PIONEER CDX-MG6047, CDX-MG6147 Service Manual

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2004

HONDA

ORDER NO.

CRT3322

CDX-MG6047ZH/UC

6 DISC IN-DASH CD CHANGER

CDX-MG6047

CDX-MG6147

VEHICLE DESTINATION

PILOT U.S.A. August 2004 39110-S9V-A110-M1 ••••• CDX-MG6047ZH/UC

PILOT U.S.A. August 2004 39110-S9V-A210-M1 ••••• CDX-MG6147ZH/UC

This service manual should be used together with the following manual(s):

Model No. Order No. Mech.Module Remarks

CX-890 CRT2376 G1 CD Mech. Module : Circuit Description, Mech. Description, Disassembly

PRODUCED

AFTER

ZH

OEM PARTS No. ID No. PIONEER MODEL No.

/UC

ZH

/UC

To operate this product, a 14-pin H-BUS head unit is required.

When performing adjustments, connect the 8-pin/14-pin conversion jig (GGD1163) and the 14-pin/13-pin

conversion jig (GGD1412) to a Pioneer 8-pin H-BUS head unit. You can use it in place of a 14-pin H-BUS

head unit.

For details, refer to "Important symbols for good services".

K-ZZA. AUG. 2004 printed in Japan

1234

SAFETY INFORMATION

CAUTION

A

This service manual is intended for qualified service technicians; it is not meant for the casual do-it-yourselfer.

Qualified technicians have the necessary test equipment and tools, and have been trained to properly and safely

complex products such as those covered by this manual.

repair

Improperly performed repairs can adversely affect the safety and reliability of the product and may void the

warranty.

trying to do so

W

ARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the

state

Health & Safety Code Section 25249.6 - Proposition 65

B

- Service Precaution

1. You should conform to the regulations governing the

product (safety, radio and noise, and other regulations),

and should keep the safety during servicing by following

the safety instructions described in this manual.

2. Never attempt to turn on this unit when the CD drive

C

mechanism is upside down. Doing so could cause

damage or malfunction to the drive mechanism.

3. For pickup unit(CXX1311) handling, please refer

to"Disassembly"(see page 58).

During replacement, handling precautions shall be

taken to prevent an electrostatic discharge(protection

by a short pin).

4. During disassembly, be sure to turn the power off

since an internal IC might be destroyed when a con-

D

nector is plugged or unplugged.

5. Please checking the grating after changing the ser vice pickup unit(see page 56).

If you are not qualified to perform the repair of this product properly and safely, you should not risk

and refer the repair to a qualified service technician.

of California to cause cancer, birth defects or other reproductive harm.

E

F

2

1234

CDX-MG6047ZH/UC

5678

[Important Check Points for Good Servicing]

In this manual, procedures that must be performed during repairs are marked with the below symbol.

Please be sure to confirm and follow these procedures.

1. Product safety

Please conform to product regulations (such as safety and radiation regulations), and maintain a safe servicing environment by

following the safety instructions described in this manual.

1 Use specified parts for repair.

Use genuine parts. Be sure to use important parts for safety.

2 Do not perform modifications without proper instructions.

Please follow the specified safety methods when modification(addition/change of parts) is required due to interferences such as

radio/TV interference and foreign noise.

3 Make sure the soldering of repaired locations is properly performed.

When you solder while repairing, please be sure that there are no cold solder and other debris.

Soldering should be finished with the proper quantity. (Refer to the example)

4 Make sure the screws are tightly fastened.

Please be sure that all screws are fastened, and that there are no loose screws.

5 Make sure each connectors are correctly inserted.

Please be sure that all connectors are inserted, and that there are no imperfect insertion.

6 Make sure the wiring cables are set to their original state.

Please replace the wiring and cables to the original state after repairs.

In addition, be sure that there are no pinched wires, etc.

7 Make sure screws and soldering scraps do not remain inside the product.

Please check that neither solder debris nor screws remain inside the product.

8 There should be no semi-broken wires, scratches, melting, etc. on the coating of the power cord.

Damaged power cords may lead to fire accidents, so please be sure that there are no damages.

If you find a damaged power cord, please exchange it with a suitable one.

9 There should be no spark traces or similar marks on the power plug.

When spark traces or similar marks are found on the power supply plug, please check the connection and advise on secure

connections and suitable usage. Please exchange the power cord if necessary.

0 Safe environment should be secured during servicing.

When you perform repairs, please pay attention to static electricity, furniture, household articles, etc. in order to prevent injuries.

Please pay attention to your surroundings and repair safely.

A

B

C

D

2. Adjustments

To keep the original performance of the products, optimum adjustments and confirmation of characteristics within specification.

Adjustments should be performed in accordance with the procedures/instructions described in this manual.

3. Lubricants, Glues, and Replacement parts

Use grease and adhesives that are equal to the specified substance.

Make sure the proper amount is applied.

4. Cleaning

For parts that require cleaning, such as optical pickups, tape deck heads, lenses and mirrors used in projection monitors, proper

cleaning should be performed to restore their performances.

5. Shipping mode and Shipping screws

To protect products from damages or failures during transit, the shipping mode should be set or the shipping screws should be

installed before shipment. Please be sure to follow this method especially if it is specified in this manual.

56

CDX-MG6047ZH/UC

E

F

7

8

3

1234

CONTENTS

SAFETY INFORMATION.....................................................................................................................................2

1. SPECIFICATIONS ............................................................................................................................................ 5

2. EXPLODED VIEWS AND PARTS LIST............................................................................................................ 6

A

B

C

D

2.1 PACKING ................................................................................................................................................... 6

2.2 EXTERIOR................................................................................................................................................. 8

2.3 CD MECHANISM.....................................................................................................................................10

