Page 1

Connect+® Series

Contact your local dealer:

16 Luzerne Avenue, Suite 145 West Pittston, Pa. 18643

(570)569-2071 fax (570)614-2222 www.firstchoicepb.com

Connect+® 1000, Connect+® 2000,

Connect+® 3000

Operator Guide

US English Edition

SV62250 Rev. G

December 13, 2012

Page 2

SV62250 Rev. G December 2012

©2012 Pitney Bowes Inc.

All rights reserved. The content of this online manual may not be reproduced in whole or in part in any fashion or stored in a retrieval system of any type or transmitted by any means, electronically or mechanically,

without the express, written permission of Pitney Bowes.

We have made every reasonable effort to ensure the accuracy and usefulness of this online manual; however, we cannot assume responsibility for errors or omissions or liability for the misuse or misapplication of

our products.

Due to our continuing program of product improvement, equipment and material specifications as well as

performance features are subject to change without notice. Your mailing system may not have some of the

features described in this book.

Connect+® Series, Connect+® 1000, Connect+® 2000, Connect+® 3000, E-Z Seal, IntelliLink, WEIGH-ONTHE-WAY, W-O-W, Postage By Phone, INVIEW, Ascent, SendSuite Express and Pitney Bowes Supply

Line are trademarks or registered trademarks of Pitney Bowes Inc. All other trademarks are trademarks or

registered trademarks of the respective owners.

Alerting Messages

Various messages are used throughout this guide to alert you to potentially hazardous or error causing conditions. These messages are as follows:

WARNING! Alerts you to conditions or practices that could cause serious injury.

CAUTION: Alerts you to conditions or practices that could cause damage to the equipment or to the

material being run.

IMPORTANT: Alerts you to conditions or practices that could adversely affect equipment operation if

instructions are not followed exactly.

NOTE: Provides a comment or explanation of the associated topic.

Page 3

Table of Contents

1 ● Getting Started

2 ● Creating and Managing Jobs

3 ● Running Mail

4 ● Accounting

5 ● Reports

6 ● Adding Postage

7 ● Rates and Updates

8 ● System Setup

9 ● Maintenance

10 ● Troubleshooting

A ● Glossary

1

26

41

102

138

143

152

157

179

208

225

Page 4

Page 5

1 ● Getting Started

What Does This Machine Do?

The Home Screen

Parts of the Mailing System

Your System's Specifications

Safety Information

Postal Security Device

WEIGH-ON-THE-WAY® (W-O-W®)/Shape Based Rating

USPS Requirements

2

2

3

16

19

22

23

23

Page 6

Connect+® Series Operator Guide

What Does This Machine Do?

The Connect+® Series is a digital envelope and mail printing system that allows you to

create custom designed content from a PC and download that content directly into a graphics library stored on the Connect+™ for use on mail runs. You can now design an outer

envelope with content that reinforces the internal message. You can add marketing, advertising, and other promotional messages to your mail pieces.

The Connect+® Series provides a unique and easy-to-use touch screen interface where you

can access all of your applications from the home screen. Each application appears on the

Home screen as a button. Simply tap on the button to run the applications. Use the full

access web applications Verify Address, Track a Package, and My Account to increase you

mailing efficiencies.

The system also provides a full range of mail system functions including:

l

Printing postage on envelopes

l

Printing postage on tapes (labels)

l

Sealing envelopes

l

Calculating postage based on item weight and size and class of mail.

The Home Screen

The Home screen is the first screen displayed when you log onto the system. It contains all

of the application buttons you need to start any of the system applications including Run

Mail, Jobs, Funds, Manage Accounts, Reports, Rates & Updates, and Settings.

The Message Center

The Message Center at the bottom of the Home screen allows Pitney Bowes to communicate directly with you. This area is routinely updated and provides:

l

Access to savings opportunities and special offers.

l

Software and rate update notifications.

l

Key USPS® information that may impact your operation (for example, Rate Change).

l

Tips on improving mail center efficiency.

SV62250 Rev. G

2

Page 7

Chapter 1

l

Notification of planned service interruptions.

The Message Center icon will appear in the header bar along the top of the screen

if you are working in one of the system applications when a new message becomes

available. You can return to the Home screen at any time to view the new message.

Additional Resources

The Home screen also provides buttons for direct links to web sites providing additional

resources and support for your mailing operation:

l

Verify Address - Enter any delivery address to verify accurate Postal data, including spelling or accurate ZIPCodes. Provide reason codes for non-matches. Print shipping labels

in standard USPS 4”x 6” format on bottom half of 8.5” x 11” sheet.

l

My Account - Provides unlimited access to My Account at PB.com. You can place a service call, access USPS tracking and value added services, check order status (product or

service call), access service chat, and access supplies chat within the PB Store.

l

Discount and Presort Services - Activating Presort Savings account gets you up to 15%

of postage discount on qualifying mail, free pickup of eligible mail, delivery point Validation and Move Update processing.

l

Buy Supplies - Provides direct access to the PB Supply Line where you can purchase

envelopes and paper, ink and toner, office products, and supplies for your Connect+®

Series Series systems.

l

Track a Package - Track your USPS, UPS, FedEx or DHL/Airborne packages. Print

status directly. View map and detailed information for each carrier as information is available.

l

Postal Tools - Learn about postal classes and services like USPS Package and Priority

rates.

Parts of the Mailing System

For important safety information, refer to Safety Information.

3

SV62250 Rev. G

Page 8

Connect+® Series Operator Guide

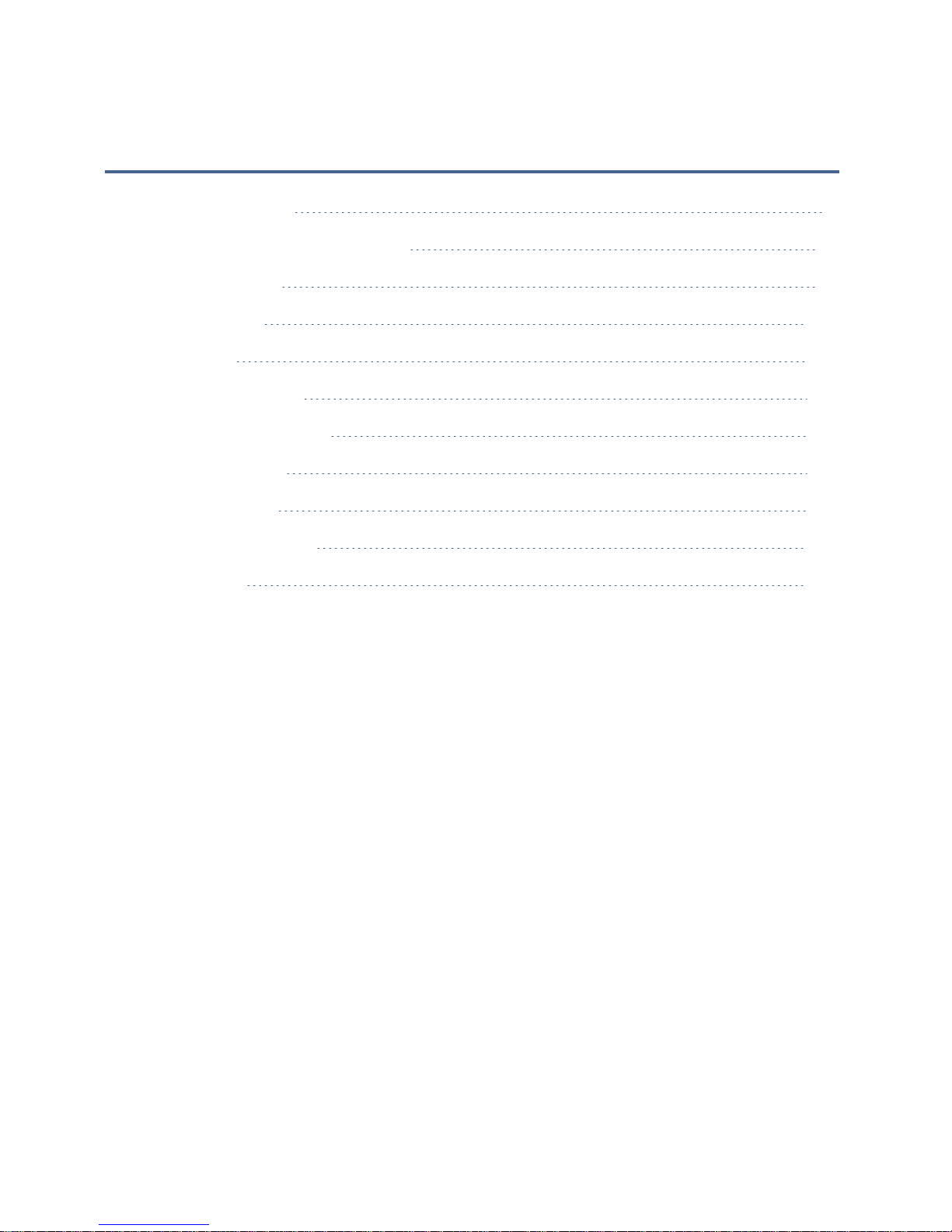

Touchscreen

The touchscreen allows you to communicate with the mailing system and the

built-in postage meter (Postal Security Device).

Your system comes equipped with a 10.2" touchscreen. An optional 15"

touchscreen is also available.

Stylus

A stylus is a pen-like tool used to make selections from a touchscreen display. The stylus may be preferred by some users over “finger touch”.

The display stylus is standard with all Connect+® Series systems. It attaches

to either side of the display and sits neatly in a tube holder.

SV62250 Rev. G

4

Page 9

Chapter 1

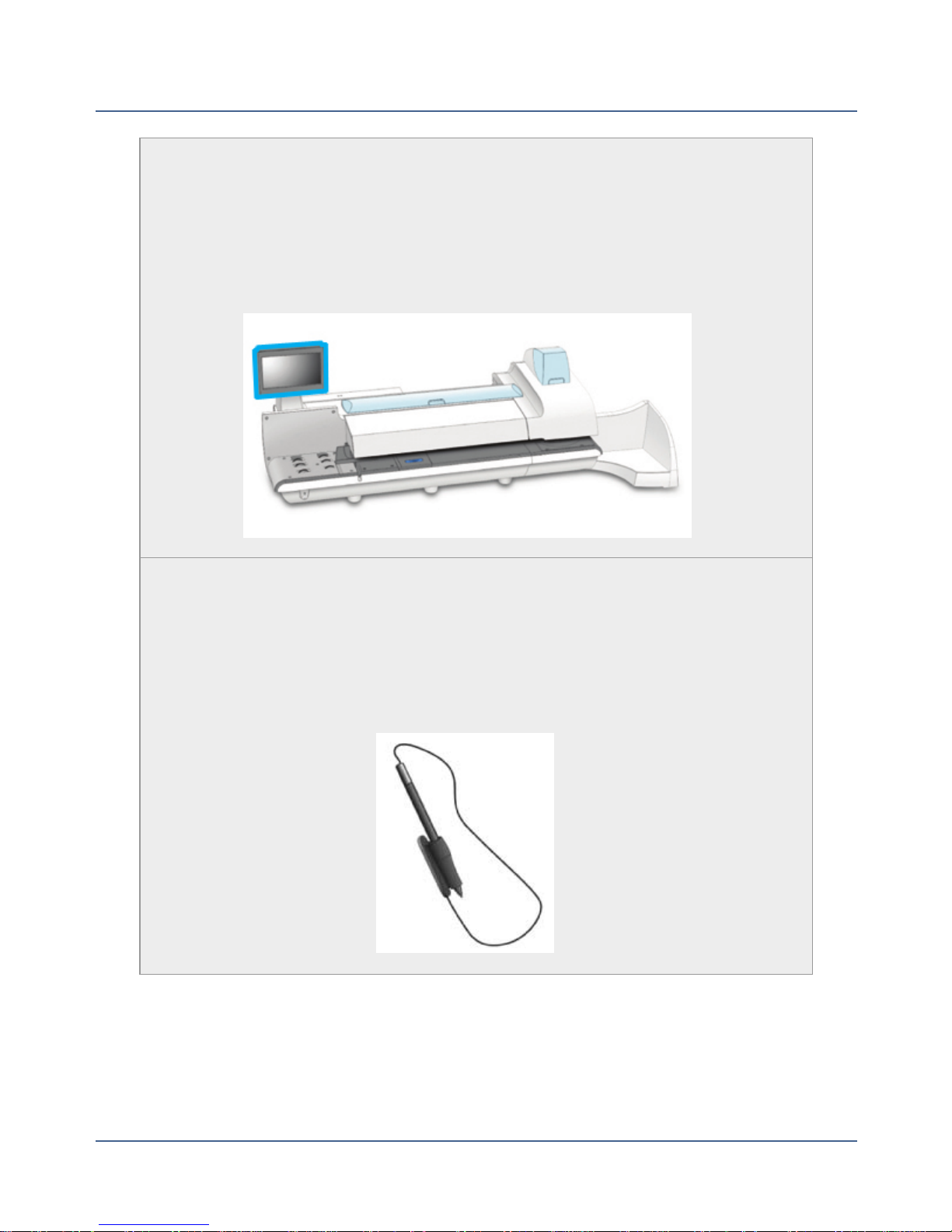

Feeder

The feeder area consists of the feeder deck, side guide and thickness adjustment knob.

