Page 1

Document Inserting System

DI500/DI600

Operator Guide

US/Canada English Version

Page 2

FCC Compliance

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to part 15 of the FCC rules. These limits

are designed to provide reasonable protection against interference when

the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instruction manual, may cause interference

to radio communications. Operation of this equipment in a residential area is

likely to cause interference, in which case the user will be required to correct

the interference at his own expense. Use only a shielded interface cable to

operate this equipment with a printer or other peripheral device.

CAUTION: Changes or modifications to this equipment not expressly

approved by the party responsible for compliance (Pitney Bowes) could void

the user’s authority to operate the equipment.

Canada EMC Compliance

This Class A digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du

Canada.

SV40221 Rev. A 9/04

©2004 Pitney Bowes Inc. All rights reserved. This guide may not be

reproduced in whole or in part in any fashion or stored in a retrieval system

of any type or transmitted by any means, electronically or mechanically,

without the express, written permission of Pitney Bowes.

We have made every reasonable effort to ensure the accuracy and

usefulness of this manual; however, we cannot assume responsibility

for errors or omissions or liability for the misuse or misapplication of our

products.

Due to our continuing program of product improvement, equipment and

material specifications as well as performance features are subject to

change without notice. Your inserter system may not have some of the

features described in this book.

E-Z Seal and PacPilot are trademarks or registered trademarks of Pitney

Bowes Inc. ENERGY STAR is a reg is tered trademark of the United States

Environmental Pro tec tion Agency.

Printed in the USA or Canada.

Page 3

Table of Contents

Pitney Bowes Contact Information List v

Chapter 1 Introduction

Safety ................................................................................1-2

To The Operator ................................................................1-3

Machine Configurations .....................................................1-4

Machine Identification ........................................................1-6

PacPilot™ Control Panel ...................................................1-8

Control Panel Keys .................................................... 1-8

Mail Piece Icon Tree ................................................ 1-10

Common Terms ...............................................................1-14

Chapter 2 Using the Menus

The Home Screen .............................................................2-2

The Menu Structure ...........................................................2-4

iSV40221 Rev. A

Page 4

Table of Contents

Chapter 3 Operator Functions

About this Chapter .............................................................3-2

Connecting Power .............................................................3-2

Running a Job ...................................................................3-3

SwiftStart™ ........................................................................3-6

Manual Feed ......................................................................3-9

Setting the Sheet Feeders ...............................................3-12

Setting the Envelope Feeder ...........................................3-14

Setting the Insert Feeder(s) .............................................3-16

Filling the Envelope Sealer ..............................................3-18

Menu ................................................................................3-19

Language ................................................................. 3-19

Display Adjustments ................................................. 3-19

Safe Seal ................................................................. 3-19

System Information .................................................. 3-19

Chapter 4 Supervisor Functions

About this Chapter .............................................................4-2

Supervisor Access Code ................................................... 4-2

Create Job .........................................................................4-3

Edit Job ..............................................................................4-4

Create From ......................................................................4-6

Delete Job .........................................................................4-7

OMR Menu ........................................................................4-8

System Menu .....................................................................4-8

Manual Feed Option .................................................. 4-8

ii SV40221 Rev. A

Page 5

Table of Contents

Chapter 5 Optical Mark Recognition (OMR)

OMR Availability ................................................................5-2

What is OMR? ...................................................................5-2

OMR Marks Available ........................................................5-3

OMR Mark Options ............................................................5-6

OMR Specifications ...........................................................5-8

Creating, Deleting and Viewing OMR Codes ..................5-10

Create New OMR Code ...................................................5-11

Delete OMR Code ...........................................................5-13

View OMR Code ..............................................................5-14

Creating an OMR Job ......................................................5-15

OMR Scanner Adjustments ............................................5-18

Chapter 6 Troubleshooting

Troubleshooting Tips .........................................................6-2

General Troubleshooting ...................................................6-3

Machine ..................................................................... 6-3

Envelopes .................................................................. 6-4

Sheets ........................................................................ 6-5

Inserts ........................................................................ 6-6

Double Detect ............................................................ 6-7

Clearing Material Stalls ......................................................6-8

The Manual Advance Knob ........................................ 6-8

Removal/Replacement of Sheet Feeder Trays .......... 6-9

Removal/Replacement of Insert Tray(s) .................... 6-9

Access to Internal Areas 1 to 5 ................................ 6-10

Access to Area 6 ...................................................... 6-12

Access to Areas 7 and 8 .......................................... 6-12

Access to Removeable Paper Path ......................... 6-13

Access to Top Cover (Sheet Feed Area) .................. 6-13

Access to Envelope Exit Area .................................. 6-14

Access to Envelope Inserting/Sealing Area ............. 6-14

Envelope Stop Position ............................................ 6-15

iiiSV40221 Rev. A

Page 6

Table of Contents

Chapter 7 Reference

Specifications ....................................................................7-2

Sheet Feeders ........................................................... 7-2

Fold Type and Overall Thickness Limits .................... 7-3

Insert Feeders ............................................................ 7-4

Envelope Feeder ........................................................ 7-4

Envelope Sealer ......................................................... 7-6

Drop Stacker .............................................................. 7-6

Material Requirements ............................................... 7-6

Machine Specifications .............................................. 7-7

Changing the Envelope Sealer Unit Felts ..........................7-8

Service .............................................................................7-10

Index I-i

iv SV40221 Rev. A

Page 7

Pitney Bowes Contact

t

Information Lis

USA Contacts

Product Name - DI500 or DI600

For frequently asked questions, go to:

www.pb.com and click on Customer Support.

To place requests for service or training, go to:

www.pb.com and click on My Account.

To order PB supplies and accessories, go to:

www.pb.com and click on Online Store.

To view and pay invoices online, go to:

www.pb.com and click on My Account.

To view inventory, go to:

www.pb.com and click on My Account.

For direct questions, call: 1.800.522.0020. Customer

Service Representatives are available Monday through

Friday, 8:00 AM - 8:00 PM ET.

Canada Contacts

Product Name - DI500 or DI600

For frequently asked questions or to order supplies, go to:

www.pitneybowes.ca

For direct questions, call: 1.800.672.6937. Customer

Service Representatives are available Monday through

Friday, 8:30 AM - 4:00 PM ET.

vSV40221 Rev. A

Page 8

vi SV40221 Rev. A

Page 9

1 • Introduction

This chapter pre sents important safety information and describes the

main controls and features of your machine.

Important Safety Notes ...................................................... 1-2

To The Operator ................................................................ 1-3

Machine Configurations ..................................................... 1-4

Machine Identification ........................................................ 1-6

PacPilot™ Control Panel ................................................... 1-8

Control Panel Keys ..................................................... 1-8

Mail Piece Icon Tree ................................................. 1-10

Common Terms ............................................................... 1-14

1-1SV40221 Rev. A

Page 10

1 • Introduction

Important Safety Notes

Follow these basic safety precautions when operating this machine:

• Use only Pitney Bowes approved supplies, in particular aerosol

dusters. Improper storage and use of aerosol dusters or

flammable aerosol dusters, can cause an explosive-like condition

that could result in a personal injury and/or property damage.

Never use aerosol dusters labeled flammable and always read

instructions and safety precautions on the duster container.

• To obtain Pitney Bowes supplies, please contact our Supply

Line or on the web at PB.com (see the Pitney Bowes Contact

Information List at beginning of this guide). Material Safety Data

Sheets can also be acquired from the Supply Line or PB.com.

• Read all instructions before operating the equipment. Only use

the equipment for its intended purpose.

• Operation of this equipment without periodic maintenance will

inhibit optimum operating performance and could cause the

equipment to malfunction. Contact your Pitney Bowes Customer

Service Representative for required service schedule.

• Use the power cord supplied with the machine. Plug it and all

other supplied power cords into a properly grounded wall outlet

that is located near the machine and easily accessible, meaning

it is free from obstruction and there is enough room around the

unit for servicing.

• The power cord wall plug is the primary means of disconnecting

the machine from the AC supply.

• Do not use an adapter plug on the line cord or wall outlet. Do not

remove the ground pin from the line cord.

• Avoid using wall outlets controlled by wall switches or shared

with other equipment. Do not route the AC power cord over

sharp edges, or allow it to be trapped between furniture and/or

furniture and the wall.

• Avoid touching moving parts or materials while the machine is

in use. Keep hands, loose clothing, jewelry, and long hair away

from all moving parts.

• Do not remove covers. Covers enclose hazardous parts that

should only be accessed by properly trained service personnel.

1-2 SV40221 Rev. A

Page 11

Introduction • 1

• Immediately report to Pitney Bowes Service any damaged or

nonfunctioning components. The unit may be unsafe for use.

• To prevent overheating, do not cover the vent openings. Allow

ample spacing around the unit for ventilation.

NOTE: Always follow the specific occupational safety and health

standards for your workplace.

To the Operator

Your new Folding/Inserting Machine has an easy to follow user

interface which makes it simple to set up, whilst offering the following

features:

• Envelope seal/no seal/safe seal.

• Fully automatic material separation on sheet feeders.

• Fully automatic fold adjustments.

• Fully automatic envelope separation.

• Fully automatic Double Detect, when selected.

• Fold only option (fold without insertion).

• Fully automatic insertion of single and multiple sheet inserts

(on models fitted with insert feeders only).

• Option of single fold, C fold, Z fold and double fold.

• 20 Job recall facility - User programmable.

• SwiftStart™ - allows you to quickly execute and save simple

jobs without programming.

• Linked Feeding - multiple feeders can be linked to allow

continuous operation.

• OMR functionality - storing up to 10 codes (on models where

OMR is enabled).

• Load on the fly operation.

• Manual Feed facility for occasional ‘one-off’ jobs.

