continuous Soft and Hard-Iron

Magnetic Auto-Calibration

Magnetic Anomaly

Compensation

I2C Interface – 100 to 3400 kHz

Small Form-Factor

Sensor Flexibility

By offloading the sensor fusion and

interface from a dedicated sensor hub MCU

or the host CPU to SENtral, overall power

requirements are dramatically lowered and

processing power is opened up for other

uses.

These advantages make SENtral the ideal

choice for mobile and consumer electronics

devices desiring ultra-lower power

consumption and best-in-class sensor fusion.

Applications

Cell Phones

Tablets

Ultrabooks

TV Remote Controls

Video Game Controllers

Ordering Information

Page 2

Table of Contents

1 PRODUCT OVERVIEW ............................................................................................... 3

1.1 SENTRAL FEATURES AND BENEFITS ........................................................ 3

1.2 SENTRAL FUNCTIONAL DESCRIPTION ...................................................... 4

2 SENTRAL SPECIFICATIONS ..................................................................................... 6

2.1 PERFORMANCE CHARACTERISTICS ......................................................... 6

2.2 ELECTRICAL CHARACTERISTICS ............................................................... 6

3 LAYOUT ....................................................................................................................... 8

3.1 SYSTEM LAYOUT .......................................................................................... 8

3.2 PIN ASSIGNMENTS ....................................................................................... 9

3.3 SENSOR LAYOUT ........................................................................................ 10

3.4 DEDICATED EEPROM (OPTIONAL) ........................................................... 11

4 I2C INTERFACE ......................................................................................................... 12

4.1 I2C TIMING .................................................................................................... 12

4.2 I2C HOST INTERFACE (HOST BUS) ........................................................... 13

4.2.1 I2C Slave Transfer formats ............................................................... 14

4.3 I2C SENSOR INTERFACE (SENSOR BUS) ................................................. 15

4.4 I2C PULL-UP RESISTANCE ......................................................................... 15

5 OPERATION .............................................................................................................. 16

5.1 POWER-UP AND CONFIGURATION FILE UPLOAD .................................. 17

5.1.1 Configuration File Upload from EEPROM ........................................ 17

5.1.2 Configuration File Upload from Host ................................................ 19

5.2 INITIAL REGISTER SET-UP ......................................................................... 20

5.3 RUNNING IN NORMAL OPERATION .......................................................... 22

5.3.1 Error .................................................................................................. 23

5.3.2 CPUReset ......................................................................................... 24

5.3.3 Read Results .................................................................................... 24

5.4 STANDBY STATE ......................................................................................... 25

5.5 PASS-THROUGH STATE ............................................................................. 25

5.6 TROUBLESHOOTING .................................................................................. 27

5.6.1 Hardware-Related Error Conditions ................................................. 27

5.6.2 Software-Related Error Conditions ................................................... 27

6 SENTRAL CONFIGURATION TOOL ........................................................................ 30

6.1 CONFIGURATION TOOL GENERAL SETTINGS ........................................ 31

6.1.1 SDK Revision ................................................................................... 31

6.1.2 Host Interrupt Pin .............................................................................. 31

6.1.3 EEPROM Max. Upload Speed ......................................................... 31

6.2 CONFIGURATION TOOL SENSOR CONFIGURATION .............................. 31

6.2.1 Sensor .............................................................................................. 31

6.2.2 Interrupt Pin ...................................................................................... 31

6.2.3 Slave Address .................................................................................. 31

6.2.4 Orientation Matrix ............................................................................. 32

6.2.5 Cal Offsets ........................................................................................ 33

7 PACKAGE INFORMATION ....................................................................................... 34

8 ASSEMBLY GUIDELINES ......................................................................................... 36

APPENDIX I – CONFIGURATION FILE IMAGE FORMAT.................................................... 39

APPENDIX II – CONVERTING QUATERNIONS ................................................................... 41

APPENDIX III – PARAMETER TRANSFER ........................................................................... 43

APPENDIX IV – SAMPLE SCHEMATIC SET ........................................................................ 49

PNI Sensor Corporation Doc #1018049 R03

SENtral Technical Data Sheet Page 1

Page 3

List of Figures

Figure 1-1: SENtral Block Diagram .......................................................................................... 4

Figure 3-1: SENtral System Reference Schematic .................................................................. 8

Figure 4-1: I2C Timing Diagram .............................................................................................. 12

Figure 4-2: I2C Slave Write Example ...................................................................................... 14

Figure 4-3: I2C Slave Read Example, with Repeated START................................................ 14

Figure 4-4: I2C Slave Write Register Address Only ................................................................ 14

Figure 4-5: I2C Slave read register from current address ....................................................... 14

Figure 5-1: SENtral Initialization Sequence ............................................................................ 16

Figure 5-2: SENtral Operational States .................................................................................. 17

Figure 5-3: SENtral Normal Operation Flow ........................................................................... 22

Figure 6-1: SENtral Configuration Tool .................................................................................. 30

Figure 7-1: Mechanical Drawing ............................................................................................. 34

Figure 7-2: Tape Dimensions ................................................................................................. 35

Figure 8-1: Typical Solder Mask and Land Pad Parameters ................................................. 37

Figure 8-2: Typical Solder Reflow Profile ............................................................................... 38

Figure A3-1: Parameter Load Process ................................................................................... 44

Figure A3-2: Parameter Retrieve Process ............................................................................. 45

List of Tables

Table 2-1: Performance Characteristics ................................................................................... 6

Table 2-2: Absolute Maximum Ratings .................................................................................... 6

Table 2-3: Operating Conditions............................................................................................... 7

Table 3-1: SENtral Pin Assignments ........................................................................................ 9

Table 3-2: Recommended Power Line Distance from Magnetometer ................................... 11

Table 4-1: I2C Timing Parameters .......................................................................................... 13

Table 4-2: I2C Pull-Up Resistance Table ................................................................................ 15

Table 5-1: Configuration File Upload from EEPROM Registers ............................................ 18

Table 5-2: Configuration File Host Upload Registers ............................................................. 19

Table 5-3: Sample Host Upload Data Order .......................................................................... 20

Table 5-4: Registers for Initial Set-Up .................................................................................... 20

Table 5-5: Normal Operation Registers .................................................................................. 23

Table 5-6: Results Registers .................................................................................................. 24

Table 5-7: Standby Registers ................................................................................................. 25

Table 5-8: Pass-Through Registers........................................................................................ 26

Table 5-9: Hardware-Related Error Indications ...................................................................... 27

Table 5-10: Software-Related Error Indications ..................................................................... 27

Table 5-11: SensorStatus Register Values ............................................................................ 28

Table 5-12: ErrorRegister Values ........................................................................................... 28

Table 5-13: RAMVersion Register Values .............................................................................. 29

Table 8-1: Typical Solder Processing Parameters ................................................................. 38

Table A1-1: Configuration File Image Format ........................................................................ 39

Table A1-2: Configuration File Data Structure ....................................................................... 40

Table A3-1: Registers Used for Parameter Transfer .............................................................. 43

Table A3-2: Parameter Numbers............................................................................................ 46

Table A3-3: DriverID & AlgorithmID Definition ....................................................................... 48

PNI Sensor Corporation Doc #1018049 R03

SENtral Technical Data Sheet Page 2

Page 4

1 Product Overview

The SENtral Motion Coprocessor is an integrated circuit that makes it easy to quickly integrate,

optimize and operate multiple sensors on mobile consumer electronics devices. SENtral manages

and uses data from a user-specified 3-axis gyroscope, 3-axis accelerometer, and 3-axis

magnetometer to provide reliable motion tracking and an accurate compass heading, while

consuming about 1% of the power of a comparable sensor fusion microprocessor.

Note: This revision of the SENtral Technical Datasheet applies to Configuration Files of revision 1.1 or

higher. The Configuration File is discussed in Sections 1.2, 5.1, 5.6.2, and 6, and Appendix I. It is

generated by the SENtral Configuration Tool and is uploaded into SENtral RAM after power up.

1.1 SENtral Features and Benefits

Features and benefits of the SENtral Motion Coprocessor include:

Low power consumption. Offloads sensor processing from the less efficient host

CPU, consuming <1% of the power of a Cortex M0 running a comparable sensor

fusion algorithm. Provides the ability to tailor the tradeoff between power

consumption and motion-tracking performance.

Industry-leading heading accuracy. Unparalleled heading accuracy for consumer

electronics applications.

Continuous hard and soft-iron magnetic auto-calibration. Provides continual

background calibration of the sensors. Leverages PNI’s more than 20 years of

experience and expertise in magnetic measurement.

Magnetic anomaly compensation. Heading and motion tracking is unaffected by

magnetic anomalies such as rebar in buildings, desks, speakers etc., that can easily

throw off the accuracy. SENtral recognizes and compensates for these anomalies.

Sensor flexibility. Works with common consumer electronic MEMS motion sensors,

so system designers can choose the sensors most appropriate for their systems.

Small form-factor. 1.6x1.6x0.5 mm chip-scale package on 0.4 mm pitch. Uses little

PCB real estate, allowing for painless integration.

I2C interface. Uses the industry-standard I2C protocol to interface to the sensors and

the host, so system integration is straightforward. Standard, Fast, Fast Plus, and High

Speed are supported on the host bus.

Outputs. SENtral outputs quaternions, Euler angles (heading, pitch, & roll), and

sensor data (rotational velocity, linear acceleration, & magnetic field).