Feed Deck

The feed deck is the area where you load the envelopes.

If you have a Connect+® 2000 or Connect+® 3000 system, this feeds the

envelopes to the WEIGH-ON-THE-WAY® (W-O-W®) transport deck.

5

SV62250 Rev. G

Page 10

Connect+® Series Operator Guide

Side Guide

The moveable guide at the front of the feed deck is used to stabilize the

envelope position when feeding it.

NOTE: The side guide is optional feature on Connect+® 3000 systems.

Power Button

Turns the mailing system on and off. This is located on the lower left side of

the feed deck.

SV62250 Rev. G

6

Page 11

Chapter 1

Envelope Sealant Bottle

The envelope sealant bottle contains the E-Z Seal® solution used for moistening envelopes. It is located under the main cover, on the left.

Tape

The system uses tape to print reports and postage indicia for packages or

pieces of mail that are outside the limits specified for mailing materials. Connect+® 1000and Connect+® 2000 systems use adhesive tape only. Connect+® 3000 systems can use either adhesive or gummed tape.

The tape is located under the supplies cover, on the right.

7

SV62250 Rev. G

Page 12

Connect+® Series Operator Guide

Attached Scale

If your mailing system has WEIGH-ON-THE-WAY® (W-O-W®) (Connect+®

2000, Connect+® 3000), the attached scale is used to weigh mail pieces that

do not fit through the mailing system.

If your mailing system does not have WEIGH-ON-THE-WAY® (W-O-W®)

(Connect+® 1000), the attached scale is used to weigh all mail pieces,

regardless of whether they fit through the machine or not.

The attached scale is behind the supplies cover and to the right of the

PSDcover.

SV62250 Rev. G

8

Page 13

Chapter 1

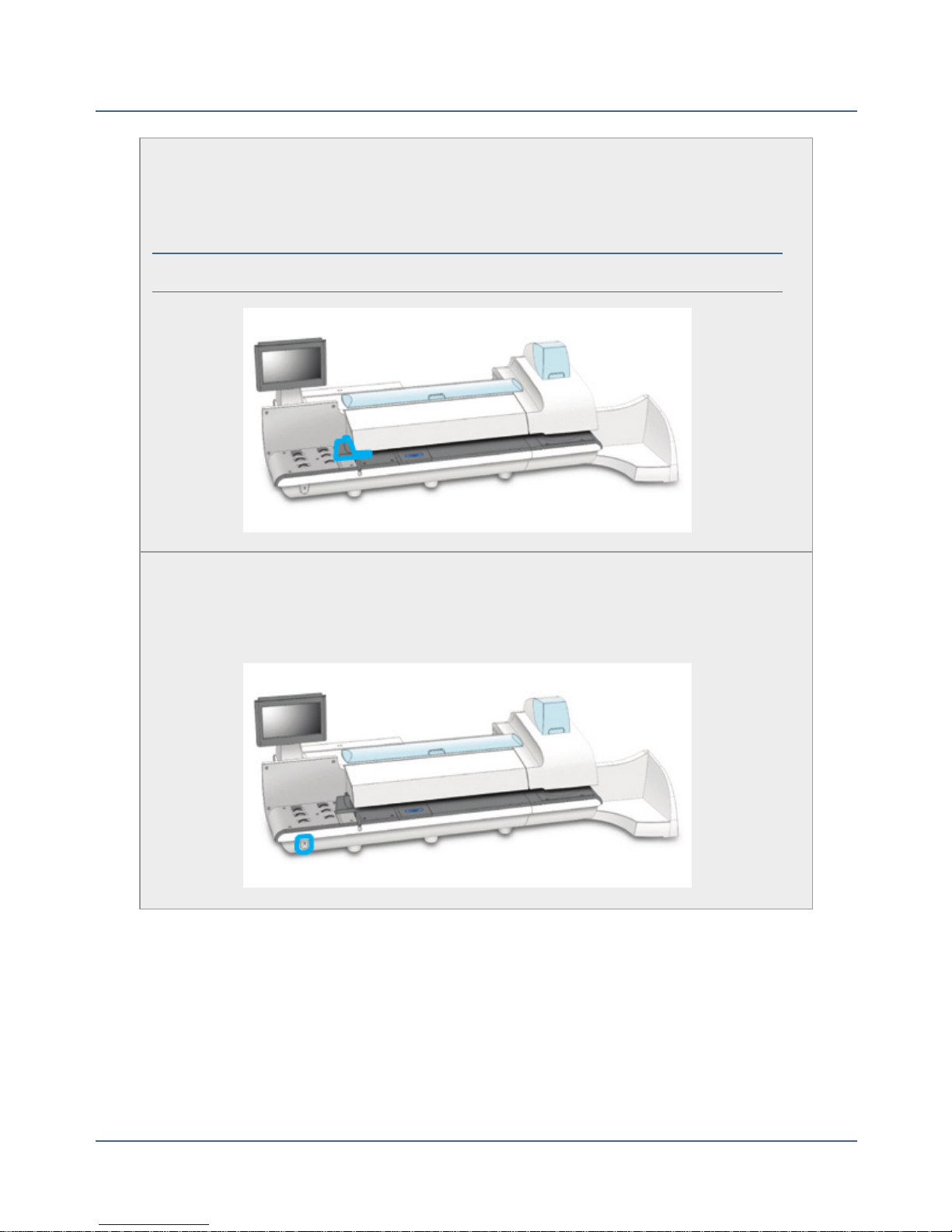

Moistener Pad Assembly

The moistener pad assembly moistens the flaps on the envelope.

NOTE: The moistener pad assembly is located beneath the moistener deck

on Connect+® 3000 systems. To access it, lift the top release lever and

then use the blue notch to pull on and open the moistener deck.

