Pioneer CX-692 Service manual

Model Service Manual DVD/CD Mechanism Unit

XDV-P9/UC,EW,ES/RC,ES/RD CRT2511 CXK7010

PIONEER CORPORATION 4-1, Meguro 1-Chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS SERVICE INC. P.O.Box 1760, Long Beach, CA 90801-1760 U.S.A.

PIONEER EUROPE N.V. Haven 1087 Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE.LTD. 253 Alexandra Road, #04-01, Singapore 159936

C PIONEER CORPORATION 2000

K-ZZS. MAY 2000 Printed in Japan

ORDER NO.

CRT2533

DVD/CD MECHANISM UNIT

CX-692

- This service manual describes the operation of the DVD/CD mechanism incorporated in models listed

in the table below.

- When performing repairs use this manual together with the specific manual for model under repair.

CONTENTS

1. CIRCUIT DESCRIPTIONS ...........................................2

2. DISASSEMBLY .........................................................20

3. MECHANISM DESCRIPTIONS.................................24

2

C X-692

Q104

PICKUP UNIT

IC103 TA1254AF

45

LDO1

MDI1

44

GND

7

VCC

8

VPS

IC101

3

4

2

1

IM

CPOUT

PICKUP UNIT

Fig. 1

Fig. 2

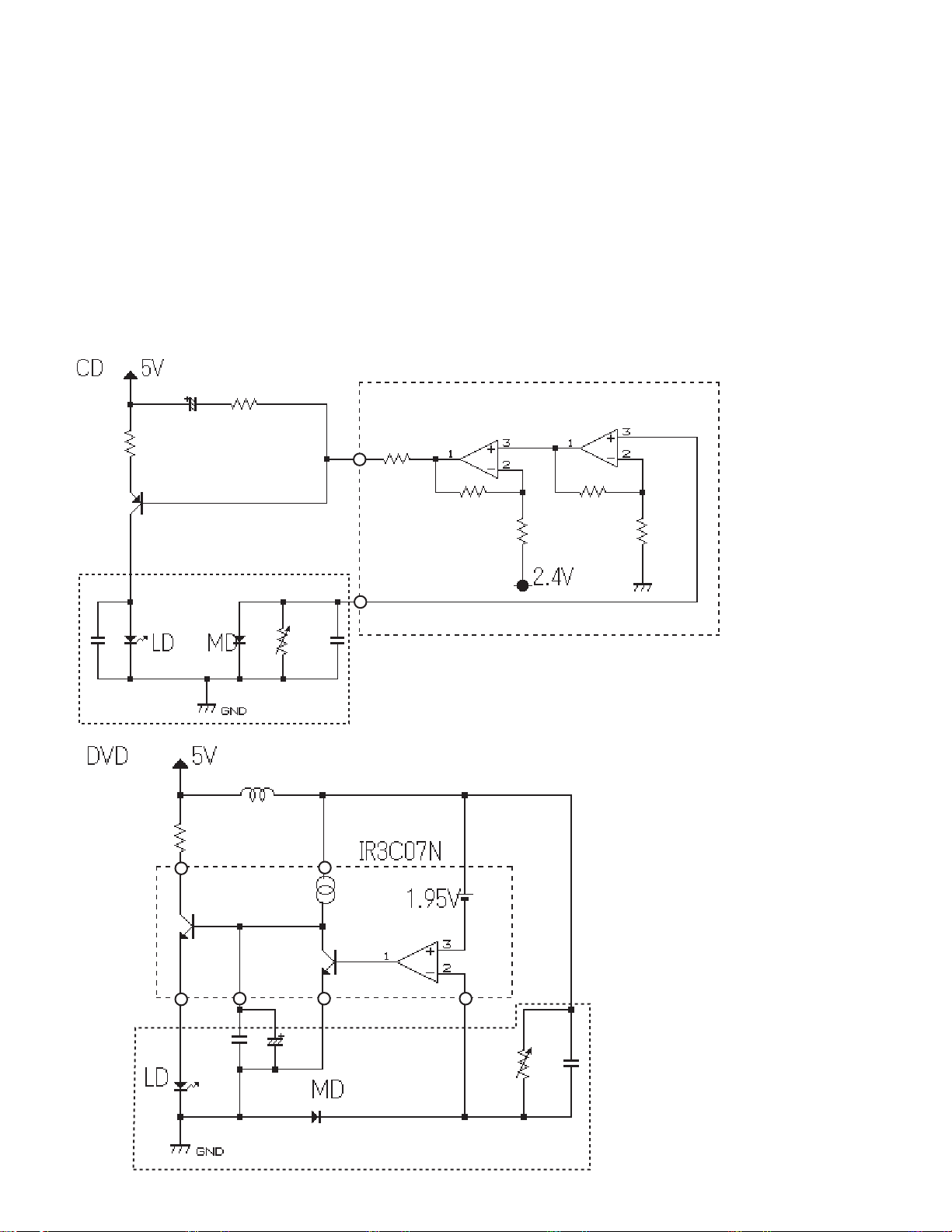

1. Circuit Description

1.1 APC circuit

- APC (Automatic Power Control) circuit

[Fig. 1 CD and Fig. 2 DVD]

Since the optical output of laser beam diodes carries a

large negatived temperature characteristic, necessary

optical power cannot be acquired when driven at a

lower current level. The APC circuit is a circuit to

control the current levels so that the output of the

monitor diode may become constant. By measuring

the voltage occurring between the LD and the drive

transistor, the LD current can be found out and such

current value should be within

±

20% of the value

indicated on the pickup unit flexible P.C. board when

handling the CD and should be 50mA or less when

handling the DVD.