1-3SV40221 Rev. A

Page 12

1 • Introduction

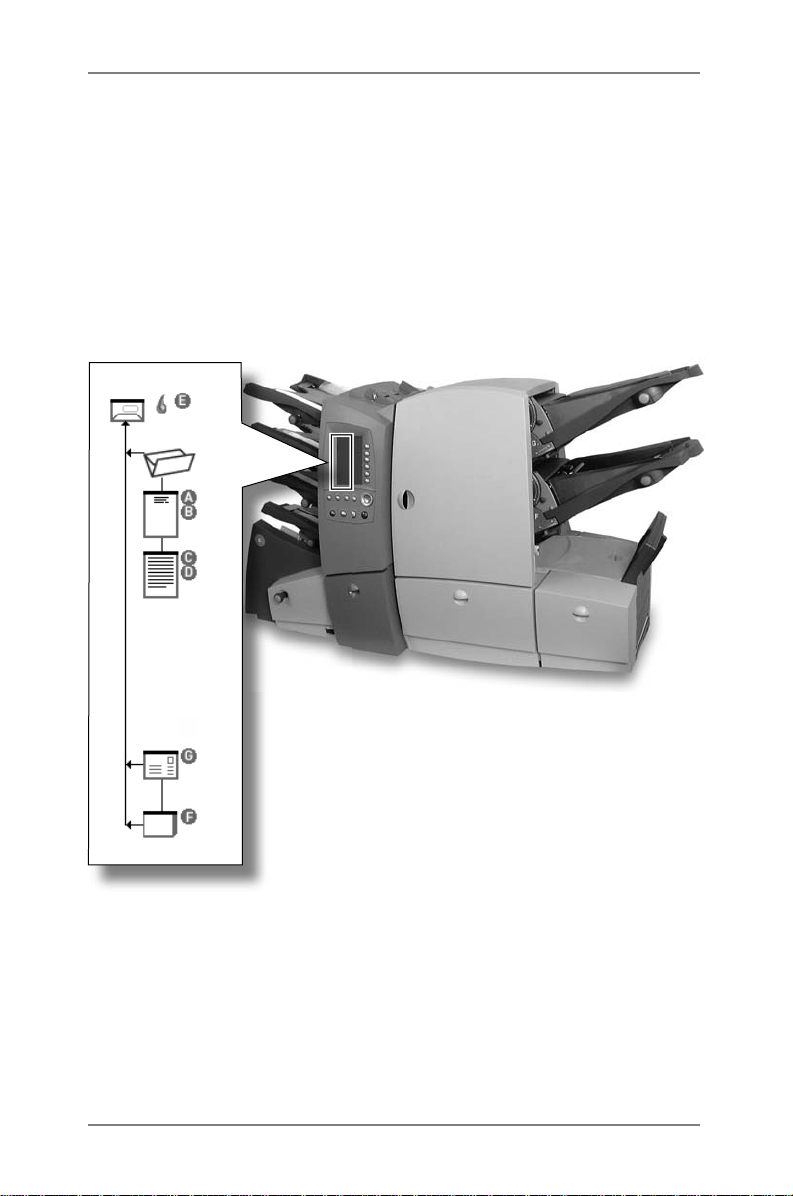

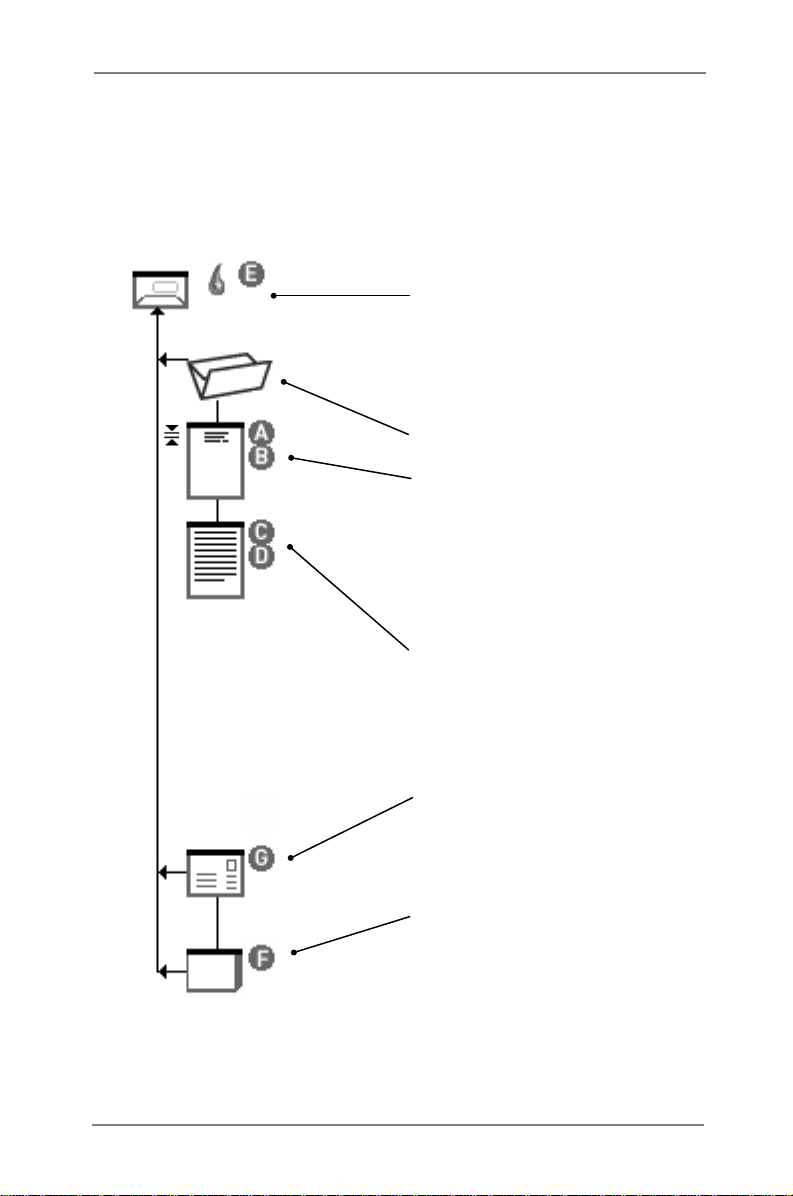

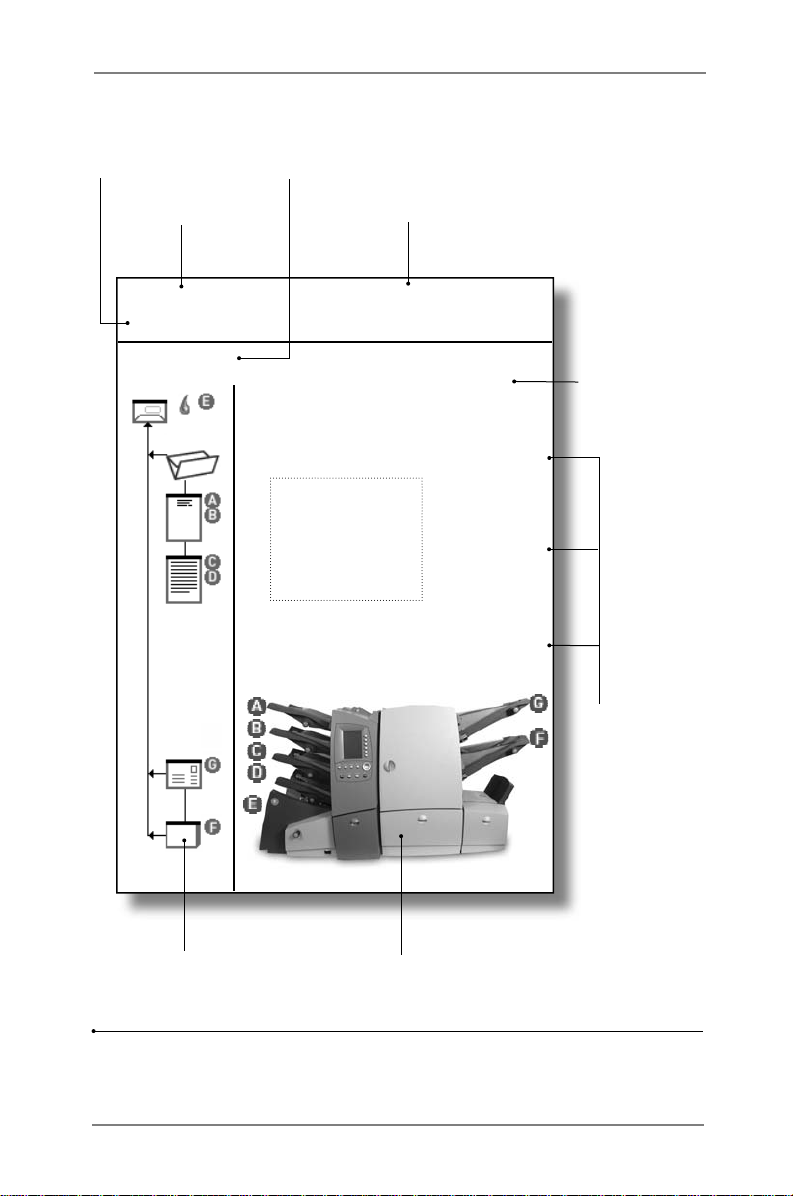

Machine Configurations

The following machine configurations are available, depending on

your local market:

• Two Sheet Feeders Only

• Four Sheet Feeders Only

• Two Sheet Feeders and One Insert Feeder

• Two Sheet Feeders and Two Insert Feeders

• Four Sheet Feeders and One Insert Feeder

• Four Sheet Feeders and Two Insert Feeders

Each feeder location has its own letter designation which remains

the same irrespective of machine configuration. Therefore, machine

configurations with less than the full complement of feeders will use

feeder designations which are not in alphabetical sequence – this is

normal.

The processing speed will also vary depending on machine

configuration. See ‘Specifications’ in Chapter 7 for further details.

The illustration on the next page shows feeder locations and

designations.

In addition, an Optical Mark Recognition (OMR) option can be added

to any model. This allows control of machine functions and Mail

Piece make-up by ‘scanning’ material passing through the machine

for machine readable marks (OMR Marks). For further information,

refer to Chapter 5 of this guide.

This guide covers all models. If a function is dependent on machine

configuration, the accompanying text will explain this.

