Page 1

ORDER NO.

CRT3896

DVD MECHANISM MODULE(MS5)

CX-3212

- This service manual describes the operation of the DVD mechanism module incorporated in models

listed in the table below.

- When performing repairs use this manual together with the specific manual for model under repair.

Model Service manual DVD Mechanism Module

AVIC-D3/XU/UC CRT3879 CXK6601

AVI C- D3/XU /EW5

CONTENTS

1. CIRCUIT DESCRIPTIONS................................................................................................................................2

2. MECHANISM DESCRIPTIONS ......................................................................................................................19

3. DISASSEMBLY ...............................................................................................................................................24

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2007

K-ZZU. FEB. 2007 Printed in Japan

Page 2

1234

1. CIRCUIT DESCRIPTIONS

1. Front end section (MN2DS0016AAUB : IC1501)

MN2DS0016AAUB is a 1 chip LSI for DVD-Player. A DVD-Player system can be constructed by connecting this LSI,

A

driver IC, SDRAM, Flash-ROM, Audio-DAC, etc.

This LSI includes a front end (SODC/FE) which executes RF signal processing, servo processing and decode

processing, a back end (AV decoder/BE) which executes video decode processing such as MPEG1/MPEG2/JPEG

and audio decode processing such as DVD-Audio/Dolby Digital /DTS/MP3, and a system controller which controls

the system.

The front end section realizes optical head signal computation processing and RF signal processing, digital signal

processing (16-8 demodulation, error correction) for DVD-ROM playback according to the DVD specifications,

digital signal processing of CD-DA/CD-ROM (error correction), AV decoder transfer, servo control, spindle motor control

and seek control.

In the case of MN2DS0016AAUB, the front end servo system waveforms, such as FE, TE and AS, are not observed

as in the case of DVD mechanism module (MS4) CX-3183. Please pay attention.

B

1.1 Analog block (MN2DS0016AAUB : IC1501)

The functions of the analog block are as described below.

1. Reference power circuit

2. SERVO system/DPD system signal processing circuit

Gain switching amplifier and Low Pass Filter (LPF)

3. RF signal processing circuit

RF adding circuit, circuit to make inline, Variable Gain Amplifier (VGA) circuit

4. Laser power control (LPC) circuit

5. A/D converter for SERVO (10 bit, DPD system-4ch), PWM

2

1.1.1 APC circuit

C

The optical output of the laser diode (LD) has a large negative temperature characteristic.

Therefore, if the LD is driven by a constant current, a constant optical output cannot be obtained.

APC circuit is a circuit to control the current so that the output at the monitor diode (MD) will be constant.

MN2DS0016AAUB includes 2 types of APC circuit, one for DVD and the other for CD.

The LD current can be obtained by dividing the measured voltage between DVDLD1 (CDLD1) and 5 V by 6 Ω

(1.5 Ω x 4=6 Ω), in the case of DVD (CD). It will be approximately 50 mA (45 mA) in the case of DVD (CD).

The potential difference between DVDLD1(CDLD1) and 5 V is set to approx. 300 mV(270 mV).

D

CDMPD

14

DVN Chip

E

(MN2DS0016AAUB : IC1501)

DVDMPD

F

2

1234

CX-3212

PU UNIT

Page 3

5 678

A

ADC

ADC driving AMP

Buffer AMP

Selector

ADC

Selector

Gain switching

6/7.5/9/10.5/

12/13.5/15/

16.5/17/19.5 dB

Gain switching

3 dB, 9 dB

DVN Chip

AMP

B

C

FE

D

Gain switching

12

G=0 dB

LPF

50 k/100 kHz

-6 dB, 0 dB, 9.5 dB

VIN5

136

11

FE1

Buffer

LPF

LPF

50 k/100 kHz

Input AMP

VIN6

137

FE = (FE1) - (FE2)

The signal from PU, FE1 and FE2, are AD converted inside IC1501 and captured. After that, a differential is obtained by taking the offset cancellation into consideration,

1.1.2 FE forming circuit

and FE is obtained.

Focus error (FE) forming circuit

56

CN1101

FE2

FE signal forming circuit

1+Pfbal0,1/0x0100

After 10 bit ADC

CX-3212

FE1

+

-

DVN Chip

1-Pfbal0,1/0x0100

Fbal coarse adjustment value

Offset cancel

FE2

7

E

F

8

3

Page 4

1234

AMP

ADC2

TE

D

+

+

Phase

comparator

ADC3

ADC4

A

TE signal forming circuit

B

LPF (integrator)

Phase comparator

C

ADC

ADC1

AMP

G=-1 dB

/5.7 MHz

HPF

100 kHz

LPF

/5.7 MHz

27 M/11.3 M

VIN3RF

121

HPF

LPF

27 M/11.3 M

VIN4RF

120

HPF

D

Buffer

E

Input AMP LPF

HPF

100 kHz

Gain switching

G=0,3,6,9,12,15 dB

LPF

/5.7 MHz

27 M/11.3 M

Gain switching

–7.5 dB, 0 dB, 3.5 dB

VIN1RF

123

HPF

100 kHz

LPF

27 M/11.3 M

VIN2RF

122

DVN Chip

100 kHz

/5.7 MHz

0.1 μF

F

CN1101

1.1.3 TE forming circuit

Tracking error (TE) forming circuit

In the case of a DVD, the phase difference method is used for TE forming, and the TE is formed from the phase difference among (A+C) and (B+D).

In the case of a CD, 3 beam method is used, and after entering the signal into a variable amplifier for tracking offset adjustment via an external resistor, it is AD converted,

4

1234

and a TE is formed by the equation of TE=(E+G_E+F)-(F+H_G+H).

DVD (phase difference TE)

8

A

7

B

CX-3212

0.1 μF

0.1 μF

9

C

0.1 μF

10

D

Page 5

5 678

A

B

ADCSelector

AMP

Buffer AMP

Buffer

LPF

LPF

Selector ADC

G=0 dB

50 k/100 kHz

Gain switching

6/7.5/9/10.5/

12/13.5/15/

16.5/17/19.5 dB

Gain switching

3 dB, 9 dB

DVN Chip

LPF

50 k/100 kHz

TE

AMP

+

TE signal forming circuit

1+Ptbal0,1/0x0100

-

1-Ptbal0,1/0x0100

C

D

DVN Chip

E

Input AMP

CD (3 beam TE)

CN1101

56

VIN9

135

21

H

F+H_G+

Gain switching

-6 dB, 0 dB, 9.5 dB

VIN10

134

22

E+G_E+F

After 10 bit ADC

CX-3212

Offset cancel Tbal adjustment value

E+G_E+F

F+H_G +H

7

8

F

5

Page 6

1234

1.2 Servo block (MN2DS0016AAUB : IC1501)

A

At the servo block, focusing, tracking, servo control of traverse, spindle motor control and seek control are performed.

1.2.1 Focus close

Close to disc.

Lens

B

Merging

point

Late

C

After issuing the focus close command, both the DVD and the CD will perform the following processing.

1. Measurement and optimization of the signal level.

D

First the PU lens is driven in the direction getting away from the disc, then it is driven in the direction getting close

to the disc. At this time, each signal level of FE, AS and RFENV are measured at the focused focal point that the

lens passes, and the levels of FE and AS are optimized. (1 and 2 in the figure)

2. Focus adjustment

Next, after detecting the drawing level of FE and AS by driving the lens away from the disc, the focus loop filter is

activated and the focus is drawn. (3~6)

3. Confirmation of adjustment

Confirm the drawing at the signal level of AS and RFENV. (6, 7)

The signal levels of FE, AS and RFENV and the focus drive voltage can be checked by the focus search in the

test mode.

