PIONEER CX 954 Service Manual

Model Service Manual CD Mechanism Module

SDV-P7/UC CRT2688 CXK6111

AVX-P7300DVD/UC CRT2672

PIONEER CORPORATION 4-1, Meguro 1-Chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS SERVICE INC. P.O.Box 1760, Long Beach, CA 90801-1760 U.S.A.

PIONEER EUROPE NV Haven 1087 Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE.LTD. 253 Alexandra Road, #04-01, Singapore 159936

C PIONEER CORPORATION 2001

K-ZZU. APR. 2001 Printed in Japan

ORDER NO.

CRT2670

DVD MECHANISM MODULE

CX-954

- This service manual describes the operation of the DVD mechanism module incorporated in models

listed in the table below.

- When performing repairs use this manual together with the specific manual for model under repair.

CONTENTS

1. CIRCUIT DESCRIPTIONS ...........................................2

2. MECHANISM DESCRIPTIONS.................................15

3. DISASSEMBLY .........................................................19

2

CX-954

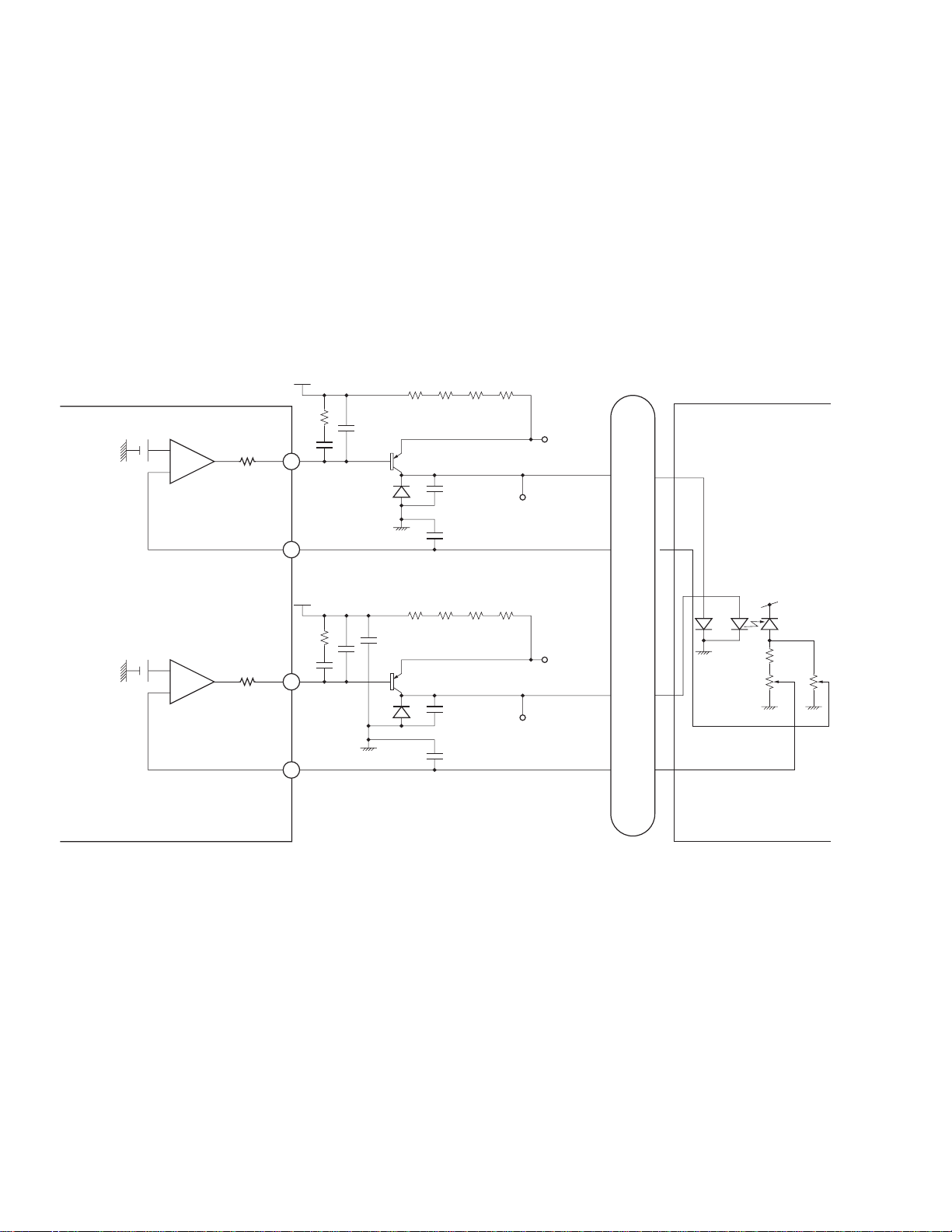

1.1.1 APC circuit

The light output of the laser diode (LD) has a large negatively charged thermal characteristic. The APC circuit is

