Page 1

^

)

DISPLAY ON/OFF TRACK NO. DIGITAL REC LEVEL

STANDBY/ON

+–

ORDER NO.

RRV2243

COMPACT DISC RECORDER

PDR-L77

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

Type

KUXJ/CA AC120V

MYXJ AC220-230V

NVXJ AC230V

¶

This product is a system(s) component.

Be sure to connect it to the prescribed system component(s), otherwise damage may result.

Model

PDR-L77

tnenopmoCledoM

REVIECERDCOERETS77L-CX7322VRR7812VRR

METSYSREKAEPS

KCEDETTESSACOERETS77L-TC—————9912VRR

REDROCERCSIDINIM77L-JM—————1022VRR

REDROCERCSIDTCAPMOC77L-RDP3422VRR.launamsihT

————WRL-A-9L-S————

————————WRL-8L-S—————8712VRR

Power Requirement Remarks

WRL-9L-S————————

ledom.S.U

9322VRR6712VRR

launamecivreS

naeporuE

ledom

skrameR

This service manual should be used together with the following manual (s).

Model No. Order No. Remarks

PDR-509 RRV2055 Service guide

CONTENTS

1. SAFETY INFORMATION

2. EXPLODED VIEWS AND PARTS LIST

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM

4. PCB CONNECTION DIAGRAM

5. PCB PARTS LIST

6. ADJUSTMENT

7. GENERAL INFORMATION

7.1 DIAGNOSIS

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS SERVICE, INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER ELECTRONIC (EUROPE) N.V. Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

c

PIONEER CORPORATION 1999

...............................................

....................................................

..................................................

......................................

...............

...

.........................

................................

2

5

10

35

46

51

57

57

FOR U.S. MODELS

NECESSARY INFORMATION FOR DHHS RULES

MARKED ON THE REAR BASE AND ON THE TOP

OF CD MECHANISM AS BELOW.

DANGER – LASER RADIATION WHEN OPEN.

AVOID DIRECT EXPOSURE TO BEAM.

7.1.1 POWER ON SEQUENCE

7.1.2 ERROR CODE

7.1.3 DISASSEMBLY

7.2 PARTS

7.1.2 IC

7.1.2 DISPLAY

8. PANEL FACILITIES AND SPECIFICATIONS

..........................................................

............................................................

.................................................

......................

.......................................

......................................

T – ZZE NOV. 1999 Printed in Japan

.......

57

59

61

63

63

68

70

Page 2

PDR-L77

1. SAFETY INFORMATION

This service manual is intended for qualified service technicians ; it is not meant for the casual do-ityourselfer. Qualified technicians have the necessary test equipment and tools, and have been trained

to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

WARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of California to cause

cancer, birth defects or other reproductive harm.

Health & Safety Code Section 25249.6 – Proposition 65

NOTICE

(FOR CANADIAN MODEL ONLY)

Fuse symbols (fast operating fuse) and/or (slow operating fuse) on PCB indicate that replacement parts must

be of identical designation.

REMARQUE

(POUR MODÈLE CANADIEN SEULEMENT)

Les symboles de fusible (fusible de type rapide) et/ou (fusible de type lent) sur CCI indiquent que les pièces

de remplacement doivent avoir la même désignation.

(FOR USA MODEL ONLY)

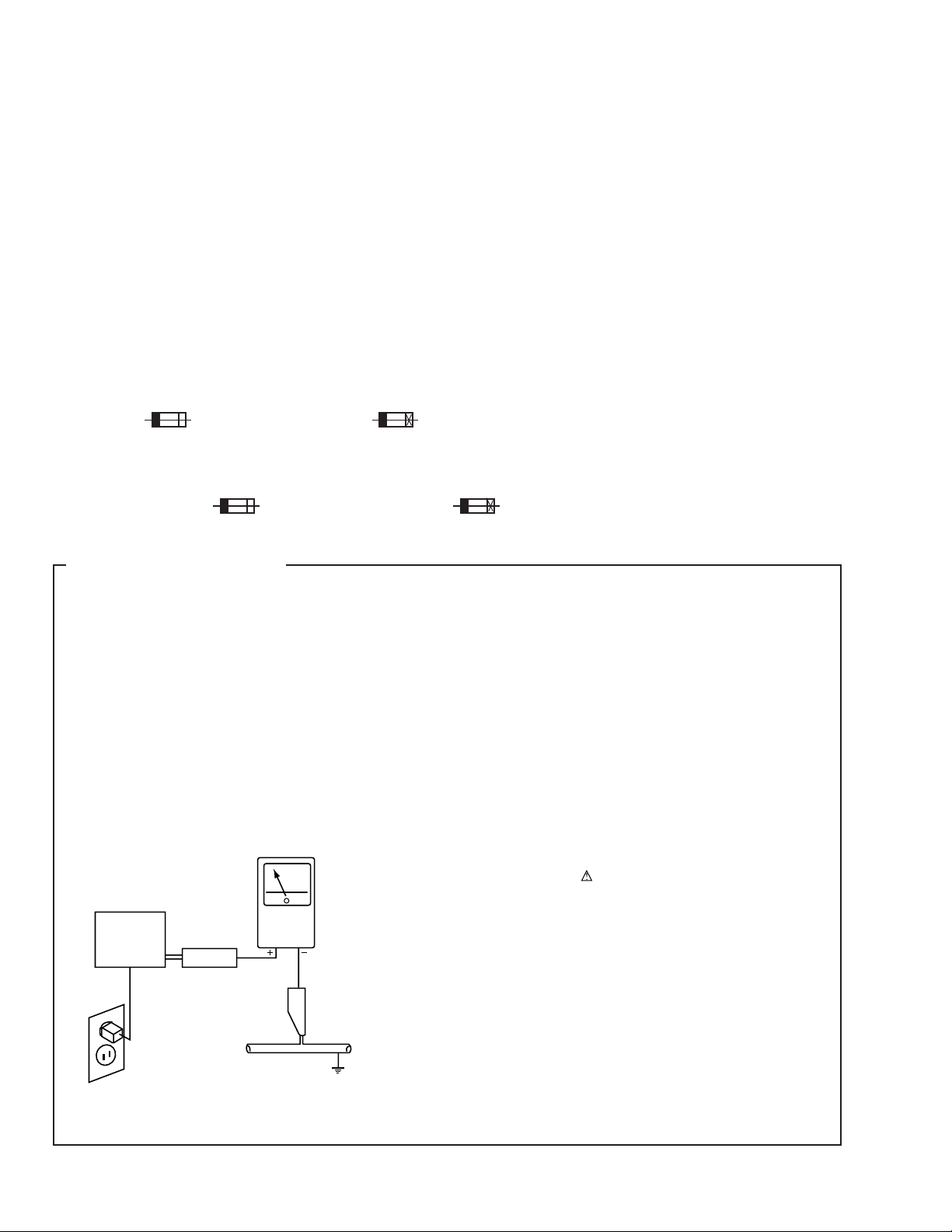

1. SAFETY PRECAUTIONS

The following check should be performed for the

continued protection of the customer and service

technician.

LEAKAGE CURRENT CHECK

Measure leakage current to a known earth ground (water

pipe, conduit, etc.) by connecting a leakage current tester

such as Simpson Model 229-2 or equivalent between the

earth ground and all exposed metal parts of the appliance

(input/output terminals, screwheads, metal overlays, control

shaft, etc.). Plug the AC line cord of the appliance directly

into a 120V AC 60Hz outlet and turn the AC power switch

on. Any current measured must not exceed 0.5mA.

Reading should

not be above

0.5mA

Earth

ground

Device

under

test

Also test with

plug reversed

(Using AC adapter

plug as required)

Leakage

current

tester

Test all

exposed metal

surfaces

ANY MEASUREMENTS NOT WITHIN THE LIMITS

OUTLINED ABOVE ARE INDICATIVE OF A POTENTIAL

SHOCK HAZARD AND MUST BE CORRECTED BEFORE

RETURNING THE APPLIANCE TO THE CUSTOMER.

2. PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in the appliance

have special safety related characteristics. These are

often not evident from visual inspection nor the protection

afforded by them necessarily can be obtained by using

replacement components rated for voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this Service Manual.

Electrical components having such features are identified

by marking with a

in this Service Manual.

The use of a substitute replacement component which does

not have the same safety characteristics as the PIONEER

recommended replacement one, shown in the parts list in

this Service Manual, may create shock, fire, or other hazards.

Product Safety is continuously under review and new

instructions are issued from time to time. For the latest

information, always consult the current PIONEER Service

Manual. A subscription to, or additional copies of, PIONEER

Service Manual may be obtained at a nominal charge from

PIONEER.

on the schematics and on the parts list

AC Leakage Test

2

Page 3

PDR-L77

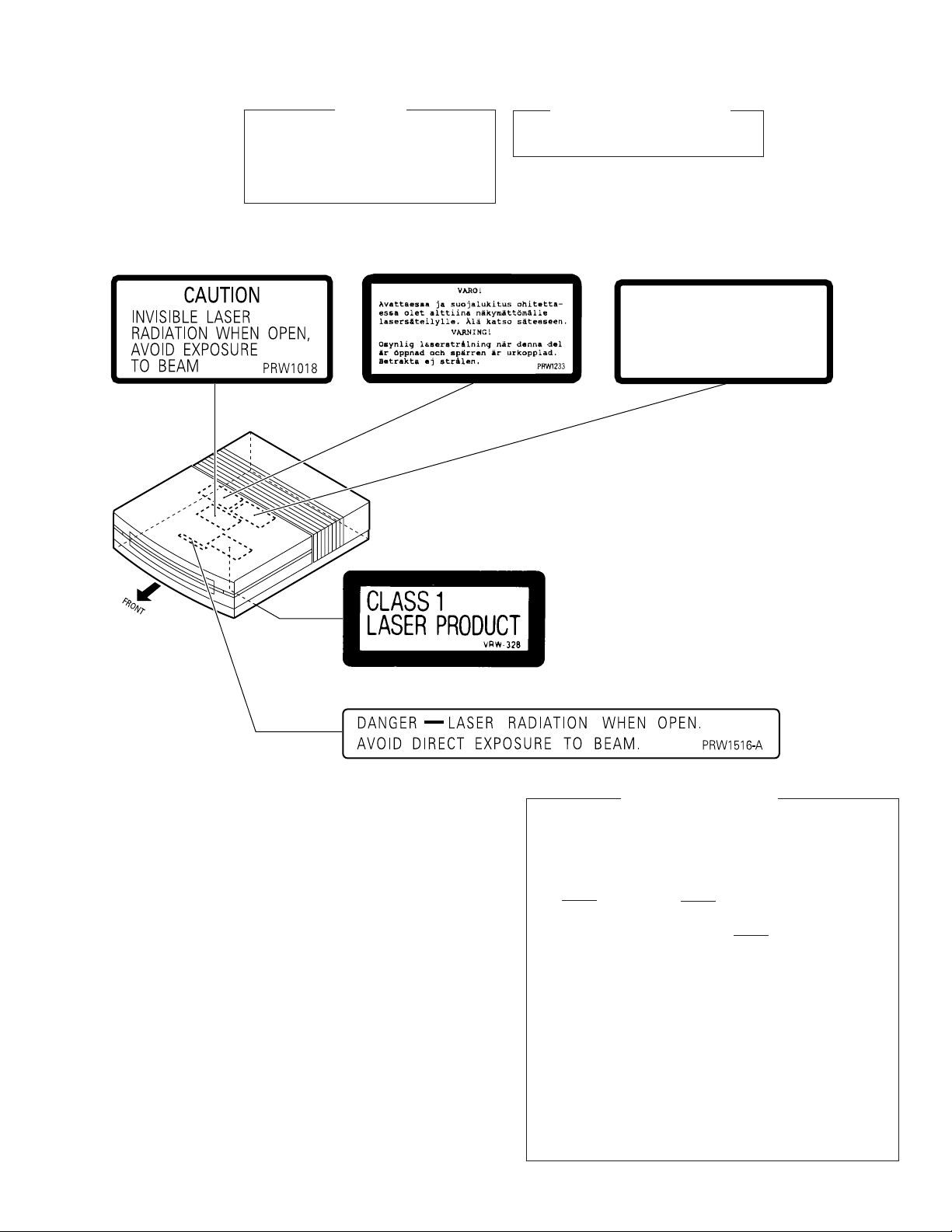

LABEL CHECK

THIS PIONEER APPARATUS CONTAINS

IMPORTANT

LASER OF CLASS ΙΙΙ b.

SERVICING OPERATION OF THE APPARATUS

SHOULD BE DONE BY A SPECIALLY

INSTRUTED PERSON.

NVXJ type

Put on Top Plate

LASER DIODE CHARACTERISTICS

MAXIMUM OUTPUT POWER: 23 mW

WAVELENGTH: 778 – 787 nm

MYXJ type

USYNLIG LASERSTRÅLING VED ÅBNING NÅR SIKKERHED SAFBRYDERE ER UDE AF FUNKTION.

UNDGÅ UDSÆTTELSE FOR STRÅLING

UNSICHTBARE LASER-STRAHLUNG TRITT AUS, WENN DECKEL

(ODER KLAPPE) GEÖFFNET IST! NICHT DEM STRAHL AUSSETZEN!

Put on Top Plate

MYXJ type

ADVARSEL

VORSICHT!

VRW1094

Put on Top Plate

MYXJ and NVXJ types

Put on Bottom Base

KUXJ/CA Type

Put on Bridge

Additional Laser Caution

1. Laser Interlock Mechanism

The position of the switch (S601) on the SERVO

MECHANISM Assy for detecting loading state is detected

by the system microprocessor, and the design prevents

laser diode oscillation when the switch (S601) is not on

CLMP terminal side (CLMP signal is OFF or high level.).

Thus, the interlock will no longer function if the switch

(S601) is deliberately set to CLMP terminal side (low

level).

The interlock also does not function in the test mode ∗.

Laser diode oscillation will continue, if pin 1 of M51593FP

(IC101) on the PRE-AMP BOARD ASSY mounted on the

CD-R PICKUP is connected to GND, or pin 19 is

connected to low level (ON), or else the terminals of Q101

are shorted to each other (fault condition).

2. When the cover is opened with the servo mechanism

block removed and turned over, close viewing of the

objective lens with the naked eye will cause exposure to a

Class 1 laser beam.

∗ Refer to page 51.