Connect+® 1000 and Connect+® 2000 Systems

Connect+® 3000 Systems

9

SV62250 Rev. G

Page 14

Connect+® Series Operator Guide

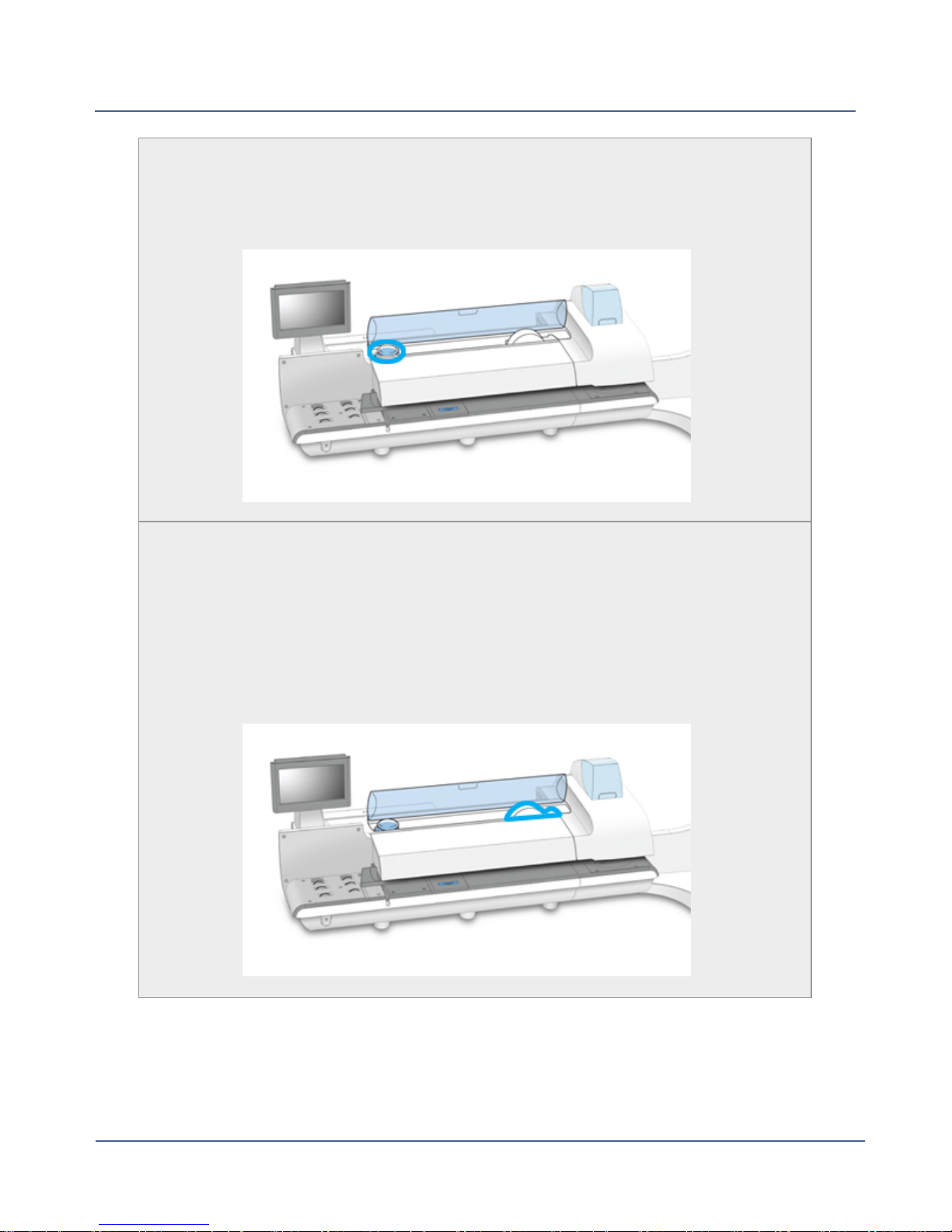

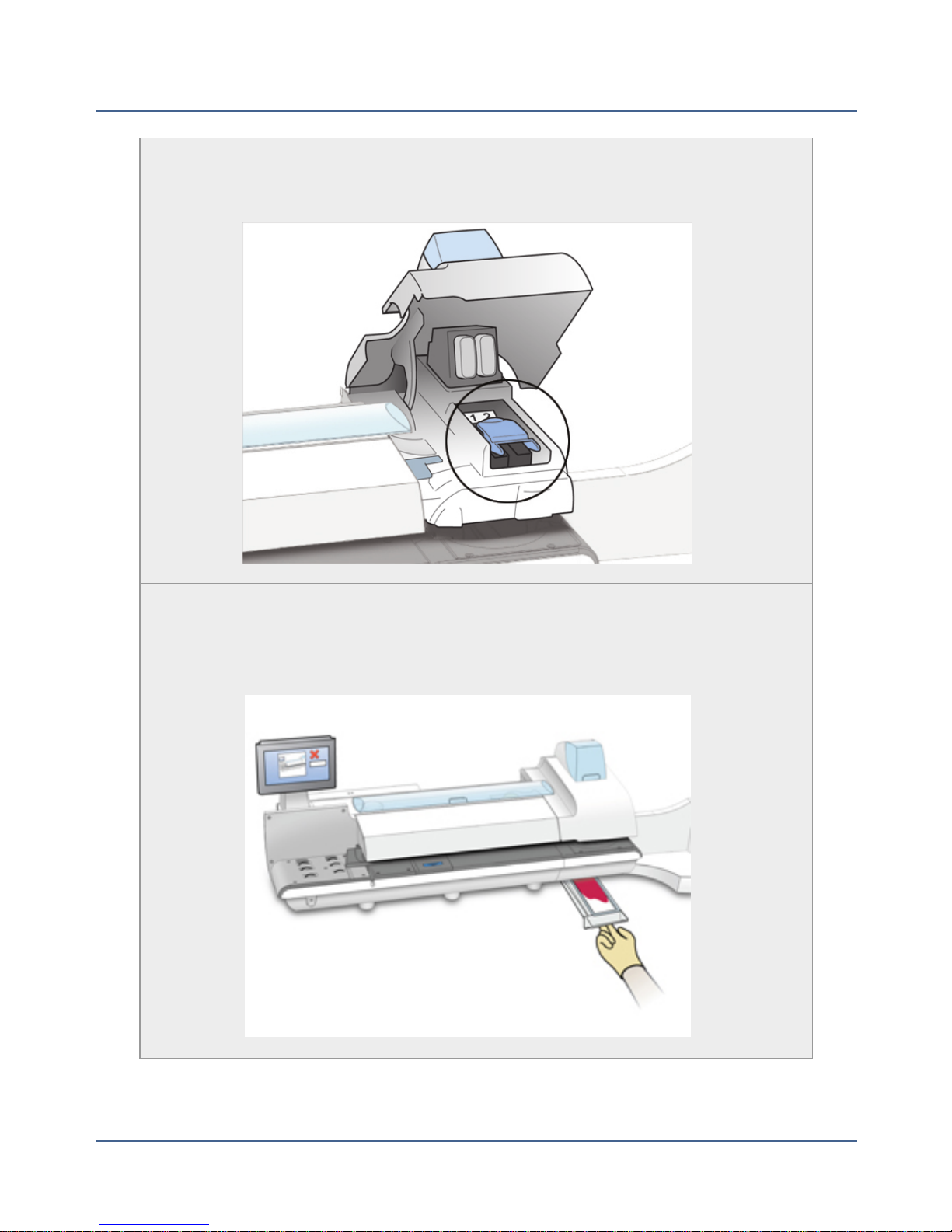

Thickness Adjustment Knob

The thickness adjustment knob is located beneath the feeder cover. Turn

this knob to adjust for the thickness of the envelopes.

To set, turn the knob until the arrow on the knob lines up with the arrow to the

right as shown below. The arrow on the knob snaps into position.

Connect+® 1000 and Connect+® 2000 Systems

l

Setting 1: Use this setting for postcards mail

pieces that are 0.007 inches (0.18 mm) to

0.375 inches (9.52 mm) thick.

l

Setting 2: Use this setting for mail pieces that

are greater than 0.375 inches (9.52 mm) to the

maximum of 0.625 inches (15.9 mm) thick.

Connect+® 3000 Systems

l

Setting 1: Use this setting for postcards and

mail pieces that are less than 0.25 inches

(6.35 mm) thick.

l

Setting 2: Use this setting for mail pieces

that are greater than or equal 0.25 inches

(6.35 mm) thick, but less than 0.50 inches

(12.7 mm) thick.

l

Setting 3: Use this setting for mail pieces

that are greater than or equal to 0.50

inches (12.7 mm) thick, but less than 0.625

inches (15.9 mm) thick.

l

Setting 4: Use this setting for mail pieces that are greater than or equal to

0.50 inches (12.7 mm) thick, but less than 0.625 inches (15.9 mm) thick.

SV62250 Rev. G

10

Page 15

Chapter 1

Printer

The main components of the printer module are the ink cartridges, print

heads and waste ink tray.

Ink Cartridges

The ink cartridges contain the ink used to print the postal indicia, as well as

any additional items (graphic ad, text message, return address, etc.) you

want to appear on your mail piece.

11

SV62250 Rev. G

Page 16

Connect+® Series Operator Guide

Print Heads

The print heads produce the postage indicia.

Waste Ink Tray

Ink is deposited in the waste ink tray during the print head cleaning process.

The system will alert you when the waste tray is nearing full capacity.

SV62250 Rev. G

12

Page 17

Chapter 1

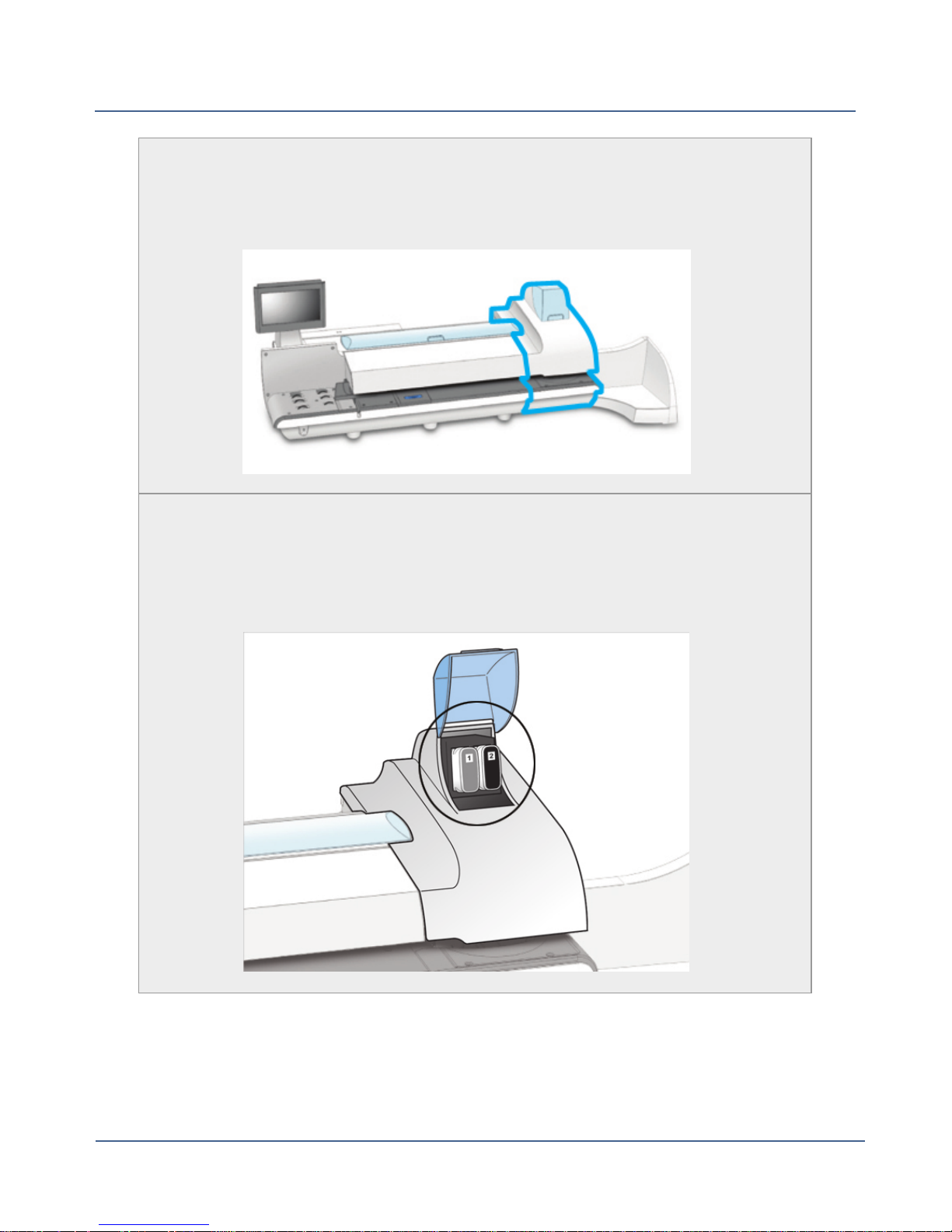

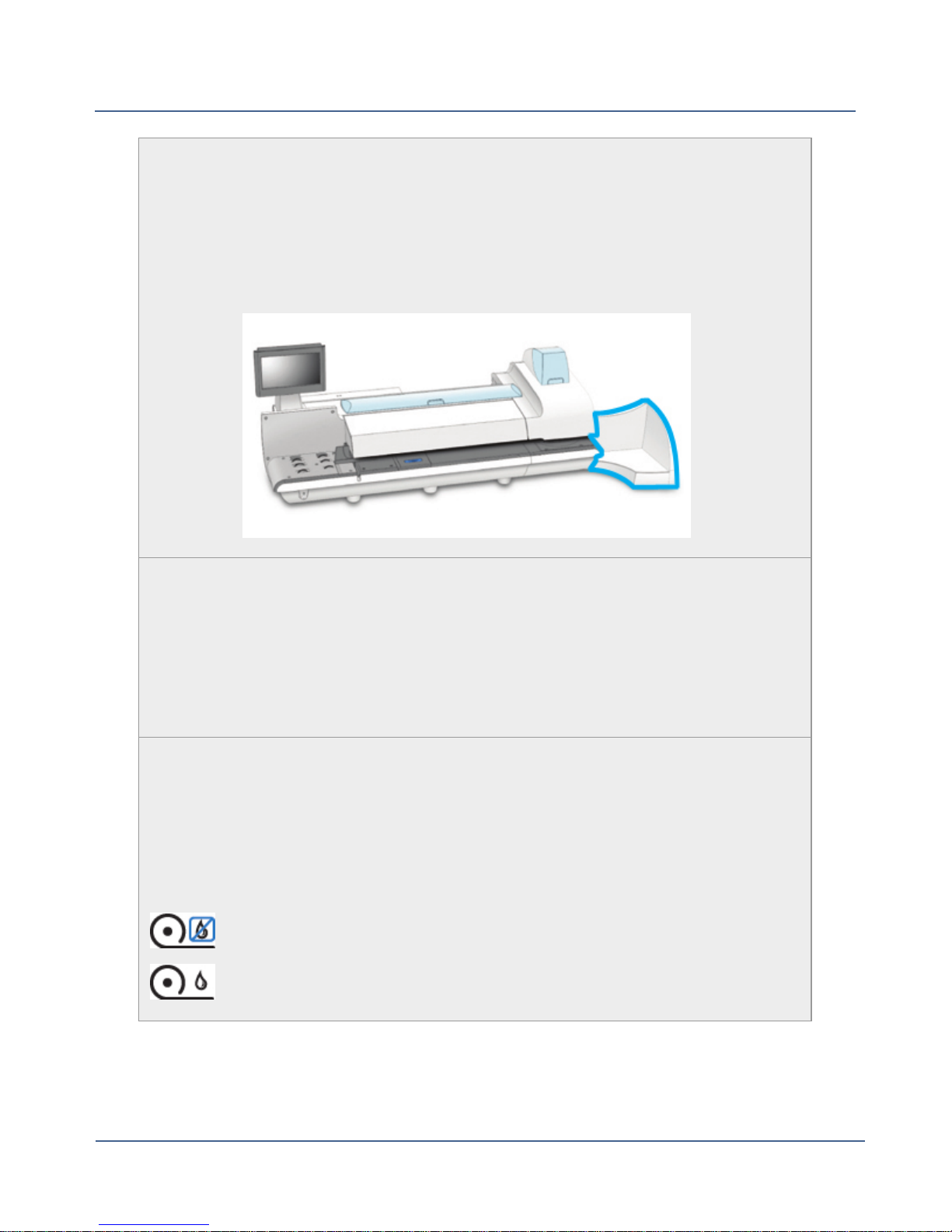

Stacker

This is where mail is deposited after the postage is applied to the piece of

mail. It is located on the right side of the system. The drop stacker shown

here is available with every mailing system.