designed to stabilize the light output at the monitor diode (MD), by controlling the current. AN8702FH contains two

types of APC circuits, one for DVDs and the other for CDs. The LD current can be obtained by dividing the voltage

reading between positions DVDLD1 (CDLD1) and 5V by 15.6 Ω (3.9 Ω x 4 = 15.6 Ω). For DVDs (CDs), it is approximately

26 mA (44mA).

1.CIRCUIT DESCRIPTIONS

1.1 Front-end processor (FEP) section (AN8702FH: IC1100)

The IC1100 generates servo signals for focus and tracking operations and increments the RF signal and also controls

the laser power of the pick-up.

The IC contains a focus calculation amplifier, a focus balance adjustment circuit, a three-beam tracking calculation

amplifier, a phase difference tracking detection circuit, a tracking balance adjustment circuit and an envelope detection

circuit for servo controls.

For the RF signal processing the AGC and equalizer functions are contained in the IC as well.

1.1.1 APC circuit

1.1.2 FE generation circuit

1.1.3 TE generation circuit

For CD

For DVD

170mV

180mV

+5V

–

+

–

+

LPC02

LPC2

LPC01

LPC1

+

4

3

+5V

+

2

1

3.9Ω 3.9Ω 3.9Ω

3.9Ω 3.9Ω 3.9Ω

+

3.9Ω

CDLD0

3.9Ω

DVDLD0

CDLD1

DVDLD1

28

10

30

12

CN1100

78LD

78MD

65LD

65MD

CD

LD

+5V

MD

DVD

LD

AN8702FH

PU UNIT

3

CX-954

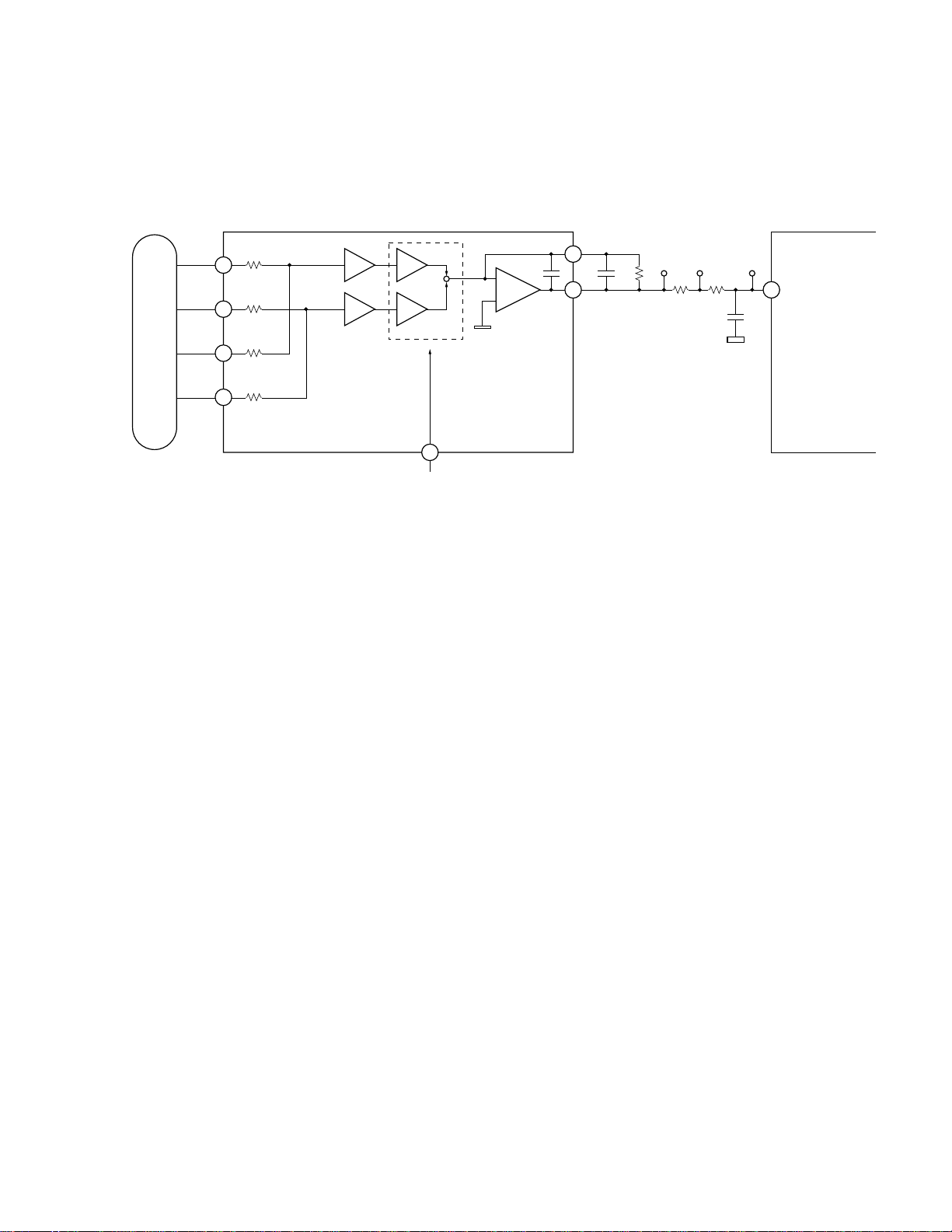

1.1.2 FE generating circuit

Focus error (FE) generating circuit

PU divides the output into four input signals of the FE circuit, B1 through B4. These input signals are fed through the

