Page 1

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2004

ORDER NO.

CRT3377

DEH-1750/XN/GS

HIGH POWER CD PLAYER WITH FM/AM TUNER

DEH-1750

DEH-1770

This service manual should be used together with the following manual(s):

Model No. Order No. Mech.Module Remarks

CX-3110 CRT3178 S10.1 CD Mech. Module:Circuit Description, Mech. Description, Disassembly

/XN/CS

/XN/GS

For details, refer to "Important Check Points for Good Servicing".

K-ZZW. OCT. 2004 printed in Japan

Page 2

1234

SAFETY INFORMATION

This service manual is intended for qualified service technicians; it is not meant for the casual do-it-yourselfer.

Qualified technicians have the necessary test equipment and tools, and have been trained to properly and safely

A

repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may void the warranty.

If you are not qualified to perform the repair of this product properly and safely, you should not risk trying to do so

and refer the repair to a qualified service technician.

- Service Precaution

1. You should conform to the regulations governing the product (safety, radio and noise, and other

B

regulations), and should keep the safety during servicing by following the safety instructions

described in this manual.

2. Before disassembling the unit, be sure to turn off the power. Unplugging and plugging the connectors

during power-on mode may damage the ICs inside the unit.

3. To protect the pickup unit from electrostatic discharge during servicing, take an appropriate treatment

(shorting-solder) by referring to "the DISASSEMBLY".

4. After replacing the pickup unit, be sure to check the grating.

C

D

E

F

2

1234

DEH-1750/XN/GS

Page 3

5678

[Important Check Points for Good Servicing]

In this manual, procedures that must be performed during repairs are marked with the below symbol.

Please be sure to confirm and follow these procedures.

1. Product safety

Please conform to product regulations (such as safety and radiation regulations), and maintain a safe servicing environment by

following the safety instructions described in this manual.

1 Use specified parts for repair.

Use genuine parts. Be sure to use important parts for safety.

2 Do not perform modifications without proper instructions.

Please follow the specified safety methods when modification(addition/change of parts) is required due to interferences such as

radio/TV interference and foreign noise.

3 Make sure the soldering of repaired locations is properly performed.

When you solder while repairing, please be sure that there are no cold solder and other debris.

Soldering should be finished with the proper quantity. (Refer to the example)

4 Make sure the screws are tightly fastened.

Please be sure that all screws are fastened, and that there are no loose screws.

5 Make sure each connectors are correctly inserted.

Please be sure that all connectors are inserted, and that there are no imperfect insertion.

6 Make sure the wiring cables are set to their original state.

Please replace the wiring and cables to the original state after repairs.

In addition, be sure that there are no pinched wires, etc.

7 Make sure screws and soldering scraps do not remain inside the product.

Please check that neither solder debris nor screws remain inside the product.

8 There should be no semi-broken wires, scratches, melting, etc. on the coating of the power cord.

Damaged power cords may lead to fire accidents, so please be sure that there are no damages.

If you find a damaged power cord, please exchange it with a suitable one.

9 There should be no spark traces or similar marks on the power plug.

When spark traces or similar marks are found on the power supply plug, please check the connection and advise on secure

connections and suitable usage. Please exchange the power cord if necessary.

0 Safe environment should be secured during servicing.

When you perform repairs, please pay attention to static electricity, furniture, household articles, etc. in order to prevent injuries.

Please pay attention to your surroundings and repair safely.

A

B

C

D

2. Adjustments

To keep the original performance of the products, optimum adjustments and confirmation of characteristics within specification.

Adjustments should be performed in accordance with the procedures/instructions described in this manual.

3. Lubricants, Glues, and Replacement parts

Use grease and adhesives that are equal to the specified substance.

Make sure the proper amount is applied.

4. Cleaning

For parts that require cleaning, such as optical pickups, tape deck heads, lenses and mirrors used in projection monitors, proper

cleaning should be performed to restore their performances.

5. Shipping mode and Shipping screws

To protect products from damages or failures during transit, the shipping mode should be set or the shipping screws should be

installed before shipment. Please be sure to follow this method especially if it is specified in this manual.

56

DEH-1750/XN/GS

E

F

7

8

3

Page 4

1234

CONTENTS

SAFETY INFORMATION..................................................................................................................................... 2

1. SPECIFICATIONS ............................................................................................................................................5

2. EXPLODED VIEWS AND PARTS LIST............................................................................................................8

A

B

C

2.1 PACKING................................................................................................................................................... 8

2.2 EXTERIOR............................................................................................................................................... 10

2.3 CD MECHANISM MODULE.....................................................................................................................12

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM..........................................................................................14

3.1 BLOCK DIAGRAM................................................................................................................................... 14

3.2 OVERALL CONNECTION DIAGRAM(GUIDE PAGE)..............................................................................16

3.3 KEYBOARD UNIT.................................................................................................................................... 22

3.4 CD MECHANISM MODULE.....................................................................................................................24

4. PCB CONNECTION DIAGRAM ..................................................................................................................... 28

4.1 TUNER AMP UNIT...................................................................................................................................28

4.2 KEYBOARD UNIT.................................................................................................................................... 32

4.3 CD CORE UNIT(S10) ..............................................................................................................................34

5. ELECTRICAL PARTS LIST ............................................................................................................................ 36

6. ADJUSTMENT ...............................................................................................................................................39

6.1 CD ADJUSTMENT................................................................................................................................... 39

6.2 CHECKING THE GRATING AFTER CHANGING THE PICKUP UNIT.................................................... 41

6.3 ERROR MODE ........................................................................................................................................43

6.4 SYSTEM MICROCOMPUTER TEST PROGRAM...................................................................................44

7. GENERAL INFORMATION.............................................................................................................................45

7.1 DIAGNOSIS............................................................................................................................................. 45

7.1.1 DISASSEMBLY .....................................................................................................................................45

7.1.2 CONNECTOR FUNCTION DESCRIPTION.......................................................................................... 48

7.2 PARTS......................................................................................................................................................49

7.2.1 IC ..........................................................................................................................................................49

7.2.2 DISPLAY............................................................................................................................................... 56

7.3 OPERATIONAL FLOW CHART ...............................................................................................................57

7.4 CLEANING............................................................................................................................................... 58

8. OPERATIONS ................................................................................................................................................ 59

