Page 1

PIONEER CORPORATION 4-1, Meguro 1-Chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS SERVICE INC. P.O.Box 1760, Long Beach, CA 90801-1760 U.S.A.

PIONEER EUROPE NV Haven 1087 Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE.LTD. 253 Alexandra Road, #04-01, Singapore 159936

C PIONEER CORPORATION 2001

K-ZZB. JULY 2001 Printed in Japan

ORDER NO.

CRT2726

6 DISC IN-DASH CD CHANGER

CDX-MG6167

ZH ES

HONDA

VEHICLE DESTINATION PRODUCED AFTER PART No. ID No. PIONEER MODEL No.

INTEGRA Australia July 2001 08A06-3D7-300 CDX-MG6167ZH/ES

- This service manual should be used together with the manual(s) listed below.

For the parts numbers, adjustments, etc. which are not shown in this manual, refer to the following

manual(s).

Model Order No. Mech. Module Remarks

CDX-MG6346ZH/ES CRT2407

CX-890 CRT2376 G1

CD Mechanism Module:Circuit Description, Mechanism Operation, Disassembly

Page 2

CDX-MG6167ZH

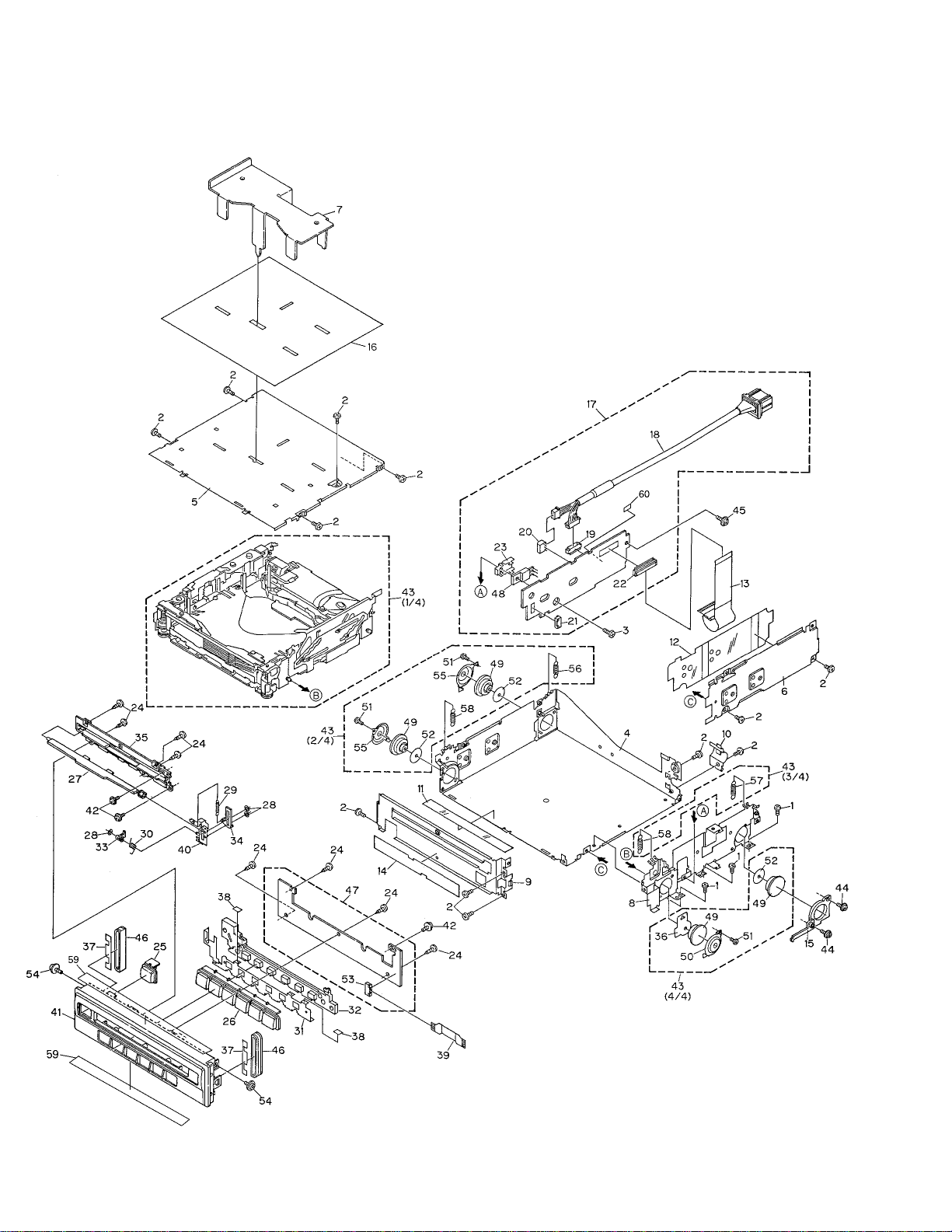

EXPLODED VIEWS AND PARTS LIST

PACKING (Page 3)

- PACKING SECTION PARTS LIST

Part No.

Mark No. Description CDX-MG6346ZH/ES CDX-MG6167ZH/ES

11 Carton CHG4457 CHG4514

12 Contain Box CHL4457 CHL4514

EXTERIOR (Page 4)

- EXTERIOR SECTION PARTS LIST

Part No.

Mark No. Description CDX-MG6346ZH/ES CDX-MG6167ZH/ES

41 Grille Unit CXB8378 CXB8264

Page 3

PIONEER CORPORATION 4-1, Meguro 1-Chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS SERVICE INC. P.O.Box 1760, Long Beach, CA 90801-1760 U.S.A.

PIONEER ELECTRONIC [EUROPE] N.V. Haven 1087 Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE.LTD. 253 Alexandra Road, #04-01, Singapore 159936

C PIONEER CORPORATION 1999

K-ZZB. OCT. 1999 Printed in Japan

ORDER NO.

CRT2407

6 DISC IN-DASH CD CHANGER

6 DISC IN-DASH CD CHANGER

CDX-MG6346ZH ES

HONDA

CONTENTS

1. SAFETY INFORMATION ............................................2

2. EXPLODED VIEWS AND PARTS LIST.......................3

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM...10

4. PCB CONNECTION DIAGRAM ................................26

5. ELECTRICAL PARTS LIST ........................................42

6. ADJUSTMENT..........................................................46

7. GENERAL INFORMATION .......................................48

7.1 DIAGNOSIS ........................................................48

7.1.1 TEST MODE..............................................48

7.1.2 DISASSEMBLY .........................................52

7.1.3 CONNECTOR FUNCTION DESCRIPTION.......56

7.2 IC ........................................................................57

8. OPERATIONS AND SPECIFICATIONS.....................61

VEHICLE DESTINATION PRODUCED AFTER HONDA PART No. ID No. PIONEER MODEL No.

Not specified THAILAND, AUSTRALIA October 1999 08A06-3B5-300 CDX-MG6346ZH/ES

Not specified THAILAND, AUSTRALIA October 1999 08A06-3B5-310 CDX-MG6446ZH/ES

- This service manual should be used together with the following manual(s):

Model No. Order No. Mech. Module Remarks

CX-890 CRT2376 G1 CD Mechanism Module:Circuit Description, Mechanism Operation, Disassembly

CDX-MG6446ZH ES

CDX-MG6346ZH/ES

Page 4

2

CDX-MG6346ZH,MG6446ZH

- CD Player Service Precautions

1. For pickup unit(CXX1311) handling, please refer

to"Disassembly"(see page 52).

During replacement, handling precautions shall be

taken to prevent an electrostatic discharge(protection

by a short pin).

2. During disassembly, be sure to turn the power off

since an internal IC might be destroyed when a connector is plugged or unplugged.

3. Please checking the grating after changing the service pickup unit(see page 46).

- When the Repair is Complete

When the repair is complete, make the CD mechanism

ready for transportation implementing the following

procedures:

1. Press the changer side 1 and 4 simultaneously to turn

the ACC on.

2. As the ACC is turned on, the disc indicator blinks in

red.

3. When the blinking is stopped, the mechanism is

ready for the transportation.

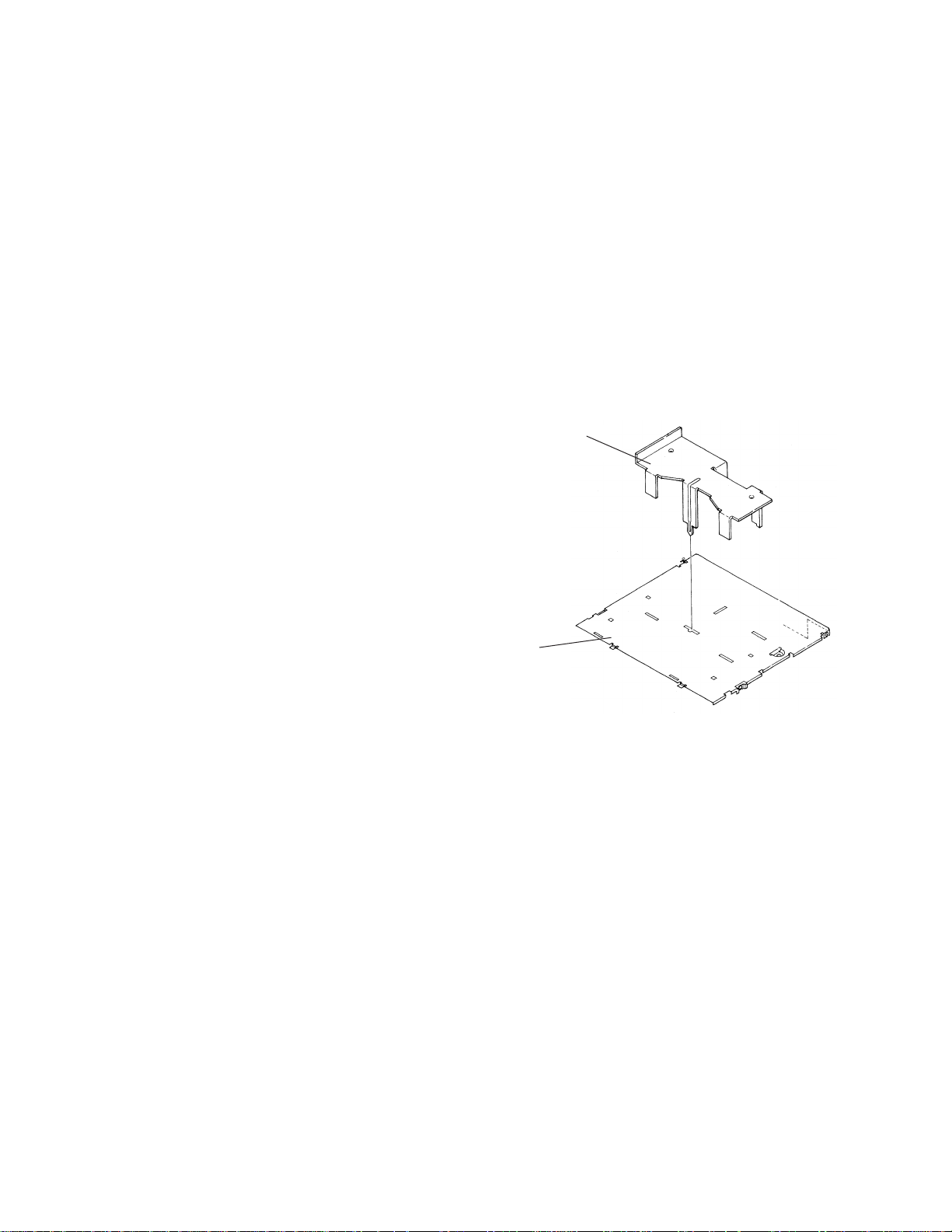

4. Attach the Transportation Bracket (CNC7878). Now

you can transport it.(See the figure below)

This service manual is intended for qualified service technicians; it is not meant for the casual do-it-yourselfer.

Qualified technicians have the necessary test equipment and tools, and have been trained to properly and safely repair

complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may void the warranty.

If you are not qualified to perform the repair of this product properly and safely; you should not risk trying to do so

and refer the repair to a qualified service technician.

1. SAFETY INFORMATION

Transportation Bracket

(CNC7878)

Case

(CNB2354)

Page 5

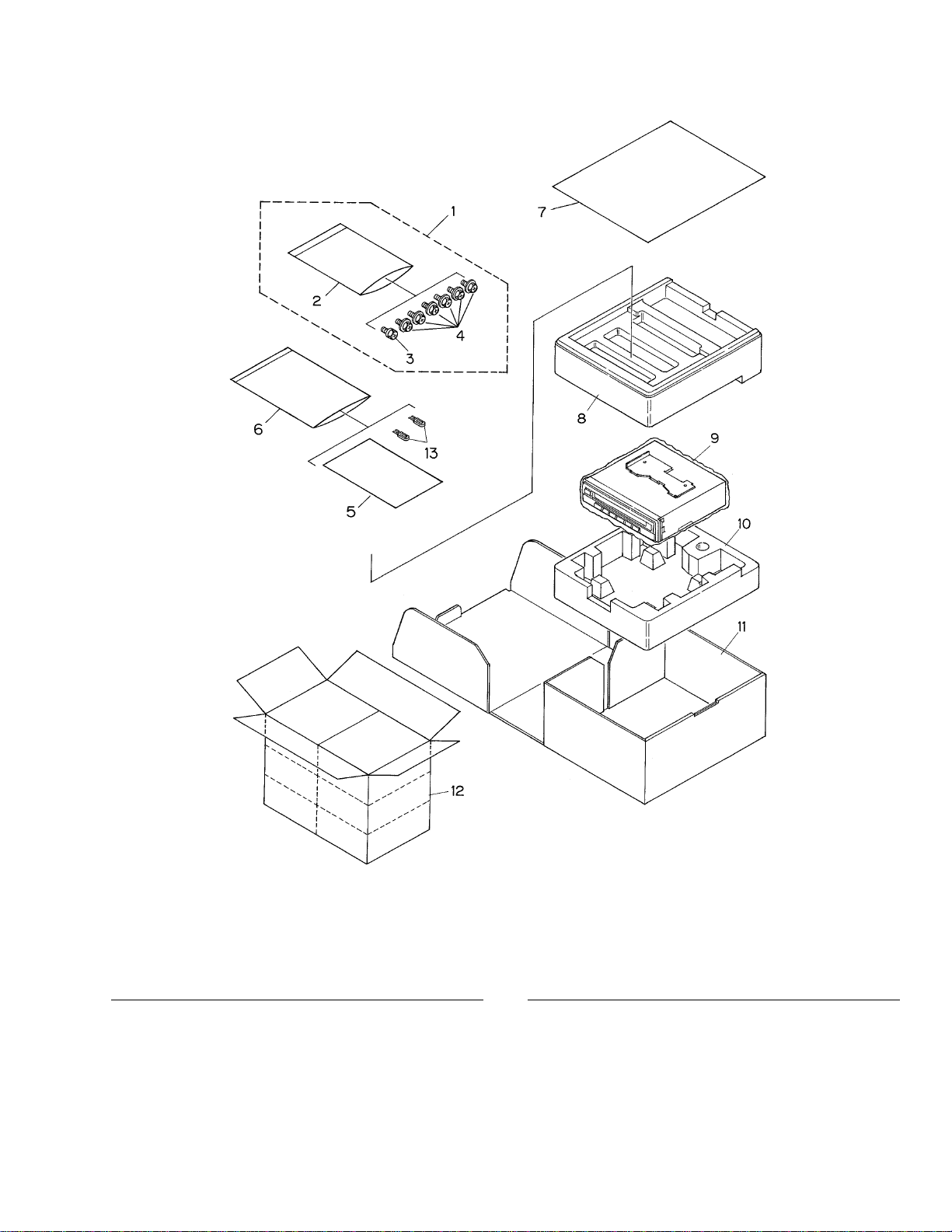

CDX-MG6346ZH,MG6446ZH

1 Screw Assy CEA2537

* 2 Polyethylene Bag CEG-127

3 Screw HMF40P060FZK

4 Screw HMF50P080FMC

5 Owner’s Manual(English) CRB1561

6 Polyethylene Bag CEG1116

* 7 Sheet CHW1402

8 Protector CHP2123

* 9 Polyethylene Bag E36-609

10 Protector CHP2124

11 Carton

(CDX-MG6346ZH/ES) CHG3909

Carton

(CDX-MG6446ZH/ES) CHG3991

12 Contain Box

(CDX-MG6346ZH/ES) CHL3909

Contain Box

(CDX-MG6446ZH/ES) CHL3991

* 13 Band CNF-512

Mark No. Description Part No. Mark No. Description Part No.

- PACKING SECTION PARTS LIST

NOTE:

- Parts marked by “*” are generally unavailable because they are not in our Master Spare Parts List.

- Screws adjacent to

∇ mark on the product are used for disassembly.

