Page 1

v

Page 2

MI'S , PF28-03

J

J

Pita> Frialator '1..20-086-01

Rev 00

Rev. Due 12117/93

Page 3

NonCES

There are three different types of noti~s that you should be familiar with, a NO11CE, CAunON,

and WARNING. A NO11CE is a special note used to call attention to a particularly important point

CAunON is used to point out a procedure or operation which may cause equipment damage. The

WARNING notice is the most important of the three because it warns of an operation that may cause

personal injury. Please familiarize yourself with your new rooter before operating it and heed the

notices throughout this manual. The WARNINGS are listed below and on the following page for

your review prior to operating the unit

~

Page 4

SAFETY

SAFETY

The fryer is equipped with an oil proof, electrical supply oord with a three

prong safety plug. This is to protect operators from electrical shock hazard

in the event of an equipment malfunction. DO NOT cut or remove the

grounding (dlird) prong from this plug.

SAFETY

SAFETY

~==I

There is an open flame inside the fryer. The unit may get hot enough to set

near by materials on file. Keep the area around the fryer free from combus-

tibles.

~==I

DO NOT supply the fryer with a gas that is DOt indicated on the data plate. If

you need to convert the fryer to another type of fuel, oontact your dealer.

SAFETY

DO NOT use an open flame to check for gas leaks!

Wait S minutes before attempting to relight the pilot to allow for any gas in

the fryer to dissipate.

1~:i~:~:~::::;;11I

Never melt blocks of shortening on

a fire, and void your warranty.

Water and shortening DO NOT mix. Keep liquids away from hot shortening.

Dropping liquid frozen food into the hot shortening will cause violent boiling.

At operating temperature the shortening temperature may be greater than

3OOoP. Extreme care should be used when filtering operating temperature

shortening to avoid personnel injury.

top of

;AFETY

~

~~~

~~~

SAFETY

SAFETY SAFETY

SAFETY

Page 5

SAFETY

S~FETY

It will be easier and safer if the filter assembly has oooled to room temperature

before handling any filter parts.

Ensure that the fryer can get enough air to keep the flame burning oorrectly.

If the flame is starved for air it can give off a dangerous carbon monoxide gas.

Carbon Monoxide is a clear odorless gas that can cause

A cooker equipped with casters and a flexible power cord, must be connected

to the gas supply with a Quick-Disconnect devi~. This quick disconnect

must comply with ANSI Z24.41. To limit the movement of the cooker

without depending on the connector or quick disconnect, a restraining cable

must also be installed.

S:AFETY

[:~:::;:::~:::;;;;III

SAFETY

suffocation.

S:AFETY

The power supply must be

applian~.

SAFETY

SAFETY

SAFETY

SAFETY

SAFETY

Page 6

Page 7

Table of Contents

Section

Safety Notice

Title

Table of Contents i-ii

Ust of Tables and Figures ill

1.1

1.2

1.2.1

1.3

1.3.1

1.3.2

1.4

1.4.1

1.4.2

1.4.2.1

1.4.2.2

1.4.2.3

1.4.2.4

1.4.3

1.4.4

1.5

1.5.1

1.5.2

1.5.2.1

1.5.2.1.1

1.5.3

1.5.3.1

1.5.3.2

1.5.4

1.5.5

1.5.6

1.5.7

WInCH FRYER DO I HAVE? 1-1

CHECKING YOUR NEW FRYER 1-2

Cleck Your Order 1-2

ASSEMBLY AND LEVEUNG 1-2

Heat Deflector In..ct31lation 1-2

Leveling 1-3

INST AUA 110 N ... 1-3

Installation Clearan~ 1-4

Gas Connection 1-4

Fuel Types 1-4

Gas Line Connection 1-5

Quick Disconnect Gas Connection 1-5

Fuel Supply Line Leak and Pressure Testing 1-5

Electrical Connection... ... ... 1-5

Ventilation and Fire Safety Systems ~ 1-6

INl11AL ADJUSTMENTS 1-7

Visual Checks 1-7

Burner Ignition Systems 1-8

lighting Instructions for Manual Pilot Lights 1-8

Pilot Flame Adjustment 1-9

Main Burner System 1-11

Gas Line Requirements 1-12

Burner Adjustment 1-12

Initial Cleaning 1-13

Thennostat Calibration Check 1-14

Thennostat Calibration

High Limit Test

-

2:

2.1

2.1.1

2.1.2

2.2

f1LLING nIB FRYER 2-1

Filling the Fryer With Liquid Shortening 2-1

Filling the Fryer With Solid Shortening 2-1

MELTING SOLID SHORTENING 2-2

i

Page 8

Table of Contents (Continued)