C X-692

3

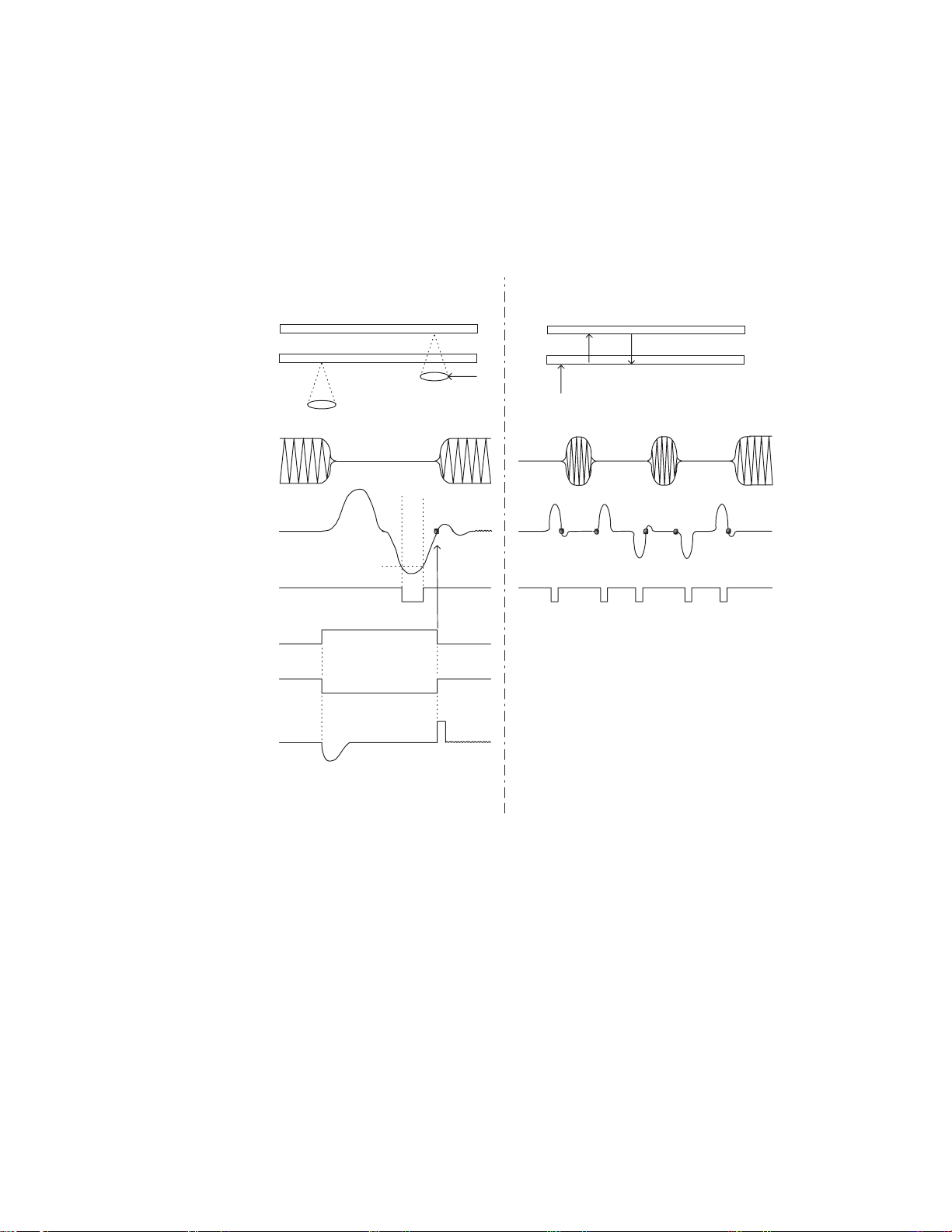

1.2 FOCUS-JUMPING CIRCUIT

Focus-jumping function is a function conforming to

single side 2-layer discs or double-side 2 layer discs.

Fig. 3 below shows the basic movement sequence.

Viewing through the objective lens, the layer on this

side is called Layer 0 (L0) and the layer on the far side is

called the Layer 1 (L1).

Objective lens

RF

FE

Focus

standby level

Focus ON

Vref

GND

Vref

A(Fig.4)

TEST00

B(Fig.4)

IO0

L0=L1

L1=L0

L0 L1

L0

L1

L0

(Layer1) L1

(Layer0) L0

L1

L0

A

B

C

D

E

A

B

C

D

E

Fig. 3

4

C X-692

Described below are the explanations of the basic

movements.

