Page 1

PIONEER ELECTRONIC CORPORATION 4-1, Meguro 1-Chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS SERVICE INC. P.O.Box 1760, Long Beach, CA 90801-1760 U.S.A.

PIONEER ELECTRONIC [EUROPE] N.V. Haven 1087 Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE.LTD. 501 Orchard Road, #10-00, Wheelock Place, Singapore 238880

C PIONEER ELECTRONIC CORPORATION 1998

K-ZZB. OCT. 1998 Printed in Japan

ORDER NO.

CRT2291

MD MECHANISM MODULE

CX-893

CONTENTS

1. CIRCUIT DESCRIPTIONS...........................................2

2. DISASSEMBLY.........................................................13

- This service manual outlines operations of the MD mechanism module used in the models listed

below.

- For repair, use this Service Manual and the Service Manual of the model used in the system.

Model Service manual MD mechanism module

MEH-P5000R/EW CRT2287 CXB2784

Page 2

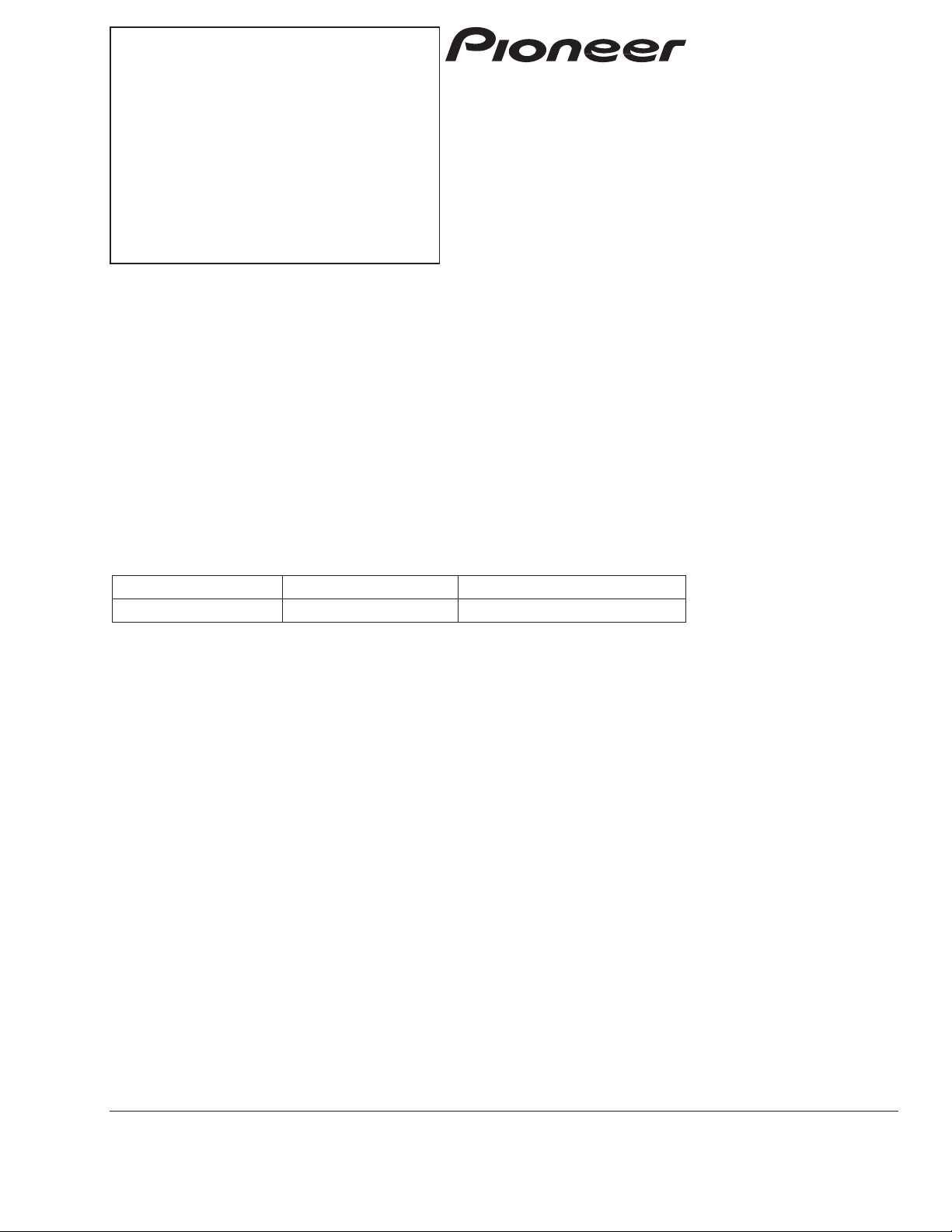

Figure 1 below shows the block diagram. This block

controls the output from the block LD to be consistent

with the monitor diode.

The block consists of IC 102 and turned to LD ON when

LDON (6 pin) is H and to LD OFF when LDON is L. LD

output level is set with the voltage value of LDVAR and

is usually around 2.4 V.

