Page 1

ORDER NO.

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2009

CRT4300

DVD MECHANISM MODULE(LS1)

CX-3250

- This service manual describes the operation of the DVD mechanism module incorporated in models listed in the table below.

- When performing repairs use this manual together with the specific manual for model under repair.

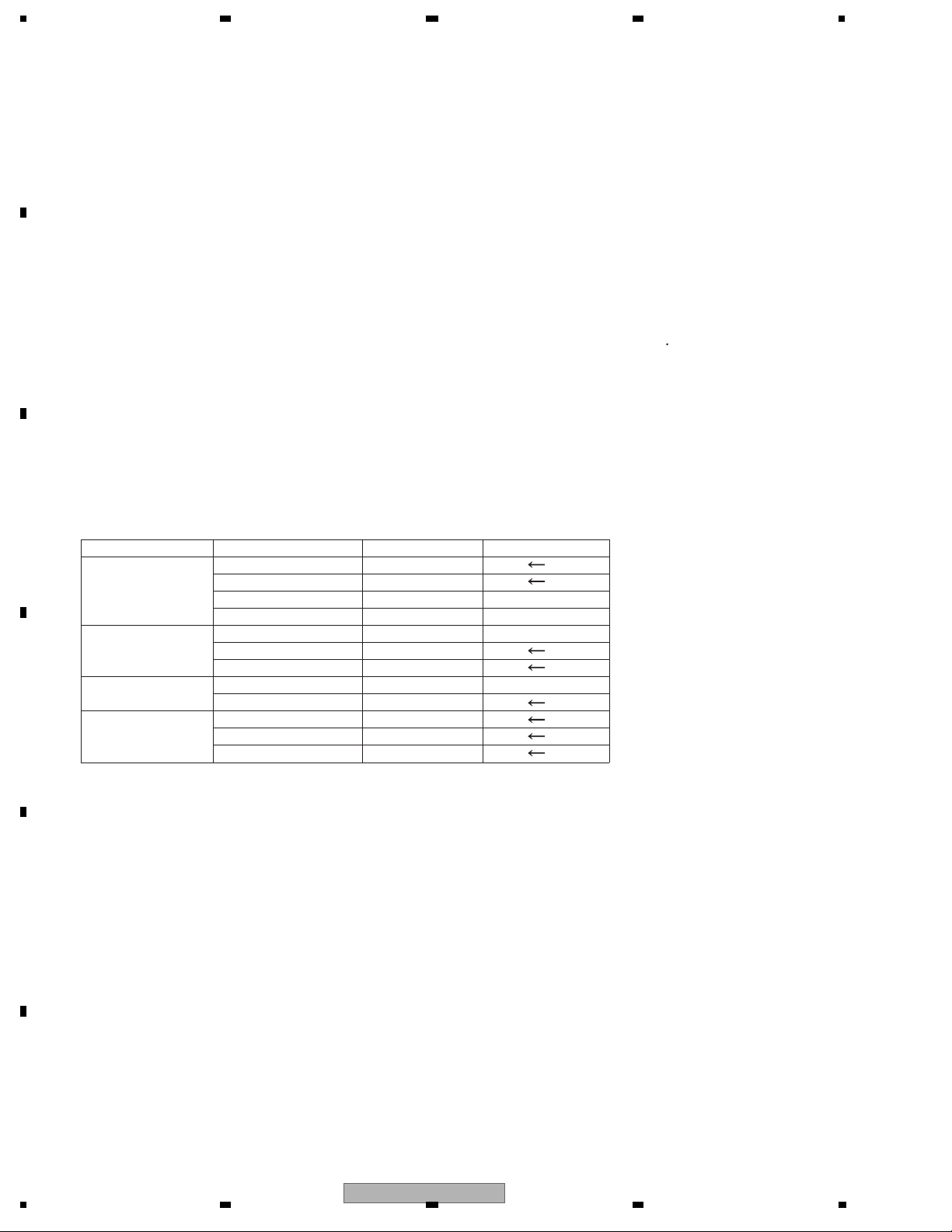

Model Service manual DVD Mechanism Module

DVH-P4100UB/XN/EW5 CRT4256 CXK6800

DVH-P4100UB/XN/UW5

DVH-P4150UB/XN/RC CRT4282 CXK6800

DVH-P4150UB/XN/RD

DVH-P4150UB/XN/RI

DVH-P4190UB/XN/ID

CONTENTS

1. CIRCUIT DESCRIPTIONS ...............................................................................................................................2

2. MECHANISM DESCRIPTIONS ......................................................................................................................17

3. DISASSEMBLY ...............................................................................................................................................22

K-ZZU. JAN. 2009 Printed in Japan

Page 2

1234

1234

C

D

F

A

B

E

1. CIRCUIT DESCRIPTIONS

1. Front end section (MN2DS0018MAUB : IC1501)

MN2DS0018MAUB is a 1 chip LSI for DVD-Player. A DVD-Player system can be constructed by connecting this LSI,

driver IC, SDRAM, Flash-ROM, Audio-DAC, etc.

This LSI includes a front end (SODC/FE) which executes RF signal processing, servo processing and decode

processing, a AV decoder(back end/BE) which executes video decode processing such as MPEG1/MPEG2/JPEG

and audio decode processing such as DVD-Audio/Dolby Digital /DTS/MP3, and a system controller which controls

the system.

The front end section realizes optical head signal computation processing and RF signal processing, digital signal

processing (16-8 demodulation, error correction) for DVD-ROM playback according to the DVD specifications,

digital signal processing of CD-DA/CD-ROM (error correction), AV decoder transfer, servo control, spindle motor control

and seek control.

In the case of MN2DS0018MAUB, the front end servo system waveforms, such as FE, TE and AS, are not observed

as in the case of DVD mechanism module (MS5) CX-3212. Please pay attention.

1.1 Analog block (MN2DS0018MAUB : IC1501)

The functions of the analog block are as described below.

1. Reference power circuit

2. SERVO system/DPD system signal processing circuit

Gain switching amplifier and Low Pass Filter (LPF)

3. RF signal processing circuit

RF adding circuit, circuit to make inline, Variable Gain Amplifier (VGA) circuit

4. Laser power control (LPC) circuit

5. A/D converter for SERVO (10 bit, DPD system-4ch),DPD converter, PWM

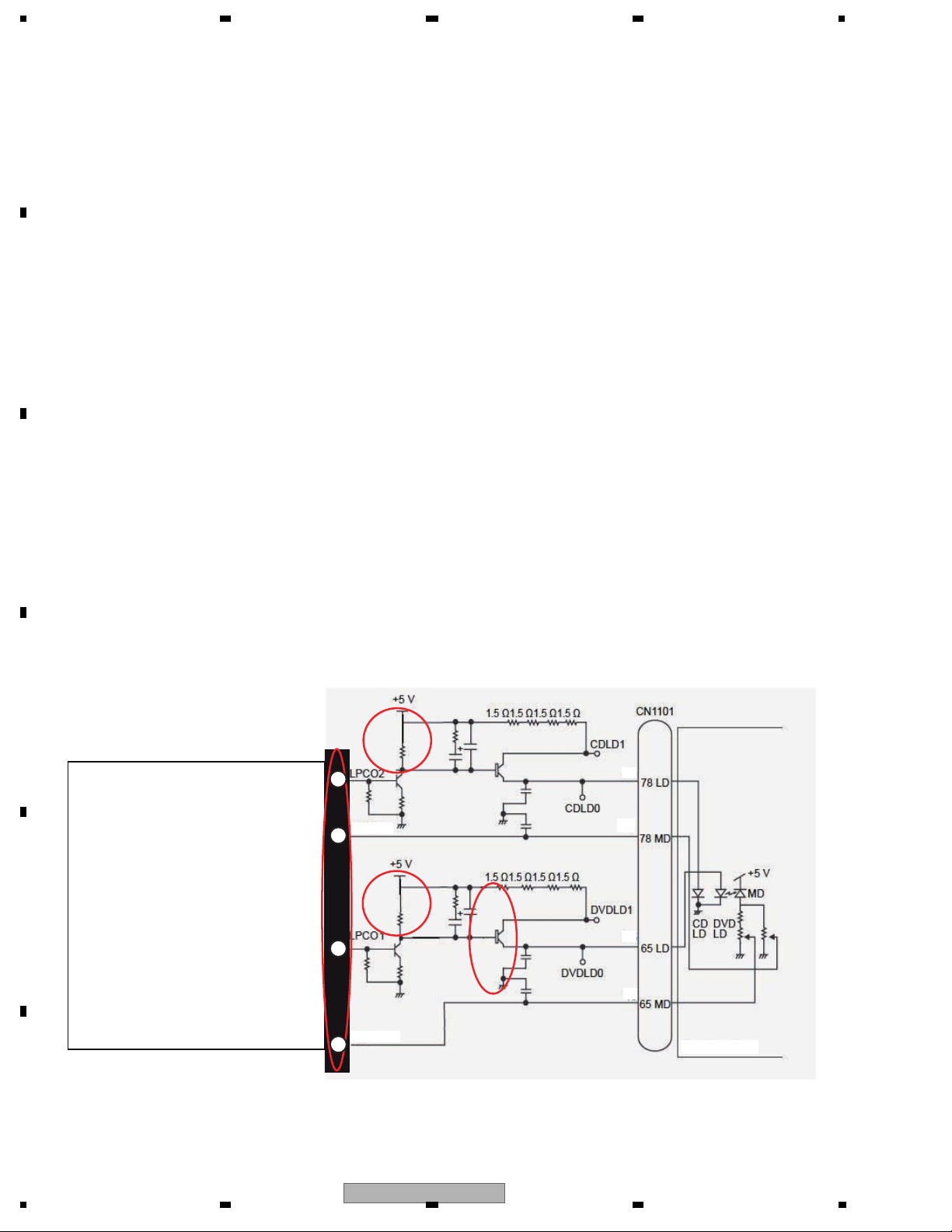

1.1.1 APC circuit

The optical output of the laser diode (LD) has a large negative temperature characteristic.