An optional power stacker is also available.

Tape Sealant Bottle

The tape sealant bottle is an optional feature for Connect+® 3000 systems. It

contains the E-Z Seal® solution used for moistening gummed tape.

The tape sealant bottle is located to the right of the printer module, behind

the stacker.

Wet/Dry Tape Lever

The wet/dry tape lever is an optional feature for Connect+® 3000 systems.

Use this lever to set the type of tape you are using on your system.

The wet/dry tape lever is located to the right of the printer module, behind the

stacker.

Push the lever to the right for dry tapes or pressure-sensitive tapes.

Push the lever to the left for wetting gummed tapes.

13

SV62250 Rev. G

Page 18

Connect+® Series Operator Guide

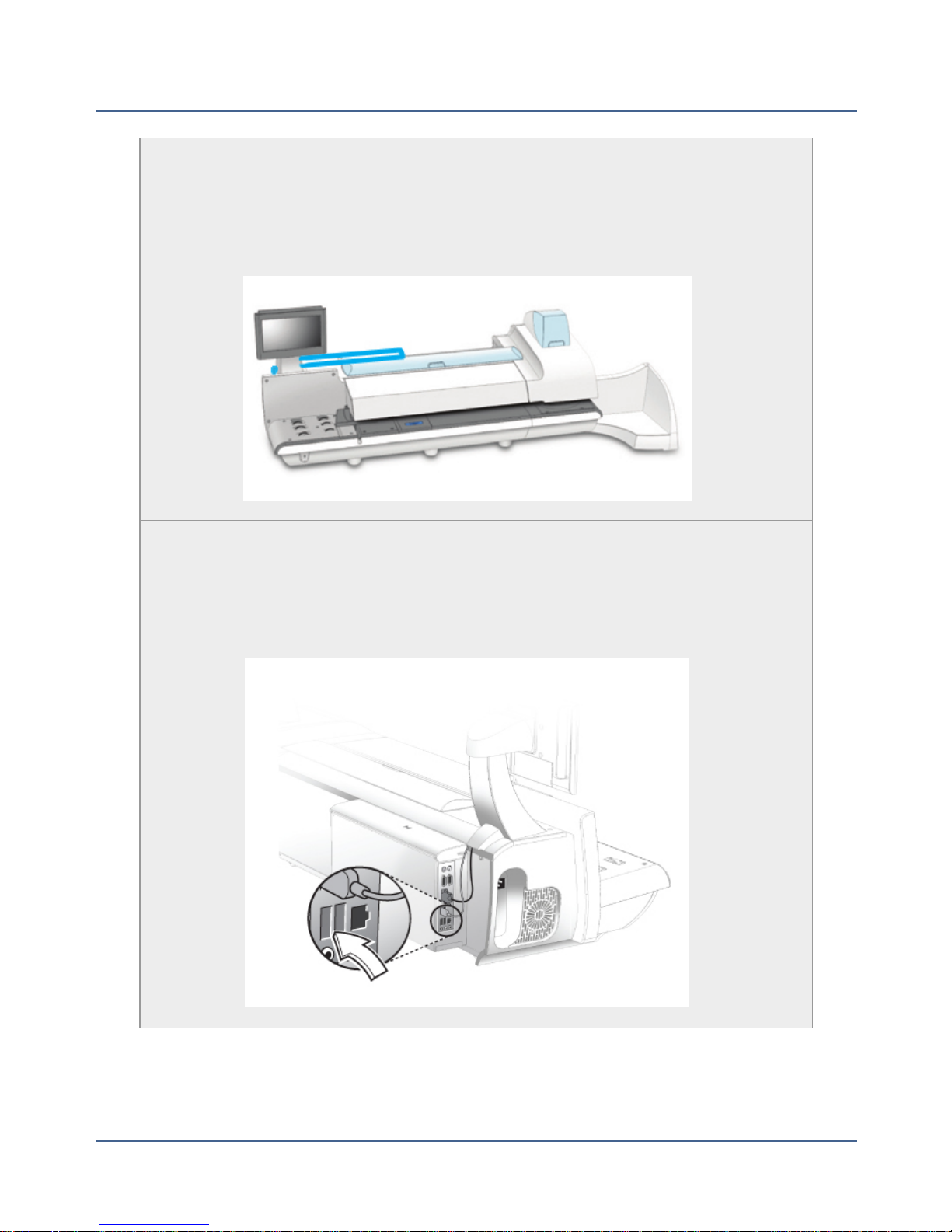

Postal Security Device

The PSD contains the funds and performs all of the calculations necessary

to print postage indicia that comply with the latest USPS standards. It is

located beneath the PSDcover on the back of the mailing system.

USBPorts

Two USB ports are located on the back, lower left side of the system. These

provide communications with external devices like a printer or an attached

scale.

SV62250 Rev. G

14

Page 19

Chapter 1

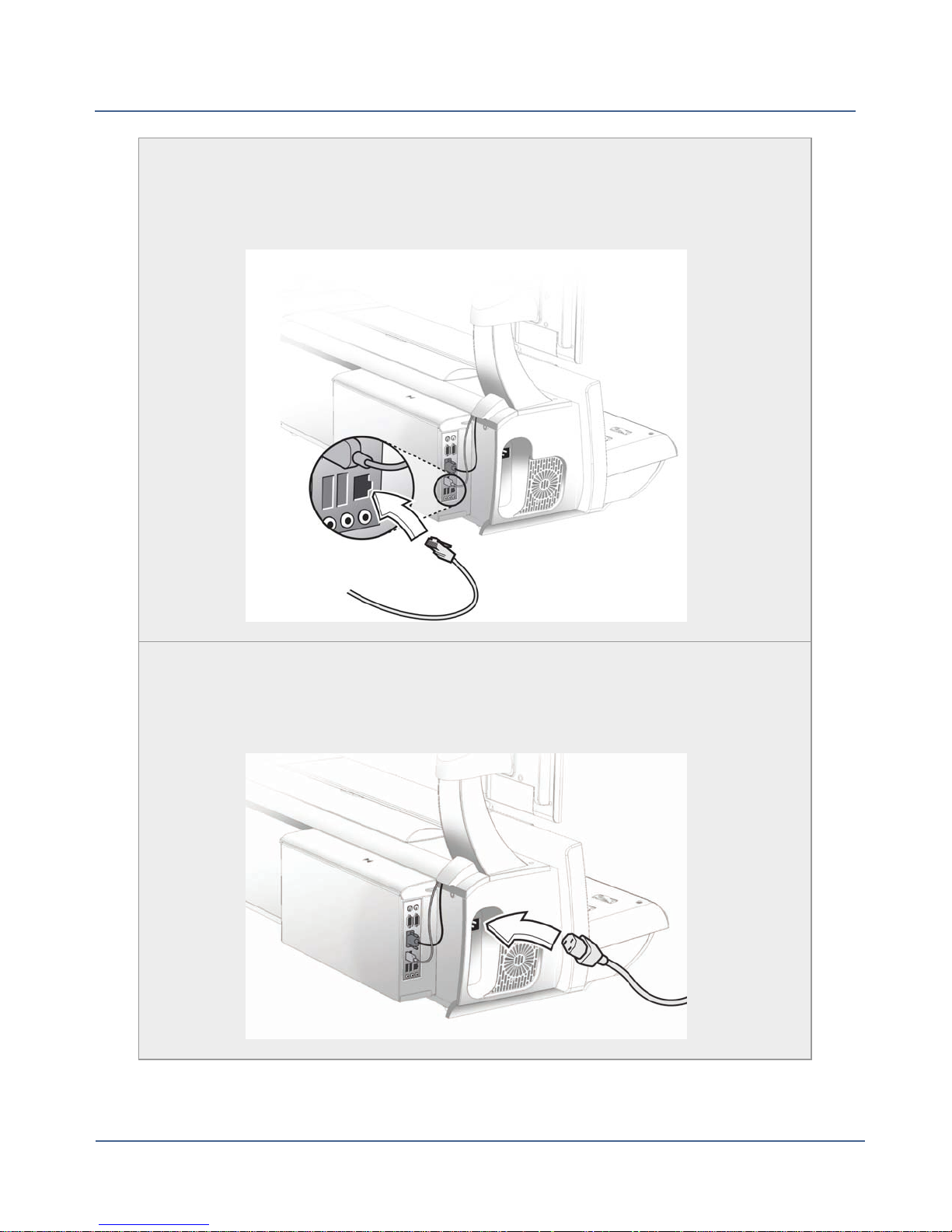

LAN Port

The LAN port is located on the back, lower left side of the system. This port

provides the mailing system with a high bandwidth Internet connection.

Power Receptacle

The power receptacle is located on the back, left side of the system. It connects to the AC power cord (supplied).

15

SV62250 Rev. G

Page 20

Your System's Specifications

System Dimensions and Weights

Connect+® 1000

Connect+® 2000

l

l

l

l

l

l

l

Connect+® Series Operator Guide

49.5" L x 22.5" D (1257mm x 635mm) with drop

stacker

Power stacker adds 31" (483mm) to length

Color adds 6.5" (185mm) to length

110 lbs. (49.9kg)

65" L x 22.5" D (1638mm x 635mm) with drop stacker

Power stacker adds 31" (483mm) to length

Color adds 6.5" (185mm) to length

l

150 lbs. (68kg)

l

Connect+® 3000

73.5" L x 25.5" D with drop stacker

l

Power stacker adds 31" (483mm) to length

l

Color adds 6.5" (185mm) to length

l

165 lbs. (74.8kg)

All systems are 24" (610mm)high with base touchscreen display.

Power and Compliance

Power 100-240Vac, 50/60Hz., 6.4 - 3.0 Amps

Compliance Optional ENERGY STAR®

NOTE: Refer to How to Set System Timeouts for infor-

SV62250 Rev. G

mation about the optional ENERGY STAR sleep

mode.

16

Page 21

Chapter 1

Operating Conditions

Operating Temperature Maximum Room Ambient 40°C (104°F)

Capacities, Features and Throughput

Sealer Capacity Approximately 3900 #10 single-insert mail pieces

Sealer Type Pump-fed pad with sealing rollers

Printer High speed dual-printing technology, at 1200 DPI(ver-

tical)

l

Mono Printer Module – prints both Postal Red and

Black.

l

Color Printer Module – prints both Postal Red, Process Color, and Black.

Print Head Life 800,000 cycles for full IBI Indicia

l

Ink Capacity (in full size

USPS IBI-C indicia)

Ink Cartridge Life

Small cartridge: 8K mail pieces

l

Medium cartridge: 18K mail pieces

l

Large cartridge: 45K mail pieces

l

Shelf life: Maximum of 24 months from date of manufacture - for monochrome and color inks

l

In use life: Maximum of 30 months from date of manufacture - includes any time on shelf before first use

for monochrome and color inks

l

Tape Method

Connect+® 1000 and Connect+® 2000: Adhesive

Tape

17

l

Connect+® 3000: Adhesive or Gummed Tape

SV62250 Rev. G

Page 22

Connect+® Series Operator Guide

Tape 5" roll, approximately 600 indicias per roll, without

graphic ads

Throughput Range of speed options available.

l

Connect+® 1000: 3-Speeds, 130 (Standard), 160,

and 180 Letters/min

l

Connect+® 2000: Non W-O-W®: 3-Speeds, 130

(Standard), 160, and 180 Letters/min

l

Connect+® 2000:W-O-W®: 3-Speeds, 70 (Standard),

90, 110 Letters/min

l

Connect+® 3000: Non W-O-W®: 4-Speed options,

160 (Standard), 210, 260, and 300 Letters/min

l

Connect+® 3000: W-O-W®: 4-Speed options, 100

(Standard), 130, 160, and 200 Letters/min

W-O-W® Weight Capacity

Stacking

High Speed Connectivity

Connect+® 1000: NA

Connect+® 2000: 16 ounce

Connect+® 3000: 32 ounce

l

Drop Stacker Standard

l

Power Stacker Optional

l

25" LAN Cable Standard

l

Wireless LANOptions

l

Sprint 3G cellular available (Subscription charge

applies).

