Page 1

Model Service Manual CD Mechanism Module Mechanism Unit

CDX-P1250/X1N/UC,ES CRT2318 CXK4900 CXB3008

CDX-P1250/X1N/EW CXK4905 CXB3008

CDX-FM1259/X1N/UC CRT2320 CXK4916 CXB3008

CDX-FM1257/X1N/UC,ES CXK4915 CXB3008

PIONEER ELECTRONIC CORPORATION 4-1, Meguro 1-Chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS SERVICE INC. P.O.Box 1760, Long Beach, CA 90801-1760 U.S.A.

PIONEER ELECTRONIC [EUROPE] N.V. Haven 1087 Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE.LTD. 253 Alexandra Road, #04-01, Singapore 159936

C PIONEER ELECTRONIC CORPORATION 1999

K-ZZU. FEB. 1999 Printed in Japan

ORDER NO.

CRT2357

CD MECHANISM MODULE

CX-938

- This service manual describes the operation of the CD mechanism incorporated in models listed in the

table below.

- When performing repairs use this manual together with the specific manual for model under repair.

CONTENTS

1. CIRCUIT DESCRIPTIONS...........................................2

2. DISASSEMBLY .........................................................18

3. MECHANISM DESCRIPTIONS.................................23

Page 2

2

C X-938

1. CIRCUIT DESCRIPTIONS

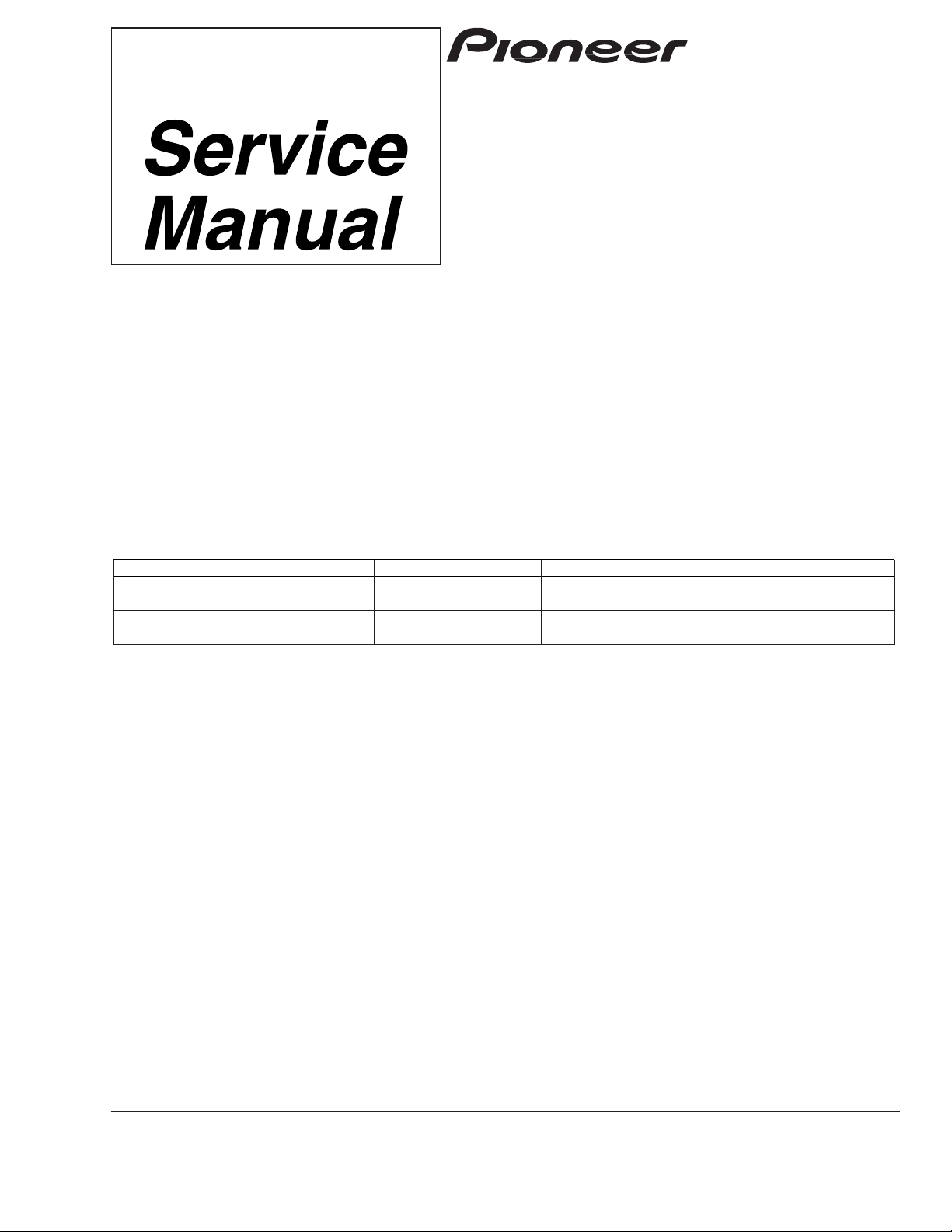

The LSI (UPD63710GC) used on this unit comprises five main blocks ; the pre-amp section, servo, signal processor,

DAC and CD text decoder (not used on this model). It also equips with nine automatic adjustment functions.

1.1 PRE-AMP SECTION

This section processes the pickup output signals to

create the signals for the servo, demodulator and

control.

The pickup output signals are I-V converted by the preamp with the built-in photo-detector in the pickup, then

added by the RF amp to obtain RF, FE, TE, TE zero cross

and other signals.

This pre-amp section is built in the servo LSI

UPD63710GC (IC201). The following describes function

of each section.

Since this system has a single power supply (+5V), the

reference voltage for this LSI and pickup are set to

REFO (2.5V). The REFO is obtained by passing the

REFOUT from the LSI through the buffer amplifier. The

REFO is output from Pin 89 of this LSI. All

measurements are done using this REFO as reference.

Note : During the measurement, do not try to short the

REFO and GND.

1) APC Circuit (Automatic Power Control)

When the laser diode is driven with constant current,

the optical output has large negative temperature

characteristics. Thus, the current must be controlled

from the monitor diode so that the output may be

constant. APC circuit is for it. The LD current is obtained

by measuring the voltage between LD1 and V+5. The

value of this current is about 35mA.

71

72

74

76

AGCI

77

RFO

75

78

79

80

73

91

90

93

92

C-3T

FEO

FE-

TEO

TE-

85

86

87

E

97

PD

99

PN

F

D

82

83

84

B

C

A

RF-

EQ1

EQ2

AGCO

RFI

ASY

EFM

PEAK DET.

LPF

BOTTOM DET.

S/H

D/A

A/D

D/A

A/D

94

98

TE2

LD

VREG

GND

APN

LDON

EFM

DEFECT

FOK

A3T

MIRR

To the

following stage

of the LSI

Vref

Vref

Vref

Vref

Vref

Vref

Vref

Vref

Vref

Vref

Vref

Vref

Vref

Vref

Vref

·····Vref(+2.5V)

97

PD

99

PN

98

LD

VREG

GND

AMP_PN

(H:Nch L:Pch)

LDON

(H:LD MOVE L:STOP)

Vref

·····Vref(+2.5V)

14

5

R102

10

R101

12

Q101

2SB1132

C102

0.1µF

C103

100µF/6.3V

PU UNIT

R103

2.2k

C105

0.33µF

+5V

1k

110k

3pF

3pF

150k

100k

100k

16k

1k

Fig.1 : BLOCK DIAGRAM OF BUILT-IN RF AMPLIFIER

Fig.2 : APC CIRCUIT

Page 3

C X-938

3

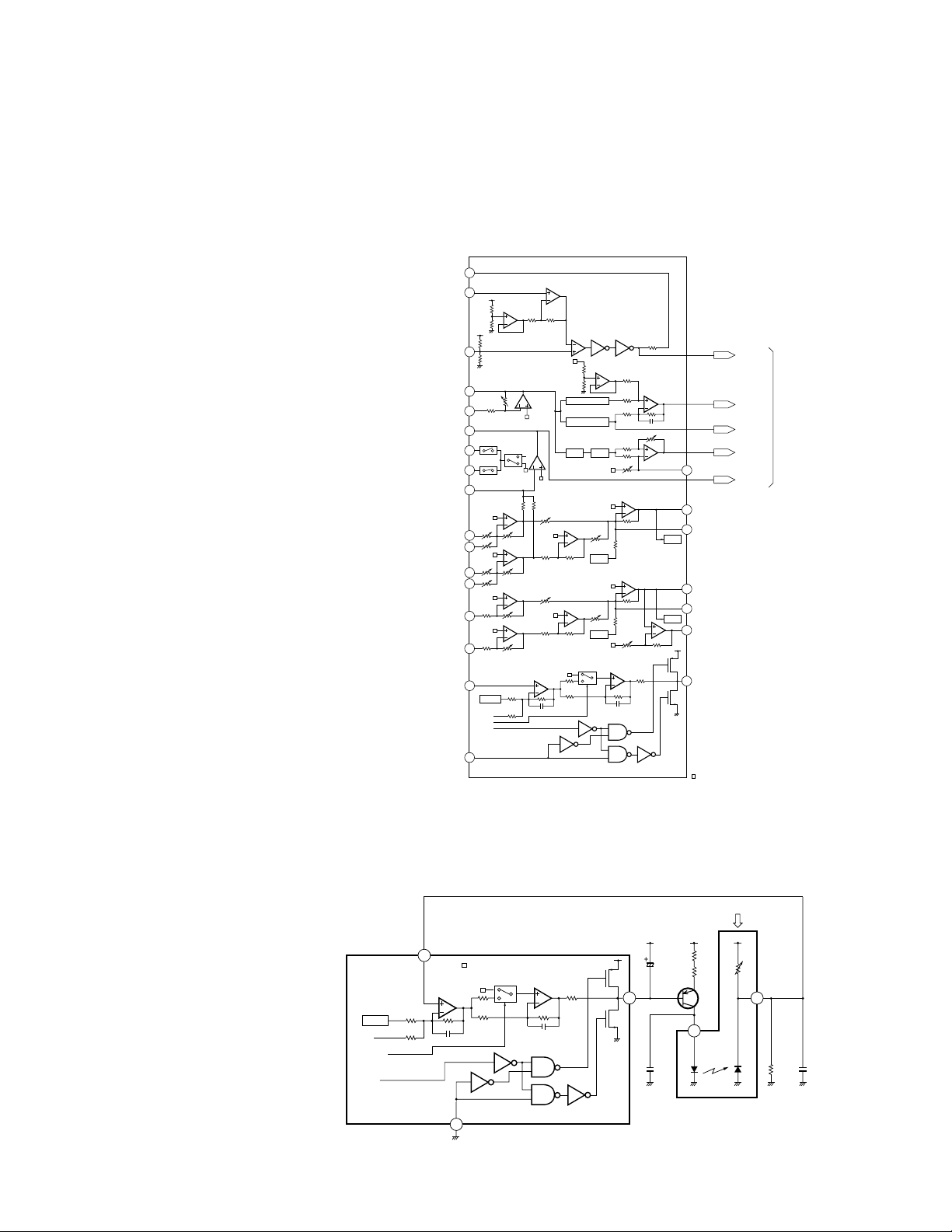

2) RF Amplifier and RFAGC Amplifier

The photo-detector outputs (A +C) and (B +D) are

added, amplified and equalized on this LSI and then

output to the RFI terminal as the RF signal. (The eye

pattern can be checked by this signal.)