PNI Sensor Corporation Doc #1018049 R03

SENtral Technical Data Sheet Page 3

Page 5

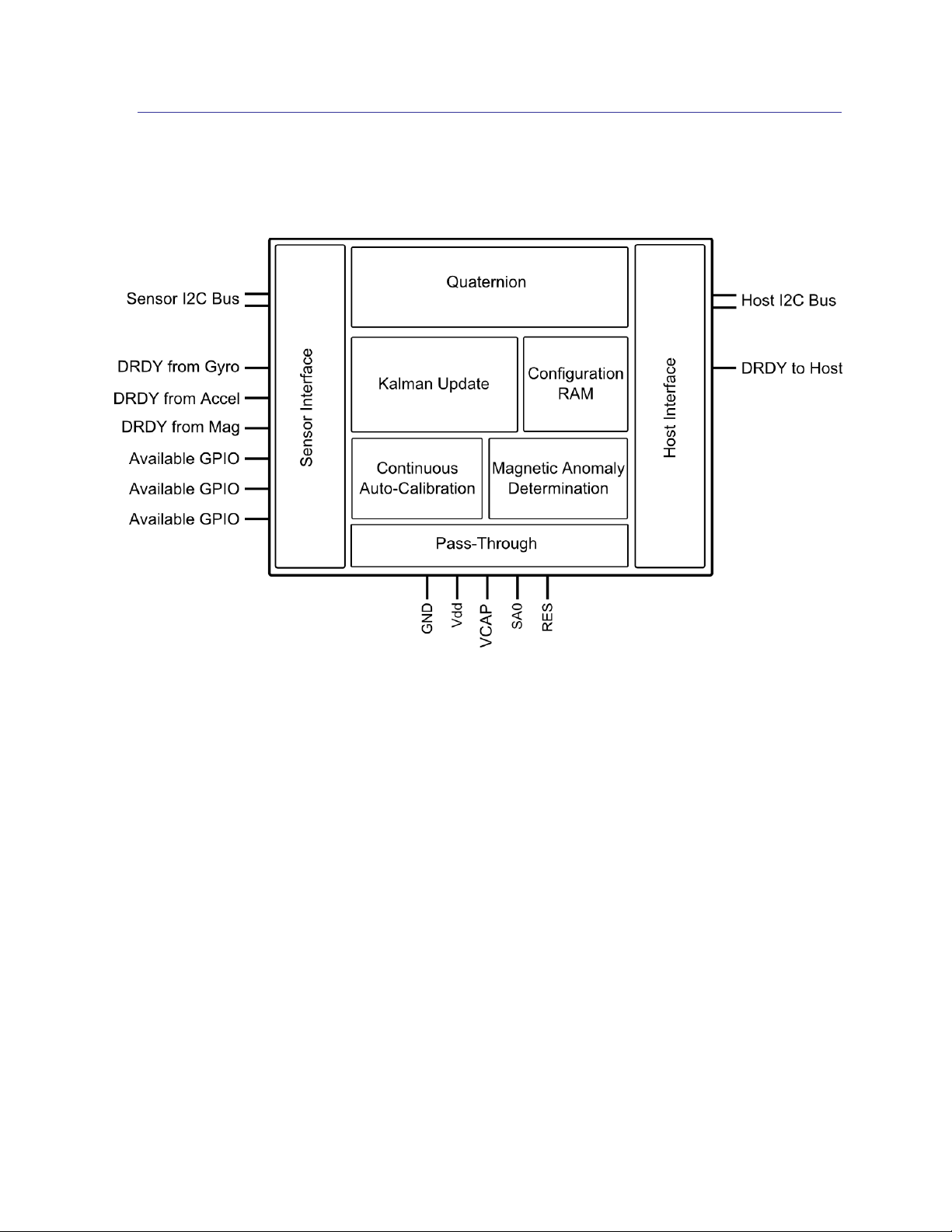

1.2 SENtral Functional Description

Figure 1-1 provides a diagram of SENtral’s primary functional blocks, and a brief description

of these functional blocks follows.

Figure 1-1: SENtral Block Diagram

Quaternion generates the orientation output, where the actual orientation outputs can

be quaternions or Euler angles (heading, pitch, & roll). The outputs are updated at a

rate limited to the gyro output data rate (ODR), to a maximum of 400 Hz.

Kalman Update fuses data from the 3-axis gyroscope, 3-axis accelerometer, and 3-

axis magnetometer, plus data from the magnetic anomaly determination and

continuous auto-calibration blocks to generate intelligent orientation updates. The

Kalman update involves a sophisticated multi-state Kalman algorithm.

Continuous Hard and Soft-Iron Auto-Calibration. SENtral is the only product in

the market that auto-calibrates for both hard-iron and soft-iron magnetic distortions.

While others may calibrate for hard-iron distortion, soft-iron distortion is more

difficult to correct for, and it can be caused by EMI shielding tape and other shielding

materials widely used in mobile and consumer electronic devices. It is important to

correct for soft-iron distortions since these can contribute up to 90° of error.

Additionally, since a host system’s magnetic signature can change over time and

temperature, SENtral’s continuous auto-calibration ensures accuracy all the time.

PNI Sensor Corporation Doc #1018049 R03

SENtral Technical Data Sheet Page 4

Page 6

Magnetic Anomaly Determination establishes if a transient magnetic distortion is

present and accounts for it.

Configuration RAM allows for customizing SENtral to match the specific sensors

being used and allows the user to tailor certain parameters for their specific system.

The SENtral Configuration Tool generates the SENtral Configuration File, and this is

subsequently uploaded into SENtral’s Configuration RAM.

Pass-Through allows for direct communication with devices on the sensor bus by

connecting SENtral’s I2C Host Interface to the Sensor Interface.

Host Interface communicates with the host system. Data is transmitted between the

host and SENtral via the host I2C bus, in which the host acts as the master and

SENtral acts as a slave device. SENtral signals the host that new data is available by

sending an interrupt signal on the host DRDY line.

Sensor Interface communicates primarily with the sensors. Sensor data is

transmitted from the sensors to SENtral via the sensor I2C bus, in which SENtral acts

as the master and the sensors as the slave devices.

PNI Sensor Corporation Doc #1018049 R03

SENtral Technical Data Sheet Page 5

Page 7

Parameter

Minimum

Typical

Maximum

Units

Heading Accuracy

2

° rms

Output Data Rate

200

400

Hz

Parameter

Symbol

Minimum

Maximum

Units

Supply Voltage

VDD

-0.3

+3.6

VDC

Input Pin Voltage

VIN

GND – 0.3

VDD + 0.3

VDC

ESD

Human Body Model

HBM

-2000

+2000

V

Machine Model

MM

-200

+200

V

Storage Temperature

-50°

+150°

C

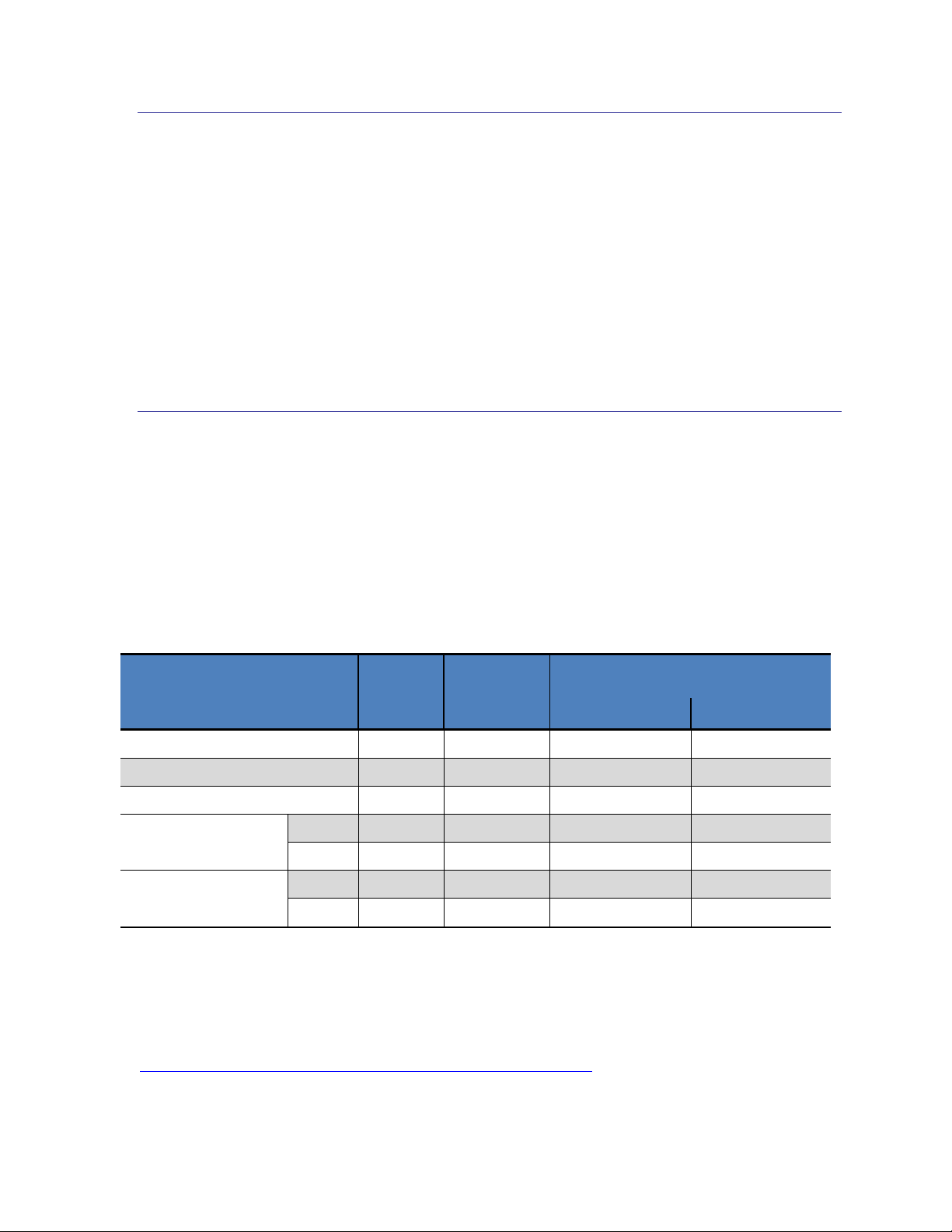

2 SENtral Specifications1

2.1 Performance Characteristics

Table 2-1: Performance Characteristics

2.2 Electrical Characteristics

Table 2-2: Absolute Maximum Ratings

CAUTION:

Stresses beyond those listed above may cause permanent damage to the device. These

are stress ratings only. Operation of the device at these or other conditions beyond those

indicated in the operational sections of the specifications is not implied.

