PIONEER DEH-P490IB, DEH-P4900IB Service Manual

ORDER NO.

CRT3846

DEH-P490IB/XN/UC

CD RECEIVER

DEH-P490IB

DEH-P4900IB

This service manual should be used together with the following manual(s):

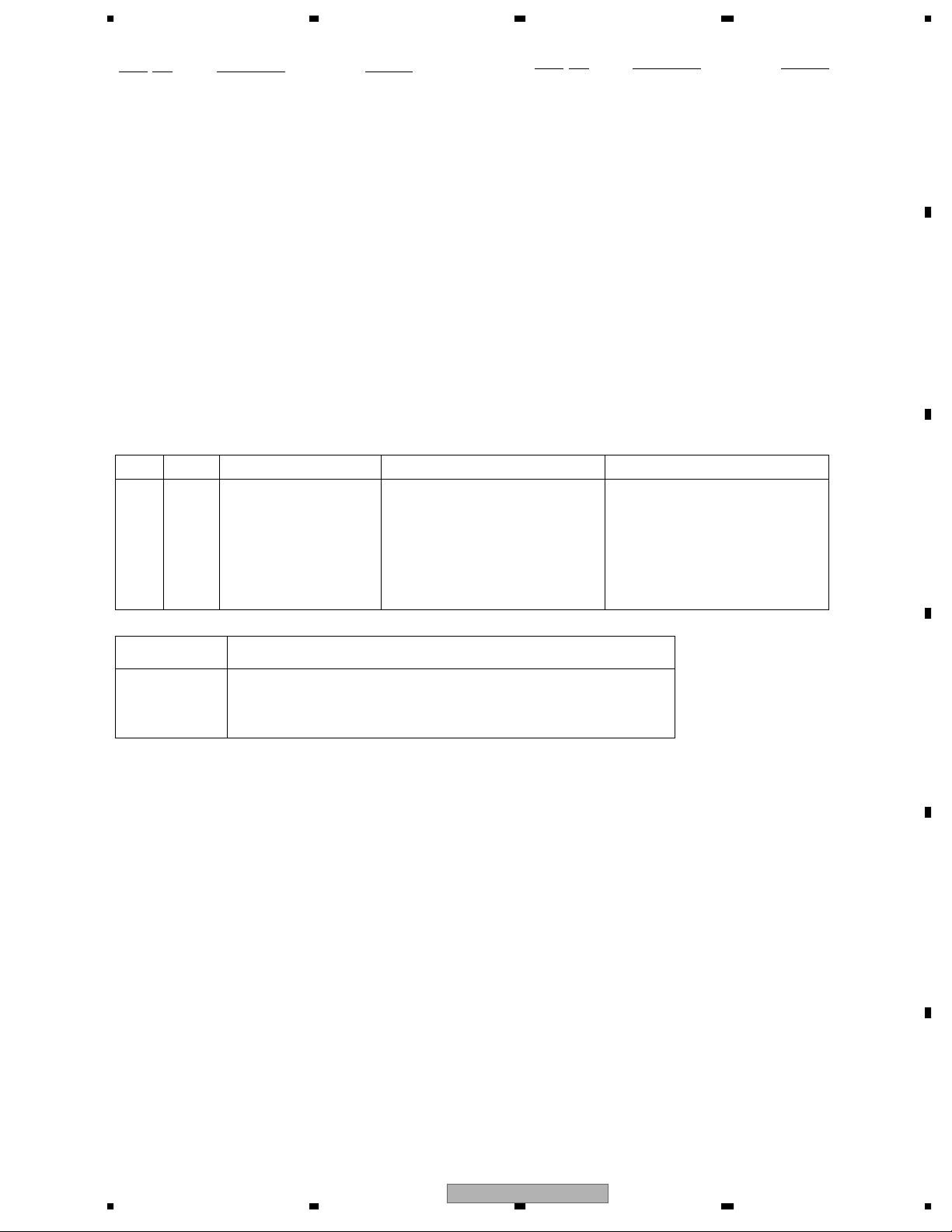

Model No. Order No. Mech.Module Remarks

CX-3195 CRT3815 S10.5COMP2 CD Mech. Module : Circuit Descriptions, Mech. Descriptions, Disassembly

/XN/UC

/XN/UC

For details, refer to "Important Check Points for Good Servicing".

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2006

K-ZZU. DEC. 2006 Printed in Japan

1234

SAFETY INFORMATION

CAUTION

A

This service manual is intended for qualified service technicians; it is not meant for the casual do-it-yourselfer.

Qualified technicians have the necessary test equipment and tools, and have been trained to properly and safely repair

complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may void the warranty.

If you are not qualified to perform the repair of this product properly and safely, you should not risk trying to do so

and refer the repair to a qualified service technician.

W

ARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of

California to cause cancer, birth defects or other reproductive harm.

B

Health & Safety Code Section 25249.6 - Proposition 65

- Safety Precautions for those who Service this Unit.

• When checking or adjusting the emitting power of the laser diode exercise caution in order to get safe, reliable

results.

Caution:

1. During repair or tests, minimum distance of 13 cm from the focus lens must be kept.

2. During repair or tests, do not view laser beam for 10 seconds or longer.

C

- Service Precaution

1. You should conform to the regulations governing

the product (safety, radio and noise, and other

regulations), and should keep the safety during

servicing by following the safety instructions

described in this manual.

2. Before disassembling the unit, be sure to turn off

the power. Unplugging and plugging the connectors

during power-on mode may damage the ICs inside

the unit.

D

3. To protect the pickup unit from electrostatic discharge

during servicing, take an appropriate treatment

(shorting-solder) by referring to "the DISASSEMBLY".

4. After replacing the pickup unit, be sure to check the

grating.

5. Be careful in handling ICs. Some ICs such as MOS

type are so fragile that they can be damaged by

electrostatic induction.

E

F

2

1234

DEH-P490IB/XN/UC

5678

[Important Check Points for Good Servicing]

In this manual, procedures that must be performed during repairs are marked with the below symbol.

Please be sure to confirm and follow these procedures.

1. Product safety

Please conform to product regulations (such as safety and radiation regulations), and maintain a safe servicing environment by

following the safety instructions described in this manual.

1 Use specified parts for repair.

Use genuine parts. Be sure to use important parts for safety.

2 Do not perform modifications without proper instructions.

Please follow the specified safety methods when modification(addition/change of parts) is required due to interferences such as

radio/TV interference and foreign noise.

3 Make sure the soldering of repaired locations is properly performed.

When you solder while repairing, please be sure that there are no cold solder and other debris.

Soldering should be finished with the proper quantity. (Refer to the example)

4 Make sure the screws are tightly fastened.

Please be sure that all screws are fastened, and that there are no loose screws.

5 Make sure each connectors are correctly inserted.

Please be sure that all connectors are inserted, and that there are no imperfect insertion.

6 Make sure the wiring cables are set to their original state.

Please replace the wiring and cables to the original state after repairs.

In addition, be sure that there are no pinched wires, etc.

7 Make sure screws and soldering scraps do not remain inside the product.

Please check that neither solder debris nor screws remain inside the product.

8 There should be no semi-broken wires, scratches, melting, etc. on the coating of the power cord.

Damaged power cords may lead to fire accidents, so please be sure that there are no damages.

If you find a damaged power cord, please exchange it with a suitable one.

9 There should be no spark traces or similar marks on the power plug.

When spark traces or similar marks are found on the power supply plug, please check the connection and advise on secure

connections and suitable usage. Please exchange the power cord if necessary.

0 Safe environment should be secured during servicing.

When you perform repairs, please pay attention to static electricity, furniture, household articles, etc. in order to prevent injuries.

Please pay attention to your surroundings and repair safely.

A

B

C

D

2. Adjustments

To keep the original performance of the products, optimum adjustments and confirmation of characteristics within specification.

Adjustments should be performed in accordance with the procedures/instructions described in this manual.

3. Lubricants, Glues, and Replacement parts

Use grease and adhesives that are equal to the specified substance.

Make sure the proper amount is applied.

4. Cleaning

For parts that require cleaning, such as optical pickups, tape deck heads, lenses and mirrors used in projection monitors, proper

cleaning should be performed to restore their performances.

5. Shipping mode and Shipping screws

To protect products from damages or failures during transit, the shipping mode should be set or the shipping screws should be

installed before shipment. Please be sure to follow this method especially if it is specified in this manual.

56

DEH-P490IB/XN/UC

E

F

7

8

3

1234

CONTENTS

SAFETY INFORMATION..................................................................................................................................... 2

1. SPECIFICATIONS ............................................................................................................................................ 5

2. EXPLODED VIEWS AND PARTS LIST............................................................................................................ 8

A

B

C

2.1 PACKING ...................................................................................................................................................8

2.2 EXTERIOR............................................................................................................................................... 10

2.3 CD MECHANISM MODULE..................................................................................................................... 14