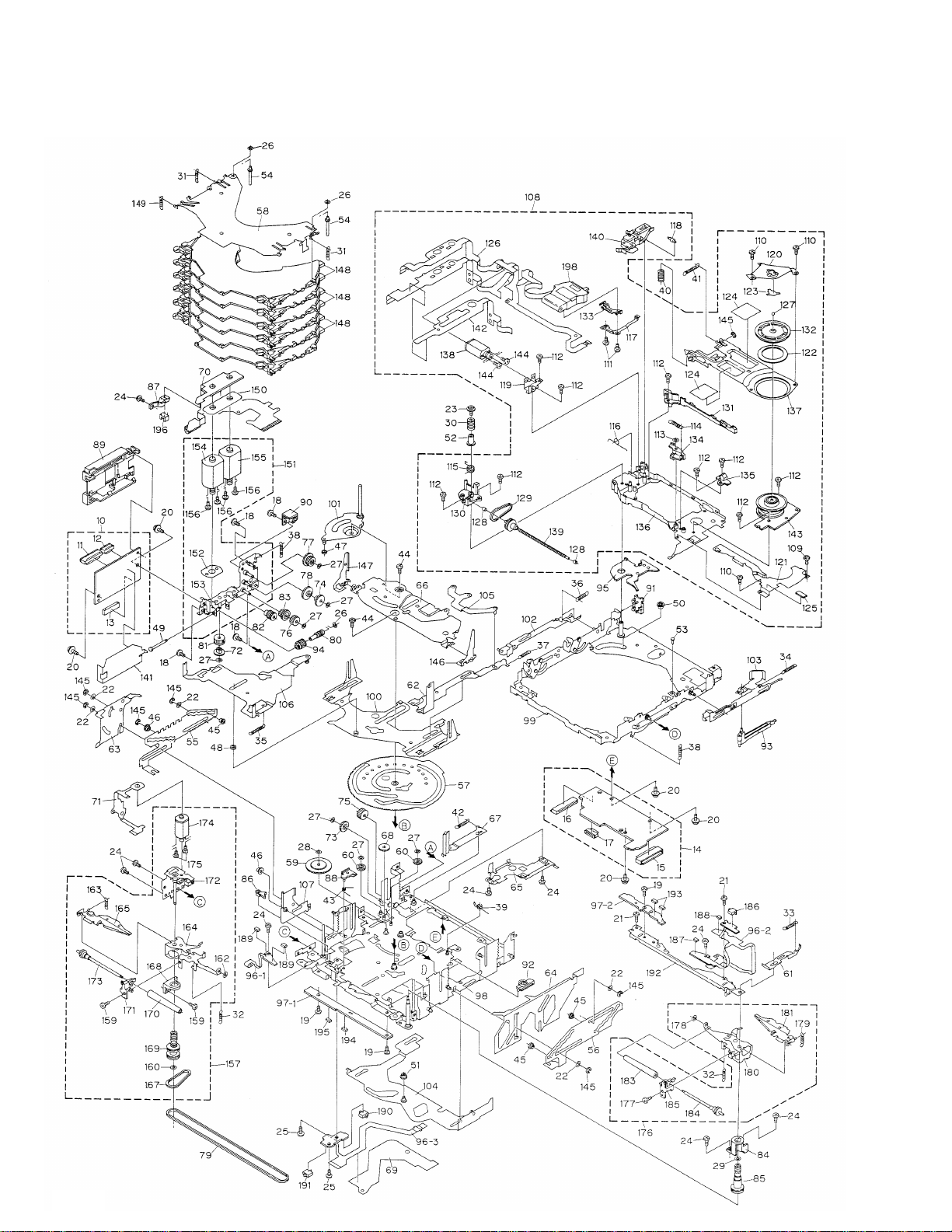

2. EXPLODED VIEWS AND PARTS LIST

2.1 PACKING

3

Page 6

4

CDX-MG6346ZH,MG6446ZH

2.2 EXTERIOR

Page 7

CDX-MG6346ZH,MG6446ZH

1 Screw BMZ20P020FMC

2 Screw BMZ26P030FMC

3 Screw BMZ26P060FMC

4 Chassis Unit

(CDX-MG6346ZH/ES) CXB3407

Chassis Unit

(CDX-MG6446ZH/ES) CXB5581

5 Case CNB2354

6 Side Frame CNB2397

7 Bracket CNC7878

8 Bracket

(CDX-MG6346ZH/ES) CNC8026

Bracket

(CDX-MG6446ZH/ES) CNC8816

9 Front Frame CNC8110

10 Holder CNC8111

11 Insulator CNM5969

12 Insulator CNM6112

13 PCB CNP5516

14 Insulator CNM6409

15 Holder CNV5543

* 16 Caution Label CRP1200

17 Extension Unit CWM6677

18 Cord CDE6148

19 Connector(CN102) CKS2200

20 Connector(CN103) CKS3597

21 Connector(CN701) CKS3785

22 Connector(CN101) CKS3989

23 Holder CNC8031

24 Screw BPZ20P060FMC

25 Button CAC5864

26 Button CAC5865

27 Door CAT2003

28 Washer CBF1038

29 Spring CBH2201

30 Spring CBH2200

31 Conductor CNC8051

32 Lighting Conductor CNV5901

33 Gear CNV5547

34 Arm CNV5548

35 Guide CNV5880

36 Sheet CNM6318

37 Double Faced Tape CNM6424

38 Insulator CNM6512

39 PCB CNP5373

40 Bracket Unit CXB3111

41 Grille Unit CXB3409

42 Screw IMS20P040FMC

43

CD Mechanism Module(G1) CXK4702

44 Screw IMS20P040FMC

45 Screw IMS26P040FMC

46 Cushion CNV5674

47 Keyboard Unit CWM6289

48 Transistor(Q708) 2SB1335A

49 Damper CNV5120

50 Holder CNC7826

51 Screw CBA1250

52 Sheet CNM5981

53 Connector(CN901) CKS3785

54 Screw IMS26P030FZK

55 Holder CNC7477

56 Spring(Left Rear) CBH2365

57 Spring(Right Rear)(Black) CBH2361

58 Spring(Front) CBH2360

59 Spacer CNM6658

60 Spacer CNM6626

- EXTERIOR SECTION PARTS LIST

Mark No. Description Part No.

Mark No. Description Part No.

5

Page 8

6

CDX-MG6346ZH,MG6446ZH

2.3 CD MECHANISM

Page 9

7

CDX-MG6346ZH,MG6446ZH

1-9 •••••

10 CD Core Unit(Servo Unit) CWX2202

11 Connector(CN101) CKS2764

12 Connector(CN301) CKS3966

13 Connector(CN201) CKS3991

14 CD Core Unit(STS Unit) CWX2203

15 Connector(CN701) CKS3989

16 Connector(CN801) CKS3989

17 Connector(CN802) CKS4054

18 Screw CBA1037

19 Screw CBA1041

20 Screw CBA1076

21 Screw CBA1250

22 Screw CBA1405

23 Screw CBA1452

24 Screw CBA1453

25 Screw CBA1479

26 Washer CBF1037

27 Washer CBF1038

28 Washer CBF1039

29 Washer CBF1064

30 Spring CBH2007

31 Spring CBH2271

32 Spring CBH2274

33 Spring CBH2014

34 Spring CBH2015

35 Spring CBH2016

36 Spring CBH2017

37 Spring CBH2290

38 Spring CBH2019

39 Spring CBH2064

40 Spring CBH2195

41 Spring CBH2196

42 Spring CBH2224

43 Spring CBH2250

44 Screw CBA1082

45 Roller CLA3154

46 Roller CLA3157

47 Roller CLA3159

48 Roller CLA3160

49 Shaft CLA3179

50 Spacer CLA3194

51 Roller CLA3248

52 Bush CLA3353

* 53 Shaft CLA3469

54 Shaft CLA3693

55 Steer CNC7215

56 Steer CNC7216

57 Cam CNC7227

* 58 Holder CNC7235

59 Gear CNC7236

60 Gear CNC7238

61 Lever CNC7243

62 Lever CNC7244

63 Lever CNC7245

64 Lever CNC7246

65 Cover CNC7441

66 Holder CNC8613

67 Lever CNC8024

68 Gear CNC8140

69 Sheet CNM5831

70 PCB CNP5680

71 PCB CNP5681

72 Gear CNR1479

73 Gear CNR1481

74 Gear CNR1495

75 Gear CNR1501

76 Gear CNR1502

77 Gear CNR1540

78 Gear CNR1541

79 Belt CNT1080

80 Worm Gear CNV5046

81 Gear CNV5047

82 Gear CNV5048

83 Gear CNV5049

84 Holder CNV5056

85 Pulley CNV5058

86 Arm CNV5061

87 Spacer CNV5066

88 Arm CNV5189

89 Cover CNV5207

90 Cover CNV5424

91 Cover CNV5425

92 Lever CNV5427

93 Arm CNV5491

94 Gear CNV5519

95 Holder CNV5648

96 Composite PCB CNX3141

97 Composite PCB CNX2989

98 Chassis Unit CXB4314

- CD MECHANISM SECTION PARTS LIST

Mark No. Description Part No.

Mark No. Description Part No.

Page 10

8

CDX-MG6346ZH,MG6446ZH

99 Frame Unit CXB2702

100 Lever Unit CXB2703

101 Arm Unit CXB2704

102 Lever Unit CXB2708

103 Lever Unit CXB2709

104 Lever Unit CXB2711

105 Arm Unit CXB2712

106 Lever Unit CXB2713

107 Lever Unit CXB2714

108

Carriage Mechanism Unit(G1) CXB5639

109 Screw CBA1041

110 Screw CBA1250

111 Screw CBA1362

112 Screw CBA1471

113 Washer CBF1038

114 Spring CBH2008

115 Spring CBH2009

116 Spring CBH2010

117 Spring CBL1335

118 Roller CLA3707

* 119 Bracket CNC7228

120 Guide Unit CXB4417

121 Cover CNC7628

122 Sheet CNM6414

123 Sheet CNM5378

124 Sheet CNM5695

125 Sheet CNM5827

126 PCB CNP4978

127 Ball CNR1189

128 Bearing CNR1423

129 Belt CNT1079

130 Holder CNV5037

131 Guide CNV5040

132 Clamper CNV5042

133 Rack CNV5111

134 Arm CNV5579

135 Holder CNV5759

* 136 Chassis CXB2698

137 Arm Unit CXB2705

138

Motor Unit(M4 CARRIAGE) CXB3178

139 Screw Unit CXB3179

140 Lever Unit CXB4450

141 Insulator CNM6306

142 Spacer CNM6345

143 Motor(M5 SPINDLE) CXM1120

144 Screw JFZ14P020FZK

145 Washer YE15FUC

146 Arm Unit CXB4953

147 Arm Unit CXB4954

148 Tray Assy CXB4307

149 Spring CBH2269

150 Sheet CNM6699

151 Cam Motor Assy CXB3170

152 Spacer CNC8289

* 153 Bracket Unit CXB4165

* 154

Motor Unit(M1 Cam Gear) CXB3174

* 155 Motor Unit(M3 ELV) CXB3175

156 Screw JFZ20P025FMC

157 Loading Arm L Assy CXB3171

158 •••••

159 Screw CBA1453

160 Washer CBF1038

161 •••••

162 Washer CBF1074

163 Spring CBH2136

* 164 Arm CNC7241

* 165 Arm CXB4449

166 •••••

167 Belt CNT1079

168 Holder CNV5055

169 Pulley CNV5057

170 Roller CNV5064

171 Guide CNV5125

* 172 Bracket Unit CXB4316

173 Roller Gear Unit CXB3176

* 174 Motor Unit(M2 LOAD) CXB3177

175 Screw JFZ14P020FMC

176 Loading Arm R Assy CXB3172

177 Screw CBA1453

178 Washer CBF1074

179 Spring CBH2136

* 180 Arm CNC7242

* 181 Arm CXB4448

182 •••••

183 Roller CNV5064

184 Roller Gear Unit CXB3176

185 Guide CNV5126

186 Switch(S885 MAX) CSN1052

187 LED(D883) CL202IRXTU

188 Photo-transistor(Q881) CPT230SCTD(CD)

Mark No. Description Part No.

Mark No. Description Part No.

Page 11

9

CDX-MG6346ZH,MG6446ZH

Mark No. Description Part No.

189 LED(D891,892) CL202IRXTU

190 Switch(S887 CLAMP) CSN1051

191 Switch(S886 ELV HOME) CSN1052

192 Bracket Unit CXB4306

193

Photo-transistor(Q851,852) CPT230SCTD(CD)

194 Resistor(R856) RS1/8S911J

195 Resistor(R857) RS1/8S821J

196 Photo-interrupter(Q1) RPI-221

197 •••••

198 Pickup Unit(Service)(P8) CXX1311

Page 12

10

CDX-MG6346ZH,MG6446ZH

1

23

4

1234

D

C

B

A

PICKUP UNIT(SERVICE)

MOTOR PCB(B)

MOTOR PCB(A)

CD CORE UNIT(SERVO UNIT)

PCB UNIT(D)

PCB UNIT(A)

PCB UNIT(C)

PCB UNIT(E)

PCB UNIT(B)