1-4 SV40221 Rev. A

Page 13

Introduction • 1

Sheet Feeders

A

B

C

D

E

Envelope Feeder

Feeder Configuration

Insert Feeders

Manual Feeder

H

G

F

1-5SV40221 Rev. A

Page 14

1 • Introduction

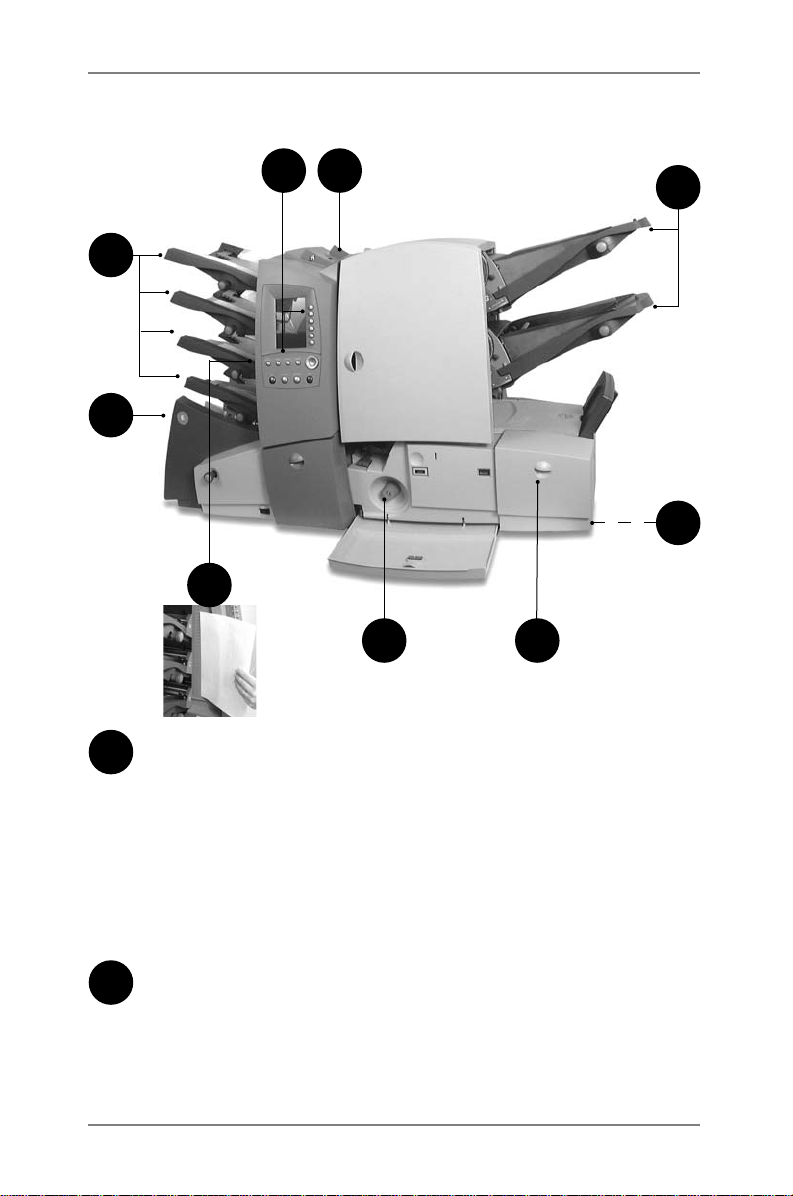

Machine Identification

32

1

9

8

7 6

Sheet Feeders

1

Use these feeders to feed sheets that require folding. They

automatically detect if more than one sheet feeds (double

detect), giving security to your mailings.

Depending on the job being run and availability of feeders,

there also is an option to ‘link’ these feeders so that when

the first feeder runs out of material, feed will automatically

switch to the next linked feeder. This allows a higher volume of

material to be processed before refilling is required.

PacPilot™ Control Panel

2

This is where you enter commands to run the machine or

configure Job Settings. The control panel display also shows

you the machine status, loading instructions and details of the

job. See 'Control Panel' on the page 1-8 for more details.

4

5

1-6 SV40221 Rev. A

Page 15

Introduction • 1

Manual Feeder (also known as Convenience Feeder or Daily

3

Mail Feeder)

Use this feeder to manually feed stapled or unstapled sets of

up to 5 sheets (see specifications, page 7-2). The machine

waits for each set to be manually fed before folding and

inserting the set automatically into the envelope. A Supervisor

can also configure the machine to place insert(s) within the set

if Insert Feeder(s) are fitted.

Insert Feeder(s) (not on all model configurations)

4

Use these feeders to add additional inserts to your envelope.

Inserts fed from these feeders cannot be folded by the

machine, so they must already be folded or be a size that

does not require folding.

Drop Stacker (not illustrated)

5

A fold down stacker is located at the exit from the machine

to collect the finished Mail Pieces. This unit can be latched

against the machine when not in use.

Power stacker (not illustrated)

This is an optional extra which automatically collects and

neatly stacks finished Mail Pieces. It locates at the exit of the

machine, in place of the Drop Stacker.

Sealer Bottle

6

The sealer bottle is located inside an opening cover at the

front right side of the machine. It provides sealing solution to

the Envelope Sealer.

Manual Advance Knob

7

The Manual Advance Knob is located inside an opening cover

at the lower center of the machine. It can be used to manually

turn the machine mechanisms to assist in clearing a material

stoppage.

Measuring Scale

8

The scale is located on the left side of the machine near the

sheet feeders as an aid in measuring material and envelopes.

Envelope Feeder

9

This feeder feeds envelopes into the inserting area where they

are filled with the material requested from the other feeder(s).

1-7SV40221 Rev. A

Page 16

1 • Introduction

PacPilot™ Control Panel

Control Panel Keys

Screen Keys

Navigation Keys

Reset Counters

If only piece count is displayed, press this key to reset the piece

count to zero. If both piece and batch counters are displayed,

pressing this key allows either or both counters to be reset.

Help (not available in some markets)

Press this key to view an electronic Quick Reference Guide giving

you quick access to basic information regarding operation of your

machine.

Cancel

Press this key to take you back to the previous screen. If you have

made changes or defined settings on the screen you are cancelling,

these will be lost. Multiple presses of the Cancel key will step you

back through the screens you have visited until you get back to the

Home Screen.

1-8 SV40221 Rev. A

Page 17

Introduction • 1

Home

Press this key to take you back to the Home Screen. The Home

Screen is where you can run jobs and is the start point for accessing

the menus.

Start

Starts automatic operation.

Trial Piece

Press this key to run test piece(s) so that you can check the machine

setup. Trial Piece(s) must be run before automatic operation can be

commenced using the Start key. If double detection is in use, the

machine calibrates itself automatically as it runs the Trial Piece(s).

If the job includes an Outer Envelope, it will be unsealed so that the

contents can be easily checked.

Clear Deck

Press this key to drive the material through and out of the system. It

can be used to clear the machine ready for automatic operation after

a stoppage has occurred, etc.

Stop

Stops automatic operation at the end of the next cycle.

Navigation Keys (▲▼◄► OK)

These keys are used to move a highlighted area around the display.

Once the desired area is highlighted, press the OK key to select it.

The ▲ and ▼ navigation keys can also be used to change values of

machine settings.

Screen Keys

These are the six round keys located directly to the right of the

display. These keys correspond to the changeable options on the

display alongside them and therefore are not labelled.

1-9SV40221 Rev. A

Page 18

1 • Introduction

Mail Piece Icon Tree

The Mail Piece Icon Tree is located on the left side of the display.

It displays the Mailing Object Icons required, based on the Job

Definition.

The icons inform you which feeders to load, the type of object (sheet,

insert, etc.) to be loaded into each designated feeder and the loading

orientation of each object. It is therefore extremely important that you

become familiar with the icons themselves and the make-up of the

Mail Piece Icon Tree.

Loading Instructions

The ▲ and ▼ navigation keys can be used to scroll through the Mail

Piece Icon Tree. When an item is highlighted, the machine will give

you the loading instructions associated with that item.

When you have viewed the loading instructions, press Home or

Cancel to return to the Home Screen or press Start or Trial Piece to

immediately begin processing.

1-10 SV40221 Rev. A

Page 19

Introduction • 1

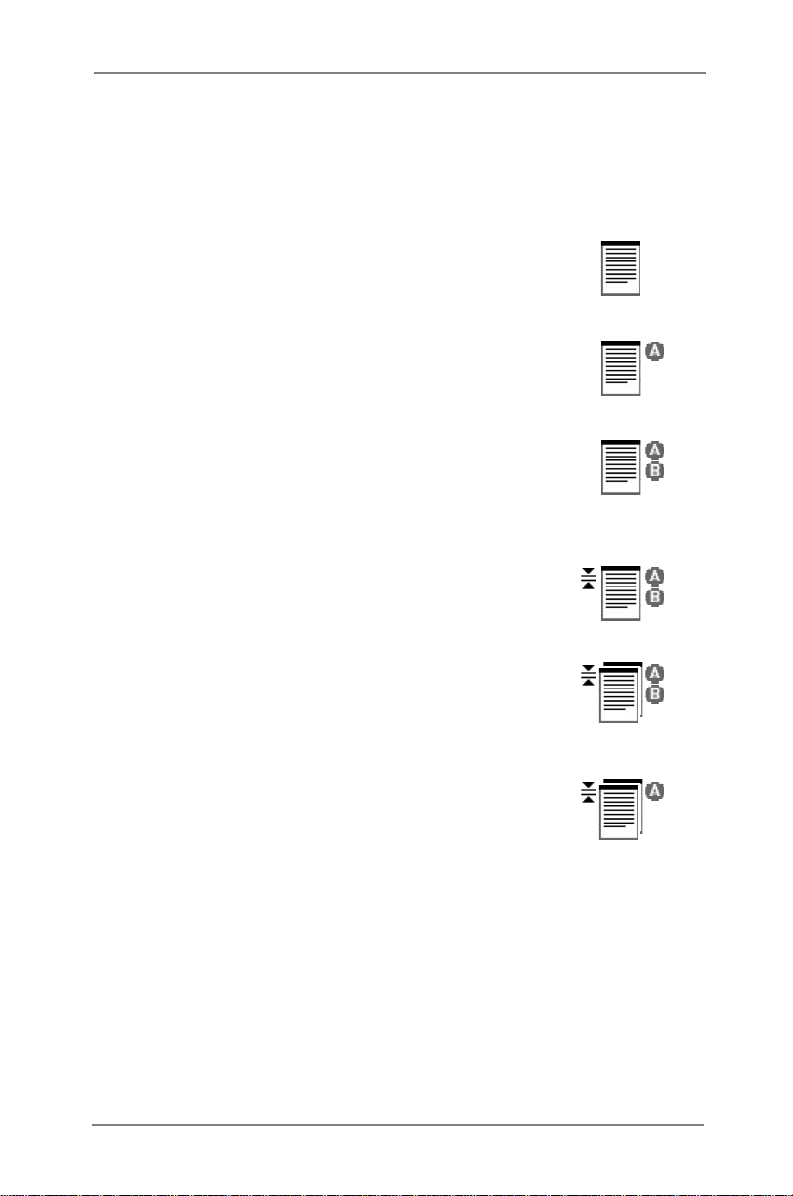

Mail Piece Icon Tree Icons

Each Mailing Object Icon has one darker edge either at the top or

bottom that indicates the leading edge of the object when loaded into

the assigned feeder. The leading edge of an object is the edge that

feeds into the machine first.

For example, a sheet that must be loaded face

up with the top of the sheet leading would be

represented by a “face-up” sheet icon containing a

“leading edge” line on top.

A feeder assignment letter (A to G) will be placed

alongside the Mailing Object Icon to indicate which

feeder the object should be loaded into.

Two or more feeder assignment letters alongside a

single Mailing Object Icon indicate that linked feeders

have been selected. The item should be loaded in

all the feeders indicated. When one feeder becomes

empty, feed will automatically switch to the next

linked feeder and so on, in a continuous cycle.

If Double Detect is in use, the Double Detect Icon will

appear immediately to the left of the relevant Mailing

Object Icon.

If any Sheet Feeder(s) are programmed to feed

Pre-Collated Sets (multiple sheets), a modified icon

indicating multiple sheets will appear, together with

a number showing the number of sheets in the PreCollated Set.

On an Optical Mark Recognition (OMR) job, a

variable number of pages might be fed under

control of the OMR marks and so a small letter ‘n’

will appear in place of the number. Also, an asterisk

(*) will be displayed in the Mail Piece Icon Tree to

remind you that the job is an OMR job.