The RFI voltage low frequency component is :

RFI = (A

+B +C +

D) ×3.2

RFI is used on the FOK generator circuit and RF offset

adjusting circuit.

R215 is an offset resistor for maintaining the bottom

reference voltage of the RFI signal at 1.5 VDC. The D/A

output used for the RF offset adjustment (to be

described later) is entered via this resistor.

After the RFI signal from Pin 77 is externally AC

coupled, entered to Pin 76 again, then amplified on the

RFAGC amplifier to obtain the RFO signal.

The RFAGC adjustment function (to be described later)

built-in the LSI is used for switching feedback gain of

the RFAGC amplifier so that the RFO output may go to

1.5

±

0.3Vpp.

The RFO signal is used for the EFM, DFCT, MIRR and

RFAGC adjustment circuits.

3) FOK Circuit

This circuit generates the signal that is used for

indicating the timing of closing the focus or state of the

focus close currently being played. This signal is output

from Pin 4 as the FOK signal. It goes high when the

focus close and in-play.

The RFOK signal is generated by holding DC level of the

RFI at its peak with the succeeding digital section, then

comparing it at a specific threshold level. Thus, the

RFOK signal goes high even if the pit is absent. It

indicates that the focus close can take place on the disc

mirror surface, too.

This signal is also supplied to the micro computer via

the low pass filter as the FOK signal and used for the

protection and the RF amplifier gain switching.

CN101

84

18

25

83

82

10k

10k

85

FOK

CIRCUIT

A/D

4

A+C

16k

B+D

10k

16k

10k

R215

12k

C209 3pF

R214

10k

R207

1.8k

C208

27pF

R213

10k

80 79 74757677

D/A

12k

66

10k

RFOAGCIRFI

C207

0.22µF

C206

3900pF

FOK

TO EFM

CIRCUIT

Fig.3 : RFAMP, RFAGC AND FOK CIRCUIT

Page 4

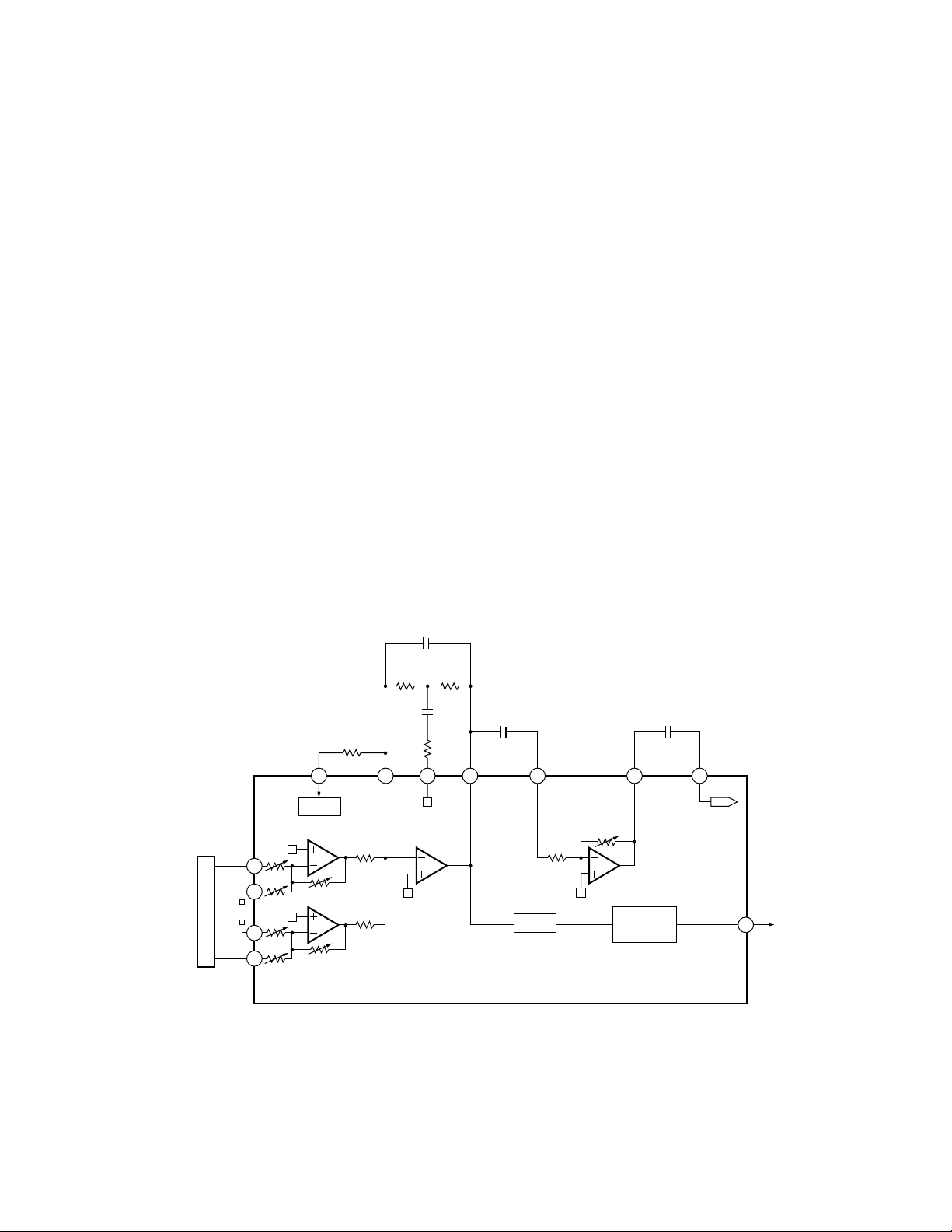

5) Tracking Error Amplifier

The photo-detector outputs E and F are passed through

a differential amplifier and an error amplifier, and then

(E −F) is output from Pin 93 as the TE signal. The TE

voltage low frequency component is :

TE

=

(E −F)

××

=

(E −F) ×5.7 (Effective LSI output is 5.0).

Using REFO as the reference, the TE waveform of

approximately 1.3 Vpp is obtained for the TE output.

The final-stage amplifier cutoff frequency is 20 kHz.

6) Tracking Zero Crossing Amplifier

TEC signal (the tracking zero crossing signal) is

obtained by multiplying the TE signal four times. It is

used for locating the zero crossing points of the

tracking error. The zero cross point detection is done for

the following two reasons :

1

To count tracks for carriage moves and track jumps.

2

To detect the direction in which the lens is moving

when the tracking is closed (it is used on the

tracking brake circuit to be described later).

The TEC signal frequency range is 300 Hz to 20 kHz.

TEC voltage

=

TE level ×4

Theoretical TEC level is 5.2V. The signal exceeds Drange of the operational amplifier and thus is clipped.

It, however, can be ignored since this signal is used by

the servo LSI only at the zero crossing point.

4

C X-938

Fig.5 TRACKING ERROR AMPLIFIER AND TRACKING ZERO CROSSING AMPLIFIER

4) Focus Error Amplifier

The photo-detector outputs (A+C) and (B+D) are passed

through a differential amplifier and an error amplifier, and

then (A

+C−B−

D) is output from Pin 91 as the FE signal.

The FE voltage low frequency component is :

FE

= (A + C − B − D) ××

=

(A + C − B − D) × 5

Using REFO as the reference, an S-curve of approximately 1.5

Vpp is obtained for the FE output. The final-stage amplifier

cutoff frequency is 11.4 kHz.

20k

CN101

84

18

25

83

82

10k

20k

85

A+C

16k

B+D

48k

16k

10k

9190

D/A

80k

110k

FE

C210 220pF

R208 300k

A/D

FE OFFSET

TO DIG. EQ

48k

38k

CN101

21

23

86

56k

38k

87

F

E

F

224k

E

48k

224k

56k

9392

D/A

80k

110k

TE

C211 100pF

A/D

TE OFFSET

TO DIG. EQ

48k

R216

27k

R215

27k

60k

20k

95

94

TE2

TEC

R212

0

C212

6800pF

16k

10k

(80k//300k)

20k

Fig.4 : FOCUS ERROR AMPLIFIER

224k

(56k

+27k)

80k

38k

Page 5

C X-938

7) DFCT (Defect) Circuit

The DFCT signal is used for detecting defects on the

mirrored disc surface. It allows monitoring from the

HOLD pin (Pin 2). It goes high when defects are found

on the mirrored surface.

The DFCT signal is generated by comparing the RF

amplified signal (which is obtained by bottom holding

the RFO signal) at a specific threshold level by the

succeeding digital section.