Therefore, if the LD is driven by a constant current, a constant optical output cannot be obtained.

APC circuit is a circuit to control the current so that the output at the monitor diode (MD) will be constant.

MN2DS0016AAUB includes 2 types of APC circuit, one for DVD and the other for CD.

The LD current can be obtained by dividing the measured voltage between DVDLD1 (CDLD1) and 5 V by 6 Ω

(1.5 Ω x 4=6 Ω), in the case of DVD (CD). It will be approximately 50 mA (45 mA) in the case of DVD (CD).

The potential difference between DVDLD1(CDLD1) and 5 V is set to approx. 300 mV(270 mV).

DV5U Chip

(MN2DS0018MAUB : IC1501)

CDMPD

17

DVDMPD

PU UNIT

2

106

105

104

103

7

8

18

2

CX-3250

Page 3

5 678

56

7

8

C

D

F

A

B

E

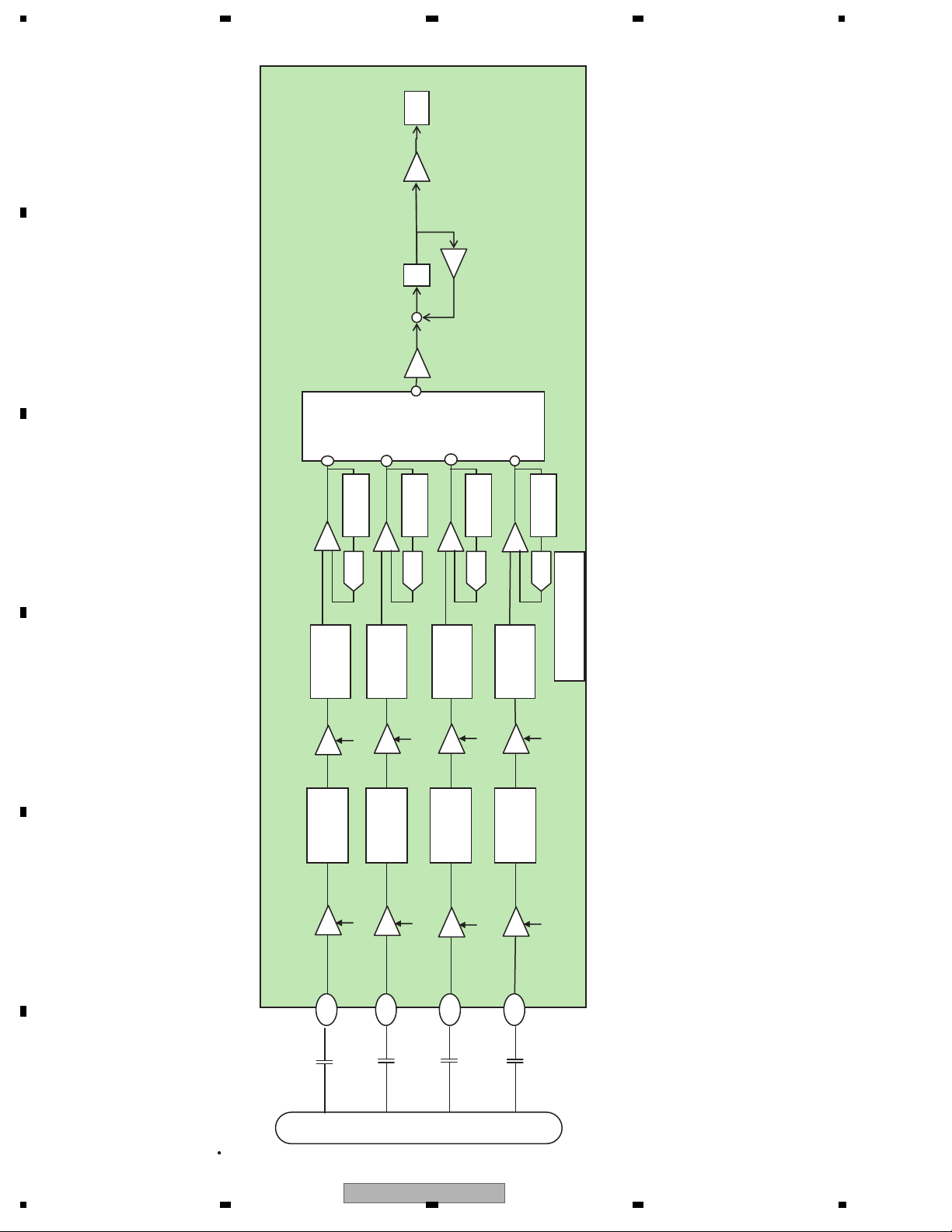

ADC

ADC driving AMP

Buffer AMP

Selector

ADC

Selector

Gain switching

6/7.5/9/10.5/

12/13.5/15/

16.5/17/19.5 dB

Gain switching

3 dB, 9 dB

FE

DV5U Chip

AMP

Gain switching

15

G=0 dB

LPF

50 k/100 kHz

-6 dB, 0 dB, 9.5 dB

VIN7

115

14

FE1

Buffer

LPF

LPF

50 k/100 kHz

Input AMP

VIN8

116

FE = (FE1) - (FE2)

The signal from PU, FE1 and FE2, are AD converted inside IC1501 and captured. After that, a differential is obtained by taking the offset cancellation into consideration,

1.1.2 FE forming circuit

and FE is obtained.

Focus error (FE) forming circuit

CN1101

FE2

FE signal forming circuit

1+Pfbal0,1/0x0100

After 10 bit ADC

CX-3250

FE1

+

-

DV5U Chip

1-Pfbal0,1/0x0100

Fbal coarse adjustment value

Offset cancel

FE2

3

Page 4

1234

1234

C

D

F

A

B

E

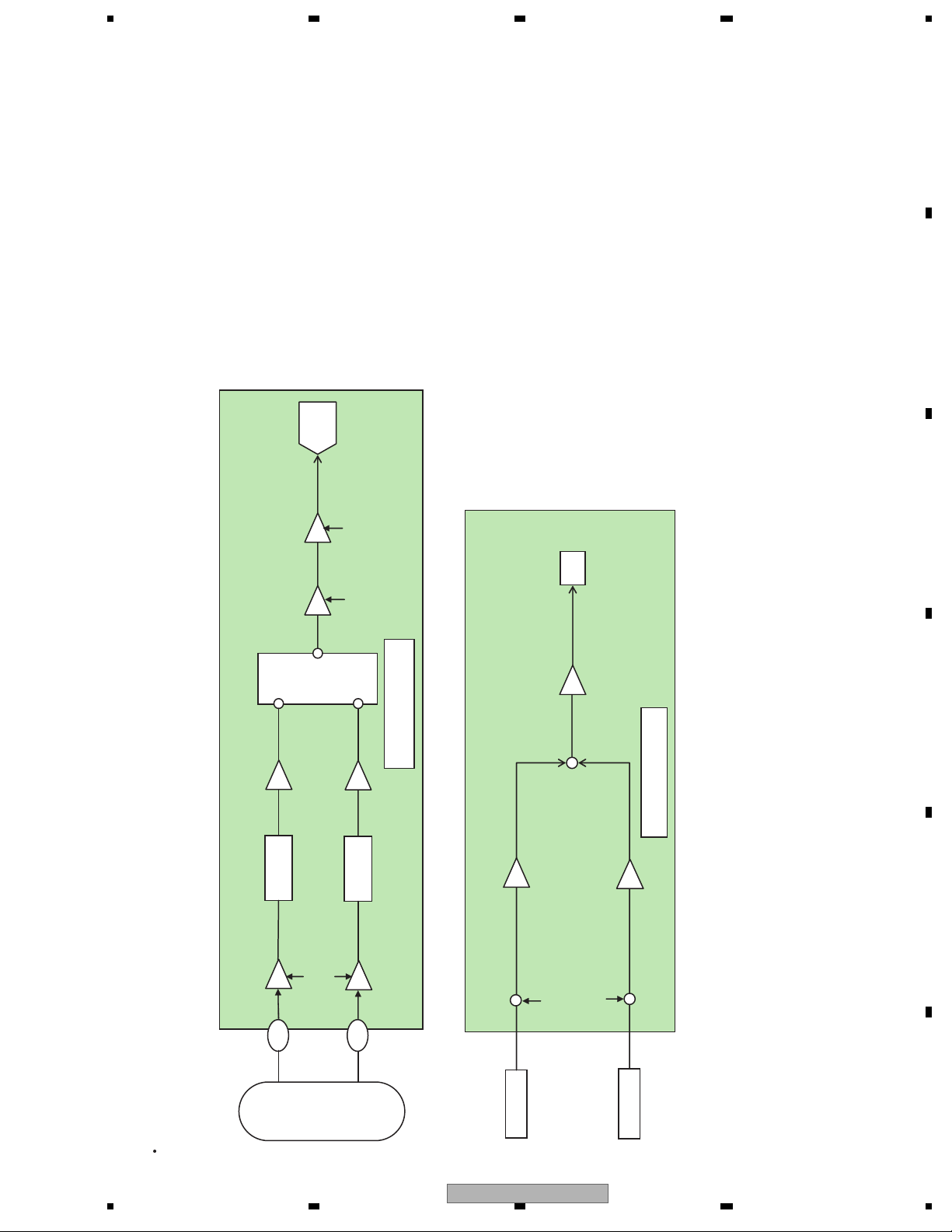

1.1.3 TE forming circuit

Tracking error (TE) forming circuit

In the case of a DVD, the phase difference method is used for TE forming, and the TE is formed from the phase difference among (A+C) and (B+D).

In the case of a CD, 3 beam method is used, and after entering the signal into a variable amplifier, it is AD converted,

and a TE is formed by the equation of TE=(F+H_G+H)-(E+G_E+F).

