Pitco MGII SERVICE MANUAL

IMPORTANT FOR FUTURE REFERENCE

Please complete this information and retain this manual

for the life of the equipment:

Model #: ___________________________

Serial #: ___________________________

Date Purchased: ____________________

Service Manual

MGII: McDonald’s Full and Split Gas Fryers

with and without Filter

ENGLISH

I

S

G

E

N

D

C

E

E

R

I

T

F

I

CIRET IFED

D

L22-236 Rev. 2 (06/11)

TO THE PURCHASER, OWNER AND STORE MANAGER

Please review these warnings prior to posting them in a prominent location for reference.

TO THE PURCHASER

Post in a prominent location the instructions to be followed

in the event that an operator smells gas. Obtain this

information from your local gas supplier.

WARNING

DO NOT store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance.

WARNING

Improper installation, alteration, service or maintenance can

cause property damage, injury or death. Read the

installation, operating and maintenance instructions

thoroughly before installing or servicing this appliance.

WARNING

Installation, maintenance and repairs should be performe d

by a Pitco Authorized Service and Parts (ASAP) company

technician or other qualified personnel. Installation,

maintenance or repairs by unauthorized and unqualified

personnel will void the warranty.

WARNING

Installation and all connections must be made according to

national and local regulations and codes in force.

WARNING

During the warranty period if a customer elects to use a nonoriginal part or modifies an original part purchased from

Pitco and/or its Authorized Service and Parts (ASAP)

companies, this warranty will be void. In addition, Pitco and

its affiliates will not be liable for any claims, damages or

expenses incurred by the customer which arises directly or

indirectly, in whole or in part, due to the installation of any

modified part and/or received from an unauthorized ser vice

center.

WARNING

This appliance, when installed, must be electrically grounded

in accordance with local codes, or in the absence of local

codes, with the National Electrical Code, ANSI/NFPA 70, or

the Canadian Electrical Code, CSA C22.2, as applicable.

WARNING

Adequate means must be provided to limit the movement or

this appliance without depending on the gas or electrical

cord connection. Single appliances equipped with legs must

be stabilized by installing anchor straps. All appliances

equipped with casters must be stabilized by installing

restraining chains, or equivalent means.

WARNING

An appliance equipped with casters and a flexible gas line

must be connected to the gas supply with a quick disconnect

device. This quick disconnect must comply with ANSI Z24.41.

WARNING

DO NOT alter or remove structural material on the appliance

to accommodate placement under a ventilation hood.

WARNING

This appliance is intended for professional use only and

should be operated by fully trained and qualified personnel.

WARNING

If the appliance is equipped with a power cord and it is

damaged, it must be replaced by a Pitco Authorized Service

and Parts (ASAP) company technician, or a similarly

qualified person in order to avoid a hazard.

WARNING

The power supply must be disconnected before servicing,

maintaining or cleaning this appliance.

WARNING

The appliance is NOT jet stream approved. DO NOT clean

the appliance with a water jet.

WARNING

DO NOT attempt to move this appliance or transfer hot

liquids from one container to another when the unit is at

operating temperature or filled with hot liquids. Serious

personal injury could result if skin comes in contact with the

hot surfaces or liquids.

WARNING

DO NOT sit or stand on this appliance. The appliance’s front

panel, tank, splash back, tank cover, workshelf, drain board

is not a step. Serious injury could result from slipping,

falling or contact with hot liquids.

WARNING

NEVER use the appliance as a step for cleaning or accessing

the ventilation hood. Serious injury could result from slips,

trips or from contacting hot liquids.

WARNING

The oil/shortening level should NOT fall below the minimum

indicated level line at any time. The use of old shortening

can be dangerous as it will have a reduced flash point and be

more prone to surge boiling.

WARNING

The contents of the crumb catch and/or filter pan of any filter

system must be emptied into a fireproof container at the end

of each day. Some food particles can spontaneously

combust if left soaking in certain types of oil or shortening.

WARNING

Completely shut the appliance down when oil/shortening is

being drained from the appliance. This will prevent the

appliance from heating up during the draining and filling

process. Serious injury can occur.

WARNING

This appliance is intended for indoor use only.

WARNING

DO NOT operate appliance unless all panels and access

covers are attached correctly.

WARNING

It is recommended that this appliance be inspected by a

qualified service technician for proper performance and

operation on a yearly basis.

WARNING

There is an open flame inside this appliance. The unit may

get hot enough to set nearby materials on fire. Keep the area

around the appliance free from combustibles.

WARNING

DO NOT supply the appliance with a gas that is not indicated

on the data plate. If you need to convert the appliance to

another type of fuel, contact your Equipment Supplier or a

Pitco Authorized Service and Parts (ASAP) Company.

WARNING

DO NOT use an open flame to check for gas leaks!

WARNING

If gas flow to appliance is interrupted, or pilots extinguish,

wait 5 minutes before attempting to relight the pilot to allow

any residual gas in appliance to dissipate.

WARNING

Ensure that the appliance can get enough air to keep the

flame burning correctly. If the flame is starved for air, it can

give off a dangerous carbon monoxide gas. Carbon

monoxide is a clear odorless gas that can cause suffocation.

2 L22-236 Rev. 2 (06/11)

MGII Full and Split Tank Gas Fryer TABLE OF CONTENTS

1. THEORY OF OPERATION.....................................................................5

1.1. HEATING SYSTEM .....................................................................................................................................5

1.2. H

1.3. H

1.4. T

1.5. F

IGH LIMIT SYSTEM:.................................................................................................................................5

OOD RELAY SYSTEM - U.S./CANADA UNITS O NLY....................................................................................5

EMPERATURE PROBE..............................................................................................................................5

ILTER SYSTEM ........................................................................................................................................6

2. TROUBLESHOOTING ...........................................................................7

2.1. FRYER TROUBLESHOOTING.......................................................................................................................7

2.2. F

ILTER TROUBLESHOOTING.......................................................................................................................9

3. COMPONENT TROUBLESHOOTING.................................................10

3.1. TEMPERATURE PROBE:...........................................................................................................................10

3.2. G

3.3. H

3.4. D

3.5. T

3.6. I

3.7. R

AS VALVE:...........................................................................................................................................10

IGH LIMITS:..........................................................................................................................................11

RAIN VALVE & RETURN VALVE SWITCHES:............................................................................................11

RANSFORMER:......................................................................................................................................11

GNITION MODULE:..................................................................................................................................11

ELAY BOARD: ......................................................................................................................................12

3.8. C

3.9. F

OMPUTER CONTROLLER: ......................................................................................................................13

LUE BAFFLE .........................................................................................................................................14

4. CE GAS TABLE...................................................................................15

5. COMPONENT REPLACEMENT FRYER.............................................17

5.1. FRONT PANEL ........................................................................................................................................17

5.1.1. Front Panel Bezel................................................................................................................17

5.1.2. Computer Removal .............................................................................................................17

5.1.3. Wire Reduction Board.........................................................................................................17

5.1.4. Front Panel and Top Deck..................................................................................................18

5.2. C

ONTROL COMPONENTS .........................................................................................................................19

5.2.1. Ignition Module....................................................................................................................19

5.2.2. Transformer Box .................................................................................................................19

5.2.3. Transformer .........................................................................................................................20

5.2.4. Cord Entrance Box..............................................................................................................20

5.2.5. Hood Relay (North America Only).....................................................................................20

5.3. G

AS TRAIN.............................................................................................................................................21