D

E

F

4

1234

DEH-1750/XN/GS

Page 5

5678

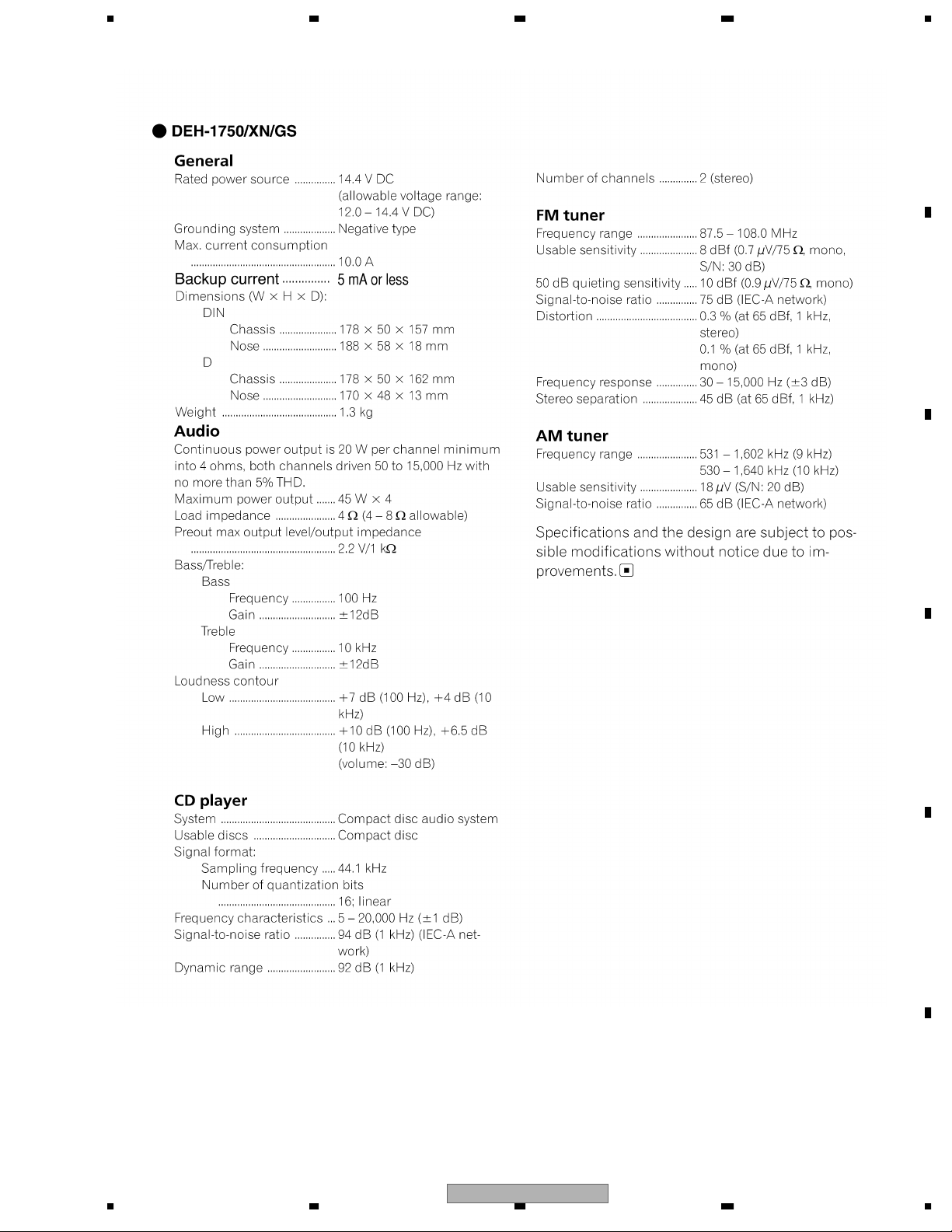

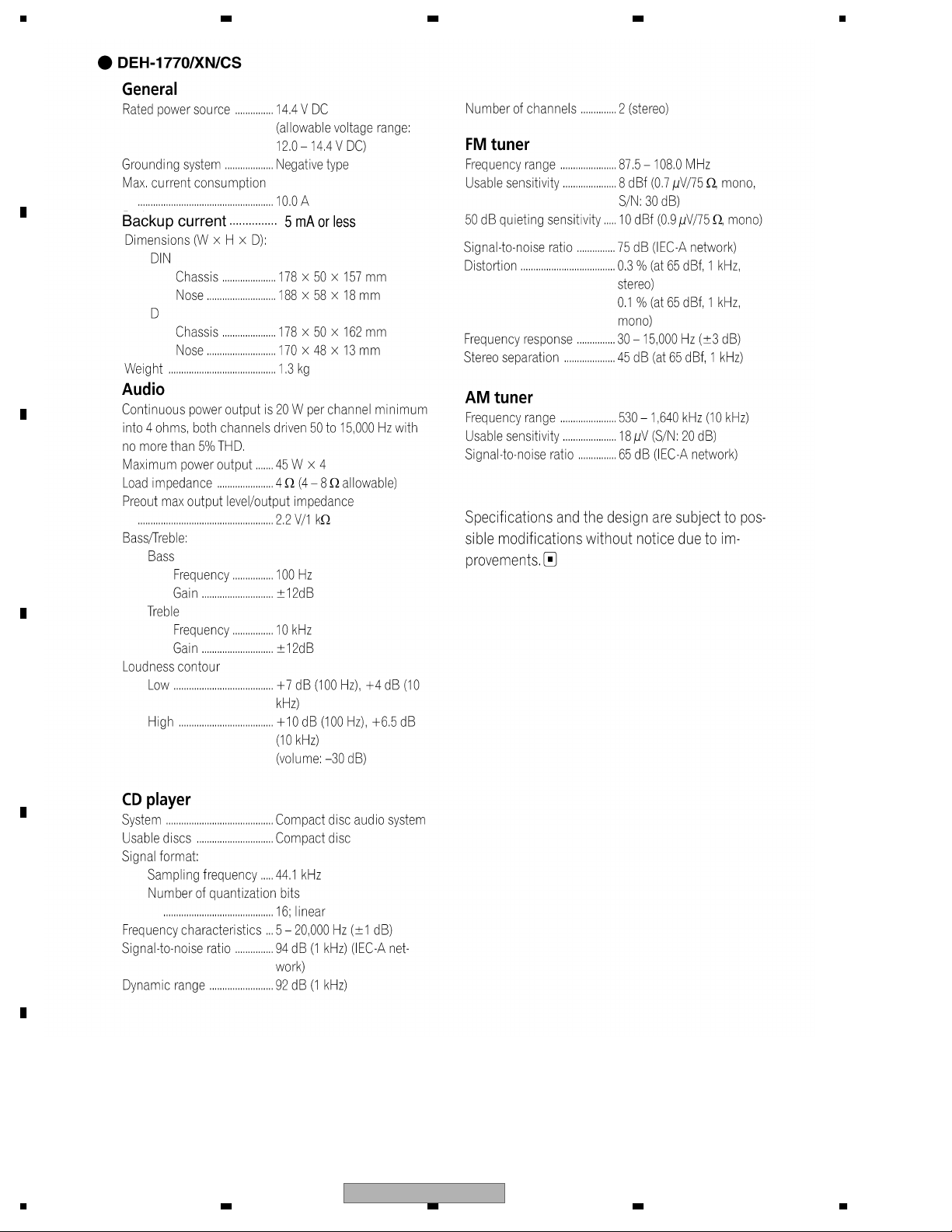

1. SPECIFICATIONS

A

B

C

D

E

56

DEH-1750/XN/GS

F

7

8

5

Page 6

1234

A

B

C

D

E

F

6

1234

DEH-1750/XN/GS

Page 7

5678

A

B

C

D

E

56

DEH-1750/XN/GS

F

7

8

7

Page 8

N

5

8

3

1234

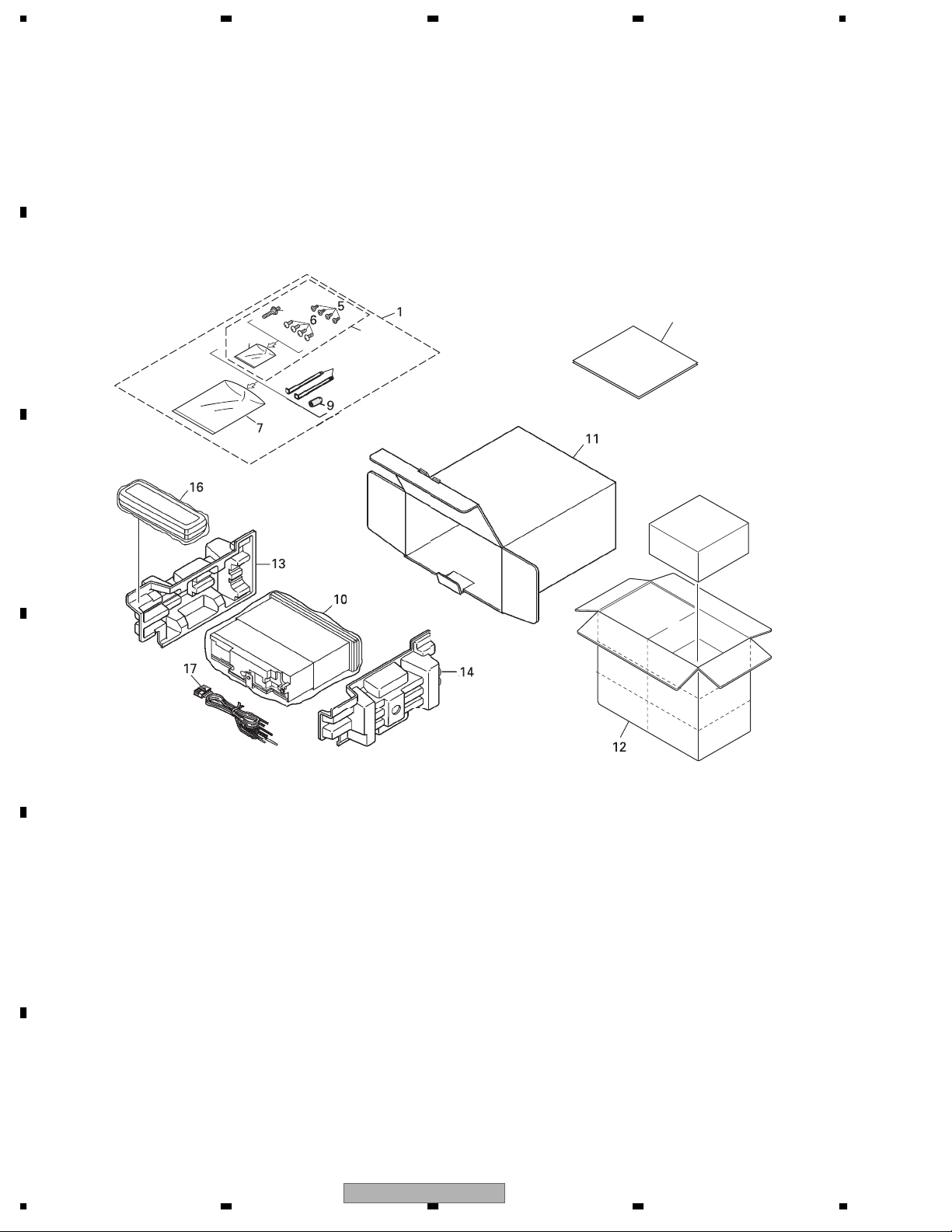

2. EXPLODED VIEWS AND PARTS LIST

OTES : • Parts marked by " * " are generally unavailable because they are not in our Master Spare Parts List.

• The > mark found on some component parts indicatesthe importance of the safety factor of the part.

A

Therefore, when replacing, be sure to use parts of identical designation.

• Screw adjacent to mark on the product are used for disassembly.

• For the applying amount of lobricants or glue, follow the instructions in this manual.

(In the case of no amount instructions,apply as you think it appropriate.)

2.1 PACKING

"

B

C

D

1

E

F

8

1234

DEH-1750/XN/GS

Page 9

5678

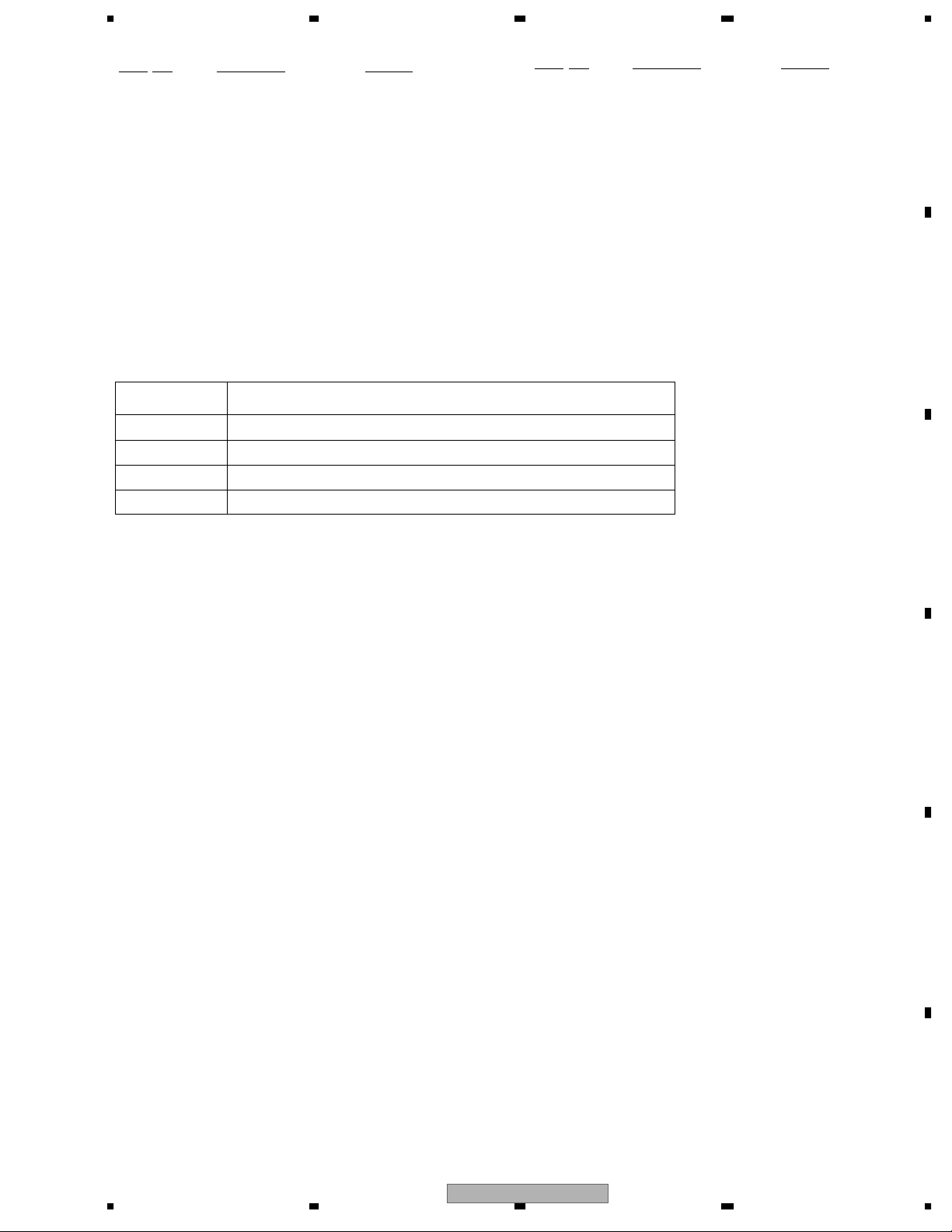

PACKING SECTION PARTS LIST

Mark No. Description Part No.

1 Accessory Assy CEA4850

2 Screw Assy CEA3849

3 Screw CBA1650

* 4 Polyethylene Bag CEG-127

5 Screw CRZ50P090FTC

6 Screw TRZ50P080FTC

* 7 Polyethylene Bag CEG-158

8 Handle CNC5395

9 Bush CNV3930

10 Polyethylene Bag CEG-162

11 Carton(DEH-1750) CHG5418

Carton(DEH-1770) CHG5419

Owner's Manual,Installation Manual

Part No. Language

CRD3910 English, Traditional Chinese, Arabic

CRD3911 English, Traditional Chinese, Arabic

CRD3912 English, Spanish, Portuguese(B)

CRD3913 English, Spanish, Portuguese(B)

Mark No. Description Part No.

12 Contain Box(DEH-1750) CHL5347

Contain Box(DEH-1770) CHL5348

13 Protector CHP2664

14 Protector CHP2868

15-1 Owner's Manual(DEH-1750) CRD3910

Owner's Manual(DEH-1770) CRD3912

15-2 Installation Manual(DEH-1750) CRD3911

Installation Manual(DEH-1770) CRD3913

15-3 Caution Card CRP1310

16 Case Assy CXB3520

17 Cord Assy XDE7008

A

B

C

D

E

F

56

DEH-1750/XN/GS

7

8

9

Page 10

1234

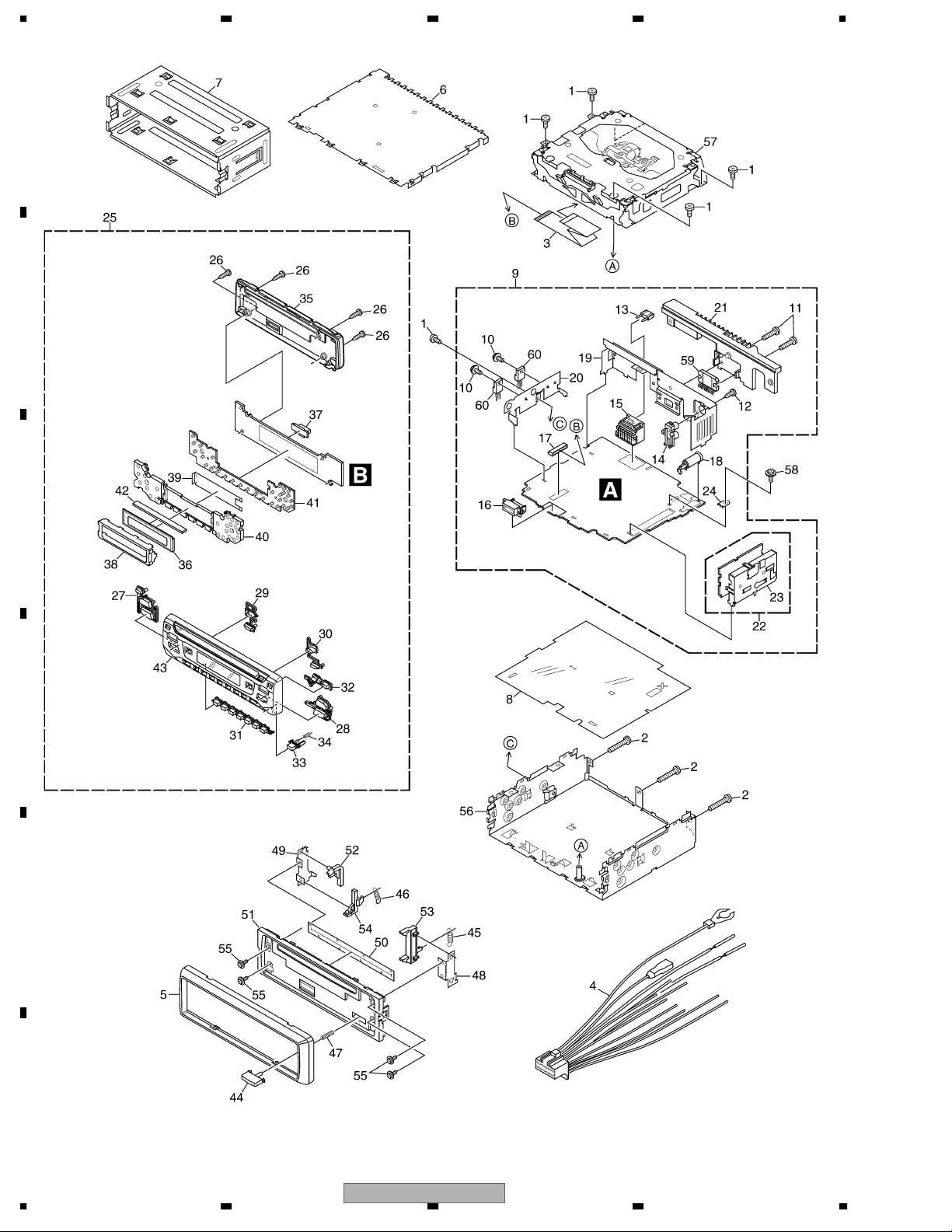

2.2 EXTERIOR

A

B

C

D

E

F

10

1234

DEH-1750/XN/GS

Page 11

5678

EXTERIOR SECTION PARTS LIST

Mark No. Description Part No.

1 Screw BSZ26P060FTC

2 Screw BSZ26P100FTC

3 Cable CDE7702

4 Cord Assy XDE7008

5 Panel CNS8048

6 Case CNB2793

7 Holder CNC8659

8 Insulator CNM9145

9 Tuner Amp Unit(DEH-1750) CWM9601

Tuner Amp Unit(DEH-1770) CWM9605

10 Screw ASZ26P060FTC

11 Screw BMZ26P160FTC

12 Screw BPZ26P080FTC

> 13 Fuse(10A) CEK1208

14 Pin Jack(CN352) CKB1059

15 Plug(CN901) CKM1376

16 Connector(CN831) CKS3581

17 Connector(CN651) CKS3835

18 Antenna Jack(CN401) CKX1056

19 Holder CND2413

20 Holder CND2414

21 Heat Sink CNR1762

22 FM/AM Tuner Unit CWE1912

23 Holder CND1054

24 Terminal(CN402) VNF1084

Mark No. Description Part No.