Section ntle Page

2.3 OPERA 11NG INSTR UcnONS 2-2

2.3.1 Fryer Start-Up 2-2

2.3.2 Fryer Shutdown 2-3

2.3.3 Power Failure ... ... " ..,.. 2-3

2.4 SHORTENING FILTER PROCEDURES .,.,." ,..",.,...,..." ,.., 2-4

2.4.1 General Filter Hints 2-5

2.4.2 Filter Procedures. 2-6

2.S DAn., Y CLEANING 2-7

3.1

3.2

3.3

3.4

3.4.1

3.4.2

Fll.. TER MEDIA REPLACEMENT 3-1

WEEKLY FRYER CLEANING (BOIL OUT) 3-4

f1..UE INSPEC'fI ON ... ... 3-4

TROUBLESHOOTING 3-5

Fryer Troubleshooting 3-5

Filter Troubleshooting ... ... 3-6

ii

Page 9

List of Tables and Figures

1-1

1-2

Figure

1-1

1-2

1-3

1-4

1-5

2-1

3-1

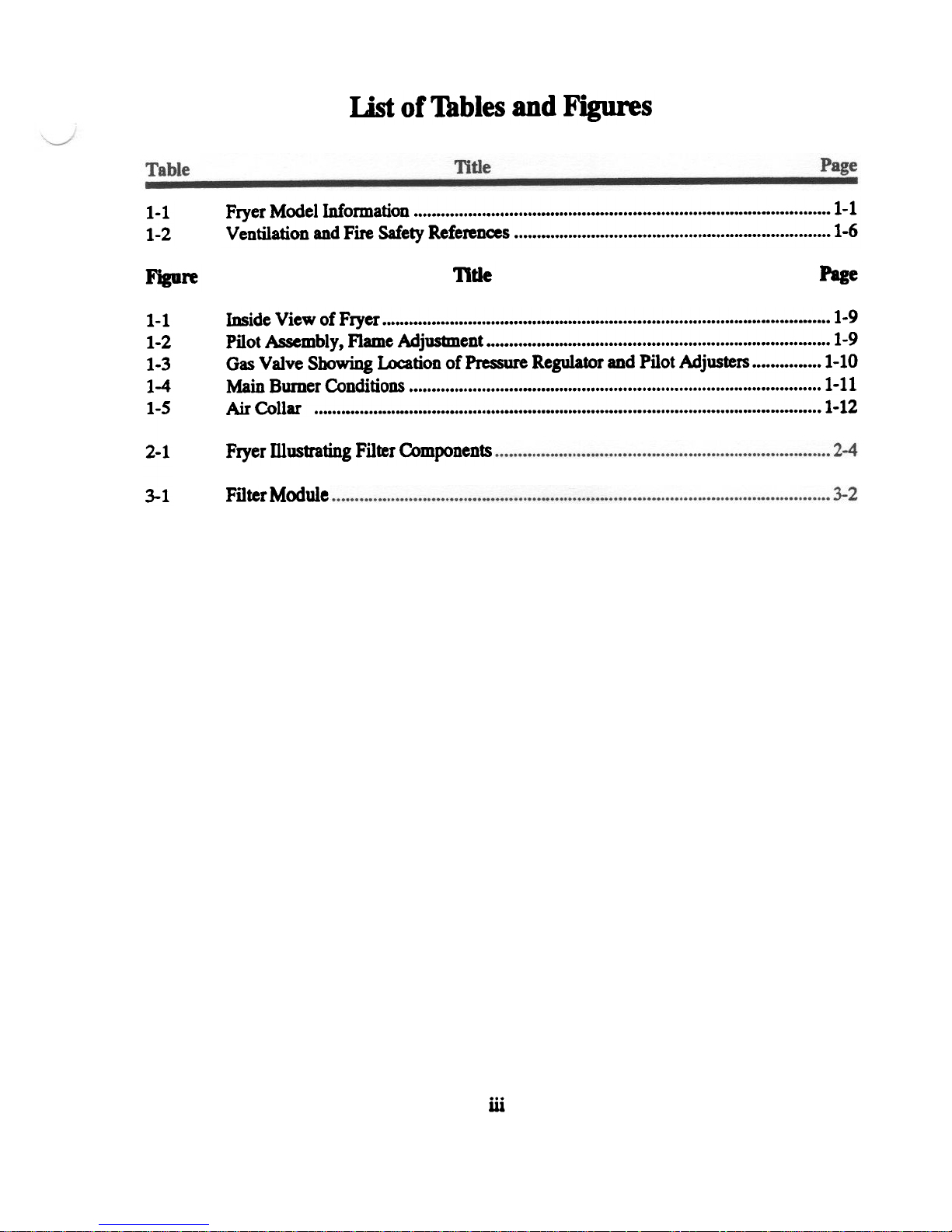

Fryer Model Information 1-1

Ventilation and Fire Safety References 1-6

Title

Page

Inside View of Fryer 1-9

Pilot Assembly, Flame Adjustment 1-9

Gas VaJve Showing Location of Pressure Regulator and Pilot Adjusters 1-10

Main Burner Conditions 1-11

Air Collar 1-12

Fryer mustrating Filter Components

FilterModule

iii

Page 10

iv

Page 11

Chapter 1: General Information and Installation

The frying system you have selected for your establishment is the Pita> Frialator Model SF14 UFM

series. This model oombines the oonvenience of built-in filtration and the compactness of under fryer

filtration into one easy to use unit. This fryer will give you many years of reliable service if you follow

the simple operation and maintenance procedures in this manual. Contained in this manual are the

general installation, operation, and maintenance procedures for the SF14UFM and SFI4RUFM.

1.1 WHICH FRYER DO I HAVE?

There are two models available with solo filters and both can use the same options. To find out which

model you have, look inside the door at the equipment identification plate. This plate has a lot of

useful information, but to identify which fryer you have, look at the model number block. The model

number identifies which fryer and what features you have. A brief description of each model and

it's features is provided in table 1-1.

Table 1-1 Fryer Model Information

1-1

Page 12

1.2 CHECKING YOUR NEW FRYER

Your new fryer and it's filter have been carefully packed into one crate. Every effort bas been made

to ensure that your fryer will be delivered to you in perfect condition. As you unpack your new fryer,

inspect each of the pieces for damage. If something is damaged, DO NOT sign the bill of lading.

Contact the shipper immediately, the shipper is only responsible for 15 days after delivery. Check

the packing list enclosed with your fryer to ensure that you have received all of the parts to the fryer.

If you are missing any parts, contact the dealer from whom the fryer was purchased. As you unpack

the fryer and it's accessories be careful to keep the weight of the fryer evenly distnbuted.

CAunON

To prevent equipment damage, don't tilt the fryer onto

any two of it's casters or pull the unit by the flue vents.

Locate your Pitco Frialator warranty and fill in the serial number of the fryer and the date received.

Y 00 will fmd the serial number on the plate inside the door. Put your warranty card in a safe place

for future referen~. DO NOT return the card to Pitco Frialator.

1.2.1 Check Your.

The crate containing the fryer unit will also contain the items listed below

important and MUST be retained for future use. A complete description

These items are very

of each oomponent is

contained in the Shortening Filter Procedure in Chapter 2.

(2)

(2)

(1)

~)

(1)

(1)

Fry baskets per fryer

Pitco Oeaner Sample

Filter Crumb Catch

Filter Paper

Fryer Crumb Scoop

Heat Deflector

Fry Basket Hanger per fryer

(1)

Drain Oean Out Rod

(1)

Precoat Filter Aid

(1)

Oeaning Brush (Fryer)

(1)

Filter Crumb Sa>op

(1)

1.3 ASSEMBLY AND LEVEUNG

When you receive your fryer it is completely assembled with the possible ex~ptioD of the heat

deflector.

You will find a removable label at the rear top edge of the unit. This label has instructions for

positioning and installation of the heat deflector. Refer to the label and the instructions below to

install the deflector.