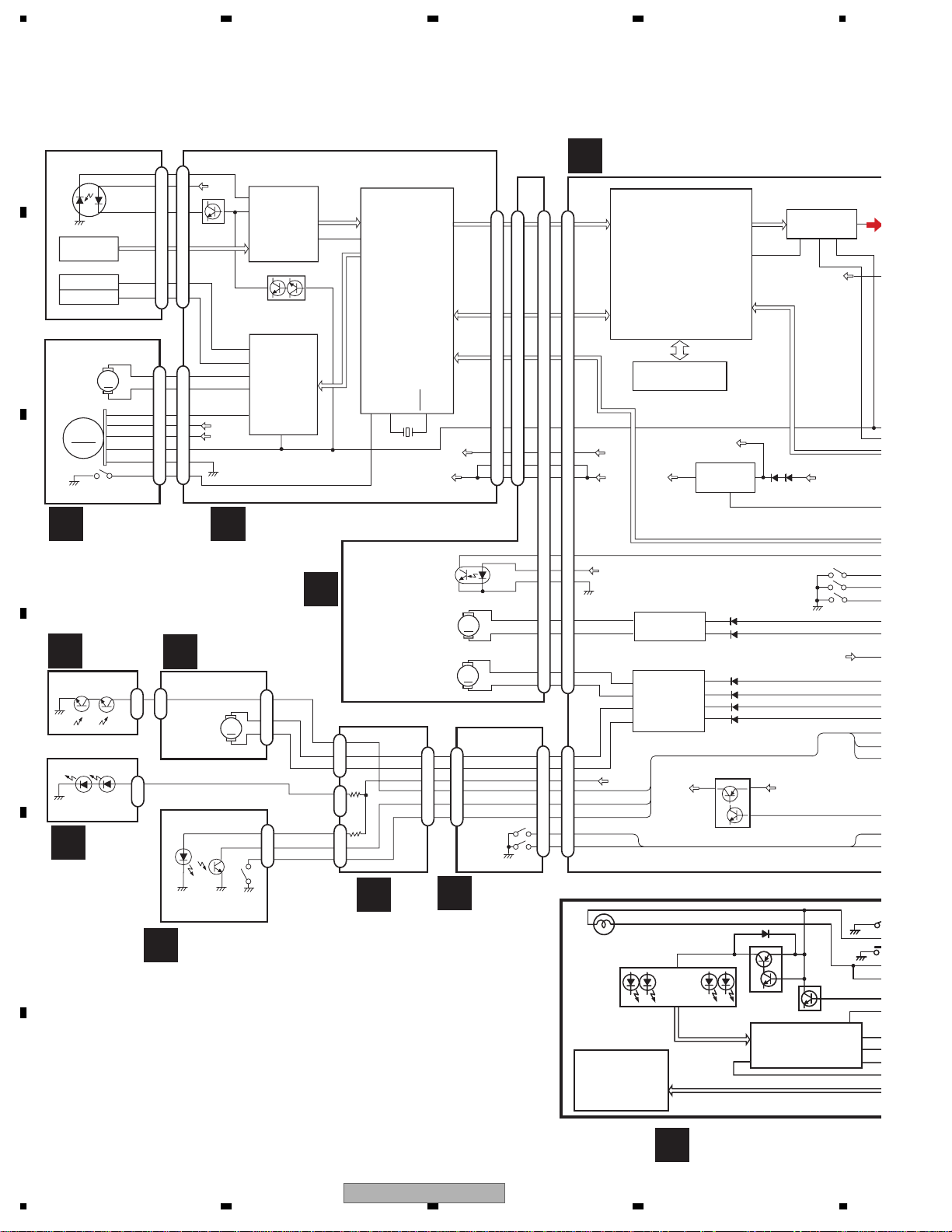

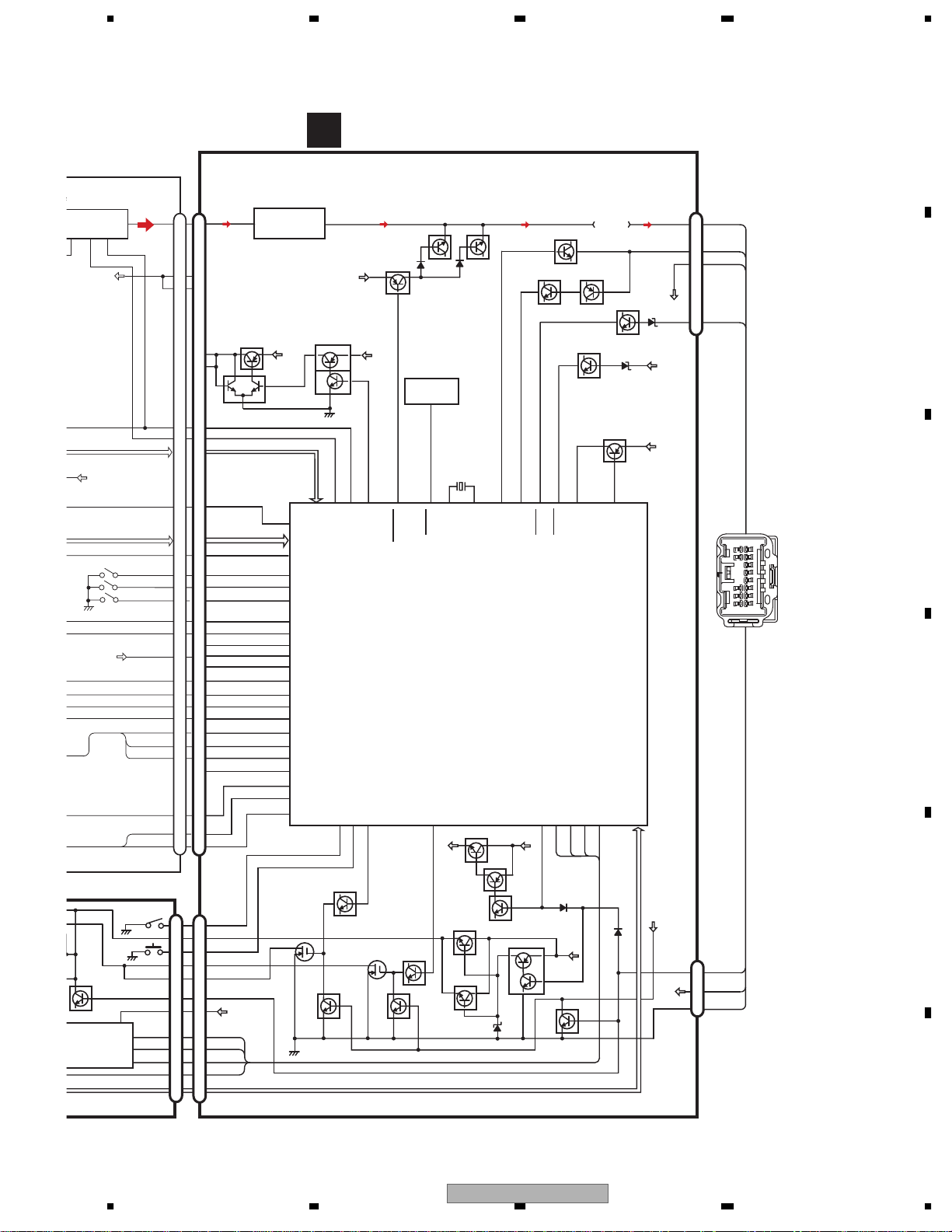

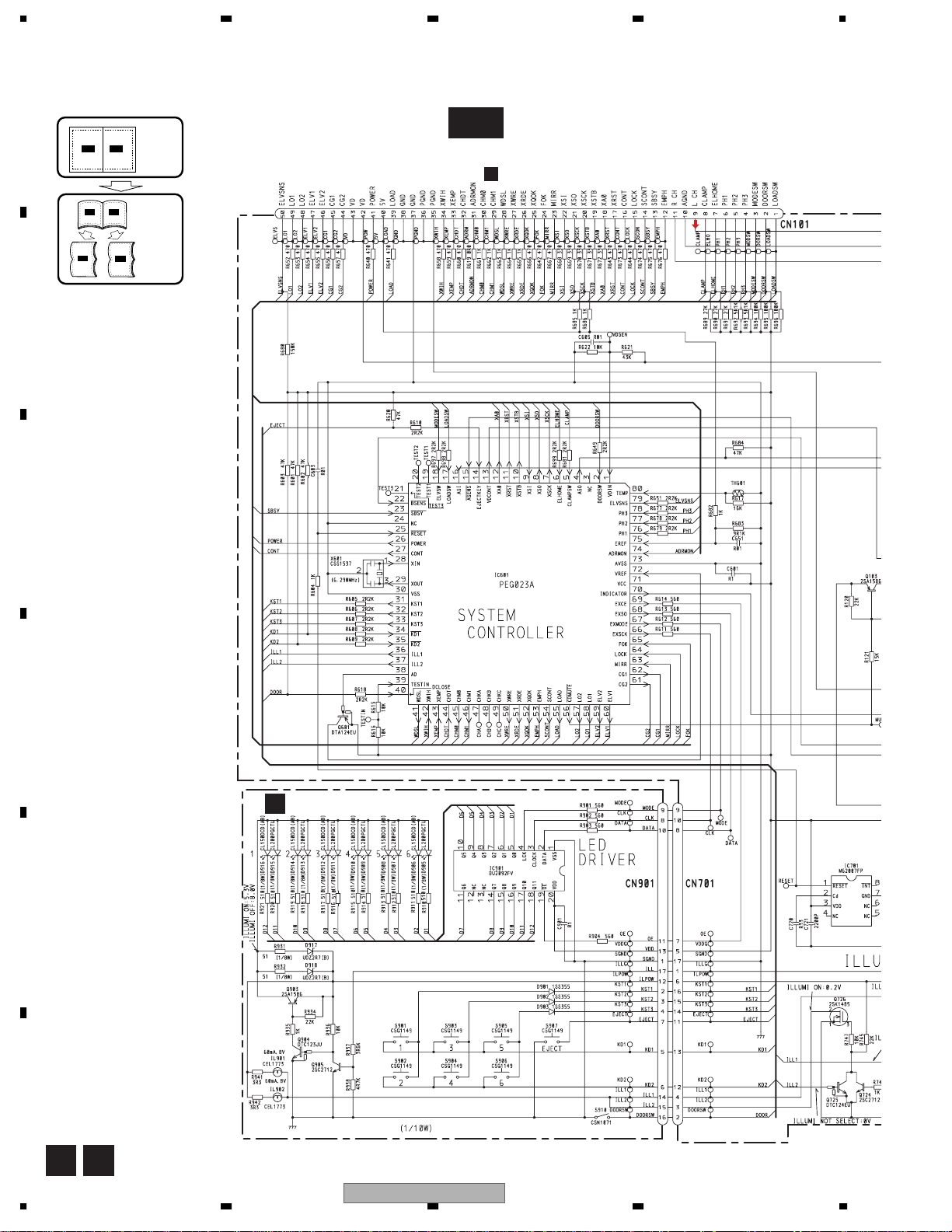

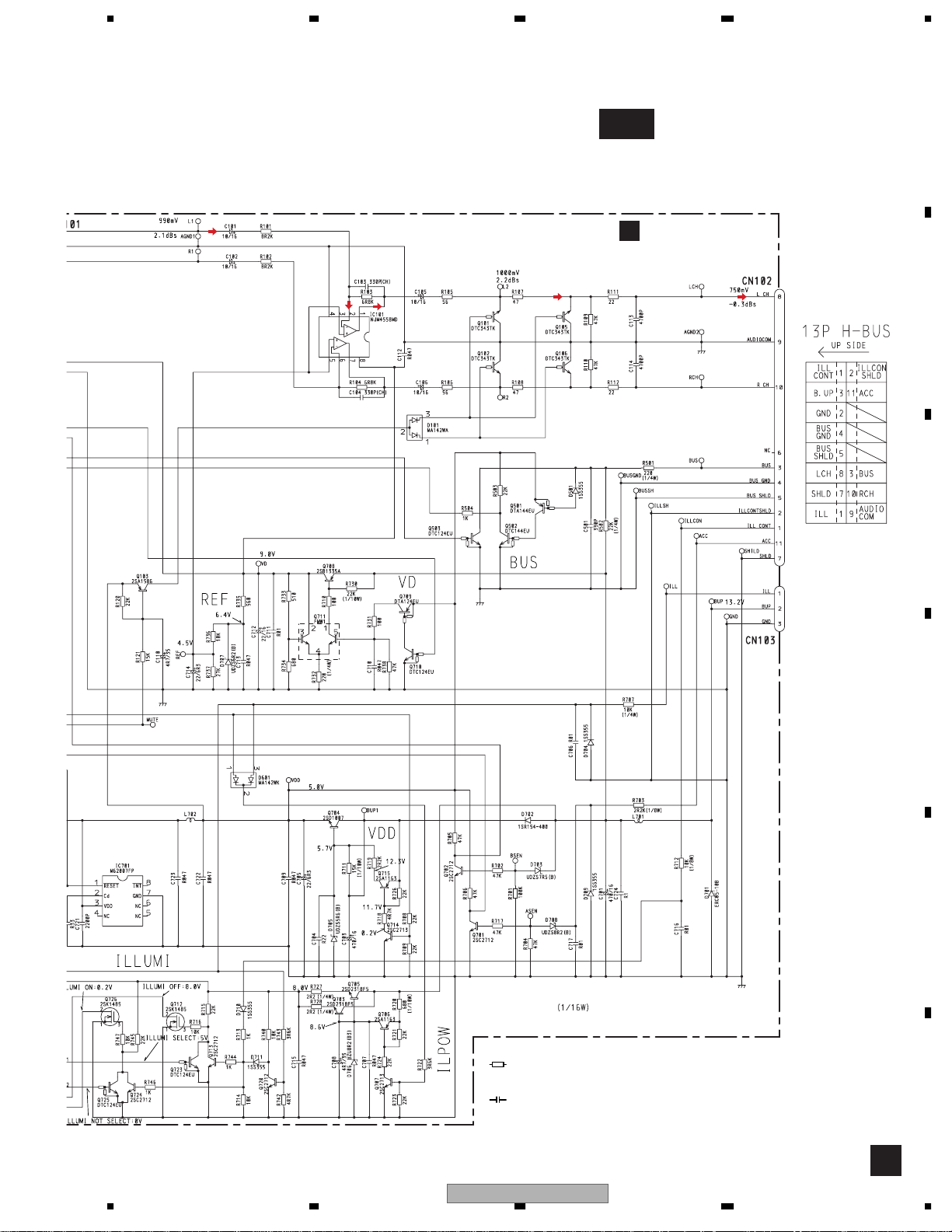