3

Page 4

PDR-L77

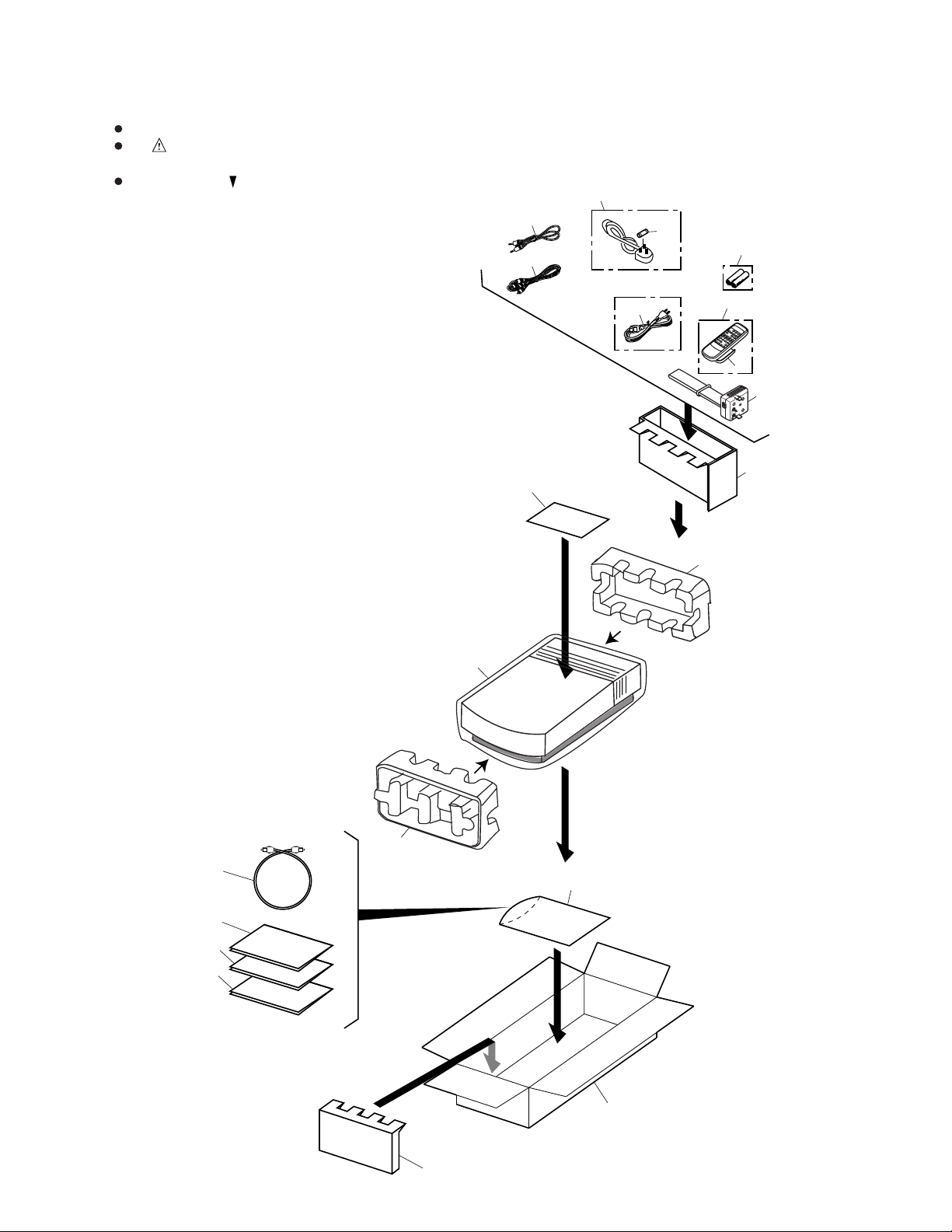

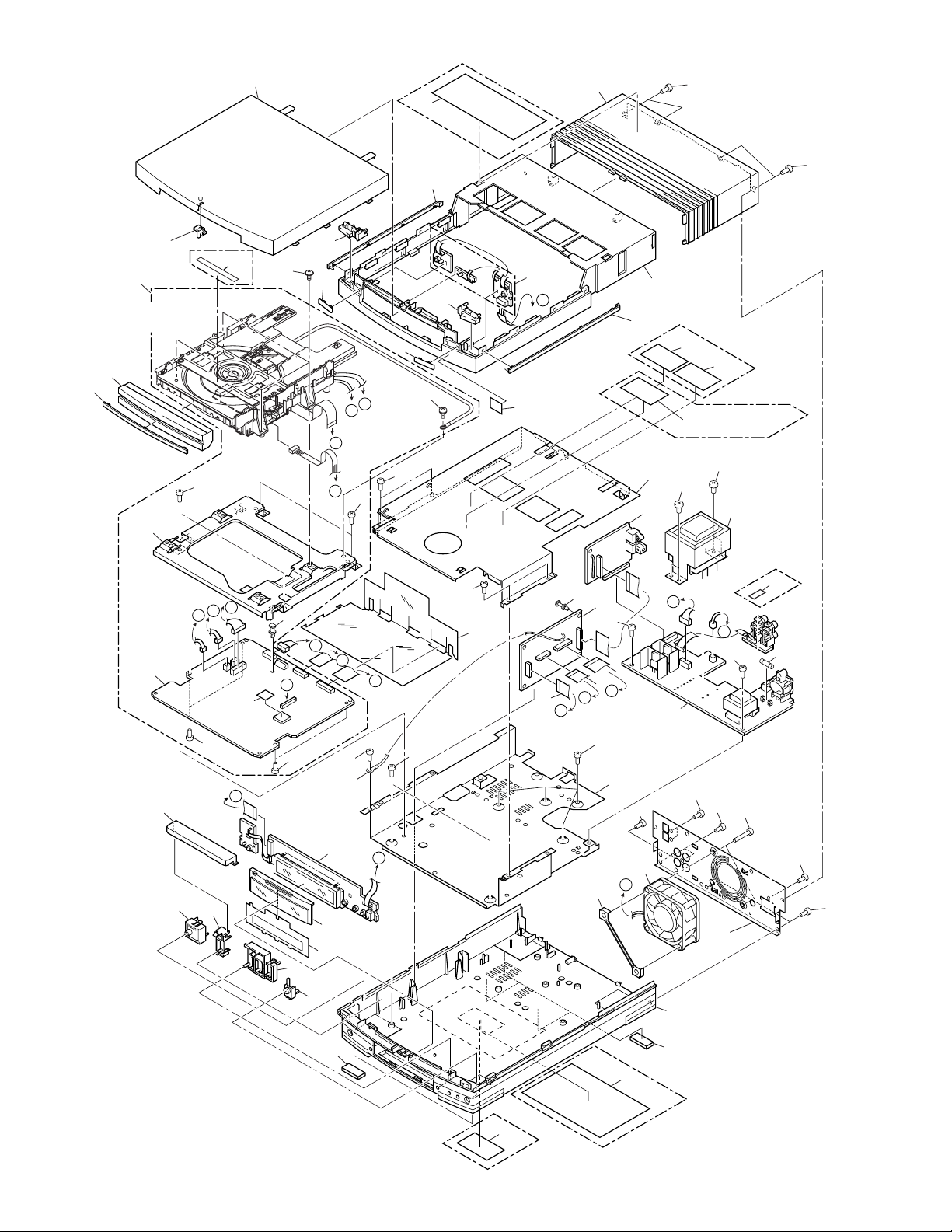

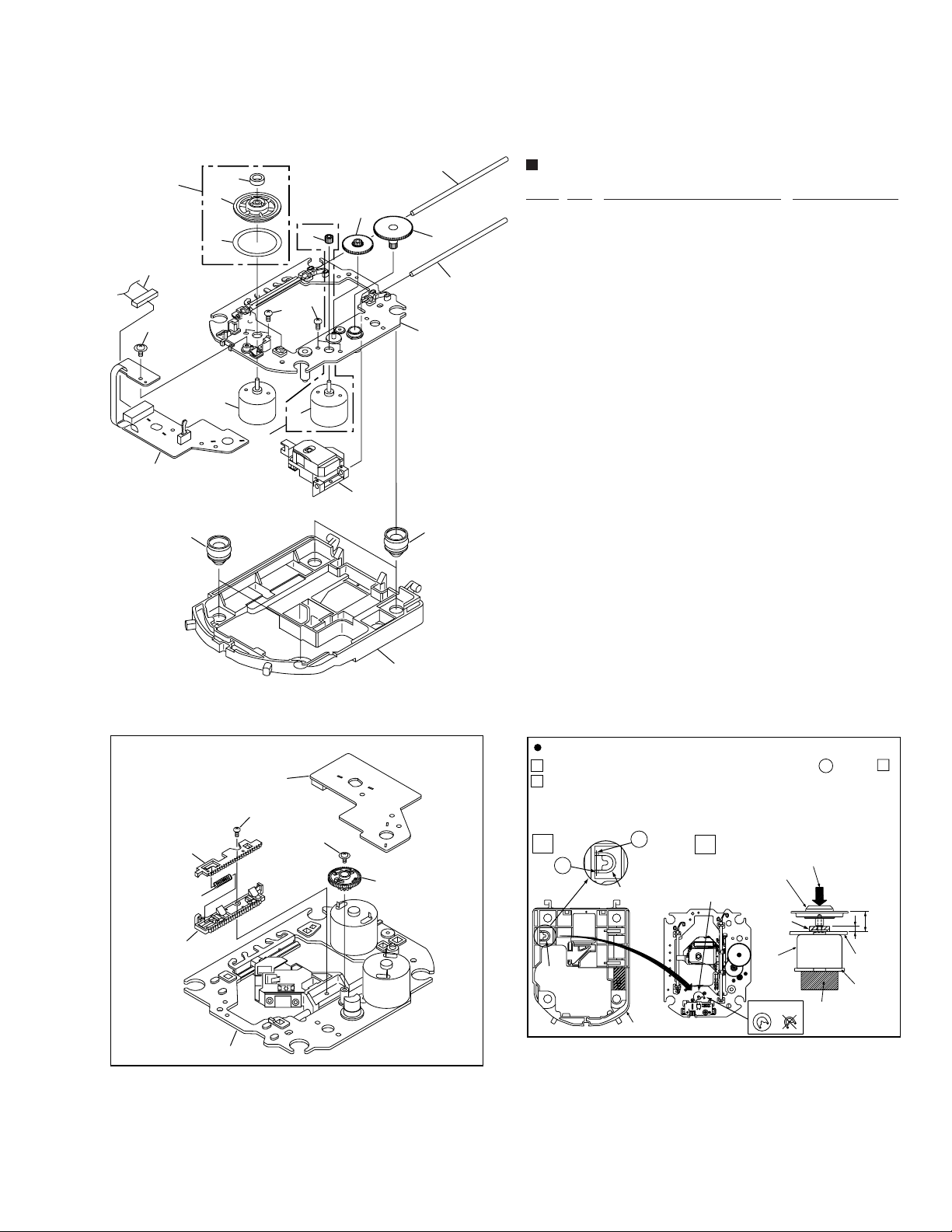

2. EXPLODED VIEWS AND PARTS LIST

NOTES : Parts marked by “ NSP ” are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

Screw adjacent to mark on the product are used for disassembly.

2.1 PACKING

10

9

1

NVXJ type

only

20

12

18

PDR-L77

Except NVXJ type

1

5

6

7

8

16

15

KUXJ/CA and NVXJ types

MYXJ type

MYXJ type

4

only

only

only

14

11

13

2

3

4

17

19

Page 5

(1) PACKING PARTS LIST

Mark No. Description Part No.

1 AC Power Cord

2 Operating Instructions

3 Operating Instructions

4 Operating Instructions

NSP 5 Warranty Card

6 Remote Control Unit AXD7242

(CU-PD113)

7 Battery Cover RZN1156

8 Analog Recording Adapter AXY7000

9 Stereo Audio Cord PDE1126

10 Control Cord(Mini-plug Cord) ADE7056

11 Optical Cord RKX1031

NSP 12 Dry Cell Battery(R6P, AA) VEM-013

13 Polyethylene Bag Z21-038

(0.03×230×340)

14 P Pad F AHA7285

15 P Pad R AHA7286

16 Sub Packing AHD7842

17 Packing Case

18 Packing Sheet AHG7065

19 Spacer AHD7856

20 Fuse (T5A)

See Contrast table (2)

See Contrast table (2)

See Contrast table (2)

See Contrast table (2)

See Contrast table (2)

See Contrast table (2)

See Contrast table (2)

PDR-L77

(2) CONTRAST TABLE

PDR-L77/KUXJ/CA, MYXJ and NVXJ are constructed the same except for the following:

No.

Symbol and Description

KUXJ/CA type MYXJ type NVXJ type

1 AC Power Cord ADG7022 ADG1154 ADG1156

2 Operating Instructions ARE7251 Not used ARE7251

(English/French)

3 Operating Instructions Not used ARC7288 Not used

(Swedish/Dutch/Portuguese/Spanish)

4 Operating Instructions Not used ARE7250 Not used

(English/French/Italian/German)

NSP 5 Warranty Card ARY7023 ARY7022 ARY7022

17 Packing Case AHD7844 AHD7841 AHD7843

20 Fuse (T5A) Not used Not used AEK7001

Part No.

RemarksMark

5

Page 6

PDR-L77

2.2 EXTERIOR

28

KUXJ/CA type only

15

Refer to

"2.3 CD-R CORE ASSY (1/2)",

"2.4 CD-R CORE ASSY (2/2)".

24

26

45

50

41

37-1

52

27

34

KUXJ/CA type only

32

42

25

3

35

27

H

I

G

J

45

52

45

A

25

43

47

37-2

54

KUXJ/CA type: 39

NVXJ type: 57

19

45

4

47

MYXJ type only

56

45

10

53

31

36

I

J

52

22(1/2)

KUXJ/CA type

45

H

B

49

48

G

52

22(2/2)

29

F

C

D

45

12

2

23

30

44

A

17

48

1

45

6

9

D

C

7

B

44

20

E

21

47

11

F

33

E

45

5

47

47

46

18

38

only

14

47

47

16

55

MYXJ and NVXJ types only

16

40

KUXJ/CA type only

6

Page 7

(1) EXTERIOR PARTS LIST

PDR-L77

Mark No. Description Part No.

NSP 1 CDR ASSY AWM7486

2 FLDP ASSY AWU7522

3 FRKB ASSY AWU7523

4 PJB ASSY AWU7524

5 PWSB ASSY

6 21P FFC/30V ADD7207

7 15P FFC/30V ADD7208

8 25P FFC/60V ADD7209

9 16P FFC/60V ADD7210

10 Power Transformer

11 DC Fan Motor AXM7014

NSP 12 Cord With Plug (J1) DE015WC0

13 Connector Assy PG06KK-F15

14 Fuse (FU101)

NSP 15 CD-R CORE Assy PXA1625

16 Leg AEB7197

17 Mecha Barrier AEC7246

18 Rear Panel

NSP 19 Top Plate ANF7014

NSP 20 Bottom Plate ANF7019

21 Fan Plate ANG7153

22 Level Button AAD7569

23 Display Window AAK7717

24 Tray Panel AAN7197

25 Main Line AAP7058

See Contrast table (2)

See Contrast table (2)

See Contrast table (2)

See Contrast table (2)

Mark No. Description Part No.

31 PCB Cover AEC7247

32 Bonnet AMA7012

33 Bottom Base AMA7016

34 Button Assy A AWL7044

35 Button Assy B AWL7045

36 Power Button Assy AWL7049

37 Top Panel Assy AWL7053

NSP 37-1 Top Panel 1 AMB7682

NSP 37-2 Top Panel 2 AMB7683

38 Fuse Label

39 65 Label

40 Name Label

NSP 41 Caution Label

42 Disc Caution Label

43 CDR Getter Label PRW1547

44 Screw BBT30P060FZK

45 Screw BBZ30P060FMC

46 Screw BBZ30P300FZK

47 Screw VPZ30P080FZK

NSP 48 PCB Spacer AEC1371

49 Radiation Seat PEB1306

NSP 50 Mecha Base PNB1613

51 • • • • • • • •

52 Screw BBZ30P080FCC

53 CD-R CORE PCB ASS'Y PYY1273

See Contrast table (2)

See Contrast table (2)

See Contrast table (2)

See Contrast table (2)

See Contrast table (2)

26 Tray Line AAP7059

27 Front Line AAP7067

28 CL Lens AAX7704

29 R.C Lens AAX7772

30 FL Filter AEC7235

54 Caution Label

55 Label

56 Caution Label

57 Caution Label

(2) CONTRAST TABLE

PDR-L77/KUXJ/CA, MYXJ and NVXJ are constructed the same except for the following:

No.

Symbol and Description

KUXJ/CA type MYXJ type NVXJ type

5 PWSB ASSY AWU7537 AWU7521 AWU7521

10 Power Transformer ATT7066 ATT7065 ATT7065

14 Fuse (400mA : FU101) REK1125 Not used Not used

14 Fuse (T200mA : FU101) Not used REK1015 REK1015

18 Rear Panel ANC7905 ANC7902 ANC7904

38 Fuse Label AAX7781 Not used Not used

39 65 Label ARW7050 Not used Not used

NSP 41 Caution Label PRW1516 Not used Not used

40 Name Label ARW7076 Not used Not used

42 Disc Caution Label ARW7087 Not used Not used

54 Caution Label Not used PRW1233 Not used

55 Label Not used VRW-328 VRW-328

56 Caution Label Not used VRW1094 Not used

57 Caution Label Not used Not used PRW1018

Part No.

See Contrast table (2)

See Contrast table (2)

See Contrast table (2)

See Contrast table (2)

RemarksMark

7

Page 8

PDR-L77

2.3 CD-R CORE ASSY (1/2)

• Bottom View

A

18

13

1

20

9

12

7

26

25

Refer to

"2.4 CD-R CORE ASSY (2/2)".

23

31

24

19

5

28

26

29

5

30

5

6

21

4

17

8

3

CD-R CORE ASSY (1/2) PARTS LIST

Mark No. Description Part No.

NSP 1 LOADING A Assy PWZ3760

NSP 2 LOADING B Assy PWZ3761

3 Connector Assy PG02KK-E15

(LOADING B CN551 ↔ LOADING A CN502)

4 DC Motor (LOADING) PXM1027

15

A

2

27

22

14

11

16

10

Mark No. Description Part No.

15 Drive Cam VNL1736

16 Lock Plate VNL1820

17 Tray Stopper VNL1739

18 Connector Assy PG03KK-E37

(LOADING A CN501 ↔ CD-R CORE CN451)

5 Screw VBA1065

6 Motor Pulley PNW1634

7 Screw VBA1055

8 Tray Stopper Spring VBH1277

9 Rubber Belt VEB1260

10 Loading Base VNL1854

11 Tray VNK4570

12 Gear Pulley VNL1733

13 Loading Gear VNL1734

14 Drive Gear VNL1735

8

19 Screw BBZ26P040FMC

20 Screw Z39-019

21 Loading Motor Assy VXX2505

NSP 22 Binder ZCA-T18S

23 Clamper Plate VNE2068

24 Bridge VNE2069

25 Clamper VNL1738

26 Screw IPZ26P060FMC

27 32P Flexible Cable / 30V PDD1195

(CD-R Pickup ↔ CD-R CORE CN101)

NSP 28 Earth Lead Unit PDF1200

29 Tray Holder PNM1346

30 Stopper DNH2076

31 Spacer PNM1334

Page 9

2.4 CD-R CORE ASSY (2/2)

PDR-L77

17

22

25

1

20

15

23

9

23

3

7

2

26

4

10

21

19

11

18

16

5

8

CD-R CORE ASSY (2/2) PARTS LIST

Mark No. Description Part No.

