Page 1

C,!) PIONEER*

The Art of Entertainment

1—1 UdjBii 1—i

1 • •**-*-=— - I

' m

—«•5

Ml-. 1. 1 0

COMPACT DISC RECORDER

PDR-04

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

Type

KU/CA

Model

PDR-04

O

Power Requirement

AC120V

ORDER NO.

RRV1722

Remarks

www.electronicsrepair.net

CONTENTS

1. SAFETY INFORMATION

2. EXPLODED VIEWS AND PARTS LIST...................... 3

3. SCHEMATIC DIAGRAM

4. PCB CONNECTION DIAGRAM.................................32

5. PCB PARTS LIST......................................................41

6. ADJUSTMENT............................................................46

............................................

............................................

10

2

7. GENERAL INFORMATION.......................................72

7.1 PARTS...............................................................72

7.1.1 1C

7.1.2 DISPLAY.....................................................94

7.2 DIAGNOSIS.......................................................95

7.2.1 DISASSEMBLY

7.3 EXPLANATION

7.3.1 BLOCK DIAGRAM

8. PANEL FACILITIES AND SPECIFICATIONS. 100

...........................................................

...........................................

................................................

.....................................

72

95

96

96

Page 2

PDR-04

1. SAFETY INFORMATION

This service manuai is intended for quaiified service technicians ; It is not meant for the casual do-ityourselfer. Qualified technicians have the necessary test equipment and tools, and have been trained

to properly and safety repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty, if you are not qualified to perform the repair of this product properly and safety, you

should not risk trying to do so and refer the repair to a quaiified service technician.

WARNING

Lead in solder used in this product is listed by the California Health and Welfare agency as a known reproductive toxicant which may

cause birth defects or other reproductive harm (California Health & Safety Code, Section 25249.5).

When serving or handling circuit boards and other components which contain lead in solder, avoid unprotected skin contact with the

solder. Also, when soldering do not inhale any smoke or fumes produced.

NOTICE

(FOR CANADIAN MODEL ONLY)

Fuse symbols -it—H- (fast operating fuse) and/or

be of identical designation.

REMARQUE

(POUR MODÈLE CANADIEN SEULEMENT)

Les symboles de fusible

de remplacement doivent avoir la même désignation.

(fusible de type rapide) et/ou Hi~~lxl (fusible de type lent) sur CCI indiquent que les pièces

■ M (slow operating fuse) on PCB indicate that replacement parts must

r(FOR USA MODEL ONLY)

1. SAFETY PRECAUTIONS

The following check should be performed for the

continued protection of the customer and service

technician.

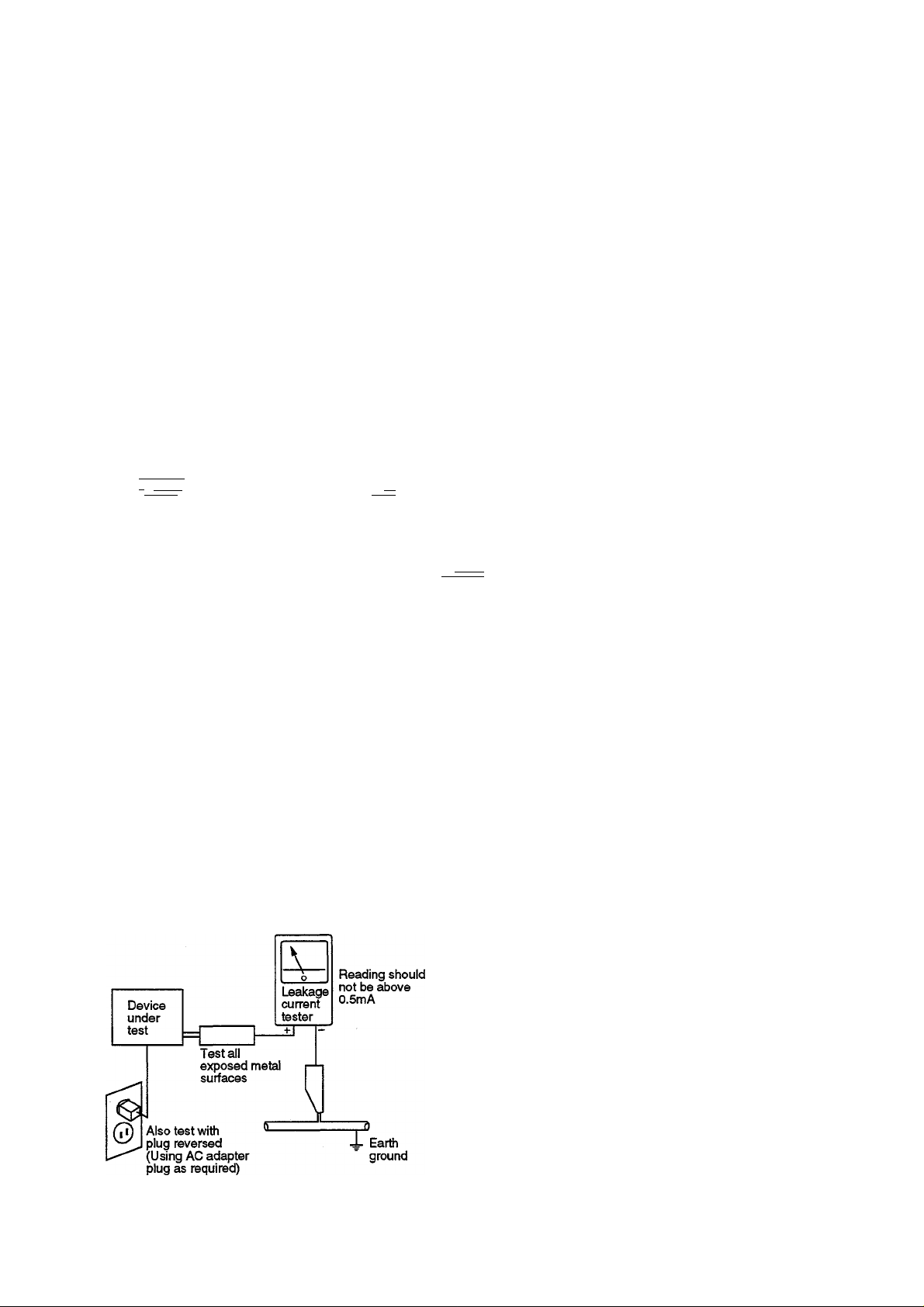

LEAKAGE CURRENT CHECK

Measure leakage current to a known earth ground

(water pipe, conduit, etc.) by connecting a leakage

current tester such as Simpson Model 229-2 or

equivalent between the earth ground and all exposed

metal parts of the appliance (input/output terminals,

screwheads, metal overlays, control shaft, etc.). Plug

the AC line cord of the appliance directly into a 120V

AC 60Hz outlet and turn the AC power switch on. Any

current measured must not exceed 0.5mA.

AC Leakage Test

ANY MEASUREMENTS NOT WITHIN THE LIMITS

OUTLINED ABOVE ARE INDICATIVE OF A

PO-TENTIAL SHOCK HAZARD AND MUST BE COR

RECTED BEFORE RETURNING THE APPLIANCE TO

THE CUSTOMER.

2. PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in the appli

ance have special safety related characteristics. These

are often not evident from visual inspection nor the

protection afforded by them necessarily can be

ob-tained by using replacement components rated for

vol-tage, wattage, etc. Replacement parts which have

these special safety characteristics are identified in

this Service Manual.

Electrical components having such features are

identified by marking with a Aon the schematics and

on the parts list in this Service Manual.

The use of a substitute replacement component which

dose not have the same safety characteristics as the

PIONEER recommended replacement one, shown in

the parts list in this Service Manual, may create shock,

fire, or other hazards.

Product Safety is continuously under review and

new instructions are issued from time to time. For

the latest information, always consult the current

PIONEER Service Manual. A subscription to, or

ad-ditional copies of, PIONEER Service Manual may

be obtained at a nominal charge from PIONEER.

Page 3

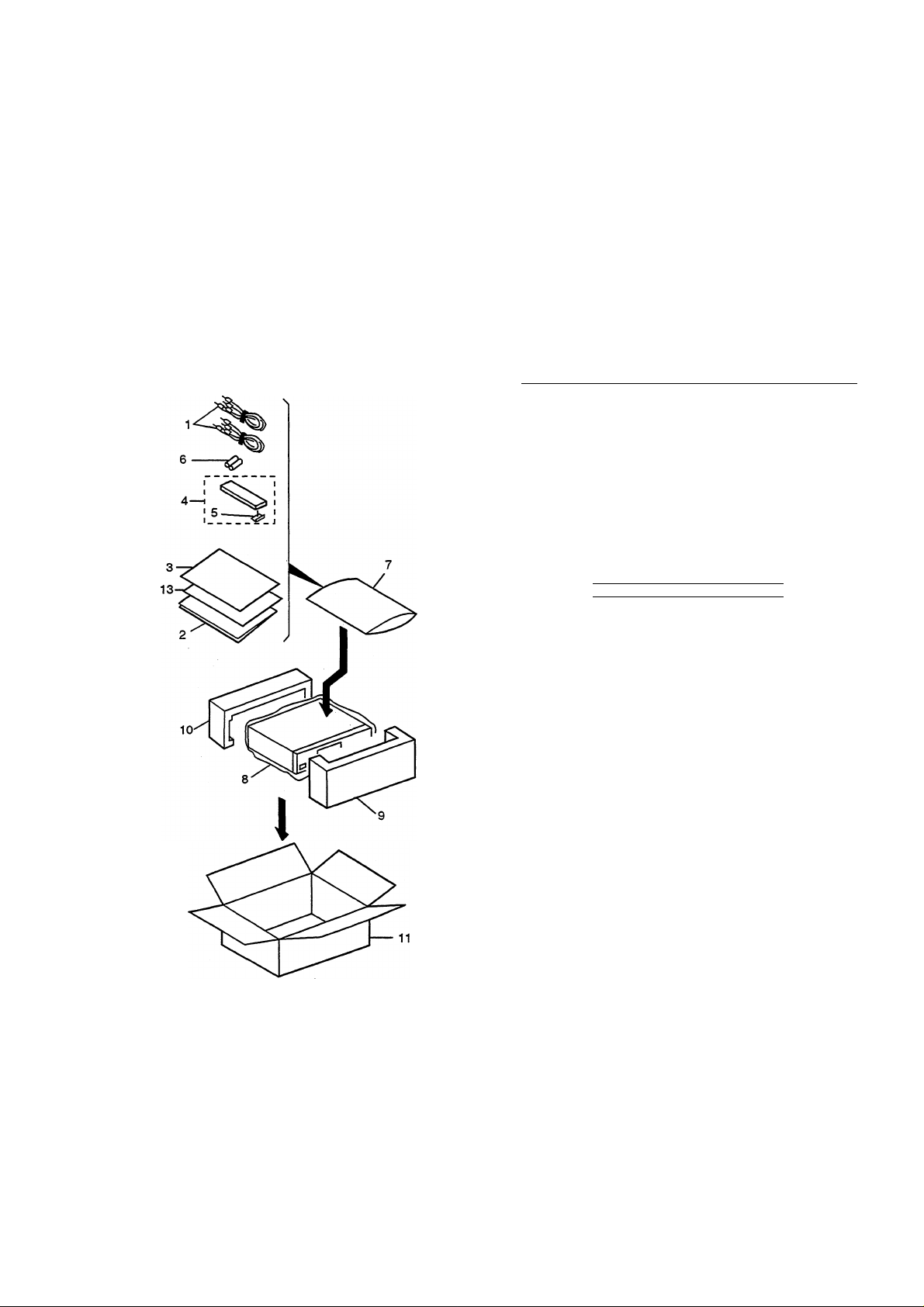

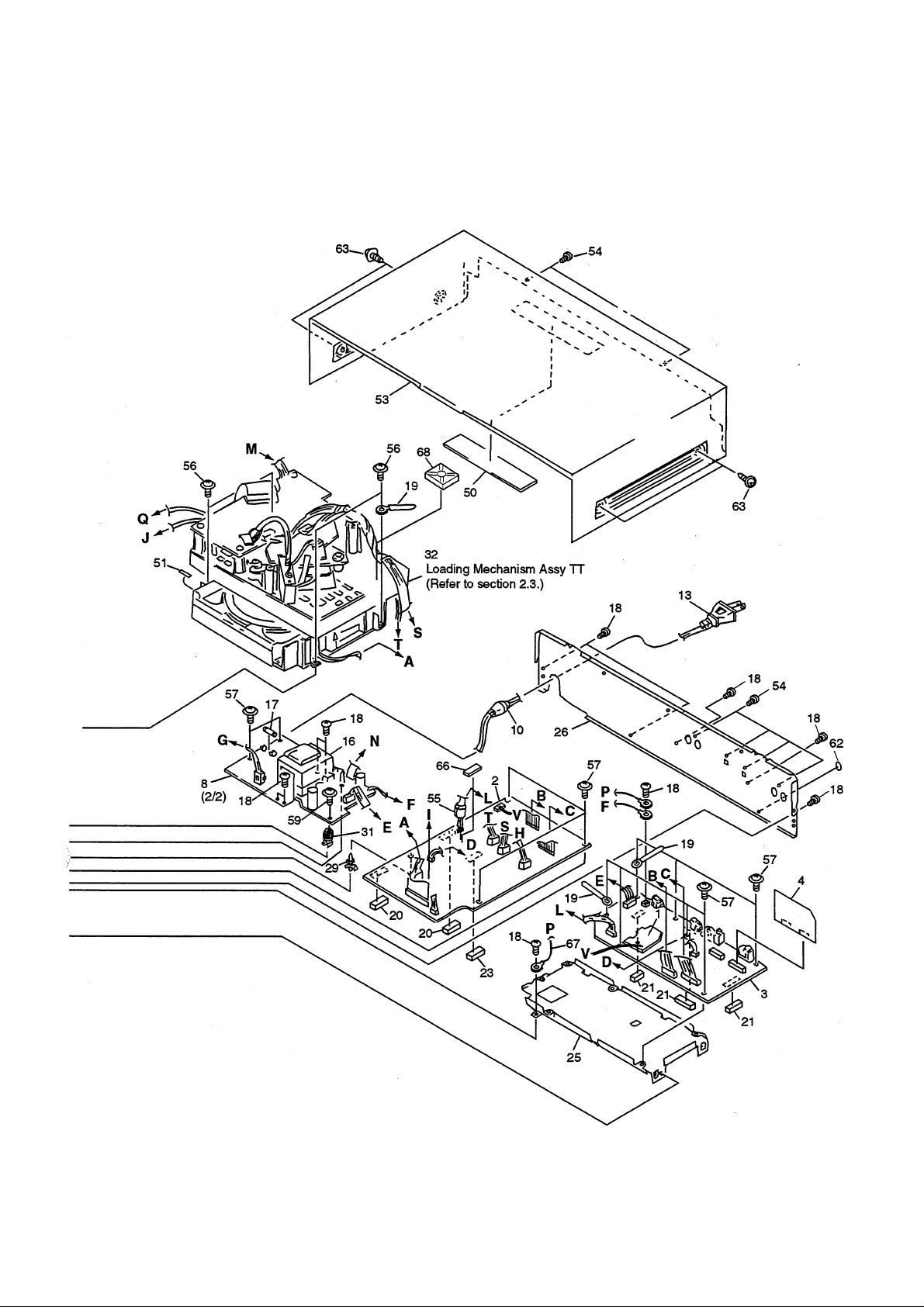

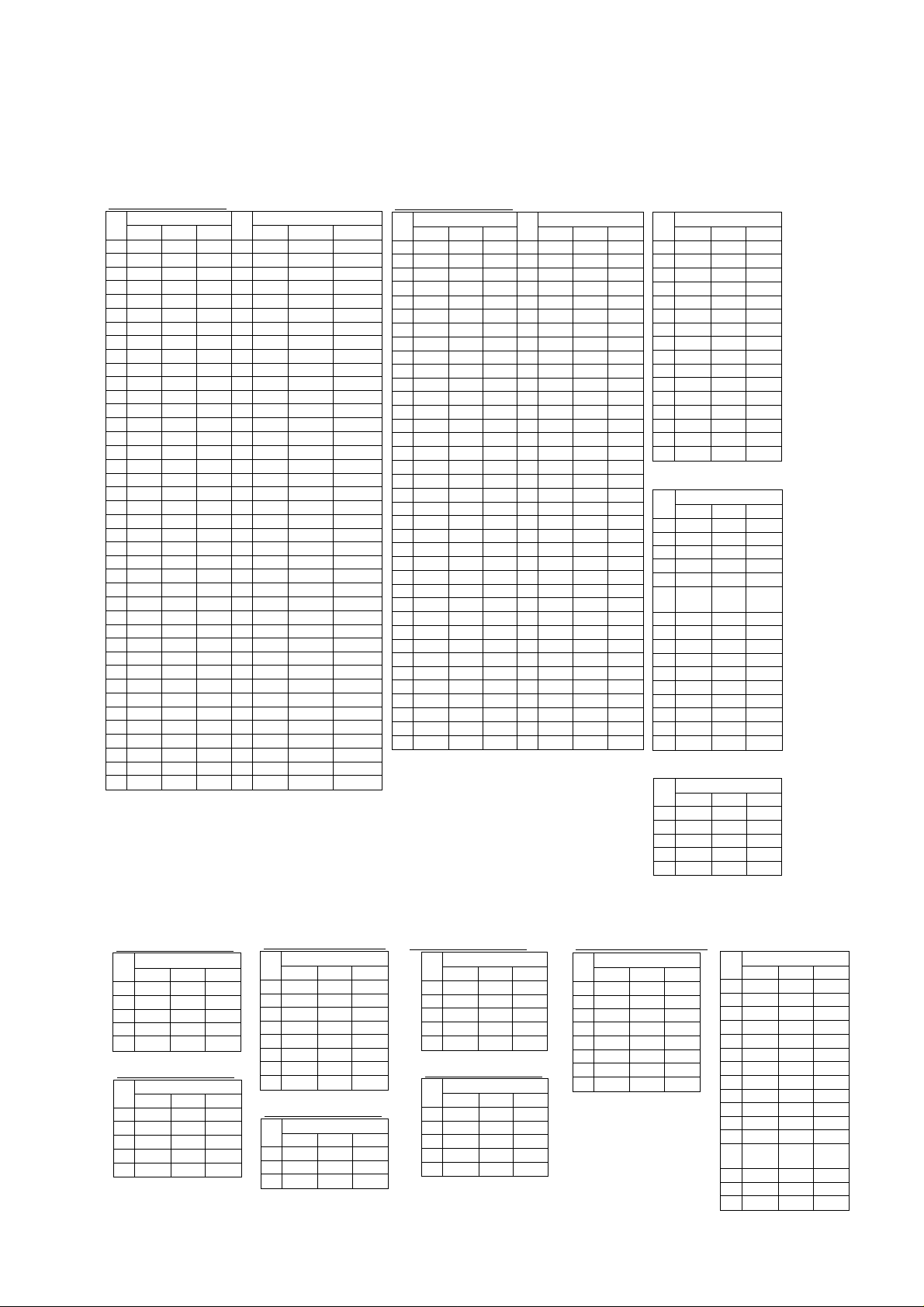

2. EXPLODED VIEWS AND PARTS LIST

NOTES: • Parts marked by ”NSP" are generally unavailable because they are not in our Master Spare Parts List

• The /1^ mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

• Screws adjacent to ▼ mark on the product are used for disassembly.

2.1 PACKING

Parts List

No. Description Part No.

Mark

Cord with Plug

1

Operating Instructions (English)

2

3 CD-R Disc Caution Card

Wireless Remote Control Unit

4

(CU-PD083)

Battery Cover AZA7123

NSP 6

5

Battery (R6P,AA)

Polyethylene Bag Z21-038

7

8 Mirror Mat

9 Styrol Protector F

PDR-04

PDE1248

PRB1251

PRM1046

PWW1116

VEM-013

Z23-007

PHA1243

NSP

10 Styrol Protector R

Packing Case

11

12

13 Warraty Card

PHA1245

PHG2223

ARY1044

Page 4

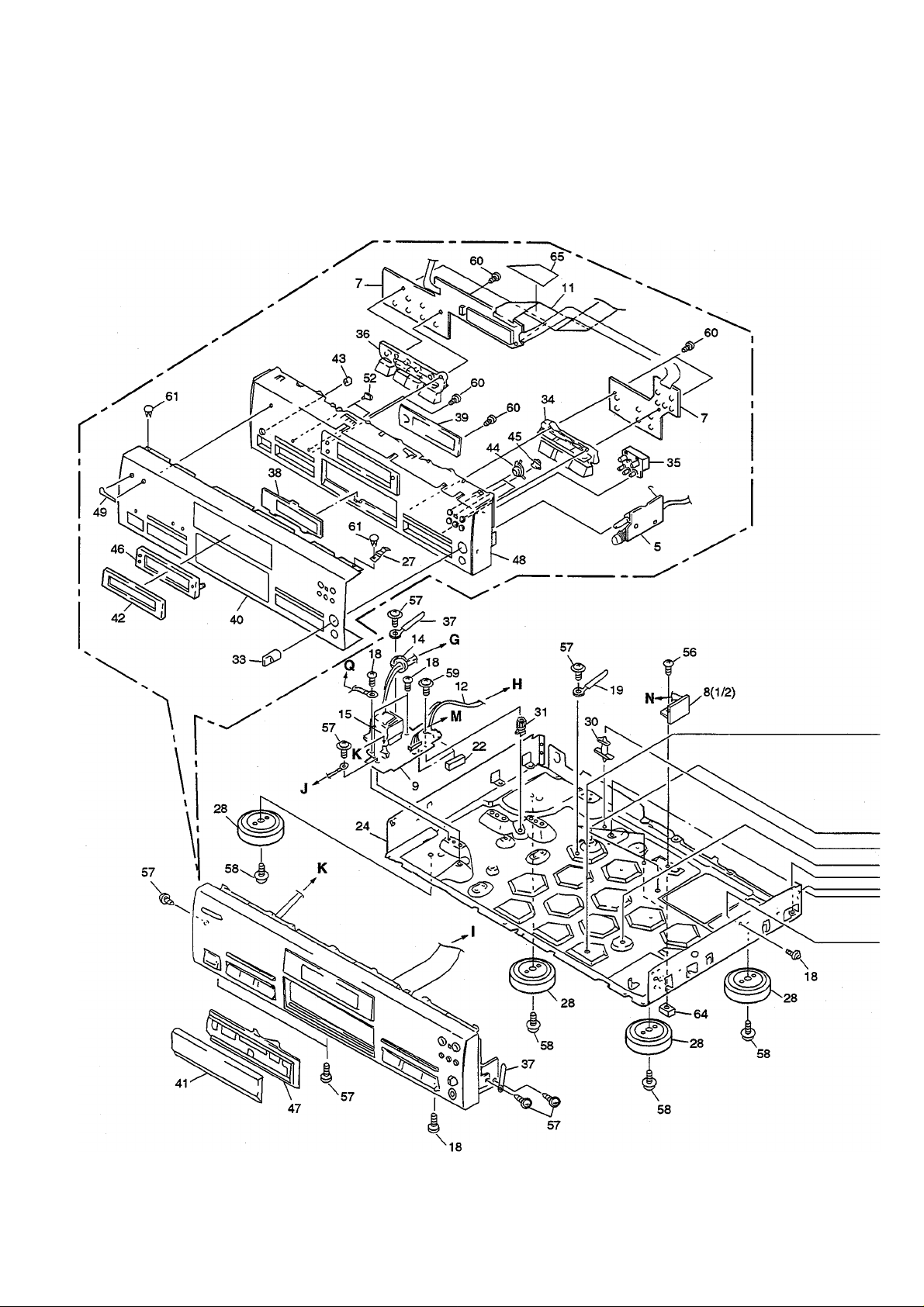

PDR-04

2.2 EXTERIOR

Page 5

PDR-04

Page 6

PDR-04

Parts List

Mark No. Description

NSP

NSP 2

NSP

NSP 4

NSP

A

A

A

A

A

NSP

NSP 21

NSP

NSP

NSP 31

NSP 32

STRATEGY SMALL BOARD ASSY

1

SERVO UCOM BOARD ASSY

3 AUDIO DIGITAL BOARD ASSY PWZ3388

ALC BOARD ASSY PWZ3389

5

HEADPHONE BOARD ASSY

e

O

7 FUNCTION BOARD ASSY PWZ3042

8 POWER A BOARD ASSY

9

POWER B BOARD ASSY

Strain Relief

10

39P F.F.C/30V

11

Connector Assy (5P) PF05PP-D37

12

AC Power Cord

13

Ferrite Core

14

Power Transformer

15

(Servo, AC120V)

Power Transformer

16

(Audio, AC120V)

17 Fuse(FU11,1A)

18 Screw

19 Cord Clamper

20 Cushion (3.5)

Spacer A

Rubber Spacer A

22

23

Rubber Spacer B

24 Under Base

25 Audio Angle

26 Rear Base

27 Earth Plate

28 Insulator

29 PCB Holder

30

PCB Holder

PCB Spacer

Loading Mechanism Assy TT

Headphone Knob PAC1600

33

Operation Button 78

34

35 REC Button

Part No.

