Page 1

NETWORK CACHE CHANGER

DRM-6NX

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

ORDER NO.

RRV2103

Type

Model

DRM-6NX

TUCYV O AC110 - 240V

Power Requirement

CONTENTS

1. SAFETY INFORMATION....................................2

2. EXPLODED VIEWS AND PARTS LIST .............4

3. SCHEMATIC DIAGRAM................................... 14

4. PCB CONNECTION DIAGRAM .......................26

5. PCB PARTS LIST.............................................32

6. ADJUSTMENT.................................................. 35

Remarks

7. GENERAL INFORMATION .............................. 45

7.1 IC................................................................ 45

7.2 DIAGNOSIS ...............................................46

7.2.1 DIAGNOSIS METHOD FOR MULTI

MECHA ASSY AND HDD................. 46

7.2.2 DISASSEMBLY................................. 46

7.2.3 TROUBLESHOOTING......................48

7.2.4 UPGRADING THE NETWORK

CACHE CHANGER .......................... 53

7.3 BLOCK DIAGRAM .................................... 56

8. PANEL FACILITIES AND SPECIFICATIONS

...................................................................57

PIONEER ELECTRONIC CORPORATION 4-1, Meguro 1-Chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS SERVICE, INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER ELECTRONIC (EUROPE) N.V. Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Allexandra Road, #04-01, Singapore 159936

c

PIONEER ELECTRONIC CORPORATION 1999

T – ZZY FEB. 1999 Printed in Japan

Page 2

DRM-6NX

1. SAFETY INFORMATION

This service manual is intended for qualified service technicians; it is not meant for the casual

do-it-yourselfer. Qualified technicians have the necessary test equipment and tools, and have been

trained to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

WARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of California to cause

cancer, birth defects or other reproductive harm.

Health & Safety Code Section 25249.6 – Proposition 65

NOTICE

(FOR CANADIAN MODEL ONLY)

Fuse symbols (fast operating fuse) and/or (slow operating fuse) on PCB indicate that replacement parts

must be of identical designation.

REMARQUE

(POUR MODÈLE CANADIEN SEULEMENT)

Les symboles de fusible (fusible de type rapide) et/ou (fusible de type lent) sur CCI indiquent que les

pièces de remplacement doivent avoir la même désignation.

(FOR USA MODEL ONLY)

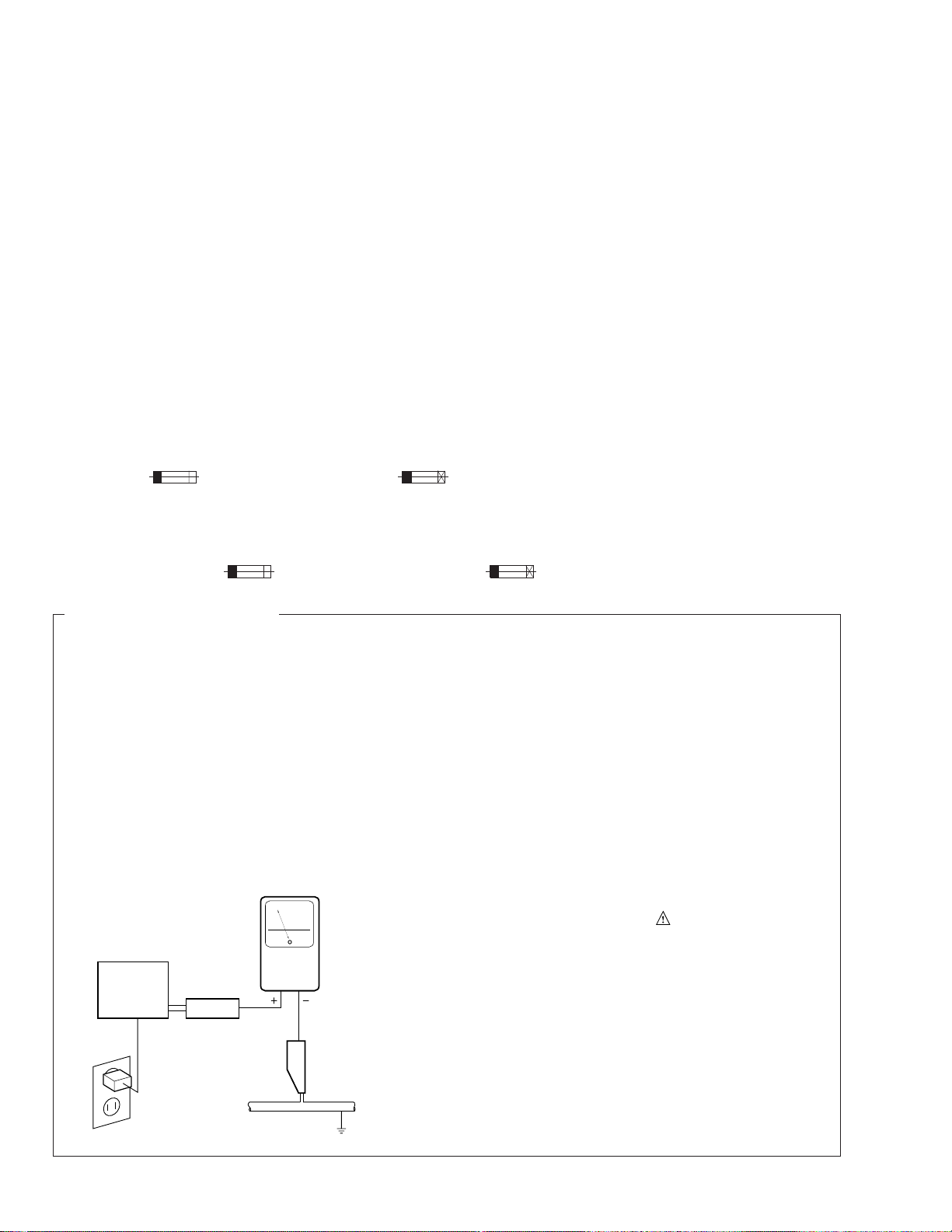

1. SAFETY PRECAUTIONS

The following check should be performed for the

continued protection of the customer and service

technician.

LEAKAGE CURRENT CHECK

Measure leakage current to a known earth ground

(water pipe, conduit, etc.) by connecting a leakage

current tester such as Simpson Model 229-2 or

equivalent between the earth ground and all exposed

metal parts of the appliance (input/output terminals,

screwheads, metal overlays, control shaft, etc.). Plug

the AC line cord of the appliance directly into a 120V

AC 60 Hz outlet and turn the AC power switch on. Any

current measured must not exceed 3.5 mA.

Reading should

not be above

3.5 mA

Earth ground

Device

under

test

Also test with plug

reversed

(Using AC adapter

plug as required)

Leakage

current

tester

Test all exposed

metal surfaces

AC Leakage Test

ANY MEASUREMENTS NOT WITHIN THE LIMITS

OUTLINED ABOVE ARE INDICATIVE OF A POTENTIAL SHOCK HAZARD AND MUST BE CORRECTED BEFORE RETURNING THE APPLIANCE

TO THE CUSTOMER.

2. PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in the appliance have special safety related characteristics. These

are often not evident from visual inspection nor the

protection afforded by them necessarily can be obtained by using replacement components rated for

voltage, wattage , etc. Replacement parts which have

these special safety characteristics are identified in

this Service Manual.

Electrical components having such features are

identified by marking with a

on the parts list in this Service Manual.

The use of a substitute replacement component which

does not have the same safety characteristics as the

PIONEER recommended replacement one, shown in

the parts list in this Service Manual, may create shock,

fire, or other hazards.

Product Safety is continuously under review and

new instructions are issued from time to time. For

the latest information, always consult the current

PIONEER Service Manual. A subscription to, or additional copies of, PIONEER Service Manual may be

obtained at a nominal charge from PIONEER.

on the schematics and

2

Page 3

DRM-6NX

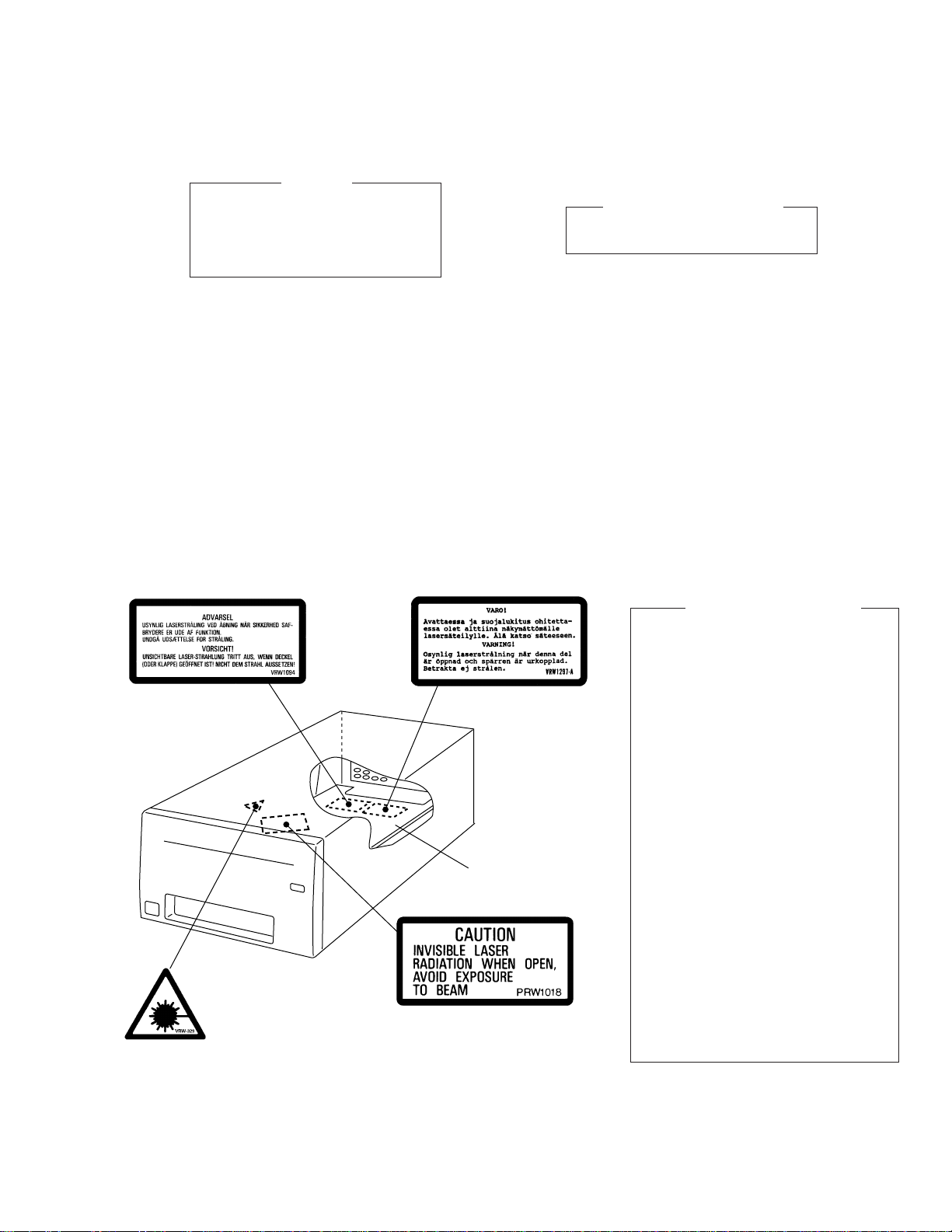

THIS PIONEER APPARATUS CONTAINS

LASER OF CLASS 1.

SERVICING OPERATION OF THE APPARATUS

SHOULD BE DONE BY A SPECIALLY

INSTRUCTED PERSON.

LABEL CHECK

IMPORTANT

LASER DIODE CHARACTERISTICS

MAXIMUM OUTPUT POWER: 5 mw

WAVELENGTH: 780 - 785 nm

Additional Laser Caution

(HDD Stay Assy Top) (HDD Stay Assy Top)

HDD Stay Assy

(Synchronize Lever Top)

(Holder Top)

1. Laser Interlock Mechanism

The ON/OFF (ON: low level, OFF: high

level) status of the LPS1 (S601) switch for

detecting the loading state is detected by

the system microprocessor, and the

design prevents laser diode oscillation

when LPS1 (S601) is not ON (low level)

(clamped srate).

Thus, interlock will no longer function if

switch LPS1 (S601) is deliberately

shorted.

In the test mode∗ the interlock mechanism

will not function.

Laser diode oscillation will continue, if pin 2

of AN8849SB (IC201) on the MAIN

BOARD assy is connected to GND, or else

the terminals of Q201 are shorted to each

other (fault condition).

2. When the cover is opened with the servo

mechanism block removed to be turned

over, close viewing of the objective lens

with the naked eye will cause exposure to

a Class 1 laser beam.

∗ Refer to page 36.