47 Spring CBH2367

48 Bracket CNC6791

49 Holder CNC8042

50 Cover CNM6276

51 Panel CNS8044

52 Arm CNV4692

53 Arm CNV4728

54 Arm CNV5576

55 Screw IMS20P030FZK

56 Chassis Unit CXC3600

57 CD Mechanism Module(S10) CXK5605

58 Screw ISS26P055FTC

59 IC(IC302) TDA7386

60 Transistor(Q921,991) 2SD2396

A

B

C

25 Detach Grille Assy(DEH-1750) CXC3538

Detach Grille Assy(DEH-1770) CXC3542

26 Screw BPZ20P100FZK

27 Button(VOLUME) CAC8924

28 Button(SELECT) CAC8925

29 Button(BTB,SRC) CAC8927

30 Button(LOUD,BAND) CAC8928

31 Button(1-6) CAC8929

32 Button(CD EJECT,AUDIO) CAC8930

33 Button(DETACH) CAC8931

34 Spring CBH2210

35 Cover CNS8042

36 LCD CAW1847

37 Connector(CN1801) CKS3580

38 Holder CND2412

39 Sheet CNM9144

40 Lighting Conductor CNV8190

41 Rubber CNV8191

42 Connector CNV8192

43 Grille Unit(DEH-1750) CXC3592

Grille Unit(DEH-1770) CXC3994

44 Button CAC4836

45 Spring CBH1835

46 Spring CBH2208

D

E

F

56

DEH-1750/XN/GS

7

8

11

Page 12

1234

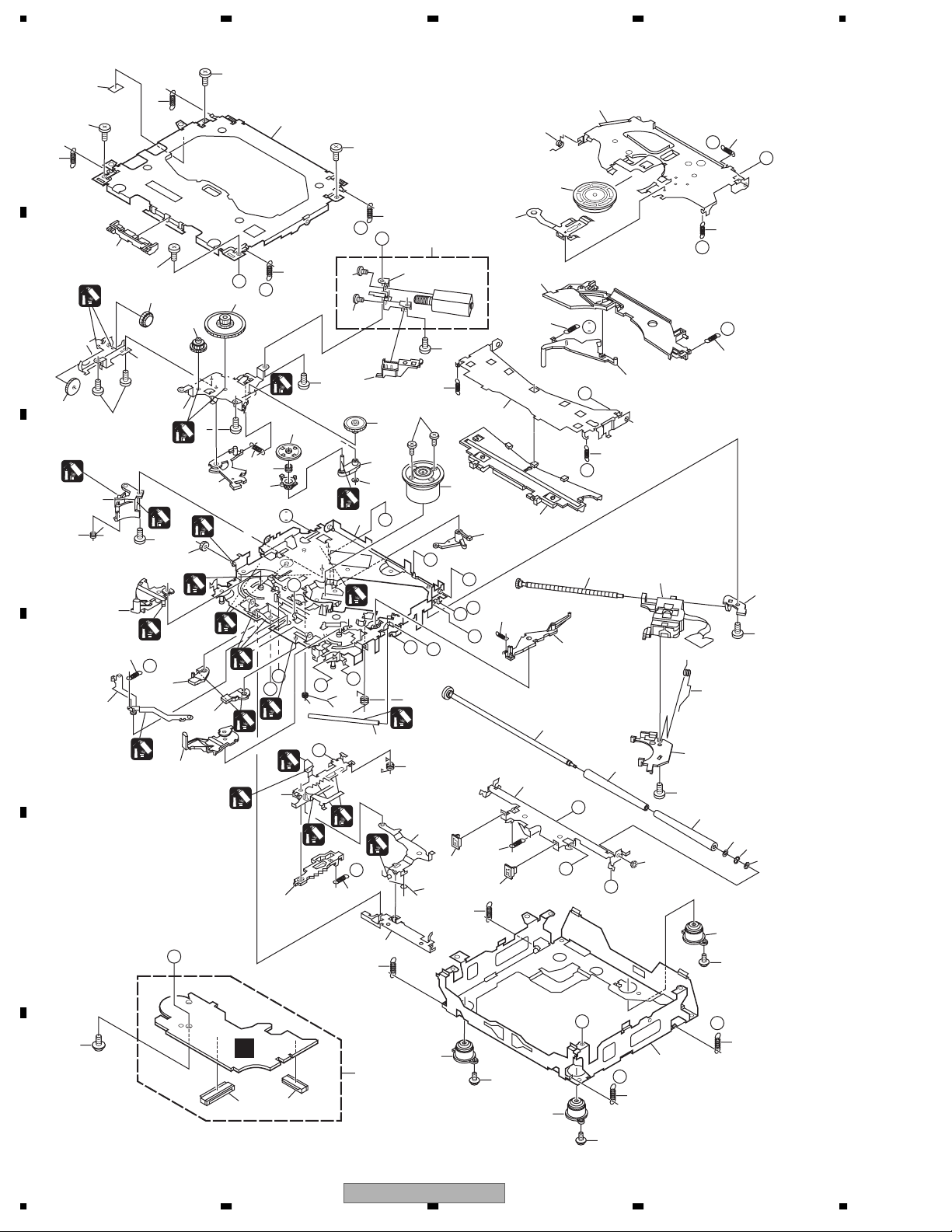

2.3 CD MECHANISM MODULE

42

A

5

13

13

5

81

34

5

15

22

E

F

93

13

A

44

B

5

B

1

54

53

C

52

13

D

86

86

82

83

4

37

71

4

29

51

1

73

50

72

10

1

I

76

B

55

5

36

4

1

18

2

64

47

C

24

2

1

7

61

2

M

1

23

87

75

E

63

57

62

58

1

G

L

1

N

R

1

1

2

1

40

56

D

O

16

P

1

33

1

P

19

J

12

3

20

39

1

69

30

2

21

M

D

79

2

1GEM1024

2GEM1045

3GEM1035

E

92

26

G

68

28

I

H

28

45

J

38

23

K

59

49

F

Q

A

27

H

77

90

48

8

67

17

78

25

70

60

80

N

L

K

43

46

6

60

11

89

10

14

74

R

31

41

85

C

91

F

C

65

1

2

3

85

66

35

O

31

Q

14

85

12

1234

DEH-1750/XN/GS

Page 13

5678

CD MECHANISM MODULE SECTION PARTS LIST

Mark No. Description Part No.

1 CD Core Unit(S10) CWX3110

2 Connector(CN101) CKS4182

3 Connector(CN701) CKS4188

4 Screw BMZ20P035FTC

5 Screw BSZ20P040FTC

6 Screw(M2x4) CBA1362

7 Screw(M2x3) CBA1824

8 Screw(M2x3) CBA1825

9 •••••

10 Washer CBF1038

11 Washer CBF1060

12 Spring CBH2390

13 Spring CBH2606

14 Spring CBH2607

15 Spring CBH2608

16 Spring CBH2609

17 Spring CBH2610

18 Spring CBH2735

19 Spring CBH2612

20 Spring CBH2613

21 Spring CBH2614

22 Spring CBH2615

23 Spring CBH2616

24 Spring CBH2617

25 Spring CBH2620

26 Spring CBH2621

27 Spring CBH2641

28 Spring CBH2642

29 Spring CBH2643

30 Spring CBH2659

31 Spring CBH2688

32 •••••

33 Shaft CLA4441

34 Frame CNC9962

35 Frame CNC9963

36 Bracket CND2712

37 Bracket CND1895

38 Arm CNC9968

39 Arm CND1909

40 Lever CND2032

41 Lever CNC9984

42 Sheet CNM8134

43 Collar CNV7798

44 Guide CNV7799

45 Arm CNV8403

Mark No. Description Part No.

50 Gear CNV8379

51 Gear CNV8380

52 Gear CNV8381

53 Gear CNV8382

54 Gear CNV8383

55 Gear CNV8384

56 Rack CNV8385

57 Arm CNV8386

58 Arm CNV8387

59 Guide CNV8388

60 Roller CNV7218

61 Gear CNV8389

62 Arm CNV8391

63 Arm CNV8390

64 Arm CNV8392

65 Damper CNV7313

66 Damper CNV7314

67 Arm CNV8394

68 Arm CNV8395

69 Guide CNV8396

70 Guide CNV8397

71 Holder CNV8398

72 Arm CNV8402

73 Gear CNV8400

74 Damper CNV7618

75 Motor Unit(M1) CXC4440

76 Chassis Unit CXC2318

77 Screw Unit CXB8729

78 Gear Unit CXC2397

79 Arm Unit CXC2316

80 Arm CND1896

81 Arm CND1894

82 Motor Unit(M2) CXB8933

83 Bracket CNC9985

84 •••••

85 Screw(M2x5) EBA1028

86 Screw JFZ20P020FTC

87 Screw JGZ17P022FTC

88 •••••

89 Washer YE20FTC

90 Pickup Unit(P10)(Service) CXX1641

91 Screw IMS26P030FTC

92 Spring CBL1635

93 Clamper CNV8372

A

B

C

D

E

46 Rack CNV8374

47 Holder CNV8376

48 Holder CNV8377

49 Arm CNV8378

56

DEH-1750/XN/GS

F

7

8

13

Page 14

Q

Q

Q

1234

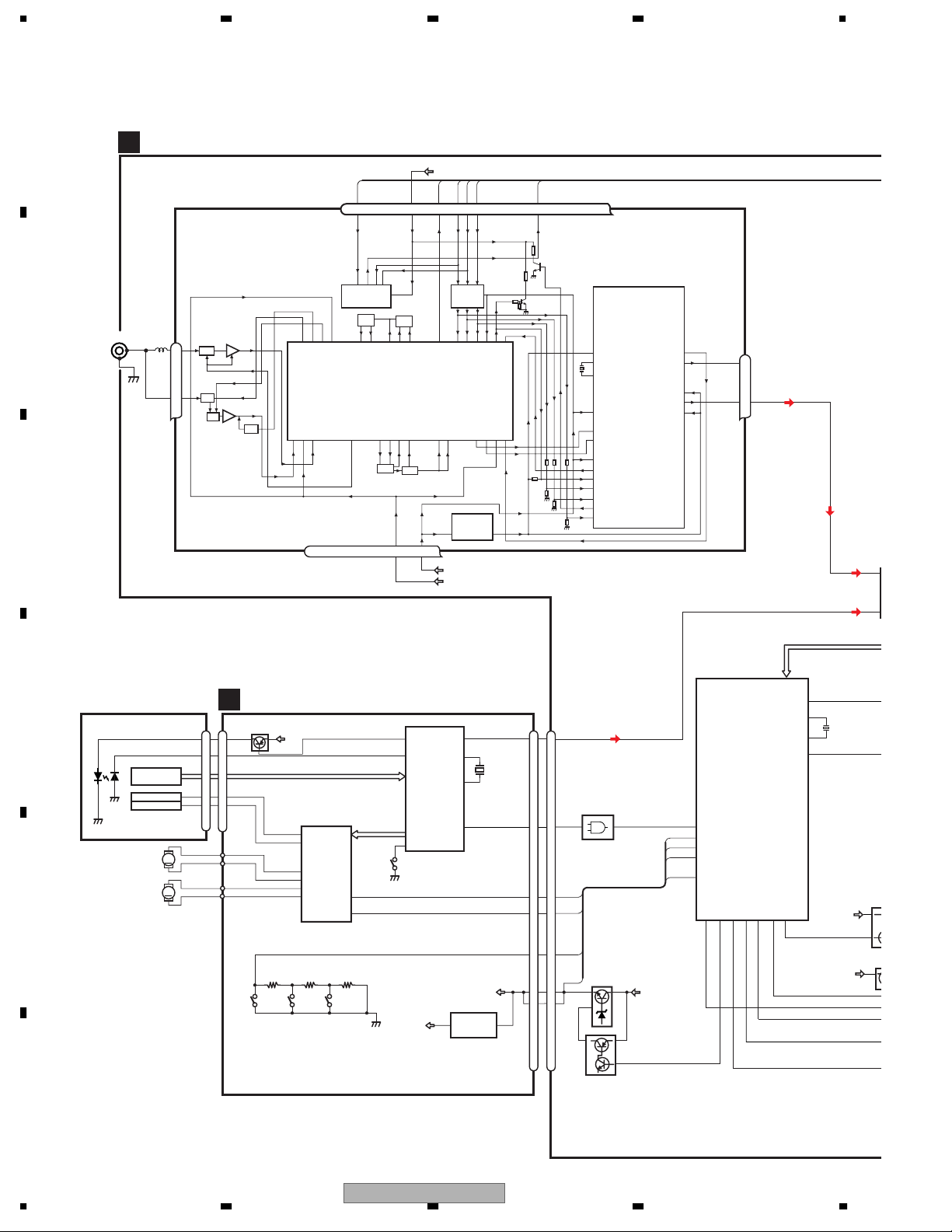

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM

3.1 BLOCK DIAGRAM

A

TUNER AMP UNIT

A

VDD

FM/AM TUNER UNIT

B

ANTENNA

CN401

1

2

1

3

AM ANT

FM ANT

ATT

ATT

ANT adj

FMRF

FMRF

RF adj

7 6 13 5 10 9 8 11 14 18 19 20 21

NC

CE2

ROM_VDD

IC 3 EEPROM

5.0V

OSC

LPF

IC 1

3.3V

MIXER, IF AMP

T51

CF52

C

RFGND

OSCGND

DGND

212 1522 16 4 17

AUDIOGNDNCVCC

VDD_3.3

3.3V

SL

TUN 3V

VCC

DI

IC 5

←

5V 3.3V

IC 4

3.3V 2.5V

CK

NC

CE1

←

2.5V

DO

NCNCNC

NC

DET, FM MPX,

RDS DECODER

Rch

IC 2

2.5V

24

Lch

23

TUN L

2

CD L

VST,VCK,VDT

3

PICKUP UNIT

D

(P10)(SERVICE)

LASER

DIODE

HOLOGRAM

UNIT

FOCUS ACT.

TRACKING ACT.