PWX1518

PWZ3387

PWZ3390

PWZ3354

PWZ3359

CM-22C

PDD1181

PDG1015

PTH1018

PTT1308

PTT1309

REK1075

ABA1207

RNH-184

PEB1110

PEB1228

PEB1280

PEB1281

PNA2195

PNA2197

PNA2314

PBK1090

PNW1912

PNW2100

PNW2562

PNY-404

PXA1568

PAC1744

PAC1804

Mark No. Description

36

Power Button

Cord Clamper

NSP

37

38

Display Window

39

FL Sheet

40

Front Panel

41 Tray Panel

42 Display Panel 7

43

LED Lens

44 REC Ring

45 REC Lens

46

Holder

Tray Holder

47

48 Control Panel

49 Name Plate

50

65 Label

51

Indicator Lens

52

53

Bonnet

54 Screw

55

Ferrite Core

56 Screw

Screw

57

58 Screw

59

Screw

60 Screw

61 Rivet

Black Label

62

63 Screw

64 Disc Guard

65

Shield Sheet

66 1C

67 Earth Lead Unit

68 Binder Holder

Part No.

PAG 1805

DNF1128

PAM 1668

PAM 1673

PAN1349

PNW2701

PNW2662

PNW2019

PNW2558

PNW2559

PNW2591

PNW2592

PNW2703

VAM1032

ORW1069

PEA1206

PYY1175

BBT30P080FCC

PTH 1009

BBZ30P080FCC

IBZ30P060FCC

IBZ30P080FCC

IBZ30P150FCC

PPZ30P150FMC

RBM-003

PRW1470

FBT40P080FZK

PNM1245

PNM1308

PYY1196

PDF1154

PNW1021

Page 7

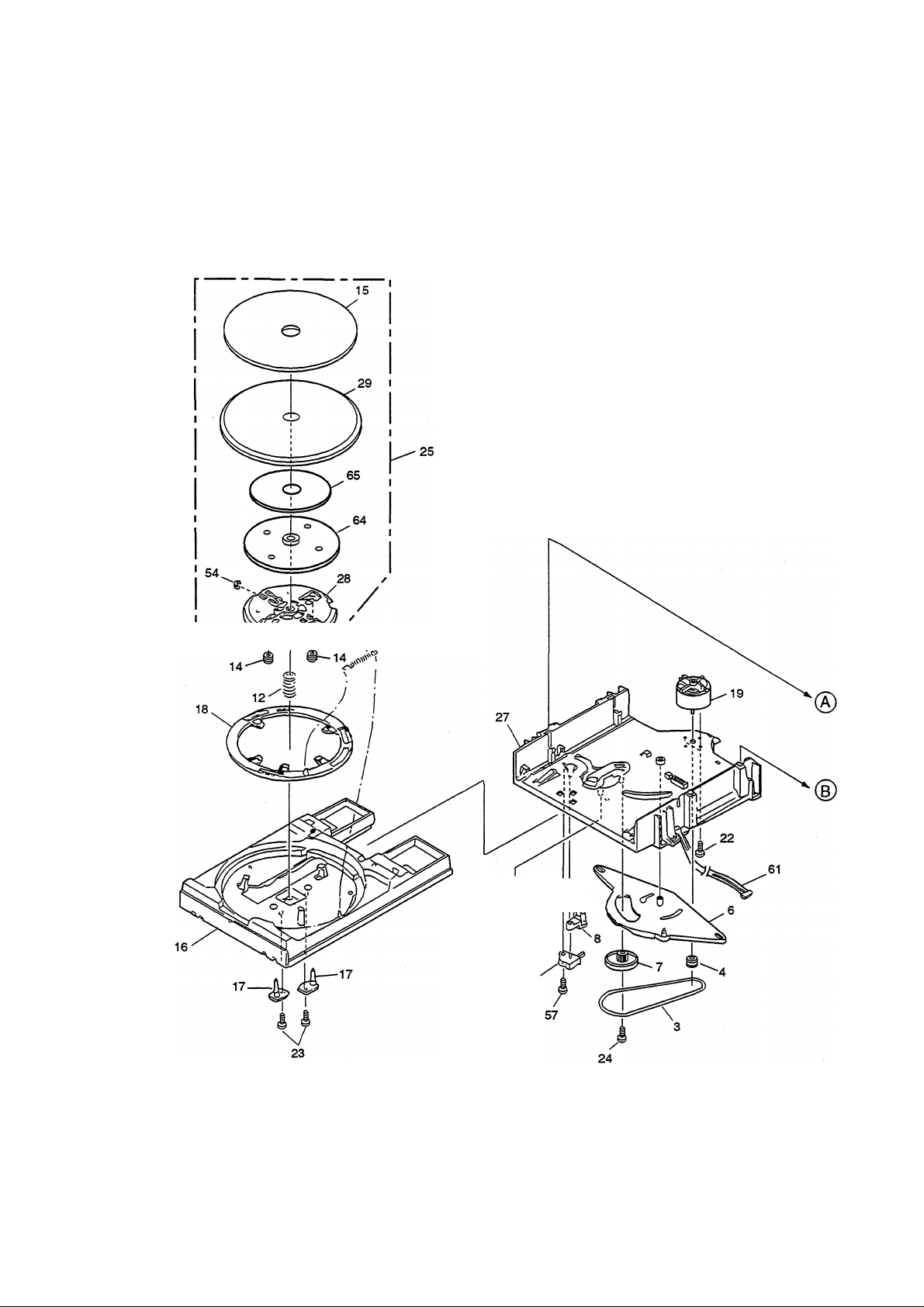

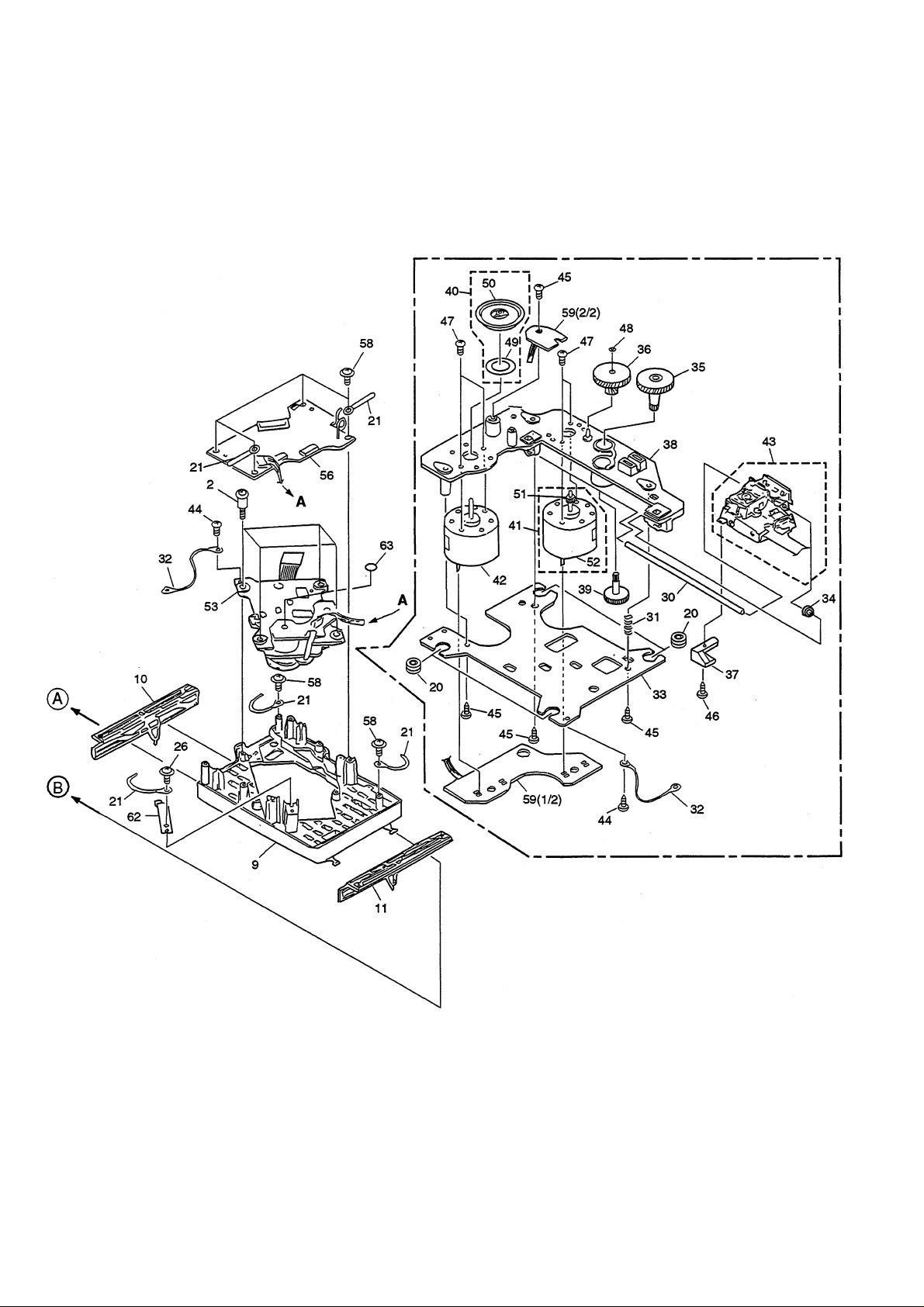

2.3 LOADING MECHANISM ASSY TT

PDR-04

13

Page 8

PDR-04

Page 9

Parts List

Mark No. Description

1 Lever Switch (Si 01)

2 Float Screw

3 Rubber Belt

4 Motor Pulley

5 Drive Gear

6 Timing Lever

7 Gear Pulley

8 SWHead

9 Float Base

10 Left Cam

11 Right Cam

12 Float Spring

13 Lock Spring

14 Float Rubber

15 Table Rubber Sheet

16 Tray

17 Table Guide

18 Lock Plate

19 D.C. Motor (0.75W,Loading)

20 Float Rubber

Part No.

DSK1003

PBA1027

PEB1186

PNW1634

PNW1996

PNW2168

PNW1998

PNW1999

PNW2563

PNW2001

PNW2002

PBH1120

PBH1121

PEB1014

PEB1181

PNW2003

PNW2004

PNW2005

PXM1010

PEB1031

PDR-04

Mark No.

NSP

NSP 53 Servo Mechanism Assy

NSP 56

NSP 59

NSP 64 Table Base Assy

NSP 65 Double Face Tape PNM1114

Description Part No.

51

Pinion Gear

52 Spindle D.C Motor (0.3W)

Stop Ring

54

55 Shaft Holder

HEAD BOARD ASSY

Screw

57

Screw

58

MECHANISM BOARD ASSY

60

61

Connector Assy 5P

62 Clamp Spring

63

Spacer PBF1014

PNW2515

PXM1033

PXA1560

YE20S

PNB1382

PWZ3386

BPZ26P060FMC

IB230P080FCC

PWZ3391

PDE1243

PBK1139

PXA1382

NSP

NSP

NSP

NSP

21 Cord Clamper

22 Screw

23 Screw

24 Screw

25 Turn Table Assy

26 Screw

27 Loading Base

28 Table Shaft Holder

29 Turn Table

30 Guide Shaft

31 Earth Spring

32 Earth Lead Unit /300V

33 TAN Base

34 Stopper Ring

35 Gear 2

36 Gear 3

37 TAN Plate TT

38 Mechanism Chassis

39 Gearl

40 Disc Table TT Assy

41 Carriage Motor Assy

42 D.C Motor Assy (Spindle)

43 Pickup Assy

44 Screw

45 Screw

46 Screw

47 Screw

48 Washer

49 Mirror Mat

50 Disc Table TT

RNH-184

BMZ26P040FMC

IPZ26P060FCU

IPZ20P080FMC

PEA1165

IPZ30P080FCU

PNW1995

PXA1383

PNR1035

DLA1530

PBH1196

PDF1088

PNB1514

PNM1246

PNW2513

PNW2514

PNW2518

PNW2520

PNW2521

PEA1323

PEA1324

PEA1325

PEA1341

BBZ26P040FMC

BBZ26P080FMC

BMZ20P040FMC

JFZ20P030FNI

WT12D032D025

PNM1247

PNW2516

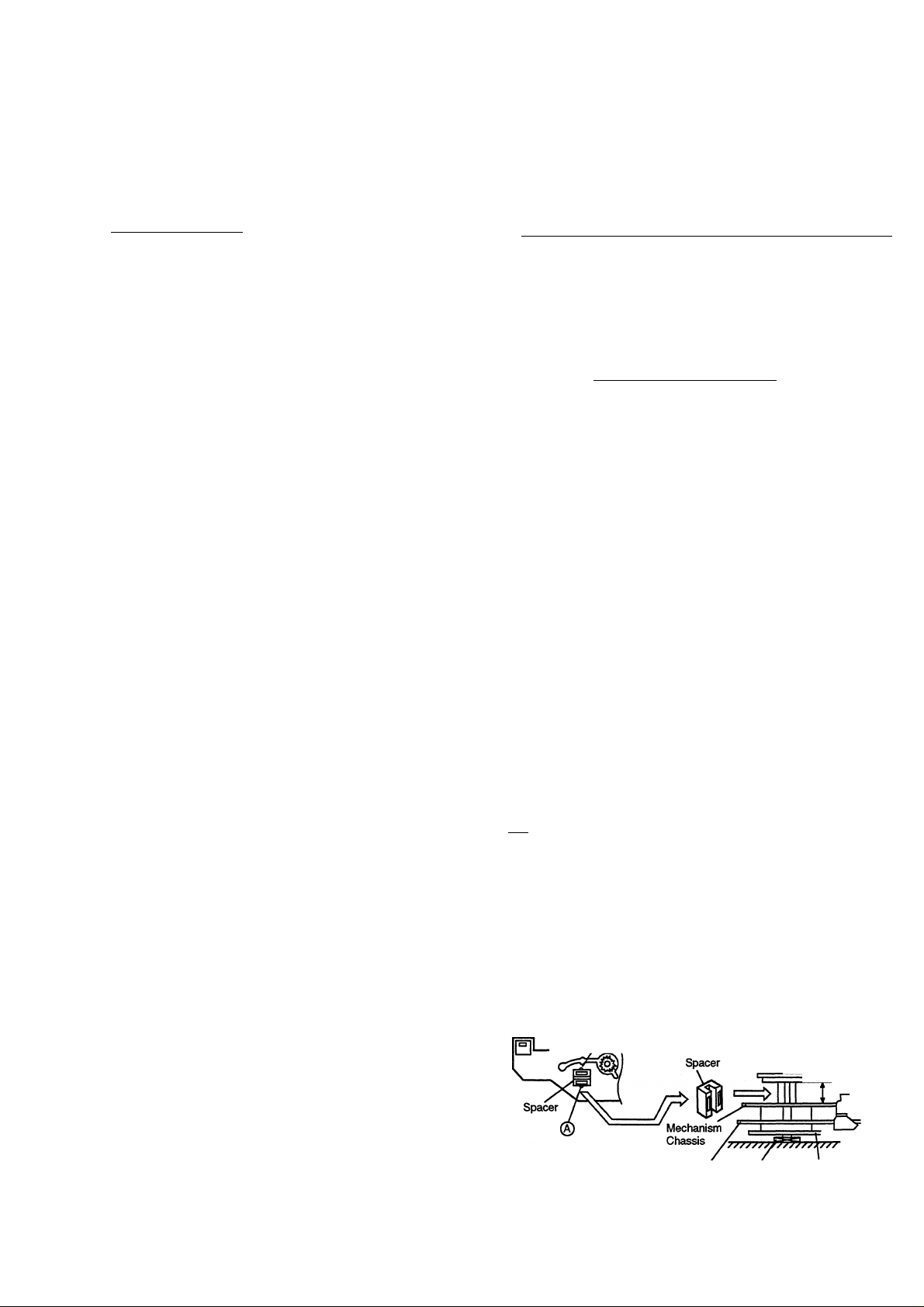

•How to install the disc table

[T1 Use nippers or other tool to cut the two sections

marked ® in figure [I]. Then remove the spacer.

While supporting the spindle motor shaft with the

stopper, put the spacer on top of the mechanism chassis

and stick the disc table TT on top (takes about 9kg

pressure). Take off the spacer.

□

Mechanism _

Ch^is (A)

(Pressure of about 9kg)

Disc Table TT

^— 8.1mm

TAN base Stopper Mechanism Board

Page 10

PDR-04

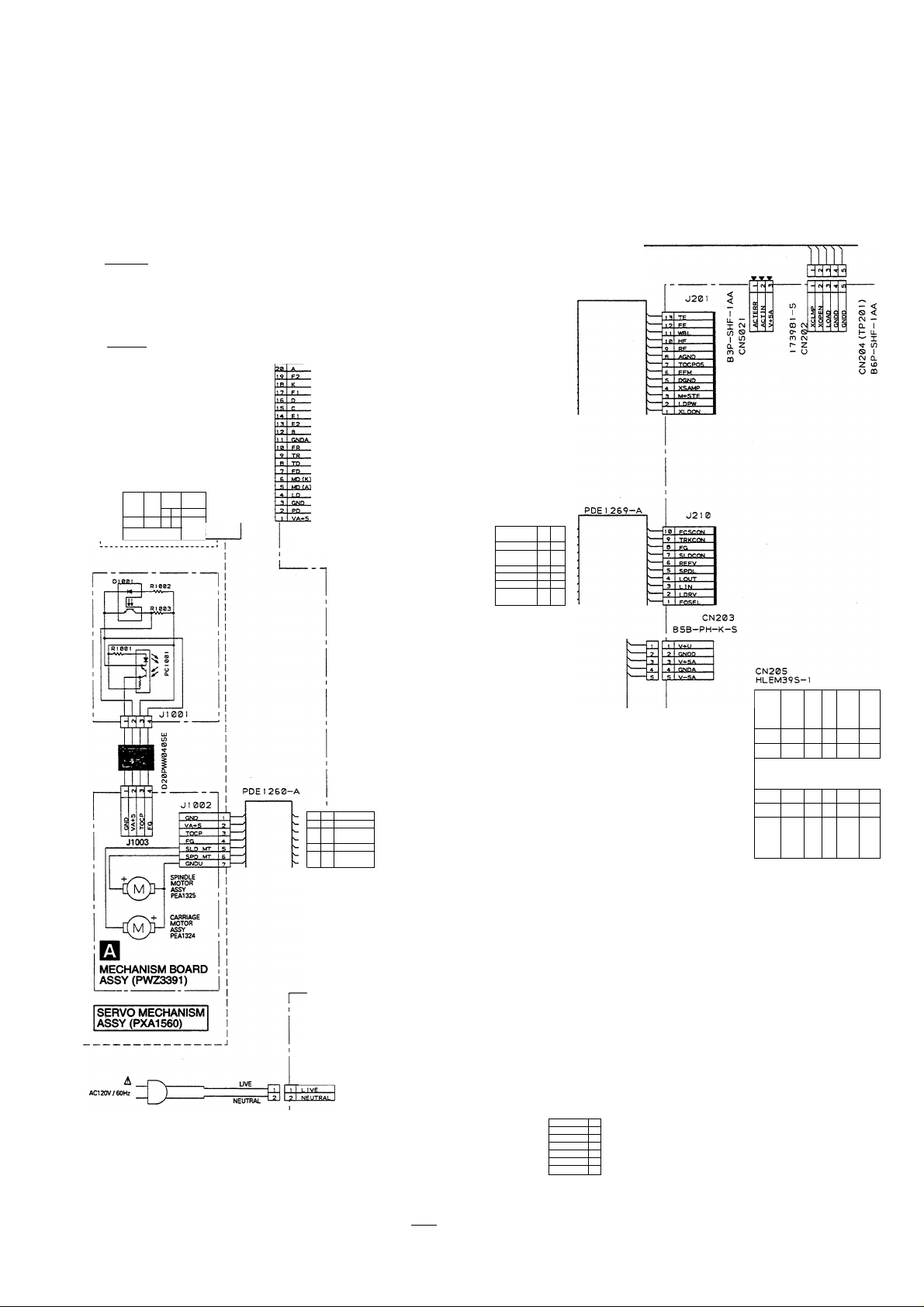

3. SCHEMATIC DIAGRAM

3.1 OVERALL WIRING DIAGRAM

S^01:DSIC1003

IPICKUPASSY]

I: PEA1341 I

D

■cTb;