LOAD MOTOR PCB

CD CORE UNI

HOLOGRAM

UNIT

FOCUS ACT

TRACKING ACT

MD

LD+

LD-

LD

MD

FO+

TO+

16

17

V5

Q101

Q102

PD

LD

CN101

IC101

UPC2572GS

RF AMP

IC201

UPD63702AGF

DIGITAL SERVO

PROCESSOR

DIGITAL SIGNAL

PROCESSOR

µ-COMPUTER

INTERFACE

35

69

EFM

CD 4CH DRIVER

IC301

BA5986FM

14

11

16

15

22

BVD

V5

MUTE

9

MD/SD/TD/FD

74

10

11

VR2

XTAL

XTAL

X201

5V

VD

CONT

CN201 CN801

5V

VD

CN301

WDCK

RFCK

RAOV

LRCK

SCKO

DOUT

MCK

IC501

CXD2511R

SHOCKPROOF

CONTROL

B

DA

LR

X

IC502

MSM514400DP-60TS

4M DRAM

V+5V

IC701

BA05S

5V REGULA

VM

4

1

XAO/XSTB/XSO/XS

MOTOR DRIVER

IC802

LB1836M

2

6

3

5

ELVSNS

MOTOR DRIVER

LB1836M

IC801

2

6

13

9

5

3

12

10

CGCG+

ELEL+

PVD

LOLO+

PVD

PVD

Q80

Q802

CLAMP

ELHOME

CN802

M

BCL

SPINDLE

MOTOR

CARRIAGE

MOTOR

HOME

SWITCH

EC

VM

VCC

ST/SR

GND

HOME

M

LOADING

MOTOR

M

CAMGEAR

MOTOR

M

ELEVATION

MOTOR

Q851

Q852

D891

D892

PH1

PVD

Q881

D883

PH2

S883

MAX

SWITCH

PH1

PVD

PH1

PH2

MAXSW

LD MOTOR-

LD MOTOR+

MAXSW

PH2

PH1

PVD

ELV HOME

S886

S887

CLAMP

ELEVATION

SENSE

KEYB

KEY MATRIX

D905~916

5

14

15

4

3

1

2

3

4

8

5

6

7

10

11

1

1

1

1

2

3

4

1

2

4

1

2

1

1

2

3

5

6

3

4

2

1

5

6

3

4

2

1

5

7

3

4

2

1

7

5

9

8

10

11

10

2

11

1

19

28

29

30

19

28

29

30

45

44

46

36

35

37

32

33

39

41

41

43

48

50

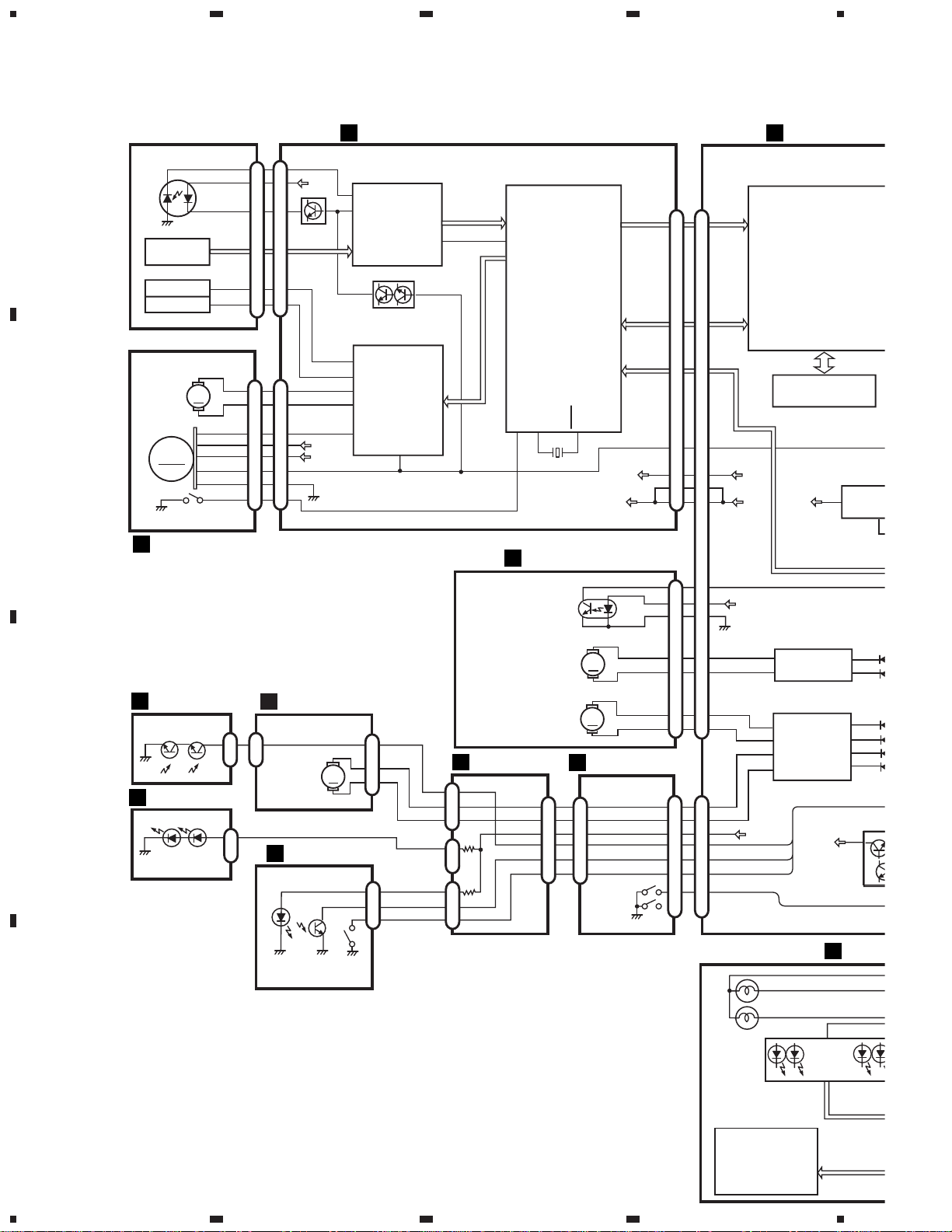

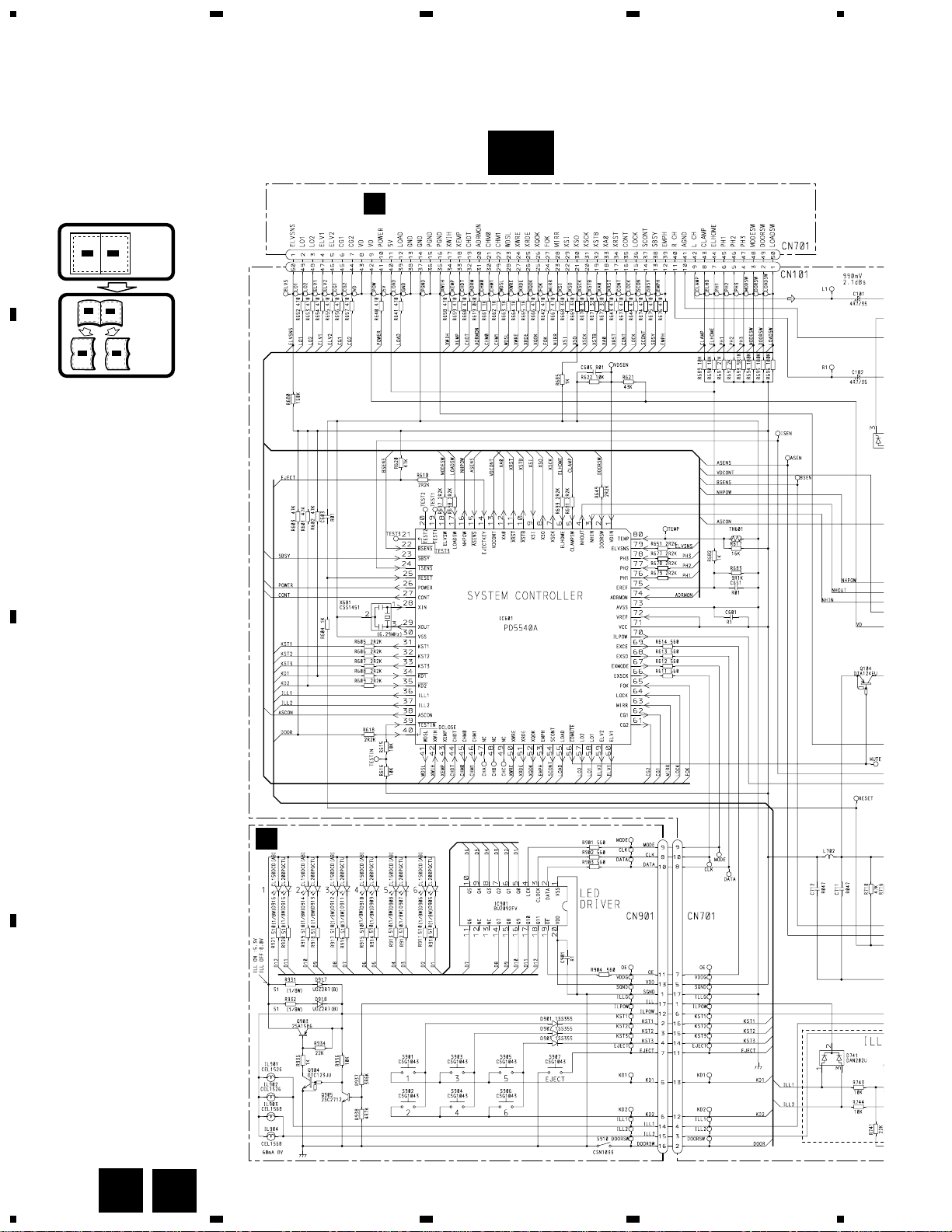

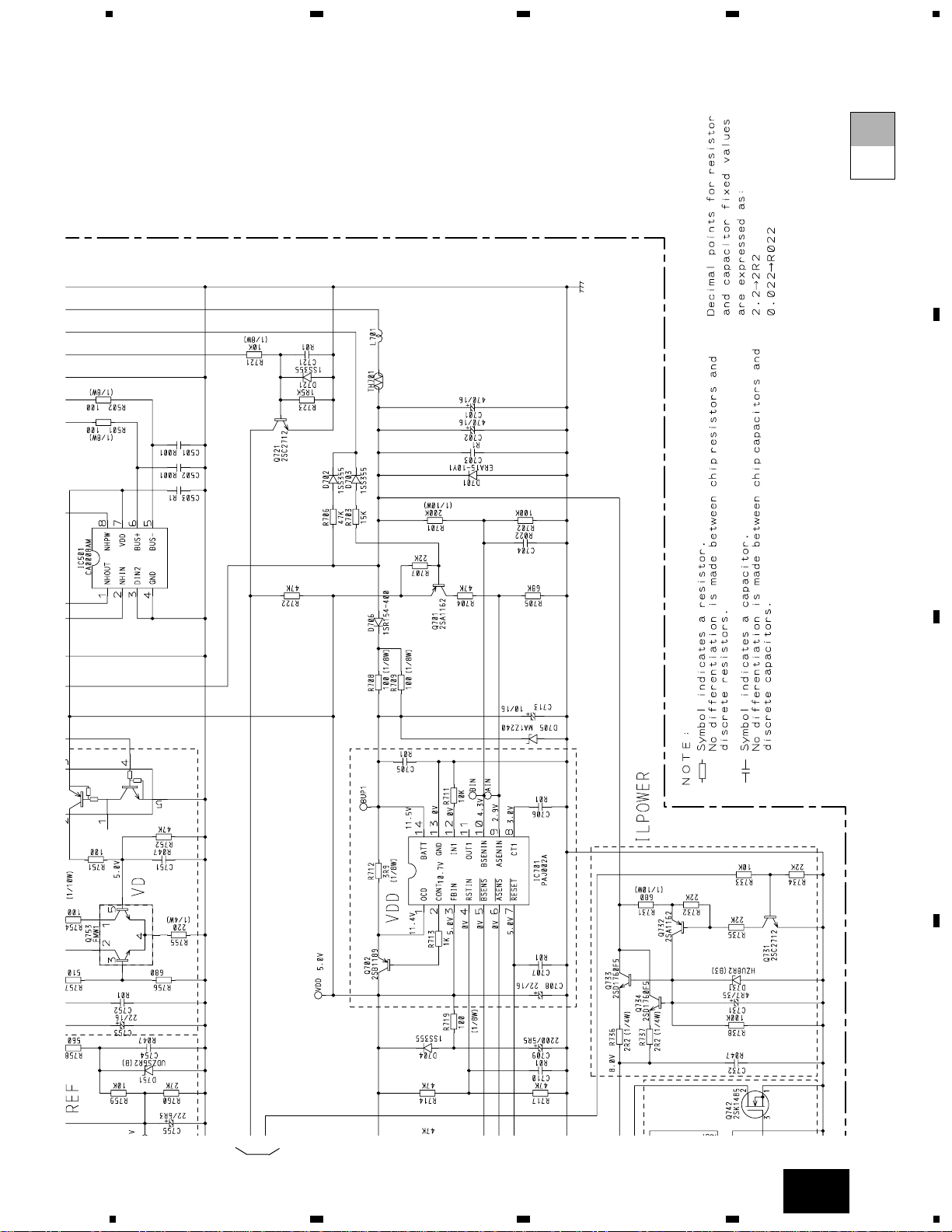

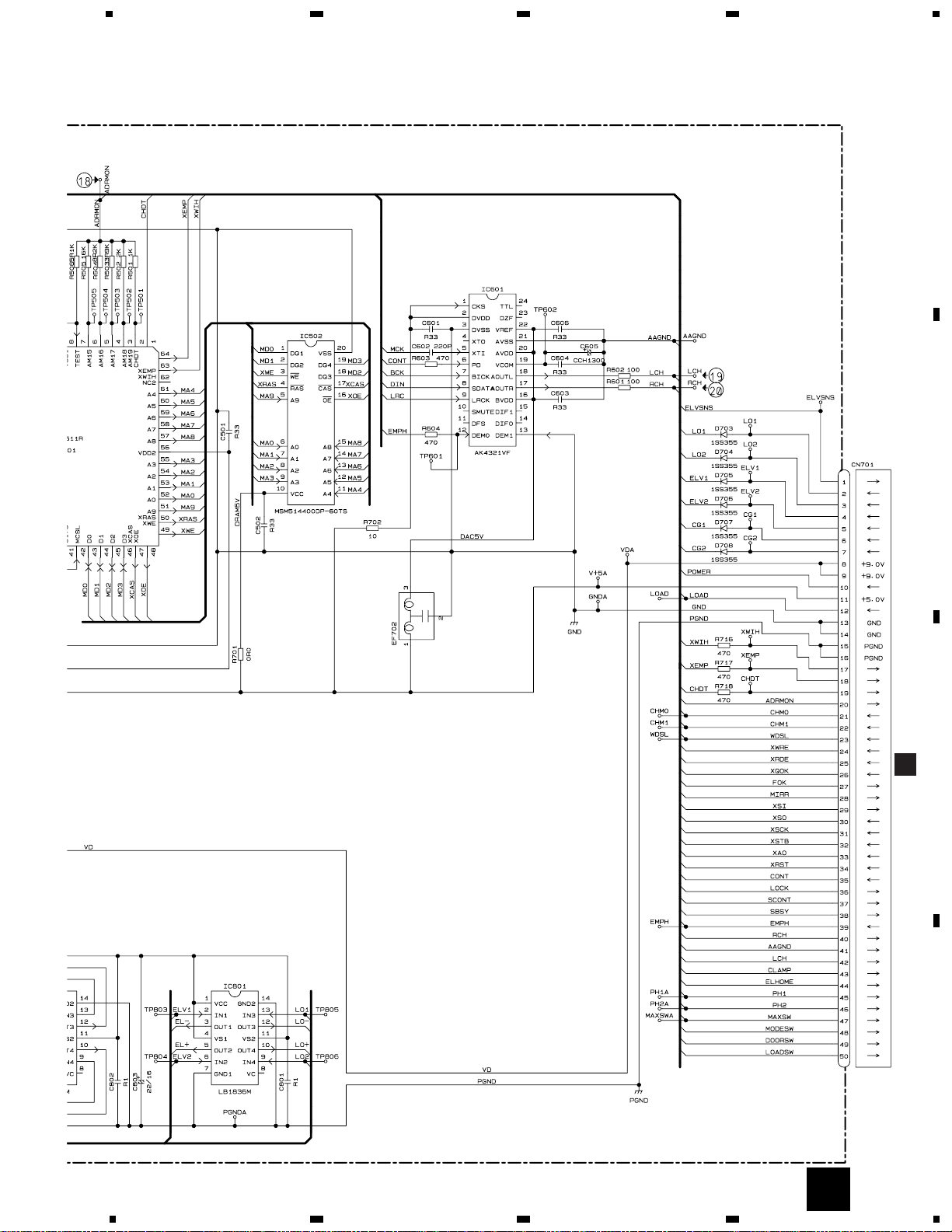

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM

3.1 BLOCK DIAGRAM

K

G

L

J

I

H

F

E

C D

B

Page 13

11

CDX-MG6346ZH,MG6446ZH

5

6

78

5

6

78

D

C

B

A

BCK

DATA

LRCK

XTLI

39

512

IC601

AK4321VF

8fs DF D/A LPF

CN701

CN101

6

18

DEMO

PD

VD

VD

LCH

WDSL/CHMO/CHMI

XWRE/XRDE/XQOK

XWIH/XEMP/ADRMON/CHDT

IC701

BA05SFP

REGULATOR

VM

VD

POWER

CONT

EMPH

2

1

TB/XSO/XSI/XSCK/XRST/SCONT

ELVSNS

LOADSW

DOORSW

MODESW

S801

S802

S803

2

6

2

6

13

9

CG1

CG2

ELV1

ELV2

LO1

LO2

MAXSW

PH2

PH1

Q801

VD

LOAD

LOAD

ELHOME

CLAMP

ELVSNS

V+5V

V+5V

KEYBOARD UNIT

EXTENSION UNIT

NJM4558MD

IC101

LPF

VD REGULATOR

VDD

B.U

B.U

WDSL/CHM0/CHM1

XWRE/XRDE/XQOK

XWIH/XEMP/ADRMON

CHDT

PD5540A

SYSTEM

CONTROLLER

IC601

ILL POWER

CD MUTE

CN102

LCH

6

7

53

27

13

56

4

16

15 22

28

29

Q101

Q104

CD-LCH

BUS+

ASENS

VDCONT

Q751

Q754

X601

Q701

Q702

SWDACC

NHOUT

NHPOW

Q753

XOUT

XIN

BSENS

ASENS

CDMUTE

VDCONT

CONT

EMPH

EXMODE

POWER

LOADSW

DOORSW

ELVSW

CG1

CG2

ELV1

ELV2

LO1

LO2

PH3

PH2

PH1

LOAD

ELHOME

CLAMPSW

26

79

17

2

18

62

61

60

59

58

57

78

77

76

55

6

5

DCLOSE

EJECTKEY

ILL1

ILL2

ILPOW

EXSO

EXCSK

DATA

EXCK

401436 37

70

686667

Q741

Q733

Q732

B.U

Q731

Q734

Q742

GND

CN701

CN901

CN103

KEY DATA

DOORSW

DOORSW

ILPOWILPOW

EJECT

EJECT

ILL1

ILL1

ILL2

ILL2

ILL

ILL

VDD

VDD

DATA

CLK

MODE

LED DRIVER

IC901

BU2092FV

Q904

Q903

Q905

16

20

2

3

4

GA-NET

14P

42

8

9

9

43

42

35 16

39

12

10 41

1

50

49

48

50

1

2

3

6

7

45

44

11 40

4

47

5

46

2

49

3

48

47

46

45

4

5

6

12 39

44

7

43

8

16

12

7

14

15

17

13

10

8

9

9

10

8

5

1

3

4

11

6

2

1

3

4

2

9

TC74HC4066AF

IC103

ANALOG SWITCH

NHPOW

NHOUT

CA0008AM

IC501

BUS

BUS-

1

6

5

1

8

VD

PAJ002A

IC701

VDD

25

RESET

6

5

7

91014

2

B.U

Q721

ISENS

24

2

ILL

4

3

VDD

ILL

A

Page 14

12

CDX-MG6346ZH,MG6446ZH

1

23

4

1234

D

C

B

A

A

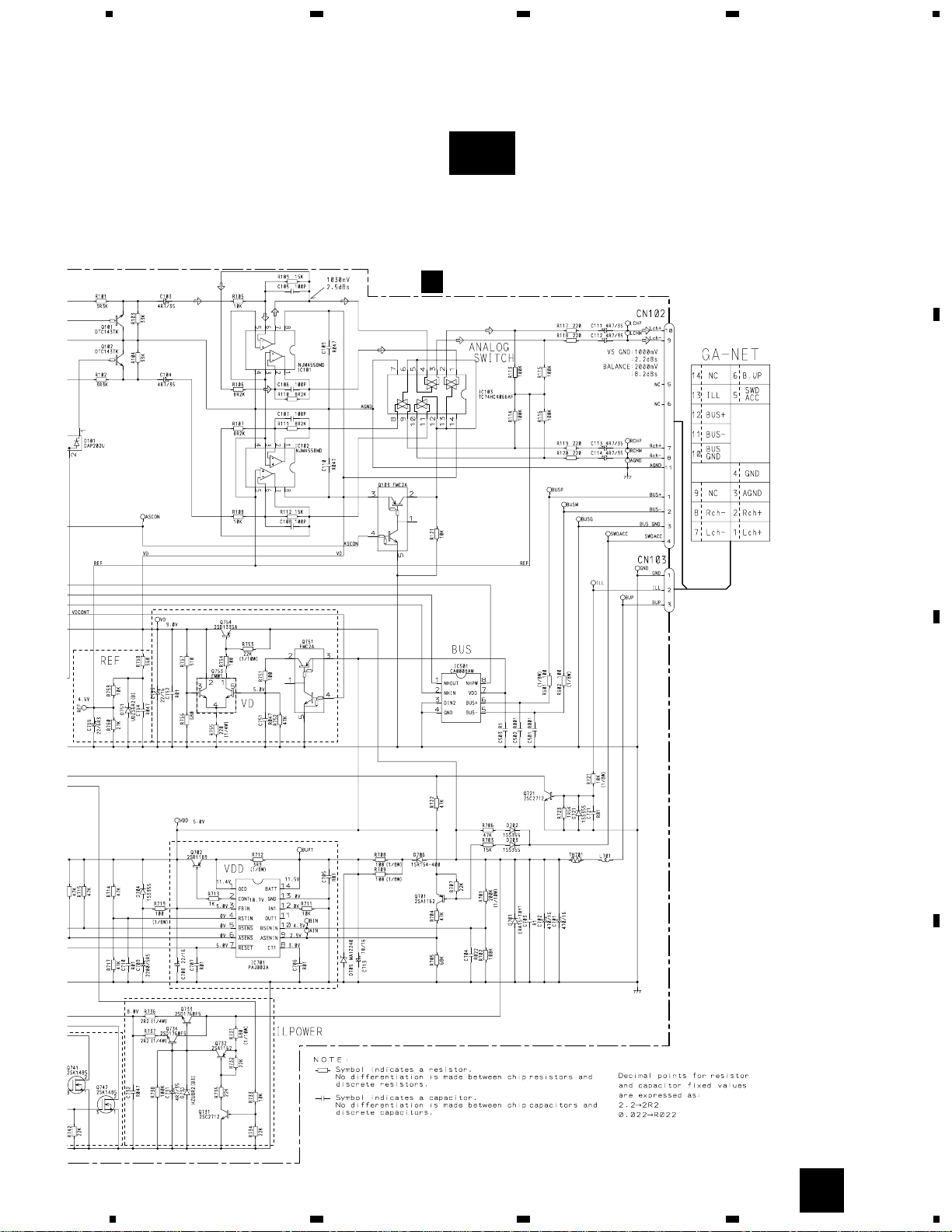

3.2 OVERALL CONNECTION DIAGRAM(GUIDE PAGE)

Note: When ordering service parts, be sure to refer to “EXPLODED VIEWS AND PARTS LIST” or “ELECTRICAL PARTS

LIST”.