E

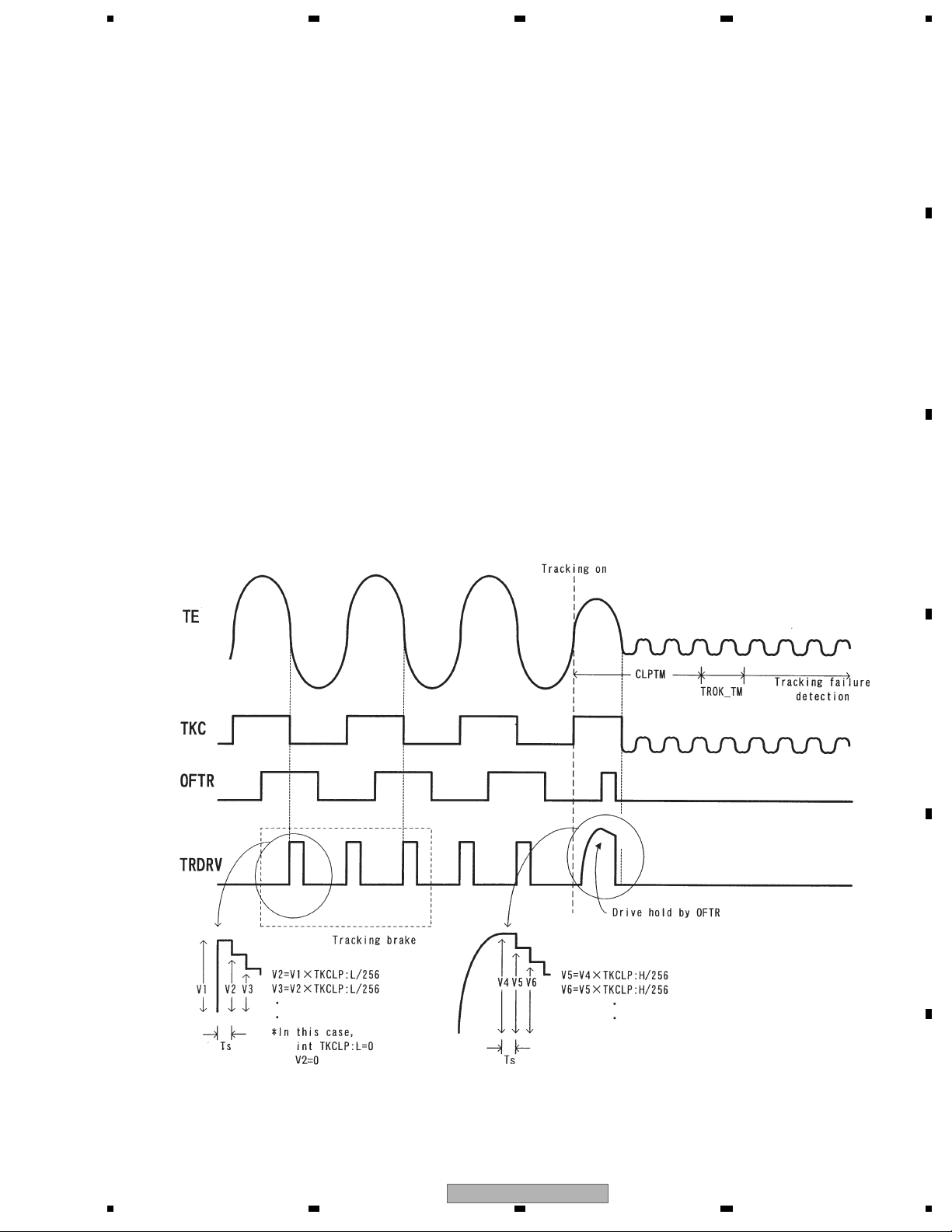

1.2.2 Tracking close

After issuing the tracking close command, both the DVD and the CD will perform the following processing.

1. Tracking brake

1/2 cycle of the track cross is measured and if the cycle is within the specified range, the brake pulse is output.

The output direction of the brake pulse is determined by the phase relationship of the OFTR and the TKC

(binary signal of TE) signals. When it is confirmed that the swinging of the lens against the disc has been controlled,

braking will be stopped and enters into drawing. If the drawing conditions are not met within 10 msec, after the brake

output, the brake will be ended and entered into drawing.

2. Tracking adjustment

Tracking drive hold processing by the OFTR signal will be performed.

3. Confirmation of adjustment

F

Checking is made that the number of track jumps within the specified period of time are at the designated numbers

or less. The time out for confirmation of adjustment is 8.4 msec. and retry is performed by the command from the

microcomputer.

6

1234

CX-3212

Page 7

5 678

1.2.3 Track jump

In this system, one of the three methods, interval jump, multi jump or traverse seek, is selected depending on the

number of target moving tracks.

1. Interval jump

Detailed seek can be performed to execute repeated track jump of 1 track, and it is used when the target track gets

close or at the time of seek operation to the adjacent track.

2. Multi jump

Both edges of the track cross signal TKC are counted, and track count move of the designated number is executed.

Furthermore, the stepping motor is driven according to the number of jumps.

3. Traverse seek

The stepping motor is controlled by F/W. Track count by TKC is not performed, and the stepping motor is moved

according to the number of jumps. In the case of a DVD, seek is performed by maintaining the pick up at the mid

point using the mid point servo by the microcomputer.

It indicates the setting for jump switching common to DVD and CD.

Types of target move number of jumps.

DVD

~10 Interval jump

1

~500 Multi jump

11

~878 Combination of multi jump and interval jump

501

~1756 Traverse seek (short)

879

~ Traverse seek (long)

1757

CD

~10 Interval jump

1

~400 Multi jump

11

~780 Combination of multi jump and interval jump

401

~928 Traverse seek (short)

781

~ Traverse seek (long)

929

The waveform of track jump is shown on the next page.

Tracking-on process

A

B

C

D

E

F

CX-3212

56

7

8

7

Page 8

1234

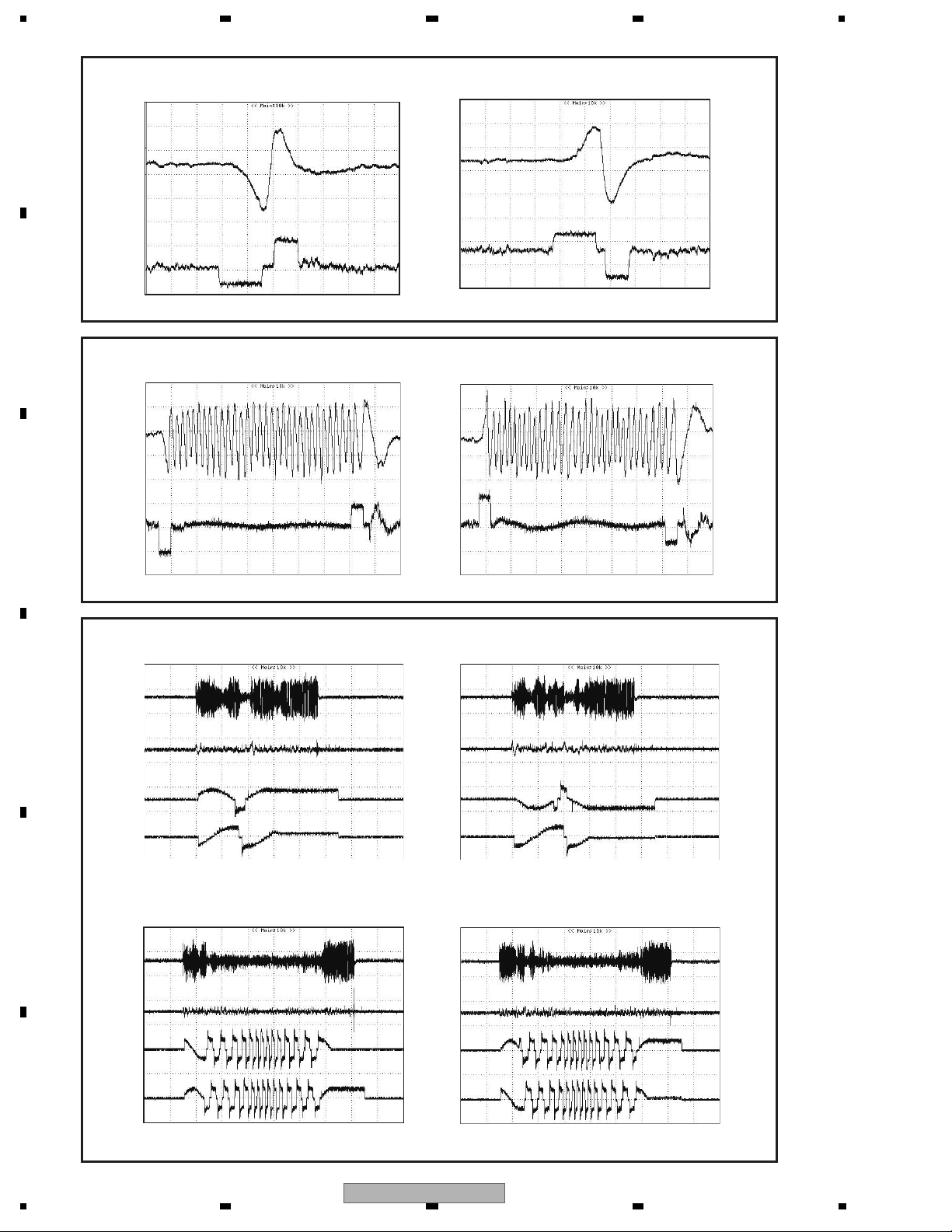

Interval jump (1 track) DVD

Outer peripheral jump Inner peripheral jump

A

TE

TD

B

Multi jump (32 track) DVD

Outer peripheral jump Inner peripheral jump

TE

C

TD

Traverse seek (900 tracks)

A ± and B ± are measured by setting the LPF of the oscilloscope to 10 kHz.