L22-236 Rev. 2 (06/11) 3

TABLE OF CONTENTS

5.3.1. Manual Gas Shutoff.............................................................................................................21

5.3.2. Gas Valve Removal.............................................................................................................21

5.3.3. Pilot Removal.......................................................................................................................23

5.3.4. Burner Removal...................................................................................................................23

5.3.5. Gas Conversion...................................................................................................................24

5.4. T

ANK .....................................................................................................................................................25

5.4.1. Probe Replacement.............................................................................................................25

5.4.2. High Limit Replacement .....................................................................................................26

5.4.3. Drain Switch Removal.........................................................................................................26

5.4.4. Tank Removal......................................................................................................................27

5.4.5. Tank Disassembly...............................................................................................................29

5.4.6. Tank Assembly....................................................................................................................30

5.4.7. Tank Installation..................................................................................................................33

6. COMPONENT REPLACEMENT – FILTER..........................................36

6.1. PUMP AND PUMP BOX.............................................................................................................................36

6.1.1. Pump Removal.....................................................................................................................36

6.1.2. Pump Box.............................................................................................................................37

6.1.3. Pump Transformer ..............................................................................................................37

6.1.4. Pump Relay..........................................................................................................................37

6.1.5. Pump Circuit Breaker..........................................................................................................37

6.2. D

RAIN LINE ............................................................................................................................................38

6.2.1. Drain Line Removal.............................................................................................................38

7. SCHEMATICS......................................................................................39

7.1. CONTROL SCHEMATIC.............................................................................................................................39

7.2. F

7.3. F

7.4. C

7.5. C

7.6. C

4 L22-236 Rev. 2 (06/11)

ILTER SYSTEM 115V.............................................................................................................................40

ILTER SYSTEM 208, 220 – 240 V..........................................................................................................41

ORD BOX & HOOD CONTROL (US & CANADA) ......................................................................................42

ORD BOX W/O HOOD CONTROL (US & CANADA)...................................................................................42

ORD BOX (EXPORT & CE)....................................................................................................................43

MGII and MG2T GAS FRYER SERVICE

1. Theory of Operation

Knowing and understanding the MGII sequence of fryer and component operation will enable you to diagnose

equipment failure more easily and accurately. (Note: The schematic references used are derived from the

schematic on pages _ - _ of this manual.)

1.1. Heating System

Power to the machine is turned ON:

When the fryer is plugged in, power is supplied to the transformer, T1. The transformer step s the line

voltage down to 24VAC to operate the heat control circuit.

If Fuse, F1, on the Relay Board, A4, is good, the “AC POWER” LED illuminates. The computer is supplied

with 24VAC and, if the drain valve handle is closed, the proximity switch, LS1, supplies 24 VAC to the DVI

(drain valve interlock) Input at the Computer Controller, (reference connector J/P1, pin #5).

The Computer Controller, A1, is turned ON by pressing the

The Side On Relay, K3, will be energized, closing the circuit and the “S.O.” LED on the Relay Board

illuminates. If the High Limit, HL1, is NOT tripped the ignition module is supplied with 24VAC at terminal 6

(24VAC).

The ignition module generates a 24VAC output from terminal 3(PV) to the PV terminal on the Gas Valve,

V1, and generates a spark at the igniter, E2. When the pilot has lit and the ignition module has proven the

pilot flame, it will have a 24VAC output at terminal 1(MV) resulting in 24VAC at connector J/P32, pin #2, on

the Relay Board. The Heat Demand Relay, K1, on the Relay Board will control the 24VAC supply to the

gas valve when the controller calls for heat. Note: When the Computer Controller is on, the pilot should

always remain lit.

When the Computer Controller calls for heat:

The Heat Demand Relay is energized supplying the Gas Valve with 24VAC and the “HD” LED on the

Relay Board illuminates. This also supplies the Computer Controller with a heat feedback signal, at

connector J/P32, pin #6.

1.2. High Limit System:

If the High Limit, HL1, opens (“trips”), it interrupts the 24VAC supply to the ignition module. As a result, the

pilot goes out. When the Computer Controller calls for heat, it will not receive a 24VAC heat feedback

signal. After 10 seconds, (90 seconds on first heat demand), of heat demand output lacking a heat

feedback signal, the Computer Controller will indicate “IGNITION FAILURE” or “HEAT FAIL”. After the

High Limit is reset, (allow unit to cool below 400ºF, (204ºC), and press red reset button.), the Computer

Controller will have to be turned off and back on for the unit to heat.

button:

1.3. Hood Relay System - U.S./Canada units only

There is one Hood Relay, K6, per system, (“battery”) of fryers (located in a box mounted below the rear

bottom brace of left-hand fryer). It is wired in parallel to the Side On signal of every Computer Controller

(both sides of an MG2T Split). When any side of any Computer Controller is turned on this relay is

energized, (providing power to the hood fan motor) and will stay energized until all Computer Controllers

are turned off.

The Side On harness is equipped with a Fuse, F_. In the event of a short or over-current in the wiring to

the Hood Relay, all the F_ fuses in the system will blow. As a result, the fryer will no longer control the

hood fan motor. To repair, first correct the over-current condition, and then replace all the F_ fuses in the

fryer system.

1.4. Temperature Probe

The Computer Controller receives temperature readings from the Temperature Probe, RT1.

The Temperature Probe resistance varies with temperature, decreasing as temperature rises.

L22-236 Rev. 2 (06/11) 5

SERVICE

1.5. Filter System

Opening the RED filter return valve handle closes the magnetically actuated Proximity Switch, LS4,

causing the “Pump Run” Relay, K5, to be energized. This allows line voltage to flow to the Filter Pump

Motor, M1. The Pump Motor begins to run. Closing the filter return valve handle will de-energize the relay

and the Pump Motor will stop running.

The pump system is equipped with a Circuit Breaker, CB1, which de-energizes the system and the heat

tape, (if so equipped), in the event of over-current. The Circuit Breaker switch must be in the ON position

for the pump and heat tape to operate.

The return piping system may be provided with optional Heat Tape, HTR1, to prevent solidification of solid

shortening. The Heat Tape is low wattage and is on constantly to maintain liquid shortening in the line.

The Filter Pump Motor, M1, is equipped with a thermal overload. In the event of over-temperature of the

pump motor, the thermal overload opens shutting off the pump. Once the pump motor has cooled, it can

be reset by pressing the red button at the end of the motor housing.