internal resistors and results in (B1 + B3) and (B2 + B4) signals. These signals are then fed into the variable amplifier

for focus balance adjustment, and the FE signal is generated by amplifying the {(B1 + B3) – B2 + B4)} signal.

Numbers and names indicated inside the brackets are identical to those of pins and terminals. Circuits for CDs and

DVDs are identical, except for the input terminals B1 through B4.

B1

CN1100

20

19

17

15

AN8702 FH

60 VIN4

(52 VIN8)

57 VIN1

(49 VIN5)

58 VIN2

(50 VIN6)

59 VIN3

(51 VIN7)

B2

B3

B4

–

+

G4 1–f

G4 1+f

+

–

VHALF

1.65V

22

FEOUT

21 FEN

FEY

RFEN

FEX FE

3 FE

VHALF

MN677061ZY

FBAL7

Control

4

CX-954

1.1.3 TE generating circuit

• CD (three-beam TE)

Tracking Error (TE) generating circuit

For DVDs, the TE is generated from the difference in phase between (B2 + B4) and (B1 + B3) signals, using the

differential phase method. For CDs, it is generated by amplifying the A + C, after passing through the external resistors

and the variable amplifiers for tracking balance adjustments.

A

C

–

+

14

63 VIN12

21

CN1100

62 VIN11

G4 1+t

G4 1–t

+

–

VHALF 1.65V

18 TEOUT

17 TEN

TEY

RTEN

TEX TE

2 TE

VHALF

MN677061ZY

TBAL6

ControlAN8702FH

B1

B2

B3

B4

–

+

15

60 VIN4

17

59 VIN3

TGBAL

TGBAL5 TBAL6

19

58 VIN2

20

57 VIN1

TBAL

DIFFERENTIAL

PHASE

DET.

VHALF

1.65V

18

TEOUT

17 TEN

RTEN

TEY TEX

MN677061ZY

TE

2 TE

VHALF

APF/HPF

· DVD (differential phase TE)