Outer peripheral jump Inner peripheral jump

D

TE

TD

A±

B±

Traverse seek (10 000 tracks)

E

Outer peripheral jump

Inner peripheral jump

TE

TD

A±

B±

F

8

1234

CX-3212

Page 9

5 678

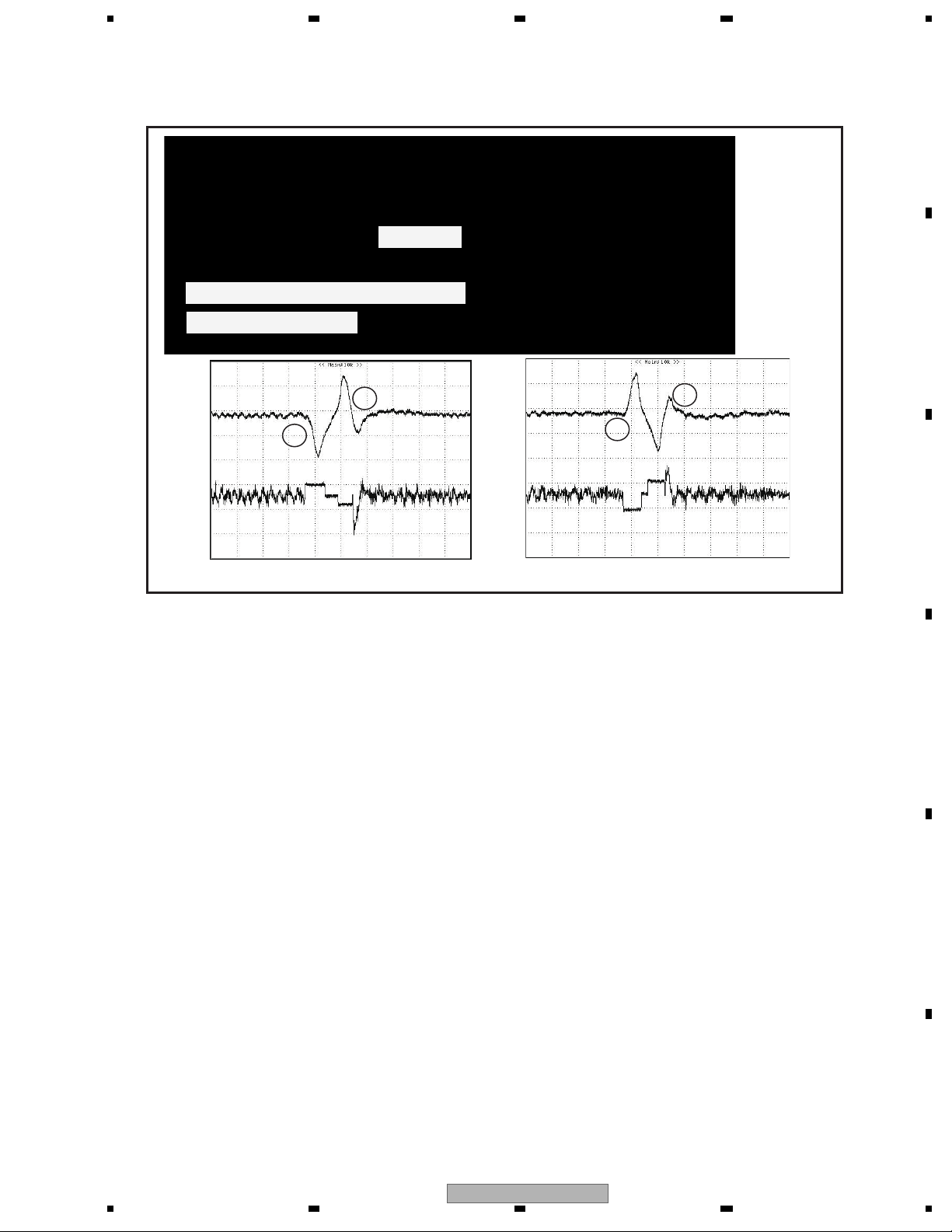

1.2.4 Focus jump

Focus jump is a function compatible to 2 layers on one side or 2 layers on both sides. Looking from the object lens,

the layer close to the lens is called “layer 0” (L0) and the layer away from the lens is called “layer 1” (L1).

Object lens

The waveform of the focus jump is shown below.

Focus jump waveform

A

B

B

D

FE

A

C

FD

The flow of the focus jump is shown below.

1. The tracking is opened by the layer being played back.

2. A command is issued to execute jump to the target layer.

3. The tracking is closed at the layer after the jump and the playback is resumed.

Incidentally, the process when the jump command is issued is as described below.

1. The lens is accelerated to the target layer until the FE signal detects the focus jump acceleration end level.

Acceleration will be ended by force, however, if the time for acceleration timeout has elapsed before detecting the

acceleration end level.

2. The drive voltage is not output until the FE signal detects the speed reduction start level, and the lens is moved by

inertia.

3. The lens speed is reduced from detection of the speed reduction start level until detection of the speed reduction

end level. Speed reduction will be ended by force, however, if the time for speed reduction timeout has elapsed

before detecting the speed reduction end level.

C

D

1.3 Auto adjustment function

All circuit adjustments are automated in this system.

Details of each auto adjustment are explained below.

1.3.1 VIN1, VIN2, VIN3, VIN4, VIN5, VIN6, VIN9, VIN10 offset cancel

Each signal from VIN1~6, 9 and 10 output by PU is converted to a digital signal by the AD converter in the servo block.

Offset cancel is a function to cancel input offset of the AD converter at the time of power ON.

1.3.2 VCO gain adjustment (VARI adjustment)

It has a function to absorb variation of VCO gain among individual LSI by learning so that auto adjustment is made to

maintain the VCO gain at a certain level. VCO is locked against the reference frequency for learning.

And, a frequency control value (FCNT) is read, and VARI register is adjusted so that the read value becomes the

same as the target FCNT value.

1.3.3 FE normalization adjustment

FE signal level measured at the time of focus close is adjusted so that it will become 190LSB at the digital equalizer

input stage.

CX-3212

56

7

8

E

F

9

Page 10

1234

1.3.4 Tracking balance (TBAL) adjustment

At the time of focus close and tracking open, the lens is oscillated in the track direction and the balanced point where

A

the DC offset becomes zero is searched and adjusted by using the Newton-Raphson method.

1.3.5 Learning of tracking error amplitude

At the time of focus close and tracking open, the lens is oscillated in the track direction and adjusted so that the TE

amplitude level becomes 190 LSB at the digital equalizer input stage.

1.3.6 OFTR adjustment

The binary threshold level is adjusted to make the OFTR signal into a binary digit.

1.3.7 RF gain adjustment

The gain setting is adjusted by the VGA value in order to set the gain setting of the RF forming circuit to an optimum

one according to the PU output.

B

1.3.8 Focus balance (FBAL) adjustment

The focus position is adjusted so that the RFENV will be the maximum at the time of focus close tracking open and

tracking close.