MONITOR

DIODE

SPINDLE

MOTOR

CARRIAGE

LOADING/

MOTOR

LD+

MD

FOP

TOP

M

M

E

CD CORE UNIT(S10)

C

D

CN101

Q101

14

5

FOP

1

TOP

4

12EJ 8EJ DSCSNS

3R3V

12

13

16

15

17

18

FOP

TOP

ACT,MOTOR

DRIVER

SOP

SOM

LCOM

LCOP

LOEJ

CONT

IC 301

BA5835FP

AC, F, E, BD

FD, TD, SD, MD

22

9

HOME

1

LD

2

PD

SERVO

CONTROL,

DSP,

LPF, DAC

IC 201

UPD63712AGC

42

LIMIT

3R3V

20

LOUT

23

xtal

X201

24

XTAL

12

SO

VD

3.3V REGULATOR

3

IC 701

CN701

LOUT

CONT

DSCSNS

1

LOEJ

CN651

8

14

SYSTEM CONTROLLER

XSI

LOEJ

CONT

DISCSENS

VDSENS

INTRQ

66

41

VDCONT

8

IC 601(2/2)

PE5449A

KYDT

DSENS

9

65

DPDT

21

XSI

16

5

7

6

VD

1

2

IC 652

24

6

TC7SET08FU

17

15

16

VDSENS

20

21

Q991

Q992

B.UP

16

29

28

79

78

swvdd

22

MUTE

SYSPW

ILMPW

48

70

X1

X601

69

X2

43

B.UP

VDD

NJM2885DL1-33

F

14

1234

DEH-1750/XN/GS

Page 15

5678

A

RESET

CE2

55

TUNPCE2

CE1

56

TUNPCE1

DO

11

TUNPDI

DI

12

TUNPDO

CK

13

TUNPCK

76

SL

1

S-80834CNY

60

reset

SYSTEM CONTROLLER

IC 601(1/2)

PE5449A

IC 961

2

DALMON

bsens

asens

ANTPW

VDD

RCA OUT

CN352

RL

VDD REGULATOR

VDD

32

64

63

49

Q911

BACKUP SENSE

Q931

ACC SENSE

Q912

B.UP

B.UP

ACC

B REMOTE

TPD1018F

IC 551

6

15

Q352

CN901

2

FUSE

16

10A

14

11

15 15

RL

B

16

14

11

BACK UP

ACC

B.REM

GND

C

TE

X1

X2

W

CD L

VST,VCK,VDT

48

70

69

43

TUN L

X601

B.UP

VDD

ELECTRONIC VOLUME/

SOURCE SELECTOR

2

IN1-L

IC 151

PML010A

3

IN2-L

CN831

Q821

ILM

7

Q822

Q801

SWVDD

5

SOURCE

66

DPDT

4

DSENS

KYDT

3

FL

RL

CN1801

7

5

4

88

KYDT

3

10

11

ILL

SW5V

SOURCE

DPDT

DSENS

MUTE

Q452

SOURCE

18

DPDT

20

KTDT

10

56

VDD

VLCD

LCD DRIVER/

KEY CONTROLLER

PD6340A

IC 1801

14

12

KEY DATA

POWER AMP

IC 302

FLIN

TDA7386

RLIN

STBYMUTE

22 4

SYS 8.4V REGULATOR

VCC

TUNER 3.3V REGULATOR

TUN 3V

Q921

IC 901

BA33BC0FP

6,20

FLFL+

RLRL+

Q923

B.UP

23

21

3

5

SYSPW

31

VCC

KEYBOARD UNIT

B

KEY MATRIX

LCD

B.UP

7

7

5

5

8

8

6

6

FLFL+

RL-

RL+

D

E

56

DEH-1750/XN/GS

F

7

8

15

Page 16

1234

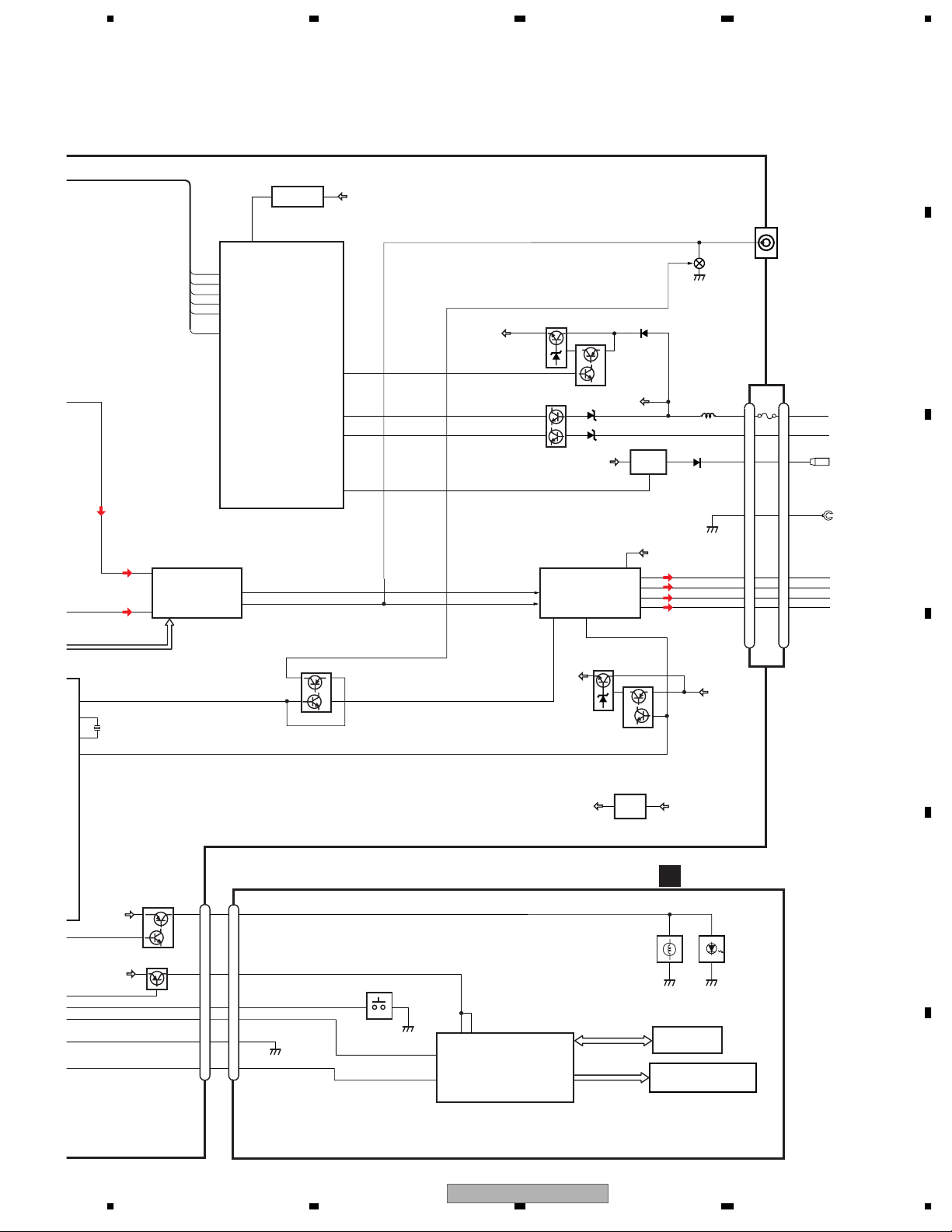

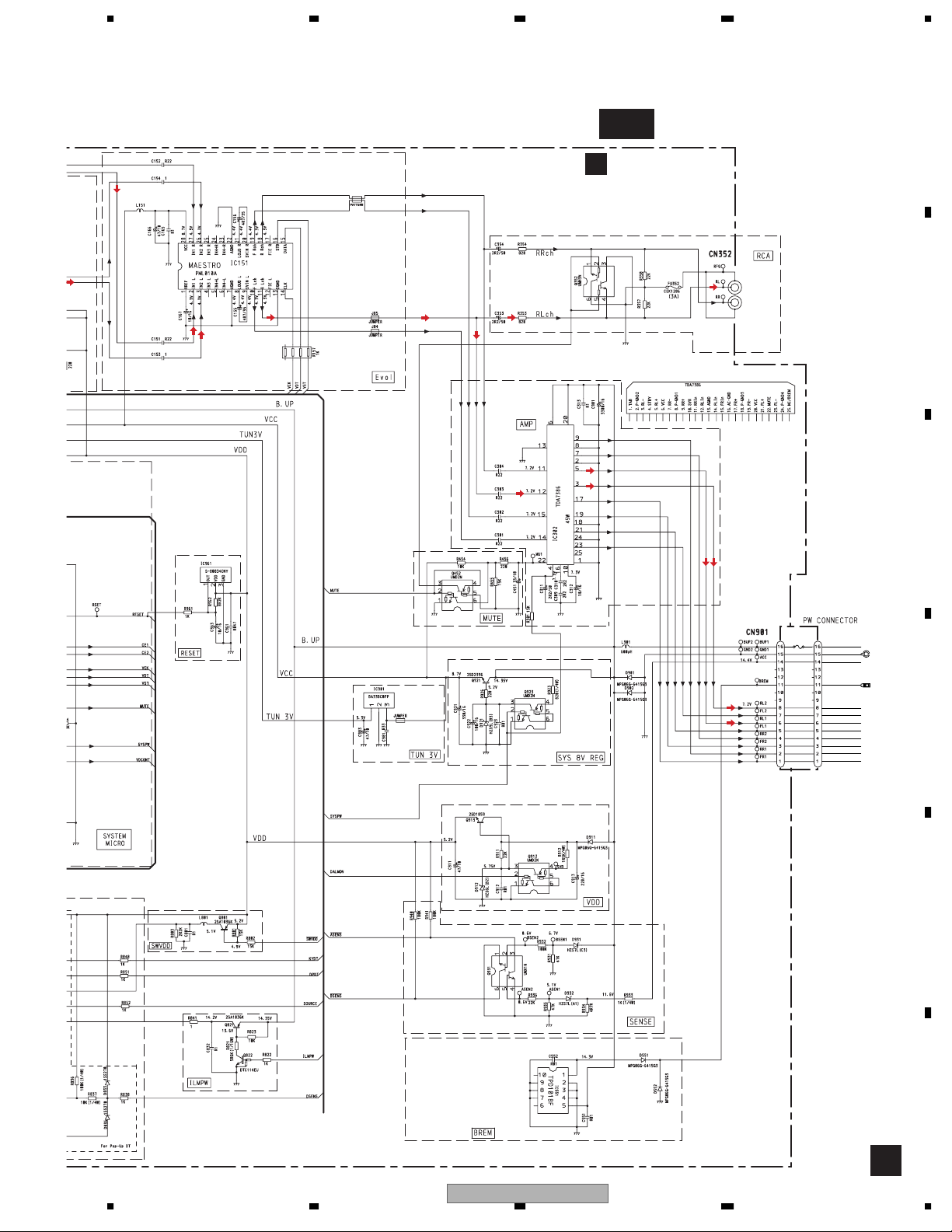

3.2 OVERALL CONNECTION DIAGRAM(GUIDE PAGE)

Note: When ordering service parts, be sure to refer to " EXPLODED VIEWS AND PARTS LIST" or

"ELECTRICAL PARTS LIST".

A

A-a

C

A-a A-b

A-a

A-b

Large size

SCH diagram

Guide page

CN701

A-b

Detailed page

CD:+0.4dBs

A-a

B

FM:-20.4dBs

AM:-31.3dBs

C

D

ANTENNA

E

NOTE :

Symbol indicates a resistor.

No differentiation is made between chip resistors and

discrete resistors.

Symbol indicates a capacitor.

No differentiation is made between chip capacitors and

discrete capacitors.

The > mark found on some component parts indicates

the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of

identical designation.

Decimal points for resistor

and capacitor fixed values

are expressed as :

←

2.2 2R2

←

0.022 R022

B

CN1801

F

16

A

DEH-1750/XN/GS

1234

Page 17

4

5678

A

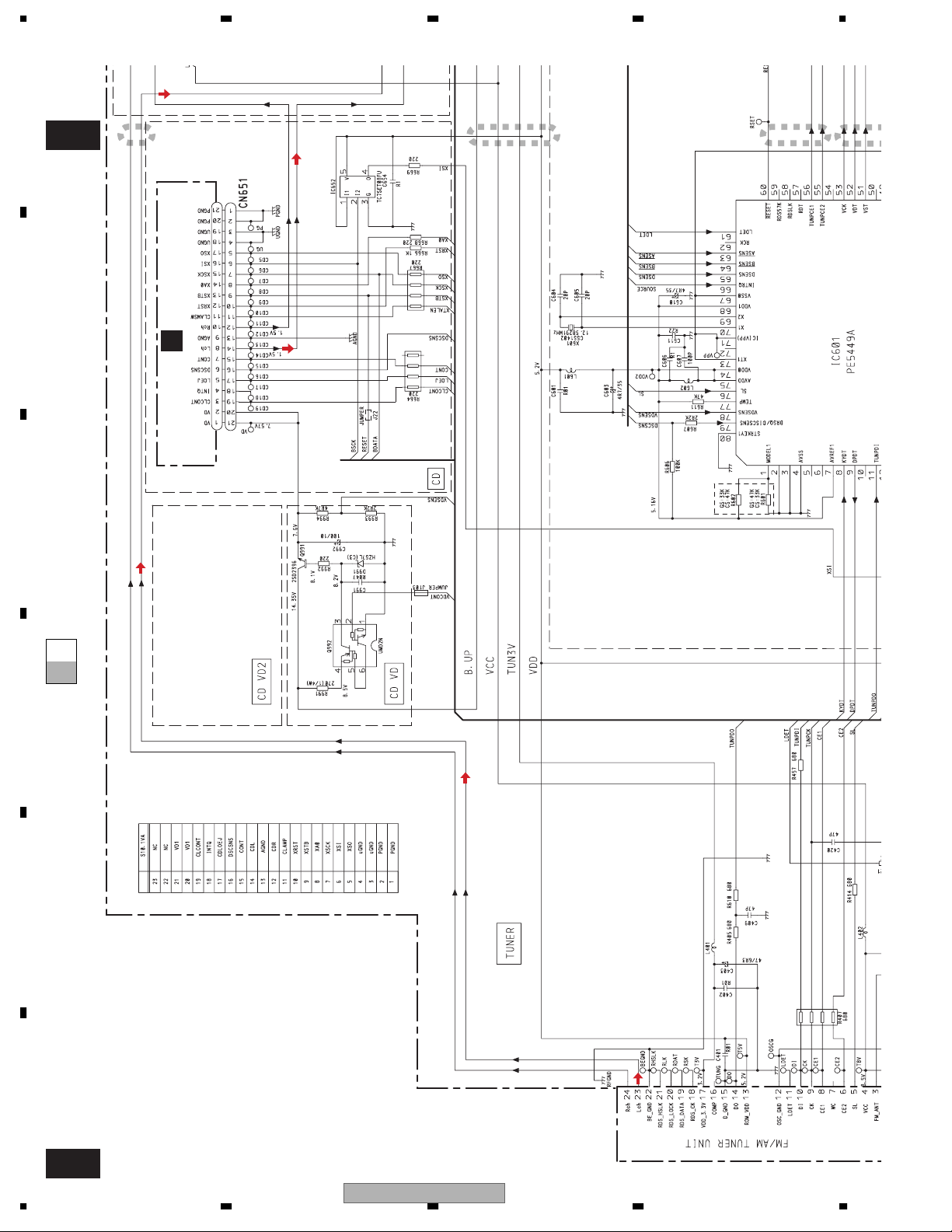

A-b

TUNER AMP UNIT

A

dBs

FM: +2.8dBs

AM: -8.1dBs

CD:+10.6dBs

>

REAR L

REAR R

FM:+2.0dBs

AM: -8.9dBs

CD:+9.8dBs

B

C

>

CEK1208

10A

BACKUP

GND

ACC

B.REM

RL–

FM:+29.3dBs

AM:+18.4dBs

CD:+36.6dBs

FL–

RL+

FL+

RR–

FR–

RR+

FR+

D

56

DEH-1750/XN/GS

E

F

A

7

8

17

Page 18

A

A-b

1234

1

CD:+0.4dBs

2 3 4

B

CN701

C

C

A-b

A-a

A-a

D

E

F

A-a

18

FM:-20.4dBs

AM:-31.3dBs

1234

DEH-1750/XN/GS

Page 19

5678

3 4 5

A

6

A-b

B

B

CN1801

←

←

Decimal points for resistor

and capacitor fixed values

are expressed as :

2.2 2R2

0.022 R022

A-b

A-a

A-a

C

D

E

Symbol indicates a resistor.