A-a A-b

A-a

A-b

A-b

A-a

Large size

SCH diagram

Guide page

Detailed page

B

A-a

D

CD CORE UNIT(STS UNIT)

B

KEYBOARD UNIT

Page 15

13

CDX-MG6346ZH,MG6446ZH

5

6

78

5

6

78

D

C

B

A

A

A-b

A

EXTENSION UNIT

Page 16

14

CDX-MG6346ZH,MG6446ZH

1

23

4

1234

D

C

B

A

1

A-a

A-b

D

CD CORE UNIT(STS UNIT)

A-a

Page 17

15

CDX-MG6346ZH,MG6446ZH

5

6

78

5

6

78

D

C

B

A

A-a

A-b

B

2

B

KEYBOARD UNIT

A-a

Page 18

16

CDX-MG6346ZH,MG6446ZH

1

23

4

1234

D

C

B

A

A-a

A-b

1

A

EXTENSION UNIT

A-b

Page 19

17

CDX-MG6346ZH,MG6446ZH

5

6

78

5

6

78

D

C

B

A

A-a

A-b

2

A-b

Page 20

(SERVICE)

M5 SPINDLE

CXM1120

DISC INSERT DETECT

M4 CARRIAGE

CXB3178

2.5V

RF AMP/

AUTO POWER

CONTROL

CD DRIVER

D

E

MOTOR PCB(B)

CD CORE UNIT(SERVO UNIT)

18

CDX-MG6346ZH,MG6446ZH

1

23

4

1234

D

C

B

A

C

E

C

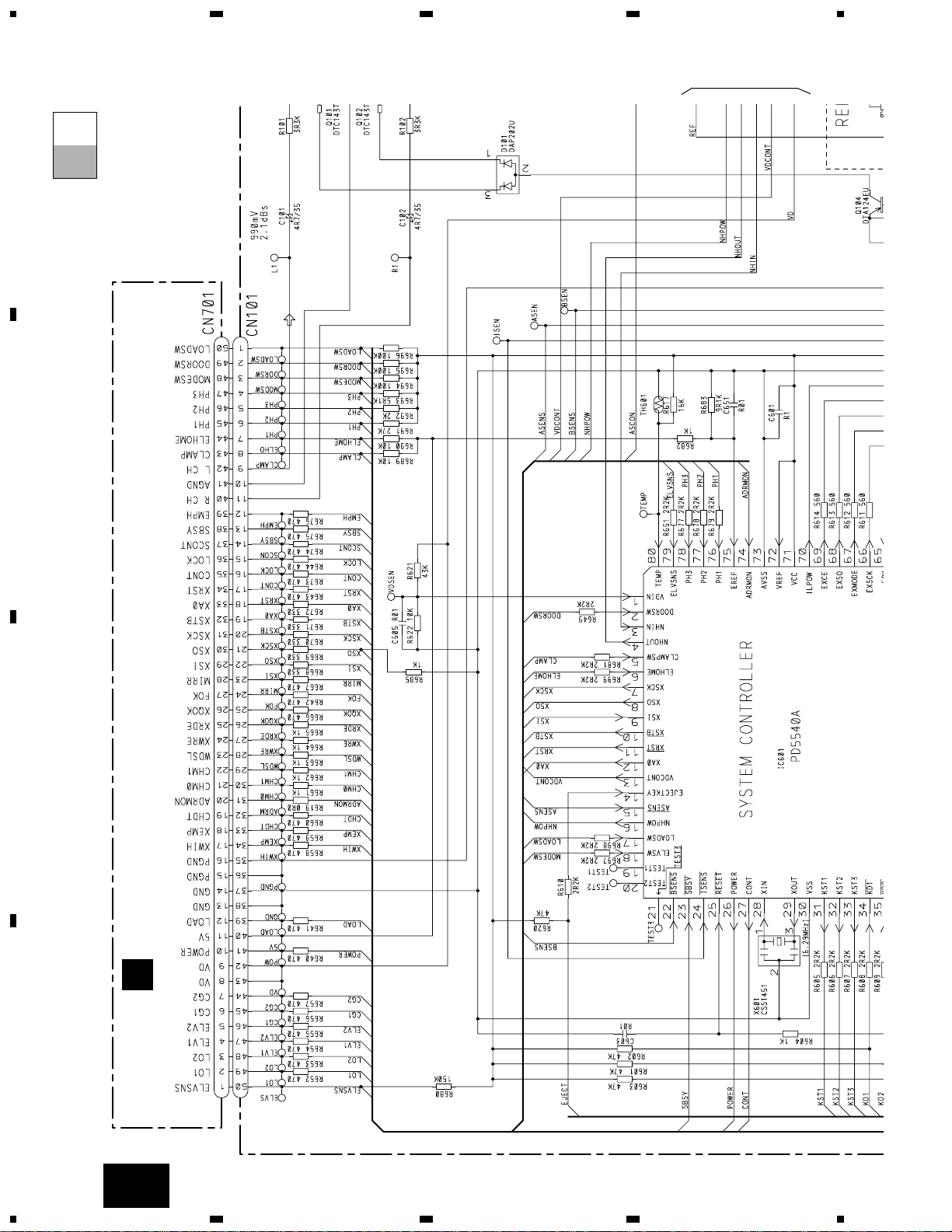

3.2 CD CORE UNIT(SERVO UNIT)

Page 21

16.934MHz

22/6R3

FOCUS/TRACKING

CARRIAGE/SPINDLE

DIGITAL SERVO

DIGITAL SIGNAL PROCESSOR

D/A CONVERTER

F

19

CDX-MG6346ZH,MG6446ZH

5

6

78

5

6

78

D

C

B

A

C

Page 22

M1 : CXB3174

Q1 : RPI-221

M3 : CXB3175

SURE TRACK

MEMORY CONTRO

+5V REGULATOR

7.5V

9.0V

MOTOR DRIVER

G

F

D

H

LOAD SWITCH

DOOR SWITCH

MODE SWITCH

CD CORE UNIT(STS UNIT)

CD CORE UNIT

(SERVO UNIT)

MOTOR PCB

(A)

ELV SENSE

20

CDX-MG6346ZH,MG6446ZH

1

23

4

1234

D

C

B

A

D

F

C

D

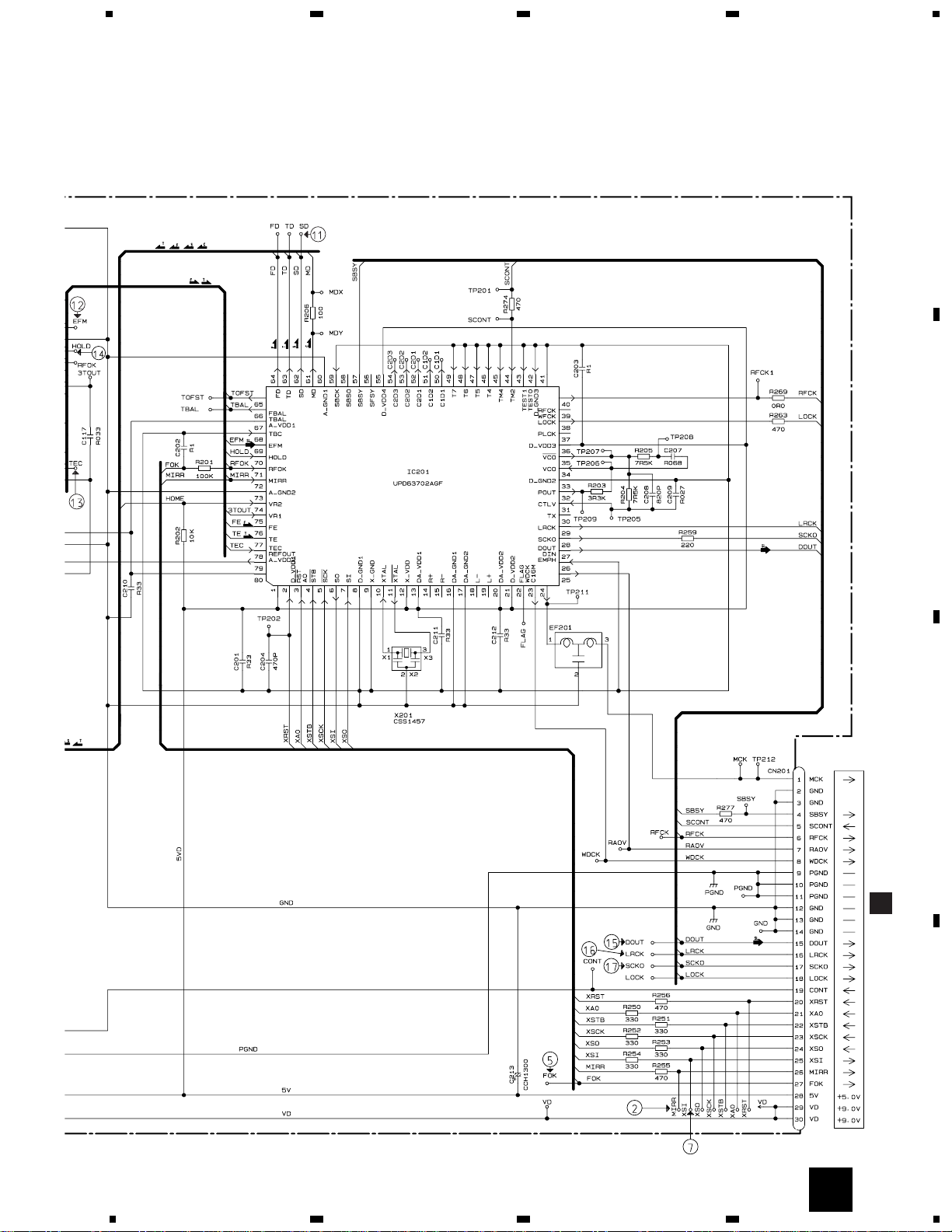

3.3 CD CORE UNIT(STS UNIT)

Page 23

22/6R3

RY CONTROLLER

MOTOR DRIVER

4M DRAM

D/A CONVERTER

A

CN101

21

CDX-MG6346ZH,MG6446ZH

5

6

78

5

6

78

D

C

B

A

D

Page 24

22

CDX-MG6346ZH,MG6446ZH

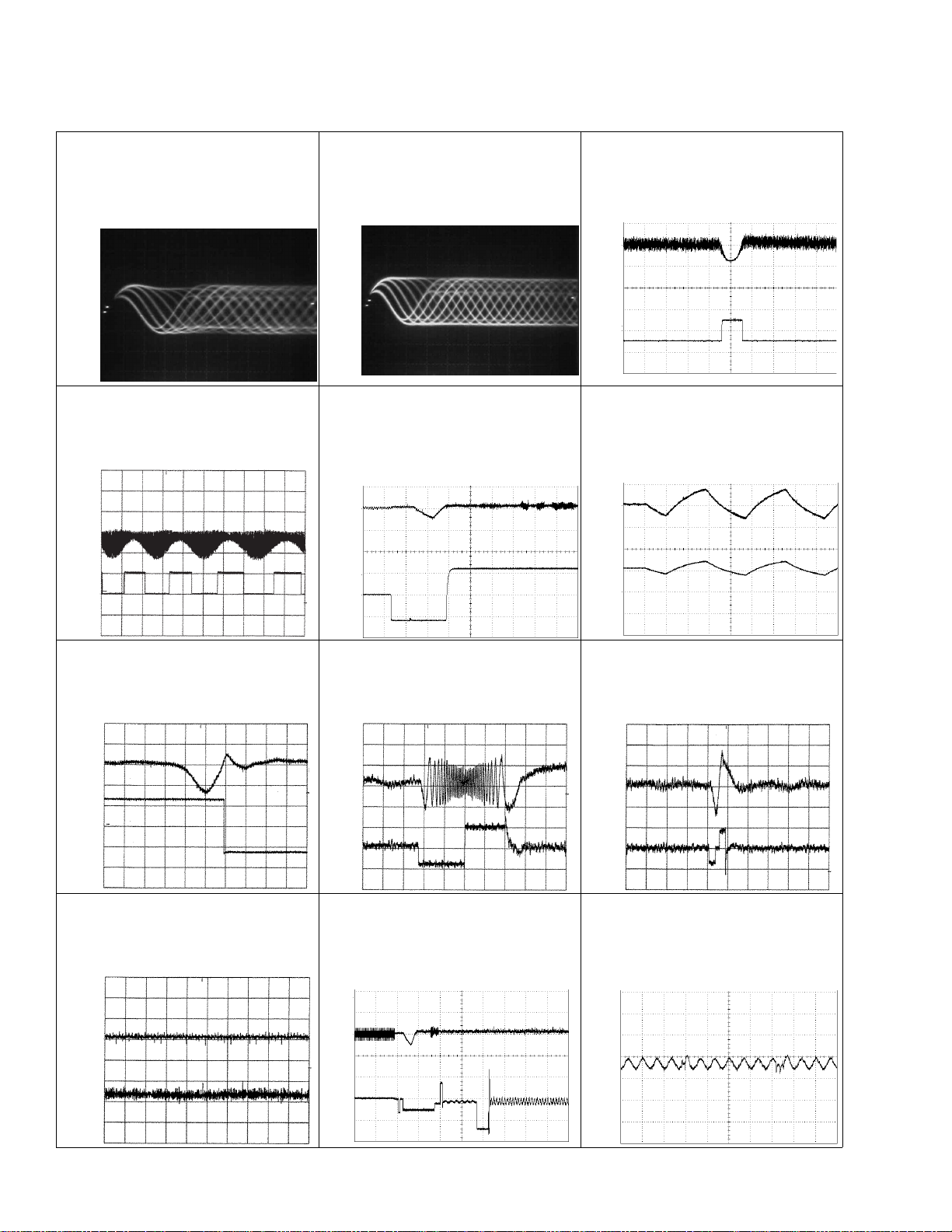

1 RFO 0.5V/div. 0.2µs/div.

Normal mode: play

1 CH1: RFO 1V/div.

2 CH2: MIRR 5V/div.

Test mode: Tracking open

0.5ms/div.

1 CH1: RFO 1V/div.

2 CH2: MIRR 5V/div.

Normal mode: The defect part

passes 500µs/div.

0.5ms/div.

3 CH1: FIN 0.5V/div.

4 CH2: FOP 2V/div.

Test mode: No disc, Focus close

0.2s/div.

3 CH1: FIN 0.5V/div.

5 CH2: FOK 2V/div.

Normal mode: Focus close

0.2s/div.

6 CH1: FEY 0.5V/div.

7 CH2: XSI 2V/div.

Normal mode: Focus close

1ms/div.

8 CH1: TEY 0.5V/div.

9 CH2: TIN 0.5V/div.

Test mode: 32 tracks jump (FWD)

0.5ms/div.

8 CH1: TEY 0.5V/div.

9 CH2: TIN 0.5V/div.

Test mode: Single jump (FWD)

0.5ms/div.

6 CH1: FEY 0.1V/div.

3 CH2: FIN 0.2V/div.

Normal mode: Play

20ms/div.

3 CH1: FIN 0.5V/div.

0 CH2: SIN 1V/div.

Normal mode: Focus close

0.5s/div.

GND

→

GND

→

GND

→

GND

→

- Waveforms

0 SIN 0.5V/div. 0.1s/div.

Normal mode: Play

REFOUT

→

REFOUT

→

REFOUT

→

REFOUT

→

REFOUT

→

REFOUT

→

REFOUT

→

REFOUT

→

REFOUT

→

REFOUT

→

REFOUT

→

REFOUT

→

REFOUT

→

REFOUT

→

REFOUT

→

REFOUT

→

1 RFO 0.5V/div. 0.5µs/div.

Test mode

REFOUT

→

REFOUT

→

REFOUT

→

Note:1. The encircled numbers denote measuring pointes in the circuit diagram.

2. Reference voltage

REFOUT:2.5V

Page 25

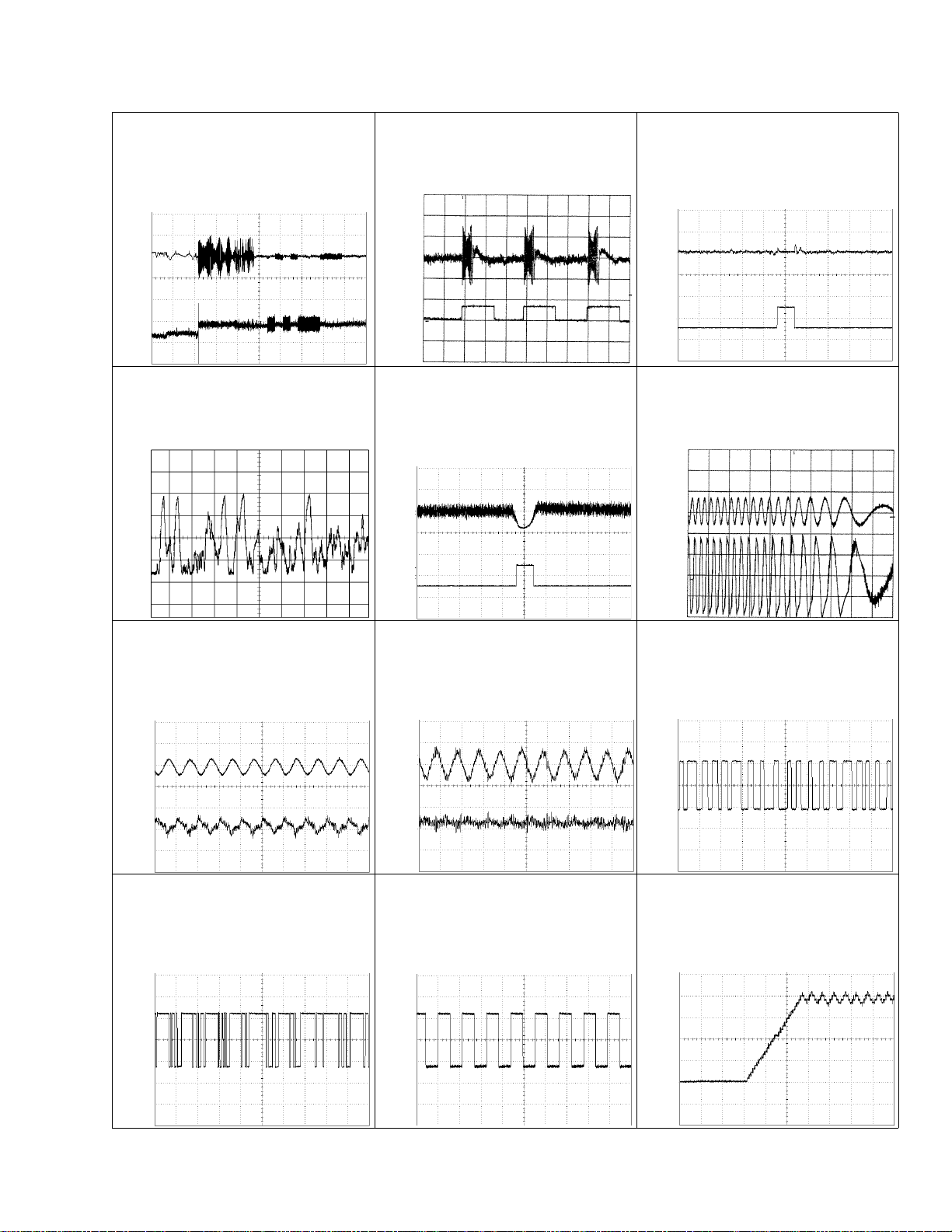

23

CDX-MG6346ZH,MG6446ZH

3 CH1: FIN 1V/div.

$ CH2: HOLD 5V/div.

Normal mode:

The defect part passes 800µm

8 CH1: TEY 0.5V/div.

6 CH2: FEY 0.1V/div.

Normal mode: AGC after focus close

8 CH1: TEY 0.5V/div.

! CH2: SD 0.5V/div.

5ms/div.