Stains or scratches on the disc can constitute the

defects on the mirrored disc surface. Thus, as long as

the DFCT signal remains high in the LSI, the focus and

tracking servo drives are held in the current state so

that a better defect prevention may be ensured.

8) 3TOUT Circuit

The 3TOUT signal is generated by entering disturbance

to the focus servo loop, comparing phase of

fluctuations of the RF signal 3T component against that

of the FE signal at that time, then converting the signal

to DC level. This signal is used for adjusting bias of the

FE signal (to be described later). This signal is not

output from the LSI, thus its monitoring is not available.

9) MIRR (Mirror) Circuit

The MIRR signal shows the on track and off track data,

and is output from Pin 3.

When the laser beam is

On track : MIRR ="L"

Off track : MIRR

=

"H"

This signal is used on the brake circuit (to be described

later) and also as the trigger to turn on track counting

when jumping take place.

The MIRR signal is supplied to the micro computer, too,

for the protection purpose.

A/D

MIRR

CIRCUIT

3T

CIRCUIT

DFCT

CIRCUIT

BOTTOM DETECT

BOTTOM DETECT

PEAK DETECT

LPFS/H

A/D

A/D

76

75

73

3

2

40k

20k

20k

40k

40k

40k

200k

200k

C205

0.1µF

C3T

AGCI

RFO

12k

10k

20k

30k

MIRR

HOLD

Fig.6 : DFCT, MIRR AND 3T DETECTION CIRCUIT

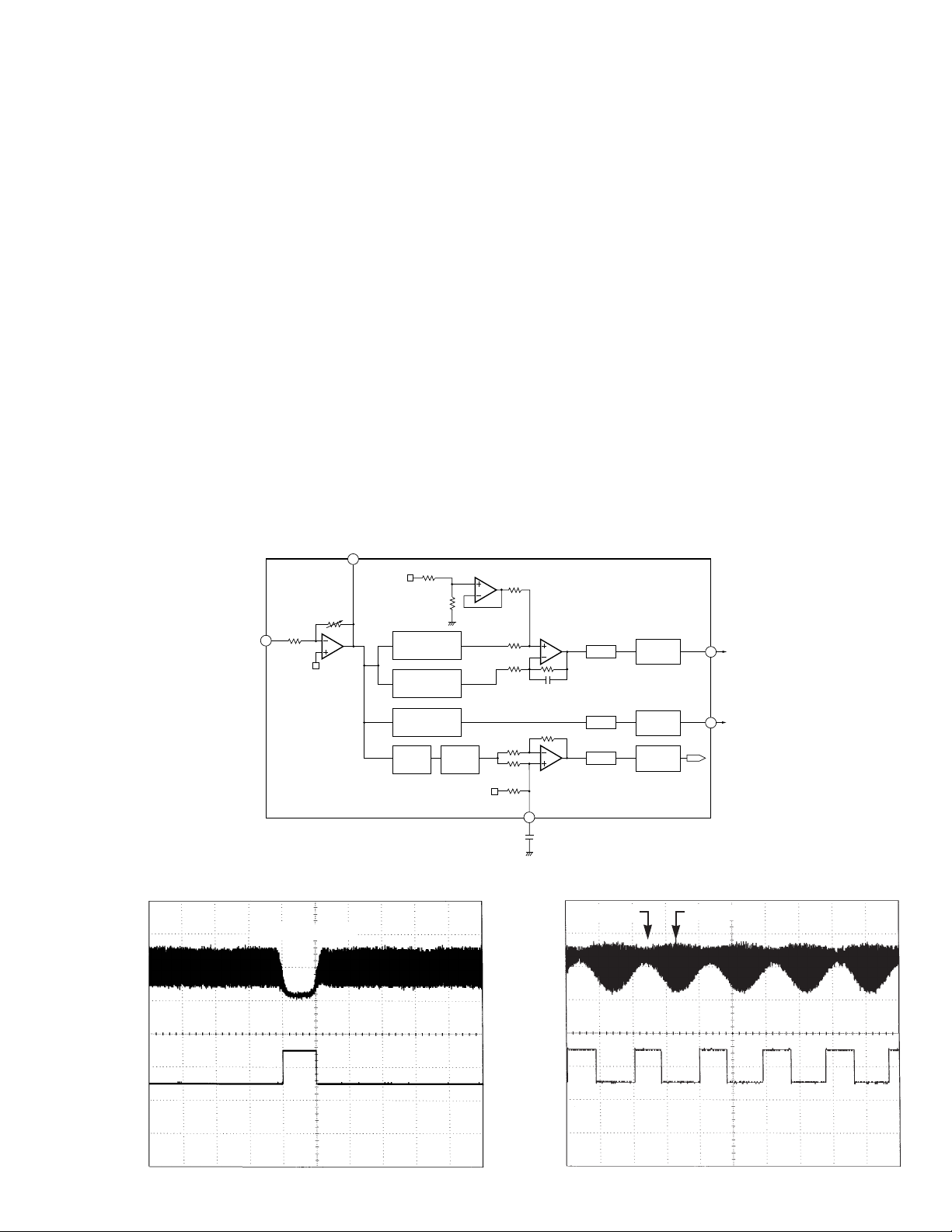

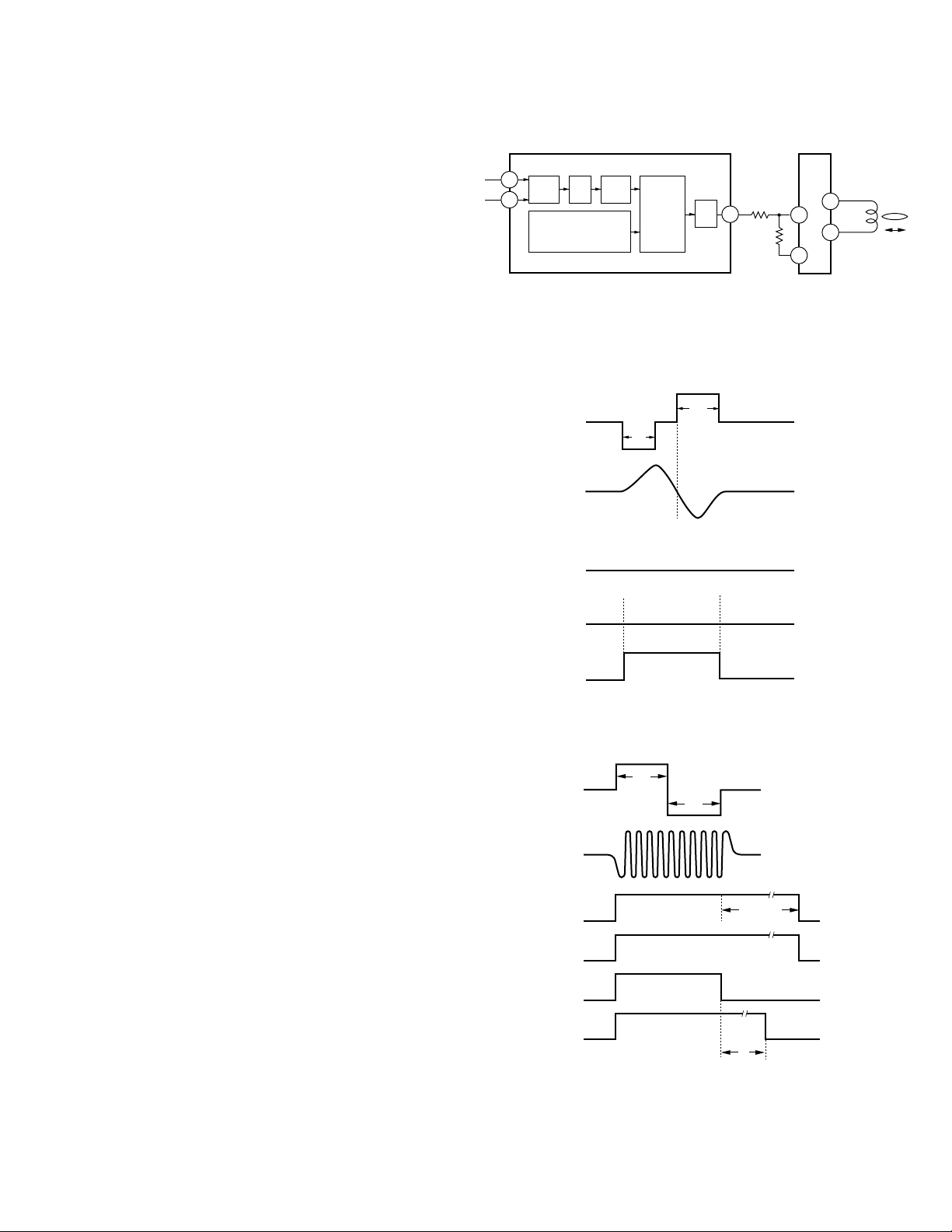

Fig.7 : HOLD OUTPUT WAVEFORM

(When surface defects are present)

Fig.8 : MIRR OUTPUT WAVEFORM

(When an access is made)

5

Surface defects

RFI

HOLD

RFI

MIRR

OFF Track ON Track

Page 6

6

C X-938

10) EFM Circuit

This circuit is used for converting the RF signal to

digital signal consisting of “0” and “1”. The RFO signal

from Pin 75 is externally AC coupled, entered to Pin 74,

then applied to the EFM circuit.