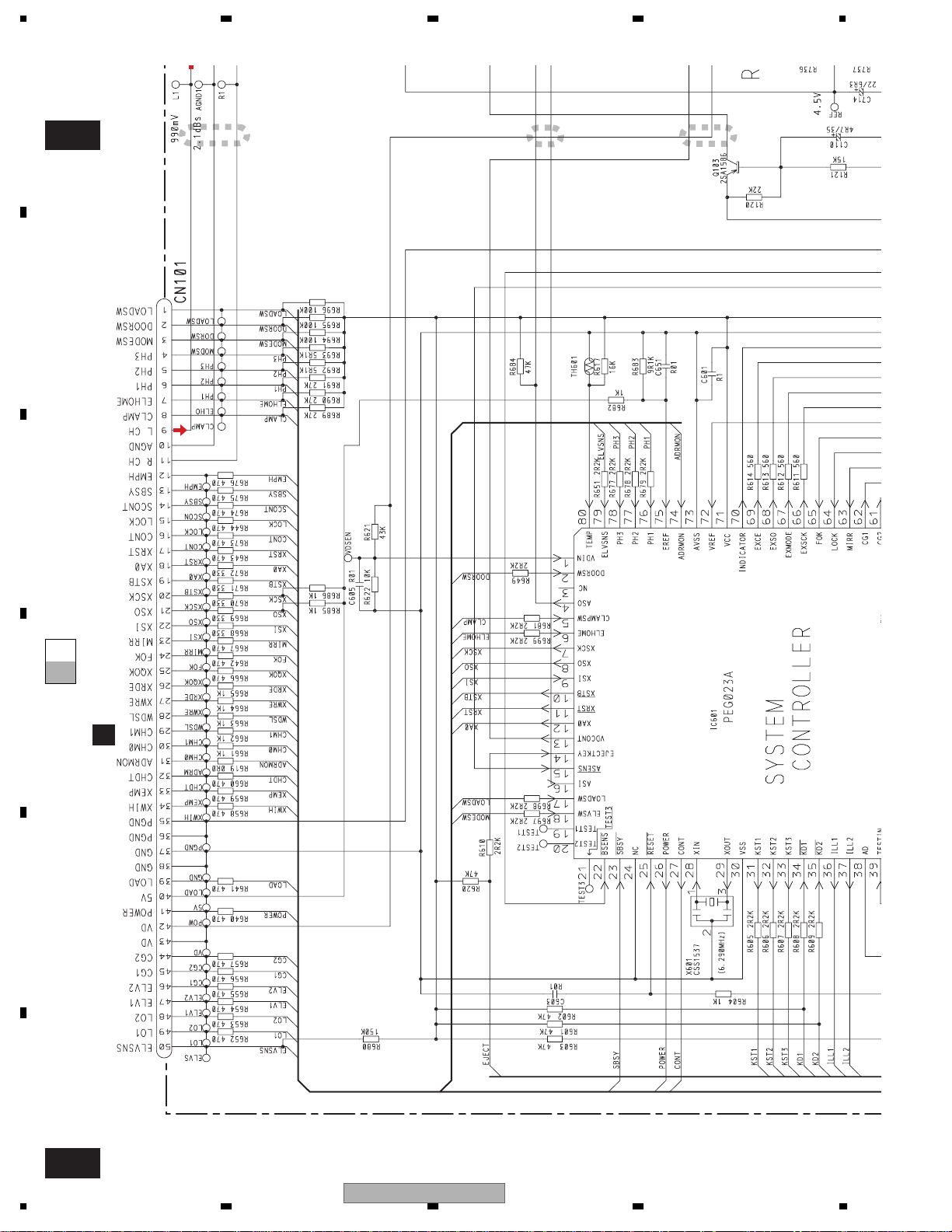

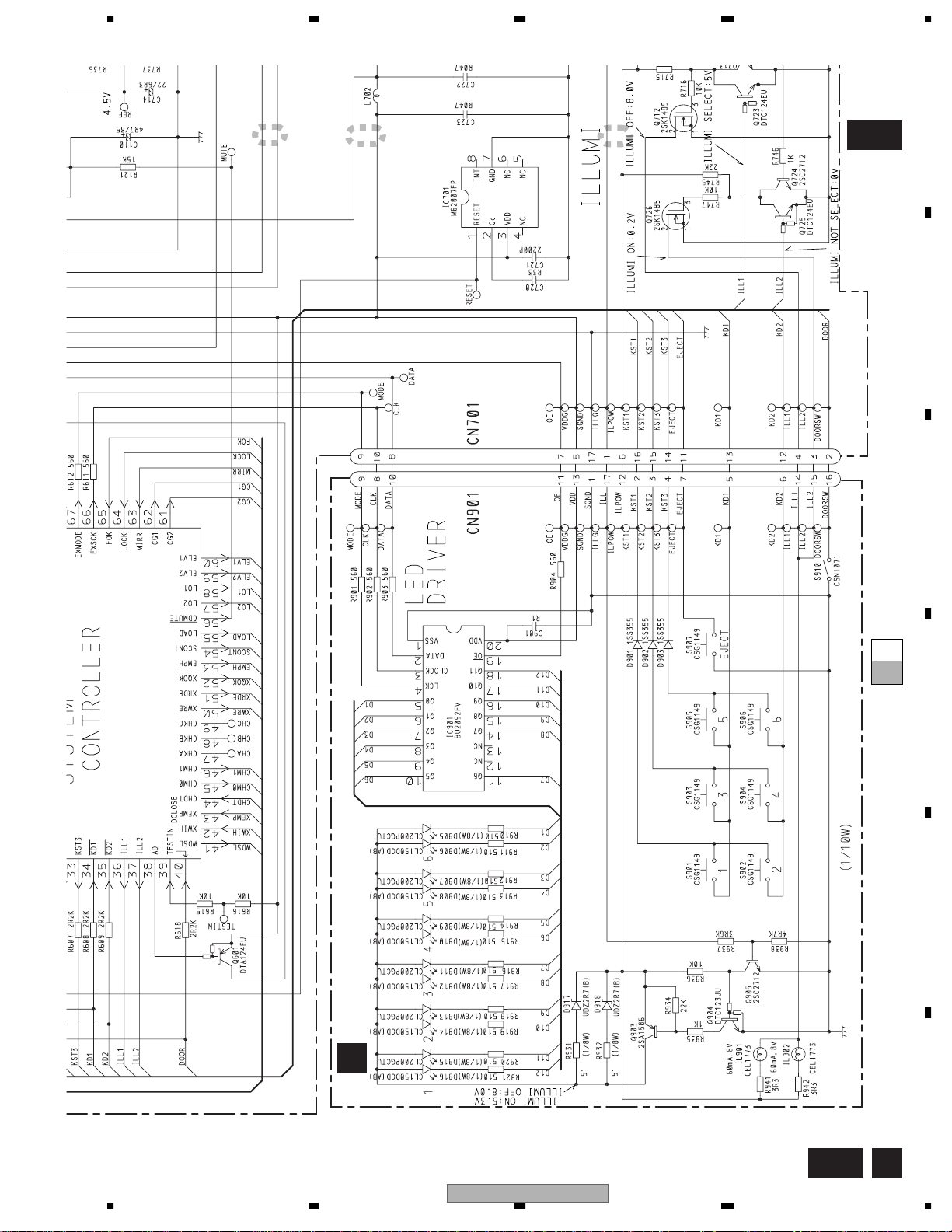

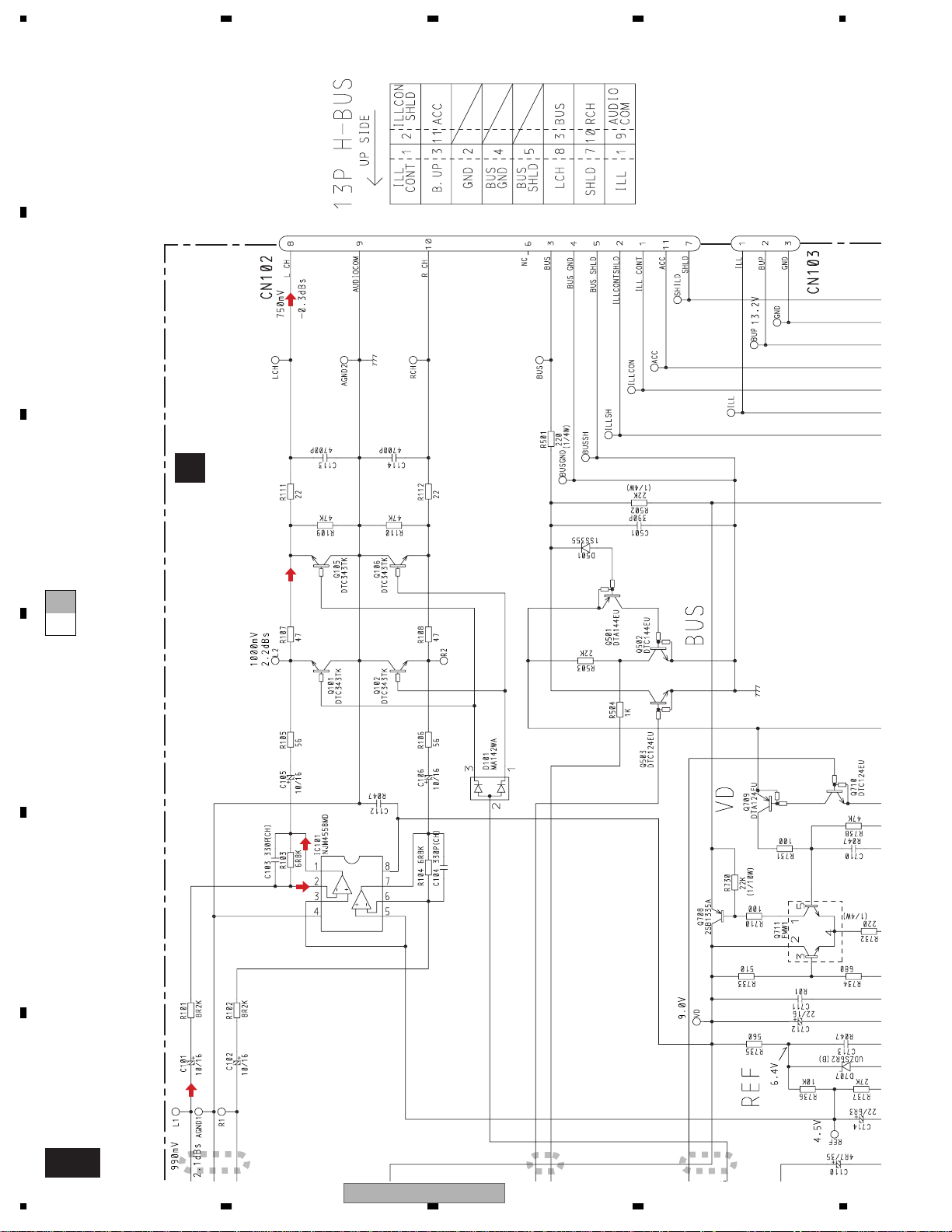

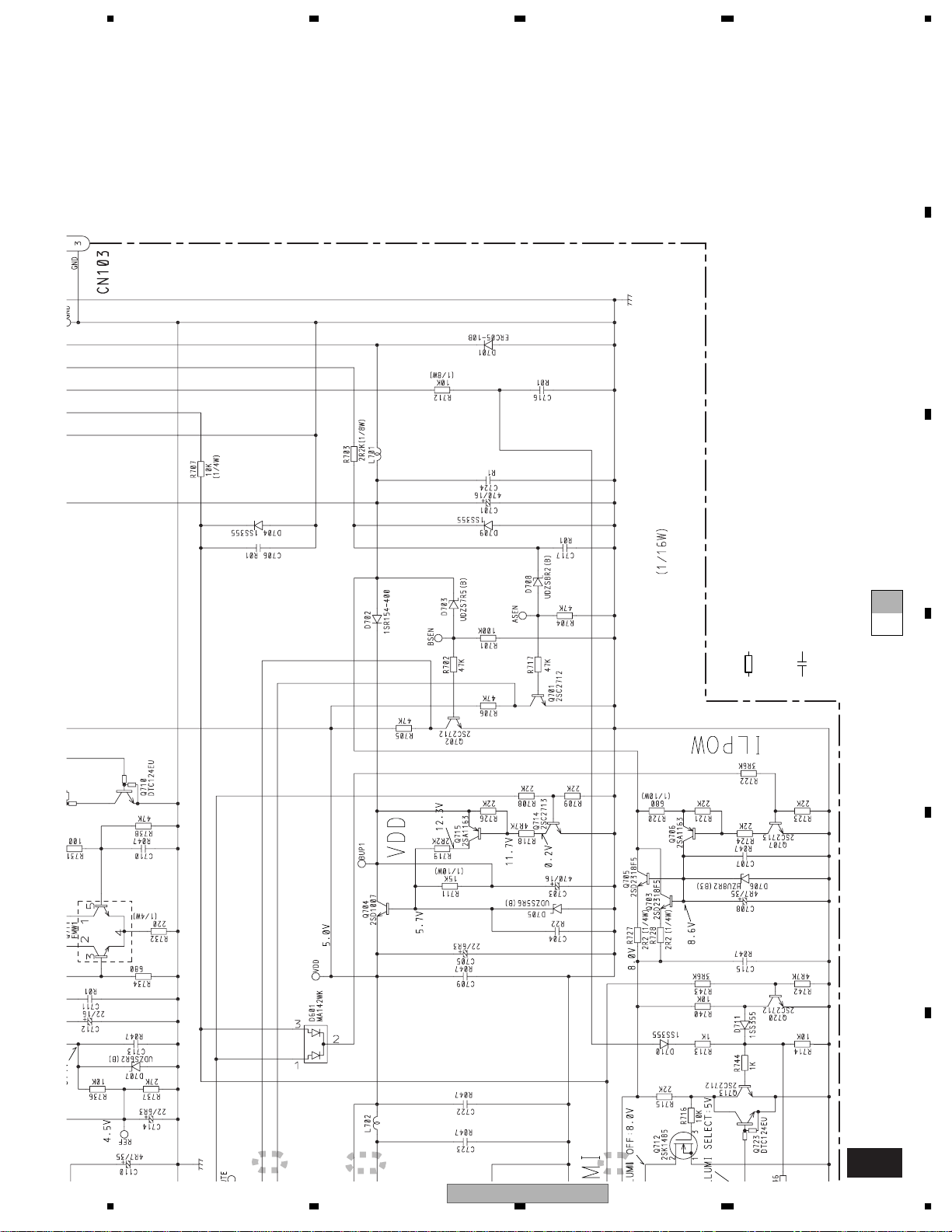

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM..........................................................................................14