0 SIN 1V/div. 10ms/div.

Long Search

8 CH1: TEY 1V/div.

# CH2: TEC 1V/div.

Test mode: Focus close

Tracking open

2ms/div.

6 CH1: FEY 0.2V/div.

3 CH2: FIN 0.5V/div.

Normal mode: During

AGC

1ms/div.

@ EFM 1V/div. 2µs/div.

Play

0.2s/div.

% Dout 2V/div. 5µs/div.

Play

^ LRCK 2V/div. 10µs/div. * ADRMON 1V/div. 1s/div.

Normal mode: Starting play

GND

→

REFOUT

→

REFOUT

→

REFOUT

→

REFOUT

→

REFOUT

→

REFOUT

→

REFOUT

→

REFOUT

→

REFOUT

→

REFOUT

→

REFOUT

→

REFOUT

→

REFOUT

→

REFOUT

→

1 CH1: RFO 1V/div.

$ CH2: HOLD 5V/div.

Normal mode:

The defect part passes 800µm

500µs/div.

REFOUT

→

REFOUT

→

8 CH1: TEY 0.2V/div.

9 CH2: TIN 0.5V/div.

Normal mode: During

AGC

1ms/div.

REFOUT

→

REFOUT

→

GND

→

GND

→

500µs/div.

Page 26

24

CDX-MG6346ZH,MG6446ZH

8 CH1: TEY 0.5V/div.

9 CH2: TIN 0.5V/div.

Test mode: 100 tracks jump(FWD)

8 CH1: TEY 0.5V/div.

9 CH2: TIN 0.5V/div.

Normal mode: Play

10ms/div.

5ms/div.

REFOUT

→

REFOUT

→

& SCKO 2V/div. 500ns/div.

Play

REFOUT

→

) CH1: RCH 2V/div.

( CH2: LCH 2V/div.

Normal mode: PLAY (0dB,1kHz)

200µs/div.

AAGND

→

AAGND

→

REFOUT

→

REFOUT

→

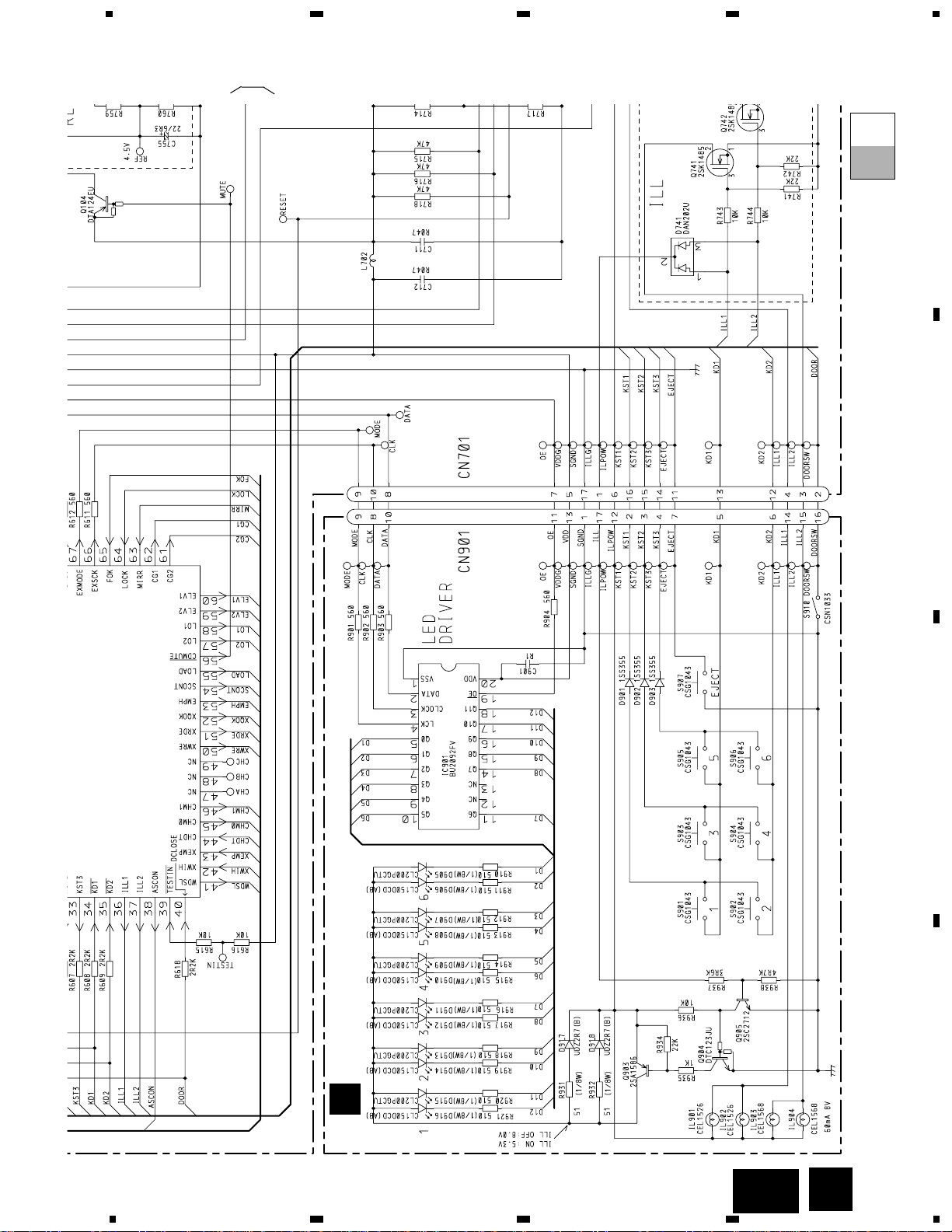

Page 27

H

I

J

L

M

K

CXB3177

G

CN802

SWITCH

PCB UNIT(A)

PCB UNIT(C)

PCB UNIT(E)

PCB UNIT(B)

PCB UNIT(D)

LOAD MOTOR PCB

CPT230SCTD(CD)

CPT230SCTD(CD)

25

CDX-MG6346ZH,MG6446ZH

1

2

34

1

2

34

D

C

B

A

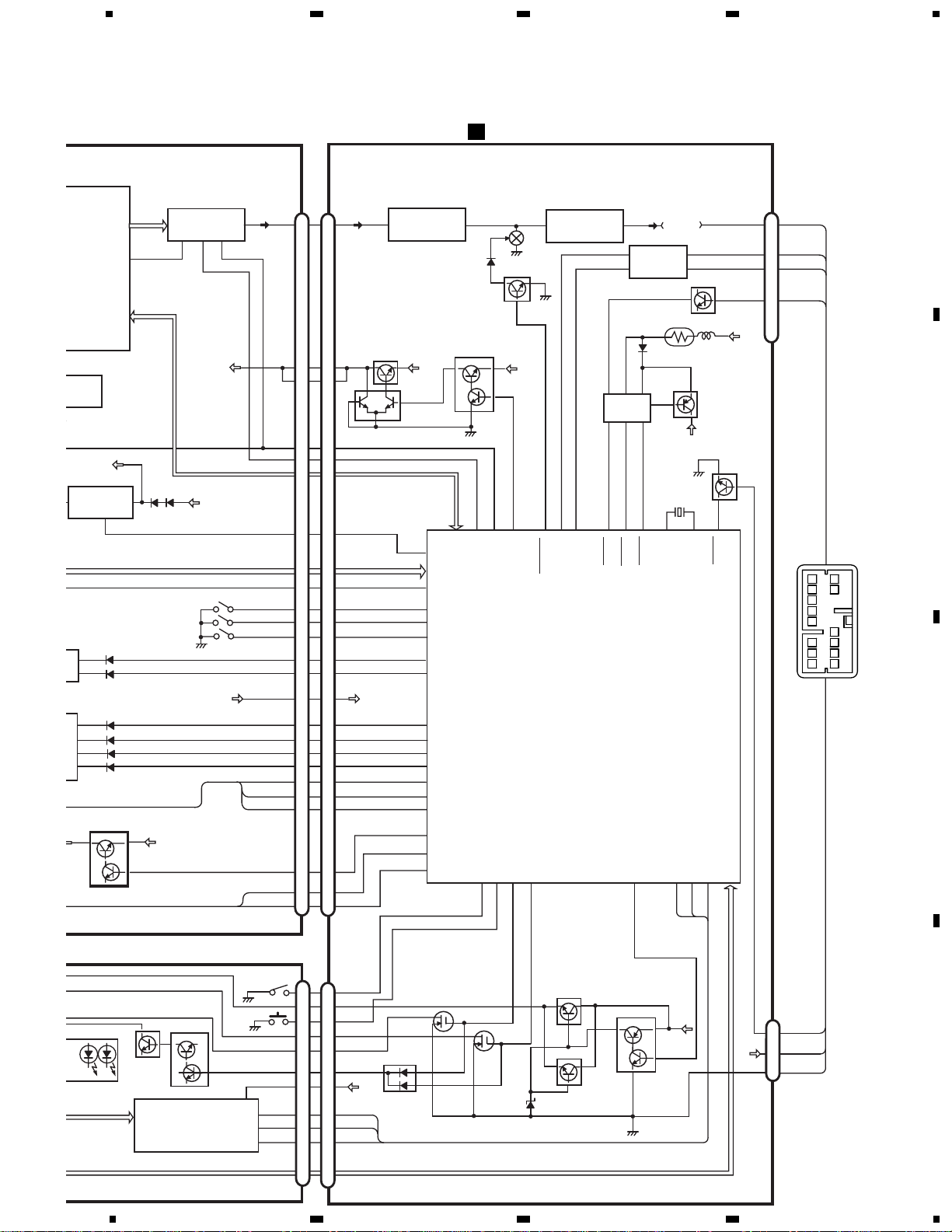

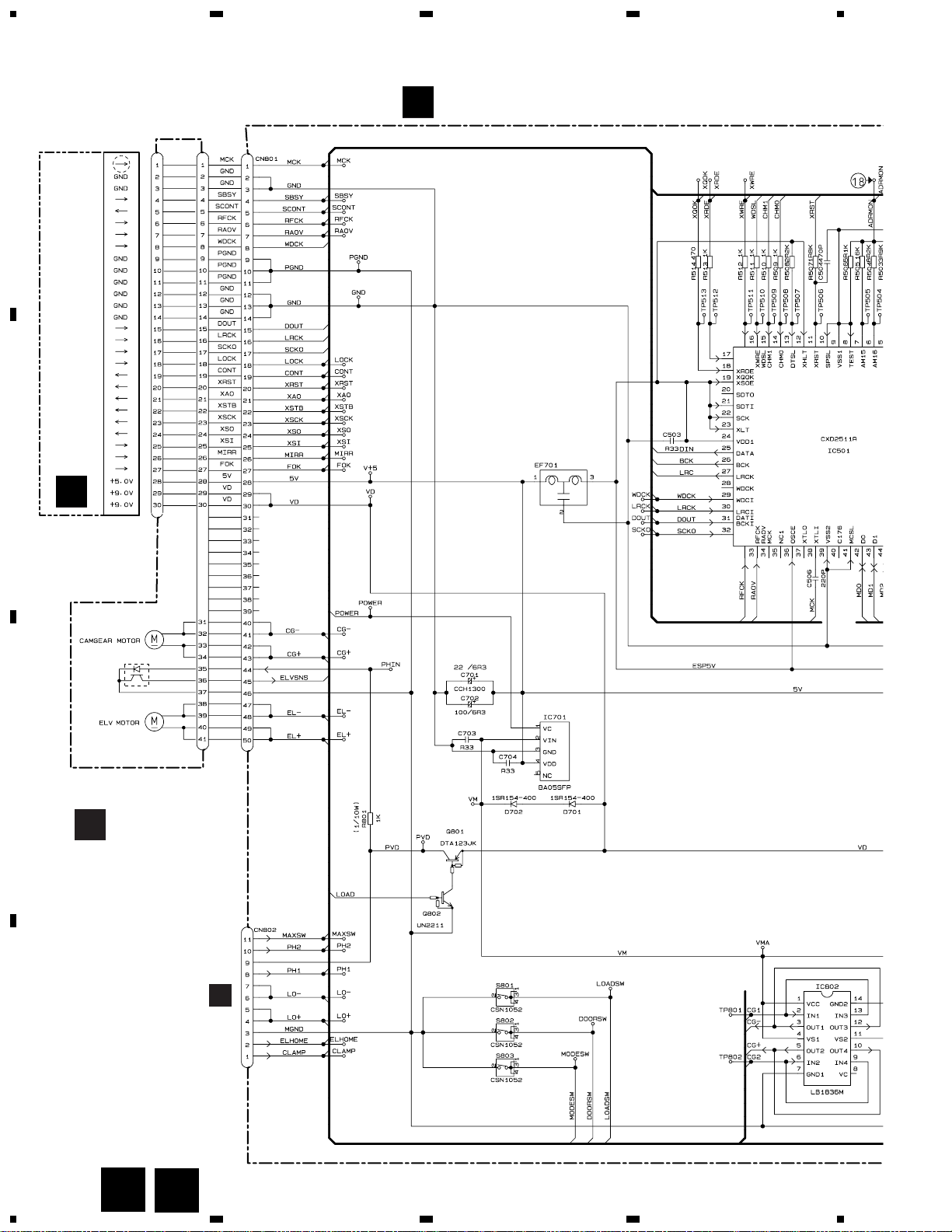

3.4 PCB UNIT(A,B,C,D,E), LOAD MOTOR PCB

L

I

H

G

J

K

G

D

Page 28

26

CDX-MG6346ZH,MG6446ZH

1

23

4

1234

D

C

B

A

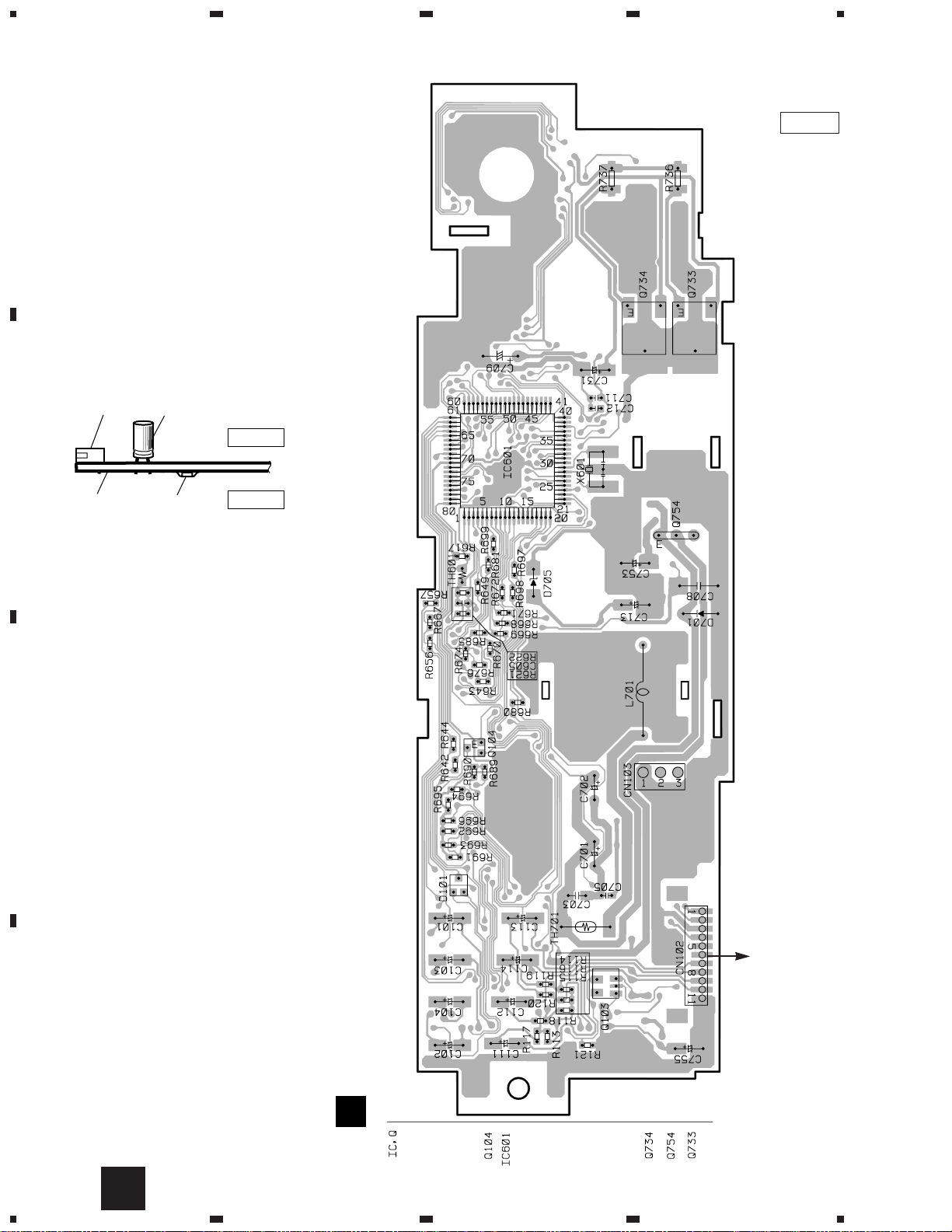

NOTE FOR PCB DIAGRAMS

1. The parts mounted on this PCB

include all necessary parts for

several destination.

For further information for

respective destinations, be sure

to check with the schematic diagram.

