Pitney Bowes DA300 User Manual

Quick Setup Instructions

for your AddressRightTM Printer DA300

What’s What

1. H-Block Separators

2. Input Area

3. Interface Panel

a. Power Switch

b. Power Cord

c. Parallel Connector

d. Serial Connector

4. Wire Frame Input Stacker

5. Material Prop and Lock Knob

6. Wireframe Slide

7. Wireframe Feed Angle Lock

Knob

8. Wireframe Slide Lock Lever

(Not Shown)

9. Feed Fence

10.Control Panel

11.Stacker Tray

12.Output Area

13.Exit Rollers (Not Shown)

14.Top Cover

5

6

7

8

Interface Panel

123 (see figure below)4

9

3d

3a

3b

14 13

12

11

10

3c

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

How to Set Your Printer Up

1. Set the H-Block Separators to the thickness of your material.

2. Center the wireframe input stacker under your material.

3. Set the feed angle of the wireframe to about 45 degrees for standard weight materials. Set it

lower for heavier materials, higher for lighter materials.

4. Set the feed fence to the width of your material plus 1/16th inch.

5. Fan (aerate) your material. Load your material (envelope flaps down and trailing, bottom edge

feeding first).

6. Set the material prop so it’s about even with the top of the stack.

7. Adjust the media thickness lever to its mid position.

8. Adjust the exit rollers so they overlap the edges of your material by 1/4 inch.

9. Print a test piece. Readjust media thickness lever to get best print quality.

10.Install the DA300 print driver and Envelope Designer™Plus application.

The following pages explain each step in a general way. The DA300 Operator Guide has complete

instructions.

SV61037 Rev. A 5/03 ©2003 Pitney Bowes Inc. All rights reserved. Printed in USA

1

Set the Separator Gap

1. Loosen the lock knobs to unlock all three

H-Blocks.

2. Lift the blocks to their highest position

and

lock in place.

3. Place a sample piece of material between

the separator fingers (the lower section of

the

H-Blocks) and the feed roller.

4. Lower only the H-Blocks that come in

direct contact with the material and let

them touch the material.

5. Lock each H-Block in place.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Separator Fingers

2

3

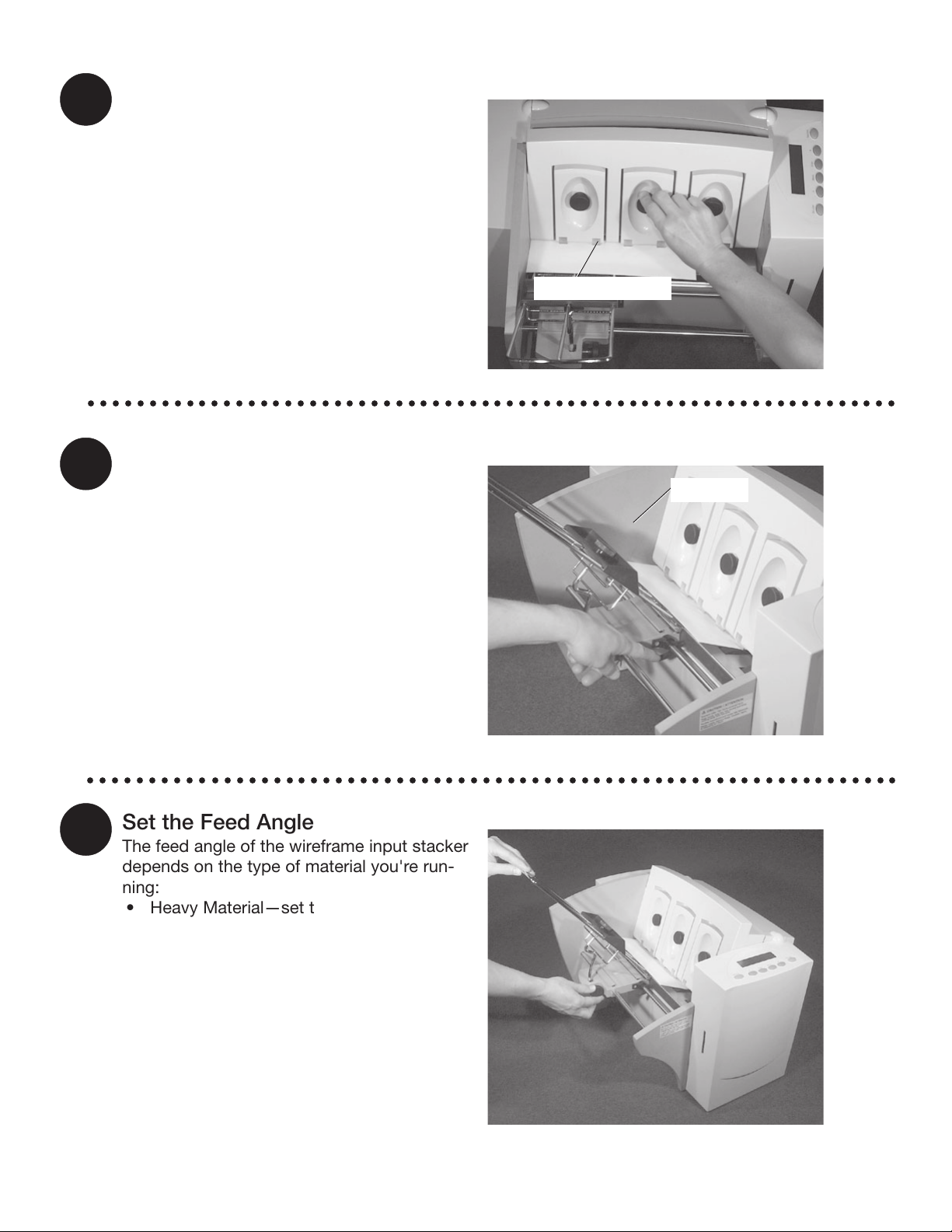

Center the Wireform under the

Material

1. Place a sample piece of material in the

feed area, up against the rear wall.

2. Push down on the wireframe lock lever

to free the wireframe slide.

3. Center the wireframe under your sample

piece.

4. Pull up on the lock lever to secure the

wireframe.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Rear Wall

Set the Feed Angle

The feed angle of the wireframe input stacker

depends on the type of material you're running:

• Heavy Material—set to a low angle (down)

• Standard material—set to the center (45

degree angle)

• Light material —set to a high angle (up)

To make the adjustment:

1. Loosen the lock knob on the wireframe

slide.

2. Move the wireframe up or down as required.

3. Tighten the lock knob to secure the

wireframe.

2

Loading...

Loading...