Page 1

SURROUND MODE

STANDBY/ON

DISPLAY INPUT

VOLUME

ORDER NO.

RRV1960

CONTROL CENTER

HTV-C1

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

Type

AUXJ AC26V power supplied from other system component

ACXJ AC26V power supplied from other system component

• This product is a system component.

For the system composition, refer to the service manual RRV1957 for HTV-A1/KUCXJ.

• This product does not operate normally by itself. Please connect it to the AMPLIFIER HTV-A1/

KUCXJ, for adjustment and operation inspection. Otherwise damage may result.

Model

HTV-C1

Power Requirement Remarks

Hometheater System Control Center

HTV-1 (This manual)

(service manual RRV1968)

Powered Subwoofer

HTV-SW1 (service manual RRV1969)

Amplifier

HTV-A1 (service manual RRV1957)

CONTENTS

1. SAFETY INFORMATION ...................................... 2

2. EXPLODED VIEWS AND PARTS LIST................ 3

3. SCHEMATIC DIAGRAM ....................................... 6

4. PCB CONNECTION DIAGRAM.......................... 12

5. PCB PARTS LIST ............................................... 16

6. ADJUSTMENT .................................................... 17

PIONEER ELECTRONIC CORPORATION 4-1, Meguro 1-Chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS SERVICE, INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER ELECTRONIC (EUROPE) N.V. Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 501 Orchard Road, #10-00 Wheelock Place, Singapore 238880

c

PIONEER ELECTRONIC CORPORATION 1998

7. GENERAL INFORMATION ................................ 18

7.1 PARTS.......................................................... 18

7.1.1 IC ........................................................... 18

7.1.2 DISPLAY................................................ 19

7.2 TEST MODE................................................. 20

7.3 BLOCK DIAGRAM........................................ 21

8. PANEL FACILITIES AND SPECIFICATIONS.... 23

T - IZY MAY 1998 Printed in Japan

Page 2

HTV-C1

1. SAFETY INFORMATION

This service manual is intended for qualified service technicians ; it is not meant for the casual do-ityourselfer. Qualified technicians have the necessary test equipment and tools, and have been trained

to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

WARNING

Lead in solder used in this product is listed by the California Health and Welfare agency as a known reproductive toxicant which may

cause birth defects or other reproductive harm (California Health & Safety Code, Section 25249.5).

When servicing or handling circuit boards and other components which contain lead in solder, avoid unprotected skin contact with

the solder. Also, when soldering do not inhale any smoke or fumes produced.

NOTICE

(FOR CANADIAN MODEL ONLY)

Fuse symbols (fast operating fuse) and/or (slow operating fuse) on PCB indicate that replacement parts must

be of identical designation.

REMARQUE

(POUR MODÈLE CANADIEN SEULEMENT)

Les symboles de fusible (fusible de type rapide) et/ou (fusible de type lent) sur CCI indiquent que les pièces

de remplacement doivent avoir la même désignation.

(FOR USA MODEL ONLY)

1. SAFETY PRECAUTIONS

The following check should be performed for the

continued protection of the customer and service

technician.

LEAKAGE CURRENT CHECK

Measure leakage current to a known earth ground (water

pipe, conduit, etc.) by connecting a leakage current tester

such as Simpson Model 229-2 or equivalent between the

earth ground and all exposed metal parts of the appliance

(input/output terminals, screwheads, metal overlays, control

shaft, etc.). Plug the AC line cord of the appliance directly

into a 120V AC 60Hz outlet and turn the AC power switch

on. Any current measured must not exceed 0.5mA.

Reading should

not be above

0.5mA

Earth

ground

Device

under

test

Also test with

plug reversed

(Using AC adapter

plug as required)

Leakage

current

tester

Test all

exposed metal

surfaces

ANY MEASUREMENTS NOT WITHIN THE LIMITS

OUTLINED ABOVE ARE INDICATIVE OF A POTENTIAL

SHOCK HAZARD AND MUST BE CORRECTED BEFORE

RETURNING THE APPLIANCE TO THE CUSTOMER.

2. PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in the appliance

have special safety related characteristics. These are

often not evident from visual inspection nor the protection

afforded by them necessarily can be obtained by using

replacement components rated for voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this Service Manual.

Electrical components having such features are identified

by marking with a

in this Service Manual.

The use of a substitute replacement component which does

not have the same safety characteristics as the PIONEER

recommended replacement one, shown in the parts list in

this Service Manual, may create shock, fire, or other hazards.

Product Safety is continuously under review and new

instructions are issued from time to time. For the latest

information, always consult the current PIONEER Service

Manual. A subscription to, or additional copies of, PIONEER

Service Manual may be obtained at a nominal charge from

PIONEER.