5

CX-954

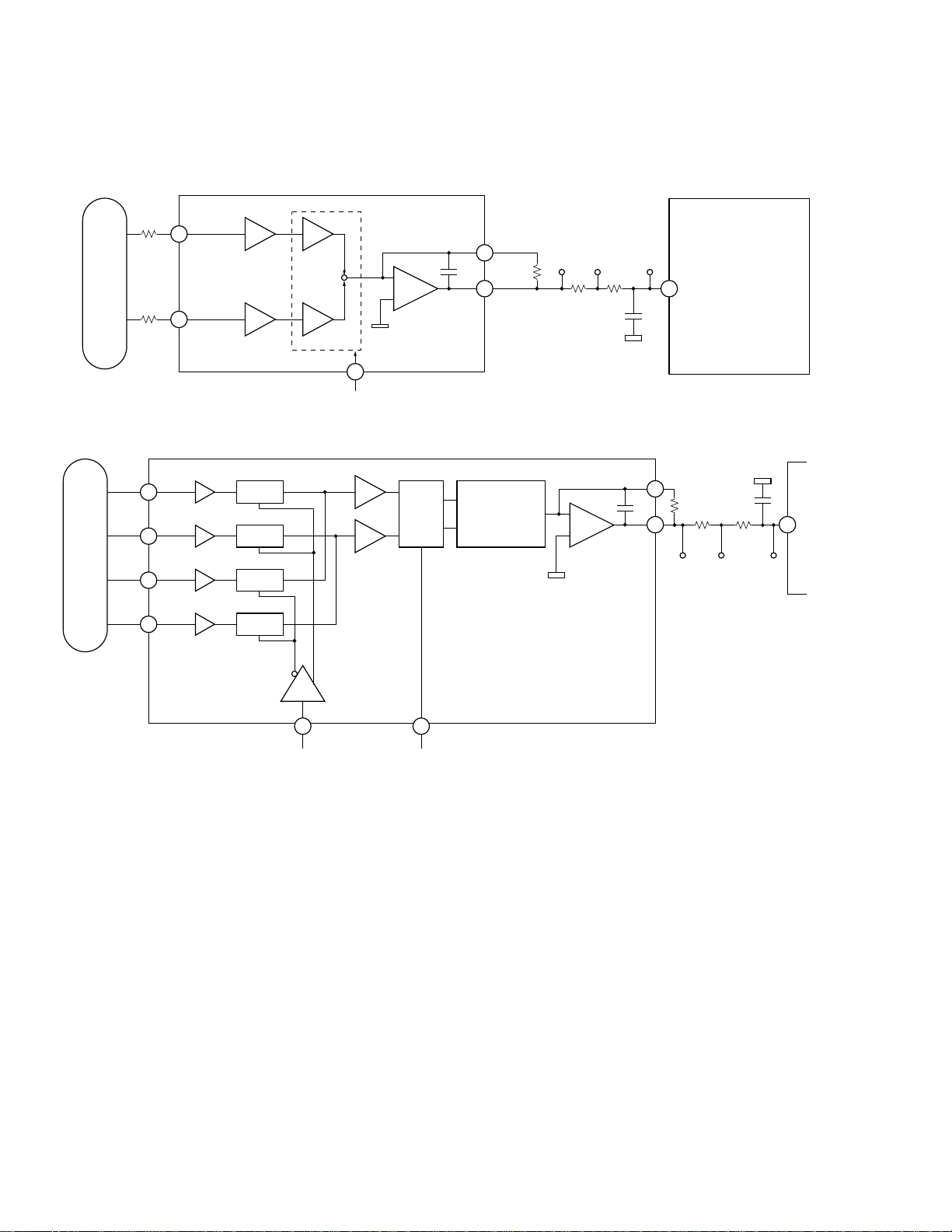

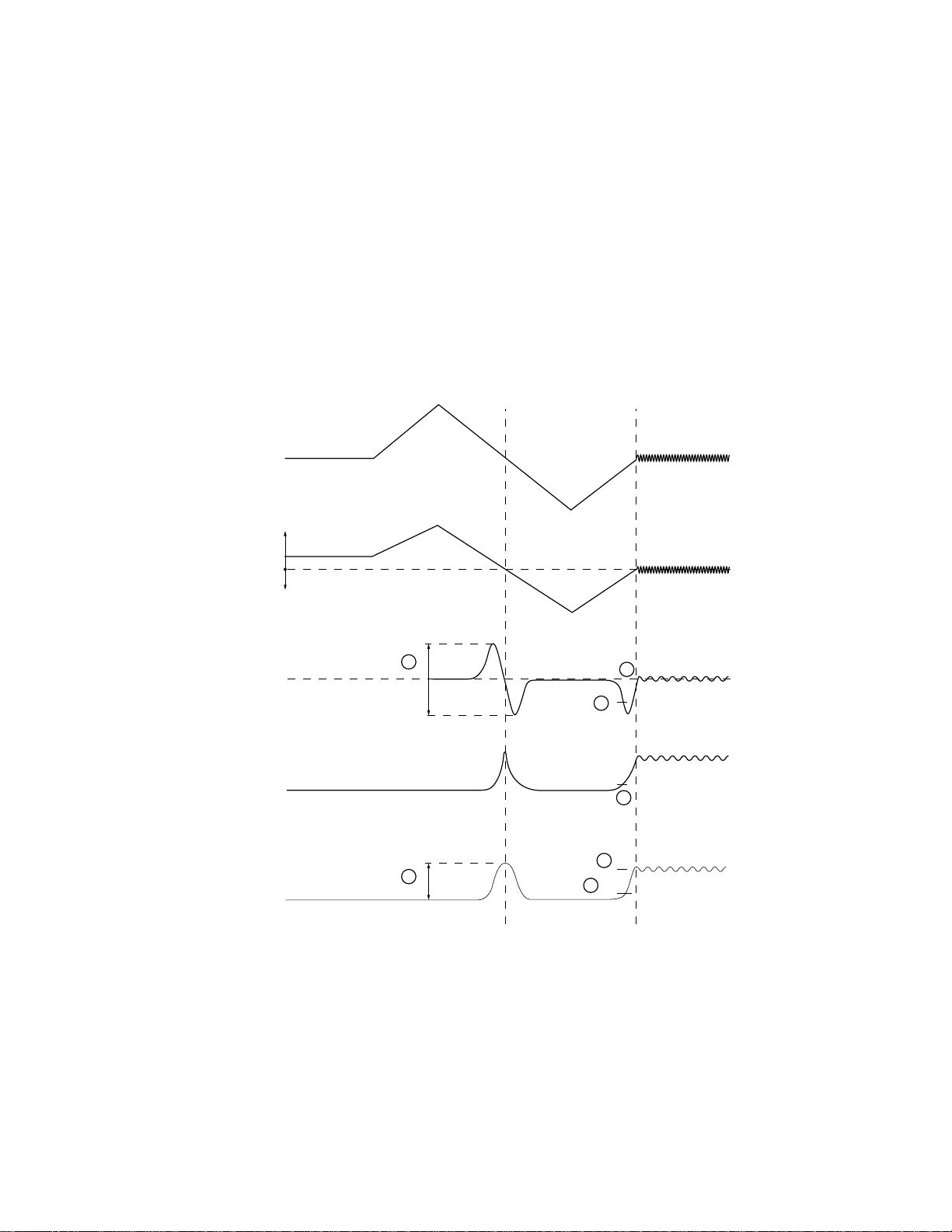

The following procedure is performed for both DVD and CD disks, whenever a focus close command is issued.

1. Measuring and optimizing the signal levels

The lens of PU is initially driven to move away from the disk, and then moved toward the disk. The signal levels of

FE, AS and RFENV are measured at the focal point. Then signal level optimization is conducted for the signals FE

and AS (1 and 2 as shown in the diagram).

Near the disk

Away from the disk

Lens

VHALF

Focal point

FE

RFENV

AS

3

6

7

4

5

1

2

1.2 Servo controller (ADSC) section (MN677061ZYUB: IC1200)

The servo processing section of the IC1200 controls focus, tracking and traverse operations, while the signal

processing section of the IC processes digital signals of the CD-DA and CD-ROM.

A digital signal processor (DSP) is used in the core section of the servo control.

An analog-digital converter, for servo signals as well as the digital-analog converter to output drive values to the driver

for focus and tracking operations, are also contained in the IC.

The PWM converter, which outputs drive values to the driver for spindle and traverse operations, the RF signal data

slicer and PLL as well as the jitter detection circuit, are also included in the IC.

Frame synchronization detection, EFM demodulation, sub-code data processor and the CIRC error correction function

are also included in the CIRC block signal processing section.

1.2.1 Focus close

1.2.2 Tracking close

1.2.3 Track jump

1.2.4 Focus jump

1.2.1 Focus close

FODRV

6

CX-954

2. Closing in the focal point

The lens is then driven away from the disk, taking a measurement for the closing in levels for signals FE and AS.

The focus loop filter is then operated to close in the focal point (3 through 6).

3. Verifying the close in

The closing in of the focal point is verified with signals AS and RFENV (6 and 7).

The signal levels of FE, AS and RFENV, as well as the voltage level of the focus drive, can be verified through the

focus search conducted in the test mode.

