6

NS series safety switches with solenoid and RFID technology

Description

These switches are used mainly on machi‑

nes where the hazardous conditions persist

even after the machine has been switched

off. Mechanical parts such as pulleys, saw

blades, etc., could continue to move after

the machine is switched off or could still be hot or under

pressure. Thus, the switches can also be used if individual

guards are only to be opened under certain conditions.

Versions with mode 1 (safety outputs active when guard

closed and locked) are interlocks with guard locking acc.

to ISO 14119; the product is labelled with the symbol

shown.

Maximum safety with a single device

PL e and SIL 3 safety levels can still be achieved through the use of a

single device on a guard. This avoids expensive wiring in the field and

allows faster installation. Inside the control cabinet, the two electro‑

nic safety outputs must be connected to a safety module with OSSD

inputs or to a safety PLC.

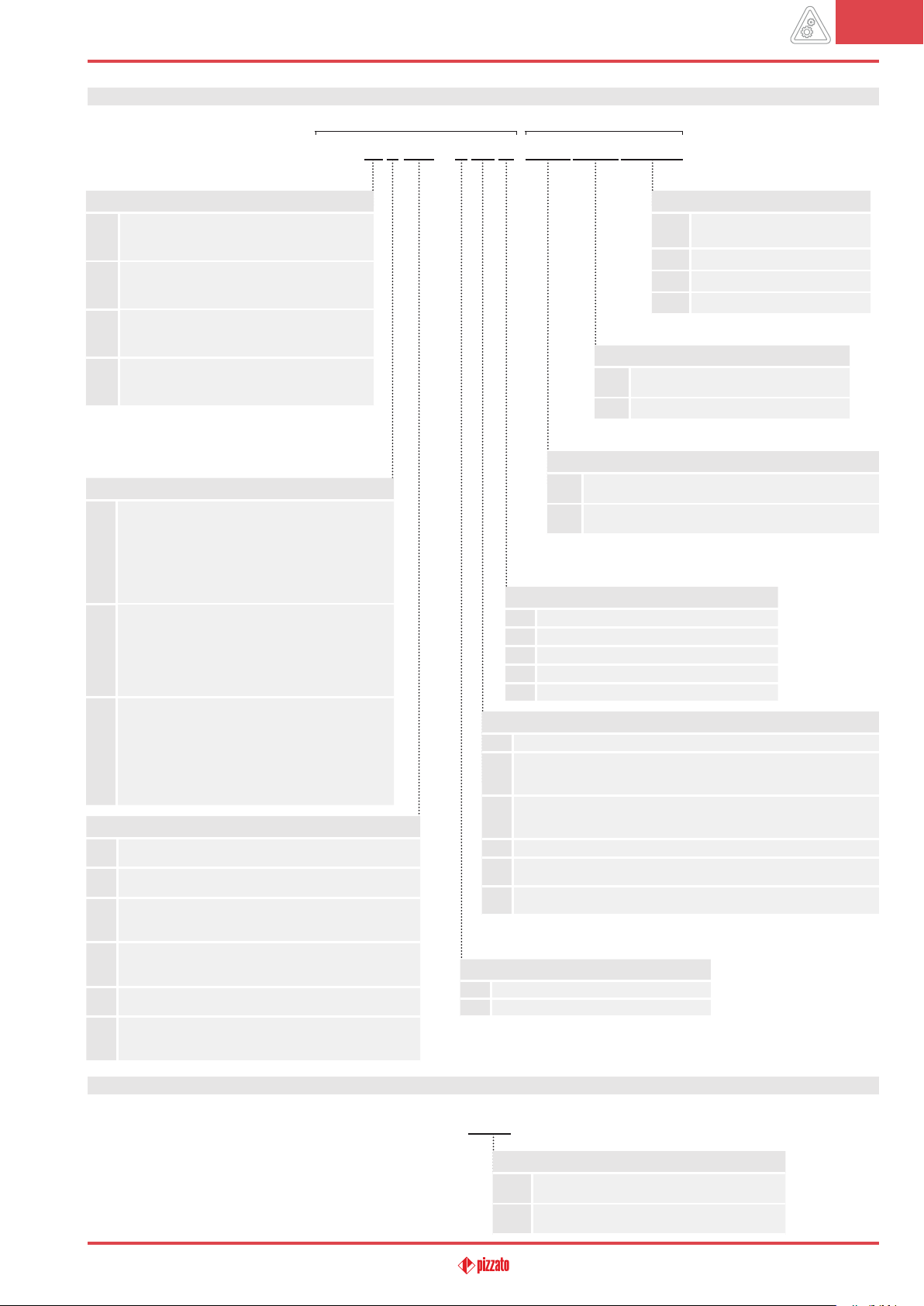

Series connection of several switches

One of the most important features of the NS series is the possibility of connecting up to 32 sensors in series,

while still maintaining the maximum safety levels PL e laid down in EN 13849‑1 and SIL 3 acc. to EN 62061.

permissible in safety systems which have a safety module at

the end of the chain that monitors the outputs of the last NS

switch.

The fact that the PL e safety level can be maintained even with

32 sensors connected in series demonstrates the extremely

secure structure of each single device.

