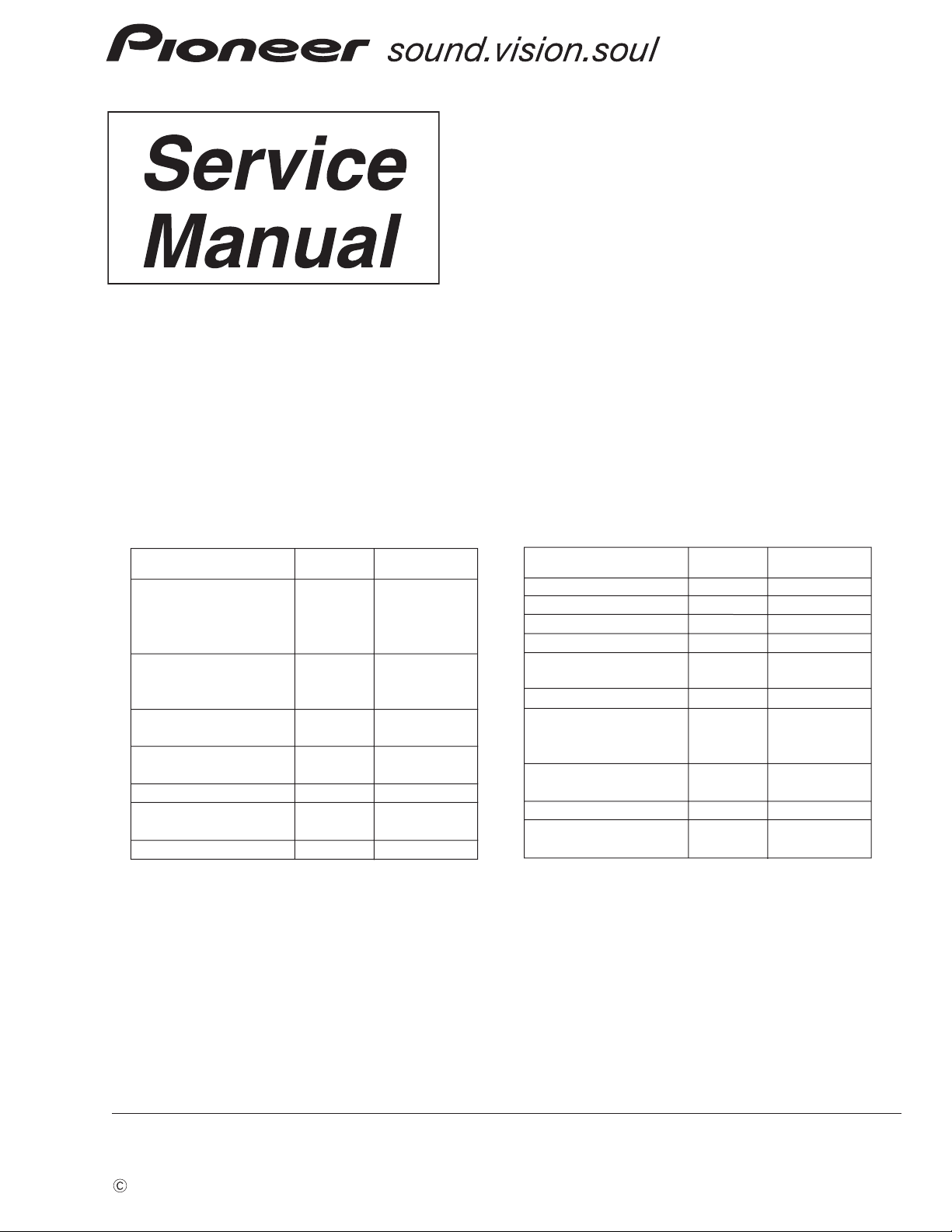

Pioneer CX-3195 Service manual

ORDER NO.

CRT3815

CD MECHANISM MODULE(S10.5COMP2)

CX-3195

This service manual describes the operation of the CD mechanism module incorporated

in models listed in the table below.

When performing repairs use this manual together with the specific manual for model

under repair.

Model

DEH-2900MP/XN/EW5 CRT3802

DEH-2920MP/XN/EW5

DEH-2900MPB/XN/EW5

DEH-2910MP/XN/UR

DEH-2950MP/XN/ES CRT3820

DEH-2950MP/XN/ES1

DEH-2990MP/XN/ID

DEH-P390MP/XU/UC CRT3816

DEH-P3900MP/XU/UC

DEH-P4950MP/XU/ES CRT3817

DEH-P4950MP/XU/CN5

DEH-P2900MP/XU/UC CRT3823

DEH-P3950MP/XU/ES CRT3824

DEH-P3950MP/XU/CN5

DEH-P5900MP/XU/EW5 CRT3828

Service

Manual

CD Mechanism

Module

CXK5760

CXK5760

CXK5760

CXK5760

CXK5760

CXK5760

CXK5760

Model

DEH-3900MP/XN/EW5 CRT3804

DEH-3990MP/XN/ID CRT3829

DEH-P40MP/XU/EW5 CRT3834

DEH-P4950MP/XU/ES CRT3835

DEH-P490IB/XN/UC CRT3846

DEH-P4900IB/XN/UC

DEH-P4900IB/XN/EW5 CRT3847

DEH-P5950IB/XN/ES CRT3848

DEH-P5950IB/XN/ES1

DEH-P5990IB/XN/ID

DEH-P590IB/XN/UC CRT3851

DEH-P5900IB/XN/UC

DEH-P6900IB/XN/EW5 CRT3852

DEH-P6950IB/XN/ES CRT3853

DEH-P6950IB/XN/ES1

Service

Manual

CD Mechanism

Module

CXK5760

CXK5760

CXK5760

CXK5760

CXK5760

CXK5760

CXK5760

CXK5760

CXK5760

CXK5760

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2006

K-ZZA. OCT. 2006 Printed in Japan

1234

CONTENTS

1. CIRCUIT DESCRIPTIONS ............................................................................................................................... 3