6 L22-236 Rev. 2 (06/11)

MGII and MG2T GAS FRYER SERVICE

2. Troubleshooting

2.1. Fryer Troubleshooting

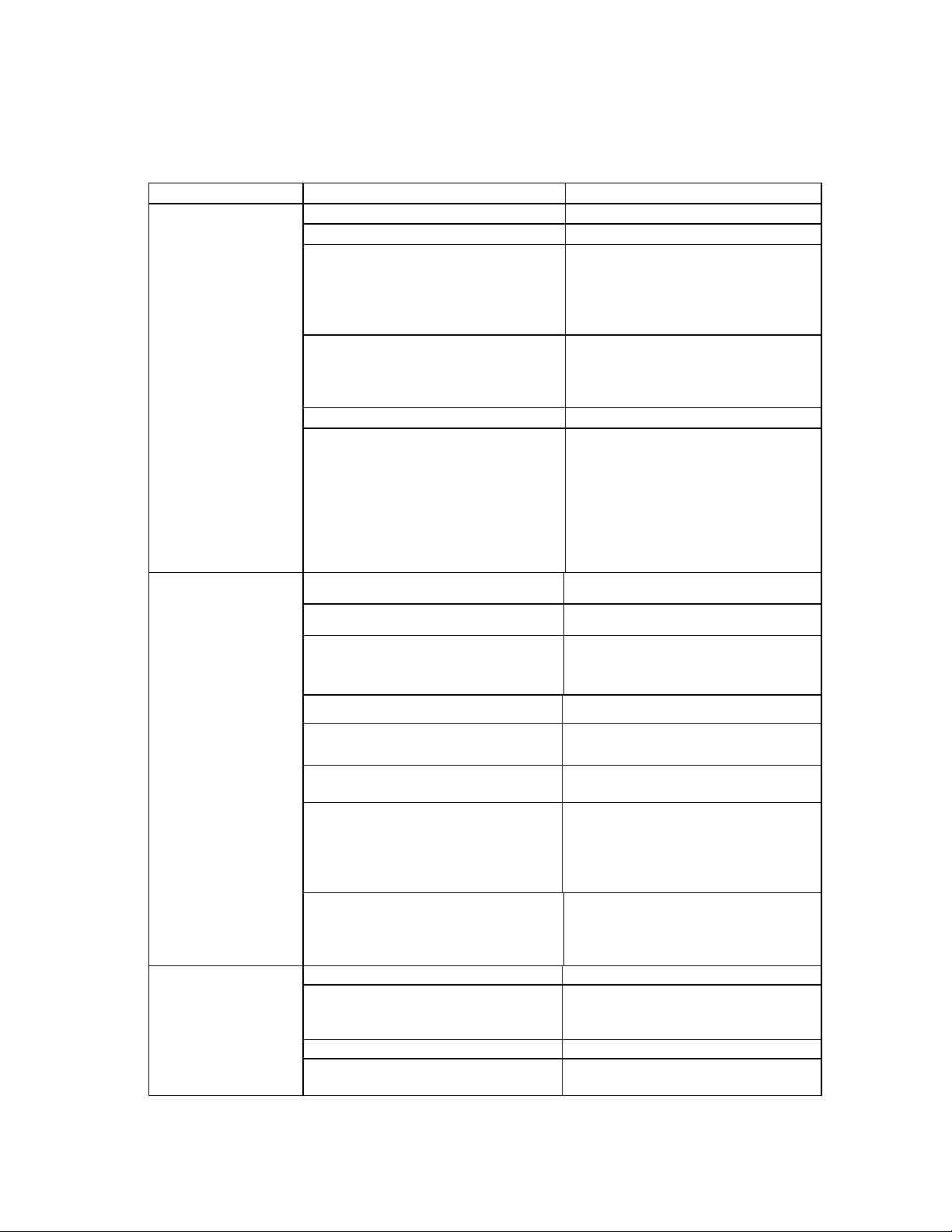

Problem Probable Causes Corrective Actions

No power to appliance. Check main building power supply.

Circuit Breaker tripped. Reset circuit breaker.

Connect power cord. Check power

cord where it enters the rear of the

Computer Controller

display does not light.

Power Cord loose or not connected.

Fuse, F1, blown.

Transformer, T1, Defective. Check and replace if defective

Defective Controller

Computer is in Melt Cycle. Allow time for unit to heat up.

fryer’s entrance box. Verify that it is

plugged all the way into the

receptacle.

Check Wire Reduction Board. If AC

Lamp is not lit check F1 fuse. If fuse

is blown, replace with a 2.5 A fast

acting fuse.

If AC Lamp on Wire Reduction

Board is lit, check for 24 VAC

between pins 1 and 2 on J/P 1. If

voltage is present and computer

display is not lit, controller is

defective. Check for shorts on

controller outputs prior to replacing

controller.

Computer Controller

shows “MELT” and

heats slowly, or not

at all.

Computer Controller

shows “IGNITION

FAILURE” and

alarms.

Main gas supply is off. Verify main gas supply is turned on.

Gas shut off valve (yellow handle) is

closed.

Gas valve is not turned on. Turn manual gas valve to “ON”.

Quick disconnect not properly

connected.

High temperature limit has tripped.

Ignition Module has locked out.

Low gas pressure

Main gas supply is off. Verify main gas supply is turned on.

Gas shut off valve (yellow handle) is

closed.

Gas valve is not turned on. Turn manual gas valve to “ON”.

Quick disconnect not properly

connected.

Verify gas shut-off valve is open,

(yellow handle is in line with the gas

line).

Verify quick disconnect is properly

seated.

Reset high temperature limit. Check

and replace if defective.

Turn Fryer off and back on again to

reset ignition module. If lockout

recurs, check for proper pilot flame

and proper module operation.

Replace if defective

Check regulated gas pressure at

burner manifold. Verify pressure

matches dataplate information.

Adjust as necessary.

Verify gas shut-off valve is open,

(yellow handle is in line with the gas

line).

Verify quick disconnect is properly

seated.