This connection type is

NS D4AZ1SMK-F41 NS D4AZ1SMK-F41 NS D4AZ1SMK-F41

Series connection with other devices

The NS series features two safety inputs and two safety outputs, which can be connected in series with other

Pizzato Elettrica safety devices. This option allows the creation of safety chains containing various devices. For

series) can be connected in series while still maintaining the maximum PL e and SIL 3 safety levels.

example, stainless steel safety hinges (HX BEE1 series), RFID sensors (ST series) and door lock sensors (NG

The NS series switches are con‑

structed with redundant electro‑

nics. As a result, the maximum

Pizzato Elettrica CS

series safety module

HX BEE1

HX BEE1

ST DD310MK-D1TNS D4AZ1SMK-F41 ST DD310MK-D1TNG 2D1D411A-F31

RFID actuators with high coding level

The NS series is provided with an electronic system

based on RFID technology to detect the actuator. This

allows to provide each actuator with different coding

and makes it impossible to tamper with a device by

using another actuator of the same series. Millions

of different coding combinations are possible for the

actuators. They are therefore classified as high level coded actuators,

according to EN ISO 14119.

Dustproof

The switch is provided with a through hole for

inserting the actuator. Thanks to this unique fea‑

ture, any dust that enters the actuator hole can

always come out on the opposite side instead of

remaining inside. Moreover, the lock pin is provi‑

ded with a diaphragm seal, making the system

suitable for critical environments with a high level

of dust.

Centring

The switch is provided with a wide

centring inlet for the actuator pin.

This solution makes it easier to

align the actuator and the opening

hole on the head during installa‑

tion. Moreover, this solution dra‑

stically reduces the probability of

a collision between the switch and

the actuator, making it possible to

install the device even on inaccura‑

tely closing doors.

Pizzato Elettrica CS

series safety module

Holding force of the locked actuator

The strong interlo‑

rantees a maximum actuator holding force

of F

= 2100 N.

1max

cking system gua‑

Modularity

The innovative design of the auxiliary releases makes possible a wide

range of combinations of auxiliary releases with lock, emergency rele‑

ase buttons or screwdriver releases with front and rear mounting.

The electrical connection is also highly flexible: outputs are available

with cables as well as with connectors, which can be oriented axially

or laterally.

Head and release devices with variable orientation, not detachable

The upper part of the switch, which contains the

release devices, can be rotated and is permanen‑

tly connected to the lower part, which contains the

outputs for the electrical connection. After loosening

the fastening screws, the individual modules can be

rotated in 90° steps. As a result, a single device can

be used to realise various configurations without the

installation technician needing to concern himself

with the correct assembly of various parts.

The fastening screws are provided with protective

caps to prevent dirt build‑up and thereby simplify

cleaning.

127

General Catalogue Safety 2017-2018

6

Six LEDs for immediate diagnosis

As the LEDs have been designed for

quick immediate diagnosis, the status of

each input and output is highlighted by

one specific LED. This makes it possible

to quickly identify the interruption

points in the safety chain, which device

is released, which door is opened and

any errors inside the device. All of this

at a glance, without needing to decode

complex flashing sequences.

Holding force of the unlocked actuator

The inside of each switch features a

device which holds the actuator in its

closed position. Ideal for all those appli‑

cations where several doors are unlo‑

cked simultaneously, but only one is

actually opened. The device keeps all

the unlocked doors in their position with

a retaining force of 20 N~, stopping any

vibrations or gusts of wind from opening

them.

Function for protecting against recoil forces

If a door is closed too quickly or with so

much force that the recoil would cause

it to open again, a special function in the

NS switch prevents locking. This fun‑

ction prevents the immediate locking of

the door if the lock signal is applied. This

protects the switch against recoil forces

that occur during instantaneous locking.

This serves to protect the switch from

damage and forces the operator to close

the door more gently.

Key release device and emergency release button

The key release device (auxiliary release)

is used to permit unlocking of the actua‑

tor only by personnel in possession of

the key. The device also functions with

no power supply and, once actuated,

prevents the guard from being locked.

The emergency release button (escape

release) allows actuator release and

immediate opening of the door. Gene‑

rally used in machines within which an operator could inadvertently

become trapped, it faces towards the machine interior, to allow the

operator to exit even in the event of a power failure. The button has

two stable states and can be freely extended in length with suitable

extensions (see accessories).

Both devices can be positioned on the four sides of the switch. As a

result, it can be installed both towards the interior and towards the

exterior of the machine.

Protection against tampering

Each actuator of the NS series is supplied

with four protective caps. Not only do the

caps prevent dirt from accumulating and

simplify cleaning, they also block access

to the fastening screws of the actuator.

As a result, standard screws can be used

instead of tamper‑proof screws.

Articulated actuator for inaccurately closing doors

All NS series actuators are articulated, the‑

reby allowing the actuator pin to be safely

guided into the switch through the centring

hole. As a result, the actuator and switch do

not need to be precisely aligned during instal‑

lation. In addition, the device can thereby be

used on doors with a minimum actuation

radius of 150 mm without the actuation pin

needing to be angled.

Front and side mounting

Integrated in the housing of the NS series is a hole for inserting the

actuator pin. Fixing holes are also provided in the robust body for front

and side mounting.

This makes it easier to mount the switch during lateral installation: the

switch is directly mounted without needing to rotate the module that

contains the hole for

inserting the actua‑

tor pin. The fixing

holes can be sealed

with the protective

caps provided for

this purpose. Dirt

deposits and tam‑

pering attempts are

thereby prevented.

High protection degree

These devices are designed to be used in the

toughest environmental conditions and they

pass the IP67 immersion test acc. to EN 60529.