on the schematics and on the parts list

AC Leakage Test

2

Page 3

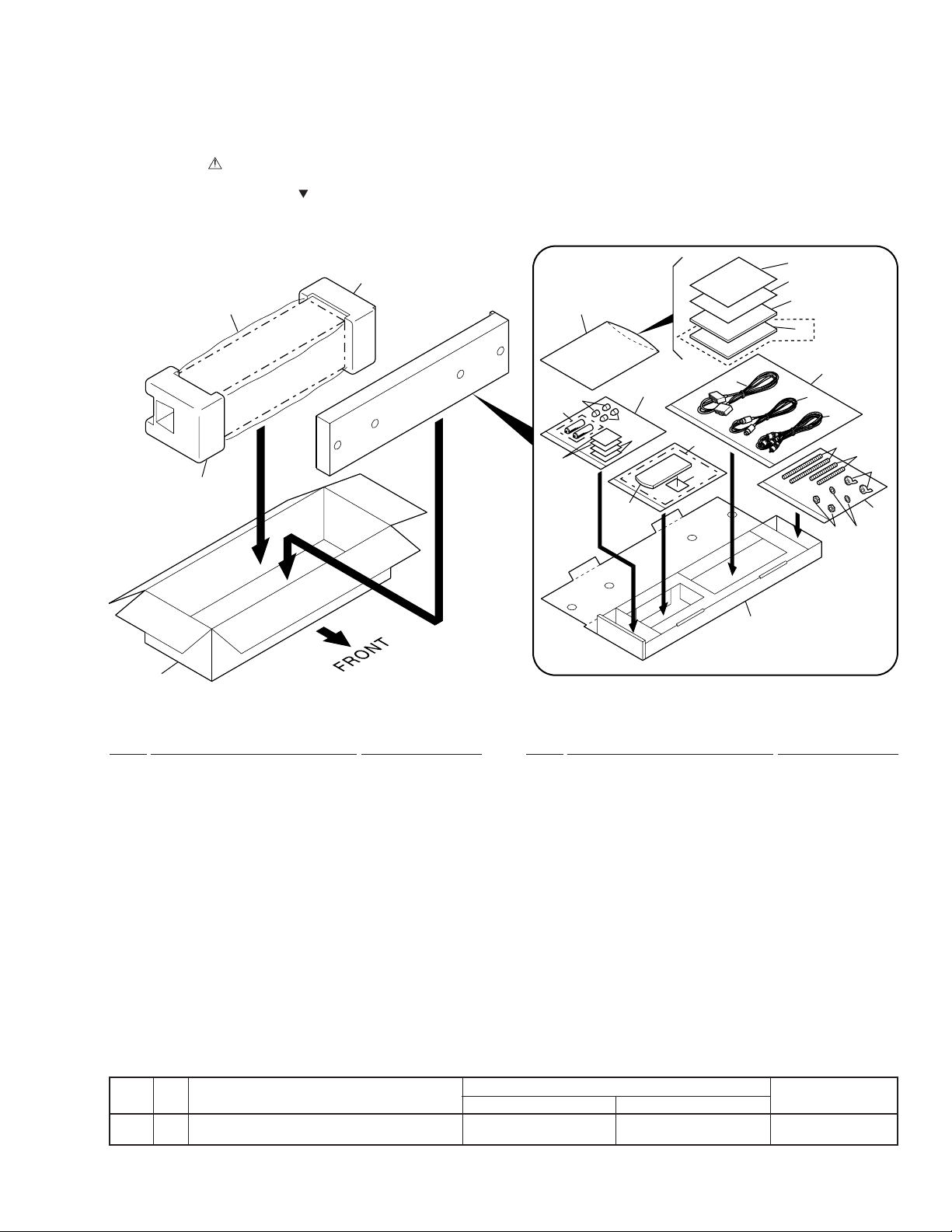

2. EXPLODED VIEWS AND PARTS LIST

NOTES:• Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

2.1 PACKING

The mark found on some component parts indicates the importance of the safety factor of the part.

•

Therefore, when replacing, be sure to use parts of identical designation.

Screws adjacent to mark on the product are used for disassembly.

•

19

22

17

HTV-C1

10

9

7

ACXJ type

8

only

18

21

(1) PACKING PARTS LIST

Mark No. Description Part No.

1 System Cable A (L=3.0m) ADX7239

2 System Cable B (L=3.0m) ADE7023

NSP 3 MOUNT Kit AEA7021

4 Bolt Cap AEB7111

5 Velcro Tape (hook) AED7028

6 Velcro Tape (loop) AED7029

7 Operating Instructions ARB7147

(English)

8 Operating Instructions See Contrast table (2)

(French)

9 Quick Instructions Guide ARH7036

NSP 10 Warranty Card See Contrast table (2)

11 Remote Control Unit AZN7713

(CU-HTV001)

NSP 12 Remote Control Unit AXD7157

(CU-HTV001)

17

2

15

5

4

16

4

6

12

1

11

13

20

Mark No. Description Part No.

13 Battery Cover RZN1156

NSP 15 Dry Cell Battery (R6P,AA) VEM-013

NSP 16 Polyethylene Bag Z21-033

14 Audio Cord (L=1.5m) VDE1033

17 Polyethylene Bag Z21-038

(0.03 × 230 × 340)

18 L Protector AHA7209

19 R Protector AHA7210

20 Paper Protector AHA7217

21 Packing Case AHD7574

22 Packing Sheet AHG7053

23 Bolt (L) ABA7042

24 Bolt (S) ABA7041

25 Nut NA60FZK

26 Wing Nut NR60FZK

27 Washer WB60FZK

14

25

23

24

26

3

27

(2) CONTRAST TABLE

Mark No. Symbol and Description

8 Operating Instructions (French) Not used ARC7200

NSP 10 Warranty Card ARY1051 ARY1075

AUXJ Type ACXJ Type

Part No.

