Page 1

English

IMPORTANT INFORMATION FOR FUTURE REFERENCE

Record the following information from the appliance ID plate

and retain this manual for the life of the equipment:

Model #: __________________________

Serial #: __________________________

Date Purchased: ___________________

Installation & Operation

for Pitco P/N’s 60149517 (Full Vat) and 60149518 (Split Vat)

I12+ Cooking Computer for ROV Fryers

w/ Options: Auto-Filter, Auto-Topoff, & Filter Data Function

This control was developed specifically for Pitco fryer products. It utilizes the latest in

microprocessor technology and is completely solid state. This control offers the latest cooking

technology, including temperature and time compensation that requires no user adjustments for

consistently cooked product. Other features include, drain valve interlock, faulty probe detection,

selectable melt cycles, beeper volume, and cook temperature. Each product key may be programmed

with cook, shake and hold times to keep pace with changing menus over time.

This manual details the operation and adjustment of the Solstice I12+ Cooking Computer For ROV

Fryers. The target audience for this text is the Store Manager.

L20-414 Rev 2 (07/14)

Page 2

Solstice I12+ Cooking Computer for ROV Fryers

Pitco P/N 60149517 & 60149518

Table of Contents:

1 Key Locations and Functions: ........................................................................................................ 4

1.1 To turn the appliance ON: ________________________________________________________ 4

1.2 To turn the appliance OFF: _______________________________________________________ 4

1.3 To start a cook: ________________________________________________________________ 5

1.4 To cancel a cook: _______________________________________________________________ 5

1.5 To check Actual and Set temperatures: _____________________________________________ 5

1.6 To View Current Settings for Cook, Shake, Hold, and Hold Pre-Alarm: _____________________ 5

1.7 Perform a Boil Out operation: _____________________________________________________ 6

1.7.1 Automatic Boil Entry (Water Detection): .................................................................................................................. 6

1.7.2 Manual Boil Entry: ................................................................................................................................................... 6

2 Oil Handling and Fryer Operations: ............................................................................................... 7

2.1 Fresh Oil Top-Off: ______________________________________________________________ 7

2.2 Manual Filtering: _______________________________________________________________ 7

2.2.1 Filter Control (Option): ............................................................................................................................................ 7

2.2.2 FDF Triggering (Option): ......................................................................................................................................... 8

2.3 Automated Filtering (Option):______________________________________________________ 8

2.3.1 Automatic Filtering: ................................................................................................................................................. 9

2.3.2 Automatic Polishing: ............................................................................................................................................... 9

2.3.3 Automatic Disposal: .............................................................................................................................................. 10

2.3.4 Blocked Drain ....................................................................................................................................................... 10

2.4 Advanced Fryer Operations (For Automated Filtering Option): ___________________________ 11

2.4.1 Full Vat/Left Return Pump: .................................................................................................................................... 11

2.4.2 Full Vat/Left Drain Valve: ...................................................................................................................................... 11

2.4.3 Full Vat/Left Manual Top-Off: ................................................................................................................................ 12

2.4.4 Right Return Pump (Split Vat Only): ...................................................................................................................... 12

2.4.5 Right Drain Valve (Split Vat Only): ........................................................................................................................ 12

2.4.6 Right Manual Top-Off (Split Vat Only): .................................................................................................................. 13

3 Control Filter Lockout (CFL): ........................................................................................................ 13

3.1 Filter Soon:___________________________________________________________________ 13

3.2 Filter Now: ___________________________________________________________________ 13

4 Fresh Oil Supply Monitoring ......................................................................................................... 14

4.1 JIB Oil Remaining: _____________________________________________________________ 14

4.2 JIB Check/Error: ______________________________________________________________ 14

5 Filter Data Function (FDF) Data Logging: .................................................................................... 15

5.1.1 Data Logging: ....................................................................................................................................................... 15

5.1.2 Data Viewing: ....................................................................................................................................................... 15

6 To Enter Programming Level 1 (for the Store Manager): ........................................................... 17

6.1 To Set Cook Temperature: ______________________________________________________ 17

6.2 To Change a Product Key–Cook, Shake, Hold, and Hold Pre-Alarm Times: ________________ 17

6.2.1 Cook Time ............................................................................................................................................................ 17

6.2.2 Shake Time: ......................................................................................................................................................... 18

6.2.3 Hold Time: ............................................................................................................................................................ 18

6.2.4 Hold Pre-Alarm: .................................................................................................................................................... 18

6.3 To Exit Level 1 programming: ____________________________________________________ 18

7 To Change Options Level 2 ( for the Store Manager): ................................................................ 19

7.1 Fahrenheit or Celsius Display: ____________________________________________________ 19

L20-414 Rev 2 Page 2 of 32

Page 3

Solstice I12+ Cooking Computer for ROV Fryers

Pitco P/N 60149517 & 60149518

7.2 Password Change or Required: __________________________________________________ 19

7.3 Beeper Volume and Tone: _______________________________________________________ 20

7.4 Language Selection: ___________________________________________________________ 20

7.5 Melt Cycle Type: ______________________________________________________________ 20

7.6 Recovery Test Value: __________________________________________________________ 21

7.7 Control or Timer: (Left side of Dual or Single Vat): ____________________________________ 21

7.8 Control or Timer: (Right side of Dual Vat): __________________________________________ 21

8 To Enter Filter Settings Menu Level 5 (for the Store Manager): ................................................ 22

8.1 Drain Time: __________________________________________________________________ 22

8.2 Filter Time: ___________________________________________________________________ 22

8.3 Polish Time: __________________________________________________________________ 23

8.4 Fill Time: ____________________________________________________________________ 23

8.5 Filter Temperature: ____________________________________________________________ 23

8.6 Cook Counts Allowed: __________________________________________________________ 24

8.7 Cook Counts Deferred: _________________________________________________________ 24

8.8 Oil Level Probe/Auto Top-Off Enable: ______________________________________________ 24

8.9 Auto Top-Off Time: ____________________________________________________________ 25

8.10 Filter Data Function Enable:____________________________________________________ 25

8.11 More Filter Menu Entry: _______________________________________________________ 25

8.11.1 JIB Monitor (Oil Remaining) Enable .................................................................................................................. 25

8.11.2 Maximum JIB Time ........................................................................................................................................... 26

8.11.3 Low JIB Time ................................................................................................................................................... 26

8.11.4 JIB Monitor (Check/Fault) Enable ..................................................................................................................... 26

8.11.5 Filter Return Key Enable................................................................................................................................... 26

8.11.6 On-Demand Top-Off Key Enable ...................................................................................................................... 27

8.11.7 To Exit More Filter Menu .................................................................................................................................. 27

8.12 To Exit Programming Level 5: __________________________________________________ 27

9 Other Displays: ............................................................................................................................... 28

10 Mechanical Dimensions: ............................................................................................................ 29

11 Electrical Connections at LEFT and RIGHT connectors): ...................................................... 30

12 Probe Resistance Chart: ............................................................................................................ 31