Lines between the Mailing Object Icons indicate the flow of material

through the machine.

3

n

Refer to the table on the following page as a reference to all the

icons that might appear on the Mail Piece Icon Tree.

1-11SV40221 Rev. A

Page 20

1 • Introduction

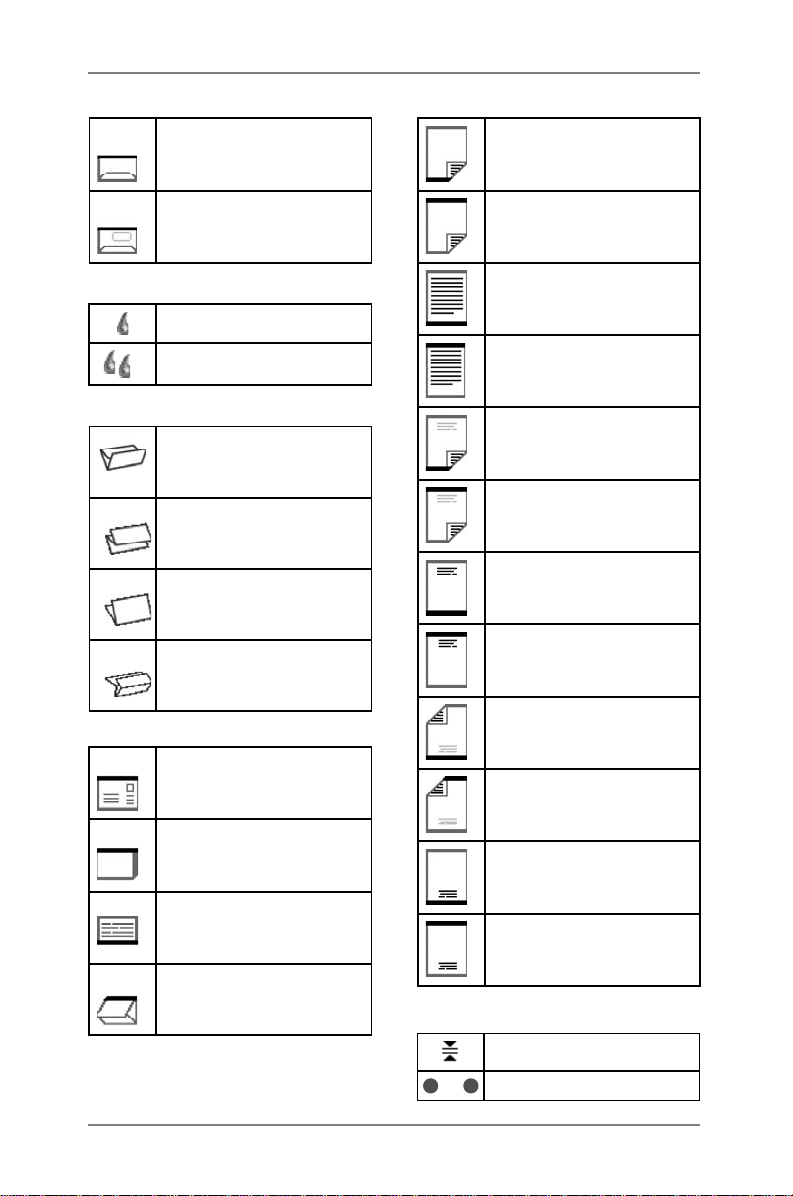

Envelope Icons

No Window,

Flap side up,

Flap Last

Window,

Flap side up,

Flap Last

Seal Icons

Seal On

Safe Seal On

Fold Icons

C Fold

(letter fold)

Z Fold

(accordion fold)

Single Fold

Double Fold

Insert Icons

Reply envelope,

Flap side down,

Flap First

Booklet,

Face Down,

Bound Edge First

Slip,

Face Up,

Bottom First

Pre-Folded Insert,

Closed Side First

Sheet Icons

No address,

Face Down,

Bottom First

No address,

Face Down,

Top First

No address,

Face Up,

Bottom First

No address,

Face Up,

Top First

Top address,

Face Down,

Bottom First

Top address,

Face Down,

Top First

Top address,

Face Up,

Bottom First

Top address,

Face Up,

Top First

Bottom address,

Face Down,

Bottom First

Bottom address,

Face Down,

Top First

Bottom address,

Face Up,

Bottom First

Bottom address,

Face Up,

Top First

Other Icons

A

Double Detect On

H

Feeder Designators

to

1-12 SV40221 Rev. A

Page 21

Introduction • 1

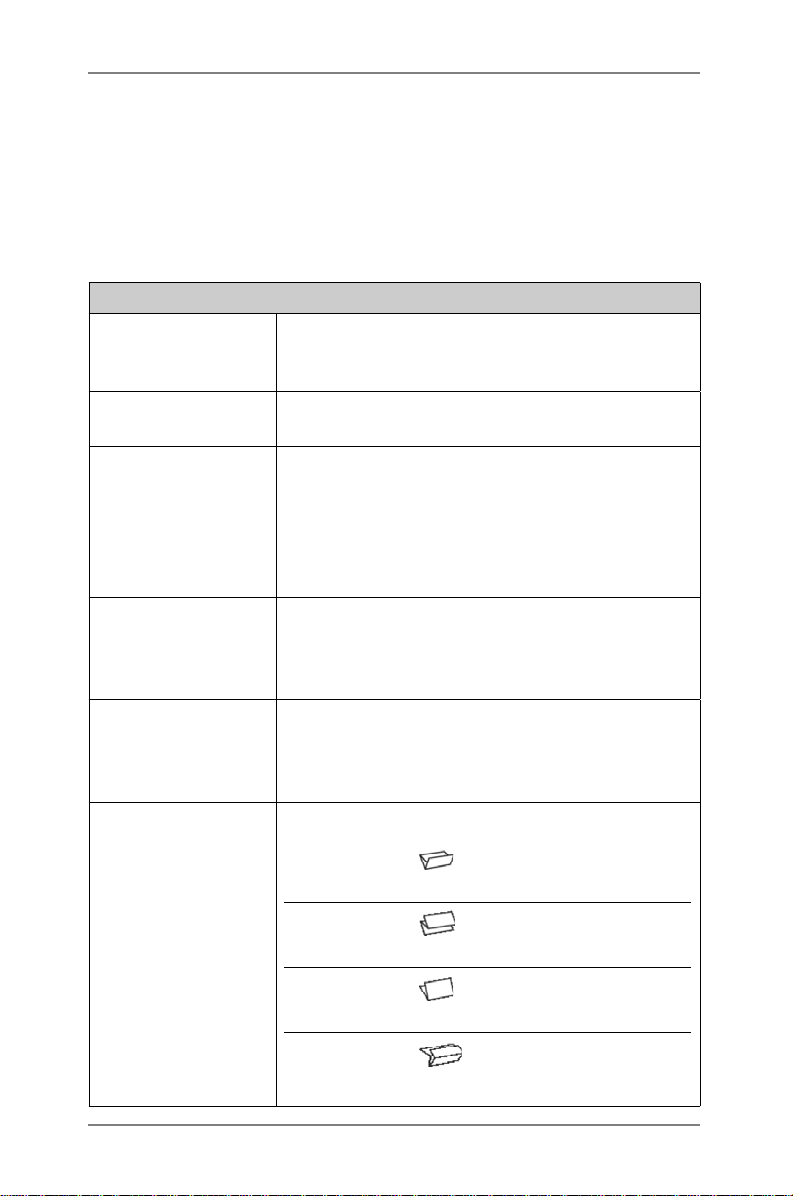

Mail Piece Icon Tree Example

An example Mail Piece Icon Tree is shown below. This explains the

information that is available and how it assists you in loading and

running a job.

Window Envelope

loaded Flap Side Up

fed Flap Last

Envelope sealing turned on

loaded into feeder E

C Fold selected

Prime Sheet with Top Address

loaded Face Up

fed Top First

loaded into feeders A and B

feeders A and B Linked

Double Detect turned on

Additional Sheet

loaded Face Up

fed Top First

loaded into feeders C and D

feeders C and D Linked

Reply Envelope

loaded Flap Side Down

fed Flap First

loaded into feeder G

Booklet

loaded Face Down

fed Bound Edge First

loaded into feeder F

1-13SV40221 Rev. A

Page 22

1 • Introduction

Common Terms

Throughout the machine screens and this guide, standard terms are

used to describe the elements of the Mail Piece and functions of the

equipment.

It is therefore important that you fully understand the following basic

terms to get the best from your machine:

MATERIAL

Sheet A single piece of paper that will require folding

by the machine before it is placed into an

envelope.

Pre-Collated Set A set of sheets printed in a collated sequence

i.e. sheet 1, sheet 2, sheet 3, etc.

Stack A pile of paper as received from the printer

that will be loaded into a feeder (or feeders)

on the machine. A stack might consist of

numerous individual Sheets or numerous

Pre-Collated Sets, depending on how it was

printed.

Prime Sheet or

Prime Set

Additional Sheet

or Additional Set

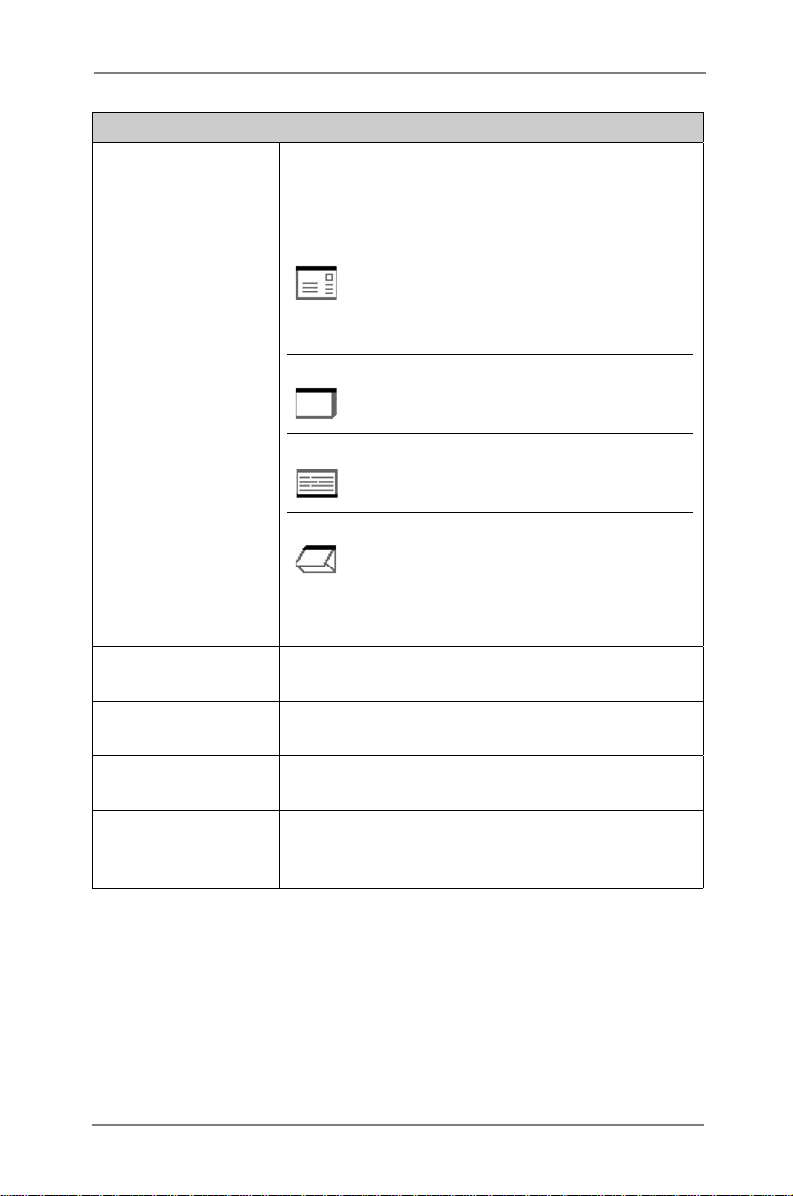

Fold Type The style of fold to be applied:

This sheet or set normally contains the

address. It will be positioned closest to the

envelope window, or the front face of a

windowless envelope.