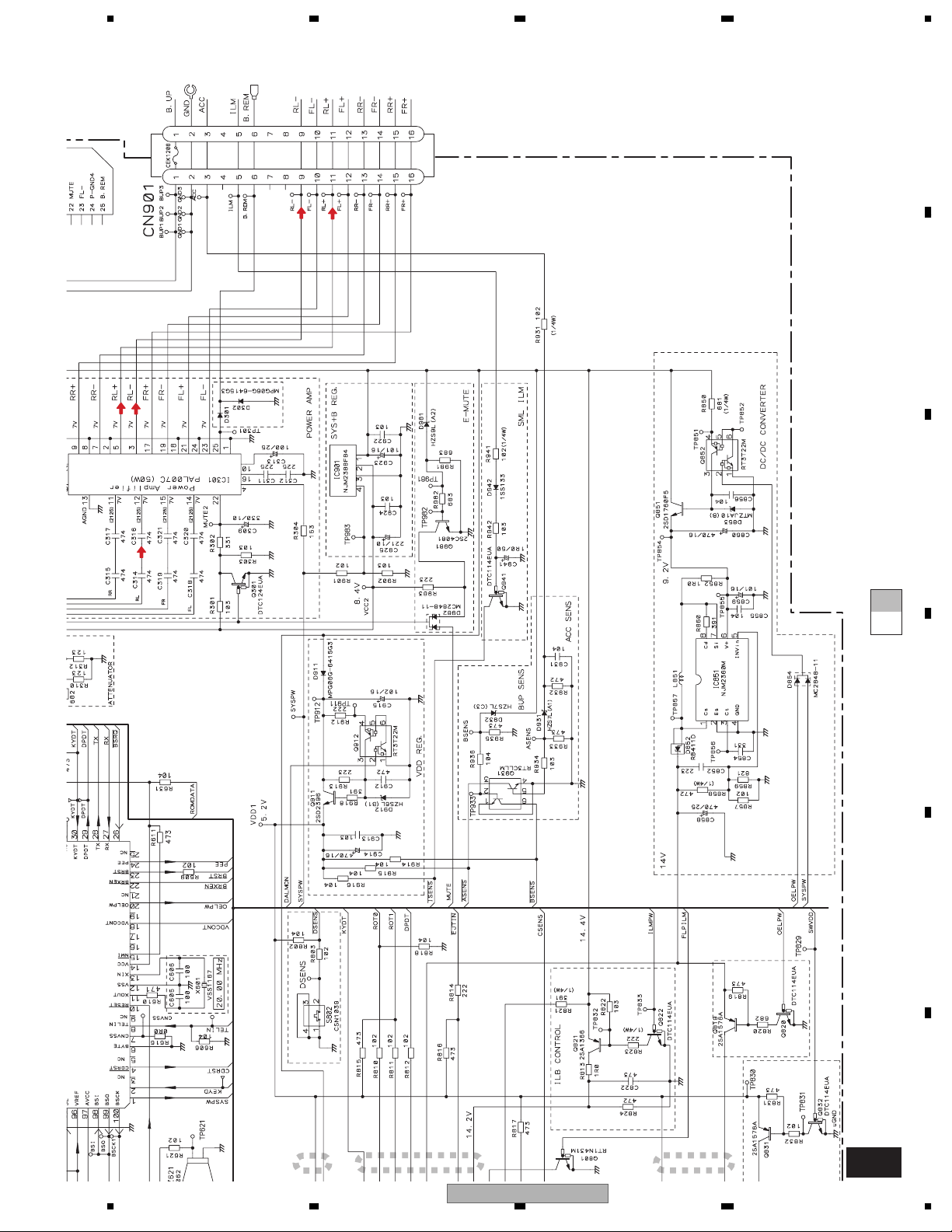

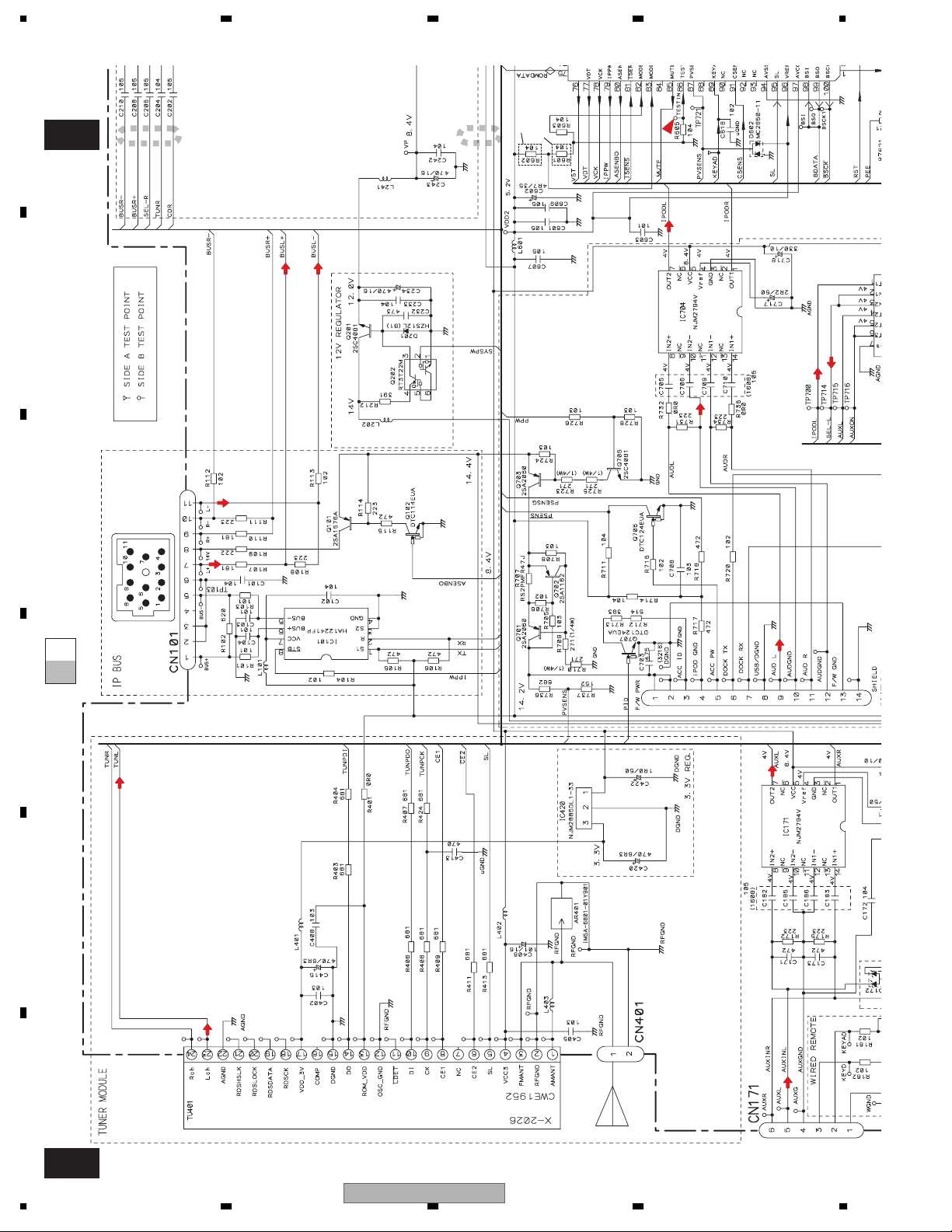

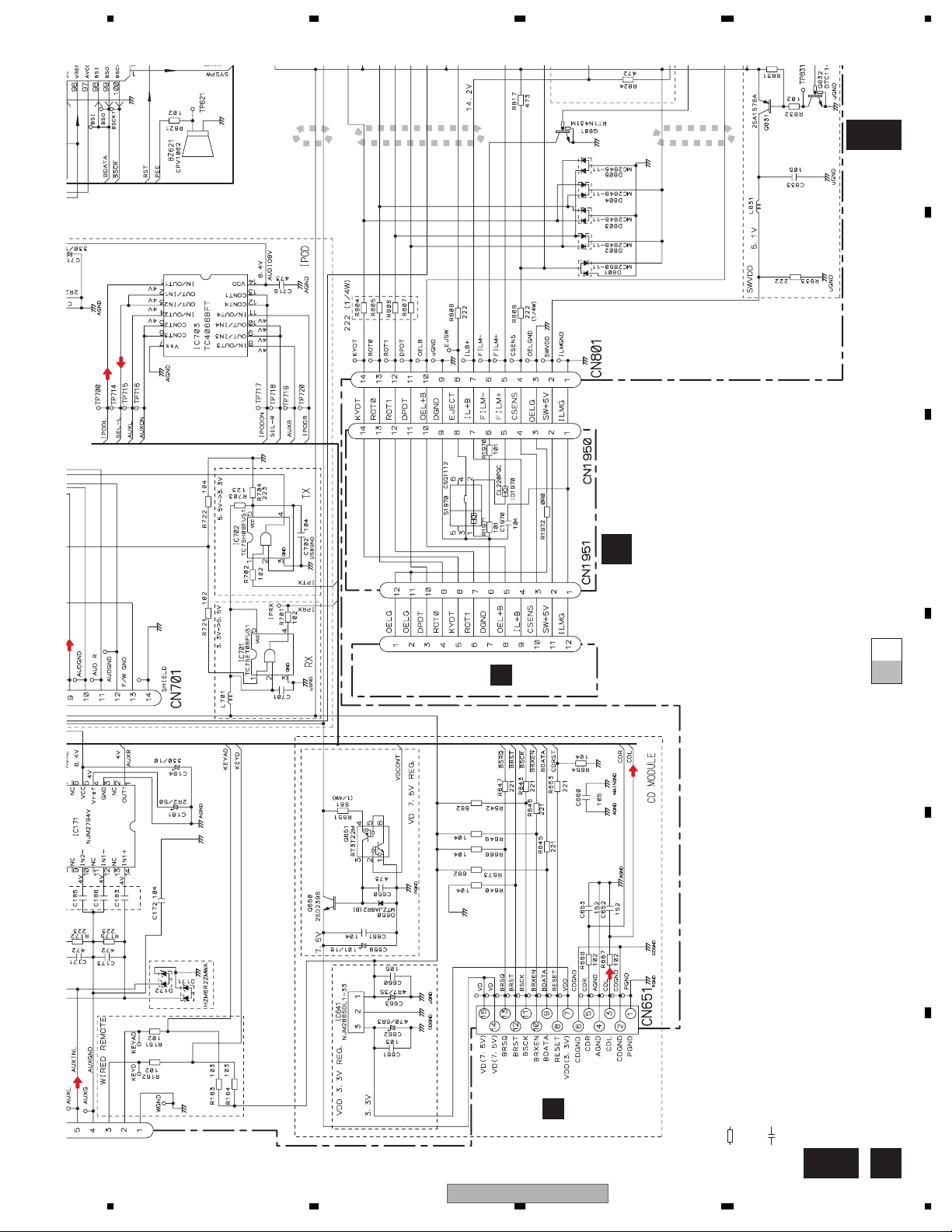

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM..........................................................................................16

3.1 BLOCK DIAGRAM ................................................................................................................................... 16

3.2 OVERALL CONNECTION DIAGRAM(GUIDE PAGE).............................................................................. 18

3.3 KEYBOARD UNIT.................................................................................................................................... 24

3.4 CD MECHANISM MODULE(GUIDE PAGE) ............................................................................................ 26

4. PCB CONNECTION DIAGRAM ..................................................................................................................... 34

4.1 TUNER AMP UNIT................................................................................................................................... 34

4.2 KEYBOARD UNIT.................................................................................................................................... 38

4.3 PANEL UNIT ............................................................................................................................................39