Remarks

3

Page 4

HTV-C1

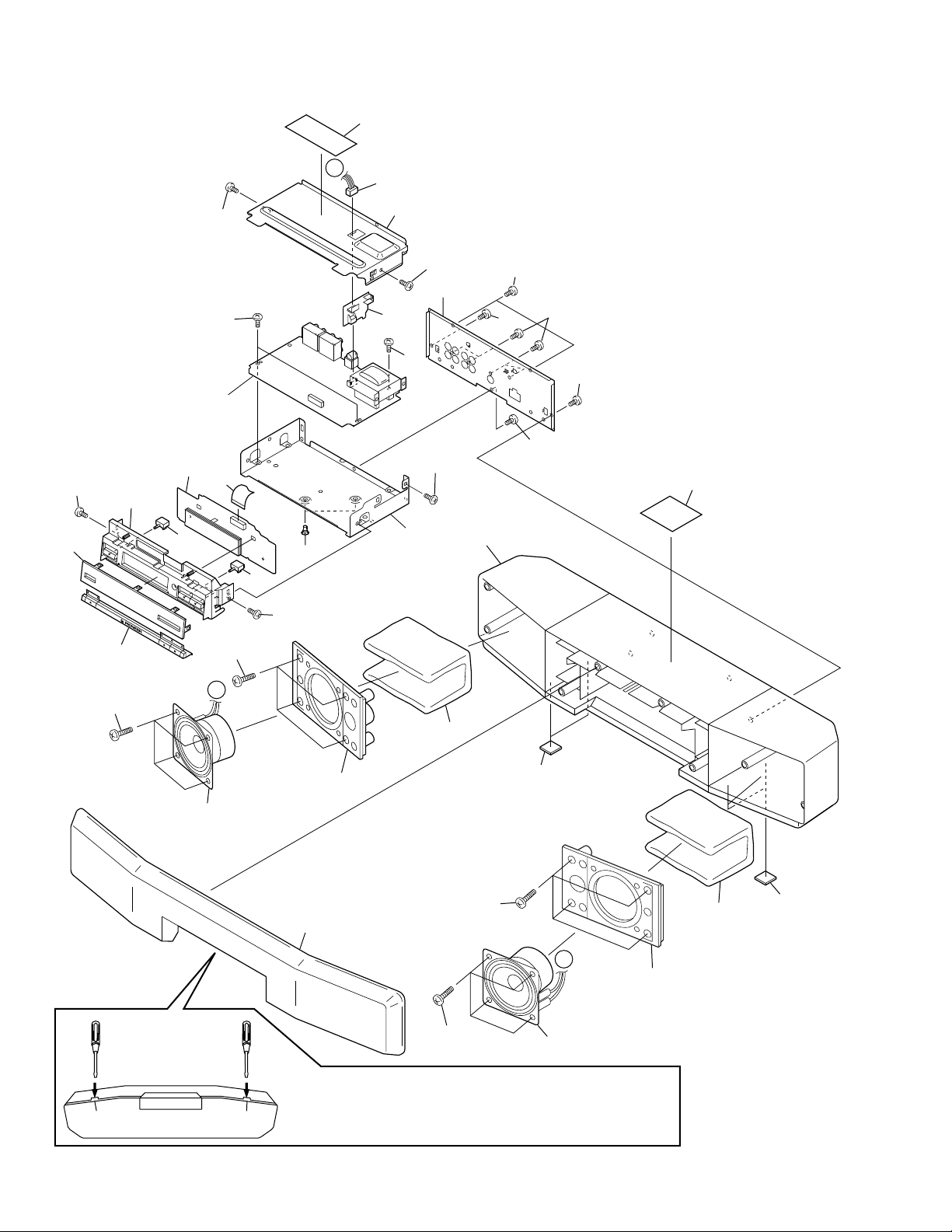

2.2 MAIN SECTION

22

22

2

1

4

16

15

22

19

13

20

A

5

9

22

8

3

22

22

7

18

23

23

22

23

22

21

24

14

16

22

24

A

12

11

6

24

17

10

12

10

A

11

Gap

(BOTTOM VIEW)

Gap

24

Note :

Grille Assy is adhered with the woodworking bond to the Rear Case.

Put a square-bar screwdriver and so on in the two gaps under the

Grille, and pry it opens when it is removed.

6

4

Page 5

MAIN SECTION PARTS LIST

•

Mark No. Description Part No.

1 DISPLAY Assy AWU7070

2 MAIN Assy AWU7071

3 TERMINAL Assy AWU7072

4 19P FFC/30V ADD7092

5 Cable Assy 4P ADX7240

HTV-C1

Mark No. Description Part No.

16 Lens AAK7551

17 Grille Assy AAS7001

NSP 18 Rear Case AMC7025

19 Sub Panel AMD7003

NSP 20 Fuse Caution Label AAX7645

NSP 7 PCB Bracket ANA7068

6 Speaker D87DU61-51F

8 Rear Panel ANC7655

NSP 9 Shield Cover ANK7040

10 Cushion 3 AEB7110

NSP 11 Baffle AMD7004

NSP 12 Acoustic Absorbent AMT7001

13 Card Spacer DNK2769

14 Button AAD7454

15 Display Panel AAK7550

NSP 21 Founding Caution AAX7649

22 Screw BBZ30P080FMC

23 Screw VPZ30P080FMC

24 Screw BPZ40P140FZK

NOTE :

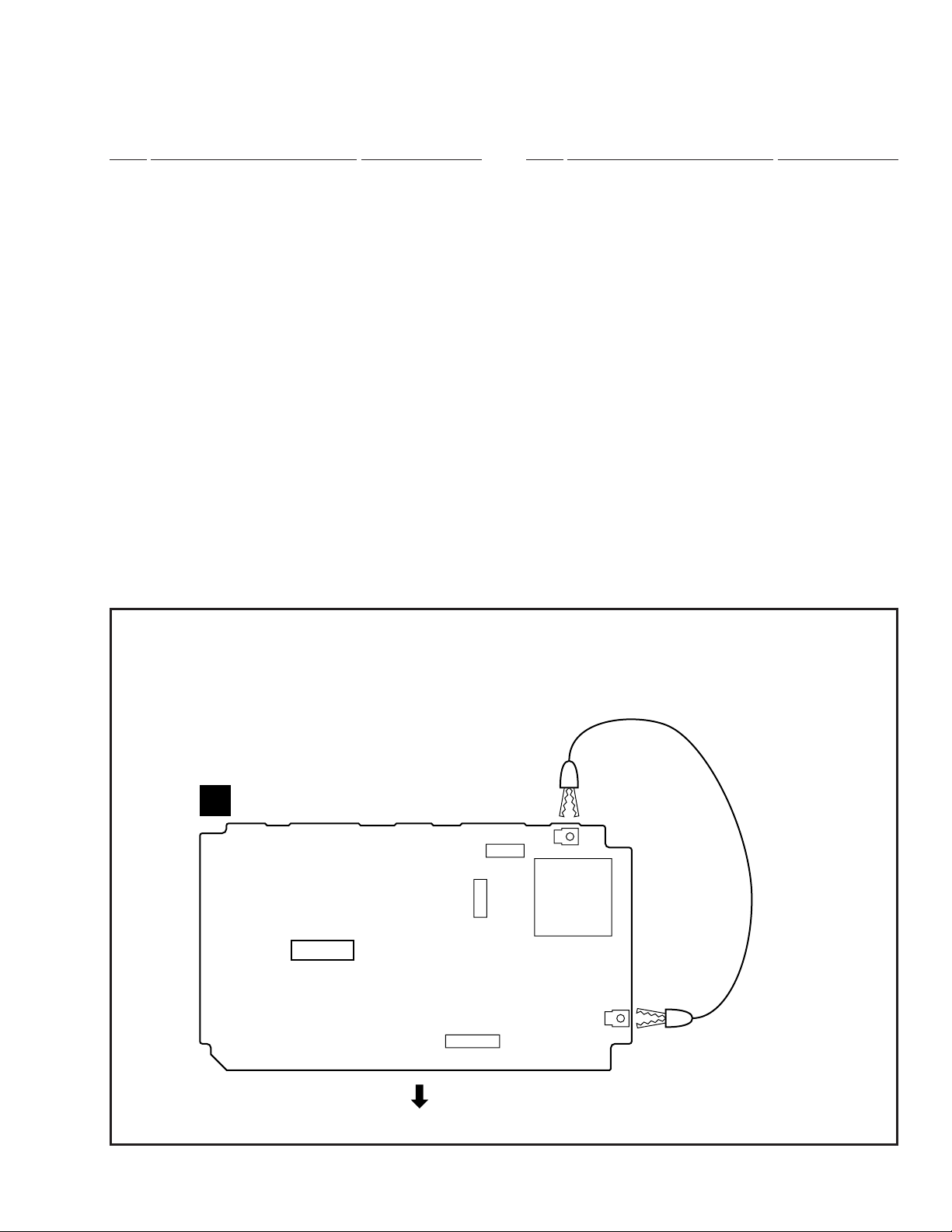

• The attention points when remove the MAIN Assy from the chassis and diagnose it

It doesn't move when Earth Plates KN501 and KN4001 aren't connected.

When you remove the MAIN Assy from the chassis and diagnose it, short-circuit Earth Plate KN501 and KN4001 and diagnose it.

Short-circuit Earth Plate KN501 and KN4001

MAIN ASSY

A

SIDE A

KN4001

CN501

T2

CN503

KN501

CN3001

FRONT

5

Page 6

1

HTV -C1

3. SCHEMATIC DIAGRAM

A

3.1 OVERALL WIRING DIAGRAM

B

23

4

DISPLAY ASSY

C

(AWU7070)

C

D

6

1234

Page 7

5

678

HTV -C1

Note : When ordering service parts, be sure to refer to "EXPLODED VIEWS and P AR TS LIST" or "PCB PARTS LIST".