3

Page 4

DRM-6NX

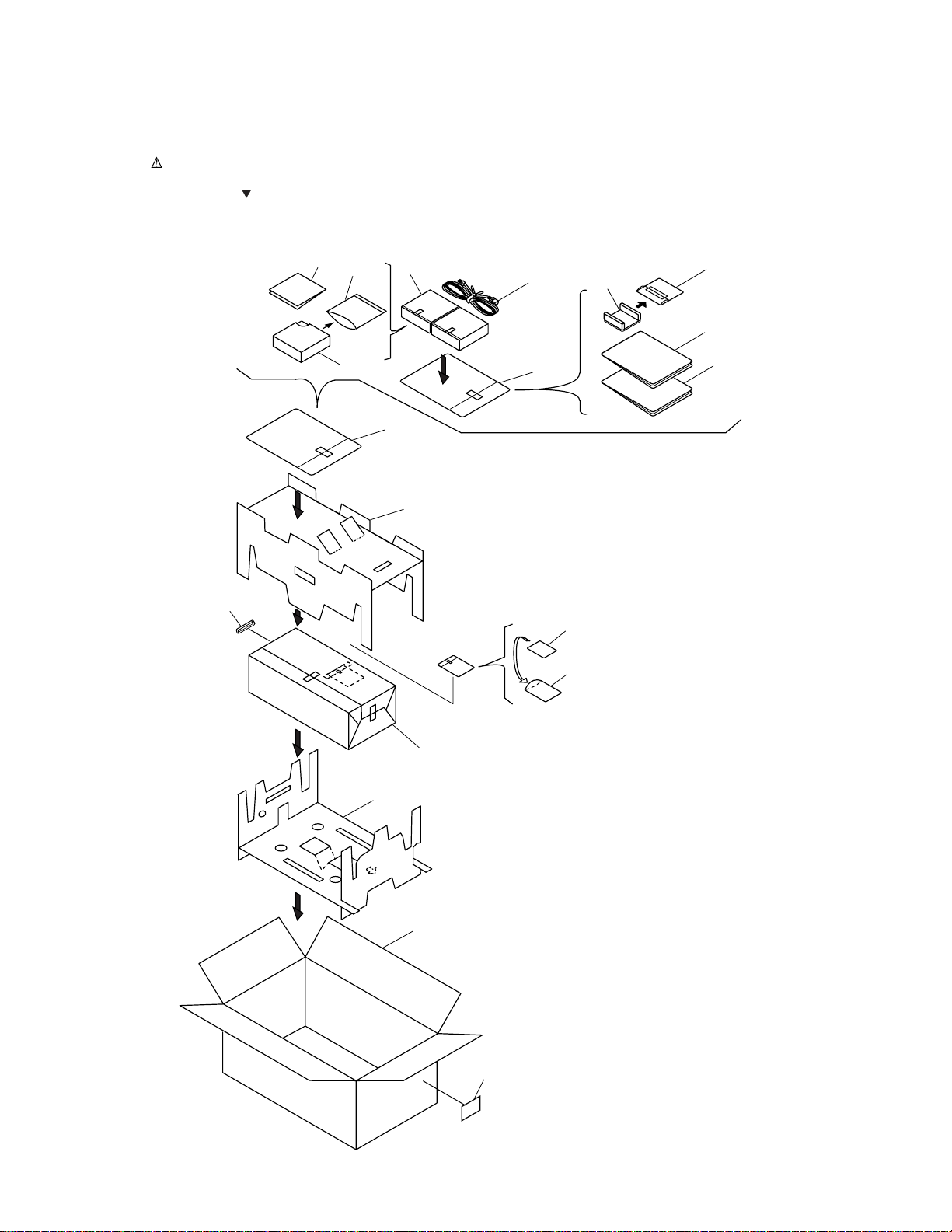

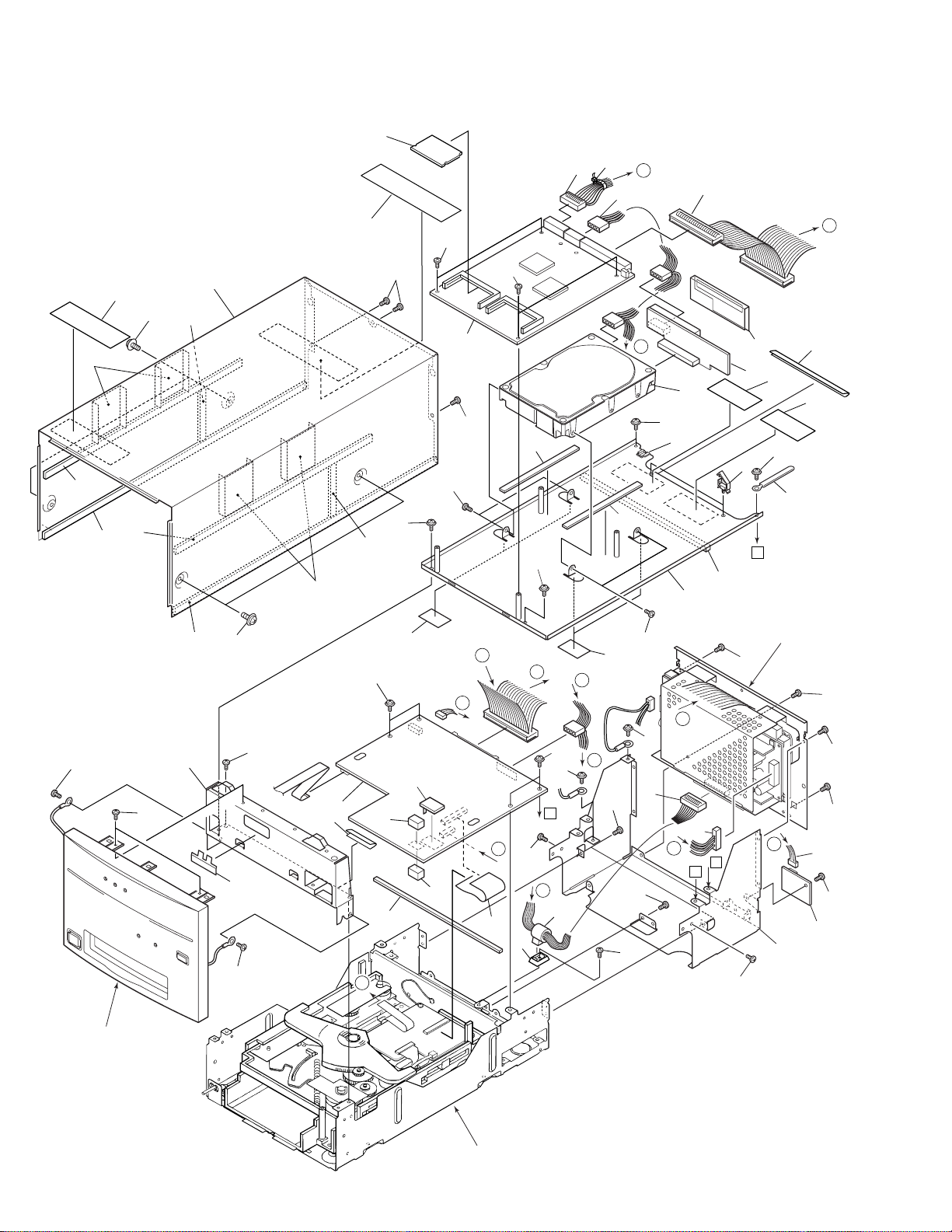

2. EXPLODED VIEWS AND PARTS LIST

NOTES:• Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

2.1 PACKING

The mark found on some component parts indicates the importance of the safety factor of the part.

•

Therefore, when replacing, be sure to use parts of identical designation.

Screws adjacent to mark on the product are used for disassembly.

•

6

9

2

1

3

7

4

18

2

15

11

FRONT

14

12

10

17

8

5

13

16

4

Page 5

PACKING PARTS LIST

•

Mark No. Description Parts No.

1 Power Cable (for U.S.and Canada) DDG1071

2 6-Disc Magazine DXA1864

3 Power Button Cover DNK3626

4 Operating Instructions DRB1239

(English)

5 Operating Instructions DRB1243

(German)

DRM-6NX

NSP 7 Polyethylene Bag Z21-002

NSP 8 Polyethylene Bag Z21-006

NSP 16 Label VRW1629

NSP 17 Network Board

6 Label DRW1928

9 Polyethylene Bag Z21-014

(165 × 200 × 0.03)

10 Polyethylene Bag Z21-038

(0.03 × 230 × 340)

11 Pad A DHA1421

12 Pad B DHA1422

13 Packing Case DHG1879

14 Sheet DHL-125

15 Polyethylene Bag DHL1020

Serial Number Label ••••••••

18 SCSI Connector Cover FCN-780C050-14

5

Page 6

DRM-6NX

2.2 EXTERIOR (1/2)

35

24

26

22

44

10

24

37

28

23

22

29

10

25

35

34

26

49

4

42

39

43

40

A

41

D

36

3

33

36

12

B

21

5

6

48

47

46

34

18

34

33

17

11

31

34

23

34

12

B

14

30

Refer to "2.5 Rear

34

B

34

Panel Section".

F

8

2

27

34

34

34

34

19

D

32

F

E

B

32

45

1

15

G

20

13

7

38

A

34

A

9

16

G

11

19

E

38

C

39

34

40

C

A

34

35

Refer to "2.4 Front Panel

Section".

6

Refer to "2.3 EXTERIOR (2/2)".

Page 7

EXTERIOR (1/2) PARTS LIST

•

Mark No. Description Part No.

DRM-6NX

Mark No. Description Part No.

1 MAIN BOARD ASSY DWX1906

2 IDSB BOARD ASSY DWZ1084

3 AXIS NETWORK BOARD ASSY DWN1001

4 MEMORY BOARD ASSY (16MB)DWX1916

5 IDE/SCSI BOARD ASSY DWX1917

6 Hard Disk DXX2434

7 Lead Card 30P DDD1121

8 Connector Assy DKP3416

NSP 9 Ferrite Clamp DTH1174

10 Screw DBA1083

11 Screw (#6-32) DBA1125

12 Cushion DEB1405

13 Barrier Packin A DEB1417

14 Barrier Packin B DEB1418

15 PCB Cushion (T8) DEB1420

16 F Clamp Holder DEC1266

NSP 17 Locking Wire Saddle DEC1305

NSP 18 Edging Saddle (S) DEC1761

19 Sheet DEC1939

20 PCB Cushion (T10) DEC2190

21 Sheet DEC2260

22 Bonnet Packin A DEC2290

23 Bonnet Packin B DEC2291

24 Bonnet Packin C DEC2292

25 Plate DEC2299

NSP 27 Chassis (S) DNA1238

26 Bonnet Sheet DEC2300

NSP 28 Front Stay DND1213

29 Bonnet DNE1365

30 HDD Stay Assy DXB1695

31 Cord Clamper RNH-184

32 Screw ABZ30P080FCC

33 Screw BBT30P060FNI

34 Screw BBT30P060FZK

35 Screw BBZ30P050FMC

36 Screw BMZ30P060FNI

37 Screw IBZ30P060FMC

38 Screw PMB40P080FMC

39 Connector 20P DKP3419

40 Connector 4P DKP3415

41 Connector 50P DKP3417

42 Binder ZCA-SKB90BK

43 65 Label ARW7050

44 Label DRW1533

45 Heat Sink DNE1352

NSP 46 Coution Label HE VRW1297

47 Coution Label VRW1094

NSP 48 Sheet VEX1023

49 Tape (G) REH1010

7

Page 8

DRM-6NX

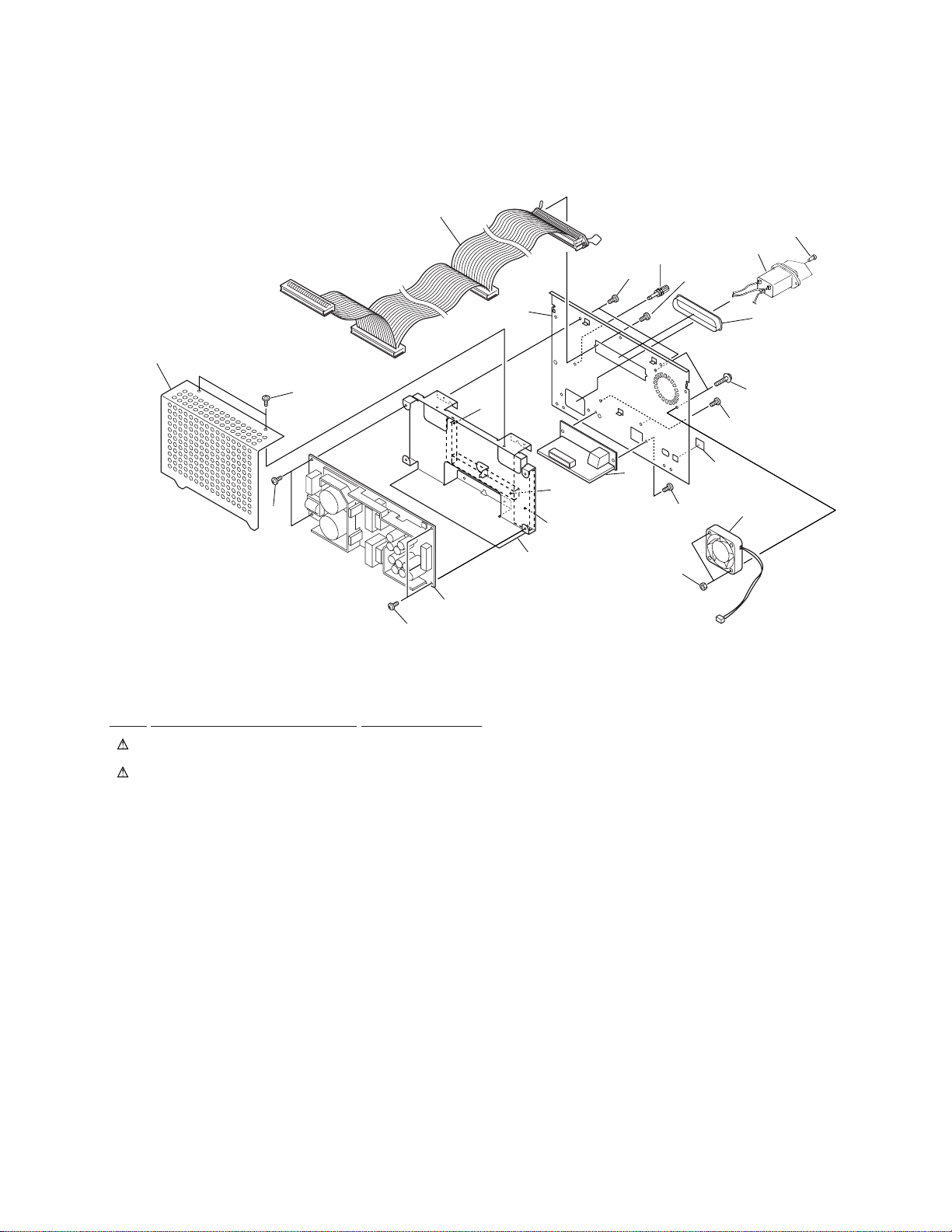

2.3 EXTERIOR (2/2)

7

Refer to

"2.6 MULTI

MECHA ASSY".

12

24

21

24

20

24

B

2

23

24

10

B

17

18

14

16

11

13

25

22

15

11

6

27

A

23

B

26

1

5

3

A

23

19

9

22

8

4

8

8

8

Page 9

EXTERIOR (2/2) PARTS LIST

•

Mark No. Description Part No.

DRM-6NX

NSP 2 Cord With Plug DE005VF0

NSP 3 PCB Spacer(3 x 12) AEC1372

NSP 9 Base Chassis DNA1177

NSP 11 Sheet E VEX1006

NSP 12 Multi Mchanism Assy DXB1653

1 PWSB BOARD ASSY DWS1296

4 Locking Card Spacer DEC1858

5 Barrier Packin C DEC2302

6 Barrier Packin D DEC2303

7 Barrier Packin E DEC2304

8 Leg DED1102

10 Barrier DNH2299

13 Joint Cap DEB1057

14 PSW Joint DLA1658

15 SW Holder DNF1500

16 Shaft Holder DNK2414

17 PSW Bush DNK1326

18 PSW Cap DNK2413

19 Cord Clamper RNH-184

20 Coution Label G VRW-329

21 Coution Lavel PRW1018

22 Screw BBT30P060FZK

23 Screw BBZ30P050FMC

24 Screw BBZ30P080FMC

25 Screw PMA30P060FMC

26 Connector Assy 2P DKP3426

27 Binder ZCA-SKB90BK

9

Page 10

DRM-6NX

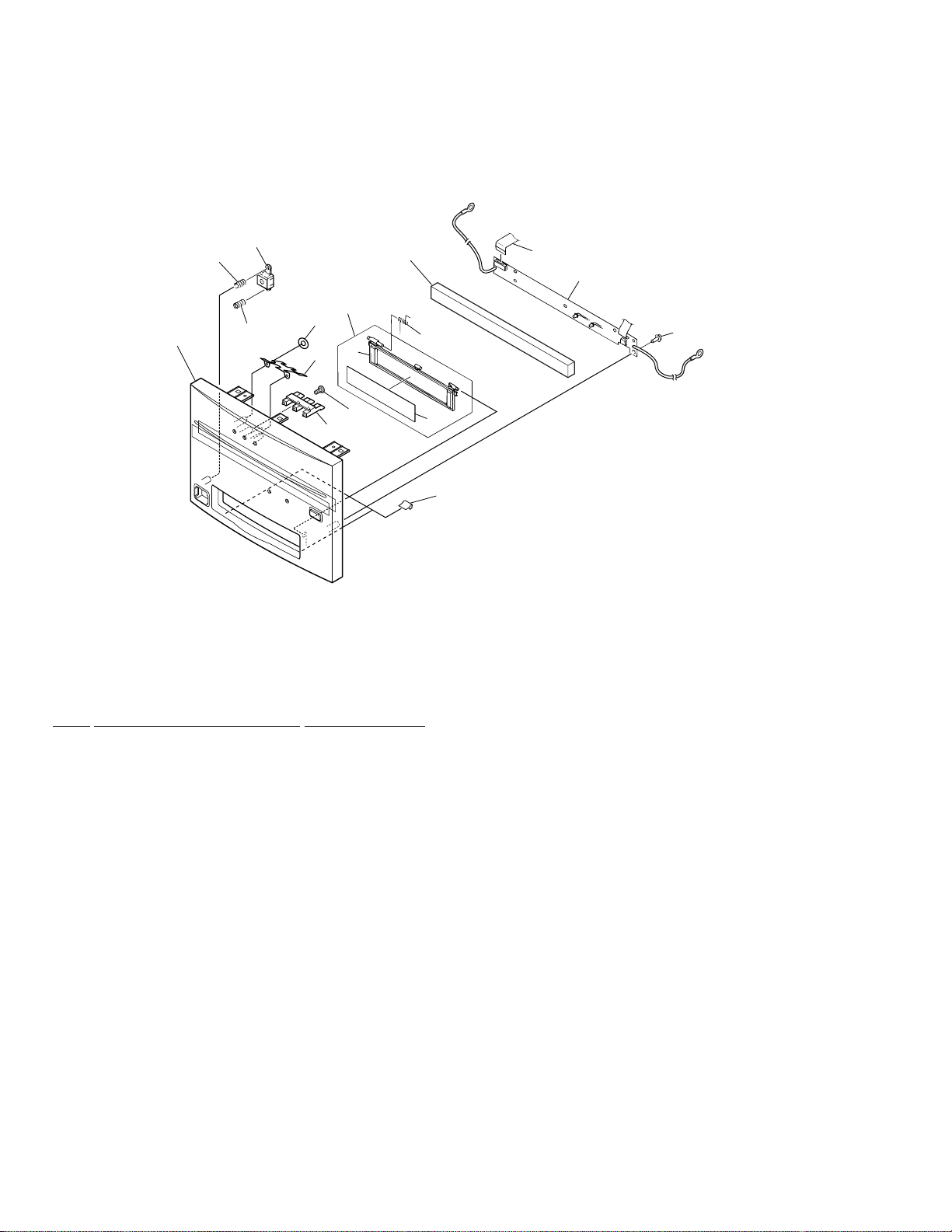

2.4 FRONT PANEL SECTION

6

3

16

9

3

17

7

4

14

8

5

11

2

13

12

1

14

FRONT PANEL SECTION PARTS LIST

•

Mark No. Description Part No.