No differentiation is made between chip resistors and

discrete resistors.

Symbol indicates a capacitor.

No differentiation is made between chip capacitors and

discrete capacitors.

NOTE :

ANTENNA

DEH-1750/XN/GS

56

The > mark found on some component parts indicates

the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of

identical designation.

A-a

7

8

F

19

Page 20

1234

GND

ACC

B.REM

>

BACKUP

10A

CEK1208

A

FM:+2.0dBs

CD:+9.8dBs

AM: -8.9dBs

REAR L

REAR R

B

>

TUNER AMP UNIT

A

C

A-b

A-a

FM: +2.8dBs

CD:+10.6dBs

D

E

AM: -8.1dBs

F

A-b

20

1

Bs

2 3 4

DEH-1750/XN/GS

1234

Page 21

>

BACKUP

10A

CEK1208

5678

FR–

FL–

RL+

B.REM

RL–

GND

ACC

FR+

FL+

RR+

RR–

A

FM:+29.3dBs

CD:+36.6dBs

AM:+18.4dBs

B

A-b

A-a

C

D

E

3 4 5

56

DEH-1750/XN/GS

F

6

7

8

A-b

21

Page 22

1234

3.3 KEYBOARD UNIT

A

B

C

D

E

F

B

22

1234

DEH-1750/XN/GS

Page 23

5678

A

KEYBOARD UNIT

B

B

A

CN831

CEL1651 (GREEN)

CEL1651 (GREEN)

CL-490S-WF-SD

D1803-D1809 : SML-310PT

C

D

E

56

DEH-1750/XN/GS

F

B

7

8

23

Page 24

1234

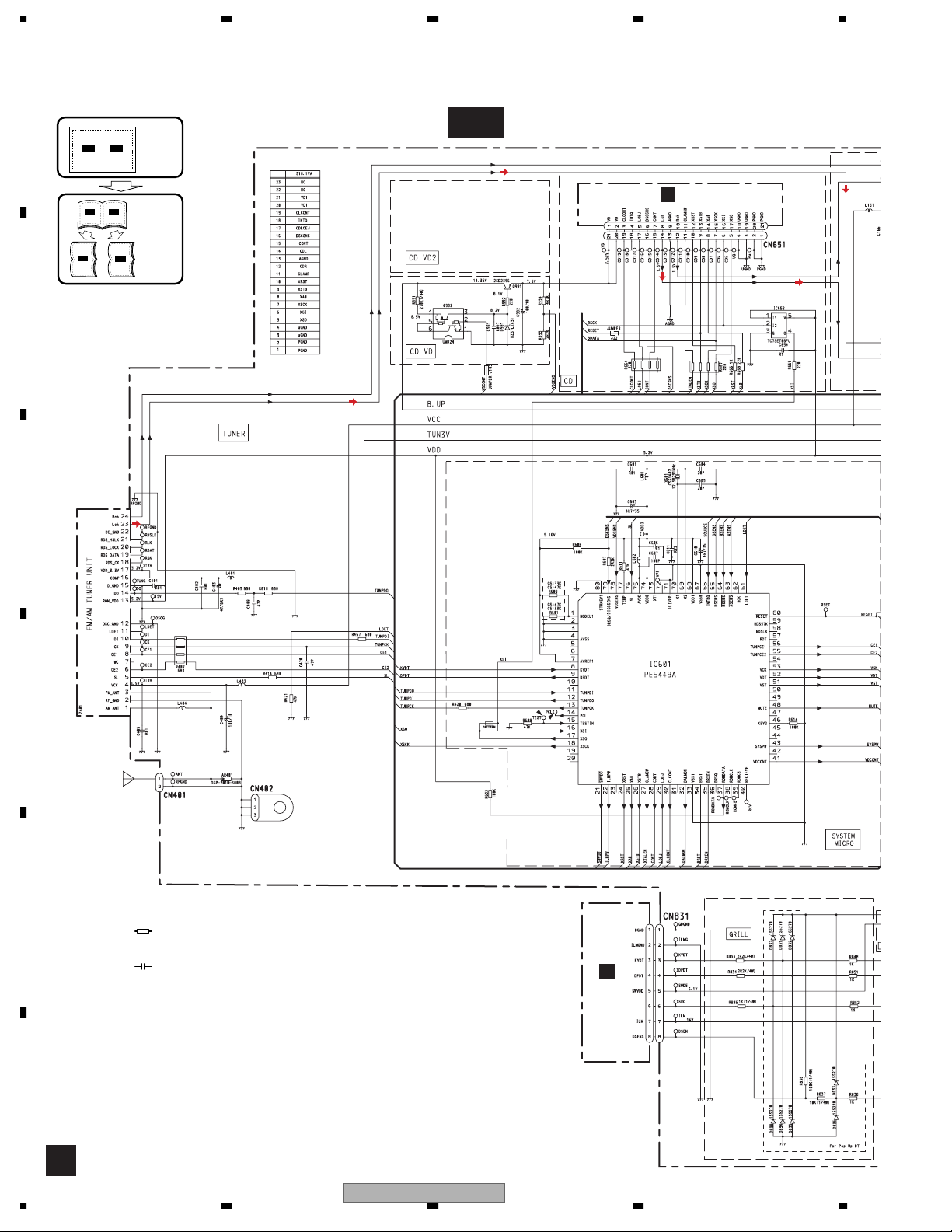

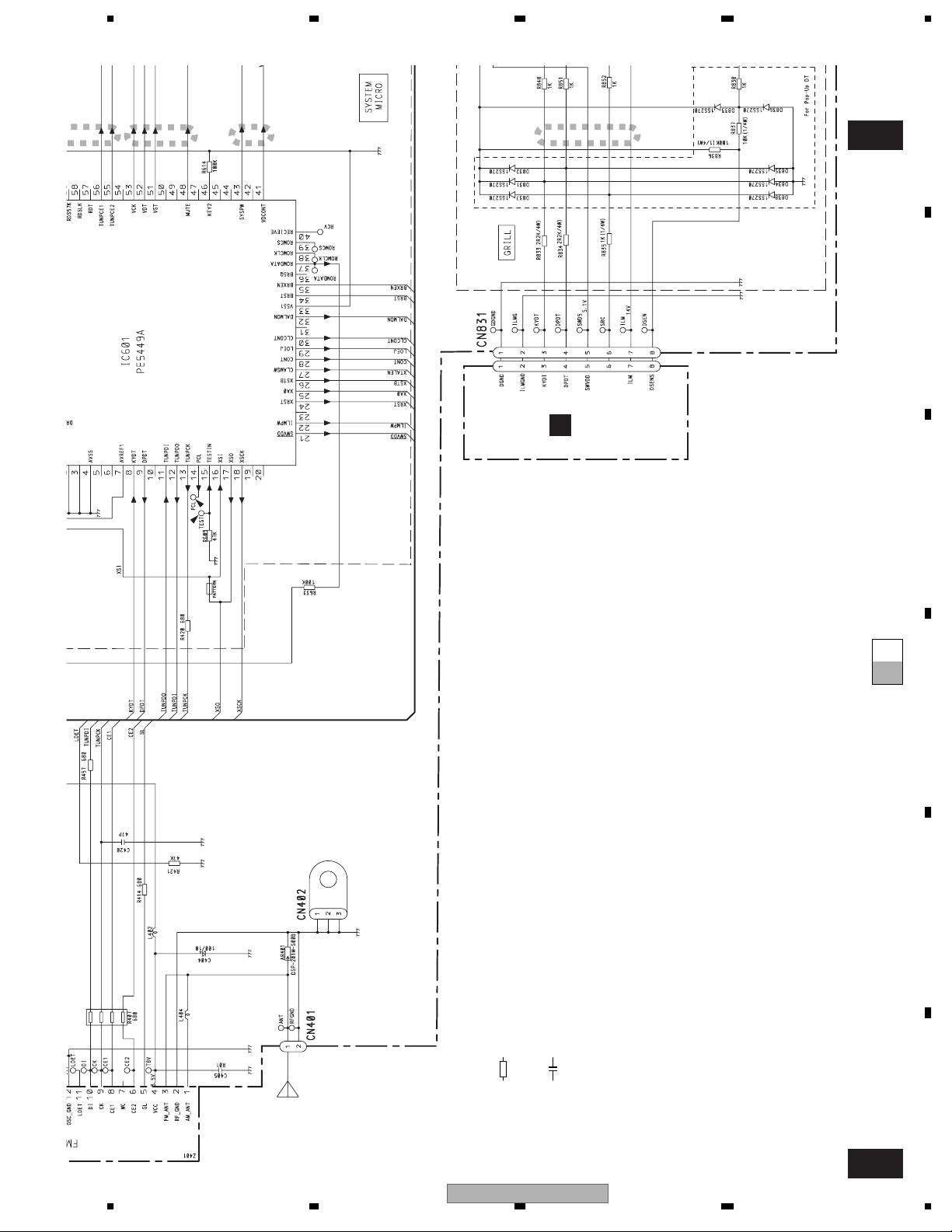

3.4 CD MECHANISM MODULE

A

PICKUP UNIT(P10)(SERVICE)

#

B

F

T

T

F F

T

T

F

F

F

T

T

F

T

T

F

F

F

T

T

!

C

0

1

9

D

MOTOR DRIVER

8

T

7

F

C

M1

CXC4440

SPINDLE MOTOR

E

M2

CXB8933

LOADING/CARRIAGE

MOTOR

S

S

C

C

3.3V

REGULATOR

F

F

T

T

@

S

5

6

3

C

C

S

S

F

24

C

DEH-1750/XN/GS

1234

Page 25

5678

A

F

T

C

S

SWITCHES:

CD CORE UNIT(S10)

S901:HOME SWITCH..........ON-OFF

S903:DSCSNS SWITCH......ON-OFF

S904:12EJ SWITCH.............ON-OFF

S905:8EJ SWITCH...............ON-OFF

The underlined indicates the switch position.

B

@

9

RF AMP / SERVO / DSP

DAC / LPF

4

SIGNAL LINE

F

FOCUS SERVO LINE

T

TRACKING SERVO LINE

C

CARRIAGE SERVO LINE

S

SPINDLE SERVO LINE

CD CORE UNIT(S10)

C

2

A

CN651

7.5V

7.5V

C

D

5

6

E

3

$

%

C

C

F

C

56

DEH-1750/XN/GS

7

8

25

Page 26

1234

- Waveforms Note : 1. The encircled numbers denote measuring points in the circuit diagram.

2. Reference voltage REFO1(1.65V)

1 DSCSNS

A

2 CLCONT

3 LOEJ

4 VD

When loading a 12cm CD

5V/div

5V/div

5V/div

10V/div

500ms/div

1 DSCSNS

2 CLCONT

3 LOEJ

4 VD

When loading an 8cm CD

5V/div

5V/div

5V/div

10V/div

500ms/div

5 SIN

6 CIN

7 TIN

When setting up after loading a 12cm CD-DA

disc

1V/div

500mV/div

500mV/div

2s/div

Ref.:

GND

Mode:

Normal

B

8 FIN

9 RFOK

5 SIN

200mV/div

2V/div

2V/div

500ms/div

Ref.:

GND

Mode:

Normal

0 TE

! FE

500mV/div

500mV/div

200ms/div

Ref.:

REFO

Mode:

Normal

! FE

8 FIN

0 TE

7 TIN

When setting up "Source On"(12cm CD-DA) During "Play"(CD-DA)

Ref.:

REFO

C

Mode:

Normal

@ MDX

5 SIN

500mV/div

1V/div

5ms/div

When setting up "Source On"

Ref.:

REFO

Mode:

Normal

@ MDX

5 SIN

500mV/div

1V/div

5µs/div

Ref.:

REFO

Mode:

Normal

# RFAGC 500mV/div 0.5µs/div

500mV/div

500mV/div

500mV/div

500mV/div

20ms/div

Spindle waveform during "Play"

D

Ref.:

REFO

Mode:

Normal

8 FIN

! FE

E

Focus Search

Ref.:

REFO

Mode:

TEST

F

500mV/div

500mV/div

200ms/div

Spindle waveform during "Play"(Magnified) RF eye pattern

Ref.:

REFO

Mode:

Normal

0 TE

# RFAGC

500mV/div

500mV/div

2ms/div

Ref.:

REFO

Mode:

Normal

# RFAGC

0 TE

7 TIN

When "Tracking Open" 1 Track Jump

Ref.:

REFO

Mode:

TEST

Ref.:

REFO

Mode:

TEST

1V/div

500mV/div

500mV/div

500µs/div

26

1234

DEH-1750/XN/GS

Page 27

5678

# RFAGC

0 TE

7 TIN

32 Track Jump

Ref.:

REFO

Mode:

TEST

# RFAGC

0 TE

6 CIN

5 SIN

When reproducing scratch(1mm)

Ref.:

REFO

Mode:

Normal

1V/div

500mV/div

500mV/div

1V/div

1V/div

500mV/div

2V/div

500ms/div

500µs/div

# RFAGC

0 TE

7 TIN

1V/div

500mV/div

500mV/div

5ms/div

# RFAGC

7 TIN

0 TE

8 FIN

100(32x3) Track Jump When reproducing black dots(1mm)

Ref.:

REFO

Mode:

TEST

# RFAGC

0 TE

6 CIN

5 SIN

When reproducing fingerprint(65µm)

Ref.:

REFO

Mode:

Normal

1V/div

1V/div

500mV/div

2V/div

5ms/div

Ref.:

REFO

Mode:

Normal

# RFAGC

0 TE

6 CIN

5 SIN

During inside/outside search

(outer circumference → inner circumference)

Ref.:

REFO

Mode:

Normal

1V/div

1V/div

1V/div

1V/div

1V/div

1V/div

500mV/div

2V/div

500µs/div

500µs/div

A

B

C

$ LOUT

% ROUT

Analog Audio

Ref.:

AGND

Mode:

Normal

1V/div

1V/div

200µs/div

1 DSCSNS

2 CLCONT

3 LOEJ

When "Eject"(12cm CD) When "Eject"(8cm CD)

Ref.:

GND

Mode:

Normal

5V/div

5V/div

5V/div

200ms/div

1 DSCSNS

2 CLCONT

3 LOEJ

Ref.:

GND

Mode:

Normal

5V/div

5V/div

5V/div

200ms/div

D

E

56

DEH-1750/XN/GS

F

7

8

27

Page 28

1234

4. PCB CONNECTION DIAGRAM

4.1 TUNER AMP UNIT

A

B

C

NOTE FOR PCB DIAGRAMS

1.The parts mounted on this PCB

include all necessary parts for

several destination.