B

TERMINAL ASSY

(AWU7072)

A

B

MAIN ASSY

A

(AWU7071)

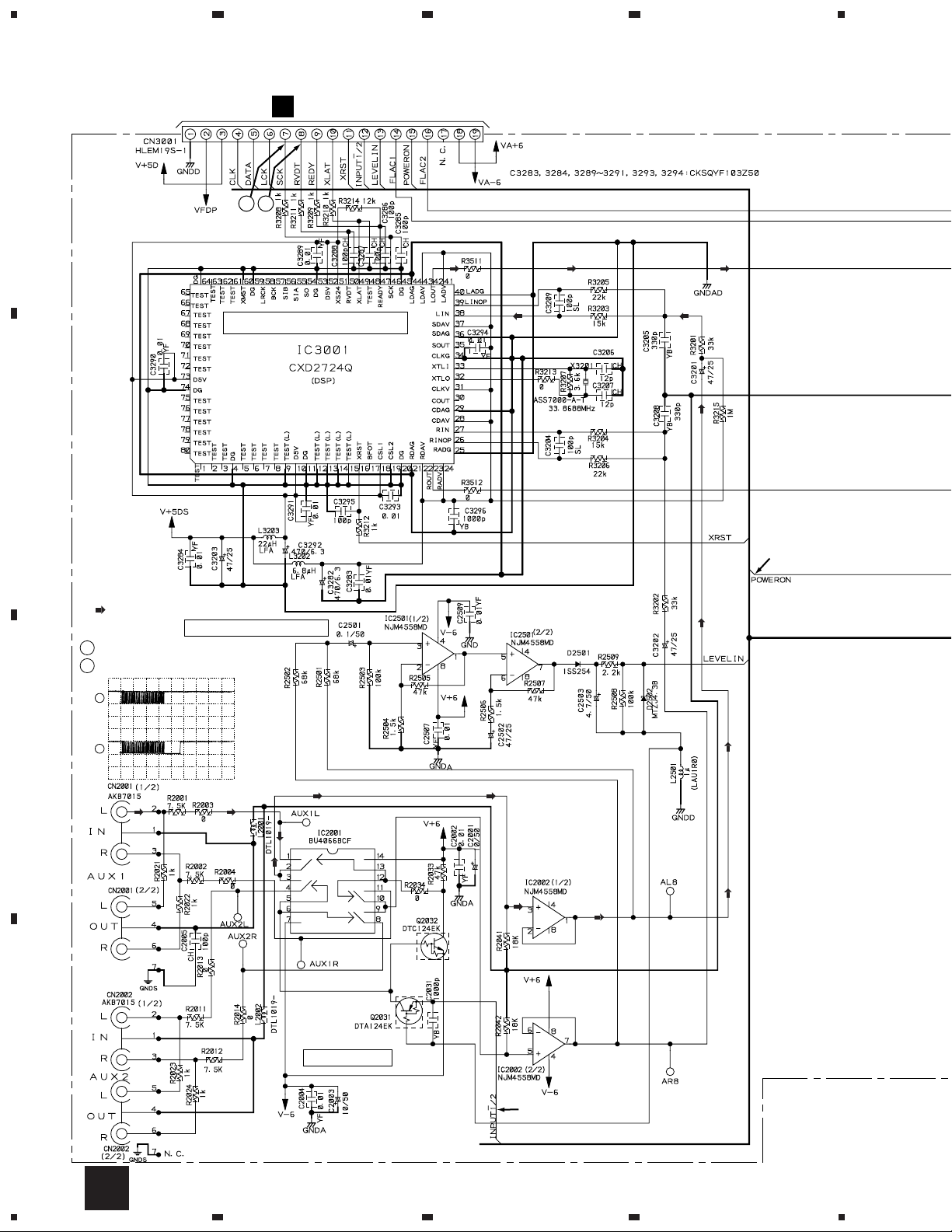

Voltages of MAIN Assy

IC3001 (CXD2724Q) (V)

CONDITION SURROUND MODE

No. Pin Name OFF VD ST WIDE

10 D5V 4.9 4.9 4.9

16 XRST 5.0 5.0 5.0

18 CSL1 4.9 4.9 4.9

22 RDAV 5.0 5.0 5.0

23 ROUT 2.5 2.9 2.9

24 RADV 5.0 5.0 5.0

26 RINOP 2.4 2.4 2.4

27 RIN 2.4 2.4 2.4

28 CDAV 5.0 5.0 5.0

31 CLKV 5.0 5.0 5.0

32 XTLO 2.5 2.5 2.5

33 XTLI 2.5 2.5 2.5

37 SDAV 5.0 5.0 5.0

38 LIN 2.4 2.4 2.4

39 LINOP 2.4 2.4 2.4

41 LADV 5.0 5.0 5.0

42 LOUT 2.5 2.9 2.9

43 LDAV 5.0 5.0 5.0

46 SCK 5.0 5.0 5.0

47 READY 4.9 4.9 4.9

49 XLAT 5.0 5.0 5.0

50 RVDT 5.0 5.0 0.0

51 XS24 4.9 4.9 4.9

52 D5V 4.9 4.9 4.9

73 D5V 4.9 4.9 4.9

FROM AMPLIFIER

(HTV-A1)

JACB ASSY

CN1003

C

TO AMPLIFIER

(HTV-A1)