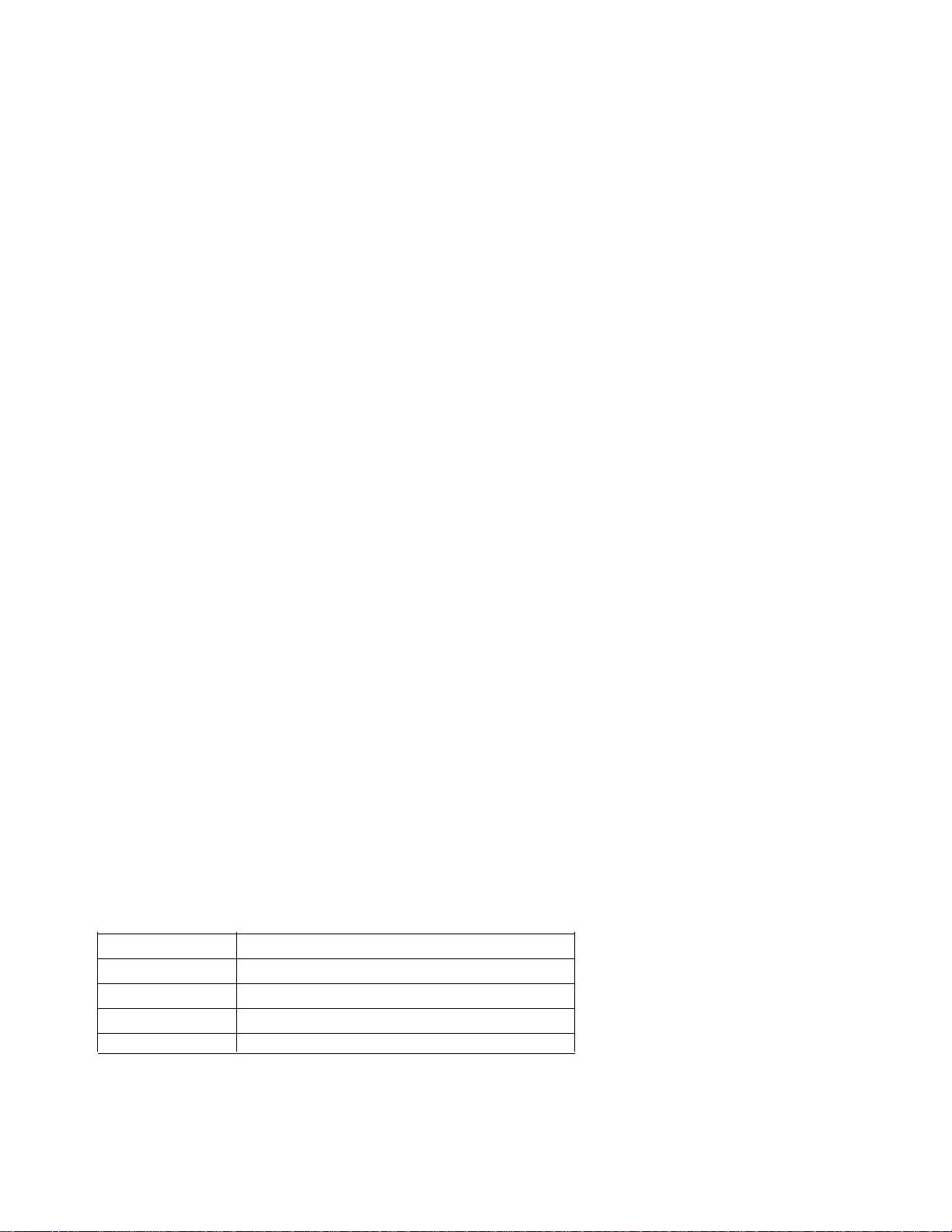

1.2.2 Tracking close

The following procedure is performed for both DVD and CD disks, whenever a tracking close command is issued.

1. Tracking brake

A half cycle of the track crossing signal is measured. If the measured cycle falls within the specified range, then a

brake pulse signal is output. The direction of the brake pulse output is determined from the phase relationship of

signals OFTR and TKC (signal resulting from the conversion of the TE signal to a binary signal). Vibration control

of the lens, with respect to the disk, is verified and if the control is carried out satisfactorily, the brake pulse output

will be terminated, moving on to the closing in of the focal point. The brake pulse is output, and if the conditions

for the closing in of the focal point are not established within 30msec., the brake pulse output will be terminated.

Monitoring will continue for a maximum of 70msec., before moving on to the closing in of the focal point.

2. Closing in the tracking

The tracking drive hold process is conducted with the OFTR signal.

3. Verifying the closing in

The track jump is counted to determine whether the number of track jumps within a specified time interval falls

within the specified number of track jumps or not. Verification of the close in reaches time out at 7msec., and a

retry will take place automatically for as many times as specified.

