Pitco Frialator Gas Fryer 65 User Manual

|

|

|

ENGLISH |

Installation, Operation, and Maintenance Manual |

|

||

|

For Gas Fryers |

|

|

|

CoveringModels |

|

FRANCAIS |

|

45C+, 35C+ and 40C+, 65 |

|

|

|

|

|

|

Pitco Frialator, Inc., |

P.O.Box501,JctI-89&I-93Concord,NH03302-0501•509Route3A,Bow,NH03304 |

|

|

|

(603) 225-6684 • FAX (603) 225-8497 |

L20-072 Rev 7 (01/13) |

|

|

|

|

|

Pitco Frialator #L20-072 Rev 7 (01/13)

NOTICES

There are three different types of notices that you should be familiar with, a NOTICE, CAUTION, and WARNING. A NOTICE is a special note used to call attention to a particularly important point. CAUTION is used to point out a procedure or operation which may cause equipment damage. The WARNING notice is the most important of the three because it warns of an operation that may cause personal injury. Please familiarize yourself with your new cooker before operating it and heed the notices throughout this manual. The WARNINGS are listed below and on the following page for your review prior to operating the unit.

FOR YOUR SAFETY

DO NOT store or use gasoline or other flammable vapors or liquids in the vicinity of this or any other appliance.

WARNING: Improper installation, adjustment, alteration, service or maintenance can cause property damage, injury or death. Read the installation, operating and maintenance instructions thoroughly before installing or servicing this equipment.

ENGLISH

TO THE PURCHASER

POST IN A PROMINENT LOCATION INSTRUCTIONS TO BE FOLLOWED IN THE EVENT THAT AN OPERATOR SMELLS GAS. OBTAIN THIS INFORMATION FROM YOUR LOCAL GAS SUPPLIER.

THIS MANUAL MUST BE RETAINED FOR FUTURE REFERENCE

SAFETY SAFETY SAFETY SAFETY SAFETY

WARNING

Thecookermustbeelectricallygroundedinaccordancewithlocal codes. Iflocalcodesdonotapply,followtherequirementsof NationalCodeANSI/NFPA70-1990.

WARNING

This cooker is equipped with a three prong safety plug. This safety plug protectsoperatorsfromelectricalshockintheeventofanequipmentmalfunction. DO NOT remove the grounding (third) prong from this plug.

WARNING

DONOTuseanopenflametocheckforgasleaks!

WARNING

A cooker that is equipped with casters and a flexible power cord must be connected to the gas supply with a Quick-Disconnect device. This quick disconnectmustcomplywithANSIZ24.41-1989. Arestrainingcablemust beinstalledtolimitthemovementofthecooker.

WARNING

Thereisanopengasflameinsidethecooker. Theunitmaygethotenough tosetnearbymaterialsonfire. Keeptheareaaroundthecookerfreefrom combustiblematerials.

WARNING

Ensurethatthecookercangetenoughairtokeeptheflameburningcorrectly.

If the flame is starved for air it can give off dangerous carbon monoxide.

CarbonMonoxideisaclearodorlessgasthatcancausesuffocationanddeath.

WARNING

Be sure the burner tubes are COMPLETELY covered with water before lightingthepilotormainburners. Ifthetubesareexposed,thecookermay overheat,causingdamagetothekettle,creatingafirehazard,andvoidingthe warranty.

SAFETY SAFETY SAFETY SAFETY SAFETY

SAFETY SAFETY SAFETY SAFETY SAFETY

WARNING

Carbon monoxide can build up if the flue is blocked. Blocking the flue will alsocausethecookertooverheat. Ensurethatminimumclearancesspecified intheinstallationinstructionsaremaintained. DONOTobstructtheflowof combustion/ventilationorairopeningaroundtheNoodleCooker. Adequate clearancearoundthecookerisnecessaryforservicingandproperburner operation. Ensurethatyoumeettheminimumclearancesspecifiedinthe installationinstructions.

WARNING

Thepowersupplymustbedisconnectedbeforeservicingorcleaningthe appliance.

WARNING

Forgascookers,DONOTsupplythecookerwithagasthatisnotlistedon thedataplate. Ifyouneedtoconvertthecookertoanothertypeoffuel,contact yourdealer. WARNING

Forgascookers,WAITfive(5)minutesbeforeattemptingtorelightthepilot. Thisallowstimeforanygasremaininginthecookertodissipate.