2

CX-893

1. CIRCUIT DESCRIPTION

1.1 APC Part

Fig.1

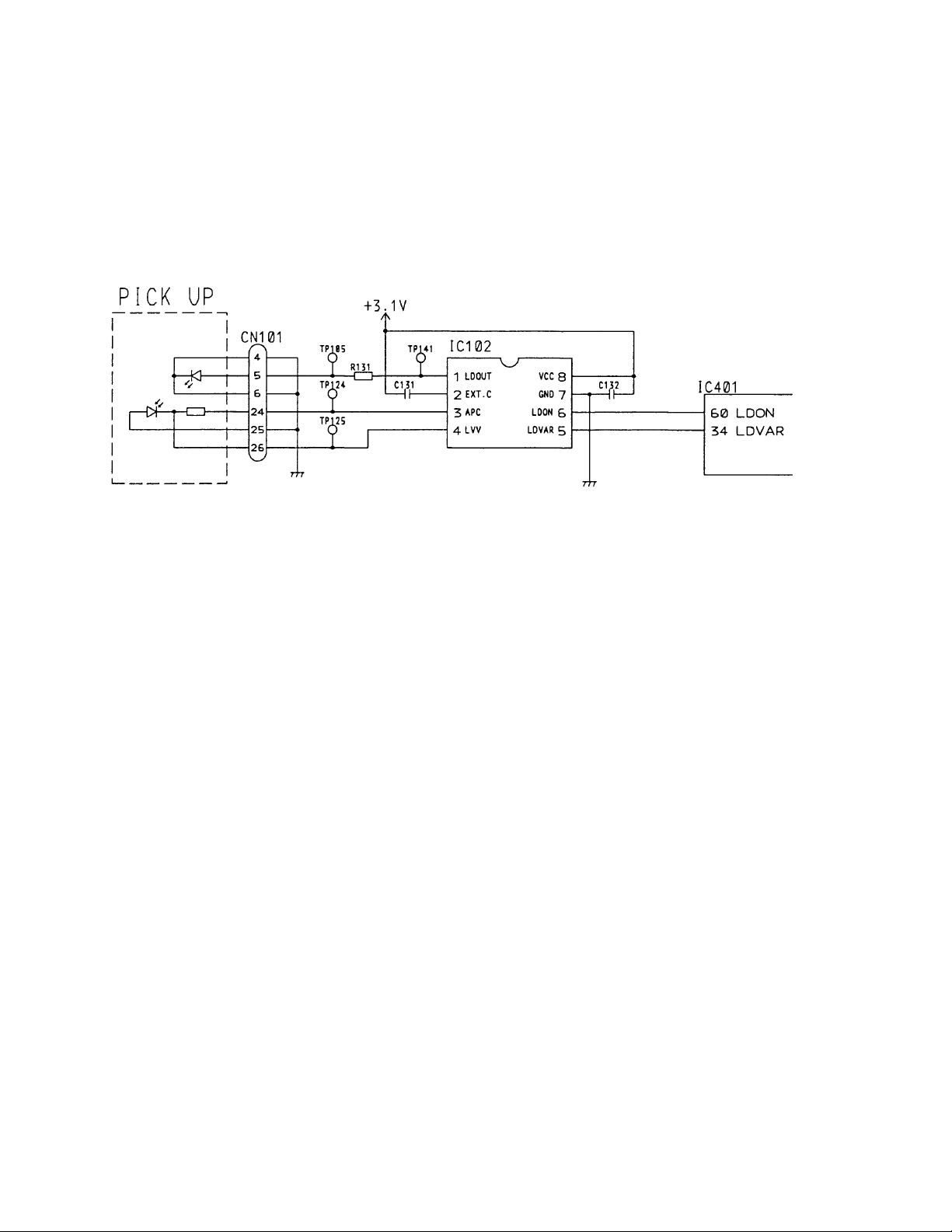

1.2 RF amplifying part

The block amplifies the pickup output signal and

generates RF and ADIP signals.

This block mainly consists of IC101.

REFO part

REFO (+1.5 V) is the reference voltage for the servo.

The signal is resistive divided at the IC (REFI: 5 pin) and

output to 6 pin through buffer. This signal will be the

reference for RFIC.

RF signal amplifying part

Figure 2 below shows the block diagram. The signal

which is I-V converted at the pickup is input to the RF1-4

(1-4 pin). Gain at the I-V amplifier contained in the PU

is switched depending on the disc types. The switching

is controlled by OPICGA (IC401, 61 pin) and H is output

at Premaster DISC and L is output at Recordable DISC.

The signal input from the I-V amplifier is operated with

the contained resistance and amplifiers (A1, A2) and the

signal (RF1 + RF2 + RF3 + RF4) (POUT) and the signal

(RF1 + RF2 + RF3 - RF4) (GOUT) are generated. Each of

POUT and GOUT is equipped with an analog switch.

The switches are controlled with the DISC signal (bits

on microprocessor serial communications). The POUT

signal is output through 48 pin when the DISC signal is

H (PIT mode) and GOUT signal is output through 47 pin

when the DISC signal is L (GRV mode).

These signals are input to EFMAGC (45 pin) through the

coupling capacitors (C133, C112) and transmitted to the

AGC circuit and filter part to be output from EFMO (40

pin). The EFMO is maintained at almost same level

(approx. 1.5 Vpp) with the AGC circuit. These signals

are input to the signal processing part (IC201: 3 pin) and

used for data processing and spindle control when

playing a Premaster Disc.

Page 3

3

CX-893

Fig.2

ADIP signal amplifying part

Figure 3 shows the block diagram of this part. The block

generates the ADIP signal which exists only on a

Recordable DISC of a MD.

Signals input to RF1 and RF2 (1,2 pin) are transmitted

through the AGC part and the filter part to be output to

22KO (32 pin). The 22KO is designed to be maintained

at almost same level (approx. 1.2 Vpp) with the AGC

circuit. However, fluctuation of about +0.5V may be

observed due to core components, responsibility of

tracking servo, etc. The signal is then converted to 1

and 0 signal with the comparator C1, input to the signal

processing part (IC201:11 pin), and used for address

control when playing disc for recording and spindle

control.

*Will not be used when Premaster Disc is played.