L22-236 Rev. 2 (06/11) 7

SERVICE

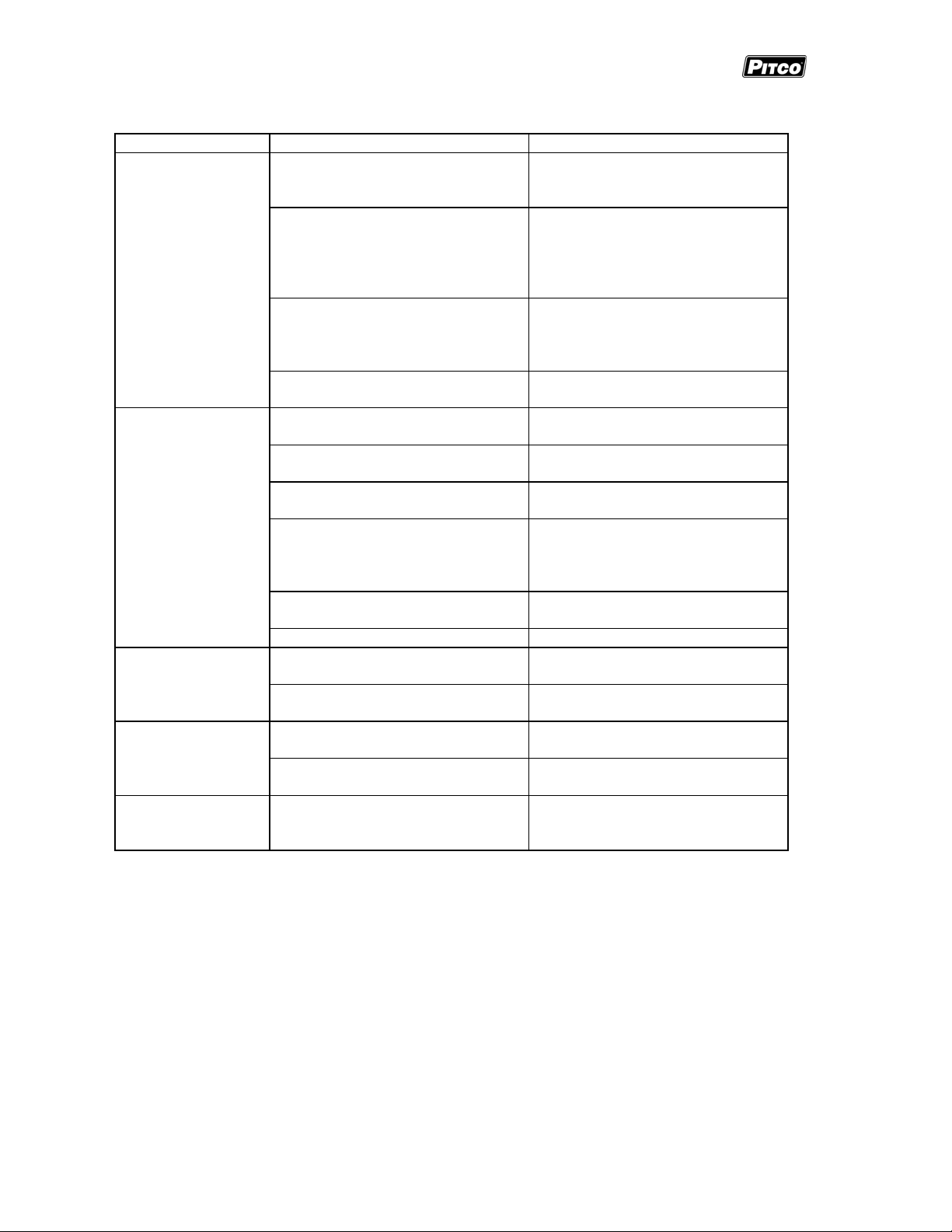

Problem Probable Causes Corrective Actions

Computer Controller

shows “IGNITION

FAILURE” and

alarms (cont.)

Excessive Recovery

Time; (Recovery

Time exceeds 2:25

Standard)

Oil Temperature is

hotter, or colder than

shown by Computer

Controller

Computer Controller

displays “DRAINING”

or “TURN OFF”

Computer Controller

displays “PROBE

FAILURE”

Allow appliance to cool and reset

High temperature limit has tripped.

Ignition Module has locked out.

Low gas pressure

Improper Flue Baffle Setting

Excessive Oil Level

Oil added during Recovery Test.

Quick disconnect not properly

connected.

Low gas pressure

Improper Flue Baffle Setting

Burners require cleaning. Remove and clean burners.

Temperature Calibration

Defective Temperature Probe

Blue drain valve is not completely

closed.

Improperly adjusted or defective

drain switch

Open or shorted temperature probe Check and replace if defective.

high temperature limit. Check and

replace if defective

Turn fryer off and back on again to

reset ignition module. If lockout

recurs, check for proper pilot flame

and module operation. Replace if

defective.

Check regulated gas pressure at

burner manifold. Verify pressure

matches dataplate information.

Adjust as necessary.

Adjust flue baffle to provide proper

burner operation.

Oil level should never exceed “MAX”

line. Drain extra oil from tank.

Repeat heat up without adding oil

during test and compare results.

Verify quick disconnect is properly

seated.

Check regulated gas pressure at

burner manifold. Verify pressure

matches dataplate information.

Adjust as necessary.

Adjust flue baffle to provide proper

burner operation.

Refer to McDonald’s PM Card

FR014.

Contact a qualified service

technician.

Close blue drain valve handle.

Check and Adjust/Replace as

needed.

8 L22-236 Rev. 2 (06/11)

MGII and MG2T GAS FRYER SERVICE

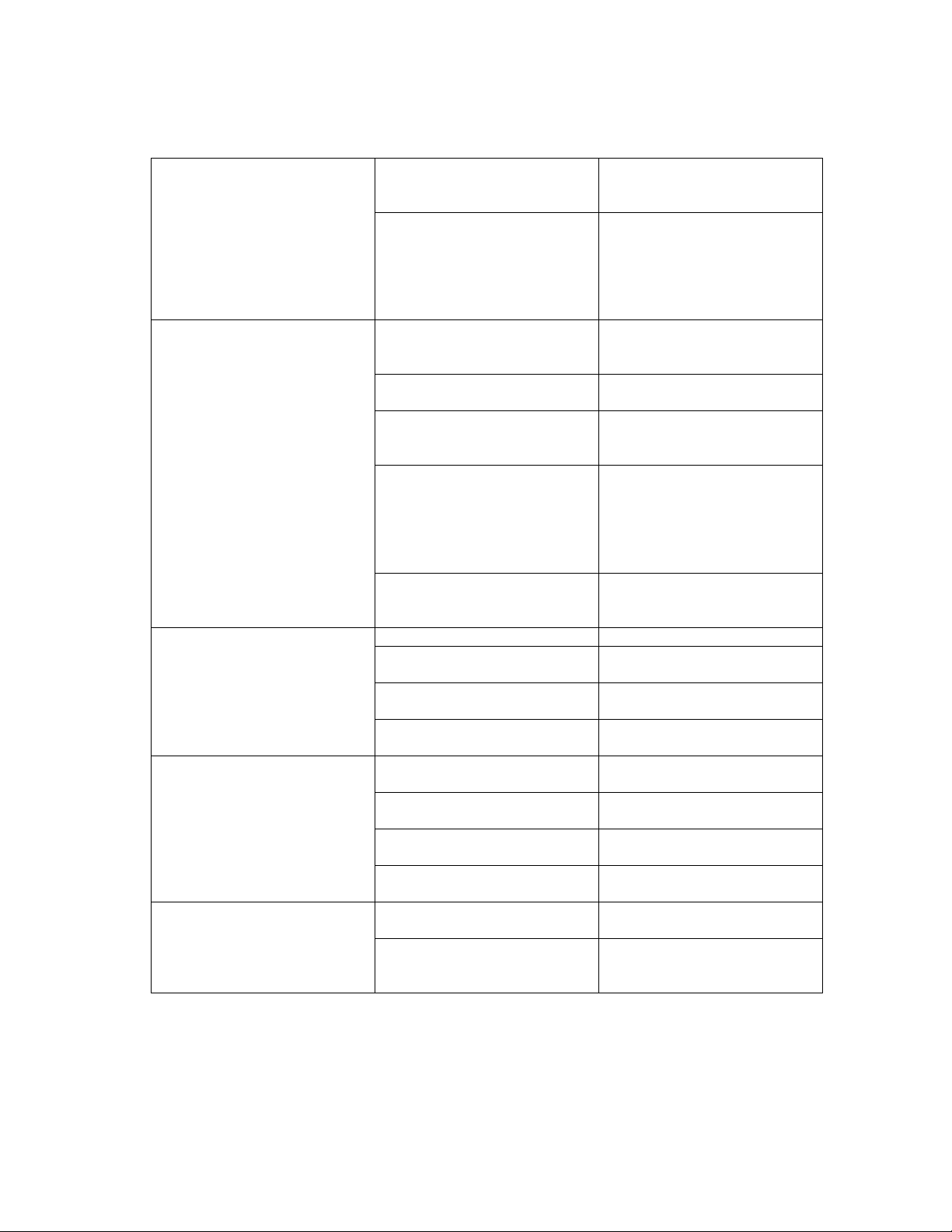

2.2. Filter Troubleshooting

Drain valve is not fully open Press down on the drain

valve handle and verify that it

is fully open

Drain Valve is open; the oil is

draining slowly or not at all

Drain is plugged with debris. Use the clean out rod to clear

the drain valve opening. If this

does not clear the blockage,

close the drain valve.

Remove drain “T” to clear

blockage.

Red return valve handle is not

completely open.

Pull on the red return valve

handle to make sure it is

completely open.

Pump return handle is pulled

out, but no pumping sound

can be heard.

Filter circuit breaker is tripped

or in the off position.

Filter motor thermal overload

is tripped.

Filter power cord is

unplugged or loose.

Reset the circuit breaker or

press it to the on position.

Push the red reset button on

the end of the filter pump

motor.

Check the power cord at the

rear of the fryer entrance box,

and at the rear of the pump

box and verify that the power

cords are pushed all the way

into their receptacles.