They can therefore be used in all environments

where maximum protection degree of the hou‑

sing is required. Due to their special design,

these devices are suitable for use in equipment subjected to cleaning

with high pressure hot water jets. These devices meet the IP69K test

requirements according to ISO 20653 (water jets with 100 bar and

80°C).

Two safety output actuation modes

Two different activation modes

are available for the switch:

active safety outputs with

guard closed and locked (mode

1) for machines with inertia or

active safety outputs with guard closed (mode 2) for machines without

inertia.

General Catalogue Safety 2017-2018

External device monitoring

On request, the switch can be supplied with

EDM function (External Device Monitoring).

In this case, the switch itself checks the

proper function of the devices connected to

the safety outputs. These devices (usually relays or safety contactors)

must send a feedback signal to the EDM input, which checks that the

received signal is consistent with the state of the safety outputs.

128

6

NS series safety switches with solenoid and RFID technology

Selection diagram

RELEASE AND OPERAT-

ING PRINCIPLE

D•ST D•SE D•CE E•TE

Locked actuator with de-

energised solenoid

key release at front

D•AZ E•ZZ

Locked actuator with de-

energised solenoid

release by means of screwdri‑

ver at front

Locked actuator with

de-energised solenoid

key release at front and

emergency release button at

back

Locked actuator with energised

solenoid

Locked actuator with de-

energised solenoid

release by means of screwdri‑

ver at front and emergency

release button at back

Locked actuator with energised

solenoid

Without release at front and

emergency release button at

back

CONNECTIONS

SMK

SPK

SQK

ACTUATORS

M12 connector,

at bottom

12‑pole

8‑pole for stand‑

alone

connection

8‑pole, for series

connection with Y

connectors

VN NS-F40 VN NS-F41

Low level coded actuator High level coded actuator

M12 connector,

lateral, orientable

12‑pole

DMK

8‑pole for stand‑

alone

DPK

connection

8‑pole, for series

connection with Y

DQK

connectors

Cable, length: 0.2 m, with

M12 connector, at bottom

12‑pole

SM0.2

8‑pole for stand‑

alone

SP0.2

connection

8‑pole, for series

connection with Y

SQ0.2

connectors

Cable, length: 0.2 m, with

M12 connector, lateral,

orientable

12‑pole

DM0.2

8‑pole for stand‑

alone

DP0.2

connection

8‑pole, for series

connection with Y

DQ0.2

connectors

With PVC cable

SA2

SB2

at bottom

12‑pole, length:

2 m

8‑pole, length:

2 m, for

standalone

connections

With PVC cable, lateral,

orientable

12‑pole, length:

DA2

2 m

8‑pole, length:

2 m, for

DB2

standalone

connections

129

product options

Sold separately as

accessory

General Catalogue Safety 2017-2018

Code structure Attention! The feasibility of a code number does not mean the effective availability of a product. Please contact our sales office.

article options

NS D4AZ1SMK-F41E36LP30

6

Operating principle

locked actuator with de‑energised solenoid.

D

mode 1: OS safety outputs active with

locked guard

locked actuator with energised solenoid.

E

mode 1: OS safety outputs active with

locked guard

locked actuator with de‑energised solenoid.

G

mode 2: OS safety outputs active with

closed guard

locked actuator with energised solenoid.

H

mode 2: OS safety outputs active with

closed guard

Inputs and outputs

2 safety inputs IS1, IS2

2 safety outputs OS1, OS2

1 signalling output O3: closed guard

3

1 signalling output O4: locked guard

2 solenoid activation inputs IE1, IE2

1 reset input I3

Note: Supplied only together with actuator

2 safety inputs IS1, IS2

2 safety outputs OS1, OS2

1 signalling output O3: closed guard

4

1 signalling output O4: locked guard

2 solenoid activation inputs IE1, IE2

1 programming / reset input I3

2 safety inputs IS1, IS2

2 safety outputs OS1, OS2

1 signalling output O3: closed guard

5

1 signalling output O4: locked guard

2 solenoid activation inputs IE1, IE2

1 programming / reset input I3

1 feedback input EDM I5

Auxiliary release at front and back

release by means of screwdriver at front

AZ

only available for operating principle D or G

key release at front

ST

only available for operating principle D or G

key release at front and emergency release button

SE

at back

only available for operating principle D or G

release by means of screwdriver at front and

CE

emergency release button at back

only available for operating principle D or G

without release

ZZ

only available for operating principle E or H

Without release at front and emergency release

TE

button at back

only available for operating principle E or H

Actuator extraction force

E36

Actuator

low level coded actuator VN NS‑F40

F40

the switch recognises any type F40 actuator

high level coded actuator VN NS‑F41

F41

the switch recognises one single type F41 actuator

Connection type

K

integrated M12 connector (standard)

0.2

cable, length: 0.2 m, with M12 connector

2

cable, length: 2 m (standard)

…

……………………

10

cable, length: 10 m

Cable or connector type

A

PVC cable 12x0.14 mm

PVC cable 8x0.34 mm

B

for stand‑alone connection

Note: without inputs IS1, IS2, I5 and without output O4

PUR cable, halogen‑free, 8x0.34 mm

E

for stand‑alone connection

Note: without inputs IS1, IS2, I5 and without output O4

M

M12 connector, 12‑pole (standard)

M12 connector, 8‑pole, for stand‑alone connections

P

Note: without inputs IS1, IS2, I5 and without output O4

M12 connector, 8‑pole, for series connection with Y connectors

Q

Note: without inputs IE2, I3, I5 and without output O3

Output direction, connections

D

cable or connector, lateral

S

cable or connector, at bottom

Release button length

for max. 15 mm

wall thickness (standard)