Page 3 of 32 L20-414 Rev 2

Page 4

Solstice I12+ Cooking Computer for ROV Fryers

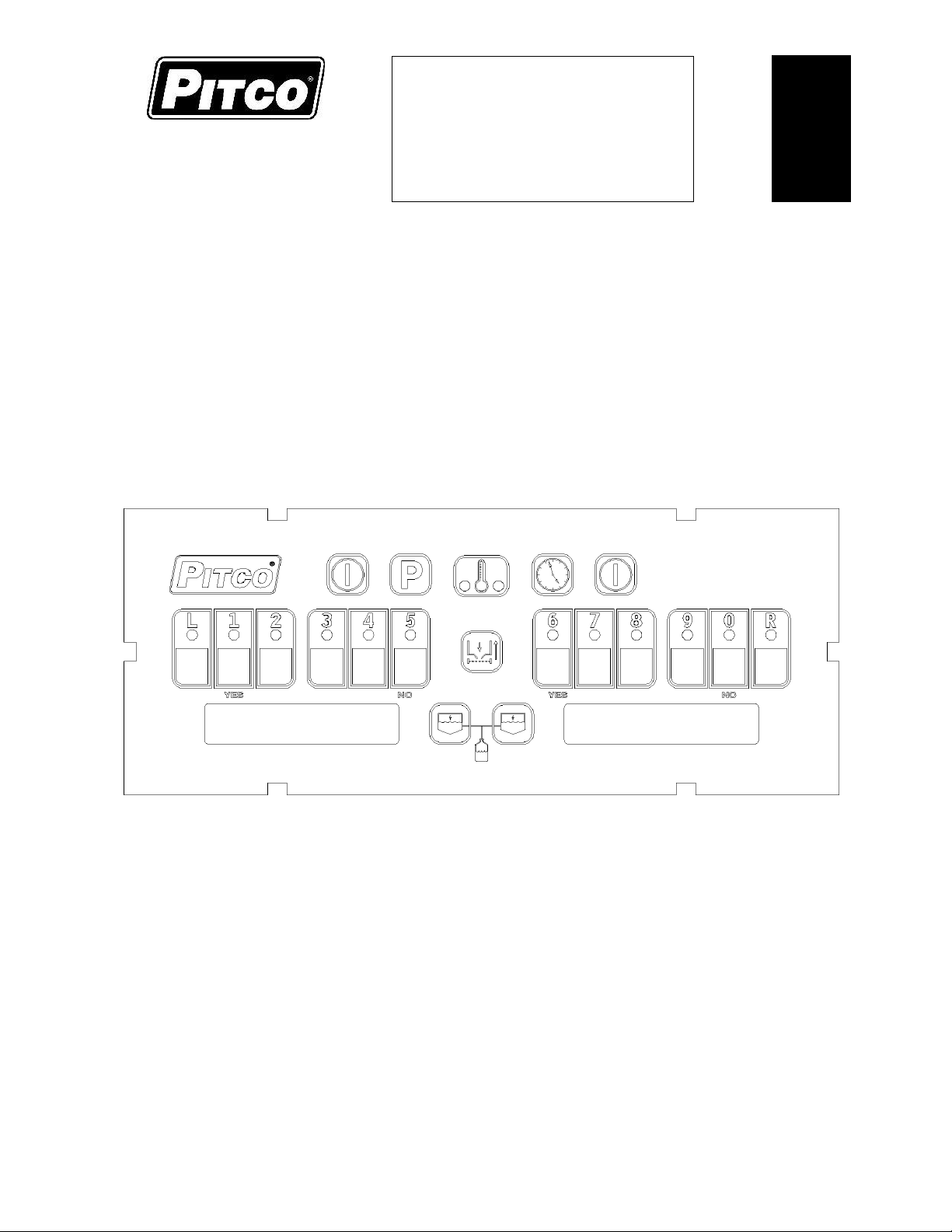

12 Product

Keys

12 Product

Key Indicators

On/Off

Key

Program

Key

Thermometer

Key

Clock

Key

On/Off

Key

Left Manual Oil

Top-Off Key

Filter Control

Key

Right Manual Oil

Top-Off Key

Pitco P/N 60149517 & 60149518

1 Key Locations and Functions:

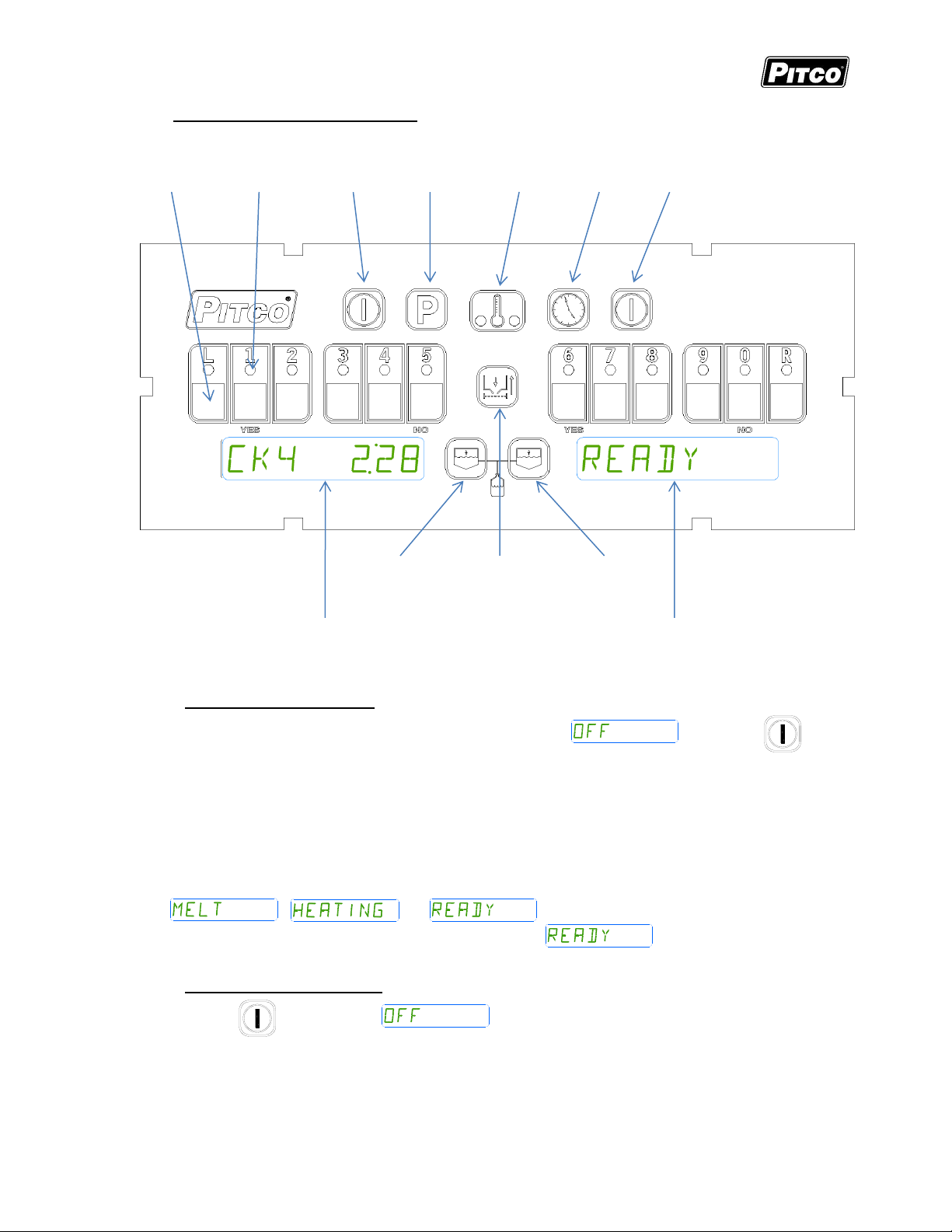

Displays show current operation. Throughout this text, a left only display will be

printed as [CK4 2:28]. When both left and right displays should be interpreted

together, this text will show them as [CK4 2:28][READY].

1.1 To turn the appliance ON:

If power is applied to the appliance, the displays will show . Press the key.

If the drain has been opened since the last time the fryer was turned on, the operator will be

prompted to check and verify that the vat is full with oil before applying heat. The screen will

display “Is vat full?” – press the YES [6/1] key if oil level is above the minimum level, otherwise

press the NO [0/5] key. Failure to accurately answer this prompt may result in unsafe

conditions.

Displays will show one of the following:

, , or . Some messages may show in both left and

right displays. Wait for the appliance to heat up to the condition before cooking.

1.2 To turn the appliance OFF:

Press the key. and then .