C1

Fig.3

Page 4

4

CX-893

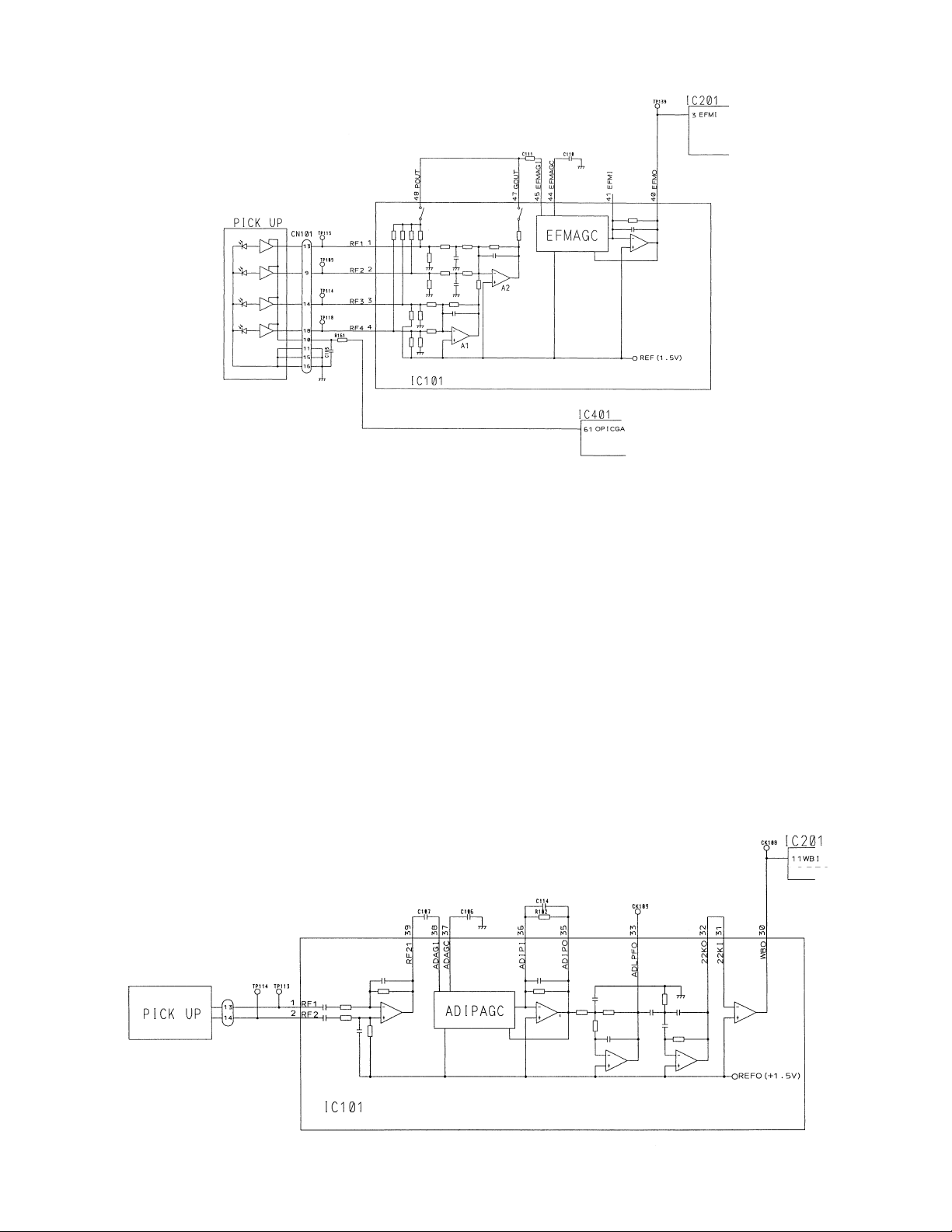

Track cross part, signal amplifying part for servo

Figure 4 shows the block diagram of these parts.

The signal input to RF1-4 (1-4 pin) is resistive divided

and amplified to be output to TCGO (29 pin). TCGO is

input to the signal processing part (IC201:7 pin) and

TCRS signal is generated and will be used when the

system skips tracks to play.

Outputs from the focus servo based photo diode are

input to AIN (9 pin) and BIN (10 pin) and are output to

AOUT (28 pin) and BOUT (27 pin), respectively, after

being amplified.

Outputs from focus servo based photo diode are input

to EIN (11 pin) and FIN (12 pin) and are output to EOUT

(26 pin) and FOUT (25 pin), respectively, after being

amplified .

These signals are input to the signal processing part

(IC201: 5,6,7,8,9 pin) and used at each servo.

Amplifying ratios of each signal are controlled by the

microprocessor and adjusted so that they reach

optimized values when mechanical modules are

shipped. Those optimized values are stored in IC402.

Therefore, when you replace IC or PU switch, etc., you

should have the IC402 memorize new optimized values

by turning EEPROM (IC402) to write mode (See the

relevant sections for details.) and running test modes

AUTO1 and AUTO2 with a Recordable DISC (MMD-211

or MMD-212).