4.4 CD CORE UNIT(S10.5COMP2)............................................................................................................... 40

5. ELECTRICAL PARTS LIST ............................................................................................................................ 42

6. ADJUSTMENT ............................................................................................................................................... 50

6.1 CD ADJUSTMENT................................................................................................................................... 50

6.2 CHECKING THE GRATING AFTER CHANGING THE PICKUP UNIT .................................................... 52

6.3 ERROR MODE ........................................................................................................................................54

6.4 IPOD TEST MODE ..................................................................................................................................55

6.5 SYSTEM MICROCOMPUTER TEST PROGRAM ................................................................................... 56

7. GENERAL INFORMATION ............................................................................................................................. 57

7.1 DIAGNOSIS ............................................................................................................................................. 57

7.1.1 DISASSEMBLY ..................................................................................................................................... 57

7.1.2 CONNECTOR FUNCTION DESCRIPTION.......................................................................................... 60

7.2 IC ............................................................................................................................................................. 61

7.3 OPERATIONAL FLOW CHART ............................................................................................................... 70

8. OPERATIONS ................................................................................................................................................ 71

D

E

F

4

1234

DEH-P490IB/XN/UC

5678

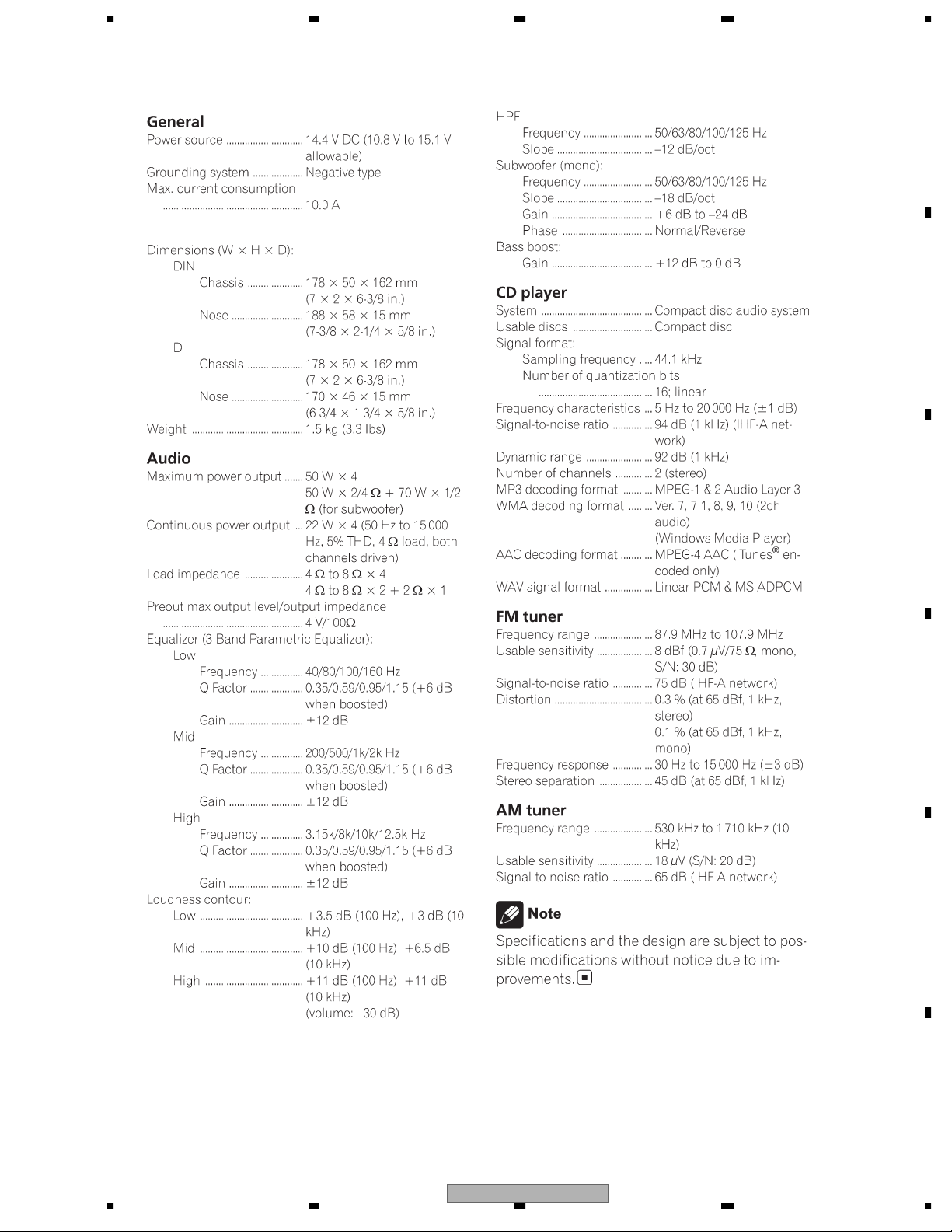

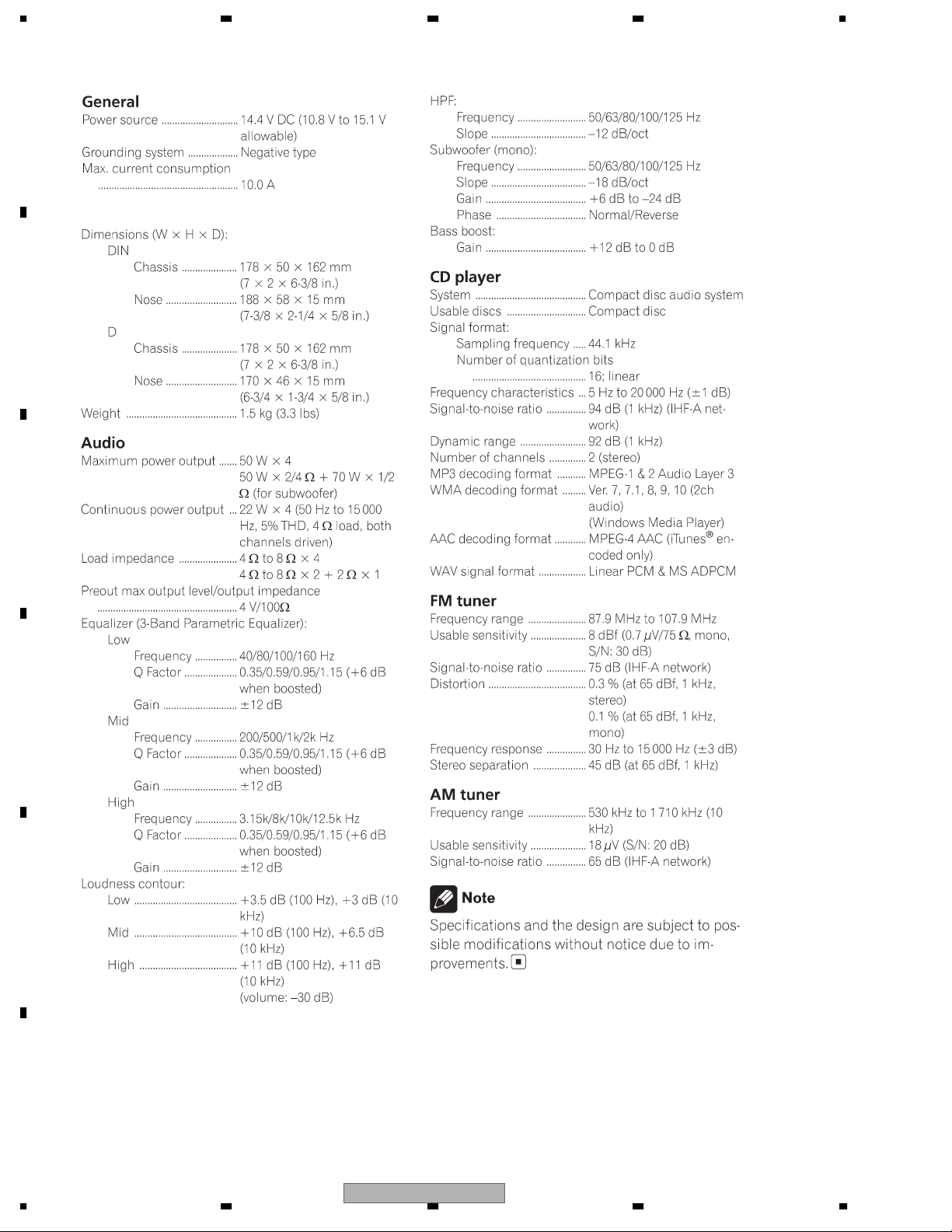

1. SPECIFICATIONS

- DEH-P490IB/XN/UC

Backup current .................... 5 mA or less

A

B

C

D

E

F

56

DEH-P490IB/XN/UC

7

8

5

1234

- DEH-P4900IB/XN/UC

A

Backup current .................... 5 mA or less

B

C

D

E

F

6

1234

DEH-P490IB/XN/UC

5678

A

B

C

D

E

56

DEH-P490IB/XN/UC

F

7

8

7

N

1234

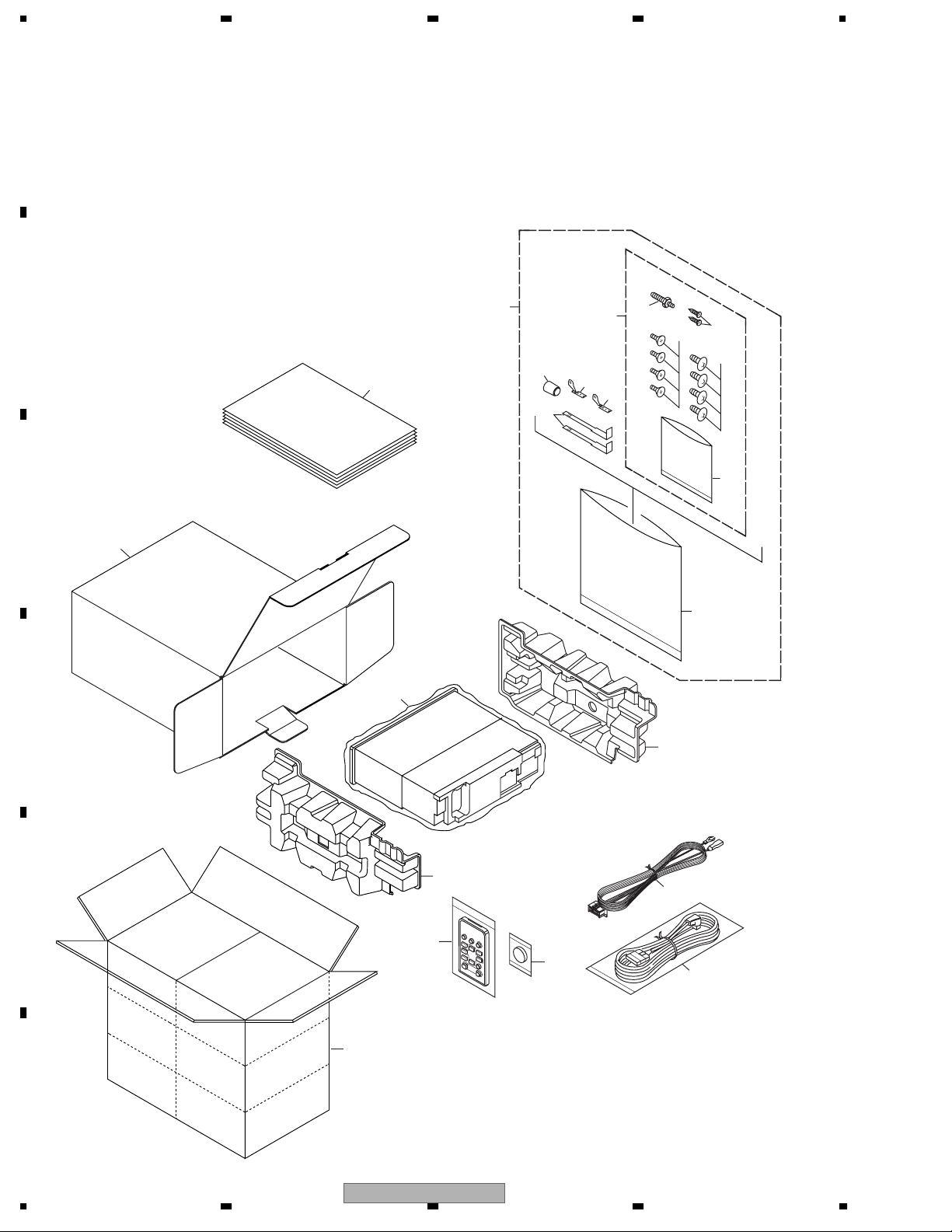

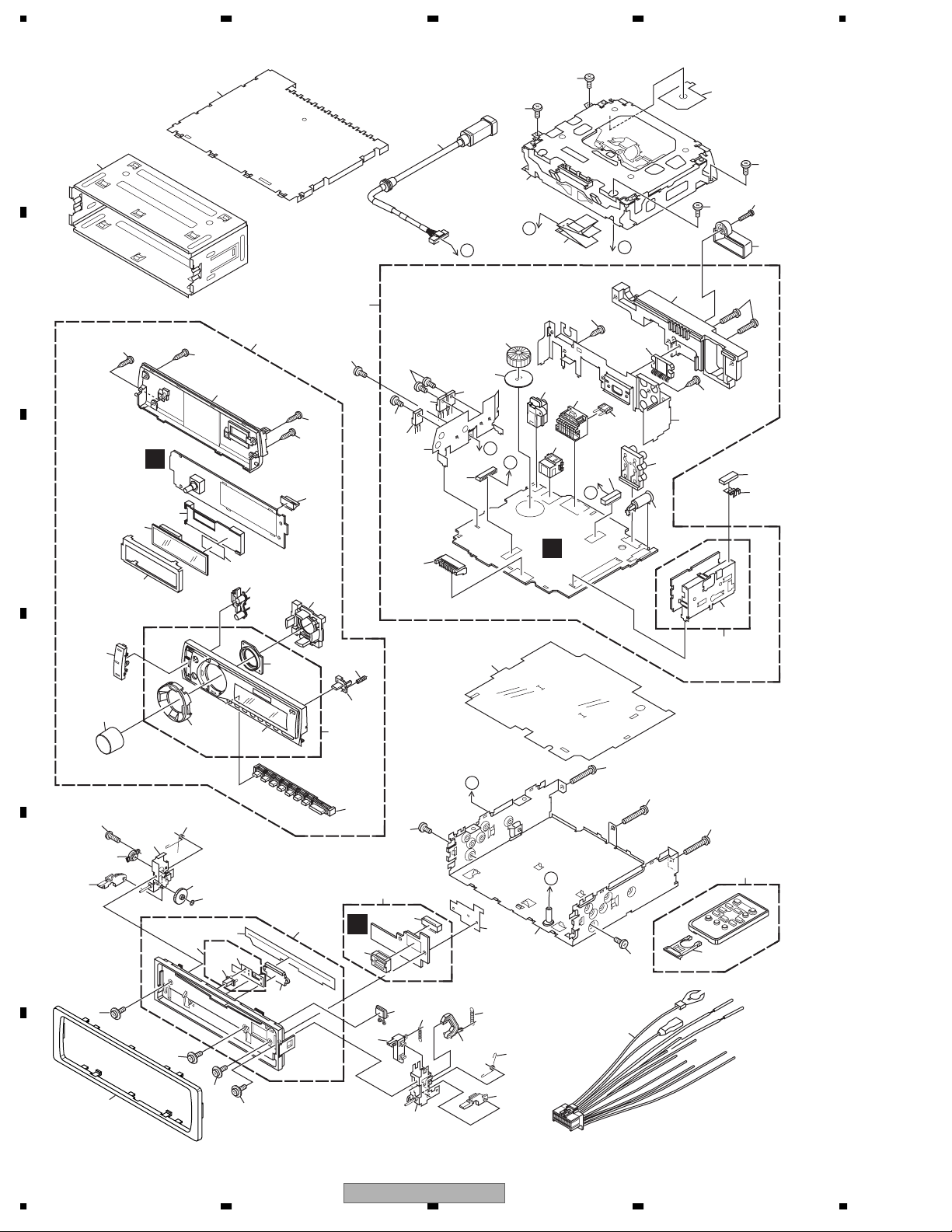

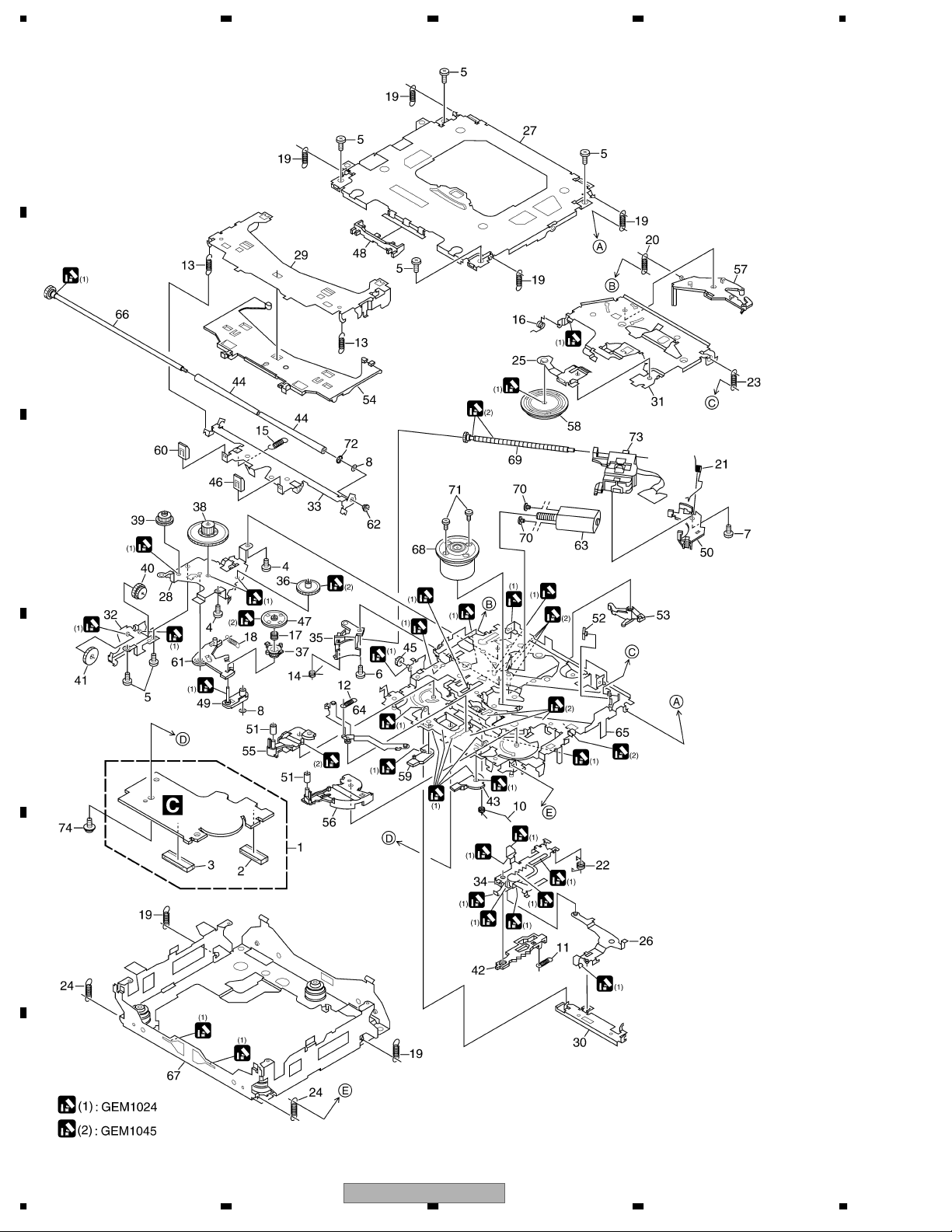

2. EXPLODED VIEWS AND PARTS LIST

OTES : • Parts marked by " * " are generally unavailable because they are not in our Master Spare Parts List.

• The > mark found on some component parts indicates the importance of the safety factor of the part.

A

Therefore, when replacing, be sure to use parts of identical designation.

• Screw adjacent to mark on the product are used for disassembly.

• For the applying amount of lubricants or glue, follow the instructions in this manual.

(In the case of no amount instructions,apply as you think it appropriate.)