1-2

Page 13

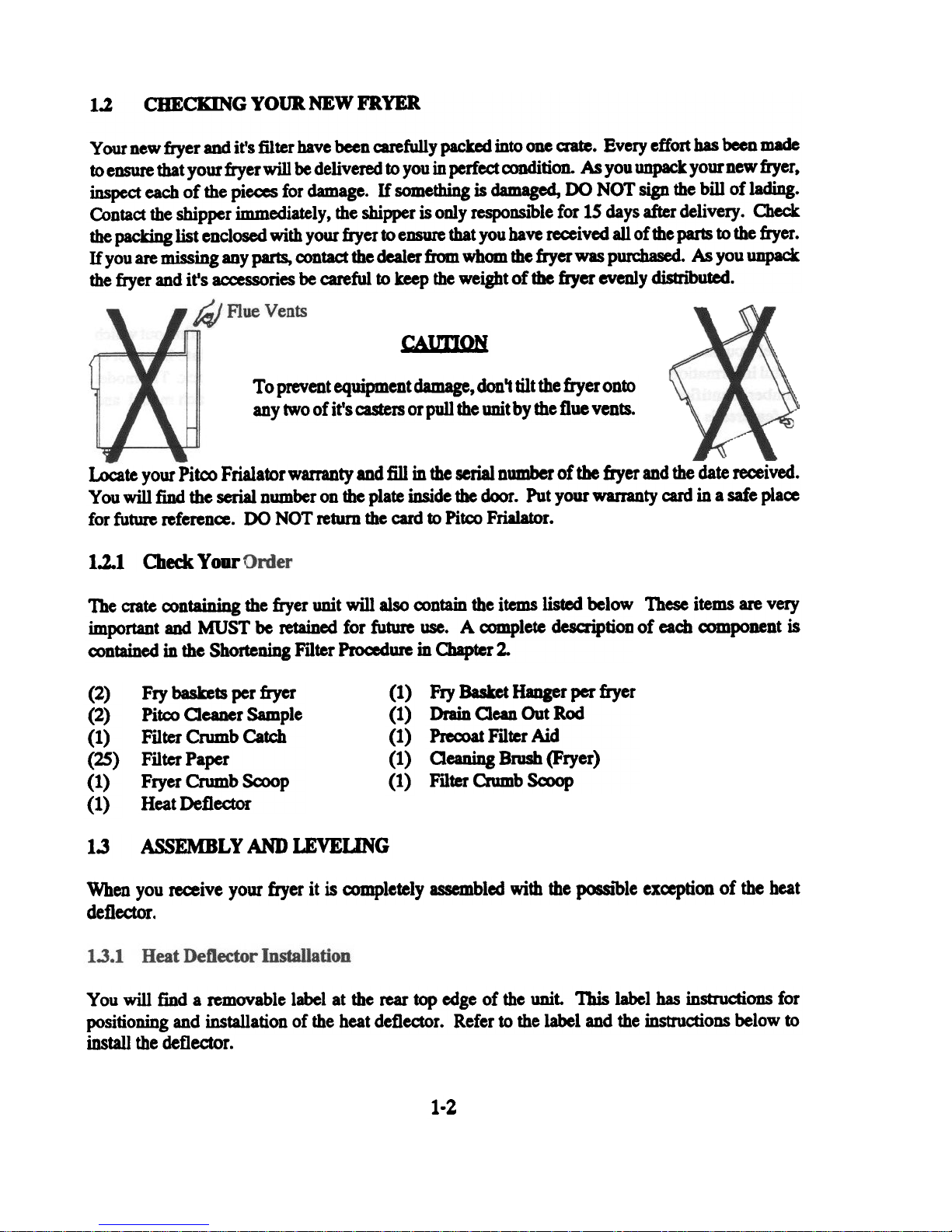

a. Remove the two self-drilling saews from the top, back area of the cooker.

b. Position the heat deflector so that the angled portion of the deflector is facing toward the

front of the fryer. Secure the heat deflector to the back of the unit using the sheet metal

saews previously removed.

~:=I

DO NOT obstruct the flow of combustioD/ventilation or air openings around

the fryer. Adequate cl~ around the fryer is necessary for servicing and

proper burner operation. Ensure that you meet the minimum clearances

specified in the installation instructions.

When properly installed the angled section of the heat deflector will extend over the flue

Co

opening to redirect the heal It SHOUlD NOT rover the flue opening. Nothing should

block the flue opening as this will cause the fryer to overheat and produce dangerous

gases.

1.3.2. Leveling

Using an appropriate wrench and level ensure that the unit is level.

a. Place the level across the front of the tank and rotate the adjustment on the front legs to

level the unit.

b. Perform step a to level the unit front to back by placing the level along the side of the tank.

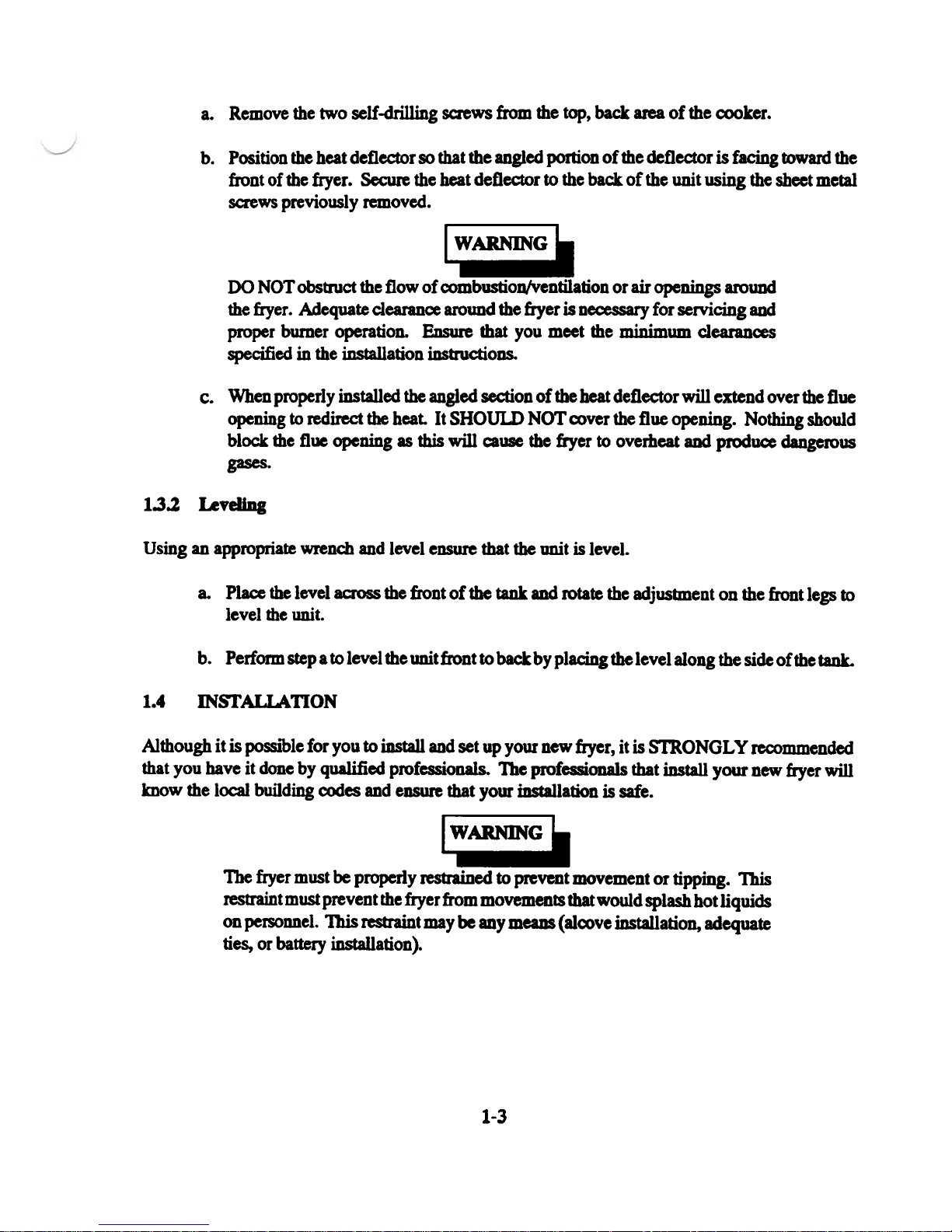

1.4 INsrAL1.ATION

Although it is poSSIble for you to install and set up your new fryer, it is STRONGLY recommended

that you have it done by qualified professionals. The professionals that install your new fryer will

know the local building codes and ensure that your installation is safe.