L20-414 Rev 2 Page 4 of 32

Page 5

Solstice I12+ Cooking Computer for ROV Fryers

+

Pitco P/N 60149517 & 60149518

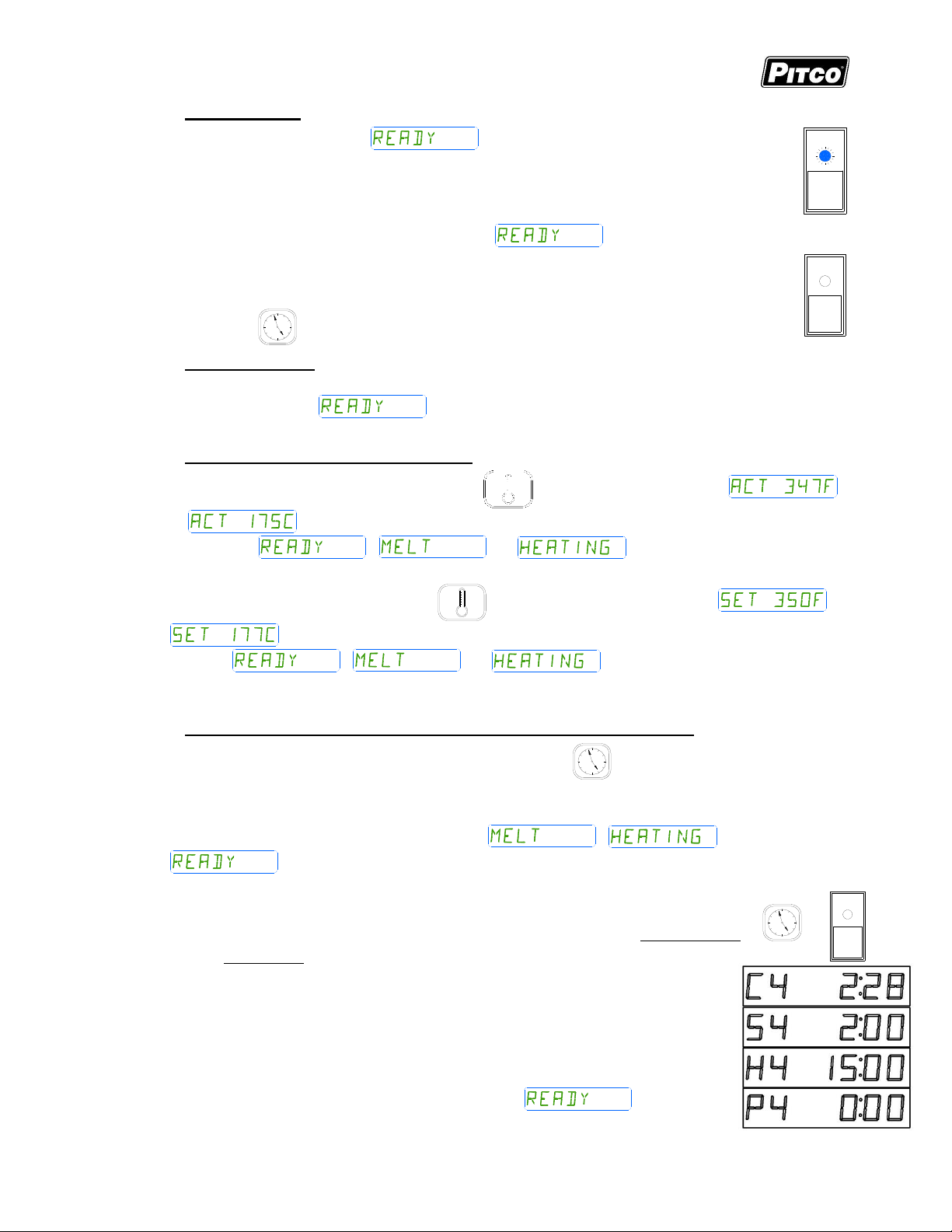

1.3 To start a cook:

When the display is showing the appliance has reached set

temperature and is ready to cook. Press the desired product key, and place

product into the vat. The indicator above the product key will flash to indicate the

cook timer is running. In the example above, product 4 is cooking with 2 minutes

and 28 seconds remaining. The right side display of the dual vat control shown

above, has no running cook timers, and shows .

Multiple cooks may run together. While cooks are running, the displays will always

show the cook with the least time remaining. Longer running cooks will flash their

indicators at a slower rate. Cook time remaining on these keys may be checked by

pressing the key then pressing a product key.

1.4 To cancel a cook:

Press and hold the product key to cancel a running cook. If no other cooks are pending, controller

displays will return to .

1.5 To check Actual and Set temperatures:

To view the actual vat temperature, press the key. The display will show

or , where “F” is Fahrenheit, and “C” is Celsius. After a few moments, the display

will return to , , or if no cooks are running. [Cn

mm:ss] will display for any cooks still running.

To view the set temperature, press the key twice. The display will show or

, where “F” is Fahrenheit, and “C” is Celsius. After a few moments, the display will

return to , , or , or, [Cn mm:ss] for any cook still

running.

1.6 To View Current Settings for Cook, Shake, Hold, and Hold Pre-Alarm:

To view the current settings for any product key, press the key, followed by the desired

product key. The display will show [Cn mm:ss], followed by [Sn mm:ss], then [Hn mm:ss], ending

with [Pn mm:ss]. Where “n” is the key number, and “mm:ss” is the time setting.

After a few moments, the display will return to , , or

, or, [Cn mm:ss] for any cook still running.

Typical displays using key 4 as an example:

Key 4 Cook Time [C4] is set for 2 minutes and 28 seconds.

Key 4 Shake Time [S4] is set for 2 minutes and :00 seconds before the end

of the Cook. Default value is 00:00, or inactive.

Key 4 Hold Time [H4] is set for 15:00 minutes. This is the amount of

time cooked product may sit in holding bins before a new batch is

started. Default value is 00:00, or inactive.

Key 4 Hold Pre-Alarm [P4] is set for 00:00 and is inactive (default

setting). When activated his alarm warns the operators that the Hold

Time is about to run out.

In a few moments, the display will return to .

Page 5 of 32 L20-414 Rev 2

Page 6

Solstice I12+ Cooking Computer for ROV Fryers

Figure 1

Pitco P/N 60149517 & 60149518

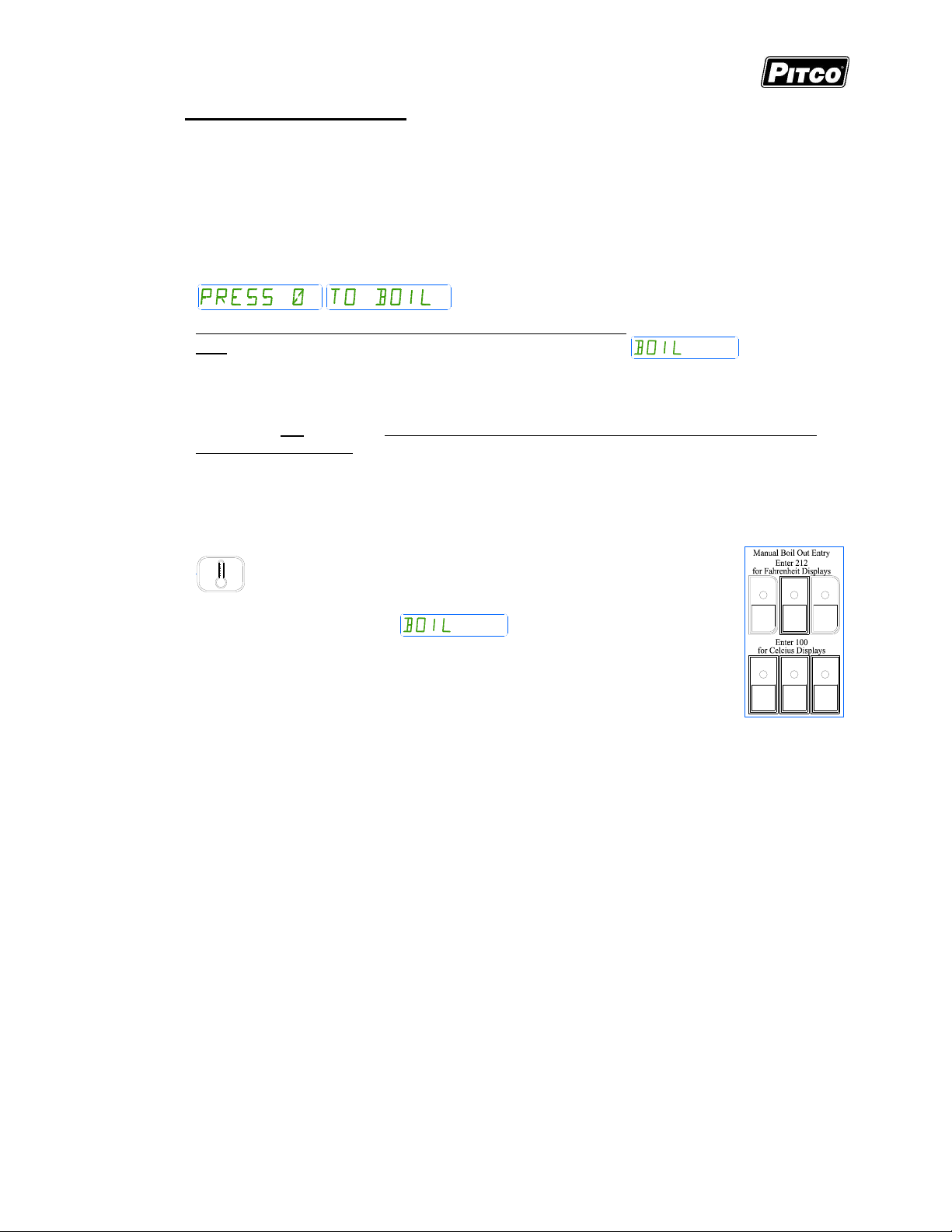

1.7 Perform a Boil Out operation:

Normal maintenance of a fryer requires regular tank cleaning. This process involves draining the

vat of oil and filling with water. Cleaning solution is added, and the control is set to boil by one of

the following methods:

1.7.1 Automatic Boil Entry (Water Detection):

Fill the appliance with water and turn the appliance on. Heat will be applied to the vat warming

the water. This control will detect the presence of water by temperatures not rising above the

boiling point of water; 212°F (100°C). After a time at this temperature, displays will show

Heat will be disabled until the operator responds to this prompt. Pressing the [10/0] key is a

YES response to the boil prompt. If pressed, display will show . Heat will

maintain vat temperature at 185°F (85°C) for cleaning as long as the control remains on. To

exit boil mode control must be turned off.

Warning: Pressing any other key at the [PRESS 0] [TO BOIL ] prompt is regarded by the

control as a NO response. With this response, the control will apply heat to the vat as if oil

were present in the vat. With water in the vat, a rolling boil will result. This will cause

undesirable foam over condition and, a potential steam burn hazards to operators performing

cleaning operations.

1.7.2 Manual Boil Entry:

After filling an empty vat with water, turn the appliance on. Press the

key and enter key sequence [2], [1], [2]. If control is set to

display in the Celsius scale, press [1], [0], [0] keys to manually enter boil

mode. The display will show to indicate entry into boil

mode.