Loss of the RF signal due to scratches or stains on the

disc, or vertical asymmetry of the RF due to variations

in the discs manufactured can’t be eliminated by AC

coupling alone. This circuit, therefore, controls the

reference voltage ASY on the EFM comparator by use

of the fact that “0” and “1” appear fifty fifty in the EFM

signal. By this arrangement, the comparate level is

constantly maintained at almost center of the RFO

signal level. The reference voltage ASY is generated

when the EFM comparator output is passed through

the low pass filter. The EFM signal is output from Pin

71. It is a 2.5 Vp-p amplitude signal centering on REFO.

74

RFI

40k

40k

C206

3900pF

72

71

ASY

EFM

40k

40k

15k75k

2k

R205

10k

R206

39k

C203

0.1µF

C204

3300pF

EFM. SIG

Fig.9 : EFM CIRCUIT

Page 7

7

C X-938

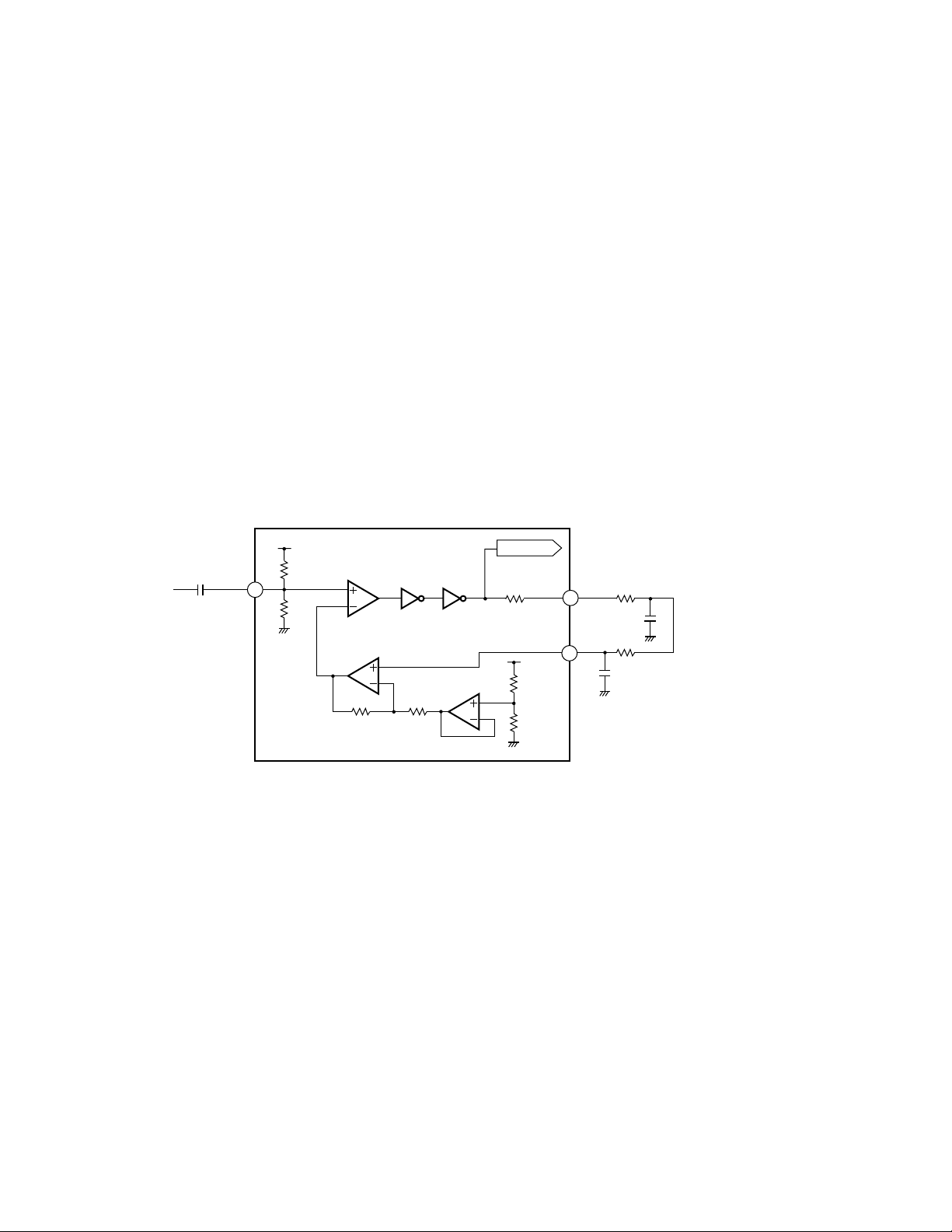

1.2 SERVO SECTION (UPD63710GC :

IC201)

The servo section controls the operations such as error

signal equalizing, in focus, track jump and carriage

move. The DSP is the signal processing section used

for data decoding, error correction and interpolation

processing, among others.

This circuit implements analog to digital conversion of

the FE and TE signals generated on the pre-amplifier,

then outputs them through the servo block as the drive

signal used on the focus, tracking and carriage system.

The EFM signal is decoded on the signal processing

section and finally output via the D/A converter as the

audio signal. The decoding process also generates the

spindle servo error signals which is fed to the spindle

servo block to generate the spindle drive signal.

The focus, tracking, carriage and spindle drive signals

are then amplified on the driver IC BA5986FM (IC301)

and fed to respective actuators and motors.

1) Focus Servo System

The focus servo main equalizer is consisted of the

digital equalizer. Fig.10 shows the focus servo block

diagram.

When implementing the focus close on the focus servo

system, the lens must be brought within the in-focus

range. Therefore, the lens is moved up and down

according to the triangular focus search voltage to find

the focus point. During this time, the spindle motor is

kicked and kept rotating as a set speed.

The servo LSI monitors the FE and RFOK signals and

automatically carries out the focus close at an

appropriate point.

The focus closing is carried out when the following

three conditions are met :

1

The lens approaches the disc from its current

position.

2

RFOK

=

"H"

3

The FZC signal is latched at high after it has once

crossed the threshold set on the FZD register (Edge

of the FZD).

As the result, the FE (

=

REFO) is forced to low.

FE

AMP

DIG.

EQ

82

A+C

B+D

FD

FOP

FOM

IC301

BA5986FM

LENS

IC201 UPD63710GC

85

62

3

4

14

13

FOCUS SEARCH

TRIANGULAR

WAVE GENERATOR

DAC

CONTROL

A/D

R302

15k

R301

10k

Fig.10 : FOCUS SERVO BLOCK DIAGRAM

Page 8

8

C X-938

When the above conditions are all met and the focus is

closed, the XSI pin goes to low from the current high,

then 40 ms later, the microcomputer begins to monitor

the RFOK signal after it that has been passed through

the low pass filter.

When the RFOK signal is recognized as low, the micro

computer carries out various actions including

protection.

Fig.11 a series of operations carried out relevant to the

focus close (the figure shows the case where focus

close is not available).

You can check the S-curve, search voltage and actual

lens behavior by selecting the Display 01 for the focus

mode select in the test mode, and then pressing the

focus close button.

REFO

FD

LENS POSITION

RELATIVE TO DISC

NEAR

FAR

"JUST FOCUSED"

MD

REFO

Expanding around "Just Focused Point"

REFO

RFI

FOK

FE

FZD

THRESHOLD

LEVEL

FZD

(INTERNAL SIGNAL)

Focus closing would normally take place at these points

XSI

(IN THE EVENT

FOCUS IS

CLOSED)

LEVEL

Fig.11 : FOCUS CLOSE SEQUENCE

Page 9

9

C X-938

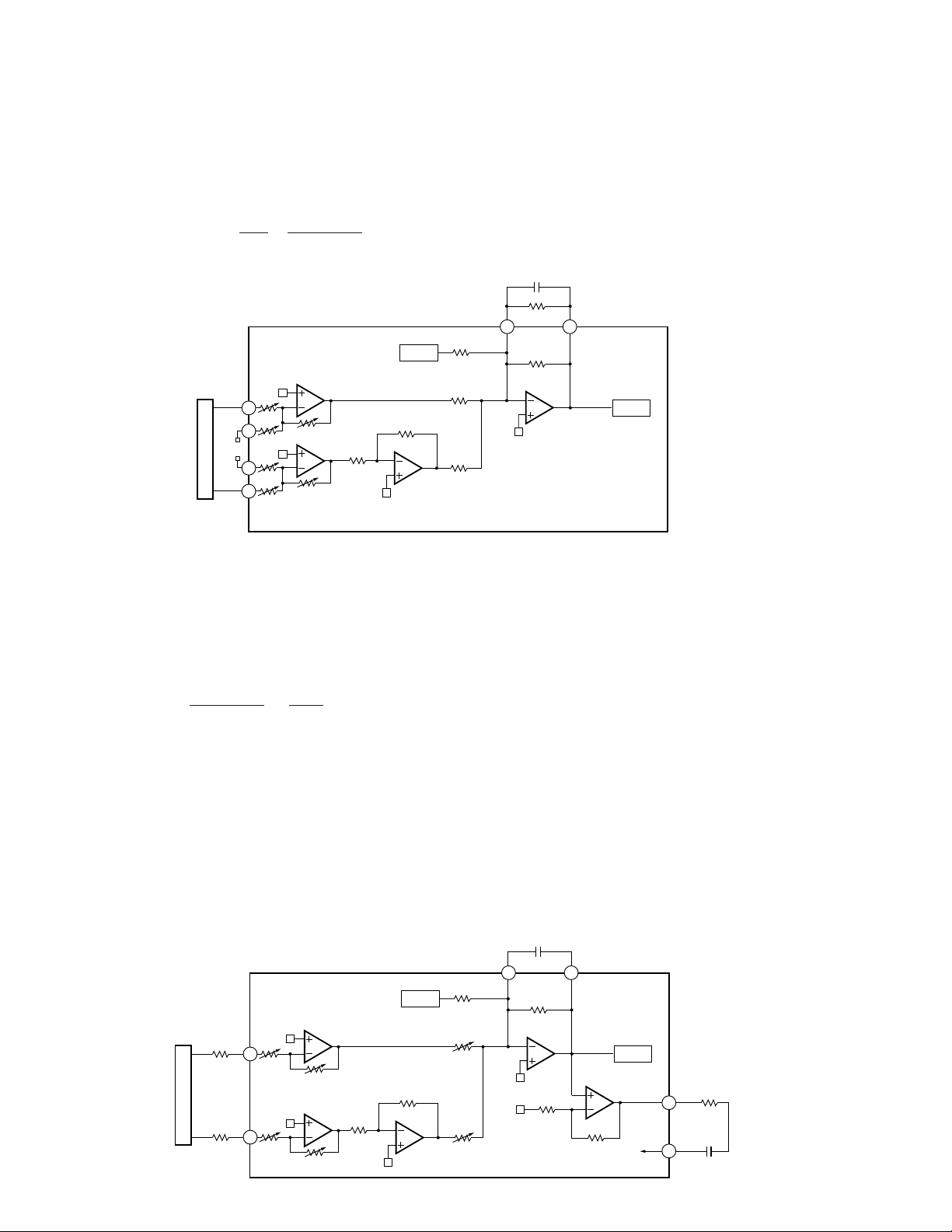

2) Tracking Servo System

The digital equalizer is employed for the main equalizer

on the tracking servo. Fig.12 shows the tracking servo

block diagram.

a) Track jump

When the LSI receives the track jump command from

the microcomputer, the operation is carried out

automatically by the auto sequence function of the LSI.