2. MECHANISM DESCRIPTIONS...................................................................................................................... 20

3. DISASSEMBLY .............................................................................................................................................. 22

A

B

C

D

E

F

2

1234

CX-3195

5 678

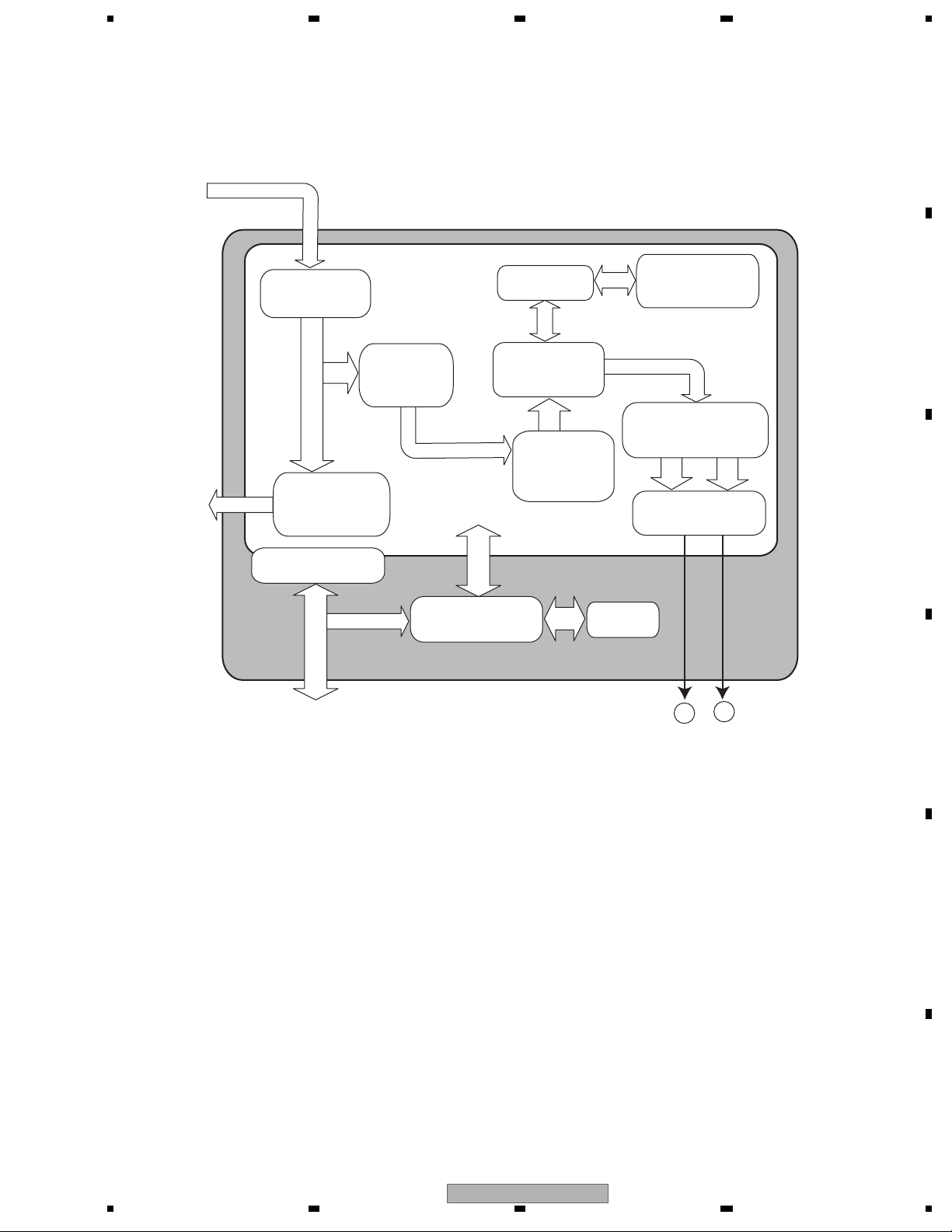

1. CIRCUIT DESCRIPTIONS

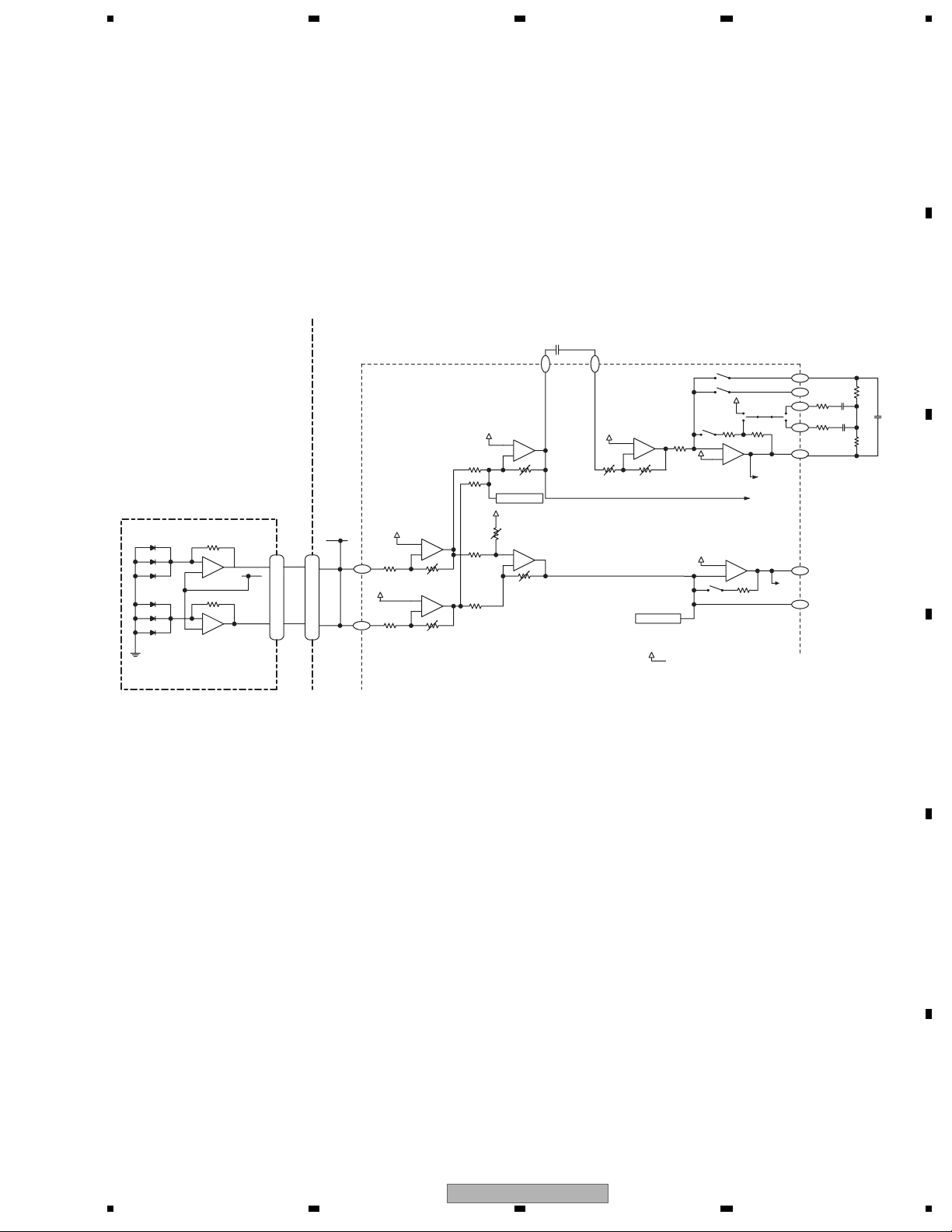

The recent mainstay of the CD LSI is the LSI integrating the core DSP with DAC or RF amplifier, which are generally

employed as peripheral circuits, however, PE5547A, used in this product, is an LSI integrating the afore-mentioned

LSI unit and microcomputer unit in one chip.

A

A,B,E,F Signal

RF amplifier

Digital servo

PORT I/F

EFM

decoder

CD-ROM

V850ES core

BMC

decoder

CIRC

Internal RAM

SRAM

PE5547A

(1Mbit)