DVD (phase difference TE)

A

B

C

D

CN1101

0.1 μF

0.1 μF

0.1 μF

0.1 μF

10

11

12

13

98

99

VIN3RF

VIN1RF

97

VIN4RF

100

VIN2RF

Gain switching

–7.5 dB, 0 dB, 3.5 dB

LPF

11.3 M

/5.7 MHz

Input AMP LPF

LPF

11.3 M

/5.7 MHz

LPF

11.3 M

/5.7 MHz

LPF

11.3 M

/5.7 MHz

Buffer

Gain switching

G=0,3,6,9,12,15 dB

HPF

HPF

DAC control

Filter

1 MHz/25 MHz

/Through

HPF

1 MHz/25 MHz

/Through

HPF

1 MHz/25 MHz

/Through

HPF

1 MHz/25 MHz

/Through

G=-1 dB

ADCAMP

DV5 Chip

Phase comparator

Phase

comparator

LPF (integrator)

D

+

TE signal forming circuit

AMP

TE

+

DAC

DAC control

Filter

DAC

DAC control

Filter

DAC

DAC control

Filter

DAC

4

CX-3250

Page 5

5 678

56

7

8

C

D

F

A

B

E

ADCSelector

AMP

Buffer AMP

Buffer

LPF

LPF

50 kHz

Selector ADC

G=0 dB

Gain switching

6/7.5/9/10.5/

12/13.5/15/

16.5/18/19.5 dB

Gain switching

3 dB, 9 dB

DV5U Chip

LPF

50 kHz

TE

AMP

+

TE signal forming circuit

1+Ptbal0,1/0x0100

-

DV5U Chip

1-Ptbal0,1/0x0100

Input AMP

VIN9

CD (3 beam TE)

CN1101

112

4

H

F+H_G+

Gain switching

-6 dB, 0 dB, 9.5 dB

VIN10

111

5

E+G_E+F

After 10 bit ADC

F+H_G+H

CX-3250

Offset cancel Tbal adjustment value

E+G_E+F

5

Page 6

1234

1234

C

D

F

A

B

E

1.2 Servo block (MN2DS0018MAUB : IC1501)

At the servo block, focusing, tracking, servo control of traverse, spindle motor control and seek control are performed.

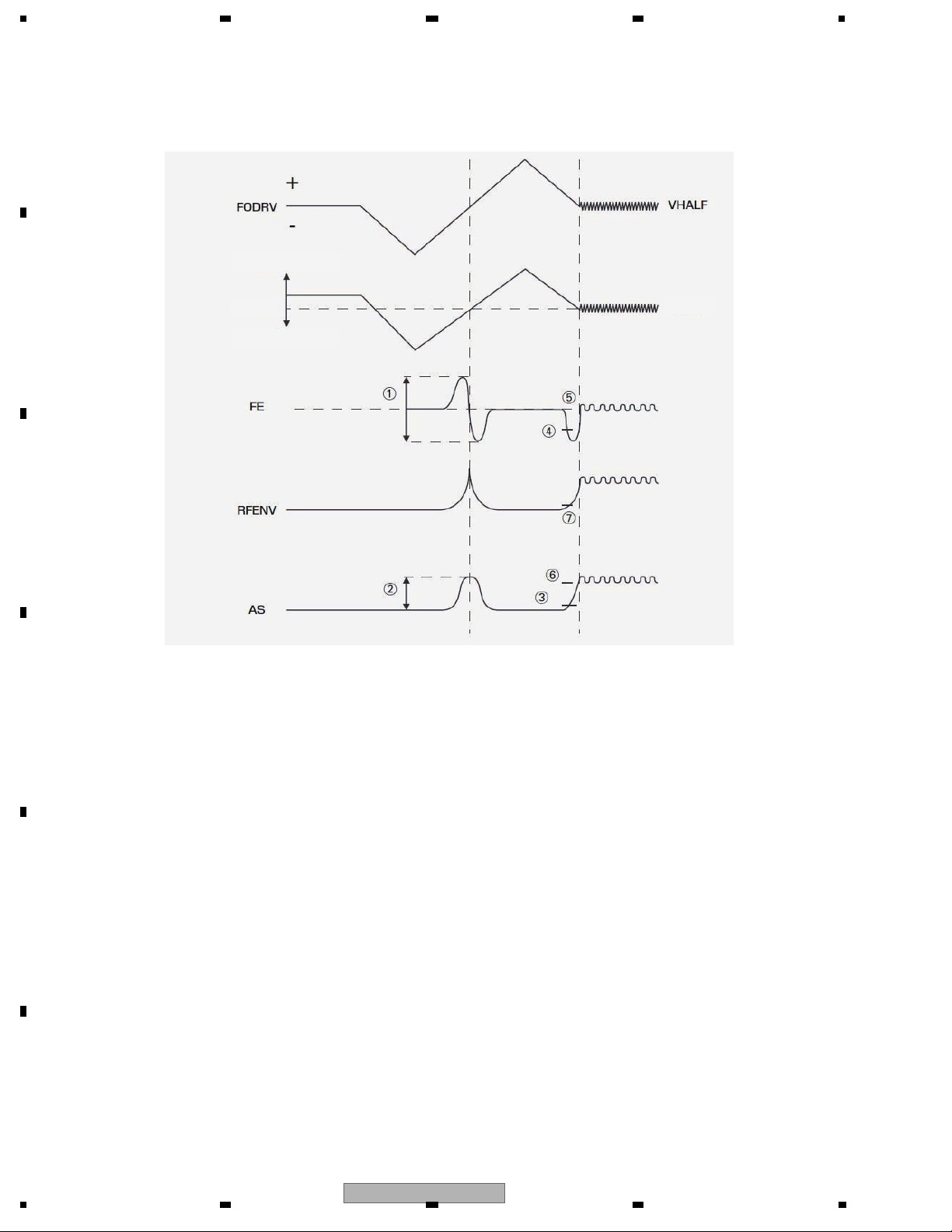

1.2.1 Focus close

After issuing the focus close command, both the DVD and the CD will perform the following processing.

1. Measurement and optimization of the signal level.

First the PU lens is driven in the direction getting away from the disc, then it is driven in the direction getting close

to the disc. At this time, each signal level of FE, AS and RFENV are measured at the focused focal point that the

lens passes, and the levels of FE and AS are optimized. (1 and 2 in the figure)

2. Focus adjustment

Next, after detecting the drawing level of FE and AS by driving the lens away from the disc, the focus loop filter is

activated and the focus is drawn. (3~6)

3. Confirmation of adjustment

Confirm the drawing at the signal level of AS and RFENV. (6, 7)

The signal levels of FE, AS and RFENV and the focus drive voltage can be checked by the focus search in the

test mode.

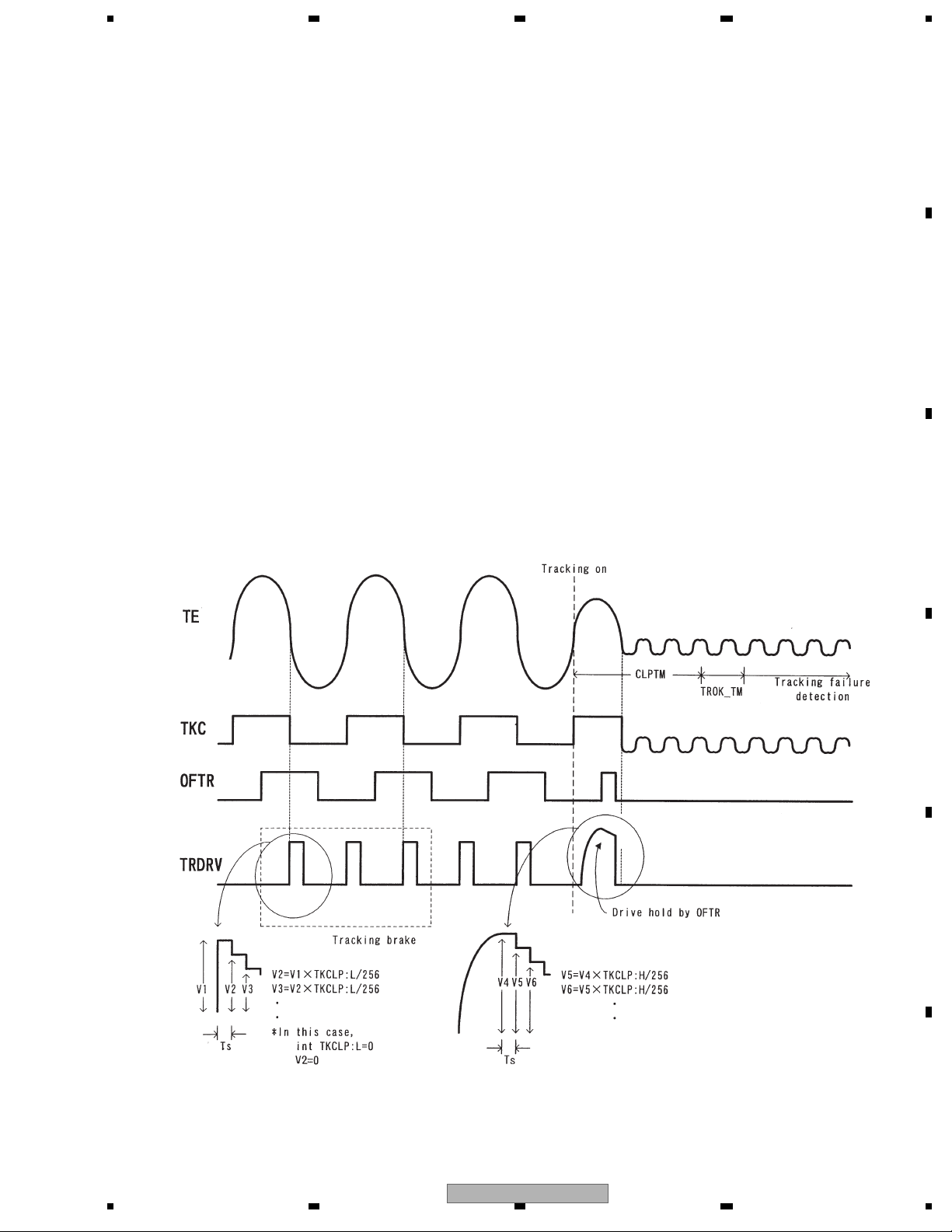

1.2.2 Tracking close

After issuing the tracking close command, both the DVD and the CD will perform the following processing.