Loose or defective sensor

switch

Check that the switch is tight

and has the correct gap.

Replace if defective.

Dirty filter media Change filter paper/pad.

Pickup tube screen clogged Remove and clean pickup

Oil is returning to the tank

slowly or not at all.

Filter pan not pushed in

completely

O-rings not sealing on pickup

tube.

tube screen cap.

Push filter pan in to complete

connection.

Check and replace o-rings if

defective.

Pickup tube screen not tight. Tighten pickup tube screen

cap.

Excessive air bubbles are in

the oil being returned to the

tank.

Drain valve is closed, but the

computer controller still

displays “DRAINING”

Pickup tube screen cap

missing

Filter pan not pushed in

completely

O-rings not sealing on pickup

tube.

Blue drain valve handle not

completely closed

Improperly adjusted or

defective drain switch.

Locate and install pickup tube

screen cap.

Push filter pan in to complete

connection.

Check and replace o-rings if

defective.

Verify that drain valve handle

is completely closed.

Check that the switch is tight

and has the correct gap.

Replace if defective.

L22-236 Rev. 2 (06/11) 9

SERVICE

A

3. Component Troubleshooting

3.1. Temperature Probe:

Electrical resistance of the Temperature Probe, RT1, changes as the

temperature changes. As temperature rises, the probe’s resistance

decreases.

If the probe is suspect, check its resistance and the oil/air temperature at

which it was taken. Compare these values to those in the table at right.

If the probe measures open circuit, (O.L. or ) or shorted, (0 Ohms), it

should be replaced. If the resistance varies more than 30 Ohms when

being checked between 325-375F, (163-190C), the probe will give a

false temperature reading to the computer controller and should be

calibrated (up to 10F) or replaced.

3.2. Gas Valve:

The Gas Valve, VI has dual 24VAC valve coils. When 24VAC is applied to

the PV connection, the pilot valve opens, allowing gas to flow to the pilot.

When 24VAC is applied to the MV connection, the main valve opens,

allowing gas to flow to the main burners.