~==I

The fryer must be properly restrained to prevent movement or tipping. This

restraint must prevent the fryer from movements that would splash hot liquids

on personnel. This restraint may be any means (alcove installation, adequate

ties, or battery installation).

1-3

Page 14

Combustible

Construction

Back

Sides

In addition to the clearances required for proper fryer operation, there must be at least 23 inches of

Your fryer will give you peak performance when the gas supply line is of sufficient size to provide

the correct gas flow. The gas line must be installed to meet the local building codes or National Fuel

Gas Code (NFPA 54-1984) and ANSI Z223.1-1988 Latest Edition. In Canada, install the fryer in

aax>rdance with CAN/CGA-B149.1 or .2 and local codes. Gas line sizing requirements can be

determined by your local gas company by referring to National Fuel Gas Code, Appendix c, Table

C-4 (natural gas) and Table C-16 (propane). The gas line needs to be large enough to supply the

necessary amount of fuel to all appliances without losing pressure to any appliance. Other factors

that are used to determine the piping requirements are BTU requirements of the appliances being

oonnected and the length of pipe between the meter (main shut oft) and the appliances.

6"

6"-

N/A

Non-Combustible

Construction

6"

6"

N/A

1.4.2.1

which the

door.

[:::1

NEVER supply the fryer with a gas that is Dot indicated on the data plate.

Using the inoorrect gas type will cause improper operation. If you need to

Fuel ~s

appliance is

- Each fryer is equipped to work with one type of fuel. The type of fuel with

intended to operate is stamped on the data plate attadled to the inside of the

DO NOT use an open

1-4

for gas leaks!

Page 15

1.4.2.2 Gas Line Connection - Connect the fryer to the gas supply line with a oonnector that

amplies with the Standard for Connectors for Movable Gas Appliances (ANSI Z21.69-1987). If you

are installing a fryer with casters use a quick disoonnect refer to the Quick Disconnect installation

instruction, 1.4.2.3. Connect the gas line to the fryer using a pipe joint sealant that is resistant to

liquefied petroleum. If the fryer was disoonnected during the fuel line testing, use a solution of soap

and water to leak test the new oonnection.

NEVER use an adaptor to make a smaller gas supply line fit the

connedion. This may not allow proper gas flow for optimum

operation, resulting in poor cooker performan~..

1.4.2.3 OuickDjsa)nnectGasConnection-Gasfryers

equipped with casters must be installed with connedors

that comply with the Standud for Connectors for Movable

Gas Appliances, ANSI 221.69-1987, and Addenda

Z21.69A-1989. This connection should include a quick

disconned device that complies with the Standard for

Quick Disamnect Devi~ for Use With Gas Fuel, ANSI

Z21.41-1989. When installing a quick disoonnect you

must also install a means for limiting the movement of the

fryer. This device will prevent the gas line or the quick

disronnect from being strained. The restraining device

should be attached to the cooker on the back panel as

shown in the illustration. The quick disconnect, hose, and

restraining device can be obtained from your dealer.

1.4.2.4 Fuel SYR~IX Line Leak and Pressure Testine - The fuel supply system must be tested

before the fryer is used. If the fuel line is going to be tested at a pressure greater than (»1/2 PSIG

(3.45 kPa), make sure that the fryer is disamneded from the fuel line. If the fuel line is to be tested

at a pressure equal to or less than (s) 1/2 PSIG (3.45 kPa), the fryer can be COft-!!e-m.rl but the unit's

gas valve must be shut. Test all gas line connections for leaks with a solution of soap and water when

pressure is applied.

1.4.3 Electrical Connection

The electrical servi~ used by the fryer must oomply with local cx>des. If there are no local a>des that

apply, refer to the National Electrical Code (NEC) to install the servi~. In Canada refer to CSA

Standard C22.1 and local codes. Wiring diagrams are provided inside the fryer door. The power

requirements for the fryer are shown below.

Input Voltage

Current per fryer

NonCE

cooker

burner

120 V Ac, 60Hz

7 Amps

220 (or 240) V Ac, SOliz

3 .s Amps

1-5

Page 16

~=:I

The fryer is equipped with an oil proof, three prong (grounding) plug for your

protection against electrical shock hazard in the event of equipment malfunction. DO NOT cut or remove the grounding (third) prong from this plug. This

plug must be plugged into a properly grounded three prong receptacle.

The fryer has one power supply for the fryer controls and the filter module. The fryer must be

grounded in accordance with local code; if there is not a local code, comply with NBC ANSI/NFP A

No. 70-1990. The fryer should be plugged into a receptacle at all times to keep power supplied to

the filter line heat tape.

1.4.4 VentilatioD and Fire Safety Systems

Your new fryer must have proper ventilation to function safely and properly. Exhaust gas

temperatures can reach as high as 1200°F. Therefore, it is very important to install a fire safety

system. Your ventilation system should be designed to allow for easy cleaning. Frequent cleaning

of the ventilation system and the fryer will reduce the chan~ of fire. Table 1-2 provides a list of

referen~ documents that provide guidance on ventilation and fire safety systems. This table is not

necessarily complete. Additional information can be obtained from the American Gas Association,

8501 East Pleasant Valley Road, Ceveland, OH 44131.

Table 1-2. Ventilation and Fire Safety Referen~s

1-6

Page 17

Excessive ventilation causes drafts, which will interfere with the proper operation of the pilot and

the burner. Leave at least 18 inches of open space between the fryer's flue vent opening and the intake

of the exhaust hood.

CAU'I10N

Ensure that your ventilation system does not cause a down draft at the fryer's

flue opening. Down drafts will not allow the fryer to exhaust properly and will

cause overheating which may cause permanent damage. Damage caused by

down drafts will not be covered under equipment warranty. NEVER allow

anything to obstrud the flow of combustibles or ventilation exiting from the

fryer flue. DO NOT put anything on top of the flue area.

NonCE

NEVER connect the blower directly to the flue openings. The direct flow of

air will cause poor temperature recovery, poor ignition, inefficient operation

of the fryer, and could extinguish the pilot.