2.1 PACKING

"

B

3

C

20

1

D

8

13

11

12

14

10

17

23

18

16

19

15

9

22

E

4

2

21

F

8

1234

DEH-P490IB/XN/UC

6

7

5678

(1) PACKING SECTION PARTS LIST

Mark No. Description Part No.

1 Polyethylene Bag CEG1173

* 2 Battery CEX1065

3-1 Caution Card CRP1310

* 3-2 Caution Card See Contrast table(2)

* 3-3 Warranty Card See Contrast table(2)

3-4 Owner's Manual See Contrast table(2)

3-5 Installation Manual See Contrast table(2)

* 3-6 Caution Card XRP7008

4 Remote Control Assy CXC5719

5 •••••

6 Cord Assy XDP7001

7 Cord Assy See Contrast table(2)

8 Accessory Assy XEA7011

9 Polyethylene Bag CEG1160

10 Holder CND1249

Mark No. Description Part No.

11 Holder CND1250

12 Handle CND3707

13 Bush CNV3930

14 Screw Assy CEA5317

* 15 Polyethylene Bag CEG-127

16 Screw BPZ20P060FTB

17 Screw CBA1650

18 Screw CRZ50P090FTC

19 Screw TRZ50P080FTC

20 Unit Box See Contrast table(2)

21 Contain Box See Contrast table(2)

22 Protector XHP7016

23 Protector XHP7017

(2) CONTRAST TABLE

DEH-P490IB/XN/UC and DEH-P4900IB/XN/UC are constructed the same except for the following:

Mark No. Description DEH-P490IB/XN/UC DEH-P4900IB/XN/UC

* 3-2 Caution Card Not used CRP1294

* 3-3 Warranty Card CRY1070 CRY1246

3-4 Owner's Manual XRD7129 XRD7127

3-5 Installation Manual XRD7130 XRD7128

7 Cord Assy XDP7005 Not used

A

B

C

20 Unit Box XHG7126 XHG7125

21 Contain Box XHL7126 XHL7125

Owner's Manual,Installation Manual

Part No. Language

XRD7127,

XRD7128,

XRD7129,

XRD7130

English, French, Spanish

D

E

56

DEH-P490IB/XN/UC

F

7

8

9

1234

A

B

D

2.2 EXTERIOR

81

A

12

6

A

38

17

3

19

83

19

32

83

84

25

B

38

C

47

38

49

37

42

38

44

2

10

85

33

D

B

24

48

46

40

45

55

43

41

82

2

B

11

34

26

23

18

C

87

22

27

A

30

28

35

31

18

15

2

2

90

89

20

7

5

A

29

86

52

88

39

71

68

70

56

72

4

D

1

C

64

36

69

63

61

67

62

74

13

4

4

8

1

9

D

E

F

66

58

57

50

16

75

73

58

60

91

53

65

59

58

80

77

54

76

79

78

58

10

1234

DEH-P490IB/XN/UC

5678

EXTERIOR SECTION PARTS LIST

Mark No. Description Part No.

1 Screw BMZ30P040FTB

2 Screw BSZ26P060FTC

3 Screw BSZ30P060FTC

4 Screw BSZ30P200FTC

5 Earth Plate CNC8915

6 Holder CND3598

7 Cushion CNM8890

8 Remote Control Assy CXC5719

9 Cover CZN7068

10 CD Mechanism Module(S10.5) CXK5763

11 Cable XDE7022

12 Cord Assy XDE7026

13 Cord Assy XDP7001

14 •••••

15 Insulator XNM7106

16 Panel See Contrast table(2)

17 Tuner Amp Unit See Contrast table(2)

18 Screw BPZ26P070FTC

19 Screw BSZ26P060FTC

20 Screw BSZ26P200FTC

21 •••••

> 22 Fuse(10 A) CEK1208

23 Plug(CN901) CKM1376

24 Plug(CN801) CKS3537

25 Connector(CN651) CKS3829

26 Connector(CN101) CKS5271

27 Connector(CN701) CKS5691

28 Antenna Jack(CN401) CKX1056

29 Holder CND1054

30 Pin Jack(CN352) XKB7001

31 Holder XNC7026

32 Holder XNC7030

33 Insulator XNM7031

34 Jack(CN171) XKS7005

35 Heat Sink YNR5031

36 Chassis Unit XXA7474

37 Detachable Assy See Contrast table(2)

38 Screw BPZ20P080FTB

39 Button XAC7149

40 Button(BAND,DISP) XAC7146

41 Spring XBH7001

42 Cover XNS7180

43 Lighting Conductor XNV7033

44 Connector(CN1901) CKS5207

45 Button(UP,DOWN,L,R) See Contrast table(2)

Mark No. Description Part No.

50 Knob Assy XXA7472

51 •••••

52 Sub Grille Assy See Contrast table(2)

53 Plate XNS7184

54 Grille Unit See Contrast table(2)

55 Button Unit(AUDIO,FUNC) XXA7491

56 Button CAC7752

57 Screw(M2 x 4) CBA1649

58 Screw(M2 x 4.5) CBA1925

59 Washer CBF1038

60 Spring CBH2650

61 Spring CBH2651

62 Spring CBH2652

63 Spring CBH2653

64 Holder CND1254

65 Gear CNV5997

66 Arm CNV7400

67 Arm CNV7401

68 Arm CNV7402

69 Arm CNV7403

70 Panel Unit CWM8758

71 Connector(CN1951) CKS4806

72 Connector(CN1950) CKS5192

73 Holder Unit CXB9501

74 Holder Unit CXB9502

75 Damper Unit CXB9503

76 Sub Panel Assy XXA7511

77 Cover CNM6854

78 Lighting Conductor CNV6487

79 Spring CBL1512

80 Pin CNV6486

81 Case YNB5014

82 Insulator YNM5062

83 Transistor(Q650,911) 2SD2396

84 IC(IC901) NJM2388F84

85 Choke Coil(L901) CTH1280

86 FM/AM Tuner Unit CWE1952

87 IC(IC301) PAL007C

88 Button(1-6,SW,EQ) See Contrast table(2)

89 Holder See Contrast table(2)

90 Screw See Contrast table(2)

91 Sub Spring Assy XXA7363

A

B

C

D

E

46 Double side Tape CNM8673

47 OLED Unit MXS8233

48 Holder XNC7028

49 Holder XNV7034

56

DEH-P490IB/XN/UC

F

7

8

11

1234

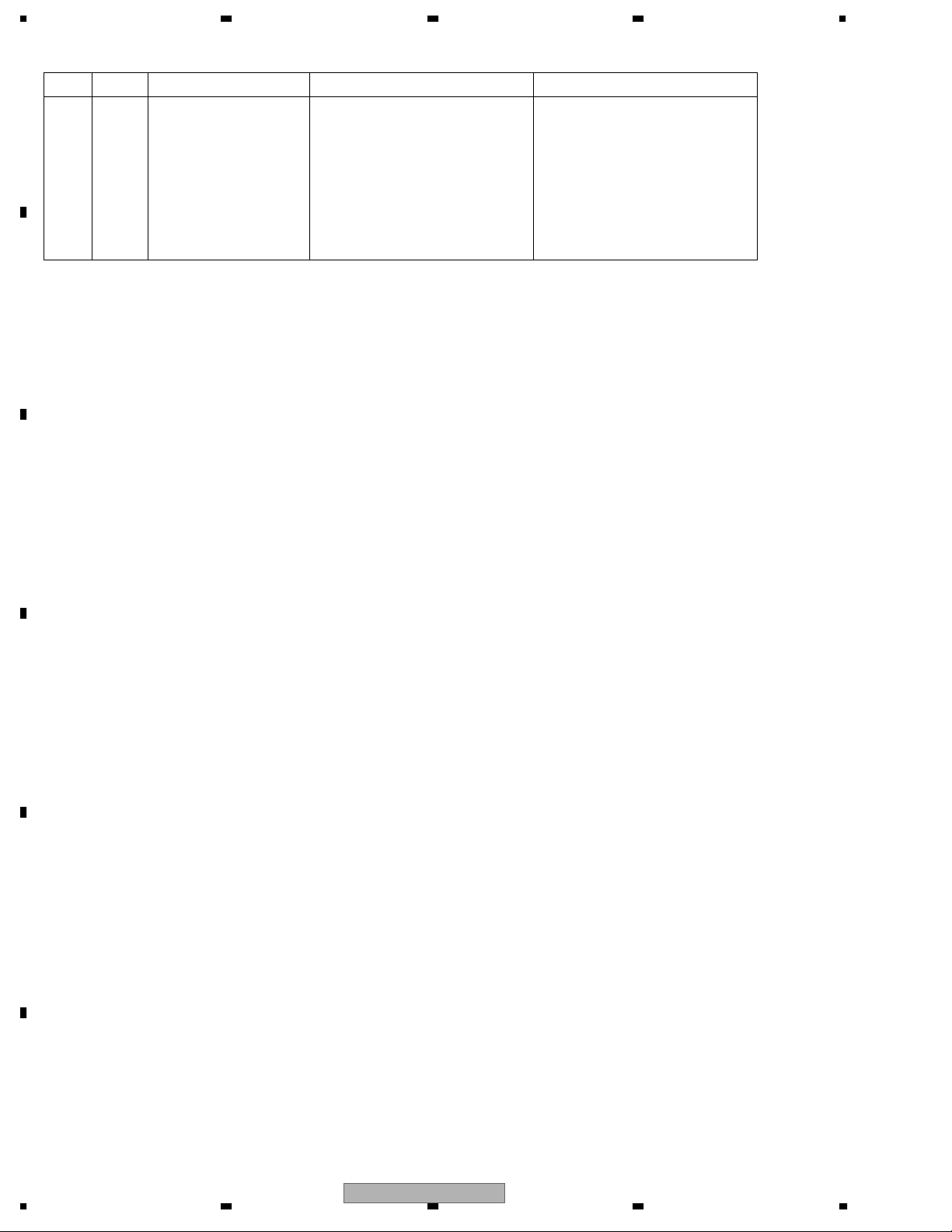

(2) CONTRAST TABLE

DEH-P490IB/XN/UC and DEH-P4900IB/XN/UC are constructed the same except for the following:

Mark No. Description DEH-P490IB/XN/UC DEH-P4900IB/XN/UC

A

B

16 Panel XNS7182 XNS7181

17 Tuner Amp Unit XWM7175 XWM7176

37 Detachable Assy XXA7476 XXA7475

45 Button(UP,DOWN.L,R) XAC7150 XAC7147

52 Sub Grille Assy XXA7483 XXA7482

54 Grille Unit XXA7464 XXA7463

88 Button(1-6,SW,EQ) XAC7151 XAC7148

89 Holder Not used CNV7619

90 Screw Not used BMZ40P140FTC

C

D

E

F

12

1234

DEH-P490IB/XN/UC

5678

A

B

C

D

E

56

DEH-P490IB/XN/UC

F

7

8

13

1234

2.3 CD MECHANISM MODULE

A

B

C

D

E

F

14

1234

DEH-P490IB/XN/UC

5678

CD MECHANISM MODULE SECTION PARTS LIST

Mark No. Description Part No.