JACB ASSY

JA4501

D

7

5

6

7

8

Page 8

1

23

HTV -C1

3.2 MAIN AND TERMINAL ASSEMBLIES

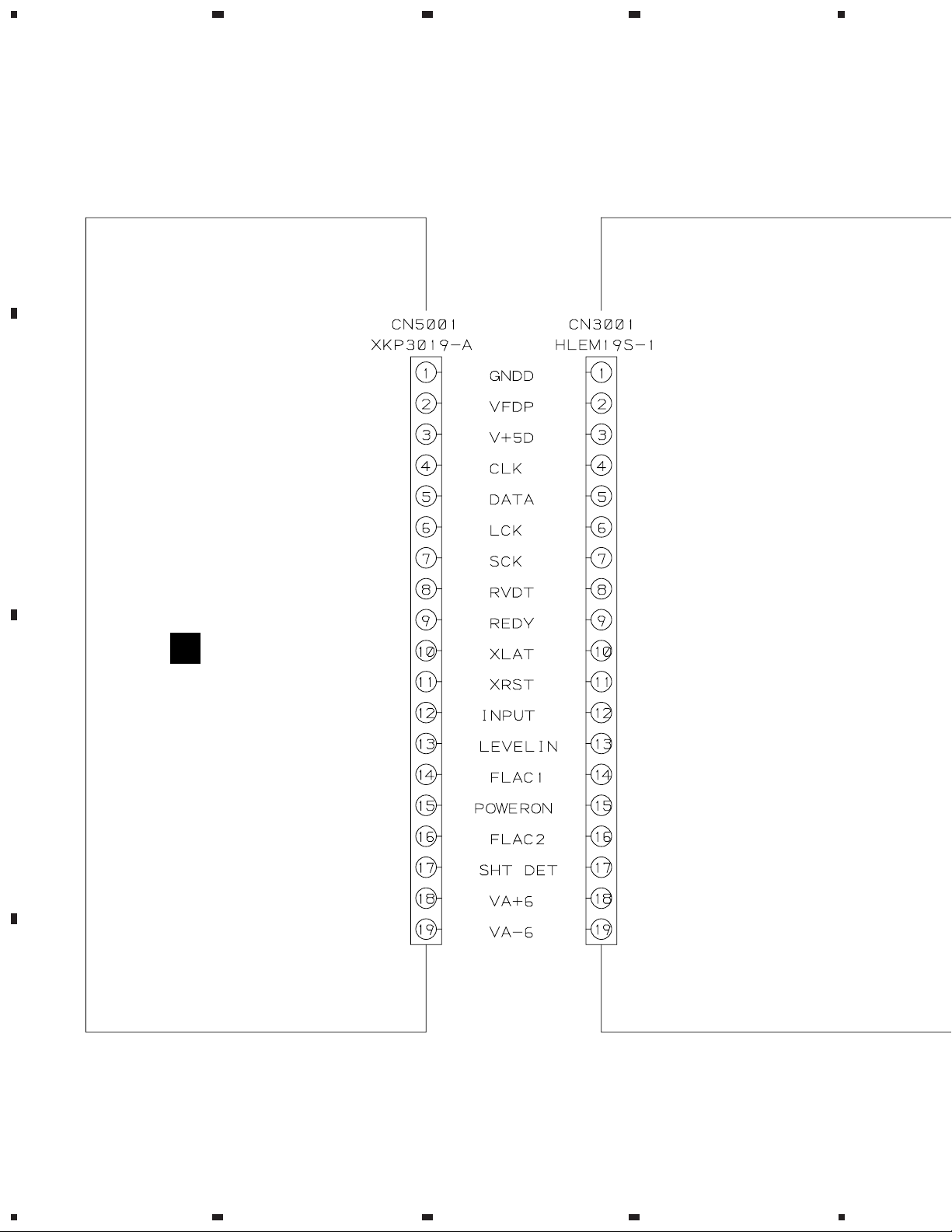

CN5001

C

A

1 2

DOLBY VIRTUAL DECODER

B

4

5.0V

SIGNAL ROUTE

: AUDIO SIGNAL ROUTE

Waveforms

CN3001-Pin7 (SCK) 0.5 V/div 50mS/sec

1

CN3001-Pin8 (RVDT) 0.5 V/div 50mS/sec

2

1

2

C

INPUT LENEL DETECTOR

– GND

– GND

D

8

A

1234

INPUT SELECT

INPUT 1 , INPUT2

0.0V 4.8V

Page 9

LPF

5

678

HTV -C1

Waveforms

JA4001-Pin4 (DATA) 0.5 V/div 1mS/sec

3

JA4001-Pin1 (CLK) 0.5 V/div 1mS/sec

4

3

– GND

JA4001-Pin2 (LCK) 0.5 V/div 1mS/sec

5

JA4001-Pin1 (CLK) 0.5 V/div 1mS/sec

4

5

– GND

A

4.8V

4

– GND

4

BALANCED OUT

4

3

5

– GND

B

POWER SUPPLY

-28.0V

-18.8V

CAUTION : FOR CONTINUED PROTECTION AGAINST

RISK OF FIRE. REPLACE ONLY WITH SAME

TYPE NO. 491.630 MFD BY LITTELFUSE

INK. FOR IC501 AND IC502 (AEK7006).

MAIN ASSY

A

(AWU7071)

13.2V

-13.2V

-40.0V

CAUTION : FOR CONTINUED PROTECTION AGAINST

RISK OF FIRE. REPLACE ONLY WITH SAME

TYPE NO. 491.200 MFD BY LITTELFUSE

INK. FOR IC503 (AEK7023).

TERMINAL ASSY

B

(AWU7072)

SW AMP UNIT

C

FRONT

SPEAKER

D

A B

5

6

7

8

9

Page 10

1

HTV -C1

3.3 DISPLAY ASSY

23

4

A

REMOCON

SENS.

DISPLAY ASSY

C

(AWU7070)

-28V

5.0V

B

7

CN3001

A

C

INDICATOR

KEY

D

-18V

∗

∗

About a voltage of IC5001-pin 22 (LEVEL IN)

This terminal is the terminal watching the level of the input signal to

make the Auto standby mode function.

About 3V DC apply to this terminal when -46dBV (about 5mVrms)

(Frequency is 1kHz with both channels as well.) is inputted to INPUT1

(INPUT2) when INPUT1 (INPUT2) is chosen.

(In the case of one of the channels, about 3V DC apply with -40dBV).

KEY MODE VOLTAGE

INPUT VOL+ VOL- DISPLAY SUR.MODE POWER

4.1V 2.9V 2.3V 1.8V 1.1V 0V

S5001 : INPUT

S5002 : VOL+

S5003 : VOL–

6

S5004 : DISPLAY

S5005 : SURROUND MODE

S5006 : POWER (STAND BY/ON)