Footnote

1. Specifications subject to change.

PNI Sensor Corporation Doc #1018049 R03

SENtral Technical Data Sheet Page 6

Page 8

Parameter

Symbol

Min

Typical

Max

Units

Supply Voltage

VDD

1.6 3.3

VDC

Power-On Reset Threshold, V

REG>VPOR

V

POR

V

REG

– 0.125

VDC

High Level Input Voltage

VIH

0.7*VDD

VDD

VDC

Low Level Input Voltage

VIL 0

0.3*VDD

VDC

High Level Output Current, VOH = VDD – 0.3V

IOH

-1

mA

Low Level Output Current, VOL = 0.3V

IOL 1

mA

Current

Consumption @

1.8 VDD

Normal Operation1

100 – 300

µA

Pass-Through State2

45

µA

Standby State

7

µA

I2C Interface

Data Rate3

Host Bus

3400

kbits/sec

Sensor Bus

1000

kbits/sec

Pass-Through

400

kbits/sec

Decoupling Capacitor (ESR <2)

C

reg

0.33

0.5

1.8

µF

Operating Temperature

TOP

-40

+25

+85

C

Table 2-3: Operating Conditions

Footnotes:

1. SENtral’s current consumption in normal operation is dependent on a number of variables,

including the sensor update rates and the I2C sensor bus rate. The range given will be

typical for most customers. There is a trade-off between sensor update rates and current

consumption, as more frequent sensor update rates result in improved motion-tracking

performance, while less frequent sensor update rates result in reduced current

consumption. Faster I2C sensor bus rates result in lower current consumption.

2. Pass-Through current consumption assumes SENtral previously was in Standby State,

which is recommended, and a sensor bus rate of 400 kbits/s (Fast mode).

3. SENtral’s I2C Host Interface supports Standard, Fast, Fast Plus, and High Speed Modes.

High Speed Mode (3400 kHz) is supported with a reduced range of VDD and bus

capacitance. SENtral’s I2C sensor bus interface supports Standard, Fast, and Fast Plus

Modes. Pass-Through State, which connects the sensor bus and host bus, supports

Standard and Fast Modes.

PNI Sensor Corporation Doc #1018049 R03

SENtral Technical Data Sheet Page 7

Page 9

3 Layout

3.1 System Layout

Figure 3-1 provides a basic reference schematic for connecting SENtral with the host system

and the various sensors.

Figure 3-1: SENtral System Reference Schematic

A few points on system layout.

SENtral communicates with the sensors as the master via a dedicated I2C sensor bus.

The layout shows a discrete magnetometer, accelerometer, and gyroscope. SENtral

also works with combo sensors, such as a single 9-axis sensor or a combo gyro/accel

with a discrete magnetometer.

SENtral acts as a slave on the host system’s I2C bus. This does not need to be a

dedicated bus, although it is shown this way in the schematic. SA0 establishes

SENtral’s slave address when communicating with the host. It is shown set to

ground, but can be set HIGH instead. See Section 4.2.

The pull-up resistance on the I2C lines depends on the number of devices on the bus

and the bus speed. Normally 4.7 kΩ is appropriate for Standard or Fast modes (≤400

kbit/sec). See Section 4.4.

There are three dedicated sensor interrupt lines between the sensors and SENtral, and

one interrupt line between the host and SENtral. The default GPIO assignments are

shown, but these can be altered with the SENtral Configuration Tool. See Section 6.

PNI Sensor Corporation Doc #1018049 R03

SENtral Technical Data Sheet Page 8

Page 10

Pin#

Pin Name

I/O Type*

Description

D1

VDD

PWR

Supply voltage

D3

VCAP

PWR

External compensation capacitor for internal core

voltage regulator

D2

GND

PWR

Ground

C3

SA0

I

I2C slave address bit [0]

B1

SCLS

IO

I2C host bus SCL clock line

A1

SDAS

IO

I2C host bus SDA data line

B4

SCLM

IO

I2C sensor bus SCL clock line

A4

SDAM

IO

I2C sensor bus SDA data line

D4

GPIO[0]

IO / PUPD

General Purpose IO – Default mag interrupt

C4

GPIO[1]

IO / PUPD

General Purpose IO – Default accel interrupt

A3

GPIO[2]

IO / PUPD

General Purpose IO – Default gyro interrupt

B3

GPIO[3]

IO / PUPD

General Purpose IO – Default not connected

A2

GPIO[4]

IO / PUPD

General Purpose IO – Default not connected

B2

GPIO[5]

IO / PUPD

General Purpose IO – Default not connected

C1

GPIO[6]

IO / PUPD

General Purpose IO – Default host interrupt

C2

RES

-

Not Used – Connect to Ground

3.2 Pin Assignments

SENtral’s pin-out is a 4x4 ball-grid array, as defined in Figure 7-1. The table below provides

the pin assignments.

Table 3-1: SENtral Pin Assignments

*I/O Types are:

PWR: Power supply Connections

I: Digital Input

IO: Digital Input / Output

PU: Pull-Up

PD: Pull-Down

PNI Sensor Corporation Doc #1018049 R03

SENtral Technical Data Sheet Page 9

Page 11

3.3 Sensor Layout

SENtral provides for considerable flexibility in sensor orientation and layout, but there are

some basic requirements, as given below.

All three axes of a sensor must be orthogonal to each other. This is by-design for

most accelerometers, gyroscopes, and magnetometers.

A sensor’s X axis and Y axis should act parallel to the primary plane of the

motherboard. A sensor’s Z axis should act perpendicular to the primary plane.

Either a sensor’s X axis or Y axis should align parallel to the line-of-sight of the

motion-tracking device.

It is NOT necessary that the gyroscope, accelerometer, and magnetometer have their

same-axis sensors (i.e. all X-axis sensors) point in the same direction, since sensor

orientation is configured when running the SENtral Configuration Tool and stored in

the SENtral Configuration File.

Assuming the Orientation Matrix is properly input in the SENtral Configuration Tool,

SENtral will output data conforming to a North-East-Down (NED) convention. To convert

to East-North-Up (ENU) see Appendix II – Converting Quaternions.

In addition to the requirements listed above, other recommendations regarding sensor layout

are given below. These represent good practices, but are not mandatory.

Accelerometer

o Locate the accelerometer near the expected center of rotation of the device to

minimize rotational accelerations being interpreted as linear accelerations.

Magnetometer

o Locate the magnetometer >1 cm away from magnetic sources (hard-iron), such as

speaker magnets or known magnetized metals. If uncertain about whether a

component is a magnetic source, check it with a Gauss meter if possible.

o For non-magnetic components, try to avoid placing wireless antenna, power

capacitors, inductors, ferrite beads, and components using ferromagnetic materials

(Fe, Co, Ni) within 1 cm of the magnetometer. Examples of components in a cell

phone which typically contain ferromagnetic materials are the memory card slot,

battery, frame, electrical and magnetic noise shields, connectors, and hinges.

o Materials that are magnetically transparent, and thus relatively safe, include

aluminum, gold, titanium, copper, brass, and magnesium. Most stainless steel

alloys have relatively weak magnetic properties and are not as safe as those just

listed, but don’t need as much attention as ferromagnetic materials.

o Locate high-frequency signal lines away from the magnetometer.

o Locate power lines away from the magnetometer, per the table below.

PNI Sensor Corporation Doc #1018049 R03

SENtral Technical Data Sheet Page 10

Page 12

Current (mA)

Recommended

Distance (mm)

2

0.2

10 1 50 5 100

10

200

20

Table 3-2: Recommended Power Line Distance from Magnetometer

3.4 Dedicated EEPROM (Optional)

A crucial step in using the SENtral coprocessor is uploading the SENtral Configuration File

into SENtral’s RAM. This file contains information on how the sensor system is configured

in the user’s system, and is generated with the SENtral Configuration Tool, as discussed in

Section 6. The Configuration File can be manually uploaded from non-volatile memory in

the host CPU or automatically uploaded from a dedicated EEPROM. The primary

advantages of using a dedicated EEPROM are freeing up host processor memory and

minimizing the time from power-up until the upload is complete. The advantages of using

host CPU memory are no additional cost and no additional system footprint requirement.

If implementing a dedicated EEPROM, connect it to SENtral as a slave device on the sensor

bus, in parallel with the sensors shown in Figure 3-1. The EEPROM upload rate should be

set with the SENtral Configuration Tool (see Section 6.1.3). Faster is generally better,

although the sensor bus rate is limited to 1 Mb/sec. Writing the Configuration File onto the

EEPROM can be accomplished either using an EEPROM programmer or by writing to the

EEPROM from the host while SENtral is in Pass-Through State.

The primary EEPROM requirements are:

≥320 Kbit (40 Kb x 8 bits) of memory.

Shifted address of 0xA0, 0xA2, 0xA4, 0xA6, 0xA8, or 0xAA. (Unshifted address of

0x50, 0x52, 0x54, 0x56, 0x58, or 0x5A.)

The following devices have been used with SENtral, but this list is not exhaustive.

Microchip 24LC256T-I/SN

ST M24M01-DRCS

Renesas R1EX24512ASAS0A

PNI Sensor Corporation Doc #1018049 R03

SENtral Technical Data Sheet Page 11

Page 13

4 I2C Interface

Communication with the host processor and sensors is via an I2C interface and interrupt lines.

The SENtral Motion Coprocessor acts as the I2C master with the sensors and as a slave with the

host processor. The sensor interrupt lines let SENtral know when new data is available, while

the host interrupt line lets the host system know when SENtral has updated the quaternions. The

sensor and host output data rates are set by the MagRate, AccelRate, GyroRate, and

QRateDivisor registers.

SENtral’s I2C interface complies with NXP’s UM10204 specification and user manual, rev 04.

Standard, Fast, Fast Plus, and High Speed modes of the I2C protocol are supported by SENtral’s

I2C host interface. Below is a link to this document.

http://www.nxp.com/documents/user_manual/UM10204.pdf

4.1 I2C Timing

SENtral’s I2C timing requirements are set forth below, in Figure 4-1 and Table 4-1. For the

timing requirements shown in Figure 4-1, transitions are 30% and 70% of VDD.