ENGLISH

THIS MANUAL MUST BE RETAINED FOR FUTURE REFERENCE

SAFETY SAFETY SAFETY SAFETY SAFETY

TableofContents

Section |

Title |

Page |

|

|

|

Table of Contents ............................................................................................................................................ |

i |

|

List of Tables and Figures ................................................................................................................................... |

ii |

|

Chapter 1: General Information and Installation ..................................................................................... |

1-1 |

|

1.1 |

WHICH FRYER DO I HAVE? .................................................................................................. |

1-1 |

1.2 |

CHECKING YOUR NEW FRYER............................................................................................ |

1-1 |

1.2.1 |

Check Your Order ................................................................................................................ |

1-2 |

1.3 |

ASSEMBLY AND LEVELING ................................................................................................. |

1-2 |

1.3.1 |

Leg/Caster Installation and Adjustment ............................................................................... |

1-2 |

1.3.2 |

Assembling Multi Fryer Systems ......................................................................................... |

1-3 |

1.4 |

INSTALLATION ........................................................................................................................ |

1-3 |

1.4.1 |

Installation Clearances.......................................................................................................... |

1-3 |

1.4.2 |

Gas Connection .................................................................................................................... |

1-3 |

1.4.2.1 |

Fuel Types ..................................................................................................................... |

1-4 |

1.4.2.2 |

Gas Line Connection ..................................................................................................... |

1-4 |

1.4.2.3 |

Quick Disconnect Gas Connection ................................................................................ |

1-4 |

1.4.2.4 |

Fuel Supply Line Leak and Pressure Testing ................................................................ |

1-5 |

1.4.3 |

Ventilation and Fire Safety Systems .................................................................................... |

1-5 |

1.5 |

INITIAL ADJUSTMENTS......................................................................................................... |

1-5 |

1.5.1 |

Visual Checks ....................................................................................................................... |

1-6 |

1.5.2 |

Burner Ignition Systems ....................................................................................................... |

1-6 |

1.5.2.1 |

Pilot Flame Adjustment ................................................................................................. |

1-7 |

1.5.3 |

Main Burner System ............................................................................................................. |

1-8 |

1.5.3.1 |

Gas Line Requirements.................................................................................................. |

1-8 |

1.5.3.2 |

Burner Adjustment ........................................................................................................ |

1-8 |

1.5.4 |

Initial Cleaning ..................................................................................................................... |

1-9 |

1.5.5 |

Thermostat Calibration Check ............................................................................................ |

1-10 |

1.5.6 |

Thermostat Calibration ....................................................................................................... |

1-11 |

Chapter 2: |

Operating Instructions ............................................................................................................. |

2-1 |

2.1 |

FILLING THE FRYER ............................................................................................................... |

2-1 |

2.1.1 |

Filling the Fryer With Liquid Shortening ............................................................................. |

2-1 |

2.1.2 |

Filling the Fryer With Solid Shortening ............................................................................... |

2-1 |

2.2 |

OPERATING INSTRUCTIONS ................................................................................................ |

2-2 |

2.2.1 |

Fryer Start-Up ....................................................................................................................... |

2-2 |

2.2.2 |

Melting Solid Shortening...................................................................................................... |

2-2 |

2.2.3 |

Fryer Shutdown .................................................................................................................... |

2-3 |

2.3 |

DAILY CLEANING ................................................................................................................... |

2-3 |

Chapter 3: Owner Maintenance and Adjustments ................................................................................... |

3-1 |

|

3.1 |

WEEKLY FRYER CLEANING (BOIL OUT) .......................................................................... |

3-1 |

3.2 |

FLUE INSPECTION .................................................................................................................. |

3-1 |

3.3 |

TROUBLESHOOTING .............................................................................................................. |

3-2 |

ENGLISH

i

ListofTablesandFigures

Table |

Title |

Page |

|

|

|

1-1 |

FryerModelInformation ................................................................................. |

1-1 |

1-2 |

VentilationandFireSafetyReferences.............................................................. |

1-7 |

Figure |

Title |

Page |

|

|

|

1-1 |

PilotAssembly,FlameAdjustment ................................................................... |

1-8 |

1-2 |

GasValveShowingLocationofPressureRegulatorandPilotAdjusters ............... |

1-9 |

ii

Chapter 1: General Information and Installation

Congratulations on the purchase of your new Pitco Frialator universal fryer. This unit will give you many years of reliable service if you follow the simple operation and maintenance procedures in this manual. Contained in this manual are the general installation, operation, and maintenance procedures for the universal fryer Models 45C+, 35C+ 40C+, and 65C+.