1 CD Core Unit(S10.5COMP2) CWX3514

2 Connector(CN101) CKS4182

3 Connector(CN701) CKS4808

4 Screw BMZ20P025FTC

5 Screw BSZ20P040FTC

6 Screw(M2 x 3) CBA1511

7 Screw(M2 x 4) CBA1835

8 Washer CBF1038

9 •••••

10 Spring CBH2609

11 Spring CBH2612

12 Spring CBH2614

13 Spring CBH2616

14 Spring CBH2617

15 Spring CBH2620

16 Spring CBH2855

17 Spring CBH2937

18 Spring CBH2735

19 Spring CBH2854

20 Spring CBH2642

21 Spring CBH2856

22 Spring CBH2857

23 Spring CBH2860

24 Spring CBH2861

25 Spring CBL1686

26 Arm CND1909

27 Frame CND2582

28 Bracket CND2583

29 Arm CND2584

30 Lever CND2585

Mark No. Description Part No.

50 Rack CNV8342

51 Roller CNV8343

52 Holder CNV8344

53 Arm CNV8345

54 Guide CNV8347

55 Arm CNV8348

56 Arm CNV8349

57 Arm CNV8350

58 Clamper CNV8365

59 Arm CNV8386

60 Guide CNV8396

61 Arm CNV8413

62 Collar CNV8938

63 Motor Unit(M2) CXC4026

64 Arm Unit CXC4027

65 Chassis Unit CXC4028

66 Gear Unit CXC4029

67 Frame Unit CXC4031

68 Motor Unit(M1) CXC7134

69 Screw Unit CXC6359

70 Screw JFZ20P020FTC

71 Screw JGZ17P022FTC

72 Washer YE20FTC

73 Pickup Unit(P10.5)(Service) CXX1942

74 Screw IMS26P030FTC

A

B

C

D

31 Arm CND2586

32 Bracket CND2587

33 Arm CND2588

34 Lever CND2589

35 Holder CNV7201

36 Gear CNV7207

37 Gear CNV7208

38 Gear CNV7209

39 Gear CNV7210

40 Gear CNV7211

41 Gear CNV7212

42 Rack CNV7214

43 Arm CNV7216

44 Roller CNV7218

45 Gear CNV7219

46 Guide CNV7361

47 Gear CNV7595

48 Guide CNV7799

49 Arm CNV7805

56

DEH-P490IB/XN/UC

E

F

7

8

15

N

N

N

N

Q

B

R

8

8

O

O

1234

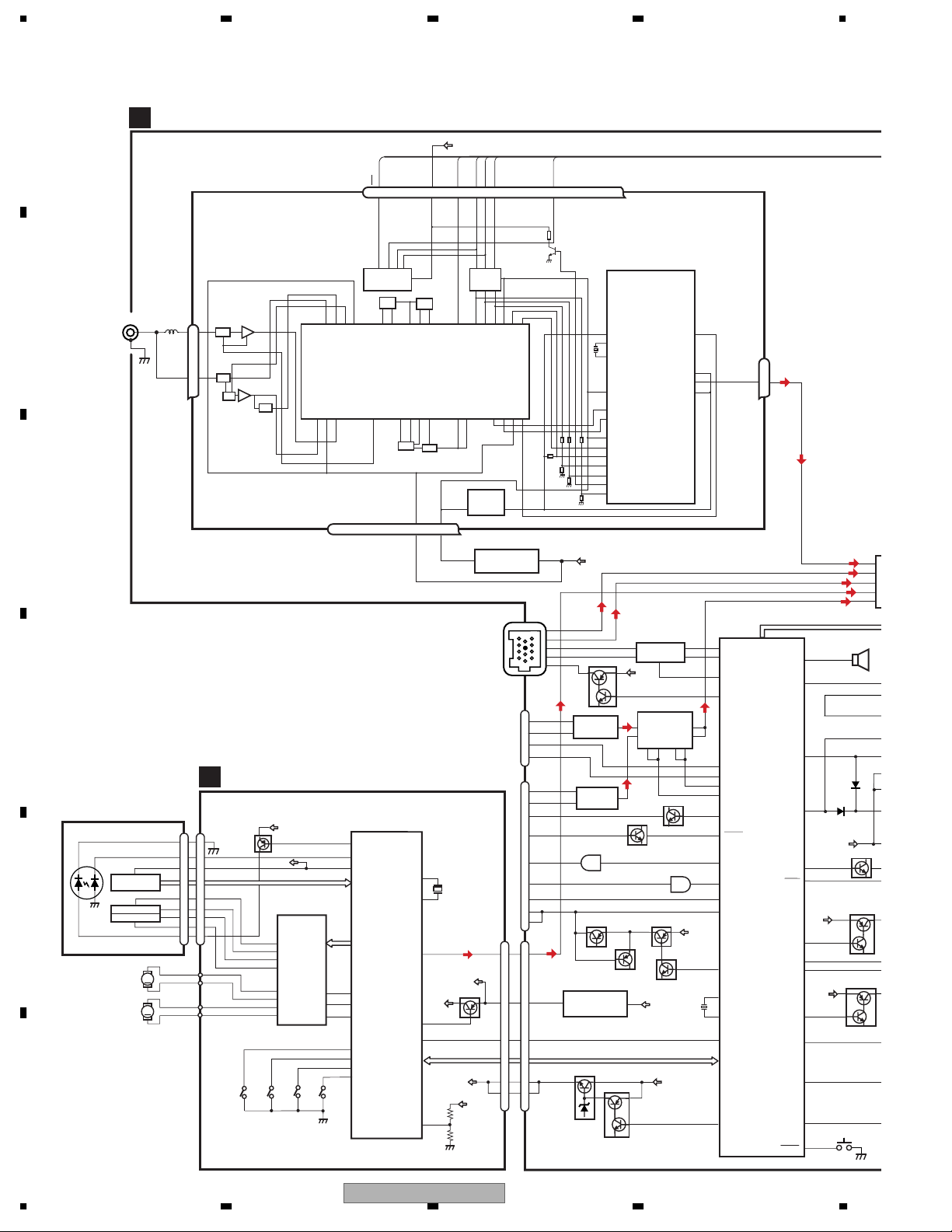

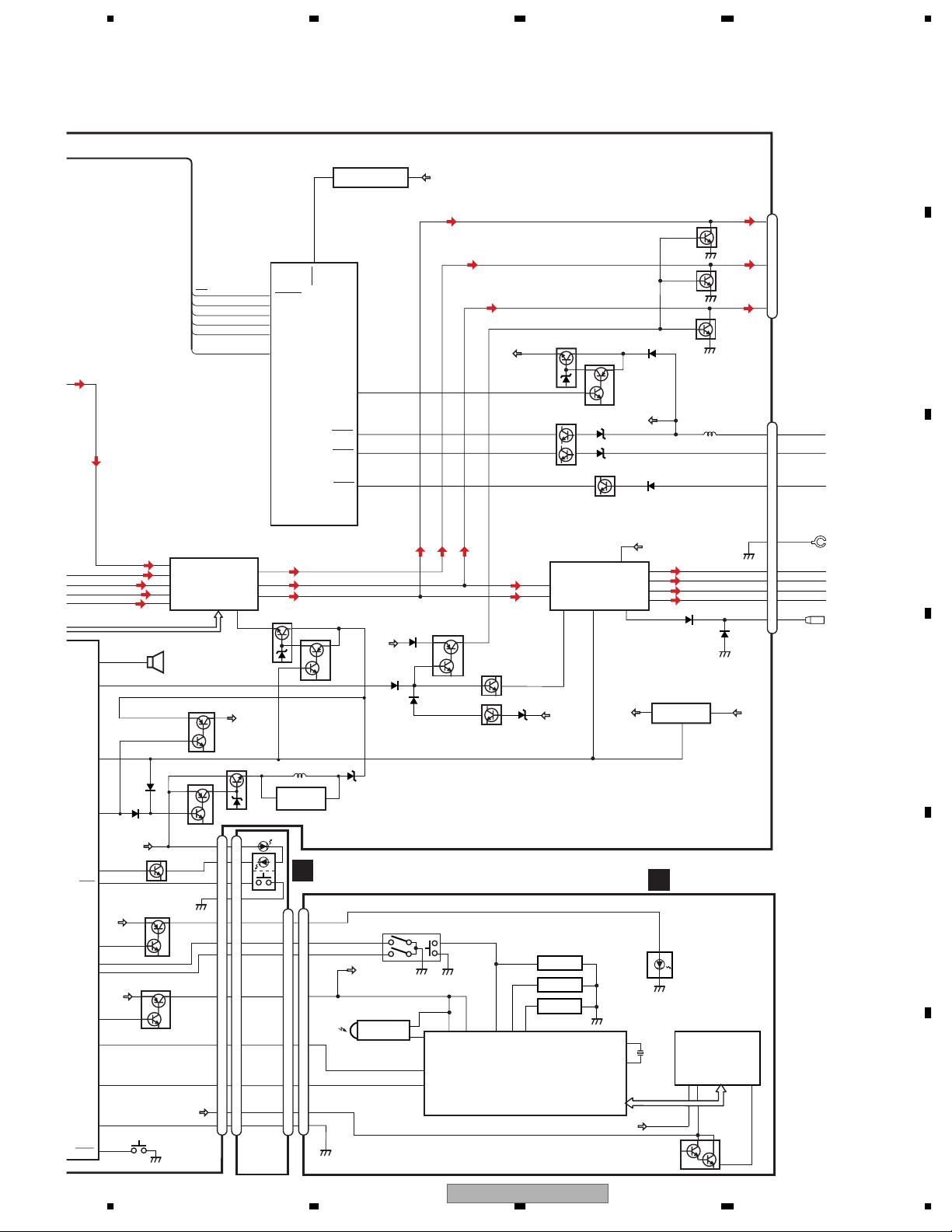

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM

3.1 BLOCK DIAGRAM

A

B

ANTENNA

C

D

PICKUP UNIT

(P10.5)(SERVICE)

LASER

DIODE

E

MONITOR

DIODE

F

LOAD/

A

TUNER AMP UNIT

CN401

1

2

HOLOGRAM

UNIT

FOCUS ACT.