LP30

for max. 30 mm wall thickness

LP40

for max. 40 mm wall thickness

LP50

for max. 50 mm wall thickness

actuator extraction force 20 N

(standard)

actuator freely removable

2

(standard)

2

2

Code structure for actuator

General Catalogue Safety 2017-2018

VN NS-F40

Actuator

low level coded actuator

F40

the switch recognises any type F40 actuator

high level coded actuator

F41

the switch recognises one single type F41 actuator

130

6

NS series safety switches with solenoid and RFID technology

Main features

•Actuation without contact, using RFID

technology

•Digitally coded actuator

•SIL 3 and PL e also with series connection of

up to 32 devices

•Actuator holding force: 2100 N

•SIL 3 and PL e with a single device

•Protection degrees IP67 and IP69K

•Versions with key release and emergency

release button

•6 signalling LEDs

Quality marks:

EC type examination certificate: M6A170475157015

UL approval: E131787

TÜV SÜD approval: Z10170475157014

EAC approval: RU C-IT.AД35.В.00454

In compliance with standards:

EN ISO 14119, EN 60947‑5‑3, EN 60947‑1,

IEC 60204‑1, EN 60204‑1, EN ISO 12100,

IEC 60529, EN 60529, EN 61000‑6‑2,

EN 61000‑6‑3, BG‑GS‑ET‑19, IEC 61508‑1,

IEC 61508‑2, IEC 61508‑3, IEC 61508‑4, SN

29500, EN ISO 13849‑1, EN ISO 13849‑2,

EN 62061, EN 61326‑1, EN 61326‑3‑1,

EN 61326‑3‑2, ETSI 301 489‑1, ETSI 301 489‑3,

ETSI 300 330‑2, UL 508, CSA 22.2 No.14

Compliance with the requirements of:

Machinery Directive 2006/42/EC

EMC Directive 2014/30/EU

RED Directive 2014/53/EU

FCC Part 15

Technical data

Housing

Housing made of glass fibre reinforced technopolymer, self‑extinguishing and shock‑proof

Versions with integrated cable 12x0.14m

lengths from 0.5 … 10 m on request

Versions with integrated M12 stainless steel connector

Versions with 0.2 m cable and M12 connector, other lengths from 0.1 … 3 m on request

Protection degree: IP67 acc. to EN 60529

General data

SIL level (SIL CL): up to SIL 3 acc. to EN 62061

Performance Level (PL): up to PL e acc. to EN ISO 13849‑1

Safety category: up to cat. 4 acc. to EN ISO 13849‑1

Interlock, no contact, coded, with guard locking: type 4 acc. to EN ISO 14119

Level of coding acc. to EN ISO 14119: low with F40 actuator

Safety parameters PFH

System 1.24 E‑09 1671 years e 3 4

Lock (locked guard) 1.23 E‑09 2657 years e 3 4

Interlock (closed guard) 1.22 E‑09 1840 years e 3 4

Locking control 2.29 E‑10 2243 years e 3 4

DC: High

Service life: 20 years

Ambient temperature: ‑20°C … +50°C

Max. actuation frequency

with actuator lock and release: 600 operating cycles/hour

Mechanical endurance: 1 million operating cycles

Max. actuation speed: 0.5 m/s

Min. actuation speed: 1 mm/s

Maximum force before breakage F

Max. holding force F

Maximum clearance of locked actuator: 4 mm

: 1615 N acc. to EN ISO 14119

Zh

Released actuator extraction force: ~ 20 N

Tightening torques for installation: see page 313‑324

Electrical data of inputs IS1/IS2/I3/IE1/IE2/I5/EDM

Rated operating voltage U

Rated current consumption I

: 24 Vdc

e1

: 5 mA

e1

Electrical data of OS1/OS2 safety outputs

Rated operating voltage U

Output type: PNP type OSSD

Maximum current per output I

Minimum current per output I

Thermal current I

Utilization category: DC‑13; U

: 0.25 A

th2

: 24 Vdc

e2

: 0.25 A

e2

: 0.5 mA

m2

Short circuit detection: Yes

Overcurrent protection: Ye s

Internal self‑resettable protection fuse: 1.1 A

Duration of the deactivation impulses at the safety outputs:

Permissible maximum capacitance between outputs: < 200 nF

Permissible maximum capacitance between

output and ground: < 200 nF

Response time upon deactivation of IS1/IS2 inputs: typically 7 ms, max. 15 ms

Response time upon actuator removal: typically 120 ms, max. 200 ms

Electrical data of O3/O4 signalling output

Rated operating voltage U

Output type: PNP

Maximum current per output I

Utilization category: DC‑13; U

Short circuit detection: No

Overcurrent protection: Ye s

Internal self‑resettable protection fuse: 1.1 A

: 24 Vdc

e3

: 0.1 A

e3

RFID sensor data

Assured operating distance S

Assured release distance S

Rated operating distance S

Repeat accuracy: ≤ 10 % s

Differential travel: ≤ 20 % s

Max. switching frequency: 1 Hz

: 2 mm

ao

: 6 mm (actuator not locked)

ar

: 3 mm

n

Power supply electrical data

Rated operating voltage U

Operating current at U

‑ minimum: 40 mA

‑ with activated solenoid: 0.4 A max.