NSP 2 Door Name Plate DAM1078

NSP 7 Door DNK3112

1 FRPB BOARD ASSY DWZ1083

3 Power Button Spring DBH1213

4 Reflector DEC2283

5 Front Packin DEC2301

6 Power Button DNK2411

8 Indicater Lens DNK3624

9 Front Panel Assy DXA1861

10 ••••••••

11 Door Spring PBH1022

12 12P F. F. C/30V DDD1097

13 Tape (G) REH1010

14 Screw IPZ30P080FMC

15 ••••••••

16 Door Assy-S DXX2403

17 Nat YP20FBT

10

Page 11

2.5 REAR PANEL SECTION

DRM-6NX

5

19

3

20

4

18

8

20

20

20

REAR PANEL SECTION PARTS LIST

•

Mark No. Description Part No.

1 PWRB BOARD ASSY DWR1307

3 AC Inlet Assembly 3P DKN1148

2 CONNECTOR BOARD ASSY DWX1921

4 Ground Terminal DKE-102

5 Connector Assy 50P DKP3417

11

10

17

15

20

2

24

14

16

7

13

12

21

1

6 ••••••••

7 DC Fan motor VXM1069

NSP 8 Power Cover DNH2426

9 ••••••••

10 SCSI Connector Cover FCN-780C050-14

11 Rear Panel DNC1499

NSP 12 Power Stay DND1215

13 Coner Cover DEC2315

14 Rear Packin A DEC2313

15 Rear Packin B DEC2314

16 Screw BMZ30P060FNI

17 Screw AMZ40P160FZK

18 Screw PMZ30P100FNI

19 Screw CBZ30P080FZK

20 Screw BBT30P060FZK

21 Nut NB40FMC

22 ••••••••

23 ••••••••

24 ID SW Cover DEC2269

11

Page 12

DRM-6NX

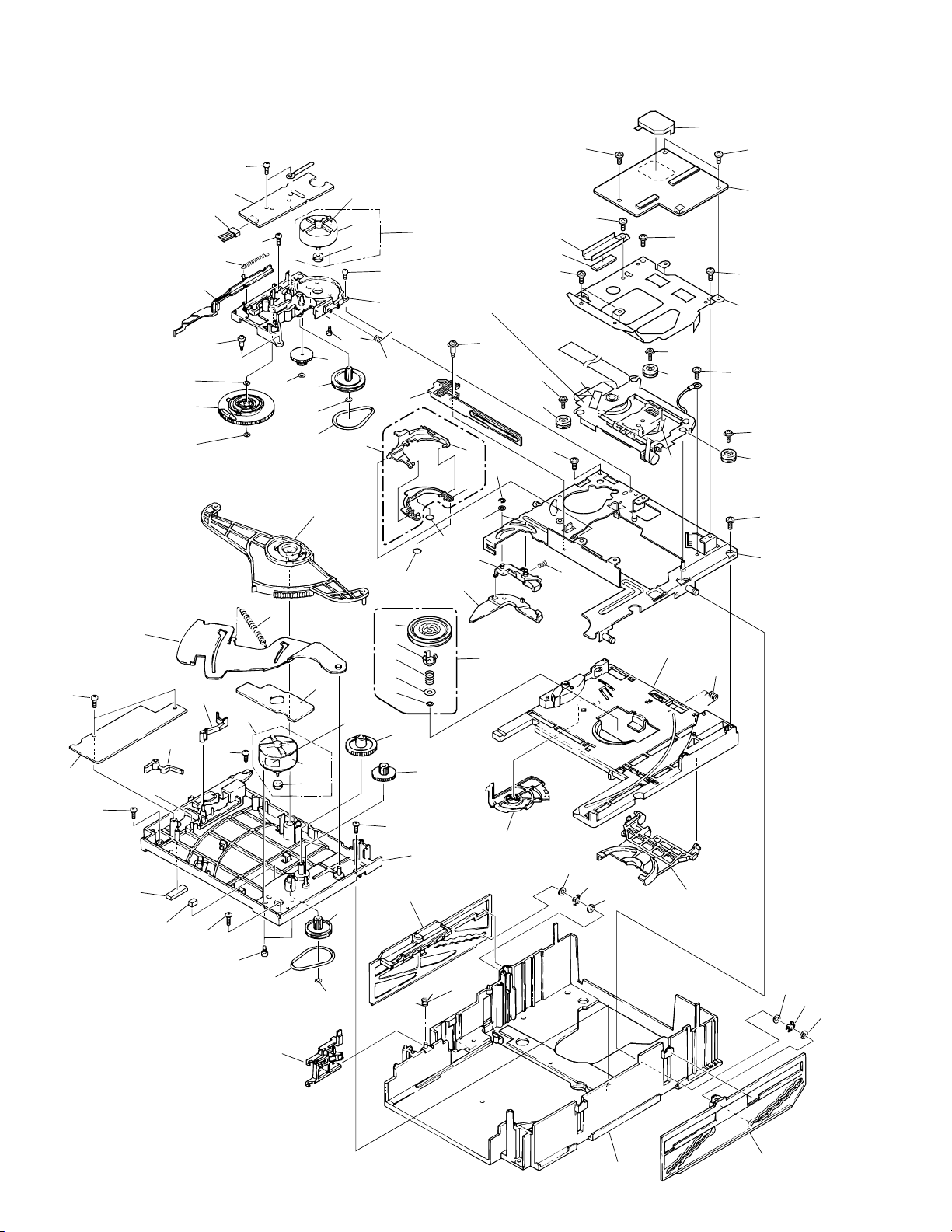

2.6 MULTI MECHA ASSY

38

63

57

38

26

25

17

38

66

60

11

41

4

40

12

38

40

10

36

40

7

5

59

1

35

67

∗1 Label

59

1

37

9

68

∗2 Label

36

39

Refer to

"2.7 SERVO MECHA

2

ASSY".

18

16

20

20

30

53

29

55

54

8

15

9

19

13

21

41

62

17

52

42

48

49

38

51

50

39

69

14

70

39

23

64

48

49

71

69

3

39

39

56

39

48

49

43

61

58

12

38

45

44

38

37

5

31

40

38

6

33

7

32

27

47

46

47

65

28

34

47

46

47

Page 13

MULTI MECHA PARTS LIST

•

Mark No. Description Parts No.

1 Motor Pulley PNW1634

2 Gear Holder PNW1929

3 SIFB BOARD ASSY DWZ1081

4 Cam Gear PNW1923

5 Belt PEB1138

6 Top Guide N PNW2441

7 Gear Pulley PNW1918

8 Gear S PNW1919

9 Gear L PNW1920

10 Eject Spring PBH1107

11 SW Lever PNW1927

12 Seven Bar PNW1931

13 Sub Revolving Lever PNW1933

14 Sub Revolving Lever Spring PBH1111

15 Revolving Lever PNW1932

16 Drive Plate DNK3450

17 Motor Screw PBA–112

18 Holder Lever Spring PBH1110

19 Disc Holder DNK3448

20 Cushion DED1111

21 Holder Lever DNK3449

22 ••••••••

23 S Flexible Wire DNP1748

24 ••••••••

25 Release Lever PNW1934

26 Release Spring PBH1106

27 Clamper Cam PNW1922

28 Clamper Holder PNW1921

29 Centering Spring DBH1389

30 Clamper Assy DXB1651

31 Lock Lever PNW1917

32 Lock Spring PBH1108

33 Stair NL PNW2443

34 Stair NR PNW2444

35 Synchronize Lever PNW1926

DRM-6NX

Mark No. Description Parts No.

36 Motor Assy PEA1130

(LOADING, DISC SELECT)

37 Screw PMZ26P040FMC

38 Screw PPZ30P080FMC

39 Screw BBZ30P060FMC

40 Washer WT26D047D025

41 Washer WA31D054D025

42 E Ring Z39–010

43 Screw IPZ30P080FMC

44 Spacer PEB1254

45 Spacer PEB1179

46 Silent Ring PBK1093

47 Washer WA62D130D025

48 Screw AMZ26P040FMC

49 Mount Bush 24 DEB1357

50 F Cushion C DEB1151

51 Hold Plate RNE1629

52 Clamper Assy S DXX2391

53 Centering Arm DNK3451

54 Washer WT21D060D025

55 Washer WA26D080D025

56 Holder DNH2297

57 Connector Assy (4P) PG04MM–F07

58 Clamp Spring PBH1109

59 Carriage Motor VXM1033

60 Eject Lever PNB1306

61 Mechanism Base DNH2305

62 Servo Mechanism Assy DXB1654

NSP 63 LOAD BOARD Assy PWZ2038

64 Sub Chassis N PNW2440

65 Main Chassis PNW2074

NSP 66 DSEL BOARD Assy PWZ2533

NSP 67 MOTB BOARD Assy PWZ2040

68 Hold Plate Assy DXB1662

69 Screw BBZ30P080FMC

70 Damp Sheet VEX1021

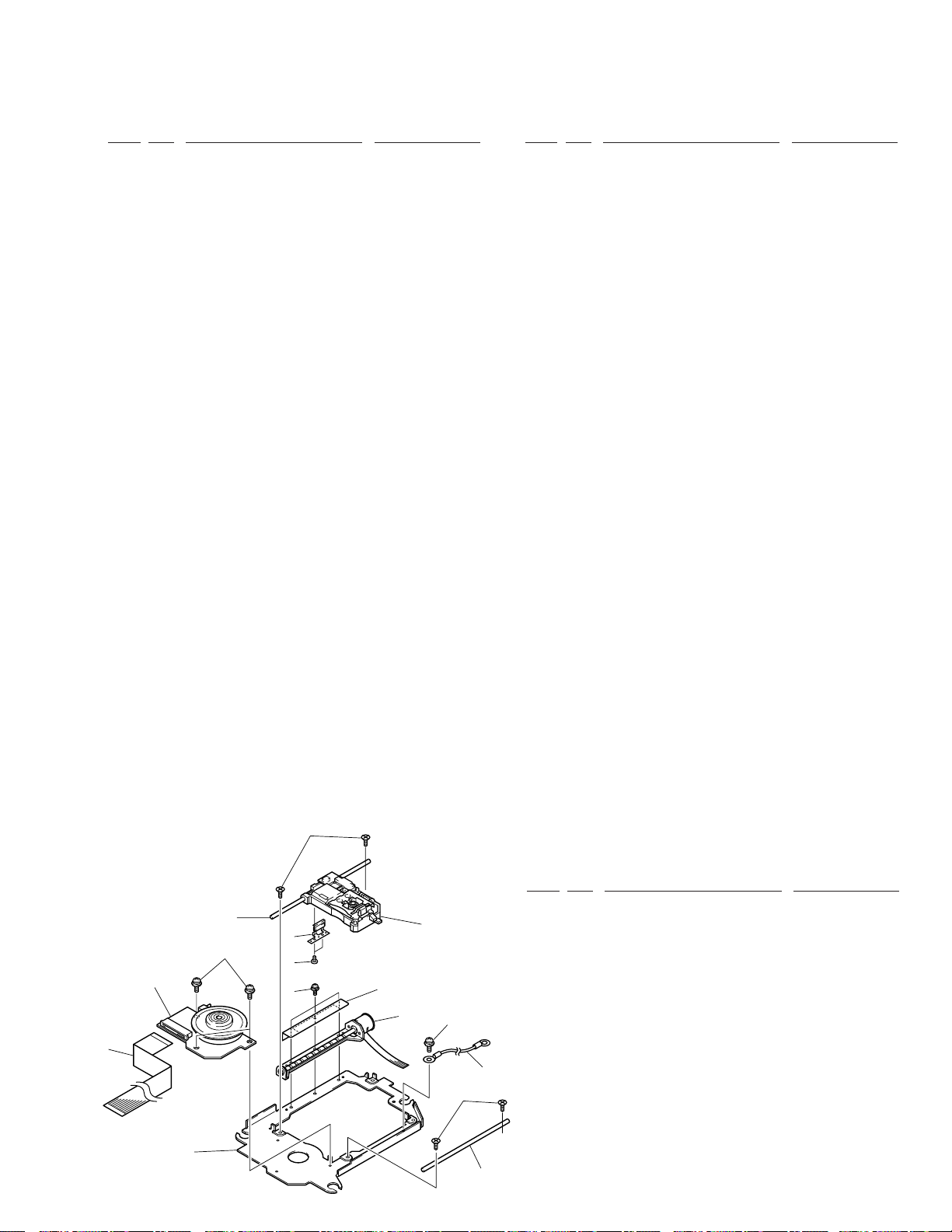

2.7 SERVO MECHA ASSY

6

7

14

1

11

10

2

9

4

71 Shield Case DNH2292

SERVO MECHA ASSY PARTS LIST

•

Mark No. Description Parts No.

1 Spindle Motor Assy DXM1097

12

5

3

14

NSP 10 Servo Mechanism Base DNH2302

13

6

NSP 12 Pickup Assy DWY1069

2 Screw Guide DNK3238

3 Pulse Motor Frame DXM1096

4 Screw PMH20P040FMC

5 Cover Plate DBK1138

6 Screw CMZ20P060FMC

7 Guide Shaft DLA1731

8 Sub Guide Shaft DLA1372

9 Screw ABA7022

11 SPD Card DDD1122

13 Earth Lead Unit PDF1074

14 Screw AMZ20P040FCC

8

13

Page 14

1

234

DRM-6NX

3. SCHEMATIC DIAGRAM

Note: When ordering service parts, be sure to refer to "EXPLODED VIEWS AND PARTS LIST" or "PCB PARTS LIST".