10

C

1234

Page 11

5

678

HTV -C1

A

B

C

Waveforms

IC5001-Pin45 (P1) 1V/div 2mS/sec

6

GND –

IC5001-Pin62 (1G) 1V/div 2mS/sec

7

GND –

C

5

6

7

8

11

D

Page 12

1

23

HTV -C1

4. PCB CONNECTION DIAGRAM

A

4.1 MAIN, TERMINAL AND DISPLAY ASSEMBLIES

MAIN ASSY

A

4

B

TERMINAL ASSY

B

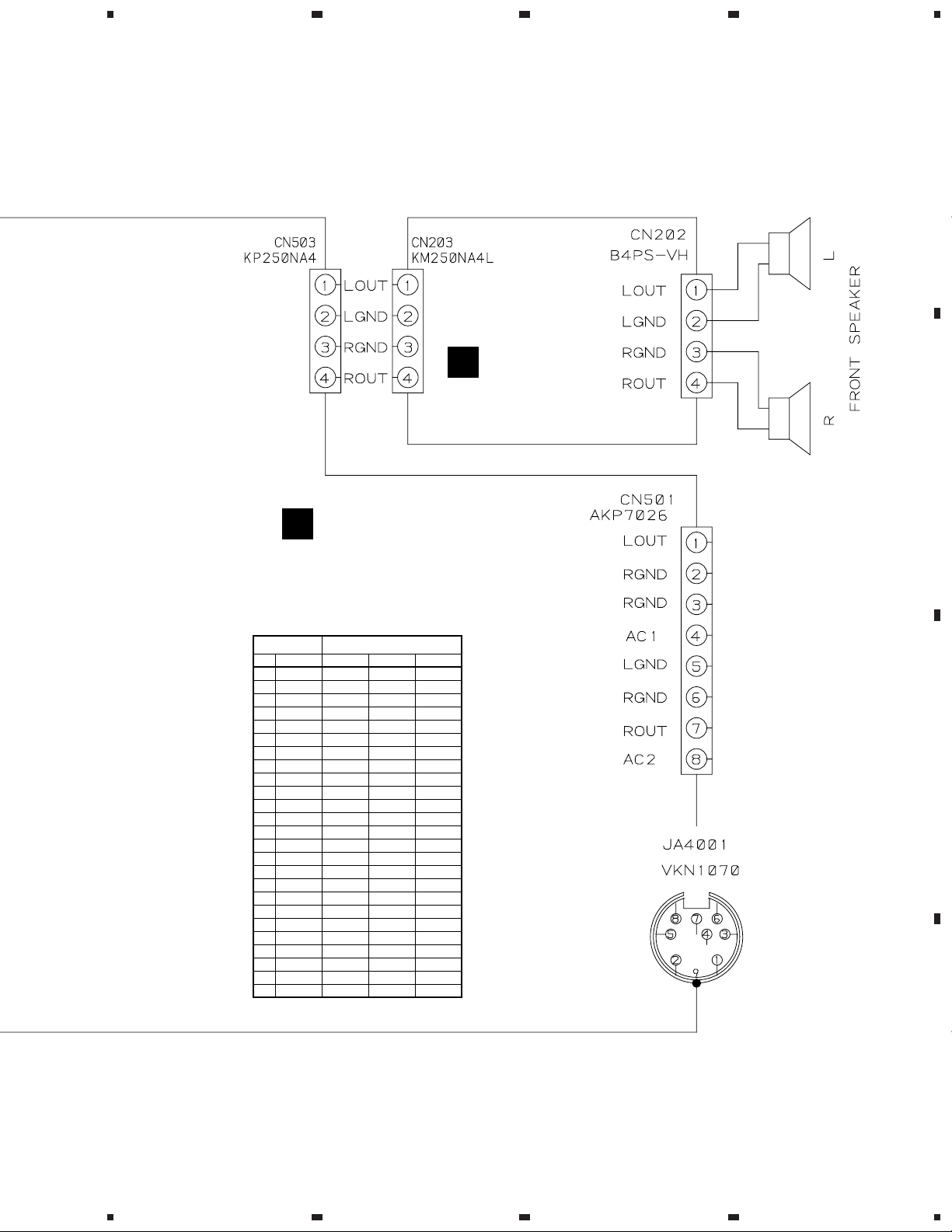

C

FRONT

SPEAKER

SW AMP

UNIT

D

(ANP7252-B)

Q501IC501–IC503 Q505Q502 IC504–IC507

SIDE A

12

A

B

1234

Page 13

5

678

NOTE FOR PCB DIAGRAMS :

1. Part numbers in PCB diagrams match those in the schematic

diagrams.

2. A comparison between the main parts of PCB and schematic

diagrams is shown below.

Symbol In PCB

Diagrams

BCE

BCE

D

Symbol In Schematic

Diagrams

BCEBCE

BCE

DGGSS

BCE

DGS

Part Name

Transistor

Transistor

with resistor

Field effect

transistor

HTV -C1

3. The parts mounted on this PCB include all necessary parts for

several destinations.

For further information for respective destinations, be sure to

check with the schematic diagram.

4. View point of PCB diagrams.

Connector

Capacitor

SIDE A

P.C.Board

Chip Part

SIDE B

A

Resistor array

3-terminal

regulator

DISPLAY ASSY

C

B

C

(ANP7252-B)

D

SIDE A

C

5

6

7

8

13

Page 14

A

B

1

HTV -C1

23

MAIN ASSY

A

4

TERMINAL ASSY

B

C

D

SIDE B

14

A B

1234

(ANP7252-B)

Q504 Q507 IC4001 IC4002

IC3501 IC2002

IC2001IC2501IC3001 Q2032 Q2031

Page 15

5

678

HTV -C1

A

B

DISPLAY ASSY

C

C

(ANP7252-B)

IC5001 Q5002 Q5004

SIDE B

D

C

5

6

7

8

15

Page 16

HTV-C1

Mark No. Description Part No.

Mark No. Description Part No.

5. PCB PARTS LIST

NOTES:•Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

•

Therefore, when replacing, be sure to use parts of identical designation.

When ordering resistors, first convert resistance values into code form as shown in the following examples.

•

Ex.1 When there are 2 effective digits (any digit apart from 0), such as 560 ohm and 47k ohm (tolerance is shown by J=5%,

and K=10%).

560 Ω→56 × 10

47k Ω→47 × 103→ 473 ........................................................ RD1/4PU 4 7 3 J

0.5 Ω→R50 .....................................................................................RN2H

1 Ω→1R0 .....................................................................................RS1P

Ex.2 When there are 3 effective digits (such as in high precision metal film resistors).

5.62k Ω→ 562 × 10

Mark No. Description Part No.

LIST OF ASSEMBLIES

COMPLEX ASSY AWM7369

MAIN ASSY AWU7071

TERMINAL ASSY AWU7072

DISPLAY ASSY AWU7070

MAIN ASSY

A

SEMICONDUCTORS

IC501,IC502(630mA) AEK7006

IC503(200mA) AEK7023

IC507 BA05ST

IC504 NJM7805FA

IC505 NJM7806FA

IC506 NJM7906FA

Q501 2SB1237X

D501-D505 11ES2

IC2001 BU4066BCF

IC3001 CXD2724Q

IC2002,IC2501,IC3501,IC4001 NJM4558MD

IC4002 NJM4558MD

Q2031 DTA124EK

Q2032 DTC124EK

D2501,D506 1SS254

D507 MTZJ27D

D2502 MTZJ4.3B

D4001-D4003 MTZJ8.2B

D508 MTZJ9.1C

D4007,D4008,D4017,D4018 UDZS8.2B

1

→ 561 ........................................................ RD1/4PU 5 6 1 J

R 5 0

1 R 0

1

→ 5621 ...................................................... RN1/4PC 5 6 2 1 F

Mark No. Description Part No.