: I , ACT TdI

I

------

-l_«c

J—

—KF

> Ar.T Pn

,.gNP

PD

-ypp-

CNI 01

52207-2090

CN 1 1 0

S7B-PH-K-S

GNDA

1 1

VA*S

7 7

4

FG

ff

SLD MT

fi

SPD MT

_z_

,»3NP.U

^ <

- <

s ^

Z 0-

o ®

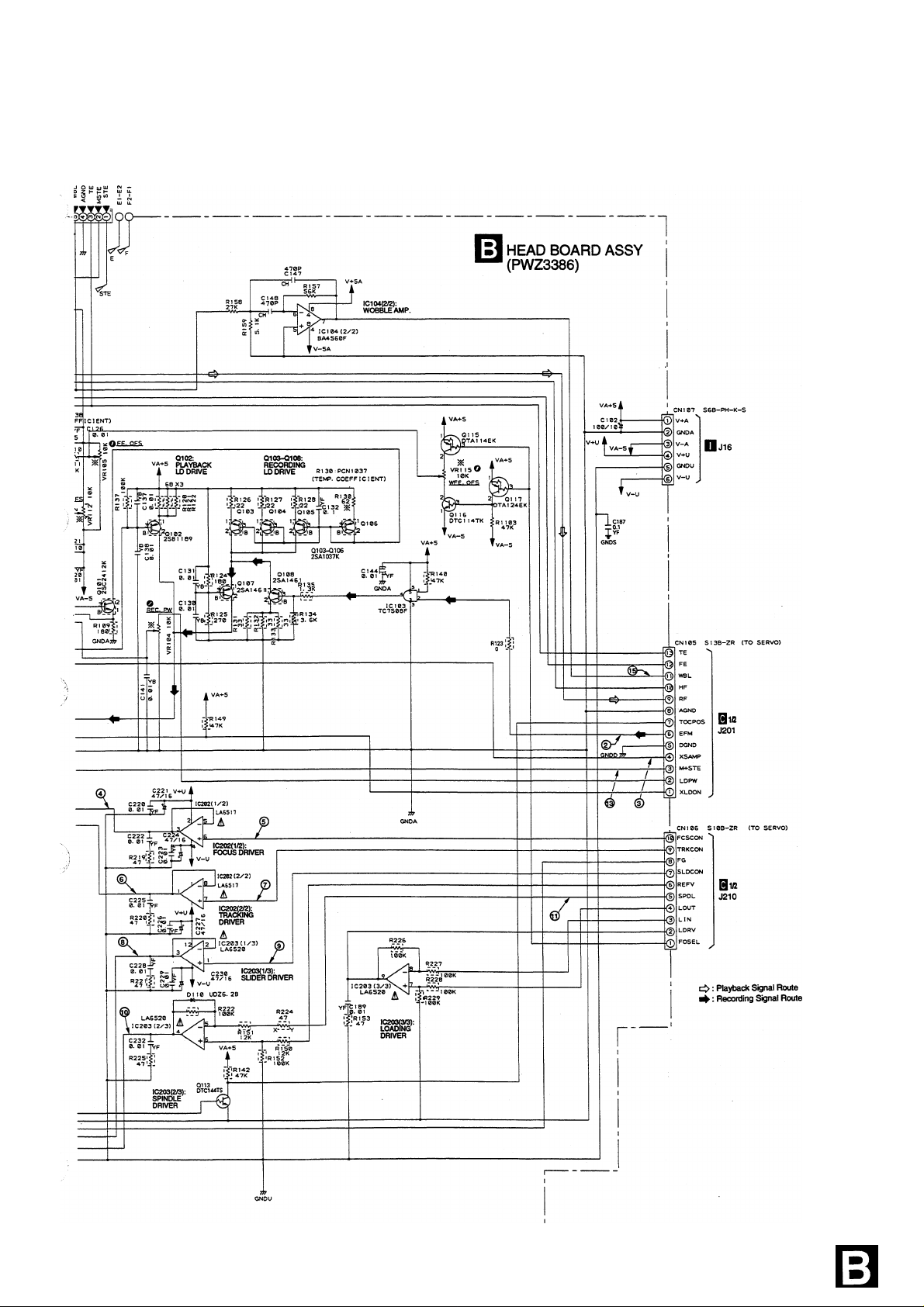

Is! HEAD BOARD ASSY

(PWZ3386)

S6B-PH-K-S

__

CNI 05

S13B-ZR

CNI 06

SI0B-ZR

TRKCQN

FG

RFFV

<;pnt

LOUT

1 IN 3

PQSgL

CN 1 07

.J

9

8 8

7

6 T

5 5

4

7 2

1

la.

9

4

3

PDE1264-A

tr □ (/;

L.

(/) Ij ^

S s| m ?i?|;r *r f

1 _ 11

1

T

- m

r‘

FUNCTION BOARD ASSY

(1/2) (PWZ3042)

^ in| U3r CO c

cl ^

K u3

tf) ujac

CN70I

HLEM39R-1

s tn r

1/) — ^

^ a

■

s - <

c ^ :

^ s ■

s - <

£ ^ :

s J

£ i

S si N i

1

1. 25mmP

T

- (N n -

s '

K ^ (0 1

IT J»

it in UJ

- I C

10

CN I I

RKC-061-0

DXWW0315E

CNI 2

B2P3-VH

m

POWER A BOARD ASSY

(PWZ3354)

[j904

PDEI273-A

J

V+AU

GAUD

V-AU

V4-5A

GNDA

V+5D

—QMPB

__

I

7

3

4

ft

fi

_2_

PF05PP-D37

PF06PG-D15

Q < 3 O

L_.

PF07PG-DI 0

Page 11

Note : When ordering service parts, be sure to refer to

"EXPLODED VIEWS AND PARTS LIST" or “PCB PARTS LIST"

HEADPHONE

BOARD ASSY

(PWZ3390)

PDR-04

B (l!]l/4,l!]2/4,l!]3/4,[!l4/4)

AUDIO DIGITAL BOARD ASSY

(PWZ3388)