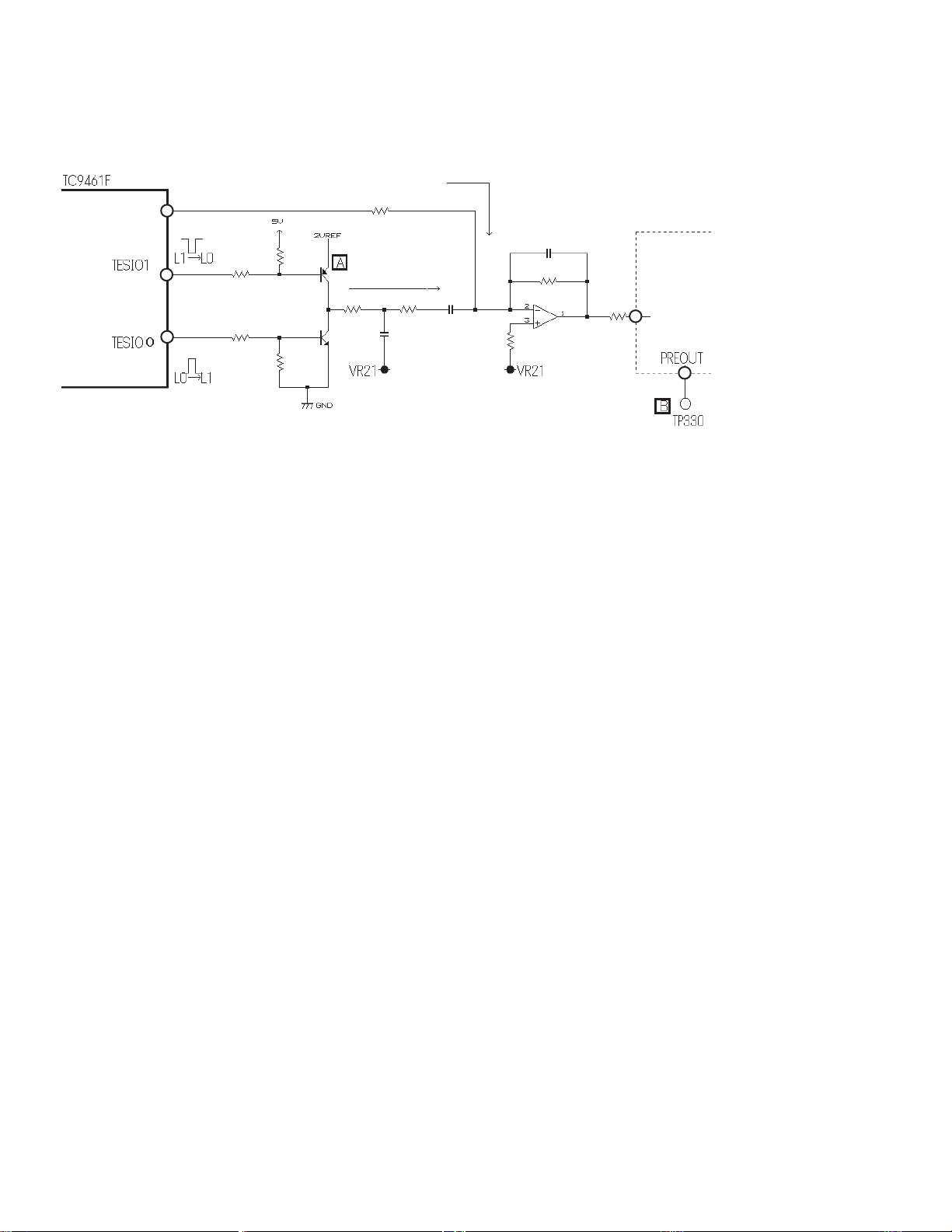

When the focus-jumping command is issued from the

mechanism controller (IC501:PD5511A), the input to the

focus equalizer is changed over from the AD converter

output (FOO) to the DC hold filter output and DC

holding is effected.

Simultaneously, the focus search drive signals are

output through the TESIO0 pin and the TESIO1 pin. By

the circuit shown in Fig. 4, these signals are made to

apply drive signals to the focusing servo loop which

work to drive the focusing actuator to complete the

layer jump.