2. Viewpoint of PCB diagrams

EXTENSION UNIT

4. PCB CONNECTION DIAGRAM

4.1 EXTENSION UNIT

Capacitor

Connector

P.C.Board

Chip Part

SIDE A

SIDE B

SIDE A

CORD

A

A

Page 29

27

CDX-MG6346ZH,MG6446ZH

1

2

34

1

2

34

D

C

B

A

CN701

CN901

EXTENSION UNIT

SIDE B

A

A

B

D

Page 30

28

CDX-MG6346ZH,MG6446ZH

1

23

4

1234

D

C

B

A

4.2 KEYBOARD UNIT

KEYBOARD UNIT

CN701

SIDE A

B

B

A

Page 31

29

CDX-MG6346ZH,MG6446ZH

1

2

34

1

2

34

D

C

B

A

SIDE B

KEYBOARD UNIT

B

B

Page 32

30

CDX-MG6346ZH,MG6446ZH

1

23

4

1234

D

C

B

A

4.3 CD CORE UNIT(SERVO UNIT)

CD CORE UNIT(SERVO UNIT)

SIDE A

C

E

C

F

PICKUP UNIT(SERVICE)

Page 33

31

CDX-MG6346ZH,MG6446ZH

1

2

34

1

2

34

D

C

B

A

CD CORE UNIT(SERVO UNIT)

SIDE B

C

C

Page 34

32

CDX-MG6346ZH,MG6446ZH

1

23

4

1234

D

C

B

A

4.4 CD CORE UNIT(STS UNIT)

CN101

SIDE A

D

A

F

H

D

CD CORE UNIT(STS UNIT)

Page 35

33

CDX-MG6346ZH,MG6446ZH

1

2

34

1

2

34

D

C

B

A

CD CORE UNIT(STS UNIT)

SIDE B

D

D

Page 36

34

CDX-MG6346ZH,MG6446ZH

1

23

4

1234

D

C

B

A

4.5 MOTOR PCB(B)

MOTOR PCB(B)

E

E

SPINDLE MOTOR

M5

Page 37

M

M4

CARRIAGE

1

12

D

CN301

35

CDX-MG6346ZH,MG6446ZH

5

6

78

5

6

78

D

C

B

A

E

C

Page 38

M

M3

ELV

M

M1

CAM GEAR

Q1

ELV SENSE

1

30

D

CN201

36

CDX-MG6346ZH,MG6446ZH

1

23

4

1234

D

C

B

A

4.6 MOTOR PCB(A)

MOTOR PCB(A)

F

SIDE A

C

F

Page 39

1

41

G

CN801

37

CDX-MG6346ZH,MG6446ZH

1

2

34

1

2

34

D

C

B

A

MOTOR PCB(A)

F

SIDE B

F

D

Page 40

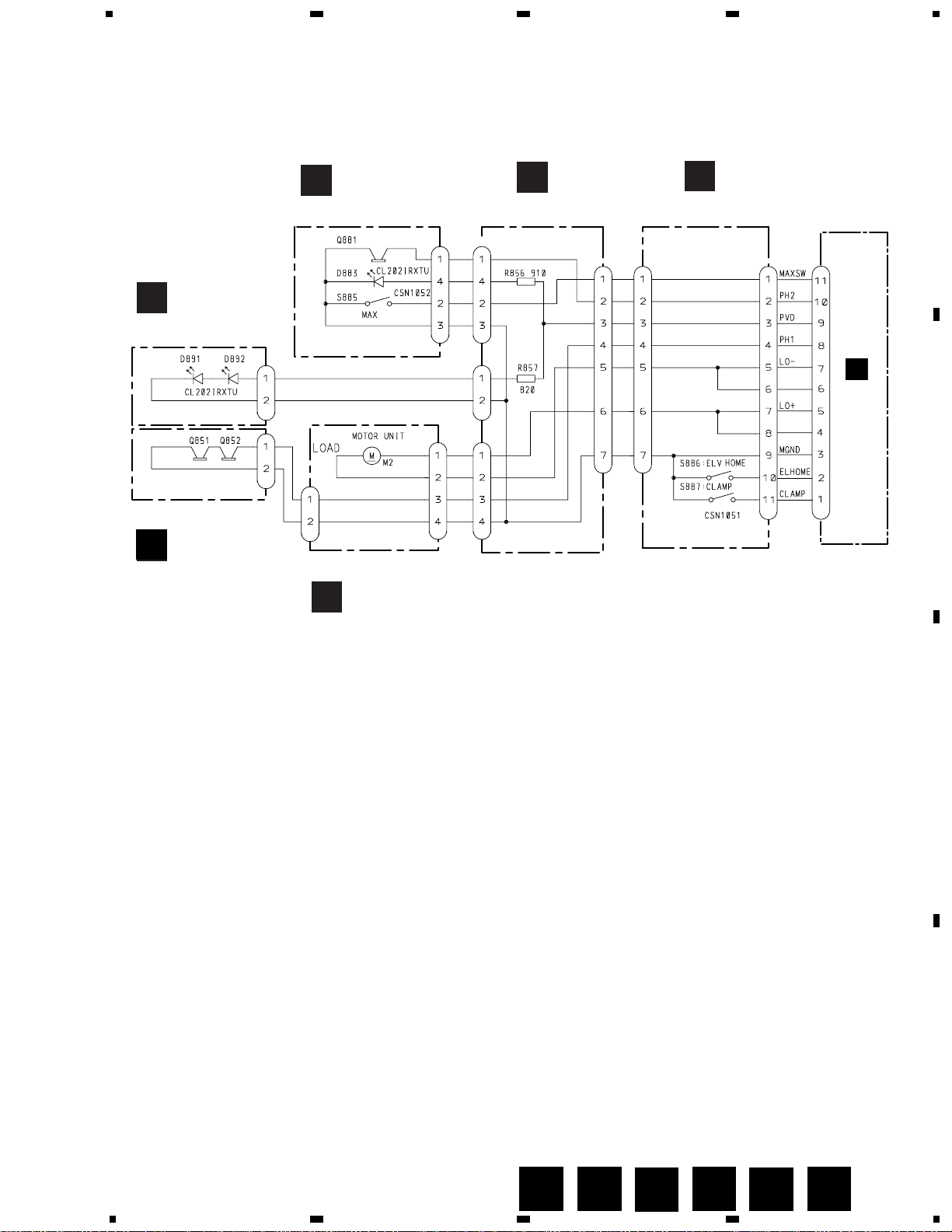

S887

CLAMP

1

11

17

S886

ELV

G

CN802

I

38

CDX-MG6346ZH,MG6446ZH

1

23

4

1234

D

C

B

A

4.8 PCB UNIT(B)

PCB UNIT(B)

4.7 PCB UNIT(D)

PCB UNIT(D)

G

H

G

H

D

Page 41

39

CDX-MG6346ZH,MG6446ZH

1

2

34

1

2

34

D

C

B

A

4.9 PCB UNIT(E)

PCB UNIT(E)

PCB UNIT(E)

SIDE A SIDE B

I

I

I

Page 42

1

4

D883

S885

MAX DETECT

Q881

40

CDX-MG6346ZH,MG6446ZH

1

23

4

1234

D

C

B

A

4.10 PCB UNIT(C)

PCB UNIT(C)

J

J

I

Page 43

M

M2

LOADING

1

1

4

2

I

M

D891

D892

1

2

41

CDX-MG6346ZH,MG6446ZH

1

2

34

1

2

34

D

C

B

A

4.11 LOAD MOTOR PCB

4.12 PCB UNIT(A)

LOAD MOTOR PCB

PCB UNIT(A)

K

L

K

L

G

I

I

Page 44

42

CDX-MG6346ZH,MG6446ZH

Unit Number : CWM6677

Unit Name : Extension Unit

MISCELLANEOUS

IC 101 IC NJM4558MD

IC 102 IC NJM4558MD

IC 103 IC TC74HC4066AF

IC 501 IC CA0008AM

IC 601 IC PD5540A

IC 701 IC PAJ002A

Q 101 Transistor DTC143TK

Q 102 Transistor DTC143TK

Q 103 Transistor FMC2A

Q 104 Transistor DTA124EU

Q 701 Transistor 2SA1162

Q 702 Transistor 2SB1189

Q 721 Transistor 2SC2712

Q 731 Transistor 2SC2712

Q 732 Transistor 2SA1162

Q 733 Transistor 2SD1760F5

Q 734 Transistor 2SD1760F5

Q 741 Transistor 2SK1485

Q 742 Transistor 2SK1485

Q 751 Transistor FMC2A

Q 753 Transistor FMW1

Q 754 Transistor 2SB1335A

D 101 Diode DAP202U

D 701 Diode ERA15-10Y1

D 702 Diode 1SS355

D 703 Diode 1SS355

D 704 Diode 1SS355

D 705 Diode MA1Z240

D 706 Diode 1SR154-400

D 721 Diode 1SS355

D 731 Diode HZU8R2(B3)

D 741 Diode DAN202U

D 751 Diode UDZS6R2(B)

L 701 Coil CTH1190

L 702 Inductor LCTB100K2125

TH 601 Thermistor CCX1032

TH 701 Switch CCX1047

X 601 Radiator 6.290MHz CSS1451

RESISTORS

R 101 RS1/16S332J

R 102 RS1/16S332J

R 103 RS1/16S333J

R 104 RS1/16S333J

R 105 RS1/16S103J

R 106 RS1/16S822J

R 107 RS1/16S822J

R 108 RS1/16S103J

R 109 RS1/16S153J

R 110 RS1/16S822J

R 111 RS1/16S822J

R 112 RS1/16S153J

R 113 RS1/16S104J

R 114 RS1/16S104J

R 115 RS1/16S104J

R 116 RS1/16S104J

R 117 RS1/16S221J

R 118 RS1/16S221J

R 119 RS1/16S221J

R 120 RS1/16S221J

R 121 RS1/16S103J

R 501 RS1/8S101J

R 502 RS1/8S101J

R 601 RS1/16S473J

R 602 RS1/16S473J

R 603 RS1/16S473J

R 604 RS1/16S102J

R 605 RS1/16S222J

R 606 RS1/16S222J

R 607 RS1/16S222J

R 608 RS1/16S222J

R 609 RS1/16S222J

R 610 RS1/16S222J

R 611 RS1/16S561J

R 612 RS1/16S561J

R 613 RS1/16S561J

R 614 RS1/16S561J

R 615 RS1/16S103J

R 616 RS1/16S103J

R 617 RS1/16S163J

R 618 RS1/16S222J

R 619 RS1/16S0R0J

R 620 RS1/16S473J

R 621 RS1/16S433J

R 622 RS1/16S103J

R 640 RS1/16S471J

R 641 RS1/16S471J

R 642 RS1/16S471J

R 643 RS1/16S471J

R 644 RS1/16S471J

R 649 RS1/16S222J

R 651 RS1/16S222J

R 652 RS1/16S471J

R 653 RS1/16S471J

R 654 RS1/16S471J

R 655 RS1/16S471J

R 656 RS1/16S471J

R 657 RS1/16S471J

R 658 RS1/16S471J

R 659 RS1/16S471J

R 660 RS1/16S471J

R 661 RS1/16S102J

R 662 RS1/16S102J

R 663 RS1/16S102J

R 664 RS1/16S102J

5. ELECTRICAL PARTS LIST

NOTE:

- Parts whose parts numbers are omitted are subject to being not supplied.

- The part numbers shown below indicate chip components.

Chip Resistor

RS1/_S___J,RS1/__S___J

Chip Capacitor (except for CQS.....)

CKS....., CCS....., CSZS.....

=====Circuit Symbol and No.===Part Name Part No.

--- ------ ------------------------------------------ -------------------------

=====Circuit Symbol and No.===Part Name Part No.

--- ------ ------------------------------------------ -------------------------

A

Page 45

43

CDX-MG6346ZH,MG6446ZH

R 665 RS1/16S102J

R 666 RS1/16S471J

R 667 RS1/16S471J

R 668 RS1/16S331J

R 669 RS1/16S331J

R 670 RS1/16S331J

R 671 RS1/16S331J

R 672 RS1/16S331J

R 673 RS1/16S471J

R 674 RS1/16S471J

R 675 RS1/16S471J

R 676 RS1/16S471J

R 677 RS1/16S222J

R 678 RS1/16S222J

R 679 RS1/16S222J

R 680 RS1/16S154J

R 681 RS1/16S222J

R 682 RS1/16S102J

R 683 RS1/16S912J

R 685 RS1/16S102J

R 689 RS1/16S103J

R 690 RS1/16S103J

R 691 RS1/16S273J

R 692 RS1/16S202J

R 693 RS1/16S512J

R 694 RS1/16S104J

R 695 RS1/16S104J

R 696 RS1/16S104J

R 697 RS1/16S222J

R 698 RS1/16S222J

R 699 RS1/16S222J

R 701 RS1/10S204J

R 702 RS1/16S104J

R 703 RS1/16S153J

R 704 RS1/16S473J

R 705 RS1/16S683J

R 706 RS1/16S473J

R 707 RS1/16S223J

R 708 RS1/8S101J

R 709 RS1/8S101J

R 711 RS1/16S103J

R 712 RS1/8S3R9J

R 713 RS1/16S102J

R 714 RS1/16S473J

R 715 RS1/16S473J

R 716 RS1/16S473J

R 717 RS1/16S473J

R 718 RS1/16S473J

R 719 RS1/8S101J

R 721 RS1/8S103J

R 722 RS1/16S473J

R 723 RS1/16S152J

R 731 RS1/10S681J

R 732 RS1/16S223J

R 733 RS1/16S103J

R 734 RS1/16S223J

R 735 RS1/16S223J

R 736 RS1/4S2R2J

R 737 RS1/4S2R2J

R 738 RS1/16S104J

R 741 RS1/16S223J

R 742 RS1/16S223J

R 743 RS1/16S103J

R 744 RS1/16S103J

R 751 RS1/16S101J

R 752 RS1/16S473J

R 753 RS1/10S223J

R 754 RS1/16S101J

R 755 RS1/4S221J

R 756 RS1/16S681J

R 757 RS1/16S511J

R 758 RS1/16S561J

R 759 RS1/16S103J

R 760 RS1/16S273J

CAPACITORS

C 101 CEV4R7M35

C 102 CEV4R7M35

C 103 CEV4R7M35

C 104 CEV4R7M35

C 105 CCSRCH101J50

C 106 CCSRCH101J50

C 107 CCSRCH101J50

C 108 CCSRCH101J50

C 109 CKSRYB473K16

C 110 CKSRYB473K16

C 111 CEV4R7M35

C 112 CEV4R7M35

C 113 CEV4R7M35

C 114 CEV4R7M35

C 501 CKSRYB102K50

C 502 CKSRYB102K50

C 503 CKSRYB104K16

C 601 CKSRYB104K16

C 603 CKSRYB103K50

C 605 CKSRYB103K50

C 651 CKSRYB103K50

C 701 CEAT471M16

C 702 CEAT471M16

C 703 CKSQYB104K25

C 704 CKSRYB223K25

C 705 CKSRYB103K50

C 706 CKSRYB103K50

C 707 CKSRYB103K50

C 708 CSZSC220M16

C 709 CCL1049

C 710 CKSRYB103K50

C 711 CKSRYB473K16

C 712 CKSRYB473K16

C 713 CEV100M16

C 721 CKSRYB103K50

C 731 CEV4R7M35

C 732 CKSRYB473K16

C 751 CKSRYB473K16

C 752 CKSRYB103K50

C 753 CEV220M16

C 754 CKSRYB473K16

C 755 CEV220M6R3

Unit Number : CWM6289

Unit Name : Keyboard Unit

MISCELLANEOUS

IC 901 IC BU2092FV

Q 903 Transistor 2SA1586

Q 904 Transistor DTC123JU

Q 905 Chip Transistor 2SC2712

D 901 Diode 1SS355

D 902 Diode 1SS355

D 903 Diode 1SS355

D 905 LED CL200PGCTU

D 906 LED CL150DCD(AB)

D 907 LED CL200PGCTU

D 908 LED CL150DCD(AB)

D 909 LED CL200PGCTU

D 910 LED CL150DCD(AB)

D 911 LED CL200PGCTU

D 912 LED CL150DCD(AB)

=====Circuit Symbol and No.===Part Name Part No.

--- ------ ------------------------------------------ -------------------------

=====Circuit Symbol and No.===Part Name Part No.

--- ------ ------------------------------------------ -------------------------

B

Page 46

44

CDX-MG6346ZH,MG6446ZH

D 913 LED CL200PGCTU

D 914 LED CL150DCD(AB)

D 915 LED CL200PGCTU

D 916 LED CL150DCD(AB)

D 917 Diode UDZ2R7(B)

D 918 Diode UDZ2R7(B)

S 901 Switch CSG1043

S 902 Switch CSG1043

S 903 Switch CSG1043

S 904 Switch CSG1043

S 905 Switch CSG1043

S 906 Switch CSG1043

S 907 Switch CSG1043

S 910 Spring Switch CSN1033

IL 901 Lamp 60mA 8V CEL1526

IL 902 Lamp 60mA 8V CEL1526

IL 903 Lamp 60mA 8V CEL1568

IL 904 Lamp 60mA 8V CEL1568

RESISTORS

R 901 RS1/10S561J

R 902 RS1/10S561J

R 903 RS1/10S561J

R 904 RS1/10S561J

R 910 RS1/8S511J

R 911 RS1/8S511J

R 912 RS1/8S511J

R 913 RS1/8S511J

R 914 RS1/8S511J

R 915 RS1/8S511J

R 916 RS1/8S511J

R 917 RS1/8S511J

R 918 RS1/8S511J

R 919 RS1/8S511J

R 920 RS1/8S511J

R 921 RS1/8S511J

R 931 RS1/8S510J

R 932 RS1/8S510J

R 934 RS1/10S223J

R 935 RS1/10S102J

R 936 RS1/10S103J

R 937 RS1/10S362J

R 938 RS1/10S472J

CAPACITORS

C 901 CKSQYB104K50

Unit Number : CWX2202

Unit Name : CD Core Unit(Servo Unit)

MISCELLANEOUS

IC 101 IC UPC2572GS

IC 201 IC UPD63702AGF

IC 301 IC BA5986FM

Q 101 Transistor 2SD1664

Q 102 Transistor UMD2N

D 301 Diode 1SR154-400

X 201 Ceramic Resonator 16.934MHz CSS1457

EF 201 Filter CCG1076

RESISTORS

R 101 RS1/8S100J

R 102 RS1/8S120J

R 104 RS1/16S822J

R 105 RS1/16S682J

R 106 RS1/16S183J

R 107 RS1/16S822J

R 108 RS1/16S333J

R 109 RS1/16S683J

R 110 RS1/16S134J

R 111 RS1/16S273J

R 112 RS1/16S222J

R 113 RS1/16S103J

R 114 RS1/16S103J

R 115 RS1/16S102J

R 116 RS1/16S163J

R 117 RS1/16S163J

R 120 RS1/16S101J

R 121 RS1/16S101J

R 125 RS1/16S0R0J

R 201 RS1/16S104J

R 202 RS1/16S103J

R 203 RS1/16S332J

R 204 RS1/16S752J

R 205 RS1/16S752J

R 206 RS1/16S101J

R 250 RS1/16S331J

R 251 RS1/16S331J

R 252 RS1/16S331J

R 253 RS1/16S331J

R 254 RS1/16S331J

R 255 RS1/16S471J

R 256 RS1/16S471J

R 259 RS1/16S221J

R 263 RS1/16S471J

R 269 RS1/16S0R0J

R 274 RS1/16S471J

R 277 RS1/16S471J

R 301 RS1/16S103J

R 302 RS1/16S153J

R 303 RS1/16S103J

R 304 RS1/16S273J

R 305 RS1/16S103J

R 306 RS1/16S752J

R 307 RS1/16S103J

R 308 RS1/16S103J

R 309 RS1/16S471J

R 311 RS1/16S471J

CAPACITORS

C 101 CEV101M6R3

C 102 CKSQYB104K16

C 103 CEV470M6R3

C 104 CKSQYB334K16

C 105 CCSRCH240J50

C 106 CKSRYB222K50

C 107 CEV4R7M35

C 108 CKSRYB273K25

C 109 CCSRCH101J50

C 110 CKSQYB104K16

C 111 CKSRYB332K50

C 112 CKSQYB473K16

C 113 CKSRYB103K25

C 114 CKSRYB391K50

C 115 CCSRCH121J50

C 116 CKSRYB682K50

C 117 CKSRYB333K16

C 118 CKSQYB334K16

C 119 CKSQYB334K16

C 120 CKSQYB334K16

C 121 CKSQYB334K16

C 122 CKSQYB104K16

C 123 CKSRYB472K50

C 124 CKSQYB104K16

C 125 CCSRCH5R0C50

C 126 CKSRYB153K25

C 127 CKSRYB102K50

C 201 CKSQYB334K16

C 202 CKSQYB104K16

C 203 CKSQYB104K16

=====Circuit Symbol and No.===Part Name Part No.