1.3.9 Focus gain adjustment, tracking gain adjustment

At the time of tracking close, a disturbance is entered into the servo loop to adjust to the target gain intersection.

1.3.10 AS normalization adjustment

The AS signal level is measured for the designated number of samples at the time of track closing, and after A/D

conversion at the ADSC, it is fine adjusted to become 64 LSB at the digital equalizer input stage.

C

D

All auto adjustments can be confirmed by displaying the adjustment result in the test mode.

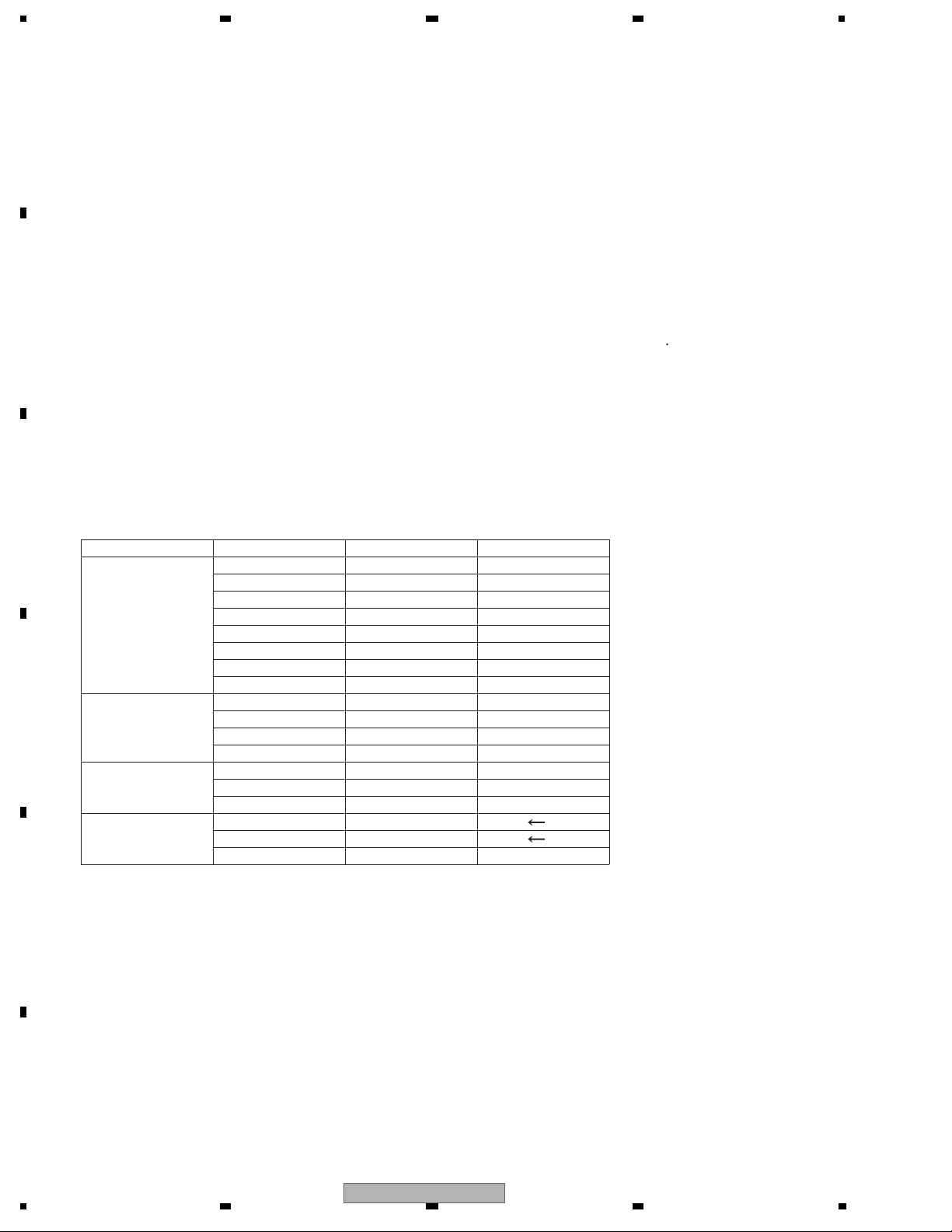

The list of auto adjustment coefficient

State

Power ON

F close

F close (after TBAL)

T close

Coefficient

VIN1 offset

VIN2 offset

VIN3 offset

VIN4 offset

VIN5 offset

VIN6 offset

VIN9 offset

VIN10 offset

FE MAX

FE MIN

AS MAX

FE normalization

TE MAX

TE MIN

TE normalization

F gain

T gain

AS normalization

DVD

06B7~08CD

06B7~08CD

06B7~08CD

06B7~08CD

06B7~08CD

06B7~08CD

-

0E48~36CD

C933~F1B8

037B~1BD9

01DD~05B4

1518~47E0

B820~EAE8

017C~0320

0100~0400

0100~0400

024C~125F

CD

-

-

-

06E1~08A3

06E1~08A3

06B7~08CD

06B7~08CD

13A5~469A

B966~EC5B

0978~3DDC

016A~045B

0337~381A

C7E6~FCC9

0230~08AF

0168~0399

Note) Coefficient values are indicated in hexadecimals. In all cases, specifications

E

at the production line are described. For discs, TDV-582 is used for DVD and TCD-792 is used for CD.

1.4 CIRC block (MN2DS0016AAUB : IC1501)

The CIRC block includes the digital signal processing function (EFM modulation and error correction) of CD-DA and

CD-ROM and the digital servo processing function of the spindle motor.

1.5 DRC block (MN2DS0016AAUB : IC1501)

The digital read channel (DRC) is equipped with A/D converter, digital equalizer (DEQ), Adaptive filter, Viterbi

detector, digital PLL circuit, RISC interface and periphery circuits for reading of signal on optical disc.

F

10

1234

CX-3212

Page 11

5 678

1.6 ATAPI I/F(MS5 base model)

[Outline]

The ATAPI interface is a ATAPI protocol control circuit compatible to ATA/ATAPI-5.

The register of the control section can be directly accessed from the system controller, and the data

transfer is made via the SODC internal bus.

? ATAPI interface

Signal Name

HDD[15:0]

NCS[1:0]

DA[2:0]

NIORD

NIOWR

IORDY

DMARQ

NDMACK

INTRQ

NDASP]

NPDIAG

NRESET

MASTER

Bits

16

2

3

1

1

1

1

1

1

1

1

1

1

* When viewed from u DVD-LSI.

I/O

Description

I/O

ATAPI data input/output

I

ATAPI host chip select

I

ATAPI host address

I

ATAPI host data read out

I

ATAPI host data write

O

ATAPI host ready output

O

DMA request to ATAPI host

I

DMA response from ATAPI host

O

Interrupt request to ATAPI host

O

ATAPI drive information

O

ATAPI slave master diagnosis

I

ATAPI host hard reset

I

ATAPI slave master selection

A

B

? ATAPI specifications

Compatible transfer mode

PIO

Single word DMA

Multi word DMA

Ultra DMA

mode 0 to 4

mode 0 to 2

mode 0 to 2

mode 0 to 4

64 Byte data FIFO for host I/F is built-in.

Auto capturing function of ATAPI command packet is built-in.