Figure 4-1: I2C Timing Diagram

PNI Sensor Corporation Doc #1018049 R03

SENtral Technical Data Sheet Page 12

Page 14

Standard

Fast

Fast Plus

Units

Symbol

Parameter

Min

Max

Min

Max

Min

Max

f

SCL

SCL Clock

0

100 0 400

0

1000

kHz

tr

SDA & SCL Rise

Time

-

1000

20

300 120

ns

tf

SDA & SCL Fall Time

-

300

20*(VDD/

5.5V)

300

20*(VDD/

5.5V)

120

ns

t

LOW

LOW period of SCL

Clock

4.7 - 1.3 - 0.5

-

s

t

HIGH

HIGH period of SCL

Clock

4.0 - 0.6 - 0.26

-

s

t

HD;STA

Hold time (repeated)

START

4.0 - 0.6 - 0.26

-

s

t

HD;DAT

Data hold time

0 - 0 - 0

-

s

t

SU:DAT

Data set-up time

250 - 100 - 50 - ns

t

SU;STA

Set-Up time for

repeated Start

4.7 - 0.6 - 0.26

-

s

t

SU;STO

Stop set-up time

4.0 - 0.6 - 0.26

-

s

t

BUF

Bus free time between

STOP & START

4.7 - 1.3 - 0.5

-

s

Table 4-1: I2C Timing Parameters

4.2 I2C Host Interface (Host Bus)

The host will control SENtral on the host bus via SENtral’s I2C host interface. The host

interface consists of 2 wires: the serial clock, SCLS, and the serial data line, SDAS. Both

lines are bi-directional. SENtral is connected to the host bus via the SDAS and SCLS pins,

which incorporate open drain drivers within the device. The host bus lines must be

externally connected to a positive supply voltage (DVIO) via a pull-up resistor. See Section

4.4 for more on the pull-up resistor.

SENtral’s 7-bit I2C slave address is 0b010100x, where the most significant 6 bits of the slave

address are pre-defined in hardware and are the same for all SENtral devices. The least

significant bit is user-configurable, using the SA0 pin to set the bit to ‘0’ or ‘1’. For

example, grounding the SA0 pin (‘0’ value) results in the 7-bit address of 0b0101000. This

should be set so the SENtral slave address is unique to any other devices on the host bus.

Note that setting SA0 to ‘1’ requires utilizing microvia technology, as discussed in Section 8.

PNI Sensor Corporation Doc #1018049 R03

SENtral Technical Data Sheet Page 13

Page 15

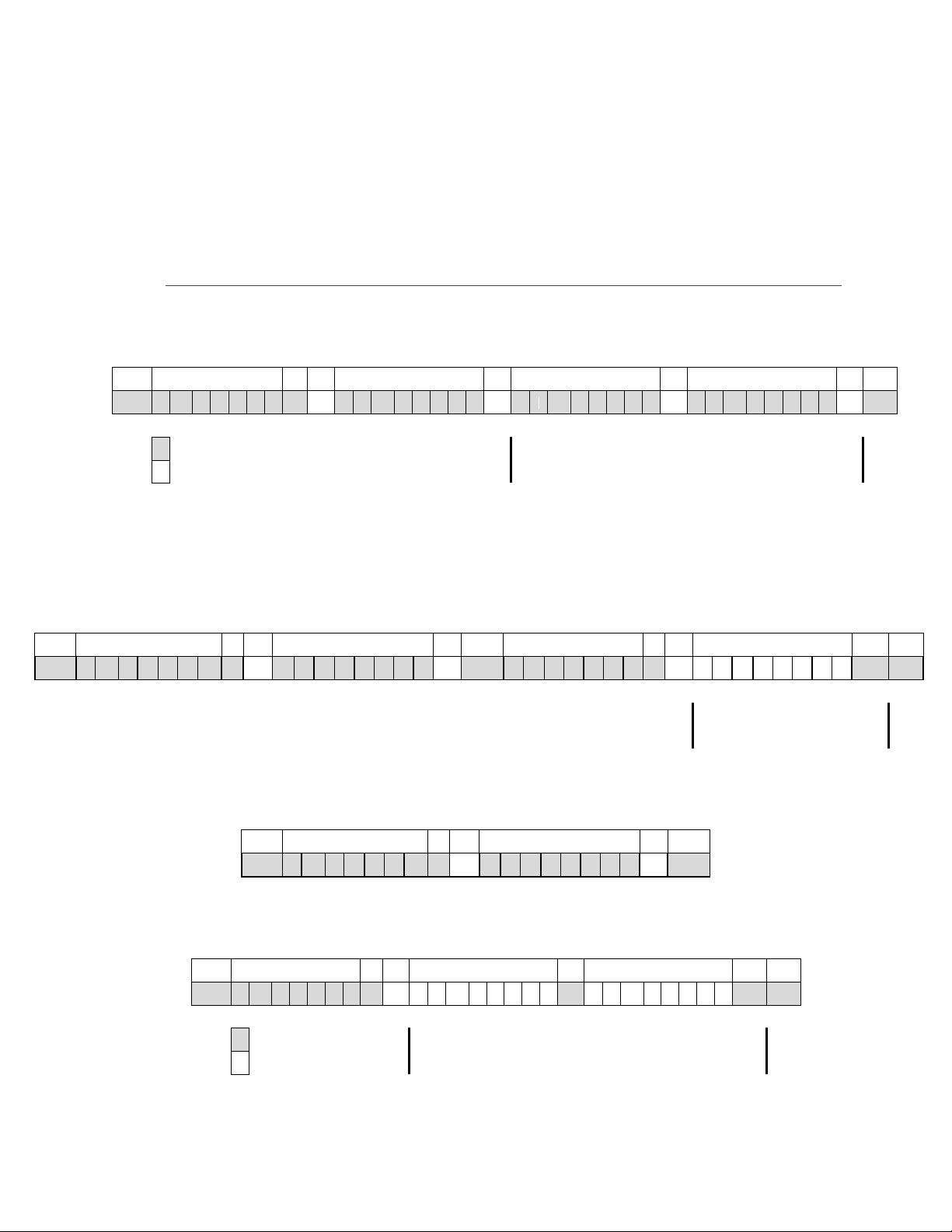

START

SLAVE ADDRESS

RW

ACK

REGISTER ADDRESS (N)

ACK

DATA TO REGISTER (N)

ACK

DATA TO REGISTER (N+1)

ACK

STOP

S

A6

A5

A4

A3

A2

A1

A0 0 0

R7

R6

R5

R4

R3

R2

R1

R0 0 D7

D5

D4

D3

D2

D1

D0 0 D7

D5

D4

D3

D2

D1

D0 0 P

From Host to SENtral

------------ Data Transferred (n bytes + acknowledge) ------------

From SENtral to Host

START

SLAVE ADDRESS

RW

ACK

REGISTER ADDRESS (N)

ACK

START

SLAVE ADDRESS

RW

ACK

DATA FROM REGISTER (N)

NACK

STOP

S

A5

A4

A3

A2

A1

A0 0 0

R7

R5

R4

R3

R2

R1

R0 0 SR

A6

A5

A4

A3

A2

A1

A0 1 0

D7

D5

D4

D3

D2

D1

D0 1 P

Data Transferred

(n bytes + acknowledge)

START

SLAVE ADDRESS

RW

ACK

REGISTER ADDRESS (N)

ACK

STOP

S

A5

A4

A3

A2

A1

A0 0 0

R7

R5

R4

R3

R2

R1

R0 0 P

START

SLAVE ADDRESS

RW

ACK

DATA FROM REG. (N)

ACK

DATA FROM REG. (N+1)

NACK

STOP

S

A5

A4

A3

A2

A1

A0 1 0

D7

D5

D4

D3

D2

D1

D0 0 D7

D5

D4

D3

D2

D1

D0 1 P

From Host to SENtral

-------------- Data Transferred (n bytes + acknowledge) --------------

From SENtral to Host

Data transfer is always initiated by the host. Data is transferred between the host and

SENtral serially through the data line (SDAS) in an 8-bit transfer format. The transfer is

synchronized by the serial clock line, SCLS. Supported transfer formats are single-byte read,

multiple-byte read, single-byte write, and multiple-byte write. The data line can be driven

either by the host or SENtral. Normally the serial clock line will be driven by the host,

although exceptions can exist when clock-stretching is implemented in Pass-Through State.

4.2.1 I2C Slave Transfer formats

Figure 4-2 illustrates writing data to registers in single-byte or multiple-byte mode.

Figure 4-2: I2C Slave Write Example

The I2C host interface supports both a read sequence using repeated START conditions,

shown in Figure 4-3, and a sequence in which the register address is sent in a separate

sequence than the data, shown in Figure 4-4 and Figure 4-5.

Figure 4-3: I2C Slave Read Example, with Repeated START

Figure 4-4: I2C Slave Write Register Address Only

Figure 4-5: I2C Slave read register from current address

PNI Sensor Corporation Doc #1018049 R03

SENtral Technical Data Sheet Page 14

Page 16

I2C Mode

Rate

(kbit/s)

Rise Time

(ns)

Max Cb (pF)

4.7 kΩ pull-up

2.4 kΩ pull-up

Standard

100

1000

251.1

491.8

Fast

400

300

75.3

147.5

Fast Plus

1000

120

30.1

59.0

High Speed-1.7 MHz

Clock

1700

80

20.1

39.3

Data

1700

160

40.2

78.7

High Speed-3.4 MHz

Clock

3400

40

10.0

19.7

Data

3400

80

20.1

39.3

4.3 I2C Sensor Interface (Sensor Bus)

SENtral communicates with the accelerometer, gyroscope, and magnetometer over the sensor

bus, where SENtral acts as the I2C master and the sensors act as the I2C slaves. On the

sensor bus, SENtral initiates data transfer and generates the serial clock. SENtral’s I2C

sensor interface supports Standard mode with a rate up to 100 kbit/s, Fast mode with a rate

up to 400 kbit/s, and Fast Plus mode with a rate up to 1000 kbit/s.