FOO

19

FOJ

Q401

Q402

IC402

NJM2904M

IC401

67

43

18

19

IC304

BA6797FM

Focus-jumping circuit

Normal state

While focus-jumping

is in progress

Fig. 4

C X-692

5

Under normal CD settings: F-GAIN = 0.5dB, FE-GAIN = 3.0dB

Under normal DVD settings: F-GAIN = -4.5dB, FE-GAIN = 6.0dB

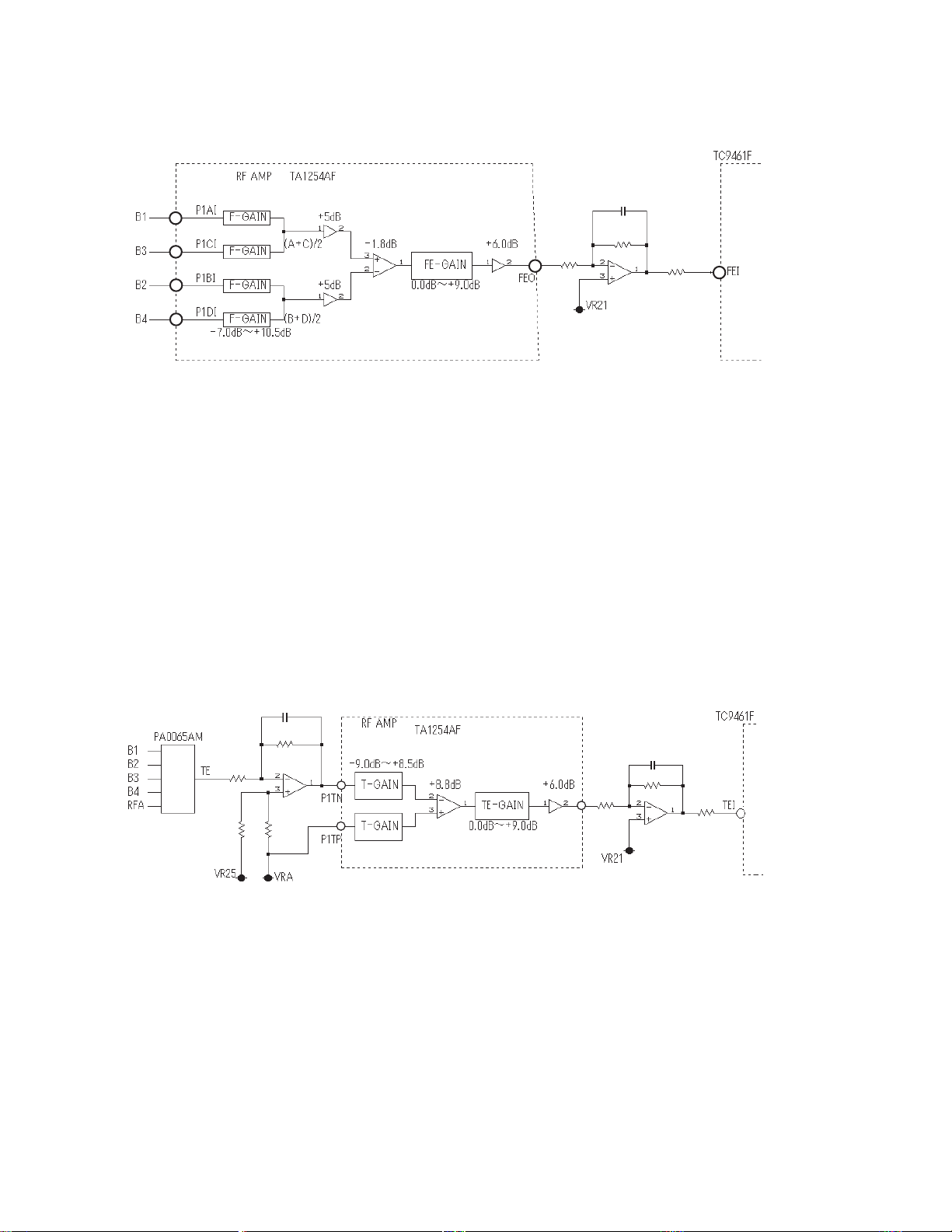

1.4 TRACKING ERROR SIGNAL

GENERATING CIRCUIT

Tracking error signals are being formed by amplifying the RFA

being generated through the B1 - B4 of the pickup unit output

and the RF amplifier (IC103:TA1254AF) by the

TC7WU04FU(IC106,109) and by inputting these signals to the

time difference IC (IC107:PA0065AM). The error signals being

output from the time difference IC are amplified through the OP

amplifier(IC108) and the RF amplifier(IC103) before being input

to the servo DSP (IC401:TC9461F pin41).