Audio

DSP

1bit DAC

B

C

Port control

Fig.1.0.1 Block diagram of CD LSI PE5547A

D

Analog output

E

F

CX-3195

56

7

8

3

1234

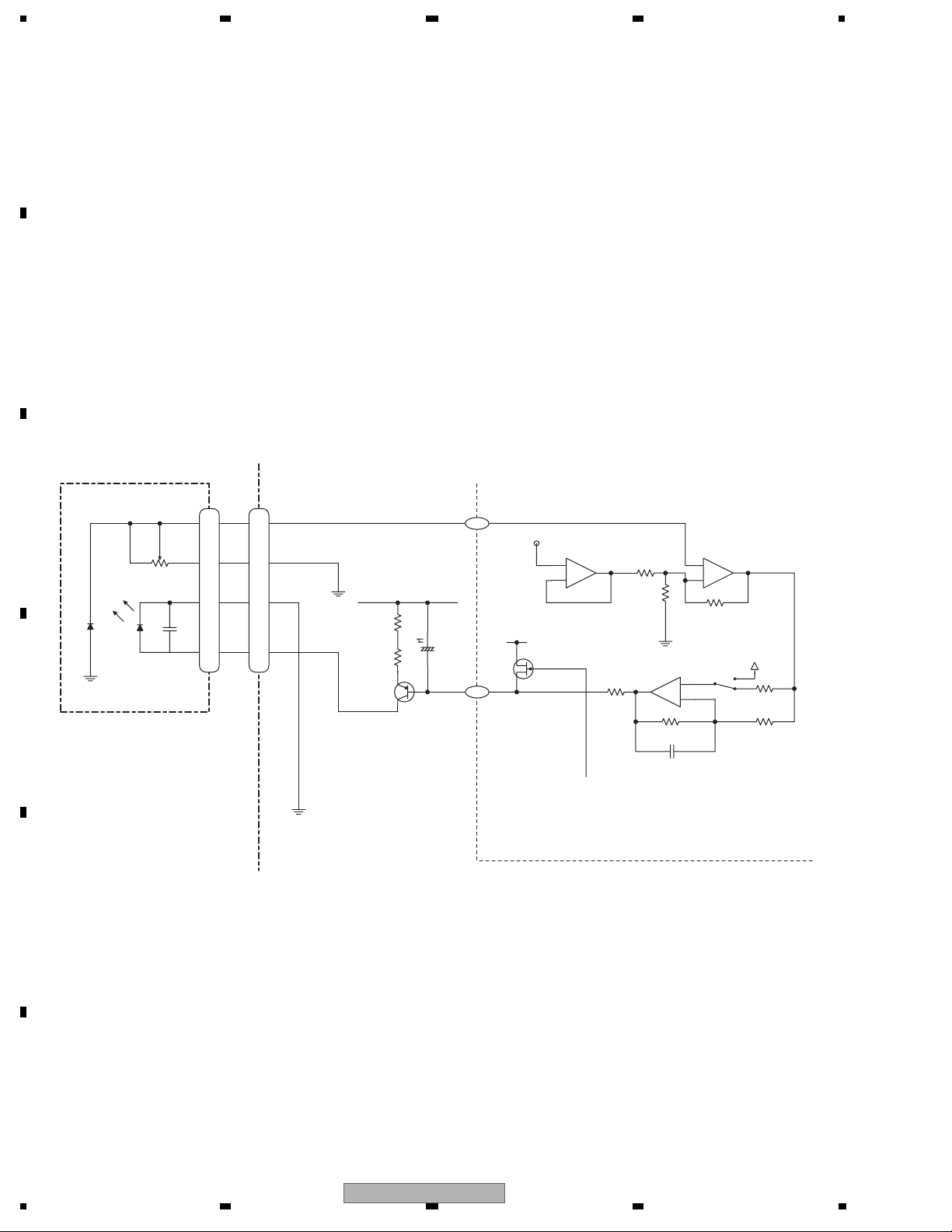

1.1 PREAMPLIFIER BLOCK

In the preamplifier block, the pickup output signals are processed to generate signals that are used in the subsequent

A

blocks: servo, demodulator, and control blocks. Signals from the pickup are I/V converted in the pickup with the

preamplifier with built-in photo detectors, and after added with the RF amplifier, they are used to produce such signals as

RF, FE, TE, and TE zero-cross signals. The preamplifier block is built in CD LSI PE5547A (IC201), whose parts are

described individually below. Incidentally, as this LSI employs a single power supply (+ 3.3 V) specification, the reference

voltages of this LSI and the pickup are the REFO (1.65 V) for both. The REFO is an output obtained from REFOUT in the

LSI via the buffer amplifier, and is output from the pin 133 of this LSI. All measurements will be performed with this REFO

as the reference.

Caution: Be careful not to short-circuit the REFO and GND when measuring.

1.1.1 APC (Automatic Power Control) circuit

B

Since laser diodes have extremely negative temperature characteristics in optical output when driven in constant current,

it is necessary to control the current with the monitor diodes in order to keep the output constant. This is the feature of the

APC circuit. The LD current is obtained by measuring the voltage between LD1 and V3R3, and divide the value by 7.5

(ohms), which becomes about 30 mA. The voltage between LD1 and V3R3 is set to about 225 mV.