This system has five types of track jumps used for the

search : 1, 4, 10, 32 and 32 ×3. In the test mode, in

addition to three jumps (1, 32 and 32

×

3), move of the

carriage can be check by mode selection. For track

jumps, the microcomputer sets almost half of tracks (5

tracks for 10 tracks, for instance) and counts the set

number of tracks using the TEC signals. When the

microcomputer has counted the set number of tracks, it

outputs the brake pulse for a fixed period of time

(duration can be specified with the command) to stop

the lens. In this way, the tracking is closed and normal

play is continued.

To improve the servo loop retracting performance just

after the track jump, the brake circuit is turned on for 50

ms after the brake pulse has been terminated to

increase gain of the tracking servo.

Fast forward and reverse operations are realized by

through consecutive signal track jumps. The speed is

about 10 times as fast as that in the normal mode.

TOP

TOM

IC301

BA5986FM

LENS

11

12

6

7

R304

15k

R303

10k

TE

AMP

DIG.

EQ

86

F

E

TD

IC201 UPD63710GC

87

63

JUMP

PARAMETERS

DAC

CONTROL

A/D

t1

t2

GAIN NORMAL

TD

KICK

BRAKE

TEC

T. BRAKE

EQUALIZER

T. SERVO

CLOSED

OPEN

NORMAL

GAIN UP

OFF

ON

t1

TD

TEC

(10 TRACK)

EQUALIZER

T. BRAKE

SERVO

SD

2.9mS (4.10 TRACK JUMP)

5.8mS (32 TRACK JUMP)

GAIN UP

NORMAL

ON

OFF

OPEN

CLOSED

t2

50mS

t

Fig.12 : TRACKING SERVOBLOCK DIAGRAM

Fig.13 : SINGLE TRACK JUMP

Fig.14 : MULTI-TRACK JUMP

Page 10

10

C X-938

b) Brake Circuit

The servo retracting performance can be deteriorate

during the setup or track jump operation. In this

connection, the brake circuit is used to ensure steady

retract of the tracking servo. The brake circuit detects in

which direction the lens is moving, then slows down its

move by outputting the drive signal that moves the

lens into the opposite direction alone. Track slippage

direction is determined by referencing the TEC and

MIRR signals and their phase.

TEC

TZC

(TEC "SQUARED UP" )

(INTERNAL SIGNAL )

MIRR

MIRR LATCHED AT

TZC EDGES

=

SWITCHING PULSE

EQUALIZER OUTPUT

(SWITCHED)

DRIVE DIRECTION

Note : Equalizer output assumed to hava same phase as TEC.

FORWARD

LENS MOVING FORWARDS

(INNER TRACK TO OUTER)

LENS MOVING BACKWARDS

Time

REVERSE

Fig.15 : TRACKING BRAKE CIRCUIT

Page 11

11

C X-938

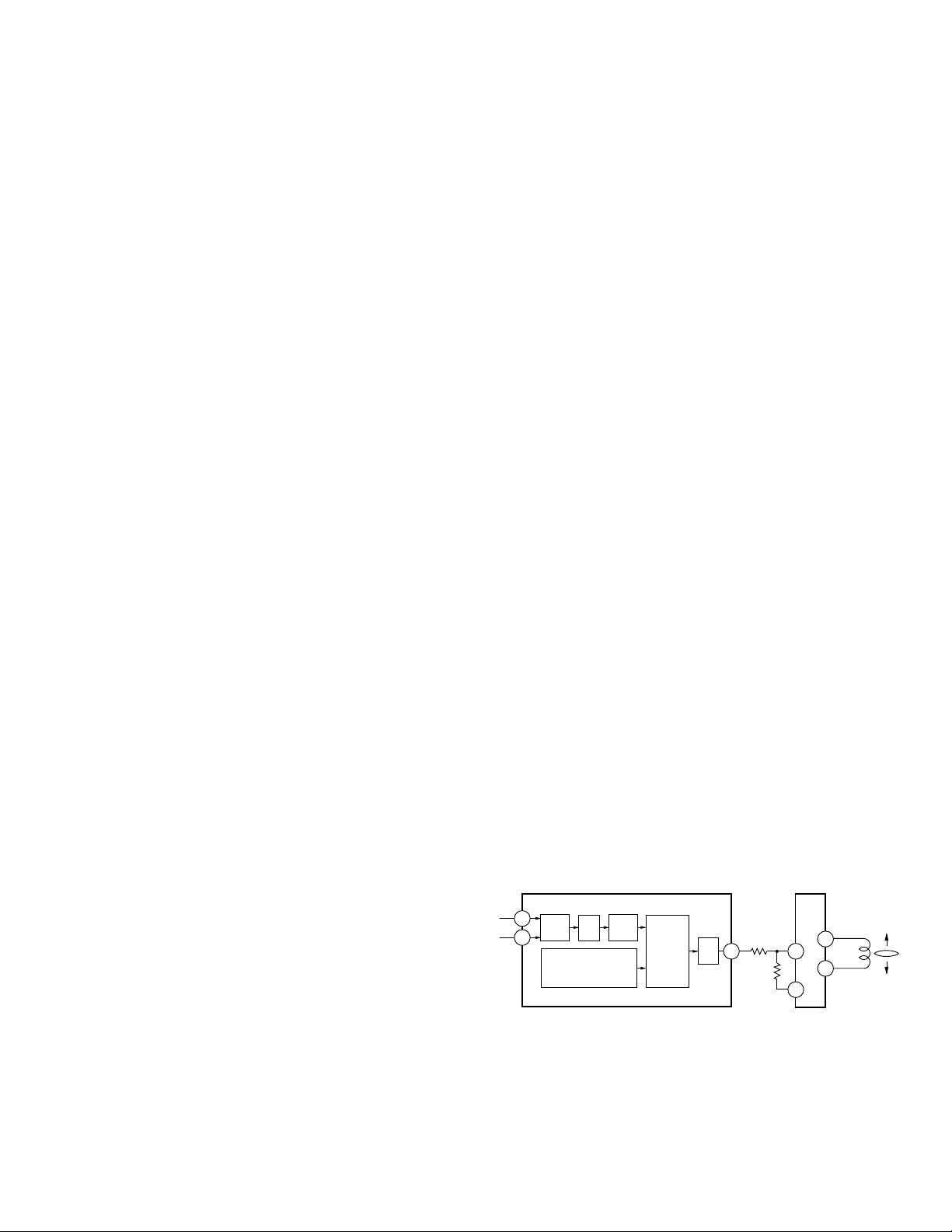

3) Carriage Servo System

The carriage servo supplies the tracking equalizer’s

low-frequency component (lens position data) output to

the carriage equalizer, then, after providing a fixed

amount of gain to it, outputs the drive signal from the

LSI. This signal is then applied to the carriage motor via

the driver IC.

When the lens offset reaches a certain level during play,

the entire pickup must be moved into the forward

direction. Therefore, the equalizer gain is set to the

level that allows to generate a voltage higher than the

carriage motor starting voltage. In actual operations, a

certain threshold level is set for the equalizer output by

the servo LSI so that the drive voltage may be output

from the servo LSI only when the equalizer output

exceeds the threshold level. This arrangement helps

reducing power consumption. Also, due to disc

eccentricity or other factors, the equalizer output may

cross the threshold level a number of times. In this

case, the drive voltage output from the LSI will have

pulse-like waveform.

COP

COM

IC301

BA5986FM

CARRIAGE

MOTOR

15

16

M

DIG.

EQ

SD

IC201 UPD63710GC

64

KICK, BRAKE

REGISTERS

DAC

CONTROL

FROM

TRACK. EQ

26

25

R306

7.5k

R305

10k

DRIVE ON/OFF THRESHOLD

CARRIAGE MOVED AT THESE POINTS

TRACKING DRIVE

(LOW FREQUENCY)

LENS POSITION

CRG DRIVE

(INSIDE UPD63710GC)

CRG MOTOR VOLTAGE

Fig.16 : CARRIAGE SERVOBLOCK DIAGRAM

Fig.17 : CARRIAGE SIGNAL WAVEFORM

Page 12

12

C X-938

4) Spindle Servo System

The spindle servo has the following modes.

1

Kick :

This mode is used for accelerating the disc rotation

during setup.

2

Offset :

(a) After the kick is over in the setup, this mode is

turned on until changing to rough servo mode.

(b) When focus is lost during play, this mode is

turned on until the focus is restored.

Both of the above are used for maintaining the disc

rotation rate near to the specified rate.

3

Applicable servo :

The CLV servo mode is turned on for the normal

operations.

In the EFM demodulation block, the frame sync

signal and internal counter output signal are

sampled for every WFCK/16 and a signal is produced

for indicating whether or not they are matching.

They are determined to be asynchronous only when

this signal fails to match 8 times in succession. In all

other cases, above two signals are assumed to be

synchronous. In the applicable servo mode, the

retracting servo is automatically selected if the two

signals are synchronous. If not, the regular servo is

automatically selected.

4

Brake :

This mode is turned on when stopping the spindle

motor.

The microcomputer outputs the brake voltage

through the servo LSI. The LSI monitors the EFM

waveform and, if its longest pattern exceeds a

certain interval (if the rotation is sufficiently slow),

the flag is set the LSI and the microcomputer turns

off the brake voltage. When the flag is not up within

a specified period time, the microcomputer switches

the mode from the brake to the stop mode, and

maintains this mode for a fixed period of time. If this

stop mode is continued for a fixed period of time,

the disc will be ejected.