NSP 1 SERVO MECHANISM Assy PWZ3759

2 DC Motor Assy (SPINDLE) PEA1235

NSP 3 DC Motor (CARRIAGE) PXM1042

4 Float Rubber A AEB7063

5 Float Rubber B AEB7066

NSP 6 Rack Spring DBH1285

NSP 7 Reflection Sheet PNM1325

8 Servo Base PNW2853

9 Pinion Gear PNW2854

10 Gear A PNW2855

11 Gear B PNW2856

12 Gear C PNW2857

13 Rack PNW2858

14 Rack Stopper PNW2859

NSP 15 Disc Table PNW2860

16 Carriage Base S PNW2874

17 Connector Assy PG09KK-E17

(SERVO MECHANISM CN601↔ CD-R CORE CN452)

18 Guide Bar VLL1488

19 Sub Guide Bar VLL1489

NSP 20 Magnet VYM1024

21 CD-R Pickup PEA1351

22 Screw Z39-018

23 Screw PMZ20P030FMC

24 Screw JGZ17P030FMC

25 Disc Table Assy PEA1349

26 Carriage Motor Assy PEA1350

• Bottom View

SERVO MECHANISM

ASSY

14

13

Carriage Base S

How to Install the Disc Table

Use nippers or other tool to cut the two sections marked A in figure 1 .

1

While supporting the spindle motor shaft with the stopper, put spacer on

2

24

22

12

6

top of the carriage base, and stick the disc table on top (takes about 9kg

pressure). Take off the spacer.

1

A

Spacer

A

Spacer

Servo Base

2

Spacer setting

Position

Disc table Assy

(Pressure of about 9kg)

Spacer

Spindle

motor

OK NG

Stopper

2.8mm

Carriage

Base

PCB

11mm

9

Page 10

1

23

PDR-L77

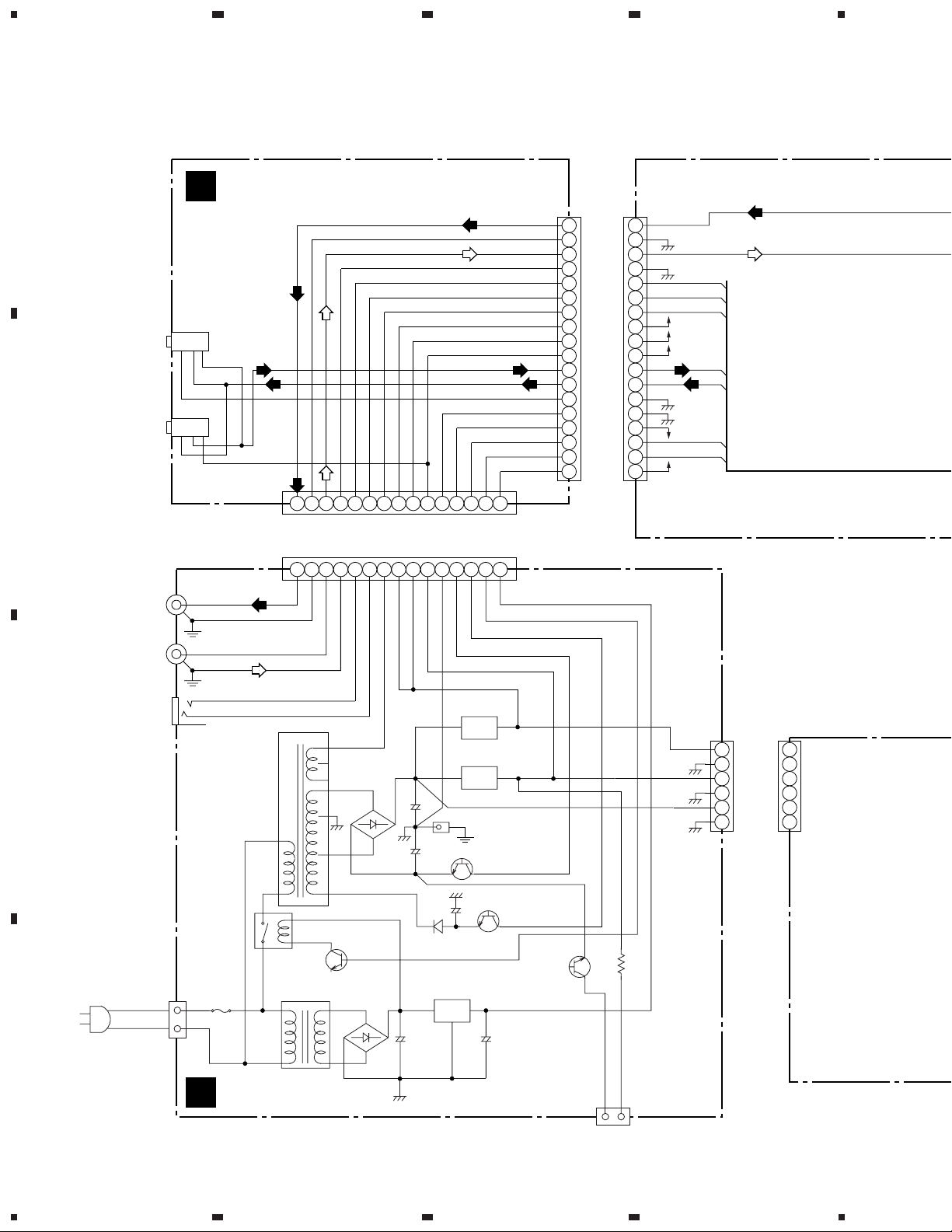

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM

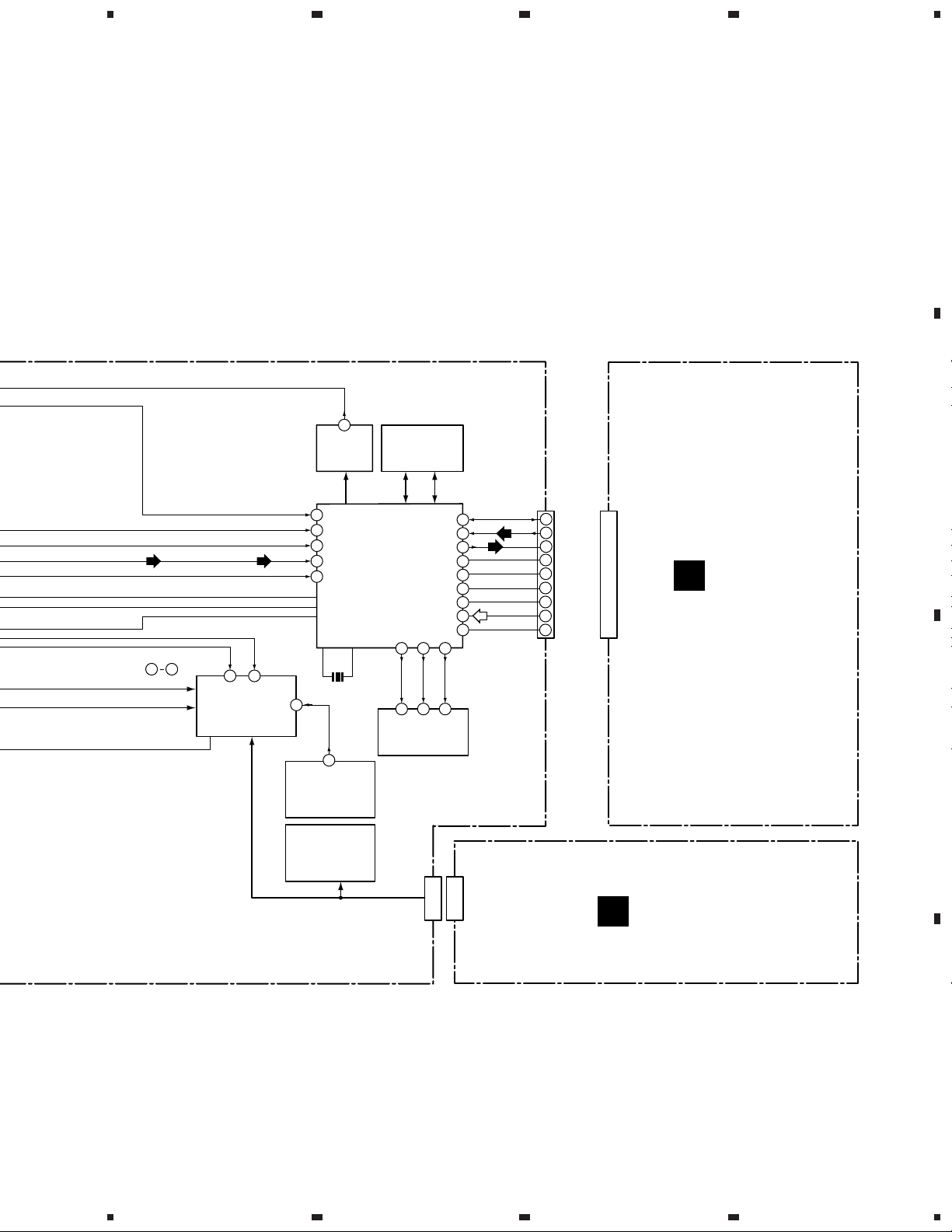

3.1 BLOCK DIAGRAM (1/2)

A

F

PJB ASSY

(PB)

(AI)

OPT OUT

OPT IN

B

JA7602

JA7601

(DI)

(DO)

(PB) (PB)

(AI) (AI)

CN7201 CN7704

23

LOUT

24

GNDA

13

LIN

24

GNDA

7

RECD

8

CDRD

2

FLAC1

12

VA+5

22

VA+5

3

(DI)

(DO)

CN7202

1

268759104111215161920

17

21

18

5

16

4

11

20

VD+5

DIN1

DOUT

GNDD

GNDD

VA-5

VFDP

POWER

VU+5

4

(PB)

3

2

13

12

19

18

24

14

4

23

9

5

8

21

10

22

15

6

GNDA1

GNDA2

VA+5A

VA+5D

(DI)

GNDD1

GNDD2

(AR)

(DO)

LINE OUT

LINE IN

JA7202

JA7201

(AI)

LIN

LOUT

GNDA

GNDA

20 1516 12

(PB)

RECD

CDRD

FLAC1

VA+5

VA+5

VD+5

VA-5

GNDD

VFDP

68759104111219

POWER

VU+5

CN7003

IC7006

JA7603

C

T7002

D7001

+

+

5V

IC7005

5V

KN7001

1

2

3

4

5

6

VA+5

GNDA

VA+5

GNDD

V+U

GNDU

1

2

3

4

5

6

CN7002 CN901

Q7007(-5V)

FU101

RY7001

T7001

Q7051

D7051

+

D7012

IC7052

5V

++

Q7008(VIDP)

Q7010

CN101

D

10

G

PWSB ASSY

CN7001

FAN

1234

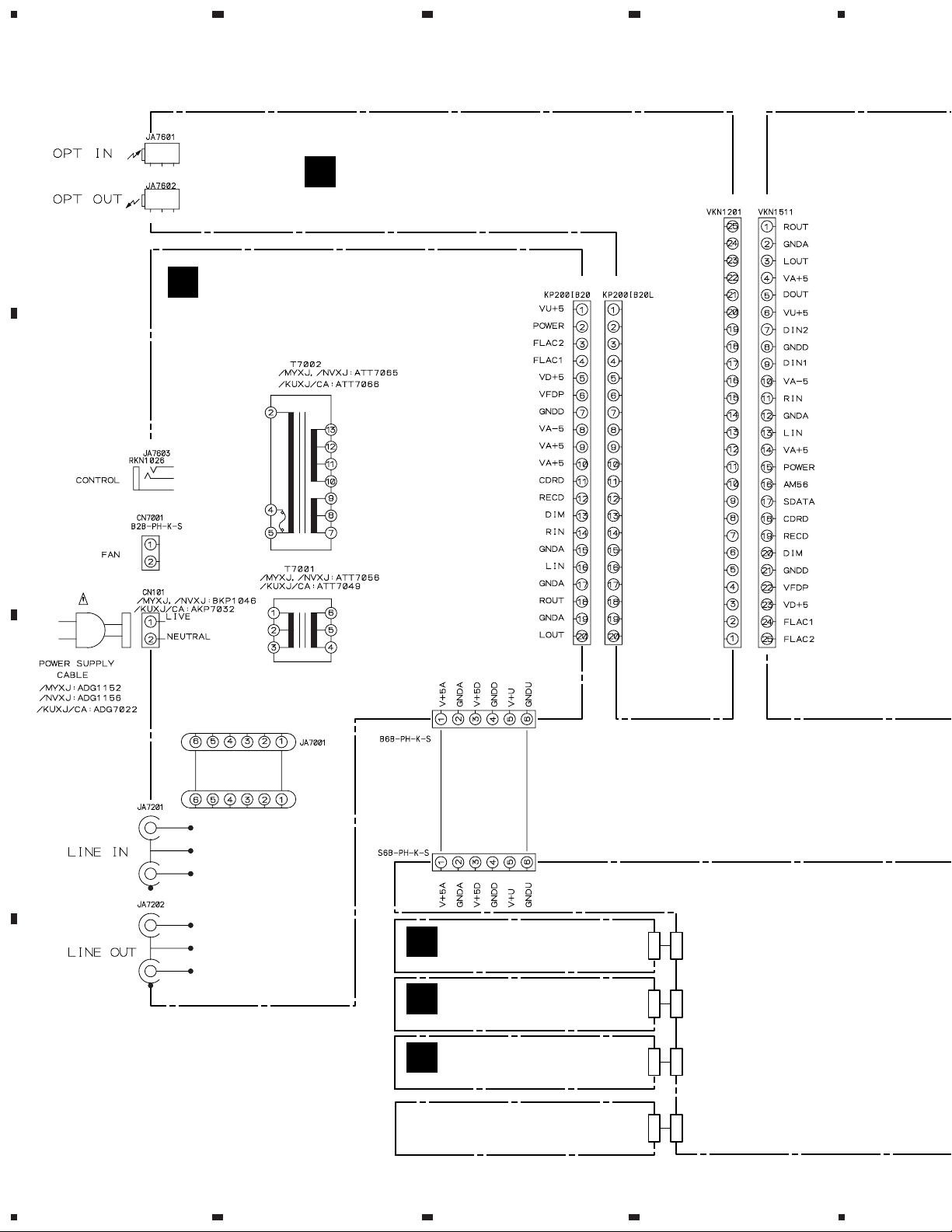

Page 11

(AR)

(PB)

Q7241

E

5

PB AMP

IC7241

BA-4558F

VA-5

GNDA1

+

–

IC7101

BA-4558F

VA+5A

VA-5

GNDA2

CDR ASSY

POWER

51 41 65 61 76 77

SYSTEM µ-com

GNDD1

CN7702

1

VA+5A

+

–

ALC

REMOTE

CDRD

RECD

IC7501

PE5138A

2

678

(PB)

P ASSIVE

L.P .F .

16 20

D/A

IC7401

PCM1716E

7

GNDD1 GNDA1

IC7102

BA-4558F

VA+5A

(AR)

VA-5

VU+5

KEY1

KEY2

(REC)

GNDD2

CN7701

(PB)

19

VA+5D

(PB)

2

19

VA+5D

123

A/D

IC7301

PCM1800

17

24

15

(PB)

GNDA2GNDD1

GNDD2

(DO)

(DI)

3

1

4

9

5

GNDD1

141621

16

REMOTE

VU+5

15

KEY2

14

KEY1

6

GNDD

5

VFDP

4

3

VD+5

2

FLAC1

CN7502

CN7501

J7501

KEY

1

2

3

11

12

13

14

15

CN7502

H

I

FRKB ASSY

3

GNDD

3

49

FL DRIVER

48

IC7551

57

MSM9202

FL TUBE

V7001

FLDB ASSY

PDR-L77

4

KEY2

4

REMOTE

RECEIVER

UNIT

X7551

GU1U26X

A

B

GNDD

GNDD

15

CN301

A

14

CD-R CORE ASSY

CN501

DOUT

DADAT A

ADDATA

19

133182117

DIN

GNDD

GNDD

GNDD

GNDD

861

GNDD

SIGNAL ROUTE

(AR)

: ANALOG REC SIGNAL

(REC)

: REC SIGNAL (after A/D)

(PB)

(PB)

: PB OUT (before D/A)

(PB)

: PB OUT

(DI)

: DIGITAL INPUT SIGNAL

(DO)

: DIGITAL OUT SIGNAL

(AI)