TRACKING ACT.

SPINDLE

M

MOTOR

CARRIAGE

M

MOTOR

FM/AM TUNER UNIT

AM ANT

1

ATT

FM ANT

3

ATT

ANT adj

CD CORE UNIT(S10.5COMP2)

C

CN101

LD-

15

15

MD

5

5

VREF

88

FOM

FOM

33

FOP

FOP

2

2

TOP

TOP

1

1

TOM

TOM

44

LD+

14

14

S904

12EJ

FMRF

Q101

FMRF

S905

8EJ

RF adj

12

11

14

13

16

15

18

17

REFO

FOM

FOP

TOP

TOM

SOP

SOM

LCOP

LCOM

VDD

AC,BD,F,E

CD

DRIVER

IC301

BA5839FP

CLCONT

S903

DSCSNS

CE2

7 6 13 5 10 9 8 11 14 18 19 20 21

NC

IC3 EEPROM

5.0V

OSC

MIXER, IF AMP

RFGND

OSCGND

DGND

212 152216 4 17

133

TD,FD

SD,MD

22

LOEJ

21

9

CONT

S901

HOME

AUDIOGNDNCVCC

RF-AMP, CD DECODER,

MP3/WMA DECODER,

DIGITAL SERVO /

DATA PROCESSOR

141

LD

142

PD

REFOUT

IC201

PE5547A

5

LOEJ

43

CLCONT

41

CONT

8

12EJ

7

8EJ

6

DSCSNS

9

HOME

CE2

IC1

3.3V

T51

XTAL

/XTAL

LOUT

/PUEN

/RESET

VDSENS

ROM_VDD

LPF

CF52

VDD_3.3

50

52

55

VCC

39

16

11

VDD

SL

TUNPCK

TUNPDO

DI

SL

IC5

5V 3.3V

IC4

3.3V 2.5V

3.3V

3.3V REGULATOR

NJM2885DL1-33

IP BUS

X201

16.93MHz

CN701

LOUT

VDD

Q102

/RESET

BRST,BRXEN,BSRQ

BDATA,BSCK

VD

VD

CE1

CK

CE1

TUNPDI

NC

DO

NCNCNC

NC

←

IC2

2.5V

DET, FM MPX,

←

2.5V

Lch

23

E

IC420

13

CN101

CN171

AUXINL

5

AUXGND

4

KEYD

3

KEYAD

2

CN701

AUDL

9

AUDGND

10

ACC ID

3

ACC PW

5

DOCK TX

6

DOCK RX

7

iPOD GND

4

F/W PWR

1

2

CN651

CDL

13

3

VDD

VDD

9

7

RESET

8

8

VD

VD

2

14

1

15

AUDIO8V

BUSL+

7

BUSL-

11

BUS-

5

BUS+

1

8

Q101

Q102

8

IC171

NJM2794V

IC704

NJM2794V

TX

←

5.5V 3.3V

IC 702

4

Q701

7

7

1

IC 701

TC7SET08FUS1

Q702

10

8

10

TC7SH08FUS1

VDD 3.3V REGULATOR

IC641

3

NJM2885DL1-33

BRST,BRXEN,BSRQ,BDATA,BSCK

CD 7.5V REGULATOR

Q650

Q651

IP-BUS DRIVER

5

IC 101

6

HA12241FP

8

B.UP

4

IC703

1

TC4066BFT

13

12

Q707

Q706

3.3V 5.5V

1

Q703

Q705

1

VDD

B.UP

5

6

RX

←

20.00MHz

X601

28

1

TX

2

27

RX

79

IPPW

80

ASENBO

SYSTEM

CONTROLLER

3

2

IC 601(2/2)

PEG270A

2

KEYD

89

KEYAD

51

AUXON

52

IPODON

63

PID

66

PSENS

33

IPTX

4

34

IPRX

64

PSENSG

87

PVSENS

B.UP

65

PPW

13

XIN

11

XOUT

4

CDRST

18

VDCONT

MUTE

SYSPW

OELPW

FLPILM

EJTIN

ILMPW

ROT0

ROT1

SWVDD

DPDT

KYDT

CSENS

DSENS

24

PEE

85

1

20

40

42

37

36

35

38

29

30

39

TUNL

BUSL+

BUSLCDL

SEL-L

B.UP

VDD

91

DETACH SENSE SW

VST,VCK,VDT

B.UP

Q801

ILB CONTR

Q821

Q822

SWVDD CONT

Q832

S802

2

I

4

I

5

I

1

I

3

I

B

Q

Q

16

1234

DEH-P490IB/XN/UC

5678

A

M

LER

/2)

A

SYSPW

OELPW

SWVDD

MUTE

FLPILM

EJTIN

ILMPW

ROT0

ROT1

DPDT

KYDT

CSENS

DSENS

24

PEE

85

1

20

40

42

B.UP

37

36

35

38

29

30

91

39

TUNL

BUSL+

BUSLCDL

SEL-L

VST,VCK,VDT

B.UP

ILB CONTROL

Q822

SWVDD CONTROL

VDD

Q832

DETACH SENSE SW

S802

CE2

CE1

TUNPDI

TUNPDO

TUNPCK

SL

ELECTRONIC VOLUME/

SOURCE SELECTOR

2

IN2_L

4

IN4+_L

IC201

5

IN4-_L

PML015B

1

IN1_L

3

IN3_L

BZ621

BUZZER

OEL+B CONTROL

Q819

Q820

Q852

CN801

Q831

OEL+B

FILM+

FILM-

EJECT

DGND

IL+B

ROT0

ROT1

SW+5V

DPDT

KYDT

CSENS

Q801

Q821

69

TUNPCE2

70

TUNPCE1

43

TUNPDI

44

TUNPDO

45

TUNPCK

95

SL

SYSTEM

CONTROLLER

IC 601(1/2)

PEG270A

12

Pre/SW_L

6

Front_L

7

Rear_L

VP

12V REGULATOR

13

Q201

OEL+B

Q851

6,7

NJM2360M

DC/DC CONVERTER

5

5

6

6

8

8

S1970

9

9

EJECT

7

7

13

13

12

12

2

2

11

11

14

14

10 10 5

44 3

CN1950

CN1951

4

9

7

2

10

8

10

RESET

Q202

IC851

D

PANEL UNIT

CN1901

IL+B

9

ROT0

4

ROT1

6

SW+5V

11

OPT IN

DPDT

3

KYDT

5

OEL+B

8

CSENS

10

RESET

1

IC602

S-80835CNMC-B8U

67

DALMON

73

BSENS

72

ASENS

81

ISENS

B.UP

1

SOURCE (ENCODER)