Under normal CD settings: T-GAIN = -9.0dB, TE-GAIN = 0.0dB

Under normal DVD settings: T-GAIN = -9.0dB, TE-GAIN = 6.0dB

IC103

55

53

54

52

21

IC105

NJM3404AM

IC401

38

IC107

2

8

4

10

6

19

IC108

NJM3404AM

IC103

46

47

20

TEO

IC108

NJM3404AM

41

IC401

Fig. 5

Fig. 6

1.3 FOCUS ERROR AMPLIFIER

6

C X-692

1.5 SERVO SYSTEMS

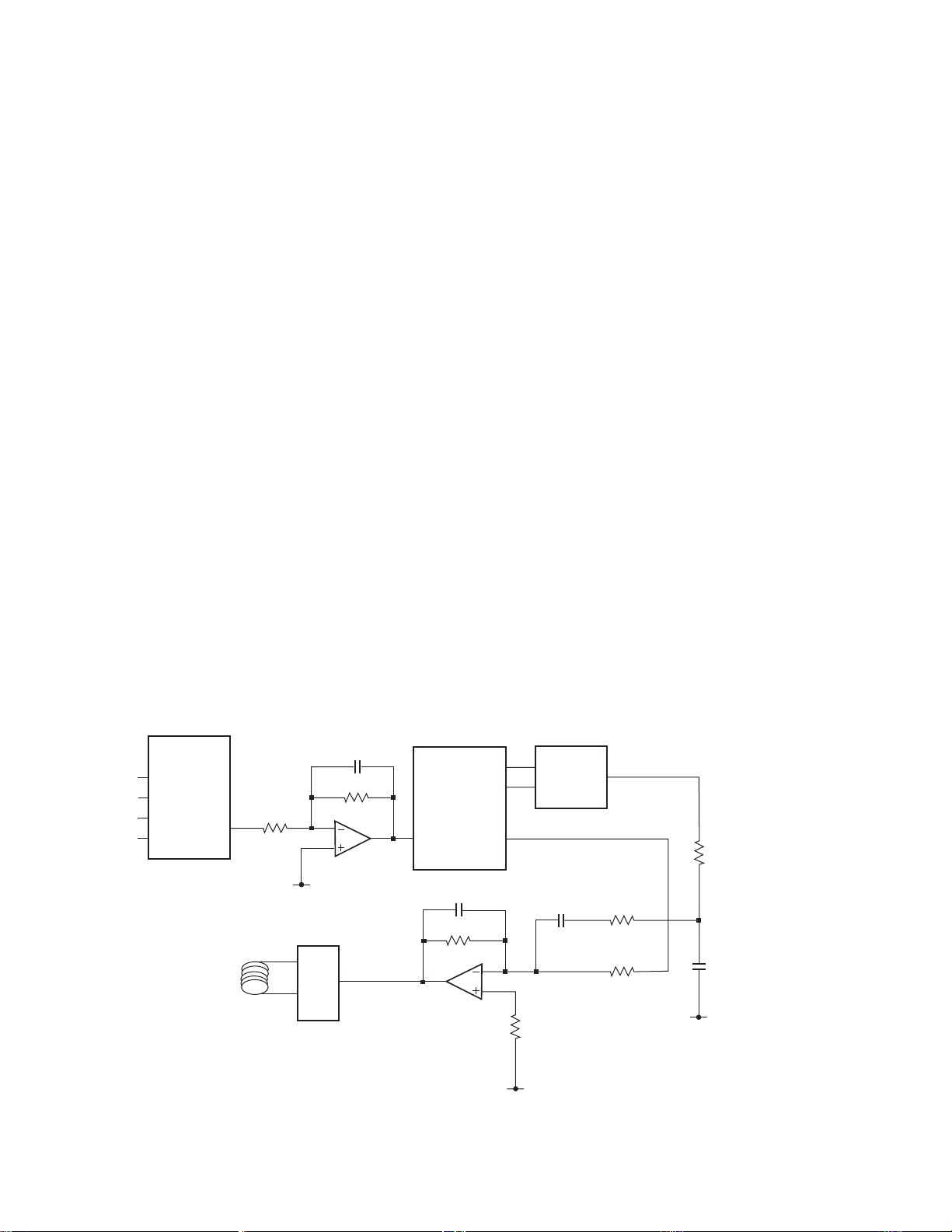

1.5.1 FOCUSING SERVO SYSTEM

The main equalizer for the focusing servo system is

being provided inside the servo DSP (IC401:TC9461F).

Fig. 7 shows the block diagram of the focusing servo

system.

With the focusing servo system, it is necessary to move

the leans into inside the focusing range to make focus

closing. For this purpose, the lens is moved up and

down by the focus search voltage of the chopping wave

to find out the focusing point. Also, while this

movement is in progress, the SPDL motor is being

kicked to maintain its speed to the preset speed.

The servo DSP works to monitor the FEI signals and the

SBAD signals (upper envelope of the RF) to issue

commands to execute automatic focus closing

movement at the optimum point. Focus closing is

executed when the following conditions are being

satisfied:

1) When the lens moves from "Near" -> "Far" as against

the disc

2) When the FEI signal level exceeds the prescribed

STANDBY level

3) When the FE becomes "0" (FE = "0", at the reference

voltage of 2.1V)

When the SBAD stays beyond the SBREF level

continuously for 32mS after focus closing, the servo LSI

recognizes the focus closed state to raise the FOK port

of the microcomputer to the "H" level.

While if the SBAD stays below the SBREF level

continuously for 12mS after focus closing, the servo LSI

recognizes that the focus is lost to activate the resetting

process.

Meanwhile, the reference voltages for the

aforementioned SBREF level and STANDBY level

coincide the offset levels for respective signals (FEI and

SBAD) for the POWER ON state and for the LD OFF

(CONT = "L") state.