1.5 INI11AL ADJUSTMENTS

After your fryer has been installed as described in section 1.4, it needs to be adjusted to ensure that

it will perform as designed. These adjustments must be performed by a qualified person. To

perform these adjustment the following tools will be needed:

. Manometer (low pressure gauge) . Digital Thermometer (Temperature probe)

. DC Millivolt Meter

1.5.1 Visual Checks

Before you begin filling and adjusting the fryer, perform the following visual

checks:

After the fryer is in its permanent location, check for levelness. Any

a.

additional leveling that is necessary can be perfonned as described

in section 1.3.

b. Oleck the temperature bulbs (thennostat/high-limit), located in the

fryer tank to ensure that the mounting screws are tight The figure

shows the probe typical location. Look down inside the fryer tanks

to see the probes. 8,. Nt 1_.

Ensure tIIIt Un. pen-

1-7

Page 18

CAtmON

Before going any further, fill the fryer with WATER. Water is used for the

installation adjustments because the temperature will never exceed 212°F

(100°C) thereby allowing plenty of adjustment time. Never let the water level

go below the OIL LEVEL mark on the rear of the tank.

G;:a

There is an open Bame inside the fryer. The unit may get hot enough to set

near by materials on fire. Keep the area around the fryer free from

1.5.2.1 Li~htin& Instroctions for Manual Pilot l1ihts - To light the pilot light refer to these

instructions and Figure 1-1. The numbers in parenthesis refer to Figure 1-1 callouts.

G:::I

Wait 5 minutes before attempting to relight the pilot to allow for any gas in

the fryer to dissipate.

a. Open the gas supply valves to the fryer.

b. Open the fryer's door to gain access to the controls. Turn the thermostat control knob

counterclockwise to the off position.

Turn the Unitrol gas valve knob (tan knob) (2) to the Pll..OT position and

c.

push in on the knob. Hold the knob in for approximately one minute to

purge the air out of the line. Hold a flame to the pilot light until the pilot

(3) ignites. This may tate a little while the first time you light the fryer

because of air in the lines. Once lit, hold the knob in for approximately

60 seconds and then release.

d. If die pilot goes out wait 5 minutes and repeat step c. If after three tries the pilot will not

remain lit, refer to the operator troubleshooting section of this manual.

e. Turn the Unitrol gas valve knob (tan knob) counterclockwise to the ON

position.

f. Set the thermostat control knob to the desired temperature setting.

(lJ0 ~

~ ~

~~

(1)

1.8

Page 19

g. The main burner (4) will light and be controlled by the thermostat. The pilot burner will

remain lit regardless of the switch position.

1.5.2.1.1 Pilot Flame Adiustment - The pilot flame should be adjusted to prod~ the ~r

millivolt output from the pilot sensing devi~. Millivolt output for the thermopile should be between

300 and 500 millivolts. Figure 1-2 shows the pilot assembly with examples of the incorrect and

correct pilot size. Example A illustrates a pilot flame size that is too small to produ~ sufficient

millivolt output. Example B is the correct size for proper millivolt output

TME~ll£ \

PILOT IUDU \ \

M

B

A

Figure 1-2 Pilot Assembly,

1-9

Page 20

a. This test requires a DC millivolt meter set to a scale of O-l(XK)mv.

b. Locate the thermopile wires coming from the thermostat!High Limit box going to the gas

shut off valve. The wire insulation size decreases near the gas valve connections.

Connect the negative (-) test probe to pilot bracket.

Co

Connect the positive (+) test probe to one of the High Limit terminal

d.

Remove the pilot flame adjustment cover.

e.

PRESSURE REGULATOR

(UNDER CAP SCREW)

PILOT ADJUSTER LOCATION

(UNDER CAP SCREW)

LOCATION

g. Rotate the screw in the direction to achieve a reading of 400 rlO mv for thermopiles.

h. Replace the pilot flame adjusting screw cover.

NonCE

1-10

Page 21

For the burners to work the gas supply valve must be open and the main power switch must be on.

The main burner receives gas from the main gas supply through the thermostatically oontrolled valve.

When the therDlostat is turned up the gas control valve opens and the pilot will ignite the burners.

After the burner system is operating, perfOrDl the burner adjustments in the following procedure.

Figure 1-5 illustrates the different oonditions possible for the main burner.

incoming gas pressure.

Adjust manifold pressure as

described in 1.53.2.

INsumCIENT GAS PRESSURE

The flame

-liftofr

The flame seems to wli:

the faa; of the burner.

To correct adjust

burner as describc

1.5.3.2.

adjust main

described in

EX~IVE FLOW

Figure 1-4 Main Burner Conditions

1-11

Page 22

1.5.3.1 Gas Une Rgrements - A properly installed gas supply system will deliver 7.0 %2.0.

W.Co natural gas (12.0 %2.0. W.c. LP) to all appliances oonnected to the line, operating at full demand.

1.5.3.2 Burner Adjustment -The burners must be

burner flame using the following procedure.

a. Ensure that the gas oontrol valve is in the OFF position. Remove the manifold pressure

tap plug and connect an accurate pressure gauge (range of 0-16" w.c. in 0.1" increments)

or manometer.

b. light the pilot burner (~ 1.5.2) for the unit being tested and adjust the thermostat to light

the main burners.

c. The installed presswe gauge reading should be tbesame, ~.1., as that marked OD the data

plate inside the door. If the pressure is correct go to step e, if DOt, adjust the pressure.

d. To adjust the pressure, remove tberegu1atoradjustmentsaewcover(~ Figure 1-3). Use

a flat tip screwdriver to adjust the screw until the proper pressure is reached. Turning the

~w clockwise will inaease the pressure, counterclockwise will deaease the pressure.

f.

To remove the pressure gauge, turn gas control valve to OFF. Remove the gauge and

install the pressure tap plug.

Adjust the

BURNER

ORIFICE

I"""""'~~

SET SCREW

BURNER FI1TING

GAS PRESSURE 1

TEST PLUG

Figure 1-5 Air

Collar

1-12

Page 23

Now that the pressure is set for proper operation, set the main burner flame. Unlock the

g.

air collars by loosening the set screw for the collars. Turn the gas control valve to ON

and turn thermostat to light the main burners.

h. Adjust the shape and size by raising

with well defined inner cones.

provided.

1.5.4 INITIAL CLEANING

When the fryer is shipped, many of its parts are covered with a thin coat of oil for protection. Before

the fryer is ready for cooking it must be cleaned. This will remove the oil coating and any foreign

matter that may have !.~JII!ulated during storage and shipment. Perform the cleaning as described

below.

a. Fill the tank with water and add one packet of Pita> fryer cleaner or a mild detergent.

b. Turn the fryer on and set the thermostat to 200~. Allow the fryer to heat for 15 minutes.