11

Page 12

PDR-04

12

Page 13

PDR-04

13

Page 14

PDR-04

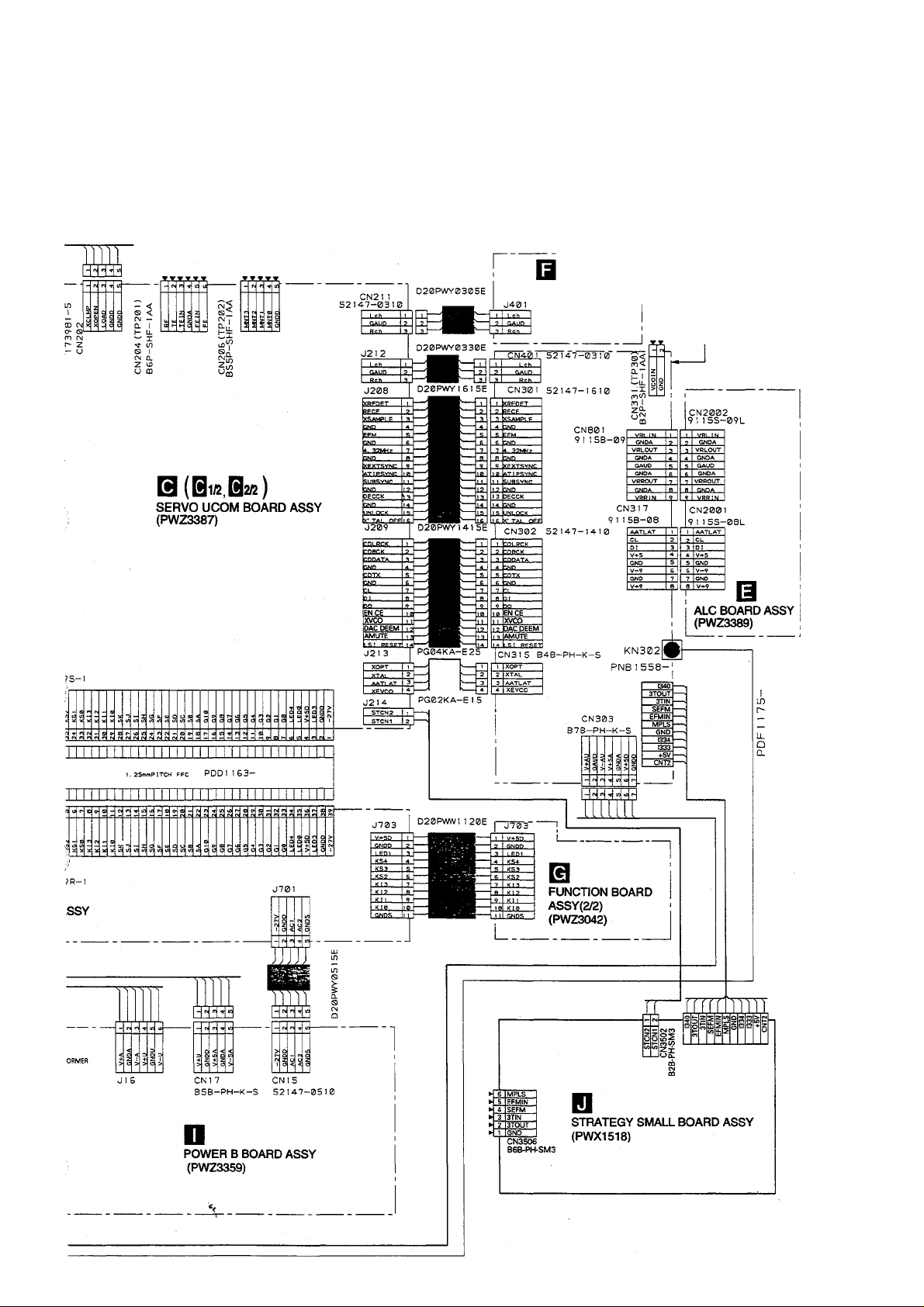

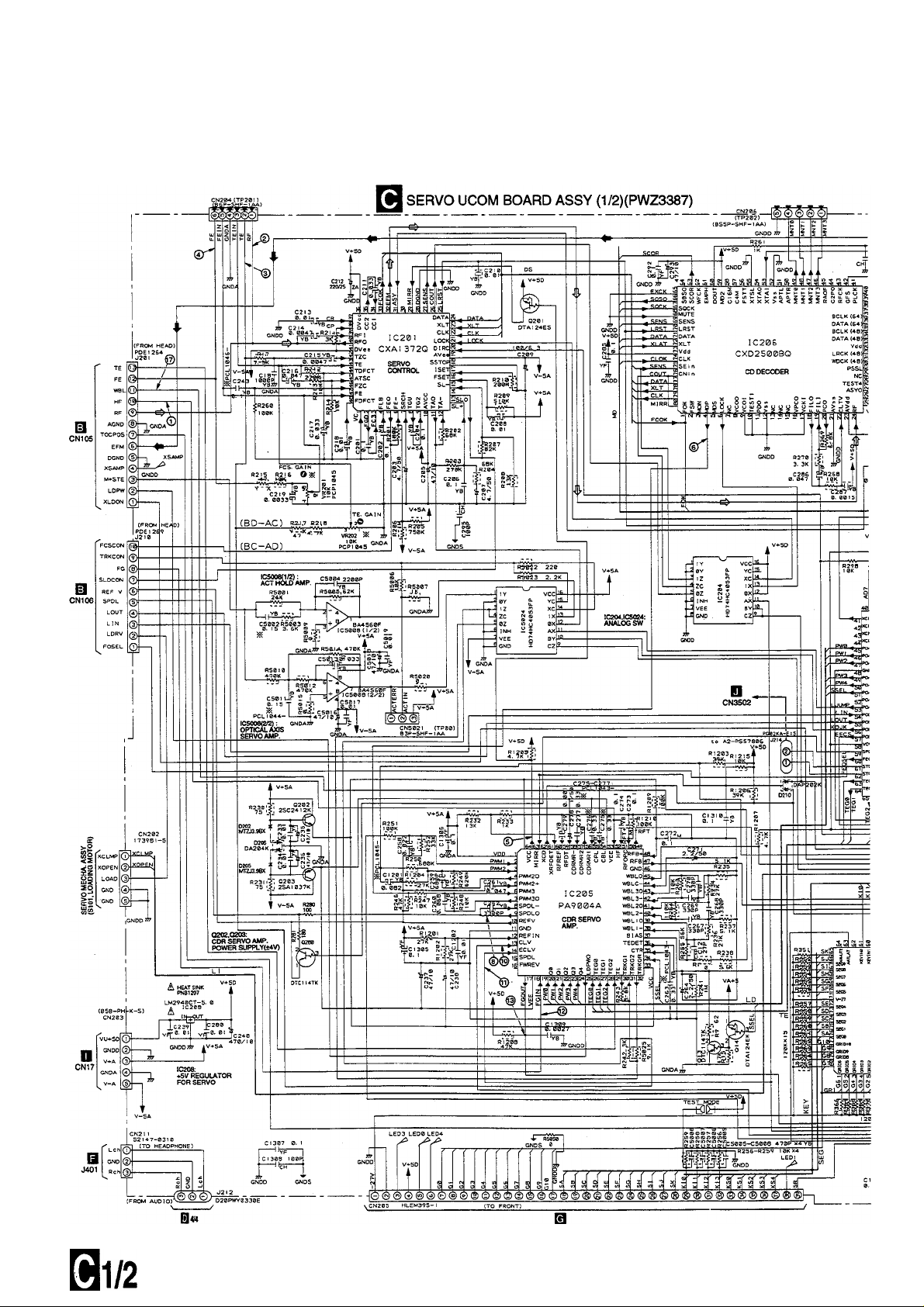

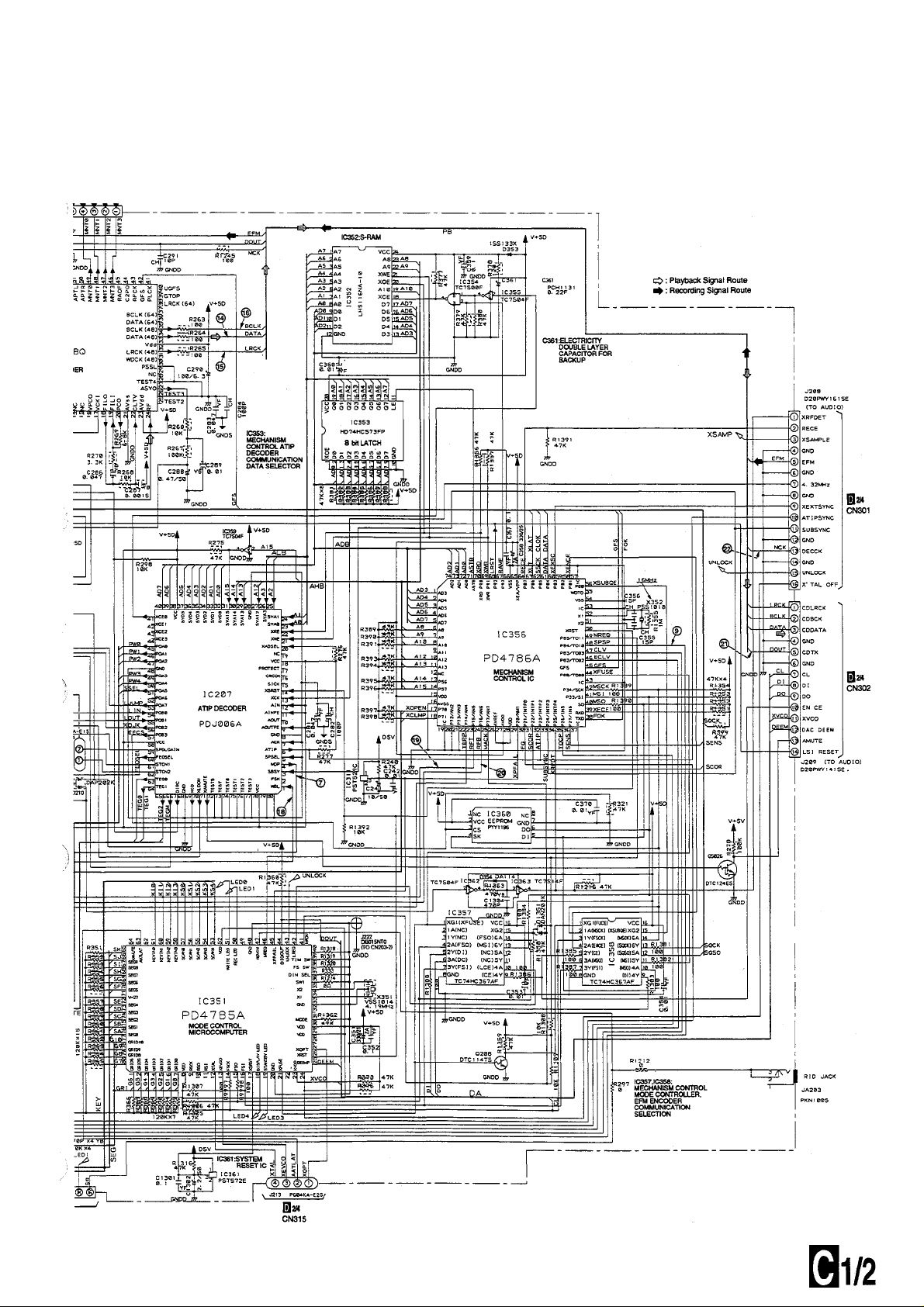

3.3 SERVO UCOM BOARD ASSY (1/2)

14

Page 15

PDR-04

15

Page 16

PDR-04

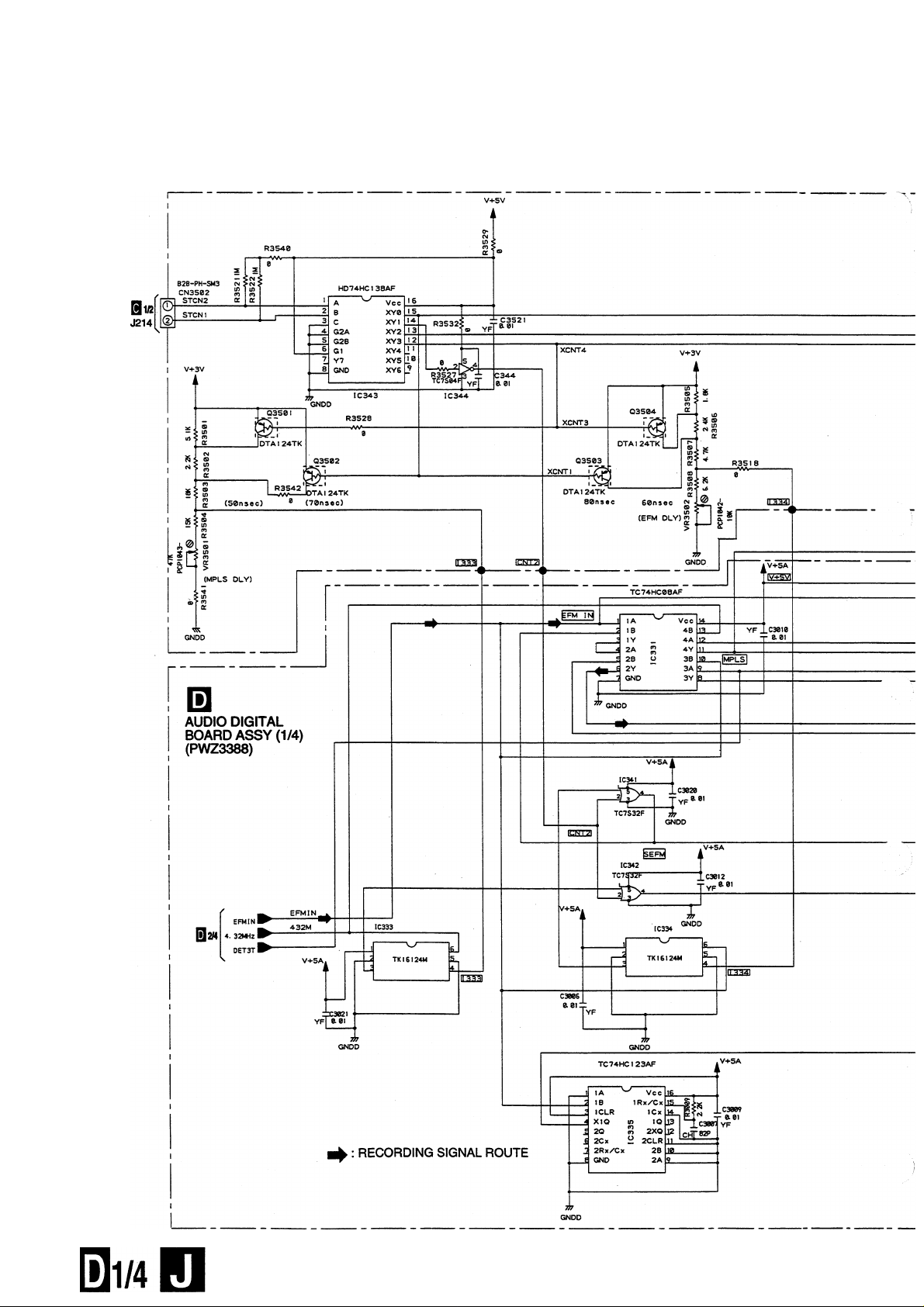

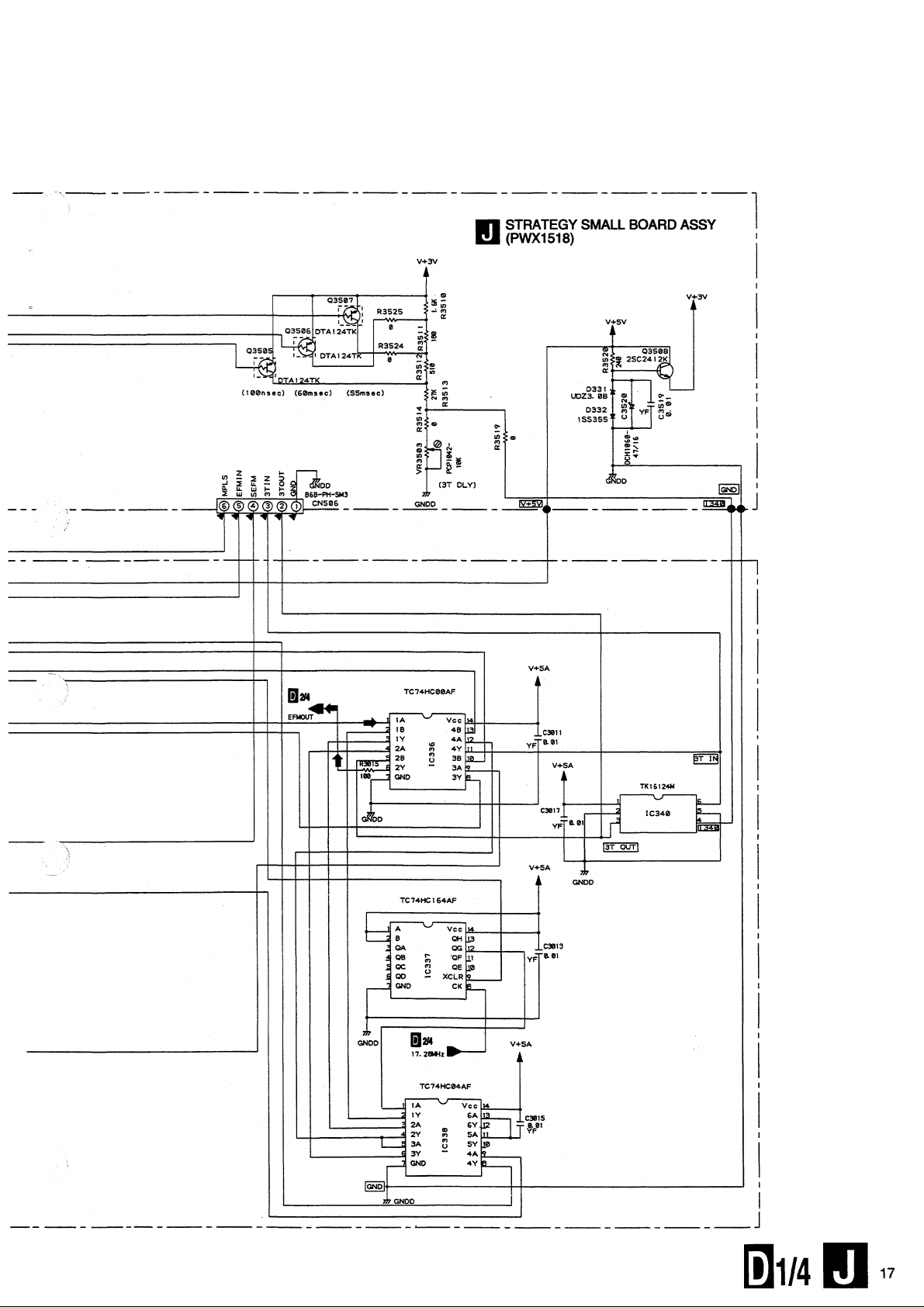

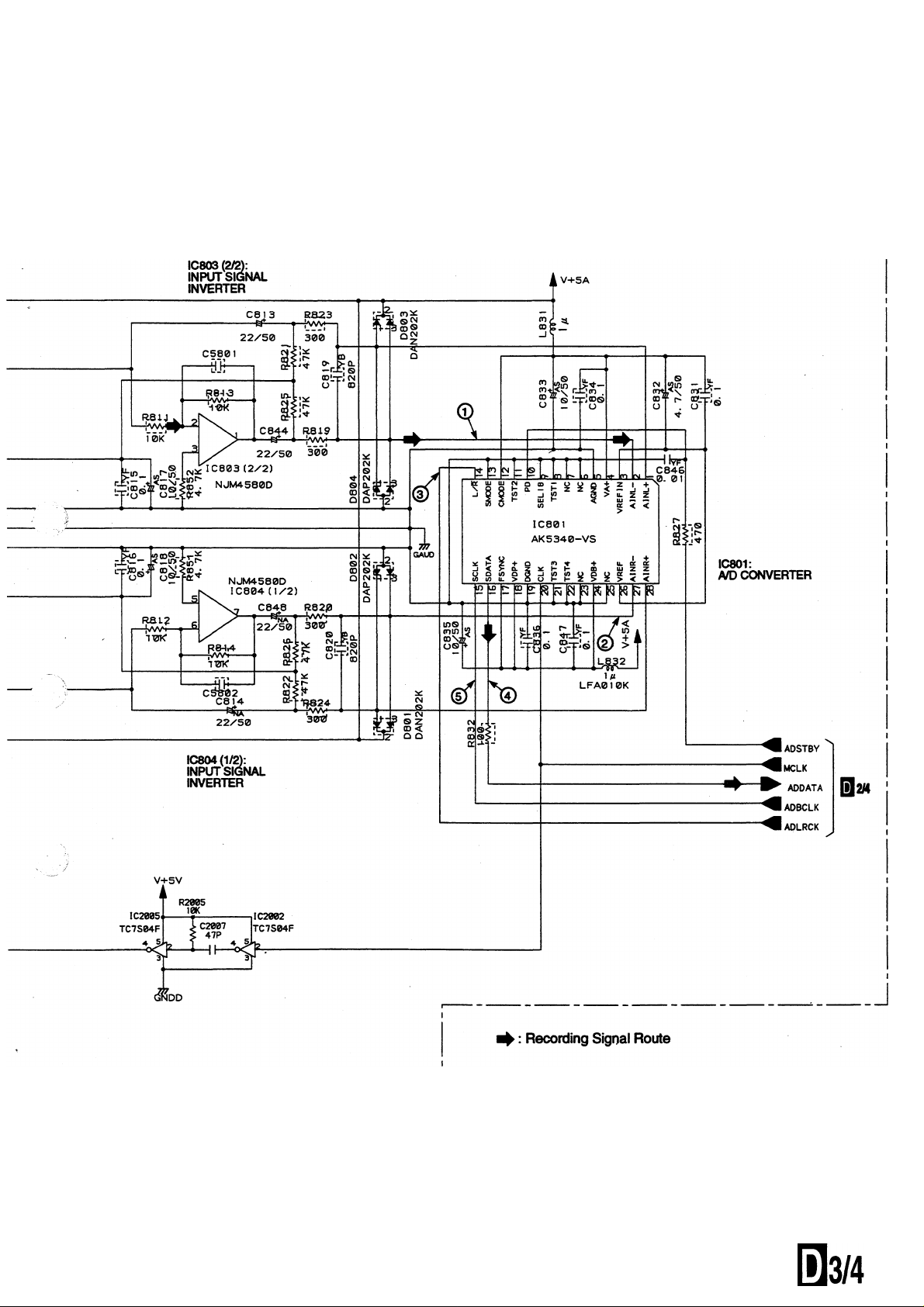

3.4 AUDIO DIGITAL BOARD ASSY (1/4) AND STRATEGY SMALL BOARD ASSY

16

Page 17

PDR-04

Page 18

PDR-04

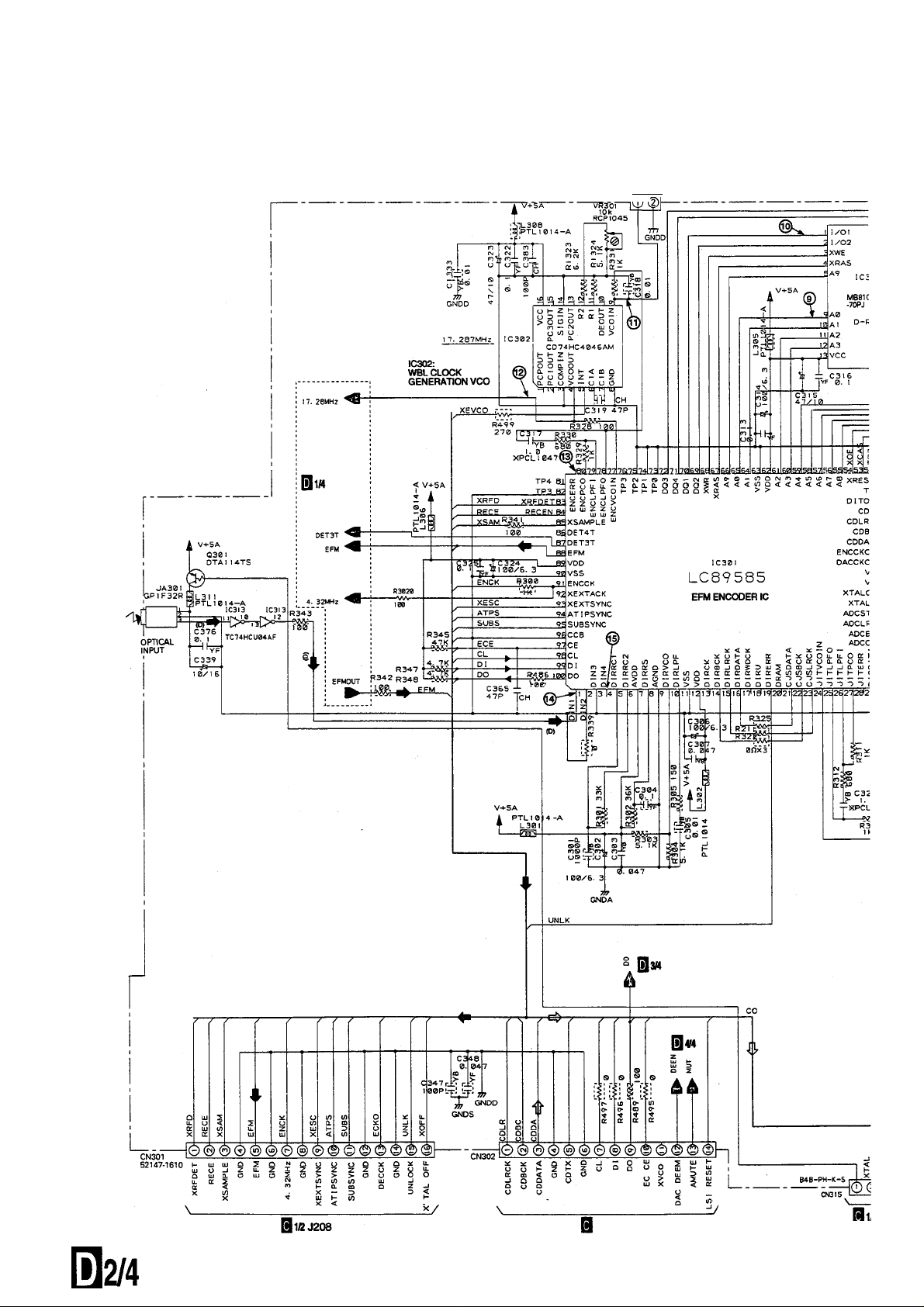

3.5 AUDIO DIGITAL BOARD ASSY (2/4)

CN331

B2P-SHF-1AA

18

1/2J209

Page 19

PDR-04

ll I/OI

d I/02

txwe

4XRAS XCAS

flA9

IC304

1/04

1/03

vss

fi1 AUDIO DIGITAL BOARD ASSY (2/4)

“ (PWZ3388)

c>: Playback Signal Route

1^: Recording Signal Route

: Recording Signal (Digital) Route

N

________

Qi/2J213

/

19

Page 20

PDR-04

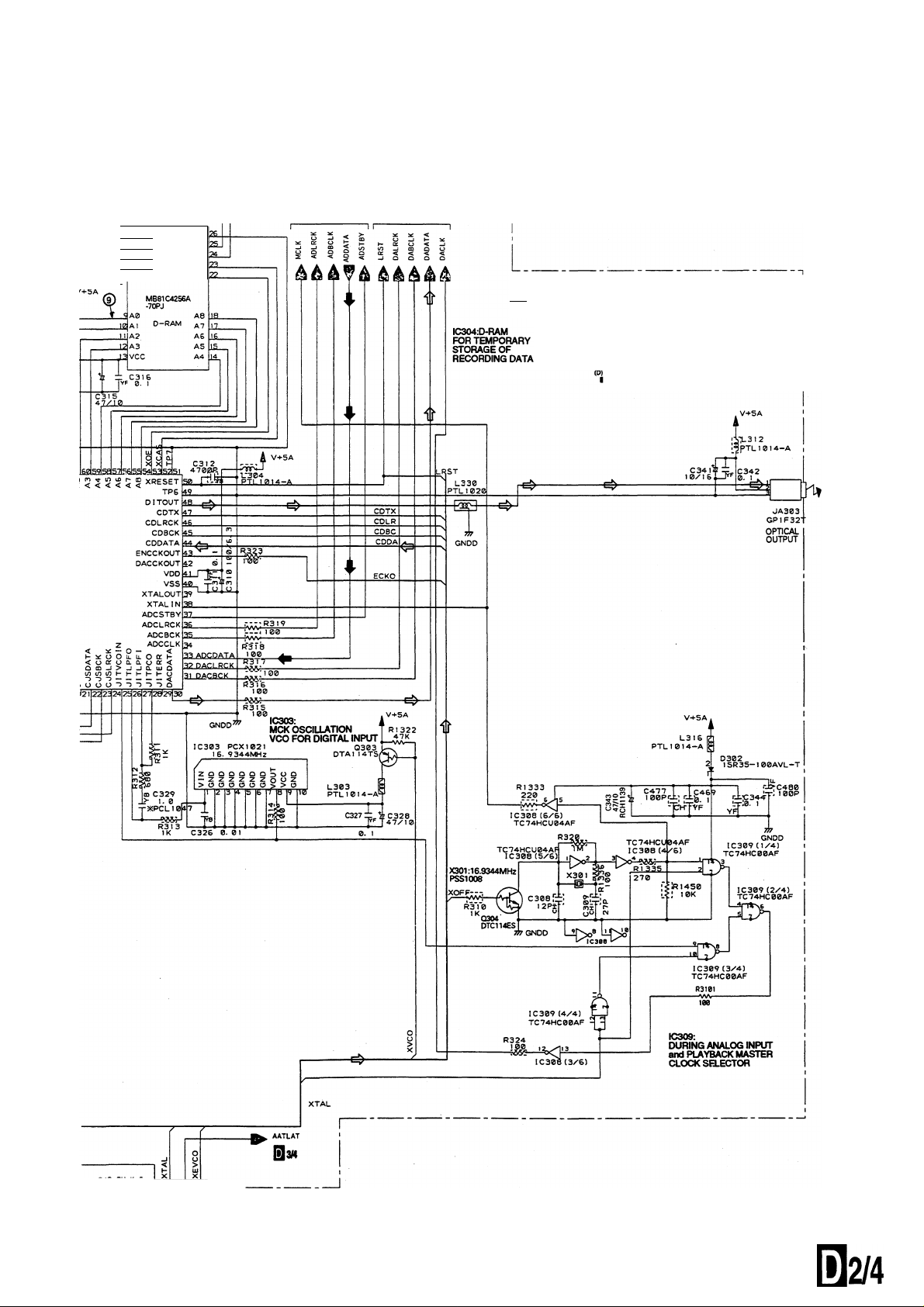

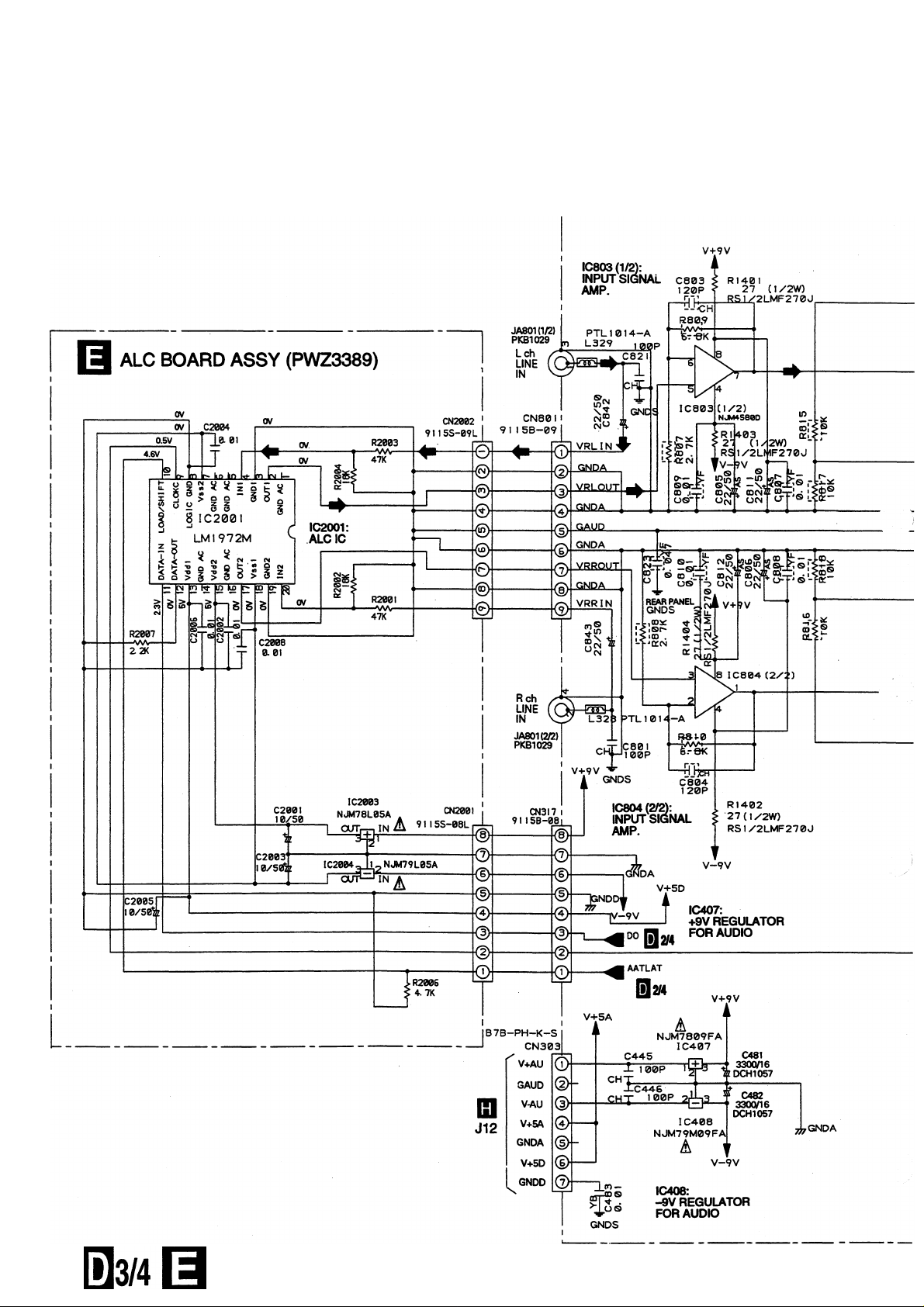

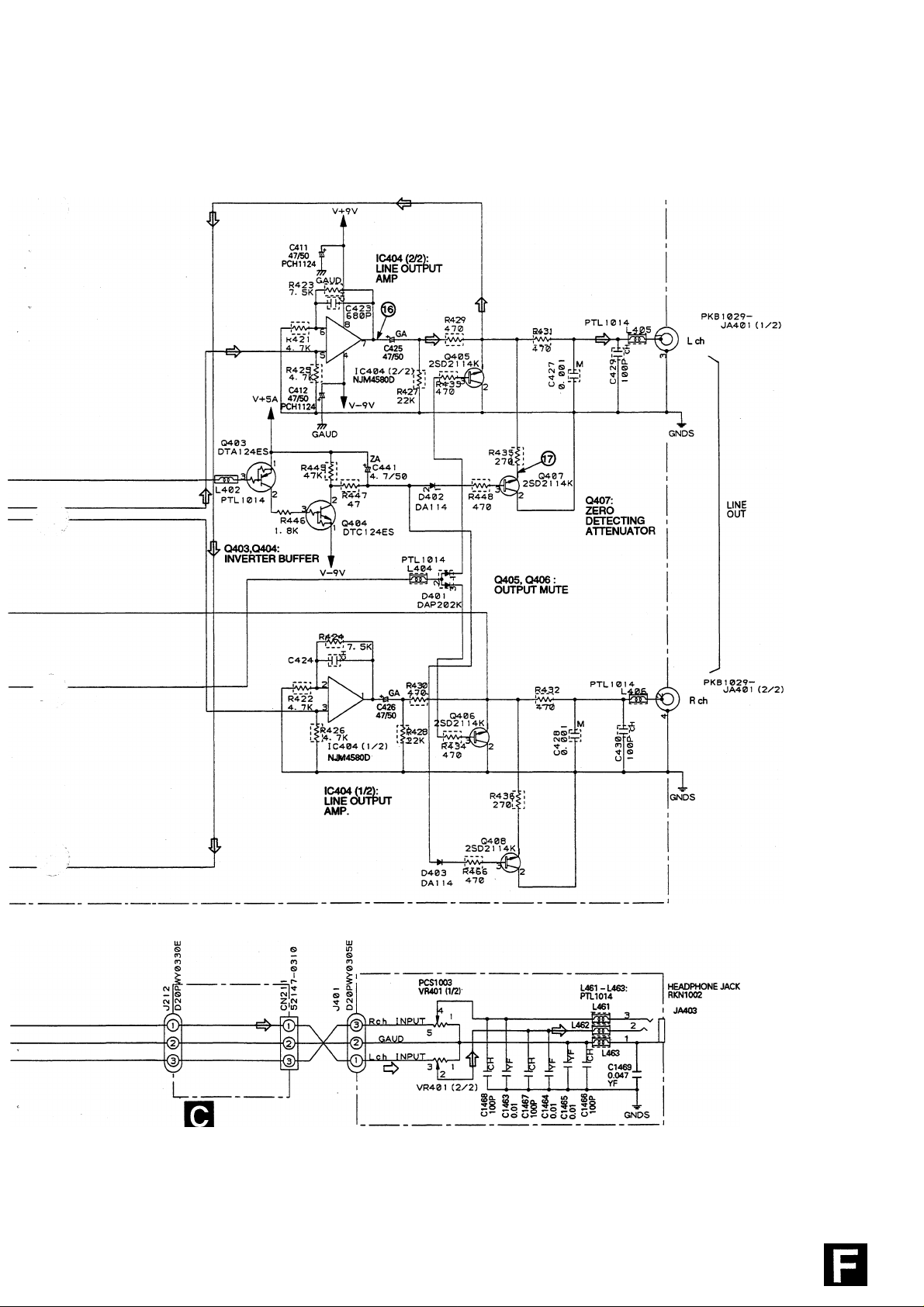

3.6 AUDIO DIGITAL BOARD ASSY (3/4) AND ALC BOARD ASSY

r—

20

Page 21

AUDIO DIGITAL BOARD ASSY (3/4)

(PWZ3388)