Additional sheet(s) or set(s) can be added

to the Prime Sheet or Prime Set. They will

be fed from other Sheet Feeder(s) and are

placed into the envelope behind the Prime.

C Fold

Z Fold

Single Fold

Double Fold

1-14 SV40221 Rev. A

also know as ‘standard’

fold.

also known as

‘accordion’ fold.

one fold applied (usually

folded in half).

folded in half and then

in half again.

Page 23

Introduction • 1

MATERIAL (continued)

Insert An item that doesn’t require folding before

being placed into an envelope. There are four

kinds of Inserts:

Reply Envelope A return envelope

placed into the Outer

Envelope with the

other Mail Piece

contents.

Booklet An item with a

stapled and folded

binding edge.

Slip A single thickness

piece of paper or

card.

Pre-Folded Insert A sheet that has

been folded prior to

loading and requires

no further folding by

the machine.

Outer Envelope The envelope which contains all the items

placed into it by the machine.

Mail Piece A single assembled article of mail, usually an

envelope with correct contents.

Fan The process of flicking through a stack of

material to separate the items prior to loading.

Shingle The method of loading Inserts into a feeder in

a partially overlapped manner, like tiles on a

roof.

1-15SV40221 Rev. A

Page 24

1 • Introduction

MACHINE FUNCTIONS

Home Screen The initial screen displayed after turning

power on. From this screen you can select

pre-programmed Job Definitions, enter the

menu functions or run the machine.

Pressing the Home key on the Control Panel

will return you to this screen at any time.

Job Definition The collection of settings that define how a

Mail Piece is to be created by the machine.

Up to 20 Job Definitions can be stored for

instant recall.

Mail Piece Icon

Tree

Trial Piece Test piece run by the machine before

Safe Seal A modified sealing mode that allows better

Linked Feeders Allows more than one feeder to be configured

Optical Mark

Recognition

(OMR)

Situated down the left side of the display.

A graphical representation of the items that

make up the currently selected Job Definition.

automatic operation can be started. A Trial

Piece allows the machine to calibrate itself

and the Mail Piece make-up to be checked.

sealing of ‘poor’ envelopes. Safe Seal will

allow more time for the envelope flap gum to

soften, but will slow machine operation.

to run the same Stack. When the first feeder

runs out of material, feed will automatically

switch to the next ‘linked’ feeder, and so on,

in a continuous cycle. This allows empty

feeder(s) to be loaded while another linked

feeder is feeding material.

The process of controlling machine functions

and Mail Piece make-up by ‘scanning’

material passing through the machine for

machine readable marks (OMR Marks).

1-16 SV40221 Rev. A

Page 25

2 • Using the Menus

This chapter explains the Home Screen and the menu structure

accessed via the PacPilot™ Control Panel

The Home Screen ............................................................. 2-2

The Menu Structure ........................................................... 2-4

2-1SV40221 Rev. A

Page 26

2 • Using the Menus

The Home Screen

The Home Screen is the first screen shown on the display after the

machine has finished powering up.

The last Job Definition selected is displayed with the relevant Mail

Piece Icon Tree on the left hand side.

The ▲ and ▼ navigation keys can be used to scroll through the

icon tree and highlight individual items. As you do this, the loading

instructions associated with the highlighted item will be shown.

From this screen you can run the job displayed. Alternatively, press

the relevant Screen Key to:

Select Another Job from those already programmed into

the machine. See page 3-3.

Initiate the SwiftStart™ feature. See page 3-6.

Select the Menu Screen Key to access:

Operator Functions. See page 3-19.

Supervisor Functions. See page 4-2.

You can also use the Manual Feed feature. See page 3-9.

2-2 SV40221 Rev. A

Page 27

Using the Menus • 2

Machine

Status

Screen

Name

Home Piece Count:

READY Batch Count:

Invoice Job

Use ▼, ▲ to view loading

instructions

Name of

selected Job

Counter(s)

Job comments

text area

Select Job

SwiftStart

Menu

Instructional

Text

>

>

>

Screen

Key

Selections

Mail Piece Icon Tree Machine Graphic

The Home Screen

2-3SV40221 Rev. A

Page 28

2 • Using the Menus

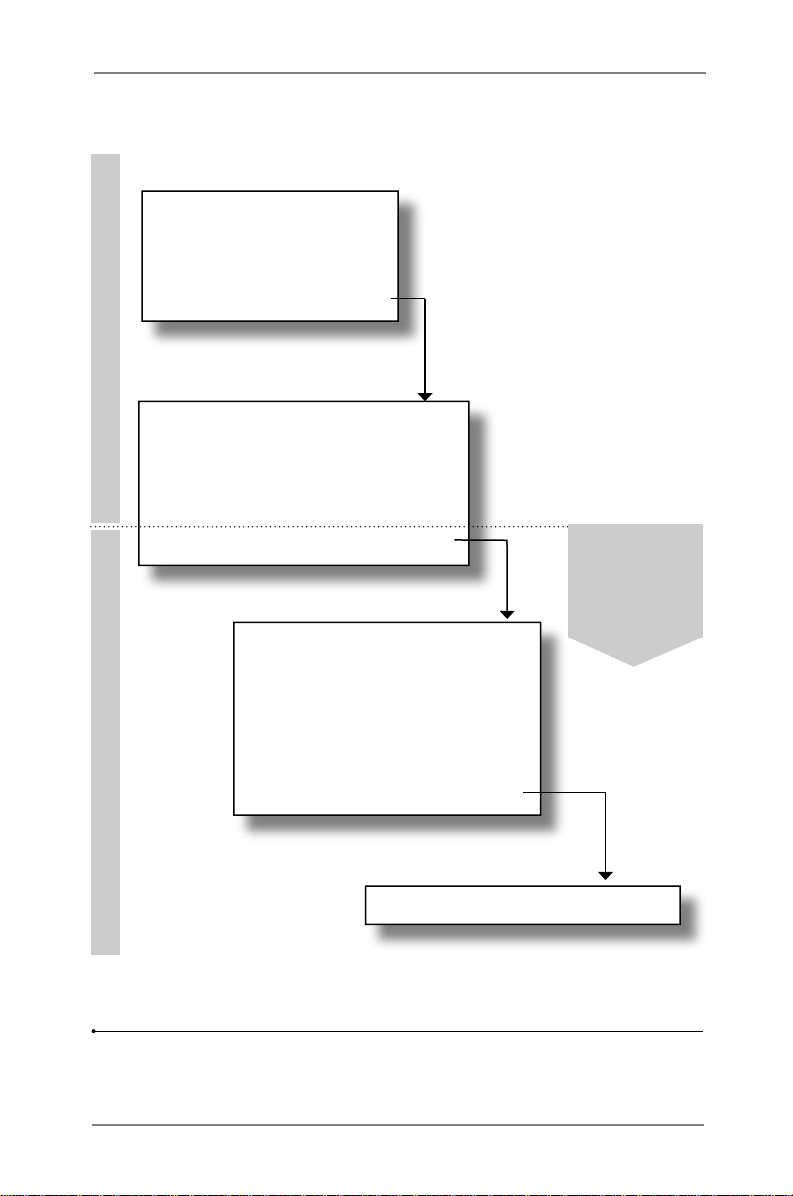

The Menu Structure

The diagram on the facing page shows the menu structure available

when you press the Menu Screen Key.

You will see that the menu follows a logical structure with similar

functions grouped together.

The menu structure is split into two sections:

The first section is available to all Operators and contains

settings and adjustments that might be required when

running jobs on the machine.

The second section is only available to a 'Supervisor' upon

entry of a Supervisor Access Code. This section allows

supervisors to create, edit and delete jobs as well as set

more advanced features.

The following two chapters in this guide; 'Operator Functions' and

'Supervisor Functions' give details of the functions available to each

level of user.

Use this diagram as a quick reference to find the function(s) that you

require, then refer to the relevant page in this guide.

Each screen can be identified by its title located in the top left corner.

2-4 SV40221 Rev. A

Page 29

Home Screen

Select Job (p.3-3) >

SwiftStart (p.3-6) >

Menu (p.3-19) >

Language (p.3-19) >

OPERATOR FUNCTIONS SUPERVISOR FUNCTIONS

Display Adjustments (p.3-19) >

Safe Seal (p.3-19) >

System Information (p.3-19) >

Supervisor Functions (p.4-1) >

Create Job (p.4-3) >

Edit Job (p.4-4) >

Create From (p.4-6) >

Delete Job (p.4-7) >

OMR Menu (p.4-8) >

Systems Menu (p.4-8) >

Using the Menus • 2

Menu items

below this

line require

a Supervisor

Access Code

The Menu Structure

Manual Feed Option (p.4-8) >

2-5SV40221 Rev. A

Page 30

2 • Using the Menus

2-6 SV40221 Rev. A

Page 31

3 • Operator Functions

This chapter lists the functions that can be carried out by an

Operator. Primarily, this includes selecting Job Definitions, running

the various operator modes and loading material.

About this Chapter ............................................................. 3-2

Connecting Power ............................................................. 3-2

Running a Job ................................................................... 3-3

SwiftStart™........................................................................ 3-6

Manual Feed ..................................................................... 3-9

Setting the Sheet Feeders ............................................... 3-12

Setting the Envelope Feeder ........................................... 3-14

Setting the Insert Feeder(s) ............................................. 3-16

Filling the Envelope Sealer .............................................. 3-18

Menu ............................................................................... 3-19

Language .................................................................. 3-19

Display Adjustments .................................................. 3-19

Safe Seal .................................................................. 3-19

System Information ................................................... 3-19

3-1SV40221 Rev. A

Page 32

3 • Operator Functions

About this Chapter

This chapter explains functions on the machine that can be carried

out by an Operator. This includes:

• Selecting and running a pre-programmed Job Definition

• Using the SwiftStart™ mode

• Using the Manual Feeder

• Loading the feeders

• Filling the sealer

Functions that can only be carried out after entry of a Supervisor

Access Code are described in the next chapter, ‘Supervisor

Functions’.