To exit boil mode, control must be turned off.

L20-414 Rev 2 Page 6 of 32

Page 7

Solstice I12+ Cooking Computer for ROV Fryers

Pitco P/N 60149517 & 60149518

2 Oil Handling and Fryer Operations:

2.1 Fresh Oil Top-Off:

The fresh oil top-off system allows the operator to add oil to the vat to compensate for loss due to

normal product draw-out. The top-off system is not intended for the refilling of an empty vat.

To add fresh oil to the vat on-demand, press and hold the key.

Release the Top-Off key when oil has reached an optimal level.

Use the Left or Right key to top-off the Left or Right vat, respectively, for split vat

fryers.

Manual top-offs are not permitted while there is an active cook.

This computer also supports the Auto Top-Off system (Option), where low oil levels will

automatically be detected and oil added. This system has no operator interface.

To disable the Auto Top-Off system, see section 8.8.

2.2 Manual Filtering:

This section applies to fryer configurations without the Automated Filtering option.

2.2.1 Filter Control (Option):

The filter return pump can be activated and deactivated through front panel for manual filter fryer

applications. Activating the filter return will move oil from the filter pan to the user selected frypot.

With no cook timers running the display will show , ,

, or .

To start the return pump for the vat, press the key.

If fryer is a split vat, and will be displayed. To return oil

to the Left vat, press product key [1] (YES), or to return oil to the Right vat, press product

key [6] (YES).

The display will show .

To stop the return pump, press the key again.

The display will show .

Page 7 of 32 L20-414 Rev 2

Page 8

Solstice I12+ Cooking Computer for ROV Fryers

Pitco P/N 60149517 & 60149518

2.2.2 FDF Triggering (Option):

With the display will showing or

, FDF enabled (section 8.10), and

the current vat temperature above the set filter temperature (section 8.5):

Pull the drain valve to filter.

Choose filter type:

o The display will show – press YES to Filter, NO to

skip.

o The display will show – press YES to Polish, NO

to skip.

o The display will show – press YES to Dispose,

NO to skip.

This display will show a countdown timer based on the filter operation selected and the

user settings in sections 8.2 and 8.3.

o The drain must remain open while the countdown timer is running.

Follow store procedures for filtering and wait until filter timer completes.

o To start and stop the return pump, press the key.

Once the timer expires, the display will show or

.

2.3 Automated Filtering (Option):

This computer supports the use of automated oil processes FILTER, POLISH, and DISPOSE.

After the selection of a process, the operator will be prompted with a series of questions verifying

the current state of the fryer battery – as outlined by the “Initiate Check List” below. Failure to

properly comply with the check list may result in unsafe or undesirable conditions. Once all

prompts have been affirmed, the selected automated function will begin.

Initiate Check List

“Filter pan in-place and empty?” – check the filter pan and verify it is fully in place and

empty.

o If filter pan is ready, press the YES key and continue.

o If filter pan is not ready, press the NO key, resolve the filter pan condition, and start

over.

“Autofilter now?” – confirm the selection.

o Press the YES key to start.

o Press the NO to cancel.

When automated processes FILTER and POLISH are complete, the operator will be prompted to

verify the current state of the battery – as outlined by the “Acknowledge Check List” below. Once

all prompts have been affirmed, the fryer will return its original state (either ON or OFF).

Acknowledge Check List

“Is vat full?” – verify the frypot has reached an appropriate oil level and the filter pan is

completely empty.

o If the filter pan is empty, press the YES key to complete.

L20-414 Rev 2 Page 8 of 32

Page 9

Solstice I12+ Cooking Computer for ROV Fryers

Pitco P/N 60149517 & 60149518

o If there is still oil in the filter pan, press the NO key to run the pump for 20

additional seconds. “Is vat full?” will be prompted again when complete.

NOTE: NO may be selected for “Is vat full?” a maximum of three times.

o The fourth time NO is selected, the fryer will turn OFF and display “Possible Filter

Issue - Check and Resolve”. Press product YES key to acknowledge.

2.3.1 Automatic Filtering:

The automated filtering process will open the drain and move oil from the vat to the filter pan,

close the drain, and pump oil back to the vat. This allows for a quick filter by passing oil

through the filter medium once.

With no cook timers running the display will show .

To perform an automatic filter, press the key.

If fryer is a split vat, and will be displayed. To perform a

filtering operation on the Left vat, press product key [1] (YES), or to perform a filtering

operation on the Right vat, press product key [6] (YES).

The display will show – press product key [6] (YES) to

confirm.

Follow the “Initiate Check List” procedures outlined above.

Wait until automated filter process completes.

Follow the “Acknowledge Check List” procedures outlined above.

Display will return to , , or .

2.3.2 Automatic Polishing:

The automated polishing process will open the drain, moving oil from the vat to the filter pan,

and then run the return pump. Oil will cycle through the vat and the filter pan, making multiple

passes through the filter medium. After a set amount of time, the drain will close and oil will be

pumped back to the vat. This allows for a longer filtering process to remove more debris from

the oil – extending oil life and increasing oil quality.

With no cook timers running the display will show .

To perform an automatic polish, press the key.

If fryer is a split vat, and will be displayed. To

perform a filtering operation on the Left vat, press product key [1] (YES), or to perform

a filtering operation on the Right vat, press product key [6] (YES).

The display will show – press product key [0] (NO) to

skip.

The display will show – press product key [6] (YES)

to confirm.

Follow the “Initiate Check List” procedures outlined above.

Wait until automated filter process completes.

Follow the “Acknowledge Check List” procedures outlined above.

Display will return to , , or .

Page 9 of 32 L20-414 Rev 2

Page 10

Solstice I12+ Cooking Computer for ROV Fryers

Pitco P/N 60149517 & 60149518

2.3.3 Automatic Disposal:

The automated disposal process will open the drain and move oil from the vat to the filter pan,

and then close the drain once empty. The operator may now dispose of oil from the filter pan.

With no cook timers running the display will show .

To perform an automatic dispose, press the key.

If fryer is a split vat, and will be displayed. To perform a

filtering operation on the Left vat, press product key [1] (YES), or to perform a filtering

operation on the Right vat, press product key [6] (YES).

The display will show – press product key [0] (NO) to

skip.

The display will show – press product key [0] (NO) to

skip.

The display will show – press product key [6] (YES)

to confirm.

Follow the “Initiate Check List” procedures outlined above.

Wait until automated filter process completes.

Display will return to .

2.3.4 Blocked Drain

During all automatic sequences listed above, the message ALERT – DRAIN CLOSING –

REMOVE TOOLS will appear with an audible alert for 10 seconds prior to the scheduled

closure of the drain. Remove tools, such as a clean-out rod, from the drain. Failure to do so

could cause damage to the equipment.

If a clean-out rod is accidently caught in a closed drain, DO NOT FORCEFULLY PULL OR

OTHERWISE TRY TO REMOVE THE TOOL. The drain will automatically reopen – remove

caught tool at that time. After 10 seconds, the drain will close again and the automatic

sequence will proceed normally. If the drain is unable to close for a second time, it will

automatically reopen again and stop the return pump.

The display will scroll the message CLEAR BLOCKED DRAIN – RETRY?. If there is a tool

still in the drain, remove it and press the YES key to continue. If there is no tool in the drain,

use a clean-out rod to attempt to clear any drain obstruction, remove the clean-out rod, and

press the YES key to continue. Once the drain is detected fully closed, the automatic

sequence will complete normally.

If after 3 retry attempts, or if the NO key is pressed when prompted to retry, the drain will

remain open and the fryer becomes inoperable. The display will show message OFFLINE –

CALL SERVICE – ERR 2002. Call for service to resolve the blocked drain issue. Other fryers

will be able to operate and filter normally.

L20-414 Rev 2 Page 10 of 32

Page 11

Solstice I12+ Cooking Computer for ROV Fryers

Pitco P/N 60149517 & 60149518

2.4 Advanced Fryer Operations (For Automated Filtering Option):

The advanced fryer operation menu can be used to manually control the drain valve and return

pump for processes such as oil rotation, custom cleaning procedures, and recovery from an

interrupted automatic process.

With no cook timers running the display will show , ,

, or .

To enter the advanced oil handling menu, press and hold the key until display shows

.

The advanced oil handing menu functions in a Select-and-Confirm interface. While in the

advanced oil handling menu, product keys [L-5] can be pressed at any time to change the currently

selected function, indicated on the left display. No action occurs during the selection a function.

When a desired function has been selected, press product key [6] to confirm the section and

perform action. The specific action of product key [6] is indicated on the right display, which varies

with the selected function.

2.4.1 Full Vat/Left Return Pump:

While in the advanced oil handling menu, press product key [L].

Display shows .

Press product key [6] to run the pump and return oil to the target vat from

the filter pan.

Display shows .