NonCE

Do not leave the fryer unattended during cleaning. Never let the water level

go below the "OIL LEVEL" mark on the back of the tank.

Using the fryer cleaning brush, scrub the inside of the fryer to remove protective coating.

c.

When cleaning is complete, turn off the fryer main burners and turn gas valve knob to the

d.

PILOT position. If the fryer has electronic ignition turn the gas control valve to the OFF

position. Drain the water into a container suitable for hot water and dispose of it.

When the tank has oooled, rinse it thoroughly with 0001 water. Continue to rinse the tank

e.

until the cleaner has been rinsed, thoroughly from the tank.

,

Using a clean dry cloth, wipe out all of the water. Be very thorough removing the water,

f.

because any residual water will cause hot oil to splatter out of the fryer.

CAImaN

Mild steel tanks must be wiped down/coated with oil to keep the tank from

rusting.

Now that the tank is clean, you are ready to fill and operate the fryer. Refer to 2.1 for

g.

instructions on adding shortening to the fryer.

1-13

Page 24

loSoS

Thermostat Calibration Check

NOnCE

Thermostat calibration requires that the temperature of the fryer be raised

above boiling. Therefore, you will need to drain the water from the fryer and

fill it with oil. Before removing the water, perform the initial cleaning of the

fryer. Oeaning the fryer now will prevent you from having to drain the oil and

refill with water later.

Filling the

fryer with oil is described in 2.1. To perform the calibration check detailed below you will

need a digital thermometer.

b. Set the thermostat at 325°F and wait for the temperature reading on the thermometer to

rise. As the temperature rises toward 325°F watch the thermometer closely.

c. If the shortening temperature reaches 350oP and the burners DO NOT turn off, turn the

thermostat down. Keep lowering the thermostat setting until the burners go out.

(X)uld be defective.

d. Let the fryer cycle 4 to 6 times before checking the temperature. Compare the

thermometer temperature against the thermostat setting. If the values are more than 5°F

apart, calibrate the thermostat using the appropriate calibration procedure in this manual.

CAtmON

Contact your ASAP representative.

1.5.6 1bennostat Calibration

To calibrate the thermostat the dial must be removed from the shaft. The adjustment for the

thermostat is inside the dial shaft.

Place the

a.

sensors.

b. Set the Thermostat to 325Of and wait for the

rise.

Let the fryer cycle 4 to 6 times to ensure that the temperature has stabilized.c.

5°F apart, calibrate the thermostat using

1-14

temperature reading on the thermometer to

Compare

If the values are more than

the

procedure.

Page 25

d. Set the thermostat dial to 32S°F.

e. Remove the thermometer dial by pulling the knob straight out. DO NOT rotate the dial.

f. Hold the outside of the shaft so it does not move. Use the tip of a small, flat tip screw driver

to scrape away the sealing compound from the adjustment screw.

g. Turn the adjustment screw clockwise to lower the temperature setting and counterclock-

wise to raise the temperature. One quarter turn changes the temperature approximately

25°F.

Turn the adjustment until the burners turn on at 32S°F. Repla~ the knob and allow the

h.

fryer to cycle 4 to 6 times. Check the temperature of the thermometer against the

thermostat dial, if it is greater than 5°F differen~ repeat the calibration procedure.

i. When the calibration is correct, remove the thermometer and rep1aC% the tube saeen.

1.5.7

HIgh Umit Test

TIllS TEST SHOULD BE PERFORMED BY OUAUFIED PER.~ONNEL ONLY

1-1'

Page 26

1-16

Page 27

Chapter

This chapter describes how to operate your fryer to obtain the best performance. Included in this

chapter are filling, operating, and cleaning instructions for gas fryers.

2.1 FIUJNG THE FRYER

Both liquid and solid shortening can be used in the fryer. If solid shortening is used, it is

recommended that you use the melt cycle feature (optional) to melt the shortening. You can melt solid

shortening without the melt option, but you must carefully follow the instruction in section 2.2.2.

2:

2.1.1

2.1.2 FllllDg the Fryer With SoUd Shortening

FUling the Fryer With liquid Shortening

a. Make sure the drain valve is completely closed.

b. Fill the fryer with oil to the "Oil Level" line marked on

the back of the tank.

.. -.

~==I

Never melt blocks of solid shortening on top of the burner

tubes. This will cause a fire, and will void your warranty.

Pa.

a.

Make sure the drain valve is completely closed.

b. Remove the screen oovering the tubes.

c. Cut the shortening into cubes DO larger than I". AL-

WAYS pack the shortening below, between, and on top

of the burner tubes. DO NOT leave any large air gaps.

Use care when packing the solid shortening in the tank.

DO NOT bend or break the temperature sensor probes.

If these are damaged the fryer will not function properly.

d. Once the fryer is packed with shortening, the shortening must be melted.

shortening refer to the Fryer Start-Up section for your fryer

~

To melt the

2-1

Page 28

2.2 MEL11NG SOLID SHORTENING

NonCE

The melting procedure below requires the manual cycling of the fryer. Watch

carefully for smoke. If smoke is noticed, die shortening is scorching. To

prevent this, decrease the time you leave the burners on.

a. Rotate the thennostat to cause the main burners to light and remain lit for 4 seconds.

Rotate the thermostat back to off for 30 seconds.

b.

Continue cycling the main burners until most of the solid shortening is liquefied and the

c.

temperature reaches 150°F. At 150°F leave the thermostat set at the desired temperature.

The burners will remain on constantly until the shortening temperature reaches the

thermostat setting.

d. On~ at temperature, the fryer is now operating normally and ready to use.

2.3 OPERATING IN~UCl10NS

To ensure the food always comes out the very best, follow the preparation insttuctions for the food

you are cooking. Using the best shortening makes the best fried foods. The best shortening will last

longer than lower grade shortening and save you money. When not in use the shortening should be

cooled and covered to prevent contamination.

CAU110N

The fryer has been installed using restraining devices to prevent accidental

tipping or movement. Do not attempt to move the fryer when it has hot 1

in it. Splashing hot liquids can cause severe bums.

[==~

Water and shortening DO NOT mix. Keep liquids away from hot shortening.

Dropping liquid frozen food into the hot shortening will cause violent boiling.

2.3.1 Fryer Start-Up

DO NOT sf ART FRYER Wn'HOtn' FILUNG WITH OW

a. Ught the pilot light as described in section 1.5.2.

2-2

Page 29

knob is located behind the front doors or on the front oontrol panel.

c. The main burners will light and cycle at the thennostat setting.

2.3.2 Fryer Shut-Down

There are two shutdown modes of fryer operation, STAND BY and COMPLETE. The standby mode

removes the ability for the fryer's main burners to cycle. Complete shutdown turns off the gas supply

to the fryer. Shut down the fryer by:

STANDBY Turn the thennostat to OFF. Depress and turn the gas valve clockwise

to the PILOT position (if fryer has an electronic ignition turn the gas

valve to the Off position). The fryer is now in Standby and can remain

this way for only brief periods of time. NEVER leave the cooker in

standby overnight.