For further information for

respective destinations, be sure

to check with the schematic dia gram.

2.Viewpoint of PCB diagrams

Connector

P.C.Board

Capacitor

Chip Part

SIDE A

SIDE B

TUNER AMP UNIT

A

Cord Assy

D

E

F

C

CN701

B

CN1801

28

A

DEH-1750/XN/GS

1234

Page 29

5678

RCA

ANTENNA

2

1

SIDE A

A

B

C

B

CN1801

FRONT

FM/AM TUNER UNIT

D

E

F

56

DEH-1750/XN/GS

A

7

8

29

Page 30

1234

A

TUNER AMP UNIT

A

B

1

C

D

E

F

A

30

1234

DEH-1750/XN/GS

Page 31

5678

SIDE B

A

B

C

D

E

F

56

DEH-1750/XN/GS

A

7

8

31

Page 32

1234

4.2 KEYBOARD UNIT

KEYBOARD UNIT

B

A

AUDIO

RIGHT

EJECT

B

C

LEFT

LOUD

LOC BAND

SIDE A

456

D

VOL+

BTB

VOL-

E

3

SRC 1 2

CLK

F

B

32

1234

DEH-1750/XN/GS

Page 33

5678

KEYBOARD UNIT

B

SIDE B

A

B

C

A

CN831

D

E

F

56

DEH-1750/XN/GS

B

7

8

33

Page 34

1234

4.3 CD CORE UNIT(S10)

CD CORE UNIT(S10)

C

A

M2

B

C

LOADING

/CARRIAGE

MOTOR

M1

SPINDLE

MOTOR

SIDE A

A

CN651

D

PICKUP UNIT(P10)(SERVICE)

E

HOME

REFO1

F

E

F

C

34

1234

DEH-1750/XN/GS

Page 35

5678

CD CORE UNIT(S10)

C

DSCSNS

8EJ

SIDE B

A

12EJ

B

C

321

D

E

56

DEH-1750/XN/GS

F

C

7

8

35

Page 36

1234

5. ELECTRICAL PARTS LIST

NOTE:

A

• Parts whose parts numbers are omitted are subject to being not supplied.

• The part numbers shown below indicate chip components.

Chip Resistor

RS1/_S___J,RS1/__S___J

Chip Capacitor (except for CQS.....)

CKS....., CCS....., CSZS.....

• The > mark found on some component parts indicatesthe importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

B

Circuit Symbol and No. Part No.

A

Unit Number:CWM9601(DEH-1750)

Unit Number:CWM9605(DEH-1770)

Unit Name:Tuner Amp Unit

MISCELLANEOUS

IC 151 (B,134,85) IC PML010A

IC 302 (A,95,135) IC TDA7386

C

IC 551 (B,62,118) IC TPD1018F

IC 601 (B,88,62) IC PE5449A

IC 652 (B,113,45) IC TC7SET08FU

IC 901 (B,144,29) IC BA33BC0FP

IC 961 (A,59,81) IC S-80834CNY

Q 352 (B,162,129) Transistor UMH3N

Q 452 (B,140,128) Transistor UMD2N

Q 801 (B,84,26) Transistor 2SA1036K

Q 821 (B,43,16) Transistor 2SA1036K

Q 822 (B,32,18) Transistor DTC114EU

D

Q 912 (B,15,145) Transistor UMD2N

Q 913 (A,16,111) Transistor 2SD1859

Q 921 (A,9,104) Transistor 2SD2396

Q 923 (B,26,79) Transistor UMD2N

Q 931 (B,62,107) Transistor UMX1N

Q 991 (A,9,69) Transistor 2SD2396

Q 992 (B,23,58) Transistor UMD2N

D 551 (A,63,126) Diode MPG06G-6415G3

D 552 (A,60,126) Diode MPG06G-6415G3

D 831 (A,110,21) Diode 1SS270

D 832 (A,113,21) Diode 1SS270

E

D 833 (A,118,21) Diode 1SS270

D 834 (A,110,13) Diode 1SS270

D 835 (A,113,13) Diode 1SS270

D 836 (A,118,13) Diode 1SS270

D 837 (A,115,21) Diode 1SS270

D 838 (A,115,13) Diode 1SS270

D 901 (A,36,132) Diode MPG06G-6415G3

D 902 (A,36,129) Diode MPG06G-6415G3

D 911 (A,20,107) Diode MPG06G-6415G3

D 912 (A,15,129) Diode HZS6L(B2)

D 921 (A,25,88) Diode HZS9L(B3)

F

D 931 (A,70,116) Diode HZS7L(C3)

D 932 (A,53,113) Diode HZS7L(A1)

D 991 (A,21,66) Diode HZS7L(C3)

Circuit Symbol and No. Part No.

L 151 (A,146,70) Inductor LAU2R2K

L 401 (A,158,58) Inductor LAU2R2K

L 402 (A,147,95) Inductor LAU2R2K

L 404 (B,161,101) Inductor LCTAW4R7J2520

L 601 (A,94,85) Ferri-Inductor LAU100K

L 602 (A,105,67) Inductor LAU2R2K

L 801 (A,94,25) Inductor LAU2R2K

L 901 (A,37,108) Choke Coil 600µH CTH1280

X 601

FU352 (B,144,135) Fuse 3A CEK1286

AR401 (A,162,110) Surge Protector DSP-201M-S00B

>

(A,104,72) Radiator 12.58291MHz

Fuse 10A CEK1208

FM/AM T uner Unit CWE1912

CSS1402

RESISTORS

R 157 (B,128,98) RAB4C102J

R 301 (B,94,104) RS1/16S153J

R 353 (B,146,128) RS1/16S821J

R 354 (B,165,128) RS1/16S821J

R 357 (B,146,133) RS1/16S223J

R 358 (B,166,135) RS1/16S223J

R 405 (B,157,63) RS1/16S681J

R 407 (B,161,88) RAB4C681J

R 414 (B,161,91) RS1/16S681J

R 420 (B,100,48) RS1/16S681J

R 421 (B,161,80) RS1/16S473J

R 454 (B,137,127) RS1/16S103J

R 455 (B,141,131) RS1/16S153J

R 456 (B,141,133) RS1/16S221J

R 457 (B,100,50) RS1/16S681J

R 601 (B,102,58) (DEH-1750) RS1/16S473J

(DEH-1770) RS1/16S333J

R 602 (B,109,56) (DEH-1750) RS1/16S333J

(DEH-1770) RS1/16S473J

R 606 (B,112,62) RS1/16S104J

R 607 (B,106,63) RS1/16S222J

R 609 (B,104,44) RS1/16S473J

R 610 (B,100,52) RS1/16S681J

R 611 (B,113,74) RS1/16S473J

R 614 (B,73,67) RS1/16S104J

R 633 (B,54,74) RS1/16S104J

R 664 (B,77,52) RAB4C221J

R 666 (A,84,44) RD1/4PU102J

R 667 (B,77,47) RAB4C221J

R 668 (A,81,44) RD1/4PU221J

R 669 (B,101,43) RS1/16S221J

>

36

1234

DEH-1750/XN/GS

Page 37

5678

Circuit Symbol and No. Part No.

R 801 (B,81,26) RS1/16S153J

R 802 (B,85,29) RS1/16S153J

R 803 (B,97,22) RS1/16S222J

R 821 (B,36,18) RS1/16S562J

R 822 (B,71,22) RS1/16S102J

R 823 (B,39,15) RS1/16S103J

R 833 (A,81,11) RD1/4PU222J

R 834 (A,84,11) RD1/4PU222J

R 835 (A,72,19) RD1/4PU102J

R 836 (A,78,22) RD1/4PU104J

R 837 (A,81,19) RD1/4PU103J

R 838 (B,91,89) RS1/16S102J

R 841 (B,50,15) RS1/16S1R0J

R 848 (A,107,48) RD1/4PU102J

R 851 (A,104,48) RD1/4PU102J

R 852 (B,93,89) RS1/16S102J

R 911 (B,20,141) RS1/16S223J

R 912 (A,13,134) RD1/4PU152J

R 923 (A,21,90) RD1/4PU821J

R 926 (B,15,101) RS1/16S221J

R 931 (B,67,112) RS1/16S473J

R 932 (B,67,110) RS1/16S104J

R 933 (A,56,116) RD1/4PU102J

R 934 (B,61,110) RS1/16S472J

R 935 (B,57,106) RS1/16S473J

R 936 (B,57,110) RS1/16S223J

R 940 (B,88,82) RS1/16S104J

R 941 (B,90,82) RS1/16S104J

R 961 (B,68,78) RS1/16S102J

R 962 (B,64,78) RS1/16S822J

R 991 (A,21,61) RD1/4PU271J

R 992 (A,16,69) RD1/4PU221J

R 993 (B,41,20) RS1/16S222J

R 994 (B,48,45) RS1/16S472J

CAPACITORS

C 151 (B,161,74) CKSRYB224K10

C 152 (B,161,76) CKSRYB224K10

C 153 (B,126,78) CKSRYB105K6R3

C 154 (B,144,79) CKSRYB105K6R3

C 155 (A,124,84) CEJQ4R7M35

C 156 (A,144,84) CEJQ4R7M35

C 165 (B,143,73) CKSRYB104K16

C 166 (A,139,71) CEJQ470M10

C 167 (A,129,71) CEJQ100M16

C 301 (A,134,129) CFTNA224J50

C 302 (A,130,111) CFTNA224J50

C 303 (A,134,125) CFTNA224J50

C 304 (A,124,111) CFTNA224J50

C 309 (B,137,132) CKSQYB225K10

C 310 (B,138,136) CKSQYB225K10

Circuit Symbol and No. Part No.

C 405 (B,169,97) CKSRYB103K50

C 409 (B,148,58) CCSRCH470J50

C 420 (B,106,44) CCSRCH470J50

C 451 (A,133,135) CEJQ330M10

C 551 (B,70,120) CKSRYB103K50

C 552 (B,67,123) CKSRYB103K50

C 601 (B,70,83) CKSRYB103K50

C 603 (A,102,89) CEJQ4R7M35

C 604 (B,100,75) CCSRCH200J50

C 605 (B,103,75) CCSRCH200J50

C 606 (B,110,71) CKSRYB104K16

C 607 (B,102,67) CCSRCH101J50

C 610 (A,102,83) CEJQ4R7M35

C 611 (B,97,80) CKSRYB224K10

C 654 (B,109,44) CKSRYB104K16

C 801 (B,95,22) CKSRYB104K16

C 832 (B,47,13) CKSRYB104K16

C 901 (A,37,140) CEAT332M16(P45)

C 911 (A,18,96) CEJQ470M10

C 912 (B,20,145) CKSRYB103K50

C 913 (A,24,144) CEAT221M16

C 921 (A,26,66) 330µF/16V CCH1326

C 922 (A,25,83) CEJQ101M16

C 923 (B,24,86) CKSRYB103K50

C 961 (B,55,82) CKSRYB473K50

C 963 (A,65,82) CEJQ100M16

C 981 (B,133,25) CKSRYB334K10

C 983 (A,145,38) CEJQ470M10

C 991 (B,18,64) CKSRYB473K50

C 992 (A,18,54) CEJQ101M10

B

Unit Number:CWM9622

Unit Name:Keyboard Unit

MISCELLANEOUS

IC 1801 (B,26,94) IC PD6340A

D 1803 (A,37,85) LED SML-310PT

D 1804 (A,37,97) LED SML-310PT

D 1805 (A,37,109) LED SML-310PT

D 1806 (A,37,49) LED SML-310PT

D 1807 (A,37,61) LED SML-310PT

D 1808 (A,37,73) LED SML-310PT

D 1809 (A,37,121) LED SML-310PT

D 1810 (A,23,120) LED CL-490S-WF-SD

X 1801 (B,33,84) Ceramic Resonator 5.00MHz CSS1547

IL 1801 (B,21,21) Lamp 40mA,14V CEL1651

IL 1802 (B,21,151) Lamp 40mA,14V CEL1651

LCD CAW1847

A

B

C

D

E

C 311 (A,98,122) CEJQ2R2M50

C 312 (A,105,125) CEJQ100M16

C 313 (B,101,142) CKSRYB104K16

C 353 (A,136,120) CEJQ2R2M50

C 354 (A,136,111) CEJQ2R2M50

C 401 (B,162,70) CKSRYB103K50

C 402 (B,156,60) CKSRYB103K50

C 403 (A,153,58) CEJQ470M6R3

C 404 (A,152,95) CEJQ101M10

56

RESISTORS

R 1801 (B,22,60) RS1/16S222J

R 1802 (B,24,60) RS1/16S222J

R 1804 (B,14,157) RS1/16S0R0J

R 1806 (B,28,156) RS1/16S0R0J

R 1807 (B,22,33) RS1/4SA471J

R 1808 (B,19,33) RS1/4SA471J

R 1809 (B,32,122) RS1/4SA471J

R 1810 (B,37,92) RS1/16S104J

DEH-1750/XN/GS

F

7

8

37

Page 38

1234

Circuit Symbol and No. Part No.

CAPACITORS

A

C 1801 (B,37,96) CKSRYB103K50

C 1802 (A,19,125) CKSRYF104Z25

C

Unit Number:CWX3110

Unit Name:CD Core Unit(S10)

Circuit Symbol and No. Part No.