Connecting Power

Read the safety information on

page 1-2 before connecting the machine.

Connect the power cord to the socket on the back of the machine.

Plug the power cord into a suitable power outlet. Make sure the

power outlet is near the machine and is easily accessible.

Turn the machine power switch

ON.

3-2 SV40221 Rev. A

Page 33

Operator Functions • 3

Running a Job

Selecting a Job

This section assumes the job to be run has already been created by

a Supervisor. If the job has not been created, refer to Create Job on

page 4-3.

When the machine is turned ON, a ‘ Startup Screen’ showing details

of your machine and contact details will be displayed for a short time.

After a few seconds, the Home Screen will appear. The last Job

Definition selected will be loaded, with the message ‘Trial Piece

Required’ displayed at the top of the screen.

If the job loaded is not the one required, press the Select Job

Screen Key. A list of Job Definitions that have been created will

appear alphabetically on the screen. Then...

• If you are certain which job you want, press the Screen Key

alongside the desired job to select it immediately.

• If you need confirmation of the job details, use the ▲ and

▼ keys to scroll through the list. As each job is highlighted,

the Mail Piece Icon Tree and Job Comments (if entered) will

change to reflect the highlighted job. When you are certain

which job you want, press the corresponding Screen Key to

select it.

TIP: In either case, if the job you require is not on the

first screen, use the ◄ and ► keys to move to the

screen containing the required job.

The selected job’s Mail Piece Icon Tree will now be

displayed. This shows the job make-up and the loading

orientation of material in the feeders. The message

‘Trial Piece Required’ will be shown at the top of the

display.

TIP: Once a job is selected, you can use the ▲ and ▼

keys to scroll through the icons on the Mail Piece Icon

Tree. As each icon is highlighted, loading instructions

related to the particular item will be displayed.

3-3SV40221 Rev. A

Page 34

3 • Operator Functions

Load material into all the feeders as indicated by the Mail Piece Icon

Tree (refer to setting the feeders on pages 3-12 to 3-17).

If required, reset the item and/or batch counters by pressing the

Reset Counters key.

If necessary, fill the Sealer with sealing solution or water (see page

3-18).

If you are running an Optical Mark Recognition (OMR) job, the OMR

Scanner must be aligned to the OMR marks on the material being

run. Refer to page 5-18 for instructions.

Now run a Trial Piece as described in the following section.

Running a Trial Piece

A Trial Piece is required to enable you to check the Mail Piece

contents and to allow the machine to calibrate itself for the material

being run.

Press the Trial Piece key. The machine runs a single Mail Piece

which exits the machine unsealed so that you can check the

contents. The machine then asks if the Trial Piece is OK.

If the Trial Piece is OK, select Yes and follow the instructions in the

section ‘ Automatic Processing’ on the following page.

If the Trial Piece is NOT OK, select No and follow the on-screen

instructions to correct the error. You can adjust the address position,

fold panel length and/or the envelope stop position. The envelope

stop position will rarely need adjusting - for more information, see

page 6-15.

Once the adjustment is made and any further Trial Piece is OK, you

will be asked if you wish to save the changed settings as part of the

Job Definition.

If you choose Yes...

The machine will save the changed setting(s) as part of the

current job. Next time the original Job Definition is selected,

the modified adjustment(s) will be remembered.

A Supervisor Access Code (see page 4-2) will be requested,

as you are editing an existing Job Definition.

3-4 SV40221 Rev. A

Page 35

Operator Functions • 3

If you choose No...

The adjustment(s) you have just changed will only be

retained while you are running the current job. If another Job

Definition is selected or if power is turned off, next time the

original Job Definition is selected, the modified adjustment(s)

will have returned to the value saved within the Job

Definition.

TIPS:

If you reload material during a run which seems to have

different characteristics (weight, colour shade, etc.), or if

you have any problems with double detect, run another

Trial Piece. This allows the machine to recalibrate the

double detect function for the new material in case the

batches vary slightly.

When loading a C-folded insert into feeder F or G,

load it with the open edge last and the double sheet

thickness face up.

Automatic Processing

After confirming a Trial Piece is OK...

Press the Start key to commence automatic operation.

The machine will operate until:

material runs out

the Stop key is pressed

the batch count is reached (if batch count is being used)

Batch Count

If the Batch Count function was set when the job was created, the

machine will stop automatically after processing the required number

of Mail Pieces. Remove the batch of Mail Pieces and press Start to

recommence processing.

3-5SV40221 Rev. A

Page 36

3 • Operator Functions

SwiftStart™

SwiftStart™ allows you to load material into the feeders and run a

simple job with minimal setup information.

The job can then either be run without saving it to the machine’s

memory, or a Supervisor can name and save the Job Definition for

future recall as and when required.

TIP:

SwiftStart™ can be used as a way to quickly program a

new Job Definition. Load material and run SwiftStart™.

A Supervisor can save the new job and then use

the Edit Job function (see page 4-4) to make minor

changes, if necessary.

Constraints and Requirements

• Only use closed flap envelopes.

• Feeds only single sheets from each Sheet Feeder.

• This mode cannot be used to run fold only or inserts only.

• You cannot link Sheet Feeders in this mode.

• The Envelope Sealer is always on (except for the Trial

Piece).

• The Batch Count is always off.

• The Maximum Sheet Length is 11”.

• Can run #10 and 6” x 9” sized envelopes.

• This mode will not work with OMR.

Loading Material for SwiftStart™

Loading Sheet Feeders

Depending on your envelope depth, the machine will automatically

select the fold type – Single or C (standard) fold.

For example, an 8-1/2” x 11” sheet inserted into a #10 envelope will

receive a C fold, whereas a 8-1/2 x 11” sheet inserted into a 6” x 9”

envelope will only require a Single Fold.

3-6 SV40221 Rev. A

Page 37

For a C fold Job: Load the

Sheet Feeders from the

top feeder downwards, in

sequence (first sheet in top

feeder).

Load Sheets Face Up and Top

First.

For a Single fold job: Load the

Sheet Feeders from the bottom

feeder upwards, in sequence

(first sheet in bottom feeder).

Load Sheets Face Down and

Bottom First.

Operator Functions • 3

Loading Insert Feeder(s)

If either or both Insert Feeders are loaded with material when

SwiftStart is selected, the machine will feed the Inserts and make

them part of the SwiftStart™ job.

For a single Insert, load Insert Feeder F. For two Inserts, load Insert

Feeders F and G.

Booklets must be loaded into Insert Feeder F only and should be

loaded with the binding edge first.

Pre-folded Inserts should be fed with the open edge last.

Loading Envelope Feeder

Envelopes are loaded into Envelope

Feeder E flap side up, flap last.

3-7SV40221 Rev. A

Page 38

3 • Operator Functions

SwiftStart™ Operation

Load material as previously described and select SwiftStart. The

machine will feed an envelope and depending on the depth of the

envelope, will automatically select the fold type – Single or C fold.

A Trial Piece is automatically produced, enabling you to check the

job and to allow the machine to calibrate itself for the material being

run.

During this process, if the material in any of the feeders is too

heavy, the Double Detect for the relevant feeder(s) will be turned off

automatically. This will be indicated by a message on the display.

The machine will ask if the Trial Piece is OK.

If the Trial Piece is OK, select Yes and follow the instructions in the

section ‘Saving a SwiftStart™ Job’ below.

If the Trial Piece is NOT OK, select No and follow the on-screen

instructions to correct the error. You can adjust the address position,

fold panel length and/or the envelope stop position. The envelope

stop position will rarely need adjusting - for more information, see

page 6-15.

Saving a SwiftStart™ Job

After confirming a Trial Piece is OK, you will be given the option to

save the current SwiftStart™ setup as a Job Definition for recall in

future. This function requires Supervisor level access (see page 4-2).

If you do NOT save the SwiftStart™ setup, it will only be retained

while you are running the current job. If another Job Definition is

selected or if power is turned off, the SwiftStart™ settings will be lost.

Automatic Processing

Whether you have chosen to save the SwiftStart™ job or not, you

can now commence automatic processing in the normal way:

Press the Start key to commence automatic operation.

The machine will operate until either material runs out or the Stop

key is pressed.

3-8 SV40221 Rev. A

Page 39

Operator Functions • 3

Manual Feed

Manual Feed allows you to feed stapled or unstapled sets of up

to 5 sheets of 20 lb. (80g/m2) to a maximum total weight of

100 lb. (400g/m2). The sets are fed by hand, one set at a time, for

processing by the machine.

Using the Manual Feed automatically turns off all Sheet Feeders.

You can, however, use the Insert Feeder(s) if they have been

enabled by a Supervisor using the Manual Feed Option explained

on page 4-8.

Constraints and Requirements

• Only use closed flap envelopes.

• This mode cannot be used to run fold only or inserts only.

• Sheet Feeders do not operate in this mode.

• The Envelope Sealer is always on (except for the Trial

Piece).

• The Batch Count is always off.

• Sets should contain sheets of the same length.

• This mode will not work with OMR.

Loading Material for Manual Feed Mode

Loading Insert Feeder(s)

Insert Feeder(s) will only operate if they have been enabled by a

Supervisor using the Manual Feed Option explained on page 4-8 of

this guide.

For a single Insert, load Insert Feeder F. For two Inserts, load Insert

Feeders F and G.

Booklets must be loaded into Insert Feeder F only and should be

loaded with the binding edge first.

Pre-folded Inserts should be fed with the open edge last.

Loading Envelope Feeder

Envelopes are loaded into Envelope Feeder E flap side up, flap last.

3-9SV40221 Rev. A

Page 40

3 • Operator Functions

Manual Feed Operation

Make sure Envelopes and Inserts (if required) are loaded as

previously described.

You must now decide which way round to feed the set into the

Manual Feeder, as this depends on the type of fold the set requires.

Depending on your Envelope depth and Sheet length, the machine

will automatically select the fold type – Single, C or double fold.

For example:

8-1/2” x 11” sheets inserted into a #10 envelope will receive a C fold.

5-1/5” x 8-1/2” sheets inserted into a 6” x 9” envelope will only

require a Single fold.

Sheets over 12” (305mm) long inserted into a #10 envelope will need

a Double fold.

Use the following list as a guide for feeding the Manual Feed set:

C Fold Feed the set Face Up, Top First

Single Fold Feed the set Face Down, Bottom First

Double Fold Feed the set Face Up, Top First

Set the Manual Feeder side

guides to control the sets to

be fed. The guides are selfcentering.

Take one set and feed it gently

into the Manual Feeder until the

machine automatically starts

and draws the set from you.