1.1WHICH FRYER DO I HAVE?

There are two models of this gas fryer available. Each fryer has its own model number. To find out which model you have, look inside the door at the equipment identification plate. This plate has a lot of useful information, but to identify which fryer you have, look at the model number block. The model number identifies which fryer you have. A brief description of each model is provided inTable 1-1.

Table 1-1 Fryer Model Information

Model |

|

|

Number |

Description |

Features |

|

This fryer can cook up to 85 lbs. of potatoes per hour. |

Frying Area: 14" x 14" |

45C+ |

Oil Capacity: 42 lbs. |

|

|

|

BTU Input: 122,000 |

|

This fryer can cook up to 63 lbs. of potatoes per hour. |

Frying Area: 14" x 14" |

35C+ |

Oil Capacity: 35 lbs. |

|

|

|

BTU Input: 90,000 |

|

This fryer can cook up to 72 lbs. of potatoes per hour. |

Frying Area: 14" x 14" |

40C+ |

Oil Capacity: 45 lbs. |

|

|

|

BTU Input: 105,000 |

65C+ |

This fryer can cook up to 120 lbs. of potatoes per |

Frying Area: 18" x 18" |

Oil Capacity: 65 lbs. |

||

|

hour. |

BTU Input: 150,000 |

1.2CHECKING YOUR NEW FRYER

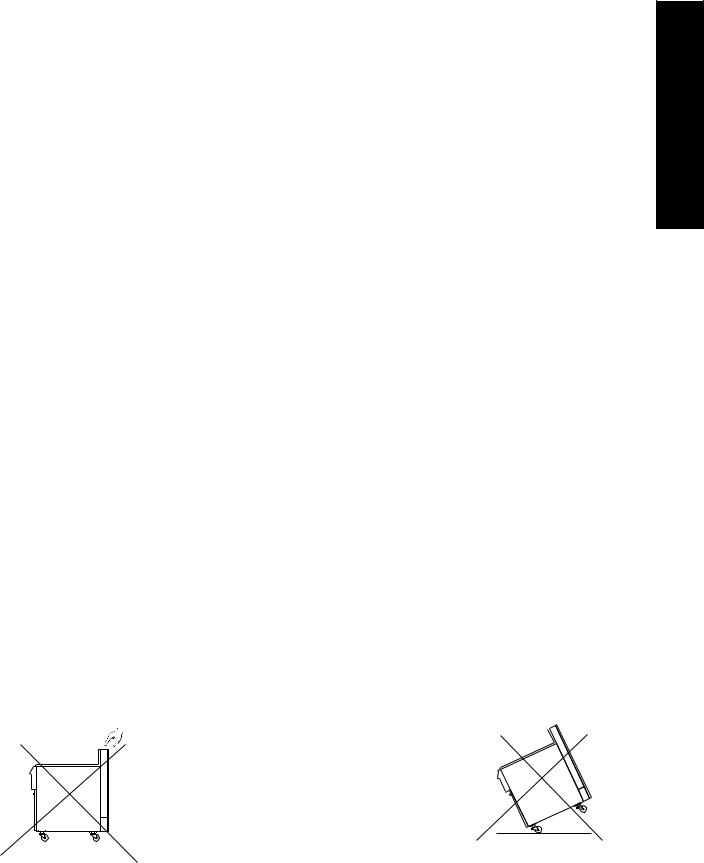

Your new fryer has been carefully packed into one crate. Every effort has been made to ensure that your fryer is delivered to you in perfect condition. As you unpack your new fryer, inspect each of the pieces for damage. If something is damaged, DO NOT sign the bill of lading. Contact the shipper immediately, the shipper is only responsible for 15 days after delivery. Check the packing list enclosed with your fryer to ensure that you have received all of the parts to the fryer. If you are missing any parts, contact the dealer from whom the fryer was purchased. As you unpack the fryer and it's accessories be careful to keep the weight of the fryer evenly distributed.