Pickup Unit

C

D

Fig.1.1.1 APC

E

MD

VR

LD-

LD+

5

7

15

14 14

CD CORE UNIT

5

7

15

2R4 x 2

2R7

4.7

+

2SA1577

143

142

PE5547A

PD

LD

REG 1.25V

+

-

LDS

+

6.5k

-

1k

6.5k

Vref

APN

+

1k

-

150k

3p

100k

100k

F

4

1234

CX-3195

5 678

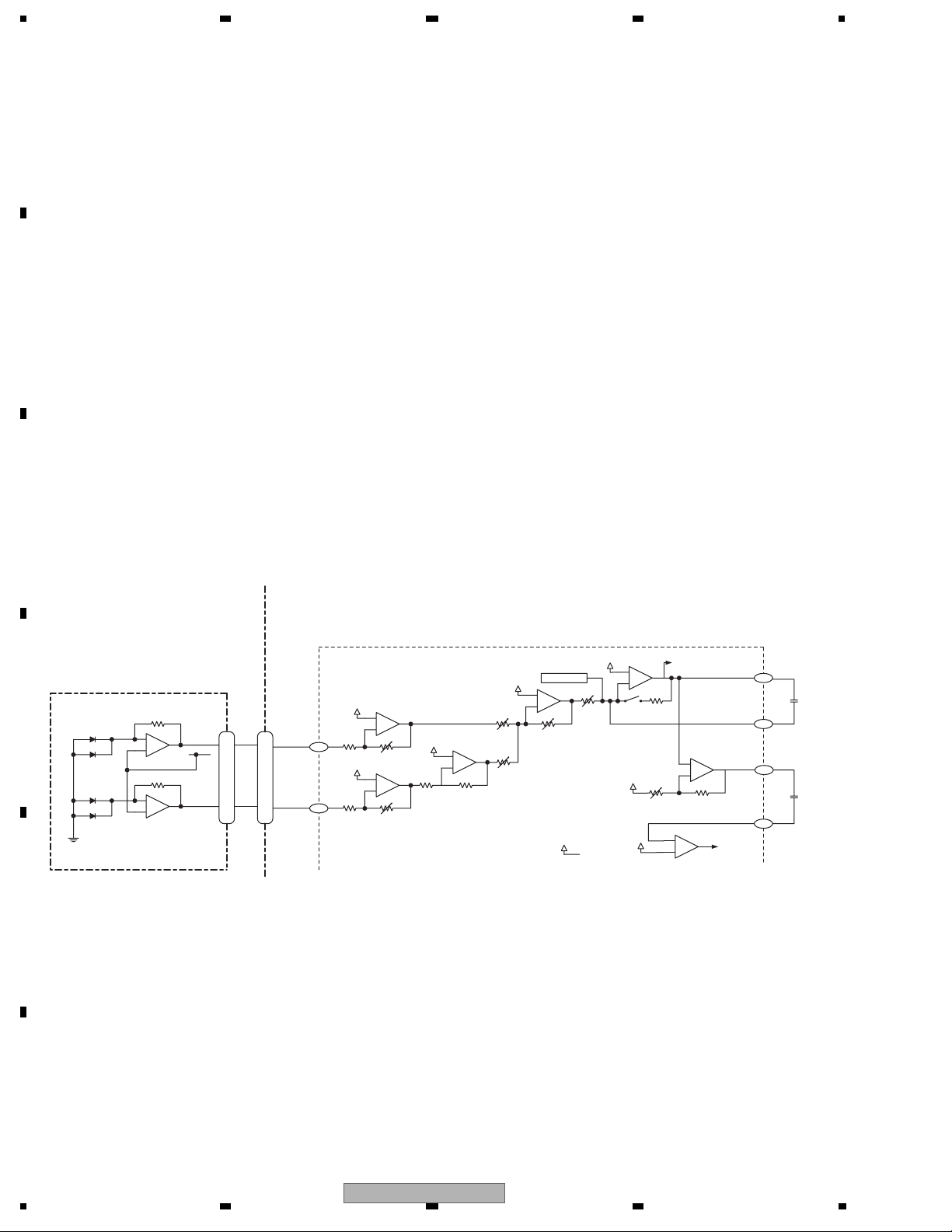

1.1.2 RF and RFAGC amplifiers

The output from the photo-detector (A + C) and (B + D) is provided from the RFO terminal as the RF signal (which can be

used for eye-pattern check), after it is added, amplified, and equalized inside this LSI. The low frequency component of the

voltage RFO is calculated as below.

RFO = (A + B + C + D) x 2

The RFO is used for the FOK generation circuit and RF offset adjustment circuit.

The RFO signal, output from the pin 122, is A/C-coupled externally, input to the pin 121, and amplified in the RFAGC

amplifier to obtain the RFAGC signal.

Also, this LSI is equipped with the RFAGC auto-adjustment function, explained below, which switches feedback gains of

the RFAGC amplifier so that the RFO output will be 1.5 V.

This RFO signal is also used for the EFM, DFCT, MIRR, and RFAGC auto-adjustment circuits.

CD CORE UNIT

Pickup Unit

P3

P7

P9

P2

P4

P8

VREF

A+C

B+C

PE5547A

15.2k

15.2k

RFOFF setup

VREF

13

6

A

13

129

B

6

130

10k

10k

+

-

8.8k

+

-

8.8k

R2

61.0k

61.0k

+

-

+

-

140k

122

RFO

44k

AGCI

121

20k

+

-

11.75k

FEOFF setup

VREF

3.55k

To DEFECT/A3T detection

For RFOK generation

RF-

126

RF2-

125

EQ2

123

5k

5k

124

160k

EQ1

AGCO

FEO

FE A/D

FE-

119

135

134

-

+

+

-

1.2k

1.2k

22p

56p

4.7k

5.6k

A

B

4p

C

Fig.1.1.2 RF/AGC/FE

D

E

F

CX-3195

56

7

8

5

1234

1.1.3 Focus error amplifier

The photo-detector outputs (A + C) and (B + D) are passed through the differential amplifier and the error amplifier, and (A

+ C - B - D) is provided from the pin 135 as the FE signal. The low frequency component of the voltage FE is calculated as

A

below.

FE = (A + C - B - D) x 8.8k / 10k x 111k / 61k x 160k / 72k

= (A + C - B - D) x 3.5

For the FE outputs, an S-shaped curve of 1.5 Vp-p is obtained with the REFO as the reference. The cutoff frequency for

the subsequent stage amplifiers is 14.6 kHz.

1.1.4 RFOK circuit

This circuit generates the RFOK signal, which indicates the timing to close the focus loop and focus-close status during

the play mode, from the pin 70. As for the signal, "H" is output in closing the focus loop and during the play mode.

Additionally, the RFOK becomes "H" even in a non-pit area, since the DC level of the RFO signal is peak-held in the

B

subsequent digital block and compared at a certain threshold level to generate the RFOK signal. Therefore, the focus is

closed even on a mirror-surface area of a disc. This signal is also supplied to the microcomputer via the low-pass filer as

the FOK signal, which is used for protection and gain switching of the RF amplifier.