‑ with activated solenoid and all outputs

at maximum power:

Rated insulation voltage Ui: 32 Vdc

Rated impulse withstand voltage U

External protection fuse: type gG fuse 2 A or equivalent device

Overvoltage category: III

Electrical endurance: 1 million operating cycles

Solenoid duty cycle: 100% ED (continuous operation)

Solenoid consumption: 9 W max.

SELV: 24 Vdc ±10%

e

voltage:

e

2

or 8x0.34m2, standard length 2 m, other

IP69K acc. to ISO 20653

from direct high‑pressure and high‑temperature jets)

High with F41 actuator

MTTF

D

: 2100 N acc. to EN ISO 14119

1max

PL SIL Cat

D

=24 Vdc, Ie2=0.25 A

e2

< 300 µs

=24 Vdc, Ie3=0.1 A

e3

10 mm (actuator locked)

n

n

1.2 A

: 1.5 kV

imp

(Protect the cables

131

General Catalogue Safety 2017-2018

Selection table for switches with high level coded actuators

6

Operating principle:

locked actuator with

de‑energised solenoid.

With screwdriver release

Mode 1

OS safety outputs active

with locked and closed

guard

Mode 2

OS safety outputs active

with closed guard

NS D4AZ1SMK-F41 NS E4ZZ1SMK-F41

NS G4AZ1SMK-F41 NS H4ZZ1SMK-F41 NS G4ST1SMK-F41 NS G4SE1SMK-F41 NS G4CE1SMK-F41 NS H4TE1SMK-F41

Selection table for switches

Operating principle:

locked actuator with

de‑energised solenoid.

With screwdriver release

Mode 1

OS safety outputs active

with locked and closed

guard

Mode 2

OS safety outputs active

with closed guard

NS D4AZ1SMK NS E4ZZ1SMK

NS G4AZ1SMK NS H4ZZ1SMK NS G4ST1SMK NS G4SE1SMK NS G4CE1SMK NS H4TE1SMK

Operating principle: locked

actuator with energised

solenoid

Operating principle: locked

actuator with energised

solenoid

Operating principle:

locked actuator with

de‑energised solenoid.

With key release

Operating principle: locked

actuator with de‑energi‑

sed solenoid. With key

release and emergency

release button

Operating principle:

locked actuator with de‑

energised solenoid. With

screwdriver release and

emergency release button

Operating principle: locked

actuator with energised

solenoid. With emergency

release button

NS D4ST1SMK-F41 NS D4SE1SMK-F41 NS D4CE1SMK-F41 NS E4TE1SMK-F41

Operating principle:

locked actuator with

de‑energised solenoid.

With key release

Operating principle: locked

actuator with de‑energi‑

sed solenoid. With key

release and emergency

release button

Operating principle:

locked actuator with de‑

energised solenoid. With

screwdriver release and

emergency release button

Operating principle: locked

actuator with energised

solenoid. With emergency

release button

NS D4ST1SMK NS D4SE1SMK NS D4CE1SMK NS E4TE1SMK

To order a product with lateral connection replace character S with character D in the order codes shown above. Example: NS D4AZ1SMK NS D4AZ1DMK

To order a product with EDM input replace number 4 with number 5 in the codes shown above. Example: NS D4AZ1SMK NS D5AZ1SMK

Legend:

interlock with lock monitoring acc. to EN ISO 14119

Selection table for actuators

The use of RFID technology in NS series devices makes them suitable for several applications. Pizzato

Elettrica offers two different versions of actuators, in order to best suit customers’ specific needs.

Type F40 actuators are all encoded with the same code. This implies that a device associated with an actua‑

tor type F40 can be activated by other actuators type F40.

Level of coding

acc. to

EN ISO 14119

low

high

Article

VN NS-F40

VN NS-F41

General Catalogue Safety 2017-2018

Type F41 actuators are always encoded with different codes. This implies that a device associated with

an actuator type F41 can be activated only by a specific actuator. Another F41 type actuator will not be

recognised by the device until a new association procedure is carried out (reprogramming). After repro‑

gramming, the old actuator F41 will no longer be recognized.

The 2D and 3D files are available at www.pizzato.comAccessories See page 299

Items with code on green background are stock items

132

6

NS series safety switches with solenoid and RFID technology

Complete safety system

The use of complete and tested solutions guarantees the electrical

compatibility between the NS series switches and the safety modules

from Pizzato Elettrica, as well as high reliability. The switches have been

tested with the modules listed in the adjacent table.

+ Vcc

VN NS-F4•

NS series switches can be used as individual devices provided that

the safety outputs be evaluated by a Pizzato Elettrica safety module

(see table for combinable safety modules).

IS1 IS2

NS

OS1 OS2

Pizzato Elettrica CS

series safety module

O3

O4

Switches

Compatible safety

modules

Instantaneous

safety contacts

Safety module

output contacts

Delayed safety

contacts

Signalling

contacts

CSAR-05•••• 3NO / 1NC

CSAR-06•••• 3NO / 1NC

CSAR-08•••• 2NO / /

NS ••••1•••

CSAT-0••••• 2NO 2NO 1NC

CSAT-1••••• 3NO 2NO /

CSMP••••••

CSMF••••••

page 255

page 283

All NS series switches can be connected, provided that compatibility is

checked, to safety modules or safety PLCs with OSSD inputs.