Fig.4

Page 5

5

CX-893

Logic part

Serial commands of the microprocessor determines the

setting of this IC.

Timing chart

DATA (23pin)

CLOCK (22pin)

LATCH (21pin)

MSB 7SB 6SB 5SB 4SB 3SB 2SB 1SB

Structure of serial data

MSB 7SB 6SB 5SB 4SB 3SB 2SB 1SB

Pattern A H L Focus gain Tracking gain

Pattern B L H STBY DISC SGAIN Track loss gain

Gain setting (+12dB when SGAIN=H at normal operation)

Setting value Focus gain Tracking gain Track loss gain

000 –40 –40 –18

001 –34 –34 –12

010 –28 –28 –6

011 –22 –22 0

100 –16 –16 6

101 –10 –10 12

110 –4 –4 18

111 –4 –4 18

STBY: Switches to stand-by mode

H: Normal L: Stand-by

DISC: Switches to disc mode

H: PIT (Premaster Disc)

L: GRV (Recordable Disc)

SGAIN: Switch of amplifier gain for servo

H: +12dB

L: Normal

Page 6

6

CX-893

1.3 Signal processing part (IC201)

This block consists of the following four parts:

1) Servo part

2) Signal processing part

3) Shock proof controlling part

4) ATRAC part

The details for each part are described below.

1) Servo part

1.1) Focus servo

Figure 5 shows the block diagram of the focus servo.

The signals input to AIN (5 pin) and BIN (8 pin) are

processed with subtraction treatment after analogdigital conversion. These signals can be monitored

with FEMON (75 pin). These signals, however, should

be monitored using LPF with cutoff of around 50 kHz

(e.g. R=100 kΩ, C=33 pF) because they are PWM signals.

These signals are equalized at subsequent D and F parts

and output to FODRF (18 pin) and FODRR (19 pin) with

PWM.

The output signals are amplified with the driver (IC601)

and drive the actuator.

You must move the lens up and down for close focus.

Close the focus when the following requirements are

met:

1) When the lens is going down.

2) FOK (82 pin) = L

3) FZC (signal inside IC ) = i

Fig.5

Page 7

7

CX-893

1.2) Tracking servo and thread (carriage) servo

Figure 6 shows the block diagram of the tracking servo

and thread (carriage) servo.

1.2.1) Tracking servo

Signals input to EIN (6 pin) and FIN (9 pin) are

processed with subtraction treatment after analogdigital conversion. These signals can be monitored

with TEMON (75 pin). These signals, however, should

be monitored using LPF with cutoff of around 50 kHz

(e.g. R=100 kΩ, C=33pF) because they are PWM signals.

These signals are equalized at subsequent D and F parts

and output to TRDRF (20 pin) and TRDRR (21 pin) with

PWM. The output signals are amplified with the driver

(IC601) and drive the actuator.

1.2.2) Thread servo

Thread servo extracts and amplifies only low frequency

signals by transmitting the outputs from tracking D and

F parts through D and F parts. When these signals

exceed a certain threshold voltage, they are output to

SLDRF (22 pin) and SLDRR (23 pin) with PWM.

These signals are amplified with the driver (IC601) and

then drives the motor.

Fig.6

Page 8

1.3) Track jumping

Tracks to play are automatically skipped using AUTO

mode which is an LSI function.

Figure 7, 8, and 9 show examples of 1TJUMP, 10JUMP

and Auto MOVE, respectively.

8

CX-893

Antiskid

SLKLEV

WAIT

SLCT

Automove

Antiskid

SENSE (terminal)

Tracking output

Tracking count

(COUT) : the no. of

tracks = TRCNT x 64

Thread output

Specified no. of tracks

Fig.7

Fig.8

Fig.9

TE

Tracking

drive output

SENSE (terminal)

TE

Tracking

drive output

SENSE (terminal)

Page 9

1.4) Spindle servo

Figure 10 shows the block diagram of the spindle servo.

Perform CLV control with EFMI (3 pin) when you play

the read-in area of a Premaster DISC or Recordable

DISC and with WBI (11 pin) when you play the program

area of a Recordable DISC.