SV62250 Rev. G

18

Page 23

Chapter 1

Peripheral Options

l

Drop or Power Stacker Options

l

Compact Platform Weighing Options, 5, 10, or 15 lb. Capacity

l

Large Platform Weighing Options: 15, 30, 70, 149 lb. Capacity

l

1E20 Laser Printer

l

Bar code scanning for Tracking Services (Confirmation Services) and Accounting

l

Wireless Keyboard option

l

USB Hub - 4 Open Ports

l

DI900/DI950 Mail Machine Interface

Safety Information

WARNING: Follow normal safety precautions for all office equipment.

Read all instructions before you attempt to operate the machine. Use the equipment only

for its intended purpose.

l

Use only Pitney Bowes approved supplies, in particular aerosol dusters. Improper storage and use of aerosol dusters or flammable aerosol dusters, can cause an explosivelike condition that could result in a personal injury and/or property damage. Never use

aerosol dusters labeled flammable and always read instructions and safety precautions

on the duster container label.

l

To obtain Pitney Bowes supplies, please contact our Supply Line™ to place orders. Material Safety Data Sheets can be obtained on the web or from our Supply Line™.

l

Use the power cord supplied with the machine and plug it into a properly grounded wall

outlet located near the machine and easily accessible. Failure to properly ground the

machine can result in severe personal injury and/or fire.

l

The wall outlet supplying power to the machine must be a single dedicated wall outlet.

Contact a licensed electrician to ensure there are no other wall outlets on the branch circuit.

l

The electrical circuit (mains) supplying power to the outlet must be switched ON.

19

SV62250 Rev. G

Page 24

Connect+® Series Operator Guide

l

Avoid touching moving parts or materials while the machine is in use. Keep hands, loose

clothing, jewelry and long hair away from all moving parts.

l

Do not remove covers or defeat safety interlock switches. Covers enclose hazardous

parts that should only be accessed by properly trained service personnel. Immediately

report to Pitney Bowes Service any damaged or non-functioning components that

renders the unit unsafe.

l

Place the unit in an accessible location to allow for proper venting of the equipment and

to facilitate servicing.

l

The power cord wall plug is the primary means of disconnecting the machine from the AC

supply.

l

Do not use an adapter plug on the line cord or wall outlet.

l

Do not remove the ground pin from the line cord.

l

Avoid using wall outlets that are controlled by wall switches, or shared with other equipment.

l

Do not route the power cord over sharp edges or trapped between furniture.

l

Insure there is no strain on the power cord where it becomes jammed between the equipment, walls or furniture.

l

Do not plug headphones into the Line Out jack (Lime Green).

l

Be certain the area in front of the wall receptacle into which the machine is plugged is

free from obstruction.

l

Before clearing a stoppage, be sure machine mechanisms come to a stop.

l

When clearing a stoppage, avoid using too much force to protect against minor personal

injury and damaging equipment.

l

To prevent overheating, do not cover the vent openings.

l

Operation of this equipment without periodic maintenance will inhibit optimum operating

performance and could cause the equipment to malfunction. Contact your Pitney Bowes

Customer Service Representative for required service schedule.

l

Read all instructions before attempting to operate the equipment.

l

Use this equipment only for its intended purpose.

SV62250 Rev. G

20

Page 25

Chapter 1

CAUTION: Moving mechanism can result in personal injury. Keep hands, long hair, ties,

jewelry and loose clothing away from moving parts.

CAUTION: In case of an ink spill, leaking ink or excessive ink accumulation, immediately disconnect the power cord from the wall plug and contact Pitney Bowes. In the USA

please call 1-800 522-0020. Customer Service Representatives are available Monday

through Friday, 8:00 AM - 8:00 PM ET. Outside the USA please refer to the country contact

sheet supplied with your system. Contact information can also be found at www.pb.com.

NOTE: Always follow the specific occupational safety and health standards for your workplace.

United States

NOTE: This equipment has been tested and found to comply with the limits for a Class A dig-

ital device, pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and,

if not installed and used in accordance with the instruction manual, may cause interference

to radio communications. Operation of this equipment in a residential area is likely to cause

interference in which case the user will be required to correct the interference at his own

expense..

CAUTION: Changes or modifications to this equipment not expressly approved by the

party responsible for compliance could void the user’s authority to operate the equipment.

Except for Ethernet/LAN connection cables, shielded I/O and USB cables must be used with

this equipment to ensure compliance with the limits. Use of unshielded cables is prohibited.

Note for California Customers Only

The battery in this product contains perchlorate material. California requires perchlorate-containing products to be accompanied by the following notice: Percholrate Material - special

handling may apply. See: http://www.dtsc.ca.gov/hazardouswaste/perchlorate/

21

SV62250 Rev. G

Page 26

Connect+® Series Operator Guide

Canada

This Class A digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du Canada.

European Union

It is certified that this system complies with all applicable Directives of the European Union.

For a formal Declaration of Conformity please contact Compliance Engineering. Contact

information is given below or on a separate document supplied with your system..

WARNING: This is a Class A product. In a domestic environment this product may

cause radio interference in which case the user may be required to take adequate measures.

Responsible Party within the USA:

Pitney Bowes

1Elmcroft Road

Stamford, CT 06926-0700

(800) 522-0700

Outside the USA:

Please refer to the country contact sheet supplied with your system. Contact information can

also be found at www.pb.com.

Servicing:

This product is serviceable. For service inquiries in the USA please call 1-800 522-0020.

Customer Service Representatives are available Monday through Friday, 8:00 AM - 8:00 PM

ET. Outside the USA please refer to the country contact sheet supplied with your system.

Contact information can also be found at www.pb.com.

Postal Security Device

The postage meter on your mailing system is a Postal Security Device (PSD) that incorporates the latest technology approved by the United States Postal Service to secure funds.

SV62250 Rev. G

22

Page 27

Chapter 1

This technology eliminates the need to perform physical inspections thereby making the system easier and more convenient to use.

WEIGH-ON-THE-WAY® (W-O-W®)/Shape Based Rating

The WEIGH-ON-THE-WAY® (W-O-W®)/Shape Based Rating module processes mixed mail

(mail of varying sizes and weights) and determines the postage amount based on the weight

and dimensions of each mail piece.

USPS Requirements

Since your postage meter (Postal Security Device) is licensed by the United States Postal

Service (USPS), you must follow a few basic requirements.

l

Mail must have the correct date and postage amount in the postage indicium.

l

Metered mail must bear the ZIP Code location of the post office where the postage meter

(Postal Security Device) is registered.

l

If you move to another ZIP Code location, you must update the ZIP Code. You can do this

by calling Postage by Phone® at 1.800.243.7800.

l

Each time you refill your postage meter (Postal Security Device) through the LAN, the

Postage By Phone® Meter Payment System computer automatically performs a postal

inspection. If the postage meter in your mailing machine has not detected a refill transaction at certain intervals, the message “Inspection Required” appears on the Run Mail

screen and then prompts you to connect to Pitney Bowes and perform an inspection.

l

The postage tape you use must meet USPS specifications.

How to Properly Shut Your System Down

1. From the Home screen, select the Shut down button at the lower right corner of the

screen.

2. Select the Shutdown option and confirm the selection.

3. Wait until all messages clear from the screen.

WARNING: Improper shutdown and the immediate removal of the print head will result

in print head damage. Replacement of the print head will be necessary

23

SV62250 Rev. G

Page 28

Connect+® Series Operator Guide

Logging In and Out of the System

If users are enabled on your system, you will be required to enter a password to log on to the

system. This prevents unauthorized use of the system.

Logging In

1. If necessary, select the appropriate username.

2. Enter your password and select OK.

Logging Out

1. Select the Shut down button on the Home screen.

2. Select Log out.

3. Select OK.

SV62250 Rev. G

24

Page 29

This page intentionally left blank.

Page 30

2 ● Creating and Managing Jobs

All About Jobs

About Job Properties

The Default Job

Opening a Job

Previewing Jobs

Creating a New Job

Editing a Job

Deleting a Job

Job Options

Creating a Duplicate Job

Setting the Default Job

Renaming a Job

Reloading a Job

27

27

28

28

28

29

30

30

31

31

31

32

32

Job Types

Weighing Methods

Printing Only a Graphic Ad

Printing a Date Correction

Printing a Postage Correction

Printing the Received Date and Time

Printing a Permit

Sealing Envelopes without Printing Postage

Counting Mail without Printing Postage

Weighing, Rating and Counting Mail without Printing Postage

Moving Between Open Jobs

Saving Changes to a Job

Closing All Jobs

33

33

34

35

35

36

37

37

38

39

40

40

40

Page 31

Connect+® Series Operator Guide

All About Jobs

The Connect+™ Series allows you to save common jobs that can be recalled and easily

modified.

A job is a collection of settings you select and a name that are stored within the system's

memory for easy recall. A job can contain set values for such items as the account name,

postage amount, class, carrier, a special service, a mode such as Attached Scale or Differential weighing, etc. If you run different kinds of mail, such as Sealed and Unsealed, you

may find it more convenient to create a job for each kind. These settings make the system

easy to learn – especially for the casual operator who does not consistently use a mailing

system.

The default job is the job you use to store your most commonly used system settings. These

are the settings your system will use whenever you restart your machine. After a certain

period of inactivity, or when you power up, the system restores the default job settings.

l

You can manage your jobs (create, edit, delete, rename, etc.) or select a job to process

mail against by selecting the Run Mail button on the Home screen.

l

You can view a master list of the jobs on your system, and the settings associated with

each job, by selecting the Jobs button on the Home screen.

Saved jobs are stored, and can be easily opened, edited, or deleted as necessary.

About Job Properties

All of the job properties for the current job are displayed in a list box on the left side of the

Run Mail screen. To view all of the job settings, select the down arrow below the list box. To

change any of the properties, select it.

If one of the job properties is required to run this job, it is displayed in red. For example, if the

job requires you to assign a class, Class Required appears in red in the list box.

The items appearing in the job properties list box depend on the job selected. If you have

selected a specific job type, or a library job, the available job properties are limited to those

options that apply specifically to the job type. For example, if the job is a Seal only, No printing job, the list box only contains the sealer setting and the account selection (if available).

SV62250 Rev. G

27

Page 32

Chapter 2

The Default Job

There is always at least one job open in Run Mail - the default job.

The default job is special:

l

it is always open, and

l

it is protected so you don't overwrite it easily.

NOTE: To clear all changes made while running mail and to return to the default job to its

original state, select the Reload job link on the Default job tab.

Opening a Job

Follow the steps below to open a job.

1. You can open a job by selecting the Open a job tab on the Run Mail screen or by select-

ing the Jobs button on the Home screen. The Jobs screen appears with a list of jobs available on your system.

2.

Select the job you want to open.

NOTE: Up to five jobs can be open at one time.

3. Select OK. A tab for the job opens on the Run Mail screen.

Previewing Jobs

The Jobs screen lists all the jobs stored on your system.

1. Select the Open a job tab from within the Run Mail screen, or select the Jobs button on

the Home screen.

2. The Jobs screen appears with a list of jobs available on your system.

l

If necessary, you can sort the jobs by name, type or creator. Select the appropriate column heading to change the sort order.

l

Use the up and down arrow buttons to scroll through the list.

3.

Select the job you want to preview. You can change the view of the job using the icons in

28

SV62250 Rev. G

Page 33

Connect+® Series Operator Guide

the upper right corner of the screen.

Job settings view - Select this icon to view all of the settings for the selected job (for

example, class, weighing type...), as well as an envelope preview.