3.1 BLOCK DIAGRAM...................................................................................................................................14

3.2 OVERALL CONNECTION DIAGRAM(GUIDE PAGE).............................................................................. 16

3.3 CD CORE UNIT(SERVO UNIT)...............................................................................................................22

3.4 CD CORE UNIT(STS UNIT) .................................................................................................................... 24

3.5 PCB UNIT(A, B, C, D, E), LOAD MOTOR PCB........................................................................................ 29

4. PCB CONNECTION DIAGRAM ..................................................................................................................... 30

4.1 EXTENSION UNIT...................................................................................................................................30

4.2 KEYBOARD UNIT.................................................................................................................................... 32

4.3 CD CORE UNIT(SERVO UNIT)...............................................................................................................34

4.4 CD CORE UNIT(STS UNIT) .................................................................................................................... 36

4.5 MOTOR PCB(B)....................................................................................................................................... 38

4.6 MOTOR PCB(A)....................................................................................................................................... 40

4.7 PCB UNIT(D) AND PCB UNIT(B)............................................................................................................42

4.8 PCB UNIT(E)............................................................................................................................................43

4.9 PCB UNIT(C) ........................................................................................................................................... 44

4.10 LOAD MOTOR PCB AND PCB UNIT(A)................................................................................................ 45

5. ELECTRICAL PARTS LIST ............................................................................................................................ 46

6. ADJUSTMENT ...............................................................................................................................................51

6.1 TEST MODE ............................................................................................................................................ 51

6.2 CHECKING THE GRATING AFTER CHANGING THE PICKUP UNIT....................................................56

7. GENERAL INFORMATION.............................................................................................................................58

7.1 DIAGNOSIS.............................................................................................................................................58

7.1.1 DISASSEMBLY ..................................................................................................................................... 58

7.1.2 PCB LOCATIONS ................................................................................................................................. 62

7.1.3 CONNECTOR FUNCTION DESCRIPTION.......................................................................................... 63

7.2 IC ............................................................................................................................................................. 64

7.3 SYSTEM BLOCK DIAGRAM ................................................................................................................... 66

7.4 NOTES ON SERVICING..........................................................................................................................67

7.4.1 CLEANING............................................................................................................................................ 67

7.4.2 FACTORY SETTINGS...........................................................................................................................67

8. OPERATIONS ................................................................................................................................................68

E

F

4

1234

CDX-MG6047ZH/UC

5678

1. SPECIFICATIONS

General

Power source ...................... 13.2 V DC (10.8 – 16 V allowable)

Grounding system ............................................... Negative type

Backup current ...................................................... 2 mA or less

Maximum current consumption ................................ 1.5 A max.

Dimensions (chassis size) ...... 180 (W) × 50 (H) × 168 (D) mm

................................................[7-1/8 (W) × 2 (H) × 6-5/8 (D) in.]

Weight ................................................................ 1.6 kg (3.5 lbs)

CD player

A

System .......................................... Compact disc audio system

Usable discs ......................................................... Compact disc

Signal format .............................. Sampling frequency: 44.1 kHz

.........................................Number of quantization bits: 16;linear

Frequency characteristics ................................. 20 – 20,000 Hz

Signal-to-noise ratio ................... 92 dB (1kHz) (IHF-A network)

Dynamic range ..................................................... 92 dB (1kHz)

Number of channels ................................................... 2 (stereo)

B

C

D

E

F

56

CDX-MG6047ZH/UC

7

8

5

N

1234

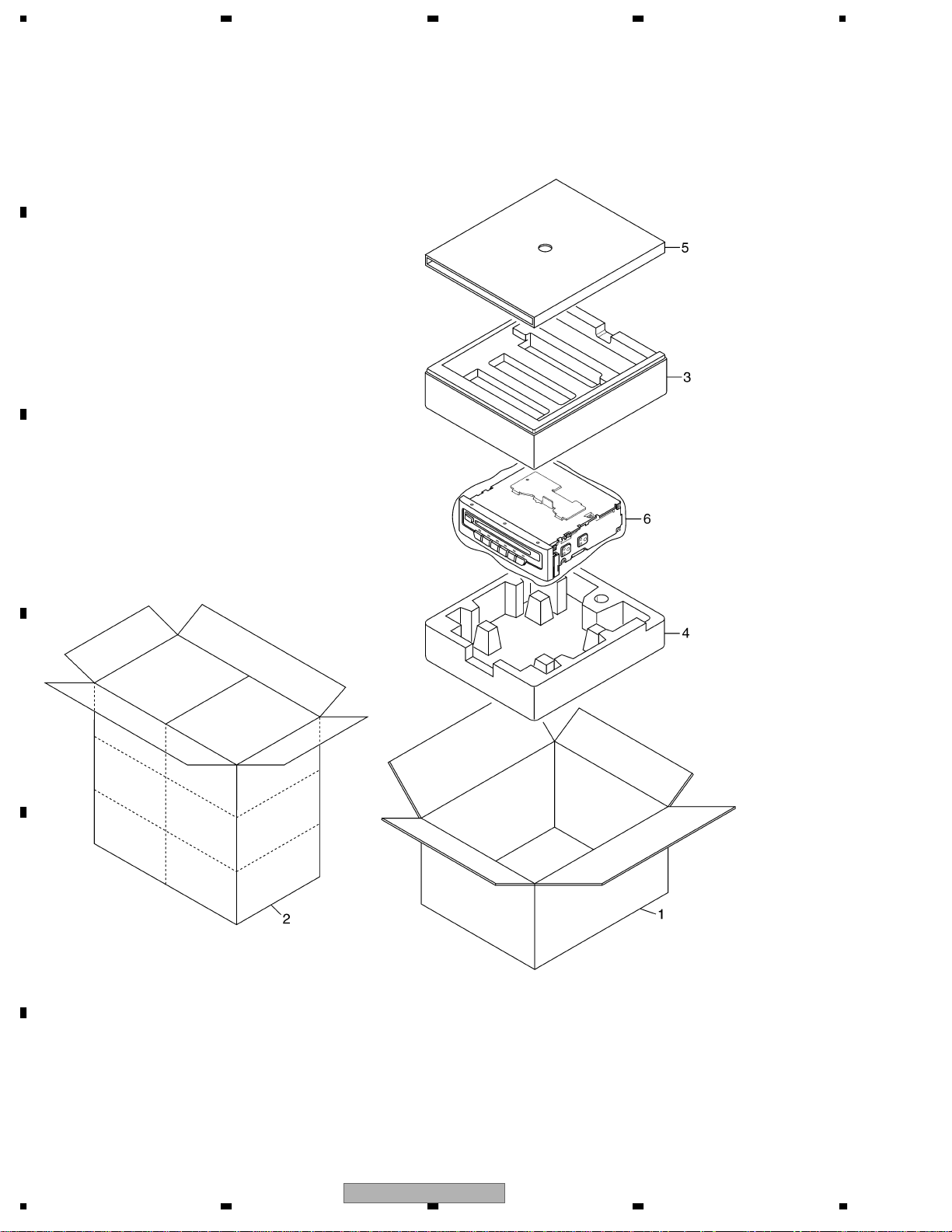

2. EXPLODED VIEWS AND PARTS LIST

OTES : • Parts marked by " * " are generally unavailable because they are not in our Master Spare Parts List.

A

• Screw adjacent to mark on the product are used for disassembly.

• For the applying amount of lobricants or glue, follow the instructions in this manual.

(In the case of no amount instructions,apply as you think it appropriate.)

"

2.1 PACKING

B

C

D

E

F

6

1234

CDX-MG6047ZH/UC

5678

(1) PACKING SECTION PARTS LIST

Mark No. Description Part No.

1 Carton See Contrast table(2)

2 Contain Box See Contrast table(2)

3 Protector CHP2123

4 Protector CHP2124

Mark No. Description Part No.