A

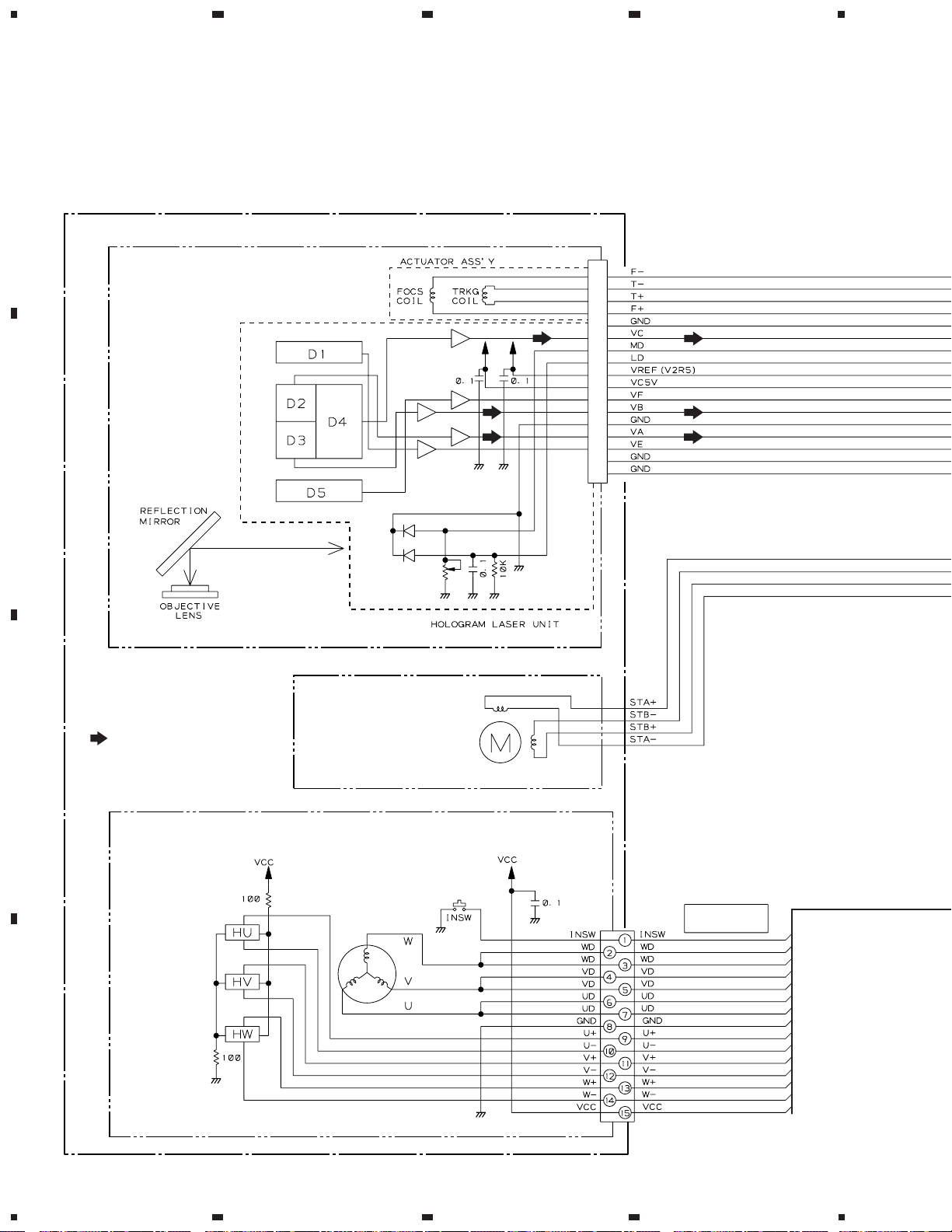

3.1 OVERALL CONNECTION DIAGRAM (1/2)

(SIFB BOARD ASSY, LOAD BOARD ASSY and IDSB BOARD ASSY)

SERVO MECHANISM ASSY (DXB1654)

PICKUP ASSY

(DWY1069)

B

SIGNAL ROUTE

: RF & AUDIO SIGNAL ROUTE

C

PULSE MOTOR FRAME

(DXM1069)

STEPPING MOTOR

SPINDLE MOTOR

(DXM1097)

FLEXIBLE CORD

DDD1122

D

14

1234

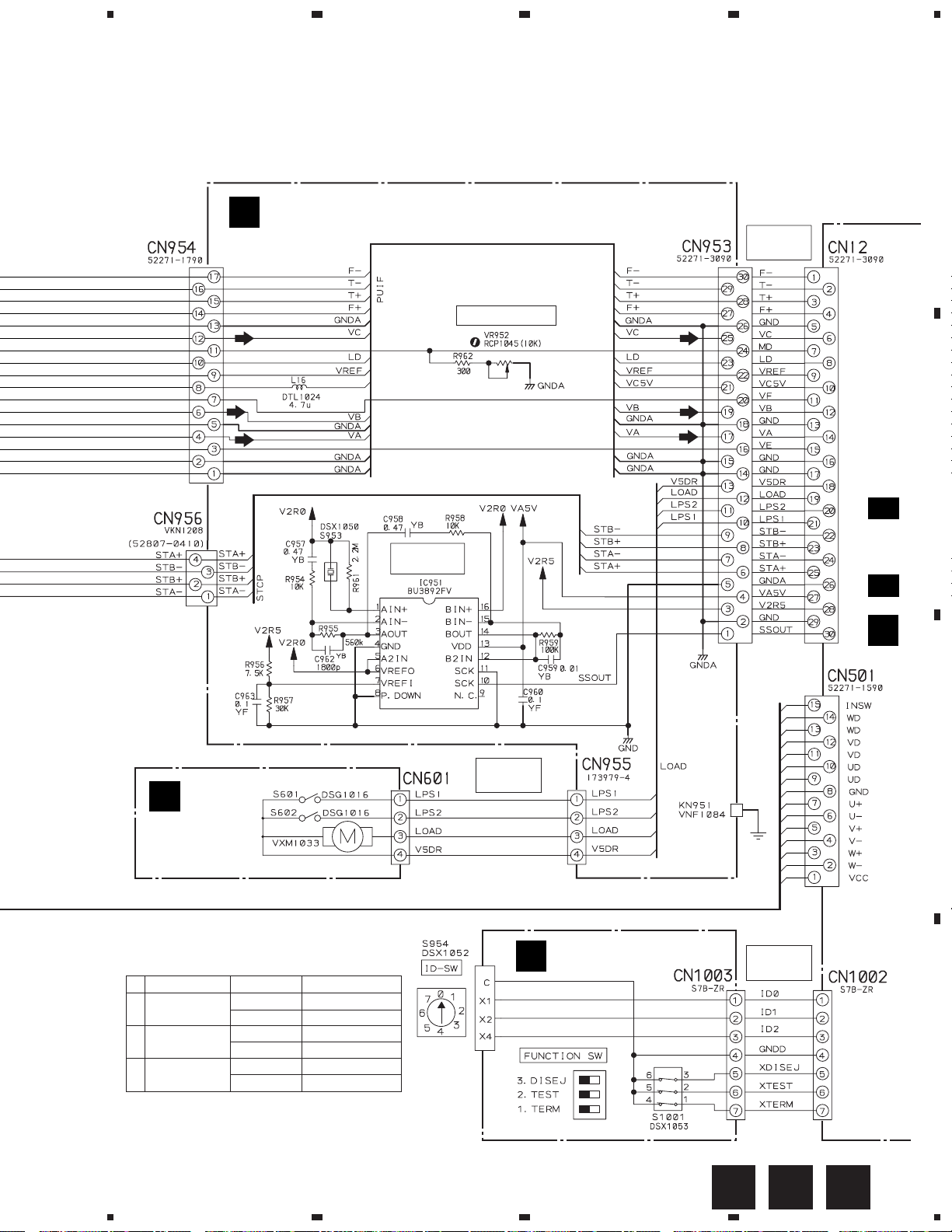

Page 15

5

67

8

DRM-6NX

A

SIFB BOARD ASSY (DWZ1081)

A

LD POWER ADJ.

FLEXIBLE

CORD

DDD1121

MAIN BOARD ASSY

(DWX1906)

B

)

B

LOAD BOARD

ASSY

(PWZ2038)

S1001 (FUNCTION SW)

No.

1

TERMINATION

2

TEST

3

DISABLE EJECT

DIP SW MODE SETTING

ON (SHORT) TERMINATOR ON

OFF (OPEN) TERMINATOR OFF

ON (SHORT) TEST MODE ON

OFF (OPEN) TEST MODE OFF

ON (SHORT) EJECT ENABLE

OFF (OPEN) EJECT DISABLE

VIBRATION

SENSOR

CONNECTOR

ASSY

PG04MM-F07

C

IDSB BOARD ASSY

(DWS1084)

CONNECTOR

ASSY

DKP3416

D 1/3 to D 3/3

(

D

C

D

CBA

5

6

7

8

15

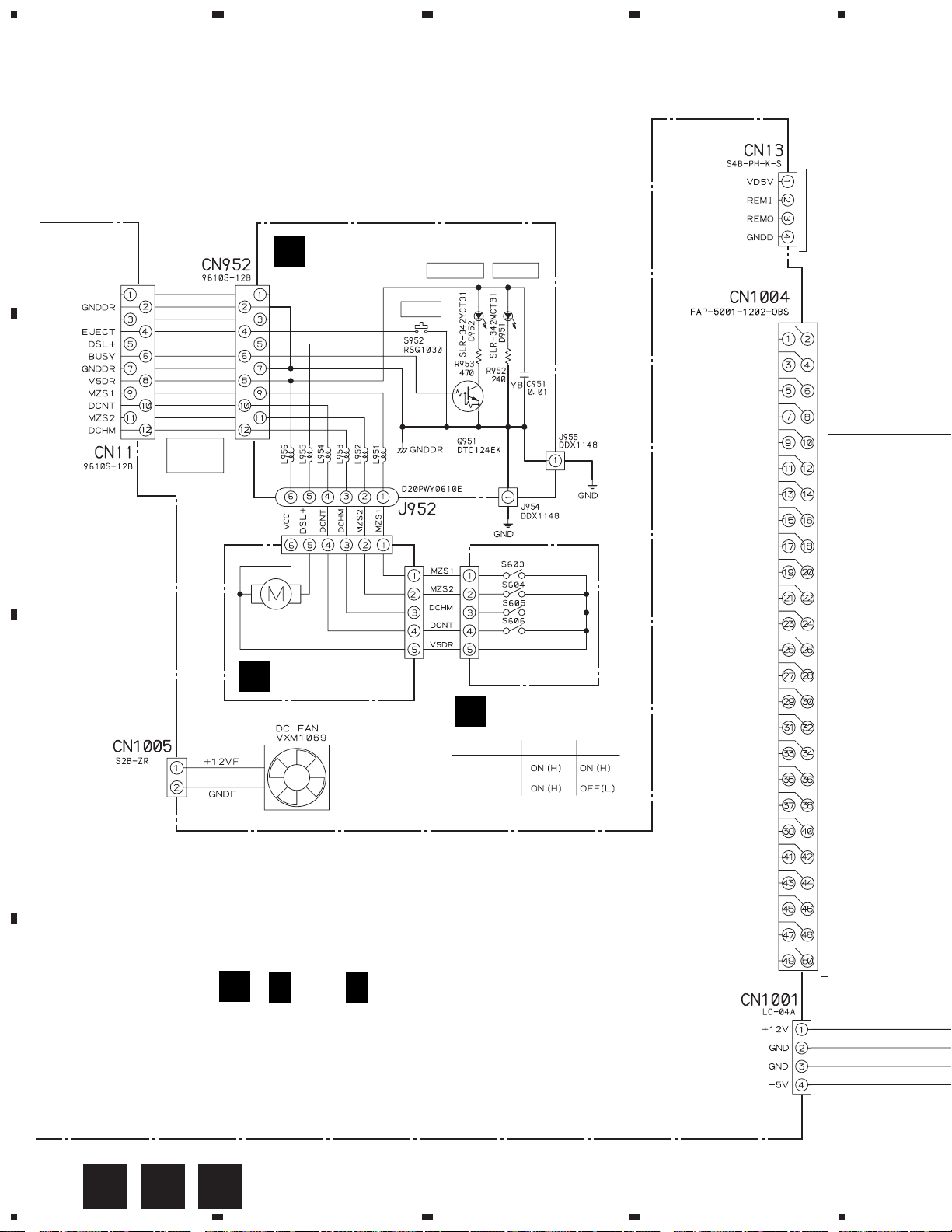

Page 16

1

234

DRM-6NX

3.2 OVERALL CONNECTION DIAGRAM (2/2)

(FRPB BOARD ASSY, MOTB BOARD ASSY, DSEL BOARD ASSY,

PWSB BOARD ASSY, PWRB ASSY, IDE/SCSI BOARD ASSY,

A

B

C

AXIS NETWORK BOARD ASSY, MEMORY BOARD ASSY and

CONNECTOR BOARD ASSY)

FRPB BOARD ASSY

E

(DWZ1083)

N. C.

N. C.

FLEXIBLE

CORD

DDD1097

D

PEA1130

MOTB BOARD

F

ASSY (PWZ2040)

(

D

1/3 to

S952: EJECT

D

EJECT

L951–L956:

RTF1167

MAIN BOARD ASSY

)

3/3

(DWX1906)

CHANGER POWER

S603:Magazine

(Existence/None)

S604: Multi/Single

DSEL BOARD

G

ASSY (PWZ2533)

Magazine

(Existence/None)

Multi/Single

PSG1010

DSG1016

DSG1016

DSG1016

Magazine IN

Single

1: GND

3: GND

5: GND

7: GND

9: GND

11: GND

13: GND

15: GND

17: GND

19: GND

21: GND

23: OPEN

25: OPEN

27: OPEN

29: GND

31: GND

33: GND

35: GND

37: GND

39: GND

41: GND

43: GND

45: GND

47: GND

49: GND

2: DB0

4: DB1

6: DB2

8: DB3

10: DB4

12: DB5

14: DB6

16: DB7

18: DBP

20: GND

22: GND

24: OPEN

TERMPWR

26:

28: OPEN

30: GND

32: ATN

34: GND

36: BSY

38: ACK

40: RST

42: MSG

44: SEL

46: C/D

48: REQ

50: I/O

Test Remote Control

(RU-V101) Interface

D

16

1234

GFE

Page 17

5

67

8

DRM-6NX

CONNECTOR

JP5, JP11: Short

JP1

2: GND

4: GND

6: GND

8: GND

10: GND

12: GND

14: GND

1: JP1

3: JP2

5: JP3

7: JP4

9: JP5

11: JP6

13: JP7

IDE/SCSI BOARD ASSY

M

(DWX1917)

Note: As this circuit board is

an assembly purchase part,

no circuit diagram is listed.

16: GND

15: JP8

18: GND

17: JP9

JP11

20: GND

19: JP10

22: GND

21: JP11

1: RESET

3: DB7

5: DB6

7: DB5

9: DB4

11: DB3

13: DB2

15: DB1

17: DB0

19: GND

21: OPEN

23: DIOW

25: DIOR

27: IORDY

29: OPEN

31: INTRQ

33: DA1

35: DA0

37: CS1FX

39: OPEN

2: GND

4: DB8

6: DB9

8: DB10

10: DB11

12: DB12

14: DB13

16: DB14

18: DB15

20: OPEN

22: GND

24: GND

26: GND

28: OPEN

30: GND

32: OPEN

34: OPEN

36: DA2

38: CS3FX

40: GND

ASSY 50P

DKP3417

HARD

DISK

UNIT

(DXB1696)

SCSI

I/F

A

B

J

I

PWRB ASSY

(DWR1307)

STATUS DRIVE NETWORK

AXIS NETWORK

BOARD ASSY

(DWN1001)

Note: As this circuit board is

an assembly purchase part,

no circuit diagram is listed.

MEMORY BOARD

K

ASSY (DWX1916)

Note: As this circuit board is

an assembly purchase part,

no circuit diagram is listed.

CONNECTOR

ASSY

DKP3426

L (BRN)

N (BLU)

16MB

72pin

DIMM

L (BRN)

N

(BLU)

CONNECTOR

ASSY 4P

CONNECTOR

ASSY 20P

DKP3419

DKP3415

CONNECTOR

L

BOARD ASSY

(DWX1917)

Note: As this circuit board is

an assembly purchase part,

no circuit diagram is listed.