1. Tracking brake

1/2 cycle of the track cross is measured and if the cycle is within the specified range, the brake pulse is output.

The output direction of the brake pulse is determined by the phase relationship of the OFTR and the TKC

(binary signal of TE) signals. When it is confirmed that the swinging of the lens against the disc has been controlled,

braking will be stopped and enters into drawing. If the drawing conditions are not met within 10 msec, after the brake

output, the brake will be ended and entered into drawing.

2. Tracking adjustment

Tracking drive hold processing by the OFTR signal will be performed.

3. Confirmation of adjustment

Checking is made that the number of track jumps within the specified period of time are at the designated numbers

or less. The time out for confirmation of adjustment is 8.4 msec. and retry is performed by the command from the

microcomputer.

Close to disc.

Lens

Late

Merging

point

6

CX-3250

Page 7

5 678

56

7

8

C

D

F

A

B

E

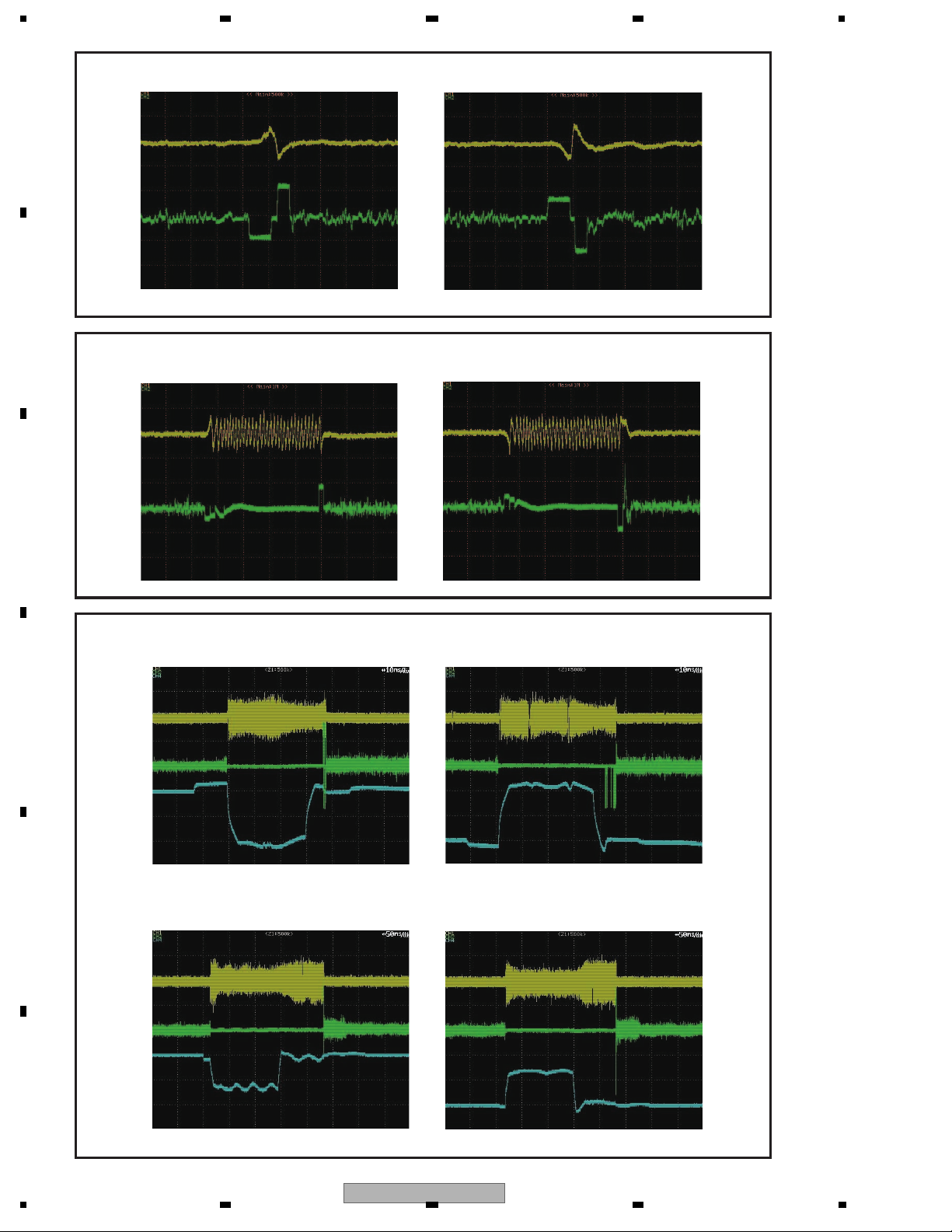

1.2.3 Track jump

In this system, one of the three methods, interval jump, multi jump or traverse seek, is selected depending on the

number of target moving tracks.

1. Interval jump

Detailed seek can be performed to execute repeated track jump of 1 track, and it is used when the target track gets

close or at the time of seek operation to the adjacent track.

2. Multi jump

Both edges of the track cross signal TKC are counted, and track count move of the designated number is executed.

Furthermore, the CRG motor is driven according to the number of jumps.

3. Traverse seek

Track count by TKC is performed, and I control movement speed and seek it.

I minimize vibration of PU occurring for movement.

It indicates the setting for jump switching common to DVD and CD.

Types of target move number of jumps.

DVD

~10 Interval jump

1

~500 Multi jump

11

~1000 Combination of multi jump and interval jump

501

~ Traverse seek (short)

1001

Tracking-on process

CD

~10 Interval jump

1

~100 Multi jump

11

~500 Combination of multi jump and interval jump

101

~ Traverse seek (short)

501

The waveform of track jump is shown on the next page.

CX-3250

7

Page 8

1234

1234

C

D

F

A

B

E

Interval jump (1 track) DVD

Outer peripheral jump Inner peripheral jump

Multi jump (32 track) DVD

Outer peripheral jump Inner peripheral jump

Traverse seek (1001 tracks) DVD

Outer peripheral jump Inner peripheral jump

Traverse seek (10 000 tracks)

Outer peripheral jump Inner peripheral jump

TE

TD

TE

TD

TE

TD

COP-COM

COP-COM

TE

TD

8

CX-3250

Page 9

5 678

56

7

8

C

D

F

A

B

E

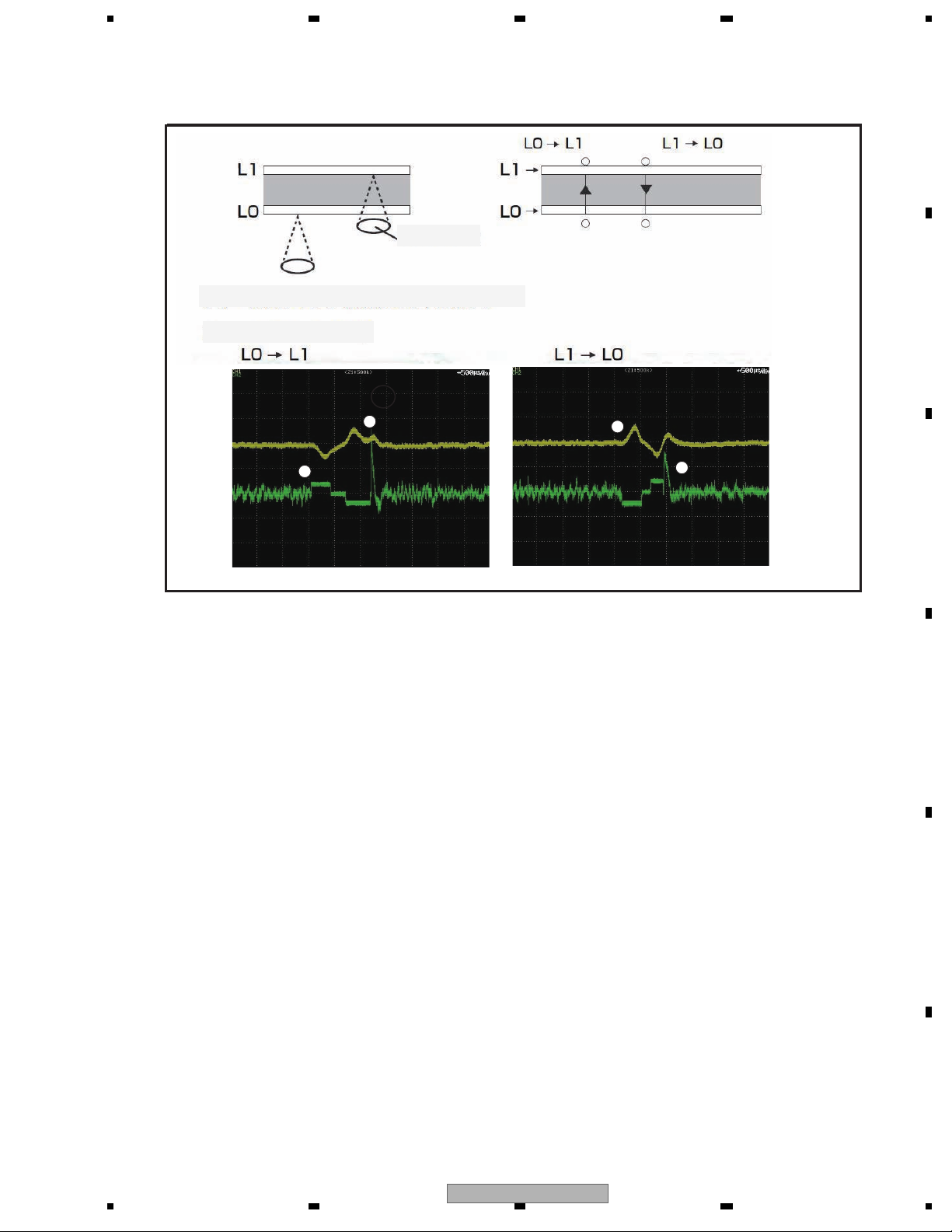

1.2.4 Focus jump

Focus jump is a function compatible to 2 layers on one side or 2 layers on both sides. Looking from the object lens,

the layer close to the lens is called “layer 0” (L0) and the layer away from the lens is called “layer 1” (L1).