List view - Select this icon to view the complete list of jobs on your system. List view

is the default view setting on your system.

NOTE: The "man at work" icon indicates that the job is missing some required elements.

4. Select the back arrow button to return to the Home screen, or select OK to open the currently selected job in the Run Mail screen.

Creating a New Job

You can create a job:

l

by editing an existing job and then selecting the Save as option on the Run Mail screen,

l

by selecting the Create new job button on the Jobs screen, or

l

by selecting Create new job... on the Options menu of the Run Mail screen.

Follow the steps below to create a new job on the Run Mail screen.

1. Select the Run Mail button on the Home screen.

2.

Select the Options button and then select Create new job....

3. Select the appropriate job type from the list.

4. Select OK. The job you selected appears in a new job tab.

5. Select the appropriate job settings.

6. Select Save As.

7. Enter the new job name and select OK.

Creating a New Job from the Jobs Screen

You can create a job:

l

by editing an existing job and then selecting the Save as option on the Run Mail screen,

l

by selecting Create new job... on the Options menu of the Run Mail screen, or

SV62250 Rev. G

29

Page 34

Chapter 2

l

by selecting the Create new job button on the Jobs screen.

Follow the steps below to create a new job from the Jobs screen.

1. Select the Jobs button on the Home screen.

2. Select the Create new job button.

3. Select the appropriate job type from the list.

4. Select OK. The Run Mail screen appears with the job you selected in a new job tab.

5. Select the appropriate job settings.

6. Select Save As.

7. Enter the new job name and select OK.

Editing a Job

You can edit a job by making changes to the job and envelope properties on the Run Mail

screen.

1. Open the job that you want to edit.

2. Select the item you want to change.

l

To change anything that prints on the envelope, including the date, select the envelope. To change anything that prints on the tape, select the tape.

l To change any of the job properties (for example, the class or mail), select the appro-

priate option in the job properties list located on the left side of the Run Mail screen.

3. Save your changes.

Deleting a Job

To delete a saved job:

1. Select the Jobs button on the Home screen.

2. Select the job you want to delete.

3.

Select the Options button and then select Delete job.

30

SV62250 Rev. G

Page 35

Connect+® Series Operator Guide

NOTE: You cannot delete the default job or jobs that are locked against editing.

4. Select Yes, delete.

5. Select OK when done.

Job Options

The Options button at the bottom of the Jobs screen allows you to manage and edit your

jobs. Select the Options button and choose from one of the following.

l

Rename job - Select this option if you want to rename the selected job. The job must be

closed on the Run Mail screen before you rename it.

l

Duplicate job - Select this option if you want to create a copy of the selected job.

l

Delete job - Select this option if you want to delete the selected job. The default job,

library jobs, and jobs that have been locked cannot be deleted.

l

Make this job the default job - Select this option if you want to make the selected job the

default job.

Creating a Duplicate Job

To create a duplicate, or copy, of a job:

1. Select the Open a job tab from within the Run Mail screen, or select the Jobs button on

the Home screen.

2. Select the job you want to duplicate.

3. Select Options then select Duplicate job.The system creates a duplicate job. This job

appears in the Job list below the original, with the word "copy" after the name.

4. Select OK when done.

Setting the Default Job

The default job is the most commonly used job on your mailing system. It is automatically

selected whenever you restart your mailing system. You can change the default job by editing it and then saving the changes, or you can open a different job and save that job as the

default job.

SV62250 Rev. G

31

Page 36

Chapter 2

NOTE: Key in Postage, Postage Correction and Date Correction jobs cannot be set as the

default job.

Setting the Default Job on the Run Mail Screen

1.

Ensure the job you want to make the default is open and active on the Run Mail screen.

2. Select the Options button.

3. Select Save as default job. the selected job appears on the Default jobs tab. The previous default job appears on a new tab.

Setting the Default Job on the Jobs Screen

1. Select the Jobs button on the Home screen.

2.

Select the job you want to make the default.

3. Select Options then select Save as default job.The system gives the selected job the

default icon.The job also appears on the Default jobs tab in the Run Mail application.

4. Select OK when done.

Renaming a Job

To rename a job:

1. Select the Open a job tab from within the Run Mail screen, or select the Jobs button on

the Home screen.

2. Select the job you want to rename.

3. Select Options then select Rename job.

4.

Enter the new job name.

5. Select OK when done.

Reloading a Job

The Reload job option allows you to reset an edited or modified job to its original state. Use

this option to discard changes you have made to a job.

On the run mail screen:

32

SV62250 Rev. G

Page 37

Connect+® Series Operator Guide

1.

Select the modified job.

NOTE: An asterisk appears next to job name when it has been edited or modified.

2. Select Reload job.The system reverts to the previously saved version of the job.

Job Types

When creating a new job, you can select from the following job types.

l

Select Seal only, no printing if you only want to seal the envelope and do NOT want to

apply postage.

l

Select Date correction when you need to print the correct date on a piece of mail that

already has postage printed on it.

l

Select Postage correction if you do not have the correct amount of postage on a piece of

mail.

l

Select Received date and time if you want to print the date or time on incoming mail for

record keeping.

l

Select Graphic ad only if you only want to print a graphic on the envelope.

l

Select Permit if you want to print a permit on a piece of mail.

l

Select Postal if you want to print postage on a piece of mail.

l

Select Count only if you want to count mail without printing postage.

l

Select Weigh-Rate-Count if you want to track the weight and rate of your mail pieces as

well as count mail without printing postage.

NOTE: The Count only and Weigh-Rate-Count job types are only available if your system

uses accounting.

Weighing Methods

When creating a postal job, you can select from the following weighing methods.

l

WEIGH-ON-THE-WAY® (W-O-W®) - This method processes mixed mail (mail of varying sizes and weights, depending your system configuration) and determines the postage amount based on the weight and dimensions of each mail piece.

SV62250 Rev. G

33

Page 38

Chapter 2

l

WEIGH-ON-THE-WAY® (W-O-W®), first piece only - Use this method for mail pieces

that are identical (same size and number of sheets). The system weighs the first piece of

mail to be fed and calculates the postage. The rest of the stack will be posted with the

same postage as the first piece.

l

Attached scale - Use this method if you do not know the weight of the piece of mail.

l

Manual weight entry - Use this method if you want to enter the weight of an item that you

weighed on a separate scale. This is useful for items that exceed the weight capacity of

the attached scale or mailings that are always the same weight.

l Differential weighing - Use this method if you want to place all of the mail on the scale at

once, then remove and run each piece through the system. The system calculates the

postage for each piece of mail you remove from the scale and applies the postage to the

piece as it goes through the mailing system. For larger pieces of mail (large envelopes or

packages), you can use differential weighing to have the system automatically print a

tape every time you remove a piece of mail from the scale.

NOTE: WEIGH-ON-THE-WAY®, manual weight entry and differential weighing are

optional features.

Printing Only a Graphic Ad

You can create a job to print only non-postal elements like a graphic ad on a tape or envelope. If your system uses accounting, a piece count will be retained for accounting reports.

Follow the steps below to create an ad only job. If you have already created an ad only job,

open the job and begin running mail.

1. Select the Options button on the Run Mail screen.

2. Select Create a new job... and then select Graphic ad only.

3. Select OK. A new job tab appears.

4. Add the graphic ad to the job.

5. Enter the envelope or tape quantity and then select Start or Tape.

6. To save the job, select the Save As link at the top of the screen.

7. Enter the job name and select OK.

34

SV62250 Rev. G

Page 39

Connect+® Series Operator Guide

Printing a Date Correction

You can print a date correction if you need to modify the date printed on your envelope. If you

have already created a date correction job, open the job and begin running mail.

Follow the steps below to create a date correction job.

1. Select the Options button at the bottom of the Run Mail screen.

2. Select Create new job... and then select Date correction.

3.

Select OK. A new job tab appears. The Job Properties list is populated with the required

date correction job settings.

NOTE: The weighing method is not displayed in the postage correction job. Sealing

mode is set to off.

4. If necessary, change the format of the date.

5. If you are printing a tape, select the Tape button.

6. If you are printing on an envelope and if the envelope is sealed, change the sealing

method to sealer off.

a. Turn the piece of mail around 180 degrees so that the postal indicia is in the lower left

corner. Place the envelope on the feed deck with the flap facing down.

b. Select the Start button.

7. To save the job, select the Save As link at the top of the screen.

8. Enter the job name and select OK.

Printing a Postage Correction

If you do not have the correct postage on a piece of mail, you can add more postage by printing a postage correction directly on the envelope or on a tape. If you have already created a

postage correction job for the amount required, open the job and begin running mail.

Follow the steps below to create a postage correction job.

1. Select the Options button at the bottom of the Run Mail screen.

2. Select Create new job... and then select Postage correction.

3.

Select OK. A new job tab appears. The Job Properties list is populated with the required

SV62250 Rev. G

35

Page 40

Chapter 2

postage correction job settings.

NOTE: The weighing method is not displayed in the postage correction job. Sealing

mode is set to off.

4. Select Additional located to the right of the envelope or tape image. Type in the additional postage required and select OK.

5. If you are printing a tape, press the Tape button.

6. If you are printing on an envelope, turn the piece of mail around 180 degrees so that the

postal indicia is in the lower left corner.

a. Place the envelope on the feed deck with the flap facing down.

b. Press the Start button.

7. To save the job, select the Save As link at the top of the screen.

8. Enter the job name and select OK.

Printing the Received Date and Time

The Received date and time option allows you to print the current time and date, along with

the word “Received” on incoming mail. If you have already created a received date and time

job, open the job and begin running mail. If your system uses accounting, a piece count will

be retained for accounting reports.

Follow the steps below to create a received data and time job.

1. Select the Options button on the Run Mail screen.

2. Select Create new job... and then select Received date and time.

3. Select OK.

4. Select the appropriate print options:

l

Print "Received"

l

Print date

l

Print time

NOTE: When printing date and/or time, the sealer is set to off.

36

SV62250 Rev. G

Page 41

Connect+® Series Operator Guide

5. Select Start or Tape.

6. To save the job, select the Save As link at the top of the screen.

7. Enter the job name and select OK.

Printing a Permit

You can print a permit on a piece of mail instead of an indicia. A permit is a postal mark containing a permit number that provides you with special processing or discount rates. You get

the permit(s) from the US Post Office. If you have already created a permit job, open the job

and begin running mail.

Follow the steps below to create a permit job.

1. Select the Options button at the bottom of the Run Mail screen.

2. Select Create new job... and then select Permit job.

3. Select OK. A new job tab appears. The Job Properties list box is populated with the

required permit job settings.

4. Select the Permit Holder City and State button.

a. Enter the city and state.

b. Select OK.

5. Select the Company Name or Permit Number button in the Job Properties list box.

a. Enter either the permit number or the company name.

b. Select OK.

6. Select the Class button.

a. Select the appropriate class.

b. Select OK.

7. To save the job, select the Save As link at the top of the screen.

8. Enter the job name and select OK.

Sealing Envelopes without Printing Postage

You can create a job to seal envelopes without printing postage. If your system uses accounting, a piece count will be included in accounting reports.

SV62250 Rev. G

37

Page 42

Chapter 2

Follow the steps below to create a seal only job. If you have already created a seal only job,

open the job and begin running mail.

1. Select theRun Mail button from the Home screen.

2. Select the Options button.

3. Select Create new job....

4.

Select Seal only, no Printing.

NOTE: Print date is off in Seal only job.

5. Select OK. The job appears in a new job tab.

6. Select Start to begin feeding and sealing envelopes.

7. If you want to save this job, select Save as.

8. Enter the job name and select OK.

Counting Mail without Printing Postage

If your system uses accounting, you can create a job to count mail without printing postage.

The piece count will be included in accounting reports.

Follow the steps below to create a count only job. If you have already created a count only

job, open the job and begin running mail.

1. Select theRun Mail button from the Home screen.

2. Select the Options button.

3. Select Create new job....

4.

Select Count only.