AC POWER CORD

DDG1071

(AC110-240V)

C

D

PWSB BOARD ASSY

H

(DWS1296)

JH

5

6

7

MLK

8

17

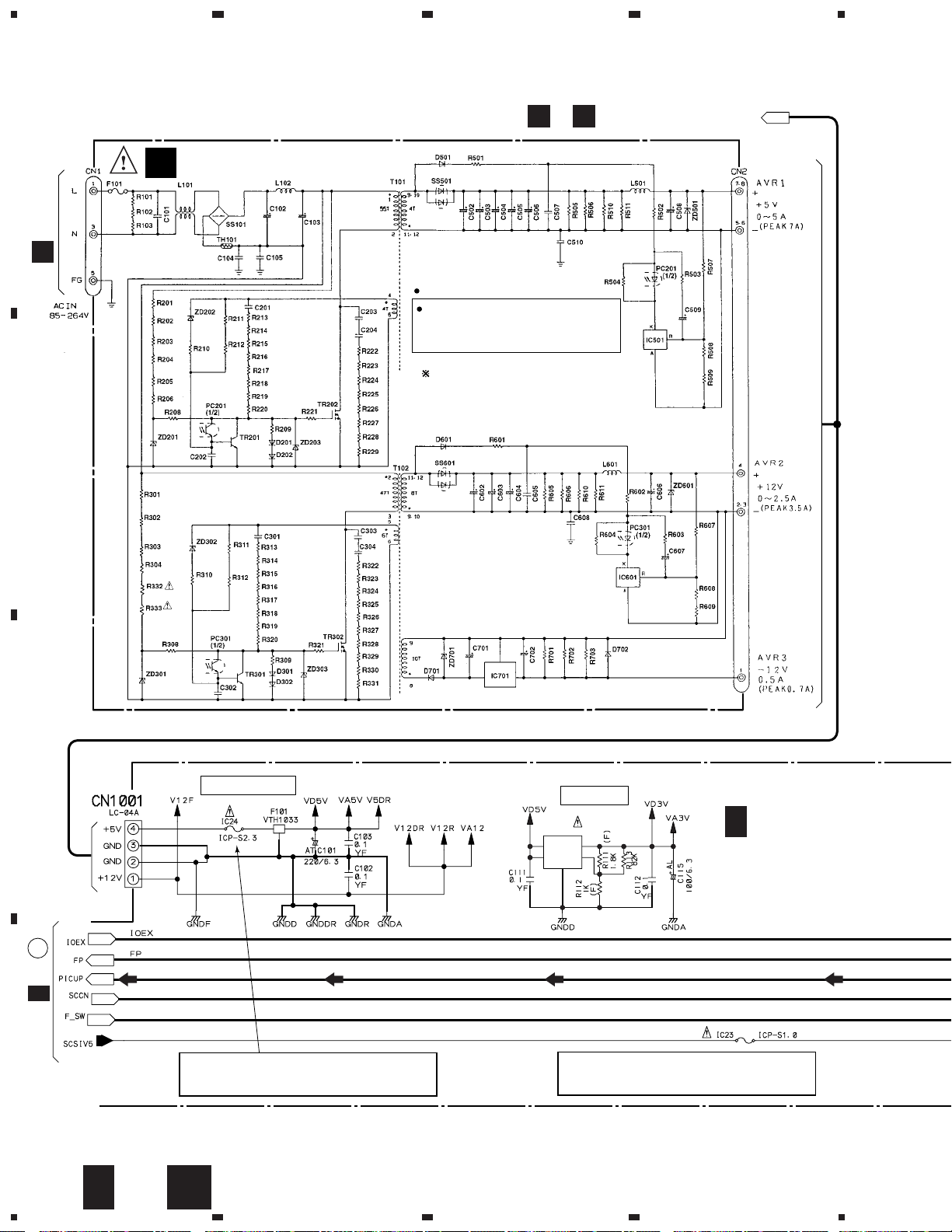

Page 18

1

234

DRM-6NX

3.3 MAIN BOARD ASSY (1/3) and

PWRB ASSY

CN3, HARD DISK UNIT,

M

J

A

PWRB ASSY (DWR1307)

I

C950

H

NOTE FOR FUSE REPLACEMENT

CAUTION: FOR CONTINUED PROTECTION

:This schematic diagrm is reference

information When it is repaired please

cope by assy exchange.

B

AGAINST RISK OF FIRE.

REPLACE WITH SAME

TIME AND RATINGS ONLY.

C

POWER SUPPLY

1

VIN

2

ON

IC111

PQ7VZ5

VOUT

/OFF

OADJ

5

3.3V REG.

3

4

D 1/3

MAIN BOARD

ASSY (1/3)

(DWX1906)

A

2/3

D

D

18

D 1/3

1234

CAUTION: FOR CONTINUED PROTECTION AGAINST RISK OF FIRE.

REPLACE ONLY WITH SAME TYPE NO. ICP–S2.3, MFD

BY ROHM CO., LTD. FOR IC24.

I

CAUTION: FOR CONTINUED PROTECTION AGAINST RISK OF FIRE.

REPLACE ONLY WITH SAME TYPE NO. ICP–S1.0, MFD

BY ROHM CO., LTD. FOR IC23.

Page 19

5

67

8

DRM-6NX

SIGNAL ROUTE

: RF SIGNAL ROUTE

A

CN1003

C

Q11, Q15:

DISC SELECT

MOTOR DRIVER

CN952

E

B

Q17, Q18:

LOADING MOTOR

DRIVER

STEPPING

MOTOR DRIVER

CN953

C

A

D

CN1, SCSI I/F

M

5

J

D 1/3

6

7

8

19

Page 20

1

DRM-6NX

3.4 MAIN BOARD ASSY (2/3)

A

B

3/3

D

234

B

Interface

TEST REMOTE CONTROL (RU-V101)

C

MB90T553PF

CPU

PD6287B

FLASH

ROM

1 Mbit DRAM

D

SCSI

TERMINATOR

20

D 2/3

1234

Page 21

5

67

8

DRM-6NX

A

B

CD-ROM DECODER

&

SCSI I/F

C

A

1/3

D

D

EEPROM

D

5

MAIN BOARD ASSY (2/3)

2/3

(DWX1906)

6

SIGNAL ROUTE

: RF SIGNAL ROUTE

7

D 2/3

8

21

Page 22

1

234

DRM-6NX

3.5 MAIN BOARD ASSY (3/3)

A

D

MAIN BOARD ASSY (3/3)

3/3

(DWX1906)

IC204: TRACKING SERVO

EQUALIZER SW

5V REG.

IC201 (AN8849SB)

Voltage [ V ]

Pin No.

B

0

1

4.6

2

2.5

3

5

4

2.5

5

1.4

6

3.5

7

2.5

8

3.2

9

1.9

10

3

11

1.8

12

3.6

13

0

14

3.6

15

0

16

4.9

17

0

18

0

19

2.5

20

2.2

21

22

|

1.8

27

0.9

28

1.8

29

1.8

30

31

|

2.5

36

3

4

HEAD

AMP

Q202:RF EQUALIZER

SW for CD-RW

1

2

IC451 (M56759FP)

Voltage [ V ]

Pin No.

12.4

1

2.5

2

0.3

3

1.2

4

2.1

5

12.4

6

0.6

7

0.3

8

0.1

9

0

10

0

C

ACTUATOR

&

LOADING MOTOR

DRIVER

11

0.1

12

0.1

13

0.2

14

IC452: TRACKING SERVO

EQUALIZER SW

Pin No.

15

16

17

18

19

20

22 0

22

23

24

25

26

27

Voltage [ V ]

12.4

0.2

0.6

0.6

1.5

0.6

0

5

0

0

5

2.5

Pin No.

28

|

31

32

33

34

35

36

37

38

39

40

41

42

Voltage [ V ]

0.6

0

0

0.2

0.2

0.8

1.3

2.1

0

0

5

3.7

6

D

IC501 (AN8480SBB)

Voltage [ V ]

Pin No.

0

1

2.5

2

2.5

3

0

4

2.6

5

2.25

6

0.3

7

2.65

8

Voltage [ V ]

Pin No.

9

10

11

12

13

|

15

16 4.95

17 1.74

2.65

4.95

4.95

Voltage [ V ]

Pin No.

1.74

18

0

19

0

0

0.23

20

12.3

21

12.3

22

23

0

|

28

22

D 3/3

1234

Page 23

IC282: RESET

5

67

8

DRM-6NX

SIGNAL ROUTE

B

2/3

D

A

B

: RF SIGNAL ROUTE

MN662752CDM1

DIGITAL SERVO

PROCESSOR

SPINDLE

DRIVER

5

C

To SPINDLE MOTOR

5

D

D 3/3

6

7

8

23

Page 24

DRM-6NX

Waveforms of MAIN BOARD Assy

1 RF – TP

0.2V/div., 0.5 µS/div.

× 1 PLAY

1 RF – TP

0.2V/div., 50 nS/div.

× 12 PLAY

1 RF – TP

0.2V/div., 20 nS/div.

× 24 PLAY

– 2.1V

– 2.1V

– 2.1V

2 AGC RF – TP

0.2V/div., 20 nS/div.

× 24 PLAY

– 1.65V

3 FE – TP

0.5V/div., 2 mS/div.

FOCUS IN

– GND

3 FE – TP

0.5V/div., 2 mS/div.

FOCUS

UP/DOWN

2 AGC RF – TP

0.2V/div., 0.5 µS/div.

× 1 PLAY

2 AGC RF – TP

0.2V/div., 50 nS/div.

× 12 PLAY

– GND

4 TE – TP

0.5V/div., 500 µS/div.

× 12 MULTI TRACK

JUMP (FWD)

– 1.65V

– GND

4 TE – TP

0.5V/div., 500 µS/div.

× 12 MULTI TRACK

JUMP (REV)

– 1.65V

– GND

24

Page 25

4

TE – TP

0.5V/div., 500 µS/div.

× 1 STILL

4

TE – TP

0.5V/div., 200 µS/div.

× 12 STILL

– GND

– GND

4

CH1: TE – TP

0.5V/div., 20 mS/div.

6

CH2: HK – TP

1V/div., 20 mS/div.

× 12 SEARCH

(REV)

(40=20 min.)

4

CH1: TE – TP

0.5V/div., 100 mS/div.

5

CH2: EC – TP

2V/div., 100 mS/div.

× 12 SEARCH

(FWD FULL STROKE)

4

6

4

5

DRM-6NX

GND

(CH1)

–

GND

(CH2)

–

GND

(CH1)

–

–

GND

(CH2)

4

CH1: TE – TP

0.5V/div., 5 mS/div.

5

CH2: EC – TP

1V/div., 5 mS/div.

× 12 PLAY

(CAV)

4

CH1: TE – TP

0.5V/div., 5 mS/div.

5

CH2: EC – TP

1V/div., 5 mS/div.

× 24 PLAY

(CLV)

4

CH1: TE – TP

0.5V/div., 20 mS/div.

6

CH2: HK – TP

1V/div., 20 mS/div.

× 12 SEARCH

(FWD)

(20=40 min.)

4

5

4

5

4

6

–

–

–

–

–

–

GND

(CH1)

GND

(CH2)

GND

(CH1)

GND

(CH2)

GND

(CH1)

GND

(CH2)

4

CH1: TE – TP

0.5V/div., 100 mS/div.

5

CH2: EC – TP

2V/div., 100 mS/div.

× 12 SEARCH

(REV FULL STROKE)

4

CH1: TE – TP

0.5V/div., 50 mS/div.

6

CH2: HK – TP

1V/div., 50 mS/div.

× 12 SEARCH

(FWD FULL STROKE)

4

CH1: TE – TP

0.5V/div., 50 mS/div.

6

CH2: HK – TP

1V/div., 50 mS/div.

× 12 SEARCH

(REV FULL STROKE)

4

5

4

6

4

6

–

–

–

–

–

–

GND

(CH1)

GND

(CH2)

GND

(CH1)

GND

(CH2)

GND

(CH1)

GND

(CH2)

25

Page 26

1

234

DRM-6NX

4. PCB CONNECTION DIAGRAM

4.1 SIFB BOARD ASSY, LOAD BOARD ASSY and

A

MAIN BOARD ASSY

B

LOAD BOARD ASSY

To PICKUP ASSY

PWZ2038 -A

SIFB BOARD ASSY

A

(PNP1331-A)

CN601

S601

S601

S602

S602

PNZ1489-A

D

To FAN MOTOR

MAIN BOARD ASSY

B

To STEPPING

MOTOR

C

IC17

IC18

IC19

VR952

IC951

(DNP1882–C)

NOTE FOR PCB DIAGRAMS:

1. Part numbers in PCB diagrams match those in the schematic

diagrams.

2. A comparison between the main parts of PCB and schematic

diagrams is shown below.

Symbol in PCB

Diagrams

BCE

D

BCE

DGS

Symbol in Schematic

Diagrams

BCE

BCEBCE

DGSDGS

26

1234

BCE

DBA

Part Name

Transistor

Transistor

with resistor

Field effect

transistor

Symbol in PCB

Diagrams

3. The parts mounted on this PCB include all necessary parts

for several destination.

For further information for respective destinations, be sure

to check with the schematic diagram.

4. Viewpoint of PCB diagrams

P. C. Board Chip Part

Symbol in Schematic

Diagrams

CapacitorConnector

Part Name

Resistor array

3-terminal

regulator

SIDE A

SIDE B

To SPINDLE

MOTOR

Page 27

5

67

8

DRM-6NX

SIDE A

CONNECTOR ASSY 4P

I

M J

CN2

CN3

To HARD DISK UNIT

CONNECTOR ASSY 50P

J M

CN1

SCSI I/F

IC24

IC282

IC205

IC20

IC411

Q411

IC21

IC451

Q201

C

CN1003

Q1003

Q1002

Q1001

IC23

IC802

Q621

IC801

Q622

IC702

IC101

IC703

IC301

IC302

Q13

IC704

Q11

Q14

Q12

IC452

IC701

Q15

IC12

IC232

A

Q21

B

Test Remote

Control Interface

(DNP1882–C)

E

CN952

IC201

Q202

Q18

IC16

Q22

IC204

IC231

IC15

Q16

Q17

IC11

IC705

IC706

Q19

Q651

Q652

IC13

Q20

C

D

D

5

6

7

8

27

Page 28

DRM-6NX

A

B

1

D

MAIN BOARD ASSY

234

SIDE B

C

(DNP1882–C)

D

28

D

1234

Page 29

5

67

8

DRM-6NX

A

SIDE B

SIFB BOARD ASSY

A

B

C

(DNP1882–C)

D

DA

5

6

7

8

29

Page 30

1

234

DRM-6NX

4.2 IDSB BOARD ASSY, FRPB BOARD ASSY, MOTB BOARD ASSY and

MAIN BOARD ASSY

SIDE A

IDSB BOARD ASSY

A

C

FRPB BOARD

E

ASSY

D

CN11

(DNP1882–C)

CN1002

D

SIDE B

DSEL BOARD

G

ASSY

B

PNZ1491-A

PWZ2533 -

S606

S606

S605

S603

S603

C

S604

S604

SIDE B

Q951

SIDE A

J602

1 5

F

(PNP1331–A)

J602

1

D

30

5

PNZ1491-A

PWZ2040 -A

EC G

1234

F

MOTB BOARD

ASSY

CN602

(PNP1331–A)

1 6

(DNP1882–C)