5

Stop :

This mode is used for powering on the system and

the eject operation. When this mode is turned on,

voltage across the spindle motor is 0V.

6

Rough servo :

This mode is used for when the carriage feed

(carriage mode for the long search, etc.) is turned on.

The linear speed is calculated from the EFM

waveform and high or low level is entered to the

spindle equalizer. In the test mode, this mode is also

used for the grating check.

SOP

SOM

IC301

BA5986FM

SPINDLE

MOTOR

17

18

M

23

22

R308

7.5k

R307

10k

DSP

BLOCK

DIG.

EQ

MD

IC201 UPD63710GC

65

DAC

EFM

SIGNAL

SPEED ERROR SIGNAL

PHASE ERROR SIGNAL

Fig.18 : SPINDLE SERVOMOTOR BLOCK DIAGRAM

Page 13

13

C X-938

1.3 AUTOMATIC ADJUSTMENT FUNCTIONS

Every circuit adjustment on the CD-LSI of this system is

automated.

Every circuit adjustment is automatically implemented

when the disc is inserted or the CD mode is selected

from the source key. The following describes how the

adjustments are executed.

1) FZD Cancel Setting

This setting is used for executing the focus close

operation without fail.

When power is turned on, the FE offset level is read and

a voltage opposite to this offset value is written to the

CRAM on the IC to cancel the offset. In this manner, the

FZD threshold level can be set to a constant value

(+240mV), thereby ensuring to meet one of the

requirements for the IC to execute the focus close that

“the FZD signal is latched at high”.

2) Automatic Adjustment of TE, FE and RF Offset

Using REFO as the reference, this function adjusts the

pre-amp TE, FE and RF offsets to the respective target

value when power is turned on (targets values of the

TE, FE and RF are 0, 0 and −1V, respectively).

The following is the adjustment procedure :

(1) Respective offset (LD off) is read by the

microcomputer via the servo LSI.

(2) The microcomputer calculates the voltages to be

corrected from the read values, then sets them to

the specified field.

3) Automatic Adjustment of Tracking Balance (T.

BAL)

This adjustment is used for eliminating differences

between the pickup E and F channels outputs by

adjusting gain of the amplifier on the LSI. In the actual

operation, the TE waveform is adjusted so that it may

be vertically symmetric with REFO.

The following is the adjustment procedure :

(1) Make sure the focus close is complete.

(2) Kick the lens in the radial direction to generate the

TE waveform.

(3) At this time, the microcomputer reads the TE signal

offset value (via the servo LSI) being calculated by

the LSI.

(4) The microcomputer determines if the read offset

value is positive, negative or zero.

If the offset value =0, the adjustment is terminated.

If the offset value =A positive or negative value,

gain of the E and F channels amplifiers are modified

according the predetermined rule.

Then above steps (2) through (4) are repeated until the

“Offset value =0” or “Specified limit count” is reached.

4) Automatic Adjustment of FE Bias

This adjustment is intended at maximizing the RFI level

by optimizing the focus point in-play. This adjustment

utilizes the phase difference between the RF waveform

3T level and the focus error signal when disturbance is

applied.

Since disturbance is applied to the focus loop, this

adjustment is designed to take place in the same timing

as the auto gain control (to be described later).

The following is the adjustment procedure :

(1) Disturbance is injected to the focus loop by the

command from the microcomputer (within the servo

LSI).

(2) The LSI detects fluctuation of the RF signal 3T

component level.

(3) The LSI determines relationship between fluctuation

of the 3T component and the injected disturbance to

detect magnitude and direction of the off-focus

introduced.

(4) The microcomputer reads the detected results from

the LSI.

(5) The microcomputer calculates necessary correction,

then hands the calculated value to the bias

adjustment term set on the LSI.

This adjustment is repeated several times, as it is so

with the auto gain control, to ensure higher accuracy.

Page 14

C X-938

5) Focus and Tracking Automatic Gain Control

This function is used for implementing automatic

control of the focus and tracking loop gain.

The following is the adjustment procedure :

(1) Inject disturbance to the servo loop.

(2) Extract the error signal (FE and TE) generated at

when the disturbance is applied to obtain the

signals G1 and G2 via the B.P.F.

(3) The microcomputer reads the G1 and G2 signals via

the LSI.

(4) Based on the necessary correction calculated by the

microcomputer, the LSI performs the loop gain

adjustment.

Above adjustments are repeated several times to

ensure higher adjustment accuracy.

6) Automatic RF Level Adjustment (RFAGC)

This adjustment is used for implementing intended

signal transmission successfully by adjusting

unevenness of the RF signal (RFO) levels, that results

from disc and machine relevant factors, to a target

value. The adjustment is actually done by varying gain

of the amplifier provided between the RFI and RFO.

The following is the adjustment procedure :

(1) Using the command, the microcomputer reads the

output from the RF level detection circuit on the

servo LSI.

(2) Based on the read value, the microcomputer

calculates an amplifier gain that will produce the

target RFO level.

(3) The microcomputer sends the corresponding

command to the servo LSI so that the above gain

value may be set.

This adjustment takes place at the following timing :

• When the focus close alone is completed during the

setup process.

• Just before the setup is completed (just before the

play takes place).

• After the off-focus has been corrected during the play.

7) Adjustment of Pre-Amp Stage Gain

It is used for adjusting the entire RFAMP (FE, TE and RF

amplifiers) to +6dB or +12dB depending on given gain

level when reflected light from the disc is significantly

below the required level due to stained lens. This

phenomena can be noticed when playing back the CDRW.

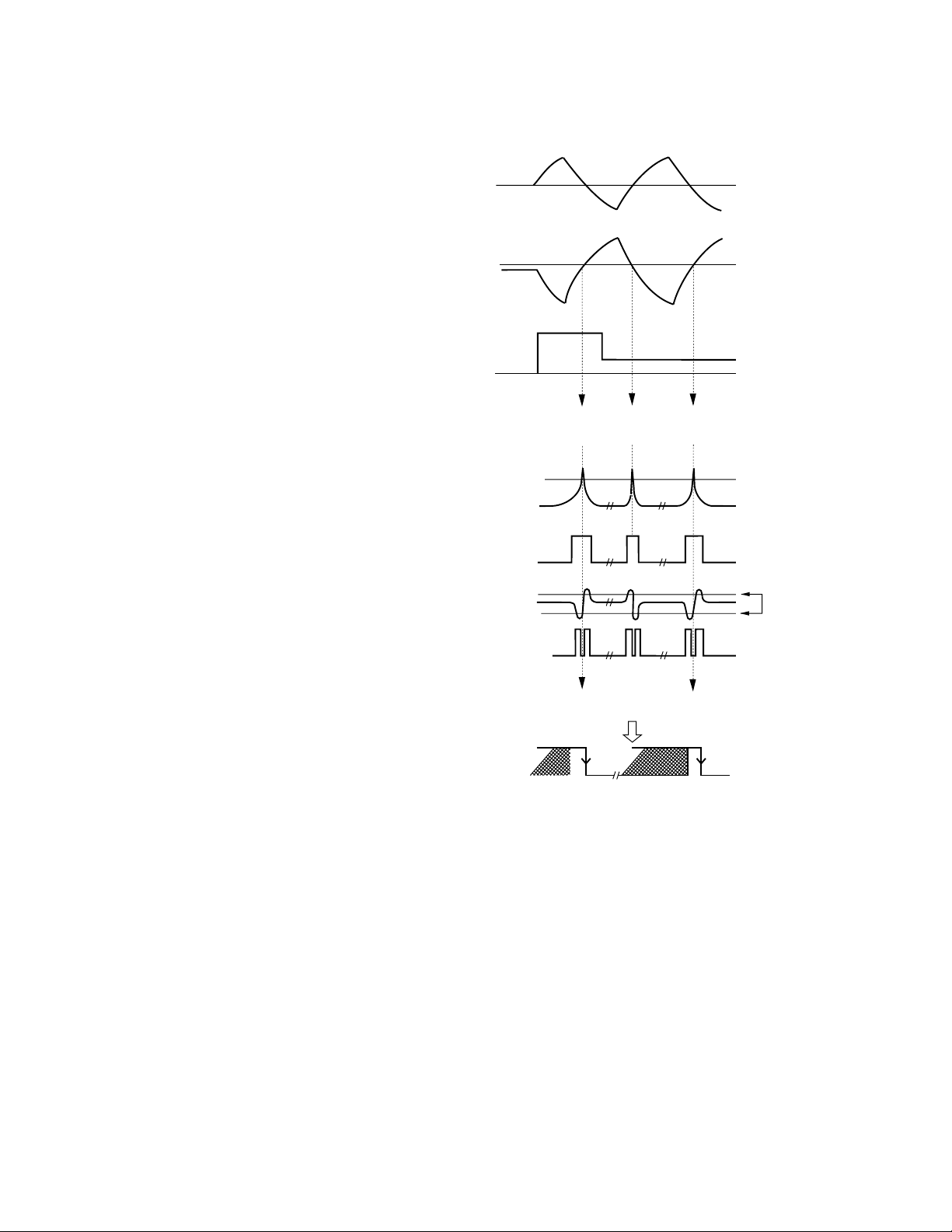

The following is the adjustment procedure :

When reflected light from disc is judged to be

significantly below the required level during the setup,

set the entire RFAMP to

+

6dB or +12dB. In this case, if

the gain is modified, the setup have to be repeated

from the first step.

Through the adjustment, if you judged the play

becomes available by setting the entire RFAMP to +6dB,

+

6dB should be selected for the setup next time on.

See the figure below :

Play at +6dB increases due to stained lens or other reasons

(the typical gain is employed for the initial setup)

Time

Gain of entire RFAMP

+ 12dB

+ 6dB

TYP

Play the CD-RW with the gain being set to +12dB

Play is started with +6dB

judging the lens is stained

Fig.19 : CONCEPTUAL DIAGRAM OF PRE-AMP GAIN ADJUSTMENT

14

Page 15

15

C X-938

8) Initial Adjusting Values

All the automatic adjustments are implemented using

the previous adjustment values as the initial values

unless the microcomputer power (the backup power) is

not turned off (though there are some exceptions).