CAUTION

To prevent equipment damage, don't tilt the fryer

onto any two of it's casters or pull the unit by the flue vents.

1-1

ENGLISH

Locate your Pitco Frialator warranty and fill in the serial number of the fryer and the date received. You will find the serial number on the plate inside the door. Put your warranty card in a safe place for future reference. DO NOT return the card to Pitco Frialator.

1.2.1 Check Your Order

The crate containing the fryer unit will also contain the following:

(2)Pitco Cleaner Sample

(1)Drain Clean Out Rod

1.3ASSEMBLY AND LEVELING

When you receive your fryer, it is completely assembled with the possible exception of the legs (or casters) and the heat shield. In some cases, if you have purchased a multi-fryer unit, you may need to assemble the system.

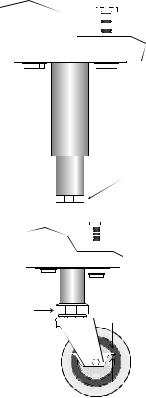

1.3.1Leg/Caster Installation and Adjustment

Installing the legs and leveling the fryer is done with a 7/16" wrench, socket, and a large pair of water pump pliers. The legs/casters must be installed to provide the necessary height to meet sanitation requirements and assure adequate air supply to the burner. Attach the legs by performing the following procedure.

a. Lay the fryer on its side being careful not to damage the flue by pulling on it. Protect the outside of the fryer with cardboard or a drop cloth when laying it down.

b.Attach each leg/caster with the hex head cap screws supplied with the fryer. Each leg/caster requires four 1/4-20 x 5/8" cap screws.

Adjust Here

Adjust Here

c.Mount the screws from the inside of the fryer with the nut on the outside. The nuts have lock washers attached to them, therefore it is not necessary to use lock washers.

d.When all four legs/casters are mounted, stand the unit up being careful not to put too much weight on any one leg/ caster. Adjust the height and level the fryer by adjusting the leveling devices on the leg/caster with the water pump pliers.

e.On units with casters, move the fryer to the desired location and lock the wheels using the locking devices on the sides of the casters.

1-2

Adjust |

Lock |

Here |

Un Lock

1.3.2 Assembling Multi Fryer Systems

If you purchased a multi-fryer unit, it could be shipped in more than one piece. To assemble the unit follow the instructions below.

|

a. Unpack the units and move them close together. Remove the front panels and both heat |

ENGLISH |

|

|

|

|

shields from the fryers. |

|

|

b. There are five joining strips to be attached to the units to make them into one system. These |

|

|

strips are attached in the rear, front, upper front, and the forward and rear caster mount. Use |

|

|

the screws supplied with your system to attach the strips. Secure them tightly to each unit. |

|

|

c. Replace the heat shield and front panels to complete the system assembly. |

|

1.4 |

INSTALLATION |

|

|

Although it is possible for you to install and set up your new fryer, it is STRONGLY recommended thatyouhaveitdonebyqualifiedprofessionals. Theprofessionalsthatinstallyournewfryerwillknow the local building codes and ensure that your installation is safe.

WARNING

The fryer must be properly restrained to prevent movement or tipping. This restraint must prevent the fryer from movements that would splash hot liquids on personnel. This restraint may be any means (alcove installation, adequate ties, or battery installation).

1.4.1InstallationClearances

The fryer needs clearance around it for proper operation. Adequate clearances allow for servicing and proper burner operation. The clearances shown below are for cooker installation in combustible and non-combustibleconstruction.

|

Combustible |

Non-Combustible |

|

Construction |

Construction |

Back |

6" |

0" |

Sides |

6" |

0" |

Floor - Combustible |

6" |

6" |

1.4.2Gas Connection

Your fryer will give you peak performance when the gas supply line is of sufficient size to provide the correct gas flow. The gas line must be installed to meet the local building codes or National

1-3

Fuel Gas Code (NFPA 54-Latest Edition) and ANSI Z223.1-Latest Edition Latest Edition. In Canada, install the fryer in accordance with CAN/CGA-B149.1 or .2 and local codes. Gas line sizing requirements can be determined by your local gas company by referring to National Fuel Gas Code, Appendix C, Table C-4 (natural gas) and Table C-16 (propane). The gas line needs to be large enough to supply the necessary amount of fuel to all appliances without losing pressure to any appliance. Other factors that are used to determine the piping requirements are BTU requirements of the appliances being connected and the length of pipe between the meter (main shut off) and the appliances.

