Pitco RSCPE14 Installation Manual

IMPORTANT FOR FUTURE REFERENCE

Please complete this information and retain this manual

for the life of the equipment:

Model #: ___________________________

Serial #: ___________________________

Date Purchased: ____________________

Installation & Operation Manual

CPE14*: Electric Counter Model Pasta Cooker

RSCPE14: Counter Model Rinse Station

Built after 7/2003, *Does not include models with solid state timers

ENGLISH

I

S

G

E

N

D

C

E

R

D

E

I

T

F

I

L20-274, rev. 0 (1/06)

TO THE PURCHASER, OWNER AND STORE MANAGER

Please review these warnings prior to posting them in a prominent location for reference.

WARNING

DO NOT store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any other

appliance.

WARNING

Improper installation, alteration, service or

maintenance can cause property damage, injury or

death. Read the installation, operating and

maintenance instructions thoroughly before installing

or servicing this appliance.

WARNING

Installation, maintenance and repairs should be

performed by a Pitco Authorized Service and Parts

(ASAP) company technician or other qualified

personnel. Installation, maintenance or repairs by an

unauthorized and unqualified personnel will void the

warranty.

WARNING

Installation and all connections must be made

according to national and local regulations and codes

in force.

WARNING

A country approved all pole circuit breaker with a

minimum open contact gap of 3mm must be used for

proper installation. (CE countries)

WARNING

During the warranty period if a customer elects to use

a non-original part or modifies an original part

purchased from Pitco and/or its Authorized Service

and Parts (ASAP) companies, this warranty will be

void. In addition, Pitco and its affiliates will not be

liable for any claims, damages or expenses incurred

by the customer which arises directly or indirectly, in

whole or in part, due to the installation of any

modified part and/or received from an unauthorized

service center.

WARNING

This appliance, when installed, must be electrically

grounded in accordance with local codes, or in the

absence of local codes, with the National Electrical

Code, ANSI/NFPA 70, or the Canadian Electrical Code,

CSA C22.2, as applicable.

WARNING

Adequate means must be provided to LIMIT the

movement or this appliance without depending on the

electrical cord connection. Single appliances

equipped with legs must be stabilized by installing

anchor straps. All appliances equipped with casters

must be stabilized by installing restraining chains.

WARNING

DO NOT alter or remove structural material on the

appliance to accommodate placement under a

ventilation hood.

WARNING

This appliance is intended for professional use only

and should be operated by fully trained and qualified

personnel.

WARNING

If the supplied power cord is damaged, it must be

replaced by a Pitco Authorized Service and Parts

(ASAP) company technician, or a similarly qualified

person in order to avoid a hazard.

WARNING

The power supply must be disconnected before

servicing, maintaining or cleaning this appliance.

WARNING

The appliance is NOT jet stream approved. DO NOT

clean the appliance with a water jet.

WARNING

DO NOT attempt to move this appliance or transfer hot

liquids from one container to another when the unit is

at operating temperature or filled with hot liquids.

Serious personal injury could result if skin comes in

contact with the hot surfaces or liquids.

WARNING

DO NOT sit or stand on this appliance. The

appliance’s front panel, tank, splash back, tank cover,

workshelf, drain board is not a step. Serious injury

could result from slipping, falling or contact with hot

liquids.

WARNING

NEVER use the appliance as a step for cleaning or

accessing the ventilation hood. Serious injury could

result from slips, trips or from contacting hot liquids.

WARNING

The water level should be maintained at the level line.

DO NOT turn the appliance on until the heating

elements are fully covered with water at all times.

Serious injury could result from hot steam vapors off

the heating element.

WARNING

If overflow drain is not equipped or if overflow drain

stop is used, do not leave appliance unattended while

filling with water. Over filling the appliance can cause

serious injuries and damage the equipment.

WARNING

Completely shut the appliance down when the water is

being drained from the appliance. This will prevent the

appliance from heating up during the draining and

filling process. Serious injury and heating element

damage can occur.

WARNING

This appliance is intended for indoor use only.

WARNING

DO NOT operate appliance unless all panels and

access covers are attached correctly.