Press product key [6] to stop the pump. (If the function selection is

changed or the advanced oil handing menu is exited while Return is

active, the pump will stop automatically.)

Press key to exit the menu or select a product key [L-5] to

perform another action.

2.4.2 Full Vat/Left Drain Valve:

While in the advanced oil handling menu, press product key [1].

Display shows .

Press product key [6] to open the drain valve and drain oil to the filter

pan. Verify the filter pan is in-place and empty before draining oil,

the operator will NOT be prompted to check.

Display shows .

Press product key [6] to close the drain valve. (If the function selection is

changed or the advanced oil handing menu is exited while Drain is open,

the drain will close automatically.)

Press key to exit the menu or select a product key [L-5] to

perform another action.

Page 11 of 32 L20-414 Rev 2

Page 12

Solstice I12+ Cooking Computer for ROV Fryers

Pitco P/N 60149517 & 60149518

2.4.3 Full Vat/Left Manual Top-Off:

While in the advanced oil handling menu, press product key [2].

Display shows .

Press and hold product key [5] to manually add fresh oil to the vat.

Display will show while product key [6]

is held down.

Release product key [6] to stop adding fresh oil.

Press key to exit the menu or select a product key [L-5] to

perform another action.

2.4.4 Right Return Pump (Split Vat Only):

While in the advanced oil handling menu, press product key [3].

Display shows .

Press product key [6] to run the pump and return oil to the target vat from

the filter pan.

Display shows .

Press product key [6] to stop the pump. (If the function selection is

changed or the advanced oil handing menu is exited while Return is

active, the pump will stop automatically.)

Press key to exit the menu or select a product key [L-5] to

perform another action.

2.4.5 Right Drain Valve (Split Vat Only):

While in the advanced oil handling menu, press product key [4].

Display shows .

Press product key [6] to open the drain valve and drain oil to the filter

pan. Verify the filter pan is in-place and empty before draining oil,

the operator will NOT be prompted to check.

Display shows .

Press product key [6] to close the drain valve. (If the function selection is

changed or the advanced oil handing menu is exited while Drain is open,

the drain will close automatically.)

Press key to exit the menu or select a product key [L-5] to

perform another action.

L20-414 Rev 2 Page 12 of 32

Page 13

Solstice I12+ Cooking Computer for ROV Fryers

Pitco P/N 60149517 & 60149518

2.4.6 Right Manual Top-Off (Split Vat Only):

While in the advanced oil handling menu, press product key [5].

Display shows .

Press and hold product key [5] to manually add fresh oil to the vat.

Display will show while product key [6]

is held down.

Release product key [6] to stop adding fresh oil.

Press key to exit the menu or select a product key [L-5] to

perform another action.

3 Control Filter Lockout (CFL):

This computer includes the Cook Count-based Control Filter Lockout (CFL) function which enforces

operator compliance with regularly scheduled filtering based on the number of cooks performed

since the last filter.

Performing any automated oil filter operation will reset the cook counter. Also, any manual

operation that includes the opening of the drain valve for 20 seconds or more will also reset the

cook counter. The cook counter may be reset at any time, where the computer does not have to

be in a Filter Soon or Filter Now state.

To check the current remaining cooks available before Filter Lockout, press the key until

the Cooks Remaining message is shown. Press the key again to show

the maximum number of cooks allowed – .

3.1 Filter Soon:

Filter Soon message will show when the number of cooks since the last filter

operation is greater than the Cook Counts Allowed value (section 8.6). It is suggested to

perform a filter operation when business levels permit.

The message will not be viewable if there are active cook timers.

Additional cooks are allowed when in Filter Soon state.

3.2 Filter Now:

Filter Lockout messages or will show on the

displays when the number of cooks since the last filter operation is equal to the sum of the

Cook Counts Allowed value and the Cook Counts Deferred value (section 8.7). It is required to

perform a filter operation at this time.

The message will display when the final allowed cook has been

completed. Perform the required filtering when this cook completes.

When in the Filter Lockout state, cooks are no longer allowed and product key presses

are ignored.

Page 13 of 32 L20-414 Rev 2

Page 14

Solstice I12+ Cooking Computer for ROV Fryers

Pitco P/N 60149517 & 60149518

4 Fresh Oil Supply Monitoring

This computer monitors the Jug-in-Box (JIB) fresh oil supply for oil remaining estimation and oil

supply problems. The computer will monitor utilization of the JIB from on-demand, manual top-offs,

automatic top-offs, and top-off events from other fryers in the battery.

4.1 JIB Oil Remaining:

Low JIB message will show and toggle with the current fryer state when the

available fresh oil has dropped below the Low JIB configuration value (section 8.11.3).

Replace JIB message will show and toggle with the current fryer state when

the available fresh oil has depleted. The operator at this time should replace the JIB with a

new, full supply.

It is not recommended to replace JIB with a less-than-full supply.

To reset the JIB Oil Remaining monitor once the supply has been replaced:

Push-and-hold until is displayed.

Press product key [6] (YES) to reset the fresh oil supply to the Max JIB configuration value

(section 8.11.2).

Note: Only one cooking computer in a fryer battery needs to have the oil remaining monitor enabled

(section 8.11.1).

4.2 JIB Check/Error:

For fryer configurations with the auto top-off option, the JIB error monitor displays the error

message when an auto top-off event has occurred three

times within 15 minutes for a single frypot. This message indicates to the operator that a JIB or

its hose has been installed improperly, the JIB has been emptied and not replaced, or there is

some other fault condition.

Check the JIB and resolve any fault conditions. Press any cook key to clear the Check JIB

message.

When the Check JIB message is displayed, auto top-off for that frypot is temporarily

disabled until the message is cleared and acknowledged.

L20-414 Rev 2 Page 14 of 32

Page 15

Solstice I12+ Cooking Computer for ROV Fryers

FDF Password

Pitco P/N 60149517 & 60149518

5 Filter Data Function (FDF) Data Logging:

The FDF feature allows managers to track oil usage and filtering events by operators. These

features can be incorporated into an overall oil management strategy to extend oil life through an

enforced filtering regimen in combination with CFL.

Only successfully completed filter events (Filter & Polish) for both manual filter and autofilter

configurations increase the respective count for FDF data logging. Interrupted filtering sequences,

or opened drains which do not meet FDF triggering criteria, will be logged as incomplete.

5.1.1 Data Logging:

The FDF will store data for three batches of oil – the current batch, and the two past batches.

The use of the Dispose function saves the current batch data to history and resets data logging

values for the new oil batch.

For a batch of oil, the FDF logs the following data:

Number of Filter Operations

Number of Polish Operations

Number of Oil Hours

Number of Incomplete Filters

Management of oil through methods other than functions Filter, Polish, and Dispose are logged

as incomplete filters.

5.1.2 Data Viewing:

With no cook timers running, displays will show one of the following displays: ,

Press the key. The left display will show . The right display

Enter password

The display will show collected data on the current batch of oil (for the Left vat if split), as

indicated by the number “1” in the first digit of the right display.

, or .

will be blank.

using the product keys as a numeric keypad for

entry.

o This is the number of filter events completed (nnnnn) for the current batch of oil.

Press product key [0] to continue, press the [P] key to exit.

o This is the number of polish events completed (nnnnn) for the current batch of oil.

Press product key [0] to continue, press the [P] key to exit.

o This is the number of hours (nnnnn) oil has been at temperature for the current

batch of oil. Press product key [0] to continue, press the [P] key to exit.

Page 15 of 32 L20-414 Rev 2

Page 16

Solstice I12+ Cooking Computer for ROV Fryers

Pitco P/N 60149517 & 60149518

o This is the number of incomplete filters (nnnnn) for the current batch of oil. Press

product key [0] to continue, press the [P] key to exit.

Display now shows data for the prior disposed batch of oil, as indicated by the number “2” in

the first digit of the right display.

o This is the number of filter events completed (nnnnn) for the prior disposed batch

of oil. Press product key [0] to continue, press the [P] key to exit.

o This is the number of polish events completed (nnnnn) for the prior disposed batch

of oil. Press product key [0] to continue, press the [P] key to exit.

o This is the number of hours (nnnnn) oil has been at temperature for the prior

disposed batch of oil. Press product key [0] to continue, press the [P] key to exit.

o This is the number of incomplete filters (nnnnn) for the prior disposed batch of oil.

Press product key [0] to continue, press the [P] key to exit.

Display now shows data for the second prior disposed batch of oil, as indicated by the number

“3” in the first digit of the right display.

o This is the number of filter events completed (nnnnn) for the prior disposed batch

of oil. Press product key [0] to continue, press the [P] key to exit.

o This is the number of polish events completed (nnnnn) for the prior disposed batch

of oil. Press product key [0] to continue, press the [P] key to exit.

o This is the number of hours (nnnnn) oil has been at temperature for the prior

disposed batch of oil. Press product key [0] to continue, press the [P] key to exit.

o This is the number of incomplete filters (nnnnn) for the prior disposed batch of oil.

Press product key [0] to continue, press the [P] key to exit.