5. Select OK. The job appears in a new job tab.

6. Select the appropriate counter and then select OK.

l

Total - Count only: total number of pieces for the current job.

l

Resettable - Count only: the total number of pieces run since you reset the counter.

7. Select an account.

38

SV62250 Rev. G

Page 43

Connect+® Series Operator Guide

8. If necessary, select a surcharge.

9. Select Start to begin feeding and counting envelopes.

10. If you want to save this job, select Save as.

11. Enter the job name and select OK.

Weighing, Rating and Counting Mail without Printing Postage

If your system uses accounting, you can create a job to weigh, rate and count mail without

printing postage. In addition, you can add a graphic ad to the mail piece. The weighing and

rating information, as well as the piece count, will be included in accounting reports.

Follow the steps below to create a count only job. If you have already created a count only

job, open the job and begin running mail.

1. Select theRun Mail button from the Home screen.

2. Select the Options button.

3. Select Create new job....

4.

Select Weigh-Rate-Count.

5. Select OK. The job appears in a new job tab.

6. Select the appropriate counter and then select OK.

l

Total - Weigh-Rate-Count: total number of pieces for the current job.

l

Resettable - Weigh-Rate-Count: the total number of pieces run since you reset the

counter.

7. If necessary, add a graphic ad to the job.

8.

Select an account

9. If necessary, select a surcharge.

10. Select the appropriate class, carrier, or special services.

11. Select Start to begin feeding and counting envelopes.

12. If you want to save this job, select Save as.

13. Enter the job name and select OK.

SV62250 Rev. G

39

Page 44

Chapter 2

Moving Between Open Jobs

To quickly move between frequently used jobs, open the jobs and then select the job tabs as

necessary on the Run Mail screen.

Saving Changes to a Job

If you have made changes to a job, an asterisk appears next to the job name on the Run Mail

screen. You can save your changes to a job at any time. If you want to discard the changes

you've made, you can reload the previously saved version of the job.

l

To save your changes to the selected job, select Save.

l

To save your changes as a new job select Save as. Enter a new job name and then

select OK.

NOTE: If the selected job is a library job, you must select Save as and create a new job to

save your changes.

Closing All Jobs

Select Start over on the Run Mail screen to close all open jobs, discard all unsaved edits

made to saved jobs, discard all unsaved jobs and reload the default job.

NOTE: The Start over option does not allow you to save changes made to the default job.

40

SV62250 Rev. G

Page 45

3 ● Running Mail

Determining the Correct Postage Method

Preparing and Correctly Feeding the Mail Pieces

Reviewing the Mail Piece Specifications

Shape Based Rating

Running Mail

Run Mail Screen Icons and Buttons

Run Mail Options

Step-by-Step Running Mail

Running Mail with the DI900™/DI950™ Inserting System Interface

Running Mail with SendSuite Xpress™ or Ascent™

Graphics and Permit-Only Printing

Changing the Class, Carrier, or Special Services

Selecting a ZIP or Zone

44

46

47

49

49

50

52

52

53

54

56

57

58

Selecting a Country

Changing or Selecting the Weighing Method

Zeroing the Scale while Running Mail

Running a Manual Weight Entry Job

Running an Attached Scale Job

Running a WEIGH-ON-THE-WAY® (W-O-W®) Job

Loading Mail for a WEIGH-ON-THE-WAY® (W-O-W®) Job

Running a WEIGH-ON-THE-WAY® (W-O-W®) - First Piece Only Job

Running Mail with Different Shapes and Weights

Running a Differential Weighing Mail Job

Changing the Sealing Method

Checking or Changing the Postage Amount on the Run Mail Screen

Key in Postage

58

59

59

60

60

61

61

61

62

63

65

66

66

Page 46

Chapter 3

Changing the Envelope or Tape Quantity

Changing the Date

Changing the Machine Speed

Printing a Sample Mail Piece

Counting Mail

Adding Graphics, Return Addresses, Messages, and Inscriptions to Your Mail

Graphic Ad

Return Address

Changing or Adding a Graphic to a Mail Piece

Viewing Available Graphics

Adding a Graphic

Positioning a Graphic/Message

How Markers are Added/Dropped

67

67

68

68

68

69

70

71

71

71

72

73

75

Changing the Image/Message Drop Order

About MyGraphics™ Designer

Prerequisites for Using MyGraphics™ Designer

Add a New Graphic Using MyGraphics™ Designer

Check Status of Graphic Images

Graphic Formats for MyGraphics™ Designer

How to Create a New Custom Graphic

Changing or Adding an Indicia

Changing or Adding an Inscription

Postal Inscriptions

Changing or Adding a Text Message or Return Address

Viewing Available Messages/Return Addresses

Adding a Message or Return Address

76

76

77

77

79

80

80

81

81

82

82

83

83

42

SV62250 Rev. G

Page 47

Connect+® Series Operator Guide

Creating a New Message or Return Address

Changing or Selecting the Envelope Characteristics

Changing the Envelope Print Area

Changing the Color Print Quality

Changing Envelope Size

What are Tracking Services

Delivery Confirmation

Signature Confirmation

Certified Mail

Selecting a Tracking Service

Electronic Return Receipt (ERR)

USPS® Mailer ID

Customer Reference Number

84

85

85

86

87

87

88

89

89

90

91

92

92

How to Use Electronic Return Receipt (ERR)

Creating a Combined Barcode Label Job

Running Mail with a Combined Barcode Label Job

Using PresortXtra Services

Qualifications for PresortXtra Service

Setting Up PresortXtra Service Jobs

Adding the Drop Ship Authorization Meter Text

Running a PresortXtra Job

Saving the PresortXtra Job

92

94

95

96

97

97

98

99

100

SV62250 Rev. G

43

Page 48

Connect+® Series Operator Guide

Determining the Correct Postage Method

l

If your mail requires no application of postage, see Chart C to choose your job settings.

l

If your mail requires postage, you must determine if you can print directly on your mail.

You can feed mail if your pieces of mail meet the requirements provided in Mail Piece

Specifications. If your mail meets these requirements, select the appropriate postage or

weighing method from Chart A.

l

If your mail does NOT meet the Mail Piece Specifications requirements for direct printing,

you MUST print a postage tape. Select the applicable postage or weighing method from

Chart B.

Chart A - Printing on Mail

If: Then use this method:

You know the amount of postage

Key in Postage

needed for your mail.

You are running postcards. Select the Postage Rate when

selecting the Class.

You do not know the weight of your

Attached Scale

piece of mail.

The pieces of mail are different

weights but fall within the guide-

WEIGH-ON-THE-WAY® (W-O-

W®)

lines listed above and in the Mail

Piece Specifications topic.

All pieces of mail are identical. WEIGH-ON-THE-WAY® (W-O-

W®), first piece only

Your pieces of mail vary in types,

Differential weighing with Auto

sizes, and/or weights and you have

several you need to process

quickly and efficiently.

SV62250 Rev. G

envelope printing selected

44

Page 49

Chapter 3

If: Then use this method:

Chart B - Printing on Tape

You know the amount of postage

Key in Postage

needed for your mail.

You do not know the weight of your

Attached Scale

piece of mail.

You have several pieces of mail

Attached Scale

and do not know the required postage amounts.

You know the weight. Manual weight entry

Your pieces of mail vary in types,

sizes, and/or weights.

Chart C - Processing with no Postage

Differential weighing with Auto tape

printing selected

If: Then use this method:

45

You only want to seal the envelopes and do not want to apply postage.

You want to print the date or time

incoming mail for record keeping.

Seal only

Date and Time non-postal jobs

SV62250 Rev. G

Page 50

Connect+® Series Operator Guide

Preparing and Correctly Feeding the Mail Pieces

If your system has WEIGH-ON-THE-WAY® (W-O-W®) (Connect+® 2000 or Connect+®

3000), you do not need to sort your mail. Simply place the larger pieces on the bottom of the

stack on the feeder. If your mail pieces are sealed, fan them to make sure they are not stuck

together as a result of previous processing.

If you system does not have WEIGH-ON-THE-WAY® (W-O-W®):

1. Sort the mail by envelope size.

2. Shingle envelopes (slant the stack as shown) so the bottom envelope feeds first. All

envelopes in a single stack should be the same size.

3. Place the stack of mail on the feed deck. Place the envelopes with the flaps down and

against the rear wall.

4. Make sure the envelopes are pushed far enough so that they cover the feed sensor

located on the feed deck near the rear wall.

5. Adjust the side guide so it is close to, but not touching, the bottom edge of the envelope

stack. Be sure and leave a slight clearance between the side guide and envelopes

(about 1/16 inch clearance).

6. Use the thickness adjustment knob to adjust for envelope thickness. .

7. For large stacks of thin mail, such as single inserts or post cards, the thin mail setting may

be needed for better performance.

8. To pick a setting, turn the knob so the setting aligns with the pointer nearby.

SV62250 Rev. G

46

Page 51

Chapter 3

Reviewing the Mail Piece Specifications

Envelope Dimensions

Minimum 3.5 in. x 5 in. (88.9mm x 127mm) postcard size

Maximum Connect+® 1000 and Connect+® 2000: 13 in. x

14 in. (330 mm x 356 mm)

Connect+® 3000: 15 in. x 15 in. (381 mm x 381

mm)

Envelope Thickness

Minimum Connect+® 1000 and Connect+® 2000: 0.18 in.

(0.007 mm)

Connect+® 3000: 0.09 in. (0.004 mm)

Maximum Connect+® 1000 and Connect+® 2000: 0.625 in.

(15.9 mm)

Connect+® 3000: 0.75 in. (19.1 mm)

Envelope Flap Depth for Sealing

Minimum 1 in. (25.4 mm)

Maximum Connect+® 1000 and Connect+® 2000: 3 in.

(76.6 mm)

Connect+® 3000: 3-7/8 in. (98 mm)

l

For envelopes with a flap length from 1 to 2.36 inches (25 mm to 60 mm), the minimum

flap angle is 18 degrees.

l

For envelopes with a flap length greater than 2.36 inches (60 mm) to the maximum flap

length for the particular model, the minimum flap angle is 21 degrees.

47

SV62250 Rev. G

Page 52

Connect+® Series Operator Guide

Acceptable Envelope Materials

Material type and finish must be matte and may include:

l

White Wove

l

Kraft/Brown Kraft

l

Manila

l

Envelopes made of recycled paper

l

Self-seal envelopes

l

Tri-fold tabbed (2 tabs minimum) inserts (20 lbs. (75 gms) to 28 lbs. (105 gms))

l

Cranes Crest

SV62250 Rev. G

48

Page 53

Chapter 3

CAUTION: Do not use envelopes made with glossy materials such as fliers, or Tyvek®

envelopes. Also do not use envelopes too fragile (such as air mail and onion skin envelopes) to pass through the feeder.

Shape Based Rating

The shape of a mailpiece (thickness, length, width) plays a large role in the pricing of FirstClass Mail®, Express Mail, and Priority Mail postage. Since May of 2007, the USPS® has

combined weight with shape to better align prices with processing costs. This is to ensure

that every type of mail covers its costs, i.e., Shape Based Rating or SBR.

When shape based rating is used, the mailing system determines the size and weight of the

mail and automatically selects the appropriate rate.

Shape based rating is available on systems with the WEIGH-ON-THE-WAY® (W-O-W®)

/Shape Based Rating module.

Running Mail

NOTE: If you have accounts enabled on your system, you must select an account before

you can run a mail job.

1. Ensure that the appropriate job is open and selected on the Run Mail screen.

2. Load the envelopes.

3. Check the postage amount on the screen.

4. Check the sealer setting.

5. Run your job (select Start or Tape).

NOTE: Select any item you want to change.

49

SV62250 Rev. G

Page 54

Run Mail Screen Icons and Buttons

Button, Icon, or Link Touching or Selecting:

Tape Preview Icon Displays a preview of the tape to be printed.

Tape Preview Image Opens the Edit Envelope screen allowing you to

make changes to your envelope.