1.3 Auto adjustment function

All circuit adjustments are automated in this system.

Details of each auto adjustment are explained below.

1.3.1 VIN7, VIN8, VIN9, VIN10 offset cancel

Each signal from VIN7,8, 9 and 10 output by PU is converted to a digital signal by the AD converter in the servo block.

Offset cancel is a function to cancel input offset of the AD converter at the time of power ON.

1.3.2 VCO gain adjustment (VARI adjustment)

It has a function to absorb variation of VCO gain among individual LSI by learning so that auto adjustment is made to

maintain the VCO gain at a certain level. VCO is locked against the reference frequency for learning.

And, a frequency control value (FCNT) is read, and VARI register is adjusted so that the read value becomes the

same as the target FCNT value.

1.3.3 FE normalization adjustment

FE signal level measured at the time of focus close is adjusted so that it will become 190LSB at the digital equalizer

input stage.

FE

FD

Object lens

The waveform of the focus jump is shown below.

Focus jump waveform

The flow of the focus jump is shown below.

1. The tracking is opened by the layer being played back.

2. A command is issued to execute jump to the target layer.

3. The tracking is closed at the layer after the jump and the playback is resumed.

Incidentally, the process when the jump command is issued is as described below.

1. The lens is accelerated to the target layer until the FE signal detects the focus jump acceleration end level.

Acceleration will be ended by force, however, if the time for acceleration timeout has elapsed before detecting the

acceleration end level.

2. The drive voltage is not output until the FE signal detects the speed reduction start level, and the lens is moved by

inertia.

3. The lens speed is reduced from detection of the speed reduction start level until detection of the speed reduction

end level. Speed reduction will be ended by force, however, if the time for speed reduction timeout has elapsed

before detecting the speed reduction end level.

B

A

C

D

CX-3250

9

Page 10

1234

1234

C

D

F

A

B

E

State

Power ON

F close

F close (after TBAL)

T close

Coefficient

VIN7 offset

VIN8 offset

VIN9 offset

VIN10 offset

FEPP(FEMAX-FEMIN)

AS MAX

FE normalization

TEPP(TEMAX-TEMIN)

TE normalization

F gain

T gain

AS normalization

DVD

05FB~0A17

05FB~0A17

-

1D84~6C08

No standard

No standard

2328~59D8

No standard

0100~0400

0100~0400

No standard

CD

0533~0B0C

0533~0B0C

2E18~A8CF

1E91~98D1

Note) Coefficient values are indicated in hexadecimals. In all cases, specifications

at the production line are described. For discs, TDV-582 is used for DVD and TCD-792 is used for CD.

1.4 CIRC block (MN2DS0018MAUB : IC1501)

The CIRC block includes the digital signal processing function (EFM modulation and error correction) of CD-DA and

CD-ROM and the digital servo processing function of the spindle motor.

1.5 DRC block (MN2DS0018MAUB : IC1501)

The digital read channel (DRC) is equipped with A/D converter, digital equalizer (DEQ), Adaptive filter, Viterbi

detector, digital PLL circuit, RISC interface and periphery circuits for reading of signal on optical disc.

The list of auto adjustment coefficient

1.3.4 Focus balance (FBAL) adjustment

The focus position is adjusted so that the RFENV will be the maximum at the time of focus close tracking open and

tracking close.

1.3.5 DPD amplitude adjustment

I perform the gain adjustment of the analog step so that the input signal of the DPD comparator of the TE generation

circuit of the DVD becomes constant.

1.3.6 Learning of tracking error amplitude

At the time of focus close and tracking open, the lens is oscillated in the track direction and adjusted so that the TE

amplitude level becomes 190 LSB at the digital equalizer input stage.

1.3.7 Tracking balance (TBAL) adjustment

At the time of focus close and tracking open, the lens is oscillated in the track direction and the balanced point where

the DC offset becomes zero is searched and adjusted by using the Newton-Raphson method.

1.3.8 OFTR adjustment

The binary threshold level is adjusted to make the OFTR signal into a binary digit.

1.3.9 AS normalization adjustment

The AS signal level is measured for the designated number of samples at the time of track closing, and after A/D

conversion at the ADSC, it is fine adjusted to become 64 LSB at the digital equalizer input stage.

1.3.10 Focus gain adjustment, tracking gain adjustment

At the time of tracking close, a disturbance is entered into the servo loop to adjust to the target gain intersection.

All auto adjustments can be confirmed by displaying the adjustment result in the test mode.

10

CX-3250

Page 11

5 678

56

7

8

C

D

F

A

B

E

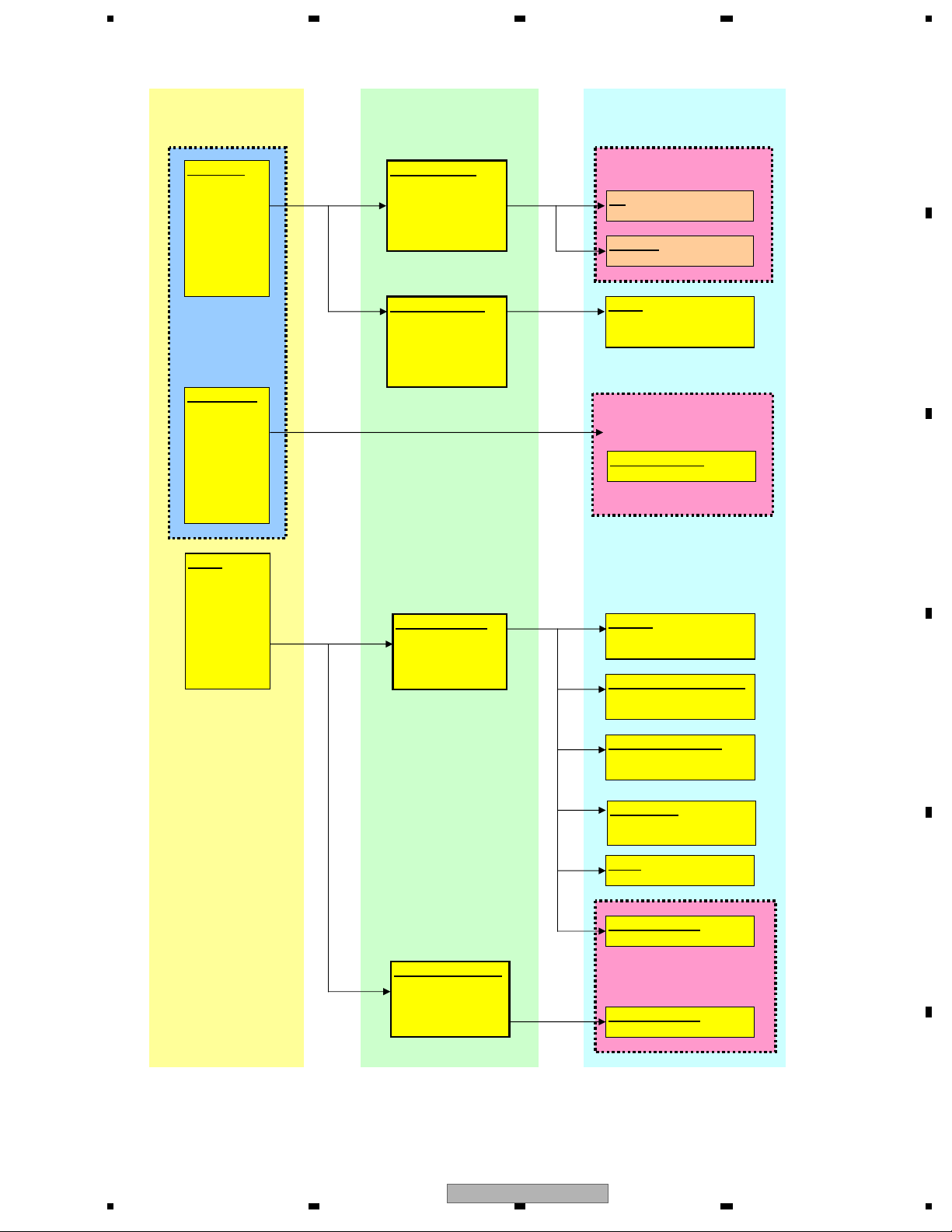

1.6 LS1 Power Supply Map

VD8(Driver)

8 V+/-0.4 V

VD8(Reg)

8 V+/-0.4 V

VDD5

5 V+/-0.4 V

1chip Driver(8 V)

5 V Reg(VCC5)

5.0 V +/-0.1 V

IC1002

S-1133B50-U5

LD

Photo IC

5 V Reg(AVCC5)

5.0 V +/-0.1 V

IC1003

S-1200B50-M5

ADAC

IC1801

PCM1753DBQ

3.3 Reg(VCC33)

3.0 V<--->3.45 V

IC1004

NJM2885DL1-33

1.2 DC/DC(VCC12)

1.08 V<---> 1.32 V

IC1005

R1232D121B

DVD1chip(3.3 V)

SDRAM

IC1480

K4S641632N-LC75

Flash-ROM 1 (Program)

IC1402

S29AL016J70TFIC10H

Other

DVD1chip(1.2 V)

VD8V

HOST

Power Supply

Mecha inside

Power Supply

Pick Up Unit

CGY5000

1chip Driver

IC1201

BD8231EFV

DVD LSI

IC1501

MN2DS0018MAUB

Supply

IC

Flash-ROM 2 (Data)

IC1401

S29AL016J70TFIC10H

USB Circuit

IC1951

TC7SZU04FU

CX-3250

11

Page 12

1234

1234

C

D

F

A

B

E

1.7 LS1 Clock circuit

[Outline]

By connecting a 27 MHz crystal oscillator to DVD-LSI (IC1501), DACCLK for externally connected Audio-DAC

is formed and supplied by the clock generator inside the DVD-LSI in addition to the clock used inside the LSI.