Page 31

1

23

DRM-6NX

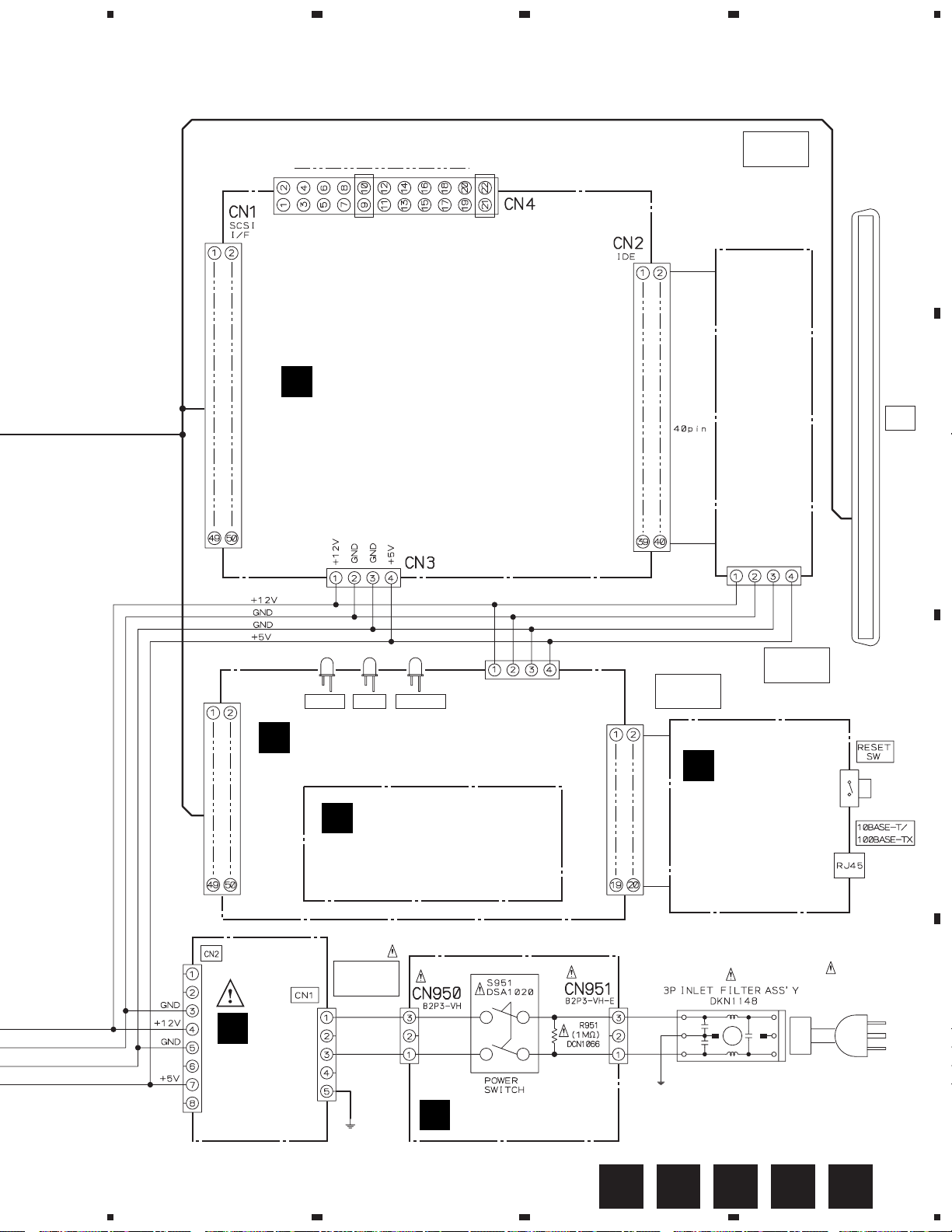

4.3 PWSB BOARD ASSY, PWRB ASSY, AXIS NETWORK BOARD ASSY,

MEMORY BOARD ASSY, CONNECTOR BOARD ASSY and IDE/SCSI

BOARD ASSY

4

D

CN1001

D

CN1004

K

MEMORY

BOARD

ASSY

SIDE A

J

AXIS NETWORK

BOARD ASSY

X5

IDE/SCSI

M

BOARD ASSY

111

CN4

50 1

40

HARD DISK UNIT

CN2

CN1

1

X1

X8

A

CN3

4

1

L

CONNECTOR

BOARD ASSY

X3

B

X6

N (BLU)

L (BRN)

N (BLU)

L (BRN)

X9

(26pin)

CN1

X3

S2

TERM POWER ON/OFF

AC POWER CORD

I

PWRB ASSY

AC110- 240V

SCSI I/F

C

CN2

D

H

PWSB BOARD ASSY

1

IH K

2

J

3

L M

4

31

Page 32

DRM-6NX

5. PCB PARTS LIST

NOTES : ÷ Parts marked by “ NSP ” are generally unavailable because they are not in our Master Spare Parts List.

÷ The

÷ When ordering resistors, first convert resistance values into code form as shown in the following examples.

Mark No. Description Part No. Mark No. Description Part No.

mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

Ex. 1 When there are 2 effective digits (any digit apart from 0), such as 560 ohm and 47k ohm (tolerance is shown by

J = 5%, and K = 10%).

1

560 Ω = 56 × 10

47k Ω = 47 × 10

= 561................................................... RD1/4PU 5 6 1 J

3

= 473 .................................................. RD1/4PU 4 7 3 J

0.5 Ω = R50 ...................................................................... RN2H Â 5 0 K

1 Ω = 1R0 ......................................................................... RS1P 1 Â 0 K

Ex. 2 When there are 3 effective digits (such as in high precision metal film resistors).

5.62k Ω = 562 × 10 1 = 5621 ........................................... RN1/4PC 5 6 2 1 F

LIST OF PCB ASSEMBLIES

MOTHER BOARD ASSY DWM2084

PWSB BOARD ASSY DWS1296

MAIN BOARD ASSY DWX1906

SIFB BOARD ASSY DWZ1081

FRPB BOARD ASSY DWZ1083

IDSB BOARD ASSY DWZ1084

NSP MULTI MECHA ASSY DXB1653

NSP MECHA BOARD ASSY PWX1279

NSP LOAD BOARD ASSY PWZ2038

NSP MOTB BOARD ASSY PWZ2040

NSP DSEL BOARD ASSY PWZ2533

∗ PWRB ASSY DWR1307

∗ AXIS NETWORK BOARD ASSY DWN1001

∗ CONNECTOR BOARD ASSY DWX1921

∗ MEMORY BOARD ASSY DWX1916

∗ IDE/SCSI BOARD ASSY DWX1917

Note *: As these circuit boards are assembly purchase parts, no

parts table is listed. Please exchange the entire assembly.

PWSB BOARD ASSY

H

SWITCHES AND RELAYS

S951 DSA1020

RESISTORS

R951 (1.0 MΩ) DCN1066

OTHERS

CN950 2P–VH CONNECTOR B2P3–VH

CN951 2P–VH CONNECTOR B2P3–VH–E

D

MAIN BOARD ASSY

SEMICONDUCTORS

IC501 AN8480SBB

IC201 AN8849SB

IC801 BH9595FP–Y

IC204 BU4S66

IC452 HD74HC4066FP

IC703, IC704 HD74HC573FP

IC232 HD74HCT244FP

IC23 ICP–S1.0

IC24 ICP–S2.3

IC411 LB1836M

IC302 LC321667CJ–25

IC301 LC895126–LF4L

IC451 M56759FP

IC701 MB90T553PF

IC231 MN662752CDM1

IC12 NM93C66EM8

IC702 PD6287B

IC111 PQ7VZ5

IC282 S–80742AN–D6

IC705 TC7S04F

Q21, Q22 2PD601A

Q201 2SA1036K

Q11, Q17 2SB1132

Q202 2SC3082K

Q13, Q15, Q18 2SD1664

Q1001–Q1003, Q12, Q14, Q16 DTC124EK

Q411 DTC124EK

D14, D281 1SS355

D801, D802 RB160L–40

D12, D13 RB400D

COILS AND FILTERS

F801–F803 DTF1069

L201, L411 (4.7 µH) DTL1024

L12–L14 OTL1040

F101 VTH1033

CAPACITORS

C210 CCSQCH100D50

C211 CCSQCH101J50

C302, C303 CCSQCH220J50

C317 CCSQCH330J50

C209 CCSQCH820J50

C227 CCSQCJ3R0C50

C115 CEAL101M6R3

C203, C205 CEAL220M6R3

C502 CEAL470M16

C208, C220, C459 CEAL470M6R3

32

Page 33

DRM-6NX

Mark No. Description Part No. Mark No. Description Part No.

C101 CEAT221M6R3

C20, C413 CEJA101M6R3

C802 CEJA470M10

C232, C240, C241 CKSQYB102K50

C223, C239, C250, C251, C306 CKSQYB104K25

SIFB BOARD ASSY

A

SEMICONDUCTORS

IC951 BU3892FV

C461, C471 CKSQYB104K25

C215, C216, C281 CKSQYB105K10

C247, C255, C258 CKSQYB154K16

C473 CKSQYB222K50

C219, C235, C242, C243 CKSQYB223K50

C212 CKSQYB272K50

C214, C217, C456, C462 CKSQYB273K50

C224, C226 CKSQYB392K50

C248, C254, C455, C504, C505 CKSQYB393K50

C213 CKSQYB472K50

C453, C454 CKSQYB473K25

C245 CKSQYB474K16

C457, C458 CKSQYB561K50

C102, C103, C111, C112 CKSQYF104Z25

C12–C14, C19, C201, C202 CKSQYF104Z25

C204, C218, C22, C221, C225 CKSQYF104Z25

C231, C233, C236, C249 CKSQYF104Z25

C252, C253, C256, C307, C412 CKSQYF104Z25

C451, C460, C472, C501, C503 CKSQYF104Z25

C701, C705–C710, C801, C803 CKSQYF104Z25

C301, C304, C305, C308–C316 CKSQYF105Z16

RESISTORS

R231 (47 Ω) DCN1090

R312 (56 Ω) DCN1091

R253, R301, R313–R317, R38 (100 Ω) DCN1092

R306, R307, R37, R801 (10k Ω) DCN1094

R112 RS1/10S1001F

COILS AND FILTERS

L16 (4.7 µH) DTL1024

SWITCHES AND RELAYS

S953 DSX1050

CAPACITORS

C959 CKSQYB103K50

C962 CKSQYB182K50

C957, C958 CKSQYB474K16

C960, C963 CKSQYF104Z25

RESISTORS

VR952 (10k Ω) RCP1045

Other Resistors RS1/10S J

OTHERS

CN955 MT CONNECTOR (4P) 173979–4

CN954 FLEXIBLE CONNECTOR 52271–1790

CN953 FLEXIBLE CONNECTOR 52271–3090

CN956 FFC CONNECTOR (4P) VKN1208

KN951 EARTH METAL FITTING VNF1084

FRPB BOARD ASSY

E

SEMICONDUCTORS

Q951 DTC124EK

D951 SLR–342MCT31

D952 SLR–342YCT31

R463–R466 RS1/10S1002F

R467, R468, R470, R471 RS1/10S1602F

R474–R477 RS1/10S1602F

R111 RS1/10S1801F

R461, R462 RS1/10S6202F

R30 RS1/2S120J

R20, R22 RS1/2S6R8J

R23 RS1/4S102J

R501–R503 RS1/4S1R0J

Other Resistors RS1/10S J

OTHERS

CN501 FLEXIBLE CONNECTOR 52271–1590

CN12 FLEXIBLE CONNECTOR 52271–3090

CN11 FFC CONNECTOR 9610S–12B

X301 (33.86 MHz) DSS1069

X701 (20 MHz) DSS1095

CN1004 CONNECTOR FAP–5001–1202–OBS

CN1001 LC CONNECTOR (4P) LC–04A

CLAMP LCC–04

CN13 KR CONNECTOR S4B–PH–K–S

CN1002 ZH CONNECTOR S7B–ZR

CN1005 ZK CONNECTOR S2B-ZR

PCB BINDER VEF1040

COILS AND FILTERS

L951–L956 RTF1167

SWITCHES AND RELAYS

S952 RSG1030

CAPACITORS

C951 CKSQYB103K50

RESISTORS

R952 RS1/10S241J

R953 RS1/10S471J

OTHERS

CN952 FFC CONNECTOR 9610S–12B

J952 WIRE ASSY (6P) D20PWY0610E

J954, J955 EARTH RUG ASSY DDX1148

33

Page 34

DRM-6NX

Mark No. Description Part No.

IDSB BOARD ASSY

C

SWITCHES AND RELAYS

S954 DSX1052

S1001 DSX1053

OTHERS

CN1003 ZH CONNECTOR S7B–ZR

LOAD BOARD ASSY

B

SWITCHES AND RELAYS

S601, S602 DSG1016

OTHERS

CN601 CONNECTOR (4P) 4–173979–4

MOTB BOARD ASSY

F

OTHERS

CN602 6PJUMPER CONNECTOR 52151–0610

DSEL BOARD ASSY

G

SWITCHES AND RELAYS

S604–S606 DSG1016

S603 PSG1010

OTHERS

J602 WIRE ASSY (5P) D20PWW0515E

34

Page 35

6. ADJUSTMENT

6.1 PREPARATIONS

6.1.1 JIGS AND MEASURING INSTRUMENTS

DRM-6NX

CD TEST DISC

(YEDS-7 or STD-903)

Low-frequency

oscillator

Precise

screwdriver

Dual-trace

oscilloscope

(10 : 1 probe)

screwdriver

Service remote

(RU-V101)

6.1.2 NECESSARY ADJUSTMENT POINTS

When Adjustment points

Exchange

1.2.3. = Page 39, 40

MAIN BOARD ASSY

(large)

controller

screwdriver

(small)

Interface

screwdriver

(medium)

External adder

amplifier

Exchange

SERVO MECH ASSY

1.2.3. = Page 39, 40

35

Page 36

DRM-6NX

6.2 ADJUSTMENT

6.2.1 HOW TO START/CANCEL TEST MODE

SERVICE REMOTE CONTROLLER

FUNCTION TABLE OF THE REMOTE CONTROLLER (RU-V101) FOR SERVICE

÷ Test Mode

Shows the function table of the remote controller (RU-V101) for service as follows. When operating the CD-ROM directly,

it is possible to operate as shown below by connecting the wired-remote control to the CD-ROM with the interface.

÷ Schematic Diagram of the Conversion Jig for Remote Control Operation

RU-V101

Interface

1

2

3

3P mini jack

Q1: DTC124ES or UN4212

TEST MODE : ON

Power Switch: ON

10k

2.2k

Q1

FUNCTION SW (S1001)

TERM/ON

1 2 3

ON

TEST MODE/ON

REAR PANEL

(IDSB BOARD ASSY)

V +5V

1

REMI

2

3

GND

4

PH type

connector

(4P)

TEST MODE 1

ID SW (S954)

0

1

7

2

6

3

5

4

SW POSITION: 1 to 7

REAR PANEL

(IDSB BOARD ASSY)

TEST MODE 2

ID SW (S954)

0

1

7

2

6

3

5

4

SW POSITION: 0 only

REAR PANEL

(IDSB BOARD ASSY)

CN13

1

CN13

1: VD5V

2: REMI

3: REMO

4: GNDD

4

MAIN BOARD ASSY

Power Switch: OFF

36

Page 37

RU-V101

DRM-6NX

REJECT : Spindle Stop

REJECT : Spindle stop

PAUSE : Pause

PLAY : Play (Trace)

STILL/STEP E :

STILL/STEP e :

MULTI-SPEED + :

MULTI-SPEED – :

CLEAR : Clear

FRAME : Frame set

TIME : Time set

CHAPTER : Track set

SEARCH : Search

10 key : Numerical input

DISPLAY (FUNC + 1) : No entry

STILL (FUNC + 2) : No entry

C-MODE (FUNC + 3) : No entry

VIDEO (FUNC + 4) : No entry

STOP. M (FUNC + 5) : Stop Marker

START (FUNC + 6) : Start

AUDIO (FUNC + 7) : No entry

SPEED (FUNC + 8) : No entry

OPEN (FUNC + 9) : Disc Return

[1] – [6] + CHAPTER : Disc Select

[0] + FRAME : Index Set

Test command

Test command

¶ Test Command

Key Operation Command Description

[0] + [TIME] {0TM} All servo OFF

[2] + [TIME] {2TM} Focus ON/OFF

[3] + [TIME] {3TM} Spindle ON (CAV: 500 rpm)

[4] + [TIME] {4TM} Tracking ON/OFF

[6] + [TIME] {6TM} Focus Up/Down

[8] + [TIME] {8TM} Spindle rotation control: CLV control (single speed)

[9] + [TIME] {9TM} Spindle rotation control : Pseudo CLV control (24 x speed)

[STILL/STEP >>] {SF} 1 Track jump : FWD

[STILL/STEP <<] {SR} 1 Track jump : REV

[

∗

] + [∗] + [∗] + [MULTI-SPEED +] {

[

∗

] + [∗] + [∗] + [MULTI-SPEED –] {

∗∗∗

∗∗∗

MF}

MR}

∗∗∗

Track jump : FWD

∗∗∗

Track jump : REV

37

Page 38

DRM-6NX

6.2.2 ADJUSTMENT LOCATIONS

MAIN BOARD ASSY

TE

FE

SIDE B

VC

VREF

VB

VA

GND

38

SIFB BOARD ASSY

SIDE A

VR952: RF LEVEL ADJ.