WARNING

It is recommended that this appliance be inspected by

a qualified service technician for proper performance

and operation on a yearly basis.

ii

CPE14: ELECTRIC COUNTER MODEL PASTA COOKER TABLE OF CONTENTS

1. INSTALLATION......................................................................................1

1.1. CHECKING YOUR NEW APPLIANCE.......................................................................................... 1

1.2. INSTALLATION CLEARANCES ................................................................................................... 1

1.3. INSTALLATION TO COUNTER ....................................................................................................2

1.4. PLUMBING CONNECTIONS......................................................................................................... 2

1.4.1. WATER INLET CONNECTIONS............................................................................................. 2

1.4.2. DRAIN CONNECTIONS..........................................................................................................2

1.5. ELECTRICAL CONNECTIONS ..................................................................................................... 3

1.6. VENTILATION AND FIRE SAFETY SYSTEMS ............................................................................4

1.7. INSPECTION..................................................................................................................................4

1.8. INITIAL CLEANING ....................................................................................................................... 5

2. OPERATION...........................................................................................6

2.1. FILLING THE APPLIANCE............................................................................................................ 6

2.1.1. FILLING THE COOKER TANK ...............................................................................................8

2.1.2. FILLING THE RINSE TANK ....................................................................................................8

2.2. APPLIANCE START UP................................................................................................................ 8

2.3. COOKING....................................................................................................................................... 9

2.3.1. SIMMER MODE ......................................................................................................................9

2.3.2. BOIL MODE.............................................................................................................................9

2.3.3. TIMER OPERATION ...............................................................................................................9

2.3.4. ADDITIONAL CONTROLLER FUNCTIONS........................................................................... 9

2.3.5. COOKING TIPS.....................................................................................................................10

2.4. APPLIANCE SHUTDOWN........................................................................................................... 10

3. PREVENTATIVE MAINTENANCE....................................................... 11

3.1. DAILY PREVENTATIVE MAINTENANCE ..................................................................................11

3.1.1. APPLIANCE INSPECTION ................................................................................................... 11

3.1.2. CLEANING THE COOK TANK (RINSE TANK IF EQUIPPED) ............................................11

3.1.3. CLEANING THE CABINET ................................................................................................... 11

L20-274, rev. 0 (1/06) iii

TABLE OF CONTENTS

3.2. MONTHLY PREVENTATIVE MAINTENANCE ...........................................................................12

3.2.1. DELIMING ............................................................................................................................. 12

3.3. ANNUAL/PERIODIC PREVENTATIVE MAINTENANCE AND INSPECTION............................12

3.3.1. HEATING ELEMENT ............................................................................................................12

3.3.2. TEMPERATURE PROBE & HIGH LIMIT PROBE ................................................................ 12

3.3.3. CONTROLLER...................................................................................................................... 12

3.3.4. CONTROL BOX & ELECTRICAL COMPONENTS............................................................... 13

3.3.5. TANK ..................................................................................................................................... 13

3.3.6. DRAIN SYSTEM ...................................................................................................................13

4. TROUBLESHOOTING .........................................................................14

4.1. POWER FAILURE........................................................................................................................14

4.2. HIGH TEMPERATURE LIMIT......................................................................................................14

4.3. DRAIN VALVE INTERLOCK .......................................................................................................14

4.4. CIRCUIT BREAKER RESET .......................................................................................................14

4.5. TROUBLESHOOTING CHART ...................................................................................................15

4.6. CONTROLLER WARNING DISPLAYS....................................................................................... 15

iv

CPE14: ELECTRIC COUNTER MODEL PASTA COOKER INSTALLATION

1. INSTALLATION

1.1. CHECKING YOUR NEW APPLIANCE

Your new Pitco appliance has been carefully packed into one crate. Every effort has been made to

ensure that it is delivered to you in perfect condition. As you unpack your new appliance, inspect each

of the pieces for damage. If something is damaged, DO NOT sign the bill of lading. Contact the

shipper immediately; the shipper is only responsible for 15 days after delivery. Check the packing list

enclosed with your appliance to ensure that you have received all the parts to the appliance. If you

are missing any parts, contact the dealer from whom the appliance was purchased. As you unpack

the appliance and its accessories be careful to keep the weight of the appliance evenly distributed.