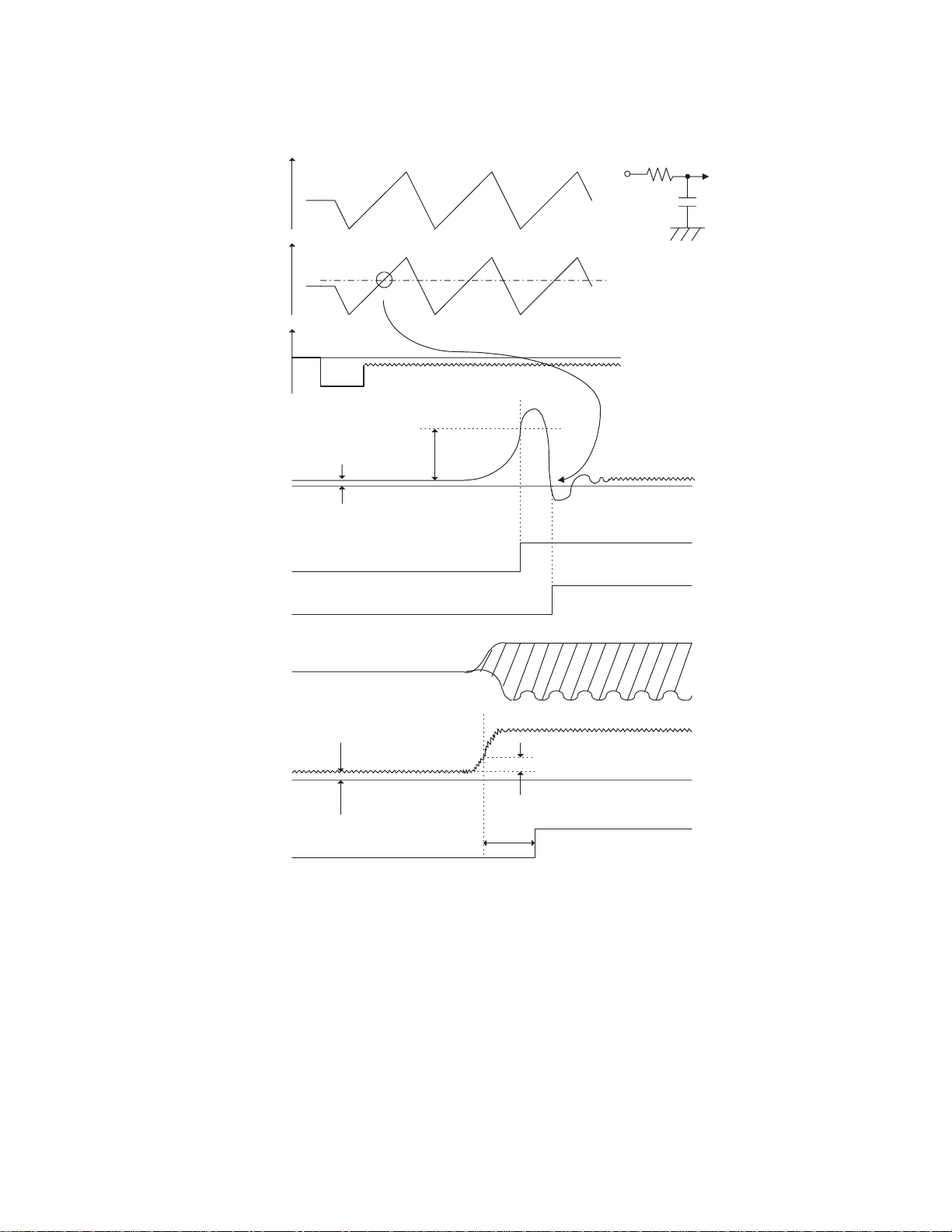

Fig. 8 shows the series of movements relevant to focus

searching and focus closing.

While a 2-layer disc of DVD is being handled, since the

reflectance is low, the focusing error signals will not

exceed the STANDBY level and focus closing is not

workable. In such case, the FE level will be raised

through the OEIC and F-GAIN to start movement to

make the closing motion once again. Since this

movement is not valid under the test mode, it is so

designed that the gain settings for 2-layer DVD discs

can be worked out manually.

B1

B2

B3

B4

RF AMP

IC103

TA1254AF

55

53

54

52

21

FEO

2

3

1

VR21

SERVO DSP

IC401

TC9461F

FEI

FOO

38

43

IC105

NJM3404AM

F.JUMP

CIRCUIT

2

3

1

VR21

VR21

F ACT.

16

17

19

DRIVER

IC304

BA6797FM

IC402

NJM2904M

Fig. 7

7

C X-692

1) Focus searching

F

±

Focusing point

Near

Far

Relative

distance between

the lens and the disc

0

EC

2) Focus closeing

Normally,focus closing is made at this point

H

L

CLOSE

OPEN

STANDBY

Close

(Inside the servo LSI)

(Inside the servo LSI)

Offsetting

SBREF

FOK

RF

SBAD

FOK

(Inside the servo LSI)

H

L

FOK = 32mS

Monitor

R=100kΩ

C= 0.016µF

Offsetting

STANDBY

(Reference voltage at 2.1V)

ECR(Reference voltage at 2.5V)

(Reference voltage at 2.1V)