VR952

Page 39

CD-ROM Player

1. Focus Offset Check

Focus Error Offset

and

Tracking Error Offset

Auto Adjustment

2. Tracking Error Barance Check

Oscilloscope

DC Mode

V: 1 V/div

H: 10 mSec/div

GND

Prove(10:1)

MAIN BOARD ASSY

FE

GND

START

GND

Prove(10:1)

VREF

VREF

GND

FCS.ERR

GND

(CH1)

(CH2)

A

B

Check

Oscilloscope

DC Mode

V: 500 mV/div

H: 5 mSec/div

GND

Prove(10:1)

PLAY

R=35mm

TEST DISC

PLAY

TEST DISC

Test mode 1

SPDL servo = CLOSE

FOCUS servo = CLOSE

TRKG servo = OPEN

PLAY MODE

6.2.3 CHECK AND ADJUSTMENT

A=B

VREF

A

B

A≠B

VREF

A

C

B

START

TE

VREF

MAIN BOARD ASSY

CD-ROM Player

When there is a DC

component

When there is no DC

component

6.2 ADJUSTMENT

DRM-6NX

39

Page 40

DRM-6NX

3. RF Level Adjustment

¶ Test mode 2

In test mode 2, the disc is started

automatically, single speed CLV (60

min) search is performed, and then

the unit goes into PAUSE status.

TEST DISC

¶

(AUTO PLAY MODE)

AUTO PLAY (CLV) /

PAUSE

VR952

SIFB BOARD ASSY

CD-ROM Player

6.2 ADJUSTMENT

330 mVP-P

±30 mV

START

MAIN BOARD ASSY

VAVREFGND VB VC

+

–

+

–

+

–

VC

VB

VA

External Adder Amplifier

10p

4.7k

4.7k

4.7k

4.7k

4.7k

–

+

+

–

–5V

+5V

75

0.1µ

0.1µ

+

47/16

47/16

+

Oscilloscope

AC Mode

V: 100 mV/div

H: 10 mSec/div

Prove(10:1)

GND

40

Page 41

6.3 FUNCTION OF PERSONAL COMPUTER FOR SERVICING

Direct Commands

〉 TA3SEPL

[Esc] to exit

Use the floppy disc furnished with the product.

DRM-6NX

6.3.1 PROGRAM INSTALLATION AND

REMOVAL

Multi-play control (MPC) has one program to make it resident in

memory and another program that removes it from memory.

(1) MPC. COM : Multi-play control program

(2) MPCRMV. COM : Removes MPC from memory

MPC is executed as follows:

MPC [Enter]

This entry places MPC in memory. Execution of the next

program removes MPC from memory.

MPCRMV [Enter]

6.3.2 CALLING THE MPC WINDOW

When MPC has been placed in memory and your PC is in the key

input wait state..........

Press the GRPH key and the hyphen key at the same to make the

MPC window pop up.

Multi Play Controler for DR-UA124X Ver 0.5

DISC:

Disc Play Pause

ESC key : Closes MPC window

[=] [+] [ ± ] [ ≠ ] key : Select functions

Space key or enter key : Executes selected function

TRACK: TIME:

Volume Open Command

Track

Fig. 1 MPC Window

[Esc] to exit

PIONEER

6.3.3 CALLING A SUB WINDOW

Execute a [Command] function to make a sub-window pop up, and

then a mnemonic command can be executed. Use the ESC key to

cancel a sub-window.

Fig. 2 Sub-Window

6.3.4 COMMAND LIST

Notes:

¶ The complete status "R" is returned when the execution of each

command is completed.

¶ Park mode : A state in which the disc is cramped.

¶ Home mode : A state in which the disc is released (the disc has

returned to the magazine).

Direct Selection of Disc

When the cursor is at the [Disc] position..........

Directly input a number from 1 to 6 to select the disc.

¶ Command List

Command

Name

ZO MAGAZlNE OUT Enters home mode by ejecting the magazine.

ZS DISC SELECT Enters park mode after removing the specified disc from the magazine and cramping it.

The address (DISC number) is to be specified prior to the command.

Example: 3ZS (to select the third disc from the top of the magazine)

ZR DISC RETURN Returns the disc to the magazine and enters home mode.

R J REJECT Stops the disc rotation and enters park mode.

SA START Starts the disc rotation. When the first track is an audio track, the disc will pause at the beginning

of the track while it will pause at 0 minutes 1 seconds 0 frames in a data track.

PL PLAY Enters play mode and plays the disc.

Automatically stops if the specified command adress is overrun during playback.

Example: TM2000PL (Pause at 20 min. 00 sec. frame.)

PA PAUSE Enters pause mode. stopping at the current point.

SE SEARCH Searches for the specified address and enters pause mode after the search operation.

Example: BK4500SE (to specify a block), TR5SE, 6SE (to specify a track)

ExplanationCommand

41

Page 42

DRM-6NX

Command

Name

SM STOP MARKER Sets a stop marker at the specified address.

Enters pause mode when passing over the stop marker during playback, clearing the marker.

The stop marker is also cleared when the CLEAR or REJECT command is supplied before the

stop marker is reached.

Example: BK200000SMPL (T0 pause at 20 minutes 0 second 0 frame sfter playback)

BK BLOCK Uses the address flag to specify blocks . Subsequently, an address entered is regarded as a

block number (BK + a 6-digit number).

TM TIME Uses the address flag to specify a tirne. Subsequently, an address entered is regarded as a time

code (TM + a 4-digit number).

TR TRACK Uses the address flag to specify a track. Subsequently, an address entered is regarded as a time

track number (TR + a 2-digit number).

IX INDEX Uses the address flag to specify an index. Subsequently, an address entered is regarded as an

index number (IX + a 4-digit number).

CL CLEAR Clears the digit buffer (numerical input) and cancels search mode, auto play mode or the stop

marker. When the buffer is cleared during a search operation, the pickup stops moving for a

pause. Resumes normal operation when the buffer is cleared during an auto play or stop marker

operation.

LO LEAD OUT SYMBOL Sets a point in the lead-out area to an address. To be used when setting the stop marker on

the last track of a disc having 99 tracks.

Example: TR99SELOPL

VL VOLUME Adjusts the audio playback level. 0: minimun, 255: maximum

ExplanationCommand

AD AUDIO CONTROL Select the audio outputs.

CM COMMUNICATION Sets the communication mode . With this model, only mode 3 can be set.

KL KEY LOCK Activates or deactivate the keys on the front panel.

?Z DISC NUMBER Displays a three-digit number which indicates the ordinal of the cramped disc from the top of the

REQUEST magazine. If no disc is cramped, "XXX" is returned.

?B BLOCK NUMBER Returns the block number by a 6-digit number. The current address is returned during playback

REQUEST and the pause target address is returned during pause. "XXXXXX" is returned in park mode and

?T TIME CODE Returns the time code by a 4-digit number. The current address is returned during playback and

REQUEST the pause traget address is returned during pause. "XXXX" is returned in park mode and "0000"

?R TRACK NUMBER Returns the track nurnber by a 2-digit number. The current address is returned during playback

REQUEST and the pause traget address is returned during pause. "XX" is returned in park mode.

?I lNDEX NUMBER Simultaneously returns the track number and the index number by a 4-digit number. The current

REQUEST address is returned during playback and the pause target address is returned during pause.

?A ADDRESS Returns the track number, the index number and the P time by a 10-digit number. The current

REQUEST address is returned during playback and the pause target address is returned during pause.

0: OFF, 1: Lch, 2: Rch, 3: STEREO, 4: OFF, 5: Lch, 6: Rch, 7: STEREO

Example: 3AD

Example: 3CM

0: Activate 1: Deactivate Example: IKL

"000000 " is returned in the lead-in area.

is returned in the lead-in area.

"00" is returned in the lead-in area and "AA" is returned in the lead-out area.

"XXXX" is returned in park mode, "0000" is returned in the lead-in area and "AA01 " is returned

in the lead-out area.

"XXXXXXXXXX" is returned in park mode, "0000000000 " is returned in the lead-in area and

"AA01000000" is returned in the lead-out area.

42

Page 43

DRM-6NX

Command

Name

?Q TOC Returns TOC data. When no track number is specified, the first track number, the last track

?G CATALOG CODE Returns the catalog code of the disc being played by a 13-digit number. If no catalog code is found

?O ISRC CODE Returns the ISRC code by a 14-digit number when ISRC code is written.

?P PLAYER ACTIVE Returns operation mode by three characters.

?K DISC STATUS Returns the attribute of the playback disc in 8 characters (Nl - N8).

Command

INFORMATION number and the absolute time of the beginning of the lead-out area are returned by a 10-digit

number.

Example: 0109665544 01: Ist track number

09: Last track number

665544: The lead-out area begins at 66 minutes 55 seconds 44 blocks.

When a track number is specified, the absolute time of the beginning of the track and the code

to indicate whether the track is an audio track or a data track are returned by an 8-digit number.

Example: 10020000 100200: Track 5 begins at 10 minutes 02 seconds 00 blocks.

00: Track 5 is an audio track. (04 = data)

REQUEST or in home mode, thirteen Xs are returned.

REQUEST

MODE REQUEST P00: home mode (without magazine) P02: Setup mode P23: Eject mode

P20: home mode (with magazine) P03: Reject mode P08: Scan mode

P01: Park mode P07: Search mode

P04: Play mode P21: Disc select mode

P06: Pause mode P22: Disc return mode

REQUEST Nl: Disc loading 0: no 1: yes

N2: Audio track 0: none 1: available X: unknown

N3: Data track 0: none 1: available X: unknown

N4: CDV 0: no 1: yes X: unknown

N5: CD-I 0: no 1: yes X: unknown

N6 - N8: (reserved)

Example: 11000XXX

Explanation

?X CDP MODEL NAME Returns the model narne of the CD player. "P155001"

REQUEST

?M COMMUNICATION Returns communication mode " 3 " with this model.

MODE REQUEST

6.3.5 ERROR MESSAGES

Command

Name

E00 COMMUNICATION ERROR Cornmunication line error

¶ Framing error

¶ Buffer overflow

E04 FEATURE NOT AVAILABLE An unusable command has been executed.

¶ Different command mnemonics or mode

E06 MISSlNG ARGUMENT Required parameter has not been specified.

E11 DISC OR MAGAZINE NOT EXIST No disc or no nagazine has not been installed.No disc can be detected.

E12 ADDRESS SEARCH ERROR No search address has not been found.

E13 FOCUS SERVO FAILURE Focus error and failure also on retry.

E14 TRACKING SERVO FAILURE Tracking error and failure also on retry.

E15 FRAME SYNC TIME-OUT PLL frame sync time-out.

ExplanationCommand

43

Page 44

DRM-6NX

Command

Name

E16 INPUT OTHER DEVICE The eject key had been depressed before the command execution was completed.

E90 DISC SELECT FAILURE Tray/disc selection time-out.

E91 CAN'T EJECT MAGAZlNE The magazine cannot be extruded.

E92 ELEVEATION FAILURE Elevation time-out.

E96 START UP FAILURE Unsuccessful start.

E99 PANlC An unrecoverable error or an error with an unknown cause has occurred during drive

Command

operation.

¶ The playback operation cannot be continued and stops.

Explanation

6.3.6 CD-ROM STATUS CHART

P21 P00

P23

LOAD

P21

MAGAZINE

(existence)

HOME

P22

MAGAZINE

(none)

SELECTOR UP

MAGAZINE EJECT

P06

PAUSE

RETURN

P01

PARK STOP

P02

SET UP

P02

TOC

P07

SEARCH

PLAY

SCAN

P08

(RESET)

P03

P04

44

Mode to return "R" when the command arrives

Normal chart (normal transition)

At reset

Brake by C/R, etc.

Page 45

7. GENERAL INFORMATION

DRM-6NX

7.1 IC

7 PD6287B: (IC702: MAIN BOARD ASSY)

¶ Flash Memory

¶ Pin Assignment (Top View)

39

6

5

A

12

A13A14A15A16BYTE

38

37

36

7

8

9

4

3

A

2

A

A

¶ Block Diagram

WE

RESET

44

43

N.C. 1

RY/BY 2

A8A9A10A11A

42

41

40

4

5

7

6

A

N.C. 3

A

¶ The information shown in the list is basic information and may

not correspond exactly to that shown in the schematic diagrams.

1

/A-

15

Vss

DQ

DQ7DQ14DQ6DQ13DQ5DQ12DQ4Vcc

35

34

33

32

31

30

29

28

27

26

25

24

2322

10

11

1

0

A

A

CS 12

Vss 13

OE 14

15

0

DQ

16

8

DQ

17

1

DQ

18

19

9

2

DQ

DQ

DQ0 – DQ

15 – 22, 24 – 31

20

10

DQ

21

3

11

DQ

DQ

15

RY/BY

WE

BYTE

RESET

CS

OE

A

0 – A16

A-

2

12 44 33 43

1414 3 – 11, 34 – 42

1

RY/BY

Buffer

Control

Circuit

Low Vcc Det.

Circuit

Write Circuit

Write/Erace

Pulse Timer

Erace

Circuit

STB

Vcc

Vss

Chip Enable

Output Enable

Circuit

Y Decoder

X Decoder

Address Latch

Input/Output

Buffer

STB

Data Latch

Y Gate

2,097,152

bits

Cell Matrix

45

Page 46

DRM-6NX

6

7

5

Disconnect the

connector.

IDE/SCSI BOARD ASSY

HARD DISK

UNIT

× 2

7

8

× 2

7.2 DIAGNOSIS

7.2.1 DIAGNOSIS METHOD FOR MULTI MECHA ASSY AND HDD

This unit is equipped with an external SCSI terminal. Accordingly, when the SCSI cable is

disconnected from the AXIS NETWORK BOARD Assy, the external SCSI terminal is connected

to the SCSI controller of the PC A/T, and the terminator setting is changed, the built-in HDD and

the MULTI MECHA Assy can be operated from the PC A/T as SCSI devices, and analysis is

possible.