1.2.3 Track jump

Three methods are available with this system, which are selected according to the number of target transition

tracks. The methods are the interval jump, multi-jump and transverse seek.

1. Interval jump

Since track jumps are conducted repeatedly on a single track a detailed seek is possible. This method is used

when the target track is near, or for seeking a neighboring track.

2. Multi-jump

Both edges of the TKC, of the track cross signal, are counted. Transition, by the number of specified track counts,

is carried out.

3. Traverse seek

The transition speed is controlled by taking a measurement of the track cross signal's TKC time. The vibration of

the pick up, which occurs during transition, is held within minimum values.

The jump switching settings for both DVDs and CDs are shown below:

Target transition Type of jumps

1~10 Interval jump

11~100 Multi-jump

101~500 Combination of multi-jump and interval jump

501~ Traverse seek

Waveforms of the tracking jumps are shown next page:

7

CX-954

TE

TD

Tracking–on process

Interval jump (one track)

External circumference jump Internal circumference jump

8

CX-954

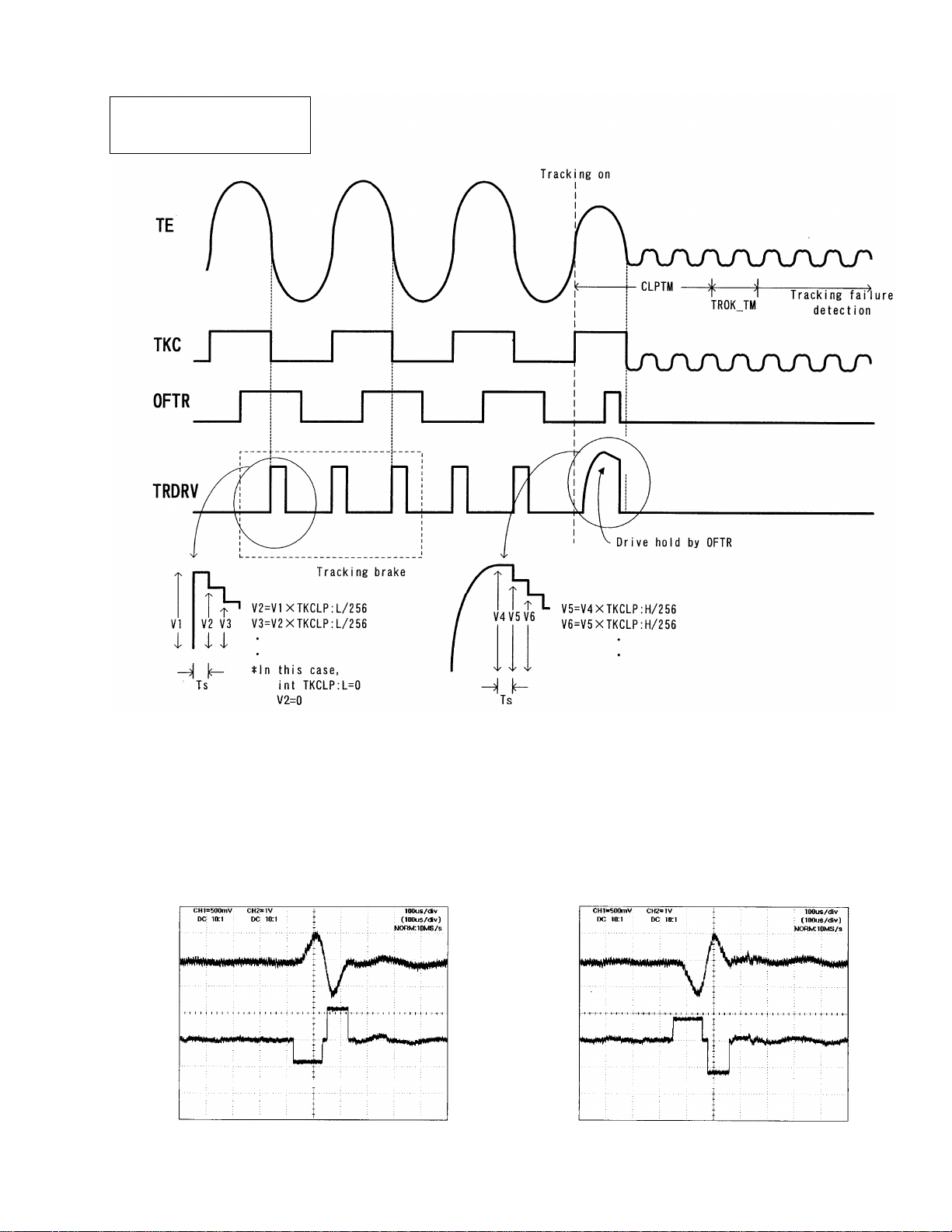

Traverse seek (501 tracks)