Fig. 8

8

C X-692

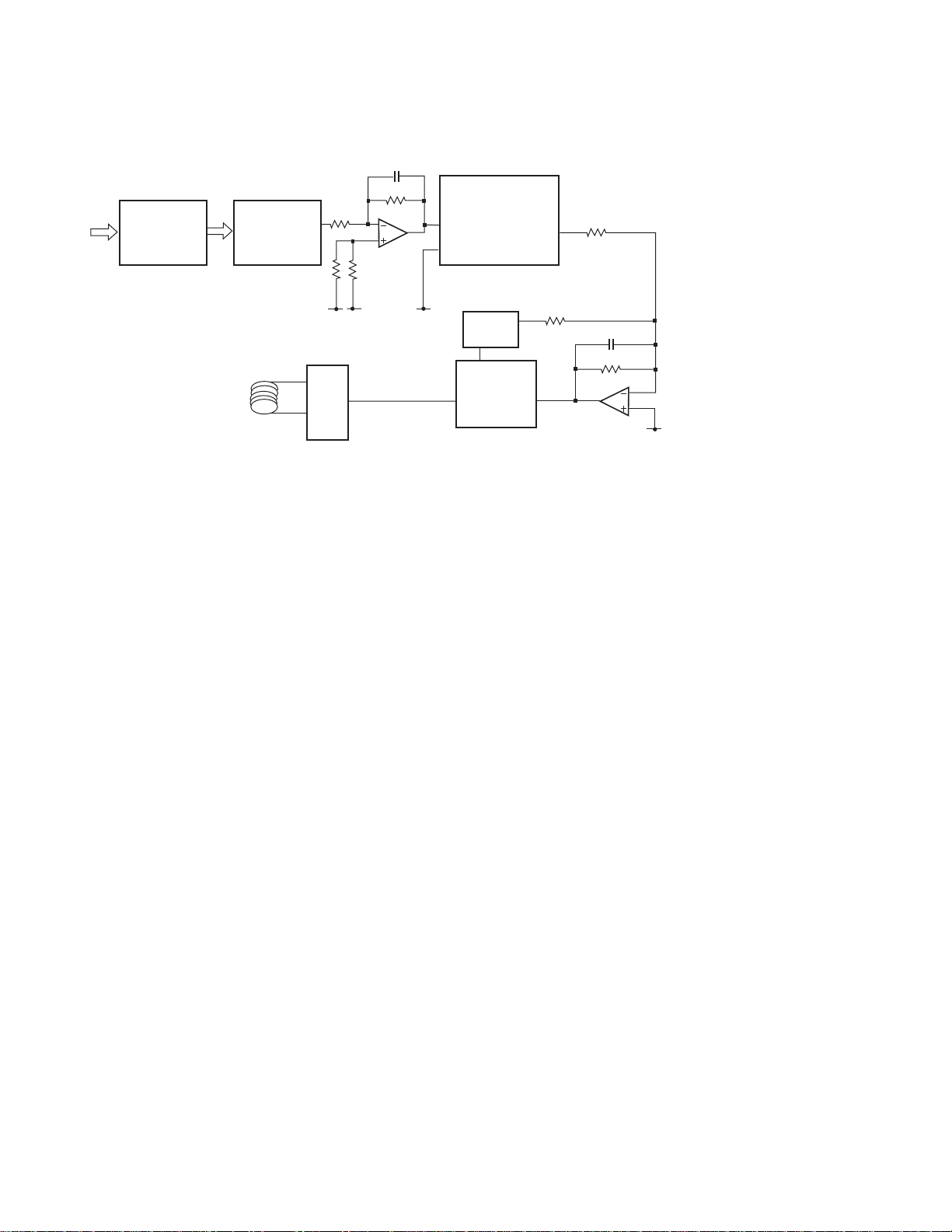

1.5.2 TRACKING SERVO SYSTEM

The main equalizer for the tracking servo system is being provided

inside the TC9461F(IC401). Fig. 9 shows the block diagram of the

tracking servo system.

Tracking closing and tracking jumping movements are being made

automatically by the auto-sequencing function incorporated inside

the servo DSP (IC401:TC9461F) after the LSI receives the command

from the microcomputer(IC501:PD5511A). This system is being

equipped with the lens kick mode which is to be used for jumping

of 255 tracks or less and the feed kick mode which is to be used for

jumping of 512 tracks or more as the track jumping means to use

for searching. Also, tracking closing movements are being

realized by the zero-track jumping command under the lens kick

mode. Under the test mode, 14 types of jumps, namely, 1, 4, 8,

16, 32, 64, 100, 255, 512, 1,000, 4,095, 4,096, 16,384 and 32760 can

be used for checking by making the mode selection accordingly.

Under the normal mode, jumps of:

CD: 1, 2, 4, 8, 10, 16, 32, 64 and 100

DVD: 1, 2, 3, 4, 8, 12, 16, 32, 64, 100 and 255

are available for lens kicks.

2

3

1

T.BAL

CIRCUIT

T ACT.