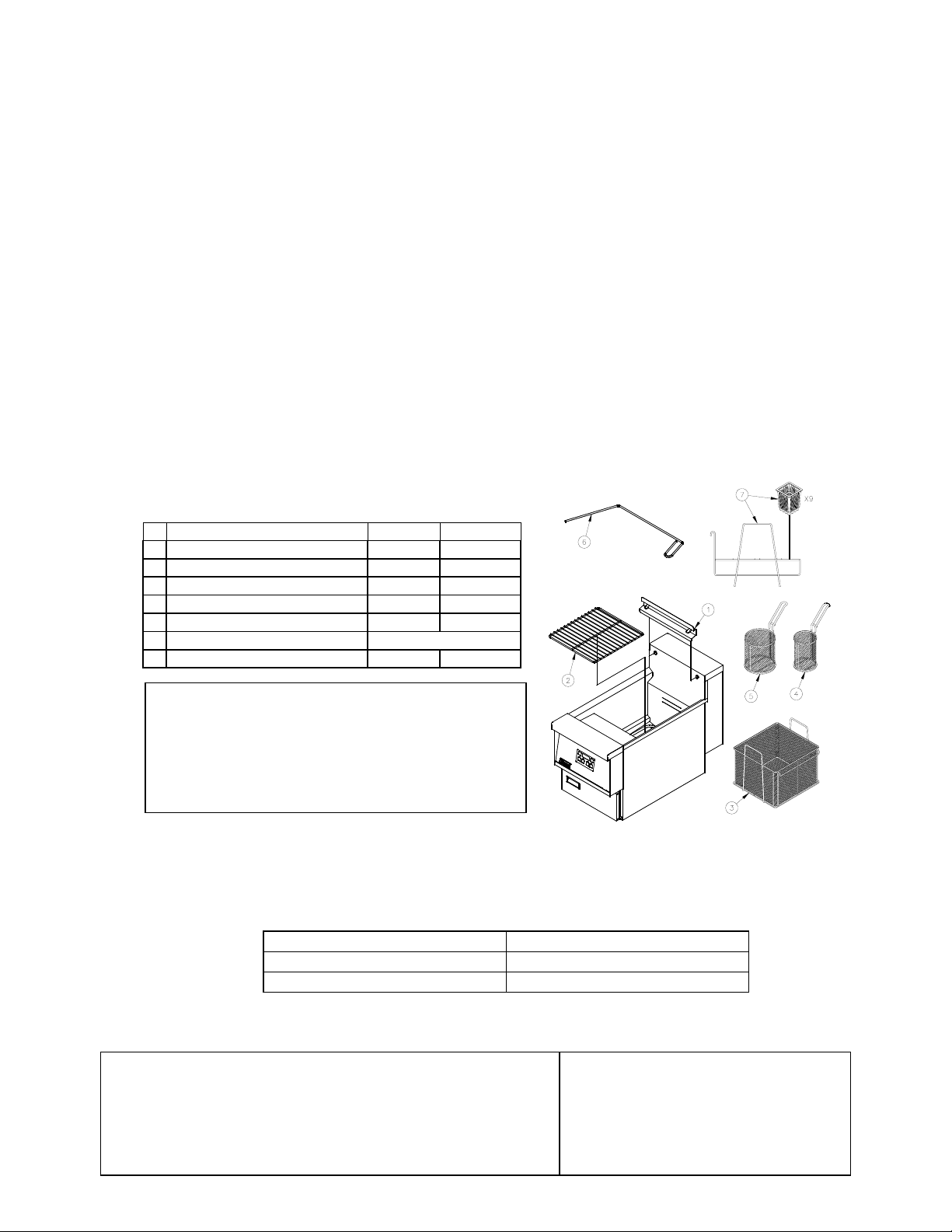

Refer to the table below to identify which accessories should be included with your appliance.

Locate your Pitco model number and serial number on the inner door of the appliance and the find

the date purchased. Write this information on the front cover of this manual for future reference.

If you have completed the above steps that are applicable to the appliance you purchased, the

appliance is now ready to be installed. Although it may be possible for you to install and set up your

new appliance, it is STRONGLY recommended that you have this done by qualified professionals. A

qualified professional will ensure that the installation is safe and meets local building and fire codes.