5 Protector CHP2435

* 6 Polyethylene Bag E36-609

(2) CONTRAST TABLE

CDX-MG6047ZH/UC and CDX-MG6147ZH/UC are constructed the same except for the following:

Mark NO Description CDX-MG6047ZH/UC CDX-MG6147ZH/UC

1 Carton CHG5268 CHG5269

2 Contain Box CHL5268 CHL5269

A

B

C

D

E

56

CDX-MG6047ZH/UC

F

7

8

7

1234

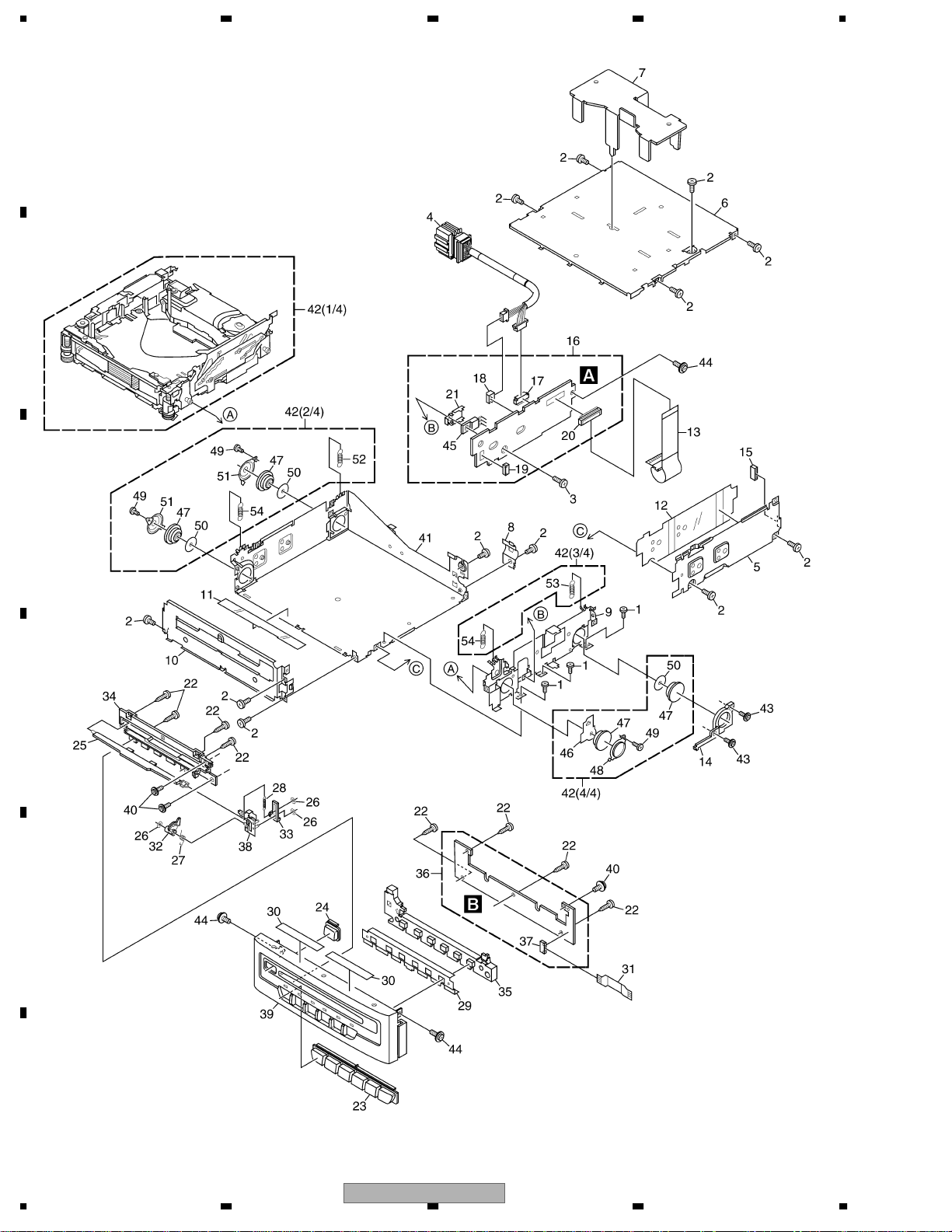

2.2 EXTERIOR

A

B

C

D

E

F

8

1234

CDX-MG6047ZH/UC

5678

(1) EXTERIOR SECTION PARTS LIST

Mark No. Description Part No.

1 Screw BMZ20P020FTC

2 Screw BMZ26P030FTC

3 Screw BMZ26P060FTC

4 Cord CDE7595

5 Side Frame CNB2397

6 Case CNB2988

7 Bracket CNC7878

8 Holder CNC8111

9 Bracket CNC8816

10 Front Frame CND2205

11 Insulator CNM5969

12 Insulator CNM6112

13 PCB CNP5516

14 Holder CNV5543

15 Spacer CNV8406

16 Control Unit CWM9600

17 Connector(CN102) CKS2200

18 Connector(CN103) CKS3597

19 Connector(CN701) CKS3785

20 Connector(CN101) CKS3989

21 Holder CNC8031

22 Screw BPZ20P060FTC

23 Button(1-6) See Contrast table(2)

24 Button(EJECT) See Contrast table(2)

25 Door CAT2587

26 Washer CBF1038

27 Spring CBH2200

Mark No. Description Part No.

28 Spring CBH2793

29 Conductor CND2203

30 Cushion CNM9229

31 PCB CNP5373

32 Gear CNV5547

33 Arm CNV5548

34 Guide CNV5880

35 Lighting Conductor CNV8067

36 Keyboard Unit CWM9467

37 Connector(CN901) CKS3785

38 Bracket Unit CXB3111

39 Grille Unit See Contrast table(2)

40 Screw IMS20P040FTC

41 Chassis Unit CXC4546

* 42 CD Mechanism Module(G1) CXK4727

43 Screw IMS20P040FTC

44 Screw IMS26P040FTC

45 Transistor(Q708) 2SB1335A

46 Sheet CNM6318

47 Damper CNV5120

48 Holder CNC7826

49 Screw(M2x2) CBA1250

50 Sheet CNM5981

51 Holder CNC7477

52 Spring(Left Rear) CBH2365

53 Spring(Right Rear)(Black) CBH2361

54 Spring(Front) CBH2409

A

B

C

(2) CONTRAST TABLE

CDX-MG6047ZH/UC and CDX-MG6147ZH/UC are constructed the same except for the following:

Mark NO Description CDX-MG6047ZH/UC CDX-MG6147ZH/UC

23 Button(1-6) CAC9015 CAC9017

24 Button(EJECT) CAC9016 CAC9018

39 Grille Unit CXC3038 CXC3040

D

E

F

56

CDX-MG6047ZH/UC

7

8

9

1234

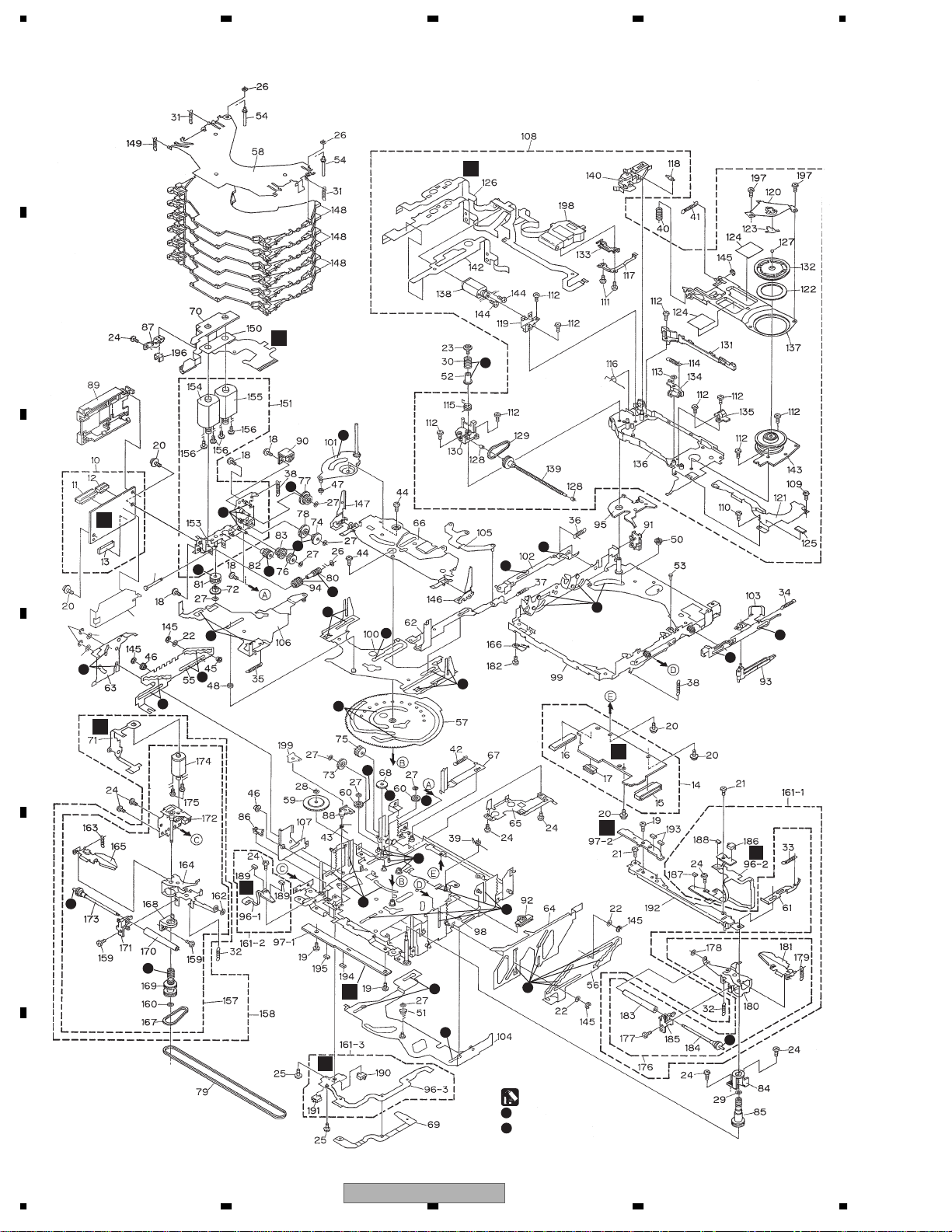

2.3 CD MECHANISM

A

B

E

F

2

1

2

C

145

D

C

49

141

22

22

1

1

2

2

2

1

1

2

2

1

1

1

2

1

1

1

1

1

K

D

2

2

2

G

2

L

E

1

1

1

J

2

I

1

1

1

1

H

1

F

10

1234

CDX-MG6047ZH/UC

:GEM1024

2

:GEM1035

5678

CD MECHANISM SECTION PARTS LIST

Mark No. Description Part No.

1-9 •••••

10 CD Core Unit(Servo Unit) CWX2202

11 Connector(CN101) CKS2764

12 Connector(CN301) CKS3966

13 Connector(CN201) CKS3991

14 CD Core Unit(STS Unit) CWX2203

15 Connector(CN701) CKS3989

16 Connector(CN801) CKS3989

17 Connector(CN802) CKS4054

18 Screw(M2x2.5) CBA1651

19 Screw(M2x2.5) CBA1041

20 Screw(M2x2.5) CBA1624

21 Screw(M2x2) CBA1250

22 Washer CBA1529

23 Screw(M2x2.5) CBA1452

24 Screw(M2x1.9) CBA1453

25 Screw(M2x2) CBA1479

26 Washer CBF1037

27 Washer CBF1038

28 Washer CBF1039

29 Washer CBF1064

30 Spring CBH2007

31 Spring CBH2520

32 Spring CBH2274

33 Spring CBH2014

34 Spring CBH2015

35 Spring CBH2016

36 Spring CBH2017

37 Spring CBH2290

38 Spring CBH2366

39 Spring CBH2064

40 Spring CBH2195

41 Spring CBH2196

42 Spring CBH2224

43 Spring CBH2250

44 Screw CBA1082

45 Roller CLA3154

46 Roller CLA3157

47 Roller CLA3159

48 Roller CLA3160

49 Shaft CLA3179

50 Spacer CLA3194

51 Roller CLA3248

52 Bush CLA3353

* 53 Shaft CLA3469

54 Shaft CLA3693

55 Steer CNC7215

56 Steer CNC7216

57 Cam CNC8774

56

No. Description Part No.

Mark

58 Holder CNC7235

59 Gear CNC7236

60 Gear CNC9512

61 Lever CNC7243

62 Lever CNC7244

63 Lever CNC7245

64 Lever Unit CXB4944

65 Cover CNC7441

66 Holder Unit CXB4946

67 Lever CNC9088

68 Gear CNC8140

69 Sheet CNM6840

70 PCB CNP5680

71 PCB CNP5681

72 Gear CNR1479

73 Gear CNR1481

74 Gear CNR1495

75 Gear CNR1501

76 Gear CNR1502

77 Gear CNR1540

78 Gear CNR1541

79 Belt CNT1080

80 Worm Gear CNV6807

81 Gear CNV5047

82 Gear CNV5048

83 Gear CNV5049

84 Holder CNV5056

85 Pulley CNV5058

86 Arm CNV5061

87 Spacer CNV5066

88 Arm CNV6595

89 Cover CNV5207

90 Cover CNV6808

91 Cover CNV5425

92 Lever CNV5427

93 Arm CNV5491

94 Gear CNV5519

95 Holder CNV5648

* 96 Composite PCB CNX3557

97 Composite PCB CNX2989

98 Chassis Unit CXB5938

99 Frame Unit CXC1923

100 Lever Unit CXB6026

101 Arm Unit CXB7533

102 Lever Unit CXB2708

103 Lever Unit CXB7070

104 Lever Unit CXB4949

105 Arm Unit CXB2712

106 Lever Unit CXB9086

CDX-MG6047ZH/UC

7

8

A

B

C

D

E

F

11

1234

No. Description Part No.

Mark

107 Lever Unit CXB2714

108 Carriage Mechanism Unit(G1) CXB5639

A

109 Screw(M2x2.2) CBA1604

110 Screw(M2x2) CBA1250

111 Screw(M2x3.8) CBA1362

112 Screw(M2x2.4) CBA1471

113 Washer CBF1038

No. Description Part No.

Mark

157 Loading Arm L Assy CXC2575

158 Load Arm L Assy(Service) CXX1747

159 Screw(M2x1.9) CBA1453

160 Washer CBF1038

161 Load Arm R Assy(Service) CXX1748

162 Washer CBF1074

163 Spring CBH2690

114 Spring CBH2008

115 Spring CBH2009

116 Spring CBH2010

117 Spring CBL1335

B

C

D

118 Roller CLA3913

* 119 Bracket CNC7228

120 Guide Unit CXB4417

121 Cover CNC9504

122 Sheet CNM6414

123 Sheet CNM5378

124 Sheet CNM5695

125 Sheet CNM5827

126 PCB CNP6164

127 Ball CNR1189

128 Bearing CNR1423

129 Belt CNT1079

130 Holder CNV5037

131 Guide CNV5040

132 Clamper CNV5042

133 Rack CNV5111

134 Arm CNV5579

135 Holder CNV5759

136 Chassis Unit CXB8450

137 Arm Unit CXB2705

138 Motor Unit(M4 CARRIAGE) CXC1389

* 164 Arm CNC7241

* 165 Arm CXC2573

166 Holder CBL1508

167 Belt CNT1079

168 Holder CNV5055

169 Pulley CNV5057

170 Roller CNV6209

171 Guide CNV5125

* 172 Bracket Unit CXB5937

173 Roller Gear Unit CXB3176

* 174 Motor Unit(M2 LOAD) CXC1388

175 Screw JFZ14P020FZK

176 Loading Arm R Assy CXC2576

177 Screw(M2x1.9) CBA1453

178 Washer CBF1074

179 Spring CBH2690

* 180 Arm CNC7242

* 181 Arm CXC2574

182 Screw JFZ20P014FTC

183 Roller CNV6209

184 Roller Gear Unit CXB3176

185 Guide CNV5126

186 Switch(S885 MAX) CSN1052

187 LED(D883) CL205IRXTU

188 Photo-transistor(Q881) CPT231SCTD

139 Screw Unit CXB3179

140 Lever Unit CXB4450

141 Insulator CNM6306

142 Spacer CNM6345

143 Motor(M5 SPINDLE) CXM1279

E

F

144 Screw JFZ14P020FZK

145 Washer YE15FTC

146 Arm Unit CXB5018

147 Arm Unit CXB5019

148 Tray Assy CXB7656

149 Spring CBH2519

150 Sheet CNM7109

151 Cam Motor Assy CXB7636

152 •••••

* 153 Bracket Unit CXB4165

* 154 Motor Unit(M1 Cam Gear) CXC1392

* 155 Motor Unit(M3 ELV) CXC1386

156 Screw JFZ20P025FTC

12

1234

189 LED(D891,892) CL205IRXTU

190 Switch(S887 CLAMP) CSN1051

191 Switch(S886 ELV HOME) CSN1052

192 Bracket Unit CXB6086

193 Photo-transistor(Q851,852) CPT231SCTD

194 Resistor(R856) RS1/8S911J

195 Resistor(R857) RS1/8S821J

196 Photo-interrupter(Q1) RPI-221

197 Screw(M2x1.4) CBA1687

198 Pickup Unit(Service)(P8) CXX1311

199 Sheet CNM7791

CDX-MG6047ZH/UC

5678

A

B

C

D

E

56

CDX-MG6047ZH/UC

F

7

8

13

N

C

V

D

X

L

R

P

D

C

O

V

1234

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM

3.1 BLOCK DIAGRAM

A

PICKUP UNIT(P8)(SERVICE)

MD

LD+

HOLOGRAM

UNIT

FOCUS ACT

LD

LD-

FO+

TO+

MD

TRACKING ACT

B

CARRIAGE

MOTOR

M

SPINDLE

MOTOR

BCL

SWITCH

HOME

VCC

ST/SR

GND

HOME

VM

EC

C

E C

MOTOR PCB(B)