CAPACITORS

C500(0.01µF,AC250V) ACG1005

C2005,C3285-C3288,C3295 CCSQCH101J50

C3206,C3207 CCSQCH120J50

C3204,C3209 CCSQSL101J50

C3517-C3520 CCSQSL331J50

C2001,C2003,C4001,C4002 CEAT100M50

C4011,C4012,C504-C506,C509 CEAT100M50

C503 CEAT101M63

C501 CEAT222M25

C502 CEAT331M25

C2502,C3201-C3203,C3523 CEAT470M25

C3524 CEAT470M25

C511 CEAT470M25

C507,C508 CEAT470M50

C3282,C3292 CEAT471M6R3

C2503,C3511,C3512,C3521 CEAT4R7M50

C3522 CEAT4R7M50

C2501 CEATR10M50

C2031,C3296,C3515,C3516 CKSQYB102K50

C3205,C3208 CKSQYB331K50

C2002,C2004,C2507,C2509 CKSQYF103Z50

C3283,C3284,C3289-C3291 CKSQYF103Z50

C3293,C3294,C3513,C3514 CKSQYF103Z50

C534-C536 CKSQYF103Z50

C540 CKSQYF104Z50

RESISTORS

R503 RD1/4PU223J

R4003-R4006 RS1/10S1002F

R502 RS1LMF122J

Other Resistors RS1/10S J

K

K

COILS

L2001,L2002 DTL1019

L2501 LAU1R0J

L3203 LFA220J

L3202 LFA6R8J

L501 VTH1024

TRANSFORMER

T2 ATT7025

16

OTHERS

CN2001,CN2002 4P PIN JACK AKB7015

CN501 8P CONNECTOR AKP7026

X3201 CRYSTAL RESONATOR ASS7000

(33.8688MHz)

CN3001 FFC CONNECTOR 19P HLEM19S-1

CN503 4P SOCKET KP250NA4

JA4001 I/O JACK VKN1070

KN4001,KN501 VNF1084

EARTH METAL FITTING

Page 17

HTV-C1

Mark No. Description Part No.

TERMINAL ASSY

B

OTHERS

CN203 4P PLUG KM250NA4L

KN201 SCREW PLATE VNE1948

DISPLAY ASSY

C

SEMICONDUCTORS

IC5001 PDG221A

Q5001,Q5004 DTC143EK

D5002 1SS254

D5003 MTZJ6.8B

D5005-D5007 SLP6118C51H

COIL

L5001 LAU220J

SWITCHES

S5001-S5006 ASG1034

CAPACITORS

C5004 CEJA100M25

C5002,C5008 CEJA101M10

C5023 CKSQYB472K50

C5001,C5003,C5007,C5013 CKSQYF103Z50

C5006 CKSQYF104Z50

Mark No. Description Part No.

6. ADJUSTMENT

There is no information to be shown in this chapter.

RESISTORS

R5017 RA15T473J

R5016 RA9T473J

R5007 RD1/4PU821J

Other Resistors RS1/10S J

OTHERS

V5001 FL TUBE AAV7052

X5001 CERAMIC RESONATOR DSS1053

X5002 REMOTE RECEIVER UNIT GP1U28X

CN5001 FFC CONNECTOR 19P XKP3019

(8MHz)

FL HOLDER VNF1085

17

Page 18

HTV-C1

7. GENERAL INFORMATION

7.1 PARTS

7.1.1 IC

• The information shown in the list is basic information and may not correspond exactly to that shown in the schematic diagrams.

BA05ST (MAIN ASSY : IC507)

• Regulator IC

Pin Assignment

•

Top Vew

Block Diagram

•

VCC

1 pin:CTL

2 pin:VCC

3 pin:GND

4 pin:VOUT

5

5 pin:N.C

1

2pin

∗

CTL

1pin

GND

3pin

∗

Vref

CTL (1pin)

CTL terminal voltage Output

More than 2.0V ACTIVE

Less than 0.8V OFF

VOUT

4pin

N.C

5pin

18

Page 19

7.1.2 DISPLAY

AAV7052 (DISPLAY ASSY : V5001)

• FL TUBE

PATTERN AREA

• Pin Connection

• Grid Assignment

HTV-C1

NOTE 1) F1,F2 -------------- Filament

2) NP ------------------No pin

3) NX ------------------ No extend pin

4) DL ------------------ Datum Line

5) 1G - 9G ----------- Grid

• Anode Connection

1G - 8G

P1

P2

P3

P4

P5

P6

P7

P8

P9

a1

a2

h

j

k

b

f

m

g

9G

P10

P11

P12

P13

P14

P15

P16

P17

1G - 8G

c

e

r

p

n

d1

d2

Dp

9G

19

Page 20

HTV-C1

7.2 TEST MODE

7.2.1 TEST MODE

7.2.1.1 How to Enter the Test Mode

Even that is possible though there are the following two methods.

(1) Receive "A55F" command with the remote control unit.

(2) Short-circuit the TEST MODE points on the foil side (pin 19 of

IC5001 and ground) of the DISPLAY Assy. Plug the power

cord into the AC socket.

DISPLAY ASSY

C

IC5001

Pin 19

Short-circuit

SIDE B

2. DSP Check

Press the SURR. MODE key → Enter the DSP check mode.

DSP check mode

Outputs TEST TONE in the DOLBY VIRTUAL state.

Output repeatedly TEST TONE in order of LEFT → CENTER →

RIGHT → SURROUND.

Confirm whether DSP moves normally at the time of the

SURROUND output.

Press the SURROUND MODE key twice → Release the DSP check

mode. FL and LED are normal display.

* A key except for the designation normally moves.

7.2.1.3 Release The Test Mode

Turn the STAND BY/OFF key to OFF during the power on or unplug

the power cord from the AC socket.

7.2.2 SINGLE OPERATION METHOD

HTV system doesn't move if it is not the combination of HTV-C1

and HTV-A1 fundamentally.

AC26V is added to the sub-transformer (T2) when the HTV-C1 is

separate and you must diagnose it. (All the functions can't be

validated.)

• When the test mode is entered, FL displays with "TEST 1" for 1

second.

• LED keeps going on and off in the Test Mode.

• At this time, the setting of VOLUME becomes 10.

• SURROUND mode becomes DOLBY VIRTUAL ON.

7.2.1.2 Test Mode Operation

FL Segment Check

Press the DISPLAY key → Switch the movement of (1) to (5)

cyclically.

(1) All lighting the FL and LED

(2) All light-out the FL and LED

(3) (segment check 1) "ABCDEFGH" display

(4) (segment check 2) "IJKLMNOP" display

(5) Normal display

1. Check The AUTO STANDBY Function

(1) Press the INPUT key →

Turn the POWER off and it becomes AUTO

STANDBY mode.