: ANALOG INPUT SIGNAL

C

D

11

5

6

7

8

Page 12

1

PDR-L77

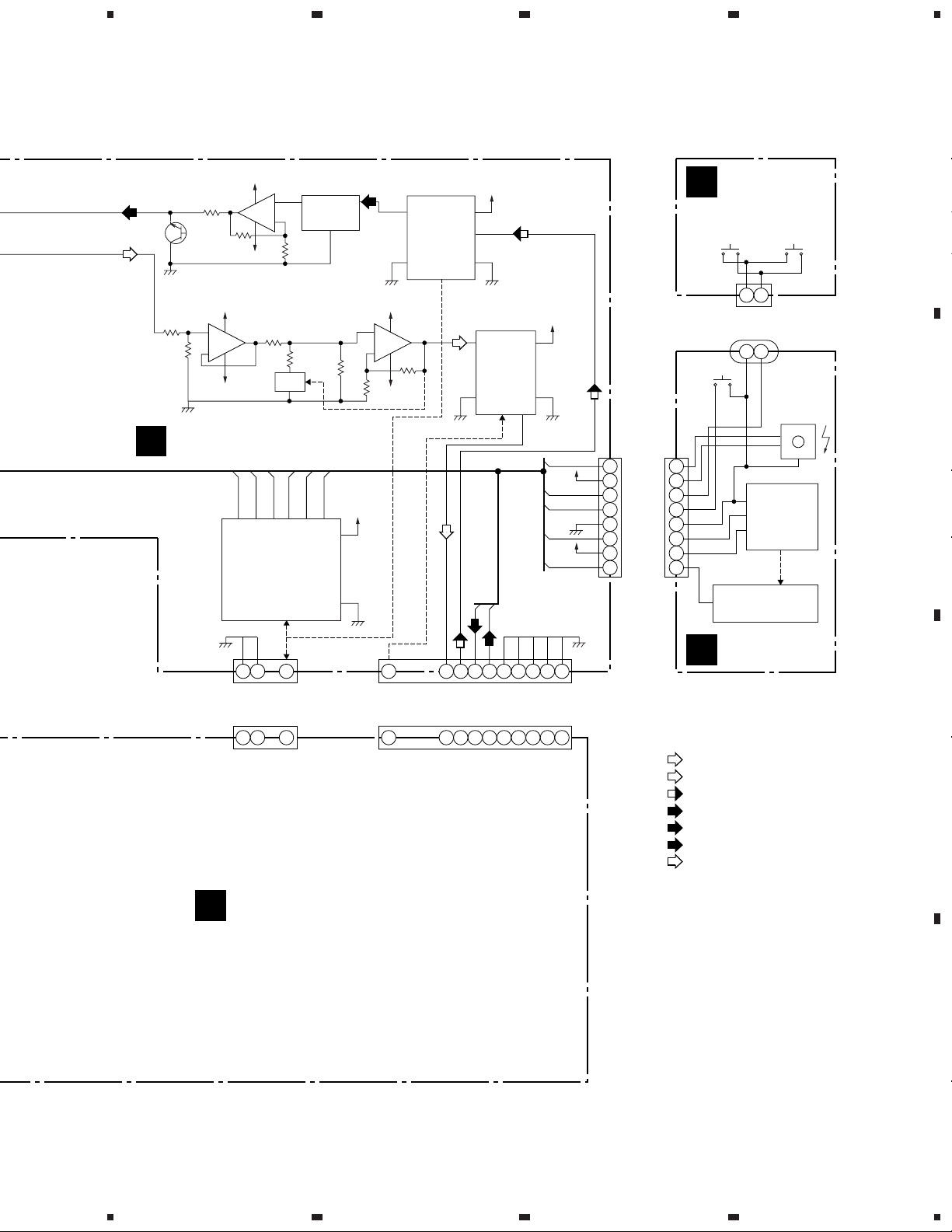

3.2 BLOCK DIAGRAM (2/2)

A

(AR)

(REC)

(PB)

(PB)

(PB)

(DI)

(DO)

23

SIGNAL ROUTE

: ANALOG REC SIGNAL

: REC SIGNAL (after A/D)

: PB OUT (before D/A)

: PB OUT

: DIGITAL INPUT SIGNAL

: DIGITAL OUT SIGNAL

: RF SIGNAL ROUTE

4

Disc (CD, CD-R, CD-RW)

B

CD-R

PICKUP

PEA1351

SERVO MECHANISM

B

ASSY

PC651

NJL5803K-F1

FG

C

M

DC MOTOR

ASSY

(SPINDLE)

PEA1235

M

CARRIAGE MOTOR

ASSY (SLIDER)

PEA1350

LOADING B

D

ASSY

CN551

1

M

LOADING

MOTOR

VXX2505

2

ASSY

CD-R CORE

A

ASSY

NJM2137M

CN1 CN101

A

10

9

16

15

17

8

14

11

4

1

3

2

CN601

9

3

4

1

2

LLL

B

C

D

E

F

G

H

FCS+

FCS–

TRK+

TRK–

FG

SPDL

SL

CN452

10

9

16

15

17

8

14

11

4

1

3

2

FG

9

3

SPDL

4

2

1

4

5

A

B

C

D

E

F

G

H

RF AMP CIRCUIT

A–D

A–H

FCS+

FCS–

TRK+

TRK–

SL

SPDL

L

CN453

IC181

6 1

76

73

71 68

RF PROCESSOR

LD CONTROL

CIRCUIT

34

35

32

M56788FP

31

TRK DRIVER

12

FCS DRIVER

13

SLD DRIVER

SPDL DRIVER

9

10

LOADING DRIVER

14

15

19

AK8563

IC451

IC101

RFDC

HF

17.2872MHz

58

11

10

29

46

WRF

FE

TE

RFAC

RFWBL

IC251-IC254

RUNNING OPC

CIRCUIT

TE

29

HF

---

RFWBL

38

BLOCK

IC201

PA9007A

SERVO AMP IC

19

FG

RFOPC

AOUT

IC431

PDK041A

STRATEGY

CONTROL IC

CXD2585Q

CD DECODER

RFDC

43

FE

39

TE

41

RFAC

50

IC351

PDJ014A

ATIP

DECODER IC

IC401

34.5744MHz

4

17.2872MHz

6

CDLRCK

65

CDBCK

67

CDDATA

66

CDTX

64

32 37

39 40

AD0-AD7

Address

D

12

1234

Page 13

5

678

PDR-L77

A

34.5744MHz

43 36

AD0-AD7

Address

17.2872MHz

CDLRCK

CDBCK

CDDATA

CDTX

AOUT

RFOPC

61 60

IC301

PE5109A

MECHANISM

CONTROL µCOM.

7

IC561

BA7082F

VCO IC

76

46

45

44

EFM ENCODER IC

47

X501

16.9344MHz

59

3

IC302

TK11041M-1

TEMPERATURE

SENSOR IC

IC303

PYY1196

(BR93LC46AF)

EEPROM

IC503

LH64256CK-70

D-RAM

Address Data

IC501

LC89585

15 16 17

DIRBCK

DIRLRCK

DIRDATA

2 4 43

IC502

AD1893JST

Fs CONVERTER

CN301 CN7002

B

CN501

CN7701

DIN2

(DI)

20

18

19

16

14

13

5

3

2

DIN1

DITOUT

DALRCK

DABCK

DADATA

ADLRCK

ADDATA

ADBCK

E

CDR ASSY

2

1

48

(DO)

1

48

30

36

(REC)

33

35

C

G

PWSB ASSY

D

13

5

6

7

8

Page 14

1

23

PDR-L77

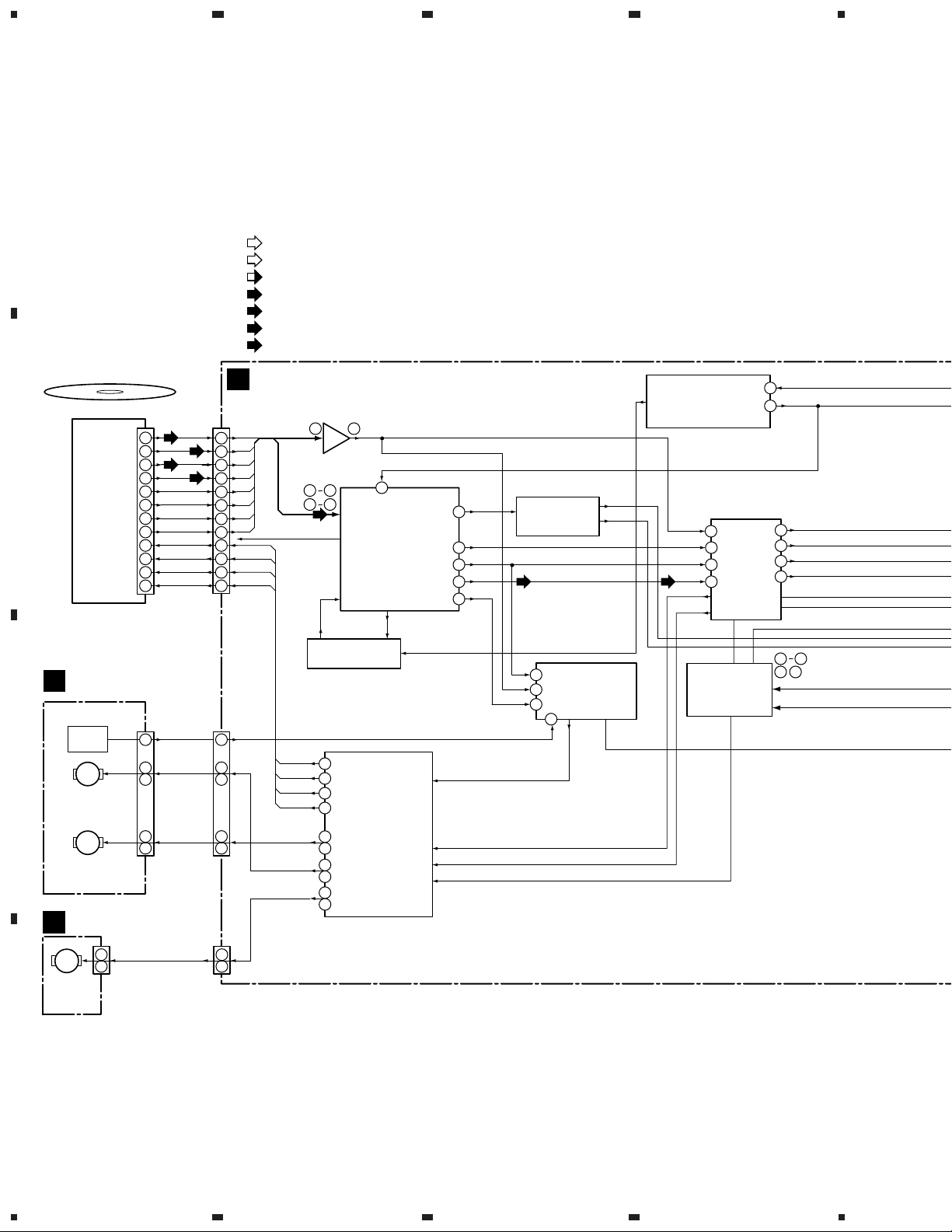

3.3 OVERALL WIRING DIAGRAM

4

A

PWSB ASSY

G

(KUXJ/CA : AWU7521)

PJB ASSY

F

(AWU7524)

CN7201 CN7704

CN7003 CN7202

(MYXJ, NVXJ : AWU7537)

B

CN7002

C

CN901

SERVO MECHANISM ASSY

B

(PWZ3759)

LOADING A ASSY

C

(PWZ3760)

LOADING B ASSY

D

D

(PWZ3761)

CN601

CN501

CN551

CN452

CN451

CN453

CD-R PICKUP

(PEA1351)

CN1

CN101

14

1234

Page 15

5

678

PDR-L77

Note : When ordering service parts, be sure to refer to "EXPLODED VIEWS and PAR TS LIST" or "PCB PARTS LIST".

FLDP ASSY

H

(AWU7522)

CN7502 CN7502

CDR ASSY

E

(AWM7486)

A

B

CN7702CN301

A

A 1/5- A 5/5

CD-R CORE ASSY

(PYY1273)

CN7701CN301

FRKB ASSY

I

(AWU7523)

J7501

C

CN7501

D

15

5

6

7

8

Page 16

1

PDR-L77

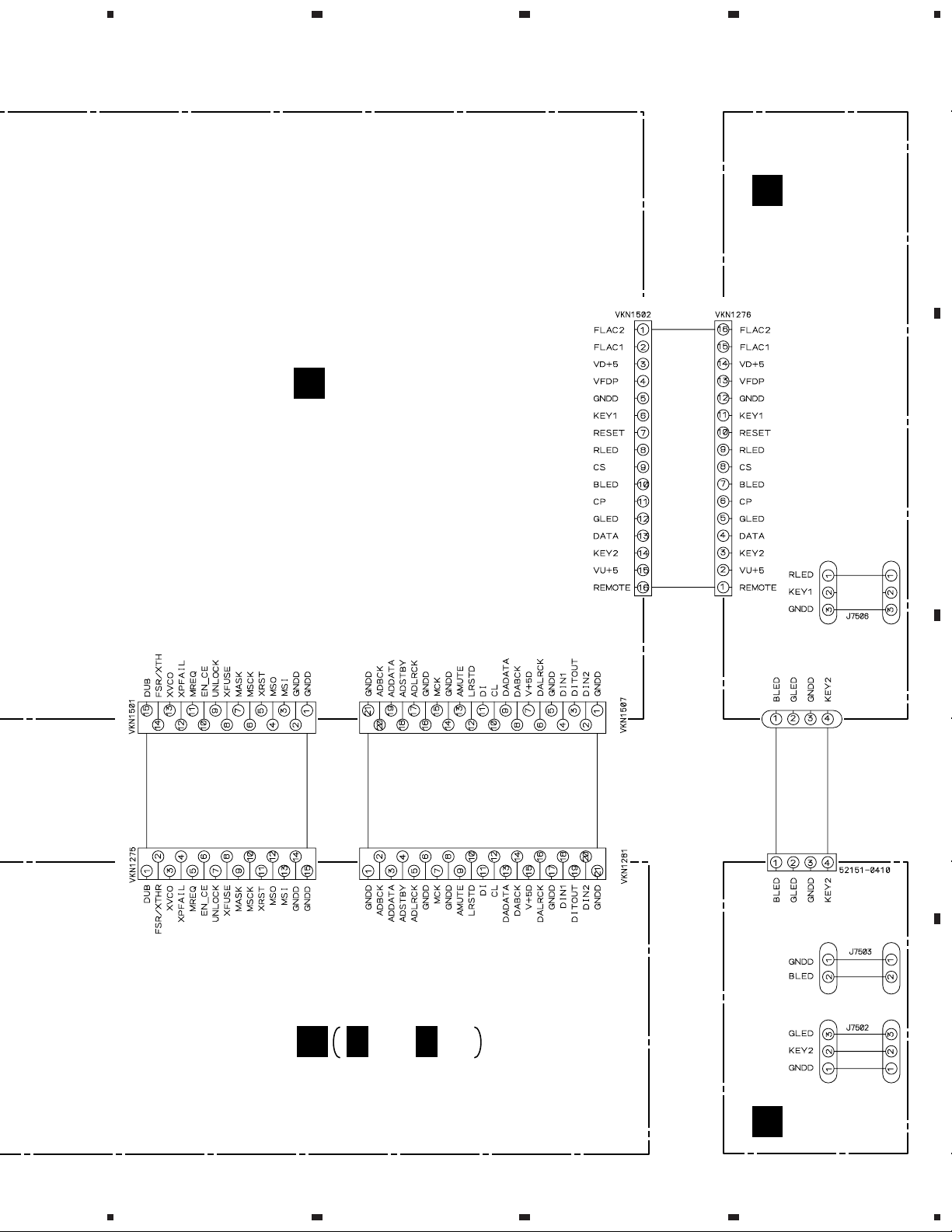

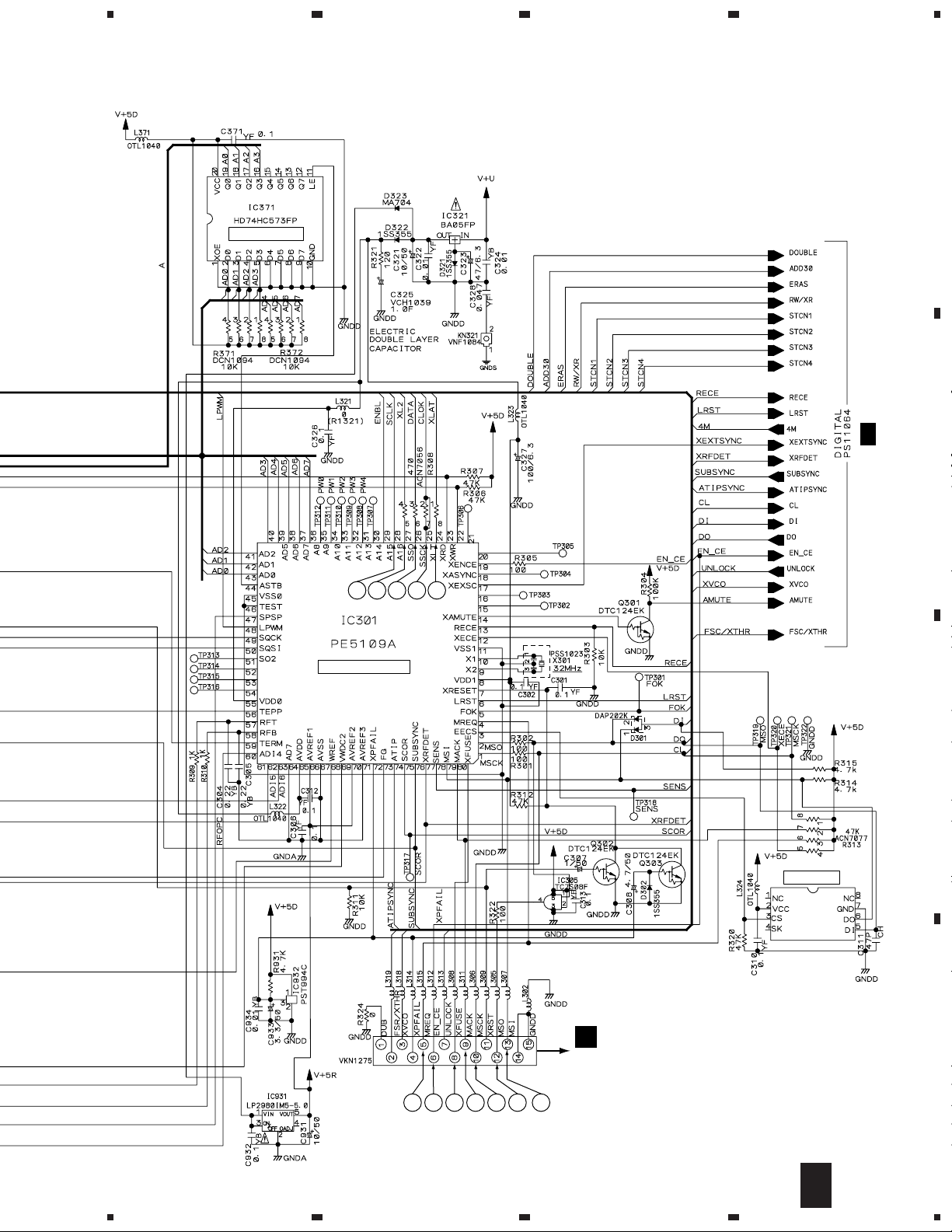

3.4 CD-R CORE ASSY (1/5)

23

4

A

A 1/5

CD-R CORE ASSY (PYY1273)