C 213 (A,21,29) CKSSYB103K16

C 214 (A,23,26) CKSSYB104K10

C 215 (A,25,23) CKSSYB104K10

C 216 (A,24,21) CKSSYB103K16

C 217 (A,21,18) CCSSCH560J50

C 218 (A,24,14) CCSSCH5R0C50

C 219 (A,28,14) CKSSYB104K10

C 220 (B,27,24) CKSSYB104K10

C 221 (B,41,21) CKSSYB104K10

C 222 (A,35,12) CKSSYB103K16

MISCELLANEOUS

IC 201 (A,35,25) IC UPD63712AGC

IC 301 (A,45,81) IC BA5835FP

B

IC 701 (B,53,56) IC NJM2885DL1-33

Q 101 (B,22,12) Transistor 2SA1577

X 201 (A,45,36) Ceramic Resonator 16.934MHz CSS1603

S 901 (A,15,44) Switch(HOME) CSN1067

S 903 (B,53,101) Switch(DSCSNS) CSN1068

S 904 (B,35,109) Switch(12EJ) CSN1067

S 905 (B,48,110) Switch(8EJ) CSN1067

RESISTORS

R 101 (B,26,13) RS1/10SR2R4J

R 102 (B,28,15) RS1/10SR2R4J

C

R 103 (B,29,12) RS1/10SR2R7J

R 201 (A,58,26) RS1/16SS102J

R 214 (A,23,28) RS1/16SS332J

R 215 (A,21,27) RS1/16SS183J

R 216 (A,24,19) RS1/16SS122J

R 217 (A,22,15) RS1/16SS562J

R 218 (A,24,16) RS1/16SS472J

R 235 (A,27,44) RS1/16SS103J

R 236 (A,31,46) RS1/16SS103J

R 301 (A,54,73) RS1/16SS183J

R 302 (A,54,70) RS1/16SS822J

D

R 303 (A,45,70) RS1/16SS183J

R 304 (A,47,69) RS1/16SS822J

C 223 (A,37,14) CCSSCH680J50

C 224 (A,45,11) CCSSCH470J50

C 225 (A,46,14) CKSSYB103K16

C 231 (A,30,43) CKSSYB102K50

C 232 (B,38,64) CKSSYB102K50

C 301 (B,37,74) 100µF/16V CCH1504

C 302 (A,54,71) CKSSYB221K50

C 303 (A,45,68) CKSSYB221K50

C 304 (A,33,73) CKSSYB472K25

C 305 (A,36,74) CKSSYB103K16

C 306 (B,45,94) CKSSYB104K10

C 501 (B,45,51) CKSSYB103K16

C 502 (A,61,68) CKSSYB103K16

C 703 (B,47,61) CKSQYB104K16

C 704 (B,54,63) CKSQYB105K10

Miscellaneous Parts List

Pickup Unit(P10)(Service) CXX1641

M 1 Motor Unit(SPINDLE) CXC4440

M2 Motor Unit(LOADING/CARRIAGE) CXB8933

R 305 (A,34,75) RS1/16SS183J

R 306 (A,32,69) RS1/16SS183J

R 307 (A,38,74) RS1/16SS183J

R 308 (A,36,67) RS1/16SS183J

R 601 (B,52,43) RS1/16SS101J

R 602 (B,46,42) RS1/16SS101J

R 603 (B,48,48) RS1/16SS0R0J

R 901 (B,48,103) RS1/16SS104J

R 902 (B,46,105) RS1/16SS473J

E

R 903 (B,44,106) RS1/16SS273J

CAPACITORS

C 103 (B,13,8) 100µF/16V CCH1504

C 109 (A,34,12) CKSSYB104K10

C 201 (A,45,19) CKSSYB104K10

C 202 (A,53,21) CKSSYB102K50

C 205 (B,37,36) 22µF/6.3V CCH1507

C 206 (B,40,30) CKSSYB103K16

C 207 (A,46,30) CKSSYB104K10

F

C 209 (A,46,31) CKSSYB104K10

C 210 (A,41,35) CKSSYB104K10

C 211 (A,33,35) CKSSYB104K10

38

1234

DEH-1750/XN/GS

Page 39

5678

6. ADJUSTMENT

6.1 CD ADJUSTMENT

A

1) Cautions on adjustments

• In this product the single voltage (3.3V) is used for the

regulator. The reference voltage is the REFO1 (1.65V)

instead of the GND.

If you should mistakenly short the REFO1 with the GND

during adjustment, accurate voltage will not be obtained,

and the servo’s misoperation will apply excessive shock

to the pickup. To avoid such problems:

a. Do not mix up the REFO1 with the GND when

connecting the (-) probe of measuring instruments.

Especially on an oscilloscope, avoid connecting the (-)

probe for CH1 to the GND.

b. In many cases, measuring instruments have the same

potential as that for the (-) probe. Be sure to set the

measuring instruments to the floating state.

c. If you have mistakenly connected the REFO1 to the GND,

turn off the regulator or the power immediately.

• Before mounting and removing filters or leads for

adjustment, be sure to turn off the regulator.

• For stable circuit operation, keep the mechanism

operating for about one minute or more after the

regulator is turned on.

• In the test mode, any software protections will not

work. Avoid applying any mechanical or electrical

shock to the mechanism during adjustment.

2) Test mode

This mode is used to adjust the CD mechanism module.

• To enter the test mode.

While pressing the 4 and 6 keys at the same time, reset.

• To exit from the test mode.

Turn off the ACC and back up.

Notes:

a. During ejection, do not press any other keys than the

EJECT key until the loaded disc is ejected.

b. If you have pressed the (→) key or (←) key during focus

search, turn off the power immediately to protect the

actuator from damage caused by the lens stuck.

c. For the TR jump modes except 100TR, the track jump

operation will continue even if the key is released.

d. For the CRG move and 100TR jump modes, the tracking

loop will be closed at the same time when the key is

released.

e. When the power is turned off and on, the jump mode

is reset to the single TR (91), the RF amp gain is set to 0dB,

and the auto-adjustment values are reset to the default

settings.

B

C

• The RFI and RFO signals with a wide frequency range

are easy to oscillate. When observing the signals,

insert a resistor of 1k ohms in series.

• The load and eject operation is not guarantied with the

mechanism upside down. If the mechanism is blocked

due to mistaken eject operation, reset the product or

turn off and on the ACC to restore it.

D

E

56

DEH-1750/XN/GS

F

7

8

39

Page 40

1234

- Flow Chart

A

[KEY]

Contents

[4]+[6]+Reset

Test Mode In

Display

[CD]or[SOURCE]

Source On

TRK MIN

[BAND]

Power On

(T.Offset is adjusted)

TRK

MIN

SEC

00

00

B

[BAND]

Power Off

TRK MIN SEC

[BAND]

Power Off

TRK MIN SEC

Focus Close /

S curve check

TRK

91

T.Close and F,T AGC

and RF AGC

Applicable servomechanism

TRK

xx

00

[3]

MIN

SEC

91

91

[1]

MIN

SEC

xx

xx

[3]

Power On

(T.Offset is not adjusted)

TRK

MIN

SEC

99

99

[6] [1]

Focus Mode

switching

TRK

MIN0xSEC

0x

[6]

T.Close and

Applicable servomechanism

TRK

MIN

SEC

xx

xx

99

Tracking Servo

*2

TRK

0x

TRK

or

RF AGC coefficient display

TRK

xx

Close

MIN

00

00

MIN

99

[3]

RF AGC /

MIN

??

??

99

[→][←]

*8

CRG+

SEC

00

SEC

99

MIN

TRK

or

SEC

00

00

99

00

MIN

SEC

99

or

99

TRK

*8

CRG-

MIN

TRK

SEC

00

00

99

00

MIN

SEC

99

99

TRK

[→][←]

CRG+

SEC

??

TRK8xMIN8xSEC

TRK9xMIN9xSEC

or

8x

9x

CRG-

TRK8xMIN8xSEC

TRK9xMIN9xSEC

or

8x

9x

[2]

Automatic adjustment

display switching

TRK

MIN

SEC

??

??

??

[2]

T.Balance adjustment

T.Balance coefficient display

TRK

MIN

SEC

??

??

??

*3

C

[BAND]

Power Off

TRK MIN SEC

[1]

F,T,RF AGC /

F.Bias display switching

TRK

MIN

SEC

??

??

*7

??

[3]

F,T AGC /F.Bias

RF AGC

TRK

MIN

SEC

xx

xx

xx

[6]

CRG/TR Jump value

switching

TRK

MIN

SEC

xx

xx

*5

xx

[→] [←]

CRG/TR Jump +

TRK

xx

*4

MIN

SEC

xx

xx

CRG/TR Jump -

TRK

MIN

SEC

xx

xx

*4

xx

*6

[2]

Tracking Open

TRK8xMIN8xSEC

TRK9xMIN9xSEC

or

8x

9x

[BAND]

Power Off

TRK MIN SEC

D

*1) TYP → -12dB

TRK MIN SEC TRK 12 MIN 12 SEC 12

*2) Focus Close → S.Curve → F EQ measurement setting

TRK 00 MIN 00 SEC 00 TRK 01 MIN 01 SEC 01 TRK 02 MIN 02 SEC 02

(TRK 99 MIN 99 SEC 99)

*3) F.Offset Display → RF.Offset Display → T.Offset Display

*4) 1TR/32TR/100TR

*5) Single TR → 32TR → 100TR → CRG Move

E

9x(8x) : 91(81) 92(82) 93(83) 94(84)

*6) Only at the time of CRG Move or 100TR Jump

*7) TRK/MIN/SEC → F.AGC → T.AGC Gain → F.bias → RF AGC

*8) CRG motor voltage = 2[V]

[2]

Tracking Open

or

[Key]

[BAND]

[→]

[←]

[1]

[2]

[3]

-

-

[6]

TRK8xMIN8xSEC

TRK9xMIN9xSEC

8x

9x

Operation

Test Mode

Power On / Off

CRG + / TR Jump +

(Direction of the external surface)

CRG - / TR Jump (Direction of the internal surface)

CLS and AGC and Applicable servomechanism /

AGC, AGC display switching

RF Gain switching / Offset adjustment display /

T.Balance adjustment / T.Open

Close, S.Curve /

Rough Servo and RF AGC / F, T, RF AGC

SPDL 1X / 2X switching

(Double-speed compatibility only)

Gop measurement

Forcus Mode switching / Tracking Close

/ CRG, TR Jump switching

F

40

1234

DEH-1750/XN/GS

Page 41

5678

6.2 CHECKING THE GRATING AFTER CHANGING THE PICKUP UNIT

• Note :

The grating angle of the PU unit cannot be adjusted after the PU unit is changed. The PU unit in the CD mechanism

module is adjusted on the production line to match the CD mechanism module and is thus the best adjusted PU

unit for the CD mechanism module. Changing the PU unit is thus best considered as a last resort. However, if the

PU unit must be changed, the grating should be checked using the procedure below.

• Purpose :

To check that the grating is within an acceptable range when the PU unit is changed.

A

• Symptoms of Mal-adjustment :

If the grating is off by a large amount symptoms such as being unable to close tracking, being unable to perform

track search operations, or taking a long time for track searching.

• Method :

• Measuring Equipment

• Measuring Points

• Oscilloscope, Two L.P.F.

• E, F, REFO1

• Disc • TCD-782

• Mode • TEST MODE

CD CORE UNIT(S10)

L.P.F.

E

100kΩ

VREF

F

VREF

F

E

REFO1

390pF

100kΩ

390pF

L.P.F.

Xch Ych

Oscilloscope

B

C

D

• Checking Procedure

1. In test mode, load the disc and switch the 3V regulator on.

2. Using the → and ← buttons, move the PU unit to the innermost track.

3. Press key 3 to close focus, the display should read "91". Press key 2 to implement the tracking balance

adjustment the display should now read "81". Press key 3. The display will change, returning to "81" on the

fourth press.

4. As shown in the diagram above, monitor the LPF outputs using the oscilloscope and check that the phase

difference is within 75° . Refer to the photographs supplied to determine the phase angle.

5. If the phase difference is determined to be greater than 75° try changing the PU unit to see if there is any

improvement. If, after trying this a number of times, the grating angle does not become less than 75° then the

mechanism should be judged to be at fault.

• Note

Because of eccentricity in the disc and a slight misalignment of the clamping center the grating waveform may be

seen to "wobble" ( the phase difference changes as the disc rotates). The angle specified above indicates the

average angle.

• Hint

Reloading the disc changes the clamp position and may decrease the "wobble".

56

DEH-1750/XN/GS

7

8

E

F

41

Page 42

1234

Grating waveform

A

0°

B

45°

C

Ech → Xch 20mV/div, AC

Fch → Ych 20mV/div, AC

30°

60°

D

75°

E

F

90°

42

1234

DEH-1750/XN/GS

Page 43

5678

6.3 ERROR MODE

- Error Messages

If a CD is not operative or stopped during operation due to an error, the error mode is turned on and cause(s) of

the error is indicated with a corresponding number. This arrangement is intended at reducing nonsense calls from

the users and also for facilitating trouble analysis and repair work in servicing.

(1) Basic Indication Method

1) When SERRORM is selected for the CSMOD (CD mode area for the system), error codes are written to DMIN

(minutes display area) and DSEC (seconds display area). The same data is written to DMIN and DSEC. DTNO

remains in blank as before.

A

2) Head unit display examples

Depending on display capability of LCD used, display will vary as shown below. xx contains the error number.

8-digit display 6-digit display 4-digit display

ERROR–xx ERR–xx

E–xx

(2) Error Code List

Code

10

Class Displayed error code Description of the code and potential cause(s)

Electricity Carriage Home NG CRG can't be moved to inner diameter.

SERVO LSI Com-

CRG can't be moved from inner diameter.

munication Error → Failure on home switch or CRG move mechanism.

Communication error between microcomputer and SERVO LSI.

11 Electricity Focus Servo NG Focusing not available.

→ Stains on rear side of disc or excessive vibrations on REWRITABLE.

12 Electricity Spindle Lock NG Spindle not locked. Sub-code is strange (not readable).

Subcode NG → Failure on spindle, stains or damages on disc, or excessive vibrations.

A disc not containing CD-R data is found.

Turned over disc are found, though rarely.

CD signal error.

17 Electricity Setup NG AGC protection doesn't work. Focus can be easily lost.

→ Damages or stains on disc, or excessive vibrations on REWRITABLE.

30 Electricity Search Time Out

Failed to reach target address.

→ CRG tracking error or damages on disc.

44 Electricity ALL Skip Skip setting for all track.

(CD-R/RW)

50 Mechanism CD On Mech Error Mechanical error during CD ON.

→ Defective loading motor, mechanical lock and mechanical sensor.

A0 System Power Supply NG

Power (VD) is ground faulted.

→ Failure on SW transistor or power supply (failure on connector).

Remarks: Mechanical errors are not displayed (because a CD is turned off in these errors).

Unreadable TOC does not constitute an error. An intended operation continues in this case.

Upper digits of an error code are subdivided as shown below:

1x: Setup relevant errors, 3x: Search relevant errors, Ax: Other errors.

B

C

D

E

56

DEH-1750/XN/GS

F

7

8

43

Page 44

1234

6.4 SYSTEM MICROCOMPUTER TEST PROGRAM

A

- PCL output

In the normal operation mode (with the detachable panel installed, the ACC switched ON, the standby mode cancelled),

shift the TESTIN (Pin 15) terminal to H. The clock signal is output from the PCL terminal (Pin 14). The frequency of the

clock signal is 786.432kHz that is one 16th of the fundamental frequency.The clock signal should be 786.432kHz ± 31.5Hz.

If the clock signal is out of the range, the X’tal (X601) should be replaced with new one.