Master slave compatible

? ATAPI connection configuration

DVD-LSI

ATAPI I/F connector

IC1501 CN2001

HDD[15:0]

NCS[1:0]

DA[2:0]

NIORD

NIOWR

IORDY

DMARQ

NDMACK

INTRQ

NDASP

NPDIAG

NRESET

MASTER

C

D

E

CX-3212

56

F

7

8

11

Page 12

1234

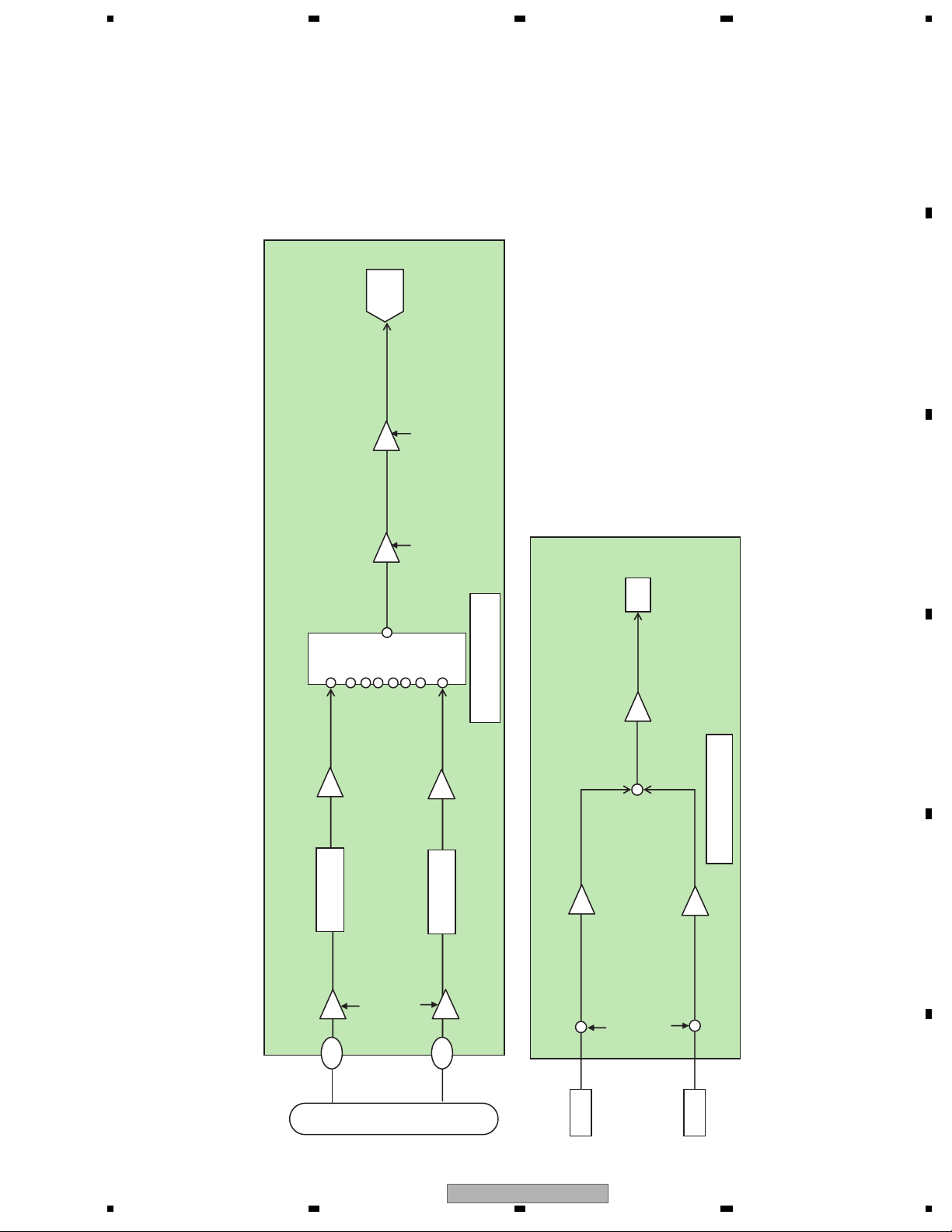

1.7 Power Supply Map(MS5 base model)

A

B

C

HOST

Power Supply

VD8(Reg)

8 V+/-0.4 V

VD8V

VD8(Driver)

8 V+/-0.4 V

Mecha inside

Power Supply

5V Reg(VCC5)

5.0 V +/-0.1 V

IC1004

NJM2880U1-05

5V Reg(AVCC5)

5.0 V +/-0.1 V

IC1005

S-L2980A50MC-C7J

Pick Up Unit

CGY4800

LD

Photo IC

ADAC

IC1801 PCM1753DBQ

Video circuit

Disc detect LED

1chip Driver

IC1201 BD7996EFV

1chip Driver(8 V)

Supply

IC

VDD5

5 V+/-0.4 V

3.3 DC/DC(VCC33)

3.21 V <---> 3.41 V

D

2 ch DC/DC

Converter

E

F

IC1001

BD9851EFV

1.2 DC/DC(VCC12)

1.17 V <---> 1.23 V

1chip Driver(5 V)

SDRAM

IC1481

EDS1232AATA-75-E

Flash-ROM 1 (Program)

IC1402

S99AL016DBT1

Flash-ROM 2 (Data)

IC1401

S99AL016DBT1

Latch

IC1352

TC74LCX16373FT

Other

DVD1chip(3.3 V)

DVD LSI

IC1501

MN2DS0016AAUB

DVD1chip(1.2 V)

12

1234

CX-3212

Page 13

5 678

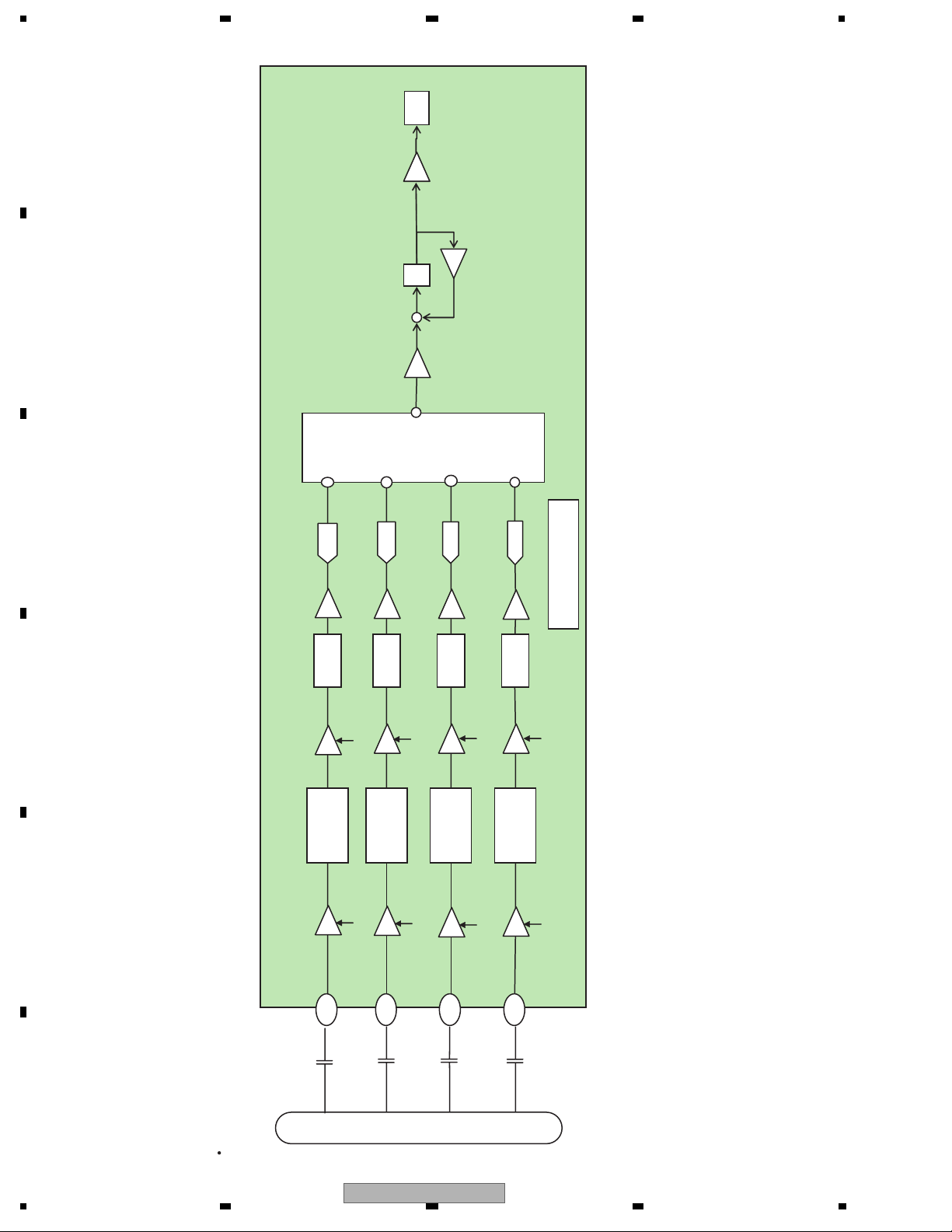

Power Supply Map(MS5AV code2 model)