WARNING

NEVER supply the fryer with a gas that is not indicated on the data plate. Using the incorrect gas type will cause improper operation. If you need to convert the fryer to another type of fuel, contact your dealer.

1.4.2.1 Fuel Types - Each fryer is equipped to work with one type of fuel. The type of fuel with which the appliance is intended to operate is stamped on the data plate attached to the inside of the door.

WARNING

DO NOT use an open flame to check for gas leaks!

1.4.2.2 Gas Line Connection - Connect the fryer to the gas supply line with a connector that complies with the Standard for Connectors for Movable Gas Appliances (ANSI Z21.69-Latest Edition). If you are installing a fryer with casters use a quick disconnect refer to the Quick Disconnect installationinstruction,1.4.2.3. Connectthegaslinetothefryerusingapipejointsealantthatisresistant to liquefied petroleum. If the fryer was disconnected during the fuel line testing, use a solution of soap and water to leak test the new connection.

NOTICE

NEVER use an adaptor to make a smaller gas supply line fit the cooker connection. This may not allow proper gas flow for optimum burner operation, resulting in poor cooker performance.

1.4.2.3 Quick Disconnect Gas Connection - Gas fryers equipped with casters must be installed with connectors that comply with the Standard for Connectors for Movable Gas Appliances, ANSI Z21.69-Latest Edition, and Addenda Z21.69A-Latest Edition. This connection should include a quick disconnect device that complies with the Standard for Quick Disconnect Devices for Use With Gas Fuel , ANSI Z21.41-Latest Edition. When installing a quick disconnect you must also install a means for limiting the movement of the fryer. This device will prevent the gas line or the quick disconnect from being strained. The restraining device should be attached to the cooker on the back panel as shown in the illustration. The quick disconnect, hose, and restraining device can be obtained from your dealer.

1-4

1.4.2.4 Fuel Supply Line Leak and Pressure Testing- The fuel supply system must be tested before the fryer is used. If the fuel line is going to be tested at a pressure greater than (>)1/2 PSIG (3.45 kPa), make sure that the fryer is disconnected from the fuel line. If the fuel line is to be tested at a pressure equal to or less than (<) 1/2 PSIG (3.45 kPa), the fryer can be connected but the unit's gas valve must be shut. Test all gas line connections for leaks with a solution of soap and water when pressure is applied.

1.4.3Ventilation and Fire Safety Systems

Yournewfryermusthaveproperventilationtofunctionsafelyandproperly. Exhaustgastemperatures can reach as high as 1200°F. Therefore, it is very important to install a fire safety system. Your ventilation system should be designed to allow for easy cleaning. Frequent cleaning of the ventilation system and the fryer will reduce the chances of fire. Table 1-2 provides a list of reference documents that provide guidance on ventilation and fire safety systems. This table is not necessarily complete. AdditionalinformationcanbeobtainedfromtheAmericanGasAssociation,8501EastPleasantValley Road, Cleveland, OH 44131.

Excessive ventilation causes drafts, which will interfere with the proper operation of the pilot and the burner. Leave at least 18 inches of open space between the fryer's flue vent opening and the intake of the exhaust hood.

CAUTION

Ensure that your ventilation system does not cause a down draft at the fryer's flue opening. Down drafts will not allow the fryer to exhaust properly and will cause overheating which may cause permanent damage. Damage caused by down drafts will not be covered under equipment warranty. NEVER allow anything to obstruct the flow of combustibles or ventilation exiting from the fryer flue. DO NOT put anything on top of the flue area.

NOTICE

NEVER connect the blower directly to the flue openings. The direct flow of air will cause poor temperature recovery, poor ignition, inefficient operation of the fryer, and could extinguish the pilot.

1.5INITIAL ADJUSTMENTS

After your fryer has been installed as described in section 1.4, it needs to be adjusted to ensure that it will perform as designed. These adjustments must be performed by a qualified person. To perform these adjustment the following tools will be needed:

• Manometer (low pressure gauge) |

• Digital Thermometer (Temperature probe) |

• DC Millivolt Meter |

|

|

1-5 |

ENGLISH

Loading...

Loading...