+ Vcc

VN NS-F4•

VN NS-F4•

VN NS-F4•

IS1 IS2

NS

OS1 OS2

IS1 IS2

NS

OS1 OS2

IS1 IS2

NS

OS1 OS2

Pizzato Elettrica CS

series safety module

O3

O4

O3

O4

O3

O4

PLC

Possibility of series connection of multiple switches for simplifying

the wiring of the safety system, whereby only the outputs of the last

switch are evaluated by a Pizzato Elettrica safety module (see table

with compatible safety modules). Each NS series switch is provided

with two signalling outputs which are activated when the guard is

closed (O3) or locked (O4). Depending on the specific requirements

of the system that has been realised, the signals of the signalling

outputs can be evaluated by a PLC.

+ Vcc

VN NS-F4•

VN NS-F4•

VN NS-F4•

IS1 IS2

OS1 OS2

IS1 IS2

OS1 OS2

IS1 IS2

OS1 OS2

Pizzato Elettrica CS MP series

O3

NS

O4

O3

NS

O4

O3

NS

O4

programmable safety module

Possibility of series connection of multiple switches for simplifying

the wiring of the safety system, whereby only the outputs of the last

switch are evaluated by a Pizzato Elettrica safety module of the CS MP

series. Both the safety‑relevant evaluation and the evaluation of the

signalling outputs are performed by the CS MP series.

TheexampleslistedaboverefertoapplicationswithNS••••1•••

Application example on page 253.

Internal block diagram

IE1

f6

IE2

EDM

f5

I5

IN

f1

IS1

IS2

f0

PWR

A2A1

133

The diagram on the side represents the 7 logic functions which

interact inside the device.

Function f0 is a basic function and includes the monitoring of

CODE

f2

f4

f3

the power supply as well as internal, cyclical tests. Function

f1 monitors the status of the device inputs, whereas function

f2 monitors the presence of the actuator within the detection

ACT

areas of the switch.

O3

Function f4 checks the actuator lock condition.

Function f3 is intended to activate or deactivate the safety

LOCK

outputs and check for any faults or short circuits in the outputs.

O4

In the EDM versions, the f5 function verifies the consistency

of the EDM signal during safety output state changes. The safety‑related function, which combines

OUT

the sub‑functions mentioned above, only activates the safety outputs for the switches in mode 1 if

the input signals are correctly applied and the actuator pin is in the safe actuation area in the head and

OS1

locked. The safety outputs for switches in mode 2 are activated if the input signals are correctly applied

OS2

and the actuator pin is in the safe actuation area in the head. The f6 function verifies the coherence of

LED Function

PWR

Power supply / self‑diagnosis

IN

status of safety inputs

OUT

status of safety outputs

ACT

actuator state

LOCK

actuator locked

state of EDM inputs

EDM

(NS•5••1•••)

the enable/disable signals of the actuator lock command. The status of each function is displayed by

the corresponding LED (PWR, IN, OUT, ACT, LOCK, EDM), in such a way that the general device status

becomes immediately obvious to the operator.

General Catalogue Safety 2017-2018

Actuation sequence in mode 1

6

The switch is supplied

with power (PWR LED on,

green), the IS1 and IS2

inputs are enabled (IN LED

on, green), the OS1 and

OS2 safety outputs are

disabled (OUT LED off).

The actuator is outside of

the actuation zone (LED

ACT off).

When the actuator is brou‑

ght inside the safe actua‑

tion area (dark grey area),

the switch turns on the

ACT LED (green). In this

position, the O3 signal‑

ling output (door‑closed) is

activated. The actuator is

not locked (LOCK LED off).

The IE1, IE2 inputs can be

used to lock the actuator

(LOCK LED on, green).

The OS1 and OS2 safety

outputs are enabled (OUT

LED on, green). The O4

signalling output is acti‑

vated at the same time.

The safe actuation area

is extended in order to

allow greater play for the

actuator.

The IE1, IE2 inputs can be

used to unlock the actua‑

tor (LOCK LED off). The

switch disables the OS1

and OS2 safety outputs

and turns off the OUT

LED. The O4 signalling

output is deactivated at

the same time. The safe

actuation area returns to

the initial values.

When the actuator leaves

the actuation limit area,

the device turns off the

ACT LED and the O3

signalling output.

Actuation sequence in mode 2

In contrast to the above mode 2 description, the safety outputs OS1 and OS2 enable when the actuator is detected, and disable when the actuator

is no longer detectable.

Operating states

PWR

IN

OUT

ACT

LOCK

EDM

LED

LED

LED

LED

LED

Legend: = off = on = flashing = alternating colours =indifferent(a)AvailableonlyinversionsNS•5••1•••

Device

LED

state

(a)

Device switched off.

OFF

POWER ONInternal tests upon activation.

Safety inputs of the device not active.

RUN

Activation of safety inputs.

RUN

Safety inputs incoherence.

Recommended action: check for presence and/or wiring

RUN

of inputs.

Incoherence of solenoid activation inputs IE1, IE2.

RUN

Recommended action: check for presence and/or

wiring of inputs.

Auxiliary release activated.

RUN

Deactivate the auxiliary release to lock the actuator

Actuator in safe area. O3 signalling output active.

RUN

Actuator in safe area and locked; O3 and O4 outputs

RUN

active.

Mode 1

Activation of safety inputs IS1, IS2. Actuator in safe area

RUN

and locked. O3, O4, OS1 and OS2 outputs active.

Mode 2

Activation of safety inputs IS1, IS2. Actuator in safe area.

RUN

O3, OS1 and OS2 outputs active.

Rapid flashing: supply voltage too high.