External circumference jump Internal circumference jump

Multi-jump (32 tracks)

External circumference jump Internal circumference jump

TE

TD

TE

TD

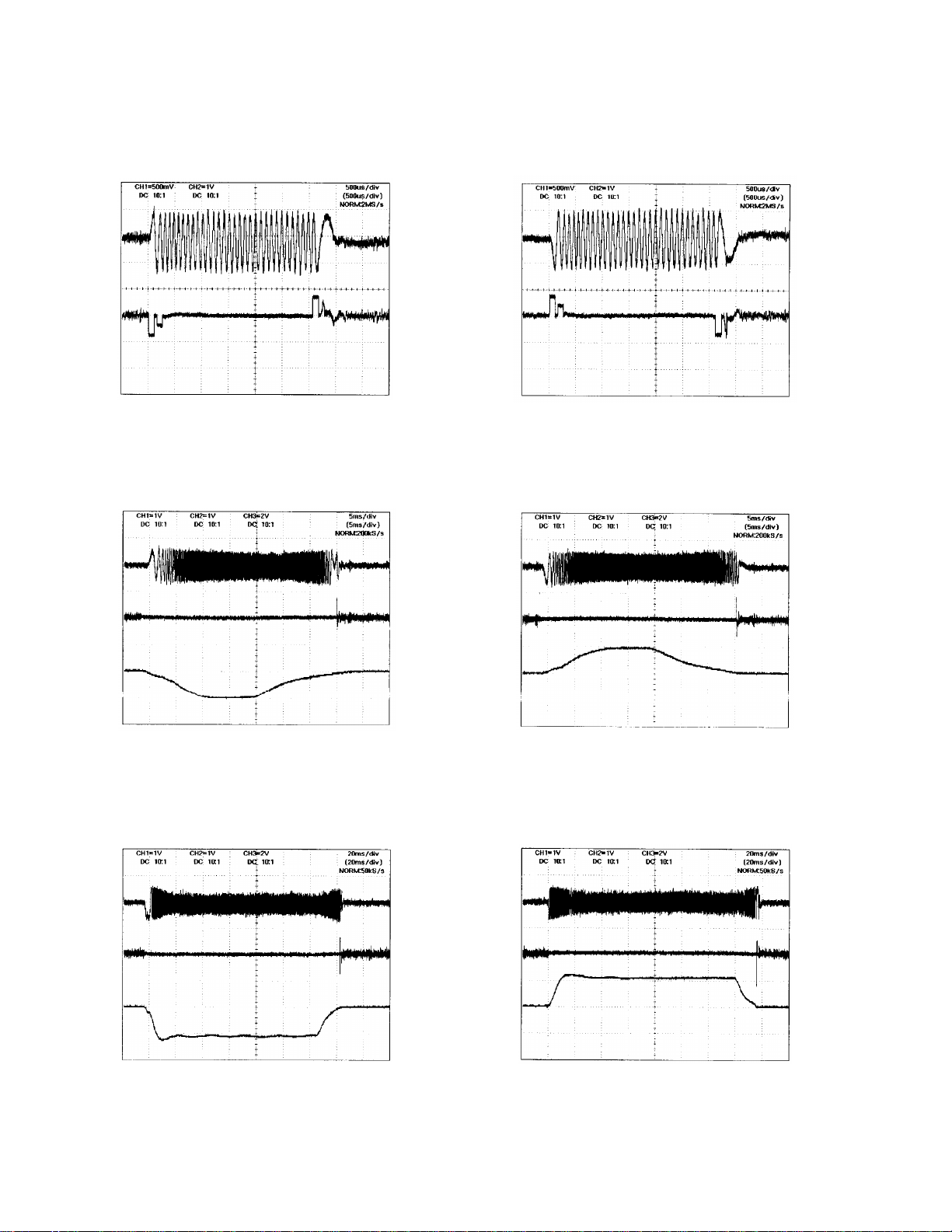

CO±

Traverse seek (5,000 tracks)

External circumference jump Internal circumference jump

TE

TD

CO±

Loading...

Loading...