1.5) Auto tuning

This mechanical module is automatically tuned so that

it absorbs dispersion among discs caused by ambient

changes or course of time thereby stabilizing the play of

discs. This auto tuning will be made whenever you

insert a disc or select MD mode with the source cue.

1.5.1) When you play Premaster DISC

Tracking ATT tuning

Measures the levels of LPFEINO, LPFFINO and EFMIO

that EIN (6 pin) and FIN (9 pin) generate and specifies

the amount of ATT that is calculated with formula.

u

Maintains the tracking loop gain at a certain level and

stabilizes the tracking servo operation.

Focus ATT tuning

Measures the levels of LPFABO that AIN (5 pin) and

EIN (8 pin) generate and specifies the amount of ATT

that is calculated with formula.

u

Maintains the focus loop gain at a certain level and

stabilizes the tracking servo operation.

1.5.2) When you play a Recordable DISC

Tracking ATT tuning (PIT. GRV)

Measures the levels of LPFEINO, LPFFINO and EFMIO

that EIN (6 pin) and FIN (9 pin) generate and specifies

the amount of ATT that is calculated with formula.

u

Maintains the tracking loop gain at a certain level and

stabilizes the stabilizes the tracking servo operation.

Focus ATT tuning (PIT. GRV)

Measures the levels of LPFABO that AIN (5 pin) and

EIN (8 pin) generate and specifies the amount of ATT

that is calculated with formula.

u

Maintains the focus loop gain at a certain level and

stabilizes the tracking servo operation.

TCRS ATT tuning

Measures the level of TCGSMIO that TOG (7 pin)

generates and specifies the amount of ATT that is

calculated with formula.

u

Stabilizes searches when you play a Recordable DISC.

9

CX-893

Fig.10

Page 10

2) Signal processing part

Figure 11 shows the block diagram of signal

processing, shock proof controlling and ATRAC parts.

The signal processing part consists of the two blocks,

one of which demodulates the music data on the disc

and corrects errors, and the other of which controls

addresses used for searches and time calculation.

2.1) Music data

The signal input from EFMI (3 pin) is equalized with the

digital filter after analog-digital conversion. This signal

can be monitored with EFMO (1 pin). The signal will be

sliced at an appropriate level and modulated to 0 and 1

signal and then transmitted to the subsequent shock

proof part after EFM demodulation and error correction

are completed.

2.2) Address control

Reads the address data on the disc and specifies targets

for time control during play and searches. The

methods of reading the address data depends on the

disc types.

When you use a Premaster DISC

Extracts the address data from the music data after

error correction is completed.

When you use a Recordable DISC

Modulates frequency of the signal input from WBI (11

pin) and reads the addresses from the data.

3) Shock proof controlling part

The data from the signal processing part is temporarily

stored in DRAM (IC202). Later, the data will be sent out

sequentially by the data requests from the subsequent

ATRAC part or instructions from the microprocessor.

This mechanical module contains the 4MB DRAM and

can store the data of approximately 10 seconds.

4) ATRAC part

The data from DRAM (IC202) will be extended for

ATRAC at this block and then converted into the audio

data.

The data formats to be used at the subsequent DAC

(IC501) are as follows:

BCLK (71 pin): 64 Fs

DADATA (74 pin): 20 bits from the last

DFCK (72 pin): 256 Fs

LRCK (70 pin): Fs, L/R

*Fs=44.1 kHz

10

CX-893

Fig.11

Page 11

1.4 Mechanical control

1) Loading

The microprocessor instructs the motor driver IC651 to

rotate backward (IC651: 3 pin: L, 4 pin:Ht¨L+: L, L-:H) if

LOAD STRAT SW (SW652) detects OFF (LOAD

STRAT=H). If LOAD STRAT SW (SW652) detects ON

(LOAD END=L) later, the microprocessor instructs the

motor driver IC651 to stop (IC651: 3pin: H, 4pin:Ht¨L+:

L, L-:H) and completes the loading and then transits to

PLAY operation. If DISC IN SW (SW903) is OFF (DISC

IN=H) or LOAD END SW has been OFF for a long time,

the microprocessor determines that there is no inserted

disc or a disc insertion error and performs EJECT or

Error STOP.