Slow flashing: supply voltage within the tolerance limits

RUN

Error on safety outputs.

ERROR

Recommended action: check for any short circuits

between the outputs, outputs and ground or outputs

and power supply, then restart the device.

Actuator detection error. Check the physical integrity of

ERROR

the device and, in case of failure, please replace the en‑

tire device. If undamaged, realign the actuator with the

switch and restart the device.

Internal error.

ERROR

Recommended action: restart the device. If the failure

persists, replace the device.

EDM signal active (external relay off)

RUN

EDM signal not active (external relay on)

RUN

ERROR

Error in the EDM

Description

a

function

a

a

External device monitoring (EDM)

+

A1

IS1

NS •5••1•••

OS1

K1

-

TheNS•5••1•••version,inadditiontomaintai‑

ning the operating and safety characteristics of

the NS series, allows control of forcibly guided

NC contacts of contactors or relays controlled

by the safety outputs of the switch itself. As an

alternative to the relays or contactors you can

use Pizzato Elettrica expansion modules CS

ME‑03.

See page 245. This check is carried out via the

EDM input (External Device Monitoring as defi‑

ned in EN 61496‑1) of the switch.

VN NS-F41

VN NS-F41

VN NS-F41

+

This version, with the IS safety inputs, can be

used at the end of a series of NS switches, up

to a maximum number of 32 devices, while

maintaining the maximum PL e safety level and

acc. to EN ISO 13849‑1 and SIL 3 safety level

acc. to EN 62061.

This solution allows you to dispense with the

safety module connected to the last device in

the chain. If present, the EDM function must be

used.

IS2

OS2

K2

-

A2

+

IS1 IS2

NS •4••1•••

OS1 OS2

IS1 IS2

NS •4••1•••

OS1 OS2

IS1 IS2

NS •5••1•••

OS1 OS2

K1 K2

-

EDM

+

O3

O3

O3

EDM

PLC

General Catalogue Safety 2017-2018

134

6

NS series safety switches with solenoid and RFID technology

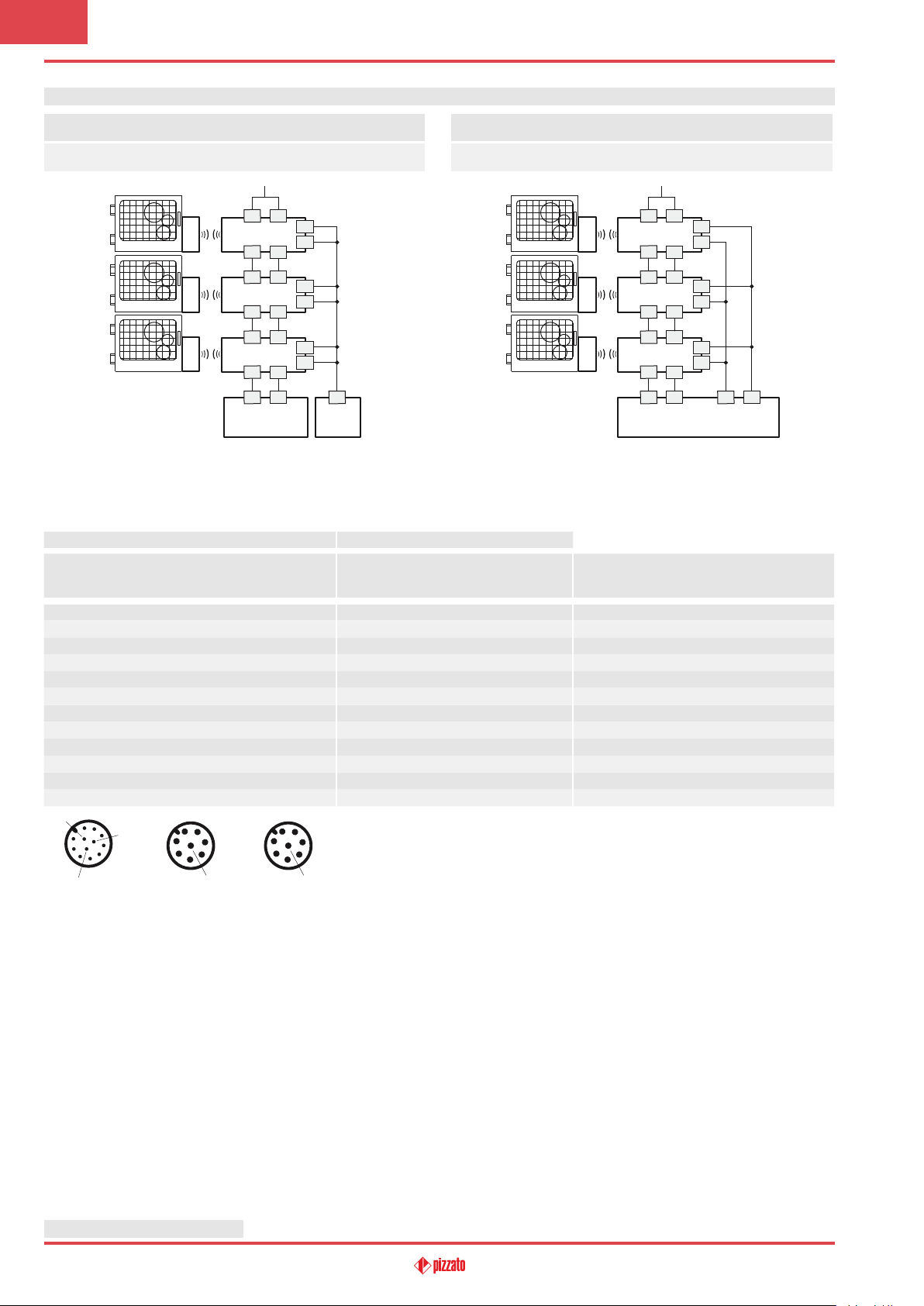

Series connection of several switches

Lock detection function (guard locked)