--- ------ ------------------------------------------ -------------------------

=====Circuit Symbol and No.===Part Name Part No.

--- ------ ------------------------------------------ -------------------------

C

Page 47

45

CDX-MG6346ZH,MG6446ZH

C 204 CKSRYB471K50

C 207 CKSQYB683K16

C 208 CKSRYB821K50

C 209 CKSRYB273K25

C 210 CKSQYB334K16

C 211 CKSQYB334K16

C 212 CKSQYB334K16

C 213 22µF/6.3V CCH1300

C 301 CEV101M10

C 302 CEV101M10

Unit Number : CWX2203

Unit Name : CD Core Unit(STS Unit)

MISCELLANEOUS

IC 501 IC CXD2511R

IC 502 IC

MSM514400DP-60TS

IC 601 IC AK4321VF

IC 701 IC BA05SFP

IC 801 IC LB1836M

IC 802 IC LB1836M

Q 801 Transistor DTA123JK

Q 802 Transistor UN2211

D 701 Diode 1SR154-400

D 702 Diode 1SR154-400

D 703 Diode 1SS355

D 704 Diode 1SS355

D 705 Diode 1SS355

D 706 Diode 1SS355

D 707 Diode 1SS355

D 708 Diode 1SS355

S 801 Spring Switch(LOAD) CSN1052

S 802 Spring Switch(DOOR) CSN1052

S 803 Spring Switch(MODE) CSN1052

EF 701 Filter CCG1051

EF 702 Filter CCG1051

RESISTORS

R 501 RS1/16S102J

R 502 RS1/16S202J

R 503 RS1/16S392J

R 504 RS1/16S822J

R 505 RS1/16S163J

R 506 RS1/16S512J

R 507 RS1/16S182J

R 508 RS1/16S222J

R 509 RS1/16S102J

R 510 RS1/16S102J

R 511 RS1/16S102J

R 512 RS1/16S102J

R 513 RS1/16S102J

R 514 RS1/16S471J

R 601 RS1/16S101J

R 602 RS1/16S101J

R 603 RS1/16S471J

R 604 RS1/16S471J

R 701 RS1/10S0R0J

R 702 RS1/10S100J

R 716 RS1/16S471J

R 717 RS1/16S471J

R 718 RS1/16S471J

R 801 RS1/10S102J

CAPACITORS

C 501 CKSQYB334K16

C 502 CKSQYB334K16

C 503 CKSQYB334K16

C 504 CCSRCH471J50

C 506 CCSRCH221J50

C 601 CKSQYB334K16

C 602 CCSRCH221J50

C 603 CKSQYB334K16

C 604 CKSQYB334K16

C 605 22µF/6.3V CCH1300

C 606 CKSQYB334K16

C 701 22µF/6.3V CCH1300

C 702 CEVL101M6R3

C 703 CKSQYB334K16

C 704 CKSQYB334K16

C 801 CKSQYB104K25

C 802 CKSQYB104K25

C 803 CEVL220M16

Unit Number :

Unit Name : Motor PCB(B)

M 4 Motor Unit(Carriage) CXB3178

M 5 Motor(Spindle) CXM1120

Unit Number :

Unit Name : Motor PCB(A)

Q 1 Photo-interrupter RPI-221

M 1 Motor Unit(Cam Gear) CXB3174

M 3 Motor Unit(ELV) CXB3175

Unit Number :

Unit Name : PCB Unit(D)

Q 851 Photo-transistor CPT230SCTD(CD)

Q 852 Photo-transistor CPT230SCTD(CD)

Unit Number :

Unit Name : PCB Unit(B)

S 886 Spring Switch(ELV Home) CSN1052

S 887 Spring Switch(Clamp) CSN1051

Unit Number :

Unit Name : PCB Unit(E)

R 856 RS1/8S911J

R 857 RS1/8S821J

Unit Number :

Unit Name : PCB Unit(C)

Q 881 Photo-transistor CPT230SCTD(CD)

D 883 Chip LED CL202IRXTU

S 885 Spring Switch(MAX) CSN1052

Unit Number :

Unit Name : Load Motor PCB

M 2 Motor Unit(Load) CXB3177

Unit Number :

Unit Name : PCB Unit(A)

D 891 Chip LED CL202IRXTU

D 892 Chip LED CL202IRXTU

Miscellaneous Parts List

Pickup Unit(Service)(P8) CXX1311

=====Circuit Symbol and No.===Part Name Part No.

--- ------ ------------------------------------------ -------------------------

=====Circuit Symbol and No.===Part Name Part No.

--- ------ ------------------------------------------ -------------------------

D

E

F

G

I

J

K

L

H

Page 48

46

CDX-MG6346ZH,MG6446ZH

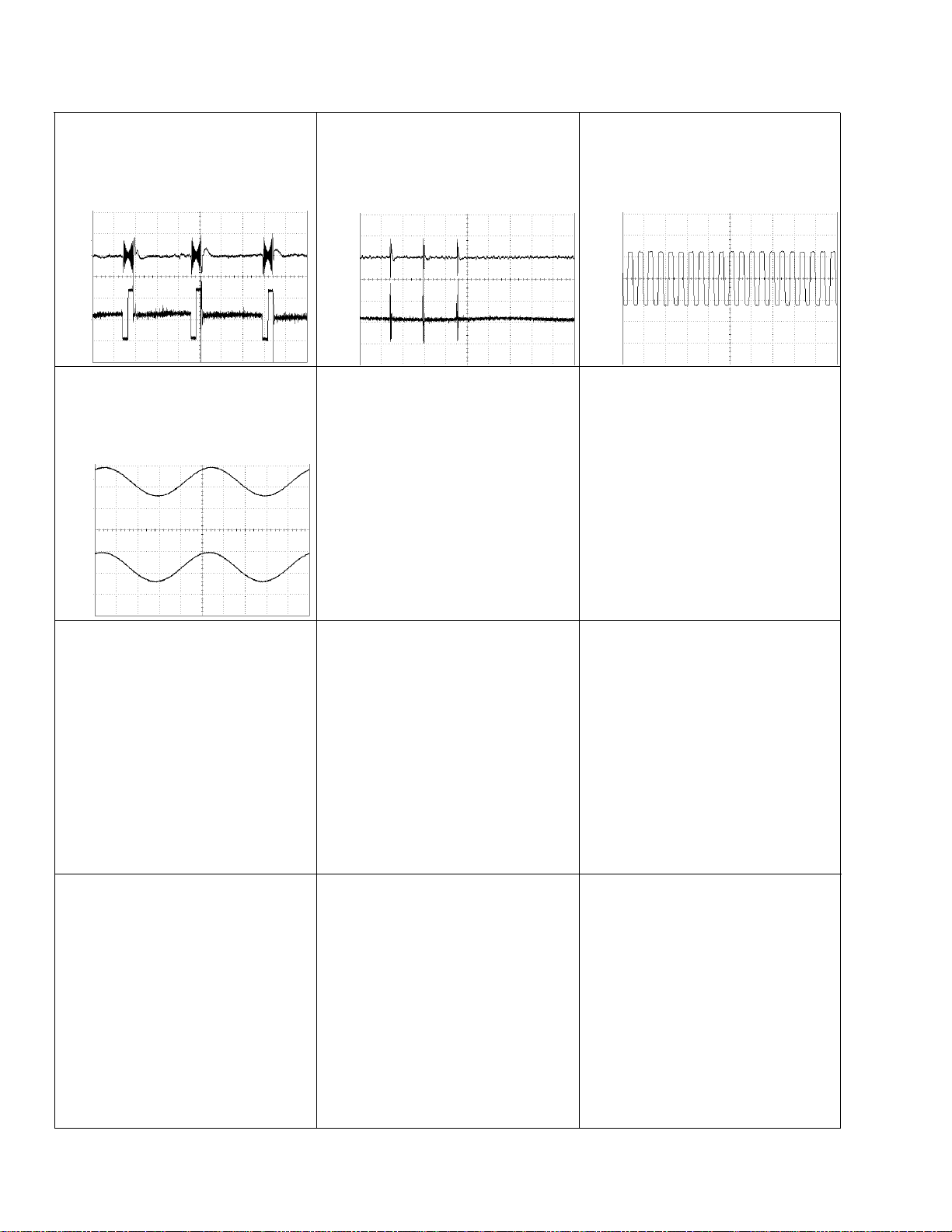

6. ADJUSTMENT

CHECKING THE GRATING AFTER CHANGING THE PICKUP UNIT

• Note :

The grating angle of the PU unit cannot be adjusted after the PU unit is changed. The PU unit in the CD mecha-

nism module is adjusted on the production line to match the CD mechanism module and is thus the best adjusted

PU unit for the CD mechanism module. Changing the PU unit is thus best considered as a last resort. However, if

the PU unit must be changed, the grating should be checked using the procedure below.

• Purpose :

To check that the grating is within an acceptable range when the PU unit is changed.

• Symptoms of Mal-adjustment :

If the grating is off by a large amount symptoms such as being unable to close tracking, being unable to perform

track search operations, or taking a long time for track searching.

• Method :

• Measuring Equipment • Oscilloscope, Two L.P.F.

• Measuring Points • E, F, REFOUT

• Disc • ABEX TCD-784

• Mode • TEST MODE

• Checking Procedure

1. In test mode, load the disc and switch the 5V regulator on.

2. Using the TRK+ and TRK- buttons, move the PU unit to the innermost track.

3. Press key 3 to close focus, the display should read "91". Press key 2 to implement the tracking balance adjustment the display should now read "81". Press key 3 4 times. The display will change, returning to "81" on the

fourth press.

4. As shown in the diagram above, monitor the LPF outputs using the oscilloscope and check that the phase difference is within 75° . Refer to the photographs supplied to determine the phase angle.

5. If the phase difference is determined to be greater than 75° try changing the PU unit to see if there is any

improvement. If, after trying this a number of times, the grating angle does not become less than 75° then the

mechanism should be judged to be at fault.

• Note

Because of eccentricity in the disc and a slight misalignment of the clamping center the grating waveform may be

seen to "wobble" ( the phase difference changes as the disc rotates). The angle specified above indicates the average angle.

• Hint

Reloading the disc changes the clamp position and may decrease the "wobble".

100kΩ

390pF

100kΩ

390pF

E

REFOUT

F

Xch Ych

Oscilloscope

L.P.F.

L.P.F.

E

F

REFOUT

REFOUT

CD CORE UNIT(SERVO UNIT)

Page 49

47

CDX-MG6346ZH,MG6446ZH

Grating waveform

Ech → Xch 20mV/div, AC

Fch → Ych 20mV/div, AC

45°

0°

75°

60°

30°

90°

Page 50

48

CDX-MG6346ZH,MG6446ZH

7. GENERAL INFORMATION

7.1 DIAGNOSIS

7.1.1 TEST MODE

- CD Test Mode

1) Precautions on Adjustment

• The unit employs a single voltage (+5V) for the regulator, thus the reference potential of the signal is

RFOUT (approximately 2.5V) rather than GND.

Inadvertent contact of REFOUT and GND during

adjustment can result not only in disabling normal

potential measurement but also in exposing the pickup to strong impacts due to malfunctioning of the

servo. Therefore, you are requested to observe the

following precautions.

• Make sure that the negative probe of the measuring

instrument is not connected to RFOUT or GND.

Special care must be exercised so that the channel 1

negative probe may not be connected to the oscilloscope and the channel 2 negative probe to GND.

Since the frame of the measuring instrument is usually at the same potential as the negative probe, the

frame of the measuring instrument must be changed

to floating status.

When RFOUT is inadvertently connected to GND, you

must immediately turn off the regulator or power

supply.

• The regulator must be turned off before mounting or

dismounting filters or wiring materials.

• You should not start adjustment or measurement

immediately after the regulator is turned on. It is recommended to run the player for approximately one

minute so that it may stabilize.

• When the test mode is turned on, various protective

functions from the software become unavailable.

Thus, you must make sure that undesirable electric or

mechanical shocks are not be given to the system.

• This model employs a photo-transistor for detecting

discs at their loading or ejection. Thus, if its outer

case is removed during repair work and internal parts

are exposed to light of strong intensity, malfunctions

including the following can result:

∗ The eject button becomes inoperable during play.

Pressing the eject button does not eject a disc and

play is continued.

∗ Loading becomes unavailable.

If a malfunction is recognized, appropriate remedial

actions must be taken. Such actions include changing the light source position, changing the unit position and applying a cover to the photo-transistor.

• When you press the [EJECT] key to eject a disc, you

must not touch any other key until the ejection is

complete.

• If you press the [TRK+] or [TRK-] for the focus search

in the test mode, you must turn the power off immediately. (Otherwise, the lens will be forced to stick to

the top or bottom, potentially resulting in the burning

of the actuator.)

2) Description of the Test Mode

Adjustment of this unit is done in parallel with the CD

control unit (DEH-M7126ZH or a head unit conforming

to the GA-NET BUS specifications), thus key operations for adjustments are done from the unit. Taking

the example of the DEH-M7126ZH, the following

describes how to turn on the test mode and operate

the keys. The keys referred to in the following are

those used on the DEH-M7126ZH.

• Turning on the Test Mode

Press the [4] and [6] keys simultaneously to turn on

the ACC and the backup.

• Ending the Test Mode

When ACC or Back up is off, the test mode is canceled.

• Operation of TR JUMPs (except 100TR) continues

after your finger has left the key. CRG MOVE and

100TR JUMP are forced to the tracking close mode as

soon as the key is released.

• Turning the power on or off resets the JUMP MODE

to the Single TR.

Page 51

49

CDX-MG6346ZH,MG6446ZH

[ASEL]

Power Off

[3]

Focus Close/S-curve/

F, EQ Measurement

[6]

Focus Mode Select

[1]

Tracking Servo

Close

[ASEL]

Power ON

(T.OFFSET adjustment required)

[3]

Power ON

(T.OFFSET adjustment not required)

[1]

Mechanism Test Mode

Initial State

[CD]or[DISC]

Source CD

MIN

TRK

[ASEL]

Power Off

[1]

Tracking Close

(AGC, Applicable Servo)

[6]

Tracking Close

(No AGC, Applicable Servo)

[3]

Auto Adjustment Display

/Rough Servo

[2]

Tracking Balance

Adjustment

[Key]

Contents

Display

[4]+[6]+Reset

Test Mode In

[3]

AGC

[6]

CRG/TR Jump Count

Select

[TRK+]

CRG+/TR Jump+

[TRK-]

CRG–/TR Jump–

[4]

SPINDLE

Uniform/

Double Switching

[ASEL]

Power Off

[1]

AGC/F.BIAS

Display Switching

or

[TRK+]

CRG+

[TRK-]

CRG-

[TRK+]

CRG+

[TRK-]

CRG-

[ASEL]

Power Off

[2]

Trackig Open

[2]

Trackig Open

*1

*6

*5

*3

*2

*2

*4

*1) Switching must take place in the following sequence.

S.Curve Check

Focus EQ Measurement.Focus Close

*2)

→→ → → →

9X(8X):91(81)

4 TR

92(82)

10 TR

93(83)

32 TR

94(84)

100 TR

95(85)

CRG Move

96(86)

*4)

→→→

F.AGC Gain F.AGC Gain F. BIAS Setting

(AGC Gain = (Current value/Initial value) x 20)

→→→

→→

Single TR /4TR / 10TR / 32TR / 100TR

Single TR

*3) Switching must take place in the following sequence.

It applies to the CRG Move and 100TR Jump alone.

Min/Sec (or Track No.)

*5) Switching must take place in the following sequence.

F.Cancel Display

*6) Switching must take place in the following sequence.

T.Offset Display T.Bal Display

Rough Servo.

(F.Bias value, F.Cancel value, T.Offset value, T.Bal value

= (Upper 8 bits of the setting (7F[H] to 80[H] + 128)/4

= 63[D] to 32[D] to 00[D]).

•

•

•

Operation of TR JUMPs other than 100TR is continued after your finger has left the key.

CRG Move and 100TR Jump are forced to the Tracking Close Mode when the key is released.

Powering on or off resets the Jump Mode to the Single TR (91).

When ACC or Back up is off, the test mode is canceled.

Note:

Note:

Note:

The GA-NET BUS head unit(made by Pioneer) must be employed for controlling the test mode.

Sound is unavailable even after the tracking has been closed

(this trouble results when the IC for the STS is not controlled in the test mode).

When you pressed the [TRK+] or [TRK-] key during the Focus Search, you must turn the power off immediately

(otherwise, the lens can stick resulting in actuator damages).

[Key]

[ASEL]

[TRK+]

[TRK-]

[1]

[2]

[3]

[4]

[5]

[6]

Operation

Power ON/OFF

CRG+/TR Jump+

(Toward outer perimeter)

Tracking Close/AGC gain,

F.Bias adjustment value display switching

Auto Tracking Balance adjustment/

Tracking Open

Focus Close, S.Curve, F.EQ measurement/

Rough Servo/AGC

Focus Open

/SpindleUniform/Double Switching

Jump Off

Focus Mode select/Tracking Close/

CRG,TR Jump Switching

CRG-/TR Jump(Toward inner perimeter)

or

or

or or

or

or

Note: To exchange CD's, insert or eject a CD, use numerical buttons 1 to 6 on the CD changer.