When the backup is turned off, automatic adjustment is

executed based on the initial values rather than the

previous adjustment values.

9) Displaying Coefficients After Adjustment

You can display and check results of some automatic

adjustments (FE and RF offset, FZD cancel and F / T /

RFAGC) from the test mode. The following coefficients

are displayed in each automatic adjustment :

(1) FE and RF offset and FZD cancel

Reference value =32 (The coefficient of 32 indicates

that no adjustment was required).

The results are displayed in multiples of

approximately 40 mV.

An example : When FZD cancel coefficient =35

35 −32 =3

3 ×40 mV =120 mV

Since the corrected value is

approximately +120 mV, the FE offset

before adjustment was −120 mV.

(2) F and T gain adjustment

Reference value =Focus/Tracking =20

A coefficient displayed indicates an amount of

adjustment conducted on the reference value.

An example : When AGC coefficient =40

40/20 =Overall gain has bee doubled

(+6dB). (The original loop gain of 1/2

has been doubled to have the targeted

overall gain.)

(3) RF level adjustment (RFAGC)

Reference value =8

Coefficient =9 to 15 ····· The direction in which the

RF level is increased (the

gain is increased).

Coefficient =7 to 0 ······· The direction in which the

RF level is decreased (the

gain is decreased).

Incrementing or decreasing the coefficient by “1”

varies the gain by 0.7 to 1dB.

Maximum gain =Typically +6.5dB. Coefficient at this

time is 15.

Minimum gain =Typically −6.0dB. Coefficient at this

time is 0.

Page 16

16

C X-938

1.4 POWER SUPPLY UNIT CONFIGURATION

The power supply unit of this system consists of 4

power sources, VD(8.6V), 5VA(5V), 4R3VLR(4.3V) and

EVREF(5V).

VD :Main power source. Generated in the expan-

sion board.

5VA :Power source for IC201 and the Pick-up Unit.

Generated by the regulator IC (IC101) from VD.

4R3VLR :Audio midpoint voltage. Generated by the

regulator IC (IC603) from VD.

EVREF :Power source for Linear Position Sensor. A/D

reference voltage of the microcomputer.

Usually taken from the microcomputer's VDD

line via on enabling switch.

1.5 MECHANISM OPERATION

1) Elevation Operation

The microcomputer determines the present elevation

position from the voltage value (EPVO) obtained from

the potential divider VR801.

The voltage of the position of the requested disk is calculated from figure 20 and the ELV Motor is controlled

so that the EPVO voltage is matched to the value

obtained from the calculation.

2) Tray Extension and Retractino

The microcomputer detects the DSP signal waveform

(voltage) and TRP signal waveform (voltage) obtained

at the DSP switch (S852) and the TRP switch (S851) by

tray retraction, tray extension and clamp completion

and controls the Tray Motor.

EJECT Voltage position EREF+446LSB

DISC1 Voltage position EREF+367LSB EREF+377LSB EREF+387LSB

DISC2 Voltage position EREF+260LSB EREF+270LSB EREF+280LSB

DISC3 Voltage position EREF+193LSB EREF+203LSB EREF+213LSB

DISC4 Voltage position EREF+125LSB EREF+135LSB EREF+145LSB

DISC5 Voltage position EREF+ 58LSB EREF+ 68LSB EREF+ 78LSB

DISC6 Voltage position EREF+ 0LSB EREF+ 0LSB EREF+ 0LSB

DISC7 Voltage position EREF- 78LSB EREF- 68LSB EREF- 58LSB

DISC8 Voltage position EREF-145LSB EREF-135LSB EREF-125LSB

DISC9 Voltage position EREF-213LSB EREF-203LSB EREF-193LSB

DISC10 Voltage position EREF-280LSB EREF-270LSB EREF-260LSB

DISC11 Voltage position EREF-348LSB EREF-338LSB EREF-328LSB

DISC12 Voltage position EREF-416LSB EREF-406LSB EREF-396LSB

[

[

[

[

[

[

[

[

[

[

[

[

[

EPVO

H

L

MAG

* 1LSB=approx 4.88mV (5/1024V)

min typ max

[

]

[

]

ON

OFF

OFF

ON

TRP switch

DSP switch

Tray retracted

Tray in transition

Clamp completed

Fig. 20

Page 17

17

C X-938

3) 0.6mm UP/DOWN Operation

In order to secure clearance with the neighboring disk

the Stage Mechanism is driven down by the ELV Motor

(M852) when clamping is complete. The microcomputer

detects the completion of clamping, and when the Tray

Motor is brought to a full stop, the ELV Motor (M852) is

forcibly driven for a 240 ms interval in the downward

direction.

When the tray is being retracted, the ELV Motor (M852)

is controlled to match the value of EPVO calculated

during the elevation operation. The tray retraction operation is started when the Tray has been moved to the

prescribed position.

Each motor is driven by the driver IC302 (LB1836M).

LB1836M is an IC which usually operated through the

combination of H and L of the 4 lines l1, l2, l3 and l4.

With this system, l1=l3 and control is realized through a

combination of H and L of the 3 lines l1, l2 and l4.

4) Disc Detection

The DSP signal waveform (voltage) at the DSP switch

(S852) is used for determinating the existence and nonexistence of a disk and the disk type (8cm or 12cm). The

disk detection operations are carried out while the Tray

is being pulled out of the magazine. Disk detection is

determined when the light passes through (DISC

waveform L:less than 2.5v) or is interrupted (DISC

waveform H:2.5V or above) with an array of LEDs and

photo transistors above and below the Tray.

The DISC waveform is continuously monitored within

the intervals A and B above and if a L is detected even

once, that interval is determined as L. If a L is not detected at all then that interval is determined as H in the

following.

[

[

]

]

OFF

ON

DSP switch

DISC(12cm)

DISC(8cm)

DISC(Tray only)

AB

40msec

ELV Motor Tray Motor l1,l3 l2 l4

Forward Brake H H L

Reverse Stand-by L L H

Brake Forward H L H

Stand-by Reverse L H L

Brake Brake H H H

Stand-by Stand-by L L L

* ELV Motor Forward : ELV-up (Disc No. Down)

Tray Motor Forward : Tray Ejection

12cm

8cm

No Disk

A

B

Page 18

18

C X-938

Cautions on Service

1) Do not hold the upper frame of the magazine insertion port in the CD mechanism module, marked by an arrow in

Fig. 21, when servicing. It's because this section is easily deformed.

2) The stage mechanism section projects below the chassis when positioned at the tenth stage or lower. So, do not

leave the stage mechanism section at these positions to avoid damage or malfunction.

3) Before removing the flexible card and pickup flexible PCB from the connectors on the relay PCB, be sure to insert a

short pin into the pickup unit first.

4) When replacing the tray motor assy, mount the 2-stage gear(Not resable) on the shaft of a new tray motor assy. (As

the gear uses snap-on fittings, push it in until it is snapped completely.)

5) When replacing the magazine holder assy, mount the worm wheel(Not resable) on the shaft of a new elevation

worm wheel.

(As the gear uses snap-on fittings, push it in until it is snapped completely.)

2. DISASSEMBLY

- Removing the Pickup Unit

1. Insert a short pin into the pickup flexible PCB.

2. Remove the pickup flexible PCB from the connector.

3. Remove the flexible card from the connector.

4. Remove the lead wires of the spindle motor assy and carriage motor assy by removing solder.

5. Loosen the two screws. Lift up the relay PCB as shown in Fig. 22.

Be careful not to excessively pull the tray motor flexible PCB and the relay flexible PCB.

Fig. 21

CD mechanism module

Fig. 22

Flexible card

Erect

Flexible PCB (*Handle

with care)

Tray motor

flexible PCB

(*Handle with

care)

Short Pin

Relay PCB

This section is easily deformed.

Page 19

19

C X-938

6. Remove three screws A and then remove the carriage motor assy, remove the lighting conductor ,feed screw holder,

feed screw and belt (see Fig. 23).

7. Remove screw C on the main side and the pickup unit together with the guide shaft (see Fig. 23).

- Removing the CD Core Unit

1. Insert a short pin into the pickup flexible PCB.

2. Remove the flexible card from the CD core unit connector.

3. Remove the lead wires of the elevation motor assy that were soldered to the CD core unit.

4. Remove screw D and three screws E and then the CD core unit (see Fig. 24).

- Cautions on Mounting the CD Core Unit

When mounting the CD core unit on the CD mechanism module, accurately insert the

linear position sensor (Slide control: VR801) mounted on the CD core unit into the Ushaped groove of the elevation front lever (see Fig. 35).

If the linear position sensor is not inserted into the U-shaped groove, elevation operation

will malfunction.

- Removing the Carriage Motor Assy

After removing the pickup unit (see "Removing the Pickup Unit" in pages 17 and 18),

remove the feed screw, belt ,and feed screw holder.

Fig. 24

Screw E

CD core unit

Screw D

Screw E

Screw E

Mechanism unit - bottom view

Screw A

Motor bracket

CRG motor

Screw B

Feed screw holder

Feed screw

Guide shaft(main)

Guide shaft(sub)

Belt

Screw C

Pickup unit

Fig. 23

Lighting conductor

Page 20

20

C X-938

- Removing the Spindle Motor Assy

1. Rotate the tray motor until the clamp joint arm moves.

2. Slide and remove the clamp spring as shown in Fig. 25.

3. Remove the clamper.

4. As shown below, match the positions of the holes of the support wheel and screws F. Then remove the two screws F

and spindle motor assy.

* When removing the clamper, be careful not to lose the ball mounted between the clamper and clamp spring.

- Cautions on Mounting the Spindle Motor Assy

1. Mount the spindle motor assy so that the lead wires face the rear of the mechanism unit (see Fig. 26).

2. Check that the torsion spring presses the side pressure plate (see Fig. 27).

3. When mounting the clamper, confirm that the ball has been installed.

Fig. 26

Fig. 27

Fig. 25

Front side (magazine insertion port)

Support wheel

Torsion spring

Side pressure plate

Mechanism unit - bottom view

Rear

Clamp spring

Release the clamp spring from the

hook(s), and then slide it in the

direction indicated with an arrow.