COMPlEI'E To oompletely shut down the cooker, turn the gas valve counterclock-

wise to the OFF position and turn the power switch off (if used). The

fryer is now completely shut down and can be cleaned and filtered.

~

~

2.3.3 Power Failure

0

If power is removed from the fryer during filtering, place the filter switch in the OFF position and

close the return valve. When power is restored restart the filter procedure

'--I

2-3

Page 30

2.4 SHORTENING FILTER PROCEDURES

This section describes the procedures used to filter fryers using the solo filter unit. Figure 2-1 shows

the locations of the components used in the filterproc:ess. The filter accessories and tools you should

have to perform normal filtering operations are described on page 2-5. Frequent filtering of your

shortening will prolong the shortening's usable life. Daily shortening filtering is strongly

recommended .

Return

Valve

Drain Valve

Handle

Hush Hose

Valve

optional)

NOTE

See Maintenance Section for Filter

Operational Information.

CLOSEDVALVE

(Handle Across Body)

Figure 2-1 Fryer mustrating Filter Components

Valve Handle

Valve Body

VALVE OPEN

(Handle Inllne With Body)

2-4

Page 31

Return Valve

pump on, allows the shortening to return to the design, this sooop is used to remove the debris

fryer tank. from the filter pan.

Drain Valve BLACK - Drain the oil from the Cleaner - Used during fryer boil-out cleaning.

fryer tanks to the filter pan.

oil from the filter unit to the fryer. Simply push

to left OD fitting to connect. Pull to right to

disa>nnect.

Filter Unit Cord - Provides electrical power to

the illter unit.

FUter

Paper

Package

of pre-cut filter

Preooat FUter AId . Coarse Diatomaceous earth

used to enhance the filter ability of the filter

media.

Cleaning Bnlsh -This long handled stiff bristle

brush is used to brush down the crumbs inside the

fryer tank during shortening filtering.

FIlter Crumb Catch - Mounts in d1e filter pan lid

and catches large debris during filtering.

flush Hose (OPl10NAL) - Attached to the

filter piping, this hose and nozzle is used to flush

out the fryer tank. This hose is an optional item.

~;=I

At operating temperature the shortening temperature may be greater than

300°F. Extreme care should be used when filtering operating temperature

shortening to avoid personal injury

2.4.1 General FDter Hints

Ensure that all oil in the filter pan is returned

important if you are using solid shortening.

FryerCmmb Scoop -Aspecia11y designed long

handle scoop for scooping out the fryer. The

scoop section is narrow enough to fit down between the fryer burner tubes.

This is very

Always use Pitco Precoad for fastest filtrations, maximum labor saving, and cleanest/

clearest shortening possible. Impaired filter performance will result without the use of

a filter aid.

The longevity of your oil is related to how clean you keep it. With a Pitco solo filter

system, it is easy to do a quick drain/refill anytime. By removing suspended particles

often, it prevents them from burning.

2-5

Page 32

4. When the time it takes to refill the fryer after filtering exceeds 3:00 minutes, scrape the

filter bag or paper. If scraping does not bring the refill time back down change the fi1ter

paper as described in 3.1.

S. The mter pump is protected from dogging by a special screen in the pickup tube.

Cean this screen each time a new mter is installed (see Chapter 3, 3.4.2)

6. If you have filter system problems refer to section 3.4.2.

7. Purge the filter lines by allowing the filter pump to run lS seconds after air bubbles are

seen inside the fryer tank.

2.4.2 Filter Procedures: Numbers in parenthesis refer to Figures 2-1 and 2-2.

NonCE

.

When working with hot oil ALWAYS wear oil-proof, insulated gloves.

NEVER

.

Run the filter system without a filter bagtpaper.

.

Attempt to filter more than one fryer tank at a time.

.

Empty the oil from the fryer before turning OFF the fryer burners.

.

Store the UFM Filter Unit anywhere other than in the fryer filter cavity.

Disconnect die filter pan, slide it out and empty the crumb basket. Scrape previously

a.

filtered residue off the filter paper. Examine the filter bag for dark, scuffed, or tom areas.

Refer to 3.1.1 for filter bag replacement instructions. Re-install the pan.

Turn die fryer OFF (See Standby Shutdown, section 2.3.2). Remove the baskets from the

b.

fryer tank( s). Use the clean out rod to lift out die tube screens. If there are excess aumbs

in the fryer tank, remove them with the crumb scoop.

If you have replaced or scraped the filter paper, stir in Preooat

Co

Filter Aid to the shortening in fryer (8 oz. by volume). After

cleaning out the excess debris with the fryer sooop sprinkle the

powder into the first fryer to be filtered and stir the powder into

the oil.

NonCE

Always open a

valve before starting the filter pump.

2-6

Page 33

Slowly open the drain valve by using the black knobbed extension rod. If necessary use

d.

the clean-out rod to clear the crumbs from the drain. Use the long handled brush to clean

the sides of the tank as the oil drains.

Open the red handled return valve to the tank you are filtering. When the tank is empty

e.

close the drain valve and turn on the filter pump. As the tank fills, brush the inside of the

tank to remove crumbs.

f. When bubbles are seen coming out of the oil return spout, turn off the pump. Open the

drain valve and allow the tank to drain again. Repeat steps b through d until the tank is

clean.

When cleaning is oomplete turn the pump off, close the drain valve, and repla~ the tube

g.

screen. Open the red handled return valve and turn on the pump to refill the fryer with

the filtered oil. Continue to run the filter pump until bubbles oome out the oil return

opening. Turn the pump off and close the red handled return valve. If necessary add more

shortening to the tank to return the shortening level to the fill mark. The fryer is now ready

for use.

2.5 DAILY CLEANING

Your fryer should be cleaned every day to maintain peak performance and appearan~. Perform the

procedures below every day,

a. Wipe up any shortening that spills onto the exterior of the fryer. This should be done with

a clean soft cloth.

b. Use WamI water with a mild detergent to clean surfaces. Be careful not to get water in

the shortening. Rinse

Co Use.

completely and dry thoroughly before use.

stains ifscouring powder or pad to dean

d. Perform the weekly boil out cleaning of your fryer deSCrIbed in section 3.2.

2.7

Page 34

2-8

Page 35

Chapter 3: Owner Maintenance and

This chapter provides you with the information and procedures necessary to perform basic fryer

mainteDan~ and adjustments. If after performing maintenan~ on your fryer it does not perform

properly, contact your

Adjustments

[==-

disconnected before

The power supply

appliance.