A 5/5

B

A 2/5

ATIP DECODER

C

A 3/5

D

16

1/5

A

1234

Page 17

5

8 bit LATCH

678

PDR-L77

A

A 4/5

B

8 9 10 11 12

MECHA µ-COM

CN301

L302,L305-L309,

L311-L315,L318,L319 :OTL1040

E

CN7702

EEPROM

IC303

PYY1196

(BR93LC46F)

C

D

1 2 3 4 5 6 7

1/5

A

5

6

7

8

17

Page 18

1

23

PDR-L77

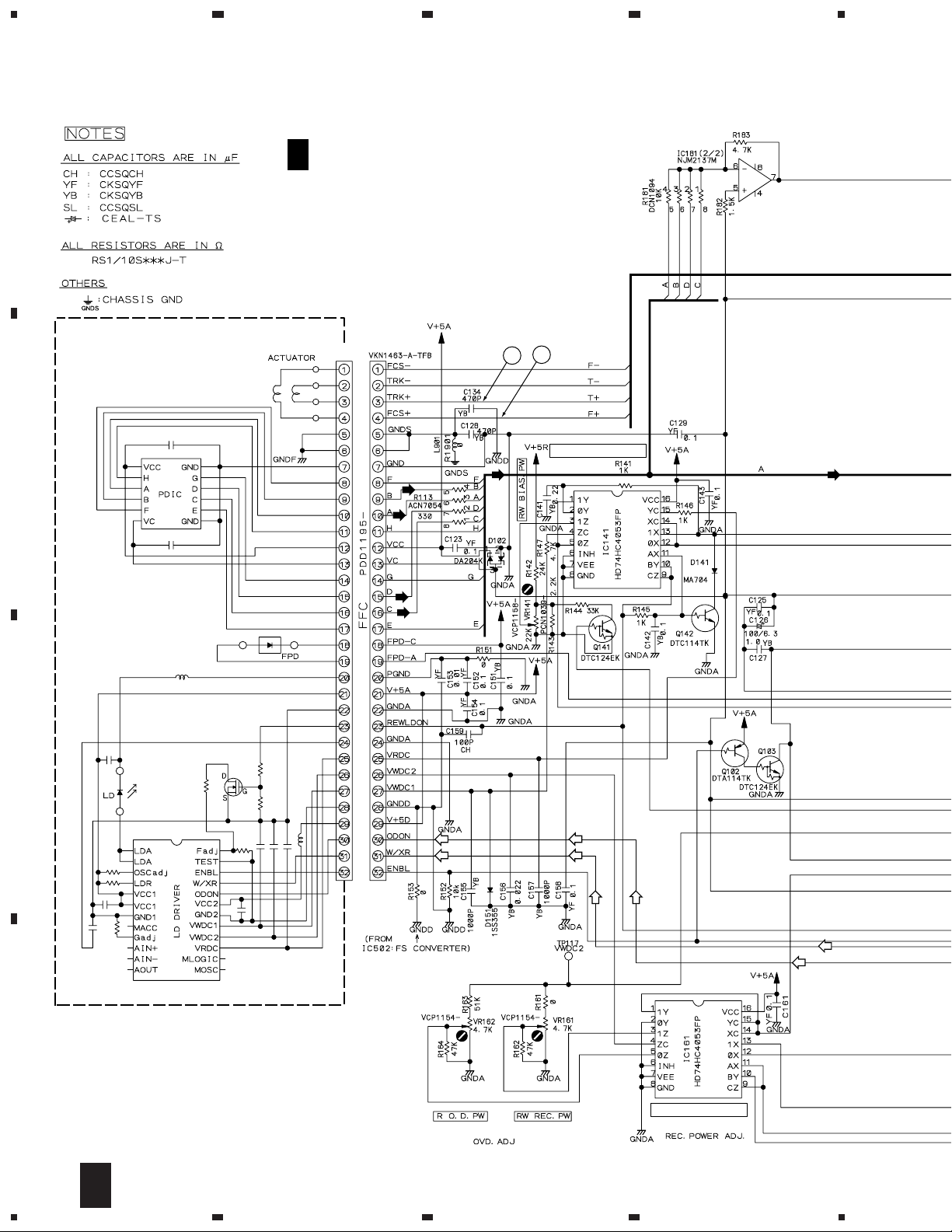

3.5 CD-R CORE ASSY (2/5) and CD-R PICKUP

4

A

A 2/5

CD-R PICKUP

(PEA1351)

B

CD-R CORE ASSY (PYY1273)

CN101

CN1

8

7

MULTI PLEXER

C

(REC)

(REC)

D

18

2/5

A

1234

(REC)

(REC)

(REC)

(REC)

MULTI PLEXER

(REC)

(REC)

Page 19

4

CN102

3

5

678

PDR-L77

: RF SIGNAL ROUTE

(REC)

: AUDIO SIGNAL ROUTE (REC)

A

A 3/5

1

2

5

A 5/5

B

(REC)

(REC)

RF PROCESSOR

(REC)

6

(REC)

(REC)

A 3/5

C

A 1/5

(REC)

A 4/5

D

2/5

A

5

6

7

8

19

Page 20

1

PDR-L77

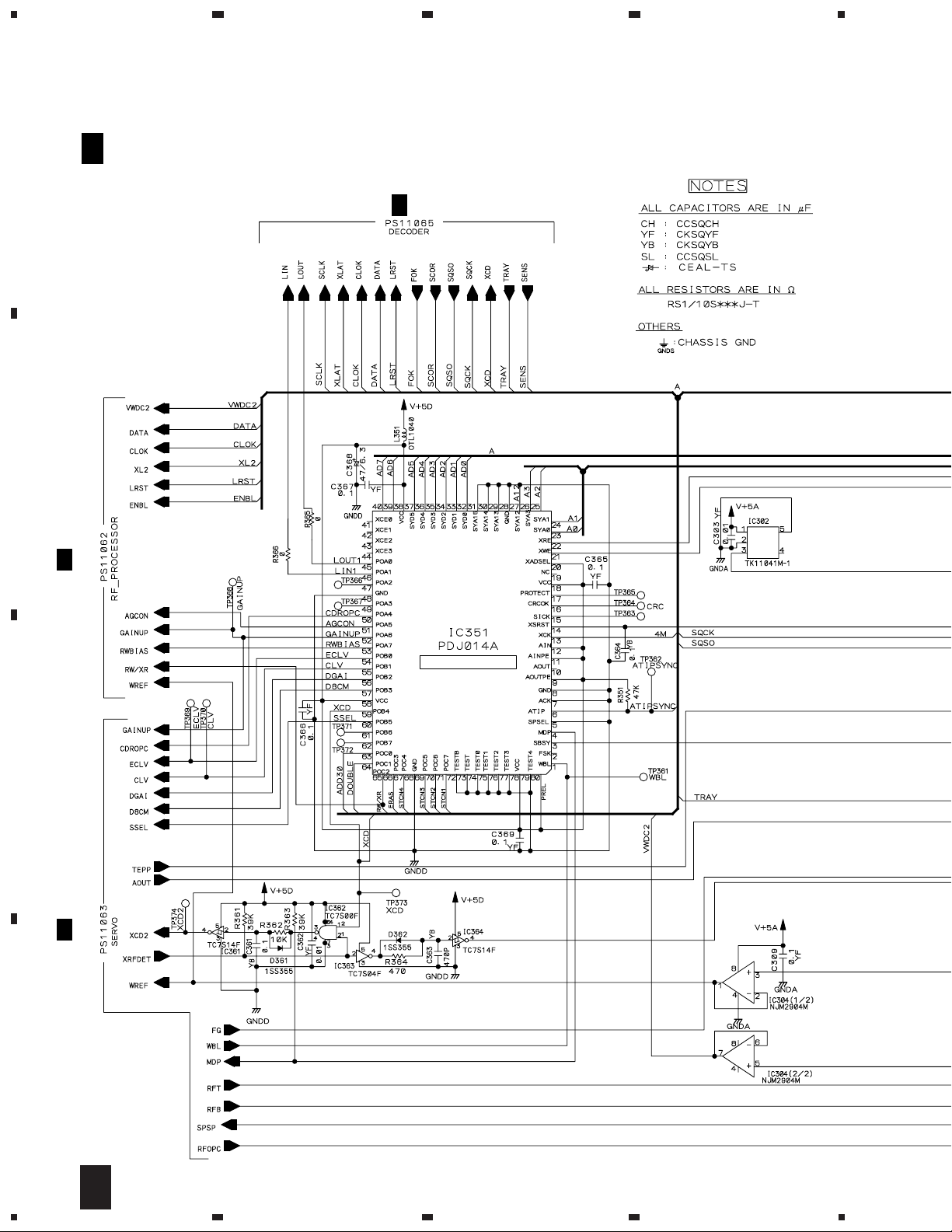

3.6 CD-R CORE ASSY (3/5)

23

4

A 3/5

A

CD-R CORE ASSY (PYY1273)

A 2/5

A 1/5

B

2

A 5/5

C

A 2/5

D

20

3/5

A

1234

Page 21

5

678

PDR-L77

A

A 1/5

A 4/5

CDR SERVO AMP

MULTI PLEXER

A 3/5

B

C

A 1/5

1

D

3/5

A

5

6

7

8

21

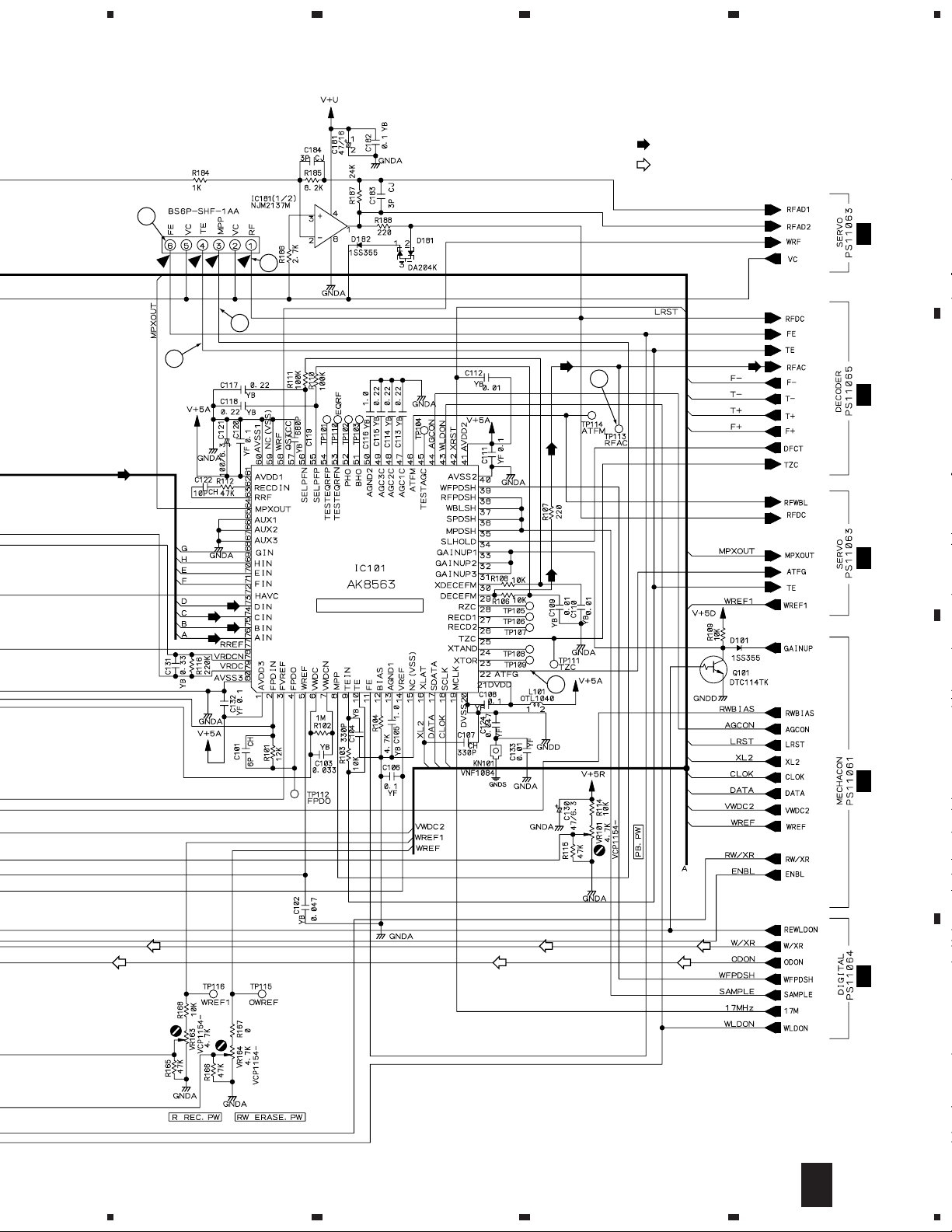

Page 22

1

A

PDR-L77

3.7 CD-R CORE ASSY (4/5)

23

4

A

A 4/5

CD-R CORE ASSY (PYY1273)

• DIGITAL BLOCK

D-R

VCO

A 3/5

(REC)

B

(REC)

13

EFM ENCODER IC

A 2/5

C

D

(REC)

(REC)

(REC)

17

(REC)

18

(REC)

15

16

14

(REC)

(REC)

STRATEGY

CONTROL

(REC)

(DI1)

(DI2)

22

4/5

A 1/5

A

1234

Page 23

D-RAM

5

678

PDR-L77

: AUDIO SIGNAL ROUTE

(REC)

: REC SIGNAL (after A/D)

(PB)

: PB OUT (before D/A)

(DI1)

: DIGITAL INPUT1

(DI2)

: DIGITAL INPUT2

(DO)

: DIGITAL OUT

: The power supply is shown with

the marked box.