The two wires comprising the sensor bus are SDAM, the serial data line, and SCLM, the

serial clock. Both are bidirectional and driven by open drain transistors within SENtral.

Each line should be attached to a pull-up resistor, which is further discussed in Section 4.4.

4.4 I2C Pull-Up Resistance

The pull-up resistor value for both the host and sensor bus will depend on the I2C data rate

and the number of devices on the bus. Table 4-2 provides the maximum acceptable bus

capacitance, as a function of bus rate, which can be accommodated with a 4.7 kΩ or 2.4 kΩ

pull-up resistor. As a general rule, each device connected to the bus represents 10 pF of

capacitance on the bus, so a bus with 4 devices would require a “Max Cb” value of >40 pF.

Table 4-2: I2C Pull-Up Resistance Table

As the table implies, for most Standard and Fast Mode implementations a 4.7 kΩ pull-up

should work well, while a 2.4 kΩ pull-up normally should be used for Fast Plus. See Section

7.1 of NXP’s UM10204 specification for additional information.

http://www.nxp.com/documents/user_manual/UM10204.pdf.

PNI Sensor Corporation Doc #1018049 R03

SENtral Technical Data Sheet Page 15

Page 17

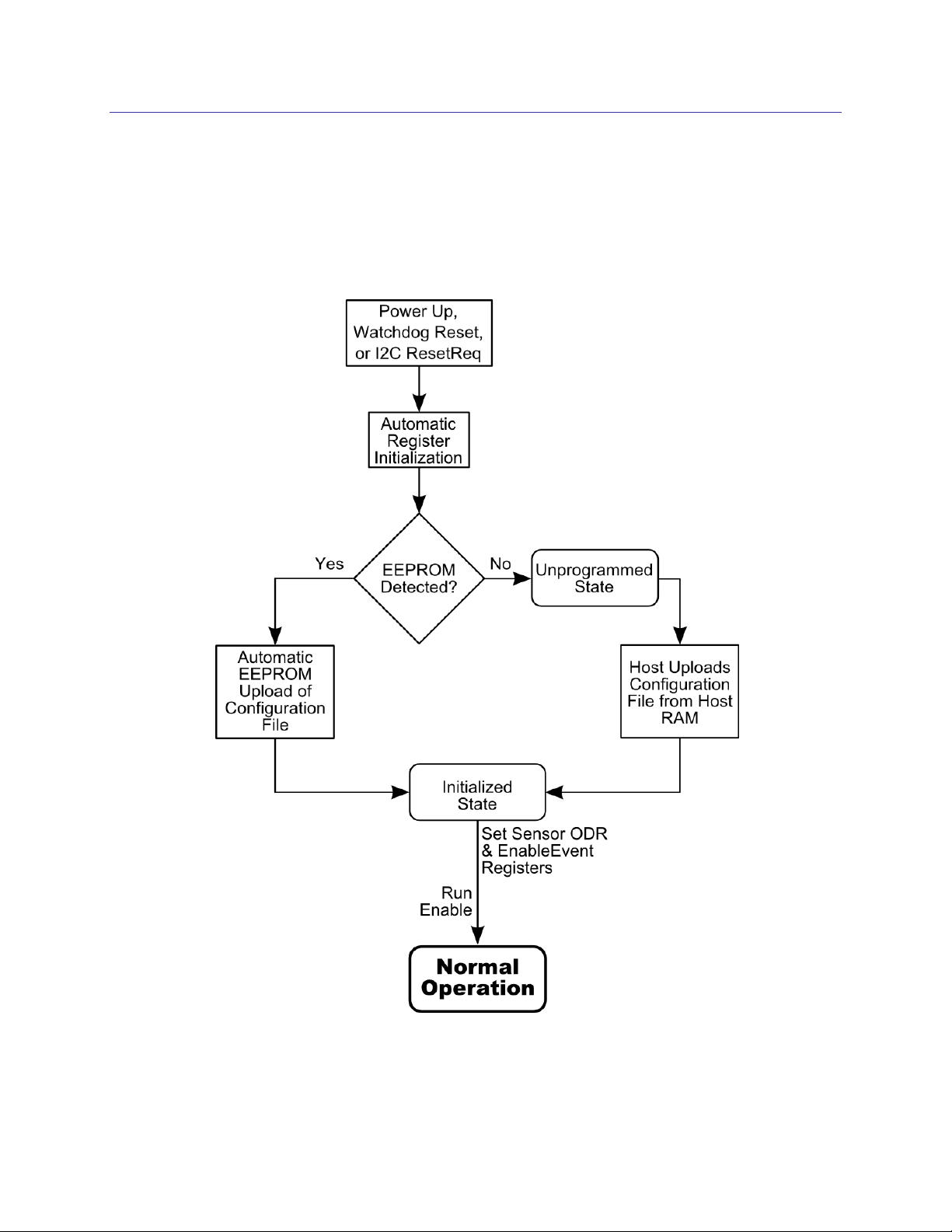

5 Operation

Figure 5-1 provides a flow chart of the initialization process, and a detailed discussion of the

initialization process follows in Section 5.1. For the registers, all multi-byte elements are

stored and transmitted using the Little Endian convention: the least significant byte is

stored at the lowest address and transmitted first over the I2C bus.

Figure 5-1: SENtral Initialization Sequence

PNI Sensor Corporation Doc #1018049 R03

SENtral Technical Data Sheet Page 16

Page 18

Prior to running SENtral, the Configuration File must be uploaded into SENtral’s Configuration

RAM. This file contains information regarding how the user’s sensor system is configured, such

as sensor models, sensor slave addresses, GPIO pin assignments, etc.. The Configuration File is

generated with the SENtral Configuration Tool, as discussed in Section 6. It may be stored in

the host processor’s non-volatile memory or in a dedicated EEPROM connected to SENtral’s

sensor bus. Once the Configuration File is uploaded, SENtral will move into Initialized state.

Once the initialization sequence is complete, there are three states in which SENtral may reside:

Normal Operation, Standby, and Pass-Through. Figure 5-2 indicates the recommended way to

get from one state to another, and these states are discussed in detail in Sections 225.3 (Normal

Operation), 5.4 (Standby), and 5.5 (Pass-Through).

Figure 5-2: SENtral Operational States

5.1 Power-Up and Configuration File Upload

After powering up or issuing a ResetReq command, SENtral automatically initializes the

registers, and then looks for an EEPROM on the sensor bus, as indicated in Figure 5-1.

The Configuration File must now be uploaded. This file contains information on how the

sensor system is configured in the user’s system, and is generated with the SENtral

Configuration Tool, as discussed in Section 6. It can be stored in non-volatile memory in the

host CPU or in a dedicated EEPROM. The primary advantages of using a dedicated

EEPROM are freeing up host processor memory and minimizing the time from powering up

until the upload is complete. The advantages of using the host CPU’s memory are no

additional cost and no additional system footprint requirement. If a dedicated EEPROM is

used, the EEPROM needs to be connected to SENtral as a slave device on the sensor bus.

5.1.1 Configuration File Upload from EEPROM

If a dedicated EEPROM is used to store the Configuration File, then this EEPROM

initially would be loaded with the Configuration File either using an EEPROM

programmer or by writing the file into the EEPROM from the host while SENtral is in

Pass-Through State. This later method also can be used if a new revision of the SENtral

algorithm is available or if the user is testing a variety of sensors and consequently needs

PNI Sensor Corporation Doc #1018049 R03

SENtral Technical Data Sheet Page 17

Page 19

Register Name

Address

Register Value

SentralStatus

0x37

[0] EEPROM. 1 = EEPROM detected

[1] EEUploadDone. 1 = EEPROM upload completed

[2] EEUploadError. 1 = Calculated CRC of EEPROM is

incorrect. Only valid when EEUploadDone = 1.

[3] Idle. 1 = Device in Unprogrammed or Initialized state.

[4] NoEEPROM. 1 = No EEPROM detected.

ResetReq

0x9B

[0] ResetRequest. 1 = Emulate a hard power down/power up.

to change the Configuration File depending on the sensors. As previously mentioned, the

EEPROM should be connected to SENtral via SENtral’s sensor bus.

Table 5-1: Configuration File Upload from EEPROM Registers

SENtral automatically checks the sensor bus after powering up or reseting to see if an

EEPROM is connected on the sensor bus. If an EEPROM is detected, SENtral checks

the first 2 bytes of the EEPROM file, which are fixed for all SENtral Configuration Files,

and if these match then it automatically uploads the SENtral Configuration File. Once

the upload is complete, SENtral enters Initialized State and waits for instructions from the

host. If an EEPROM is not detected, SENtral enters Unprogrammed State.

The host should confirm a successful EEPROM upload by following the steps below:

Read the value from the SentralStatus register.

Check bit [0], the EEPROM bit, to ensure an EEPROM is detected by SENtral.

Check bit [1], the EEUploadDone bit. If this is ‘0’ then the Configuration File upload

is not complete, and reread the SentralStatus register until bit [1] = 1.

Once bit [1] = 1, check bit [2], the EEUpload Error bit. If this is ‘0’, then the upload

was successful.

If the Configuration File upload failed, try the following:

Reinitialize SENtral and retry the process. Send a Reset command by writing 0x01 to

the ResetReq register.

Upload the Configuration File from the host, as discussed in the next section.

Download the Configuration File from the EEPROM and verify its contents, as given

in Appendix I – Configuration File Image Format.

Reload the Configuration File from the host into the EEPROM.

PNI Sensor Corporation Doc #1018049 R03

SENtral Technical Data Sheet Page 18

Page 20

Register Name

Address

Register Value

HostControl

0x34

[0] 1 = RunEnable

[1] 1 = HostUpload Enable

UploadAddr

0x94 to 0x95

Initial RAM address (0x0000)

UploadData

0x96

Data to be uploaded

CRCHost

0x97 to 0x9A

CRC32 of the uploaded data since

host upload was enabled

ResetReq

0x9B

[0] 1 = Reset SENtral

5.1.2 Configuration File Upload from Host

If an EEPROM is not used for storing the Configuration File, then SENtral will enter

Unprogrammed State after failing to identify an EEPROM. The host now should upload

the Configuration File from host memory. The registers involved are given below:

Table 5-2: Configuration File Host Upload Registers

To upload the Configuration File from the host, perform the following transactions:

Write value 0x01 to the ResetReq register. This results in a hard reset of SENtral.