PDR-04

21

Page 22

PDR-04

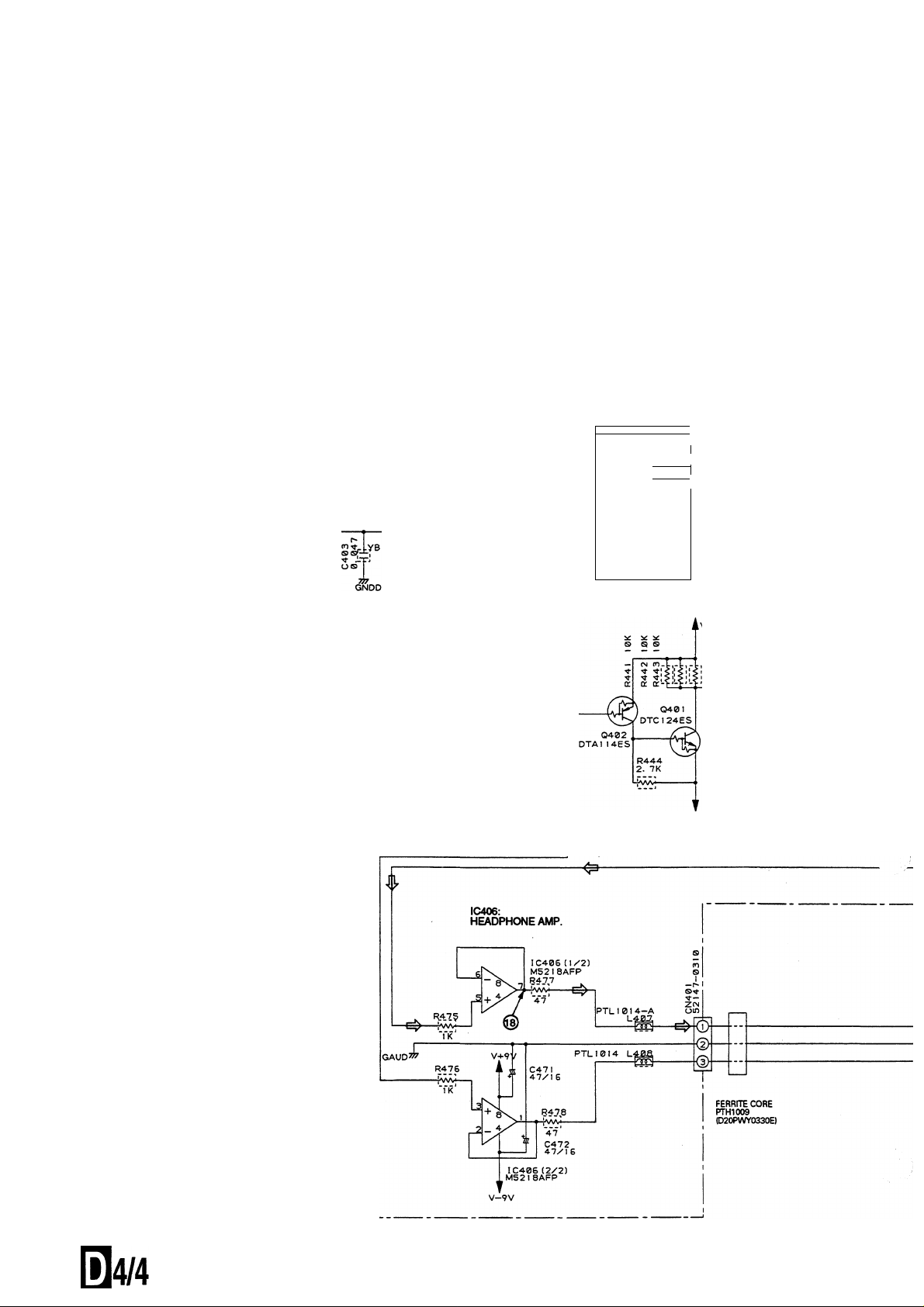

3.7 AUDIO DIGITAL BOARD ASSY (4/4), SERVO UCOM BOARD ASSY (2/2) AND HEADPHONE BOARD ASSY

AUDIO DIGITAL BOARD ASSY (4/4)

(PWZ3388)

Q2/4

DALRCK I

DADATA I

DABCLK I

lrstI

R3IS 100

----------

VVV

---

_R3i^..l00_

R437

—wv

-----

C405:

RCH1139

Ю Ljf

if

100

IC40I

/

OKS

DVDD

DVSS

XTO

LL

>

XT I

1

1

XPD

04

BIOK

SDATA

LROK

SMUTE

DFS

DEM0 DEMI

IC401:

D/A CONVERTER

AOUTL

AOUTR

TLL

DZF

VREF

AVSS

AVDD

VOOM

BVDD

DIFl

DIF0

□

2Z.

22.

C408:

RCH1139

C406 C407

Ì

*1 0408

1 г 47/10

m

GAUD

0421

47/50

PCH1124

■—;й

- 0422

в 47/50

POR1124

--

---

[=>: Playback Signal Route

П

0401.0402:

INVERTER BUFFER

22

Page 23

PDR-04

SERVO UCOM

BOARD ASSY (2/2)

(PWZ3387)

HEADPHONE BOARD ASSY

(PWZ3390)

2/2 014/4

23

Page 24

PDR-04

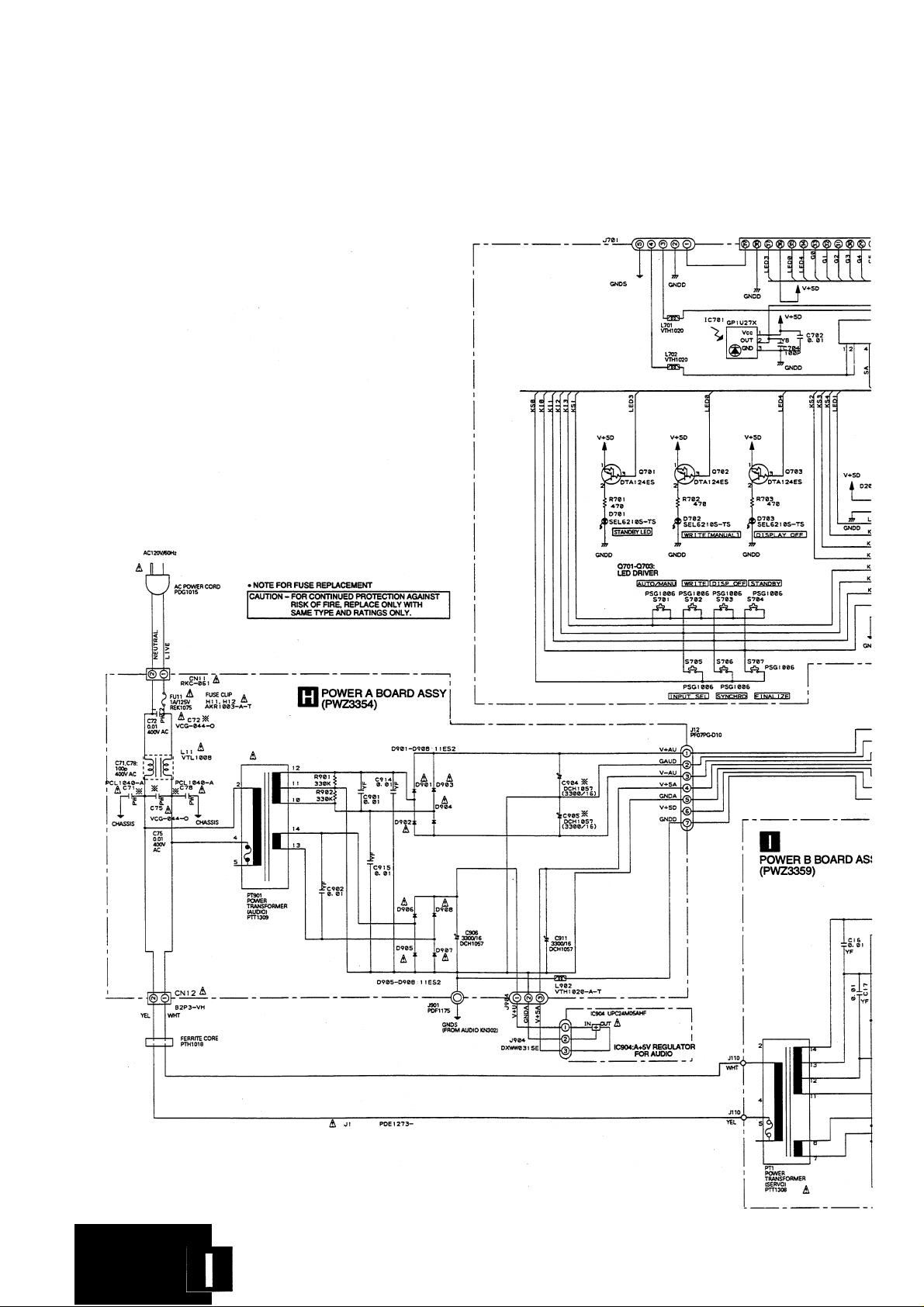

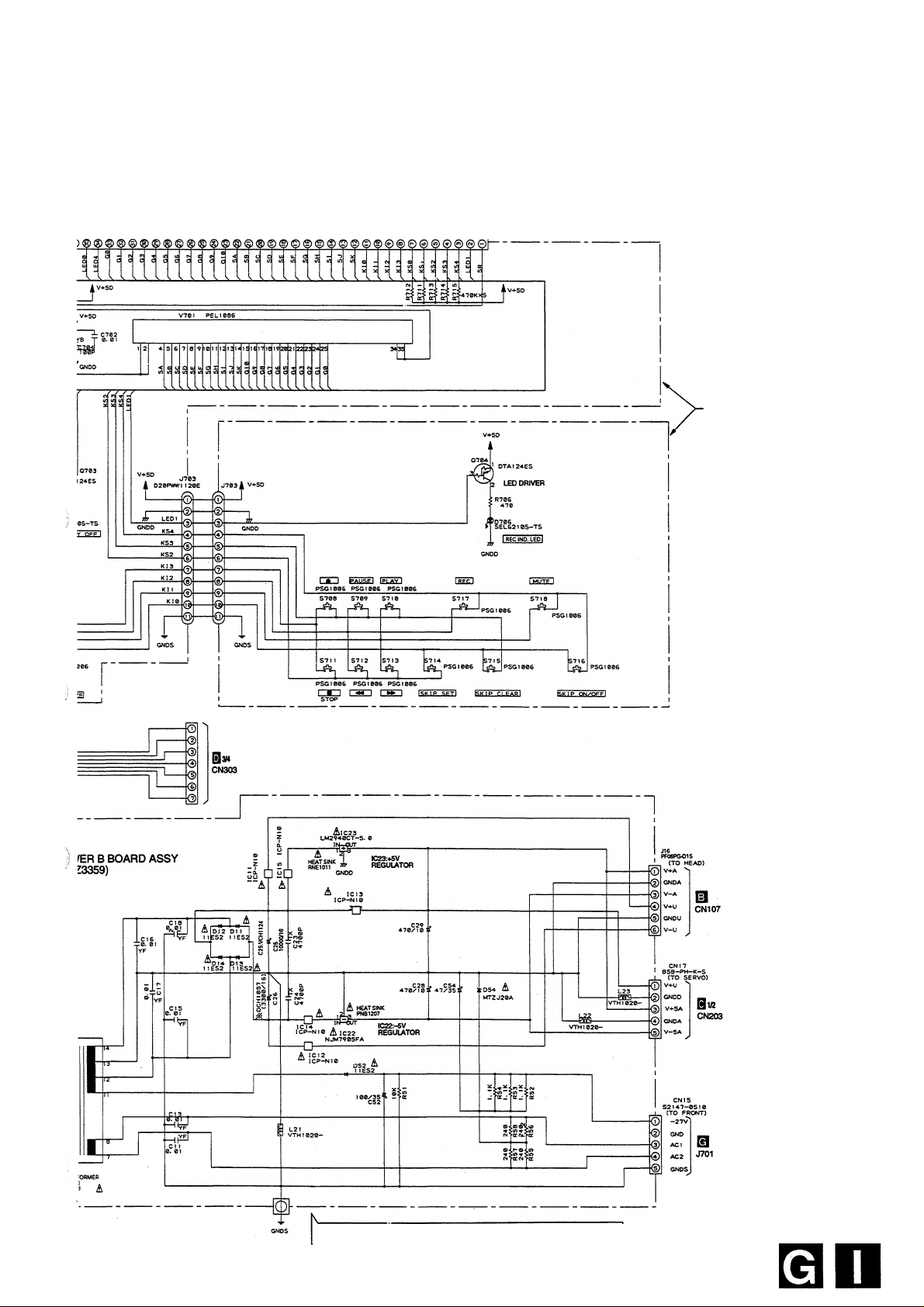

3.8 FUNCTION, POWER A AND POWER B BOARD ASSEMBLIES

D20PWY05ISE « <

24

GlH

Page 25

CN70I HLEM-39R-1 (FROM SERVO)

PDR-04

FUNCTION BOARD ASSY

(PWZ3042)

• SWITCHES

S701 : AUTO/MANUAL

S702: WRITE

S703: DISPLAY OFF

S704: STANDBY/ON

S705: INPUT SELECTOR

S706: DIGITAL SYNCHRO

S707: FINALIZE

S708: ± (OPEN/CLOSE)

S709: II (PAUSE)

S710: ► (PLAY)

5711 : ■ (STOP)

5712 (TRACK/MANUAL REV)

5713 : (TRACK/MANUAL FWD)

S714: SKIP SET 1 gKIP ID

5715 : SKIP CLEAR ^

5716 : SKIP PLAY ON/OFF

S717:#(REC)

S718 : O (REC MUTE)

CAUTION - FOR CONTINUED PROTECTION AGAINST RISK OF FIRE. REPLACE ONLY

WITH SAME TYPE No. ICP-N10, MFD BY ROHM CO.. LTD. FOR IC11 - IC15.

25

Page 26

PDR-04

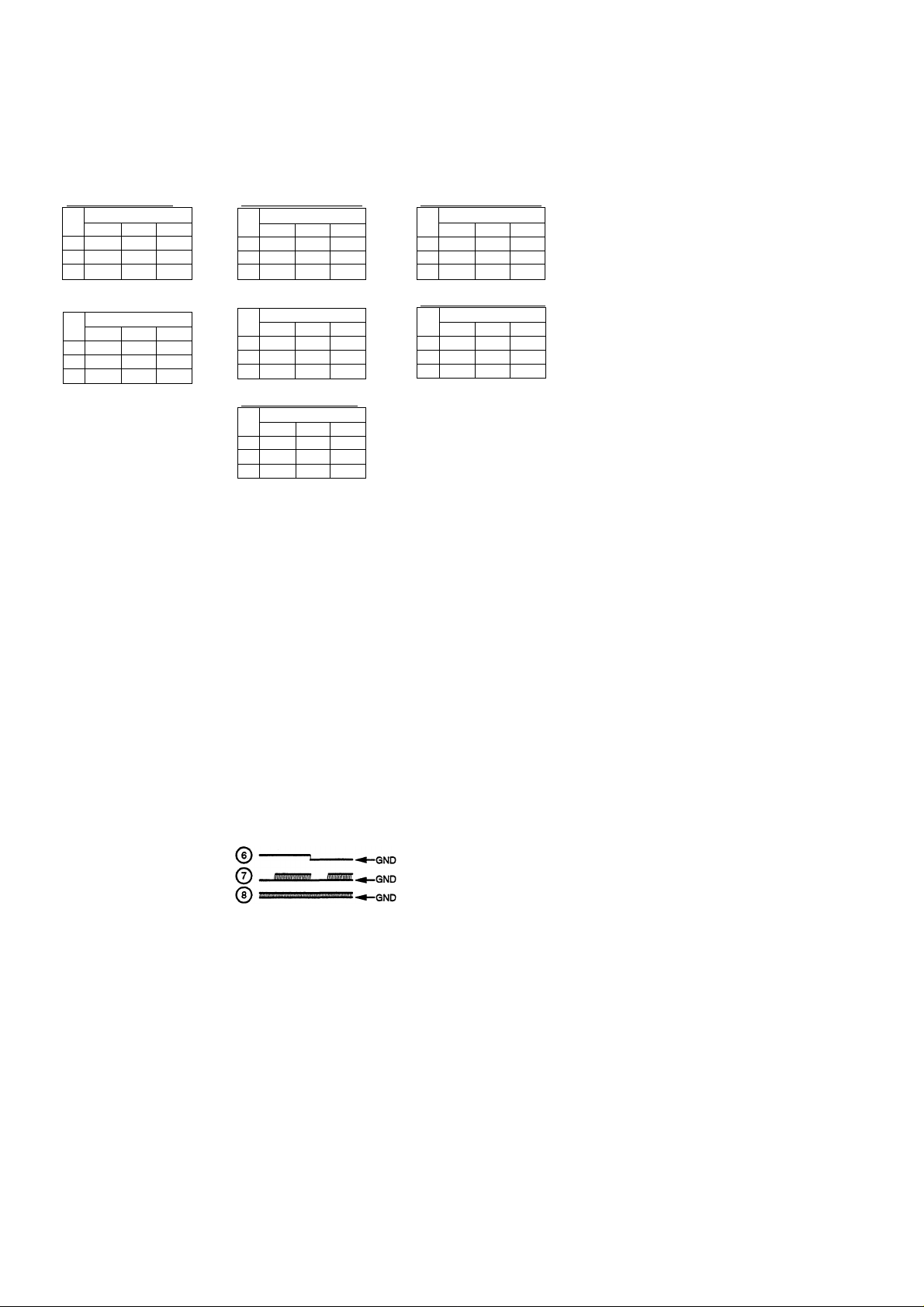

3.9 WAVEFORMS AND VOLTAGES

HEAD BOARD ASSY

• Waveforms and voltages of HEAD BOARD ASSY

• Measuring condition : DC input unless othenwise noted.

CN105 pin 6 (EFM)

©

CN105 pin 4 (XSAMP)

©

Test mode

During maximum recording

power laser diode ON

2V/div 0.2pS/div

(t ) IC202pin7(TRKCON)

^ 2V/div 0.5mS/div

6) IC202pin1 (TD)

0.2V/div 0.5mS/div

During PLAY

©

®nn

©I

IC202 pin 6 (PCS ON)

(4) IC202 pin 3 (FD)

During PLAY

SV/div ImS/div

©

-GND

(9) IC203pin 1 (SLDCON)

(i) IC203 pin 3 (SLD MT)

During PLAY

O.SV/div 0.2mS/div

©

©

©

IC101 (PA4022A) [ V

Pin

No.

1 0.01 2

3 0

4

5 0

6 0

7 0 0 0 41 0

8

9 0

10 0

11 0

12 0

13 0 0 0 47 0 0

14 0

15 0

16 0

17 0

18

19 0

20 0

21

22 0 0 0 56 0 0

23 1.4

24

25 0 0 0.9 59 -2.9

26 0

27 0

28

29 5.0

30 4.2

31 -3.4 -1.7 -1.7 65 0 -0.1 0

32 0 0 0 66

33 -1.0 0 0 67

34 4.3

MODE

STOP

PLAY REC

0.02 -0.12 -0.4 36

-0.16 0

-4.9 -4.9 -4.9 38 0.1 0.1

0 0

0

0

0 0 42

0 0 43

0 0

0 0

0 0

0 0 48

0 0

0 0 0

0

0 0 52 0 -0.1 0

0 0 S3

0 0 54

0

0 0

1.4

1.4

1.4 1.4 58 -4.0

0.2

0 ^2

0

0 0 62

5.0 5.0

1.2 1.2

3.6

-GND

©

-GND

Pin

No.

-0.1 35

37

39 5.0 0

0 40 0

44 0

45 -4.9 -4.9

46 0 -0.1

49 0 0

50 0 0

51 0 0

55 0 0

1.4. 57 0.1 0.1

02 60

61 0 0

63 5.0 5.0

64 -0.1

3.6 68 -0.1

MODE

STOP

0.6 0.6

0.6 0.6

1.2 1.2 1.5

0 0

0 0

0 0

0

0

0 0

0 0

-0.3 1.4

0 0

PLAY

0

0

-0.1 -0.1

-0.1

0.2

■4.0

-2.7

0.3

0

REC

0.8

0.8

3.1

-0.1

0.1

-4.9

-0.1

-0.1

0.2

0.1

-4.0

-2.7

5.0

0.3

1.2

CN106 pin 5 (SPDL)

1V/div 2mS/div

(10) IC203pin4(SPDMT)

^ 2V/div 2mS/div

During PLAY

©-

GND

-GND

IC101 pin 47 (MTE)

200mV/div

CN105 pin 3 (M+STE)

@

500mV/div

@ TP1 pin 5 (WBL)

@ CNIOSpinll (WBL)

-GND

(is)-/V/V/V/V/i»-GND

-GND

During CD-R PLAY

lOOmV/div 20pS/div

Test mode

'^°'spdl)'^'-ose

-GND

-GND

0

IC102(BA4560F)[V]

Pin

No.

1

2

3 4.4 1.4

0

0

0

4 -5.0 -5.0 -5.0

5

6 0 0 0

7 0 0

8

MODE

STOP PLAY REC

0

0.2 1.5

1.4 1.4

0 0

5

0.1 to

5 5

1.5

1.4

0.6

0

IC103 (TC7S08F) [ V

Pin

0

0

0

0

0

0

0

0

0

0

0

0

No.

1

2

3

4

5 5 - -

IC104(BA4560F)[V]

Pin

No.

1

2 0 -0.1 -0.1

3 0

4

5

6 0 0 0

7 0 0

8

MODE

STOP PLAY

0 0

0 0 2.0

- -

0

0

0 2.0

MODE

STOP PLAY

0 -0.1

-0.1

_

-5.0

0 0 • 0

5.0

- -

REC

0

REC

-0.2

-0.1

-

C

TRK OPEN

-GND

-GND

IC202(LA6517)[V]

STOP

0

9.4

-0.4

0 0

MODE

PLAY REC

0 0

- -

-0.4 -0.4

-

Pin

No.

1

2

3

4 -10.0

5 -0.4 -0.4

6 -0.4 -0.4 -0.4

7

8 0 0 0

IC203(LA6520)[V]

Pin

No.

1 0.01 0.01

2 0.01 0.3

3 0 0.3

4 0.04 -0.1

5 Z2 2.2 2.2

6 2.2 Z2 2.2

7 0 0

8 0 0

9 0 0

10

11 12

FIN -10.0

MODE

STOP PLAY REC

-

-

-

-

9.4

-

-

-0.4

0

Oto

0.2

0.1 to

0.4

0.2 to

0.3

-0.5 to

-0.7

0

0

0

-

-

-

-

Q101 (2SC2412K) [V]

Pin

No.

E 0.6

C

B 12 1.2

MODE

STOP PLAY REC

0.6

0.8

-

-

1.4

Q102(2SB1189)[V]

Pin

No.

E

C 1.5

B 42

MODE

STOP PLAY

5.0

5.0

1.5 1.8

3.8

REC

4.5

3.8

Q103(2SA1037K)[V]

STOP

5.0 5.0

1.0 1.0

-

MODE

PLAY REC

4.8

2.2

- -

Pin

No.

E

C

B

26

Page 27

PDR-04

Q104(2SA1037K)[V] Q106 (2SA1037K) [ V] Q109 (DTC114TS) [ V]

Pin

No.

E 5.0 5.0

C 1.0 1.0

B

MODE

STOP PLAY RED

4.8

2.2

- -

-

Pin

No.

E

c

B

Q105(2SA1037K)[V] Q107 (2SA1461) [ V]

STOP

- -

MODE

PLAY

1.0 2.2

REC

-

Pin

No.