A

(DO)

16.9344MHz

(REC)

FS CONVERTER

(PB)

(DO)

(REC)

(PB)

(REC)

(PB)

(REC)

VCO

B

CN501

E

12

10

11

1

2

3

4

5

6

7

8

9

C

(REC)

(REC)

(PB)

(DI1)

(D0)

(DI2)

(PB)(PB)

CN7701

A 5/5

MULTI PLEXER

5

6

L511-L513,L515-L518,

L522,L524,L526 : OTL1040

F510,F514,F520

F521,F527 : VTH1097

7

A

4/5

8

D

23

Page 24

1

23

4

PDR-L77

3.8 CD-R CORE (5/5), SERVO MECHANISM, LOADING A and LOADING B

ASSYS

A

A 5/5

CD-R CORE ASSY (PYY1273)

• DECODER BLOCK

A 3/5

5ch ACTUATOR DRIVER

CN453

B

CN451

CN452

1 2

3

C

CN501

S501

LOADING A

C

ASSY (PWZ3760)

LOADING B

D

ASSY (PWZ3761)

CN551

CARRIAGE MOTOR

ASSY (SLIDER)

CN601

D

PEA1350

DC MOTOR ASSY

(SPINDLE)

PEA1235

S601

SERVO MECHANISM

B

ASSY (PWZ3759)

LOADING MOTOR

ASSY

VXX2505

PC651

NJL5803K-F1

J601

A 2/5

24

5/5

A

1234

B C D

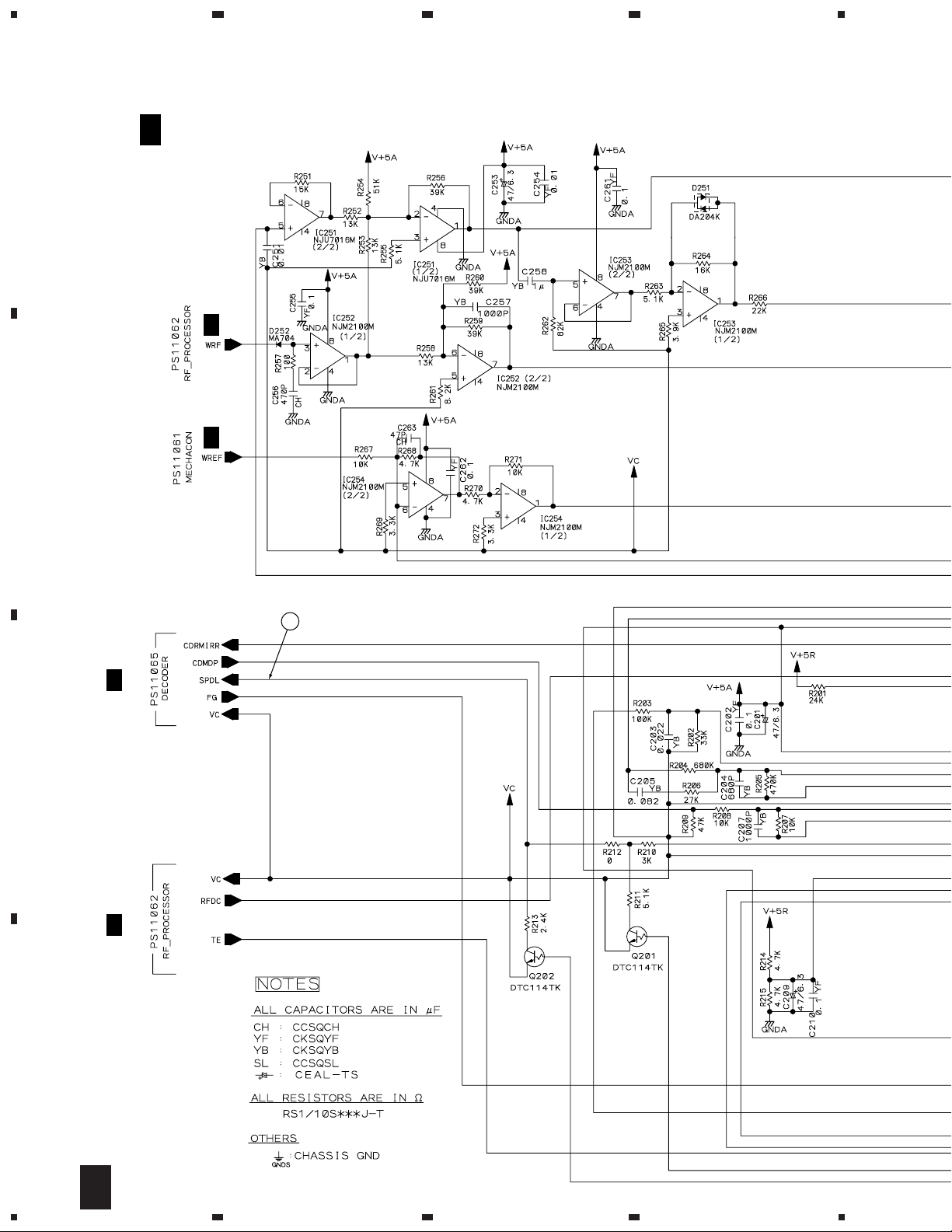

Page 25

5

678

PDR-L77

A 2/5

A

A 1/5

5

B

4

CD DECODER

CN901

A 4/5

C

CN7002

G

D

: RF SIGNAL ROUTE

: AUDIO SIGNAL ROUTE

: The power supply is shown with the marked box.

5

6

5/5

A

7

8

25

Page 26

1

PDR-L77

3.9 CDR ASSY

23

4

A

B

CDR ASSY

E

(AWM7486)

CN7704

(DI)

(DO)

(AR)

(PB)

(PB)(PB)

(PB)

(PB)

CN7201

F

(AR)

(AR)

C

CN7502

(AR)

CN7502

H

(REC)

D

26

1234

Page 27

(PB)

5

678

PDR-L77

SIGNAL ROUTE

(AR)

: ANALOG REC SIGNAL

(REC)

: REC SIGNAL (after A/D)

(PB)

(PB)

: PB OUT SIGNAL (before D/A)

(PB)

: PB OUT SIGNAL

(DI)

: DIGITAL INPUT SIGNAL

(DO)

: DIGITAL OUT SIGNAL

(REC)

A

(PB)

(DI1)

(PB)

(DO)

CN7701

CN7702

CN501CN301

A 4/5A 4/5

B

C

(REC)

D

27

5

6

7

8

Page 28

1

23

PDR-L77

3.10 PWSB and PJB ASSYS

4

A

PWSB ASSY

G

(KUXJ/CA : AWU7521)

(MYXJ, NVXJ : AWU7537)

(AI)

5.0

5.0

(PB)

B

10.3

FAN

-12.8

C

VEC-063

5.0

VEC-063

D

-26.9

• NOTE FOR FUSE REPLACEMENT

CAUTION -

FOR CONTINUED PROTECTION AGAINST RISK OF FIRE.

REPLACE WITH SAME TYPE AND RATINGS ONLY.

28

1234

Page 29

5

678

PDR-L77

A

SIGNAL ROUTE

(AI)

: ANALOG INPUT SIGNAL

(PB)

: PB OUT SIGNAL

(DI)

: DIGITAL INPUT SIGNAL

(DO)

: DIGITAL OUT SIGNAL

CN7002

CN901

E

CN7704

A 5/5

B

(AI)

-5.1

(PB)

CN7003

CN7201

CN7202

F

(AI)

(PB)

PJB ASSY

(AWU7524)

(AI)

(PB)

(DO)

(DI)

C

(DO)

(DI)

D

29

5

6

7

8

Page 30

1

PDR-L77

3.10 FLDP and FRKB ASSYS

A

FRKB ASSY

I

(AWU7523)

23

4

CN7501

B

CN7502

J7501

E

C

CN7502

D

FLDP ASSY

H

(AWU7522)

30

1234

Page 31

5

678

PDR-L77

A

B

64 63 62 61 60 59 58 57 56 55 54 53 52 51 50 49

148

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

FL DRIVER

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

C

D

31

5

6

7

8

Page 32

PDR-L77

VOLTAGES and WAVEFORMS

CD-R CORE ASSY

A 1/5

Media Pickup Position

12cm Inner 0V 0V

12cm Outer 5V 0V

CD

8cm Inner 0V 0V

8cm Outer 5V 0V

12cm Inner 5V 0V

CD-R

CD-RW

12cm Outer 5V 0V

8cm Inner 0V 5V

8cm Outer 5V 5V

at FS = 44 kHz

(at FS Converter through)

FSR/XTHR

(CN301-pin 2)

at DIGITAL LOCK at DIGITAL UNLOCK

XVCO

(CN301-pin3)

UNLOCK

(CN301-pin7)

XPFAIL

(CN301-pin4)

XRST

(CN301-pin11)

0V 5V

0V 5V

0V 5V

5V

5V

DGAI

(IC351-pin56)

D8CM

(IC351-pin57)

Others

−

−

Note :

The encircled numbers denote measuring point in the schematic diagram.

CD-R CORE ASSY

A 1/5

CN301 - pin 5 (MREQ)

1

V: 0.2V/div.(10 : 1) H: 5msec/div.

(STOP)

CN301 - pin 6 (EN_CE)

2

V: 0.2V/div.(10 : 1) H: 5msec/div.

(STOP)

CN301 - pin 8 (XFUSE)

3

V: 0.2V/div.(10 : 1) H: 5msec/div.

(STOP)

CN301 - pin 13 (MSI)

7

V: 0.2V/div.(10 : 1) H: 5msec/div.

(STOP)

IC301 - pin 28 (SCLK)

8

V: 2V/div. H: 2µsec/div.

(Disck Loading)

IC301 - pin 27 (XL2)

9

V: 0.2V/div.(10 : 1) H: 5msec/div.

(STOP)

CD-R CORE ASSY

A 3/5

Operating

Mode

CLV

(IC201-pin13)

ECLV

(IC201-pin14)

STOP 0V 0V

CAV 0V 5V

CLV 5V 0V

ECLV 5V 5V

CD-R CORE ASSY

A 4/5

A/D Converter used

ADSTBY

(CN501-pin4)

AMUTE

(CN501-pin9)

LRSTD

(CN501-pin10)

at Analog REC Pause

or REC

0V 5V

at MUTE ON

(Audio Signal Not Output)

5V 0V

5V −

Others

at MUTE OFF

(Audio Signal Output)

CN301 - pin 9 (MACK)

4

V: 0.2V/div.(10 : 1) H: 5msec/div.

(STOP)

CN301 - pin 10 (MSCK)

5

V: 0.2V/div.(10 : 1) H: 0.5µsec/div.

(PLAY)

CN301 - pin 12 (MSO)

6

V: 0.2V/div.(10 : 1) H: 5msec/div.

(STOP)

IC301 - pin 26 (DATA)

10

V: 0.2V/div.(10 : 1) H: 5msec/div.

(STOP)

IC301 - pin 25 (CLOK)

11

V: 0.2V/div.(10 : 1) H: 5msec/div.

(STOP)

IC301 - pin 24 (XLAT)

12

V: 0.2V/div.(10 : 1) H: 5msec/div.

(STOP)

32

Page 33

PDR-L77

CD-R CORE ASSY

A 2/5

CN102 - pin 1 (RF)

1

V: 20mV/div.(10 : 1) H: 0.5µsec/div.

(PLAY)

CN102 - pin 3 (MPP)

2

V: 10mV/div.(10 : 1) H: 2msec/div.

(PLAY)

CN102 - pin 4 (TE)

3

V: 5mV/div.(10 : 1) H: 2msec/div.

(PLAY)

TP113 (RFAC)

5

V: 0.2V/div.(10 : 1) H: 0.2µsec/div.

(PLAY)

IC101 - pin 22 (ATFG)

6

V: 0.2V/div. H: 20µsec/div.

(REC)

CN101 - pin 3 (TRK +)

7

V: 0.2V/div.(10 : 1) H: 5msec/div.

(STOP)

CD-R CORE ASSY

A 3/5

TP210 (FG)

1

V: 0.2V/div.(10 : 1) H: 1msec/div.

(PLAY)

Foot of R212 (SPDL)

2

V: 20mV/div. H: 2msec/div.

(PLAY)

CN102 - pin 6 (FE)

4

V: 5mV/div.(10 : 1) H: 2msec/div.

(PLAY)

CN101 - pin 4 (FCS +)

8

V: 0.2V/div.(10 : 1) H: 5msec/div.

(STOP)

33

Page 34

PDR-L77

CD-R CORE ASSY

A 4/5

CN501 - pin 2 (ADBCK)

1

V: 0.2V/div.(10 : 1) H: 0.2µsec/div.

(STOP)

CN501 - pin 3 (ADDATA)

2

V: 0.2V/div.(10 : 1) H: 0.2µsec/div.

(REC)

CN501 - pin 5 (ADLRCK)

3

V: 0.2V/div.(10 : 1) H: 10µsec/div.

(STOP)

CN501 - pin 14 (DABCK)

7

V: 0.2V/div.(10 : 1) H: 0.2µsec/div.

(STOP)

CN501 - pin 16 (DALRCK)

8

V: 0.2V/div.(10 : 1) H: 10µsec/div.

(STOP)

CN501 - pin 18 (DIN1)

9

V: 0.2V/div.(10 : 1) H: 0.2µsec/div.

(REC_OPTICAL)

IC501 - pin 88 (EFM)

13

V: 0.2V/div.(10 : 1) H: 0.5µsec/div.

(REC)

IC431 - pin 6 (17M)

14

V: 0.2V/div.(10 : 1) H: 50msec/div.

(REC)

IC431 - pin 25 (ODON)

15

V: 0.2V/div.(10 : 1) H: 0.1µsec/div.

(REC)

CD-R CORE ASSY

A 5/5

CN452 - pin 2 (SL +)

1

V: 0.2V/div.(10 : 1) H: 5msec/div.

(PLAY)

CN452 - pin 3 (SP +)

2

V: 0.2V/div.(10 : 1) H: 5msec/div.

(PLAY)

CN452 - pin 9 (FG)

3

V: 0.2V/div.(10 : 1) H: 1msec/div.

CN501 - pin 7 (MCK)

4

V: 0.1V/div.(10 : 1) H: 50msec/div.

(STOP)

CN501 - pin 12 (CL)

5

V: 0.2V/div.(10 : 1) H: 0.5µsec/div.

(STOP)

CN501 - pin 13 (DADATA)

6

V: 0.2V/div.(10 : 1) H: 0.5µsec/div.

(PLAY)

CN501 - pin 19 (DITOUT)

10

V: 0.2V/div.(10 : 1) H: 0.2µsec/div.

(STOP)

CN501 - pin 20 (DIN2)

11

V: 0.2V/div.(10 : 1) H: 0.2µsec/div.

(REC_Coaxial)

CN501 - pin 11 (DI)

12

V: 0.2V/div.(10 : 1) H: 5msec/div.

(STOP)

IC431 - pin 29 (WLDON)

16

V: 0.2V/div.(10 : 1) H: 1msec/div.

(REC)

IC431 - pin 34 (REWLDON)

17

V: 0.2V/div.(10 : 1) H: 1msec/div.

(REC)

TP503 (W/XR)

18

V: 0.2V/div.(10 : 1) H: 1msec/div.

(REC)

IC401 - pin 25 (MDP)

4

V: 0.2V/div.(10 : 1) H: 5µsec/div.

(PLAY)

IC401 - pin 25 (MDP)

V: 0.2V/div.(10 : 1) H: 5µsec/div.

(REC)

IC401 - pin 20 (MIRR)

5

V: 0.2V/div.(10 : 1) H: 20µsec/div.

(REC_CD-RW)

34

Page 35

1

234

4. PCB CONNECTION DIAGRAM

4.1 SERVO MECHANISM, LOADING A and LOADING B ASSYS

NOTE FOR PCB DIAGRAMS :

1. Part numbers in PCB diagrams match those in the schematic

diagrams.

2. A comparison between the main parts of PCB and schematic

diagrams is shown below.

Symbol In PCB

Diagrams

BCE

BCE

D

Symbol In Schematic

Diagrams

BCEBCE

BCE

BCE

DGGSS

DGS

Part Name

Transistor

Transistor

with resistor

Field effect

transistor

Resistor array

3-terminal

regulator

3. The parts mounted on this PCB include all necessary parts for

several destinations.

For further information for respective destinations, be sure to

check with the schematic diagram.

4. View point of PCB diagrams.

Connector

Capacitor

SIDE A

P.C.Board

Chip Part

SIDE B

PDR-L77

A

CARRIAGE

MOTOR

M

SPINDLE

MOTOR

SERVO

B

MECHANISM

ASSY

M

CN452

A

C

LOADING A

ASSY

SERVO

B

MECHANISM

ASSY

LOADING A

C

ASSY

B

C

LOADING B

D

ASSY

1

CN451

A

LOADING B

LOADING

MOTOR

D

ASSY

A

M

SIDE A SIDE B

2

CN453

(PNP1471-B)

3

D

DCB

4

35

Page 36

1

PDR-L77

4.2 CD-R CORE ASSY

A

CD-R CORE ASSY

A

B

23

• This PCB is a four-layered board.

4

D

CN551

C

CN501

B

CN601

J

CN21

E

CN804

To

CD-R

PICKUP

C

E

CN801

(PNP1465-B)

VR164

VR161 VR141 VR162 VR163 VR101

IC361-IC364 IC303 IC302 IC305IC931-IC933

IC351 IC371 IC301 IC304 IC503Q301

D

Q302 Q303 Q402 Q401 IC401 IC501 IC507 IC506IC352

IC451 IC201 IC502 IC509Q203 Q203IC251-IC254

Q201 IC101 Q142 IC562 IC431

36

SIDE A

A

1234

Page 37

1

234

PDR-L77

CD-R CORE ASSY

A

• This PCB is a four-layered board.

A

B

Q551 Q202 IC255

IC505 IC508 IC181

Q102 IC561 IC141 IC161

Q103 Q141

SIDE B

1

2

C

(PNP1465-B)

D

A

3

4

37

Page 38

1

PDR-L77

4.3 CDR ASSY

23

4

A

E

CDR ASSY

F

CN7201

SIDE A

A

CN501

B

C

D

A

CN301

H

CN7502

38

E

(ANP7336-B)

IC7451Q7423 Q7513

1234

Q7451

Q7454

Q7453

Q7101

Q7103

Q7104

Q7509–Q7511

IC7501

Q7512

Page 39

SIDE B

1

234

PDR-L77

A

E

CDR ASSY

B

(ANP7336-B)

1

Q7107

Q7508

Q7507

IC7101 Q7301

Q7105

IC7102

Q7505

Q7506

Q7502

Q7501

2

IC7301

Q7246

Q7245

3

Q7241

IC7241

IC7401

E

4

C

D

39

Page 40

1

PDR-L77

4.4 PJB ASSY

23

4

A

F

PJB ASSY

SIDE A

B

G

CN7003

(ANP7337-B)

F

PJB ASSY

E

CN7704

SIDE B

C

D

40

F

1234

Page 41

1

4.5 FRKB ASSY

234

PDR-L77

A

SIDE A

(ANP7337-B)

I

FRKB ASSY (1/3)

I

FRKB ASSY (2/3)

I

FRKB ASSY (3/3)

H

J7501

B

SIDE B

I

FRKB ASSY (1/3)

I

FRKB ASSY (3/3)

I

FRKB ASSY (2/3)

C

D

41

I

1

2

3

4

Page 42

1

PDR-L77

4.6 PWSB ASSY

A

Q7007

IC7005IC7006

B

G

PWSB ASSY

23

F

CN7202

A

CN901

4

SIDE A

Q7010

Q7008

DC FAN

MOTOR

(ANP7337-B)

C

IC7052

D

AC

POWER

CORD

42

G

1234

Page 43

SIDE B

1

234

PDR-L77

G

PWSB ASSY

Q7006

A

B

(ANP7337-B)

Q7009

C

Q7051

D

G

1

2

3

4

43

Page 44

A

B

1

PDR-L77

4.7 FLDP ASSY

I

CN7501

23

H

FLDP ASSY (1/2)

4

SIDE A

C

E

CN7502

D

44

H

1234

(ANP7337-B)

H

FLDP ASSY (2/2)

Page 45

SIDE B

1

234

PDR-L77

H

FLDP ASSY (1/2)

A

B

H

FLDP ASSY (2/2)

1

(ANP7337-B)

2

C

D

H

3

4

45

Page 46

PDR-L77

5. PCB PARTS LIST

NOTES : Parts marked by “ NSP ” are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

When ordering resistors, first convert resistance values into code form as shown in the following examples.