For split vat fryers, continuing will display FDF data logged information for the Right vat.

With the display showing , press key to return to normal operations.

Display will now show , , or .

L20-414 Rev 2 Page 16 of 32

Page 17

Solstice I12+ Cooking Computer for ROV Fryers

Level 1 & 2 Password

Pitco P/N 60149517 & 60149518

6 To Enter Programming Level 1 (for the Store Manager):

Note: The factory default setting for this control does not require a password to be entered.

However, the operator password requirement and value may be changed in section 3.2.

Entry of a password when NOT required will not interfere with the programming process.

With no cook timers running, displays will show one of the following displays: ,

, or . Press the key.

If display shows:

, a password is required.

If display shows:

; you do not need

to enter a password.

Enter password

using the product keys as

a numeric keypad for entry. With correct password entry, display

will show .

From the display, continue with this section or go to section 3, or 4.

6.1 To Set Cook Temperature:

Press the key once. The display will show [SET xxxF] [TEMP] or [SET xxxC] [TEMP],

where “xxx” is the temperature setting.

Use the product keys for numeric entry to adjust the current setting. Press the key to

save setting. Display now shows . To exit here, press again, or

continue.

6.2 To Change a Product Key–Cook, Shake, Hold, and Hold Pre-Alarm Times:

For each product key, Cook, Shake, Hold, and Hold Pre-alarm times are set in this section.

With display showing , continue with the following section for each product key to

change.

6.2.1 Cook Time

Cook Time may be set for each product key. To deactivate any product key enter a zero value

for cook time.

Press the key.

Display will show . Press the desired product key to

change.

The display is now showing [CKn mm:ss] where “n” is the key number, “CK” means Cook, and

“mm:ss” is minutes and seconds. Use the product keys for numeric entry to adjust the current

setting. Press the key to save cook time and continue setup for this product key.

Page 17 of 32 L20-414 Rev 2

Page 18

Solstice I12+ Cooking Computer for ROV Fryers

Pitco P/N 60149517 & 60149518

6.2.2 Shake Time:

Shake time is an alarm that sounds during Cook Time to prompt operators to shake the basket.

Default for this value is zero, meaning the Shake Time is inactive. To use Shake Time, the time

value must be a non-zero value, and, must be set to a value less than cook time.

Display shows [SHn mm:ss] where “n” is the key number, “SH” means Shake, and “mm:ss”

is time in minutes and seconds.

Use the product keys for numeric entry to adjust the current setting. Press the key

to save shake time and continue setup for this product key.

Note: The value entered for shake time is the time from the end of the cook.

6.2.3 Hold Time:

Cooked product may stand in holding bins for a period of time. This timer produces an alarm

to inform operators to discard old product and start a new cook. Default for this value is zero,

meaning the Hold Time is inactive.

Display is showing [HDn mm:ss], where “n” is the key number, “HD” means HOLD, and

“mm:ss” is minutes and seconds.

Use the product keys for numeric entry to adjust the current setting. Press the key

to save hold time and continue setup for this product key.

6.2.4 Hold Pre-Alarm:

Hold Pre-Alarm is a timer setting that is used to warn operators that the Hold Time is about to

expire. To use Hold Pre-Alarm, the time value must be a non-zero value, and, must be set to a

value less than Hold Time. Default value is zero, meaning the Hold Pre-Alarm is inactive.

Display is showing [PAn mm:ss] where “n” is the key number, “PA” means Pre-Alarm, and

“mm:ss” is minutes and seconds.

Use the product keys for numeric entry to adjust the current setting. Press the key

to save pre-alarm time.

Note: Value entered for hold pre-alarm time is the time from the end of the hold period.

Display will again return to . Repeat steps from section

2.2.2 to make changes to any other product keys or continue.

6.3 To Exit Level 1 programming:

Display shows .

Press the key. Display shows . Continue to section 3 “To Change

Options”, or, exit here in the next step.

To exit Level 1 programming, press the key again.

Displays will show , , or , when no active cooks

are running.

L20-414 Rev 2 Page 18 of 32

Page 19

Solstice I12+ Cooking Computer for ROV Fryers

Pitco P/N 60149517 & 60149518

7 To Change Options Level 2 ( for the Store Manager):

The display must show from section 2 to change these options. When the

product key [0] is pressed, the display will show . Indicator

lights above product keys will illuminate to represent options that may be changed. Each

option listed below uses the product key [0] to toggle or scroll through available choices in the

display. When the correct value is displayed, press the key to save choice. The

display will again return to for another option selection.

7.1 Fahrenheit or Celsius Display:

The Controller will display temperatures in the Fahrenheit or Celsius scales. The default scale is °F.

With display showing , press the product key [10/0].

Display shows .

Press product key 1, display shows [DEGREE n] [F OR C], where “n” is the current

setting.

Use the product key [0] to scroll through choices (F or C). Press key to save

choice.

Display shows .

7.2 Password Change or Required:

With factory settings, an operator password is not required to enter programming Levels 1 and 2.

The password may be activated or changed in these steps.

With display showing , press the product key [0].

Display will show .

Press product key 2, display shows [SET PAS] [NEW PASS]. Use the product key [0] to

scroll through choices [NO PASS] or [PASS REQ]. Press key to save choice.

If [NO PASS] is selected Display returns to .

If [PASS REQ]. is selected, display will show [PASSnnnn] [NEW PASS] to prompt for new

password. Displayed value “nnnn” is the current password. Use the product keys for numeric

entry to change password. Press [P] key to save choice. Display then shows .

Note: The factory default password (6684) will always work even if a different password is selected

here.

Page 19 of 32 L20-414 Rev 2

Page 20

Solstice I12+ Cooking Computer for ROV Fryers

Pitco P/N 60149517 & 60149518

7.3 Beeper Volume and Tone:

Volume and Tone of the beeper alarm may be changed in this section. Volume ranges are 1,2 and

3, where 3 is the loudest setting. This model also has a selection for tone.

With display showing , press the product key [0].

Display will show . Press product key 3, display shows

[VOLUME n] [BEEPER].

Use the product key [0] to scroll through choices (n= 1,2,3, or T). Beeper volume will

change as each selection is made.

Press key on 1, 2, or 3 to save volume choice. Display shows .

Press key on “T” to set tone – an additional display is shown, [TONE n] [BEEPER]. Use

the product key [0] to scroll through choices (n= 1,2,3). Beeper tone will change as each

selection is made.

Press key on to save tone choice. Display shows .

7.4 Language Selection:

With display showing , press the product key [0].

Display will show .

Press product key 4, display shows [ENGLISH] [LANGUAGE].

Use the product key [0] to scroll through choices (ENGLISH, ESPANOL, FRANCAIS,

DEUTSCH, HOLLAND).

Press key to save choice. Display shows .

7.5 Melt Cycle Type:

This adjustment allows selection of the melt cycle type and requirement when starting the

appliance from a cold start.

With display showing , press the product key [0].

Display will show .

Press product key 5, display shows [LIQUID], the default setting.

Use the product key [0] to scroll through choices (liquid, solid, or, no melt).

Press key to save choice. Display will again return to .

L20-414 Rev 2 Page 20 of 32

Page 21

Solstice I12+ Cooking Computer for ROV Fryers

Pitco P/N 60149517 & 60149518

7.6 Recovery Test Value:

This controller maintains a record of heat up times for the appliance. A poorly running appliance

will have increased recovery times stored in this display. There is no selection done here, just the

display of recovery time values.

With display showing , press the product key [0].

Display will show .

Press product key 6; display will show [RECOVERY] [TEST].

Press the product key [0]. Display will show [FnnnLyyy], where nnn is the factory

recovery value, and yyy is the last warm- up recovery value.

After recording these values, press the key. Display will again return to

.

7.7 Control or Timer: (Left side of Dual or Single Vat):

With display showing , press the product key [0].

Display will show .

Press product key 7; display will show [CONTROL].

Use the product key [0] to scroll through choices (Control, Timer).

Press key to save choice. Display shows .

Note: If timer is selected, heat control outputs are disabled, leaving only the timer functions active.

Do not make this selection on Solstice fryer models.

7.8 Control or Timer: (Right side of Dual Vat):

Note: This key has no function on single vat control # 60149518.

With display showing , press the product key [0].

Display will show .

Press product key 8; display will show [CONTROL].

Use the product key [0] to scroll through choices (Control, Timer).

Press [P] key to save choice. Display shows .

Note: If timer is selected, heat control outputs are disabled, leaving only the timer functions active.

Do not make this selection on Solstice fryer models.

Page 21 of 32 L20-414 Rev 2

Page 22

Solstice I12+ Cooking Computer for ROV Fryers

Level 5 Password

Pitco P/N 60149517 & 60149518

8 To Enter Filter Settings Menu Level 5 (for the Store Manager):

Not all menu options will be available. Available menu options are determined by your fryer

configuration and optional features.

With no cook timers running, displays will show one of the following displays: ,

, or .