26

27

25

DRIVER

IC304

BA6797FM

SERVO DSP

IC401

TC9461F

44

TRO

TEI

41

6

5

7

RF AMP

IC103

TA1254AF

20

46

47

TEO

P1TN

P1TP

VR21

VR21

VR25

VR21

IC108

NJM3404AM

47

TE IC

IC107

PA0065AM

B1

B2

B3

B4

RFA

IC106,109

TC7WU04FU

19

Fig. 9

9

C X-692

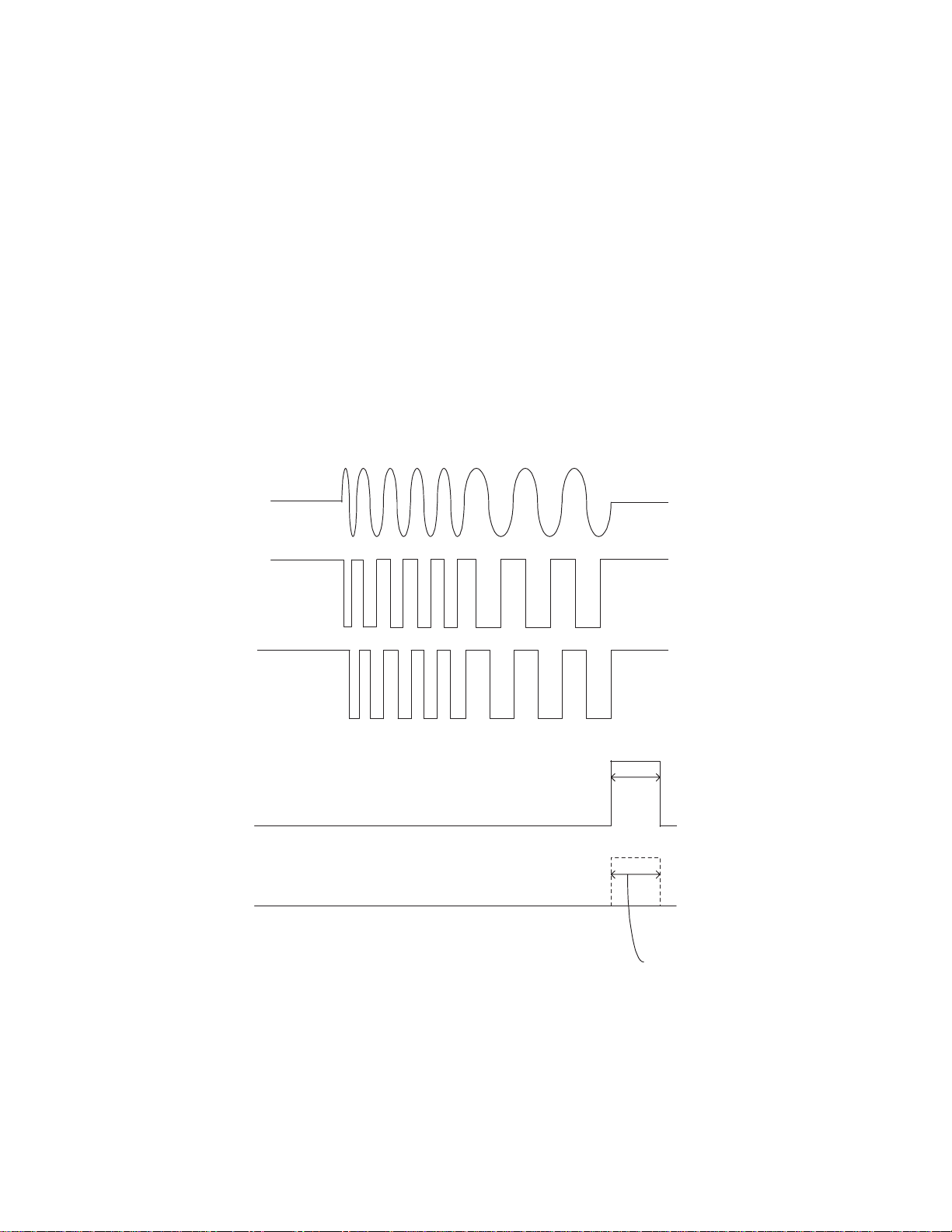

Lens kick mode jumping

The lens kick mode jumping is being executed by the

lens kick command being issued by the

microcomputer(IC501:PD5511A).The jumping direction

and the number of jumping tracks (1 - 255) are being

designated by the command. Receiving the lens kick

command, the LSI applies the kick pulse to the front

stage of the tracking EQ to execute the jumping. At

this time, the LSI works to control the moving speed of

the lens referring to the table carrying inside the LSI.

By this function, when the number of remaining tracks

is still large, the speed is raised, while the speed is

lowered as the number of remaining tracks decreases

to facilitate taking-in action by the servo when the jump

has been finished. While jumping is in progress, the

track counting is being made in observation of the RFRP

signals. Also, the jumping direction is being detected

by the phases of the RFRP and the TEZ1.

Meanwhile, when a track jumping has been finished, in

order to stabilize the taking-in action by the servo, the

tracking servo gain will be raised for about 2 to 3mS

after a jump has been finished, or with some jumps,

hysteresis movements are being employed.

8 track jumping

Equalizer

Hysteresis

TE

RFZC

(IC401's internal signals

being formed by the RFRP)

TEZC

(IC401's internal signals

being formed by the TEI)

GAIN UP

NORMAL

ON

OFF

2-3mS

The hysteresis ON for 2mS to 3mS

for 100 or 255 track jumping only

Fig. 10

Loading...

Loading...