Ex. 1 When there are 2 effective digits (any digit apart from 0), such as 560 ohm and 47k ohm (tolerance is shown by

J = 5%, and K = 10%).

560 Ω = 56 × 10

47k Ω = 47 × 10

0.5 Ω = R50 ...................................................................... RN2H Â 5 0 K

1 Ω = 1R0 ......................................................................... RS1P 1 Â 0 K

Ex. 2 When there are 3 effective digits (such as in high precision metal film resistors).

5.62k Ω = 562 × 10

LIST OF WHOLE PCB ASSEMBLIES

Mark Symbol and Desacription

CD-R CORE ASSY

NSP

MECHANISM ASSY

NSP

SERVO MECHANISM ASSY

NSP

LOADING A ASSY

NSP

LOADING B ASSY

1

= 561................................................... RD1/4PU 5 6 1 J

3

= 473 .................................................. RD1/4PU 4 7 3 J

1

= 5621 ........................................... RN1/4PC 5 6 2 1 F

Part No.

KUXJ/CA type MYXJ type NVXJ type

PYY1273

PWX1570

PWZ3759

PWZ3760

PWZ3761

PYY1273

PWX1570

PWZ3759

PWZ3760

PWZ3761

PYY1273

PWX1570

PWZ3759

PWZ3760

PWZ3761

Remarks

NSP

CDR ASSY

NSP

COMPLEX ASSY

PJB ASSY

PWSB ASSY

FLDPASSY

FRKB ASSY

AWM7486

AWM7496

AWU7524

AWU7537

AWU7522

AWU7523

AWM7486

AWM7487

AWU7524

AWU7521

AWU7522

AWU7523

AWM7486

AWM7487

AWU7524

AWU7521

AWU7522

AWU7523

Mark No. Description Part No. Mark No. Description Part No.

IC301 PE5109B

CD-R CORE ASSY

SEMICONDUCTORS

IC502 AD1893JST

IC101 AK8563

IC321 BA05FP

IC561 BA7082F

IC303 (BR93LC46F) PYY1196

IC401 CXD2585Q

IC141, IC161, IC255, IC508 HD74HC4053FP

IC371 HD74HC573FP

IC501 LC89585

IC503 LH64256CK-70

IC931 LP2980IM5-5.0

IC451 M56788FP

IC252–IC254 NJM2100M

IC181 NJM2137M

IC304 NJM2904M

IC932 PST994C

IC362 TC7S00F

IC363, IC562 TC7S04F

IC305, IC509 TC7S08F

IC361, IC364 TC7S14F

IC302 TK11041M-1

Q102 DTA114TK

Q204, Q401, Q402 DTA124EK

Q551 DTA143EK

Q101, Q142, Q201–Q203 DTC114TK

Q103, Q141, Q301–Q303 DTC124EK

D101, D151, D182, D201, D302 1SS355

D321, D322, D361, D362 1SS355

D102, D181, D202, D251 DA204K

D551 DAN202K

D301 DAP202K

D141, D252, D323 MA704

D204 UDZ3.0B

IC251 NJU7016M

IC201 PA9007A

IC507 PCX1026

IC351 PDJ014A

IC431 PDK041A

46

Page 47

PDR-L77

Mark No. Description Part No. Mark No. Description Part No.

COILS AND FILTERS

L434, L505 CHIP COIL DTL1058

L101, L302, L305–L309 OTL1040

CHIP SOLID INDUCTOR

L311–L315, L318, L319 OTL1040

CHIP SOLID INDUCTOR

L322–L324, L351, L371 OTL1040

CHIP SOLID INDUCTOR

L511–L513, L515–L518, L522 OTL1040

CHIP SOLID INDUCTOR

L524, L526 OTL1040

CHIP SOLID INDUCTOR

L568 CHIP SOLID INDUCTOR QTL1015

F401, F403, F432, F433 VTF1097

CHIP SOLID INDUCTOR

F501–F504, F506–F508, F510 VTF1097

CHIP SOLID INDUCTOR

F514, F520, F521, F527 VTF1097

CHIP SOLID INDUCTOR

F551, F552, F561 VTF1097

CHIP SOLID INDUCTOR

CAPACITORS

C122, C507

C159, C434, C551, C564 CCSQCH101J50

C508 CCSQCH120J50

C563 CCSQCH160J50

C406 CCSQCH221J50

C107, C404 CCSQCH331J50

C263, C311 CCSQCH470J50

C213, C256, C408 CCSQCH471J50

C418 CCSQCH681J50

C101

C518 CCSQCH820J50

C183, C184

C480–C482 CCSQSL471J50

C321, C465, C931 CEAL100M50

C121, C126, C327, C401, C409 CEAL101M6R3

C417, C901, C902 CEAL101M6R3

C307 CEAL1R0M50

C216 CEAL2R2M50

C933 CEAL3R3M50

C181, C452, C477, C903 CEAL470M16

C130, C201, C209, C211, C253 CEAL470M6R3

C323, C368, C431, C502, C512 CEAL470M6R3

C515, C520, C553, C559, C566 CEAL470M6R3

C308 CEAL4R7M50

C155, C157, C207, C233, C257 CKSQYB102K50

C403, C407, C501, C517 CKSQYB102K50

C109, C110, C112, C230, C231 CKSQYB103K50

C251, C324, C412, C454–C459 CKSQYB103K50

C470–C473, C505, C510, C558 CKSQYB103K50

C567, C934 CKSQYB103K50

CCSQCH100D50

CCSQCH6R0D50

CCSQCJ3R0C50

C208, C414 CKSQYB152K50

C451 CKSQYB182K50

C156, C203 CKSQYB223K50

C113–C115, C117, C118 CKSQYB224K16

C304, C305, C460, C462 CKSQYB224K16

C212 CKSQYB272K50

C104, C221 CKSQYB331K50

C103 CKSQYB333K50

C131, C215, C227–C229 CKSQYB334K16

C128, C134, C363, C474, C475 CKSQYB471K50

C206, C413 CKSQYB473K25

C102 CKSQYB473K50

C119, C204, C468, C469 CKSQYB681K50

C463, C464 CKSQYB682K50

C205 CKSQYB823K25

C133, C153, C254, C303, C322 CKSQYF103Z50

C362, C416, C433, C519 CKSQYF103Z50

C521, C522, C555, C561, C562 CKSQYF103Z50

C568, C569, C905 CKSQYF103Z50

C106, C108, C111, C120, C123 CKSQYF104Z25

C125, C129, C132, C143, C152 CKSQYF104Z25

C154, C158, C161, C202, C210 CKSQYF104Z25

C214, C217, C255, C260–C262 CKSQYF104Z25

C301, C302, C306, C309, C310 CKSQYF104Z25

C312, C313, C326, C365–C367 CKSQYF104Z25

C369, C371, C402, C405 CKSQYF104Z25

C410, C411, C415, C432 CKSQYF104Z25

C466, C467, C503, C506, C509 CKSQYF104Z25

C511, C513, C516, C523, C552 CKSQYF104Z25

C554, C560, C565 CKSQYF104Z25

C124, C328, C570, C904 CKSQYF473Z25

C325 (1F/5.5V) VCH1039

RESISTORS

R113, R441, R442, R514 (330Ω) ACN7054

R308, R417 (470Ω) ACN7056

R313 (47kΩ) ACN7077

R401, R416, R433 (100Ω) DCN1092

R507 (220Ω) DCN1093

R181, R371, R372, R501 (10kΩ) DCN1094

R570 (0Ω) DCN1106

R143 (2.2kΩ) PCN1039

VR101, VR161–VR164 (4.7kΩ) VCP1154

VR141 (22kΩ) VCP1158

Other Resistors RS1/10S&&&J

OTHERS

CN453 CONNECTOR POST B2B-PH-K-S

CN451 CONNECTOR POST B3B-PH-K-S

CN901 CONNECTOR S6B-PH-K-S

CN301 15P CONNECTOR VKN1275

CN501 21P CONNECTOR VKN1281

C142, C151, C182, C224–C226 CKSQYB104K25

C361, C364, C453, C476, C504 CKSQYB104K25

C932 CKSQYB104K25

C105, C116, C127, C232, C258 CKSQYB105K10

C514, C557 CKSQYB105K10

CN101 32P CONNECTOR VKN1463

KN101, KN321, KN501, KN901 VNF1084

EARTH METAL FITTING

X501 (16.9344MHz) PSS1008

X301 (32.00MHz) PSS1023

47

Page 48

PDR-L77

Mark No. Description Part No. Mark No. Description Part No.

CAPACITORS

SERVO MECHANISM ASSY

SEMICONDUCTORS

PC651 NJL5803K-F1

SWITCHES AND RELAYS

S601 PSG1013

RESISTORS

All Resistors RD1/4PU&&&J

OTHERS

J601 3P JUMPER WIRE D20PWW0305E

CN601 CONNECTOR POST S9B-PH-K-S

LOADING A ASSY

SWITCHES AND RELAYS

501 VSK1011

OTHERS

CN501 CONNECTOR POST S3B-PH-K-S

LOADING B ASSY

OTHERS

CN551 CONNECTOR POST B2B-PH-K-S

CDR ASSY

C7101, C7102, C7117, C7118 CCSRCH101J50

C7413, C7414, C7507, C7516 CCSRCH101J50

C7103, C7104 CCSRCH220J50

C7107, C7108 CCSRCH470J50

C7105, C7106, C7109, C7110 CEV100M16

C7119, C7120, C7241, C7242, C7504 CEV100M16

C7253, C7254 CEV100M35

C7243, C7244 CEV100M50

C7306, C7311, C7402, C7407 CEV101M6R3

C7411, C7412, C7509 CEV101M6R3

C7301, C7302 CEV2R2M50

C7111, C7112, C7121 CEV330M6R3

C7303, C7304, C7403, C7404 CEV4R7M35

C7409 CKSRYB102K50

C7313, C7505, C7508, C7512, C7513 CKSRYB103K50

C7597, C7598 CKSRYB103K50

C7307, C7308 CKSRYB471K50

C7249–C7252 CKSRYB681K50

C7113, C7114, C7305, C7309, C7310 CKSRYF104Z25

C7312, C7401, C7405, C7406, C7408 CKSRYF104Z25

C7410, C7416, C7451, C7506 CKSRYF104Z25

C7510, C7511, C7514 CKSRYF104Z25

RESISTORS

R7545 RS1/10S0R0J

R7129, R7130, R7267, R7268 RS1/8S330J

Other Resistors RS1/16S&&&J

OTHERS

CN7702 15P CONNECTOR VKN1501

CN7502 16P CONNECTOR VKN1502

CN7701 21P CONNECTOR VKN1507

CN7704 25P CONNECTOR VKN1511

X7501 (4.19MHz) DSS1105

SEMICONDUCTORS

IC7101,IC7102,IC7241 BA4558F-HT

IC7401 PCM1716E

IC7301 PCM1800-1

IC7501 PE5138A

IC7451 TC7SU04F

Q7501, Q7502 2SA1576A

Q7103, Q7104, Q7503 2SC4081

Q7107, Q7246, Q7506, Q7507 DTA124EU

Q7512, Q7513 DTA124EU

Q7301, Q7451, Q7504, Q7508 DTC124EU

Q7101, Q7105, Q7241 UMX1N

D7301, D7401 1SS184

D7101, D7102, D7403, D7404, D7501 1SS355

D7241, D7302, D7402 DAP202K

COILS AND FILTERS

L7301, L7401, L7501 OTL1040

CHIP SOLID INDUCTOR

48

PJB ASSY

COILS AND FILTERS

L7601 LFA100J

CAPACITORS

C7611, C7612 CEAT100M50

C7602 CEAT101M10

C7601, C7604 CKSQYB103K50

RESISTORS

All Resistors RS1/10S&&&J

OTHERS

JA7601 OPTICAL RECEIV MOD. GP1F37R

CN7202 20P SOCKET KP200IB20L

JA7602 OPTICAL OUTPUT JACK TOTX178

7002 PCB BINDER VEF1040

CN7201 25P CONNECTOR VKN1201

Page 49

PDR-L77

Mark No. Description Part No. Mark No. Description Part No.

T7001 STANDBY TRANSFORMER ATT7049

PWSB ASSY

(1) CONTRAST TABLE

AWU7537 and AWU7521 are constructed the same except

for the following :

AKP7032

ATT7049

Part No.

BKP1046

ATT7056

Remarks

Mark

Symbol and

Description

AN101 POWER SOCKET

T7001 STANDBY TRANS.

AWU7537 AWU7521

(2) PARTS LIST FOR AWU7537

SEMICONDUCTORS

IC7005,IC7006 BA05T

IC7052 NJM78M05FA

Q7006, Q7009 2SA1037K

Q7008 2SB1238X

Q7011, Q7051 2SC2412K

CN7001 CONNECTOR POST B2B-PH-K-S

CN7002 CONNECTOR B6B-PH-K-S

SCREW BBZ30P080FCC

JA7201, JA7202 JACK BKB1017

J7001 6P JUMPER WIRE D20PYY0605E

CN7003 20P PLUG KM200IB20

JA7603 JACK RKN1026

7003 PCB BINDER VEF1040

KN7001 EARTH METAL FITTING VNF1084

FLDP ASSY

SEMICONDUCTORS

IC7551 MSM9202-01

D7510 1SS355

D7554

SLR-343VC(NPQ)

Q7007, Q7010 2SD1858X

D7005, D7006, D7010, D7055–D7057 1SS355

D7001 D3SBA20(B)

D7013, D7014 MTZJ6.8B

D7051 S1WB(A)60SD

D7012 S5566G(TPB2)

D7009 UDZ4.7B

COILS AND FILTERS

L7001 LINE FILTER ATF7024

SWITCHES AND RELAYS

RY7001 ASR7018

CAPACITORS

C101, C7023 (10000pF/AC250V) ACG7033

C7203–C7210 CCSQCH101J50

C7006, C7015, C7016, C7022, C7053 CEAT100M50

C7009, C7011 CEAT101M10

C7052 CEAT102M16

C7013 CEAT221M50

C7002 CEAT471M16

C7608, C7609 CKSQYB102K50

C7012, C7021 CKSQYB103K50

C7201, C7202, C7606 CKSQYF104Z25

C7020 CQMA103K2E

C7018, C7019, C7051 CQMBA103J50

C7007(6800µF/16V) VCH1060

RESISTORS

R7010 RD1/4VM123J

R7026 RFA1/4PL4R7J

Other Resistors RS1/10S&&&J

COILS AND FILTERS

L7501 LCTB100K2125

SWITCHES AND RELAYS

S7501–S7504, S7506 ASG7013

CAPACITORS

C7564, C7567, C7568, C7574 CCSQCH101J50

C7565 CCSQCH470J50

C7555 CEJA100M50

C7561 CEJA101M6R3

C7571 CEJA470M6R3

C7573, C7580 CKSQYB103K50

C7551, C7553 CKSQYB473K50

C7563, C7569 CKSQYF104Z25

C7566 CKSQYF104Z50

RESISTORS

All Resistors RS1/10S&&&J

OTHERS

3P CABLE HOLDER 51048-0300

4P CABLE HOLDER 51048-0400

12P CABLE HOLDER 51048-1200

13P CABLE HOLDER 51048-1300

V7001 FL TUBE AAV7074

FL SPACER AEB7069

J7506 JUMPER WIRE D20PYY0305E

J7501 JUMPER WIRE D20PYY0405E

7551 REMOTE RECEIVER UNIT GP1U26X

CN7502 16P CONNECTOR VKN1276

OTHERS

6P CABLE HOLDER 51048-0600

1, 2 COVER AEC-294

AN101 POWER SOCKET AKP7032

H101, H102 FUSE CLIP AKR7001

7005, 7006 HEAT SINK M ANH-697

49

Page 50

PDR-L77

Mark No. Description Part No.

FRKB ASSY

SEMICONDUCTORS

D7552 EB3804X(BCDE)

D7555

D7553 UDZS8.2B

SWITCHES AND RELAYS

S7505, S7507 ASG7013

RESISTORS

All Resistors RS1/10S&&&J

OTHERS

3P CABLE HOLDER 51048-0300

CN7501 4PJUMPER CONNECTOR 52151-0410

J7503 JUMPER WIRE D20PYY0210E

J7502 JUMPER WIRE D20PYY0325E

SLR-343MC(NPQ)

50

Page 51

6. ADJUSTMENT

PDR-L77

6.1 DISCS TO BE USED

1. When adjusting the servo system adjustment

CD : Test disc for adjustment (STD-903 or equivalent)

6.2 JIGS AND MEASURING

INSTRUMENTS

(1) Laser Power Meter

Following power meter manufactured by Advantest Corporation

or equivalent :

TQ8210 + TQ82017

TQ8215 + TQ82021

TQ8215 + TQ82010 + TQ82017

LE8010 (by LEADER)

(2) Oscilloscope

(3) CD Jitter Meter

(4) Remote control supplied with PDR-L77 (AXD7242)

[(5)LD service remote control (GGF1067)]

6.3 TEST MODE

6.3.1 Test Mode

For adjustment, set the unit to Test mode. To enter Test mode, turn

on the unit with the Test Mode Short-Circuit pattern on the CDR

Assy. In Test mode, the display (FL) on the unit lights as follows.