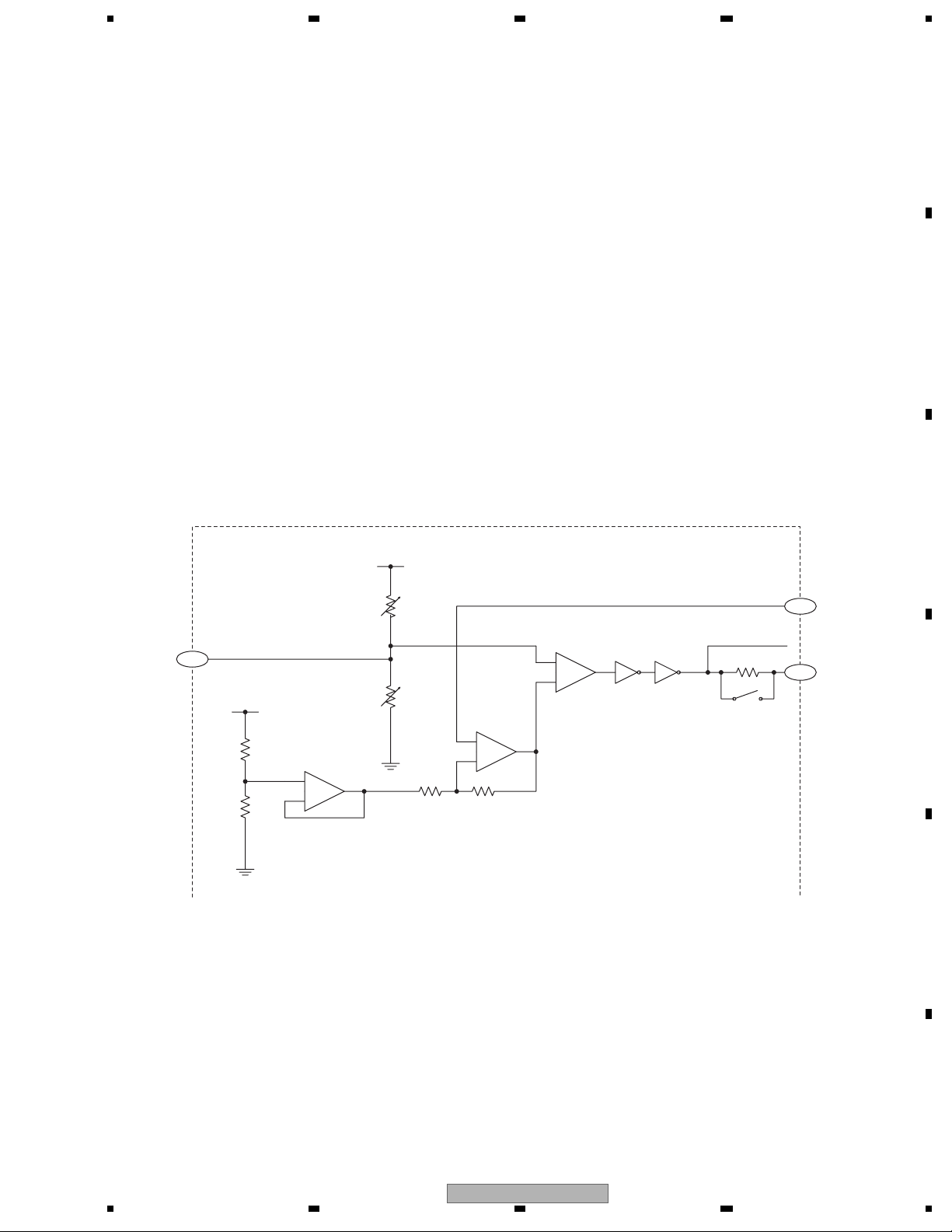

1.1.5 Tracking error amplifier

The photo-detector outputs E and F are passed through the differential amplifier and the error amplifier to obtain (E - F),

and then provided from the pin 138 as the TE signal. The low frequency component of the voltage TE is calculated as

below.

TEO = (E - F) x 63k / 112k x 160k / 160k x 181k / 45.4k x 160k / 80k

C

= (E - F) x 4.48

For the TE output, TE waveform of about 1.3 Vp-p with the REFO as the reference. The cutoff frequency in the subsequent

is 21.1 kHz.

D

E

Fig.1.1.3 TE

Pickup Unit

P5

P10

P1

P6

VREF

CD CORE UNIT

PE5547A

TE A/D

VREF

+

-

160k

+

-

60k

20k

-

+

Inside TEC

TEOFF setup

+

-

+

112k

112k

-

63k

+

-

160k

63k

E

11

F

9

E

11

9

132

F

131

+

-

45.36k

45.36k

160k

80k

161k

138

137

139

140

TEO

47p

TE-

TE2

10000p

TEC

F

6

1234

CX-3195

5 678

1.1.6 Tracking zero-cross amplifier

The tracking zero-cross signal (hereinafter referred to as TEC signal) is obtained by amplifying the TE signal by fourfold,

and used to detect the tracking-error zero-cross point. As the purpose of detecting the zero-cross point, the following two

points can be named:

1. To use for track-counting in the carriage move and track jump modes

2. To use for detecting the direction in which the lens moves in tracking close. (Used in the tracking brake circuit to be

explained later.)

The frequency range of the TEC signal is from 300 Hz to 20 kHz, and

TEC voltage = TE level x 4

The TEC level can be calculated at 4.62 V, which, at this level, exceeds the D range of the operational amplifier, and clips

the signal, but, because the CD LSI only uses the signal at the zero-cross point, it poses no particular problem.

A

1.1.7 EFM circuit

The EFM circuit converts the RF signal into digital signals of 0 and 1. The AGCO signal output from the pin 119 is

A/C-coupled externally, input to the pin 118, and supplied to the EFM circuit.

Missing RF signal due to scratches and stains on the disc, and asymmetry of the upper and lower parts of the RF, caused

by variation in disc production, cannot be entirely eliminated in AC coupling process, the reference voltage ASY of the

EFM comparator is controlled, using the probability that 0 and 1 occur at 50%. Thus, the comparator level will always stay

around the center of the RFO signal. This reference voltage ASY is generated by passing the EFM comparator output

through the low-pass filter. The EFM signal is output from the pin 113.