A Trial Piece is produced, enabling you to check the job setup. The

machine will ask if the Trial Piece is OK.

If the Trial Piece is OK, select Yes and refer to ‘Manually Feeding

Further Sets’ on the next page.

If the Trial Piece is NOT OK, select No and follow the on-screen

instructions to correct the error. You can adjust the address position,

fold panel length and/or the envelope stop position. The envelope

stop position will rarely need adjusting - for more information, see

page 6-15.

3-10 SV40221 Rev. A

Page 41

Operator Functions • 3

Manually Feeding Further Sets

After confirming a Trial Piece is OK, the machine will remember it’s

settings and process further manually fed sets automatically.

While the motor runs, the machine will remain in Manual Feed mode.

If no further sets are fed whilst the motor is running, after a brief

delay, the motor stops and the machine reverts to the previous Job

Definition selected.

If you wish to leave Manual Feed mode while the motor is running,

press Cancel twice.

The Manual Feed settings will be lost once a pre-programmed Job

Definition is selected or SwiftStart™ is operated.

3-11SV40221 Rev. A

Page 42

3 • Operator Functions

Setting the Sheet Feeders

Sheet Feeders A to D feed sheets that require folding by the

machine.

The Mail Piece Icon Tree for the job being run will show which

feeders need to be loaded and the sheet orientation. If you need help

understanding the sheet icons, refer to page 1-11 of this guide.

The First Sheet or Set (normally containing the address) will be fed

from the top feeder for C or Double Fold jobs and from the bottom

feeder for single or Z fold jobs. This will be indicated by the Mail

Piece Icon Tree.

Sheet Feeders can feed single Sheets or Pre-Collated Sets,

depending on job setup. The Mail Piece Icon Tree will tell you the

quantity of sheets that the machine is programmed to run from

each feeder if Pre-Collated sets are programmed. If you need help

understanding the terms Sheet or Pre-Collated Set, refer to page

1-14 of this guide.

1. Adjust the side guides to

the width of the material

being fed using the Side

Guide Adjustment Knob,

then back-off 1/4 of a turn.

This will set the correct

clearance between the

guides and sheets.

2. Take the relevant Stack of

sheets and fan it to ensure

individual sheets are not

stuck together.

3-12 SV40221 Rev. A

Page 43

Operator Functions • 3

3. Jog the stack back into

alignment.

4. The Mail Piece Icon Tree will show the correct orientation of the

sheets in the Stack. Make sure you load sheets in the orientation

indicated.

5. The Sheet Feeders take

the paper Stack in a similar

way to a photocopier paper

cassette.

Place the Stack onto the

deck of the feeder.

Depress the Stack and

slide it fully under the feed

roller.

3-13SV40221 Rev. A

Page 44

3 • Operator Functions

Setting the Envelope Feeder

Envelope Feeder E feeds the Outer Envelope for the inserting job

being run.

The Mail Piece Icon Tree for the Job Definition being run will show

if the feeder needs to be loaded and the envelope orientation. If you

need help understanding the envelope icons, refer to page 1-12 of

this guide.

1. Press the Envelope

Feeder loading switch to

lower the feeder tray ready

for loading.

2. Adjust the side guides to

the width of the envelopes

being fed using the Side

Guide Adjustment Knob,

then back-off 1/4 of a turn.

This will set the correct

clearance between the

guides and envelopes.

3. Take the stack of

envelopes and fan it

to ensure individual

envelopes are not stuck

together.

3-14 SV40221 Rev. A

Page 45

4. Place the stack of

envelopes into the feeder

with the flap side up and

flap last.

5. Press the Envelope

Feeder loading switch

again to raise the envelope

stack to the normal feeding

position.

Operator Functions • 3

TIP:

To quickly load envelopes during a run, without the need

to stop and start the machine...

• Press the Envelope Feeder loading switch to

lower the feeder tray.

• Load envelopes as described above.

• Press the Envelope Feeder loading switch

again. The envelope stack will rise to the normal

feeding position and processing will continue

automatically.

3-15SV40221 Rev. A

Page 46

3 • Operator Functions

Setting the Insert Feeder(s)

Insert Feeders F and G feed items that do not require folding by the

machine. Depending on configuration, your machine may have no

Insert Feeders, one Insert Feeder or two Insert Feeders.

Insert Feeder F is capable of feeding thicker Inserts than Insert

Feeder G. Therefore, booklets must only be fed from Feeder F.

The Mail Piece Icon Tree for the job being run will show if the feeder

needs to be loaded and the Insert orientation. If you need help

understanding the Insert icons, refer to page 1-12 of this guide.

1. Adjust the side guides to

the width of the Inserts

being fed using the Side

Guide Adjustment Knob,

then back-off 1/4 of a turn.

This will set the correct

clearance between the

guides and Inserts.

2. Refer to the labels located on each Insert Feeder. Match your

insert type (Slip, Reply Envelope, Pre-Folded or Booklet) with the

relevant icon and colour indicator on each label. Where a range

of settings is indicated on the label, the thicker the insert, the

higher the number or letter that should be selected.

i.e., The blue Booklet range runs from 6 to 9 and from C to D.

A thin Booklet might be set to 6 or 7 and C, whereas a thick

booklet might need settings 9 and D to run effectively.

3. Set the blue separator

gap lever to the number

required.

3-16 SV40221 Rev. A

Page 47

4. Set the blue separator

shield lever to the letter

required.

5. Take the stack of inserts

and fan it to ensure

individual Inserts are not

stuck together.

6. ‘Shingle’ the inserts to be

run so that they look like

the photograph on the right

and place them onto the

feed deck.

The Mail Piece Icon Tree

will show the correct

orientation of the Inserts.

Operator Functions • 3

7. Let the Wedge slide down

behind the stack so that

the Inserts are supported.

Note: If Insert Feeders F and G are linked (running the same

inserts), make sure the lever settings in steps 3 and 4 are

set the same on both feeders.

3-17SV40221 Rev. A

Page 48

3 • Operator Functions

Filling the Envelope Sealer

Make sure the Envelope Sealer is filled with sealing solution before

running a job that has sealing turned on.

When the sealer needs refilling, a warning message will

automatically appear on the display and, if sealing, the sealing icon

will flash.

Add sealing solution (EZ-Seal™ is recommended) in the following

way:

Hinge open the Sealer Bottle

Cover located at the front right

hand side of the machine.

Remove the bottle.

Unscrew the cap and fill the bottle with sealing solution (EZ-Seal™).

Refit the cap and place the bottle back into the machine.

Close the Sealer Bottle Cover.

TIPS:

If filling the Envelope Sealer for the first time, or if the

sealer has been allowed to completely empty, you

should allow time for the solution to soak through the

sealer mechanism before processing material.

The use of water in the sealer is not recommended.

We recommend EZ-Seal™ as it improves sealing

performance and minimises growth of algae and scale

build-up. It can be purchased directly from Pitney

Bowes.

When refitting the Sealer Bottle cap, the ‘pointed’ part of

the cap fits into the bottle neck and the cap screws into

place.

3-18 SV40221 Rev. A

Page 49

Operator Functions • 3

Menu

Select the Menu Screen Key to access the following Operator

Options within the menu structure:

• Language

• Display Adjustments

• Safe Seal

• System Information

Language

When this option is selected, a choice of languages will be displayed.

Choose the required language from the list and all display text will

change to the selected language.

This is a temporary setting. Switching the machine Off and then back

On will revert to the default language. (The default language is set to

your preference by your local service engineer at installation).

Display Adjustments

Select this option and follow the simple on-screen instructions to

change the contrast or brightness levels of the display to suit your

needs.

Safe Seal

This option allows you to switch Safe Seal on or off. When on, the

Safe Seal icon appears on the Mail Piece Icon Tree alongside

the Outer Envelope icon.

Safe Seal allows more time for moisture to soften the gum on the

Outer Envelope, allowing it to become more sticky. This function

therefore improves sealing of certain types of envelope but will slow

the machine down.

System Information

This screen displays information such as machine serial number,

your local service and supplies telephone number, software versions

and total item count.

3-19SV40221 Rev. A

Page 50

3 • Operator Functions

3-20 SV40221 Rev. A

Page 51

4 • Supervisor Functions

This chapter lists the functions that can be carried out by a

Supervisor. Primarily this includes creating, editing and deleting jobs.

About this Chapter ............................................................. 4-2

Supervisor Access Code ................................................... 4-2

Create Job ......................................................................... 4-3

Edit Job ............................................................................. 4-4

Create From ...................................................................... 4-6

Delete Job ......................................................................... 4-7

OMR Menu ........................................................................ 4-8

System Menu .................................................................... 4-8

Manual Feed Option ................................................... 4-8

4-1SV40221 Rev. A

Page 52

4 • Supervisor Functions

About this Chapter

This chapter describes the functions available within the Supervisor

Functions menu.

All of the functions are set by following a sequence of screens and

answering simple questions presented on the display. Therefore,

this chapter does not take you through every function step by step. It

gives you background information on the function and offers helpful

tips to get the best out of your machine.

Supervisor Access Code

Before you can access any of the functions in this menu you must

enter a Supervisor Access Code. This prevents unauthorised access

to functions mainly related to administration of jobs and OMR.

Your installing engineer will tell you the Supervisor Access Code. If

you wish, you can write it in the box on this page as a reminder.

However, please be aware that this is then available to anyone

using this Operator Guide and so you may wish to make a note

of it and keep it in a more secure location.

The Supervisor Access Code cannot be changed from the one given

to you by the installing engineer.

Supervisor Access Code:

Entering the Code

When asked to enter the Supervisor Access Code, use the ▲▼◄►

keys to highlight the first digit of the code on the Numeric Matrix

displayed, and confirm this digit by pressing OK. Repeat for the

second digit. When complete, select Finished.

4-2 SV40221 Rev. A

Page 53

Supervisor Functions • 4

Create Job

What is it?

This function allows a Supervisor to create new Job Definitions to be

stored within the machine’s memory for easy access by an Operator.

The machine can store a maximum of 20 Job Definitions.

Where is it?

From the Home Screen...

select Menu

select Supervisor Functions

enter the Supervisor Access Code (see page 4-2)

select Create Job

Action…

The machine will ask you a number of specific easy to answer

questions about the make up of the finished Mail Piece in order to

create the Job Definition.

Some of the questions asked will be based on the answers

previously given and so the sequence will vary from job to job. As

you create the job, the Mail Piece Icon Tree will be built on the left

side of the display. This shows how to load material into each feeder.

Once the job is created, named and any comments entered, you

must select Save to store it in the machine’s memory.

TIPS:

Placing a job description in the job comments will make

it easy for an Operator to select the correct job.

Use the Batch Counter if you want to automatically

process a pre-defined number of Mail Pieces. When the

Batch Count is complete, the machine will stop, allowing

the Operator to empty the stacker. Pressing Start will

commence processing of the next batch.