0 00 00´00´´

If not, turn the power off and repeat the same steps again.

6.3.2 Operations in Test Mode

Please use the remote control provited with the PDR-L77(AXD7242)

or the LD service remote control(GGF1067).

In Test mode, the following adjustment functions are assigned to

the buttons, as explained below.

7 During adjustment of LD power

(“DIGITAL” segment does not light this time)

COMPACT DISC RECORDER

ERASE button

(TV/LDP button)

: Switching CD/CD-R/CD-RW

(STOP/OPEN CLOSE button)

INPUT SELECTOR button

STOP button

: LD off

(DIG/ANA button)

: Test mode switch

Fig.2 During adjustment of LD power

REMOTE CONTROL UNIT

CU–PD113

Î

@ STANDBY/ON

FADER

FINALIZE

DIGITAL

AUTO/

ERASE

SYNCHRO

SELECTOR

PROGRAM

MANUAL

&

*#

!

⁄

INPUT

SKIP PLAY

SET CLEAR

1526374

9

10/0 >10

CHECK

CLEAR

• ‡

TRACK NO.

WRITE

TIME

$›

SKIP ID

REPEAT

RANDOM

REC MUTE button

(SIDE B button)

: LD on 2

REC

RECORD button

(SIDE A button)

: LD on 1

1, ¡ button

(4, ¢ button)

: Sled move

8

AXD7242

(The button shown in

corresponds in GGF1067.)

CDR ASSY

SIDE B

Fig. 1 Enter the Test mode

Short-circuit

7 During adjustment of servo system

(“DIGITAL” segment lights this time)

FINALIZE button

(REP. A button)

: Focus in

ERASE button

(TV/LDP button)

: Adjustment value decision

DIGITAL SYNCHRO button

(STILL STEP e button)

: Adjustment value decision

(STOP/OPEN CLOSE button)

INPUT SELECTOR button

STOP button

: Stop

PAUSE button

(PAUSE button)

: Tracking servo close

(DIG/ANA button)

: Test mode switch

1, ¡ button

(4, ¢ button)

: Sled move

Fig.3 During adjustment of servo system

COMPACT DISC RECORDER

REMOTE CONTROL UNIT

CU–PD113

Î

@ STANDBY/ON

FINALIZE

FADER

DIGITAL

SYNCHRO

SELECTOR

PROGRAM

AUTO/

ERASE

MANUAL

&

*#

!

⁄

INPUT

SKIP PLAY

SET CLEAR

1526374

9

10/0 >10

CHECK

CLEAR

• ‡

REC

TRACK NO.

WRITE

TIME

$›

SKIP ID

8

REPEAT

RANDOM

REC MUTE button

(SIDE B button)

: Adjustment

RECORD button

(SIDE A button)

: Adjustment

AUTO/MANUAL,

TRACK No. WRITE button

(CX button)

: Servo adjustment mode switch

PLAY button

(PLAY button)

: Spindle kick

CLEAR button

(X3 3 button)

: Adjustment value initialization

BET button

(TV/LDP button)

: Adjustment value decision

AXD7242

(The button shown in

corresponds in GGF1067.)

51

Page 52

PDR-L77

6.4 ADJUSTMENT 1 (LASER DIODE POWER ADJUSTMENT)

CD-R CORE ASSY

RW ERASE

VR164

VR141

RW BIAS

VR161

RW REC

VR162

R O.D.

VR163

R REC

VR101

PB. PW

CN102

6

1

1 : RF

2 : VC

3 : MPP

4 : TE

5 : VC

6 : FE

CD-R overdrive

CD-R record

power

Playback power

Playback CD-R recording

CD-RW erase

power

CD-RW record power

CD-RW bias

power

CD-RW recording

Fig.5 Output power of the laser diode

Note 1 : Attach the remote sensor of the laser power meter to a

Note 2 : When adjusting with VRs, first turn them completely

Note 3 : The wave length setting of the laser power meter is

assumed to be 780nm.

point angled away about 10 degrees against the pickup

lens and where the maximum power is detected, so that

there will be no light reflected onto the pickup.

counter-clockwise and then adjust clockwise, so that the

value to be reached is not exceeded.

Fig. 4 Adjustment points

DANGER – LASER RADIATION WHEN OPEN.

6.4.1 Playback Power Adjustment

Test Point

Adjustment Point

Adjustment Value

[Procedure]

(1) Check that "CD" is displayed on the FL display. If "CD-R" or "CD-RW" is displayed, press the ERASE button repeatedly until "CD" is

displayed.

(2) Press the RECORD button.

(3) Press the REC MUTE button. The LED for confirmation of LD emission will light in red. The LD is emitting in this status.

(4) Turn VR101 clockwise until the adjustment value to be reached is obtained.

(5) Press the STOP button to shut off the LD.

Pickup objective lens

VR101 (PB. PW)

0.60 mW ± 0.05 mW

AVOID DIRECT EXPOSURE TO BEAM.

52

Page 53

6.4.2 CD-R Record Power Adjustment

PDR-L77

DANGER – LASER RADIATION WHEN OPEN.

AVOID DIRECT EXPOSURE TO BEAM.

Test Point

Adjustment Point

Adjustment Value

Pickup objective lens

VR163 (R REC), VR162 (R O.D.)

VR163 : 4.60 mW ± 0.1 mW

VR162 : Addition of 0.1 mW ± 0.01 mW to the adjustment value of VR163

[Procedure]

(1) Turn VR163 and VR162 completely counterclockwise to set their power output to minimum.

(2) Press the ERASE button once so that "CD-R" appears on the FL display.

If the indication is "CD" or "CD-RW," press the ERASE button repeatedly until "CD-R" is displayed on the FL display.

(3) Press the RECORD button.

(4) Press the REC MUTE button. The LED for confirmation of LD emission will light in red. The LD is emitting in this status.

Adjustment of CD-R record power

(5) Turn VR163 clockwise until the adjusted value is 4.60 mW ± 0.1 mW.

Adjustment of CD-R overdrive power

(6) Turn VR162 clockwise until the adjusted value becomes adjustment value at Step 5 above + (0.1 mW ± 0.01 mW).

(7) Press the STOP button to shut off the LD.

DANGER – LASER RADIATION WHEN OPEN.

6.4.3 CD-RW Record Power Adjustment

AVOID DIRECT EXPOSURE TO BEAM.

Test Point

Adjustment Point

Adjustment Value

Pickup objective lens

VR141 (RW BIAS), VR161 (RW REC), VR164 (RW ERASE)

VR141 : 0.40 mW ± 0.05 mW

VR161 : 2.00 mW ± 0.1 mW

VR164 : 5.70 mW ± 0.1 mW

[Procedure]

(1) Turn VR141, VR161 and VR164 completely counterclockwise to set their power output to minimum.

(2) Press the ERASE button twice so that "CD-RW" appears on the FL display.

If the indication is "CD" or "CD-R," press the ERASE button repeatedly until "CD-RW" appears on the FL display.

(3) Press the RECORD button.

(4) Press the REC MUTE button. The LED for confirmation of LD emission will light in red. The LD is emitting in this status.

Adjustment of BIAS power

(5) Turn VR141 clockwise until the adjusted value is 0.40 mW ± 0.05 mW.

Adjustment of CD-RW record power

(6) Turn VR161 clockwise until the adjusted value is 2.00 mW ± 0.1 mW.

Adjustment of CD-RW erase power

(7) Turn VR164 clockwise until the adjusted value is 5.70 mW ± 0.1 mW.

(8) Press the STOP button to shut off the LD.

53

Page 54

PDR-L77

6.5 ADJUSTMENT 2 (SERVO SYSTEM ADJUSTMENT)

CD-R CORE ASSY

For servo adjustment, set the INPUT SELECTOR to DIGITAL.

“DIGITAL” segment lights this time.

INPUT

SELECTOR

Use the RECORD button and the REC MUTE button to make

the adjustments.

• ‡

To register an adjustment, press the SET button.

SET

REC

SKIP ID

CN102

1 : RF

2 : VC

3 : MPP

4 : TE

5 : VC

6 : FE

6

1

To reset the adjusted values to the initial settings, press and hold the

CLEAR button for 4 seconds.

SKIP ID

CLEAR

Fig. 6 Adjustment points

6.5.1 Focus Offset Adjustment

Test Point

Adjustment Point

Adjustment Value 0 mV ± 10 mV

Symptom when out of

adjustment

[Procedure]

(1) Press the AUTO/MANUAL button until "01 F4" appears on the FL display.

(2) Adjust with the RECORD button and the REC MUTE button until the value for Pin 6 of CN102 is 0 mV ± 10 mV.

(3) Press the SET button to register the adjustment.

Once the adjustment is registered with the SET button, "D.VOL" on the FL display lights.

CN102 - pin 6 (FE)

RECORD button and REC MUTE button

The model does not focus-in

54

FE

VC

10 : 1

10:1 probe

Oscilloscope

Page 55

6.5.2 M-S Mix Ratio Adjustment

PDR-L77

Test Point

Adjustment Point

Adjustment Value

Symptom when out of

adjustment

CN102 - pin 4 (TE) and pin 3 (MPP)

RECORD button and REC MUTE button

Adjust until the value of the output signals from pin 4 (TE) and pin 3 (MPP) of CN102 are the same,

or the differential output of these signals is minimal.

Sound broken, record characteristics deteriorate

Test Disc

STD-903

[Procedure]

(1) Press the AUTO/MANUAL button so that "02 F3" appears on the FL display.

(2) Press the FINALIZE button for focus-in.

(3) Press the PLAY button for CAV-servo spindle kick (the status where the spindle rotates with the focus servo on and tracking servo off).

(4) Adjust with the RECORD button and the REC MUTE button until the value to be reached is obtained.

(5) Press the SET button to register the adjustment.

Once the adjustment is registered with the SET knob, "D.VOL" on the FL display lights.

(6) Press the STOP button to stop the unit.

Note: For adjustment, use the following circuits.

TE

MPP

VC

39kΩ

39kΩ

0.001µF

0.001µF

10 : 1

10 : 1

10:1 probe

CH1

CH2

Oscilloscope

Note: Adjustment must be done around mid-radius on a disc.

6.5.3 Tracking Offset Adjustment

Test Point

Adjustment Point

Adjustment Value

[Procedure]

(1) Press the AUTO/MANUAL button so that "03 F6" appears on the FL display.

(2) Adjust with the RECORD button and the REC MUTE button until the above adjustment value to be reached is obtained.

(3) Press the SET button to register the adjustment.

Once the adjustment is registered with the SET button, "D.VOL" on the FL display lights.

TE

VC

Note: Perform the adjustment in Stop mode.

This adjustment is possible with the low-pass filter used in adjustment 5 above attached.

CN102 - pin 4 (TE)

RECORD button and REC MUTE button

0 mV ± 10 mV

10 : 1

10:1 probe

Oscilloscope

55

Page 56

PDR-L77

6.5.4 Focus Bias Adjustment

Test Point

Adjustment Point

Adjustment Value

Symptom when out of

adjustment

CN102 - pin 1 (RF)

RECORD button and REC MUTE button

Adjust until RF jitter is minimal or that the eye pattern of the RF waveform is most open.

Sound broken, record characteristics deteriorate

Test Disc

STD-903

[Procedure]

(1) Press the DIGITAL SYNCHRO button in Stop mode.

Note: Make sure the unit is in Stop mode.

(2) Check that "SYNC" appears on the FL display.

(3) Press the AUTO/MANUAL button so that "04 34" appears on the FL display.

(4) Press the FINALIZE button for focus-in.

(5) Press the PLAY button for CAV-servo spindle kick.

(6) Press the PAUSE button to close the tracking servo, then set the unit to Playback mode.

(7) Adjust with the RECORD button and the REC MUTE button until the above adjustment value to be reached is obtained.

Press the SET button to register the adjustment. Once the adjustment is registered with the SET button, "D.VOL" on the FL display lights.

(8) Press the STOP button to stop the unit.

RF

VC

10 : 1

10:1 probe

Jitter Meter

or

Oscilloscope

Note: Adjustment must be done around mid-radius on a disc.

56

Page 57

7. GENERAL INFORMATION

7.1 DIAGNOSIS

7.1.1 POWER ON sequence

P** is made to occupy No. of SYSTEM µ-com.

H = Hi L = Low

PDR-L77

State of standby

POWER ON

PBMUTE ON

POWER ON

Mechanism Control IC reset release

XPFAIL : " H "

Yes Nomal

DET : " H "

• depends on LED

P27 RLED(STBY) : " H " Lighting

P28 BLED(PWON) : " H " Turning off

P29 GLED(PLAY) : " H " Turning off

• depends on single goods key.

• depends on the system communication.

• P57 PBMUTE : " L"

• P51 POWER : " H "

• P78 XRST : " H "

• P63 XPFAIL

The power supply is abnormal.

No

• P58 DET

The power supply is abnormal.

No

• the system communication

P65 SCLK

P43 SDATAIN

P42 SDATAOUT

P41 SREQ

State of standby

State of standby

Yes Nomal

" POWER ON " display

after FL driver is initialized

PBMUTE release after begins

with Mechanism Control IC

two way communication,

and normal communication

is confirmed

IS there DISC.?

No

DISC distinction beginning

" NO DISC " display Display at total time

Yes

• depends on FL driver

P17 FLDATA

P18 FLCLK

P19 FLCS

P20 FLRST

• P57 PBMUTE : " H "

• depends on Dimmer

P38 DIM_2

P39 DIM_1

• depends on LED

P27 RLED(STBY) : " L " Turning off

P28 BLED(PWON) : " L " Lighting

P29 GLED(PLAY) : " H " Turning off

• depends on Mechanism Control IC

communication

P11 DATA IN

P12 DATA OUT

P13 CLOCK

P3 XFUSE

P64 MREQ

P46 MACK

57

Page 58

PDR-L77

7 System operation supported by cable connection only for CD-CDR

Synchronization of power supply

It is on/also turns off the power supply of CD-R synchronizing with on/off the power supply of the CD receiver.

Function [CD-R] display

When the AUX function and CD-R is connected, it is displayed without displaying as [AUX] as [CD-R].

CD-R auto function (1)

System automatically changes into the CD-R function if the PLAY button to CD-R is pushed.

CD-R auto function (2)

The reproduction of CD-R stops if the function is switched on the CD receiver side while CD-R is reproducing.

REC lock

The function is locked while CD-R is recording.

÷ In the ASES relation, System does not do especially at all.

System synchronous with CD records by the level synchronized function of CD-R.

memo:

• Because the receiver does not return arc ridge in ASES it, CD-R is not reproduced though CD-R lodges the receiver the AUTO

FUCTION demand when System tries to do CD-R in ASES (for instance, CD-MD) in PLAY.

• CD-R must send the receiver the REC lock demand when becoming a level synchronized standby.

58

Page 59

7.1.2 ERROR CODE

Laser Hour Meter Indication and Error Code Display for Service

The PDR-L77 can display the total turn-on time of the laser diode

and error codes for service.

When the TIME button is held down for about 5 seconds in stop

state in Normal mode, an FL display as shown below is obtained.

Display

∗∗∗∗ ∗∗

" 5100 "

Error code Number

PDR-L77

Right 2 FL digits : Error code for service

The total turn-on time of the laser diode is displayed in the range

of 0 to 5100.

The error code for service is displayed as a number (ERROR

NUMBER), which follows a message "CHECK DISC" or

"CHECK". For details, see the table below.

Error code table for service

Code Symptom Contents of Error Possible Cause Checkpoints

No operation even when

H0

power is supplied.

(CHECK display)

H1

Pre-recording process does

not complete, and the tray

H2

does not open.

(CHECK display)

Pre-recording process

H5

disabled (CHECK display)

The unit stops during the

tray open/close operation.

L∗

(CHECK display)

The unit stops when PLAY

or REC/PAUSE starts.

E∗

(CHECK display)

The unit does not read the

inserted disc, and stops.

P∗

(CHECK DISC display)

Communication between mechanism

controller and mode controller is not

achieved.

Defective mechanism controller

terminals

Improper input voltage at the

mechanism-control terminals

(pins 22, 23, 24)

Improper IC303 data writing • Defect in IC303 IC303 (PYY1196)

Improper loading

Defective slider

• The pickup cannot be returned to the

specified position.

Defect in spindle

• Disc upside-down.

• Dirty or cracked disc

• Abnormal disc rotation

• No signal obtained from the disc

• Improper soldering

• Pattern short

• Short-circuiting of parts

• Improper power supply

• Defective tray position sensor

• Defective loading motor

• Improper soldering

• Pattern short

• Improper power supply

• Disconnected flexible cable

• Defective drive circuit