E

c

B

Pin

No.

E 5.0 5.0 4.8

C 1.0

B

MODE

PLAY

STOP

5.0 5.0 4.8

- - -

- -

-

MODE

PLAY

STOP

- - -

1.5 1.5 1.8

3.0 3.0 3.0

REC

REC

Pin

No.

E 0

C 0 1.1

B

MODE

STOP PLAY

-

5.0 0

REC

-

1.2

0

Q111 (DTA114TK)[V]

Pin

No.

E 5.0

C

B 5.0 0 0

MODE

PLAY

STOP

- -

0 0 4.4

REC

SERVO UCOM BOARD ASSY

I Waveforms and voltages of SERVO UCOM BOARD ASSY

> Measuring condition : DC input unless otherwise noted.

J201 pin 10 (HF)

@ CN204 pin 1 (RF)

During CD PUY

SOOmV/div 0.5pS/div

@ 1C205 pin 63 (MIRR) 2V/div

@ CN204 pin 1 (RF) 0.5V/div

During manual search

0.5mS/div

©I

-GND

-GND

IC356pin48(SPSP)2V/div

@ IC205 pin 13 (CLV) lOV/div

IC205 pin 14 (ECLV) 10V/div|

In the /FCSON

test mod(

test mode SPDLON (CD)

20fiS/div

®

------------

®==

TRK OPEN

(?) J201 pin 10 (HF)

©1

GND

0

■GND

(2Ò)

•GND

IC356pin23(RFT)

@) IC356pin24(RFB)

During CD-R PLAY

(in common with GND of ® and

IV/div ImS/div

-GND

-GND

CN204 pin 2 (TE)

(D

Test mode

TRK, CLOSE state

Top : FILTER exist

Bottom; FILTER none

SOOmV/div 0.5mS/div

CN204 pin 2 (TE)

©

Test mode/FSC, SPDLON

Top ; FILTER%xist

Bottom: FILTER none

SOOmV/div 0.5mS/div

CN204 pin 6 (FE)

©

Test mode

TRK, CLOSE state

0.5V/div 2mS/div

I TRK, OPEN

@ IC206pin4(MDP)2V/div

@ IC205 pin 13 (CLV) lOV/div

@ IC205 pin 14 (ECLV) lOV/div

During CD PLAY

20pS/div

©

-GND

-GND

IC207 pin 4 (MDP) 2V/div

@ IC205 pin 13 (CLV) lOV/div

IC205 pin 14 (ECLV) lOV/div

During CD-R RE

20pSMiv

-GND

® '

...........

-GND

®

@ IC205 pin 13 (CLV) lOV/div

@ IC205 pin 14 (ECLV) lOV/div

....

--------------

IC205 pin 9 (SPDLO) IV/div

During STOP

20pSraiv

@ IC205pin19(FGIN)

@ IC205 pin 17 (FGOUT)

In the test mode

/FCSON

SPDLON (CD)

\TRK OPEN

2V/div 2mS/div

©ruuuuinr.

-GND

-GND

-GND

©jiniuinri-

IC206pin34(DATA)

@ IC206pin32(LRCK)

@ IC206pin35(BCLK)

During CD PLAY (1kHz OdB)

lOV/div 2pS/div

-GND

=

0

-GND

0

-GND

@ J201 pin 11 (WBL) 50mV/div

@ IC207 pin 1 (WBL) 2V/div

During CD-R PLAY

20nS/div

-GND

-GND

-GND

-GND

@ J209 pin 5 (DOUT) 5V/div

J208 pin 13 (MCK) 2V/div

During CD PLAY

O.lpS/div

-GND

-GND

-GND

©■

®.

©y\AAA/- GND

-GND

-GND

-GND

27

Page 28

PDR-04

IC201 (CXA1372Q) [V]

Pin

No.

1 0 0

2 0 0

3 0 0

4

5 -0.4 -0.4

6 0 0

7

e 0

9 0 0

10

11

12 0 0

13 0

14 0 0.3

15

16 -4.0 -4.0 -4.0

17

18 0 0

19 -4.0 -4.9

20

21 5.0 5.0

22 4.8 4.9

23 5.0 5.0

24 0.7 0.7

MODE

STOP PLAY

0 0

0.3 0.3

0

5.0 5.0

0 0

0

0

0

1.3 1.3

5.0

5.0

Pin

No.

REC STOP PLAY REC

0 25 4.9

0

26

0 27 0.8 1.5 1.9

0 28

-0.4

29

0 30 -4.9

0.3 31 2.5

0

32

0 33 0.1 5.0 5.0

5.0 34 1.4

0 35 -1.0 -1.4

0 36

0 37 0 -0.4 -4.0

0.3

38 -4.0 -3.2 -1.9

0 39 0 0 0

40 -0.1 0.1 3.9

1.3 41 -4.9 -4.9 -4.9

0

42

-4.9

43 0 0 0

5.0 44 0 0 0

5.0 45 0 0 0

5.0 46 0 0 0

5.0 47

0.7 48

MODE

4.9

0.1

0.1 1.2

0

0 0

0

0 3.7

-4.9 -4.9

2.5 2.5

2.6 2.6 2.8

-1.1 -4.8

5.0

5.0 5.0

0

0 0

0 0

0.2

0 0

0.2

IC207 (PDJ006A) [ V

STOP

0.1 2.3

5.0 5.0

0

0.3

0

2.4

0

0.1 0.1

3.3

3.2

1.2

MODE

PLAY

0

0

0

Pin

No.

REC

41 4.9

2.1

2.8 42 5.0 5.0

0.1 43 5.0 5.0 5.0

2.S 44 5.0 5.0 5.0

45 0

0

0.2 46

47 0 0 0

0

0

48

5.0 49 0 0 0

02 50

5.0 51

5.0 52

0

5.0

2.4

3.3

3.2

1.4

53 0 0 0.

2A

4.9

54

5.0 55

5.0 56 0 0 0

5.0

57

5.0 58 5.0 5.0

59 1.9

04

-

60 5.0

4.9 61

4.9 62

1.3 63

2.2 64

65 5.0 0 0

22

67 5.0 5.0 5.0

1.1

0 68

1.7 69

0.8 70 5.0 0 0

4,7 71 0 5.0 5.0

3,1 72

73 0 0 0

3.3

2.8 74

2.9 75

2.5 76

3.4 77

5.0 78

1JS 79

80 0 0 0

3.3

Pin

No.

1

2 5.0 0

3 0.1 0

4

5

6

7

8 0 0

9 5.0 5.0

10 0.1 0.1

11 5.0 5.0

12 5.0 5.0

13

14 4.9 4.9

15 0 0

16 0 0

17

18 5.0 5.0

19

20 4.9 4.9

21 4.9 4.9

22 4.9 4.9

23 1.6 0.9

24

25 3.6

26 4.1 3.2 3.5 66 5.0 5.0 5.0

27 1.1 0.9

28 0 0

29 1.4 1.0

30 0.5 0.7

31 4.7 4.7

32 2.8 3.4

33 3.0 3.1

34

35 3.2 3.4

36 1.8 1.8

37 3.4 3.2

38 5.0 5.0

39

40 2.9 2.6

MODE

STOP PLAY REC

5.0

0

0

0

0 0 0

0

0 0

0 0

0

0 0

0

0

0

0 0

0

0

1.6

5.0

0

0

0

0 0

0

5.0

0 5.0 0

0

0 0

5.0

0 5.0

0 0 0

0

0

0 0 0

0 0 0

0

0

5.0 5.0 5.0

0 0 0

IC205(PA9004A)[V

Pin

No.

0

1

2

3 3.1

4

5

6

7

8

9

-4.8

10

11 0

12

13 0

14 0

15

16 0

17

18

19 0

20

21 0

22 0 0 5.0

23 0

24 0 0

25

26

27

28 0

29 0

30 0

31 0

32 0

4.9

5.0

0

0

IC208 (LM2940CT-5.0) [ V ]

Pin

No.

0

IC311 (PST529C)[V

0

No.

0

5.0

2.5

5.0

0

IC204 (HD74HC4053FP) [V]

5.0

No.

0

0

MODE

STOP PLAY REC

5.0 5.0 5.0

2.5 2.4 2.5 34

3.1 2.5

0.8 0.8

0.8 0.8 2.3 37 0 0 0

2.5 2.5

2.5

2.5 2.4 1.8

2.5 2.5 2.5 40 0

2.4

2.6

2.5 2.5 2.5

0

2.4 2.4 24 44 0

4.9 4.9

4.9

2.5

2.5

0 0 48 1.6

5.0 2.8 2.8 49 1.6

-4.0 -4.0 -4.0 50 1.6

3.3 3.3 51

0

0 0 52 -0.3 1.4 1.8

0 0 53 -4.0

0 5.0 55 -1.0 1.5 1.3

1.0 1.0 57 0 0 0

5.0 5.0

0

5.0 0 59 0 0.9 0.3

0 0 60 0.4 0.4 0.4

0 0

0

0 0 63

0 0 64 3.9 3.9 3,9

MODE

STOP PLAY REC

U

G

Pin

1

2 0 0 0

3

Pin

1

2 0 0 0

3

4

5

6

7

B

9

10

11

12 5.0 5.0 5.0

13

14

15

16

- -

9.3

-

0

5.0

- -

MODE

STOP PLAY REC

5.0 5.0 5.0

5.0 5.0 5.0

MODE

PLAY REC

STOP

0 0 0

0.9 1.5 1.9

0.1 9

0.9

0.1

0.1

0 0

0

0 0

0

0 0

0

5.0 0

0 0 0

0 4.9 0.2

0 5.0

5.0 5.0 5.0

0 0 0

5.0 5.0

Pin

No.

STOP PLAY

3.9

33

0 0 0

35 0.6 0.6 0.6

2.3

36

0.1 0.1

38 0 0 0

0

39

41 0

ZJS

0 43

0 46 0 0 0

2.6 47 1.6

0 56 -0.3 1,9 1.9

5.0

0 62

-

1.3

0

42

0

5,0

45

1.6 1.6 1.6

54 0.3 1.4 2.3

58 -0.8

5.0

61

1.7

5.0

s.o

5.0

S.O

MODE

3.9 3.9

0 0

0 0

0 0

0 0

0 0

0 0

2.4 2.4

0.9 1.2

2.6 1.2

2.6

2.6

-4.0

-0.6

0 5.0

0.4 1.7

5.0 2.8

IC206 (CXD2500BQ)

Pin

No.

REC

0.1

1.9

1.9

-4.0

-0.8

1 0.1 4.9

2 0

3 0 5.0 5.0

4 2.4 2.5 3.8

5

6

7 0.1

8 S.O S.O 5.0

9 0 0 0 49 0

10 0 0 0

11 0.1 0.2

12 0 0 0

13 0.1

14 0.1

15 0.1

16 5.0 5.0 5.0

17

18

19 2.5

20 2.5 2.5 2.5 60

21

22 2.6 2.6 2.6

23 5.0 5.0 5.0

24

25

26 0 0

27 2.5 2.5 2.5 67

28 0

29 0 0,1 0.4 69 0.1

30 0 0 0 70 4.9

31 2.5 2.5 2.5 71 0.7

32 0

33 5.0 5.0 5.0 73 5.0

34 0 1.2 0 74 4.8

35 1.9 1.9 1.9 75 0.9

36 0 1.2 0 76 0.8

37 1.9 1.9 1.9 77 0.7

38 2.5 2.5

39 5.0 0 0 79 4.8

40 5.0 5.0 5.0 80 0.9

MODE

STOP PLAY REC

0.2 0.6 42

0.1 0.2

S.O 5.0

0

0.2

0.2

0.2

0.2

0

0

2.6

2.6

2.5

0 0

2.6 2.8

2.6

0.1 0.4

0

0

0.1 2.5

V]

Pin

No.

STOP

41 1.1

4.8

43

44 S.O

0.6

45

46 4.3

0.6 47

48

50 1.2

0.6 51

52

0.6

53 2.1

0.6 54

0.3

55

56 2.8

0 57 1.0

2.6 58

2.5 59 5.0

0 61

62

63

64

65

0 66

0 68

72

78 5.0

2S

MODE

PLAY REC

0

2.5

0

3.3

3.3

1.2

0

2.8

0

2.1 2.1

2.1

0

2.5

0

1.5

0

0

4.9

0

4.9

1.1 1.1

5.0 5.0

2.5 2.5

0 0

5.0 5

4.4 4.4

0 0

0 0

0 0

1.2 1.2

1.2 1.2

0

2.1 2.1

2.7 2.7

0 0

2.7 2.7

1.0 1.0

5.0

2.1 2.1

0

2.5 2.5

0.1 0.1

0.1

0

4.6

4.9

0

2.7 2.8

4.9 4.9

0.6

4.9

5.0

4.9 4.9

1.4

0.1 1.7

0.6

5.0 5.0

4.9 4.9

0.1 1.8

IC352(LH5116NA-10)[V] IC353 (HD74HC573FP) [ V]

Pin

No.

STOP

1 2.8

0.7

2

3 3.8

4 2.7

5 4.0

6 3.6

7

3.2 2.5 2.6

1.5

8

9 2.7

10 3.0

11 3.2

0

12

3.3

13

1.8

14

3.4

15

16 1.2

2.9

17

18 4.5

19 0.9

4.9

20

21 4.9

22 2.7

23 2.8

4.6

24

MODE

PLAY REC

2.7 2.7

1.4 1.1

3.7

3.3

2.0 2.5

3.4 3.7

3.0 2.6

0.9 1.1

3.3 3.1

3.3

3.1

3.0

3.1

0 0

3.4 3.2

2.0

1.8

3.4

3.3

1.5

2.8

2.7

4.5

4.5

0.8 1.1

4.9

4.9

4.9

4.9

2.5

2.5

2.9

2.8

4.5

4.6

Pin

No.

1

2

3 3.0 3.2

4 3.2 3.2 3.0

5 3.2

6

7

8 1.2

9

10 0

11 0.1 0.1

12 2.8

13 0.8

14

1.4

15 0.3 1.9

16

17

18 3.2

19 1.5 0.9

20 5.0

STOP

0 0

2,7

1.9

3.5

2.8 2.7

3.9 3.5

4.1 3.0

3.6

MODE

PUY

3.4

3.3

1.8

3.1

1.4

0

2.7

1.6

3.2 Z2

2.3

5,0

REC

0

3.1

3.4

3.2

2.1

3.3

1.4

2.7

0

0.1

3.0

1.0

3.7

2.9

3.4

Z2

1.4

5.0

0

2.1

5.0

0

0.1

0

4.7

4.9

0

0.7

4.9

5.0

1.7

0.7

28

Page 29

PDR-04

IC351 (PD4785A) [ V

Pin

No.

1

2 0 0 0

3 0 0 0 43 0

4 0 0 -22.0 44 0.1

5 -22.6 0 -22.0 45 5.0 0 0.1

6 0 -22.0 -22.0 46 0.08 0 0.1

7 -22.6

8

9 0.06

10 0.06 0 0 or 5 50

11 0 0 0 51 4.9 4.9 0

12

13 5.0

14

15 4.5 0 0 55

16 0.8 0 0 56 -23.6 -23.2

17 5.0 0 0 57 -23.6

18

19 0.08 0 0 59

20 0.08 0 0 60 0 0 0

21 0.08 0 0 61

22 0.05 0 0 62

23

24 0

25 5.0

26 0.06 5.0

27 5.0 5.0 67 -21.8

28

29 0.06 0 0.1 69 -24.6

30 0.06 0 0.1 70 -8.8

31 0 0 0.1 71

32 0.07

33 0.07 0 0.1 73

34

35 0.06

36 0

37 0.06 0 0.1

38 0

39

40

MODE

PLAY

STOP

-22.0 -22.0 41 4.8 4.8

-22.6

-22.0

5.0 5.0 5.0 48 0.07 0 0.1

5.0

5.0 5.0

5.0 0

5.0 0 0 54

5.0 5.0 0 58 0 0

5.0 5.0 63 4.6 4.6

0 0

5.0

0 0 0.1

0

0.07 0 0.1 74 -9.6

0

0

0 0 78 -22.4 -22.1 -22.0

0 0 79 -22.3

4.9

0.05

Pin

No.

REC

42

-22.0 47 0.08 0 0.1

5.0 49

52

53

64 0 5.0

5.0 65 -24.6

-

66 -13.8

68

0.1 72 -12.1

75 -9.6

0.1

0.1 76

77 -22.4 -22,1 -22.0

80 -22.4 -22.0

4.9

MODE

PLAY

STOP

4.8 4.8 4.8

5.0

4.9

0.07

-24.5 -24.4 -21.4

-25.0 -24.6

-12.0 (-1410 8)

-12.1

4.9 4.9

5.0 5.0

4.7 4.7

4.7 4.7

4.7 4.7

-23.3

0 0

0

0 0

-24.3

-13.6

-13.4

-16.3

-13.3 -13.4

-11.7

-9.4

-9.4

-6.9

-22.0

0 0.1

0 0

(-1210 14)

REC

4.8

5.0

0.1

5.0

4.7

4.7

4.7

-23.2

-23.1

4.6

5.0

-16.0

-10.9

-13.3

-16.2

-24.7

-9.3

-22.0

-22.0

IC356 (PD4786A) [ V

Pin

No.

1 3.3

2 1.9

3 3.4

4

5 0

6 0

7 0

8 0

9 0

0

10 0

11

12 0

13 0.6

14 0.2

15

16 0

17 4.9

0

18 0 0 0 55 5.0

0

19

20 0

21 0

0

22 0

23

24 1.6

25

26 5.0

27 5.0

28 5.0

29

30 0.4

31 0.4

32 0.3

0

33 0

0

34 5.0

0

35 0

36 0.8 0 2.8 73 0.1

37 0.2 0

MODE

STOP PLAY

3.4 3.3 38 0.1

1.8 2.0 39 4.7

3.3 ZA 40 4.3

1.2

1.6

0

0.8

0.3

5.0

5.0

4.9 4.9 54 0 0

0

0.1 0

1.7

2.6

0.8

4.8

4.8

5.0

5.0 5.0 64 0.1

5.0 5.0 65 0.1

4.9

5.0

2.8

5.0

Pin

No.

REC STOP

1.3

41

0.3

0

0 02 43 0 0

0 02 44 4.3

0

0 0.2 46 0

0 0.2 47 0

0 14 48

0

0 0 53

0 0 56 0.1

0 0

0 0 58 5.0

0

0 0 69 4.9

0 0 70 4.9

0 5.0 71 0.1

42

1.0 45 0

0.2 49

0.9 50

0.3

51

5.0

52

57

59

2.0 60 0.1

1.2

61

4.8

62

5.0

63 0.1 5.0 4.9

4.9 66 0.1

2.8 67 4.9

0 68 4.9

5.0

72

74 0.1

0

MODE

PLAY REC

4.8

4.9

2.5

0.1

0.1

2.6

2.6

0

0 0 0

3.5

5.0 5.0

4.8 4.8

2.0 2.6

4.7 4.7

4.9 4.8

4.3

4.2

5.0 5.0

4.9 0

4.9 4.9

2.6 2.3

0.1

0.1

0.1

4.9

- -

- -

0 0

5.0 5.0

4.8

4.8

4.9

4.9

5,0 5.0

0 4.9

5.0 5.0

0 0

4.9 4.9

4.9 4.9

4.9 4.9

4.9

4.9

0.1

3.3 3.1

3.2 3.3

3.0

3.2

IC357 (TC74HC367AF) [ V]

Pin

No.

1 4.4

2

3 0

4 4.5 4.4 4.4

5 4.5

6 5^ 5.0 5.0

0

7 4.7

8

9 4.8

10 4.8 4.8 4.8

11

12

13 4.8 4.7 4.7

14

15

16

0

MODE

STOP PLAY REC

4.3

0

0

0

2.3

2.5 2.5

0

0 0

4.8 4.7

0

0 0

0

0 0

4.5

4.4 4.5

4.5

4.4 4.5

5.0

5.0 5.0

IC358 (TC74HC367AF) [ V ]

STOP

0.6

4.9

4.9

4.9

4,3

4.7

AA

4.8

s.o

5.0

5.0

0

MODE

PLAY REC

0.6 0.6

4.9 4.8

4.9 -

4.9 4.8

1.8 to

2.3

2.5 2.5

0

2.2 2.2

2.2 2.3

4.7 4.7

4.6 4.6

4.9 4.9

4.8 4.8

4.8 4.8

5.0 5.0

Pin

No.

1

2

3

4

5 4.8 4.8 4.7

6

7

8 0

9 4A

10

11

12

0.1

13

14 4.9

15

16

IC359 (TC7S04F) [ V

STOP

0.2

4.7

5.0

0

MODE

PLAY

0 0.1

0.3 0.3

0

4.7

5.0 5.0

Pin

No.

1

2

3 0

4

5

4.3

0

0

2.3

2.2 to

2.7

0

REC

0

4.7

IC354 (TC7S00F) [ V

STOP

4.9

0

MODE

PUY

0

4.9

0

4.5 4.5

4.5 4.5

REC

0

4.9

0

Pin

No.

1 0

2

3

4 4.5

5 4.5

IC355 (TC7S04F) [ V

STOP

0

0

MODE

PLAY

0

5.0 5.0

0

0

5.0 5.0

REC

0

0

0

Pin

No.

1 0

2 4.9

3

4

5 5.0

IC360 (XL93LC46AF)

Pin

No.

1

2

3

4

5 4.3

6 4.8 4.7 4.7

7 0

8

MODE

STOP PLAY REC

0

0 0

5.0

5.0 5.0

0

0

4.9

0

4.8

4.8

2.2

2.2

0

0

0

0

0

IC361 (PST572E) [ V

Pin

No.

1

2

3

MODE

STOP PLAY

5.0

5.0

0

0

4.9

S.O

REC

5.0

0

5.0

V] IC362 (TC7S04F) [ V

Pin

No.

1

2 5.0 0

3

4

5

MODE

PLAY REC

STOP

02 0 0.1

0 0

0

5.0 0

0

5.0 5.0 5.0

IC363 (TC7S14F) [ V

Pin

No.

1

2 0 5.0 0

3

4

5

MODE

STOP PLAY REC

0 0.1

02

0 0

0

0 5.0

S.0

5.0 5.0

IC5008 (BA4560F) [ V ] IC5024 (HD74HC4053FP) [ V ]

STOP

-5.0

0

0

5.0

MODE

PLAY REC

-0.5

-5.0 -S.O

0 0

0 0

5.0 5.0

Pin

No.

5.0

5.0

1 0 -0.2

2 0 0

3 0 0

4

5

6

7 0 0.1 -0.3

8

Pin

No.