IC1501

DVD-LSI

R1508

220ohm

MN2DS0018MAUB

156pin 155pin

OSCO OSCI

R1501

12 pF

R1503

1Moh

CSS1768

1200ohm

27 MHz

X1501

10 pF

C1512

C1510

[

USB_Clock outline]

DACCLK

33.868 8 MHz

or 36.864 MHz

IC1801

Audio-DAC

PCM1753DBQ

By connecting a 48 MHz crystal oscillator to DVD-LSI (IC1501), clock is formed and supplied by the clock

generator inside the DVD-LSI in addition to the clock used inside the USB circuit.

IC1501

DVD-LSI

MN2DS0018MAUB

50pin

USB_Clock

R1953

10 pF

C1951

4pin(OUT_Y)

R1952

1 Moh

X1950

CSS1760

680 ohm

48 MHz

IC951

TC7SZU04

2pin(IN_A)

m

FU

10 pF

C1952

12

CX-3250

Page 13

5 678

56

7

8

C

D

F

A

B

E

1.8 LS1 Audio circuit

[Analog audio signal]

[Digital audio signal]

Zo=820 ohm

AVCC5

Radio audio circuit

17 pin

(Lch)

A

udio GND

LS1 Mechanism module

Audio DAC

(PCM1753)

15 pin

(Rch)

14,16,18 pin

(AudioGND)

fc=88 kHz

MUTE

Circuit

AMUTE

8 pin

47 kohm or more

47 kohm or more

IC1801

820 ohm

R1804

C1804

R1803

C1803

C1802

C1801

4.7 uF

4.7 uF

R1802R1801

100 kohm

100 kohm

CN1901

[Outline]

1 Analog audio signal

Serial 3 line digital output + DACCLK (audio clock) output from DVD-LSI (IC1501) are converted to

analog audio signal by Audio-DAC (IC1801), and are output from HOST IF connector (CN1901).

Furthermore, analog MUTE signal is also output from DVD-LSI (IC1501) via HOST IF connector

(CN1901) simultaneously.

2 Digital audio signal (IEC60958/IEC61937)

Digital audio signal (IEC60958/IEC61937), output from DVD-LSI (IC1501), is output via Multi-ch/Ripping

IF connector (CN1901).

25pin

(IECOUT)

IC1501

DVD_LSI

152pin

CN1901

R1504

12 ohm

820 ohm

1 800 pF

1 800 pF

CX-3250

13

Page 14

1234

1234

C

D

F

A

B

E

1.9 LS1 Video circuit

[Outline]

Composite signal is output from DVD-LSI (IC1501), and output from HOST IF (CN1901).

LS1 Mechanism module

VCC33

LPF & 75 ohm Video

CN1901

(*1)

DVD LSI

(DV5U)

IC1501

100 ohm

200 ohm

Zo=300 ohm

19 pin(CVBS)

138pin:Comopsite

20 pin

14

CX-3250

Page 15

5 678

56

7

8

C

D

F

A

B

E

1.10 LS1 SDRAM I/F

SDRAM interface

*When viewed from DVD-LSI

Signal Name Bits I/O

MDQ[15:0] 16 I/O

MA[11:0] 12 O

BA[1:0] 2 O

NRAS 1 O

NCAS 1 O

NEW 1 O

NCS 1 O

DQM[0] 1 O

DQM[1] 1 O

MCK 1 O

MCKI 1 I

SDRAM specifications

Data bus width: 32 bit

Operating frequency: 121.5 MHz

CAS latency=3

8 word burst transfer

Manual precharge

CAS before RAS refresh (Auto refresh)

SDRAM connection configuration

DVD-LSI SDRAM

I

C1501 IC1480

MDQ[15:0] DQ[15:0]

MA[11:0] A[11:0]

BA[1:0] BA[1:0]

NRAS XRAS

NCAS XCAS

NEW XWE

DQM[1:0] DQM[1:0]

NCSM XCS

MCK CLK

MCKI

Description

Data bus of external SDRAM

SDRAM address

SDRAM bank address

RAS signal of SDRAM

CAS signal of SDRAM

Write enable signal of SDRAM

Chip select signal of SDRAM

SDRAM data mask 0

SDRAM data mask 1

Clock input to SDRAM

Clock input for data input from SDRAM

[Outline]

It is a memory for realizing the AV decoding function of DVD-LSI (IC1501). It is used for various purposes

such as buffering of stream data before decoding, working area for decoding, and storing of AV data or

output data after decoding.

CX-3250

15

Page 16

1234

1234

C

D

F

A

B

E

[Outline]

It inputs a D-/D+ signal into DVD - LSI (IC1501) than HOST IF (CN1901).

It uses CP_RESET, SDA, SCL by the iPod certification.

DVD LSI

(DV5U)

VCC33

CN1901

IC1501

R 1951

28pin(SDA)

29pin(RESET)

VCC33

VCC33

VCC33

1.11 LS1 USB(iPod)circuit

LS1 Mechanism module

6.8 kohm

10 kohm

R 1527

R 1535

61pin

(CP_Reset)

46pin

(I2C_SDA)

47pin

(I2C_SC)

144pin

(LOUT)

146pin

(ROUT)

24 ohm

R 1950

24 ohm

R1546

R 1955

15 kohm

6.8 kohm

R 1532

100 ohm

R 1544

180 ohm

R 1543

180 ohm

R 1954

27pin(SCL)

22pin(D-)

23pin(D+)

15 kohm

24pin(DGND)

16

CX-3250

Page 17

5 678

56

7

8

C

D

F

A

B

E

Construction

CRG motor

PU Unit

Spindle motor

Module PCB

Connector PCB

Damper

CRG mechanism

Upper/Under Frame

2. MECHANISM DESCRIPTIONS

CX-3250

17

Page 18

1234

1234

C

D

F

A

B

E

State of CRG mechanism

Clamper arm assy

SW armRoller arm assy

Disc guide assy

18

CX-3250

Page 19

5 678

56

7

8

C

D

F

A

B

E

Disc loading operation

1.When the disc is inserted, the SW arm L and R rotate and then SW1 turns ON from OFF.

By the SW1 turning ON from OFF, the load carriage motor starts and then the rubber roller rotates.

2.In the case for a 12cm disc, SW1 is turned OFF from ON by the SW arm being opened widely and then the

microcomputer determines that the disc is 12cm.

3.In the case for a 8cm disc, SW arm does not open widely, so SW1 is not turned OFF from ON but goes into the clamp

movement and then the microcomputer determines the disc to be 8cm.

(SW arms are jointed on both sides, and even if one side is pushed, the joint part is locked and the arms do not open

more than a fixed width. (SW1 is not turned OFF from ON.))

Load carriage motor

PU unit

Roller

SW arm L

SW3

SW2

SW1

DISC

SW arm R

CX-3250

19

Page 20

1234

1234

C

D

F

A

B

E

Disc centering mechanism

1. 8cm disk is centered with the guide pin and the centering pin.

2. 12cm disk passes under the guide pin and the centering pin, and is centered at the mechanism interior position.

Centering pin

Guide pin Guide pin

8cm disc

Guide pin

Centering pin

Centering pin12cm disc

20

CX-3250

Page 21

5 678

56

7

8

C

D

F

A

B

E

Clamp Operation Structure

1.Drive the detection arm at the position where 8 or 12 cm disc is centered on the spindle.

2.Detection arm matches the jumping rack with the rack drive gear.

3.The drive lever that was jointed with the jumping rack slides and then lowers the clamp arm (it clamps the disc.).

At the same time, it rotates the roller arm and separates the rubber roller from the disc.

Moreover,rotation of the roller arm releases the upper and lower mecha locks and completes the clamp operation.

4.After the completion of the clamp operation, the control by the cam above the drive lever is released and then the

switching lock arm rotates.

When the same arm rotates, the switching idler gear is separated from the rack drive gear and meets with the feed screw

drive gear and then the carriage operation is executed.

Detection arm

Switching idler arm

Clamp arm

1

Switching lock arm

Feed drive gear

Worm wheel

Feed screw gear

1

4

Switching idler gear

5

Rubber roller

Jumping rack

2

Drive lever

Rack drive gear

3

Ejecting Operation

1.It starts the ejecting operation in the reverse order of above procedures when the load carriage motor rotates in the

reverse direction and the pick up is sent to the inner periphery with the home SW ON or more.

2.Ejection is completed when SW1 goes OFF->ON->OFF for 12cm disc.

3.Ejection is completed when SW1 goes ON->ON->OFF for 8cm disc.

CX-3250

21

Page 22

1234

1234

C

D

F

A

B

E

3. DISASSEMBLY

1.Have a specified part.

Please note that holding the front part of the upper frame or the CRG mechanical part,

or inserting a foreign substance could cause deformation.

Handling OK

Handling NG

How to have it

22

CX-3250

Page 23

5 678

56

7

8

C

D

F

A

B

E

Connector (relay FFC)

Relay FFC

Fig. 1 Fig. 2

GND the brown line

4V to the gray line

Mecha Module_Bringing into the Clamp State with No Disc Loaded

1. Remove the relay FFC from the connector on the module PCB side (Fig. 1).

(Precaution) When it is difficult to apply 4V to the motor in procedure 2 below, remove the connector on the relay

PCB side, then remove the FFC, and remove the solder of the CRG motor lead and apply voltage to the lead.