HOST

Power Supply

VD8(Reg)

8 V+/-0.4 V

VD8V

VD8(Driver)

8 V+/-0.4 V

Mecha inside

Power Supply

5V Reg(VCC5)

5.0 V +/-0.1 V

IC1004

NJM2880U1-05

5V Reg(AVCC5)

5.0 V +/-0.1 V

IC1005

S-L2980A50MC-C7J

Supply

IC

Pick Up Unit

CGY4800

LD

Photo IC

ADAC

IC1801 PCM1753DBQ

Video circuit

Disc detect LED

1chip Driver

IC1201 BD7996EFV

1chip Driver(8 V)

A

B

C

VDD5

5 V+/-0.4 V

3.3 Reg.(VCC33)

3.15 V <--> 3.45 V

IC1007

NJM2885DL1-33

1.2 DC/DC(VCC12)

1.08 V <--> 1.32 V

IC1008

R1232D121B

1chip Driver(5 V)

SDRAM

IC1481

EDS1232AATA-75-E

Flash-ROM 1 (Program)

IC1402

S99AL016DBT1

Flash-ROM 2 (Data)

IC1401

S99AL016DBT1

Latch

IC1352

TC74LCX16373FT

Other

DVD1chip(3.3 V)

DVD LSI

IC1501

MN2DS0016AAUB

DVD1chip(1.2 V)

D

E

F

CX-3212

56

7

8

13

Page 14

1234

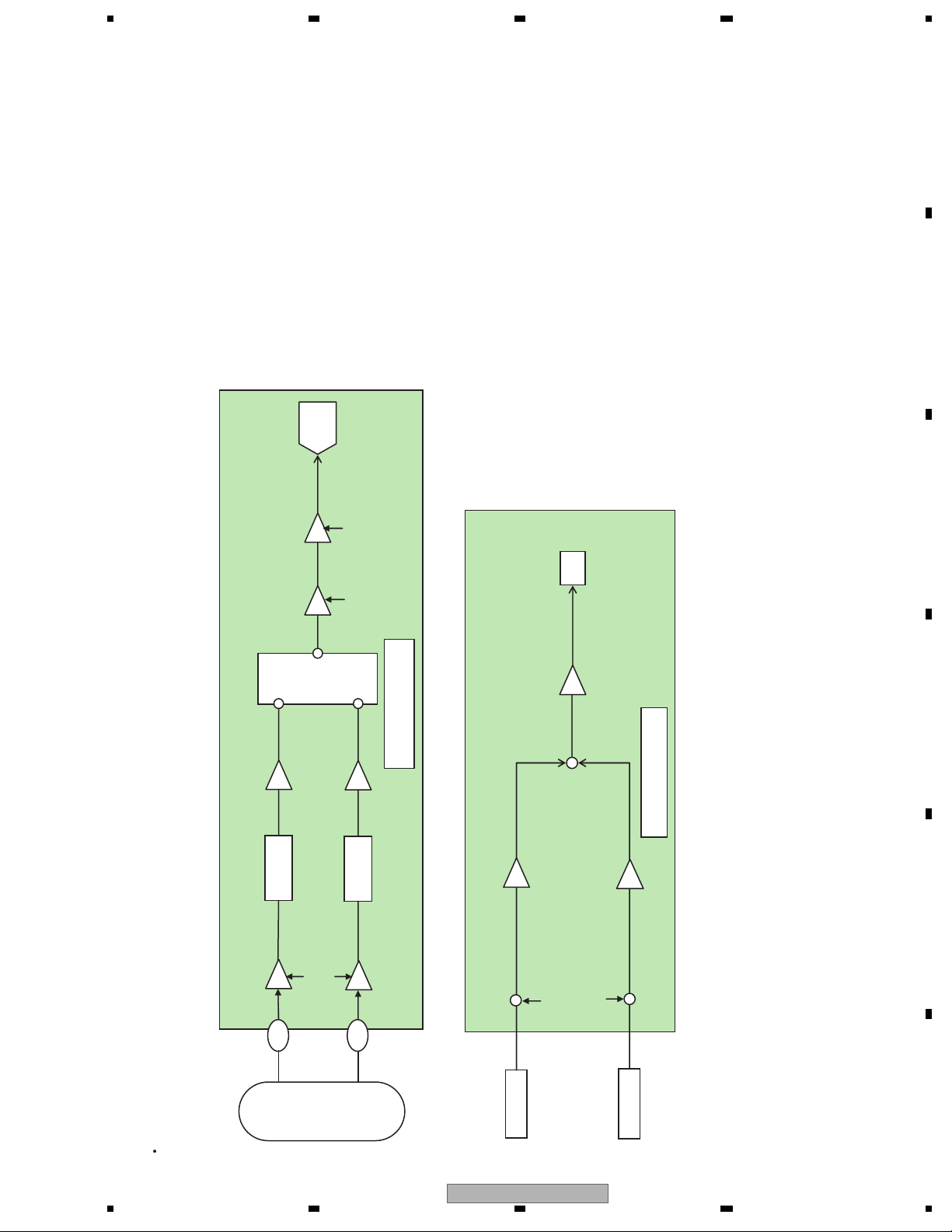

1.8 Clock circuit

A

[Outline]

By connecting a 27 MHz crystal oscillator to DVD-LSI (IC1501), DACCLK for externally connected Audio-DAC

is formed and supplied by the clock generator inside the DVD-LSI in addition to the clock used inside the LSI.

IC1501

DVD-LSI

B

C

MN2DS0016AAUB

169pin

OSCO

R1528

8 pF

C1519

R1530

1 Mohm

X1501

CSS1714

100 ohm

27 MHz

170pin

OSCI

8 pF

C1518

DACCLK

33.868 8 MHz or 36.864 MHz

R1526

27 ohm

IC1801

Audio-DAC

PCM1753DBQ

D

E

F

14

1234

CX-3212

Page 15

5 678

1.9 Audio circuit

[Outline]

1 Analog audio signal

Serial 3 line digital output + DACCLK (audio clock) output from DVD-LSI (IC1501) are converted to

analog audio signal by Audio-DAC (IC1801), and are output from HOST IF connector (CN1901).

Furthermore, analog MUTE signal is also output from DVD-LSI (IC1501) via HOST IF connector

(CN1901) simultaneously.

2 Digital audio signal (IEC60958/IEC61937)

Digital audio signal (IEC60958/IEC61937), output from DVD-LSI (IC1501), is output via Multi-ch/Ripping

IF connector (CN1851).

3 Digital multi-channel audio serial signal

Serial 6 line output from DVD-LSI (IC1501) is output via Multi-ch/Ripping IF connector (CN1851).

4 CD-DA ripping signal

Serial 3 line signal output + SUB-CODE signal, output from DVD-LSI (IC1501), are output in 4 times

speed via Multi-ch/Ripping IF connector (CN1851).

[Analog audio signal]

MS5 Mechanism module

AVCC5

IC1801

Audio DAC

(PCM1753)

R1804

820 ohm

C1809

1 800 pF1 800 pF

C1811

4.7 μF

fc=88 kHz

Zo=820 Ω

R1806R1805

29 pin

CN1901

(Lch)

26,28,30 pin

(AudioGND)

100 kohm

A

B

Radio audio circuit

C

47 kohm or more

R1803

820 ohm

C1808

C1810

4.7 μF

AMUTE

27 pin

(Rch)

100 kohm

20 pin

Audio GND

47 kohm or more

MUTE

Circuit

D

E

CX-3212

56

F

7

8

15

Page 16

1234

[Digital audio signal]

A

172pin

174pin

173pin

175pin

DACCLK

BCK

LRCK

ADOUT3

IC1801

ADAC(Stereo)

179pin

IC1851

TC74VHC125FTx2

BCK

178pin

B

IC1501

177pin

176pin

ADOUT0

ADOUT1

ADOUT2

DVD_LSI

LRCK

ADOUT

IECOUT

24PIN

CN1851

86pin

C

76pin

75pin

IC1852

IC1853

IC1853

BMUTE

MCKENA

Pull-UP

RIPP

"H"Fixed

EMPH

Multi ch Output (Digital)

[CD-DA 4 times speed ripping signal]

190pin

174pin

D

173pin

175pin

179pin

IC1851

TC74VHC125FTx2

178pin

177pin

IC1501

E

DVD_LSI

176pin

86pin

IC1852

IC1853

F

76pin

75pin

SBCK

BCK

SUBC

BLKCK

CLDCK

LRCK

DATAOUT

IPFLG

BMUTE

"Low"Fixed

MCKENA

Pull-UP

RIPP

"Low"Fixed

EMPH

24PIN

Multi ch Output (Digital)

CN1851

16

1234

CX-3212

Page 17

5 678

1.10 Video circuit

[Outline]

Composite signal and component signal are output from DVD-LSI (IC1501), and output from HOST IF (CN1901).