This is unnecessary if SENtral has just been powered up or Reset.

Verify the Configuration File image, as given in Appendix I – Configuration File

Image Format. Specifically:

o Ensure the Magic Numbers are correct.

o Ensure the Uploaded Image Length matches the Uploaded Firmware Image Size.

o Ensure the Upload Image Length is a multiple of 4 bytes.

Write 0x02 to the HostControl register. This sets the UploadEnable bit, which

enables uploading of the Configuration File.

Write the initial RAM address, 0x0000, into the UploadAddr register. This normally

is an unnecessary operation, since the default after powering up or sending a

ResetReq is 0x0000.

Upload the Configuration File to SENtral’s program RAM. This represents the range

from 0x10 to 0x10+UIL-1 in the Configuration File image, as discussed in Appendix

I – Configuration File Image Format. The file is sent one byte at a time, using the

UploadData register. Data can be burst uploaded. Each group of 4 bytes should be

sent in byte-reverse order (i.e. little Endian format). Table 5-3 provides an example.

PNI Sensor Corporation Doc #1018049 R03

SENtral Technical Data Sheet Page 19

Page 21

Byte Order in Config File Image

i

i+1

i+2

i+3

i+4

i+5

i+6

i+7

Config File Image Example

0x01

0x02

0x03

0x04

0x05

0x06

0x07

0x08

Byte Order During Host Upload

i+3

i+2

i+1 i i+7

i+6

i+5

i+4

Example Bye Sent during Upload

0x04

0x03

0x02

0x01

0x08

0x07

0x06

0x05

Register Name

Address

Register Value

MagRate

0x55

Requested magnetometer output data rate

AccelRate

0x56

Requested accelerometer output data rate divided by 10

GyroRate

0x57

Requested gyroscope output data rate divided by 10

QRateDivisor

0x32

Along with GyroRate, establishes output data rate for

quaternion data.

AlgorithmControl

0x54

[0] 1 = StandbyEnable

0 = Disable Standby State

[1] RawDataEnable. 1 = Raw data provided in MX, MY,

MZ, AX, AY, AZ, GX, GY, & GZ.

0 = Scaled sensor data.

[2] HPRoutput. 1 = Heading, pitch, and roll output in QX,

QY, & QZ. QW = 0.0.

0 = Quaternion outputs.

EnableEvents

0x33

‘1’ indicates an interrupt to the host will be generated for

the event.

[0] CPUReset. Non-maskable

[1] Error

[2] QuaternionResult

[3] MagResult

[4] AccelResult

[5] GyroResult

[6] Reserved

[7] Reserved

Table 5-3: Sample Host Upload Data Order

Read the CRCHost register. Compare this to the host-calculated CRC-32 to confirm

a successful upload.

After the reset, write value 0x00 to the HostControl register, which clears the

HostUpload bit and places SENtral in Initialized State.

5.2 Initial Register Set-Up

After the initialization process is complete, it is necessary to configure a few of SENtral’s

registers before running in Normal Operation. These registers are given in Table 5-4.

Table 5-4: Registers for Initial Set-Up

PNI Sensor Corporation Doc #1018049 R03

SENtral Technical Data Sheet Page 20

Page 22

Perform the following:

Set the sensor output data rates (ODRs): MagRate, AccelRate, and GyroRate. If a

sensor rate is set to 0x00, SENtral will shutdown the sensor and disable SENtral

background calibration. There are two major points regarding setting these registers:

o The AccelRate and GyroRate register values should be 1/10th the desired rate,

while the MagRate value should match the desired ODR. For example, if the

desired ODR is 30 Hz for the magnetometer, 100 Hz for the accelerometer, and

200 Hz for the gyroscope, then the respective register values should be 0x1E

(30d), 0x0A (10d), and 0x14 (20d).

o The actual accelerometer and gyro ODRs are limited to the ODRs supported by

the specific sensors. If the AccelRate or GyroRate register values do not

correspond to a supported ODR, then the next highest ODR will be used. For

instance, if the GyroRate register is set to 0x14, which corresponds to 200 Hz, but

the gyro supports 95 Hz, 190 Hz, and 380 Hz, then the actual gyro ODR will be

380 Hz since this is the closest supported rate above that requested by the register.

Establish the quaternion or Euler angle output data rate, where the output data rate

equals GyroRate divided by QRateDivisor. The default for QRateDivisor is 0x00,

which is interpreted as ‘1’ and results in the output data rate equaling GyroRate.

Establish how SENtral’s orientation and sensor data is to be output. The

AlgorithmControl register allows the user to select either quaternion or Euler angles

(heading, pitch, and roll) for orientation outputs, and either scaled or raw sensor data

outputs. The default is 0x00, corresponding to quaternion and scaled sensor data.

Establish which events will trigger an interrupt to the host by configuring the

EnableEvent register. PNI specifically recommends enabling bit [1], the Error

interrupt bit, in addition to whichever other interrupts the user wants.

Example steps to do this are below:

Write 0x640A0F to the MagRate register. Since SENtral automatically increments to

the next register, this also populates the AccelRate and GyroRate registers. This sets

MagRate to 100 Hz, AccelRate to 100 Hz, and GyroRate to 150 Hz.

Write 0x01 to the QRateDivisor Register. This sets the quaternion output data rate to

equal the GyroRate. For writing 0x01 this step is optional, since the default also sets

the quaternion output data rate equal to GyroRate.

Write 0x06 to the AlgorithmControl register. This enables heading, pitch, and roll

orientation outputs and raw sensor data outputs. This step is optional, as the default

register value of 0x00 results in outputs of quaternions and scaled sensor data.

PNI Sensor Corporation Doc #1018049 R03

SENtral Technical Data Sheet Page 21

Page 23

Write 0x07 to the EnableEvents register. This sets up the host to receive interrupts

from SENtral whenever the quaternion results registers are updated, an error has been

detected, or when SENtral needs to be reset.

Note: It is necessary to set the MagRate, AccelRate, AND GyroRate registers to non-zero values for

the SENtral algorithm to function properly and to obtain reliable orientation and scaled sensor data. If

a [Sensor]Rate register is left as 0x00 after power-up, or is changed to 0x00, this effectively disables

that sensor within the SENtral algorithm. Also, the CalStatus, MagTransient, and AlgorithmSlow bits

become undefined.

5.3 Running in Normal Operation

After performing the steps listed above, SENtral is ready to start generating orientation data.

Below is a flow diagram for Normal Operation, followed by the pertinent registers, and then

the steps to follow when running.

Figure 5-3: SENtral Normal Operation Flow

PNI Sensor Corporation Doc #1018049 R03

SENtral Technical Data Sheet Page 22

Page 24

Register Name

Address

Register Value

HostControl

0x34

[0] 1 = RunEnable

0 = Enable Initialized State

EventStatus

0x35

‘1’ indicates a new event has been generated.

[0] CPUReset

[1] Error

[2] QuaternionResult

[3] MagResult

[4] AccelResult

[5] GyroResult

Table 5-5: Normal Operation Registers

Below are the steps to follow when operating in Normal Operation state.

a) Write 0x01 to the HostControl register. This sets the RunEnable bit to ‘1’ and

enables the sensors and the SENtral algorithm.

b) If operating in an interrupt-driven mode, then the host waits until it receives an

interrupt signal from SENtral. Alternatively the host may operate on a polling basis,

rather than an interrupt-driven basis, in which case the interrupt line may not be used.

c) Once an interrupt is received by the host or the host otherwise decides to read new

data, read the EventStatus register.

d) Interpret and act on the EventStatus register in the priority shown in Figure 5-3. If bit

[1], the Error bit, is ‘1’, see Section 5.3.1. If bit [0], the CPUReset bit, is ‘1’, see

Section 5.3.2. If bits [2], [3], [4], or [5], the Results bits, are ‘1’, see Section 5.3.1.

e) Repeat steps c and d until new orientation data is not needed and/or the host decides

to enter a different state.

Note that reading the EventStatus register clears it. It is possible for more than one bit

position to be ‘1’ in the EventStatus register, especially if the host does not always read the

EventStatus register after receiving an interrupt. Similarly, if multiple bits are set to ‘1’ in

the EventStatus register, once the register is read all the bits will be set to ‘0’. For this reason

the EventStatus register should be processed in the priority shown in Figure 5-3, as

information will be cleared for events that are not handled.

5.3.1 Error

In the event of an error, SENtral will trigger an error interrupt and SENtral will enter

Standby State. See the Section 5.6 for recommendations on Troubleshooting and/or reset

SENtral by sending 0x01 to the ResetReq register, at address 0x9B.