3.1 ~TER MEDIA REPLACEMENT

This section the filter system's components and

media.

be

the procedures necessary to replace the filter

~=:I

At operating temperature, the shortening in the fryer may be hotter than 375Of

(190°C). This hot, melted shortening will cause severe bums. Do not let the

hot shortening touch your skin or clothing. Always wear insulated oil-proof

gloves when working on the filter system.

The filter module stores neatly under die fryer. The unit is very easy to use and allows for quick

installation and filtration, even under die busiest conditions. The filter module is shown in Figure

3-1 widl specific components and features pointed out and briefly described.

Follow the procedures below to

the fIlter

or cleaning the

It will be easier and safer if the filter assembly has cooled to room temperature

before handling any filter parts.

a. To remove the filter pan, disconnect the filter tube oonnection. This is done by sliding

the insulated portion of the connector out of the receiving portion of the oonnector.

b. Graspthe

pan lid.

Remove the aumb catch tray from the top of the filter pan. Discard any debris that may

be in the crumb catch.

filter pan and

~=:I

gently pull the assembly out the front of the fryer, remove the flIter

3-1

Page 36

(1) Fdter Pan - Holds the oil from the fry tank.

(2) Pick-Up Tube - ConnedS filter envelope

assembly to piping. Inoorporates a strainer to

protect filter pump from grit in the event of

envelope failure.

(3) FOter Assembly CoDDector - An insulated

handle covers the filter pan assembl y connection.

This connection separates the filter pick-up as-

sembly from the filter piping for removing the

filter pan for cleaning.

(4) FOter Media Connector -Connects the filter

pick-up tube to the filter media rack. An internal

screen keeps debris out of the filter pump.

c: @

,

Figure 3-1 Filter Module

(5) Flexible Coupling. Flexible coupling allows

for easy movement when connecting and discon-

necting the pickup tube from the fryer.

(6) Casters . Allows for easy movement of the

pan.

3-2

Page 37

Lift up on the filter paper assembly and remove from the filter pan. Unscrew the suction

d.

tube from the filter paper support rack. Remove the clip screen and slide the filter paper

support rack assembly out of the filter bag.

e. All of the filter pick up assembly

parts can be washed in a dish washer

~ or a pot sink. Hush out the suction

0 tube assembly with hot water. The

pick up tube screen keeps grit and

solid material from binding the pump.

After flushing the pick up tube screen

check to ensure that the screen is free

of debris. After cleaning, it is very

important to thoroughly dry the parts

before re-assembling. Water and oil

000 do not mix. Water in hot oil will

cause the oil to splatter.

Start fe-assembling the filter pick up

f.

assembly by sliding the new filter

paper on to the filter paper support

rack. Ensure that the hole in the filter

paper goes over the pick up tube assembly threaded connector.

Pick

aip

(Designed

low scraping

sediment with out

tearing paper)

Tube

Conn

~

'Filter Paper

Support Rack

Fold the open end of the bag in two folds. The fIrSt

g.

fold should be approximately 1 inch from the end

and the second should be over the edge of the rack

assembly.

Slide the clip screen over the folded end of the filter

h.

paper. Ensure the opening of the clip screen goes

over the pick up tube connection. Screw the

suction tube assembly onto the threaded connection.

i. Place the filter rack assembly in the filter pan and install the aumb catch tray in the top

of the filter pan lid.

Place lid on filter pan.

j. Slide the illter pan assembly back into the fryer and attach the pick up tube connector to

the filter unit connection.

3-3

Page 38

3.2 WEEKLY FRYER CLEANING (BOIL OUT)

The fryer should be thoroughly cleaned once a week. This cleaning should include a complete

draining of the fryer and a boil out. This would also be a good tinle to replace the filter paper if

necessary .

a. You will need a container large enough to hold the volume of the tank. This container

should also be able to withstand boiling water temperatures.

CAU110N

Completely shut down the fryer when the oil is to be replaced by water, and

when the heating portion of the cleaning is complete. This will prevent the

heating system from coming on during the oil draining and water filling

procedure.

Drain the oil from the fryer and discard or save for reuse. Remove tube rack/mesh tube

b.

screens and remove any large debris from the bottom of the fry tank. Once clean, return

tube rack/mesh screens to the fry tank. Cose the drain valve and fill the fry tank with

water and noncaustic detergent. For best results use Pita> Fryer Cleaner.

Restart your fryer as described in 2.3 and set the thermostat

c.

to a slow boil. DO NOT allow water to boil because excessive J

the water is at a slow boil turn off the fryer.

Allow the fryer to soak for 20 minutes to soften shortening deposits and carbon. Use fryer

d.

brush to remove any residue from tank, beating tubes, and side walls. Perform the daily

cleaning procedure described in section 2.5.

e. Remove the filter unit from under the fryer. Slide a container to catch the water under the

fryer so that the pipe that is nonnally aimed

and open the drain valve.

f. Drain the hot water to the oontainer and rinse the tank with clean warm water.

g. Wipe

the tank dry with clean cloth wipes. Close the drain valve and remove

h. Refer to section 2.1 to refill the fryer.

3.3 FLUE INSPECI'lON

to 200°F and bring the water

will occur. Once

into the filter pan is aimed into the container

the large

It is recommended that once every six months, with the cooker cooled down, you examine the flue

area. Check for corrosion or blockage of the flue. Ensure that the cooker is shutdown and do not turn

it on during the examination. Examination of the flue area during cooking may cause bodily injury.

3-4

Page 39

3.4 TROUBLESBOO11NG

This section is provided to aid you in the event of fryer or filter troubles. If these troubleshooting

procedures do not correct your problem contact a qualified technician or the factory. The

troubleshooting procedures are in a flowchart format.

3.4.1 Fryer Troubleshooting

Refer to this section to correct common problems that may be encountered in equipment operation.

3-5

Page 40

3.4.2 Filter Troubleshooting

Refer to this section to correct common problems that may be encountered during filter operation.

3-6

Page 41

YES

~

~"~\I8Iv."'I.n~~ e ..~. ~..~~ t.-8~

~ "-8 ~ ~ .. ~ .. .. -1.JIDe' ~ ...

... .. ~ bI' - 8'8.

~ .. de8ed v8V8 ... ...

~~..~. ~..

"'_1d8d ~b*8~.~ --~~..

ra~~. ~..~.. -~

~ ~ «*aJI: ~.

..va ~.~~-,

tC)

~ .-u ~ ~ be

YES ~- ~ lie ~ dI8dWg8

*-. ~10~12~

b*8 ~ .. PI8I1»

MIdI ON.

Sold 8tut81~ ~ be

~ oW tie ~ di8dwge

YES b*8 mq 1118 ~ 8WId1

... ~10~12"""

ON. If tie .. hM been

,. ... - ~ tyer ..

".~...b'45

b8b8 ~.

)-7

Page 42

3-8

Page 43

v

~

.., I

Loading...

Loading...