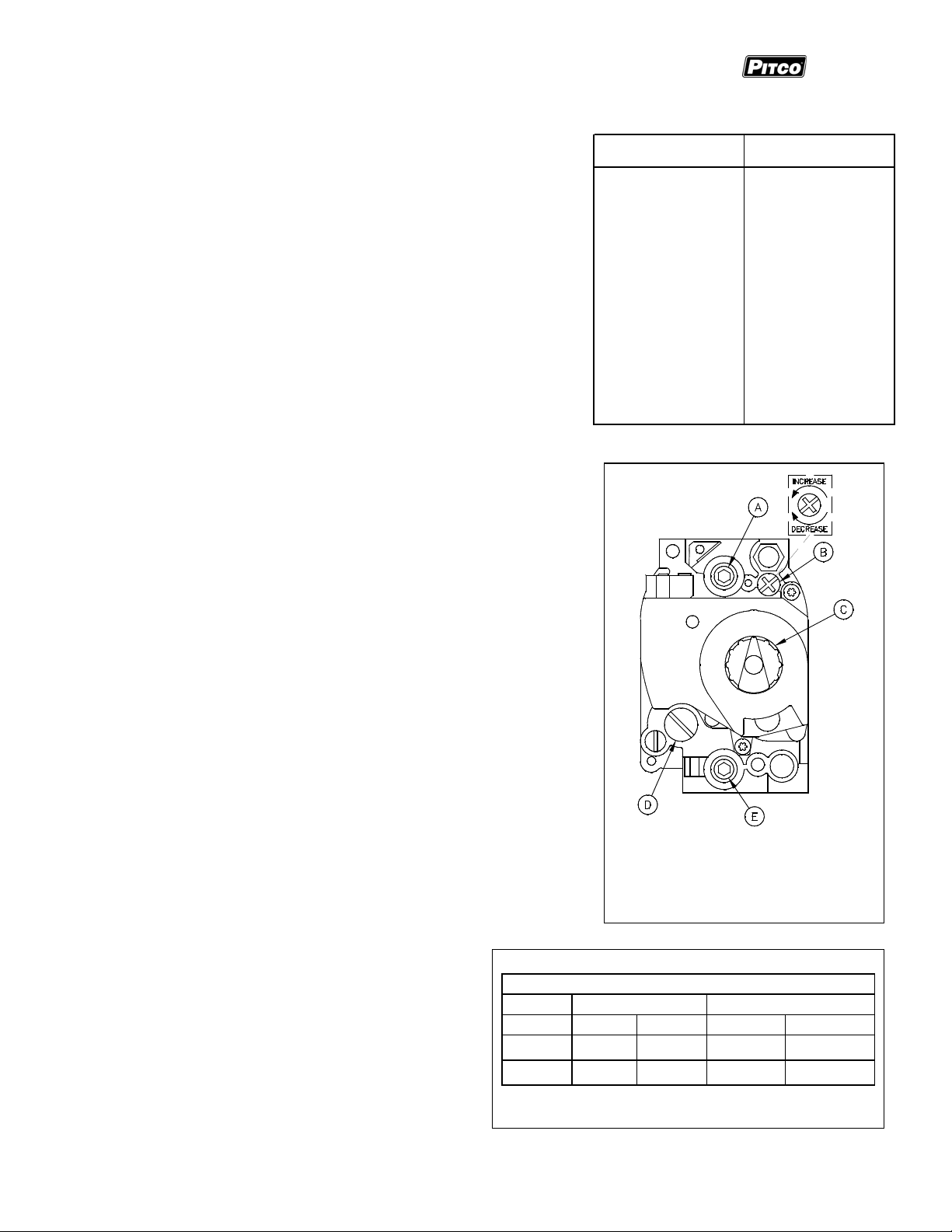

TEMP RESISTANCE TEMP RESISTANCE

°F/°C

60/16 139,055 330/166 1,192

80/27 84,644 335/168 1,123

100/38 53,146 340/171 1,058

120/49 34,328 345/174 998

140/60 22,755 350/177 942

160/71 15,446 355/179 890

180/82 10,716 360/182 841

200/93 7,586 365/185 795

210/99 6,427 370/188 752

220/104 5,470 375/191 712

240/116 4,013 380/193 675

260/127 2,991 385/196 640

280/138 2,262 390/199 607

300/149 1,734 395/202 576

320/160 1,347 400/204 547

325/163 1,267

OHM

°F/°C

OHM

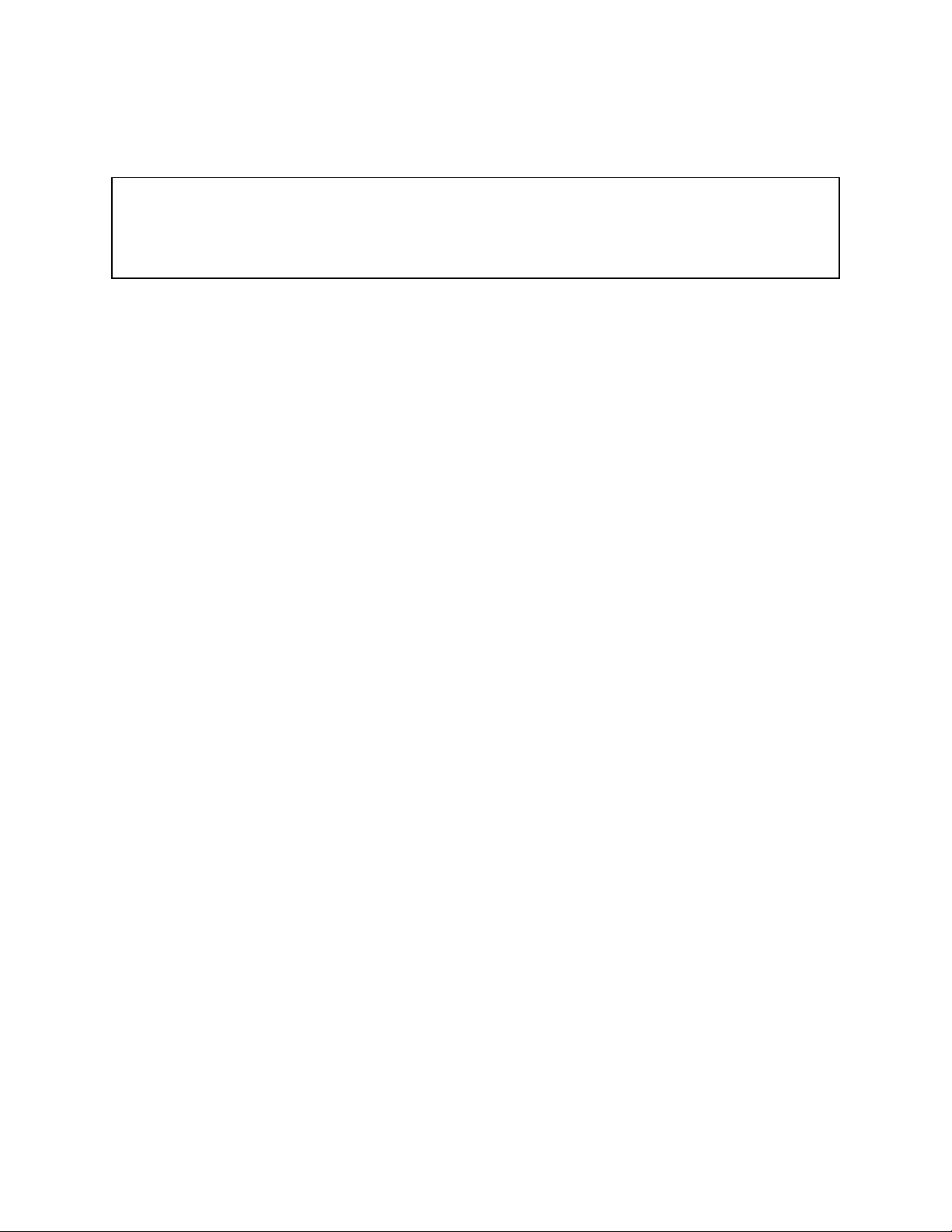

Pilot flame is adjustable using the pilot adjustment screw. It should be

adjusted at installation to achieve a flame sense current of 0.15 A or

greater.

Note: This procedure requires the use of a DC microammeter. The

meter should be wired with a switch that allows the meter to be

switched out of the circuit while the ignition system is sparking.

Connect the DC microammeter between the flame sensor (spark) terminal

and the flame sensor lead, (spark cable). Once the pilot is lit, and sparking

has stopped, switch the meter into the circuit. Observe proper polarity: if

the meter needle goes below 0, reverse the leads. The flame current

reading must be 1.0 A or greater, (0.15 A or greater for CE units).

Remove the pilot adjustment screw cap screw, (B), to expose the pilot

adjustment screw. Turning the pilot adjustment screw clockwise

decreases the size of the pilot flame and flame sense current. Turning the

pilot adjustment screw counterclockwise increases the pilot flame size and

the flame sense current. Once the pilot flame has been adjusted properly,

replace the pilot adjustment screw cap screw and remove the

microammeter.

The gas valve is equipped with a pressure regulator to

regulate burner pressure. Regulated pressure should be

the same, ±0.1” W.C. (.25mbar, .02kPa), as that marked

on the data plate on the inside door of the appliance. To

measure regulated gas pressure, connect an accurate

pressure gauge (range of 0-16 “W.C. (0-39.85mbar, 0-

3.98kPa) in 0.1” (.25mbar, .02kPa) increments) or

manometer to the burner pressure tap, (A). To adjust the

pressure, remove the burner pressure regulator

adjustment screw cap and, with a flat head screwdriver,

adjust the regulator screw until the proper burner

Model Gas Type Gas Pressure (in W.C.)

MG2 #46 #55 4.0 10.0

MG2S #46 #55 4.0 10.0

Orifice Tip Size and Burner Pressure

(for CE Countries see Section 4.0)

ON

OFF

) Burner Pressure Tap

B) Pilot Adjustment Screw Cap

C) ON/OFF Knob

D) Burner Pressure Regulator Adjustment

Screw Cap

E) Inlet Pressure Tap

NON-CE COUNTRIES

Nat LP Nat LP

10 L22-236 Rev. 2 (06/11)

MGII and MG2T GAS FRYER SERVICE

g g

pressure is reached. Turning the screw clockwise will increase the burner pressure. Turning the screw

counterclockwise will decrease the burner pressure. When the pressure is correct, replace the regulator

adjustment screw cap.

NOTE: A properly sized and installed gas line will deliver a minimum supply pressure of 7.0”

W.C. (17.4mbars, 1.74kPa) natural gas or 13.0” W.C. (32.4mbars, 3.25kPa) propane to all

appliances connected to the supply line, operating simultaneously at full demand. If regulated

gas pressure cannot be achieved with all appliances in the store running, there may be a

buildin

as supply deficiency.

3.3. High Limits:

The High Limit switch, HL1, is a normally closed switch that opens when the temperature at the high limit

sensing bulb reaches 450F15F, (232C 8).

The high limit can be tested by utilizing the Computer Controller high limit test feature. Refer to McDonald’s

PM Card FR015 for instructions on how to perform this test.

WARNING!

This test should be performed by a qualified technician only! Monitor the fryer closely. This test will

cause the oil to heat past the normal operating temperature and can cause damage to the machine and

its operator if care is not taken.

WARNING!

This test will cause the burners to run continuously.

If the switch does not open, (“trip”), between the prescribed limits it is defective and should be replaced. Once

tripped, the switch cannot be reset until the oil has cooled to approximately 400F, (204C). If the switch

cannot be reset, (by pressing the red reset button), after the oil has cooled it is defective.

3.4. Drain Valve & Return Valve Switches:

These switches, LS1 and LS4, are magnetically actuated proximity switches.

When the Drain Valve Handle is moved to the open position, the Actuator magnet will move away from the

switch causing the Drain Valve Switch, LS1, to open. When the Drain Valve is closed the switch will close.

Opening the Red Return Valve Handle will close the proximity switch causing the “Pump Run” Relay, K5, to be

energized. The pump will begin to pump. Closing the return valve handle will open the proximity switch

causing the relay to de-energize and the pump will stop pumping. These switche s can be checked with an

Ohmmeter. When the switch is closed, you should have continuity, (near 0 Ohms). The normal gap between

the Actuator magnet on the valve handle and the Sensor switch is

1

/8” – ¼” (3 – 6mm).

3.5. Transformer:

The Transformer, T1, is a Class 2 step-down, multiple tap primary to 24VAC secondary device. The

transformer can be checked by reading the input and output voltages. A quick check for transformer 24VAC

output can be done at the relay board behind the front panel. The AC LED is illuminated if the F1 fuse is good

and the board is receiving 24 VAC at connector J/P35 between pins #2 and #4.