PE5547A

Vdd

ASY

114

RFI

118

40k

40k

Vdd

+

-

+

-

+

-

1.5k

7.5k

EFM signal

2k

113

EFM

B

C

D

Fig.1.1.4 EFM

CX-3195

56

E

F

7

8

7

1234

1.2 SERVO BLOCK (PE5547A: IC201)

The servo block performs servo control such as error signal equalizing, in-focus, track jump and carriage move. The DSP

A

block is the signal-processing unit, where data decoding, error correction, and compensation are performed. The FE and

TE signals, generated in the preamplifier stage, are A/D-converted, and output drive signals for the focus, tracking, and

carriage systems via the servo block. Also, the EFM signal is decoded in the signal-processing unit, and ends up in

outputting D/A-converted audio signals through the D/A converter. Furthermore, in this decoding process, the spindle

servo error signal is generated, supplied to the spindle servo block, and used to output the spindle drive signal.

Each drive signal for focus, tracking, carriage, and spindle servos (FD, TD, SD, and MD) are output as PWM3 data, and

then converted to analog data through the LPF. These drive signals, after changed to analog form, can be monitored with

the FIN, TIN, CIN, and SIN signals, respectively. Subsequently, the signals are amplified and supplied to the actuator and

motor for each signal.

B

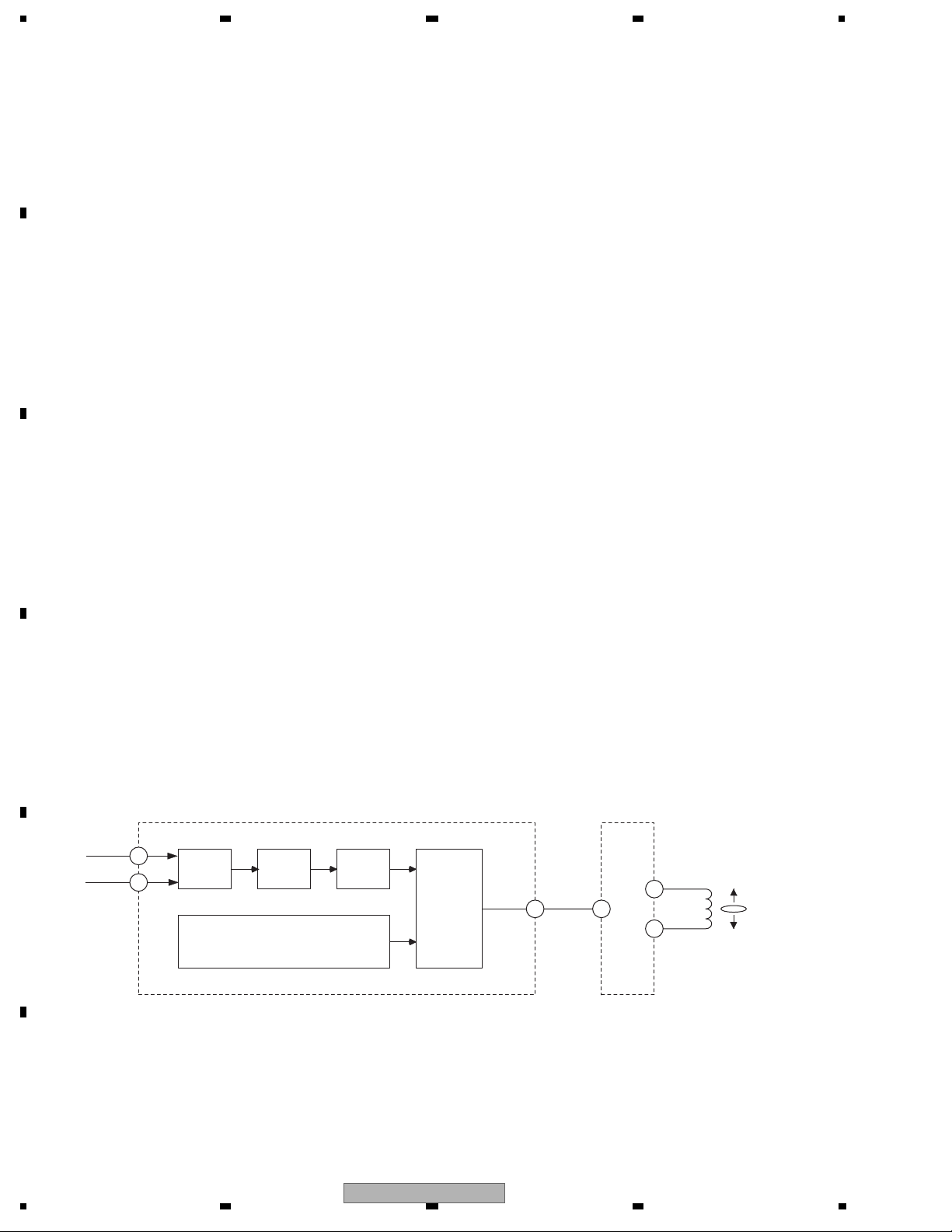

1.2.1 Focus servo system

The main equalizer of the focus servo consists of the digital equalizer block. The figure 1.2.1 shows the block diagram of

the focus servo system.

In the focus servo system, it is necessary to move the lens within the in-focus range in order to close the focus loop. For

that purpose, the in-focus point is looked for by moving the lens up and down with the focus search voltage of triangular

signal. During this time, the rotation of the spindle motor is retained at a certain set speed by kicking the spindle motor.

The servo LSI monitors the FE and RFOK signals and automatically performs the focus-close operations at an appropriate

timing. The focus-close operation is performed when the following three conditions are satisfied at the same time:

1) The lens moves toward the disc surface.

C

2) RFOK = "H"

3) The FE signal is zero-crossed.

Consequently, the FE converges to "0" (= REFO).