2. Push the Disc detection arm while applying 4V to the CRG motor (Fig. 2)

By this action, the mecha moves to the clamp state and the PU moves to the outer periphery.

3. Stop the motor when the PU comes to the vicinity of the intermediate periphery.

(Precaution) If the PU goes to the outer most periphery, it idles.

It is not a problem, but please try not to let it idle as much as possible.

CX-3250

23

Page 24

1234

1234

C

D

F

A

B

E

T-case washer

Drive gear

Fig. 1

Fig. 2

b.Open-lock state

c.Clamp state with no disc loaded

CRG Mecha_Bringing into the Clamp State with No Disc Loaded

1.Remove the CRG mecha assy according to the “Removing the CRG Mecha assy” manual

(mecha is in the ejecting state).

2.Remove the T-case washer and then remove the drive gear. (Fig. 1)

3.Lift the clamp arm assy until it is in the state shown in Fig. 2_b (open-lock state).

4.Put your finger on the area A of Fig. 2_c and then slide it to the direction of the arrow (the direction of the playing state).

5.Push down the clamp arm.

(Precaution) When bringing the CRG mecha into the ejecting state again, install the drive gear after sliding the drive lever

and bringing it to the ejecting state, in order to prevent the cog of the pinion in the drive gear from chipping at the time of

its installation.

a.Ejecting state

There is a

space

There is

no space

A

24

CX-3250

Page 25

5 678

56

7

8

C

D

F

A

B

E

Connector (pick up FPC)

Connector(Relay FFC)

PCB clinch screw

Short-circuit

Fig.1

Fig. 2

Fig.3

Pick up FPC

Relay FFC

Fig. 4

Solder on the lead

Relay PCB clinch screw

Hook A

Hook B

Fig. 5

Hook B

Fig. 6

Fig. 7

Fig. 8

Removing the Module PCB

1.Short-circuit two spots on the land of the pick up FPC. (Fig. 1)

2.Remove the pick up FPC and the relay FFC from the connector. (Fig. 2)

3.Temporarily attach the pick up FPC to the pick up rack. (Fig. 3)

(in order to prevent the damage to the pick up FPC)

4.Remove the two PCB clinch screws and then remove the module PCB. (Fig. 2)

Removing/Installing the Relay PCB

Removing)

1.Remove the relay FFC from the connector

(remove both sides so that the entire FFC will be removed). (Fig. 2)

2.Remove the solder on the lead for the CRG motor. (Fig. 4)

3.Remove the one relay PCB clinch screw. (Fig. 4)

4.Slide the relay PCB to the direction of the arrow and then remove

the relay PCB from the hook A and the hook B. (Fig. 4)

5.Turn the relay PCB over and then remove the SPDL motor FFC

from the connector.

Installing)

1.Check the mecha is in the ejecting state (disc-load suspended state).

When it is not in the ejecting state, apply 4V to the lead (motor) and

then bring it to the ejecting state (4V to the brown line and GND the gray line).

2.Fit the SPDL motor FFC to the connector (back of the relay PCB).

3.Hold the relay PCB so that it does not touch the SW knob as in Fig. 5.

4.Insert it into the hook B as it is a little off to the clockwise direction.

(Precaution) This is to prevent the SW knob from getting into the NG

position as in Fig. 6.

5.Push down the relay PCB lightly and then rotate it to the

counterclockwise direction.

It sets the relay PCB in the hook A and the positioning dowel.

(Precaution) Pay attention so the SW knob will not get onto the PU rack.

(Fig. 6)

6.As in the Figures, while supporting the location A with your fingers,

screw the relay PCB. (Fig. 7 / Fig. 8)

7.Solder the lead for the CRG motor.

8.Fit the relay FFC to the connector.

NGOK

A

CX-3250

25

Page 26

1234

1234

C

D

F

A

B

E

Fig. 2a

Permanently hooked position

Temporary hooked position

Fig. 2b

Slide to the direction of inner periphery

Fig. 1

Fig. 3

Fig.4

Regularly installed position

Install avoiding the

area with blue broken

line (the connected

metal plate part)

The spring is installed under the resin flange and inside

the bended metal plate.

Outside holder

Back end of

the feed screw

Removing the PU Unit

1.Bring to the clamp state with no disc loaded according to the “Bringing into the Clamp State with No Disc Loaded

(Motor Drive)” manual.

2.Remove the module PCB according to the “Removing the Module PCB” manual.

3.Hook the feed screw biasing spring on the temporary hook (Fig. 2b). Be careful not to get injured by the tip of the spring.

4.Hold the PU at the location A in Fig. 1 and slide and scoot it to the direction of the inner periphery.

5.As in Fig. 3, shift the back end of the feed screw to the side and then to above and remove it from the outside holder.

6.Remove the tucking joint for the chassis at the location B and the PU unit by lifting them up without changing their

position and then remove the PU unit.

(Precaution) When installing the PU again, make sure to tuck the chassis in B and the PU unit (Fig. 4) first.

Moreover, do not forget to permanently hook the feed screw biasing spring (Fig. 2a).

Adjustments to the PU after its installation should be made according to the service manual.

Sending the PU to the outer periphery

1.Bring to the clamp state with no disc loaded according to the “Mecha Module_Bringing into the Clamp State with

No Disc Loaded” manual.

(Precaution) The relay FFC must be removed for certainty in order to prevent the IC damage.

2.Apply 1.5V to the CRG motor and then transfer the PU to the outer periphery.

(Precaution) Do not forget to reinstall the relay FFC after sending the PU to the outer periphery and take the

necessary measures.

[Installation NG]

The chassis is not tucked

between the PU case and the

PU rack.

A

B

26

CX-3250

Page 27

5 678

56

7

8

C

D

F

A

B

E

Spindle motor

Spindle motor clinch screws

Removing the Spindle Motor

1.Remove the CRG mecha assy according to the “Removing the CRG Mecha assy” manual

(mecha is in the ejecting state).

2.Bring to the clamp state with no disc loaded according to the “Bringing into the Clamp State with No Disc Loaded

(Manual)” manual.

3.Remove the clamp arm according to the procedure 3 and after of the “Removing the Clamp Arm” manual.

4.Remove the relay PCB according to the “Removing the Relay PCB” manual.

5.Remove the two spindle motor clinch screws and then remove the spindle motor assy.

CX-3250

27

Page 28

1234

1234

C

D

F

A

B

E

Removing the Clinch of the Bottom Frame

1.Use the needle-nose pliers when removing the clinch on the right side.

Nip the clinch at the location in Fig. 1a and then open it until it is in the position

circled by the red broken line in Fig. 2a.

2.Also to remove the clinch on the left side, use the needle-nose pliers,

nip the clinch at the location in Fig. 1b and then open it until it is in the position

circled by the red broken line in Fig. 2b.

(Precaution) When clinching again, use Fig. 2a and Fig. 2b as a guide.

It is okay as long as the tip of the clinch does not come off from the side a and

the side b by the vibration stroke (from front to back and from side to side).

Check Fig. 3a and Fig. 3b for the height of the clinch.

Correct the height with the needle-nose pliers when the height does not meet

the standard listed in those Figures.

In case of metal fatigue on the clinch part, exchange the lower frame.

Caution: After repairing, make sure to clinch to the lower frame again.

Fig. 1a

Fig. 1b

L

It is bended orthogonally

in the initial condition

Clinch on the left side

It is in the L/2 position

in the initial condition

Clinch on the right side

Fig. 2a

Fig. 3a

28.9+0.6/-0.3

(28.6 - 29.5)

Fig. 2b

Fig. 3b

25.45+0.6/-0.3

(25.15 - 26.05)

28

CX-3250

Page 29

5 678

56

7

8

C

D

F

A

B

E

OK:The end of the groove of the shaft

is hidden by the damper exterior.

NG:The end of the groove of the shaft

is found outside the damper exterior.

OK:A shaft is found

inside the spring.

NG:A shaft is found

outside the spring.

Removing the CRG Mecha assy

1.Follow up to the procedure 3 of the “Removing the Module PCB” manual and then remove the PU FPC from the

connector.

2.Remove the relay FFC from the connector (both ends) and then remove the FFC. (Fig. 1)

3.Open the clinch of the bottom frame according to the “Removing the Clinch of the Bottom Frame” manual.

4.Remove the front-pulling springs on both sides. (Fig. 2a & Fig. 2b)

5.Remove four clinch screws of the top frame and then remove the top frame. (Fig. 3)

6.As lifting the carriage mecha, remove it from the dampers at three locations. (Fig. 3)

(Precaution) When assembling the CRG mecha assy again, apply alcohol on the dampers.

Make sure that the damper shafts are inside the three neutral springs (Fig. 4) and that the springs on both sides are hooked.

Before connecting to the module PCB after installing the CRG mecha, bring to the clamp state with no disc loaded

according to the “Mecha Module_Bringing into the Clamp State with No Disc Loaded” manual, push the upper part of the

damper of the CRG mecha by the finger and then make sure that the damper and the CRG mecha are jointed with certainty.

(Fig. 5)

Fig. 1

Fig. 4

Caution : After repairing, make sure to clinch to the lower frame again.

Caution : After repairing, make sure to clinch to the lower frame again.

Clinch screw of the top frame

Front-pulling spring

Fig. 2a

Fig. 3

Dampers

Front-pulling spring

Fig. 2b

Fig. 5

CX-3250

29

Page 30

1234

1234

C

D

F

A

B

E

Guide bracket clinch screw

Roller transmission side gears

Fig. 1

Fig. 2

Roller assy biasing spring

Fig. 3

Disc guide assy

Roller Guide assy

Fig. 4

Removing the Disc Guide assy

(Removing the Roller Transmission Side Gear)

1.Remove the CRG mecha assy according to the “Removing the CRG Mecha assy” manual (mecha is in the ejecting state).