1

0

0

2

3

4 0

5

6 0

7

8

9 0

10

11

12

13

14 0 0

15 0 0

16

STOP

0 0.3

0 0

0 0

0 0

-4.9

0 0

0 0

0 0

0

0

5.0

MODE

PLAY REC

-0.5

0

0

-4.9 -5.0

4.9

0

-1,0 to

-0.7 to

-0.2

5.0

0

0

0

0

0

0

5.0

0

0

0

-0.5

0

0

5.0

29

Page 30

PDR-04

Q13(DTC114TK)[V

Pin

No.

E

C 0

B

MODE

STOP PLAY

0 0

0

5.0

5.0

REC

0

0

5.0

Q14 (DTA124EK) [ V

Pin

No.

E

C

B 0 0 0

MODE

STOP

PLAY REC

5.0 5.0

5.0 5.0 5.0

5.0

Q201 (DTA124ES)[V]

STOP

5.0

5.0

MODE

PLAY

5.0

0 3.4

5.0

REC

5.0

2.8

Pin

No.

E

C 0

B

Q202 (2SC2412K) [ V ]

STOP

-4.7 4.6

MODE

PLAY

5.0

REC

3.9

5.0

4.6

Pin

No.

E -3.8 0

C -4.9

B

Q203(2SA1037K)[V]

Pin

No.

E

C

B

MODE

STOP PLAY

3.9 -3.9

5.0

-4.9

4.6 -4.7

REC

-3.9

-4.9

-4.7

Q208 (DTC114TS)[V]

STOP

0

0.6

4.4

MODE

PLAY REC

0

0.6 0.6

4.3

0

4.3

Pin

No.

E

C

B

Q5026(DTC124ES)[V]

Pin

No.

E

C 5.0

B 0

MODE

STOP PLAY REC

5.0

5.0

5.0

3.6

3.6

5.0 5.0

AUDIO DIGITAL BOARD ASSY

> Waveforms and voltages of AUDIO DIGITAL BOARD ASSY

• Measuring condition : DC input unless otherwise noted.

(T) 1C801 pin 2

^ (ADCLDATA)

©

pin 27

RDATA)(ADC

During REC

(Analog 1 kHz OdB)

IV/div ImS/div

(?) IC401 pin9(LRCK)

(t) IC401 pin 8 (SDATA)

IC401 pin? (BiCK)

During REC

lOV/cSv 2pS/div

(ÍÍ) ÍC302 pin 9 (VCO iN)

1V/div

1V/div

(12) IC302 pin 4 (VCO OUT)

IC302 F

>< lOV/div

lOV/div

IC301 pii

(13) ÍC301 pin 80 (EC ERR)

10V/div

During REC 50nS/div

©■

OAAAAAAAAA/V

® ^/\J\r\/\r\f\f' ÍIgnd

--------------------

(3) IC801 pin 14 (ADC LRCK)

IC801 pin 16 (ADC DATA)

(D IC801 pin 15 (ADC BCK)

During REC (1kHz OdB)

lOV/div 2riS/div

©

©

©

♦-GND

-GND

GND

ND

(9) IC304 pin 9 (AO)

@ IC304pin1 (I/O)

Optical input during REC

5V/div 0.2iiS/div

©

0

v\5) IC301pin4

^ (DIN2 : COAX IN)

-GND

-GND

0

- -GND

IC301 pin 1

PN1 : OPT IN)

Optical, coaxial and

simultauieous input

During REC

lOV/drv 0.2jiS/div

(IS) s-

IC404pin7

>< (LIN oDt Lch) 5V/div

(179 0407 (Emitter) 5V/div

nW IC406pin7

^ (HPOUTLch)10V/div

During PLAYBACK

(CD llcHz)

0.5mS/div

© ^\/\/\/\y -^GND

© vAAA/'

© \/\/\/\/^ -»-GND

-GND

-GND

30

Page 31

PDR-04

IC301 (LC89585)[V]

Pin

No.

1 0 0 0

2 0 0 0

3 0 0 0

4 0 0 0

5

6 2.4 2.4

7 5.0 5.0 5.0

8

9 0

10 2.5 2.5 2.5

11 2.5 2.5 2.5

12

13

14 2.0 2.3

15 0 0 0

16 0

17

18 0 5.0

19 0 5.0 5.0 69 0 0 0.8

20 5.0 5.0

21 0 0

22 0 0

23 0 0

24 0 0

25 0 0

26 2.4 2.4

27 2.4 2.4

28 2.4 2.4

29 5.0 5.0 5.0

30 0 1.6

31 2.0 2.0

32 2.5 0

33 0 0

34 0 0.6

35 2.0

36

37 0 5.0

38 2.2 2.2

39

40 0 0 0

41 5.0 5.0 5.0

42

43 2.0 2.2

44 0 2.4 0 94 0.2 0

45 2.0 2.0 2.0 95 0 0

46 2.5 2.5

47 2.4 2.4

48

49 0 0

50 4.9 4.9

MODE

STOP PLAY REC

2.4 2.4

1.8 1.8

0

0 0 0

5.0 5.0

0 0

0 0

2.0 2.0

0 2.5 2.5 86 0 0 0.6

2.7 2.7 2.6 89 5.0 5.0 5.0

2.0 2.0 2.2

2.0 2.0 2.1 98 4.9 4.8

Pin

No.

51 0 0

52

53 5.0 5.0

54 0 0 2.3

2.4

55 0 0 2.3

2.4

56

57

1.8

58

0

59

60 0 0

61

62

5.0

63 0 0 1.4

2.4

64 0 0 1.3

65

66 5.0 5.0 2.0

0

67 5.0 5.0 4.1

5.0

68

5.0

70 0 0 0

0

71 0 0 0.7

0

72

0

73

0

74 0 0 0

0.1

75 5.0 5.0 5.0

5.0

76 2.6 0 2.5

Oto

77 2.7 5.0 2.7

3.4

0 to

78

24

79 2.4 0

0

80 0 5.0

22

81 0 0

2.5

82 0 0 0

0.6

83 5.0 0

0.6

84

85

0

87 0 0 0.7

2.2

88

90

91

92

2.2

93

2.5

96

2.4

97 4.8 4.8

0

99 0.6 2.3

4.9

100 5.0

MODE

STOP PLAY REC

5.0

5.0

0

0

0

0

0

0

0

0

5.0

5.0

0

0

0 0 2.4

0 0 0.9

0 0 0

0 0

2.4 0 2.4

0

0

0 0 3.1

0 0 1.9

0 0 0

1.4 5.0

5.0 5.0

5.0 4.9

0 0

5.0 5.0

IC302 (CD74HC4046AM) [ V ] IC404 (NJM4580D) [ V ] IC801 (AK5340-VS)[\/]

MODE

Pin

No.

0

3.9

4.1

2.4

2.5

2.5

2.5

2.4

5.0

0

STOP

1 5.0

2

3 0

4 2.5

5 0

0.7

6

7

0.7

8

2.5

9

10

11 2.5

12 AA

13 0

14 0

5.0

15

16 5.0

0

0

0

IC304 (MB81C4256A-70PJ)[V]

Pin

No.

1 0 0 1.4

0

2.4

0

0

5.0

4.9

1.3

5.0

4.9

0.3

0

0

4.8

4.8

2.3

2

3 5.0 5.0 4.1

4 5.0 5.0 2.0

5 0 0 2.5

6

7 -

8

9 0 0

10 0 0 1.4

11 0 0

12

13

14 0 0

15 0 0 2.5

16

17 0 0 2.5

18 0 0 2.5

19

20

21

22

23

24 0 0 0.9

25

26 0 0 0

IC803(NJM4580D)[V3

Pin

No.

1

2

3

4 -9 -9 -9

5 0 0 0

6

7

8

MODE

STOP PLAY

0 0 1.4

- -

_

0 0

5.0 5.0

0 0 2.5

- - -

- - -

- - -

5.0 5.0 4,1

5.0 5.0 3.9

0 0 0.8

MODE

PLAY

STOP

0 0 0

0 0 0

0 0 0

0

0 0

0 0

9 9 9

REC

-

-

-

1.3

2.5

2.5

5.0

2.5

REC

0

IC804(NJM4580D)[V]

STOP

0

-9 •9

0 0

0 0

MODE

PLAY

0 0

REC

-9

0

0

Pin

No.

1 0 0 0

2

3 0 0 0

4

5 0 0 0

6

7

8 9 9 9

Pin

No.

1 0 0

2

3 1.2 1.2

4 -9

5 0 0

6

7

8 9

IC406 (MS218AFP) [V]

Pin

No.

1 0 0

2

3

4

5 0

6 0 0 0

7 0

8 9

Q301 (DTA114TS)[V] Q403 (DTA124ES) [ V]

Pin

No.

E 5.0

C OS 0.4

B

Q303(DTA114TS)[V ] Q404 (DTC124ES) [ V ]

Pin

No.

E 5.0

C

B

Q304 (DTC114ES)[V3 Q405 (2SD2114K) [ V ]

Pin

No.

E 0

C 2.0

B 02

Q401 (DTC124ES)[V]

Pin

No.

E

C 14

B -9

Q402 (DTA114ES)[V]

Pin

No.

E

C -9

B

MODE

PLAY

STOP

1.2

1.2

-9

0 0

0 0

9

MODE

PLAY

STOP

0 0

0 0

-9 -9

0

0

9

MODE

PLAY

STOP

5.0

5.0 5.0 5.0

MODE

PLAY

STOP

5.0

0.9 0.8 0.8

5.0 5.0 5.0

MODE

PUY

STOP

0

-

-0.1 to

0

MODE

PLAY

STOP

-9 -9 -9

-9

2.0 2.0

MODE

PLAY

STOP

5.0

5.0

5.0

5.0 3.6 3.6

REC

1.2

1.2

REC

REC

5.0

0.4

REC

5.0

REC

REC

REC

5.0

Pin

0

-9

0

0

0

9

0

0

0

-9

0

0

9

0

-

0

No,

1 2.5 2.5

2 2.5 2.5 2.5

3 5.0 5.0 2.4

4 5.0 5.0 0

5 0 0

6 0 0

7 0 0 0

8 0 0 0

9 0 0 0

10 5.0 5.0 0

11 0

12 5.0 5.0 5.0

13 0 0 0

14

15 2.0 2.0

16 0

17 5.0

18 5.0

19 0

20 2.1 2.1 2.1

21 0

22

23 0

24 5.0

25 0 0 0

26

27 2.5 2.5 2.5

28 2.5 2.5 2.5

Pin

No.

E

C -9 5,0 5.0

B 5.0

Pin

No.

E

C -9

B

Pin

No.

E

C

B

MODE

PLAY

STOP

2^

0 0

5.0 5.0 2.4

STOP PLAY REC

5.0 5.0 5.0

STOP

5.0 5.0 5.0

5.0

STOP

-9 -9 -9

1.1 -9 -9

-9

0

2.5

0

5.0

5.0

0

0

0

5.0

MODE

0.2

MODE

PLAY

5.0

0.2

MODE

PLAY

3.7

REC

2.5

2.5

2.2

2.5

5.0

5.0

5.0

REC

REC

0

0

0

0

0

0

0

0.2

5.0

0.2

3.7

Q406 (2SD21 UK) [ V ]

STOP

-9

-9

MODE

PLAY REC

-9

-9 -9

3.7

-9

3.7

Pin

No.

E

-9

C 1.1

B

Q408 (2SD2114K) [ V ]

Pin

No.

E 0

5.0

C

B

MODE

STOP PLAY

0 0

0 0 0

0.6

-0.7

REC

-0.1

31

Page 32

PDR-04

4. PCB CONNECTION DIAGRAM

NOTE FOR PCB DIAGRAMS :

1. Part numbers in PCB diagrams match those in the schematic

diagrams.

2. A comparison between the main parts of PCB and schematic

3. The parts mounted on this PCB include all necessary parts for

several destinations.

For further information for respective destinations, be sure to

check with the schematic diagram.

4. View point of PCB diagrams.

Connector Capacitor

(zi#.-:7ir) (a>-r>+h)

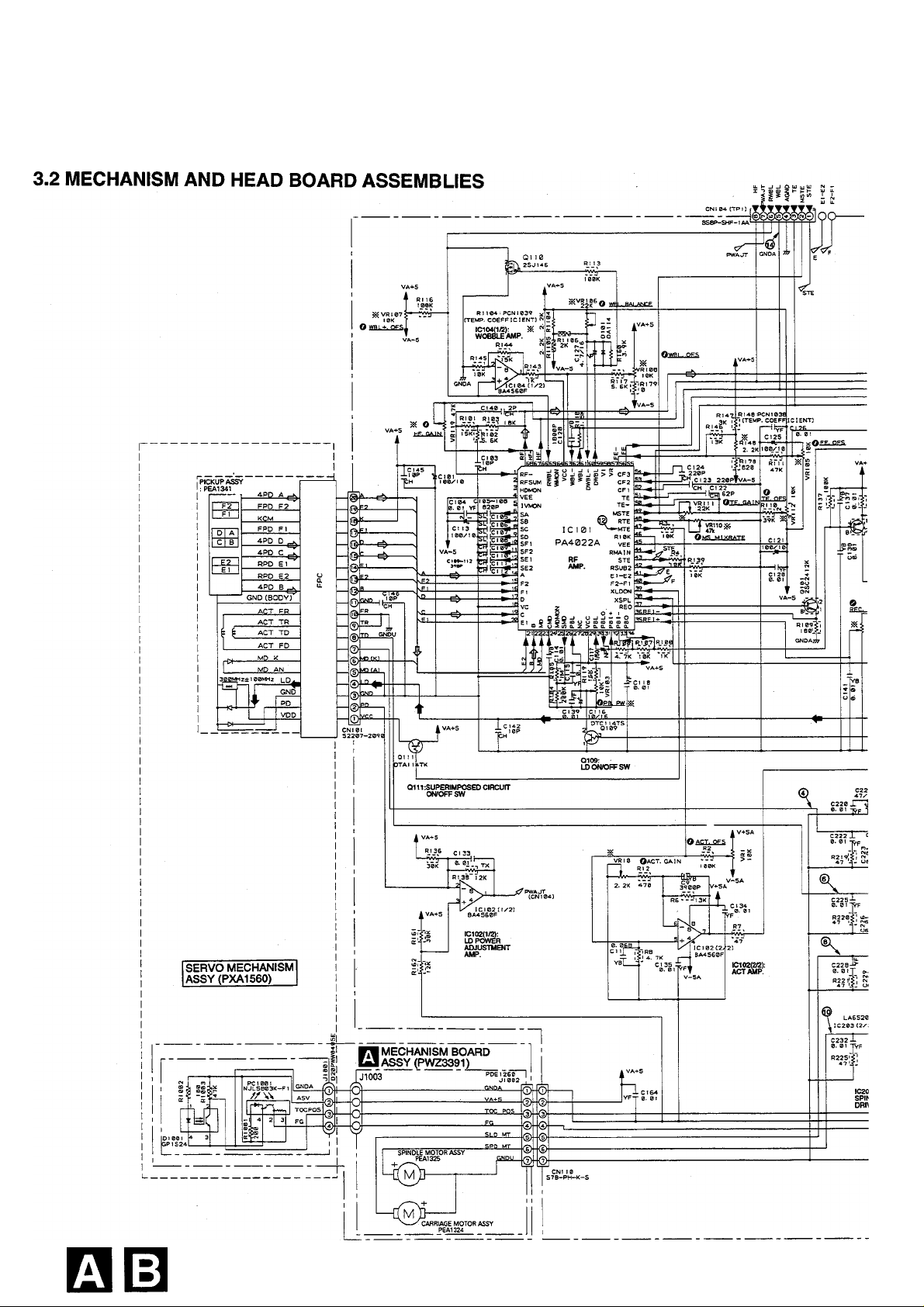

4.1 MECHANISM AND HEAD BOARD ASSEMBLIES

VR104

VR115

VR105

VR108

VR107

VRl

VR10

VR119

VRH1

VR106

VRl 12

VRl 10

VR103

IC202

IC203

Q111

0109

1C102

IC103

0113

32

Page 33

HEAD BOARD ASSY

PDR-04

0102

0115

0117

0116

0107

IC101

0106

0104

0101

0109

0105

0103

0108

IC104

0110

3« V "O- JS

0 -^-O i/'-i

«a« ITS.- 3 O'

il. 0

C C

-O

(PNP1418-A)

MECHANISM

BOARD ASSY

SIDEB

AlB

33

Page 34

PDR-04

4.2 SERVO UCOM BOARD ASSY

H SERVO UCOM BOARD ASSY

O 0 O o]

o

'CNl

i to o ol

........

i.rrB«v

p 0 o ol 1

..............

^

è èÈ

JS05

................

^'sK3Ì0

...............................

0

' ...........................................

:

£CC:' ■ c ;

] = C . --1

C3

■■■■ a,, ■

n

kSig

3.IWT1

4, -N'?

S:.

'

'03

O

Q5026

IC207

IC206

RS66

C289

Rg67

IC355

13

IC354

CN301

IC208

IC358

IC357

1C205

IC360

Q208

Q280

IC5024

IC311

IC361

Q201

IC201

34

13

CN701

(PNP1418-A)

SIDE A

Page 35

IC359

IC352

IC204

IC362

1C363

1C353

PDR-04

SERVO UCOM BOARD ASSY

IC356

Q14

Q13

IC5008

Q202

Q203

IC351

(PNP1418-A)

SIDEB

35

Page 36

PDR-04

4.3 AUDIO DIGITAL AND STRATEGY SMALL BOARD ASSEMBLIES

H AUDIO DIGITAL BOARD ASSY

IC408

Q403

Q404

Q405

Q407

IC407

IC404

IC401

Q408 Q406

Q401 Q3002

0402 03001

IC406

IC338

IC33I

IC333 03006

IC340 03005

IC342

IC334

IC302

IC304

IC34I

IC339

1C 301

03007

IC335

IC312

IC337

IC308

IC305

0304 0301

IC309

0303 IC3001

IC303

IC2002 1C2005

IC803

1C 801

IC804

Page 37

AUDIO DIGITAL BOARD ASSY

PDR-04

SIDE B

37

Page 38

PDR-04

4.4 FUNCTION, POWER A AND POWER B BOARD ASSEMBLIES

POWER A BOARD ASSY

□

CN303

AC POWER CORD

38

GlH

(PNP1393-D)

SIDE A

Page 39

PDR-04

Page 40

PDR-04

4.5 ALC AND HEADPHONE BOARD ASSEMBLIES

ALC BOARD ASSY

SIDE A

HEADPHONE BOARD ASSY

-------------------------------

o

K№U/

ft-

.fib

PWZ3590-

^wz34se-

O

CN211

1 I

SK5V0

--------------------------------

■B-

so ci|ti

-VR40i

CI39J ■"

o

cn-

Utm

ALC BOARD ASSY

HEADPHONE BOARD ASSY

SIDEB

40

E F

Page 41

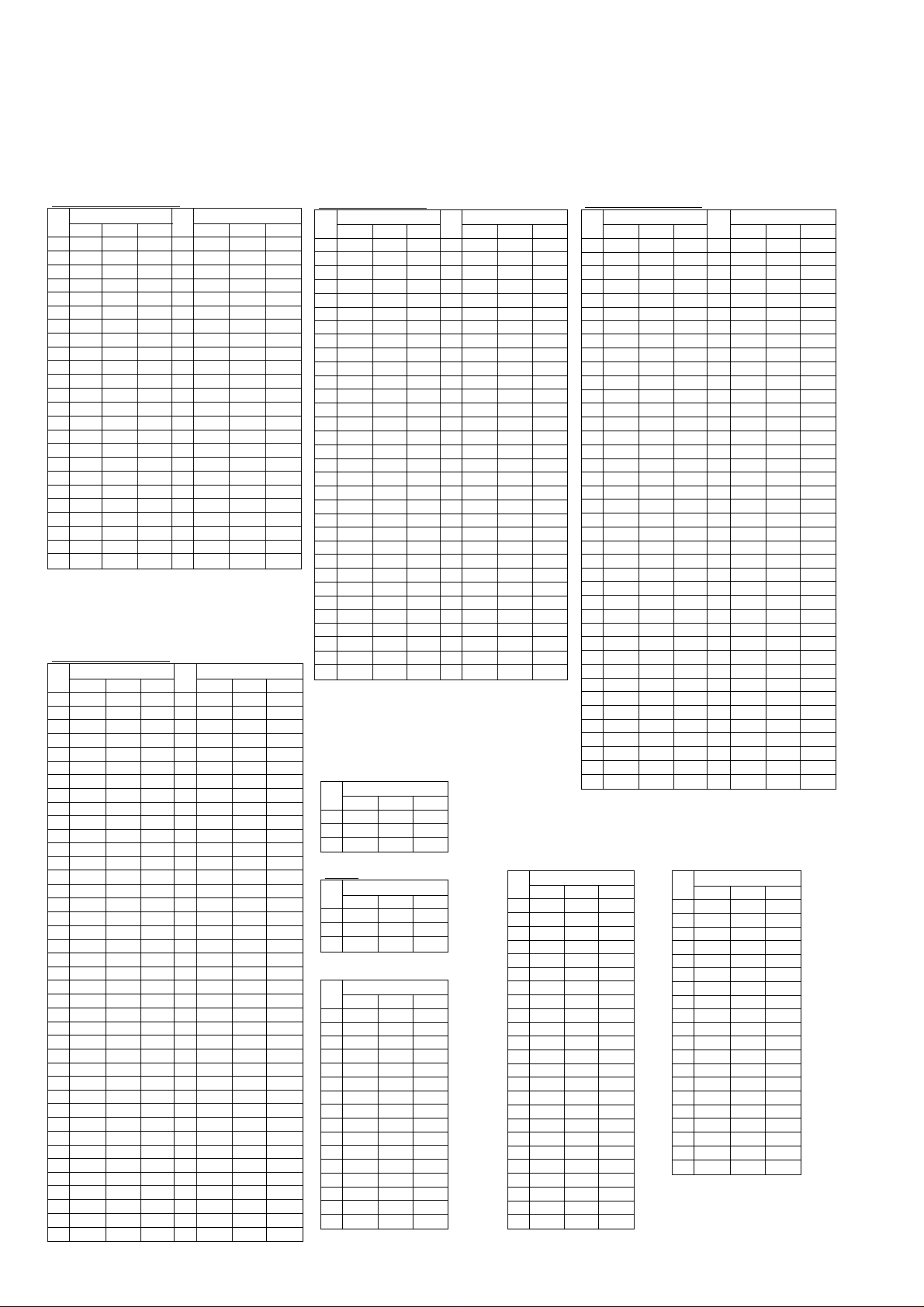

5. PCB PARTS LIST

NOTES: • Parts marked by *NSP" are generally unavailable because they are not in our Master Spare Parts List.

• The ^ mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

• When ordering resistors, first convert resistance values into codeform as shown in the following examples.

Ex.l When there are 2 effective digits (any digit apart from 0), such as 560 ohm and 47k ohm (tolerance is shown by J-5%,

andK=:10%).