If you are using OMR within a job, an OMR code must

be pre-programmed into the machine’s memory. For

details of programming OMR codes, refer to Chapter 5.

OMR jobs cannot utilise linked feeders.

4-3SV40221 Rev. A

Page 54

4 • Supervisor Functions

Edit Job

What is it?

Edit Job allows a Supervisor to add and delete items within an

existing Job Definition. It also lets a Supervisor alter the job setup

such as batch count, job comments and job name.

The Edit Job function is used to change a Job Definition, and so

always over-writes the original Job Definition in the machine’s

memory (even if the Job Name has been edited). If you wish to

create a NEW Job Definition which is similar to an existing job and

leave the existing Job Definition untouched, use the Create From

function described on page 4-6.

Where is it?

From the Home Screen...

select Menu

select Supervisor Functions

enter the Supervisor Access Code (see page 4-2)

select Edit Job

Action…

Once Edit Job has been selected, choose the Job Definition you

wish to edit from the alphabetical job list using the ▲▼◄► keys in

the normal way.

Edit Job allows a Supervisor to modify all Job Definition parameters

except for adding or removing the Outer Envelope and the First

Sheet or Set.

Highlight the item you wish to edit by scrolling through the Mail Piece

Icon Tree using the ▲▼ keys.

To add an Additional Sheet/Set or a second Insert, highlight the icon

in the Mail Piece Icon Tree immediately adjacent to the point you

wish to add the new item, then select Add Item After or Add Item

Before as applicable.

To add an Insert to a job currently without Inserts, select Add Insert.

4-4 SV40221 Rev. A

Page 55

Supervisor Functions • 4

TIPS:

Highlight the Job Name to edit the following items:

Job Name

Job Comments

Batch Counter

Maximum Sheet Length

OMR set up

Highlight the Envelope icon to edit envelope and

sealing settings.

The Outer Envelope and First sheet cannot be added or

deleted.

Don’t forget to edit the job comments to correspond to

your revised job setup!

When editing a job, it is recommended that you

start at the top of the Mail Piece Icon Tree and work

downwards.

OMR jobs cannot utilise linked feeders.

4-5SV40221 Rev. A

Page 56

4 • Supervisor Functions

Create From

What is it?

A Supervisor can use the Create From function to create a NEW Job

Definition which is SIMILAR to an existing job and leave the existing

Job Definition untouched. This can save time programming a new

Job Definition when it is almost identical to an existing job but for a

small change such as an extra Insert or Sheet, etc.

The machine will copy the existing Job Definition and ask for the new

job to be named. It will then allow you to edit the new job to meet the

slightly changed requirements.

Where is it?

From the Home Screen...

select Menu

select Supervisor Functions

enter the Supervisor Access Code (see page 4-2)

select Create From

Action…

Once Create From has been selected, choose the Job Definition

you wish to use as the basis of the new job from the alphabetical job

list using the ▲▼◄► keys in the normal way.

Once the Job Definition that you are ‘creating from’ has been

selected, the machine will prompt you to enter a new Job Name (as

no two Job Definitions can have the same name).

After the Job Name has been entered, the machine will ask you to

enter the Job Comments. The following screens will then be as in

Edit Job described on page 4-4.

TIPS:

The machine’s memory holds a maximum of 20 Job

Definitions.

All the tips for Edit Job (page 4-5) also apply.

4-6 SV40221 Rev. A

Page 57

Supervisor Functions • 4

Delete Job

What is it?

Delete Job allows a Supervisor to remove a stored Job Definition

permanently from the machine’s memory.

Where is it?

From the Home Screen...

select Menu

select Supervisor Functions

enter the Supervisor Access Code (see page 4-2)

select Delete Job

Action…

Once Delete Job has been selected, choose the Job Definition you

wish to delete from the alphabetical job list using the ▲▼◄► keys

in the normal way.

Once the required Job Definition is selected, a message will be

displayed which requires confirmation before the job is deleted.

TIP:

Make sure the Job Definition you are deleting is the

correct job! Once deleted, it cannot be retrieved.

4-7SV40221 Rev. A

Page 58

4 • Supervisor Functions

OMR Menu

This function lets a Supervisor setup Optical Mark Recognition

(OMR) codes for inclusion within Job Definitions.

All OMR functions are explained fully within Chapter 5 - OMR.

System Menu

What is it?

This menu lets a Supervisor adjust the following system setting:

Manual Feed Option

Where is it?

From the Home Screen...

select Menu

select Supervisor Functions

enter the Supervisor Access Code (see page 4-2)

select System Menu

Manual Feed Option

This function lets a Supervisor choose whether or not the Insert

Feeder(s) are active when a Manual Feed operation is carried out.

The default setting is for both Insert Feeders to be ignored with a

Manual Feed. Changing this setting will feed Insert(s) from either or

both Insert Feeders, if they are loaded.

For more details of Manual Feed see page 3-9 of this guide.

4-8 SV40221 Rev. A

Page 59

5 • Optical Mar

k

Recognition (OMR)

This chapter gives background and setup information for using

Optical Mark Recognition (OMR) on a machine equipped with the

OMR option.

OMR Availability ................................................................ 5-2

What is OMR? ................................................................... 5-2

OMR Marks Available ........................................................ 5-3

OMR Mark Options ............................................................ 5-6

OMR Specifications ........................................................... 5-8

Creating, Deleting and Viewing OMR Codes .................. 5-10

Create New OMR Code ...................................................5-11

Delete OMR Code ........................................................... 5-13

View OMR Code .............................................................. 5-14

Creating an OMR Job ...................................................... 5-15

OMR Scanner Adjustments ............................................ 5-18

5-1SV40221 Rev. A

Page 60

5 • Optical Mark Recognition (OMR)

OMR Availability

Your machine can be equipped with Optical Mark Recognition

(OMR) functionality either on installation or as an added option after

purchase. The machine can store up to 10 different codes for you to

select when creating Job Definitions that use OMR.

What is OMR?

An OMR mark is normally a dark solid

line on a sheet of light coloured paper

that is perpendicular to the direction of

travel of the paper. This line must be

sufficiently thick, dense and placed in the

correct area to trigger the OMR scanner

on the system.

There are many different OMR options

available to you, from a Single Mark

option to Multi-Mark options, which have

a maximum of 24 marks.

The OMR scanner, working with the

OMR system software, checks for one or

more different marks on the sheets while they are being fed through

the system. The tracking of these OMR marks by the system will aid

the integrity of your mailing through error checking, so generally the

more marks you use, the better the integrity of your Mail Piece.

As mentioned on page 7-3 of this guide, there are limits on how

many sheets the machine can fold at one time. These limits are

dependent on the paper weight of your sheets, and fold type

selected, and should not be exceeded. It is therefore strongly

recommended that, when programming your system to print your

OMR sheets, these limits are taken into account. If these limits are

exceeded, it could result in a material stoppage or damage to the

material and the machine.

Typical

OMR marks

5-2 SV40221 Rev. A

Page 61

Optical Mark Recognition (OMR) • 5

OMR Marks Available

This section gives brief descriptions of the OMR Marks that can be

allocated to an OMR Code and lists the options available for use with

each mark. The section following, OMR Mark Options on page 5-6

then gives greater detail of each option.

NOTE: Some marks within this section are available as added

features which expand OMR capability. Contact your machine

supplier for details. OMR features available will vary depending on

the country you are in.

BM - Benchmark

This is a mandatory mark within the Multi-Mark option, it must be

either the first or last mark of the code and will appear on every page

within the first set.

This mark may only be selected once within the code.

SAF - Safety

This mark improves the integrity of your Mail Piece. It can be placed

anywhere within the code but benefits from being at the opposite end

of the code to the Benchmark.

When the Safety mark is placed in this position with the option

Always Present, and No other marks other than the OMR code

in the margin is chosen when creating the job, the machine will

automatically work out the length of the code. This makes creating

jobs using this code easier. Otherwise, the machine will ask for a

code length when creating a job.

This mark may appear more than once within the code.

Options available:

• Always Present or Never Present

BOC - Beginning of Collation

This mark indicates that it is the first sheet fed within a set. This mark

may only be selected once within the code.

Options available:

• Present or Absent

5-3SV40221 Rev. A

Page 62

5 • Optical Mark Recognition (OMR)

EOC - End of Collation

This is a mandatory mark which indicates that it is the last sheet fed

within the OMR set. This can only be selected once within the code

and is the only mark used when using the Single Mark option.

Options available:

• Present or Absent

STP - Stop

This mark is a processing feature which tells the machine to stop

once the completed Mail Piece has exited the machine.

Options available:

• Present or Absent

• All Sheets, Page 1 Only or Last Page Only

• Marked Piece to be left Unsealed (Yes or No)

SF(n) - Select Feed

These marks instruct the machine to select material from specified

feeders.

This feature is only available to select sheets when C fold is used

and the material is under 12“ (305mm) in length.

Selectively fed inserts are available for all types of folds and sheet

lengths within the specifications of the machine.

Up to 8 Select Feed Marks can be within to the code. 5 of these

marks can be allocated to specified feeders when creating a Job

Definition. The other 3 marks will be automatically ignored. Allowing

8 Select Feed Marks to be used gives greater flexibility in reusing

existing codes from production type machines which may have

greater Select Feed capability.

Options available:

• Present or Absent

• All Sheets, Page 1 Only or Last Page Only

5-4 SV40221 Rev. A

Page 63

Optical Mark Recognition (OMR) • 5

PAR - Parity

This mark is a security feature, that when printed always makes

the number of marks total an odd or even number. If any one of the

marks within the code is missed during scanning, the machine will

stop functioning, allowing the error to be rectified. No more than 1

Parity mark can be used within the code.

Options available:

• Odd or Even

WAS - Wrap Around Sequence

This is a numbering system which uses a sequential binary coding. If

a page becomes missing or the set becomes out of sequential order,

the system will stop processing and declare an error message. Up to

6 Wrap Around Sequence marks can be within the code.

Options available:

• Increment (Ascending) or Decrement (Descending)

• Include or Omit Zero (0) as a value within the sequence

• Continuous Sequence or Page 1 Reset

• Least or Most Significant Mark nearest to Bench Mark

(code orientation)

• Number of Wrap Around Sequence Marks

TM - Timing

This mark is needed by some other machines to read OMR marks

correctly. This machine does NOT need Timing marks, but the

mark(s) may be left within an existing code and will add integrity to

your Mail Piece.

Timing mark(s) may appear more than once within the code and, if

used, must always be present within the code.

IGN - Ignore

This feature is used to ignore a mark within the code. It may be used

more than once within the code.

This can be useful to enable existing codes from other equipment to

be used, as certain marks might not be applicable to this machine.

5-5SV40221 Rev. A

Page 64

5 • Optical Mark Recognition (OMR)

OMR Mark Options

This section gives brief descriptions of the OMR Mark Options that

can be allocated to relevant OMR marks. The previous section, OMR