When the above-mentioned conditions are met and the focus loop is closed, the FSS bit is shifted from "H" to "L," and

then, in 10 ms, the CPU of the LSI starts monitoring the RFOK signal obtained through the low-pass filter.

If the RFOK signal is determined to be "L," the CPU of the LSI takes several actions including protection.

Fig.1.2.2 shows a series of actions concerning the focus close operations. (It shows a case where the focus loop cannot

be closed.)

With the focus mode selector displaying 01 in the test mode, pressing the focus close button, allows to check the

S-shaped curve, search voltage, and actual lens behavior.

D

IC201 PE5547A

A + C

129

B + D

130

E

FE

AMP

A/D

FOCUS SEARCH

TRIANGULAR

WAVE GENERATOR

Fig.1.2.1 Block diagram of the focus servo system

F

8

1234

DIG.

EQ

CONTROL

CX-3195

PWM

IC301 BA5839FP

FD

109

FOP

12

6

11

FOM

LENS

5 678

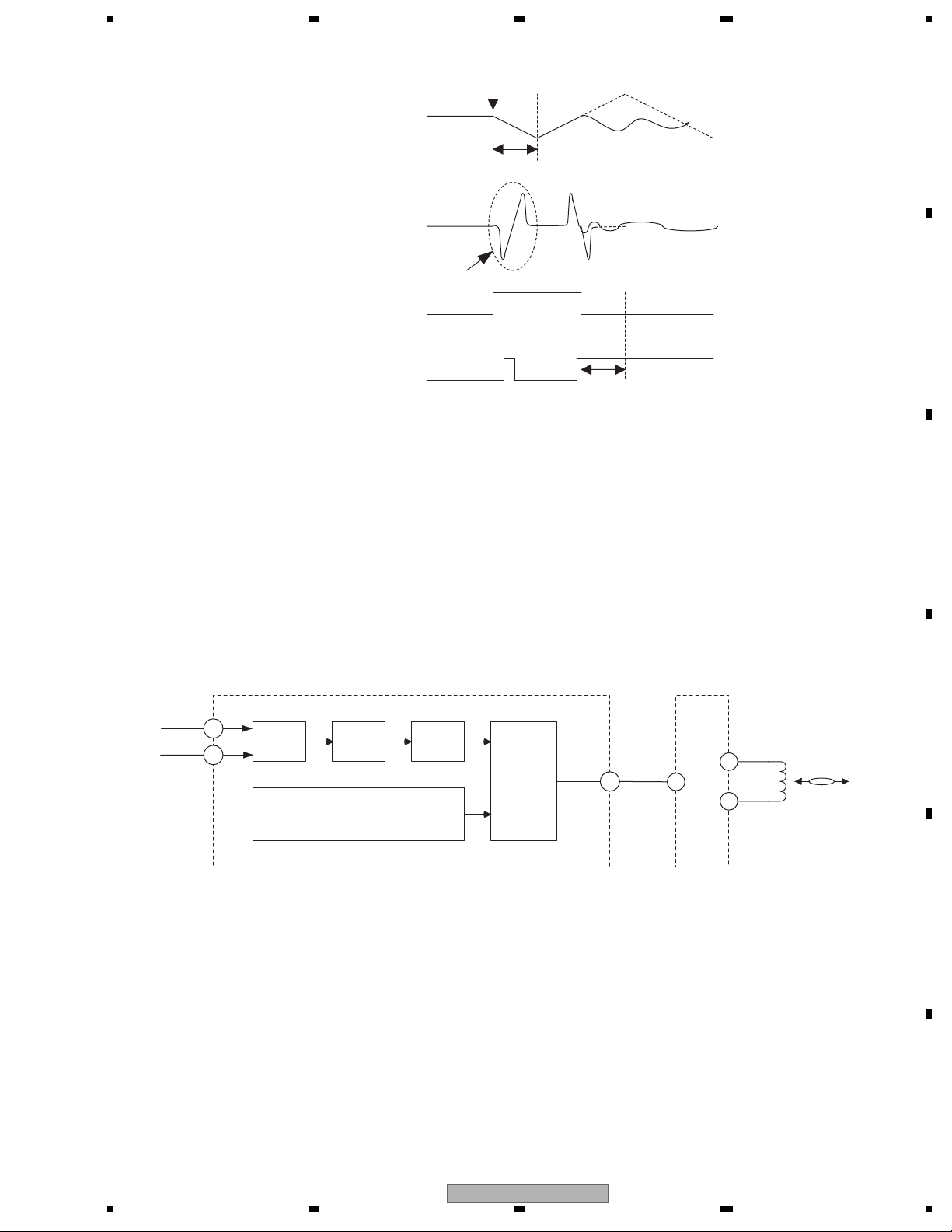

Search start

Output from FD terminal

A blind period

FE controlling signals

You can ignore this for blind periods.

FSS bit of SRVSTS1 resistor

RFOK signals

The broken line in the figure is assumed in the

case without focus servo.

The status of focus close is judged from the statuses

of FSS and RFOK after about 10 mS.

Fig.1.2.2 Timing chart for focus close operations

1.2.2 Tracking servo system

The main equalizer of the tracking servo consists of the digital equalizer block. The figure 1.2.3 shows the block diagram of

the tracking servo system.

A

B

C

IC201 PE5547A

E

132

F

131

TE

AMP

A/D

DIG.

EQ

JUMP

PARAMETERS

Fig.1.2.3 Block diagram of the tracking servo system

CONTROL

PWM

IC301 BA5839FP

TD

110

D

TOP

14

2

13

TOM

LENS

E

F

CX-3195

56

7

8

9

Loading...

Loading...