560 n 56x10' 561

47kD. -► 47x10' -► 473................................................................................................................................................................RD1/4PU\À]\7]{^J

0.5 a -► R50........................................................................................./?a^2h1II[I1!IIa:

la -► iRO..............................................................................

Ex.2 When there are 3 effective digits (such as in high precision metal film resistors).

5.62kQ -► 562x10' 5621

................

............................................

.........................................................

RD1/4PU [Hll]|I] 7

RN1/4PCMEM\1\F

PDR-04

Mark No.

Description Part No.

LIST OF ASSEMBLIES

NSP MOTHER BOARD ASSY PYY1209

NSP h HEAD BOARD ASSY PWZ3386

NSP - ALC BOARD ASSY PWZ3389

NSP - HEADPHONE BOARD ASSY PWZ3390

NSP L mechanism BOARD ASSY PWZ3391

NSP auD 10 DIGITAL BOARD ASSY PWZ3388

NSP •- SERVO UCOM BOARD ASSY PWZ3387

NSP STRATEGY SMALL BOARD ASSY PWX1518

NSP SUB BOARD ASSY PWX1505

HEAD BOARD ASSY PYY1211

-AUDIO DIGITAL BOARD ASSY PYY1212

LSERVO UCOM BOARD ASSY PYY1214

-FUNCTION BOARD ASSY PWZ3042

- POWER A BOARD ASSY PWZ3354

L POWER B BOARD ASSY PWZ3359

MOTHER BOARD ASSY

OTHERS

PC BOARD PNP1418

MECHANISM BOARD ASSY

SEMICONDUCTORS

D1001

PCI 001

GP1S24

NX5803K-F1

RESISTORS

All Resistors

Rsi/iosnnnj

OTHERS

J1002 CONNECTOR ASSY 7P

PDE1260

! HEAD BOARD ASSY

SEMICONDUCTORS

A

A

I Cl 02,I Cl 04

IC202

IC203

ICIOI

I Cl 03

BA4560F

LA6517

LA6520

PA4022A

TC7S08F

Mark No.

0103-0106 2SA1037K

0107,0108 2SA1461

0102 2SB1189

0101 2SC2412K

QUO 2SJ146

0115 DTA114EK

0111 DTA114TK

0117 DTA124EK

0116 DTC114TK

0109 DTC114TS

0113 DTC144TS

D101 DAI 14

DUO UDZ6.2B

Description

CAPACITORS

Cl03, Cl42, Cl 45, Cl46 CCSQCH100D50

Cl23,Cl 24 CCSQCH221J50

C109-C112 CCSQCH391J50

Cl47, Cl 48 CCSQCH471J50

Cl 22 CCSQCH620J50

Cl 40 CCSQCK2R0C50

C105-C108 CCSQSL821J50

Cl 16 CEJA100M16

Cl 01, Cl 02, Cl 13, Cl 21, Cl 25 CEJAl 01 Ml 0

C221,C224, C227, C230 CEJA470M16

Cl 17 CEJANP1R0M50

Cl 27 CEJANP4R7M16

Cl 33 CRXA103J50

Cl 14, Cl 30, Cl 31, Cl 37, Cl 38 CKSQYBl 03K50

C141 CKSQYB103K50

Cl 28 CKSQYBl82K50

Cn CKSQYB683K25

Cl04, Cl 18, Cl 20, Cl26 CKSQYF103Z50

Cl 34, Cl 35, Cl 39, Cl 64, Cl 89 CKSQYF103Z50

C220,C222, C223, C225,C226 CKSQYF103Z50

C228,C229,C232 CKSQYF103Z50

Cl15,Cl 32,Cl 87 CKSQYFl04Z25

C9 CKSRYB392K50

Cl 44 CKSRYF103Z50

RESISTORS

R130 (62n) PCN1037

R148 (2.2kD) PCN1038

R1104 (2.2ka) PCN1039

R138,R162 RN1/10SE1202D

R136,R161 RN1/10SE3002D

Part No.

41

Page 42

PDR-04

Mark No. Description

R2 RS1/16S104J

R135 RS1/16S132J

R6 RSI/168133J

R1106 RS1/16S202J

Rn05 RS1/16S222J

R134 RS1/16S362J

R12 RS1/16S471J

R8 RS1/16S472J

VRIO (2.2ka) RCP1019

VR1, VR103-VR105, VRl 07 (1 Oka) RCPl 045

VR108,VR112,VR115 (lOkn) RCPl 045

VRl06, VRl11 (22kn) RCPl046

VRl 10, VRl 19 (47ka) RCPl 047

Other Resistors RSl/lOSOODJ

OTHERS

CN106 2H CONNECTOR lOP SIOB-ZR

CN105 ZH CONNECTOR 13P S13B-ZR

CN107 KR CONNECTOR S6B-PH-K-S

PCB BINDER VEF1008

I SERVO UCOM BOARD ASSY

SEMICONDUCTORS

IC5008

IC201

IC206

IC204,IC5024

IC353

IC352

A IC208

IC205

IC351

IC356

IC207

IC311

IC361

IC357,IC358

IC354

IC355, 1C359, 1C362

IC363

IC360

Q203

Q202

Q14

Q201

013,0280

0208

05026

D353

D354

D206

D1351

D210

D202,D205

CAPACITORS

C291

C1308,C284,C295

C247-C257

C355,C356

C282

Part No.

BA4560F

CXA13720

CXD2500B0

HD74HC4053FP

HD74HC573FP

LH5116NA-10

LM2940CT-5.0

PA9004A

PD4785A

PD4786A

PDJ006A

PST529C

PST572E

TC74HC367AF

TC7S00F

TC7S04F

TC7S14F

PYY1196

2SA1037K

2SC2412K

DTA124EK

DTA124ES

DTC114TK

DTC114TS

DTC124ES

1SS133X

DAI 14

DA204K

DAN202K

DAP202K

MTZJ3.9BX

CCS0CH100D50

CCS0CH101J50

CCS0CH121J50

CCSOCH150J50

CCSRCH101J50

Mark No.

Cl 2 CCSRCH270J50

C241 CEAS100M50

C209,C212,C290 CEAS101M6R3

C278 CEAS1R0M50

Cl 302,C264,C271 CEAS2R2M50

C205,C235-C238, C293,C5016 CEAS470M10

C5018 CEAS470M10

C240 CEAS471M10

C351,C358 CEAS471M6R3

C203,C207 CEAS4R7M50

C288 CEASR47M50

Cl 8 CKS0YB102K50

Cl 310, C201, C202, C204, C206 CKSOYBl04K25

C274 CKSOYBl04K25

C5004 CKS0YB222K50

Cl 309 CKS0YB272K50

C5013 CKS0YB333K50

Cl 304 CKS0YB471K50

C260 CKS0YB683K25

C233,C234,C239, C242, C280 CKSOYFl03Z50

C5017,C5019 CKSOYFl03Z50

Cl 301,Cl 307,C285, C292, C352 CKSOYFl04Z25

C357 CKSOYFl04Z25

C283 CKS0YF473Z50

C279 CKSRYB102K50

C208,C210,C213, C218,C289 CKSRYBl03K50

C287 CKSRYBl52K50

C258 CKSRYB223K25

C267-C270 CKSRYB331K50

C219,C262 CKSRYB332K50

C211,C217 CKSRYB333K16

C5005-C5008 CKSRYB471K50

C214,C215 CKSRYB472K50

C216,C261,C286 CKSRYB473K16

C259 CKSRYB681K50

Cl202, C353,C354, C360, C370 CKSRYFl03Z50

Cl 305, Cl 306, C359 CKSRYFl04Z25

C281 CKSRYF473Z25

C272,C273 C0MA104J50

C361 (0.22F,5.5V) PCH1131

C263, C275-C277 (0.33^iF, 16V) PCLl 043

C5002,C5011 (0.15^F,16V) PCLl044

C1201 (0.082iiF,16V) PCL1045

C243 (0.1jliF,16V) PCLl 046

RESISTORS

R1, R1212, R1214, R297,R32 RSI/16S0R0J

R1381-R1388,R280 RSI/16S1OIJ

R233,R5007 RS1/16S102J

R1215,R1308,R213,R214,R216 RSI/16S103J

R247, R248,R256-R259,R266 RS1/16S103J

R268,R5006 RS1/16S103J

R251, R260,R267 RSI/16S104J

R206,R241 RS1/16S105J

R253,R254 RS1/16S114J

R353-R361 RS1/16S124J

R208,R232 RS1/16S133J

R281 RS1/16S181J

R201 RS1/16S184J

R210 RS1/16S204J

R5022 RS1/16S221J

Description Part No.

42

Page 43

PDR-04

Mark No. Description

R5023

R1202,R1204,R234,R236

R203,R212

R211,R242

R270

R252

R243

R1206

R215,R217

R1205,R218

R1351 -R1354, R1356-R1358, R1360

R246,R373,R377,R379-R383

R389-R391, R393-R399

R235,R237

R209

R238

R255

R249

R269

R202,R204

R250

R205

R207

R5025

VR201,VR202 (lOkil)

Other Resistors

OTHERS

CN202

WT 5P CONNECTOR

CN211

CN5021

X352 CERAMIC RESONATOR(16MHz)

X351 CERAMIC RES0NAT0R(4.19MHz) VSS1014

3P JUMPER CONNECTOR

3P TOP POST

KR CONNECTOR 5P

CN203

CN204 6P TOP POST

CN206 5P SIDE POST

J222 LEAD WIRE UNIT

CN205 FFC CONNECTOR 39P

J201 CONNECTOR ASSY 13P

J210 CONNECTOR ASSY 10P

J214 CONNECTOR ASSY 2P

J213 CONNECTOR ASSY 4P

JA203 MINI JACK

PCB BINDER

I AUDIO DIGITAL BOARD ASSY

SEMICONDUCTORS

IC401

IC801 AK5340-VS

IC302

IC301 LC89585

IC406 M5218AFP C3011,C304,C311,C313, C316 CKS0YF104Z25

IC304

IC404, IC803, IC804 NJM4580D C831,C834,C836, C847

A

IC407 NJM7809FA C401,C404,C469

IC408 NJM79M09FA

A

IC303

IC309, IC336 TC74HCOOAF

IC338 TC74HC04AF

IC331 TC74HC08AF C317,C329 (1цF/16V) Pai047

IC335 TC74HC123AF

IC337

Part No.

RS1/16S222J

RS1/16S273J

RS1/16S274J

RS1/16S302J

RS1/16S332J

RS1/16S333J

RS1/16S362J

RS1/16S393J

RS1/16S470J

RS1/16S472J

RS1/16S473J

RS1/16S473J

RS1/16S473J

RS1/16S512J

RS1/16S514J

RS1/16S562J

RS1/16S563J

RS1/16S624J

RS1/16S682J

RS1/16S683J

RS1/16S684J

RS1/16S754J

RS1/16S823J

RS1/16S912J

RCP1045

RS1/10Snnnj

173981-5

52147-0310

B3P-SHF-1AA

B5B-PH-K-S

B6P-SHF-1AA

BS5P-SHF-1AA

DB015NT0

HLEM39S-1

PDE1264

PDE1269

P(k)2KA-E15

PG04KA-E25

PKN1005

PSS1010

VEF1008

AK4321-VF C403

CD74HC4046AM

MB81C4256A-70PJ

PCX1021 C318

TC74HC164AF C343,C405,C408 (47nF/10V) RCH1139

Mark No.

IC308,IC313 TC74HCU04AF

IC2002,IC2005 TC7S04F

IC341,IC342 TC7S32F

IC333, IC334,IC340 TK16124M

0405-0408 2SD2114K

0402 DTA114ES

0301,0303 DTA114TS

0403 DTA124ES

0304 DTC114ES

0401,0404 DTC124ES

D302 1SR35-100AVL

D402,D403 DA114

D801,D803 DAN202K

D401,D802,D804 DAP202K

COILS

L831,L832 LFA1R0K

L301-L306,L308,L311,L312 PTL1014

L316, L328, L329,L402 PTL1014

L404-L408 PTL1014

L330 EMI FILTER PTL1020

CAPACITORS

C383,C429, C430,C445,C446 CCS0CH101J50

C477,C480,C801,C821 CCS0CH101J50

C803,C804 CCS0CH121J50

C308,C331 CCSRCH120J50

C330 CCSRCH180J50

C309 CCSRCH270J50

C2007, C319, C365 CCSRCH470J50

C3007 CCSRCH820J50

C339,C341 CEAS100M50

C817,C818,C833,C835 CEAS100M50

C385 CEAS101M25

C302,C306,C310,C314,C324 CEAS101M6R3

C332,C335,C402 CEAS101M6R3

C805,C806 CEAS220M50

C811-C814, C842-C844,C848 CEAS220M50

C411,C412 CEAS221M25

C315, C323, C328 CEAS470M10

C471,C472 CEAS470M16

C407,C409 CEAS471M6R3

C441,C832 CEAS4R7M50

C347 CKCYB101K50

C348,C823 CKCYF473Z50

C301 CKSOYB102K50

C421,C422,C425,C426 CEZA470M50

C305 CKSQYB103K50

C312,C390 CKSQYB472K50

C303,C307,C333,C334 CKS0YB473K25

C819,C820

C807-C810,C846

C322,C325, C327,C342,C344

C376,C406,C410, C815,C816

C3006, C3009, C3010, C3012, C3013

C3015,C3017,C3019-C3021

C427,C428

C481,C482 (3300|iF/16V)

Description Part No.

CKS0YB473K50

CKS0YB821K50

CKSQYF103Z50

CKSOYF104Z25

CKSQYF104Z25

CKS0YF104Z25

CKS0YF104Z50

CKSRYB103K50

CKSRYF104Z25

CKSRYF104Z25

C0MA102Z50

DCH1057

43

Page 44

PDR-04

Mark No. Description

RESISTORS

R421,R422

R423,R424

R342

R1336, R3015,R3020,R3101

R318,R319,R323,R324,R328

R341,R486

R300,R3n,R329,R331

R1450,R2005,R339

R320

R305

R1333

R3009

R1335,R499

R301

R302

R347,R348

R345

R1324,R303

R1323

R312,R330

R1401-R1404

VR301 (ioidi)

Other Resistors

OTHERS

CN401 3P JUMPER CONNECTOR 52147-0310

CN317 CONNECTOR 8P

CN801 CONNECTOR 9P

CN331 2P TOP POST

CN315 KE CONNECTOR 4P B4B-PH-K-S

JA301 OPTICAL TRANS. MODULE

JA303 OPTICAL TRANS. MODULE

JA401,JA801 2P JACK

KN302 SCREW TERMINAL PNB1558

X301 CRYSTAL RESONATOR

(16.9344MHz)

PCB BINDER

f3 ALC BOARD ASSY

SEMICONDUCTORS

IC2001

A IC2003

A IC2004 NJM79L05A

CAPACITORS

C2001,C2003,C2005

C2002,C2004,C2006, C2008

RESISTORS

All Resistors RSl/lOSDDDJ

OTHERS

CN2001 CONNECTOR 8P 9115S-08L

CN2002 CONNECTOR 9P

Part No.

RN1/10SE1002D

RN1/10SE1602D

RS1/16S0R0J

RSI/168101J

RS1/16S101J

RS1/16S101J

RSI/168102J

RS1/16S103J

RS1/16S105J

RS1/16S151J

RS1/16S221J

RS1/16S222J

RS1/16S271J

RS1/16S333J

RS1/16S363J

RS1/16S472J

RS1/16S473J

RS1/16S512J

RS1/16S622J

RS1/16S681J

RS1/2LMF270J

RCP1045

RSl/lOSDDDJ

9115B-08

9115B-09

B2P-SHF-1AA

GP1F32R

GP1F32T

PKB1029

PSS1008

VEF1008

LM1972M

NJM78L05A

CEAS100M50

CKSQYF104Z25

9115S-09L

Mark No.

Description

[HEADPHONE BOARD ASSY

COILS

L461-L463

CAPACITORS

C1466-C1468

C1463-C1465

Cl 469

RESISTORS

VR401 VARIABLE RESISTOR (5kii)

OTHERS

JA403 HEADPHONE JACK

SUB BOARD ASSY

OTHERS

PC BOARD

FUNCTION BOARD ASSY

SEMICONDUCTORS

0701-0704

D701-D703,D706 SEL6210S

r^r\U C

L701,L702 FERRITE BEADS VTH1020

SWITCHES

S701-S718 PSG1006

CAPACITORS

C704

C702

RESISTORS

All Resistors

OTHERS

IC701 REMOTE RECEIVER UNIT GP1U27X

CN701 FFC CONNECTOR 39P HLEM39R-1

V701 FL INDICATOR TUBE

fil POWER A BOARD ASSY

SEMICONDUCTORS

A IC904

A D901-D908 11ES2

COILS

L902 FERRITE BEADS

A L11 LINE FILTER

CAPACITORS

C901,C902,C914,C915

C904-C906, C911 (3300nF,16V)

A C71,C78 (100pF,400V AC)

RESISTORS

All Resistors

A C72,C75 (0.01nF,400V AC)

Part No.

PTL1014

CCSQCH101J50

CKSQYF103Z50

CKSQYF473Z50

PCS1003

RKN1002

PNP1393

DTA124ES

CKCYB101K50

CKCYF103Z50

RD1/4PUDDDJ

PEL!086

UPC24M05AHF

VTH1020

VTL1008

CKCYF103Z50

DCH1057

PCL1040

VCG-044

RD1/4PUDDDJ

44

Page 45

PDR-04

Mark No.

Description

OTHERS

A FUSE aiP

A

cm 2

J901

J12

A

cmi

J905

POWER B BOARD ASSY

SEMICONDUCTORS

IC11-IC15

A

IC23

A

A

IC22

A

D11-D14,D52

D54

A

COILS

L21-L23 FERRITE BEADS

CAPACITORS

C52

C54

C28,C29

C11,C13,C15-C18

C23,C24

C26 (3300^iF,16V)

C25 (10000hF,16V)

RESISTORS

Other

OTHERS

cm 5

CN17

A J1

J16

2P-VH CONNECTOR

EARTH LEAD UNIT

CONNECTOR

TERMINAL

PCB BINDER

Resistors

5P JUMPER CONNECTOR

KR CONNECTOR 5P

CONNECTOR ASSY 2P

CONNECTOR 6P

PCB BINDER

EARTH METAL

Part No.

AKR1003

B2P3-VH

PDF!175

PF07PG-D10

RKC-061

VEF1040

PDF1176

ICP-NIO

LM2940CT-5.0

NJM7905FA

11ES2

MTZJ20A

VTH1020

CEAS101M35

CEAS470M35

CEAS471M10

CKCYF103Z50

CQMZA472J50

DCH1057

VCH1124

RDl/4PUnnnj

52147-0510

B5B-PH-K-S

PDE1273

PF06PG-D15

VEF1008

VNF-091

Mark No.

Description

STRATEGY SMALL BOARD ASSY

SEMICONDUCTORS

IC343

IC344

03508

03501-03507

D332

D331

CAPACITORS

C3520

C344,C3519,C3521

RESISTORS

R3514

R3504

R3510

R3511

R3505

R3503

R3502

R3520

R3506

R3513

R3507

R3512

R3501

R3508

VR3502,VR3503 (lOkii)

VR3501 (47ka)

Other Resistors

OTHERS

CN3502

CN3506

PH C0NNEa0R(2P)

PH CONNEaOR(6P)

Part No.

TC74HC138AF

TC7S04F

2SC2412K

DTA124TK

1SS355

UDZ3.0B

CEV470M16

CKSQYF103Z50

PCN1039

RN1/10SE1502D

RN1/10SE1601D

RNV10SE1800D

RN1/10SE1801D

RN1/10SE1802D

RN1/10SE2201D

RN1/10SE2400D

RN1/10SE2401D

RN1/10SE2701D

RN1/10SE4701D

RN1/10SE5100D

RN1/10SE5101D

RN1/10SE6201D

PCP1042

PCP1043

RSViosnnnj

B2B-PH-SM3

B6B-PH-SM3

45

Page 46

PDR-04

6. ADJUSTMENT

6.1 ADJUSTMENT METHODS

If a compact disc recorder is adjusted incorrectly or inadequately, it may malfunction or not work at all even though there

is nothing at all wrong with the pickup or the circuitry. Adjust correctly following the adjustment procedure.

# Measuring instruments and Tools

(1 ) Dual trace oscilloscope (10:1 probe) (6) Resistor (1 OOkQ)

(2) Low-frequency oscillator (7) Hexagonal screwdriver (1.27mm diagonal)

(3) Test disc (STD-903), (STD-R03) (8) Standard tools

(4) Low-pass filter (15kQ + 0.001 jxF), (39kQ + 0.001 pF) (9) Small screwdriver

(5) Hi-pass filter (3.9kD + 180pF) (10) Multimeter (Voltage accuracy : Below 1 mV)

# Adjustment Kerns / Verification items and Order

Adjustment 1

Step

1 Playback Power Adjustment

2 Coarse Focus Offset Adjustment

3 Coarse Skew Adjustment

4 Coarse Grating Adjustment

5

DPP (Tracking Offset) Adjustment

6 Fine Focus Offset Adjustment CN204 (TP201), Pin 1 (RF) VR105 (FE. OFS)

7 Fine Skew Adjustment

8 Grating Re-adjustment

Adjustment 2

Step Item Test Point Adjustment Location

CD-R VCO Control Voltage Adjustment

1

2 Multi Pulse Time Adjustment

3

EFM Rising Edge Time Adjustment

4 3T Falling Edge Time Adjustment

5 WBL+ Offset Adjustment

6 Coarse WBL Offset Adjustment

7 Playback Power Re-adjustment

8 Coarse Focus Offset Adjustment

9 Main and Sub Mix Ratio Adjustment

10 Tracking Amp. Gain Adjustment

11 Tracking Offset Adjustment

12 ACT Offset Adjustment

13 ACT GAIN Adjustment

14 Fine Focus Offset Adjustment

15 WBL BALANCE Adjustment

Item

CN104 (TP1), Pin 7 (PWAJT) VR103 (PB. PW)

CN204 (TP201), Pin 1 (RF)

CN204 (TP201), Pin 1 (RF)

CN104(TP1), Pin3(TE) Grating adjustment slit

CN104 (TP1), Pin 3 (TE) VR112 (TE. OFS)

CN204 (TP201), Pin 1 (RF)

CN104 (TP1), Pin 3 (TE)

CN331 (TP30), Pin 1 (VCOIN)

CN3506, Pin 6 (MPLS) VR3501 (MPLS DLY)

CN3506, Pin 5 (EFM IN)

CN3506, Pin 4 (SEFM)

CN3506, Pin 3 (3T IN)

CN3506, Pin 2 (3T OUT)

CN104(TP1), Pin6(RWBL) VR107 (WBL+. OFS)

CN104 (TP1), Pin 5 (WBL)

CN104 (TP1), Pin 7 (PWAJT) VR103 (PB. PW)