FL displays with "AUTO".

(It becomes the condition that it passes for three

minutes during POWER ON with no signal.)

AC26V

MAIN ASSY

A

SIDE A

(2) Input the input signal to INPUT terminal →

AUTO POWER ON.

(It moves only when it is inputted to the selected

INPUT terminal.)

20

Page 21

7.3 BLOCK DIAGRAM

HTV-C1

HTV-C1/AUXJ,ACXJ

CONTROL CENTER

DEC143EK

GP1U28X

AAV7052

BU4066BCF

NJM4558MD

NJM4558MD

NJM4558MD

NJM4558MD

CXD2724Q

To HTV-A1 JA4501

PDG221A

BA05ST

NJM7806FA

ATT7025

NJM7805FA

NJM7906FA

2SB1237X

To HTV-A1 CN1003

21

Page 22

HTV-C1

HTV-A1/KUCXJ

AMPLIFIER

To HTV-C1 JA4001

(Refer to the service manual

RRV1957 for HTV-A1/KUCXJ)

To HTV-C1 CN501

22

Page 23

8. PANEL FACILITIES AND SPECIFICATIONS

Control Center

HTV-C1

SURROUND MODE

STANDBY/ON

1 2 11 12 13 14

SURROUND MODE

STANDBY/ON

1 STANDBY/ON switch

Turns the power ON/OFF (Standby).

Auto Standby Function

The unit is equipped with a function that will automatically turn the

power ON/OFF (Standby) according to the presence or absence of

an input signal.

÷ When the power is ON, the AUTO indicator will be illuminated.

Standby status will automatically be engaged if there is no input

signal for 5 minutes.

÷ If the selected input terminal receives an input signal while the

AUTO indicator is illuminated (Standby status is engaged), the

power will automatically be turned ON.

÷ If power to the unit has been turned OFF (Standby status is

engaged) using the STANDBY/ON button on either the unit or the

remote control, Standby status will remain engaged even if the

selected input terminal receives an input signal.

2 SURROUND MODE button

Selects Surround Mode.

3 DISPLAY button

When pressed once, displays each setting in sequence for 2 seconds; when pressed again, switches to Dimmer Mode, changing the

brightness of the display.

VOLUME

DISPLAY INPUT

15

16 17 3 4 5

VOLUME

DISPLAY INPUT

- INPUT indicator

When the INPUT 1 terminal is selected, “1” is illuminated; when the

INPUT 2 terminal is selected, “2” is illuminated.

= ST.WIDE indicator

Lights up when Surround Mode is switched to “STEREO WIDE.”

~ DOLBY VIRTUAL indicator

Lights up when Surround Mode is switched to “DOLBY VIRTUAL.”

! AUTO indicator

Lights up when Auto Standby status is engaged.

@ Standby indicator

Lights up when the power is OFF (Standby status) . Goes out when

the power is turned ON.

# ON indicator

Lights up when the power is turned ON. This is the only indicator that

will stay illuminated even when the Display is turned OFF.

$ Character display

4 VOLUME+, – buttons

5 INPUT button

Selects the input device.

23

Page 24

HTV-C1

Remote Control Unit

PRESET

SOURCE

STANDBY/ON

TV FUNC.

ENTER

TV/VCR

2

1

4 5 6

8

7

0+10

SOUND

SUR.MODE

DISPLAY

LEVEL

INPUT

RECALL

CHANNEL

VOLUME VOLUME

CH.ENTER

OFF

GUIDE

3

9

MENU

A/B

MUTING

VOLUME

CU-HTV001

TV

CA

TV

1

2

3

SAT

VCR

LD

DVD

CONTROL

SOURCE

SYSTEM

CONTROL

PRESET

4

5

STANDBY/ON

6

PRE-PROGRAMMED REMOTE CONTROL UNITPRE-PROGRAMMED REMOTE CONTROL UNIT

7

10

11

12

13

1 SOURCE CONTROL buttons

Select the device to be operated.

2 SOUND button

Selects the sound control function (BASS/TREBLE/BALANCE/S.W.

LEVEL/EFFECT).

3 SUR.(surround) MODE button

Selects Surround Mode.

4 PRESET button

To preset other brand devices, press any one of the SOURCE

CONTROL buttons together with this button.

5 DISPLAY button

When pressed once, displays each setting in sequence for 2 seconds; when pressed again, switches to Dimmer Mode, changing the

brightness of the display.

6 STANDBY/ON button

Turns the Home Theater System power ON/OFF (Standby).

7 INPUT button

Selects the input device.

24

0 Other device operation buttons

Select the device to be operated with the SOURCE CONTROL

buttons and then operate the device.

- MUTING button

Press to mute the volume.

= VOLUME +,– button(s)

Use to adjust the volume.

~ LEVEL +,– button(s)

Use to adjust the sound control mode selected with the SOUND

button.

Page 25

7 SPECIFICATIONS

Input (Sensitivity/Impedance)

INPUT 1, 2 ...........................................................200 mV/22 kΩ

Speaker Section

Front L/R ..............................................................8.7 cm cone type

Miscellaneous

Dimensions

Control center.......................... 610 (W) × 110 (H) × 166 (D) mm

24-3/16 (W) × 4-5/16 (H) × 6-9/16 (D) in

Weight (without package)

Control center................................................... 3.8 kg (8 lb 6 oz)

Furnished Parts

System cable A .............................................................................1

System cable B ............................................................................. 1

Audio cord .....................................................................................1

Mount kit .......................................................................................1

Dry Cell Batteries (AA/R6P).......................................................... 2

Remote Control Unit .....................................................................1

Operating Instructions ................................................................... 1

Warranty card................................................................................1

HTV-C1

Manufactured under license from the Dolby Laboratories.

DOLBY and the double-D symbol are trademarks of Dolby

Laboratories.

NOTE:

Specifications and the design are subject to possible modifications

without notice, due to improvements.

Checking Accessories

• Remote control unit

(AZN7713)

• Mount kit (AEA7021)

Washers × 2

(WB60FZK)

Wing nuts × 2

(NR60FZK)

(These parts are included in the accessory box.)

• System cable A

(ADX7239) (L=3.0m)

• System cable B

(ADE7023) (L=3.0m)

• Audio cord

(VDE1033) (L=1.5m)

• Operating instructions

• Warranty card

• Quick instructions guide

Dry cell batteries

(VEM-013)

Nuts × 2

(NA60FZK)

Bolts (S) × 2

(ABA7041)

Bolts (L) × 2

(ABA7042)

Bolt caps × 4

(AEB7111)

Velcro tapes

(hooks) × 2

(AED7028)

Velcro tapes

(loops) × 2

(AED7029)

25

Loading...

Loading...