2

1

5.1V

REMOTE CONTROL

SENSOR

IC 1902

GP1UX51RK

S1988

2

VDD

CN352

MUTE

RL

RL

2

2

Q351

SWL

SWL

4

Q353

FL

VDD REGULATOR

VDD

Q911

BACKUP SENSE

Q931

ACC SENSE

Q912

B.UP

Q941

Q352

FL

6

B

CN901

B.UP

1

ACC

3

ILM

5

B.UP

ACC

ILM

SML ILM SENSE

C

GND

FLFL+

RLRL+

B.REM

D

MUTE

Q982

MUTE

Q301

Q981

E-MUTE

14

12

B.UP

POWER AMP

FLin

PAL007C

RLin

22 4

SYSPW

IC 301

STBYMUTE

VCC

AUDIO8V

6,20

B.REM

25

B.UP

23

FL-

21

FL+

3

RL-

5

RL+

SYS +B REGULATOR

2

IC 901

NJM2388F84

4

KEYBOARD UNIT

B

2

FL-

10

FL+

12

RL-

9

RL+

11

B.REM

6

1

B.UP

E

5

4

3

3

16

7

1

10

REM

VCC

VREF

12

DPDT

13

KYDT

KEY/OEL CONTROLLER

18

ADKEY0

17

15

ADKEY1

ADKEY2

IC 1921

PEG268A

KEY MATRIX

S1971-S1975

S1976-S1981

S1982-S1987

XIN

XOUT

6

4

X1921

10.000MHz

OEL DATA

5.1V

8.5V

REGULATOR

ILLUMINATION

REGS

13,16

14V

Q2011

OLED UNIT

VDD

VAH

7

Q2012

VKH

6

F

8.5V

56

DEH-P490IB/XN/UC

7

8

17

A-a A-b

A-a

A-b

A-b

A-a

P

1234

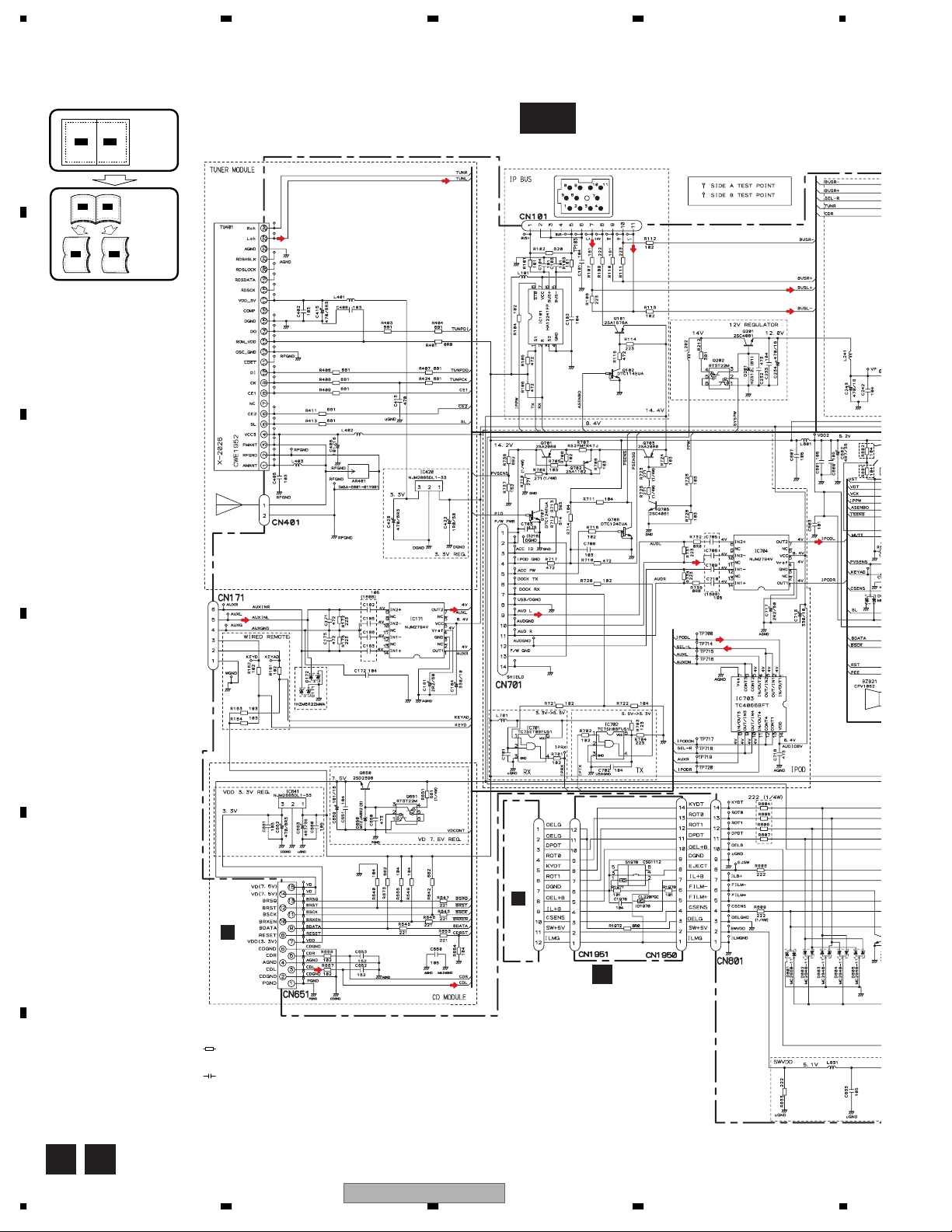

3.2 OVERALL CONNECTION DIAGRAM(GUIDE PAGE)

Note: When ordering service parts, be sure to refer to " EXPLODED VIEWS AND PARTS LIST" or

"ELECTRICAL PARTS LIST".

A

Large size

A-a

SCH diagram

A-a

B

C

Guide page

FM,AM(400 Hz,30 %) : -24 dBs

Detailed page

IPBUS:2.2 dBs

FM/AM TUNER UNIT

AUX/IPOD : 2.2 dBs

D

105

CN1901

B

E

C

CN701

PANEL UNIT

D

CD:0 dBs

NOTE :

Symbol indicates a resistor.

No differentiation is made between chip resistors and

discrete resistors.

Symbol indicates a capacitor.

No differentiation is made between chip capacitors and

discrete capacitors.

F

For resistors and capacitors in the circuit diagrams, their resistance values or

capacitance values are expressed in codes:

Ex. *Resistors

Code Practical value

123 12k ohms

103 10k ohms

*Capacitors

Code Practical value

103 0.01uF

101/10 100uF/10V

A D

18

1234

DEH-P490IB/XN/UC

5678

P4900IB

P490IB

NC

NC

SYSTEM CONTROLLER

A-b

A

TUNER AMP UNIT

A

SUB

100/25

FM,AM:-4.9 dBs

IPBUS:10.3 dBs

CD:10.1 dBs

AUX/IPOD:9.3 dBs

PPOWER

NC

NC

NC

100/25

100/25

3A

>

100/25

100/25

100/25

600uH

WOOFER

L CH

SUB

WOOFER

R CH

FRONT

L CH

FRONT

R CH

REAR

L CH

REAR

R CH

B

C

DETACH

NCNCNC

>

10A

D

E

FM,AM:21.1 dBs

IPBUS:36.3 dBs

CD:36.1 dBs

AUX/IPOD:35.3 dBs

The > mark found on some component parts indicates

the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of

identical designation.

DEH-P490IB/XN/UC

56

F

A

7

8

19

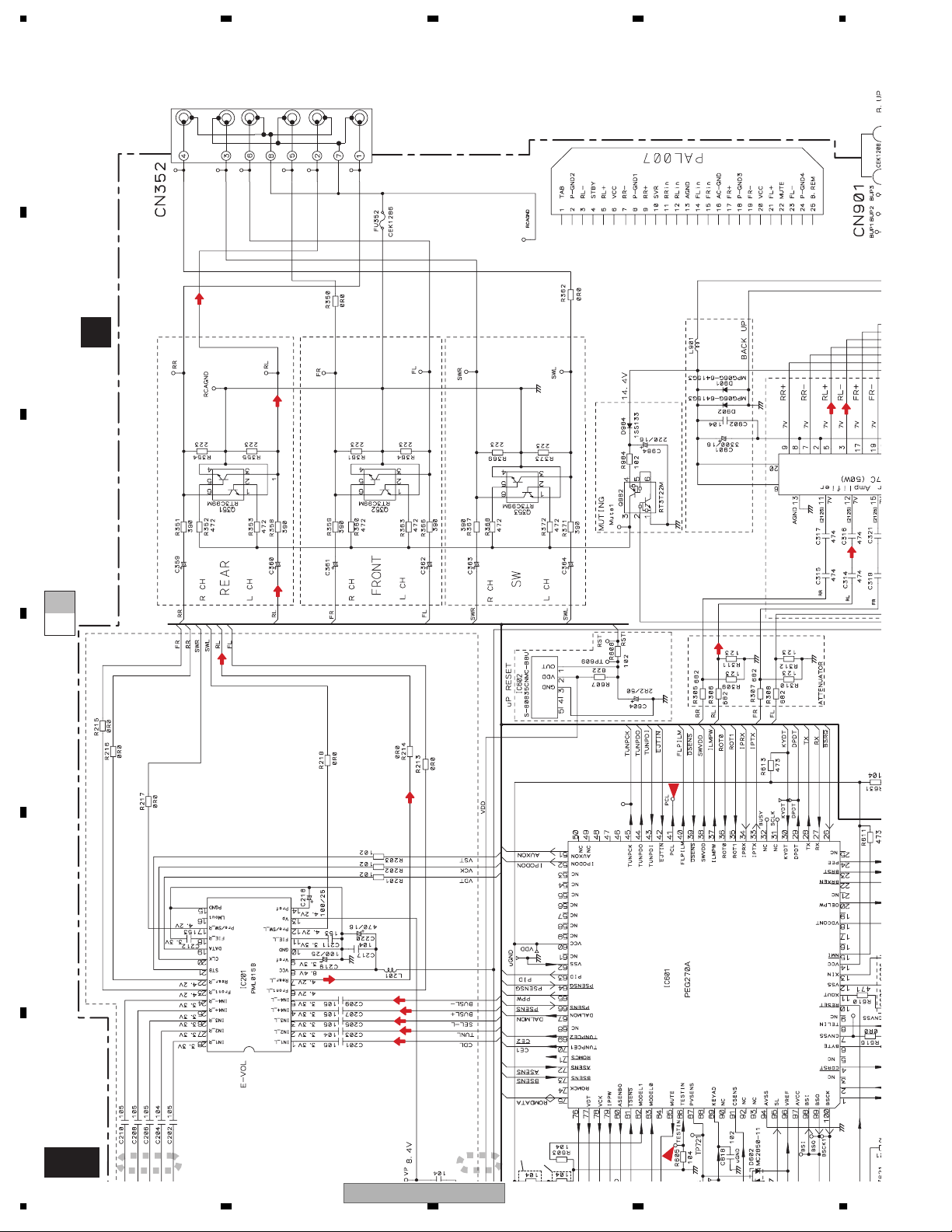

1234

REAR

L CH

R CH

3A

>

>

FRONT

FRONT

L CH

R CH

REAR

SUB

WOOFER

L CH

R CH

SUB

A

WOOFER

B

TUNER AMP UNIT

A

600uH

C

A-a A-b

100/25

100/25

100/25

100/25

100/25

100/25

D

E

F

A-b

20

FM,AM:-4.9 dBs

IPBUS:10.3 dBs

CD:10.1 dBs

AUX/IPOD:9.3 dBs

NCNCNC

PPOWER

NC

NC

NC

SYSTEM CONTROLLER

NC

NC

P4900IB

1

2

P490IB

DEH-P490IB/XN/UC

1234

5678

A

>

10A

FM,AM:21.1 dBs

IPBUS:36.3 dBs

CD:36.1 dBs

AUX/IPOD:35.3 dBs

B

C

The > mark found on some component parts indicates

the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of

identical designation.

A-a A-b

D

NC

NC

NC

E

DETACH

3

4

DEH-P490IB/XN/UC

56

F

5

7

8

A-b

21

A

B

A-b

1234

NC

NC

P4900IB

1

2

P490IB

IPBUS:2.2 dBs

C

A-bA-a

D

E

F

A-a

22

FM,AM(400 Hz,30 %) : -24 dBs

FM/AM TUNER UNIT

AUX/IPOD : 2.2 dBs

DEH-P490IB/XN/UC

1234

5678

A

3

4

5

A-b

B

PANEL UNIT

C

D

B

105

CN1901

For resistors and capacitors in the circuit diagrams, their resistance values or

capacitance values are expressed in codes:

Ex. *Resistors

Code Practical value

123 12k ohms

103 10k ohms

*Capacitors

A-bA-a

D

Code Practical value

103 0.01uF

101/10 100uF/10V

E

C

CN701

DEH-P490IB/XN/UC

56

CD:0 dBs

Symbol indicates a resistor.

No differentiation is made between chip resistors and

discrete resistors.

Symbol indicates a capacitor.

No differentiation is made between chip capacitors and

discrete capacitors.

NOTE :

A-a

7

8

D

F

23

Loading...

Loading...