PCB UNIT(D)

G

Q852

Q851

1

D

1

D892

D891

L

PCB UNIT(A)

E

J

F

CN101

5

14

V5

15

Q101

4

3

16

PD

17

LD

UPC2572GS

RF AMP

IC 101

Q102

CD 4CH DRIVER

14

11

BVD

V5

16

15

22

IC 301

BA5986FM

MUTE

9

1

2

3

4

8

5

6

7

10

11

CN301

CD CORE UNIT(SERVO UNIT)

D

MOTOR PCB(A)

LOAD MOTOR PCB

K

PH1

M

S885

MAX

SWITCH

PVD

PH2

3

2

1

4

1

2

1

LOADING

MOTOR

D883

Q881

PCB UNIT(C)

69

EFM

UPD63702AGF

35

DIGITAL SERVO

PROCESSOR

DIGITAL SIGNAL

PROCESSOR

MD/SD/TD/FD

µ-COMPUTER

INTERFACE

VR2

10

74

F

PH1

3

2

1

1

MAXSW

4

1

2

I

PCB UNIT(E)

IC 201

XTAL

X201

PVD

PH2

XTAL

11

ELEVATION

SENSE

CAMGEAR

MOTOR

ELEVATION

MOTOR

5

6

3

PH1

4

2

1

CN201 CN801

WDCK

RFCK

RAOV

LRCK

SCKO

DOUT

MCK

CONT

19

28

5V

29

VD

30

M

M

LD MOTOR-

5

LD MOTOR+

6

3

4

2

1

ELV HOME

S886

S887

CLAMP

PCB UNIT(B)

H

19

28

29

30

PVD

PH1

PH2

MAXSW

19

28

29

30

36

35

37

32

33

39

41

5

7

3

4

2

1

10

11

CD CORE UNIT(STS UNIT)

D

19

28

5V

29

30

VD

ELVSNS

45

PVD

44

46

MOTOR DRIVER

41

43

48

50

7

5

9

8

10

11

2

1

CGCG+

ELEL+

LOLO+

ELHOME

CLAMP

3

5

MOTOR DRIVER

3

5

12

10

PVD

CN802

KEY MATRIX

S901-906

BCK

DATA

SHOCKPROOF

CONTROLLER

IC 501

CXD2511R

IC 502

MSM514400DP-60TS

LRCK

XTLI

4M DRAM

VM

5V REGULATOR

4

PVD

Q802

IC 701

BA05SFP

1

2

6

2

6

13

9

Q801

19

KST1-KST3/KD1,KD2

V+5V

XAO/XSTB/XSO/XSI/XSCK/XRST/SCONT

IC 802

LB1836M

IC 801

LB1836M

D905-916

8fs DF D/A LPF

39

2

S801

VD

LOAD

Q903

Q904

LED DRIVER

IC901

BU2092FV

oe

IC 601

AK4321VF

512

WDSL/CHMO/CHMI

S802

S803

Q905

18

6

PD

DEMO

VD

XWRE/XRDE/XQOK

XWIH/XEMP/ADRMON/CHDT

VD

V+5V

EJECT

20

VDD

DATA

CLOCK

LCK

EL

LOA

DOO

MOD

MA

ELH

DOO

2

3

4

CN

C

E

PO

CL

IL

M

14

KEYBOARD UNIT

B

CDX-MG6047ZH/UC

1234

IT)

5678

A

A

CONTROL UNIT

s DF D/A LPF

IC 601

AK4321VF

12

WDSL/CHMO/CHMI

ONT

801

802

803

Q905

RIVER

01

2FV

1,KD2

18

6

PD

DEMO

VD

XWRE/XRDE/XQOK

XWIH/XEMP/ADRMON/CHDT

VD

V+5V

EJECT

20

VDD

DATA

CLOCK

LCK

CN701

LCH

CONT

EMPH

POWER

ELVSNS

LOADSW

DOORSW

MODESW

CG1

CG2

ELV1

ELV2

LO1

LO2

MAXSW

PH2

PH1

LOAD

ELHOME

CLAMP

DOORSW

ILL1

ILL2

ILL

VDD

2

DATA

3

CLK

4

MODE

OE

CN901

2

NJM4558MD

Q708

CHDT

CLAMP

Q711

LPF

IC101

BUP

26

79

17

2

18

62

61

64

63

65

60

59

58

57

78

77

76

75

55

6

5

Q726

1

VDD

Q709

Q710

53

POWER

EMPH

ELVSNS

LOADSW

DOORSW

ELVSW

CG1

CG2

LOCK

MIRR

FOK

ELV1

ELV2

LO1

LO2

PH3

PH2

PH1

EREF

LOAD

ELHOME

CLAMPSW

DCLOSE

401437 36

Q725

ILL

Q724

KEY DATA

VDD

VDCONT

27

13

CONT

VDCONT

EJECTKEY

ILL2

Q712

Q103

RESET

IC701

M62007FP

56

CDMUTE

Q723

Q713

Q101

1

CD MUTE

Q105

X601

(6.29MHz)

25

28

29

XIN

XOUT

RESET

SYSTEM

CONTROLLER

IC601

PEG023A

ILL1

Q704

VDD

Q715

Q705

Q703

KST1-KST3/KD1,KD2

Q502

16

4

15

ASI

ASO

70

BUP

Q714

ILL POWER

Q706

Q707

Q503

BSENS

ASENS

INDICATOR

69

BSENS

Q702

72 38

22

VREF

BSENS

EXCE

EXSO

686667

OE

DATA

BUP

Q720

Q501

ASENS

EXSCK

CLK

CD-LCH

ASENS

Q601

EXMODE

MODE

Q701

AD

CN102

VDD

A

ILL CONT

BUP

ILL

BUP

LCH

BUS

A

ACC

GND

CONT

ILL

8

3

1

11

H-BUS

1

2

3

CN103

B

C

13P

D

E

F

CN101

9

42

LCH

VD

8

9

VD REGULATOR

VD

43

42

CONT

16

35

EMPH

39

12

WDSL/CHM0/CHM1

XWRE/XRDE/XQOK

XWIH/XEMP/ADRMON

POWER

10

41

ELVSNS

1

50

LOADSW

50

1

DOORSW

49

2

MODESW

48

3

CG1

45

6

CG2

44

7

LOCK

15

MIRR

23

11

FOK

24

ELV1

47

4

ELV2

46

5

LO1

2

49

LO2

48

3

PH3

47

4

PH2

5

46

PH1

6

45

40

LOAD

ELHOME

12

39

7

44

43

8

DOOR

2

16

ILPOWILPOW

12

6

EJECT

7

11

ILL1

14

4

ILL2

15

3

ILL

17

1

13

5

VDD

DATA

10

8

CLK

10

8

MODE

9

9

OE

7

11

CN701

IT

56

CDX-MG6047ZH/UC

7

8

15

1234

3.2 OVERALL CONNECTION DIAGRAM(GUIDE PAGE)

Note: When ordering service parts, be sure to refer to " EXPLODED VIEWS AND PARTS LIST" or

"ELECTRICAL PARTS LIST".

A

A-a

D

CN701

A-a A-b

A-a

A-b

Large size

SCH diagram

Guide page

A-b

Detailed page

A-a

B

C

D

KEYBOARD UNIT

B

E

F

A B

16

1234

CDX-MG6047ZH/UC

5678

A

A-b

CONTROL UNIT

A

B

C

D

E

NOTE :

Symbol indicates a resistor.

No differentiation is made between chip resistors and

discrete resistors.

Symbol indicates a capacitor.

No differentiation is made between chip capacitors and

discrete capacitors.

CDX-MG6047ZH/UC

56

Decimal points for resistor

and capacitor fixed values

are expressed as :

←

2.2 2R2

←

0.022 R022

F

A

7

8

17

A

B

A-b

1234

1

2 3

C

A-b

A-a

A-a

D

CN701

D

E

F

A-a

18

1234

CDX-MG6047ZH/UC

5678

A

4

5

6

A-b

B

A-b

A-a

A-a

C

D

E

KEYBOARD UNIT

B

CDX-MG6047ZH/UC

56

F

A-a

7

8

B

19

1234

A

B

CONTROL UNIT

A

C

A-b

A-a

D

E

F

A-b

20

1

CDX-MG6047ZH/UC

1234

2 3

5678

A

←

←

Decimal points for resistor

and capacitor fixed values

are expressed as :

2.2 2R2

0.022 R022

B

C

A-b

Symbol indicates a resistor.

No differentiation is made between chip resistors and

discrete resistors.

Symbol indicates a capacitor.

No differentiation is made between chip capacitors and

discrete capacitors.

A-a

NOTE :

D

E

4

5

CDX-MG6047ZH/UC

56

F

6

7

8

A-b

21

Loading...

Loading...