Press the key. The left display will show . The right display will be

blank.

Enter password

Display will show . Product key indicators will illuminate to

using the product keys as a numeric keypad for entry.

prompt operator to select a key. This section details parameters that may be changed in Filter

Configuration.

8.1 Drain Time:

This adjustment controls the drain time for auto-filter operations FILTER, POLISH, and

DISPOSE. This value should be selected to allow adequate time for the vat to completely

drain into the filter pan before continuing the automatic process. Factory default: Full – 0:30,

Split – 0:20.

With display showing , press product key [1].

Display shows , where m:ss is the time

the vat will drain.

To change this value, use the product keys for numeric entry of a new

value. Acceptable entry range is 0:20 to 4:00.

Press the key to save entry. Display returns to

.

8.2 Filter Time:

This adjustment controls the oil cycle time for filter operation FILTER. This value should be

selected to allow oil to make multiple passes through the filter pan. Factory default – 1:00.

With display showing , press product key [2].

Display shows , where m:ss is the time

the vat will filter.

To change this value, use the product keys for numeric entry of a new

value. Acceptable entry range is 00:00 to 99:59.

Press the key to save entry. Display returns to

.

L20-414 Rev 2 Page 22 of 32

Page 23

Solstice I12+ Cooking Computer for ROV Fryers

Pitco P/N 60149517 & 60149518

8.3 Polish Time:

This adjustment controls the oil cycle time for filter operation POLISH. This value should be

selected to allow oil to make multiple passes through the filter pan. Factory default – 30:00.

With display showing , press product key [3].

Display shows , where m:ss is the time

the vat will polish.

To change this value, use the product keys for numeric entry of a new

value. Acceptable entry range is 00:00 to 99:59.

Press the key to save entry. Display returns to

.

8.4 Fill Time:

This adjustment controls the vat fill time for auto-filter operations FILTER and POLISH. This

value should be selected to allow adequate time for the filter pan to be completely emptied

and return lines cleared of oil. Factory default: Full – 1:15, Split – 0:45.

With display showing , press product key [4].

Display shows , where m:ss is the time

the vat will fill.

To change this value, use the product keys for numeric entry of a new

value. Acceptable entry range is 0:30 to 4:00.

Press the key to save entry. Display returns to

8.5 Filter Temperature:

This adjustment selects the minimum oil temperature allowed for auto-filter operations to be

initiated. Manual filter operations are unaffected by this value. Factory default – 275 °F.

With display showing , press product key [5].

Display shows , where nnn is the

minimum oil temperature autofilter operations can be performed, and

where X is F (Fahrenheit) or C (Celsius).

To change this value, use the product keys for numeric entry of a new

value.

Press the key to save entry. Display returns to

.

.

Page 23 of 32 L20-414 Rev 2

Page 24

Solstice I12+ Cooking Computer for ROV Fryers

Pitco P/N 60149517 & 60149518

8.6 Cook Counts Allowed:

This adjustment selects the number of cooks allowed before FILTER SOON is displayed to

the operator. Factory default: Full – 10, Split – 5.

With display showing , press product key [6].

Display shows , where nn is the

number of cooks allowed before recommended filtering.

To change this value, use the product keys for numeric entry of a new

value. A value of 0 will disable Cook Filter Lockout.

Press the key to save entry. Display returns to

.

8.7 Cook Counts Deferred:

This adjustment selects the number of defers allowed before FILTER NOW is displayed and

additional cooks are prohibited. The total number of cooks allowed after a filter event is the

sum of Cook Counts Allowed and Cook Counts Deferred. Factory default – 2.

With display showing , press product key [7].

Display shows , where nn is the

number of defers allowed before forced filtering.

To change this value, use the product keys for numeric entry of a new

value. A value of 0 will not prevent operator from preforming additional

cooks once the Cook Counts Allowed value has been reached.

Press the key to save entry. Display returns to

.

8.8 Oil Level Probe/Auto Top-Off Enable:

This selection allows the enabling and disabling of the Auto Top-Off feature.

With display showing , press product key [8].

Display shows , where xxx is either ON or OFF.

To change this value, use product key [0] to toggle between ON and

OFF.

Press the key to save entry. Display returns to

.

L20-414 Rev 2 Page 24 of 32

Page 25

Solstice I12+ Cooking Computer for ROV Fryers

Pitco P/N 60149517 & 60149518

8.9 Auto Top-Off Time:

This adjustment selects the amount of time fresh oil is added to the vat during Auto Top-Off

events. An event can only occur once every 3 minutes. Factory default: Full – 0:09, Split –

0:05.

With display showing , press product key [9].

Display shows , where m:ss is the time

auto top-off will add oil to the vat per event.

To change this value, use the product keys for numeric entry of a new

value. Acceptable entry range is 0:03 to 0:20.

Press the key to save entry. Display returns to

.

8.10 Filter Data Function Enable:

This selection allows the enabling and disabling of the Filter Data Function feature.

With display showing , press product key [0].

Display shows , where xxx is either ON or OFF.

To change this value, use product key [0] to toggle between ON and

OFF.

Press the key to save entry. Display returns to

.

8.11 More Filter Menu Entry:

With display showing to press product key [R] to enter submenu.

Display now shows .

Product keys will illuminate where adjustments are permitted; all other keys are inactive. The following

section details each product key function in the menu.

8.11.1 JIB Monitor (Oil Remaining) Enable

This selection allows the enabling and disabling of the JIB monitor for oil remaining feature.

With display showing , press product key [1].

Display shows , where xxx is either ON or OFF.

Use product key [0] change value. Press the to save choice.

Display returns to .

Page 25 of 32 L20-414 Rev 2

Page 26

Solstice I12+ Cooking Computer for ROV Fryers

Pitco P/N 60149517 & 60149518

8.11.2 Maximum JIB Time

This adjustment selects the amount of oil in terms of “pump time” for a full JIB. Factory default

– 1:30.

With display showing , press product key [2].

Display shows , where m:ss is the time the reset value

for a new JIB.

To change this value, use the product keys for numeric entry of a new value. Acceptable

entry range is 0:00 to 4:00.

Press the key to save entry.

Display returns to .

8.11.3 Low JIB Time

This adjustment selects the amount of oil remaining in terms of “pump time” for a low JIB.

Factory default – 0:20.

With display showing , press product key [3].

Display shows , where m:ss is the time remaining when

“LOW JIB” is displayed.

To change this value, use the product keys for numeric entry of a new value. Acceptable

entry range is 0:00 to 4:00.

Press the key to save entry.

Display returns to .

8.11.4 JIB Monitor (Check/Fault) Enable

This selection allows the enabling and disabling of the JIB monitor for error conditions

feature.

With display showing , press product key [4].

Display shows , where xxx is either ON or OFF.

Use product key [0] change value. Press the to save choice.

Display returns to .

8.11.5 Filter Return Key Enable

This selection allows the enabling and disabling of the Filter Return key for manual filter

configurations.

With display showing , press product key [5].

Display shows , where xxx is either EN or DIS.

Use product key [0] change value. Press the to save choice.

L20-414 Rev 2 Page 26 of 32

Page 27

Solstice I12+ Cooking Computer for ROV Fryers

Pitco P/N 60149517 & 60149518

Display returns to .

8.11.6 On-Demand Top-Off Key Enable

This selection allows the enabling and disabling of the Manual Top-Off key.

With display showing , press product key [6].

Display shows , where xxx is either EN or DIS.

Use product key [0] change value. Press the to save choice.

Display returns to .

8.11.7 To Exit More Filter Menu

With display showing , press the key.

Display returns to .

8.12 To Exit Programming Level 5:

With display showing , press the key.

Display will show . Continue with changes in sections 2 or 3, or continue exit with

the next step.

To return to normal operations, press the key again.

Display will return one of the normal displays: , , or

.

Page 27 of 32 L20-414 Rev 2

Page 28

Solstice I12+ Cooking Computer for ROV Fryers

Open probe detection is standard on all Pitco

controls. If probe is detected open, normal

heating and cooking activities are suspended.

This display warns operators that the vat

temperature has exceeded set temperature by

+40°F (+22°C), or an absolute maximum of 410°F

(210°C). The alarm will also sound. This display

does not show the status of the mechanical high

limit switch.

This message indicates that the drain valve has

been opened, the vat is assumed to be empty by

the controller. Normal heat control activities are

suspended. Display will show an alternating

message [DRAINING] [TURN OFF]. To restore to

normal operation, close the drain value. Display

will show [TURN OFF] [TURN OFF].

Turn controller off, and refill the vat. Continue

with normal operations at section 1.

This message indicates that the heating system

failed to respond. Typically, the high temperature

limit switch has tripped and is in need of resetting.

In the case on gas fired appliances, this message

will display if the pilot fails to light or is detected

marginal by the ignition module.

This message indicates a shorted probe. If probe

is detected as a short circuit, normal heating and

cooking activities are suspended.

This message indicates the computer has lost

communication with the autofilter control board

and oil management operations are suspended.