Clamper

Match the positions of the

holes and screws F.

Screw F

Support wheel

Screw F

Orientation of the lead wire

Ball

Spindle motor assy

Spindle

motor

assy

Lift here

Clamper

Clamp joint

arm

Page 21

21

C X-938

- Removing the Tray Motor Assy (see Fig. 28)

1. Remove screw G.

2. Remove the elevation joint arm spring.

3. Remove the polyslider washer and the 2-stage gear.

4. Move the front lever to move the stage mechanism unit to the "4" position on the front lever.

5. Remove screw H.

6. Move the front lever again to move the stage mechanism unit to the uppermost stage.

7. Remove the tray motor assy.

- Cautions on Mounting the Tray Motor Assembly (see Fig. 28)

When mounting the 2-stage gear, verify that the positions of the holes of the 2-stage gear

and the stage chassis match each other. For easy confirmation, check that the shapes of the 2-stage gear and the stage

chassis form a concentric circle, as shown in the figure.

- Removing the Elevation Motor Bracket Assy (see Fig. 28)

1. Remove the elevation joint arm spring.

2. Remove the polyslider washer and the 2-stage gear.

3. Remove two screws I and the elevation motor bracket assy.

Fig. 28

Shape of the 2-stage gear

Shape of the stage chassis

Polyslider

washer

2-stage gear

Elevation joint arm spring

Stopper

Magazine

lock spring

Screw I

Elevation motor

bracket assy

Screw I

Screw G

Polyslider

washer

Front frame

Screw H

Front lever

Match the edge of the

front frame and the

reading "4" on the

front lever.

Tray motor assy

Front lever

Page 22

22

C X-938

- Removing the Stage Mechanical Unit Section (see Fig. 29)

1. Remove the elevation joint arm spring.(See Fig. 28)

2. Remove the magazine lock spring.(See Fig. 28)

3. Remove the 2-stage gear.(See Fig. 28)

4. Remove the screw J and then the stopper.

5.Fully slide the front lever in the direction that the stage mechanism assy moves upwards. Then, the front lever and

the rear lever can be removed at the same time.

6. Remove three screws K and two screws L, and then the magazine holder Assy.

7. Remove four screws M and then the lower frame.

8. Remove three screws N and then the front frame.

9. Move the stage mechanism assy to the lowest position. Slide the bent section of the stage mechanism assy along

the L-shaped groove in the front frame to remove the stage mechanism assy.

Fig. 29

Front frame

Screw N

Screw N

Screw L

Screw K

Screw K

Stopper

Screw N

Screw M

Screw M

Lower frame

Magazine

holder Assy

Screw J

Screw K

Screw M

Screw M

Screw L

Rear view of the CD

mechanism module

with the front and rear

levers removed.

Front frame L-shaped groove

Move to this position

Stage bent section

Page 23

23

C X-938

3. MECHANISM DESCRIPTIONS

- Inserting the Magazine

1. When the magazine is inserted against the force of the EJECT lever spring, the lock arm comes in along the groove

in the rear side of the magazine to lock (see Fig. 30).

2. The magazine lock is detected when the detection arm moves along the EJECT lever cam section and presses the

magazine detection switch mounted on the CD core unit.

When the magazine is not inserted, the detection arm is held at the SW OFF position by the EJECT lever cam (see

Fig. 31).

When the magazine starts insertion, the lock arm starts moving along the groove in the rear of the magazine. Then

the lock arm stops at the detection arm "stop" position. Although the detection arm tries to move in the SW ON

direction, the lock arm stops it. (See Fig. 32.)

When the magazine is completely inserted, the magazine to lock. At the same time, the detection arm is released to

press the magazine detection switch with spring force. (See Fig. 33)

Fig. 30

Fig. 31 Fig. 32 Fig. 33

EJECT lever cam

Magazine detection

switch

Detection arm

Lock arm

Stop

Stop

SW ON

Moves along

the groove in

the magazine.

Located at the lock

position along the groove.

When the magazine is not inserted

After the magazine has been inserted

Magazine

Lock arm

EJECT lever

EJECT spring

Lock arm

Groove in the rear of

the magazine

When the magazine is locked

Direction of the magazine insertion

Page 24

24

C X-938

- Elevation Operation (see Fig. 34)

When the elevation motor is driven, the elevation joint arm rotates. The front and rear

levers, engaged with the ends of the elevation joint arm respectively, slide to move the

stage mechanism unit up and down.

- Detecting Elevation (see Fig. 35).

When the elevation joint arm rotates, the front lever slides.

Because the knob of the linear position sensor (slide control: VR801) is inserted in the U-shaped groove of this front

lever, the elevation joint arm moves in synchronization with the lever and detects the voltage at that time.

Fig. 34

Fig. 35

Linear position sensor (Slide

control: VR801)

Front lever

Front leverShaft

Bottom view

Rear leverShaft

Stage mechanism unit

Elevation

joint arm

Stage mechanism unit

Page 25

25

C X-938

- Tray Extraction to Clamp Operation (Loading Motor Drive Section) (See Fig. 36.)

When the loading motor drives the cam gear, the cam gear moves the tray extraction arm along the cam groove to

extract the tray. At that time, the carriage assy (including the spindle motor assy and tray positioning pin) waits until

the tray passes it. When tray extraction has been completed, the cam gear swings the clamp joint arm and slides the

clamp lever engaged with the clamp joint arm. The shaft of the carriage assy is lifted along the step-shaped groove as

the clamp lever slides. The carriage assy swings toward the stage chassis. Subsequently, the spindle motor assy

comes to a CD disc to load and lift it up from the tray.

Fig. 36

Clamp spring

Clamper

CD

Tray

Spindle

motor assy

Carriage assy

Carriage chassis

Waiting state

Stage chassis

Tray

Clamp joint arm

Cam gear

Clamper

Spindle motor assy

Carriage chassis

Shaft

Positioning pin

Clamp lever

Tray extraction arm

Clamp position

Page 26

26

C X-938

- Elevation Mechanism - Play Elimination

Immediately before the clamp operation is completed, the bent sections of the clamp lever comes into the frame

stopper section and press it downward to control the vertical position. This operation can press the stage downward

by means of the elevation mechanism. At this time, the elevation motor stops, not by the detection of the pressed

position, but in a certain period of time after the elevation mechanism moves up to the limit of the movement. (See

Fig. 37)

The figure 37 shows the pressing mechanism. When the clamp lever bent sections press the framestopper section, the

carriage chassis shaft inserted into the clamp lever groove is lifted up until it is pressed against the end of the vertical

groove in the stage chassis. At this time, the stage chassis shaft, which is also inserted into the other groove in the

clamp lever, is located at the wider portion of the groove so that the carriage chassis shaft can move to the end of the

vertical groove in the stage chassis. This pressing operation eliminates the play at each of the stage chassis, carriage

chassis, clamp lever, and the frame to improve the resistance against vibration. (See Fig. 39.)

* The elevation joint arm spring has been installed to keep this pressing state.

- Disc detection

The cam gear for tray extraction operation moves the DSP switch lever to turn the DSP switch (S852) ON and OFF. The

photo sensors (Q851 and D852) detect the presence of discs and their types (8 or 12 cm) with a certain timing.

Fig. 37

Clamp lever

bent section

Clamp lever

bent section

Clamp lever

bent section

Frame stopper

Stage chassis vertical

groove end

Stage chassis shaft

Carriage chassis shaft

Frame stopper

Clamp lever

The play of each

section is eliminated

by pressing the

sections marked by

circles.

Stage

chassis

Carriage

chassis

Looseness

After being pressed

Before being pressed

Gaps

Total amount of

carriage shaft

looseness

Fig. 38

Fig. 39

Page 27

27

C X-938

- Detecting Tray Extraction and Return

A) Tray extraction (Fig. 40)

The clamp joint arm moves the clamp lever and performs clamping. After clamping has been completed, the

protrusion on the clamp joint arm presses the TRP switch (S851) via the TRP switch (S851) via the plate spring on

the DSP switch lever and turns on the switch.

B) Tray return (see Fig. 41)

The TRP switch (S851) is turned on by the DSP switch lever moved by the cam gear.

Fig. 40

Fig. 41

DSP switch lever

LED (D851)

DSP switch (S852)(ON)

TRP switch (S851)(ON)

Cam gear

Clamp lever

Clamp joint arm

DSP switch (S852)(OFF)

TRP switch (S851)(ON)

Page 28

28

C X-938

- Tray Lock Mechanism

In other modes than the PLAY mode, the tray bouncing prevention spring is deflected by the rear lever and functions

as a stopper to prevent the tray from coming out of the magazine. (Fig. 43)

In the PLAY mode, the window in the rear frame catches the projection of the tray bouncing prevention spring.

Accordingly, the spring is not deflected to enable the tray's insertion and extraction. (Fig. 42)

Consequently, in other modes than the PLAY mode (during the waiting mode), the tray will not come out of the

magazine even if external shock is applied to it. (Fig. 43)

- Ejecting the Magazine (see Fig. 44)

When the rear lever is further driven from the uppermost stage position of the elevation, the bent end face of the rear

lever presses the boss on the lock arm to release the lock and the magazine is ejected by the EJECT lever.

Fig. 42

Fig. 43

Fig. 44

Lock arm

Boss

Rear lever

When set in the

PLAY position

When set to a position

other than PLAY

Functions as a stopper

Rear lever

Tray

Bouncing

prevention spring

Window

Page 29

29

C X-938

- Lubrication points (Fig. 45)

(3) For the other sections, use the E paste.

Fig. 45

Feed screw tip

Pickup Unit

Sub guide shaft

(1) Around the pickup assy ->

Use EM-60L for all points.

(2) Slide section with clamp ball

Main shaft

Feed screw tip

Feed screw

thread

Spacer

Clamper

EM-60L (Dow

Corning)

Clamp spring

Loading...

Loading...