Incidentally, the buffer circuit of MS5AVcode2 model ->

CXK6631-,CXK6601-,CXK6610- and CXK6611- : No Mount, and the output signal from DVD-LSI is output as is.

CXK6630- : The buffer circuit is installed.

CXK6631-,CXK6601-,CXK6610- and CXK6611-

MS5 Mechanism module

A

VCC33

DVD LSI

(DVN)

IC1501

161pin:Composite

154pin:Component Y

153pin:Component Cb

152pin:Component Cr

CXK6630-

MS5 Mechanism module

VCC33

Zo=200 Ω :

CXK6601-,CXK6610- and CXK6611Zo=300 Ω :

CXK6631-

32,34,36,38 pin

(CVBS,Y,Cb,Cr)

31,33,35,37 pin

Zo=75 Ω

CN1901

LPF & 75 Ω Video Driver

CN1901

LPF & 75 Ω Video Driver

B

C

D

DVD LSI

(CVBS,Y,Cb,Cr)

(DVN)

IC1501

31,33,35,37 pin

161pin:Composite

154pin:Component Y

153pin:Component Cb

152pin:Component Cr

CX-3212

56

32,34,36,38 pin

E

F

7

8

17

Page 18

1234

1.11 SDRAM I/F

A

[Outline]

It is a memory for realizing the AV decoding function of DVD-LSI (IC1501). It is used for various purposes

such as buffering of stream data before decoding, working area for decoding, and storing of AV data or

output data after decoding.

? SDRAM interface

* When viewed from u DVD-LSI

Description

Signal Name

MDQ[31:0]

MA[11:0]

B

BA[1:0]

NRAS

NCAS

NEW

NCS

DQM[0]

DQM[1]

DQM[2]

DQM[3]

MCK

MCKI

C

Bits

32

12

2

1

1

1

1

1

1

1

1

1

1

I/O

Data bus of external SDRAM

I/O

SDRAM address

O

SDRAM bank address

O

RAS signal of SDRAM

O

CAS signal of SDRAM

O

Write enable signal of SDRAM

O

Chip select signal of SDRAM

O

O

Mask signal for writing lower level byte of the lower 2 bytes in SDRAM

O

Mask signal for writing higher level byte of the lower 2 bytes in SDRAM

O

Mask signal for writing lower level byte of the higher level 2 bytes in SDRAM

O

Mask signal for writing higher level byte of the higher 2 bytes in SDRAM

O

Clock input to SDRAM

I

Clock input for data input from SDRAM

? SDRAM specifications

Data bus width: 32 bit

Operating frequency: 121.5 MHz

CAS latency=3

8 word burst transfer

Manual precharge

CAS before RAS refresh (Auto refresh)

D

? SDRAM connection configuration

DVD-LSI

SDRAM

IC1501 IC1481

MDQ[31:0]

MA[11:0]

BA[1:0]

NRAS

NCAS

NEW

E

DQM[3:0]

NCSM

MCK

DQ[31:0]

A[11:0]

BA[1:0]

XRAS

XCAS

XWE

DQM[3:0]

XCS

CLK

MCKI

F

18

1234

CX-3212

Page 19

5 678

2. MECHANISM DESCRIPTIONS

Construction

CRG motor

PU unit

A

B

Load motor

Spindle motor

C

D

E

SW5(clamp SW)

SW4

8/12 detection lever L

SW1

SW2

8/12 detection lever R

SW6

SW3

CX-3212

56

F

7

8

19

Page 20

1234

2.1 Disc loading operation

A

1. When the disc is loaded, 8/12 detection lever R L will slide, either SW1 or SW2 will be ONtOFF,

and the loading motor will start.

2. In the case of a 12 cm disc, the disc is transported and SW3 becomes OFF and SW4 becomes ON,

and the microcomputer judges as a 12 cm disc.

B

C

3. In the case of an 8 cm disc, even if the disc is transported, the SW3 OFF and SW4 ON state will not be realized,

and the clamping motion will be taken. The microcomputer will judge as an 8 cm disc.

D

E

F

20

1234

CX-3212

Page 21

5 678

2.2 Disc centering mechanism

1. In the case of a 12 cm disc, the centering arm R L will open by the disc being transported and both the lock arm

R L being pushed. Furthermore, the disc will be centered by the stopper of either the clamp arm or the centering

arm R and stopped, and the clamping motion will be taken.

12 cm DISC positioning section

A

B

Lock arm

Centering arm

Lock arm

Centering arm

Clamp arm

2. In the case of an 8 cm disc, if a disc is inserted being shifted to the left or the right, the disc will first hit the lock

arm R or L.

As the lock arm R and L are coupled via the centering arm R and L and the lock will not be released unless both

are pushed, the disc will be restricted by the fixed lock arm and centered.

The disc pushes out the detection arm while being centered, the disc stops at a position where the motion of the

detection arm is completed, and the clamping motion will be taken.

C

D

8 cm DISC positioning section

CX-3212

56

E

F

7

8

21

Page 22

1234

2.3 Clamping operation

A

1. When a disc is loaded, the clamp lever will be driven by the disc detection arm being pushed by an 8 cm or a 12 cm

disc. By engagement of the jump rack and the lever driving gear, the disc clamping motion will start.

Disc detection arm

Disc pushing section

Clamp lever

Jump rack

B

Load lever R

C

2. When the load lever R pushed by the jump rack moves to the front side of the mechanism, the roller shaft restricted

by the cam of the load lever R will move downward.

And the roller shaft is also restricted by the cam of the cam ring.

The power of the roller shaft is transferred to the load lever L via the cam ring, and the load lever L will move to the

front side of the mechanism.

D

The coupling of the load cam attached to each load lever, three shafts of the CRG chassis unit and the shaft of the

clamp arm will be released, and the clamping motion will be completed at a position where the switch pushing section

of the load lever R turns the clamp SW to ON.

The shaft coupling to the cam

(CRG)

The shaft coupling to the cam

E

(Clamp arm)

The shaft coupling

to the cam (CRG)

The shaft coupling to the cam

(CRG)

F

22

1234

CX-3212

Page 23

5 678

2.4 Ejection operation

1. The loading motor reverse rotates, and the ejection motion will start.

2. In the case of a 12 cm disc, the ejection will be completed by OFFtONtOFF of SW4.

3. In the case of an 8 cm disc, the ejection will be completed when both SW3 and SW6 become ON after either SW3

or SW6 is ONtOFF.

A

B

C

D

E

F

CX-3212

56

7

8

23

Page 24

1234

3. DISASSEMBLY

A

- How to hold the mechanism section (Fig 1)

1. Hold the main frame and the top frame.

2. As the mechanical strength of the front part of the top frame is not strong, do not hold this part.

3. Do not touch the switches provided on the top face of the mechanism section.

4. Be careful not to pull the flexible PCB on the side face.

B

Fig 1

C

Do not touch this part. Do not touch this part.

Do not touch this part.

- How to remove the module PCB (Fig 2, Fig 3)

1. Put the mechanism section in locked state (disc load standby position).

2. Hold the mechanism module with its top face down.

3. Make the lands at 2 locations on the pick up flexible PCB short.

4. Disconnect the connectors of the pick up flexible PCB and the SPDL flexible PCB.

D

E

(Be sure to disconnect the connectors as the flexible PCB will be damaged if the PCB is removed without removing

the flexible PCB.)

5. Remove the solder joint of the lead wire of the load motor and the clamp SW.

6. Remove the two screws, and then remove the module PCB.

(Lift up point A slightly and remove it toward B direction. Be careful as the point C is connected with a flexible PCB.)