Accessories

# Description CPE14 RSCPE14

1 Basket Hanger Standard Standard

2 Element Rack Standard N/A

3 Small Bulk Pasta Basket Optional Optional

4 Small Round Pasta Basket Optional Optional

5 Large Round Pasta Basket Optional Optional

6 Drain Cleanout Rod Standard

7 Portion Cups with Rack Optional Optional

WARNING

DO NOT sit or stand on this appliance. The

appliance’s front panel, tank, splash back, tank

cover, workshelf, drain board is not a step.

Serious injury could result from slipping, falling

or contact with hot liquids.

1.2. INSTALLATION CLEARANCES

The clearances shown below are for combustible and non-combustible installations and will allow for

safe and proper operation of your appliance.

Combustible Construction Non Combustible Construction

Inches (centimeters) Inches (centimeters)

Back

Sides

Counter

6.0" (15.24cm) 0.0" (0.0cm)

6.0" (15.24cm) 0.0" (0.0cm)

4.75" (12.07cm) 0.0" (0.0cm)

In addition to the above clearances there must also be at least 16 inches (40.64cm) of aisle space in

front of the unit.

WARNING

DO NOT obstruct the flow of ventilation, or air openings

around the appliance. Adequate clearance around the

appliance is necessary for servicing and proper

component ventilation. Ensure that you meet the

DO NOT install this appliance next

to a deep fat fryer. A splash over of

water into the hot oil may cause a

flash fire.

WARNING

minimum clearance requirements specified in this manual.

L20-274, rev. 0 (1/06) 1

INSTALLATION

WARNING

The appliance should be secured to the counter top to prevent accidental

moving of the appliance and the splashing of hot liquid on the operator.

1.3. INSTALLATION TO COUNTER

After the appliance is in its permanent location, check the levelness. Level the counter as needed.

The appliance must be sealed to the counter to comply with applicable sanitation standards. A bead

of silicone sealant, approximately ½ inch wide, is to be applied to the bottom of the unit approximately

¼” in from the front, back and side edges. We suggest Dow Corning ®, GE ® or Permatex ® silicone

‘RTV’ adhesive sealant or equivalent. (See NSF Basic Criteria C-2 for details). This appliance also

has four 3/8” holes in its base that are intended for the optional use of fasteners when securing the

appliance to a counter.

WARNING

DO NOT perform leveling procedure when appliance is in

operation or full of hot liquids. Serious injury could result.

1.4. PLUMBING CONNECTIONS

The plumbing installation should be done by a licensed plumber and must comply with local and

national codes.

1.4.1. WATER INLET CONNECTIONS

If a faucet or water fill option is equipped on your appliance connections to a potable water supply

will be required. If a single water connection is required it is recommended that the appliance is

connected to hot water supply. This will greatly decrease the time it takes for the appliance to

reach operating temperature. Prior to installation, a water treatment specialist should inspect the

water supply. Water hardness should contain no more then 2.0 grains/gallon. The pH level

should be between 6.5 and 8.0. These conditions can be obtained with the use of a properly

maintained water softener. The incoming water pressure should be between 20 psi (1.38 bars) to

60 psi (4.14 bars). For higher water pressures, a high-pressure regulator must be installed to

inlet plumbing to avoid damage caused by water hammer. The maximum allowable incoming

water temperature is 180°F (82°C). Have your water tested and record the measured values

below.

Water Quality Checklist

Measured Range OK

Temperature 180°F (82°C) Max.

Hardness 2.0 Grains/Gal. Max.

pH 6.5 to 8.0

Pressure 20 psi to 60 psi

1.4.2. DRAIN CONNECTIONS

Each tank has a drain that can be inserted into a drainage system. Each tank may also have an

overflow line. The overflow connection is after the drain valve to provide an unobstructed

overflow path. The drain and/or overflow line for each tank may be connected together to form a

common drain line. Drain connections for this appliance will be either 1NPT or 1” ID tubing.

When water is at a high

temperature and high

pressure, excessive

splashing of hot water

may occur that could

result in injury.

WARNING

2

Loading...

Loading...