3.6. Ignition Module:

The Ignition Module, A2, is a 24VAC input, single ignition trial, (with multiple retrials upon flame loss), device. It

senses flame through the spark lead using flame rectification. When 24VAC is input between the 24V (THS on

CE modules) terminal and 24V (GND), the ignition module generates a 24VAC output from its PV terminal.

The igniter sparks until the module senses pilot flame, or for 85-90 seconds, at which time the module will lock

out, whichever occurs first. When the module has proven the pilot flame, it will generate a 24VAC output at the

MV terminal resulting in 24VAC at connector J/P32, pin #2 on the relay board. (The relay board then controls

the 24VAC to the gas valve when the Computer Controller calls for heat.)

L22-236 Rev. 2 (06/11) 11

SERVICE

Note: When the Computer Controller is on, the pilot should always remain lit. If the pilot is not lit, either the

high limit is open, or the ignition module has locked out. Ignition module lockout can be reset by turning the

fryer off and back on again.

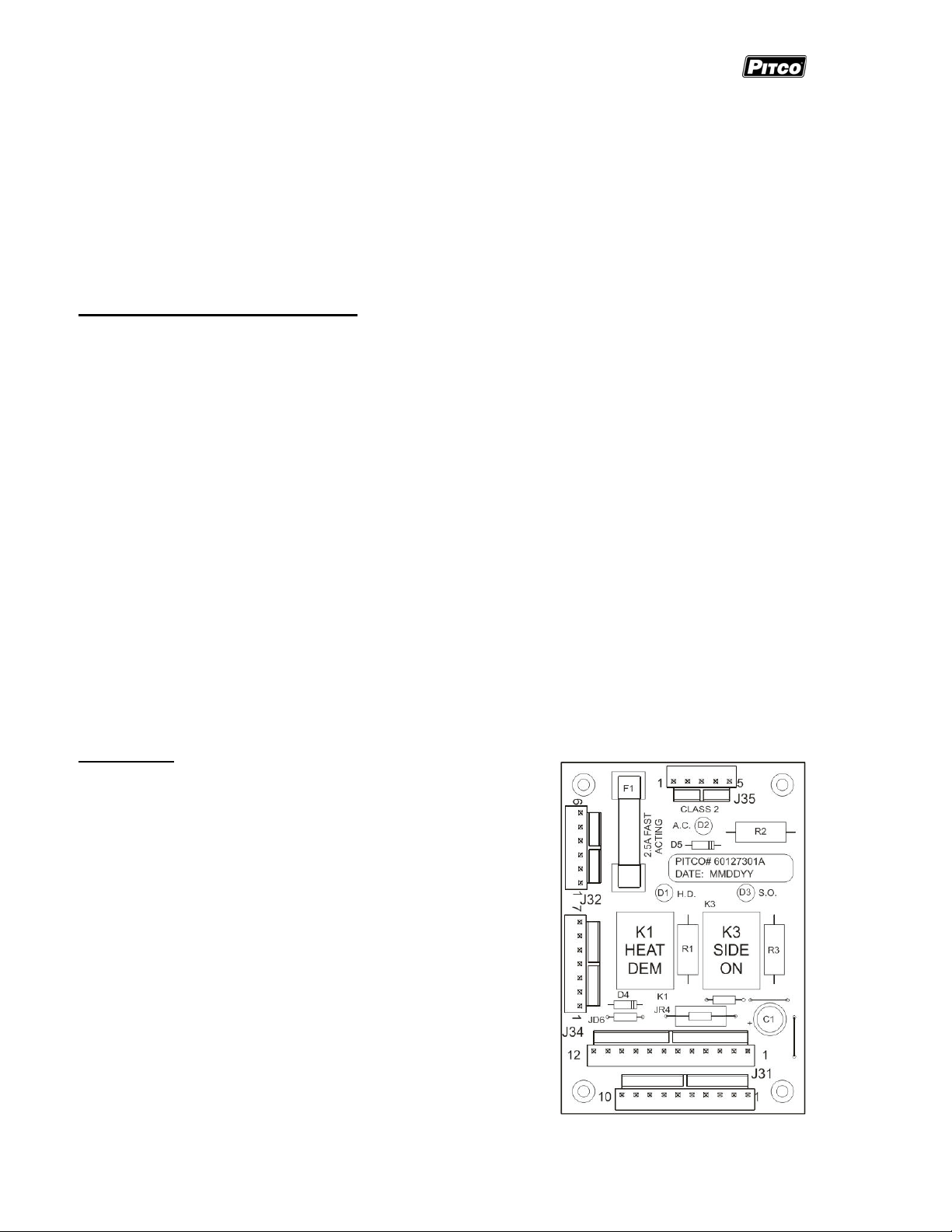

3.7. Relay Board:

The relays on the relay board have 24VDC coils. They are soldered to the board and are non-repairable.

In the event of a relay failure, replace the relay board

When installed, the relay board must have fish paper installed between it and the heat shield to which it is

mounted. This prevents the leads on the board from shorting against the metal heat shield.

Relay Board Component Explanation:

Fuse:

F1 – If fuse is blown, AC will not be lit.

Trouble Shooting Lights:

A.C. – When lit, F1 Fuse and T1 Transformer are good.

S.O. – When lit, A1 Computer is on and K3 Side On Relay should be energized.

H.D. – When lit, A1 Computer is on and calling for heat, K1 Heat Demand Relay should be energized.

Relays:

K1 – Heat Demand Relay, will be energized when A1 Computer calls for heat and wh en H.D. is lit.

K3 – Side On Relay, will be energized when A1 Computer is on and A.C. is lit.

Connectors:

J31 – Connects to A1 Computer.

J32 – To Side On and Heat Demand Contactors and Heat Feed Back.

J33 – To 24 VAC jumper harness.

J34 – To Drain Switch.

J35 – Input voltage from transformer.

Relay Board:

Note: J connectors are marked on the relay board.

With 24 VAC supplied to pin #2 at connector J35 and a good

F1 fuse, the relay board will have a 24 VAC output at pin #2 on

connectors J33 and J34 and the A.C. indicator will be

illuminated.

Note: Since the fryer is equipped with a computer, at

connection J33 there will be a jumper from pin #2 to pin

#10 to supply 24 VAC to pin #2 at connection J31 to supply

the controller with 24 VAC.

When the board receives a 24 VDC side on input at pin #7 on

connectors J31 and J33, the S.O. indicator will illuminate, the

side on relay (S.O.) will energize and there will be a 24 VAC

output at pin #4 on connector J32.

When the board receives a 24 VDC heat demand input at pin

#6 on connectors J31 or J33, the H.D. indicator will illuminate,

the heat demand relay (H.D.) will energized and there should

be continuity between pin #1 and pin #2 at connector J32.

12 L22-236 Rev. 2 (06/11)

MGII and MG2T GAS FRYER SERVICE

3.8. Computer Controller:

The McDonald’s Computer controller is an electronic temperature control, timer and menu control. Input

signals to the controller, (Power, DVI, Heat Feedback) are 24VAC. Controller outputs, (Side On, Heat

Demand), are 24VDC. Temperature is measured via a thermistor temperature probe, RT1.

The same controller is used for McDonald’s Gas and Electric Fryers and for both Full and Split Tanks. When

the controller is powered up, it looks at probe and drain valve inputs to determine if it is a full or split

configuration. (For this reason, always connect the right harness first and then the left harness when

connecting a Split, as power comes into the controller via the left harness.)