7. Disconnect the connector of the 8-12 detection flexible PCB from the PCB.

Fig 2

Module PCB

Short

B

Connector

(pick up flexible)

Connector

(8-12 detection flexible)

F

Solder land

(load motor, lead wire of the clamp SW.)

24

1234

Connector (SPDL flexible)

CX-3212

A

C

Fig 3

Page 25

5 678

- How to remove the spindle motor (Fig 4)

1. Remove the module PCB according to the instructions in “How to remove the module PCB”.

2. Remove the flexible PCB of the CRG motor from the connector of the spindle motor.

3. Remove the three motor mounting screws. When mounting or removing the motor, be careful not to deform the

CRG chassis.

- How to remove the CRG motor assy (Fig 4)

1. Remove the module PCB according to the instructions in “How to remove the module PCB”.

2. Remove the Mylar tape.

3. Remove the flexible PCB of the CRG motor from the connector of the spindle motor.

4. Remove the two screws, and then remove the CRG motor assy.

A

Set screw (CRG)

CRG motor assy

Set screw (CRG)

Feeding screw

PU rack

Set screw (spindle)

Mylar tape

Spindle motor

Set screw (spindle)

Fig 4

- How to remove the upper frame assy (Fig 5)

1. Remove the module PCB according to the instructions in “How to remove the module PCB”.

2. Remove the vibration-proof spring (right front).

3. Remove the four screws, and then remove the upper frame assy.

B

C

D

Set screw

Set screw

CX-3212

56

Set screw

Vibration-proof spring

(right front)

E

Upper frame assy

Set screw

Fig 5

F

7

8

25

Page 26

1234

- How to remove the PU unit (Fig 6)

1. Remove the module PCB according to the instructions in “How to remove the module PCB”.

2. Hang the main shaft holding spring to the CRG chassis temporary hanger.

3. Remove the CRG motor assy according to the instructions in “How to remove the CRG motor assy”.

A

4. Remove the holding plate spring of the main shaft.

5. While lifting up the tip of the pick up rack, slide the main shaft, and remove the PU unit.

(Note) When mounting the PU unit again, make sure to do the adjustments of the devices mounted thereon

according to the descriptions of the service manual. Furthermore, make sure to hang the main shaft

holding spring permanently.

B

Holding plate spring

Main shaft

PU unit

Main shaft holding spring

C

Sub shaft

D

CRG chassis temporary hanging section

Fig 6

E

Temporary hanging

F

26

1234

Permanent hanging

CX-3212

Page 27

5 678

- How to remove the load gear assy (Fig 7)

1. Remove the module PCB according to the instructions in “How to remove the module PCB”.

2. Remove the upper frame assy according to the instructions in “How to remove the upper frame assy”.

3. Remove the two screws, and then remove the load gear assy.

4. Remove the jump rack and the rack attached spring.

Set screw

Load gear assy

Set screw

A

B

Fig 7

- How to make the empty clamp state (motor driven empty clamp) (Fig 8)

1. While driving the motor in the clamping direction, pull the clamp lever toward you.

2. Even if the clamp lever has pushed the jump rack putting it in the clamped state, continue pulling the clamp lever

toward you lightly until it is stopped. It should be noted that the ejection will not work if the bar ring of the clamp

lever is positioned at the center of the hook shape. (Fig 9)

3. When the clamping motion is finished, stop the motion before the convex shape of the jump rack touches the load

lever R. (Fig 10)

Clamp lever

(pull toward you)

C

D

E

CX-3212

56

Fig 8

F

7

8

27

Page 28

1234

Bar ring of the clamp lever

A

Clamp spring

B

Fig 9

Make sure that the bar ring of the clamp

lever does not get inside the clamp spring.

C

Make it stop before this clearance

Load lever R

no longer exists.

Jump rack

D

E

Fig 10

F

28

1234

CX-3212

Page 29

5 678

- How to make the empty clamp state (manual empty clamp) (Fig 11)

1. Remove the module PCB according to the instructions in “How to remove the module PCB”.

2. Remove the upper frame assy according to the instructions in “How to remove the upper frame assy”.

3. Remove the load gear assy according to the description in “How to remove the load gear assy”.

4. While pulling the clamp lever toward you, pull the slip stopper of the load lever R, and make it clamp.

Clamp lever

(pull toward you)

A

Hold this part

and pull toward you.

Load lever R

Fig 11

- How to remove the load motor assy (Fig 12)

1. Remove the module PCB according to the instructions in “How to remove the module PCB”.

2. Remove the upper frame assy according to the instructions in “How to remove the upper frame assy”.

3. Remove the load gear assy according to the description in “How to remove the load gear assy”.

4. Make the empty clamp state according to the description in “How to make the empty clamp state

(manual empty clamp)”.

5. Remove the screw and then pull out the load motor assy from the side.

B

C

D

Make it slide and pull out.

CX-3212

56

E

Set screw

Fig 12

F

7

8

29

Page 30

1234

- How to remove the CRG assy (Fig 13)

1. Make the empty clamp state according to the description in “How to make the empty clamp state (motor driven

empty clamp)”.

2. Remove the module PCB according to the instructions in “How to remove the module PCB”.

A

3. Remove the upper frame assy according to the instructions in “How to remove the upper frame assy”.

4. Remove the three vibration-proof springs.

5. Remove the CRG assy by lifting it up until the shaft slips out of the damper.

- How to remove the disc guide assy (Fig 13)

1. Make the empty clamp state according to the description in “How to make the empty clamp state (motor driven

empty clamp)”.

2. Remove the module PCB according to the instructions in “How to remove the module PCB”.

3. Remove the upper frame ASSY according to the instructions in “How to remove the upper frame assy”.

4. Remove the two screws, and then remove the disc guide by lifting it up and placing it at 45° position and further

B

sliding it to the left.

Vibration-proof spring

CRG assy

Vibration-proof spring

Vibration-proof spring

C

D

Disc guide spring

Disc guide

Disc guide spring

Fig 13

E

F

30

1234

CX-3212

Page 31

5 678

- How to remove the roller assy (Fig 14)

1. Remove the module PCB according to the instructions in “How to remove the module PCB”.

2. Remove the upper frame assy according to the instructions in “How to remove the upper frame assy”.

3. Remove the extension spring.

4. Remove the load gear assy according to the description in “How to remove the load gear assy”.

5. Make the empty clamp state according to the description in “How to make the empty clamp state (manual empty

clamp)”.

6. Remove the disc guide assy according to the description in “How to remove the disc guide assy”.

7. Remove the CRG assy according to the description 4 and 5 in “How to remove the CRG assy”.

8. Push the slip stopper of load lever R toward the back, and move it until the end.

9. Remove the load motor assy according to the description in “How to remove the load motor assy”.

10. Remove the roller arm spring R L.

As for the roller arm spring R, remove only the tip hanging on the load lever R.

11. Remove the extension spring, and then remove the roller assy by lifting it up to the highest position and sliding it

toward the right.

(Note) Be careful not to deform the shutter when removing the roller assy.

A

B

Roller arm spring L

Shutter

Roller assy

Extension spring

Shutter

Load lever R

(move it toward the back)

Roller arm spring R

Fig 14

C

D

E

CX-3212

56

F

7

8

31

Page 32

1234

- How to remove the damper (Fig 15)

1. Make the empty clamp state according to the description in “How to make the empty clamp state

(manual empty clamp)”.

2. Remove the module PCB according to the instructions in “How to remove the module PCB”.

A

3. Remove the upper frame assy according to the instructions in “How to remove the upper frame assy”.

4. Remove the three vibration-proof springs.

5. Remove the CRG assy according to the description 4 and 5 in “How to remove the CRG assy”.

6.1 Release the clinch by holding the A section of the damper attached to the main frame using a pair of pliers and

lifting it up toward B direction.

(As there will be a gap made at section C, remove the damper.)

6.2 Insert a screwdriver into section D, release the clinch by lifting up a metal plate on the other side, and remove the

damper.

7.1 Remove the CRG motor assy according to the description 3 and 4 in “How to remove the CRG motor assy”.

7.2 Remove the damper.

B

C

C

A

B

Fig 15

D

D

E

F

32

1234

CX-3212

Loading...

Loading...