B

C

D

E

F

44

1234

DEH-1750/XN/GS

Page 45

5678

-

-

)

-

)

Case.

-

)

.

s.

sconnect the connector and the

e

odule.

ease the two latchs and the

e

y.

s.

dicated.

3

e

.

7. GENERAL INFORMATION

7.1 DIAGNOSIS

7.1.1 DISASSEMBLY

Removing the Case (not shown

1. Remove the

A

Removing the CD Mechanism Module (Fig.1)

Remove the four screw

Di

D Mechanism M

n remove th

Removing the Grille Assy (Fig.1

Rel

the Grille Ass

n remov

Removing the Tuner Amp Unit (Fig.2

Remove the screw

Remove the three screw

CD Mechanism Module

B

1

1

1

1

Grille Assy

2

2

2

Fig.1

2

C

D

Straighten the tabs at three locations

in

Remove the screw and then remov

the Tuner Amp Unit

1

3

56

DEH-1750/XN/GS

Tuner Amp Unit

7

4

E

3

3

Fig.2

F

8

45

Page 46

1234

- How to hold the Mechanism Unit

1. Hold the top and bottom frame.

2. Do not squeeze top frame's front portion too tight,

A

because it is fragile.

B

- Removing the Upper and Lower Frames

1. With a disc clamped, remove the four springs (A),

the two springs (B), the two springs (C), and the

four screws.

2. To remove the upper frame, open it on the fulcrum

A.

C

3. While lifting the carriage mechanism, remove the

three dampers.

4. With the frames removed, insert the connectors

coming from the main unit and eject the disc.

Caution: Before installing the carriage mechanism in

the frames, be sure to apply some alcohol to the

dampers and set the mechanism to the clamp mode.

Do not squeeze.

A

Upper Frame

A

C

A

A

Carriage Mechanism

B

A

C

Damper

D

E

Lower Frame

Damper

B

Damper

F

46

1234

DEH-1750/XN/GS

Page 47

5678

- Removing the Pickup Unit

1. Apply shorting solder to the Pickup flexible cable.

Disconnect the cable.

2. Set the mechanism to the clamp mode.

3. Remove the lead wires from the inner holder.

4. Remove the washer, styling holder, change arm,

and pickup lock arm.

5. While releasing from the hook of the inner holder,

lift the end of the feed screw.

Caution: In assembling, move the planet gear to the

load/eject position before setting the feed screw

in the inner holder.

A

Shorting

Solder

B

Pickup Lock Arm

Styling Holder

Feed Screw

Inner Holder

Washer

Planet Gear

C

Change Arm

D

E

56

DEH-1750/XN/GS

F

7

8

47

Page 48

1234

7.1.2 CONNECTOR FUNCTION DESCRIPTION

A

B

ANTENNA JACK

C

D

RCA OUTPUT

Pin No.

12345678910111213

14

15

16

10A

Pin No.

1

FR+

2

RR+

3

FR-

4

RR-

5

FL+

6

RL+

7

FL-

8

RL-

9

10

11

12

13

14

15

16

-

B.REMOTE

-

ACC

GND

B.UP

E

F

48

1234

DEH-1750/XN/GS

Page 49

5678

7.2 PARTS

7.2.1 IC

- Pin Functions(PE5449A)

1

4

7

8

9

10

11

12

13

14

15

16

17

18

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

Pin Name

MODEL1

NC

AVSS

NC

AVREF1

KYDT

DPDT

NC

TUNPDI

TUNPDO

TUNPCK

PCL

TESTIN

XSI

XSO

XSCK

NC

swvdd

ILMPW

NC

XRST

XA0

XSTB

CLAMSW

CONT

LOEJ

CLCONT

NC

DALMON

VSS1

BRST

BRXEN

BRSQ

ROMDATA

ROMCLK

ROMCS

RECIEVE

VDCONT

NC

SYSPW

NC

KEY2

NC

MUTE

ANTPW

NC

VST

VDT

VCK

NC

TUNPCE2

TUNPCE1

RDT

RDSLK

RDS57K

reset

LDET

Pin No.

2,3

5,6

19,20

44,45

Function and Operation

I/O

Model port 1

Not used

A/D GND

Not used

A/D converter reference voltage

Key data input

I

Display data output

O

Not used

PLL IC data input

I

PLL IC data output

O

PLL IC clock output

O

Clock adjustment output

O

Test program mode input

I

Serial data input

I

Serial data output

O

Serial data clock output

O

Not used

Keyboard unit power supply control output

O

Illumination power supply control output

O

Not used

CD LSI reset output

O

CD LSI identification control signal output

O

CD LSI strobe output

O

Not used

Servo driver power supply control output

O

CD load motor LOAD/EJECT direction exchange output

O

Driver input select output

O

Not used

Stand-by output

O

GND

Not used

Not used

Not used

ROM collection data output (Not used)

O

ROM collection clock output (Not used)

O

ROM collection chip select output (Not used)

O

During RDS data reception

VD control output

O

Not used

System power supply control output

O

Not used

Not used

Not used

System mute output

O

B. REMOTE output

O

Not used

Strobe pulse output for electronic volume

O

Data output for electronic volume

O

Clock output for electronic volume

O

Not used

EEPROM chip enable output 2

O

EEPROM chip enable output 1

O

RDS demodulation data input (Not used)

I

RDS LK signal input (Not used)

I

RDS 57kHz pulse count input (Not used)

I

Reset input

I

Not used

A

B

C

D

E

F

56

DEH-1750/XN/GS

7

8

49

Page 50

1234

Function and Operation

Pin No.

A

B

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

Pin Name

RCK

asens

bsens

DSENS

INTRQ

VSS0

VDD1

X2

X1

IC(VPP)

NC

XT1

VDD0

AVDD

SL

TEMP

VDSENS

DISCSENS

STRKEY1

I/O

RDS demodulation clock input (Not used)

I

ACC sense input

I

Back up sense input

I

Grille detach sense input

I

SOURCE key sense input

I

GND

Power supply

Crystal oscillator connection pin

Crystal oscillator connection pin

Connect to GND

Not used

Connect to GND

Power supply

Positive power supply terminal for analog circuit

SD level input from tuner

I

Connect to VDD

VD power supply voltage sense input

I

CD DISC sense input

I

NC

* PE5449A

80

1

C

20

21

D

BA33BC0FP

Vref

61

60

41

40

-

Vref

IC's marked by * are MOS type.

Be careful in handling them because they are very

liable to be damaged by electrostatic induction.

+

E

OCP TSD

1

2

NCOUT

F

50

1234

3

VCC

DEH-1750/XN/GS

Page 51

5678

49

48

33

32

17

16

1

64

- Pin Functions(PD6340A)

Pin No. Pin Name I/O Function and Operation

1-5 SEG4-0 O LCD segment output

6-9 COM3-0 O LCD common output

10 VLCD LCD drive power supply

11-14 KST3-0 O Key strobe output

15,16 KDT0,1 I Key data input (analogue input)

17 REW I Remote control reception input

18 DPDT I Display data input

19 NC Not used

20 KYDT O Key data output

21 MODA GND

22 X0 Crystal oscillator connection pin

23 X1 Crystal oscillator connection pin

24 VSS GND

25,26 KDT2,3 I Key data input

27 NC Not used

28 KST4 O Key strobe output

29-32 NC Not used

33-55 SEG35-13 O LCD segment output

56 VDD Power supply

57-64 SEG12-5 O LCD segment output

* PD6340A

A

B

C

D

E

56

DEH-1750/XN/GS

F

7

8

51

Page 52

1234

- Pin Functions(UPD63712AGC)

Pin No. Pin Name I/O Function and Operation

A

B

C

D

E

F

1 LD O Output of LD

2 PD I Input of PD

3 PN I Assignment of pickup polarity

4 AVDD Power supply for the analog system

5 DGND Ground for digital circuits

6 RFOK O Output of RFOK

7 INTQ O Interruption signals to the external microcomputer

8 rst I Input of reset

9 A0 I Command/Parameter discrimination signal input

10 stb I Data strobe signal input

11 sck I Serial data clock input

12 SO O Serial data output

13 SI I Serial data input

14 DVDD Power supply for digital circuits

15 DAVDD Power supply for DAC

16 ROUT O Output of audio for the right channel

17 DAGND GND for DAC

18 REGC Connected to the capacitor for band gap

19 DAGND GND for DAC

20 LOUT O Output of audio for the left channel

21 DAVDD Power supply for DAC

22 XVDD Power supply for the crystal oscillator

23 xtal O Connected to the crystal oscillator

24 XTAL I Connected to the crystal oscillator

25 XGND Ground for the crystal oscillator

26 DVDD Power supply for digital circuits

27 C1D1 O Information on error correction

28 C1D2 O Information on error correction

29 C2D1 O Information on error correction

30 C2D2 O Information on error correction

31 C2D3 O Information on error correction

32 LOCK O Output of LOCK

33 MIRR O MIRR signal

34 HOLD O HOLD signal

35 PLCK O Output of PLCK

36 C16M O Output of 16.9344MHz

37 DGND Ground for digital circuits

38 TX O DAI output

39 EMPH O Pre-emphasis information output

40 FLAG O The flag for which output sound data cannot be corrected is outputted

41 DVDD Power supply for digital circuits

42 LIMIT I Signal is inputted when the register can be read

43 xtalen I Permission to oscillate

44 DGND Ground for digital circuits

45 DIN I Input of audio data

46 DOUT O Output of audio data

47 SCKIN I Clock input for audio data

48 SCKO O Clock output for audio data

49 LRCKIN I Input of LRCK for audio data

50 LRCK O Output LRCK for audio data

51 DVDD Power supply for digital circuits

52 FD+ O Output of focus drive PWM

53 FD- O Output of focus drive PWM

54 TD+ O Output of tracking drive PWM

55 TD- O Output of tracking drive PWM

56 SD+ O Output of thread drive PWM

57 SD- O Output of thread drive PWM

58 MD+ O Output of spindle drive PWM

59 MD- O Output of spindle drive PWM

60 DGND Ground for digital circuits

52

1234

DEH-1750/XN/GS

Page 53

5678

Pin No. Pin Name I/O Function and Operation

61 TESTEN I Connected to GND

62-66 TEST4-0 I Connected to GND

67 ADGND GND for DAC

68 EFM O Output of EFM signals

69 ASY I Input of asymmetry

70 ADVDD Power supply for DAC

71 RFI I Input of RF

72, 73 EQ2, 1 Equalizer 2, 1

74 RF- I Reversal input of RF

75 RF2- I Reversal input of RF2

76 AGCO O Output of RF

77 AGCI I Input of AGC

78 RFO O Output of RF

79 ATEST O Analog tests

80 C3T Connection to the capacitor for detecting 3T

81 AGND Ground for the analog system

82 A I Input of A

83 C I Input of C

84 B I Input of B

85 D I Input of D

86 F I Input of F

87 E I Input of E

88 VREFIN I Photo-detector input bias voltage

89 AVDD Power supply for the analog system

90 REFOUT O Output of reference voltage

91 REFC Connected to the capacitor for output of REFOUT

92 FE- I Reversal input of FE

93 FEO O Output of FE

94 ADCIN I TEST

95 TE- I Reversal input of TE

96 TEO O Output of TE

97 TE2 O TE2

98 TEC I TEC

99 AGND Ground for the analog system

100 PWMSW I Servo PWM mode switching

A

B

C

* UPD63712AGC

50

51

75

76

D

26

25

E

1

100

F

56

DEH-1750/XN/GS

7

8

53

Page 54

1234

- Pin Functions(BA5835FP)

Pin No. Pin Name Function and Operation

A

B

C

1 VR Input pin for reference voltage

2 OPIN2(+) Input pin for non-inverting input for CH2 preamplifier

3 OPIN2(-) Input pin for inverting input for CH2 preamplifier

4 OPOUT2 Output pin for CH2 preamplifier

5 OPIN1(+) Input pin for non-inverting input for CH1 preamplifier

6 OPIN1(-) Input pin for inverting input from CH1 preamplifier

7 OPOUT1 Output pin for CH1 preamplifier

8 GND Ground pin

9 MUTE Mute control pin

10 POWVCC1 Power supply pin for CH1, CH2, and CH3 at "Power" stage

11 VO1(-) Driver CH1 - Negative output

12 VO1(+) Driver CH2 - Positive output

13 VO2(-) Driver CH2 - Negative output

14 VO2(+) Driver CH2 - Positive output

15 VO3(+) Driver CH2 - Positive output

16 VO3(-) Driver CH2 - Negative output

17 VO4(+) Driver CH4 - Positive output

18 VO4(-) Driver CH4 - Negative output

19 POWVCC2 Power supply pin for CH4 at "Power" stage

20 GND Ground pin

21 CNT Control pin

22 LDIN Loading input

23 OPOUTSL Output pin for preamplifier for thread

24 OPINLSL Input pin for preamplifier for thread

25 OPOUT3 CH3 preamplifier output pin

26 OPIN3(-) Input pin for inverting input for CH3 preamplifier

27 OPIN3(+) Input pin for non-inverting input for CH3 preamplifier

28 PREVCC PreVcc

BA5835FP

114

D

15 28

NJM2885DL1-33

Thermal

Protection

E

+

Bandgap

Reference

-

F

54

1234

DEH-1750/XN/GS

1

IN

2

GND

3

OUT

Page 55

5678

- FM/AM Tuner Unit

76 13 5 1098 11 14 18192021

NC

CE2

ROM_VDD

DI

SL

CK

NC

CE1

DO

NCNCNC

NC

A

VDD_3.3

3.3V

IC 5

←

5V 3.3V

IC 4

3.3V 2.5V

Rch

IC 2

2.5V

DET, FM MPX

←

2.5V

24

Lch

23

1

3

AM ANT

FM ANT

ATT

ATT

ANT adj

FMRF

FMRF

RF adj

IC 3 EEPROM

5.0V

OSC

LPF

IC 1

3.3V

MIXER, IF AMP

T51

CF52

RFGND

OSCGND

DGND

212 1522 16 4 17

AUDIOGNDNCVCC

No. Symbol I/O Explain

1 AMANT I AM antenna input AM antenna input high impedance AMANT pin is connected with

an all antenna by way of 4.7µH. (LAU type inductor) A series circuit

including an inductor and a resistor is connected with RF ground for

the countermeasure against the hum of power transmission line.

2 RFGND RF ground Ground of antenna block

3 FMANT I FM antenna input Input of FM antenna 75Ω Surge absorber(DSP-201M-S00B) is necessary.

4 VCC power supply The power supply for analog block. D.C 8.4V ± 0.3V

5 SL O signal level Output of FM/AM signals level