SCSI Cable

Disconnect the

SCSI connector

FUNCTION SW (S1001)

TERMINATOR:

(IDSB BOARD ASSY)

1 2 3

ON

OFF

REAR PANEL

PC/AT

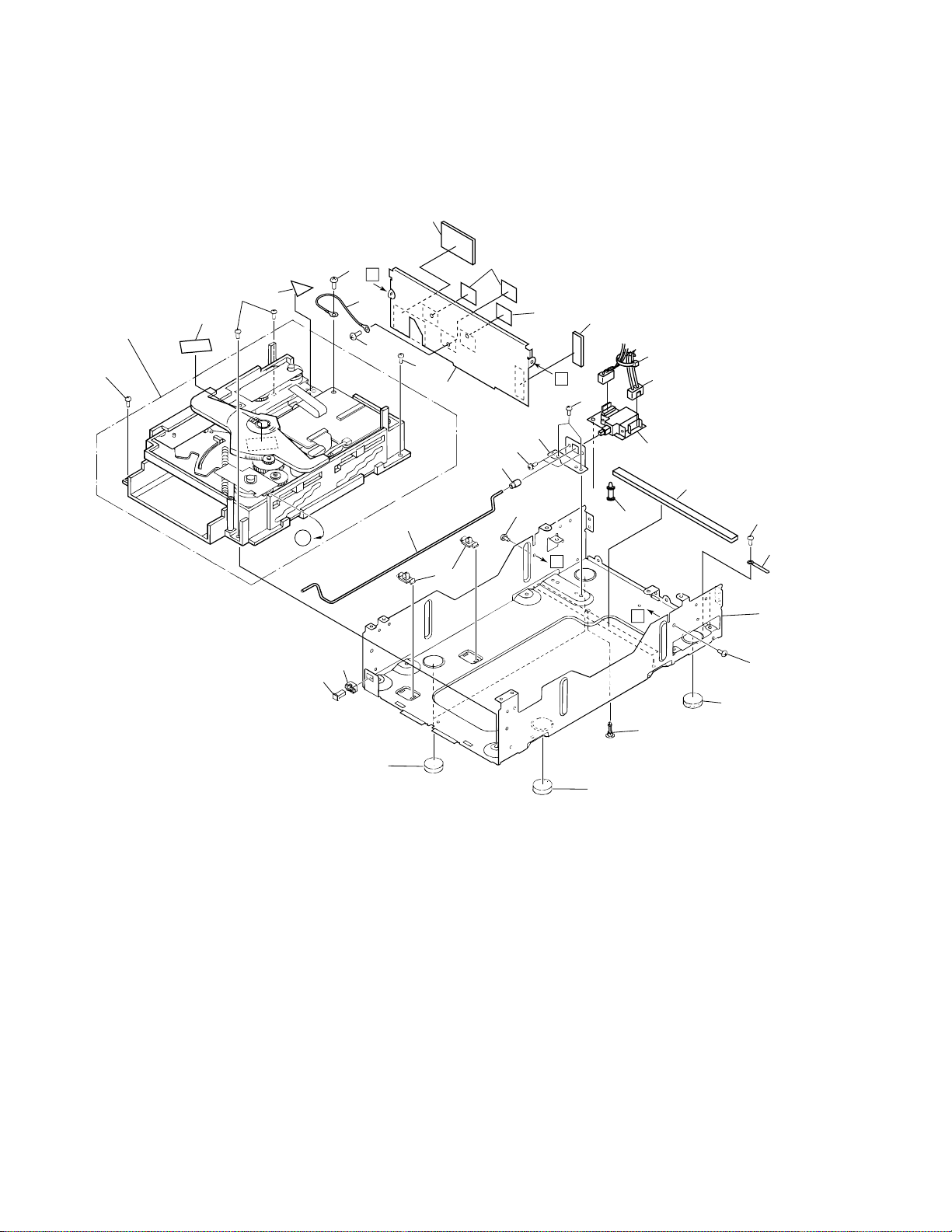

7.2.2 DISASSEMBLY

Removal of the AXIS Network Board Assy and

Hard Disk Unit

1 Remove the Bonnet.

2

Disconnect the

connectors.

3

4

3

× 2

AXIS NETWORK

BOARD ASSY

HARD DISK UNIT

(SLAVE)

MASTER

IDE/SCSI BOARD ASSY

CN4

JP5

JP11

TERMINATOR:

OFF = ON

JP11 (Closed) = (Open)

46

3

AXIS NETWORK

BOARD ASSY

Page 47

Removal of the Power Supply Assy

9

Power Supply

Assy

DRM-6NX

6

5

2

1

× 4

4

3

Rear Side

7

8

CN1

Power Supply

Assy

8

CN2

47

Page 48

DRM-6NX

7.2.3 TROUBLESHOOTING

This section provides useful information to help you

resolve any difficulty you might have with your DRM-

6NX, namely:

÷ The front panel indicators

÷ Errors when accessing the DRM-6NX

÷ Problems running CD-ROM software

÷ Difficulties locating the DRM-6NX in NetWare

÷ Problems locating the domain controller in SMB

÷ Problems when accessing disc changers

÷ Restoring the factory default settings

The Front Panel Indicators

The front panel indicators show the status of the DRM6NX. The indicators have the following functions:

÷ Status - Flashes during startup. When the DRM-6NX

is ready for use, the light goes out. The LED remains

off, unless an error condition occurs.

÷ HDD - Flashes to indicate hard disk activity and SCSI

activity.

Caution!

Never turn off the power when the hard disk

drive is active (while HDD indicator is flashing).

÷ Network - Flashes to indicate the presence of network

traffic.

÷ CHANGER - Light when data is read from the internal

changer and when the SCSI bus is accessed.

÷ Power - Indicates that power is connected to the

DRM-6NX. This LED should remain lit and is only

used to indicate power is present in the DRM-6NX

unit.

Error Conditions

This table shows the front panel indicators under various

error conditions:

Event

CD-ROM has incorrect format

or SCSI bus not connected**

Faulty network connection OFF OFF

Illegal serial no. Flash Flash Flash

Flash load failed Flash OFF OFF

Token-Ring loopback failure

Token-Ring speed error ON OFF Flash

Error in EEPROM Flash OFF OFF

Error in FLASH PROM Flash OFF Flash

Error in SRAM Flash Flash OFF

Error in DRAM/DIMM Flash OFF OFF

Error in DRAM/DIMM

configuration error

Software/Hardware

combination error

Disconnect/reselect drive

error ****

* The Network LED will flash when there is network traffic.

** Check the logfile.txt file in the System folder for more information.

*** The HDD LED and Network LED will flash alternately in this condition.

**** Disable the function by setting the Disconnect/Reselect parameter to

off.

Status LED HDD LED Network LED

OFF Flash Flash*

Flash Flash OFF

Flash Flash OFF

Flash Flash*** Flash***

Flash

Status Indicator On

If the Status indicator remains lit after startup, this may

indicate an error. Most likely there is a problem with the

SCSI bus or with any of the connected disc drives. Make

sure all connected drives have unique SCSI addresses

and that only the last drive in the SCSI chain is terminated.

÷ If some drive error occurs during caching/reading,

caching/reading is canceled and the drive and discs

become disable.

Only restarting this product can clear this condition.

Normal Conditions

The Power LED is controlled by hardware and is always

lit when power is connected.

This table shows the other front panel indicators under

normal conditions:

Event

Initial power to unit ON ON ON

During power-up/Self-test.

Approx. 30 seconds.

After power-up/Self-test OFF ON Flash*

First disc inserted OFF ON Flash*

Last disc removed OFF OFF Flash*

Network Packet arrived OFF N/A Flash*

Flash loading

* The Network LED will flash when there is network traffic.

48

Status LED HDD LED Network LED

Flash OFF OFF

1 Flash/sec 1 Flash/sec 1 Flash/sec

Errors when Accessing the Network

Cache Changer or Inserted Discs

If you get error messages when trying to access the

DRM-6NX or an inserted disc:

÷ Using TCP/IP, make sure that you have assigned a

unique Internet address to the DRM-6NX.

÷ Check the SCSI chain and ensure that all external disc

drives are switched on and that only the last unit is

terminated.

÷ Using Microsoft Windows Network, verify that you

have enabled the SMB protocol.

÷ Consult the error table in section “Error Conditions”

to see if the front panel indicators can help you

identify the problem.

Page 49

DRM-6NX

Problems Running CD-ROM Software

If you have inserted a CD-ROM successfully, but the

software on it refuses to run or produces error messages,

the software may expect the CD-ROM data to be at root

level. In NetWare as well as in the Microsoft and IBM

network operating system environments, you then

need to assign a drive letter to that particular CD-ROM.

In NetWare, the Show All Volumes parameter must be

enabled. See also “Accessing the Network Cache

Changer Resources”.

Some CD-ROMs, e.g the single user version of

“Computer Select”, requires the MSCDEX (Microsoft)

driver. The volume is usually released in a network

version as well. An MSCDEX emulation, called

PIONEERCDEX, is available on the Axis web site. The

PIONEERCDEX makes a CD-ROM on the DRM-6NX

look as if it was locally connected to the PC.

PIONEERCDEX supports Windows for Workgroups.

An MSCDEX emulation for Windows 95 is also available.

If the CD-ROM is a single user version, you must restrict

the number of simultaneous users to one.

Some applications look for information on the CD-ROM

using its default name - if you have set an alias name it

may not recognize the disc and fail to run.

Difficulties Locating the Network Cache

Changer in NetWare

Frame Types - Ethernet

There are basically two different frame types on Ethernet

networks, Ethernet II or IEEE 802.3. The IEEE 802.3

frame can be encapsulated in an IEEE 802.2 LLC frame

or a SNAP frame. All four frame types are enabled by

default with the value

6NX automatically adapts to the frame type used on the

network. This will meet most requirements. Frame

types that are not in use in your network will not be used

by the DRM-6NX.

However, depending on your network, you may want

the DRM-6NX not to operate on some frame types. If

your network has multiple sections with different frame

types on some of the sections, then the DRM-6NX

might log on to the wrong network section and adapt to

a frame type incompatible with the intended network

section. For this reason, you have the option to disable

those frame types by changing the parameter from

to

off

.

auto

, which means that your DRM-

auto

Alternatively, it is possible to use the eight digit network

number appropriate to your segment of the network, in

the form xx-xx-xx-xx (e.g. 00-3F-B5-01). In all normal

cases this will not be necessary since autodetection will

handle most cases. However, this has to be done by

directly editing the

config.txt

file using a text editor.

Although you cannot enter the network number from a

Web browser, you can display the frame type and

change the value to

auto

or

off

, if required.

Problems Locating the Domain Controller

in Windows (SMB)

If there is a problem locating the primary domain

controller when using user-level security mode in

Windows (SMB), all users will be denied access to the

DRM-6NX.

Web Browser

You can verify the configuration settings from the DRM6NX web interface. Within the Administration pages,

click Network Settings, Detailed View, and open the

Windows (SMB) tab to do that.

Local Administrator Account

In Windows NT, you can correct the problem by logging

on to the DRM-6NX as local administrator. Note that the

local administrator is not the same as an Administrator

with an account on the domain.

In the Map Network Drive dialog, specify the following:

Path: The DRM-6NX name

Connect as: Server name\Administrator

Password: The password set in the

Example:

The host name of the DRM-6NX is cdserv.

Path:

Connect as:

NOTE:

7 In Windows 95, you cannot tell the SMB client to change domain and user

when you are already logged in. Therefore, you cannot use the local

administrator account to solve domain problems in the Windows 95

environment.

ServerPassword parameter

\\cdserv\root

cdserv\Administrator

49

Page 50

DRM-6NX

Problems When Accessing Disc Changers

Disc changer flutter can occur if a user requests access

to a CD-ROM when another user is already reading data

from another CD-ROM. The changer may then attempt

to service both requests by repeatedly changing

between the two CD-ROMs and transferring a small

amount of data each time. Because of the relatively long

time needed to change CD-ROMs, the data transfer

rate to both users will become unacceptably low.

The JukeBox Lock Time parameter in the DRM-6NX

configuration file specifies how long a user has exclusive

access to a CD-ROM during a data read operation. This

is to prevent disc change flutter in order to optimize

access speed when many users are accessing different

discs in the same changer.

The JukeBox Lock Time parameter will ensure that

when there are simultaneous requests for access to

different discs, a sizable block of data is transferred to

each user before the access is changed.

÷ If the JukeBox Lock Time parameter is set too low,

the data transfer rate will be unacceptably low.

÷ If the JukeBox Lock Time parameter is set too high,

the disc drive will time-out on a second user’s request

before the first user’s access is completed. This will

result in users receiving a ‘CD-ROM not available’

notice.

The default setting is 0 seconds which disables this

function.

NOTE:

7 If some drive error occurs during caching/reading,Caching/Reading is

canceled and the drive and discs become disable.

Only restarting this product cam clear this condition.

Web Browser

To restore the defaults settings using a Web browser:

1. Start the Web browser.

2. Click Administration.

3. Click PIONEER Changer.

4. Click Factory Defaults.

The factory default setting will now be restored and the

DRM-6NX will then automatically restart.

FTP

To restore the default settings using FTP:

1. Log in to the DRM-6NX with the command:

ftp <host name>

, where

<host name>

is the name assigned

in your system host table.

2. You will be prompted for user id and password. Use

the user id

(

root

is the user id with the highest priority).

root

, which has the default password

pass

3. Restore the default setting with the command:

get defaults

The unit will then automatically restart.

4. Log out using any of the commands

quit, bye

or

exit

depending on your FTP version.

Reset Button

To restore the default settings using the Reset button:

1. Turn off the DRM-6NX.

2. Press and hold the Reset button while you switch on

the DRM-6NX. Keep the Reset button pressed until

the Network indicator flashes at regular two second

intervals.

Restoring Factory Default Settings

If required, you can restore the factory default settings

to your DRM-6NX , e.g. if you have disabled all network

protocols. You can use any of these methods:

÷ Web browser

÷ FTP on a TCP/IP network

÷ Reset button

Step by step instructions for each method are given

below.

NOTES:

7 The node address, the Hardware Address parameter, will remain

unchanged, but all other parameters will be restored. You will thus need

to re-assign the Internet address to re-establish the Web browser

connection.

7 All Cached data in the HDD is cleared when restoring the factory default

setting.

50

Reset button

3. Release the Reset button and wait at least two

seconds (one flash of the Network indicator).

4. Press and hold the Reset button for at least five

seconds until the Network indicator remains

constantly lit.

5. Turn off the DRM-6NX. And switch on the DRM-6NX

again.

The factory default setting will now be restored.

Page 51

Troubleshooting Know-how Collection

DRM-6NX

Details of Error

Q1. The Status LED continues to flash (5 minutes

or more) and never stops.

Q2. How can I reset to the factory default settings?

Q3. The firmware version can not be upgraded.

Measure

A1. Check that the SCSI Termination switch on the rear

of the DRM-6NX is ON. If this does not help, reset to

the factory default settings.

A2. Resetting to the factory default settings can be done

as described below.

1. Hold the Reset button pressed while switching

the power to the DRM-6NX ON, and keep it

pressed until all three LEDs flash at the same

time. At this time, release the Reset button once,

and press it again after waiting for about 5 sec.

When the Status LED and the Network LED have

lit and gone out, switch off the power to the DRM6NX and then restart it.

2. Connect with a web browser, enter Administration,

and press the Factory Default button.

3. Log in at the DOS prompt with ftp 192.36.253.80

(IP address). (The User Name is root and the

Password is pass.) Enter "get defaults" to obtain

the Factory Default settings.

A3. Enter FLASH in capital letters When you issue "put"

command at ftp command line.

Q4. Connection is possible with ping and ftp, but

opening with a Web Browser is not possible.

Q5. Ping passes, but connection by ftp or web

browser is not possible.

Q6. Changing of the IP address is not possible with

arp and ping Command.

Q7. The network computer does not see the DRM-

6NX.

A4. Has the Status LED stopped flashing? The DRM-6NX

is ready when the Status LED has stopped flashing.

If the LED has not stopped flashing, wait for about 5

minutes. If it still does not stop flashing, refer to Q1.

A5. Restart the DRM-6NX once and start again from IP

address setting. Changing of the IP address with arp