(During the test mode, even when no disc is stored on a tray. If so, first press the EJECT button once.)

SEC

MIN

TRK

00 00

SEC

00

MIN

TRK

99 99

SEC

99

MIN

TRK

SEC

MIN

TRK

91 91

SEC

91

MIN

TRK

0X 0X

SEC

0X

MIN

TRK

00 00

SEC

00

MIN

TRK

99 99

SEC

99

MIN

TRK

SEC

MIN

TRK

XX XX

SEC

XX

MIN

TRK

XX XX

SEC

XX

MIN

TRK

?? ??

SEC

??

MIN

TRK

SEC

MIN

TRK

?? ??

SEC

??

MIN

TRK

XX XX

SEC

XX

MIN

TRK

XX XX

SEC

XX

MIN

TRK

72 0*

SEC

**

MIN

TRK

00 00

SEC

00

MIN

TRK

99 99

SEC

99

MIN

TRK

00 00

SEC

00

MIN

TRK

99 99

SEC

99

MIN

TRK

8X 8X

SEC

8X

MIN

TRK

9X 9X

SEC

9X

MIN

TRK

8X 8X

SEC

8X

MIN

TRK

9X 9X

SEC

9X

MIN

TRK

8X 8X

SEC

8X

MIN

TRK

XX XX

SEC

XX

MIN

TRK

8X 8X

SEC

8X

MIN

TRK

9X 9X

SEC

9X

MIN

TRK

XX

SEC

XX

MIN

TRK

8X 8X

SEC

8X

MIN

TRK

9X 9X

SEC

9X

MIN

TRK

XX XX

SEC

XX

MIN

TRK

SEC

MIN

TRK

00 00

SEC

00

MIN

TRK

99 99

SEC

99

(

)

MIN

TRK

00 00

SEC

00

MIN

TRK

99 99

SEC

99

(

)

MIN

TRK

00 00

SEC

00

MIN

TRK

99 99

SEC

99

(

)

- CD Player Flowchart

Page 52

50

CDX-MG6346ZH,MG6446ZH

[ASEL]

Mecha Test Out

CD Test In

[1]

CAM MOTOR

select

[2]

ELV MOTOR

select

[3]

LOAD MOTOR

select

[1]

Mechanism Test In

Initial State

[ASEL]

CD Test Mode

[CD]or[DISC]

Source CD

[Key]

Contents

Display

[4]+[6]+Reset

Test Mode In

[4]

CAM+LOAD MOTOR

select

[TRK+]

MOTOR FWD drive

- Operating Procedures:

1)

2)

3)

Turn on the CD Test Mode, then select the

CD-CHANGER for the SOURCE.

Select the motor to be driven

using the [1] to [3] ,[6] keys.

Press the [TRK+] or [TRK-] in this state to drive

the selected motor.

[Key]

[ASEL]

[TRK+]

[TRK-]

[1]

[2]

[3]

[4]

Operation

Mechanism Test is initialized.

Valid only when the motor selected (using the

[1] to [3] ,[6] keys) is driven in FWD direction.

CAM MOTOR is selected.

[3]

CD Test Mode

[TRK-]

MOTOR REV drive

Valid only when the motor selected (using the

[1] to [3] ,[6] keys) is driven in REV direction.

ELV MOTOR is selected.

LOAD MOTOR is selected.

CAM + LOAD MOTOR is selected.

<Screen Display during Mecha Test Mode>

TRK : 72

MIN : Upper (10th order):

Type of motors selected

Lower (order of 1): State of DISC

sensing phototransistor and switch

1* : CAM motor

2* : ELV motor

3* : LOAD motor

4* : CAM+LOAD motor

PH1 PH2

MAXSW

Display

L

H

L

H

L

H

L

H

L

L

H

H

L

L

H

H

L

L

L

L

H

H

H

H

*0

*1

*2

*3

*4

*5

*6

*7

L:H:Phototransistor is OPEN and switch is ON.

Phototransistor is CLOSE and switch is OFF.

SEC : 1 When ELV motor is selected, ELV position is displayed

01: ELV at home position (1st disc).

10: ELV at a position other than home (2nd to 6th).

11: ELV moving to a specified position. * Note 1

00: Reserved (for an error)

2 When CAM.LOAD motor is selected:

Indicates CAMSW (CAM gear) status.

EJECT

SW1 (DOORSW)

SW2 (LOADSW)

SW3 (MODESW)

SW4 (CLAMPSW)

Display

10

30

31

21 20

222333 32

REV

FWD

Note 2

- Precautions

*

Note 1:

Note 2:

While the CD mechanism is moving to exchange CDs, eject or insert a CD, never

perform key operations for motor selection or drive operation.

When driving the CAM MOTOR in 31 → 30 → 10 (in REV direction),

the elevation position must be at the EJECT/LOAD position (the top position).

When the elevation is situated at the Note 1 position, move of any motor

other than the REV is disabled.

Before performing the elevation, make sure that the CAM SW (switch) is

set to a position between 22 and 20.

As a rule, driving of the ELV MOTOR must be started immediately after

the CAMSW indication has changed from 22 to 20.

clamp

MIN

TRK

SEC

MIN

TRK

72 0*

SEC

**

MIN

TRK

SEC

MIN

TRK

72 1*

SEC

**

MIN

TRK

72 2*

SEC

**

MIN

TRK

00 00

SEC

00

MIN

TRK

99 99

SEC

99

MIN

TRK

72 3*

SEC

**

MIN

TRK

72 4*

SEC

**

MIN

TRK

72 **

SEC

**

MIN

TRK

72 **

SEC

**

MIN

TRK

72 X*

SEC

**

(

)

*

- CD Changer Mechanism Flowchart

Page 53

51

CDX-MG6346ZH,MG6446ZH

- Operating Procedures for Ejecting a Clamped Disc

1

2

3

4

5

6

Select CAM MOTOR using [1], then press the REV direction while the disc is being clamped (CAMSW state is 32).

The CAMSW status indication sequentially changes through 32→33→23→22.

When the disc to be ejected is not identical with the disc being clamped, select the [2] ELV MOTOR in the vicinity of where

the display changes from 22 to 20, then match the elevation to the disc to be ejected according to the following procedures:

After selecting ELV MOTOR, lower the elevation until the ELV position display becomes 01 (1st disc) using the REV direction.

Drive the elevation up until the display is changed to 10. This is the elevation where the second disk is situated.

The next display of 10 tells you the elevation of the 3rd disc. Repeating this operation allows you to establish an elevation

matching each disc. (When the elevation is driven from the 1st through 6th disc, the status display changes as

01→11→10→11→10→11→10→11→10→11→10.)

(When the disc to be ejected coincides with the disc being clamped, the above operations are not necessary.)

Select the [1] CAM MOTOR and then, using the REV direction, drive it until the display changes from 20 (or 22) to 21 and 31.

Select the [2] ELV MOTOR, then drive the tray of the disc to be ejected up to the EJECT/LOAD position (using the FWD direction).

Select the [4] CAM+LOAD MOTOR, then drive it in the REV direction until the display changes from 31 to 30 and 10.

The door will open immediately before the display changes to 10 and part of the disc will be pushed out.

When 10 is displayed, select the [3] LOAD MOTOR, then drive it in REV direction until the disc is completely ejected.

Page 54

7.1.2 DISASSEMBLY

- Removing the Extension Unit (Fig. 1)

1. Remove the three screws B, then remove the side

frame and holder.

2. Remove the screw C, screw D and PCB from the

connector.

3. Straighten the three currently bent claws, then

remove the extension unit.

- Removing the CD Mechanism Module (Fig. 2)

1. Remove the three screws A, then remove the

front frame.

2. Remove the three screws B and two screws C,

then remove the damper and holder.

3. Remove the two spring As, spring B and spring

C from the hook, then remove the CD mechanism module.

- Removing the Keyboard Unit (Fig. 3)

1. Remove the screws A and four screws B, then

remove the keyboard unit.

2. Remove the four screws C, then remove the

guide.

– Precautions on Assembly –

Apply spring C (black) to the front

side hook.

Remaining springs A and B are to be

hung on the center hook.

Fig. 1

Fig. 2

Fig. 3

- Removing the Grille Assy (Fig. 1)

1. Remove the two screws A and the connector,

then remove the grille assy.

- Removing the upper case (not shown)

1. Remove the five screws, then remove the upper

case.

52

CDX-MG6346ZH,MG6446ZH

Page 55

53

CDX-MG6346ZH,MG6446ZH

- How to remove the Tray Assy

1. Apply about 6V current to the Cam gear motor until

all holes match at the position (A) (elevation OK position).

2. Hook the three springs B temporarily as shown in Fig.

5. While pushing the Tray holder lock arms (right and

left) in the direction (C), remove the Tray holder.

3. Lift up the Tray assy to remove it.

* Be careful not to remove the Tray hooks from the Tray

assy.

- How to remove the Carriage Mech Assy

1. Insert a short pin into the flexible PCB of the Pickup

unit.

2. While opening the resin hooks, remove the cover

from the Servo unit.

3. Disconnect the flexible PCBs from the connectors

CN101 and CN301.

4. Remove the Tray holder and the Tray assy. (See

above)

5. Rotate the Cam gear motor until the positions of all

holes (E) match, then stop the motor.

(The Carriage Mech assy will stop as shown in the

Fig.7.)

* When the positions of all holes match, they will be

completely covered by the Carriage mech assy.

* To rotate the Cam Gear motor, see "How to remove

the Tray assy".

6. Unhook the spring A.

7. Remove the flexible holder B (while opening the

hooks).

8. Remove the flexible PCB (C) from the motor. (The

flexible PCB (C) has been stuck on the motor with

double-sided adhesive tape.)

9. Loosen the fixing screw and remove the flexible

holder.

ELV motor

Cam gear motor

Approximately DC 6V

Tray holder

Tray holder lock arm

Tray holder

lock arm

Tray

hooks

Tray Assy

Cover

CN101

CN301

Match the hole positions

Flexible

holder

Fig.4

Fig. 5

Fig. 6

Short pin

Tray

hooks

Page 56

54

CDX-MG6346ZH,MG6446ZH

- How to remove the Pickup unit

1. Remove the pulling spring, torsion spring and Eshaped ring. Then remove the Clamper arm.

* The spring (A) will be removed with the Clamper

arm.

10. Remove the screw, pressure spring and collar. Lift

up the Carriage mechanism assy to remove it.

* Screw tightening torque: 2.6kgfcm

2. Slide the Clamp UP lever (B) to remove it.

3. Loosen the 2 screws. Remove the feed-screw cover

by sliding it.

4. Remove the feed-screw pressure spring (D).

5. Loosen the 2 screws. Remove the feed-screw holder

(E).

6. Remove the belt.

7. Remove the Pickup unit together with the feed screw.

* Be careful not to lose the shaft holders at the both

ends of the feed screw.

* Be careful not to damage the 2 flexible PCBs(for the

Pickup and motor) when separating them. The flexible PCBs have been stuck each other with doublesided adhesive tape.

Carriage mechanism Assy

Screw

Collar

Pressure spring

Clamper arm

E-shaped ring

Pulling spring

Torsion spring

White

Black

Pickup

unit

Feed screw

Belt

Carriage

motor

Fig. 7

Fig. 8

Fig. 9

Page 57

55

CDX-MG6346ZH,MG6446ZH

8. Loosen the 2 screws. Remove the plate spring and

the rack.

9. Pull out the feed screw from the Pickup unit.

Rack

Plate spring

Feed screw

Pickup

unit

Grease (White: KD-1)

Grease (Yellow:

PG-641)

Fig. 10

Grease (Yellow:

PG-641)

Page 58

56

CDX-MG6346ZH,MG6446ZH

7.1.3 CONNECTOR FUNCTION DESCRIPTION

14

13

12

11

10

9

8

7

6

5

4

3

2

1

1 Lch+

2 Rch+

3 AGND

4 GND

5 SWDACC

6 B.UP

7 Lch8 Rch9NC

10 BUS GND

11 BUS12 BUS+

13 ILL

14 NC

Page 59

57

CDX-MG6346ZH,MG6446ZH

7.2 IC

- Pin Functions (PD5540A)

Pin No. Pin Name I/O Function and Operation

1 VDIN I VD power supply sensor input

2 DOORSW I Door open position sense input

3 NHIN I NH-BUS dada input

4 NHOUT O NH-BUS dada output

5 CLAMPSW I Disk clamp sense input

6 ELHOME I Elevation sense input

7 XSCK O LSI clock output

8 XSO O LSI data output

9 XSI I LSI data input

10 xstb O LSI strobe output

11 xrst O LSI reset output

12 XA0 O LSI data discernment control signal output

13 VDCONT O VD power supply control output

14 EJECTKEY I Eject key input

15 asens I ACC power sense input

16 NHPOW O NH-BUS dada output

17 LOADSW I Loading sense input

18 ELVSW I Elevation OK input

19–21 TEST1-3 Not used

22 bsens I Back up power sense input

23 sbsy I Signal indicating head of subcode block input

24 isens I Illumination sense input

25 reset I Reset input

26 POWER O +5V power supply control output

27 CONT O Servo driver power supply control output

28 XIN I Crystal oscillating element connection pin

29 XOUT O Crystal oscillating element connection pin

30 VSS GND

31–33 KST1-3 O Key strobe output

34,35 kd!,@ I Key data input

36,37 ILL1,2 O Illumination output

38 ASCON O Analog switch control output

39 testin I Test program mode input

40 DCLOSE I Door close sense input

41 WDSL O Data comparison designation output

42 XWIH I DRAM data white inhibit input

43 XEMP I DRAM data read inhibit input

44 CHDT I Data comparison mode monitor input

45,46 CHM0,1 O Data comparison mode output

47-49 NC Not used

50 XWRE O DRAM data white enable output L:enable

51 XRDE O DRAM data read enable output L:enable

52 XQOK O SUB-Q OK output L:SUBQ OK

53 EMPH O DAC EMPH output

54 SCONT O Double speed select output

55 LOAD O LED power supply control output

56 cdmute O Mute output

57,58 LO2,1 O Load motor control output

59,60 ELV2,1 O ELV motor control output

61,62 CG2,1 O CAM motor control output

63 MIRR I Mirror detector input

64 LOCK I Spindle lock detector input

65 FOK I FOK signal input

66 EXSCK O Shift clock output

67 EXMODE O Latch clock output

68 EXSO O Serial data output

Page 60

58

CDX-MG6346ZH,MG6446ZH

Pin No. Pin Name I/O Function and Operation

69 EXCE O Chip enable output

70 ILPOW O Illumination power supply control output

71 VCC Power supply terminal

72 VREF I A/D converter reference voltage input

73 AVSS I A/D converter GND

74 ADRMON I DRAM memory remaining monitor input

75 EREF I DRAM A/D converter reference voltage input

76-78 PH1-3 I Disc photo sense input

79 ELVSNS I ELV position sense input

80 TEMP I Temperature detector input

80

1

20

21 40

41

60

61

*PD5540A

IC's marked by* are MOS type.

Be careful in handling them because they are very

liable to be damaged by electrostatic induction.

20

19

18

17

VDD

oe

Q11

Q10

16

15

14

13

Q9

Q8

Q7

NC

12

11

NC

Q6

1

2

3

4

VSS

DATA

CLOCK

LCK

5

6

7

8

Q1

Q2

Q3

Q4

9

10

Q5

Q0

Output buffer (Open drain)

12bit storage-register

12bit shift-register

Control circuit

BU2092FV

Page 61

59

CDX-MG6346ZH,MG6446ZH

MSM514400DP-60TS

20

19

18

16

VSS

DQ4

DQ3

oe

17

cas

15

14

13

11

A8

A7

A6

A4

12

A5

1

2

3

5

4

6

7

8

10

9

DQ1

DQ2

we

A9

ras

A0

A1

A2

VCC

A3

Timing

Generator

Column

Address

Buffers

Timing

Generator

Column

Decoders

Write

Clock

Generator

Internal

Address

Counter

Refresh

Control

Clock

Sense

Amplifiers

I/O

Selector

Output

Buffers

Input

Buffers

Row

Address

Buffers

Row

Decoders

Word

Drivers

Memory

Cells

On Chip

Vbb Generater

10

10

10

10

4

4

4

4

4

4

4

28

27

26

25

PreVcc

OPIN4(+)

OPIN4(-)

OPOUT4

24

23

22

OPIN3(+)

OPIN3(-)

OPOUT3

21

20

19

18

GND

STBY

PowVcc

VO3(-)

17

16

15

VO3(+)

VO4(-)

VO4(+)

1

2

3

4

BIAS IN

OPIN1(+)

OPIN1(-)

OPOUT1

5

6

7

OPIN2(+)

OPIN2(-)

OPOUT2

8

9

10

11

GND

MUTE

PowVcc

VO2(-)

12

13

14

VO2(+)

VO1(-)

VO1(+)

Stand-by

Mute

Level shift

Level shift

Level shift

Level shift

BA5986FM

Page 62

60

CDX-MG6346ZH,MG6446ZH

1

2

3

4

CHDT

AM19

AM18

AM17

5

6

7

8

AM15

TST0

VSS

SPSL

9

10

XRST

AM16

11

12

13

14

TST1

DTSL

CHM0

CHM1

15

16

XWRE

WDSL

17

18

19

20

XRDE

XQOK

XSOE

SDTO

21

22

23

24

SCK

XLT

VDD

DATA

25

26

BCK

SDTI

27

28

29

30

LRCK

WDCK

WDCI

LRCI

31

32

BCKI

DATI

48

47

46

45

XOE

XCAS

D3

D2

44

43

42

41

D0

MCSL

C176

VSS

40

39

XTLI

D1

38

37

36

35

XTLO

OSCE

NC

MCK

34

33

RFCK

XROI

64

63

62

61

XEMP

XWIH

NC

A4

60

59

58

57

A6

A7

A8

VDD

56

55

A3

A5

54

53

52

51

A2

A1

A0

A9

50

49

XWE

XRAS

Timing

controller

CPU

interface

VWA

register

CK

generator

WA

generator

RA

generator

Remain area

calcurator

S/P

P/S

Status

controller

Data

comparator

RAM

interface

Selector

CXD2511R

Page 63

61

CDX-MG6346ZH,MG6446ZH

8. OPERATIONS AND SPECIFICATIONS

8.1 OPERATIONS

LOADING THE CD (1 of 2)

CD Loading Slot

Disc status LED

6 DISC IN-DASH CD CHANGER

Disc Number Buttons

Flashes green

Flashes green and orange

1

EXPLANATION OF THE HAND MARKS