2 channels / Category 4 / up to SIL 3 / PL e

Locking control function

1 channel / Category 2 / up to SIL 2 / PL d

VN NS-F4•

OS1 OS2

VN NS-F4•

OS1 OS2

VN NS-F4•

OS1 OS2

+ Vcc

IS1 IS2

IS1 IS2

IS1 IS2

Ixx Ixx Ox

IE1

NS

IE2

IE1

NS

IE2

IE1

NS

IE2

CS

CS AM

CS FS

Lock detection function (guard locked)

2 channels / Category 4 / up to SIL 3 / PL e

Locking control function

2 channels / Category 4 / up to SIL 3 / PL e

+ Vcc

VN NS-F4•

VN NS-F4•

VN NS-F4•

IS1 IS2

NS

OS1 OS2

IS1 IS2

NS

OS1 OS2

IS1 IS2

NS

OS1 OS2

Ixx Ixx

IE1

IE2

IE1

IE2

IE1

IE2

OS1 OS2

CS MP

Connector pin assignment Internal cable wiring

6

5

M12 connector,

8-pole

series connection

with “Y” connectors

1

7

2

3

5

4

8

6

Cable

12x0.14 mm

external Ø 6 mm

2

Cable

8x0.34 mm2

external Ø 7 mm

Connection

(a) Available for NS•5••1•••versiononly

(b) Available for 8‑pole connector, not available for the end of a

chain with Y connectors.

M12 connector,

12-pole

M12 connector,

8-pole

stand-alone

connection

3 3 3 White Blue A2 Supply input 0 V

10 8 8 Purple Red IE1 Solenoid activation input

12 5 / Red‑Blue Purple IE2 Solenoid activation input

5 2 / Pink Black O3 Signalling output, actuator inserted

9 / 5(b) Red / O4 Signalling output, actuator inserted and locked

8 6 / Grey purple‑white I3 Actuator programming input / reset

1 1 1 Brown Brown A1 Supply input +24 Vdc

2 / 2 Blue / IS1 Safety input

6 / 6 Yellow / IS2 Safety input

11 / / Grey‑Pink / I5 EDM input (a)

4 4 4 Green Red‑White OS1 Safety output

7 7 7 Black Black‑White OS2 Safety output

1

9

10

2

3

8

12

7

6

4

5

11

1

7

2

3

4

8

Female connectors see page 299

135

General Catalogue Safety 2017-2018

6

Dimensional drawings

Switch

NS ••AZ1SMK

NS ••ZZ1SMK

40

9.2

24 17.6

128 25

190.8

5 2

10.8

37.8

Actuator VN NS-F4•

36

23

6.5

32

51

11 8

5.2

27 24

40

5.3

M12x1

20

7 2

51

Switch

NS ••AZ1DMK

NS ••ZZ1DMK

178

128 25

25

59.4

39.4

15

Ø

R > 150

40

9.2

5 2

17.6

24

10.8

5.3

M12x1

13.8

40

Switch

NS ••ST1SMK

NS ••SE1SMK

40

38.2

204

12837.8

5 2

NS ••CE1SMK

NS ••TE1SMK

39.3

30

21.4

Ø38

4.8

24 20.6

10.8

5.3

Accessories

Article Description

VF KLB300

All values in the drawings are in mm

Switch

NS ••ST1DMK

NS ••SE1DMK

42.6

40

22.8

M12x1

191.2

40

38.2

12825

5 2

NS ••CE1DMK

NS ••TE1DMK

Ø38

20.6

24

10.8

39.3

30

4.8

M12x1

21.4

5.3

13.8

42.6

40

22.8

Set of two locking keys

Extra copy of the locking keys to be

purchased if further keys are needed

(standard supply: 2 units).

The keys of all switches have the same

code. Other codes on request.

Extensions for release button

Article Description Drawing

11

M

10

11

M

10

11

M

10

38

VN NG-LP30

VN NG-LP40

VN NG-LP50

VN NG-ERB

Metal extension for rele‑

ase button. For max. wall

thickness of 30 mm

Metal extension for rele‑

ase button. For max. wall

thickness of 40 mm

Metal extension for rele‑

ase button. For max. wall

thickness of 50 mm

Red metal release button

Series connection

To simplify series connections of the devices,

various M12 connectors are available that allow

complete wiring.

This solution significantly reduces installation

times while at the same time maintaining the

maximum safety levels PL e and SIL 3 for the

interlocking function.

For further information see page 304.

OS2

OS1

10

M

10

M

10

M

A2

A1

70 max

13

Ø

20

10

13

Ø

30

10

13

Ø

20

20

10

‑ Metal extensions can be combined with one another to achieve

the desired length.

‑ Do not exceed an overall length of 70 mm between the release

button and the switch.

M10

10

4.8 9

‑ Use medium‑strength thread locker to secure the extensions

IE

Items with code on green background are stock items

General Catalogue Safety 2017-2018

The 2D and 3D files are available at www.pizzato.com

136

Loading...

Loading...