Note: When replacing a controller, it must be set up for the appliance type, (GAS, GAS2 or ELECTRIC) on

which it is installed. The MGII fryer uses the GAS2 temperature algorithm. Failure to set the control up for

the correct appliance type may result in poor appliance operation.

Note: All controller test points are at connector P/J1 (closest connector to the controlle r).

With 24 VAC supplied to pin #1 (24 VAC supply) and pin #5 (24 VAC input from DVI), the display should

read “OFF”.

With the controller turned on, there will be a 24 VDC output at pin #9 (side on).

When the controller calls for heat, there will be a 24 VDC output at pin #8 (heat demand) and a 24 VAC

input at pin #6 (heat feed back). If the controller does not receive the 24VAC input at pin #6 within 10

seconds, (90 seconds on first heat demand), the controller will display “HEAT FAIL” or “IGNITION

FAILURE”. This indicates that the controller did not receive a heat feedback signal when it called for heat.

If this occurs:

Look to see if the pilot is lit. If not:

1. Check the high-limit switch, HL1. (Is it open (“tripped”)?)

2. Check the ignition module, A2, (Sensing pilot flame? locked out?).

If the pilot is lit:

3. Check the heat demand (HD) relay, K1, on the relay board; (Is heat demand relay energized?

Continuity through COM and NO contacts?).

If display reads “PROBE”, check the resistance of the temperature probe, RT1. See the table on page 5.

Check the wires and connectors between the probe and controller for continuity.

If display reads “SYSTEM” “FAILURE”, or “HOT HI-1”, test the temperature probe and the wires and

connectors between the probe and controller for a short.

If display reads “DRAINING” “TURN OFF”, this indicates that there is no 24VAC input at pin # 5, (DVI

Input). Verify that the drain valve is closed, check the proximity switch on the drain valve, turn the fryer off,

then turn the fryer on.

L22-236 Rev. 2 (06/11) 13

SERVICE

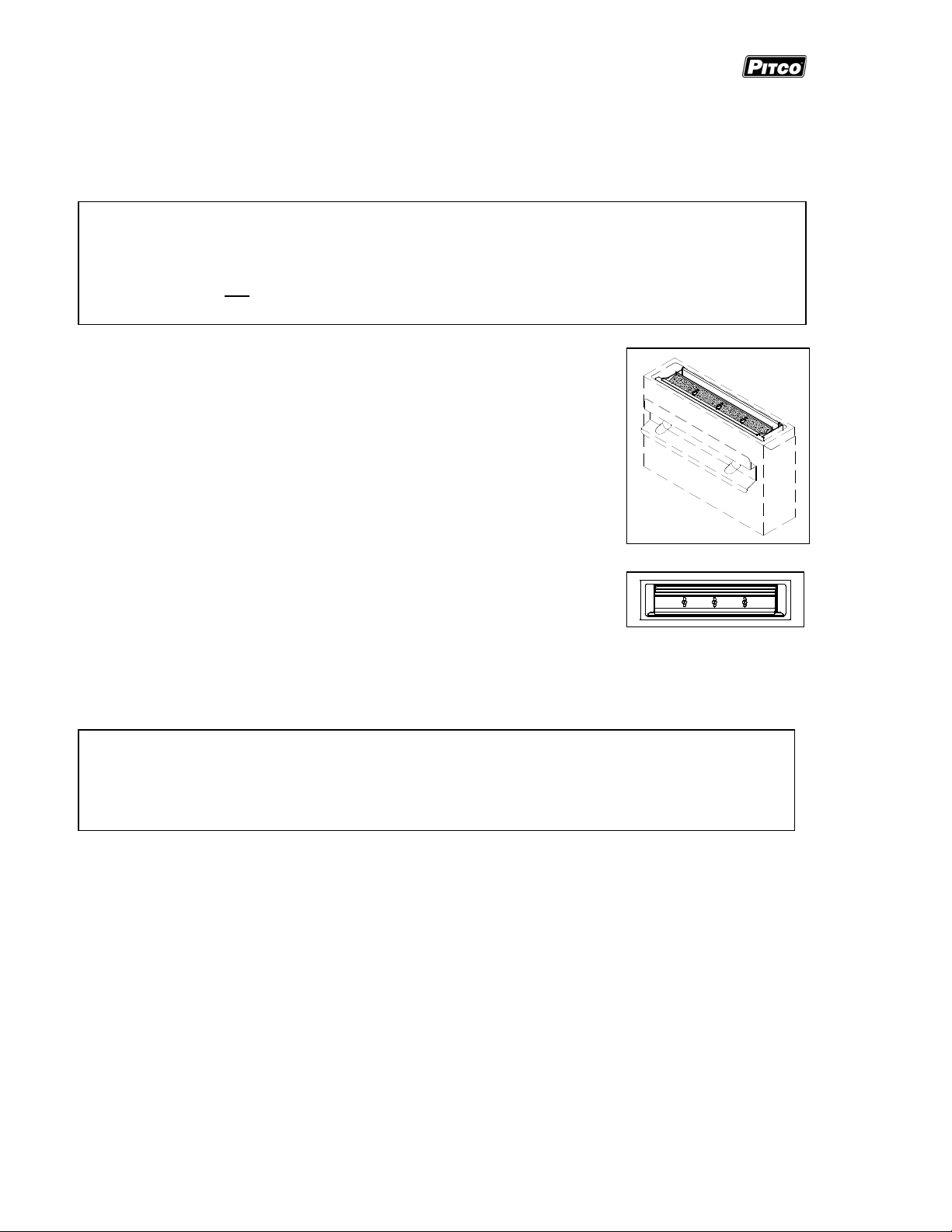

3.9. Flue Baffle

The McDonald’s MGII Gas Fryers are typically installed in a direct-coupled ventilation hood. They a re shipped

from the factory with adjustable baffles installed in the flue of each fryer. Upon installation, these baffles must

be adjusted to provide proper operation within the ventilation hood.

WARNING

Failure to properly adjust the flue baffles may result in improper operation, poor temperature

recovery, poor ignition, pilot extinction, and damage to the appliance.

If the appliance is not installed in a direct-coupled hood system, (e.g. canopy hood), the flue

baffles must be removed before installation for proper operation.

The fryer will ship with the baffle set in the normal position for most

McDonald’s “Universal” hoods. (McDonald’s direct-coupled hoods

manufactured after 1995 are of the “Universal” type.) If upon installation

under the hood, the burner flame is found to be lifting or pulsing, the draw of

the hood may be higher than nominal and adjustment of the flue baffle may

be necessary. The flame can be viewed by looking through the burner shield.

If the flue baffle requires adjustment, pulsing can often be heard when the

burners fire.

The baffle can be adjusted as follows:

1. Pull the fryer out from under the ventilation hood.

2. Loosen the 2 screws securing the baffle slide plate, move the plate to a

more closed position and retighten the screws.

3. Reinstall fryer under ventilation hood.

4. Recheck burner operation

5. Repeat as necessary

The burners should be rechecked after baffle adjustment. If there is pulsing or the flame is lifting off the burner

face, the baffle is still too far open. If there is significant flame roll out on ignition, then the baffle is too far

closed. The baffle should be set in the most open position that allows for stable, non-pulsing, non-lifting burner

operation.

WARNING!

If the baffle can not be adjusted properly, the facility must have the ventilation system checked

immediately to be sure that it is within normal operating specifications. After the ventilation system is

corrected, the baffle setting must be rechecked. Failure to correct ventilation problems or properly set

flue baffles will result in extremely poor fryer operation and possible equipment damage.

14 L22-236 Rev. 2 (06/11)

Loading...

Loading...