Connect+® Series Operator Guide

Envelope Preview Icon Displays a preview of the envelope to be printed.

Envelope Preview Image Opens the Edit Envelope screen allowing you to

make changes to your envelope.

Postage Amount Image Opens the Key in Postage dialog screen.

SV62250 Rev. G

50

Page 55

Chapter 3

Button, Icon, or Link Touching or Selecting:

Date image Opens the Print Date dialog box within the Edit

Envelope screen so you can modify the date

printed on tape or envelope.

Start button If the job is selected and envelopes loaded, this

starts the job running.

Tape button If the job is selected and ready, this results in run-

ning the job.

The weighing icon opens the weighing method

dialog screen. The shape of this icon varies

depending on the weighing method for the current job.

The sealer icon opens the sealing method dialog

screen. The icons shown here indicates sealing

is on.

51

SV62250 Rev. G

Page 56

Connect+® Series Operator Guide

Run Mail Options

Select Options button at the bottom of the Run Mail screen and select the appropriate

option.

These options include:

l

Print a sample piece - prints an envelope or tape so you can see exactly how the

address, inscriptions, ads or graphics elements will print on the mail piece for the current

job.

l

Zero scale - this ensures that the attached scale is reading zero when there are no mail

pieces on it.

l

Create a new job - select this to create a new job.

l

High value warning - set a value at which the mailing system warns you that you have

entered a postage value that is more than the amount you are setting here. This feature

prevents you from accidentally printing a postage amount that is more than you need.

Step-by-Step Running Mail

Use the Run Mail screen to select your job or review current job settings. This screen also

keeps a running count of the processed mail. Refer to Run Mail Screen Icons and Buttons for

a summary of the screen icons.

NOTE: if you have accounts enabled on your system, you must select an account before

you can run a mail job.

1. Select theRun Mail button from the Home screen.

2. Select an available job tab (or jobs) or open another job using the Open a Job tab along

the top of the screen.

3. Verify the current job settings displayed in the Job Properties list box on the left side of

the Run Mail screen. To change any of the settings, simply select the item, for example,

select Class to change the class.

More information:

a. To change the weighing or sealing method, select its icon on the Run Mail screen.

b. To enter a new postage amount, select the Key in Postage tab at the bottom of the

screen, or select the postage amount in the Run Mail screen.

SV62250 Rev. G

52

Page 57

Chapter 3

c. To change the number of envelopes or tapes to print for this job, select the Envelope

or Tape link tab on the Run Mail screen.

4. To make changes to the envelope, or to the items that print on the envelope, select the

Edit envelope link on the Run Mail tab. This opens the Edit envelope screen.

5. To change the speed at which you process mail, select Machine speed from the Job Properties list box.

6. To preview the envelope, select the View full preview button at the bottom of the Edit

envelope screen.

7. To view other possible options (for example, to print a sample mail piece) select the

Options button at the bottom of the screen.

8. Load envelopes and press the Start button, or if printing to tape, press the Tape button.

More information:

a. If the message "Optimizing print quality..." displays, the system may be performing nor-

mal printer maintenance. Once complete, it will start printing.

b. If you have not loaded the envelopes onto the feeder, or if you need to add more mail

to the feeder, the Run Mail screen shows the message "Waiting for Envelope".

c. If after a certain time you have not loaded envelopes, the feeder will stop and the mes-

sage "Stopping..." is displayed.

9. As the system processes the mail pieces, it keeps track of the number of pieces and the

total postage amount. To check or clear the piece count, select the Counter button at the

bottom of the Run Mail screen

10. If an envelope or tape jams during printing, the system stops and displays the location of

the jam. Once you clear the jam you have to option of printing another envelope or tape.

11. To save any changes you have made to this job, select Save or Save as on the top of the

Run Mail screen.

Running Mail with the DI900™/DI950™ Inserting System Interface

The inserting system interface enables communication between DI900™/DI950™ FastPac®

inserting systems and Connect+® Series systems via an Ethernet/LAN connection. When

the inserting interface is in place, the inserter feeds mailpieces onto the Connect+® Seriessystem feed deck for metering.

NOTE: Mail pieces must be sealed by the inserter.

53

SV62250 Rev. G

Page 58

Connect+® Series Operator Guide

NOTE: On Connect+® 1000systems, all mail pieces in a job must be identical.

l

The inserter sends start and stop signals to the Connect+® Series system. The Connect+® Series system can send error messages back to the inserter to stop feeding.

l

If the Connect+® Series system is overcome with mail, it can pause the inserter to prevent it from producing any additional mail pieces, process the mail pieces on the feeder,

then signal the inserter to resume once it has caught up.

l

When the mailing system is in maintenance mode, it will pause the inserter, then signal

the inserter to resume once maintenance is complete.

For more information about the DI900™/DI950™ FastPac® inserting system, refer to the

refer to the documentation provided with the inserter.

Running Mail with SendSuite Xpress™ or Ascent™

When a Connect+® Series system is interfaced with SendSuite Xpress™ or Ascent™, the

shipping application sends a shipping job to the mailing system.

NOTE: Accounting must be turned off and user logins must be disabled on your Connect+®

Series system before SendSuite Xpress™ or Ascent™ can successfully send a shipping

job.

The Start and Tape buttons are replaced by a "Printing Remotely Controlled" message while

the shipping application sends the job properties to the system. There are two types of jobs

sent from the shipping system: trip and batch.

l

If a trip job is sent, the Connect+® Series system displays the postage amount and

changes the job to Key in Postage mode. The Start and Tape buttons remain unavailable. Running mail is remotely controlled by the shipping application and your postage is

printed on a tape or tapes. Non-postal job properties (graphic ads, text messages, etc.)

cannot be added to a trip job.

l

If a batch job is sent, the Start and Tape buttons become available once the job is

received by the Connect+® Series system. You can add or edit non-postal job properties,

and print to either envelopes or tapes.

Lock Spend

If "lock spend"option is checked in SendSuite Xpress™ or Ascent™, printing (spending) on

the Connect+® Series is locked; this means that the Start and Tape buttons are not available

SV62250 Rev. G

54

Page 59

Chapter 3

on the Run Mail screen when a postal job is selected. You will be able to run non-postal jobs

in lock spend mode. All other system features and functions remain available. Once a job run

is complete, the system will return to lock spend mode.

For more information about SendSuite Xpress™ or Ascent™, refer to the help system provided with the application.

Running Mail with the Residual Rate Surcharge

The Residual Rate Surcharge allows you to process mail at a discounted rate while charging your customer back for the normal postage amount in the form of a surcharge.

NOTE: The Residual Rate Surcharge is a purchasable option. Accounting is required to utilize this surcharge.

How Does the Residual Rate Surcharge Work?

Residual Rate Surcharge selections are made out of the Run Mail application. The surcharge can be used with any postal job. The ResidualRate Surcharge must be enabled (set

to "Yes") for the job.

l

Select the carrier and class necessary to obtain the discounted rate. This is the rate that

will be used to process the mail.

l

Select the billing class. The class you select should contain the normal postage rate.

l The Residual Rate Surcharge is the difference between the postal rate for the billing

class and discounted postal rate used to process the mail.

EXAMPLE: If you processed the mail with the First Class Commercial Presorted rate

($0.414), and selected First Class Letter as the billing class ($0.44), the Residual Rate

Surcharge would be $0.026 per piece of mail ($0.44 - $0.414 = $0.026).

Selecting the Residual Rate Surcharge

1. Ensure that the appropriate job is open and selected on the Run Mail screen.

2. Ensure that the Residual Rates Surcharge is set to Yes. If necessary, select Residual

Rate Surcharge in the Job Properties list box to toggle between Yes and No.

3. Select the carrier, class and special services you want to use to process the mail.

55

SV62250 Rev. G

Page 60

Connect+® Series Operator Guide

4. Select Billing Class in the Job Properties list box.

a. Select the class of postage you want to use to bill your customer.

b. Select OK.

5. Select Start to begin running mail.

Graphics and Permit-Only Printing

If you have a graphics and permit-only printing system, you have a fully-featured Connect+®

Series system with a deactivated meter, which prevents postage printing. Graphics and permit-only systems can run non-postal jobs as well as utilize sealing and accounting features

with no meter charges.

NOTE: Although a Connect+® Series graphics and permit-only system cannot print postage, the United States Postal Service (USPS) still requires an electronic inspection of the

meter. Periodically, you will receive a "Postal Inspection Required" message on your system. You can check your balance at Pitney Bowes to satisfy this requirement. Refer to Your

Postage Meter for more information about postal inspections.

Running Mail

With a graphics and permit-only system you can:

l

Print the correct date on a piece of mail that already has postage printed on it.

l

Print the received date and time on incoming mail for record keeping.

l

Print a graphic on the envelope.

l

Print a permit on a piece of mail.

l

Seal envelopes without printing postage.

l

Count how many pieces of mail you run.

l

Track the mail you run with the integrated accounting feature.

NOTE: If the default job on your system is a postal job, the Low Funds warning will appear

each time you open the Run Mail application. Change the default job to a job that does not

print postage (e.g. Permit or Graphic ad only) to prevent this message from appearing.

SV62250 Rev. G

56

Page 61

Chapter 3

NOTE: The following message will appear on the Run Mail screen:

Alert 1 of 1: Funds

Manager:PSD funds available are below monetary limit set by user in FMRefill Setup

screen

. You can ignore this message on graphics and permit-only printing systems.

Changing the Class, Carrier, or Special Services

1. Select theRun Mail button from the Home screen.

2. To display and select the classes and services available on your system or in your country open a postal job and select Class in the Job Properties list box on the Run Mail

screen.

3.

Select the appropriate tab on the classes and services screen.

Tabs include:

l

All classes and services - lists all of the classes available and any additional

service associated with the class. When you select this tab, the last class selected

is displayed. To clear the selected class and any associated services, select Start

over within this tab.

4.

Select the class from the class list box.

More information about selecting a class:

l

If the class has other subclasses associated with it, it will have a plus sign (+) in

front of it. Selecting the class will display the additional subclasses within the

Class list box. For example, in the US, you can select First Class, then Letter.

l

If an option button appears in front of the class, the postage amount is typically displayed after the class name.

l

Selecting the Back button at the top of the Class list box returns you to

the previous class level. For example, if you have selected First Class >Letter,

selecting Back returns you to the Class list box.

l

If the class requires additional information, it will display ellipses "... " after the

name. When you select this class, you are prompted to enter the additional information.

l

When you select a class, the rating factors for that class appear in the list box on

the left of the Run Mail screen. For example, for USPS rates, this may include the

Weighing method, Destination, and Print date. To change any of these factors,

select the item in the list box.

57

SV62250 Rev. G

Page 62

Connect+® Series Operator Guide

l

If special services are available for a class, they are displayed in the Extra services list box. To select a service, touch the checkbox for the service. For example,

in the US for First Class letter, you can add insurance or COD. You can also add

confirmation tracking services like Delivery confirmation, E-Certified, or Certified.

l

If you select a class or service that is incompatible with a.) the weighing method,

b.) the weight of a mail piece currently on the scale, c.) a weight or amount of postage entered manually, d.) or a destination, a dialog box appears and prompts you

to modify the item. For example, if the weighing method is incompatible you are

prompted to select a new method.

5. If the class or weight requires a ZIPor Zone code, the system prompts you to enter it.

6. If you select an International rate, the system prompts you to select the country.

7. Select any extra service or services available for the class from the Extra services list

box.

8. Select OK.

Selecting a ZIP or Zone

If you select a class or weight from within the Run Mail screen that requires a destination ZIP

or Zone code (for example, Express Mail Parcel), the system prompts you to enter it.

Use the keyboard enter the ZIPor Zone code, then select This isa ZIP or This is a Zone.

NOTE: You are only prompted to enter a ZIP/Zone code if the job does not have a code, or

if you have re-powered the system. Once you enter a ZIP/Zone code, the system stores that