Normal cooking activities are unaffected.

Pitco P/N 60149517 & 60149518

9 Other Displays:

L20-414 Rev 2 Page 28 of 32

Page 29

Solstice I12+ Cooking Computer for ROV Fryers

Pitco P/N 60149517 & 60149518

10 Mechanical Dimensions:

Page 29 of 32 L20-414 Rev 2

Page 30

Solstice I12+ Cooking Computer for ROV Fryers

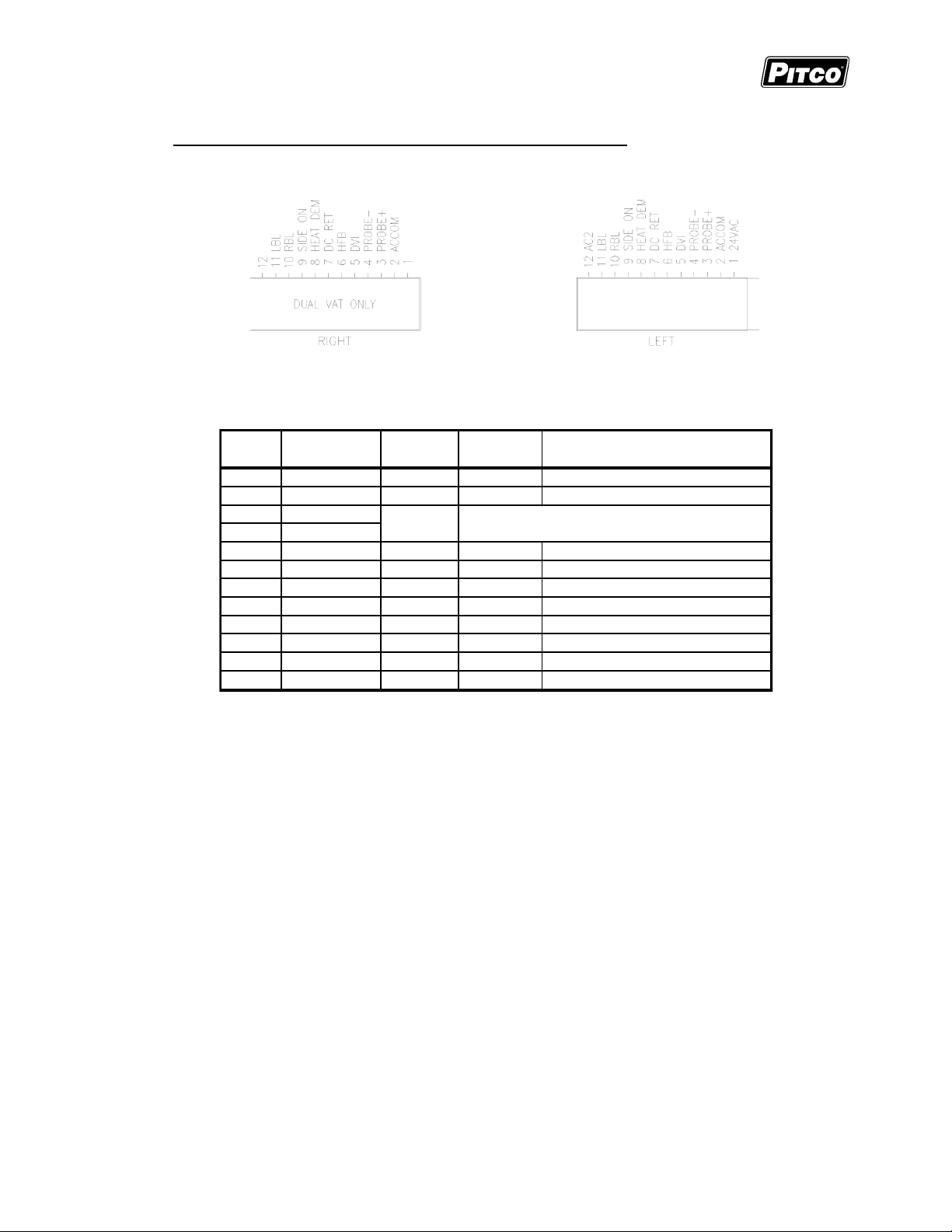

J1(Left) Inputs Type Nominal Notes:

1 ACH PWR 24VAC

24VAC +20% -15% 50/60Hz.

2 ACN PWR 24VACN

24VAC Return.

3 PROBE+

4 PROBE5 DVI IN 24VAC Drain Valve Interlock

6 HFB IN 24VAC Heat Feed Back

7 24VDC COM IN 24VDC DC Returm

8 HD OUT 24VDC Heat Demand

9 SO/xFER OUT 24VDC Side ON or XFER

10 RBL OUT 24VDC Right Basket Lift

11 LBL OUT 24VDC Left Basket Lift

12 AC2 PWR 24VAC Aux Power Input

Thermistor

Proble

Resistance varies with vat temperature. 942 Ohms

@ 350°F

Pitco P/N 60149517 & 60149518

11 Electrical Connections at LEFT and RIGHT connectors):

As viewed from the rear of the control.

Tip: Use the diagnostic menu to verify operation of outputs, and inputs.

L20-414 Rev 2 Page 30 of 32

Page 31

Solstice I12+ Cooking Computer for ROV Fryers

Probe

Temp

(°F)

Probe

Temp

(°C)

Resistance

(Ohms)

Probe

Temp

(°F)

Probe

Temp

(°C)

Resistance

(Ohms)

Probe

Temp

(°F)

Probe

Temp

(°C)

Resistance

(Ohms)

10 -12.2

562734 175 79.4 11719 340 171.1 1058.23

15 -9.4

483875 180 82.2 10716 345 173.9 998.09

20 -6.7

417167 185 85.0 9812 350 176.7 942.00

25 -3.9

360589 190 87.8 8995 355 179.4 889.67

30 -1.1

312474 195 90.6 8255 360 182.2 840.78

35 1.7

271446 200 93.3 7586 365 185.0 795.10

40 4.4

236370 205 96.1 6979 370 187.8 752.38

45 7.2

206311 210 98.9 6427 375 190.6 712.41

50 10.0 180491 215 101.7 5926 380 193.3 674.95

55 12.8 158252 220 104.4 5470 385 196.1 639.87

60 15.6 139055 225 107.2 5055 390 198.9 606.96

65 18.3 122489 230 110.0 4675 395 201.7 576.09

70 21.1 108051 235 112.8 4329 400 204.4 547.09

75 23.9 95539 240 115.6 4013 405 207.2 519.86

80 26.7 84644 245 118.3 3723 410 210.0 494.24

85 29.4 75136 250 121.1 3458 415 212.8 470.16

90 32.2 66823 255 123.9 3214 420 215.6 447.49

95 35.0 59540 260 126.7 2991 425 218.3 426.13

100 37.8 53146 265 129.4 2785 430 221.1 406.02

105 40.6 47523 270 132.2 2597 435 223.9 387.04

110 43.3 42569 275 135.0 2422 440 226.7 369.14

115 46.1 38195 280 137.8 2262 445 229.4 352.24

120 48.9 34328 285 140.6 2113.9 450 232.2 336.29

125 51.7 30902 290 143.3 1977.3 455 235.0 321.21

130 54.4 27862 295 146.1 1851.0 460 237.8 306.94

135 57.2 25161 300 148.9 1734.3 465 240.6 293.46

140 60.0 22755 305 151.7 1626.1 470 243.3 280.69

145 62.8 20610 310 154.4 1525.9 475 246.1 268.61

150 65.6 18695 315 157.2 1433.0 480 248.9 257.15

155 68.3 16981 320 160.0 1346.7 485 251.7 246.30

160 71.1 15446 325 162.8 1266.6 490 254.4 236.00

165 73.9 14069 330 165.6 1192.1 495 257.2 226.24

170 76.7 12823 335 168.3 1122.8 500 260.0 216.96

Probe Resistance in 5°F Increments.

Pitco P/N 60149517 & 60149518

12 Probe Resistance Chart:

Notes: Resistance, of either probe lead, to the frame of the appliance should read as “open’ on the

meter. Typically this is 1Meg ohms or more.

°C = 5/9 (°F-32)

°F = (9/5 * °C) +32

Page 31 of 32 L20-414 Rev 2

Page 32

Solstice I12+ Cooking Computer for ROV Fryers

In the event of problems with or questions

about your order, please contact the Pitco

In the event of problems with or questions

MAILING ADDRESS – P.O. BOX 501, CONCORD, NH 03302-0501

SHIPPING ADDRESS – 10 FERRY ST., CONCORD, NH 03301

Pitco P/N 60149517 & 60149518

Frialator factory at

(603) 225-6684 World Wide

www.pitco.com

L20-414 Rev 2 Page 32 of 32

about your equipment, please contact the

Pitco Frialator Authorized Service and

Parts representative (ASAP) covering your

area, or contact Pitco at the numbers listed

to the left.

Loading...

Loading...