PNI Sensor Corporation Doc #1018049 R03

SENtral Technical Data Sheet Page 23

Page 25

Name

Address

(Hex)

Description

Format

Full-Scale Range

QX

00 – 03

Normalized Quaternion – X, or Heading

Float32

0.0 – 1.0, or ±

QY

04 – 07

Normalized Quaternion – Y, or Pitch

Float32

0.0 – 1.0, or ±/2

QZ

08 – 0B

Normalized Quaternion – Z, or Roll

Float32

0.0 – 1.0, or ±

QW

0C – 0F

Normalized Quaternion – W, or 0.0

Float32

0.0 – 1.0

QTime

10 – 11

Quaternion Data Timestamp

UInt16

0 – 2048 msec

MX

12 – 13

Magnetic Field – X Axis, or Raw Mag Data

Int16

±1000 µT when scaled

MY

14 – 15

Magnetic Field – Y Axis, or Raw Mag Data

Int16

±1000 µT when scaled

MZ

16 – 17

Magnetic Field – Z Axis, or Raw Mag Data

Int16

±1000 µT when scaled

MTime

18 – 19

Magnetometer Interrupt Timestamp

UInt16

0 – 2048 msec

AX

1A – 1B

Linear Acceleration – X Axis, or Raw Accel Data

Int16

±16 g when scaled

AY

1C – 1D

Linear Acceleration – Y Axis, or Raw Accel Data

Int16

±16 g when scaled

AZ

1E – 1F

Linear Acceleration – Z Axis, or Raw Accel Data

Int16

±16 g when scaled

ATime

20 – 21

Accelerometer Interrupt Timestamp

UInt16

0 – 2048 msec

GX

22 – 23

Rotational Velocity – X Axis, or Raw Gyro Data

Int16

±5000°/s when scaled

GY

24 – 25

Rotational Velocity – Y Axis, or Raw Gyro Data

Int16

±5000°/s when scaled

GZ

26 – 27

Rotational Velocity – Z Axis, or Raw Gyro Data

Int16

±5000°/s when scaled

GTime

28 – 29

Gyroscope Interrupt Timestamp

UInt16

0.0 – 2.048 sec

5.3.2 CPUReset

SENtral will report a CPUReset event after the ResetReq command has been issued, and

prior to uploading the Configuration File. In this case, SENtral is in Unprogrammed

State and needs the Configuration File to be uploaded. If a dedicated EEPROM is used

to store the Configuration File, then CPUReset should not be encountered as the

Configuration File is automatically uploaded.

5.3.3 Read Results

The Results Registers’ addresses, formats, and full-scale ranges are given below in Table

5-6. For an explanation of how to convert quaternions to the rotation vector, the rotation

matrix, or heading, pitch, and roll (Euler angles), see Appendix II – Converting

Quaternions. The resolution is 32 kHz for all timestamps.

Note: All multi-byte elements are stored and transmitted using the Little Endian convention: the

least significant byte is stored at the lowest address and transmitted first over the I2C bus.

Table 5-6: Results Registers

PNI Sensor Corporation Doc #1018049 R03

SENtral Technical Data Sheet Page 24

Page 26

Register Name

Address

Register Value

AlgorithmControl

0x54

[0] 1 = StandbyEnable

0 = Disable Standby State

AlgorithmStatus

0x38

[0] 1 = SENtral in Standby State

0 = SENtral not in Standby State

5.4 Standby State

In Standby State overall system power consumption is dramatically reduced because both the

SENtral algorithm and the sensors are shut down. Table 5-7 provides the registers associated

with Standby State.

Table 5-7: Standby Registers

The steps to enter and exit Standby State are given below:

Write 0x01 to the AlgorithmControl register. This places SENtral in Standby State.

Read the AlgorithmStatus register. If bit [0] is ‘1’, then SENtral is in Standby State.

This step is optional.

When you are ready to exit Standby State, write 0x00 to the AlgorithmControl

register. This takes SENtral out of Standby State and normally will place it back into

Normal Operation.

Read the AlgorithmStatus register. If bit [0] is ‘0’, then SENtral is not in Standby

State. This step is optional.

5.5 Pass-Through State

SENtral can be configured so the host communicates directly with devices on the sensor bus

by placing SENtral into Pass-Through State. In Pass-Through State, SENtral’s sensor and

host interfaces are connected by internal switches so the host system communicates directly

with the sensors and/or dedicated EEPROM. To enter Pass-Through State, SENtral first

should be in either Standby, Initialized, or Unprogrammed State. Consequently, in PassThrough State the SENtral algorithm, host interrupt line, and sensors are disabled, unless a

sensor is directly turned on by the host. When exiting Pass-Through State, SENtral will

return to its prior state.

Note: When entering Pass-Through State the sensor’s registers retain the values established by

SENtral, and when exiting Pass-Through State any register changes will be retained.

PNI Sensor Corporation Doc #1018049 R03

SENtral Technical Data Sheet Page 25

Page 27

Register Name

Address

Register Value

AlgorithmControl

0x54

[0] 1 = StandbyEnable

0 = Disable Standby State

AlgorithmStatus

0x38

[0] 1 = SENtral in Standby State

0 = SENtral not in Standby State

PassThroughControl

0xA0

[0] 1 = Enable Pass-Through State

0 = Disable Pass-Through State

PassThroughStatus

0x9E

[0] 1 = SENtral in Pass-Through State.

0 = SENtral not in Pass-Through State.

Uses for the Pass-Through State include:

Direct control of sensors, if desired.

Debugging.

Communication with the dedicated EEPROM, if implemented. Specifically, if a new

Configuration File is generated, the host can write this into the EEPROM when in

Pass-Through State.

Since operating in Pass-Through State requires stopping the SENtral algorithm, PassThrough State is not recommended for accessing sensor data unless reliable heading data is

not required. If sensor data and reliable heading data are both desired, scaled sensor data can

be accessed during Normal Operation from the Results Registers, as given in Table 5-6.

Table 5-8 provides the registers associated with Pass-Through State.

Table 5-8: Pass-Through Registers

The steps to go in and out of Pass-Through State are given below.

Write 0x01 to the AlgorithmControl register. This places SENtral in Standby State.

Write 0x01 to the PassThroughControl register. This places SENtral in Pass-Through

State.

Read the PassThroughStatus register. If bit [0] is ‘1’, then SENtral is in Pass-

Through State. This step is optional.

When you are done in Pass-Through State, write 0x00 to the PassThroughControl

register. This terminates Pass-Through mode and returns SENtral to Standby State.

Write 0x00 to the AlgorithmControl register. This takes SENtral out of Standby State

and normally will place it back into Normal Operation.

PNI Sensor Corporation Doc #1018049 R03

SENtral Technical Data Sheet Page 26

Page 28

Register Name

Address

Error Indication

EventStatus

0x35

[0] 1 = CPURest. SENtral Configuration

File needs uploading. See Section 5.1.

SentralStatus

0x37

[2] 1 = EEUploadError. Issue with

uploading from the dedicated EEPROM.

See Section 5.1.

MagRate

0x55

0x00 – Value lost

AccelRate

0x56

0x00 – Value lost

GyroRate

0x57

0x00 – Value lost

Register Name

Address

Error Indication

EventStatus

0x35

[1] 1 = Error.

SensorStatus

0x36

Non-zero value indicates sensor-related error. Check

sensors by communicating in Pass-Through State.

See Table 5-11

SentralStatus

0x37

[3] 1 = Idle. SENtral in Initialized or Unprogrammed

State.

ErrorRegister

0x50

Non-zero value indicated an error. See Table 5-12.

RAMVersion

0x72, 0x73

Unexpected Configuration File revision level.

5.6 Troubleshooting

This section provides guidance in troubleshooting SENtral, and is divided into hardwarerelated and software-related errors.

5.6.1 Hardware-Related Error Conditions

Possible indications of a hardware-related problem are given below in Table 5-9.

Table 5-9: Hardware-Related Error Indications

In the event of such errors, SENtral will enter Standby State, shut down the sensors, and

generate an interrupt to the host. Possible reasons for hardware-related errors include

problems with an external EEPROM upload, power transients detected by power

management, and errors in software detected by Watchdog. Often the error can be

cleared by sending the ResetReq command and reloading the Configuration File.

5.6.2 Software-Related Error Conditions

Possible indications of software-related errors are given below in Table 5-10:

Table 5-10: Software-Related Error Indications

PNI Sensor Corporation Doc #1018049 R03

SENtral Technical Data Sheet Page 27

Page 29

Register Name

Address

Error Indication

SensorStatus

0x36

[0] MagNACK. 1 = NACK from magnetometer

[1] AccelNACK. 1 = NACK from accelerometer

[2] GyroNACK. 1 = NACK from gyroscope

[4] MagDeviceIDErr. 1 = Unexpected DeviceID

from magnetometer

[5] AccelDeviceIDErr. 1 = Unexpected DeviceID

from accelerometer

[6] GyroDeviceIDErr. 1 = Unexpected DeviceID from

gyroscope.

Value

Error Condition

Response

0x00

No error

0x80

Invalid sample rate selected

Check sensor rate settings.

0x30

Mathematical Error

Check for software updates

0x21

Magnetometer initialization failed

This error can be caused by a wrong

driver, physically bad sensor

connection, or incorrect I2C device

address in the driver

0x22

Accelerometer initialization failed

0x24

Gyroscope initialization failed

0x11

Magnetometer rate failure

This error indicates the given sensor

is unreliable and has stopped

producing data.

0x12

Accelerometer rate failure

0x14

Gyroscope rate failure

If the SensorStatus register indicates a non-zero value, then the value provides additional

information on the sensor that is causing a problem, as given in Table 5-11.

Table 5-11: SensorStatus Register Values

If the ErrorRegister indicates a non-zero value, then the value provides additional

information on the sensor that is causing a problem, as given in Table 5-12.

Table 5-12: ErrorRegister Values

If the RAMVersion register values do not correspond to the expected Configuration File

revision level, as given in Table 5-13, certain features or functions that are expected to be

PNI Sensor Corporation Doc #1018049 R03

SENtral Technical Data Sheet Page 28

available may not be available, or they may not function as expected. This normally can

be remedied by generating the latest Configuration File revision level using the SENtral

Page 30

0x72 Register

Value

0x73 Register

Value

RAM Version

(Hex / Decimal)

Config File

Revision

0x04

0x0C

0x0C04 / 3076

1.0

0xD5

0x0C

0x0CD5 / 3285

1.1

0x37

0x0E

0x0E02 / 3639

1.2

Configuration Tool, as discussed in Section 6, and then loading this into an optional

dedicated EEPROM or otherwise uploading it into SENtral.

Table 5-13: RAMVersion Register Values

PNI Sensor Corporation Doc #1018049 R03

SENtral Technical Data Sheet Page 29

Page 31

6 SENtral Configuration Tool

Before using the SENtral Motion Coprocessor, the SENtral Configuration File must be generated

using the SENtral Configuration Tool. As discussed in prior sections, the Configuration File

contains information on how the sensor system is configured in the user’s system.

To access the SENtral Configuration Tool, go to: http://www.sentraltoolkit.com. The tool is for

SENtral customers, and registration is required. Registration requests are reviewed at PNI.