2.Remove the two guide bracket clinch screws and then remove the Disc guide assy. (Fig. 1)

3.Remove the two roller transmission side gears. (Fig. 2)

(Precaution) When assembling the Disc guide assy again, do not forget to install two gears on the side panel.

Removing the Roller assy

1.Remove the CRG mecha assy according to the “Removing the CRG Mecha assy” manual (mecha is in the ejecting state).

3.Remove the Roller assy biasing spring. (Fig. 3)

4.Remove the Disc guide assy according to the procedure 2 and after of the “Removing the Disc Guide assy” manual.

5.Hold the Roller assy at the locations A, slide it to the left and then remove it. (Fig.4)

(Precaution) When assembling the Disc guide assy again, do not forget to install two gears on the side panel.

A

30

CX-3250

Page 31

5 678

56

7

8

C

D

F

A

B

E

Removing/Reassembling the Clamp Arm assy

1.Remove the CRG mecha assy according to the “Removing the CRG Mecha assy” manual

(mecha is in the ejecting state).

2.Bring to the clamp state with no disc loaded according to the “Bringing into the Clamp State with No Disc Loaded

(Manual)” manual.

3.Remove the right clamp arm biasing spring. (Just on the clamp-arm side. Do not remove on the chassis side.)

4.Lift the clamp arm assy until it is in the state shown in Fig. 2 (open-lock state).

5. Lightly push the part A and lift the clamp arm assy further to the position in Fig. 3.

6. Remove the left clamp arm biasing spring.

7. Lift the clamp arm assy further to 45-60 degrees, slide it to the left and then remove it. (Fig. 1)

Fig. 2

Fig. 3

Fig. 1

Left biasing spring

A

Right biasing spring

Poly slider

Installing)

1.With the clamp arm assy tilted at 45-60 degrees, install it to the rotation fulcrum by sliding it from the left.

2.Bring down the clamp arm assy to the position in Fig. 3 (position where it meets the chassis and then stops).

3.Install the left clamp arm biasing spring.

4.Completely turn the detection arm to the position OK in Fig. 4 and then push the clamp arm assy to the bottom.

5.Install the right clamp arm biasing spring.

(Precaution) –When replacing the clamp arm assy, replace the poly slider with a new part as well.

Do not forget to apply the E paste on the poly slider (Fig. 4).

Fig. 3

Fig. 4

NGOK

Apply the E paste on the yellow area.

Clamper convexity contact zone

CX-3250

31

Page 32

1234

1234

C

D

F

A

B

E

Fig. 1

Remove the solder

Line clamper

Slide the spring

to remove it

CRG motor biasing spring

Fig. 2a

Fig. 2b

Correctly installed condition

Joint removed condition

Fig. 4

Switching idler arm (Pull upward)

Fig. 3

Idler gear

Worm wheel

Switching idler arm biasing spring

CRG motor clinch screw

Fig. 5

Remove the joint

hook

Fig. 6a

Fig. 6c

Fig. 6b

A

Removing the CRG Motor assy

(Removing the Drive Transmission Gear)

1.Remove the CRG mecha assy according to the “Removing the CRG Mecha assy” manual (mecha is in the ejecting state).

2.Remove the clamp arm assy according to the “Removing the Clamp Arm assy” manual.

3.Remove the solder of the CRG motor lead and then remove the lead from the line clamper. (Fig. 1)

4.Remove the clinch screw of the CRG motor biasing spring and then slide the biasing spring to the direction of the arrow to remove it. (Fig. 1)

5.Nip the gear hook of the switching idler arm by the tips of your fingers and then push it below from the top of the gear. (Fig. 2a -> Fig. 2b)

6.Bend the hook on the chassis side of the switching idler arm to the direction of the arrow by tweezers and then remove the joint with the chassis.

(Fig. 3)

7.Pull off the switching idler arm from the top of the mecha (Fig. 4) and then remove the worm wheel and the idler gear. (Fig. 3)

8.Remove the switching idler lock arm biasing spring. (Fig. 3)

9.Remove two CRG motor clinch screws and then remove the CRG motor. (Fig. 3)

(Precaution) When installing the switching idler arm again, temporarily set the idler gear and the worm wheel as in Fig. 5, press the idler gear

from its top by your finger and then install the switching idler arm according to the steps in Fig. 6 from the opposite side of the chassis.

Do not forget to install the switching idler arm biasing spring.

Since the idler arm is in the snap fit structure, do not use them again.

When installing the CRG motor, scoot it to the center of the mecha in order to ensure that the gear engages.

Step 1: Insert the arm rotation fulcrum boss in the worm

wheel through the chassis hole.

Insert only the tip of the boss as in the figure.

Step 2: As pressing the idler gear from the opposite,

insert the gear fulcrum boss into the gear and joint them

until they are in the correctly installed condition in Fig. 2a.

When the idler arm is not installed correctly, there could be

an interference either in the location a or in the location b of

Fig. 4. Make a fine adjustment by moving it left and right.

Step 3: As matching the tip of the rotation fulcrum boss

with the metal plate hole by your finger (Fig. 6b), push the

area A in Fig. 6c to install the idler arm.

a: Match the fulcrum hole of the worm wheel

with the metal plate hole.

b: Engage the idler gear with the worm wheel.

c: Align the gear with the outer shape of the metal plate concavity as a guide.

Biasing spring cylind screw

Switching idler arm

a

b

c

32

CX-3250

Page 33

5 678

56

7

8

C

D

F

A

B

E

Fig.5

Part C : NG

Position with

inadequate

approach

Part C : OK

Position with

adequate

approach

Idler gear

Removing the Drive Lever assy

1.Remove the CRG mecha assy according to the “Removing the CRG Mecha assy” manual (mecha is in the ejecting state).

2.Remove the clamp arm assy according to the “Removing the Clamp Arm assy” manual.

3.Remove the drive lever biasing spring. (Fig. 1)

4.Slide the drive lever to the direction of the arrow (the direction of ejecting), lift it to the direction of upper right and then

remove it. (Fig. 2)

(Precaution) When installing the drive lever assy again, install the part B (Fig. 2) first with the part A in Fig. 3 scooted to

the direction of the arrow(*1). Next, install the part C (Fig. 4) of the drive lever in the channel bending the side of the

chassis, and in the end, install the part D (Fig. 4) into the L-shaped channel of the chassis and then slide the drive lever to

the position in Fig. 1.

Fig. 3

*1: If approach of Part A (Fig 3) is inadequate, the drive lever will not be

able to be well incorporated.

In this case, the idler gear might be located at the red dashed line (Fig 5).

Therefore, approach Part A (Fig 3) to the direction of the arrow as

approaching the idler gear to the direction of the arrow (Fig 5).

Determine, with the position of Part C in Fig 5, if the approach of

Part A is adequate.

Drive lever biasing spring

Fig. 1 Fig. 2

A

Fig. 4

D

B

C

CX-3250

33

Page 34

1234

1234

C

D

F

A

B

E

Connecting lever biasing spring

Fig. 1

Fig. 2

Removing the SW Arm

1.Remove the roller arm assy according to the “Removing the Roller Arm assy” manual.

2.Remove the SW arm connecting lever biasing spring. (Fig. 1)

3.Open the SW arms on both left and right sides until their tips touch the chassis. (Fig. 2)

4.Keep the SW arms open, lift them upward and then remove them.

Removing the Damper

1.Remove the CRG mecha according to the “Removing the CRG Mecha assy” manual

2.Insert the screwdriver under the part A of the metal plate configuration which joints the damper, lift the metal plate to

release the damper from being clinched by the part C.

3.Insert the screwdriver under the part D as well. Lift the metal plate, release the damper from being clinched to remove it.

A

C

D

Open the SW arms on both left and right side

Open the SW arm

on left sides until their tips

Open the SW arm

on right sides until their tips

Caution: After repairing, make sure to clinch to the lower frame again.

Caution: When mounting a damper, hold it tight with a clinch in order to avoid backlash.

In case of metal fatigue on the clinch part, exchange the frame.

34

CX-3250

Page 35

5 678

56

7

8

C

D

F

A

B

E

Fig. 7

Fig. 2

Hook

PU rack

Fig. 1

PU rack clinch screw

Fig. 3

Fig. 6

Fig. 4

FFC folding line

FFC folding back part

C

Fig. 8

Actuator

Removing the PU Rack

1.Remove the PU unit according to the “Removing the PU Unit” manual.

2.Remove the PU rack clinch screw. (Fig. 1)

3.Pick up the root of the hook on the PU rack (Fig. 2) with tweezers as in Fig. 3. While bending it so the tip of the hook

would open to the direction of the arrow (unhooked direction), pull out the PU rack upward.

(Precaution) When handling the PU unit, do not “touch the actuator in Fig. 9 or hit the desk with it during the operation.”

Handle the PU and the PU unit according to “Holding the PU” manual.

When installing the PU rack into the PU again, fold back the PU FPC as in Fig. 5 according to the folding line in Fig. 4

before installing the rack and settle it in the channel on the PU case. To install the PU rack, first install the part a and the

part b in Fig. 6 into the PU case, install the FPC folding back part in Fig. 5 so that it is held by the part A in Fig. 7, and push

the part B (top of the snap fit) to fit the PU rack.

When it is hard to fit the PU rack, try again as scooting it to the direction of the arrow C in Fig. 7.

After installing the PU rack, insert the feed screw from the side c in Fig. 8. Insert approximately 18mm on the part shown in

the figure.

Fig. 5

A

B

Fig. 7b

OK

NG

Fig. 9

CX-3250

35

Page 36

1234

1234

C

D

F

A

B

E

Handling OK

Handling NG

Do not touch the object lens.

Do not touch the ACT.

Do not touch the Hologram.

Do not pull the FPC.

Holding the PU

1.Hold the “Handling OK” area of the PU indicated by the figure. Do not hold the “Handling NG” area.

36

CX-3250

Loading...

Loading...