2) EJECT

The microprocessor instructs the motor driver IC651 to

positively rotate (IC651: 3 pin: H, 4 pin:Lt¨L+: H, L-:L)

when it receives the EJECT instruction. If EJECT END

SW (SW653) detects ON (EJECT END=L) later, the

microprocessor instructs the motor driver IC651 to stop

(IC651: 3pin: H, 4pin:Ht¨L+: H, L-:H) and completes the

EJECT operation.

11

CX-893

1.5 Others

1) Temperature detection

This module detects high temperatures, to protect PU.

When the temperature of the output from the

temperature sensor (IC402) exceeds a certain voltage

level, it is determined as high temperature and an

appropriate process such as Error STOP will be

performed. The ambient temperature which causes

that high temperature on the module is approximately

80 degree Celsius.

2) Voltage monitoring

This module monitors voltage to protect the system.

The signals which are resistive divided (R803, 804) from

the input VD from the product (CN301: 1,2) are

monitored (IC401, 25 pin). If the voltage of the signal is

higher than 2.86 V (VD7V or higher) or lower than 2.04

V (VD5V or lower), an appropriate process such as Error

STOP will be performed.

Page 12

12

CX-893

1.6 How to rewrite EEPROM

This mechanical module stores adequate values for the

servo, etc., in the EEPROM (IC402). Therefore you need

to rewrite the data in the EEPROM when you replaced

mechanism, PU, LSI, or microprocessor.

- When you replaced EEPROM (IC402),

microprocessor (IC401)

1 Make TP435 (IC402: 6 pin) and TP421 (IC402: 8 pin)

short-circuited.

2 Start the product in Test mode. (See manuals for

each product for how to start.)

3 Display the EEPROM setting menu and view any

setting value, e.g., Focus “FGP__XX”. (You should

not change the value.)

4 Switch to Test STOP mode.

5 Turn ACC off. * After turning ACC off, wait for about

10 seconds because EEPROM is written into during

that time.

6 Turn Backup off.

7 Disconnect the short-circuits you have done in the

step 1).

- When you replace pickup, mechanism, LSI

(IC101, 201) or their peripherals.

1 Make TP435 (IC402: 6 pin) and TP421 (IC402: 8 pin)

short-circuited.

2 Start the product in Test mode. (See manuals for

each product for how to start.)

3 Load Recordable DISC (MMD-211 or MMD-212) and

run AUTO1. When “Complete” sign appears, press

the FUNC key and run AUTO2. When “Complete”

sign appears again, press the FUNC key and confirm

the indicated addresses are normally counted up.

*If “Can’t ADJ” sign appears in this step, check the

soldering if it has any problem.

4 Switch to Test STOP mode.

5 Turn ACC off. * After turning ACC off, wait for about

10 seconds because EEPROM is written into during

that time.

6 Turn Backup off.

7 Disconnect the short-circuits you have done in the

step 1).

Page 13

2. DISASSEMBLY

- How to remove mechanism

1. Remove No.3 screws and remove the loading motor.

2. Rotate No.4 gear in the direction indicated by the arrow.

3. Remove the No.1 screw and then No.2 screw and take out the mechanism.

13

CX-893

Fig.12

Fig.13

Page 14

- How to remove the disc motor

1. Remove the connector from the mechanism PCB.

2. Release the three screws and remove the disc motor.

CX-893

- How to remove the sled motor.

1. Remove the two points of solder on the sled motor

terminal.

2. Release the two screws and remove the sled motor.

Note) Be sure not to damage the motor gear.

- How to remove optical pickup

1. Release the three screws.

2. Pull one shaft out a little to the slide motor side and

lift the optical pickup upward slowly.

Disc motor

Mechanism PCB

MD mechanism

Sled motor

x2

Remove the solder

x2

x1

x1

Shaft

Optical pickup

Fig.14

Fig.15

Fig.16

Loading...

Loading...