Typically it takes less than one business day to activate a registration request.

The SENtral Configuration Tool provides an intuitive GUI which allows the user to easily

generate the Configuration File. A screen shot of the tool is given in Figure 6-1, and a discussion

of the settings follows. Once the various fields are correctly populated, click <Generate> to

create the SENtral Configuration File. A zip file will automatically download onto your

computer containing the Configuration File, “sentral_[rev]_[mag]_[accel]_[gyro].fw”, and a .cfg

file providing the data input into the Configuration Tool. The .cfg file can be opened with a text

editor. Additionally, the .cfg file can be uploaded into the Configuration Tool by clicking <Load

Config> and then selecting the desired .cfg file. The “GS and M&M Configuration” link opens a

pop-up window with the configurations for the various SENtral M&M and GS modules.

Figure 6-1: SENtral Configuration Tool

PNI Sensor Corporation Doc #1018049 R03

SENtral Technical Data Sheet Page 30

Page 32

6.1 Configuration Tool General Settings

6.1.1 SDK Revision

This establishes the revision of the firmware to be generated. Normally the latest

revision is most desirable, but prior revisions are retained for customers that have

qualified an older revision level.

6.1.2 Host Interrupt Pin

This establishes which GPIO pin is used to send an event interrupt to the host system.

The default is GPIO[6], but any of the GPIO pins can be used for this function.

6.1.3 EEPROM Max. Upload Speed

If the user incorporates a dedicated EEPROM to store the SENtral’s Configuration File,

then this field establishes the maximum data rate the configuration EEPROM can

accommodate. If there is no EEPROM, this setting has no meaning. SENtral

automatically determines if a dedicated EEPROM is present.

6.2 Configuration Tool Sensor Configuration

The sensors attached to SENtral must be configured correctly for SENtral to properly

function. The magnetometer, accelerometer, and gyroscope are configured in a similar

manner, so the parameters discussed below apply to all three sensors.

6.2.1 Sensor

The drop-down menus are used to select the sensor models incorporated into the user’s

system. If a sensor is not listed, then a driver has not been developed for that sensor.

6.2.2 Interrupt Pin

This drop-down menu establishes which General Purpose IO pin is used to send a sensor

interrupt signal to SENtral. As shown in the reference schematic, Figure 3-1, the default

is to use GPIO[0] for the magnetometer, GPIO[1] for the accelerometer, and GPIO[2] for

the gyroscope. However, the GPIO pins are interchangeable and can be configured as is

most convenient for the user.

6.2.3 Slave Address

This establishes the slave address for the respective sensor, and the user needs to input

the sensor’s slave address here. The 7-bit slave address will be provided in the sensor’s

PNI Sensor Corporation Doc #1018049 R03

SENtral Technical Data Sheet Page 31

Page 33

technical data sheet and normally will be a function of 5 or 6 fixed bits and 1 or 2 bits

that are configurable by 1 or 2 of the sensor’s pins.

6.2.4 Orientation Matrix

This matrix defines how the sensors are physically laid out in the host system. The

values are normally 1s, -1s, or 0s. The matrix is used to convert the physical layout into a

north-east-down (NED) convention, where “north” is defined as the line-of-sight or

direction of travel. The matrix is defined as shown in the equation below:

where A through I are the matrix values that need to be populated (1s or 0s), X, Y, and Z

represent the orientation of the x-axis, y-axis, and z-axis sensors, where north is defined

as the line of sight, and NED is the north-east-down convention that the orientation

matrix converts [X, Y, Z] into.

For the accelerometer matrix, it is necessary to multiply the matrix by –1.

Examples:

Below are three examples. The first is if the sensor is laid out in an NED convention,

such that the x-axis points north, the y-axis points east, and the z-axis points down.

Recall that “north” is defined as the line-of-sight or direction of travel. In this case

the orientation matrix is the identity matrix, as given below.

Another common convention is east-north-up (ENU), where the x-axis points east,

the y-axis points north, and the z-axis points up, in which case the orientation matrix

and associated matrix math are given below.

PNI Sensor Corporation Doc #1018049 R03

SENtral Technical Data Sheet Page 32

Page 34

The final example is west-south-down (WSD). This matrix would be appropriate for

an ENU accelerometer, since it incorporates the -1 multiplication factor. The

orientation matrix and associated matrix math are given below.

6.2.5 Cal Offsets

Normally these fields will be ‘0’. However if the user has information indicating a given

model of sensor consistently has a fixed measurement offset, then these fields allow the

user to tailor the SENtral algorithm. For example, assume statistical data from a

manufacturer regarding their accelerometer indicates their z-axis sensor has an average

reading of 1.1 g when actually experiencing 1.0 g of gravitational force. In this case, the

user can enter an offset on the z-axis of 0.1g for the accelerometer. The fields are given

in X, Y, Z order, and the units are as follows:

Magnetometer: 1.0 = +50 T

Accelerometer: 1.0 = +1 g

Gyroscope: 1.0 = +1 radian/second

PNI Sensor Corporation Doc #1018049 R03

SENtral Technical Data Sheet Page 33

Page 35

7 Package Information

Note: For Pin-Out, see

Table 3-1

Figure 7-1: Mechanical Drawing

PNI Sensor Corporation Doc #1018049 R03

SENtral Technical Data Sheet Page 34

Page 36

Figure 7-2: Tape Dimensions

PNI Sensor Corporation Doc #1018049 R03

SENtral Technical Data Sheet Page 35

Page 37

8 Assembly Guidelines

SENtral is provided in a lead-free wafer-level chip-scale package (WL-CSP). General design

guidelines can be found in Amkor’s “Application Note for Surface Mount Assembly of Amkor’s

Eutectice and Lead-Free CSPnl Wafer Level Chip Scale Packages”, which is available from

Amkor’s website. Specific assembly guidelines are discussed below.

Comments specific to SENtral include:

Microvia technology is NOT required if GPIO[3] and GPIO[5] are not used and the

slave address pin, SA0, is set LOW. In this case the slave address pin, C3, should be

connected to C2 (unused), and C2 should be connected to D2, which is GND. Pins

B2, GPIO[5], and B3, GPIO[3], should be left unconnected.

If either GPIO[3] and GPIO[5] are to be used or the slave address pin, SA0, is to be

set HI, then microvia technology is required. Due to SENtral’s ball-grid-array 0.4

mm pitch and 0.26 mm ball diameter, connections to these inner pins should be made

with a via-in-pad design using microvias.

General CSP assembly guidelines for SENtral include:

A non-solder mask defined (NSMD) land pattern is recommended.

Solder mask registration is critical and the correct solder mask opening dimension

should be 50um either side of the copper pad.

The actual size of the copper pad should be between 80% and 100% of the diameter

of the solder ball.

The copper layer thickness should 30 um or less.

The copper pads should be finished with Organic Solderability Preservative (OSP)

coating, such as ENTEK-PLUS Cu 106A.

Standard epoxy glass PCB substrates are compatible. High temperature FR4 is

preferred over standard FR4 for improved package reliability.

PNI Sensor Corporation Doc #1018049 R03

SENtral Technical Data Sheet Page 36

Page 38

Figure 8-1 provides design parameters for a typical SENtral solder mask and pad pattern.

Figure 8-1: Typical Solder Mask and Land Pad Parameters

A typical recommended solder reflow profile is given in Figure 8-2 and the associated processing

parameters are given in Table 8-1, both on the following page. Oven type and tolerances,

thermocouple tolerance, solder type, and the temperature difference across the board will affect

the actual implemented profile.

PNI Sensor Corporation Doc #1018049 R03

SENtral Technical Data Sheet Page 37

Page 39

Parameter

Value

Ramp Up Rate

3°C/second

Preheat Temperature Range

150°C to 180°C

Preheat Time

60 – 180 seconds

Liquidus Temperature

220°C

Time above Liquidus

30 – 90 seconds

Peak Temperature

255°C ±5°C

Time within 5°C of Peak Temperature

10 – 20 seconds

Ramp Down Rate

6°C/second maximum

PB

Figure 8-2: Typical Solder Reflow Profile

Table 8-1: Typical Solder Processing Parameters

PNI Sensor Corporation Doc #1018049 R03

SENtral Technical Data Sheet Page 38

Page 40

Byte Index

Content

Note

0x00

Magic Number Lower Byte

0x2A is expected value

0x01

Magic Number Upper Byte

0x65 is expected value

0x02 & 0x03

Flags

Bit [0] – EEPROMExec

0 = Execute after EEPROM

upload (default)

1 = Do not execute after

EEPROM upload

Bits [8] to [10] – I2CClockSpeed

000 – 1 Mbit/s

001 – 833 kbit/s

010 – 400 kbit/s

011 – 333 kbit/s

100 – 100 kbit/s

Others – 83 kbit/s

Bits [11] to [14] – ROMVerExp.

0001 – version 0x7A8

0010 – version 0x9E6

0x04 to 0x07

CRC32 of uploaded image

Stored in Little Endian Format

0x08 to 0x0B

Reserved

0x00000000

0x0C & 0x0D

Uploaded Image Length (UIL)

Stored in Little Endian Format

0x0E & 0x0F

Reserved

0x0000

0x10 to

0x10+UIL-46

Uploaded Image – Instructions &

Configuration File Data

CRC32 is calculated over

uploaded image

0x10+UIL-45 to

0x10+UIL-1

Uploaded Image –Config. File

Data Structure. See Table A1-2.

Appendix I – Configuration File Image Format

Table A1-1 provides the format for the Configuration File image. While understanding the

Configuration File image format is not mandatory for operation, it can be useful when debugging

errors.

Table A1-1: Configuration File Image Format

PNI Sensor Corporation Doc #1018049 R03

SENtral Technical Data Sheet Page 39

Page 41

Byte Index

Content

Note

0x00

Signature Lower Byte

Value is 0x8B. Can be used to locate

the data structure within the image.

0x01

Signature Upper Byte

Value is 0xC8. Can be used to locate

the data structure within the image.

0x02 to 0x07

Reserved

0x08 & 0x09

RAM Version

Firmware version number

0x0A

Version

Configuration Structure Version